Page 1

MCO 305 Design Guide

Contents

How to Read this MCO 305 Design Guide..................................3

How to Read this Design Guide ......................................................................3

Symbols and Conventions .............................................................................5

Abbreviations ..............................................................................................5

Definitions ..................................................................................................6

Introduction to VLT Motion Control Option MCO 305..............11

What is VLT Motion Control Option MCO 305?................................................. 11

System Overview....................................................................................... 12

Configuration Examples ..............................................................................13

Interface between MCO 305, FC 300, and other Option Modules........................ 14

Control Loops ............................................................................................14

Encoder.................................................................................................... 15

Program Execution ..................................................................................... 15

Functions and Examples.........................................................17

Positioning ................................................................................................ 17

Synchronizing............................................................................................ 24

CAM Control .............................................................................................. 35

CAM Box................................................................................................... 46

Mechanical Brake Control ............................................................................47

Limited-Jerk.............................................................................................. 49

PC Software Interface ............................................................55

Specifics of the User Interface .....................................................................55

The APOSS Window.................................................................................... 56

The Edit Window........................................................................................ 58

File Menu..................................................................................................61

Edit Menu ................................................................................................. 62

Development Menu ....................................................................................64

Controller Menu .........................................................................................70

Tools Menu................................................................................................78

Settings Menu ........................................................................................... 79

Window Menu............................................................................................83

Help Menu ................................................................................................83

Download Menu .........................................................................................84

Debugging Programs ..................................................................................86

MG.33.L5.02 – VLT® is a registered Danfoss trademark 1

Page 2

MCO 305 Design Guide

__ How to Read this MCO 305 Design Guide __

APOSS Tools...........................................................................89

CAM-Editor ...............................................................................................89

Array Editor ............................................................................................ 105

APOSS Oscilloscope.................................................................................. 116

How to Program ...................................................................157

Programming the MCO with the APOSS Macro-language................................. 157

Basics .................................................................................................... 157

Preprocessor ........................................................................................... 172

APOSS Command Groups.......................................................................... 175

Get a General Idea of Program Samples ...................................................... 191

Parameter Reference............................................................195

FC 300, MCO 305, and Application Parameters ............................................. 195

FC 300 Parameters Overview ..................................................................... 197

Application Settings.................................................................................. 199

MCO Parameters ...................................................................................... 200

MCO Basics Settings................................................................................. 201

MCO Advanced Settings ............................................................................ 217

MCO Data Readouts.................................................................................. 238

Parameter Lists........................................................................................ 242

Troubleshooting ...................................................................251

Warnings and Error Messages .................................................................... 251

APOSS Software Messages ........................................................................ 259

Index....................................................................................261

Copyright © Danfoss A/S, 2010

Trademarks VLT is a registered Danfoss trademark.

Hiperface® is a registered trademark used for Rotational Position Sensors, Namely, Electronic Feedback Systems

For Motors and owned by Sick Stegmann GmbH, Max Stegmann GmbH Antriebstechnik-Elektronik.

Microsoft, Windows 2000, and Windows XP are either registered trademarks or trademarks of the Microsoft

Corporation in the USA and other countries.

2 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 3

MCO 305 Design Guide

__ How to Read this MCO 305 Design Guide __

How to Read this MCO 305 Design Guide

How to Read this Design Guide

This Design Guide will introduce all aspects of your MCO 305. Please read also the Operating Instructions, in

order to be able to work with the system safely and professionally, particularly observe the hints and

cautionary remarks.

Chapter How to Read this Design Guide introduces the design guide and informs you about the

symbols, abbreviations, and definitions used in this

manual.

Page divider for ‘How to Read this Design Guide’.

Chapter Introduction to MCO 305 informs you

about the functionality and features of the

MCO 305, gives a system overview including

configuration examples, and informs you about

some basic topics like encoder and program

execution.

Page divider for ‘Int roduction’.

Chapter Functions and Examples guides you

through some applications examples from simple

positioning to different synchronizations as well as

CAM controls. Setting the parameters, programming of controls, and editing of curves can be

reconstructed in detail with these examples.

Page divider for ‘Fun ctions and Examples’.

MG.33.L5.02 – VLT® is a registered Danfoss trademark 3

Page 4

MCO 305 Design Guide

__ How to Read this MCO 305 Design Guide __

Chapter PC Software Interface informs you

about the APOSS specific menus and functions.

Click on → Help in the APOSS menu bar for more

details. Chapter APOSS Tools provides detailed

information about the CAM-Editor, Array-Editor as

well as the APOSS Oscilloscope.

Page divider for ‘PC Software Interface’.

Chapter How to Program shows you how to

program controls for the Frequency Converter

using MCO 305. This chapter provides a description

of all commands arranged in groups and all parameters in the Parameter Reference.

Page divider for ‘How to Program’.

Chapter Troubleshooting assists you in solving

problems that may occur when using the frequency

converter with MCO 305. The next section explains

the most important messages from the PC user

interface.

Page divider for ‘Trouble shooting’.

The manual ends with an index.

The Online Help provides in Chapter Program Samples almost 50 program samples which you can use to

familiarize yourself with the program or copy directly into your program.

Available Literature for FC 300, MCO 305, and MCT 10 Motion Control Tool

− The MCO 305 Operating Instructions provide the necessary information for built-in, set-up, and optimize

the controller.

− The MCO 305 Design Guide entails all technical information about the option board and customer design

and applications.

− This MCO 305 Command Reference completes the MCO 305 Design Guide with the detailed description of

all commands.

− The VLT® AutomationDrive FC 300 Operating Instructions provide the necessary information for getting

the drive up and running.

− The VLT® AutomationDrive FC 300 Design Guide entails all technical information about the drive and

customer design and applications.

− The VLT® AutomationDrive FC 300 MCT 10 Operating Instructions provide information for installation

and use of the software on a PC.

Danfoss Drives technical literature is also available online at www.danfoss.com/drives.

4 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 5

MCO 305 Design Guide

__ How to Read this MCO 305 Design Guide __

Symbols and Conventions

Symbols used in this manual:

NB!:

Indicates something to be noted by the reader.

Indicates a general warning.

Indicates a high-voltage warning.

*

Indicates default setting.

Conventions

The information in this manual follows the system and uses the typographical features described below to

the greatest extent possible:

Menus and Functions

Menus and functions are printed italics, for example: Controller → Parameters.

Commands and Parameters

Commands and parameter names are written in capitals, for example: AXEND and KPROP; Parameters are

printed in italics, for example: Proportional factor.

Parameter Options

Values for use to select the parameter options are written in brackets, e.g. [3].

Keys

The names of keys and function keys are printed in brackets, for example the control key [Cntl] key, or just

[Cntl], the [Esc] key or the [F1] key.

Abbreviations

Automatic Motor Adaptation AMA

Control word CTW

Direct Current DC

Digital Signal Processor DSP

Frequency Converter FC

Local Control Panel LCP

Least significant bit LSB

Main actual value MAV

Motion Control Option MCO

Motion Control Tool MCT

Minute min

Most significant bit MSB

Main Reference MRV

Master Unit MU

Digital output switching to high side. NPN

Switch normally closed nc

Switch normally open no

Parameter par.

Position Control Loop PID

Digital output switching to low side. PNP

Pulses per Revolution PPR

Quad-counts qc

Reference REF

Revolutions per Minute RPM

Second, Millisecond s, ms

Sample time st

Status word STW

User Unit UU

Volts V

MG.33.L5.02 – VLT® is a registered Danfoss trademark 5

Page 6

MCO 305 Design Guide

__ How to Read this MCO 305 Design Guide __

Definitions

MLONG

An upper or lower limit for many parameters:

-MLONG = -1,073,741,824

MLONG = 1,073,741,823

Online / Offline Parameters

Changes to online parameters are activated immediately after the data value is changed. Changes to offline

parameters are not activated until you enter [OK] on the LCP.

Quad-counts

Incremental encoders: 4 quad-counts correspond

to one sensor unit.

Absolute encoders: 1:1 (1 qc correspond to one

sensor unit).

Through edge detection, a quadrupling of the increments is produced by both tracks (A/B) of the

incremental encoder. This improves the resolution.

Encoder Direction

The direction of encoder is determined by which

order the pulses are entering the drive.

Clockwise direction means channel A is 90 electrical degrees before channel B.

Counter Clockwise direction means channel B is

90 electrical degrees before A.

The direction determined by looking into the shaft

end.

Derivation of quad counts

6 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 7

MCO 305 Design Guide

__ How to Read this MCO 305 Design Guide __

Virtual Master

Virtual master is an encoder simulation which

serves as a common master signal for

synchronization of up-to 32 axes.

MG.33.L5.02 – VLT® is a registered Danfoss trademark 7

Page 8

MCO 305 Design Guide

__ How to Read this MCO 305 Design Guide __

User Units

The units for the drive or the slave and the master, respectively, can be defined by the user in any way

desired so that the user can work with meaningful measurements.

Starting with MCO 5.00 the factors SYNCFACTM / SYNCFACTS, POSFACT_Z / POSFACT_N are no longer

limited to small values

Internally, it is act as follows: Whenever a value must be multiplied by the gear factor (i.e. master increments per ms), at first it is looked if a multiplication will result in an overflow. If so, a factor (64 bit) is used

which consists of

SYNCFACTS/SYNCFACTM to multiply the delta_master.

If no overflow occurs, first it is multiplied by SYNCFACTS and then divided by SYNCFACTM.

Concerning the error we are dealing with, this means:

Normal case

Multiplying by SYNCFACTS has no error, but dividing by SYNCFACTM means that the result may be wrong by

. That means that (worst case) such an error occurs every ms, i.e. that after 1193 hours (49,71 days)

1/2³²

we made an error of 1 qc (Slave).

Big factors

In that case, the used factor (SYNCFACTS/SYNCFACTM) itself could be wrong by 1/2³²

the worst case an error of delta_master * 1/2³²

occurs every ms. Assume that we have an encoder with

. This means that in

1000 counts (4000 qc) per revolution. Assume further, that we drive with 2000 rpm, i.e. we have a velocity

of 133 qc/ms. This means we make an error of 133 * 1/2³²

per ms. From this follows that in worst case

(maximum error every ms always in same direction) we could have an error of 1 qc after 9 hours.

This should not be relevant in most applications.

User Units [UU]

All path information in motion commands are made in user units and are converted to quad-counts

internally. These also have an effect on all commands for the positioning: e.g. APOS.

The user can also select meaningful units for the CAM control in order to describe the curve for the master

and the slave, for example 1/100 mm, or 1/10 degrees in applications where a revolution is being observed.

In the CAM control, the maximum run distance of the slave or the slave cycle length are indicated in User

Units UU (qc).

You can standardize the unit with a factor. This factor is a fraction which consists of a numerator and

denominator:

UU UnitUser 1 =

12-32 par.

11-32 par.

Numerator Unit User

Denomintor Unit User

par. 32-12 User Unit Numerator POSFACT_Z

par. 32-11 User Unit Denominator POSFACT_N

Scaling determines how many quad-counts make up a user unit. For example, if it is 50375/1000, then one

UU corresponds to exactly 50.375 qc.

NB!:

When user units are transferred into qc, then they get truncated. When qc are transferred into

user units, then they get rounded.

8 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 9

MCO 305 Design Guide

__ How to Read this MCO 305 Design Guide __

Master Units [MU]

A factor (fraction) is used for the conversion into qc, as with the user unit:

1033 par.

par. 33-10 Synchronization Factor Master SYNCFACTM

par. 33-11 Synchronization Factor Slave SYNCFACTS

Open Loop vs. Closed Loop

Open loop is control without feedback. Closed loop control compares velocity or position feedback with the

commanded velocity or position and generates a modified command to make the error smaller. The error is

the difference between the required speed and the actual speed.

Open loop can be used on systems where motor velocity is not critical, and where accurate positioning is

not necessary. Applications such as fan and blower control, pump control, and some low-end home

appliances are examples.

MU UnitMaster 1

=

−

1133 par.

−

Master Factor ationSynchroniz

Slave Factor ationSynchroniz

MG.33.L5.02 – VLT® is a registered Danfoss trademark 9

Page 10

Page 11

MCO 305 Design Guide

Introduction to VLT Motion Control Option MCO 305

What is VLT Motion Control Option MCO 305?

MCO 305 is an integrated programmable Motion Controller for VLT Automation Drive FC 312 and FC 312; it

adds functionality and flexibility to the already very comprehensive standard functionality of these drives.

FC 312 and FC 312 with MCO 305 is an intelligent drive offering highly accurate and dynamic motion control

featuring, Synchronization (electronic shaft), Positioning and electronic CAM control. In addition the programmability offers the possibility to implement a variety of application functions such as monitoring and

intelligent error handling.

Development of application programs for MCO 305 and configuration/commissioning is done via easy to use

PC software tools integrated in VLT Motion Control Tools MCT 10. The PC software tools includes programming editor with program examples, CAM profile editor as well as “test-run” and “scope” function for controller optimizing. MCO 305 is based on event controlled programming using a structured text programming

language developed and optimized for this application.

FC 312 can be delivered as an “all-in-one” drive with the MCO 305 module preinstalled or MCO 305 can be

delivered as option module for field installation.

Basic Features and specifications:

– Home function.

– Absolute and relative positioning.

– Software and Hardware end limits.

– Velocity, Position and Marker synchronizing.

– CAM control.

– Virtual master function for synchronizing of

multiple slaves.

– On-line adjustable gear-ratio.

– On-line adjustable offset.

– Definition of application parameters accessible

via FC 300 local control panel.

– Read/Write access to all FC 300 parameters.

– Sending and receiving data via Field-bus

interface (requires Field-bus option).

– Interrupts triggered by various events: Digital

input, position, Field-bus data, parameter

change, status change and time.

– Calculation, comparison, bit manipulation and

logical gating.

– Conditional and unconditional jumps.

– Graphical PID optimizing tool.

– Debugging tools.

– Supported encoder types: 5V Incremental

RS422 and SSI absolute single- and multi-turn,

Gray code, adjustable clock frequency and data

length.

– 3 supply voltages: 5V, 8V and 24V.

MG.33.L5.02 – VLT® is a registered Danfoss trademark 11

Page 12

MCO 305 Design Guide

__ Introduction to VLT Motion Control Option MCO 305 __

System Overview

The MCO 305 system includes at least the following elements:

– FC 300.

– MCO 305 module.

– Motor/geared motor.

– Feedback encoder. Encoder must be mounted on motor shaft when operating FC 300 in Flux closed loop,

feedback encoder for positioning and synchronizing can be mounted anywhere in the application. See

“Encoders in applications” for more details.

– Master encoder (only for synchronizing).

– PC with MCT 10 for programming.

The following might also be required:

– Brake resistor for dynamic braking.

– Mechanical brake.

12 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 13

MCO 305 Design Guide

__ Introduction to VLT Motion Control Option MCO 305 __

Configuration Examples

One encoder used as motor feedback for closed

loop Flux control as well as position feedback.

One encoder used as motor feedback for closed

loop Flux control (connected via encoder option

MCB 102), linear encoder used as slave position

feedback and a third encoder as master.

MG.33.L5.02 – VLT® is a registered Danfoss trademark 13

Page 14

MCO 305 Design Guide

__ Introduction to VLT Motion Control Option MCO 305 __

Interface between MCO 305, FC 300, and other Option Modules

The Interface between MCO 305 and the FC 300 control card provides read/write access to all parameters

as well as reading status of all inputs and the possibility to control all outputs. In addition various process

data such as status word and actual motor current can be read by the MCO 305 application program.

MCO 305 is controlling FC 300 via the speed/torque reference; see section “Control loops” for further

details.

Field-bus interface (e.g. PROFIBUS and

DeviceNet): MCO 305 has read/write access to

data received/send via the various Field-bus

interfaces (requires optional Field-bus option

module).

Relay option MCB 105: The relay outputs of MCB

105 can be controlled by the MCO 305 application

program.

General purpose I/O option MCB 103: Status of

inputs can be read and outputs can be controlled

via the MCO 305 application program.

Up-/download of MCO 305 application programs and configuration data is done via the FC 300 interfaces

(RS485 or USB) or via PROFIBUS DPV1 (requires optional PROFIBUS module). The same applies for the online PC software functions such as test-run and debugging.

Control Loops

MCO 305 has a PID (Proportional, Integral, Derivative) controller for position control based on actual

position (encoder feedback) and commanded position (calculated). The MCO 305 PID is controlling the

position in all modes of operation except velocity synchronizing where the velocity is controlled instead.

FC 300 is an “amplifier” in the MCO 305 control loop and it must therefore be optimized for the connected

motor and load before the MCO 305 PID can be set-up. FC 300 can be operated in open loop or closed loop

within the MCO 305 control loop, see example below:

Guideline for optimizing MCO 305 PID can be found in MCO 305 Operating Instructions.

Guideline for optimizing FC 300 can be found in FC 300 Operating Instructions.

14 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 15

MCO 305 Design Guide

__ Introduction to VLT Motion Control Option MCO 305 __

Encoder

MCO 305 supports various encoder types:

– Incremental encoder with RS422 signal type.

– Incremental encoder with sine–cosine signal type.

– Absolute encoder with SSI interface.

Master and feedback/slave encoder type can be selected independently; encoders can be rotary or linear.

Selection of encoder type depends on application requirements and general preferences. Attention must

however be paid to the resolution of the selected encoder. There are 3 important selection criteria:

– Maximum position accuracy is +/- 1 encoder increment.

– To ensure stable and dynamic control a minimum of 20 encoder increments per PID controller sample

period (default is 1 millisecond) is needed at the minimum application velocity.

– Maximum frequency of the MCO 305 encoder inputs must not be exceeded at maximum velocity.

The feedback encoder can be mounted directly on the motor shaft or behind gearboxes and/or other types

of transmissions. There are how ever some important issues to be aware of when mounting the encoder:

– There should be a firm connection between motor and encoder. Slip, backlash, and elasticity will reduce

control accuracy and stability.

– When the encoder is running at a low speed it must have a high resolution in order to meet the above

requirement (minimum 20 encoder increments per controller sample).

Program Execution

MCO 305 can store multiple programs, up-to 90. Only one of these programs can be executed at a time,

there are three ways to control which program to execute:

− Via parameter 33-80 Activated Program Number.

− Via digital inputs (parameters 33-50 through 33-59, 33-61 and 33-62).

− Via PC software.

One program must be defined as Autostart program, the Autostart program is automatically executed after

power up. Without Autostart program it is only possible to execute a program via PC software.

The Autostart program is always executed first, if the Autostart program is terminated (no loop or by EXIT

command) the following can happen:

1. When parameter 33-80 (Activated Program Number) = -1 and no input (parameters 33-50 through 33-

59, 33-61 and 33-62) is selected as Start program execution ([13] or [14]). The Autostart program will

restart.

2. When parameter 33-80 (Activated Program Number) ≠ -1 and no input (parameters 33-50 through 3359, 33-61 and 33-62) is selected as Start program execution ([13] or [14]). The selected program (par.

33-80) will be executed.

3. When an input (parameters 33-50 through 33-59, 33-61 and 33-62) is selected as Start program

execution ([13] or [14]) and one or more inputs are selected as Program select ([15]). The selected

program (Program select inputs) will be executed when the Start program execution input is activated.

The active program can be aborted via a digital input when defining an input as Break program execution

(Option [9] or [10] in 33-50 through 33-59, 33-61 and 33-62). The aborted program can be restarted via a

digital input when defining an input as Continue program execution (Option [11] or [12] in 33-50 through

33-59, 33-61 and 33-62).

Starting the Autostart program after power-up can be avoided by pressing the [Cancel] key of the FC 300

LCP during power-up. The key must be pressed until the message User abort (error 119) appears in the

display.

MG.33.L5.02 – VLT® is a registered Danfoss trademark 15

Page 16

MCO 305 Design Guide

__ Introduction to VLT Motion Control Option MCO 305 __

A temporary program can be executed from the program editor (MCT10/APOSS), temporary programs are

only stored in RAM and are thus lost at power-down. The temporary program can also be executed in a

special Debug mode where it is possible to influence the program execution as well as reading out data and

variables, see on-line help of APOSS for further details.

When connecting a PC with MCT 10 to the drive, the active program might be aborted e.g. when

downloading a new program or when working with the program editor ([Esc] will abort program

execution).

NB!:

In case of an error the active program will be terminated if no error handler (ON ERROR GOSUB

xxxx) is defined and the program will not be restarted.

16 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 17

MCO 305 Design Guide

Functions and Examples

Positioning

Basically the term positioning in connection with drives means moving the shaft to a specific position. In

order to obtain accurate positioning it is necessary to use a closed loop system to control the actual

position, based on position feedback from an encoder.

A positioning procedure with a closed loop positioning controller requires the following: Set velocity,

acceleration, deceleration and a target position; a velocity profile is calculated based on the actual position

of the shaft as well as the before mentioned parameters; the shaft is moved according to the velocity profile

until the target position is reached.

Typical applications where accurate positioning is required:

− Palletizers, for example stacking boxes on a pallet.

− Index tables, for example filling material into trays on a rotating table.

− Conveyors, for example when cutting material to length.

− Hoists, for example a lift stopping at different levels.

MCO 305 offers three main positioning types

− Absolute

− Relative

− Touch Probe

Absolute Positioning

Absolute positioning always relates to the absolute zero point of the system, this also means that the absolute zero point must be defined before an absolute positioning procedure can be conducted. When using

incremental encoders the zero point is defined by means of a Home function, where the drive approaches a

reference switch, stops and defines the actual position as zero. When using absolute encoders the zero

point is given by the encoder.

If the starting position is 0 and with an absolute positioning to 150.000 the target position is 150.000, the

drive will thus move a distance of 150.000. If on the other hand the starting position is 100.000 and with an

absolute positioning to 150.000 the target position is still 150.000 but the drive will only move a distance of

50.000 because it moves to position 150.000 related to the zero point.

MG.33.L5.02 – VLT® is a registered Danfoss trademark 17

Page 18

MCO 305 Design Guide

__ Functions and Examples __

Relative Positioning

Relative positioning is always relating to the actual position, it is therefore possible to execute a positioning

procedure without defining the absolute zero point.

If the starting position is 100.000, with a relative positioning to 150.000 the target position is 250.000

(100.000 + 150.000), the moving distance is thus 150.000.

Touch Probe Positioning

With touch probe positioning, the positioning is related to the actual position when the touch probe input is

activated, that means the target position is the position of the touch probe + the positioning distance. Touch

probe positioning is thus relative positioning relating to a touch probe instead of the actual starting position.

The touch probe is a sensing device; it can be a mechanical switch, a proximity sensor, an optical sensor or

the like. Once the touch probe is activated, for example by a box moved on a conveyor belt, the reference

for the positioning is set.

With touch probe positioning to position 50.000 the drive is running until the touch probe is activated for

example at position 200.000 and it continues to a target position of 250.000 (200.000 + 50.000). Touch

probe positioning is also called “marker related positioning”.

18 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 19

MCO 305 Design Guide

__ Functions and Examples __

Application Example: A Bottle Box Palletizer

The following samples show a palletizer stacking

boxes with bottles. The boxes are unloaded using a

pack gripper. The three positioning modes are used

in this sample and explained in three steps.

NOTE: The following are just examples and the

presented settings and programs might not cover

the complete functionality required by a real

application.

It is assumed that the motor and encoder connections are checked and that all basic parameter

settings such as motor data, encoder data and PID

controller are done. Instructions for setting up parameters can be found in FC 300 Operating

Instructions and MCO 305 Operating Instructions.

Absolute Positioning

Absolute Positioning is explained with following function of the palletizer: The horizontal axis has two fixed

target positions; one is above the pick-up and the other one is above the pallet. The horizontal axis is controlled with absolute positioning between the pick-up position and the deliver position.

Parameter Settings and Commands for Palletizer Application

The following MCO 305 parameters are relevant for

absolute positioning:

32-0* Encoder 2 – Slave page

32-6* PID-Controller page

32-8* Velocity & Acceleration page 213

33-0* Home Motion page 217

33-4* Limit Handling page

Command Description Syntax Parameter

Absolute Positioning (ABS)

ACC Sets acceleration ACC a a = acceleration

DEC Sets deceleration DEC a a = deceleration

HOME Move to device zero point (reference switch) and set

as the real zero point.

POSA Positions axis absolutely POSA p p = position in UU

VEL Sets velocity for relative and absolute motions and

set maximum allowed velocity for synchronizing

HOME –

VEL v v = scaled velocity value

201

210

229

MG.33.L5.02 – VLT® is a registered Danfoss trademark 19

Page 20

MCO 305 Design Guide

__ Functions and Examples __

Program Example: Absolute Positioning for Palletizer Application

/********************** Absolute Positioning program sample **************************/

// Inputs: 1 Go to pick up position

// 2 Goto deliver position

// 3 Home switch

// 8 Clear Error

// Outputs: 1 In pick up position

// 2 In deliver position

// 8 Error

/****************************** Interrupts **************************************/

ON ERROR GOSUB errhandle

// In case of error go to error handler routine, this must always be included

/**************************** Basic settings ***********************************/

VEL 80 // Sets positioning velocity related to par. 32-80 Maximum velocity

ACC 100 // Sets positioning acceleration related to par. 32-81 Shortest ramp

DEC 100 // Sets positioning deceleration related to par. 32-81 Shortest ramp

/*********************** Define application parameters *****************************/

LINKGPAR 1900 "Pick up Position" 0 1073741823 0

LINKGPAR 1901 "Deliver Position" 0 1073741823 0

/****************** Define Home(0) position after power up *************************/

SET I_FUNCTION_3 1 // Define input 3 as Home switch input

HOME // Go to Home and set position to 0

/****************************** main loop **************************************/

MAIN:

IF (IN 1 == 1) AND (IN 2 == 0) THEN // Go to pick up position when only input 1 is high

OUT 2 0 // Reset "In deliver position" output

POSA (GET 1900) // Go to position

OUT 1 1 // Set "In pick up position" output

ELSEIF (IN 1 == 0) AND (IN 2 == 1) THEN // Go to deliver position when only input 2 is high

OUT 1 0 // Reset "In pick up position" output

POSA (GET 1901) // Go to position

OUT 2 1 // Set "In deliver position" output

ELSE

MOTOR STOP // Stop if both inputs are low or high.

ENDIF

GOTO MAIN

/*********************** Sub programs start *************************************/

SUBMAINPROG

/************************* Error handler ****************************************/

SUBPROG errhandle

err = 1 // Set error flag to remain in error handler until error is reset.

OUT 8 1 // Set error output

WHILE err DO // Remain in error handler until the reset is received

IF IN 8 THEN // Reset error when Input 8 is high.

ERRCLR // Clear error

err=0 // Reset error flag

ENDIF

ENDWHILE

OUT 8 0 // Reset error output

RETURN

/*****************************************************************************/

ENDPROG

/*************************** End of program ************************************/

20 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 21

MCO 305 Design Guide

__ Functions and Examples __

Relative Positioning

Relative Positioning is explained with following function of the palletizer: When leaving the deliver position

the vertical axis just needs to move up one box height so that it is clear of the stack before the horizontal

axis can move back to the pick-up position. This is done by relative positioning to “box height” in the “updirection”.

Parameter Settings and Commands for Palletizer Application (Relative Positioning)

The following MCO 305 parameters are relevant for

relative positioning:

Command Description Syntax Parameter

Relative Positioning (REL)

ACC Sets acceleration ACC a a = acceleration

DEC Sets deceleration DEC a a = deceleration

POSR Positioning relative to the actual position POSR d d = distance to actual position in UU

VEL Sets velocity VEL v v = scaled velocity value

32-0* Encoder 2 – Slave page

32-6* PID-Controller page 210

32-8* Velocity & Acceleration page

201

213

Program Example: Relative Positioning for Palletizer Application

/********** Relative positioning sample program for palletizer application example **********/

// Inputs: 1 Go to position

// 8 Clear Error

// Outputs: 1 In position

// 8 Error

/*************************** Interrupts *****************************************/

ON ERROR GOSUB errhandle

// In case of error go to error handler routine, this must always be included

/************************ Define flags *****************************************/

flag = 0

/********************* Basic settings ****************************************/

VEL 80 // Sets positioning velocity related to par. 32-80 Maximum velocity.

ACC 100 // Sets positioning acceleration related to par. 32-81 Shortest ramp.

DEC 100 // Sets positioning deceleration related to par. 32-81 Shortest ramp.

/******************* Define application parameters *********************************/

LINKGPAR 1900 "Box high" 0 1073741823 0

/************************** main loop *****************************************/

MAIN:

IF (IN 1 == 1) AND (flag == 0) THEN // Go to position once (ensured by flag) when input 1 is high.

OUT 1 0 // Reset "In position" output.

POSR (GET 1900) // Go to position.

OUT 1 1 // Set "In position" output.

flag = 1 // Set "flag" to ensure that distance is only traveled once.

ELSE

MOTOR STOP // Stop if input is low.

flag = 0 // Reset "flag" to enable new positioning.

ENDIF

GOTO MAIN

/********************** Sub programs start **************************************/

SUBMAINPROG

/************************ Error handler *****************************************/

SUBPROG errhandle

MG.33.L5.02 – VLT® is a registered Danfoss trademark 21

Page 22

MCO 305 Design Guide

__ Functions and Examples __

err = 1 // Set error flag to remain in error handler until error is reset.

OUT 8 1 // Set error output.

WHILE err DO // Remain in error handler until the reset is received.

IF IN 8 THEN // Reset error when Input 8 is high.

ERRCLR // Clear error.

err=0 // Reset error flag.

ENDIF

ENDWHILE

OUT 8 0 // Reset error output.

flag = 0 // Reset "flag" to enable new positioning.

RETURN

/*****************************************************************************/

ENDPROG

/********************* End of program *****************************************/

Touch Probe Positioning

Touch Probe is explained with following function of the palletizer:

When the horizontal axis is in the deliver position the vertical axis has numerous target positions depending

on the height of the already stacked boxes, which again depends on the box height and the number of

layers of boxes. This is controlled with Touch probe positioning where the touch probe detects the top of the

stack in order to calculate the deliver position on top of the stack.

Parameter Settings and Commands for Touch Probe Application

The following MCO 305 parameters are relevant for

touch probe positioning:

32-0* Encoder 2 – Slave page

32-6* PID-Controller page 210

32-8* Velocity & Acceleration page 213

33-4* Limit Handling page

201

229

Command Description Syntax Parameter

Touch Probe

ON INT Defining an interrupt input. ON INT n

GOSUB name

ACC Sets acceleration. ACC a a = acceleration

DEC Sets deceleration. DEC a a = deceleration

POSR Positioning relative to the actual

position.

CVEL Sets velocity for speed controlled

motor movements.

CSTART Starts the speed mode. – –

POSR d d = distance to actual position in UU

CVEL v v = velocity value (negative value for

n = number of the input to be monitored

1 - 8 = reaction to the rising edge

–1 - 8 = reaction to the falling edge

name = subroutine name

reversing)

22 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 23

MCO 305 Design Guide

__ Functions and Examples __

Program Example: Touch Probe Positioning for Palletizer Application

/******** Touch probe positioning sample program for palletizer application example *********/

// Inputs: 1 Go to position

// 2 Touch probe

// 8 Clear Error

// Outputs: 1 In position

// 8 Error

/********************************* Interrupts ************************************/

ON ERROR GOSUB errhandle // In case of error go to error handler routine, this must always be included

ON INT 2 GOSUB tp_handler // Call touch probe handler on positive edge of input 2.

/******************************* Define flags ***********************************/

flag = 0

tp_active = 0

/***************************** Basic settings **********************************/

VEL 80 // Sets positioning velocity related to parameter 32-80 Maximum velocity.

ACC 100 // Sets positioning acceleration related to parameter 32-81 Shortest ramp.

DEC 100 // Sets positioning deceleration related to parameter 32-81 Shortest ramp.

/************************** Define application parameters ***************************/

LINKGPAR 1900 "Touch probe distance" 0 1073741823 0

/******************************* main loop **************************************/

MAIN:

IF (IN 1 == 1) AND (flag == 0) THEN // Start movement once (ensured by flag) when input 1 is high.

OUT 1 0 // Reset "In position" output.

CVEL 80 // Set constant velocity.

CSTART // Start with constant velocity.

tp_active = 0 // Reset "tp_active" to enable new touch probe positioning.

flag = 1 // Set "flag" to ensure that distance is only traveled once.

ELSE

MOTOR STOP // Stop if input is low.

flag = 0 // Reset "flag" to enable new start.

ENDIF

GOTO MAIN

/****************************** Sub programs start *******************************/

SUBMAINPROG

/****************************** Touch probe handler ******************************/

SUBPROG tp_handler

IF (tp_active == 0) THEN

POSR (GET 1900) // Go to touch probe target position

WAITAX // Halt program execution until position is reached (This is necessary as

// NOWAIT ON is automatically set in a subroutine called by interrupt).

OUT 1 1 // Set "In position" output.

tp_active = 1 // Set "tp_active" to ensure that touch probe positioning is done only once

ENDIF

RETURN

/******************************** Error handler *********************************/

SUBPROG errhandle

err = 1 // Set error flag to remain in error handler until error is reset.

OUT 8 1 // Set error output.

WHILE err DO // Remain in error handler until the reset is received.

IF IN 8 THEN // Reset error when Input 8 is high.

ERRCLR // Clear error.

err=0 // Reset error flag.

ENDIF

ENDWHILE

OUT 8 0 // Reset error output.

flag = 0 // Reset "flag" to enable new positioning.

RETURN

/*****************************************************************************/

ENDPROG

/******************************** End of program ********************************/

MG.33.L5.02 – VLT® is a registered Danfoss trademark 23

Page 24

MCO 305 Design Guide

__ Functions and Examples __

Synchronizing

Synchronizing is used in applications where 2 or more shafts need to follow each other in velocity or position. It can be a simple master-slave system where a slave is following the velocity or position of a master

or it can be a multi-axis system where multiple slaves are following the velocity or position of a common

master signal. Electronic synchronization is very flexible compared to a mechanical shaft, belt or chain as

the gear-ratio and position offset can be adjusted during operation. Velocity and position of the slave drive

is controlled based on a master encoder signal, a feedback encoder signal as well as the set gear-ratio.

During synchronization the slave is always restricted by maximum velocity and acceleration/ deceleration

(parameter group 33-8*). In addition the allowed deviation between master and slave velocity can be

restricted by parameter 33-14, e.g. 33-14 = 5% means that the slave can only be 5% faster or slower than

actual master velocity when doing position corrections.

MCO 305 offers 3 basic types of synchronization:

For synchronous operation of two or more drives you can use

− Velocity synchronization

− Position synchronization

− Marker synchronization

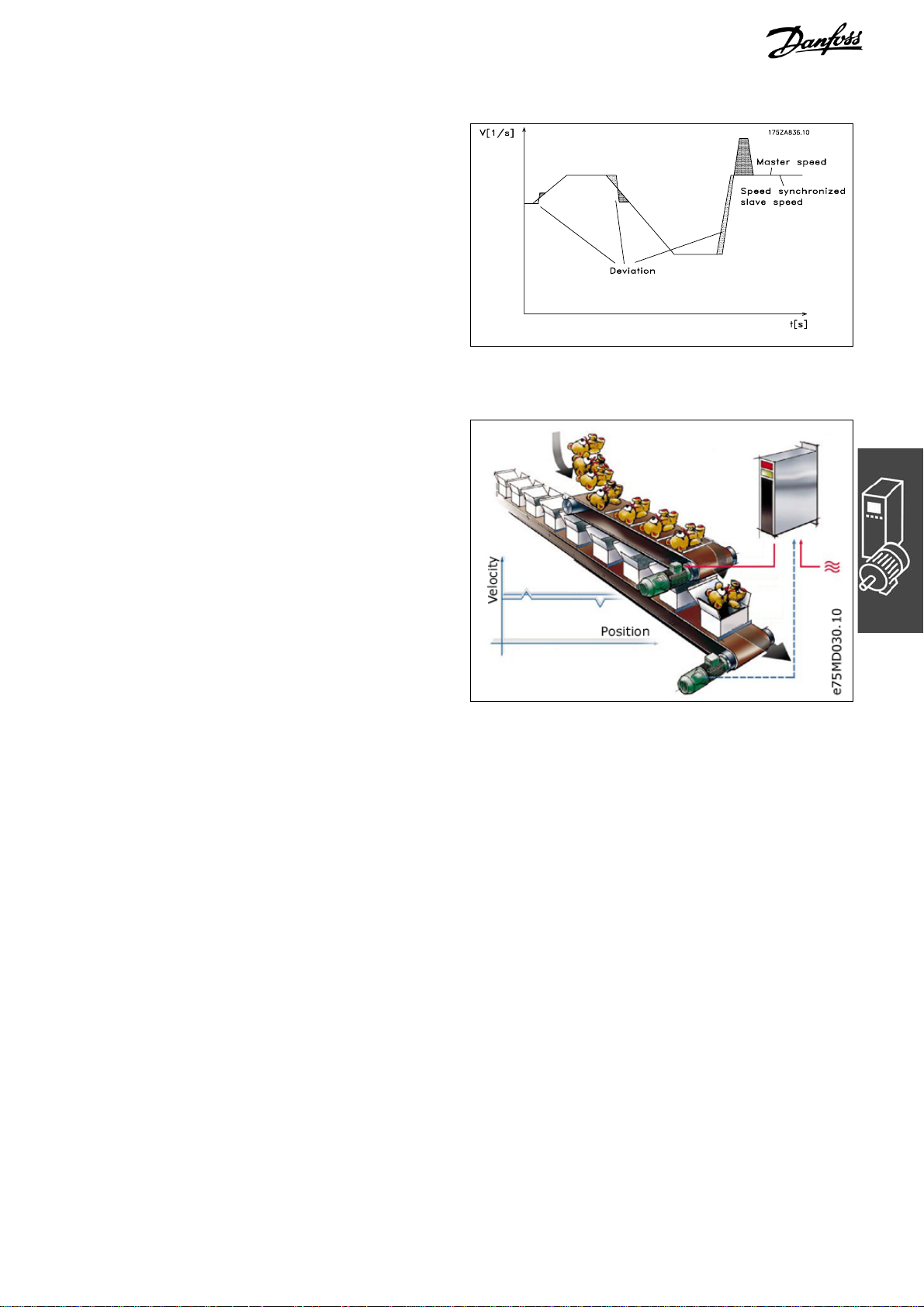

Velocity Synchronization (SYNCV)

Velocity synchronization (SYNCV) is closed loop velocity control where the set-point is the master velocity

multiplied by the gear-ratio and the actual velocity is measured by the slave encoder; position deviations

will not be corrected. Note however that using the Integral part of the PID controller will lead to some level

of position correction as the integral sum of velocity is equal to position.

The slave must be at least as fast and dynamic as

the master in order to maintain accurate synchronization, i.e. the slave must be able to match the

maximum velocity, acceleration and deceleration of

the master. Already during the design phase it is

thus important to consider making the least dynamic shaft the master as this shaft will anyway be

the limiting factor for the system performance.

Typical applications are:

− Synchronizing of two or more conveyors

− Material stretching

− Mixing

Application Example: Suit Case Conveyor Belt

Control behavior with velocity synchronization.

Two or more conveyor belts must run at the same

speed in order to get a smooth transfer of the suit

case from one conveyor belt to the next.

In addition to start and stop of velocity synchronizing the sample program has a manual mode with

the possibility to increase and decrease the velocity

via digital inputs.

NOTE: The following is just an example and the presented settings and programs might not cover the

complete functionality required by a real application.

It is assumed that the motor and encoder connections are checked and that all basic parameter settings

such as motor data, encoder data and PID controller are done. Instructions for setting up parameters can

be found in FC 300 Operating Instructions and MCO 305 Operating Instructions.

24 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 25

MCO 305 Design Guide

__ Functions and Examples __

Parameter Settings and Commands for Conveyor Belt Application

The following MCO 305 parameters are relevant for

velocity synchronization:

Command Description Syntax Parameter

SYNCV Synchronization of velocity SYNCV –

ON ERROR GOSUB Definition of an error subroutine

Program Example: Velocity Synchronizing

/************************ Velocity synchronizing sample program ***********************/

// Inputs: 1 Start/stop synchronization

// 2 Start manual mode

// 3 Increase manual velocity

// 4 Decrease manual velocity

// 8 Clear Error

// Outputs: 1 In synchronizing mode

// 2 In manual mode

// 8 Error

/********************************* Interrupts **************************************/

ON ERROR GOSUB errhandle // In case of error go to error handler routine, this must always be included

/***************************** Basic settings *************************************/

VEL 100 // Sets maximum slave velocity related to parameter 32-80 Maximum velocity

ACC 100 // Sets slave acceleration related to parameter 32-81 Shortest ramp

DEC 100 // Sets slave deceleration related to parameter 32-81 Shortest ramp

/************************** Define application parameters *****************************/

LINKGPAR 1900 "Manual velocity" 0 100 0

LINKGPAR 1901 "Velocity step" 0 10 0

/*************************** Define flags and variables *******************************/

sync_flag = 0

done = 0

err = 0

man_vel = 0

/********************************** main loop *************************************/

MAIN:

IF (IN 1 == 1) AND (sync_flag == 0) THEN // Start synchronizing once when input 1 is high

SYNCV // Start velocity synchronizing mode

sync_flag = 1 // Set sync_flag to ensure synchronizing is only started once.

OUT 1 1 // Set "In synchronizing mode" output

ELSE

MOTOR STOP // Stop if input 1 is low.

sync_flag = 0 // Reset sync_flag after stop

OUT 1 0 // Reset "In synchronizing mode" output

ENDIF

IF (IN 2 == 1) AND (sync_flag == 0) THEN // Start manual mode if input 2 high and not synchronizing

OUT 2 1 // Set "In manual mode" output

man_vel = GET 1900 // Set manual velocity to parameter 1900

CVEL man_vel

CSTART // Start constant velocity mode

WHILE (IN 2 == 1) DO // Stay in manual mode while input 2 is high

CVEL man_vel // Update manual velocity

IF (IN 3 == 1) AND (done == 0) THEN // Increase manual velocity by one step when input 3 is set

32-0* Encoder 2 – Slave page

32-3* Encoder 1 – Master page 205

32-6* PID-Controller page

32-8* Velocity & Acceleration page 213

33-1* Synchronization page 218

ON ERROR GOSUB

name

name = name of the subroutine

201

210

MG.33.L5.02 – VLT® is a registered Danfoss trademark 25

Page 26

MCO 305 Design Guide

__ Functions and Examples __

man_vel = man_vel + GET 1901

done = 1

ELSEIF (IN 4 == 1) AND (done == 0) THEN // Decrease manual velocity by 1 step when input 3 is set

man_vel = man_vel - GET 1901

done = 1

ELSE

done = 0

ENDIF

ENDWHILE

CSTOP // Stop when leaving manual mode

OUT 2 0 // Reset "In manual mode" output when leaving manual mode

ENDIF

GOTO MAIN

/****************************** Sub programs start ********************************/

SUBMAINPROG

/******************************** Error handler ***********************************/

SUBPROG errhandle

err = 1 // Set error flag to remain in error handler until error is reset.

OUT 8 1 // Set error output

OUT 1 0 // Reset "In synchronizing mode" output in case of error

OUT 2 0 // Reset "In manual mode" output in case of error

WHILE err DO // Remain in error handler until the reset is received

IF (IN 8) AND NOT (IN 1) AND NOT (IN 2) THEN

// Reset error when Input 8 is high and input 1+2 is low.

ERRCLR // Clear error

err=0 // Reset error flag

ENDIF

ENDWHILE

OUT 8 0 // Reset error output

sync_flag = 0 // Reset sync_flag after an error

done = 0 // Reset done flag after an error

RETURN

/*******************************************************************************/

ENDPROG

/******************************* End of program **********************************/

Position/Angle Synchronization (SYNCP)

Position synchronization (SYNCP) is closed loop position control with a moving target where the set-point

(commanded position) is the master position multiplied by the gear-ratio also considering any position offset. The slave position is controlled based on this set-point and the actual position feedback from the slave

encoder. Any position deviation will continuously be corrected considering maximum velocity, acceleration

and deceleration of the slave. The gear-ratio is set as a fraction (numerator and denominator) to avoid

rounding errors e.g. when using prime numbers. The gear-ratio must be 100% correct, even the smallest

rounding error will lead to position drifting over time.

When starting position synchronizing the actual slave position will be locked to the actual master position, it

is thus necessary to bring the slave into the right physical position with respect to the physical position of

the master. This can be done manually or be means of an automatic homing procedure (requires external

reference switches or absolute encoders).

The slave must be faster and more dynamic than the master in order to maintain accurate synchronization

both at maximum master velocity and during acceleration/deceleration. I.e. the slave must be able to

exceed the maximum velocity, acceleration and deceleration of the master to allow it to catch up if getting

behind the master. Already during the design phase it is thus important to consider making the least dynamic shaft the master as this shaft will anyway be the limiting factor for the system performance.

26 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 27

MCO 305 Design Guide

__ Functions and Examples __

Typical applications are:

− Bottle washing machines.

− Foil wrapping.

− Packaging machines.

− Conveyors.

− Multi axis hoists.

− Filling.

− Printing.

− Cut on the fly.

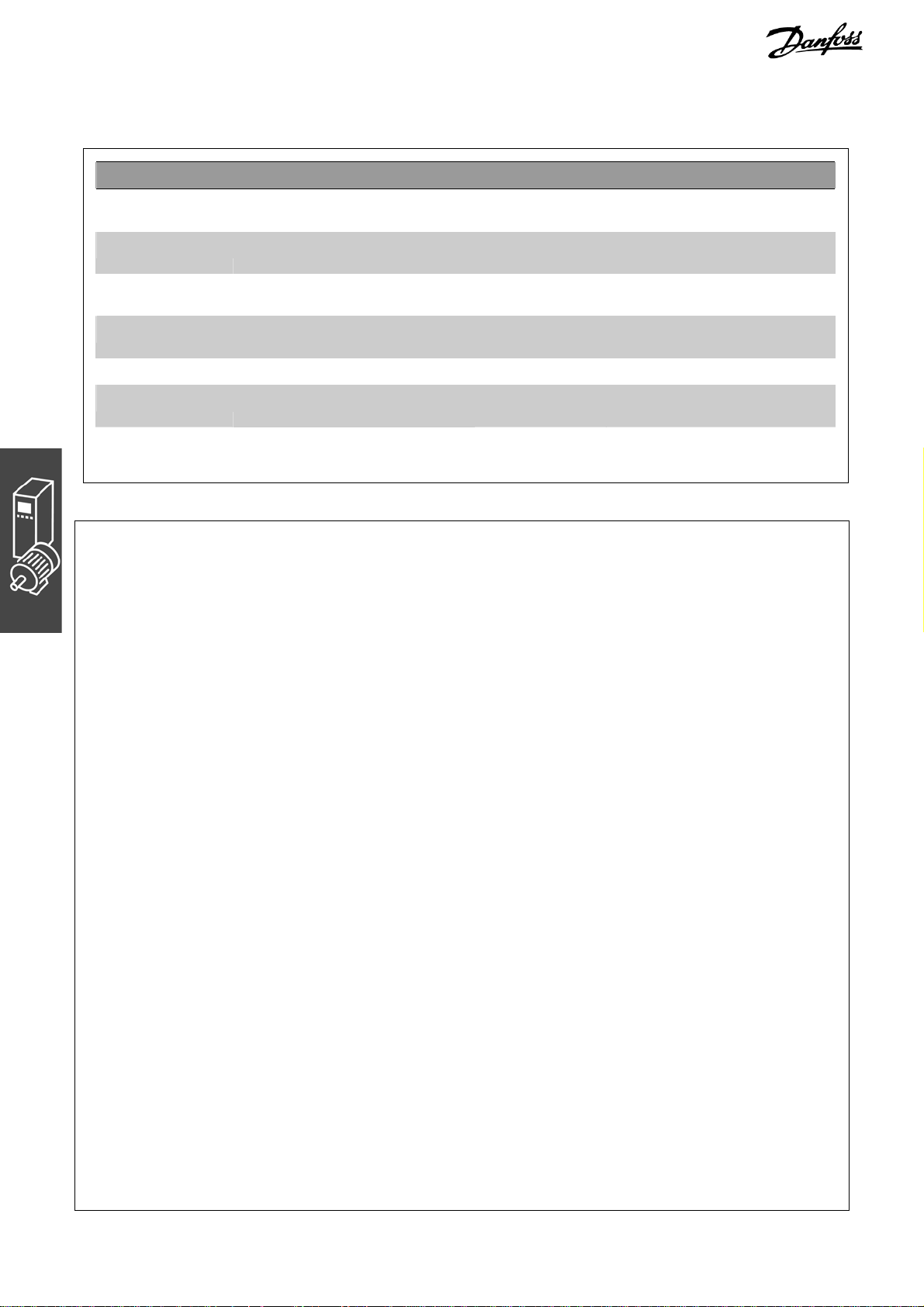

Control behavior with position synchronization

Application Example: Packaging with Fixed Product Distances

This application consists of two conveyors, 1 carrying empty boxes another one carrying teddy bears;

the purpose of the machine is to put teddies into the

boxes. Both boxes and teddies come with a fixed

distance and it is ensured that there is no slip

between the encoders and the boxes and teddies. It

is thus sufficient to position synchronize based on

the encoders. At start it is ensured that the master

(box conveyor) it always in the same position, the

teddy conveyor needs to be homed prior to starting

synchronization. There are 3 ways to ensure that

the teddies are aligned with the boxes when

starting:

− Adjust the physical position of the home/reference switch.

− Adjust home offset in parameter 33-01.

− Adjust position offset for synchronization in parameter 33-12.

NOTE: The following is just an example and the presented settings and programs might not cover the

complete functionality required by a real application.

It is assumed that the motor and encoder connections are checked and that all basic parameter settings

such as motor data, encoder data and PID controller are done. Instructions for setting up parameters can

be found in FC 300 Operating Instructions and MCO 305 Operating Instructions.

Parameter Settings and Commands for Packaging Application

The following MCO 305 parameters are relevant for

position synchronization:

MG.33.L5.02 – VLT® is a registered Danfoss trademark 27

32-0* Encoder 2 – Slave page

201

32-3* Encoder 1 – Master page 205

32-6* PID-Controller page

210

32-8* Velocity & Acceleration page 213

33-1* Synchronization page 218

Page 28

MCO 305 Design Guide

__ Functions and Examples __

Command Description Syntax Parameter

DEFSYNCORIGIN Defines master-slave relation for the

next SYNCP or SYNCM command

MOVESYNCORIGIN Relative shifting of the origin of

synchronization

PULSACC Sets acceleration for master

simulation

PULSVEL Sets velocity for master simulation PULSVEL v v = velocity in pulses per second

SYNCP Synchronization of angle/position SYNCP –

SYNCSTAT Queries flag for synchronization

status

SYNCERR Queries actual synchronization error

of the slave

DEFSYNCORIGIN

master slave

MOVESYNCORIGIN

mvalue

PULSACC a a = acceleration in Hz/s

res = SYNCSTAT –

res = SYNCERR –

master = reference position in qc

slave = reference position

mvalue = Relative offset

(Hz)

Position Synchronizing Sample Program

/************************* Position Synchronizing Sample Program ***********************/

// Inputs: 1 Start/stop synchronization

// 2 Start homing

// 3 Home switch

// 4 Increase offset

// 5 Decrease offset

// 8 Clear Error

// Outputs: 1 Within synchronizing accuracy, set accuracy window in par. 33-13

// 2 Homing done

// 8 Error

/****************************** Interrupts **************************************/

ON ERROR GOSUB errhandle

// In case of error go to error handler routine, this must always be included

/************************** Basic settings ************************************/

VEL 100 // Sets maximum slave velocity related to par. 32-80 Maximum velocity

ACC 100 // Sets slave acceleration related to par. 32-81 Shortest ramp

DEC 100 // Sets slave deceleration related to par. 32-81 Shortest ramp

/*********************** Define application parameters *****************************/

LINKGPAR 1900 "Offset step" 0 10000 0

LINKGPAR 1901 "Offset type" 0 1 0

/********************** Set parameters and flags ********************************/

SET I_FUNCTION_3 1 // Define input 3 as Home switch input

next_step = 0

home_done = 0

new_offset = 0

/************************************* main loop ******************************/

MAIN:

IF (IN 2 == 1) THEN // Start homing if input 2 high

HOME // Go to Home and set position to 0

home_done = 1 // Set home_done flag

OUT 2 1 // Set home done output

ENDIF

IF (IN 1 == 1) AND (home_done == 1) THEN // Start synchronizing when input 1 = 1 and homing done.

SYNCP // Start position synchronizing mode

28 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 29

MCO 305 Design Guide

__ Functions and Examples __

old_offset = GET SYNCPOSOFFS

WHILE (IN 1 == 1) DO // Stay in synchronizing mode while input 1 = 1

IF (IN 4 == 1) THEN

GOSUB increase_offset

ELSEIF (IN 5 == 1) THEN

GOSUB decrease_offset

ENDIF

IF (SYNCSTAT & 4) THEN

OUT 1 1

ELSE

OUT 1 0

ENDIF

ENDWHILE

MOTOR STOP // Stop if input 1 is low.

home_done = 0 // Reset home_done flag after stop

OUT 1 0

OUT 2 0 // Reset home done output after stop

IF (new_offset != old_offset) AND (GET 132 == 0) THEN // Save absolute offset if changed

SAVE AXPARS // NOTE: Saving more that 10000 times can damage flash PROM

ENDIF

ENDIF

GOTO MAIN

/*************************** Sub programs start *********************************/

SUBMAINPROG

/***************************** Increase offset **********************************/

SUBPROG increase_offset

IF (Next_step) THEN // Check if next offset step is enabled

IF (GET 1901 == 0) THEN // Absolute offset

new_offset = old_offset + GET 1900 // Read existing offset and add step value

SET SYNCPOSOFFS new_offset // Set new position offset

ELSE // Relative offset

MOVESYNCORIGIN GET 1900 // Execute relative offset with offset step

ENDIF

ENDIF

Next_step=0 // Disable next offset step

ON TIME 500 GOSUB Enb_Step // Enable next offset step after 500 ms

RETURN

/*************************** Decrease offset ***********************************/

SUBPROG decrease_offset

IF (Next_step) THEN // Check if next offset step is enabled

IF (GET 1901 == 0) THEN // Absolute offset

new_offset = GET SYNCPOSOFFS - GET 1900

// Read existing offset and subtract step value

SET SYNCPOSOFFS new_offset // Set new position offset

ELSE // Relative offset

MOVESYNCORIGIN (- GET 1900) // Execute relative offset with - offset step

ENDIF

ENDIF

Next_step=0 // Disable next offset step

ON TIME 500 GOSUB Enb_Step // Enable next offset step after 500 ms

RETURN

/************************* Enable new offset step *******************************/

SUBPROG Enb_step

MG.33.L5.02 – VLT® is a registered Danfoss trademark 29

Page 30

MCO 305 Design Guide

__ Functions and Examples __

Next_step = 1 // Enable next offset step

RETURN

/***************************** Error handler ***********************************/

SUBPROG errhandle

err = 1 // Set error flag to remain in error handler until error is reset.

OUT 8 1 // Set error output

OUT 2 0 // Reset home done output in case of error

WHILE err DO // Remain in error handler until the reset is received

IF (IN 8) AND NOT (IN 1) THEN // Reset error when Input 8 is high and input 1 low.

ERRCLR // Clear error

err=0 // Reset error flag

ENDIF

ENDWHILE

OUT 8 0 // Reset error output

home_done = 0 // Reset home_done flag after an error

RETURN

/****************************************************************************/

ENDPROG

/***************************** End of program *********************************/

30 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 31

MCO 305 Design Guide

__ Functions and Examples __

Marker Synchronization (SYNCM)

Marker synchronization (SYNCM) is extended position synchronizing where an additional position correction

is done to align a slave marker with a master marker. Master and slave marker signals can be the encoder

zero pulse or external sensors connected to digital inputs. As with position synchronizing it is possible to

adjust gear-ratio and offset, in addition a marker ratio can be set e.g. 1 master marker to 3 slave markers

which mean that every master marker will be aligned with every 3

The marker signals can be monitored by defining a position window, only one marker (the first one) will be

accepted within the marker window and any marker signal outside the marker window will be ignored.

Without marker windows every marker signal including noise pulses and jitter will be accepted and used to

correct the slave position. The first master marker and first slave marker after starting are not monitored as

the system does not know where the first marker is supposed to be. After detecting the first marker the

anticipated position of the following markers is known as the marker distance must be specified by parameter individually for master and slave.

When starting marker synchronization the initial behavior will be like position synchronization but when the

first set of markers has been detected marker correction will start. Which markers to use for the first

marker correction can be defined by parameter 33-23, by defining the start behavior it is possible to define

whether the slave must always wait for the master, catch up with the master or make the smallest

correction, see parameter 33-23 for a detailed description of the available options. Homing procedures are

thus not necessary prior to starting as the marker correcting will automatically align the slave with the

master.

The slave must be faster and more dynamic than the master in order to make marker correction and maintain accurate synchronization both at maximum master velocity and during acceleration/deceleration. I.e.

the slave must be able to exceed the maximum velocity, acceleration and deceleration of the master to

allow it to make marker correction and to catch up if getting behind the master. Already during the design

phase it is thus important to consider making the least dynamic shaft the master as this shaft will anyway

be the limiting factor for the system performance.

Typical applications are:

Basically the same application types as position

synchronizing but where one or more of the

following is true:

− Automatic alignment after start is required.

− Gear-ratio cannot be set 100% correct.

− There is slip somewhere between the

encoder and the part the must be

synchronized.

− Varying distance between products.

Control behavior with marker synchronization

rd

slave marker.

Application Example: Packaging with Varying Product Distance and Slip

This application consists of two conveyors, 1 carrying empty boxes and another one carrying teddy bears,

the purpose of the machine is to put teddies into the boxes. Both boxes and teddies are moved by friction

and can thus move on the conveyor belt. It means that there is no fixed relationship between the encoders

and the position of box and teddy bear and the distance can vary. It is therefore necessary to use external

marker detection on both boxes (master) and teddies (slave) in order to synchronize the teddy bear

position to the box position. Alignment can be obtained by adjusting the physical position of the marker

detectors or by adjusting the position offset in parameter 33-12.

MG.33.L5.02 – VLT® is a registered Danfoss trademark 31

Page 32

MCO 305 Design Guide

__ Functions and Examples __

In addition to start and stop of marker synchronizing the sample program has measuring of both

Master and Slave Marker Distance. The average

distance between the detected markers is

calculated and the marker distance parameters

(33-17 and 33-18) are automatically set.

NOTE: The following is just an example and the

presented settings and programs might not cover

the complete functionality required by a real

application.

It is assumed that the motor and encoder connections are checked and that all basic parameter

settings such as motor data, encoder data and PID

controller are done. Instructions for setting up

parameters can be found in FC 300 Operating

Instructions and MCO 305 Operating Instructions.

Parameter Settings and Commands for Packaging Application

The following MCO 305 parameters are relevant for

marker synchronization:

32-0* Encoder 2 – Slave page

32-3* Encoder 1 – Master page 205

32-6* PID-Controller page

32-8* Velocity & Acceleration page 213

33-1* Synchronization page 218

201

210

Command Description Syntax Parameter

DEFSYNCORIGIN Defines master-slave relation for

the next SYNCP or SYNCM

command.

MOVESYNCORIGIN Relative shifting of the origin of

synchronization.

PULSACC Sets acceleration for master

simulation.

PULSVEL Sets velocity for master simulation. PULSVEL v v = velocity in pulses per

SYNCM Synchronization of angle/position

with marker correction.

SYNCSTAT Queries flag for synchronization

status.

SYNCERR Queries actual synchronization

error of the slave.

IPOS Queries last index or marker

position of the slave.

MIPOS Queries last index or marker

position of the master.

DEFSYNCORIGIN

master slave

MOVESYNCORIGIN

mvalue

PULSACC a a = acceleration in Hz/s

SYNCM –

res = SYNCSTAT

res = SYNCERR –

res = IPOS –

res = MIPOS –

master = reference position in

qc

slave = reference position

mvalue = Relative offset

second (Hz)

32 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 33

MCO 305 Design Guide

__ Functions and Examples __

Program Example: Marker Synchronization

/********************* Marker synchronizing sample program ************************/

// Inputs: 1 Start/stop synchronization

// 2 Measure slave marker distance

// 3 Measure master marker distance

// 5 Master marker

// 6 Slave marker

// 8 Clear Error

// Outputs: 1 Within synchronizing accuracy, set accuracy window in parameter 33-13

// 2 Marker measurement active.

// 8 Error

***************************** Interrupts ****************************************/

ON ERROR GOSUB errhandle

// In case of error go to error handler routine, this must always be included

/****************************** Basic settings ********************************/

VEL 100 // Sets maximum slave velocity related to parameter 32-80 Maximum velocity

ACC 100 // Sets slave acceleration related to parameter 32-81 Shortest ramp

DEC 100 // Sets slave deceleration related to parameter 32-81 Shortest ramp

/************************ Define application parameters *****************************/

LINKGPAR 1900 "Measuring velocity" 0 100 0

/************************* Set parameters and flags *******************************/

SET SYNCMTYPM 2 // Set master marker type to external

SET SYNCMTYPS 2 // Set slave marker type to external

sync_flag = 0

/****************************** main loop ***************************************/

MAIN:

IF (IN 1 == 1) AND (sync_flag == 0) THEN // Start synchronizing once when input 1 is high.

SYNCM // Start marker synchronizing mode

sync_flag = 1 // done flag

ELSE

MOTOR STOP // Stop when input 1 is low.

sync_flag = 0 // Reset sync_flag after stop.

ENDIF

IF (IN 2 == 1) AND (sync_flag == 0) THEN // Start measuring slave marker distance

GOSUB slave_measure // Note: Slave motor will rotate

ELSEIF (IN 3 == 1) AND (sync_flag == 0) THEN // Start measuring slave marker distance,

GOSUB master_measure // master must run.

ENDIF

GOTO MAIN

/*************************** Sub programs start **********************************/

SUBMAINPROG

/********************** Measure slave marker distance ******************************/

SUBPROG slave_measure

OUT 2 1 // Set "Marker measurement active" output

CVEL GET 1900 // Set measuring velocity

CSTART // Start constant velocity mode

old_ipos = IPOS // Read "old" marker position

marker_number = 0 // Reset variable

total_dist = 0 // Reset variable

skip_first = 0 // Reset variable

WHILE (IN 2 == 1) DO // Stay in measuring mode while input 2 high

new_ipos = IPOS // Read "new" marker position

IF (new_ipos != old_ipos) THEN // Check if a new marker was detected

marker_distance = new_ipos - old_ipos // Calculate marker distance

IF (marker_distance < 0) THEN // Change sign if negative

marker_distance = (marker_distance * -1)

ENDIF

MG.33.L5.02 – VLT® is a registered Danfoss trademark 33

Page 34

MCO 305 Design Guide

__ Functions and Examples __

IF (skip_first == 0) THEN // Do not use first value as it might be invalid

skip_first = 1

ELSE

marker_number = marker_number + 1 // Increment counter

total_dist = total_dist + marker_distance // Summarize marker distances

ENDIF

old_ipos = new_ipos // Set "old" marker position to "new" marker position

ENDIF

ENDWHILE

CSTOP // Stop when leaving slave marker measurement

SET SYNCMPULSS (total_dist rnd marker_number) // calculate average marker distance and set par.

OUT 2 0 // Reset "Marker measurement active" output

RETURN

/*********************** Measure master marker distance ****************************/

SUBPROG master_measure

OUT 2 1 // Set "Marker measurement active" output

old_mipos = MIPOS // Read "old" marker position

marker_number = 0 // Reset variable

total_dist = 0 // Reset variable

skip_first = 0 // Reset variable

WHILE (IN 2 == 1) DO // Stay in measuring mode while input 2 high

new_mipos = MIPOS // Read "new" marker position

IF (new_mipos != old_mipos) THEN // Check if a new marker was detected

marker_distance = new_mipos - old_mipos // Calculate marker distance

IF (marker_distance < 0) THEN // Change sign if negative

marker_distance = (marker_distance * -1)

ENDIF

IF (skip_first == 0) THEN // Do not use first value as it might be invalid

skip_first = 1

ELSE

marker_number = marker_number + 1 // Increment counter

total_dist = total_dist + marker_distance // Summarize marker distances

ENDIF

old_mipos = new_mipos // Set "old" marker position to "new" marker position

ENDIF

ENDWHILE

SET SYNCMPULSM (total_dist rnd marker_number) // calculate average marker distance and set par.

OUT 2 0 // Reset "Marker measurement active" output

RETURN

/******************************** Error handler ************************************/

SUBPROG errhandle

err = 1 // Set error flag to remain in error handler until error is reset.

OUT 8 1 // Set error output

OUT 2 0 // Reset "Marker measurement active" output in case of error

WHILE err DO // Remain in error handler until the reset is received

IF (IN 8) AND NOT (IN 2) THEN // Reset error when Input 8 is high and input 2+3 low

ERRCLR // Clear error

err=0 // Reset error flag

ENDIF

ENDWHILE

OUT 8 0 // Reset error output

sync_flag = 0 // Reset sync_flag after error

RETURN

/****************************************************************************/

ENDPROG

/********************************* End of program ******************************/

34 MG.33.L5.02 – VLT

®

is a registered Danfoss trademark

Page 35

MCO 305 Design Guide

__ Functions and Examples __

CAM Control

In order to realize CAM control, you need – depending on the application – at least one curve which

describes the slave position in relation to the master position, as well as the engaging and disengaging

behavior. Of course, many additional parameters are required for a CAM control which, together with the Fix

points of the curve, produces a curve profile.

The synchronization in CAM-Mode (SYNCC command) can also be performed with marker correction

(SYNCCMM and SYNCCMS). This would be required, for example, if the products are transported irregularly

on a conveyor belt, or if adding errors need to be compensated for.

Diagram of the principle

and the mechanical camshaft are shown on the

left, the curves for the electronic CAM control and

the electronic CAM box are shown on the right:

In order to create the curve profile, use the →

CAM-Editor. into which you first load the controller

parameters that have already been set. Then you

set the Fix points of the curve and define the

parameters required for your application. You can

enter all values in physical or user-defined units

under a Windows interface. You can constantly

control the curve profile graphically; in this way,

you can check velocity and acceleration of the slave

axis.

: The mechanical cam disc

Interpolation

The CAM-Editor calculates the curve from Fix points with the help of a spline interpolation. This is optimized

to a minimum torque. In order to prevent speed leaps in the case of repeated curve cycles, the velocity at

the beginning and the end is equated. You can choose between three types of curve for this calculation. In

either type, the interpolation takes account of the gradient of the curve at the beginning and the end. Either

the gradient at the beginning and at the end is averaged; or the gradient at the beginning of the curve is

also used for the end of the curve, or the gradient of the curve at the beginning and the end is set to zero.

Tangent Points for Straight Sections

For areas where the velocity must be constant and the acceleration = 0, you need to use tangent points. A

straight line will be drawn instead of a spline between these points.

Accuracy

The Fix points are used directly as interpolation points provided that this is permitted by the interval