Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

Positioning Controller MCO 351

VLT® AutomationDrive FC 301/302

www.danfoss.com/drives

Page 2

Page 3

Contents Operating Instructions

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Overview

1.3.1 Software Version 4

1.4 Approvals

1.5 Disposal

2 Safety

2.1 Safety Symbols

2.2 Safety Warnings

2.3 Functional Safety

3 Mechanical Installation

4 Electrical Installation

4.1 MCO 350/351 Control Terminals

4.1.1 Enclosure Types A2 and A3 10

4

4

4

4

5

5

6

6

6

7

8

10

10

4.1.2 Enclosure Types A5, B1, and B2 10

4.2 Frequency Converter Control Card Terminals

4.3 Wiring Diagram

4.4 MCO Option Card Terminals

4.4.1 X55 Feedback Encoder Input 14

4.4.2 X56 Master Encoder Input/Virtual Master Output 14

4.4.3 X57 Digital Input 14

4.4.4 X58 24 V DC Supply 15

4.4.5 X59 Digital Outputs 15

4.4.6 X62 MCO-CAN 15

4.5 Description of Terminals

4.5.1 Frequency Converter Control Card Terminals 16

4.5.2 MCO Digital Inputs Terminal (X57) 17

4.5.3 MCO Digital Outputs Terminal (X59) 17

4.5.4 MCO Encoder Connection 18

4.5.4.1 Encoder Connection Examples 18

4.6 Fieldbus Interface

11

13

14

16

20

4.6.1 Introduction 20

4.6.2 Data Layout 20

5 Commissioning

5.1 Safety Instructions

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 1

23

23

Page 4

Contents Operating Instructions

5.2 Basic Parameters Set-up

5.3 Basic Set-up

5.4 PID Settings

5.5 Description of Application Parameters

5.5.1 19-** Application Parameters 24

5.6 MCO Basic Settings

5.6.1 32-0* and 32-1*, Encoder 2 Parameters 29

5.6.2 32-3* and 32-4*, Encoder 1 Parameters 31

5.6.3 32-5* Feedback Source 33

5.6.4 32-6* and 32-7*, PID-Controller Parameters 34

5.6.5 32-8* Velocity & Acceleration 36

5.7 MCO Advanced Settings

5.7.1 33-0* Home Motion 38

5.7.2 33-4* Limit Handling 38

5.7.3 33-8*, Global Parameters 40

5.7.4 33-9*, MCO Port Settings 40

5.8 MCO Data Readouts

23

23

23

24

29

38

41

5.8.1 34-0*, PCD Write Parameters 41

5.8.2 34-2*, PCD Read Parameters 41

5.8.3 34-4*, Inputs and Outputs 41

5.8.4 34-5*, Process Data 41

6 Application Examples

6.1 Homing

6.2 Touch Probe Positioning

6.3 Brake Control

6.4 Hardware End Limit

6.5 Software Limits

6.6 Index Positioning

6.7 Quick Bus Positioning

7 Diagnostics

7.1 Troubleshooting

7.2 Error Messages

42

42

42

42

43

43

43

44

45

45

46

8 Appendix

8.1 Abbreviations and Conventions

8.2 Glossary of Key Terms

8.3 Positioning

8.3.1 Positioning Table 50

8.3.2 Positioning Templates 51

2 Danfoss A/S © 04/2014 All rights reserved. MG33R302

48

48

48

50

Page 5

Contents Operating Instructions

8.3.2.1 Example of Index Positioning via Fieldbus 51

8.3.2.2 Example of Index Positioning via Quick Bus 51

Index

52

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 3

Page 6

Introduction Operating Instructions

1

1 Introduction

1.1 Purpose of the Manual

These Operating Instructions provide information for safe

installation and commissioning of the VLT® Positioning

Controller MCO 351. The Operating Instructions are

intended for use by qualified personnel. Read and follow

the Operating Instructions to use the product safely and

professionally, and pay particular attention to the safety

instructions and general warnings. Keep these Operating

Instructions available with the MCO 351 at all times.

Compliance with the information in these Operating

Instructions is a prerequisite for:

Trouble-free operation

•

Recognition of product liability claims

•

Therefore, read the Operating Instructions before working

with the MCO 351.

VLT® is a registered trademark.

1.2 Additional Resources

1.3

Overview

The VLT® Positioning Controller MCO 351 is for use with

the FC 300 series frequency converters. The control card

option expands the functional properties of the frequency

converter in positioning applications. It is user-friendly,

enabling the set-up of all parameters via the VLT

AutomationDrive Local Control Panel (LCP) or via the VLT

MCT 10 Set-up Software.

The module is available as an option card for field installation or as a built-in option in all VLT® AutomationDrives.

It is available with and without conformal coating.

As the MCO 351 is a standard product with fixed

functional properties, no additional application

programming is required.

The positioning controller can handle most positioning

applications with vertical as well as horizontal movements.

The option is suited for applications with an overall control

system, for example a PLC.

®

®

Resources available to understand advanced frequency

converter and MCO functions and programming:

VLT® AutomationDrive FC 301/FC 302 Operating

•

Instructions

VLT® AutomationDrive FC 301/FC 302 Design

•

Guide

VLT® AutomationDrive FC 301/FC 302

•

Programming Guide

Motion Control Option MCO 305 Operating

•

Instructions

Motion Control Option MCO 305 Design Guide

•

Supplementary publications and manuals are available

from Danfoss. See www.danfoss.com/BusinessAreas/DrivesSo-

lutions/Documentations/VLT+Technical+Documentation.htm

for listings.

The main features are:

Direct positioning via fieldbus

•

Relative, absolute, and touch probe positioning

•

32 fixed positions (64 via fieldbus)

•

End limit handling (software and hardware)

•

Mechanical brake handling

•

Error handling

•

Jog speed/manual operation

•

Home function

•

Auto PID calculation

•

Software Version

1.3.1

Refer to parameter 19-90 Type/Version for the software

version number.

4 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 7

Introduction Operating Instructions

1.4 Approvals

NOTICE

The T7 (525-690 V) frequency converters are not certified

for UL.

1.5 Disposal

Equipment containing electrical

components can not be disposed of

together with domestic waste.

It must be separately collected with

electrical and electronic waste according

to local and currently valid legislation.

1

1

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 5

Page 8

Safety

Operating Instructions

2 Safety

22

2.1 Safety Symbols

The following symbols are used in this document:

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE

Indicates important information, including situations that

may result in damage to equipment or property.

2.2 Safety Warnings

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input power. Failure to perform

installation, start up, and maintenance by qualified

personnel could result in death or serious injury.

Installation, start up, and maintenance must be

•

performed by qualified personnel only.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

DC power supply, or load sharing, the motor may start at

any time. Unintended start during programming, service,

or repair work can result in death, serious injury, or

property damage. The motor can start by means of an

external switch, a serial bus command, an input

reference signal from the LCP or LOP, via remote

operation using MCT 10 software, or after a cleared fault

condition.

To prevent unintended motor start:

Disconnect the frequency converter from the

•

mains.

Press [Off/Reset] on the LCP before

•

programming parameters.

Ensure that the frequency converter, motor, and

•

any driven equipment is fully wired and

assembled when the frequency converter is

connected to AC mains, DC power supply, or

load sharing.

WARNING

DISCHARGE TIME

Frequency converters contain DC link capacitors that can

remain charged even when AC mains is disconnected. To

avoid electrical hazards, remove AC mains from the

frequency converter before doing any service or repair

and wait the amount of time specified in Table 2.1.

Failure to wait the specified time after power has been

removed before doing service or repair on the unit could

result in death or serious injury.

Voltage [V]

200–240 0.25–3.7 kW 5.5–37 kW

380–480 0.25–7.5 kW 11–75 kW

525–600 0.75–7.5 kW 11–75 kW

525–690 N/A 11–75 kW

High voltage may be present even when the warning indicator

lights are off.

Table 2.1 Discharge Time

6 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Minimum waiting time (minutes)

4 15

Page 9

Safety Operating Instructions

NOTICE

Installation at high altitudes:

380–500 V: Enclosure A, B, and C: At altitudes

•

above 2 km, contact Danfoss regarding PELV.

380–500 V: Enclosure D, E, and F: At altitudes

•

above 3 km, contact Danfoss regarding PELV.

525–690 V: At altitudes above 2 km, contact

•

Danfoss regarding PELV.

2.3 Functional Safety

Safe Torque Off is an option. To run Safe Torque Off,

additional wiring for the frequency converter is required.

Refer to VLT® Frequency Converters Safe Torque Off

Operating Instructions for further information.

2 2

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 7

Page 10

Mechanical Installation Operating Instructions

3 Mechanical Installation

This chapter is only relevant if the MCO 350/351 is

delivered as an option for upgrading an existing VLT

33

AutomationDrive. When ordered with the frequency

converter, MCO 350/351 is pre-installed. For retrofit,

purchase a mounting kit.

There is a different mounting kit for different enclosures.

Use MCO 350/351 in slot C0 or combine it with another

option in slot C1.

Mounting kit depending on enclosure Order no.

Bookstyle Enclosure

A2 and A3 (40 mm for 1 C option) 130B7530

A2 and A3 (60 mm for C0 + C1 option) 130B7531

B3 (40 mm for 1 C option) 130B1413

B3 (60 mm for C0 + C1 option) 130B1414

Compact Enclosure

A5 130B7532

B, C, D, E, and F (except B3) 130B7533

®

Table 3.1 Mounting Kits

Do not mount the small fan for B4, C3, C4, D, E, and F.

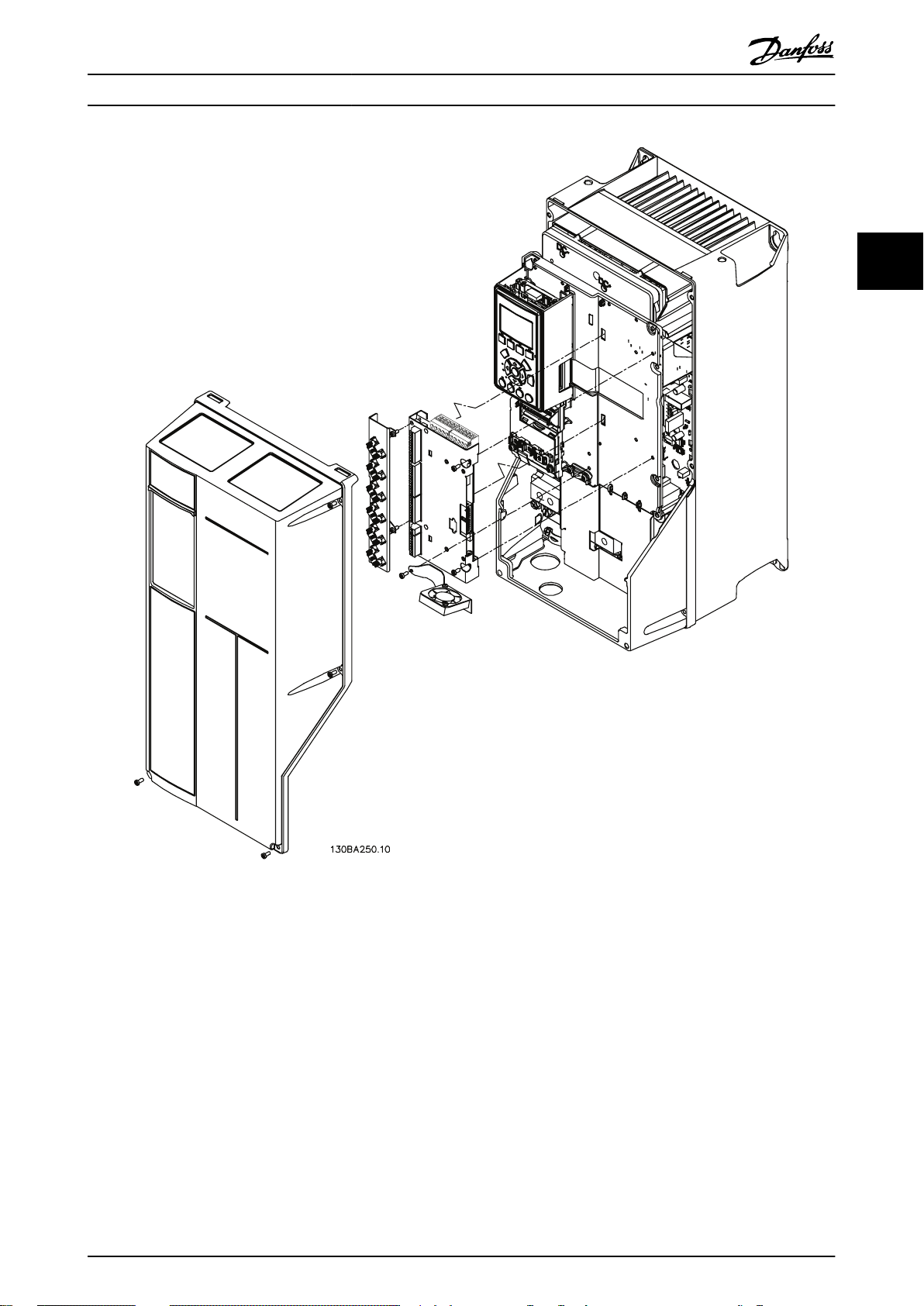

Illustration 3.1 Bookstyle Enclosure – A2, A3, B3

8 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 11

Mechanical Installation Operating Instructions

3 3

Illustration 3.2 Compact Enclosure – A5, B (except B3), C, D, E, F

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 9

Page 12

130BA248.11

130BT334.10

Electrical Installation Operating Instructions

4 Electrical Installation

Refer to the safety warnings in chapter 2 Safety before

installing the MCO.

Screen all control cables and connect the cable screen to

ground at both ends to avoid EMC problems. Always

44

follow the instructions of the encoder supplier. See also

®

VLT

AutomationDrive FC 301/FC 302 0.25-75 kW Design

Guide for more information regarding cable installation.

4.1 MCO 350/351 Control Terminals

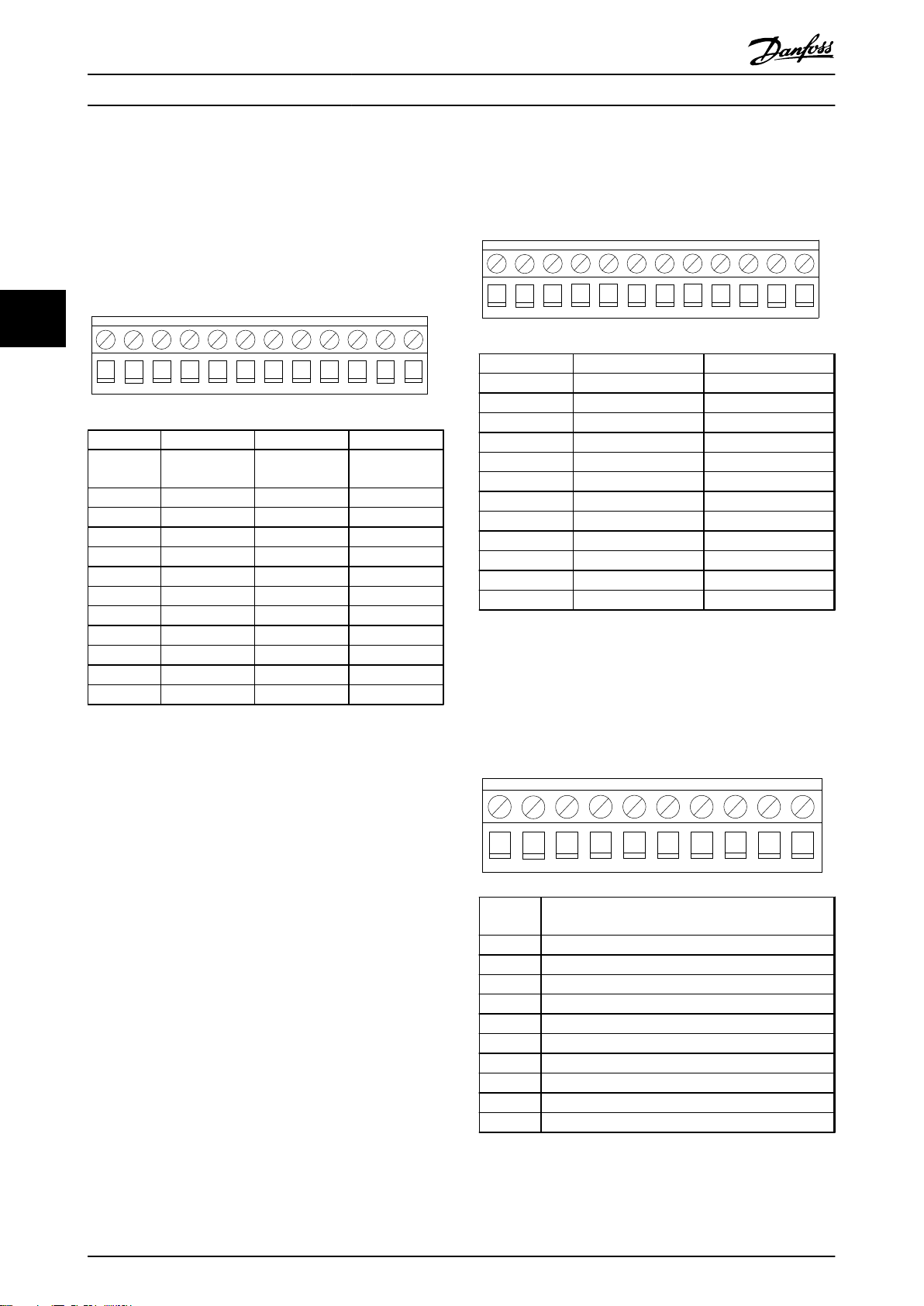

4.1.1 Enclosure Types A2 and A3

Encoder and I/O terminal are located behind the C option

terminal cover, see Illustration 4.1.

MCO CAN bus terminals and debug terminals (RS-485) are

on the top of the C option cover. If these connections are

used, cut out the plastic parts above the connectors and

mount the cable relief.

Enclosure Types A5, B1, and B2

4.1.2

All MCO 350/351 terminals are located next to the VLT

AutomationDrive control card. Remove the front cover to

get access. See Illustration 4.2.

MCO control terminals are plug connectors with screw

terminals. Terminals X55, X56, X57, X58, and X59 are

duplicated to be used for both bookstyle and compact

enclosure type.

See Illustration 4.3 to locate the terminal blocks.

®

Illustration 4.1 Location of Encoder and I/O Terminals

Illustration 4.2 Removing the Front Cover

10 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 13

X62

X55

X56

X57

X58

X59

2

X60

130BB794.10

1

Electrical Installation Operating Instructions

4.2

Frequency Converter Control Card

Terminals

The terminals on the VLT® AutomationDrive control card

are allocated for the MCO 351.

Do not change the following parameters for I/O settings:

Parameters 5-10 to 5-15 set to [0] No operation

•

(default setting)

Parameters 3-15, 3-16 and 3-17 set to [0] No

•

function (default setting)

Parameter 6-50 set to [52] MCO 0–20 mA

•

4 4

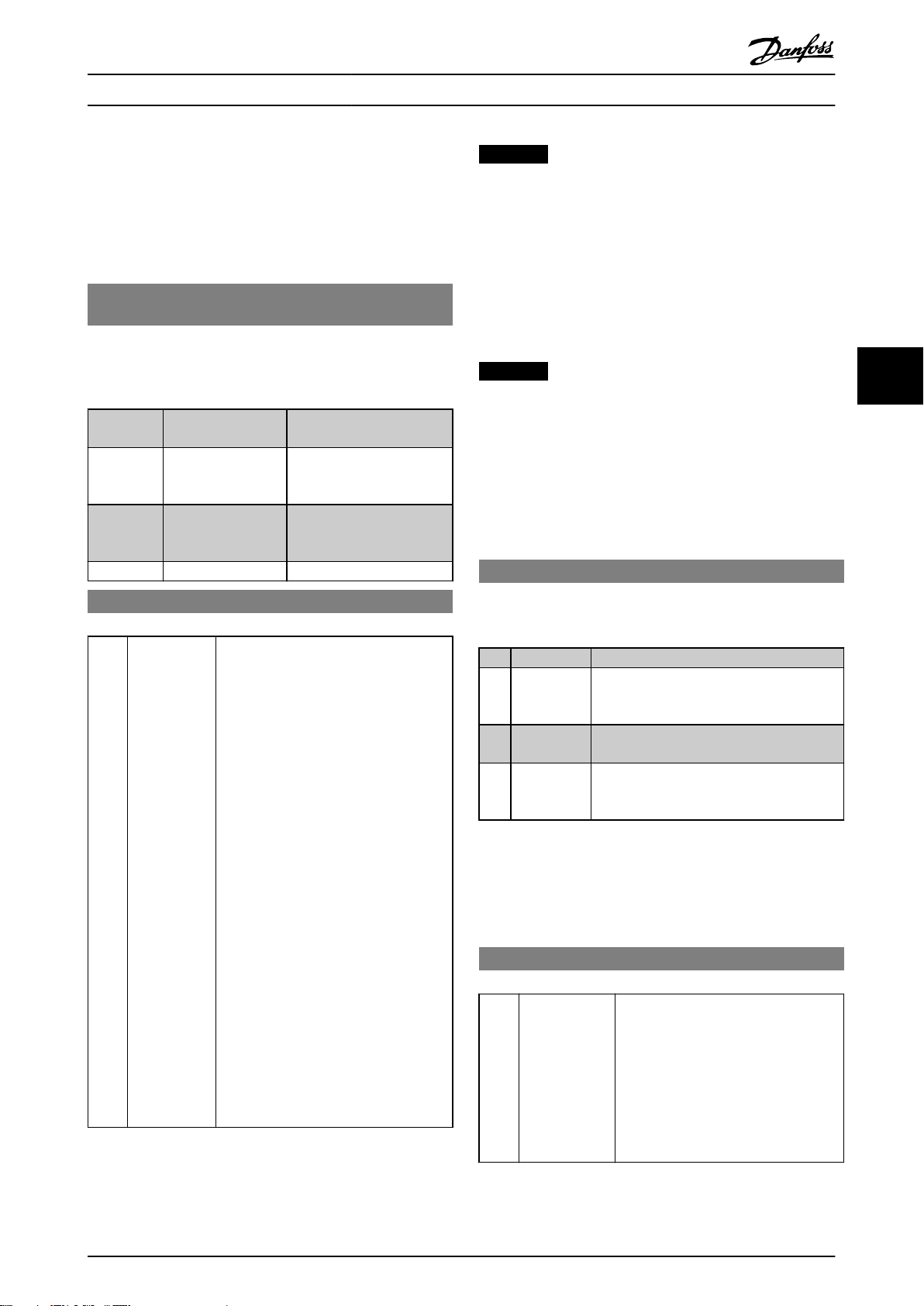

1 Terminal block 1

2 Terminal block 2

X55 Encoder 2

X56 Encoder 1

X57 Digital inputs

X58 24 V DC supply

X59 Digital outputs

X60 MCO CAN Bus

X62 Debug connections (RS 485)

Illustration 4.3 Location of Terminal Blocks 1 and 2

Illustration 4.4 FC 300 Terminals

Technical data on these terminals can be found in the

VLT® AutomationDrive FC 301/FC 302 Design Guide.

Use terminal block 1 with bookstyle and terminal block 2

with compact.

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 11

Page 14

Electrical Installation Operating Instructions

Digital inputs

12 +24 V OUT

13 +24 V OUT

18 Reference index bit 0

19 Reference index bit 1

27 Enable (error clear in digital control mode)

29 Reference index bit 4

44

32 Reference index bit 3

33 Reference index bit 2

20 COM D in

37 Safe Torque Off (STO)

Table 4.1 Digital Inputs

Relay 1:

Mechanical brake (normally open)

Relay 2:

Mechanical brake monitoring (normally closed)

Analog input:

53 ±10 V-In Manual jog positive

54 ±10 V-In Manual jog negative

55 Common for analogue inputs

Supply voltage:

12, 13 +24 V Out

20 Common for digital inputs (common with X55/4-X56/4X58/2)

12 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 15

FC300

Reference index Bit 1

Enable (error clear in dig. control mode)

Reference index Bit 4

Reference index Bit 3

Reference index Bit 2

Touchprobe pos. locked

Manual Jog positive

Reset Touchprobe pos.

Go to Home position

Latch new index

2

Homing completed

Reference pos. reached

Reference index Bit 0

Reference index Bit 1

Reference index Bit 2

Reference index Bit 3

Reference index Bit 4

02

03

04

06

+24 V DC out

+8 V DC out

+5 V DC out

COM

+24 V DC out

+8 V DC out

+5 V DC out

COM

A

/A

B

/B

CLK

/CLK

DATA

/DATA

Analog

Output

Analog

Inputs

S201, S202 = O

MCO 351

Relay

01

Relay

02

Mains

Motor

X56

Encoder 1

X55

Encoder 2

+24 V OUT

+24 V OUT

Reference index Bit 0

COM D in

Safe torque o (STO)

COM A in

+10 V OUT

Quickstop

Manual Jog negative

COM A out

Touchprobe switch

Positive HW limit switch

Negative HW limit switch

Home reference switch

Go to target position

Reset Home ag

+24 V supply

COM

Error occured

12

13

18

19

27

29

32

33

20

37

39

42

50

53

54

55

1

2

3

4

5

6

7

8

9

10

1

1

2

3

4

5

6

7

8

Digital

Inputs

X57

Digital

Inputs

X58

24 V DC

Supply

X59

Digital

Outputs

91

92

93

PE

96

97

98

99

U

V

W

01 Brake Supply

Brake Brake COM

05

L1

L2

L3

PE

PE

TTL SSI SINCOS

A

/A

B

/B

Z

/Z

CLK

/CLK

DATA

/DATA

SIN

REFSIN

COS

REFCOS

1

2

3

4

5

6

7

8

9

10

11

12

Z

/Z

1

2

3

4

5

6

7

8

9

10

11

12

130BD658.10

Electrical Installation Operating Instructions

4.3 Wiring Diagram

4 4

Illustration 4.5 Wiring Diagram

NOTICE

Input 29 is not available in FC 301. Therefore only 16 positions can be selected via digital inputs in FC 301.

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 13

Page 16

130BD653.10

1 2 3 4 5 7

9

116

8 10

12

130BD653.10

1 2 3 4 5 7

9

116

8 10

12

1 2 3 4 5 7 96 8 10

130BD655.10

Electrical Installation Operating Instructions

X56 Master Encoder Input/Virtual

4.4 MCO Option Card Terminals

4.4.2

Master Output

Technical data on these terminals can be found in the

Motion Control Option MCO 305 Operating Instructions.

4.4.1 X55 Feedback Encoder Input

44

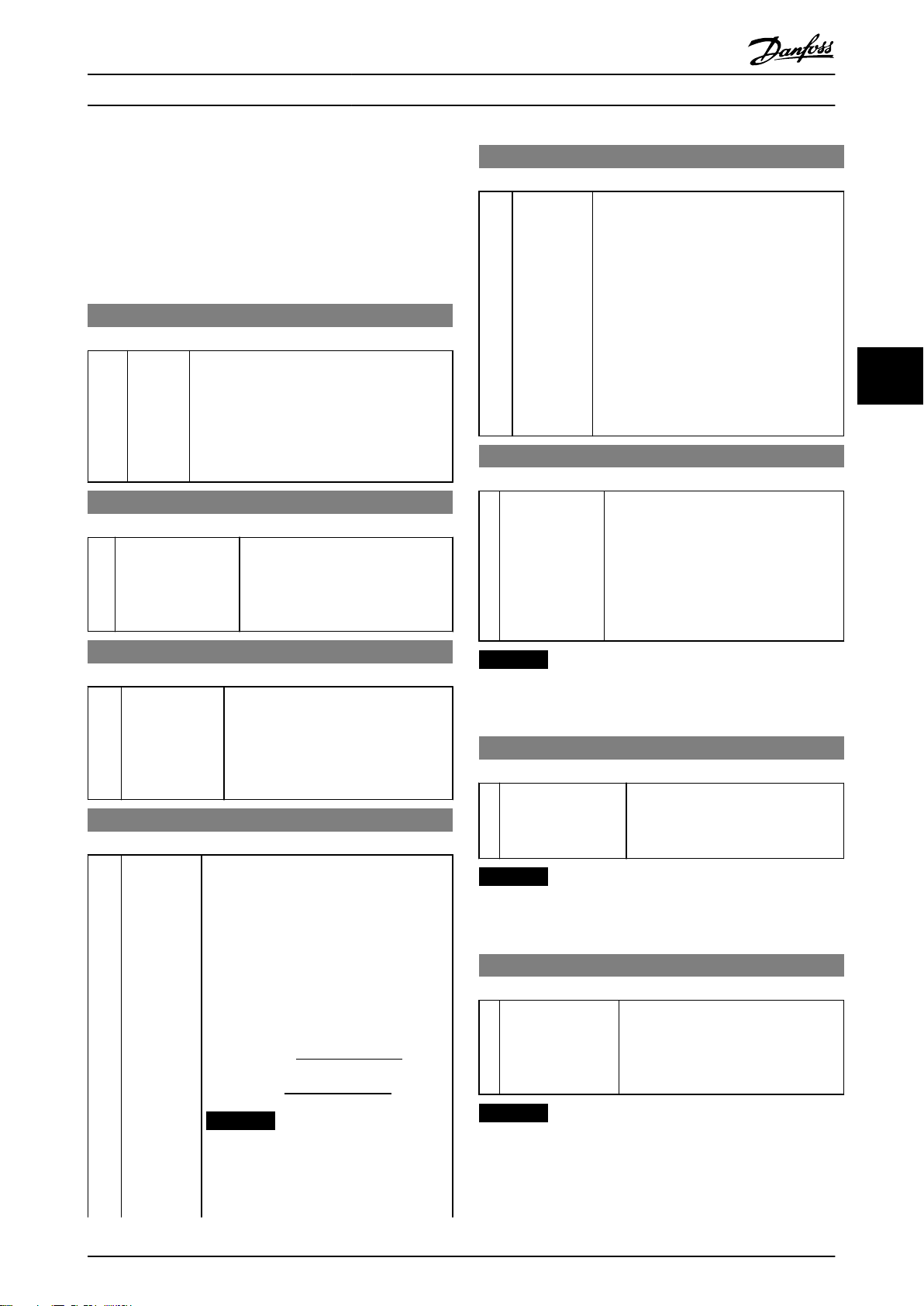

Pin number TTL encoder SSI encoder

1 +24 V DC Supply +24 V DC Supply

2 +8 V DC Supply +8 V DC Supply

3 +5 V DC Supply +5 V DC Supply

Pin number TTL encoder SSI encoder SinCos encoder

1 +24 V DC

Supply

2 +8 V DC Supply +8 V DC Supply +8 V DC Supply

3 +5 V DC Supply +5 V DC Supply +5 V DC Supply

4 GND GND GND

5 A - +SIN

6 A not - REFSIN

7 B - +COS

8 B not - REFCOS

9 Z CLK 10 Z not CLK not 11 - DATA 12 - DATA not -

Illustration 4.6 X55 Feedback Encoder Input

+24 V DC

Supply

+24 V DC

Supply

4 GND GND

5 A 6 A not 7 B 8 B not 9 Z CLK

10 Z not CLK not

11 - DATA

12 - DATA not

Illustration 4.7 X56 Master Encoder Input/Virtual Master

Output

X57 Digital Input

4.4.3

14 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Pin

number

1 Touch probe switch

2 Positive hardware limit switch

3 Negative hardware limit switch

4 Home switch

5 Go to target position

6 Reset home flag

7 Reset touch probe position

8 Quick stop

9 Go to home position

10 Latch new reference position index number

Illustration 4.8 X57 Digital Inputs

Description

Page 17

1 2

130BD656.10

1 2 3 4 5 76 8

130BD657.10

1

2

3 4 5

130BD672.10

Electrical Installation Operating Instructions

4.4.4 X58 24 V DC Supply

Pin

number

1 +24 V

2 COM

Illustration 4.9 X58 24 V DC Supply

4.4.5

Description

X59 Digital Outputs

X62 MCO-CAN

4.4.6

Pin number Description

1 –

2 CAN_L (CAN low)

3 Drain

4 CAN_H (CAN high)

5 –

Illustration 4.11 X62 MCO CAN

4 4

Pin

number

1 Homing completed

2 Reference position reached

3 Error

4 Reference index bit 0

5 Reference index bit 1

6 Reference index bit 2

7 Reference index bit 3

8 Reference index bit 4

Illustration 4.10 X59 Digital Outputs

Description

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 15

Page 18

Electrical Installation

Operating Instructions

4.5 Description of Terminals

4.5.1 Frequency Converter Control Card Terminals

Connector Terminal Designation Description

Inputs

44

Relay 01

Relay 02

Analogue I/O

RS-485

12, 13 +24 V OUT 24 V (+1, –3 V) power supply

Max. load:

VLT® AutomationDrive FC 301: 130 mA

VLT® AutomationDrive FC 302: 200 mA

18 Reference index bit 0 (LSB) Reference position index number bit 0 (least significant bit). Not used in

fieldbus mode.

19 Reference index bit 1 Reference position index number bit 1. Not used in fieldbus mode.

20 COM D IN Ground for 24 V – common with 39, 55, X55/4, X56/4, and X58/2

27 Enable (error clear in digital

control mode)

29 Reference index bit 4 (msb) Reference position index number bit 4 (most significant bit). Not used in

32 Reference index bit 3 Reference position index number bit 3. Not used in fieldbus mode.

33 Reference index bit 2 Reference position index number bit 2. Not used in fieldbus mode.

37 Safe Torque Off (STO) Safe input. Used for STO.

01 COM Relay 01 Common terminal for Relay 01.

02 Connect to electro-mechanical

brake NO

03 NC Normal Closed

04 COM Relay 02 Common terminal for Relay 02.

05 Brake activated NC Normal Closed Relay 02 is closed to indicate an activated electrome-

06 NO Normal Open

39 COM A OUT Ground for analog output. Common with 20 and 55.

42 Touch probe position locked in This analog output delivers either 0 mA (not locked in) or 20 mA (locked

50 +10 V OUT Power supply for manual JOG inputs (terminal 53 and 54).

53 ±10 V-In Manual jog positive When high (above 5 V), the drive travels with jogging speed (parameter

54 ±10 V-In Manual jog negative When high (above 5 V), the drive travels with jogging speed (parameter

55 COM A IN Ground for analogue inputs. Common with 20 and 39.

61 Shield

68 RxTx+ A control card switch is provided for termination resistance.

69 RxTx–

To enable operation, this input must be maintained at high in both

digital control mode and fieldbus control mode.

Digital control mode: Errors are cleared on the rising edge. Must be 0 V

for at least 1 ms to guarantee edge detection.

fieldbus mode. Not available in VLT® AutomationDrive FC 301.

Normal Open Relay 01 is open (brake activated) during power off and

start-up of the FC 300. It is always open after a Quick Stop procedure or

with an error situation. Relay 01 only closes with motion procedures or if

specified in parameter 19-09 Automatic Brake Control.

chanical brake. It is open to indicate a deactivated electromechanical

brake. Not used in fieldbus control mode.

in) at a maximum of 500 Ω.

Maximum 15 mA.

19-16) and ramp (parameter 19-17) in the positive direction. When low

(below 5 V), the drive ramps down and stops if no other motion

procedure is activated. Jog positive has higher priority than jog negative.

Not used in fieldbus mode by default. Can be enabled via parameter

19-31 Digital Jog in field Bus mode.

19-16) and ramp (parameter 19-17) in the negative direction. When low

(below 5 V), the drive ramps down and stops if no other motion

procedure is activated. Not used in fieldbus mode by default. Can be

enabled via parameter 19-31 Digital Jog in field Bus mode.

Integrated RC-filter for cable screen. Only for connecting the screen

when experiencing EMC problems.

Table 4.2 Control Card Terminals

16 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 19

Electrical Installation Operating Instructions

4.5.2 MCO Digital Inputs Terminal (X57)

Terminal Designation Description

1 Touch probe switch input Input triggered on the rising edge. If this signal goes high when no touch probe target

position is locked, a new touch probe target position is calculated and locked in

memory.

2 Positive hardware limit switch

input

3 Negative hardware limit switch

input

4 Home reference switch input Active high. Marks the home position in the application.

5 Go to the target position Active high. Upon activation the motor goes to the specified target position. A low

6 Reset home flag Active high. This input clears the home flag. This allows the performance of a 2nd

7 Reset touch probe position Active high. This input clears the touch probe position flag. The reset is necessary to

8 Quick stop

9 Go to home position While this input is high the motor executes the homing sequence and no position or

10 Latch new reference position

index number

Input triggered on the falling edge. Triggers a hardware limit error and the motor is

stopped according to parameter 19-06 Error Behaviour.

Input triggered on the falling edge. Triggers a hardware limit error and the motor is

stopped according to parameter 19-06 Error Behaviour.

signal interrupts any positioning sequence. Not used in fieldbus mode.

homing sequence.

carry out a touch probe positioning command to a new target position. Not used in

fieldbus mode.

Active low. This input activates the Quick Stop function. The motor is stopped according

to the setting of parameter 19-06 Error Behaviour. After that, the electromechanical brake

is always activated when the Quick stop input is activated, regardless of the parameter

19-06 Error Behaviour setting.

jog operations are carried out. Any homing sequence is interrupted by a low state on

this input. Not used in fieldbus mode.

Active on the rising edge (must be 0 V for at least 1 ms to guarantee edge detection):

Latches reference position index number specified on terminal 18, 19, 29, 32, 33 into

memory. Digital output 4-8 is changed to mirror the new reference index specified when

using digital input control. Not used in fieldbus mode.

4 4

Table 4.3 MCO Digital Inputs Terminal (X57)

MCO Digital Outputs Terminal (X59)

4.5.3

Terminal Designation Description

1 Homing completed Active high. This output is always high if an absolute encoder is used.

2 Referenced position

reached

3 Error occurred Active high. This output is set every time an error occurs. It is cleared every time a successful error

4 Reference index bit 0 Mirror of the currently locked-in reference index bit 0. Not used in fieldbus mode.

5 Reference index bit 1 Mirror of the currently locked-in reference index bit 1. Not used in fieldbus mode.

6 Reference index bit 2 Mirror of the currently locked-in reference index bit 2. Not used in fieldbus mode.

7 Reference index bit 3 Mirror of the currently locked-in reference index bit 3. Not used in fieldbus mode.

8 Reference index bit 4 Mirror of the currently locked-in reference index bit 4. Not used in fieldbus mode.

Table 4.4 MCO Digital Outputs Terminal (X59)

Active high. This output is set when the target position is reached according to the setting of

parameter 33-47 Size of Target Window.

clear is carried out. This output remains high as long as the power recovery function is selected

(parameter 19-08 Power-Recovery) and active.

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 17

Page 20

MOTOR

X55 X56

130BD828.10

MOTOR

X55 X56

130BD829.10

Electrical Installation Operating Instructions

4.5.4 MCO Encoder Connection

MCO 351 provides 2 encoder interfaces, X55 and X56.

Terminal block X55 is configured as the default feedback

encoder input.

Encoder supported

TTL/RS422 incremental encoder (X55, X56)

•

SSI absolute encoder - Grey code (X55, X56)

44

•

Sin/Cos Encoder 1 Vpp (only X55)

•

Resolver (needs extra option MCB103) - only in

•

speed closed loop.

CANopen encoder (X62)

•

Example 2

Encoder connected to X55 for positioning loop. Since the

encoder is not mounted directly on the motor shaft, this

configuration can be used for the MCO positioning loop

and the FC speed control loop.

NOTICE

Use parameter 32-50 Source Slave for setting encoder

feedback to [1] Encoder 1 X56 or [3] Motor Control.

4.5.4.1 Encoder Connection Examples

Example 1

Encoder connected to X55 for positioning loop. Since the

encoder is mounted directly on the motor shaft, the same

feedback can be used for the MCO positioning loop and

the FC speed control loop.

Illustration 4.12 Encoder Mounted on the Motor

Illustration 4.13 Encoder Mounted on the Gear Box

18 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 21

130BD830.10

MOTOR

X55 X56

MOTOR

X55 X56

MCB 103

130BD831.10

Electrical Installation Operating Instructions

Example 3

Encoder connected to X55 for positioning loop. Since the

encoder is not mounted directly on the motor shaft, a 2nd

encoder connection (X56) is needed for running closed FC

speed control loop.

Example 4

Resolver feedback used. MCB 103 option is needed. FC

speed control loop must be closed.

4 4

Illustration 4.14 Encoders Mounted on the Motor and the Gear

Box

Illustration 4.15 Resolver Mounted on the Motor

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 19

Page 22

175ZA813.12

Quick bus go to target

Electrical Installation Operating Instructions

4.6 Fieldbus Interface

4.6.1 Introduction

This section is only relevant if the frequency converter is equipped with a fieldbus interface (option) as well as the

positioning controller.

The positioning controller is controlled via the digital/analog inputs or via fieldbus. Select the control source in parameter

19-04 Control Source. There can only be 1 control source at a time, meaning that the digital/analog inputs are inactive when

44

fieldbus is selected as control source and vice-versa. The only exceptions are listed in Table 4.5. In fieldbus mode, it is

possible to specify the target position and velocity. If the acceleration and deceleration PCDs are left blank, the values for

acceleration and deceleration from index 1 are used.

Data Layout

4.6.2

Control and status signals are transferred via the so-called process data channel (PCD) of the various fieldbus interfaces. The

telegram structure and the available number of data words depends on the fieldbus used. Refer to the manual of the

fieldbus option in use for further details. The example in Illustration 4.16 is based on the layout of a Profibus telegram, the

so-called PPO:

Illustration 4.16 Example using PROFIBUS PPO Type 5

20 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 23

Electrical Installation Operating Instructions

Fieldbus control signals (inputs)

Fieldbus

[word.bit]

1.1 Quick bus go to target (high) N/A

1.2 Reset error (high) 27

1.3 Go to home position (high) 9

1.4 Read new trajectory index (high) 10

1.5 Start index positioning (high)/Stop index

1.6 Reset home status (high) 6

1.7 Reset touch probe position (high) 7

1.8 Quick stop (low) 8

1.9 Positive jog (high) 53

1.10 Negative jog (high) 54

1.11 Quick bus type absolute (high) N/A

1.12 Quick bus type relative (high) N/A

1.13 Quick bus type touch probe positive (high) N/A

1.14 Quick bus type touch probe negative (high) N/A

1.15 Teach in (via LCP or fieldbus) (high) [Back] and [Cancel] on the LCP

1.16 Change sign on quick bus target position (high) N/A

2 Quick bus target position (MSB) N/A

3 Quick bus target position (LSB) N/A

4 Quick bus target velocity N/A

5 Quick bus target acceleration N/A

6 Quick Bus target deceleration N/A

7.1 Reference index bit 0 18

7.2 Reference index bit 1 19

7.3 Reference index bit 2 33

7.4 Reference index bit 3 32

7.5 Reference index bit 4 29

7.6 Reference index bit 5 N/A

Fieldbus mode Corresponding input

5

positioning (manual mode activated) (low)

4 4

Table 4.5 Fieldbus Control Signals (Inputs)

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 21

Page 24

Electrical Installation Operating Instructions

Fieldbus control signals (outputs)

Fieldbus

[word.bit]

1.1 Homing done (high) 1

1.2 Referenced position reached (high) 2

1.3 Error occurred (high) 3

1.4 Electro-mechanical brake closed (high) 04

44

1.5 Touch probe position locked (high) N/A

1.6 Watchdog output (toggling) N/A

1.7 Positive hardware limit (high) N/A

1.8 Negative hardware limit (high) N/A

2.1 Current index bit 0 4

2.2 Current index bit 1 5

2.3 Current index bit 2 6

2.4 Current index bit 3 7

2.5 Current index bit 4 8

2.6 Current index bit 5 N/A

3 Actual position (high word)

4 Actual position (low word)

5 Error status

Table 4.6 Fieldbus Control Signals (Outputs)

Fieldbus mode Corresponding output/parameter

Parameter 34-50 Actual Position (high word)

Parameter 34-50 Actual Position (low word)

19-93 Error Status

22 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 25

Commissioning

5 Commissioning

Operating Instructions

5.1 Safety Instructions

Refer to the safety warnings in chapter 2 Safety before

commissioning.

5.2 Basic Parameters Set-up

VLT Parameter Groups

Parameter 1-** Motor data, open or closed loop,

•

AMA

Parameter 2-** Dynamic brake

•

Parameter 3-** Reference range and limits, Ramps

•

Parameter 4-** Speed limits, Torque limits

•

Parameter 7-** If using the Drive speed closed

•

loop, tune it before MCO PID

MCO Basic Parameters

Parameter 32-0* Encoder2 (feedback) set-up type

•

and resolution

Parameter 32-3* Encoder1 (if used) set-up type

•

and resolution

Parameter 32-6* Set PID values

•

Parameter 32-8* Maximum velocity, Ramps

•

5.3

Basic Set-up

Refer to the safety warnings in chapter 2 Safety before

commissioning.

For information on applying power and operation of the

LCP, refer to the VLT® AutomationDrive FC 301/FC 302

Operating Instructions.

1. Check the motor connection. Control the brake

externally from the option until set-up is finished,

because the mechanical brake control cannot be

guaranteed during this basic set-up. Also ensure

that the motor can rotate freely without causing

damage or injury.

2. Remove all signals to inputs. Only Input 27

(coast), I8 (Qstop), I3 (Negative HW limit) and I2

(Positive HW limit) must be connected and high.

3.

Select Off Mode

4. Run the Quick Set-up with the correct motor

data.

5.

Go to Hand on mode and set the frequency for a

low positive value, for example +3 Hz in the

reference value. The motor should now rotate.

6. If the motor rotates in the wrong (negative)

direction, exchange the motor phases.

7. Set the parameters for feedback encoder in

parameter group 32-0* Encoder 2 parameters and,

if needed, parameters for encoder in parameter

group 32-3* Encoder 1 parameters.

7a

For incremental encoder:

Set parameter 32-00 Incremental Signal

Type to the type needed. Set the

resolution of the encoder in parameter

32-01 Incremental Resolution. Set

parameter 32-00 Incremental Signal Type.

7b

For absolute encoder:

Set parameter 32-00 Incremental Signal

Type to [0]. Set parameter 32-02 Absolute

Protocol to the encoder type used and

32-03 Absolute Resolution to the encoder

resolution. Set the data bit and clock

settings for the absolute encoder from

parameter 32-05 Absolute Encoder Data

Length to 32-08 Absolute Encoder Cable

Length.

8. Press the [Status] button on the LCP. Now the

RPM and Actual Position values appear in the

upper line of the display.

9. Optimise the PID controller(s).

5.4

PID Settings

Calculate Feed forward velocity (FFVEL – 32-65 Velocity

Feed Forward)

FFVEL =

Use parameter 19-19 FFVEL Auto-calculation to specify if the

calculation should be made automatically. This is only

possible when encoder and speed parameters have been

set.

MaxVelEnc x EncRes x Tsample

FFVEL = 32-65 Velocity Feed Forward

•

MaxVelEnc = parameter 32-80 Maximum Velocity

•

(Encoder)

EncRes = Encoder resolution

•

Tsample = PID sampling time (32-69 Sampling

•

Time for PID Control)

62914560000

For incremental and sinusoidal encoders:

-

EncRes = 4 x (32-01 Incremental

Resolution)

For CAN encoders: EncRes = 1 x

-

(parameter 32-01 Incremental Resolution)

For absolute encoders: EncRes = 32-03

-

Absolute Resolution

5 5

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 23

Page 26

Commissioning Operating Instructions

Setting of PID:

19-05 User Actual Position Setting

Range: Function:

32-60 Proportional factor ≈ FFVEL/50

32-61 Derivative factor ≈ FFVEL/10

32-62 Integral factor = 5

5.5 Description of Application Parameters

5.5.1 19-** Application Parameters

The 19-** parameters configure the MCO 351 Positioning

Controller specific application software. The other

55

parameters configure the underlying MCO firmware.

19-00 Control Mode

Option: Function:

[0] * MCO

control

[1] VLT control The motor is controlled by VLT and not by

The motor is controlled by MCO.

MCO. Manual running is possible. Note that

the standard controller functions, for example,

limit switches and other safety-related

functions, are not active.

0 [–1073741824 to

1073741824]

At power-up, if parameter 33-00 Force

Home is set to [0] Home not forced, the

actual position is equal to the value set

here.

19-06 Error Behaviour

Option: Function:

[0] * Electronic

brake

[1] Mechanical

brake

This parameter determines the behaviour of

the motor after an error is detected.

The motor ramps down to standstill with the

shortest possible ramp (parameter 32-81).

After achieving standstill it activates the

electronic brake according to the setting of

parameter 19-10 Coast Delay. If the motor is

coasted at any point during ramp down (for

example, due to an overcurrent trip), the

motor immediately activates the brake and

coasts the motor.

The motor immediately activates the brake

and coasts the motor.

NOTICE

19-01 Endless Positioning

Option: Function:

[0] * Limited The positioning is performed in a limited position

range without position overflow.

[1] Endless The positioning is performed continuously in 1

direction. Also remember to set parameters 19-08

Power Recovery, 33-43 Negative Software End Limit

Active, and 33-44 Positive Software End Limit Active

to [0].

19-02 Block Direction

Option: Function:

[0] * No blocking The motor is enabled to move in both

directions.

[1] Block

reverse

[2] Block

forward

Defined as an error situation (“Reverse

operation prohibited” – ERROR STATUS = 12)

if the motor is moving in reverse direction.

Defined as an error situation (“Forward

operation prohibited” – ERROR STATUS = 13)

if the motor is moving in forward direction.

19-03 Touch Probe Delay

Range: Function:

0 [1–100000 ms] This parameter enables compensation for any

fixed delay in the touch probe.

19-04 Control Source

Option: Function:

[0] * Digital I/O The positioning is controlled via digital inputs.

[1] Fieldbus The positioning is controlled via fieldbus.

The brake is always activated after an error situation (or

quick stop), regardless of the setting in parameter 19-09

Automatic Brake Control.

19-07 Error Reset

Option: Function:

[0] * No reset No error reset.

[1] Reset

error

By selecting this option, it is possible to clear

the error flag (if the reason for the error is not

still present). The parameter automatically resets

to [0] No reset when the error is successfully

cleared.

19-08 Power-Recovery

Option: Function:

[0] Disabled When the power recovery function is disabled (set

to [0]), it is not possible to drive the application

by any means (neither jogging nor positioning) as

long as the application is outside the HW or SW

limits. The only way to recover from this situation

is to move the application by hand.

[1]*Enabled When the power recovery function is enabled (set

to [1]), it is possible to make a partial reset of the

limit error (ERROR STATUS = 2/3/4/5), whereby it

is possible to use the jogging function to drive

the application out of the HW or SW limit area. It

is not possible to drive the application with

homing, positioning, or jogging (in the wrong

direction), as long as the application is still within

the HW or SW limit area. The error occurred output

remains high to indicate that these restrictions are

in effect. As soon as the application is moved

24 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 27

Commissioning Operating Instructions

19-08 Power-Recovery

Option: Function:

outside the HW or SW limit area, the error is

automatically cleared and the error occurred signal

goes low to indicate that normal operation is

restored.

19-09 Automatic Brake Control

Option: Function:

[0] Disabled When the automatic brake control function is

disabled (set to [0]), the frequency converter

control loop is active, even at standstill.

[1] * Enabled When the automatic brake control function is

enabled (set to [1]), the electromechanical brake

is automatically activated every time the

application has been at standstill for a time

period specified in parameter 19-12 Hold Delay.

This is especially useful in hoist applications

where the motor could overheat if it has to

deliver full torque at standstill for a prolonged

period.

19-10 Coast Delay

Range: Function:

200ms [0–

1000

ms]

Used with the automatic brake control function.

The coast delay is the delay after activating the

electro-mechanical brake before disabling the

controller and coasting the motor. Useful in

hoisting applications where the load would

otherwise drop a little after each stop. This is

because the activation of the brake is slower

than the deactivation of the motor.

19-11 Brake Delay

Range: Function:

200ms [0–

1000

ms]

Used with the automatic brake control function.

The brake delay is the delay after activating the

control and magnetising the motor, before the

brake is deactivated. Useful in applications with

(typically large) motors that take a longer time

to be fully magnetised than the time it takes for

the electro-mechanical brake to deactivate.

19-12 Hold Delay

Range: Function:

0 s [0–

10000 s]

Used with the automatic brake control function.

The hold delay is a waiting period in which the

brake is not activated, even though the

application is at standstill. Useful in applications

where a sequence of fast positioning commands

is followed by longer standstill periods.

19-13 Brake Wear Limit

Range: Function:

0 [0–

1073741824

UU]

If a value higher than [0] (disabled) is set,

the motor defines an error situation (Brake

wear limit exceeded – ERROR STATUS = 7) if

the drive moves more than the number of

user units (UU) specified in this parameter

while the electronic brake is activated.

19-14 Motor/Encoder Gear Numerator

Range: Function:

1 [1–

100000]

If the encoder is mounted on a gear where 5

revolutions of the motor correspond to 2

revolutions of the encoder, this parameter should

be set to [5] (the number of motor revolutions)

and parameter 19-15 Motor/Encoder Gear

Denominator should be set to [2] (the number of

encoder revolutions). If the encoder is mounted

directly on the motor shaft, this parameter setting

should remain at [1].

19-15 Motor/Encoder Gear Denominator

Range: Function:

1 [1–100000]

See the description of parameter 19-14 Motor/

Encoder Gear Numerator. If the encoder is

mounted directly on the motor shaft, this

parameter setting should remain at [1].

19-16 Maximum Jog Velocity

Range: Function:

100 ERPM [1–20000

ERPM]

The maximum speed allowed while

jogging the application is specified in

terms of Encoder Revolutions Per

Minute (ERPM).

NOTICE

This setting must never exceed a value that is approximately 5% lower than the value in parameter 32-80

Maximum Velocity (Encoder).

19-17 Jog Ramp Time

Range: Function:

5000ms [10–

100000

ms]

19-18 Jog Velocity Scaling

Option: Function:

[0] * No scaling The jog velocity is defined in encoder

[1] Scaling The jog velocity is scaled by Motor/Encoder

This parameter specifies the ramp-up time

and the ramp-down time used during

jogging. The ramp time is defined as the

time in milliseconds it would take to ramp

from standstill to the maximum allowed

velocity in parameter 32-80 Maximum

Velocity (Encoder).

revolutions per minute (ERPM).

Gear Numerator/Gear Denominator.

5 5

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 25

Page 28

Commissioning Operating Instructions

19-19 FFVEL Auto-calculation

Option: Function:

[0] * Disabled Automatic calculation is disabled for both

velocity feed forward (FFVEL) and velocity

control loop (PID).

[1] FFVEL

enabled

[2] FFVEL +

PID

55

enabled

The optimal setting of parameter velocity feed

forward is calculated automatically. This

parameter automatically resets to [0] Disabled

when the calculation is complete.

The optimal setting of parameter velocity feed

forward, proportional, derivative, and integral

factor is calculated automatically. This

parameter automatically resets to [0] Disabled

when the calculation is complete.

Parameter 32-80 Maximum Velocity

Parameter 32-00 OR 32-02 Encoder type

Parameter 32-01 OR 32-03 Encoder resolution

Parameter 19-14 motor/encoder gear ratio

numerator

Parameter 19-15 motor/encoder gear ratio

denominator

NOTICE

A change to any one of these parameters prompts a

recalculation, since the optimum value of the regulation

parameters has changed.

19-20 Factory Reset

Option: Function:

[0] * Disabled No parameters reset.

[1] Enabled Resets all parameter values to default and also

resets all trajectory data. The parameter automatically resets to [0] Disabled when the reset is

successfully carried out.

19-21 Link LCP Input to Index

Option: Function:

[0] * Disabled Disables the automatic update of parameter

19-23 Index Number. This is necessary when

programming a position number different from

the one loaded into the PLC memory.

[1] Enabled

Parameter 19-23 Index Number is automatically

updated with the last position reference number

that has been loaded into memory. This enables

the operator to see what position reference is

given by the PLC system.

19-23 Index Number

Range: Function:

0 [0–31

(0–63 in

fieldbus

mode)]

Specifies which position data should be

displayed in parameters 19-24 Index Target

Position to 19-28 Index Trajectory Type. Whenever

this number is changed, the current values of

the index parameters are stored in the memory

under the previously specified index number.

After that, the values of the index parameters

are updated with the data stored in the memory

relevant to the newly specified index number.

19-24 Index Target Position

Range: Function:

0 [–

1073741824

to

1073741824

UU]

The meaning of this parameter depends on

the position type specified in parameter 19-28

Trajectory Type.

If parameter 19-28 Index Trajectory Type = [0]

Absolute, the value of this parameter refers to

an absolute position (relative to the fixed

Home position).

If parameter 19-28 Index Trajectory Type = [1]

Relative, and the last position was obtained

through jogging, the value of this parameter

is a position relative to that position. If the

last position was reached as a result of a

positioning command, then the value of this

parameter specifies a position relative to the

last target position (whether it was reached or

not).

If parameter 19-28 Index Trajectory Type = [2]

Touch probe positive, the application moves in

the positive direction until a touch probe

position is defined. If a touch probe position is

already defined, the application moves directly

to that position.

A touch probe position is defined as the

position at which the touch probe switch input

goes high plus the value of parameter 19-24

Index Target Position.

A touch probe position is cleared by a high

signal on the reset touch probe position input.

The output Touch probe position locked is high

if a touch probe position is defined.

If parameter 19-28 Trajectory Type = [3] Touch

probe negative, the application moves in a

negative direction until a touch probe position

is defined. If a touch probe position is already

defined, the application moves directly to that

position.

NOTICE

This parameter is automatically updated depending on

parameter 19-23 Index Number.

26 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 29

Commissioning Operating Instructions

19-25 Index Ramp Up Time

Range: Function:

5000 [10–

100000 ms]

The index ramp-up time is defined as the

time in milliseconds it would take to ramp

from standstill to the maximum allowed

velocity set in parameter 32-80 Maximum

Velocity (Encoder). This setting is relevant

during positioning with the current trajectory

index.

NOTICE

This parameter is automatically updated depending on

parameter 19-23 Index Number.

19-26 Index Ramp Down Time

Range: Function:

5000 [10–

100000 ms]

The index ramp-down time is defined as the

time in milliseconds it would take to ramp

from the maximum allowed velocity set in

parameter 32-80 Maximum Velocity (Encoder)

to standstill. This setting is relevant during

positioning with the current trajectory index.

NOTICE

This parameter is automatically updated depending on

parameter 19-23 Index Number.

19-27 Index Maximum Velocity

Range: Function:

100 ERPM [1–20000

ERPM]

The index maximum velocity is defined

as the velocity in encoder revolutions

per minute (ERPM). This setting is

relevant during positioning with the

current trajectory index.

NOTICE

This parameter is automatically updated depending on

parameter 19-23 Index Number. The setting should never

exceed a value that is approximately 5% lower than the

value calculated in parameter 32-80 Maximum Velocity

(Encoder).

19-28 Index Trajectory Type

Option: Function:

[0] * Absolute

[1] Relative Positioning is relative to the last target

[2] Touch probe

positive

[3] Touch probe

negative

Positioning is absolute, related to the Home

position.

position, whether it was reached or not.

When jogging was executed previously,

positioning is relative to the position

reached via jogging.

Positioning is relative to a touch probe

position expected in positive direction.

Positioning is relative to a touch probe

position expected in negative direction.

Also see parameter 19-24 Index Target Position.

NOTICE

This parameter is automatically updated depending on

parameter 19-23 Index Number.

19-29 Parameter Save

Option: Function:

[0] * No action No trajectory data saved. Trajectory data are

not automatically saved and are therefore

not automatically available after powercycle.

[1] Save

persistent

19-30 Main Screen Setup Save

Option: Function:

[0] * No action Main screen set-up is not saved persistent.

[1] Save

persistent

19-31 Digital Jog in Field Bus mode

Option: Function:

[0] * Off

[1] Activates jog with digital inputs (53, 54), also in field

bus mode.

19-90 Type/Version

Range: Function:

[351xxyy] The text in this parameter shows the MCO product

19-91 Software Version

Range: Function:

[xxyy] The text in this parameter shows the software version

number (xx = major version code, yy = minor version

code).

19-92 New Index

Range: Function:

0 [0–31

(0–63 in fieldbus mode)]

Saves trajectory data persistent and

parameters too. This parameter automatically resets to [0] when the data is saved

successfully.

The main screen set-up is not automatically

saved and is therefore not automatically

available after a power-cycle.

Saves main screen set-up persistent. This

parameter automatically resets to [0] No

action when the main screen set-up is

saved successfully.

type/software version.

Currently latched index number.

5 5

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 27

Page 30

Commissioning Operating Instructions

19-93 Error Status

Option: Function:

[0] * 0 = OK

1 = Homing needed

2 = Positive HW limit

3 = Negative HW limit

4 = Positive SW limit

5 = Negative SW limit

6 = VLT not running

7 = Brake wear limit

8 = Quick stop

55

9 = PID error too big

12 = Reverse operation

13 = Forward operation

92 = Encoder hardware error

This is a read-only parameter.

It displays the current fault

code.

28 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 31

Commissioning Operating Instructions

5.6 MCO Basic Settings

5.6.1 32-0* and 32-1*, Encoder 2

Parameters

The 32-0* and 32-1* parameters configure the interface for

encoder 2.

32-00 Incremental Signal Type (0x1234)

Slave Denominator (Subindex 02)

This parameter specifies the type of incremental encoder

connection to Encoder 2 interface (X55 and X62 if a CAN encoder

is used).

Option: Function:

[0] None No incremental encoder is

used.

[1] * RS422 (5 V TTL) Digital incremental encoder

with an interface according

to RS422 is connected.

[2] Sinusoidal 1 Vpp Analog incremental encoder

with 1 V peak-peak signal is

connected.

[3] CAN encoder CAN encoder is used.

32-01 Incremental Resolution

Range: Function:

1024* [1073741823] The encoder resolution is used to

calculate velocity in RPM (revolutions per

minute) as well as time-out for detection

of the zero pulse with homing. Set the

resolution of the incremental encoder

connected to Encoder 2 interface (X55 and

X62 if a CAN encoder is used). The

encoder resolution can be found on the

encoder nameplate or datasheet.

If parameter 32-00 Incremental Signal Type

is set to:

[0] Digital incremental encoder,

•

the resolution must be set in

pulses per revolution.

[1] Analog incremental encoder,

•

the resolution must be set in

sinusoidal signal periods per

revolution.

[2] CAN encoder and the CAN

•

encoder is an incremental

encoder, the resolution must be

set in pulses per revolution. If

the CAN encoder is an absolute

encoder, the resolution must be

set in (pulses per revolution)/4.

NOTICE

The parameters for the incremental resolution (32-01 or

32-31) are always used, even if the CAN encoder is an

absolute encoder. But a quarter of the encoder

resolution must be set for a CAN absolute encoder. The

reason is the internal calculation, which uses 4 times the

number of counts, because an incremental encoder

returns 4 times more quad counts than its counts. An

absolute encoder only returns this real resolution as a

maximum value.

NOTICE

When [3] Motor Control is selected in parameter 32-50

Source Slave, the resolution can be set with this

parameter. The resolution value must be a second

power, otherwise rounding errors lead to positioning

drifts. The maximum frequency of the encoder signal

must not exceed 410 kHz. The parameter is only visible

when parameter 32-00 Incremental Signal Type is not set

to [0] None.

32-02 Absolute Protocol

This parameter specifies the type of absolute encoder connected

to Encoder 2 interface (X55 and X62 if a CAN encoder is used).

Option: Function:

[0] * None No absolute encoder is connected.

[1] HIPERFACE HIPERFACE absolute encoder is connected.

The selection includes the default settings

encoder ID 1 and encoder parity even.

[4] SSI An absolute encoder with SSI interface is

connected

[5] SSI with filter An absolute encoder with SSI interface is

connected and the communication/ signal is

unstable.

A leap in the position data is detected if it is larger than

the encoder resolution/2. The correction is made with an

artificial position value, which is calculated from the last

velocity. If the error continues for more than 100 readouts

(>100 ms), there is no further correction, which then leads

to a position error (error 108).

32-03 Absolute Resolution

Range: Function:

8192* [1 to

1073741823]

The encoder resolution is used to

calculate the velocity in RPM

(revolutions per minute).

Set the resolution of the absolute

encoder connected to Encoder 2

interface (X55/X62) in positions per

revolution. The encoder resolution can

be found on the encoder nameplate or

datasheet.

5 5

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 29

Page 32

Commissioning Operating Instructions

NOTICE

The parameter is only visible when parameter 32-02

Absolute Protocol is not set to [0] None.

32-04 Absolute Encoder Baudrate X55

Select the baud rate of the attached encoder.

Option: Function:

[0] 600 Baud

[1] 1200

[2] 2400

55

[3] 4800

[4] * 9600

[5] 19200

[6] 38400

32-05 Absolute Encoder Data Length

Range: Function:

25* [8-37 Bit] Specify the number of data bits for the

connected absolute encoder, see encoder

datasheet. This is required for the MCO to

generate the correct number of clock bits.

NOTICE

The parameter is only visible when parameter 32-02

Absolute Protocol is not set to [0] None.

32-06 Absolute Encoder Clock Frequency

Range: Function:

262.000* [78.124–

2000.000 kHz]

Specifies the frequency of the

absolute encoder clock signal

generated by the MCO. Set a

frequency appropriate for the

connected encoder.

NOTICE

This parameter is only visible when parameter 32-02

Absolute Protocol is not set to [0] None.

32-07 Absolute Encoder Clock Generation

Select whether the MCO should generate an absolute encoder

clock signal or not.

Option: Function:

[0] Off Select this option if more MCOs are connected to the

same absolute encoder and another MCO generates

the clock signal. Only 1 device is allowed to generate

the clock signal and only 1 device (encoder or MCO) is

allowed to generate the data signal when multiple

MCOs are interconnected.

[1] * On Select this option if the MCO is the only clock

generator for the connected absolute encoder.

NOTICE

This parameter is only visible when parameter 32-02

Absolute Protocol is not set to [0].

32-08 Absolute Encoder Cable Length

Range: Function:

0* [0-300m]The absolute encoder (SSI) clock and data signals

will be out of synchronisation if the signal delay

caused by the encoder cable is too long. The MCO

automatically compensates the cable delay when

the cable length is known. The cable delay

compensation is based on a cable delay of approximately 6 ns (6 x 10-9 seconds) per meter. Specify

the total cable length (in meters) between the

MCO and the absolute encoder.

NOTICE

This parameter is only visible when parameter 32-02

Absolute Protocol is not set to [0] None.

32-09 Encoder Monitoring

Monitoring of open-circuit and short-circuit of the encoder inputs

can be enabled or disabled.

An encoder error issues fault code 192.

Option: Function:

[0] * Off Hardware monitoring is not

required.

[1] 3 channels All 3 channels (A, B, and

Index) are monitored.

[2] 2 channels Channels A and B are

monitored.

32-10 Rotational Direction

Normally, a positive reference value initiates a positive change of

the position. If not, the reference value can be reversed

internally.

Option: Function:

[1] * No action No change. Positive reference values

produce positive encoder values.

[2] Reference

reversed

[3] User Units

reversed (–1)

The sign of the reference value is

reversed internally (plus becomes minus

and vice-versa). This is equal to a reversal

of the motor cables, or a transposition of

the A and B tracks on the encoder.

The sign of the user unit is reversed.

Thus, positive reference values produce

positive encoder values which are

indicated as negative values, however.

This applies to all outputs (parameters

34-50 Actual Position, 34-51 Commanded

Position, …), all user inputs (parameter

19-24 Index Target Position, …), and all

synchronization factors, as well as the

velocities (parameter 33-03 Velocity of

Home Motion).

30 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 33

130BD771.10

25

1

500 25

50 1

qc =

1000

1

qc = qc = 1 UU

4 10 4

130BD772.10

5

1

500 5

3600 3600

qc =

qc = 1 UU

25

9

qc = 1 UU =

Parameter 32-12 User Unit Numerator

Parameter 32-11 User Unit Denominator

4 500 4

Commissioning Operating Instructions

32-10 Rotational Direction

Normally, a positive reference value initiates a positive change of

the position. If not, the reference value can be reversed

internally.

Option: Function:

[4] User Units and

Reference

reversed (–2)

The sign of the reference value is

reversed internally; in addition, the sign

of the user unit is negated as in option

[3].

32-11 User Unit Denominator

Range: Function:

1* [1 to

1073741823]

All path information in motion commands is

made in user units and are converted to quadcounts internally. By selecting these scaling

units correspondingly, it is possible to work

with any technical measurement unit (for

example mm). This factor is a fraction, which

consists of a numerator and denominator.

1 UU =

P32-12 User Unit Numerator

P32-11 User Unit Denominator

Scaling determines how many quad-counts

make up a user unit. For example, if it is

50375/1000, then 1 UU corresponds to exactly

50.375 qc.

32-12 User Unit Numerator

Range: Function:

1* [1 to

10737418237/

max. position

(UU)]

All path information in motion commands is

made in user units and is converted to quadcounts internally. By selecting these scaling

units correspondingly, it is possible to work

with any technical measurement unit (for

example mm). This factor is a fraction, which

consists of a numerator and denominator.

1 UU =

P32-12 User Unit Numerator

P32-11 User Unit Denominator

Scaling determines how many quad-counts

make up a user unit.

Example 1

Shaft or spindle

25 motor revolutions result in 1 spindle

revolution; gearing factor = 25/1

Encoder resolution (incremental encoder) =

500

Spindle gradient = 1 revolution of the spindle

= 5 mm

Scaling factor when working with 1/10 mm

resolution = 5 x 10 = 50

Illustration 5.1 Example 1

32-12 User Unit Numerator

Range: Function:

Parameter 32-11 User Unit Denominator = 1

Example 2

Cylinder

Gear factor = 5/1

Encoder resolution (incremental encoder) =

500

One revolution of the cylinder is 360 degrees.

Work with a resolution of 1/10 degrees, which

means that 1 revolution of the cylinder is

divided into 3600 units.

Scaling factor = 3600

Illustration 5.2 Example 2

Parameter 32-12 User Unit Numerator = 25

Parameter 32-11 User Unit Denominator = 9

32-14 Encoder 2 node ID

Range: Function:

127* [1-127] Enter the feedback CAN encoder node ID.

32-15 Encoder 2 CAN Guard

Feedback CAN encoder guardians can be enabled or disabled.

Option: Function:

[0] * Off Default setting. No monitoring.

[1] On Feedback CAN encoder is monitored.

5.6.2 32-3* and 32-4*, Encoder 1

Parameters

The 32-3* and 32-4* parameters configure the interface for

encoder 1.

32-30 Incremental Signal Type

Specifies the type of incremental encoder connected to Encoder 1

interface (X56 and X62 if a CAN encoder is used).

Option: Function:

[0] None No incremental encoder is

connected.

[1] * RS422 (5 V TTL) A digital incremental encoder with

an interface according to RS-422 is

connected.

[3] CAN encoder An encoder with a CAN interface is

connected.

5 5

Parameter 32-12 User Unit Numerator = 1000

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 31

Page 34

Commissioning Operating Instructions

32-31 Incremental Resolution

Range: Function:

1024* [1 to

1073741823]

55

Set the resolution of the incremental

encoder connected to Encoder 1 interface

(X56). The encoder resolution can be

found on the encoder nameplate or

datasheet.

Digital incremental encoder

•

(parameter 32-30 = [1]): The

resolution must be set in pulses

per revolution.

CAN encoder (parameter 32-30 =

•

[3]):

Incremental encoder:

-

Pulses per revolution

Absolute encoder:

-

Pulses per revolution/4

32-34 Absolute Encoder Baudrate X56

Select the baud rate of the attached encoder.

Option: Function:

[0] 600 Baud

[1] 1200 Baud

[2] 2400 Baud

[3] 4800 Baud

[4] * 9600 Baud

[5] 19200 Baud

[6] 38400 Baud

32-35 Absolute Encoder Data Length

Range: Function:

25* [8-37 Bit] Specifies the number of data bits for the

connected absolute encoder, see encoder

datasheet. This is required for the MCO to

generate the correct number of clock bits.

NOTICE

NOTICE

The parameters for the incremental resolution (32-01 or

32-31) are always used, even if the CAN encoder is an

absolute encoder. However, a quarter of the encoder

resolution must be set for a CAN absolute encoder.

The maximum frequency of the encoder signal must not

exceed 410 kHz.

This parameter is only visible when parameter 32-30 is

not set to [0] None.

32-32 Absolute Protocol

Specifies the type of absolute encoder connected to Encoder 1

interface (X56/X62).

Option: Function:

[0] * None No absolute encoder is connected.

[4] SSI An absolute encoder with SSI interface is

connected.

[5] SSI with filter An absolute encoder with SSI interface is

connected and the communication/signal is

unstable.

32-33 Absolute Resolution

Range: Function:

8192* [1 to 1073741823] This parameter is only visible when

parameter 32-32 Absolute Protocol is

not set to [0] None.

The parameter is only visible when parameter 32-32

Absolute Protocol is not set to [0] None.

32-36 Absolute Encoder Clock Frequency

Range: Function:

262.000* [78.125–

2000.000 kHz]

Specifies the frequency of the

absolute encoder clock signal

generated by the MCO. Set a

frequency appropriate for the

connected encoder.

NOTICE

The parameter is only visible when parameter 32-32

Absolute Protocol is not set to [0] None.

32-37 Absolute Encoder Clock Generation

Select whether the MCO should generate an absolute encoder

clock signal or not.

Option: Function:

[0] Off Select this option if more MCOs are connected to the

same absolute encoder and another MCO generates

the clock signal. Only 1 device is allowed to generate

the clock signal and only 1 device (encoder or MCO) is

allowed to generate the data signal when multiple

MCOs are interconnected.

[1] * On Select this option if the MCO is the only clock

generator for the connected absolute encoder.

NOTICE

This parameter is only visible when parameter 32-32

Absolute Protocol is not set to [0] None.

32 Danfoss A/S © 04/2014 All rights reserved. MG33R302

Page 35

Commissioning Operating Instructions

32-38 Absolute Encoder Cable Length

Range: Function:

0* [0–

300 m]

The absolute encoder (SSI) clock and data signals

will be out of synchronisation if the signal delay

caused by the encoder cable is too long. The MCO

automatically compensates the cable delay when the

cable length is known. The cable delay compensation is based on a cable delay of approximately 6

ns (6 x 10-9 seconds) per meter. Specify the total

cable length (in meters) between the MCO and the

absolute encoder.

NOTICE

This parameter is only visible when parameter 32-32

Absolute Protocol is not set to [0] None.

32-39 Encoder Monitoring

Monitoring of open-circuit and short-circuit of the encoder inputs

can be enabled or disabled.

An encoder error issues fault code 192.

Option: Function:

[0] * Off Hardware monitoring is not

required.

[1] 3 channels All 3 channels (A, B, and

Index) are monitored.

[2] 2 channels Channels A and B are

monitored.

32-40 Encoder Termination

Termination resistors can be switched on or off for encoder 1.

Option: Function:

[0] Off Select this option if high input impedance is required

when 1 encoder is connected to multiple MCOs.

[1] * On Select this option when the encoder is only connected

to this MCO.

32-43 Encoder 1 Control

The encoder control word configures the position evaluation

after a change of encoder source. Soft encoder changing is

useful if encoders should be switched while running. If this is

done without using this parameter, then setting the new encoder

typically causes a position error because the encoder values are

not the same.

Option: Function:

[0] * No soft changing Select this option to switch

directly to the position data of

the new encoder.

[1] Encoder soft

changing enable

Select this option to not switch

entirely to the value of the new

encoder. Instead, the old value is

kept and the differences from the

new encoder are added. This

makes it possible to change

encoders “on the run”.

32-43 Encoder 1 Control

The encoder control word configures the position evaluation

after a change of encoder source. Soft encoder changing is

useful if encoders should be switched while running. If this is

done without using this parameter, then setting the new encoder

typically causes a position error because the encoder values are

not the same.

Option: Function:

[2] Soft zero setting

enable

[3] Encoder soft

changing and soft

zero enable

Select this option if it is not

desired to really change the

encoder value when homing is

carried out. If the soft zero

setting is on, then homing can

be carried out and the new

reported actual position is [0]

afterwards.

This option enables the smooth

changing of the feedback

encoder in the software while

running, and setting the position

to [0] without losing the actual

position.

32-44 Encoder 1 node ID

Range: Function:

127* [1–127] Enter the CAN encoder node ID.

32-45 Encoder 1 CAN Guard

CAN encoder guardians can be enabled or disabled.

Option: Function:

[0] * Off Default setting. No monitoring.

[1] On CAN encoder is monitored.

5.6.3 32-5* Feedback Source

The 32-5* parameters configure the feedback source.

32-50 Source Slave

Specifies the feedback source for MCO.

Option: Function:

[1] Encoder 1

X56

[2] * Encoder 2

X55

[3] Motor Control Select this option for MCO feedback from

Select this option to use encoder 1 as the

feedback source.

Select this option to use encoder 2 as the

feedback source.

the feedback source specified in parameter

1-02 Flux Motor Feedback Source. This can

be an internal 24 V encoder, encoder

option, or resolver option. The resolution

for Motor Control can be set in parameter

32-01 Incremental Resolution.

5 5

MG33R302 Danfoss A/S © 04/2014 All rights reserved. 33

Page 36

Commissioning Operating Instructions

32-52 Source Master

Option: Function:

[1] * Encoder 1 X56 Source master is encoder 1 on X56.

[2] Encoder 2 X55 Source master is encoder 2 on X55.

[3] Motor Control This source master can be an internal 24 V

encoder, encoder option, or resolver option.

5.6.4 32-6* and 32-7*, PID-Controller

Parameters

The 32-6* and 32-7* parameters optimise the controller.

55

32-60 Proportional Factor

Range: Function:

30* [0–

100000]

The proportional factor indicates the linear

correction factor with which the deviation

between the current set and actual position is

evaluated and a corresponding correction of the

motor speed is made. The greater the value, the

stiffer the motor behaviour becomes. There is a

tendency to overswing if the value is too high.

32-61 Derivative Value for PID Control

Range: Function: