Page 1

Contents MCO 305 Operating Instructions

Contents

1 Introduction

1.1 Available Literature for VLT AutomationDrive, MCO 305 and MCT 10 Motion

Control Tool

1.2 Symbols and Conventions

1.3 Abbreviations

2.1 High Voltage Warning

2.2 Safety Instructions

2.3 Before Commencing Repair Work

2.4 Avoid Unintended Start

2.5 Safe Stop of FC 302

2.6 General Warning

3 How to Install

3.1 How to Get Started

3.1.1 Initialisation to Default Settings 7

3.2 System Overview

3.2.1 Electrical Installation 10

3.2.2 MCO 305 Control Terminals 10

3

3

3

4

5

5

5

5

6

6

7

7

8

3.2.3 Terminal overview 11

3.2.4 Encoder Connections Examples 12

3.2.5 Virtual Master Connection 13

3.3 Commissioning Guide

3.4 Basic MCO Parameter Settings

3.4.1 Setting of Encoder Parameters 14

3.4.2 Setting of parameters for CANopen feedback encoder 14

3.4.3 Setting of parameters for CANopen Master encoder 15

3.4.4 Setting of Velocity Parameters 15

3.4.5 Setting of Home Parameters 15

3.4.6 Setting of Synchronization Parameters 15

3.5 Connecting and Testing the Encoder(s)

3.5.1 Execute the Encoder Test Program 16

3.5.2 Checking Master Encoder for Synchronizing Applications 16

3.5.3 Ending the Encoder Check 16

3.6 PID Controller Settings

3.6.1 Sample Program: Feed-forward Calculation 17

14

14

16

16

3.6.2 Influence to the Control Loop when Changing Parameters 17

3.7 Executing a Test Program

4 Optimizing the PID controller

4.1 How to Control Process Works

MG.33.K3.02 - VLT® is a registered Danfoss trademark 1

18

19

19

Page 2

Contents MCO 305 Operating Instructions

4.2 Significance and Influence of the Controller Parameters

4.3 PID Factors

4.3.1 Derivative Value for PID Control 21

4.3.2 Integral Factor: KINT 21

4.3.3 Limit Value for Integral Sum: KILIM 21

4.3.4 Velocity Feed-forward: FFVEL 21

4.3.5 Acceleration Feed-forward: FFACC 21

4.3.6 Sampling Time for PID Control: TIMER 21

4.3.7 PID Bandwidth 22

4.4 Optimizing your Controller Settings Step-by-Step

4.4.1 Ten Steps for Optimum Control 22

5 How to Install the Application

5.1 Download Application Program and Configuration

5.2 Backup and Restore

5.3 How to Connect and Run Multiple Frequency Converters

6 General Specifications

19

20

22

24

24

24

25

26

6.1 Protection and Features

6.2 Technical Data

6.3 Supply Voltage Overview

7 Troubleshooting

7.1 Warnings and Error Messages

7.2 APOSS Software Messages

8 Appendix

8.1 Parameter Lists

8.1.1 Application Parameters, Parameter Group 19-** 35

8.1.2 MCO Basics Settings, Parameter Group 32-** 36

8.1.3 MCO Advanced Settings, Parameter Group 33-** 38

8.1.4 MCO Data Readouts, Parameter Group 34-** 41

Index

26

26

27

28

28

33

35

35

42

2 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 3

Introduction MCO 305 Operating Instructions

1 Introduction

1.1 Available Literature for VLT

AutomationDrive, MCO 305 and MCT 10

Motion Control Tool

-

The MCO 305 Design Guide entails all technical

information about the option board and customer

design and applications.

-

The MCO 305 Command Reference completes the

MCO 305 Design Guide with detailed description of

all commands available for programming MCO 305.

-

The VLT AutomationDrive Operating Instructions

provide the necessary information for getting the

frequency converter up and running.

-

The VLT AutomationDrive Programming Guide

provides complete descriptions of all parameters in

the frequency converter.

-

The VLT AutomationDrive Design Guide entails all

technical information about the frequency

converter and customer design and applications.

-

The VLT AutomationDrive Profibus Operating

Instructions provide the information required for

controlling, monitoring and programming the

drive via a Profibus fieldbus.

-

The VLT AutomationDrive DeviceNet Operating

Instructions provide the information required for

controlling, monitoring and programming the

drive via a DeviceNet fieldbus.

-

The VLT AutomationDrive MCT- 10 Operating

Instructions provide information for installation and

use of the software on a PC.

Danfoss Drives technical literature is also available online at

www.danfoss.com/drives.

CAUTION

Indicates a situation that may result in equipment or

property-damage-only accidents.

NOTE

Indicates highlighted information that should be regarded

with attention to avoid mistakes or operate equipment at

less than optimal performance.

Approvals

Conventions

The information in this manual follows the system and uses

the typographical features described below to the greatest

extent possible:

Menus and Functions

Menus and functions are printed italics, for

→

example:Controller

Commands and Parameters

Commands and parameter names are written in capitals, for

example: AXEND and KPROP; Parameters are printed in

italics, for example: Proportional factor.

Parameter Options

Values for use to select the parameter options are written in

brackets, e.g. [3].

Parameters.

1 1

1.2

Symbols and Conventions

Symbols

The following symbols are used in this manual.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices.

MG.33.K3.02 - VLT® is a registered Danfoss trademark 3

Keys

The names of keys and function keys are printed in brackets,

for example the control key [Cntl] key, or just [Cntl], the [Esc]

key or the [F1] key.

Page 4

Introduction MCO 305 Operating Instructions

11

1.3 Abbreviations

Automatic Motor Adaptation AMA

Direct Current DC

Frequency Converter FC

Local Control Panel LCP

Master Unit MU

Millisecond ms

Minute min

Motion Control Option MCO

Motion Control Tool MCT

Parameter par.

Protective Extra Low Voltage PELV

Position Control Loop PID

Pulses per Revolution PPR

Quad-counts qc

Revolutions per Minute RPM

Second sec.

Switch normally closed nc

Switch normally open no

User Unit UU

Volts V

4 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 5

Safety Instructions and Gen... MCO 305 Operating Instructions

2.1 High Voltage Warning

MCO 305

Operating Instructions

Software version: 5.xx

These Operating Instructions can be used for the MCO 305 option board

with all FC 300 frequency converters with software version later than 5.xx.

The software version number can be seen from 15-43 Software Version for the frequency converter and in 15-61 Option SW Version for the MCO

305

2.1.1 High Voltage Warning

2 2

The voltage of the VLT AutomationDrive is dangerous

whenever the converter is connected to mains. Incorrect

fitting of the motor or VLT AutomationDrive may cause

damage to the equipment, serious injury or death.

Consequently, it is essential to comply with the instructions

in this manual as well as local and national rules and safety

regulations. At altitudes above 2km, please contact Danfoss

Drives regarding PELV.

2.2 Safety Instructions

- Make sure the VLT AutomationDrive is properly

connected to earth.

- Do not remove mains plugs or motor plugs while

the VLT AutomationDrive is connected to mains.

- Protect users against supply voltage.

- Protect the motor against overloading according to

national and local regulations.

- Motor overload protection is not included in the

default settings. To add this function, set par. 1-90

Motor thermal protection to value ETR trip or ETR

warning. For the North American market:

- ETR functions provide class 20 motor overload

protection, in accordance with NEC.

- The earth leakage current exceeds 3.5 mA.

- The [OFF] key is not a safety switch. It does not

disconnect the VLT AutomationDrive from mains.

2.3

Before Commencing Repair Work

1. Disconnect VLT AutomationDrive from mains.

2. Disconnect DC bus terminals 88 and 89.

3. Wait at least 4 minutes.

4. Remove motor plugs.

2.4 Avoid Unintended Start

While VLT AutomationDrive is connected to mains, the

motor can be started/stopped using digital commands, bus

commands, references or via the LCP.

- Disconnect the VLT AutomationDrive from mains

whenever personal safety considerations make it

necessary to avoid unintended start.

- To avoid unintended start, always activate the

[OFF] key before changing parameters.

- Unless terminal 37 (safe stop) is turned off, an

electronic fault, temporary overload, a fault in the

mains supply, or lost motor connection may cause

a stopped motor to start.

MG.33.K3.02 - VLT® is a registered Danfoss trademark 5

Page 6

Safety Instructions and Gen... MCO 305 Operating Instructions

2.5 Safe Stop of FC 302

22

The FC 302 can perform the Designated Safety Function

Uncontrolled Stopping by removal of power (as defined by

IEC 61800-5-2) or Stop Category 0 (as defined in EN 60204-1).

It is designed and approved suitable for the requirements of

Safety Category 3 according to EN 954/PLd according to ISO

13849-1. This functionality is called Safe Stop.

In order to install and use the Safe Stop function in

accordance with the requirements of Safety Category 3

according to EN 954-1/PLd according to ISO 13849-1, the

related information and instructions of the VLT

AutomationDrive Design Guide MG.33.BX.YY must be

followed! The information and instructions of Operating

Instructions are not sufficient for a correct and safe use of the

Safe Stop functionality.

2.6 General Warning

WARNING

Touching the electrical parts may be fatal – even after the

equipment has been disconnected from mains. Also make

sure that all voltage inputs have been disconnected, such as

load-sharing (linkage of DC intermediate circuit), as well as

the motor connection for kinetic back-up. Using VLT

AutomationDrive (at and below 7.5kW):

wait at least xx minutes.

xx = The waiting time using the VLT AutomationDrive is

different for different sizes: Please see period of waiting time

xx in the VLT AutomationDrive Operating Instructions, MG.

33.AX.YY.

6 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 7

How to Install MCO 305 Operating Instructions

3 How to Install

Manual initialisation

3.1 How to Get Started

Please consult the VLT AutomationDrive Operating

Instructions for correct installation of VLT AutomationDrive,

these instructions cover installation of MCO 305.

3.1.1 Initialisation to Default Settings

Initialize the frequency converter to default setting in two

ways:

Recommended initialisation (via 14-22 Operation Mode)

1.

Select 14-22 Operation Mode

2. Press [OK]

3. Select “Initialization”

4. Press [OK]

5. Cut off the mains supply and wait until the displays

turns off.

6. Reconnect the mains supply – the frequency

converter is now reset.

1. Disconnect from mains and wait until the display

2. Press [Status] – [Main Menu] – [OK] at the same

3. Reconnect mains supply while pressing the keys.

4. Release the keys after 5 sec.

5. The frequency converter is now programmed

NOTE

When carrying out manual initialization, serial communication and fault log settings are reset. All MCO 305 programs

and arrays are deleted!

This method initializes all except:

15-00 Operating Hours

15-03 Power Up's

15-04 Over Temp's

15-05 Over Volt's

turns off.

time:

according to default settings.

3

3

NOTE

MCO 305 programs and arrays are not affected.

14-22 Operation Mode initialises all except:

14-50 RFI Filter

8-30 Protocol

8-31 Address

8-32 FC Port Baud Rate

8-35 Minimum Response Delay

8-36 Max Response Delay

8-37 Max Inter-Char Delay

15-00 - 15-05 Operating Data

15-20 - 15-22 Historic log

15-30 - 15-32 Fault log

33-90 X62 MCO CAN node ID

33-91 X62 MCO CAN baud rate

MG.33.K3.02 - VLT® is a registered Danfoss trademark 7

Page 8

How to Install MCO 305 Operating Instructions

3.2 System Overview

3

This is only relevant if the MCO 305 is delivered as an option

for upgrading an existing VLT AutomationDrive. When

ordered with the frequency converter, MCO 305 is

preinstalled from factory. For retrofit, a mounting kit must be

purchased.

There is a different mounting kit for different frames. MCO

305 is to be used in slot C0 but can be combined with

another option in slot C1.

Mounting kit depending on frame Order no.

Bookstyle

A2 and A3 (40 mm for one C option) 130B7530

A2 and A3 (60 mm for C0 + C1 option) 130B7531

B3 (40 mm for one C option) 130B1413

B3 (60 mm for C0 + C1 option) 130B1414

Compact

A5 130B7532

B, C, D, E and F (except B3) 130B7533

Do not mount the small fan for B4, C3, C4, D, E and F

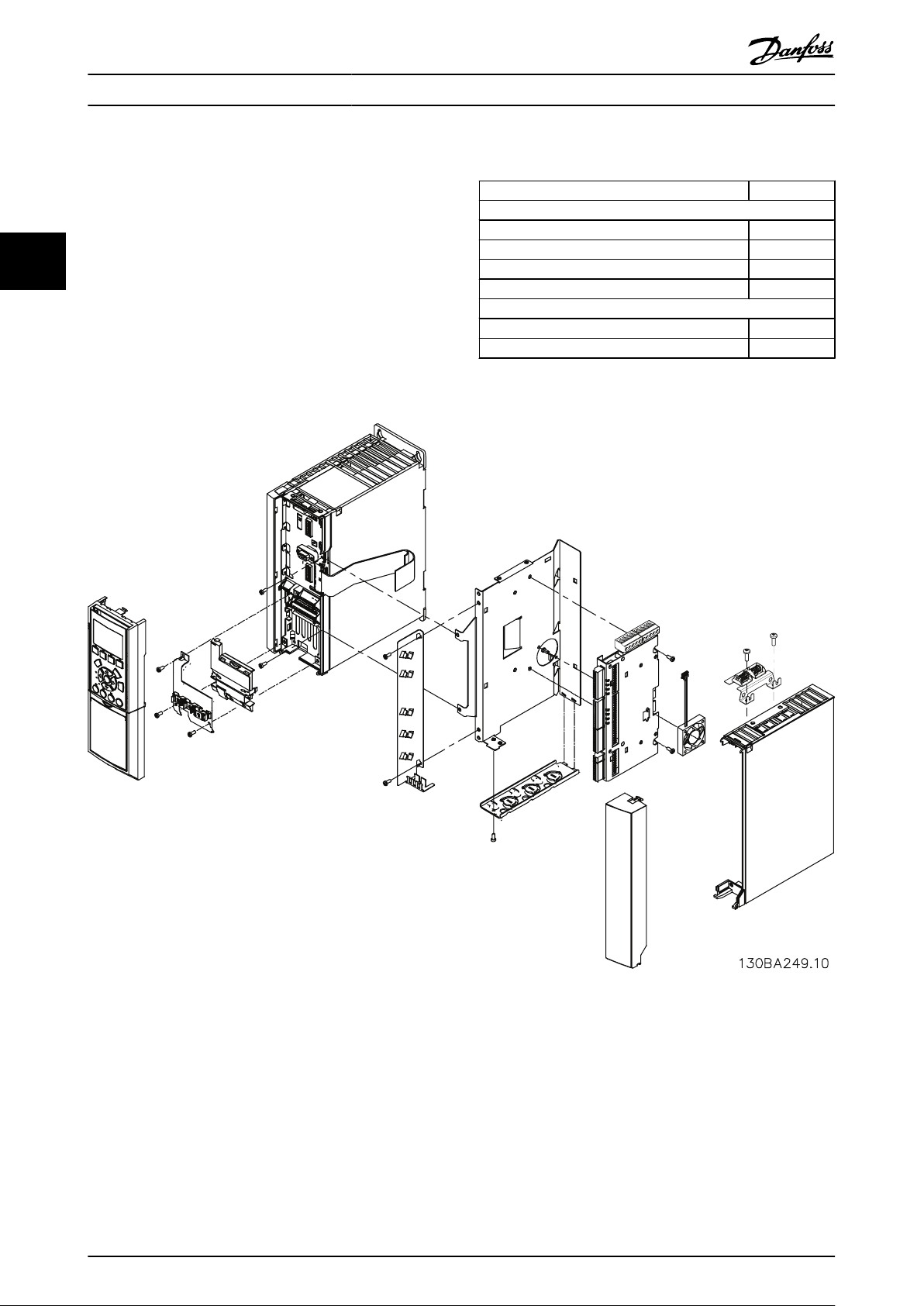

Illustration 3.1 Bookstyle - A2, A3, B3

8 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 9

How to Install MCO 305 Operating Instructions

3

3

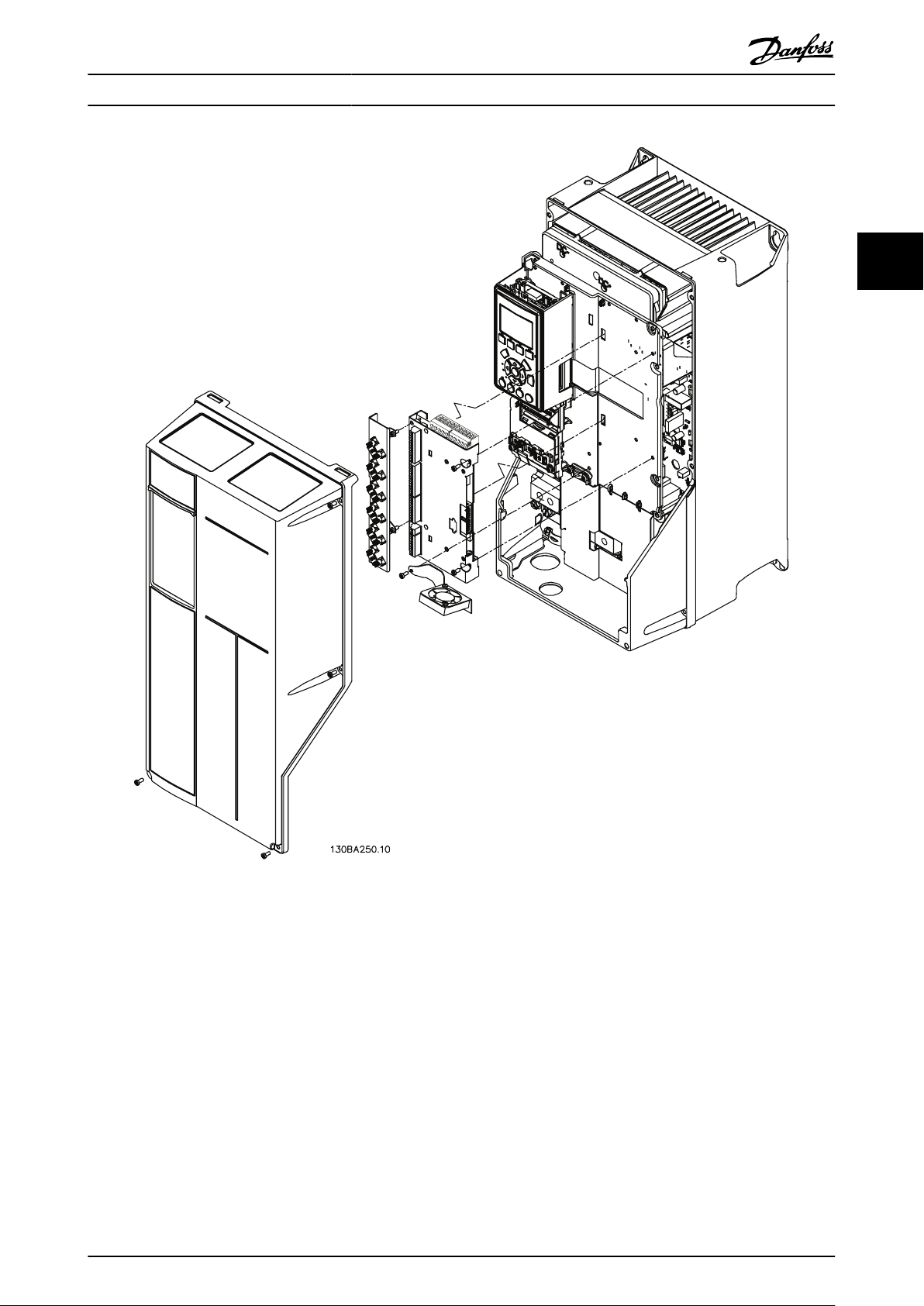

Illustration 3.2 Compact - A5, B (except B3), C, D, E, F

MG.33.K3.02 - VLT® is a registered Danfoss trademark 9

Page 10

130BA248.11

130BT334.10

How to Install MCO 305 Operating Instructions

3

3.2.1 Electrical Installation

All control cables must be screened and the cable screen

must be connected to earth at both ends. It is very important

to use the correct cable for encoders to avoid noise

problems, always follow the prescriptions of the encoder

supplier. See also VLT AutomationDrive Design Guide (MG.

33.AX.YY) for more information regarding EMC correct cable

installation.

3.2.2 MCO 305 Control Terminals

Frame size A2 and A3:

Encoder and I/O terminal are located behind the C option

terminal cover, see Illustration 3.3.

MCO CAN bus terminals and debug terminals (RS485) are

located on the top of the c-option cover. If these connections

are used cut out the plastic parts above the connectors and

mount the cable relief

Frame size A5, B1 and B2:

All MCO 305 terminals are located next to the VLT

AutomationDrive control card. Remove the front cover to get

access, see illustration.

MCO 305 control terminals are plug connectors with screw

terminals; the terminal blocks are duplicated to enable use of

the same MCO 305 in all frame sizes. See Illustration 3.5 to

locate the terminal blocks:

Illustration 3.3 Location of Encoder and I/O Terminals

Illustration 3.4 Removing Front Cover

10 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 11

X62

X55

X56

X57

X58

X59

2

X60

130BB794.10

1

How to Install MCO 305 Operating Instructions

MCO control terminals are plug connectors with screw

3.2.3

Terminal overview

terminals. Terminals X55, X56, X57, X58 and X59 are

duplicated to be used for both bookstyle and compact frame

size.

X55 = Encoder 2

X56 = Encoder 1

X57 = Digital inputs

X58 = 24V DC supply

X59 = Digital outputs

X62 = MCO CAN Bus

X60 = Debug connections (RS-485)

Illustration 3.5 Location of Terminal Blocks

Terminal block 1 is to be used with bookstyle and terminal

Terminal

block

X55

Terminal

block

X56

Terminal

block

X57

Terminal number Descriptive Name Encoder 2

(Feedback)

1 +24V Supply

2 +8V Supply

3 +5V Supply

4 GND

5 A

6 A not

7 B

8 B not

9 Z / Clock

10 Z not / Clock not

11 DATA

12 DATA not

Terminal number Descriptive Name Encoder 1

(Master)

1 +24V Supply

2 N/A

3 +5V Supply

4 GND

5 A

6 A not

7 B

8 B not

9 Z / Clock

10 Z not / Clock not

11 DATA

12 DATA not

Terminal number Descriptive Name Digital inputs

1 Digital Input

2 Digital Input

3 Digital Input

4 Digital Input

5 Digital Input

6 Digital Input

7 Digital Input

8 Digital Input

9 Digital Input

10 Digital Input

3

3

block 2 with compact.

Terminal

block

X58

Terminal number Descriptive Name Supply

1 +24V Supply

2 GND

MG.33.K3.02 - VLT® is a registered Danfoss trademark 11

Page 12

5V incremental encoder

1

2 3 12

130BA163.10

754 6 8 9 10 11

24V

8V 5V GND A A B B Z Z D D

How to Install MCO 305 Operating Instructions

3

Terminal

block

X59

Terminal

block

X60

Terminal

block

X62

Terminal number Descriptive Name Digital

outputs

1 Digital Output/Input

2 Digital Output/Input

3 Digital Output

4 Digital Output

5 Digital Output

6 Digital Output

7 Digital Output

8 Digital Output

Terminal number MCO Debug (RS485)

1

CS

Control Select

62 RxD/TxD - P

63 RxD/TxD - N

66 OV

67 +5V

1

CS is high when transmissions is active

Terminal number MCO CAN Bus

1 N/A

2 CAN - L

3 DRAIN

4 CAN - H

5 N/A

Illustration 3.7 5V Incremental Encoder (RS-422) Supplied by an

External Power Source

Illustration 3.8 24V Absolute Encoder (SSI) Supplied by MCO 305

3.2.4 Encoder Connections Examples

Illustration 3.6 5V Incremental Encoder (RS-422) Supplied by MCO

305

Illustration 3.9 24V Absolute Encoder (SSI) Supplied by an External

Power Source

NOTE

When external power supply is used, ensure the same

potential between GND on external supply and encoder

connections (4). This is to avoid common mode disturbances.

12 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 13

How to Install MCO 305 Operating Instructions

3.2.5 Virtual Master Connection

When more than 2 MCO 305 master encoder interfaces are

interconnected termination must be on (32-40 Encoder

Termination = ON) at both ends of the bus. Termination must

be off (32-40 Encoder Termination = OFF) in all other MCOs.

3

3

MG.33.K3.02 - VLT® is a registered Danfoss trademark 13

Page 14

How to Install MCO 305 Operating Instructions

3

3.3 Commissioning Guide

This guideline is only describing basic configuration and

optimizing of MCO 305, before starting the following steps

must be completed.

1. Basic commissioning of VLT AutomationDrive.

NOTE

VLT AutomationDrive must be optimized and have good

control over the motor and application before commissioning MCO 305. Guidelines can be found in VLT

AutomationDrive Operating Instructions (MG.33.AX.XX).

2. Install the PC software tools (MCT 10 Set-up

Software)

3. Establish communication between PC and VLT

AutomationDrive using USB, RS-485 or PROFIBUS

DPV1.

Then follow these steps to set-up and optimize MCO 305.

1. Setting of basic MCO 305 parameters (groups 32-**

and 33-**).

2. Connect and test encoder(s).

3. Optimize PID controller.

The MCT 10 Set-up Software will support you to set the

parameters in LCP. For a detailed description of all

parameters, please refer to 8 Appendix.

3.4.1 Setting of Encoder Parameters

Define the used type of feedback encoder in parameter

group 32-0*.

These defaults are set:

32-0* Encoder 2 - Feedback Default

32-00 Incremental Signal Type

32-01 Incremental Resolution

32-02 Absolute Protocol

32-03 Absolute Resolution

32-05 Absolute Encoder Data Length

32-06 Absolute Encoder Clock Frequency

32-07 Absolute Encoder Clock Generation

32-08 Absolute Encoder Cable Length

32-09 Encoder Monitoring

For CAN Encoders

32-14 Enc.2 node ID

32-15 Enc.2 CAN guard

33-91 X62 MCO CAN baud rate

[1] RS422

1024

[0] None

8192

25

262000

[1] On

0

[0] Off

127

[0] Off

[20] 125 kbps

NOTE

Error 113 will show up right after power up if the VLT

AutomationDrive is not ready. The VLT AutomationDrive is in

the “Not ready” state when

- it has an alarm (trip),

- it is in hand mode, [Hand on] key,

- local LCP stop is activated, [OFF] key,

- there is no signal on input 37 safe stop (only FC

302).

Error 113 can only be reset using the ERRCLR command or

with BREAK [Esc] in the PC software and only when the VLT

AutomationDrive is in the “ready” state, which means none

of the above may be true. The VLT AutomationDrive

monitoring function can be switched off by selecting [0] in

33-82 Drive Status Monitoring.

Read the Safety Instructions before installing the frequency

converter.

3.4 Basic MCO Parameter Settings

3.4.2 Setting of parameters for CANopen

feedback encoder

-

In 32-00 Incremental Signal Type select the setting

[3] “CAN encoder”.

-

In 32-01 Incremental Resolution set the resolution of

the encoder.

-

In 32-14 Enc.2 node ID set the CAN ID of the

encoder.

-

In 32-15 Enc.2 CAN guard activate or deactivate the

guarding.

-

In 33-91 X62 MCO CAN baud rate set in the CAN bus

baud rate.

The following parameters are only relevant for synchronizing

applications when a master encoder signal is used. These

defaults are set:

The following parameters must always be checked and if

necessary adjusted. Depending on the requirements of the

application it might be necessary to adjust other parameters

as well.

For the other parameters, use the default settings at first and

then optimize the controller as needed at a later point in

time with a Testrun.

14 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 15

How to Install MCO 305 Operating Instructions

32-3* Encoder 1 - Master

32-30 Incremental Signal Type

32-31 Incremental Resolution

32-32 Absolute Protocol

32-33 Absolute Resolution

32-35 Absolute Encoder Data Length

32-36 Absolute Encoder Clock Frequency

32-37 Absolute Encoder Clock Generation

32-38 Absolute Encoder Cable Length

32-39 Encoder Monitoring

32-40 Encoder Termination

For CAN Encoders

32-44 Enc.1 node ID

32-45 Enc.1 CAN guard

33-91 X62 MCO CAN baud rate

[1] RS422

1024

[0] None

8192

25

262000

[1] On

0

[0] Off

[1] On

127

[0] Off

[20] 125 kbps

3.4.3 Setting of parameters for CANopen

Master encoder

-

In 32-30 Incremental Signal Type select the setting

[3] “CAN encoder”.

-

In 32-31 Incremental Resolution set the resolution of

the encoder.

-

In 32-44 Enc.1 node ID set the CAN ID of the

encoder.

-

In 32-45 Enc.1 CAN guard activate or deactivate the

guarding.

-

In 33-91 X62 MCO CAN baud rate set in the CAN bus

baud rate.

Setting of Velocity Parameters

3.4.4

Define 32-80 Maximum Velocity (Encoder), the Maximum

Velocity of the shaft where the encoder is mounted in RPM.

32-8* Velocity & Acceleration

32-80 Maximum Velocity (Encoder)

32-81 Shortest Ramp

Default

1500

1.000

NOTE

For synchronizing application the setting of the follower

drive must be at least the same as the maximum velocity of

the master in order to be able to synchronize. For position

synchronizing it must even be higher so that the follower

drive can catch up lost position related to the master. All

velocity commands (VEL, CVEL) are related to this value.

Define 32-81 Shortest Ramp. That is the time from 0 to

maximum velocity and from maximum velocity to 0. All

acceleration and deceleration commands (ACC, DEC) are

related to this value.

3.4.5 Setting of Home Parameters

Homing is not necessary in standard synchronization

applications and applications using an absolute encoder.

When using an incremental encoder the controller must be

run to home after being switched on. During this process the

reference switch defines the position at which 0 is located

and how the VLT AutomationDrive functions during a home

run: input depends on the application. Define 33-03 Velocity

of Home Motion: Home speed is entered in % relative to the

maximum speed of the frequency converter.

33-0* Home Motion Default

33-00 Force HOME

33-01 Zero Point Offset from Home Pos.

33-02 Ramp for Home Motion

33-03 Velocity of Home Motion

33-04 Behaviour during HomeMotion

[0] not forced

0

10

10

[0] Reverse +

Index

3.4.6 Setting of Synchronization Parameters

The following parameters are only relevant for synchronizing

applications:

33-10 Sync Factor Master

•

33-11 Sync Factor Slave

•

The Synchronizing Factors Master and Slave must be set

according to the gear ratio between master and slave

encoder.

Example:

Both encoders have 1024 PPR, master is running

305 RPM and slave must run 1220 RPM.

33-10 Sync Factor Master

33-11 Sync Factor Slave

Alternative:

33-10 Sync Factor Master

33-11 Sync Factor Slave

The following parameters are only relevant when using

synchronizing with marker correction (SYNCM):

33-15 Marker Number for Master

•

33-16 Marker Number for Slave

•

Marker Number for Master and Slave must be set according to

the ratio between the number of marker signals from master

and slave. A ratio of 1:1 means that each slave marker will be

aligned with each master marker. A ratio of 2:1 means that

each slave marker will be aligned with each second master

marker.

= 305 and

= 1220

= 1

= 4

3

3

MG.33.K3.02 - VLT® is a registered Danfoss trademark 15

Page 16

How to Install MCO 305 Operating Instructions

3

33-1* Synchronization Default

33-10 Sync Factor Master

33-11 Sync Factor Slave

33-15 Marker Number for Master

33-16 Marker Number for Slave

33-17 Master Marker Distance

33-18 Slave Marker Distance

33-19 Master Marker Type

33-20 Slave Marker Type

33-17 Master Marker Distance

•

33-18 Slave Marker Distance

•

When using the encoder zero pulse as marker signal the

distance between 2 markers is the resolution (qc) of the

encoder.

When external marker signals are used, the marker distance

can be measured by means of the program sample “Marker

count”.

33-19 Master Marker Type

•

33-20 Slave Marker Type

•

Master marker signal: Input 5

Slave marker signal: Input 6

Marker signal type must be selected for master and slave:

Default setting is [0] Encoder Z positive flank for both.

3.5

Connecting and Testing the Encoder(s)

1

1

1

1

4096

4096

[0] Enc. Z pos.

[0] Enc. Z pos.

monitoring is activated in

32-39 Encoder Monitoring.

Check the encoder connections by means of the test

program: Select the file “Enc-S.m” via the MCT 10. APOSS and

with that the file is opened automatically .

32-09 Encoder Monitoring and

3.5.1 Execute the Encoder Test Program

In the Development menu click on→ Execute to start the test

program. Run the frequency converter forward for example

in hand mode – [Hand on] key – then the position must

count positive. If the position is counting negative, swap A

and B channels from the encoder or two motor phases. If the

motor is turned on by hand (the motor should not be

connected!), test whether the encoder functions: the

position is continuously registered in the communications

window. For a full rotation you should receive 4 times the

value of the resolution of the encoder, that means 2000 if the

Encoder Counts per Revolution is 500.

Checking Master Encoder for

3.5.2

Synchronizing Applications

To check the master encoder change the test program:

replace the command APOS by MAPOS in “Enc-S.m” and run

the master forward then the master position must count

positive as well. If the position is counting negative, swap A

and B channels from the master encoder.

Ending the Encoder Check

3.5.3

NOTE

The controller and the motor must be able to be switched off

at any time with an EMERGENCY STOP button.

The motor must be able to turn completely freely so that a

sudden jolt can not cause damage.

NOTE

If not yet connected, now is the time to connect and test the

encoder. When using an absolute encoder, enter [0] in

32-00 Incremental Signal Type and in 32-02 Absolute Protocol

the used type of encoder. Then enter the resolution in

32-03 Absolute Resolution.

WARNING

Turn off the power before connecting the encoder.

Each encoder channel (A, B, Z, and D) is monitored, open

circuit as well as short circuit is detected. A green LED shows

the status of each active channel, LED on means that the

channel is ok. Monitoring if the channels are automatically

enabled/disabled depending on the selected encoder type,

e.g. A, B, and Z is monitored when an incremental encoder is

selected. Additionally an alarm will be triggered if encoder

End the test of the encoder with the [Esc]-key and close the

test program with File Close. A successful test of the encoder

is a requirement for further starting up of operations. Repeat

the test when using other encoders.

What to do, if … ?

....the encoder does not work?

This could be a result of incorrect cable installation. Measure

the signals coming from the encoder and compare them to

the values listed in the specifications. Check whether the

connection was made according to the specification.

....the count is descending?

If the Count is Descending with an incremental encoder,

exchange the feedback encoder track A by B and A/ by B/. If

there is no counting in the display then check the wiring of

the encoder.

3.6

PID Controller Settings

This is a quick guide to set-up the PID controller, further

details can be found in the chapter “Optimizing the PID

controller”.

16 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 17

How to Install MCO 305 Operating Instructions

The following basic settings can be used in most applications

with a 1024 PPR encoder connected directly to the motor

shaft and maximum reference (3-03 Maximum Reference) is

1500 RPM:

32-60 Proportional factor

32-61 Derivative factor

32-62 Integral factor

32-65 Velocity Feed-Forward

Velocity Feed-forward (32-65 Velocity Feed-Forward) can also

be calculated using the following formula:

Velocity Feed forward

Where:

- “envel” is encoder velocity in RPM at maximum

reference (3-03 Maximum Reference).

- eres” is the encoder resolution

(Incremental encoder: eres = 32-01 Incremental

Resolution * 4.

Absolute encoder: eres = 32-03 Absolute

Resolution).

- “tsample” is PID sample time

(tsample = 32-69 Sampling Time for PID Control

except with SYNCV where tsample = 32-70 Scan

Time for Profile Generator).

The sample program “Feed-forward calculation” is making

the above calculation and sets the parameters:

=

envel

62914560000

×

eres

×

tsample

= 200

= 1000

= 5

= 10200

Sample Program: Feed-forward

3.6.1

Calculation

This program calculates basic settings for Velocity Feedforward and PID settings based on the following inputs:

Encoder type (32-00 Incremental Signal Type and

32-02 Absolute Protocol), Encoder resolution

(32-01 Incremental Resolution or 32-03 Absolute Resolution),

Encoder velocity (par. 19-00), and Motion type (par. 19-00).

These parameters must thus be set before starting the

calculation.

The program performs the following steps when setting

input 1:

1. Check encoder type and resolution

2. Calculate PID sample time in order to get sufficient

resolution

3. Check motion type and select sample time

4. Calculate Feed-Forward.

Parameters are updated when setting input 2.

The updated parameters can be saved by setting input 3.

New calculation is enabled by setting input 4.

Influence to the Control Loop when

3.6.2

Changing Parameters

The gain of the control loop changes when one or more of

the following parameters is changed: Maximum reference,

encoder resolution, and gearing between motor and

encoder.

When changing these parameters the following rules apply:

Increased maximum reference = P and D factors as well as

Feed-forward must be reduced.

Higher encoder resolution = P and D factors as well as Feedforward must be reduced.

Increase gear-ratio between motor and encoder (encoder

turning slower) = P and D factors as well as Feedforward

must be increased.

3

3

MG.33.K3.02 - VLT® is a registered Danfoss trademark 17

Page 18

How to Install MCO 305 Operating Instructions

3

Examples 32-60 32-61 32-62 32-65

1024 PPR encoder

connected directly to the

motor shaft and maximum

reference 1500 RPM

4096 PPR encoder

connected directly to the

motor shaft and maximum

reference 1500 RPM

1024 PPR encoder

connected behind a 10:1

gearbox and maximum

reference 1500 RPM

1024 PPR encoder

connected directly to the

motor shaft and maximum

reference 3000 RPM

Further optimizing can easily be done by means of the

graphical Test-run tool which is included in the APOSS editor

this however implies that the motor/application can move.

200 1000 5 10200

50 250 5 2550

2000 10000 5 102000

100 500 5 5100

3.7 Executing a Test Program

Check the VLT AutomationDrive enable (terminal 37 = 24V)

and check that the VLT AutomationDrive was not stopped

via the LCP. Then increase 32-60 Proportional factor. (See

4 Optimizing the PID controller).

....the motor vibrates heavily?

If the motor vibrates, optimize the PID controller and adjust

the other parameters of the controller: Reduce either

32-60 Proportional factor or increase 32-61 Derivative factor

.

....a "Tolerated Position Error is exceeded" is reported?

If the frequency converter stops due to a "Tolerated Position

Error is exceeded" message it is possible to determine

whether the frequency converter was rotating in the wrong

direction by comparing the curves of the set and actual

values. Check the connections of the motor or encoder. If the

connections are correct, then it is necessary to increase the

par. 32-67 Maximum Tolerated Position Error. (See Optimizing

the PID controller.)

Now connect the motor to the VLT AutomationDrive, make

sure that the motor can turn completely freely.

NOTE

The motor must be provided with an EMERGENCY STOP

button.

Select the file “Move-S.m” via the VLT AutomationDrive.

APOSS and with that the file is opened automatically.

Click on Development and start the test program with →

Execute or [F5].

The test is successful if the motor runs slowly back and forth

and position 500 is registered.

End the test with [Esc] and Close the File.

What to do, if … ?

....the motor sets off uncontrolled or vibrates heavily?

NOTE

Turn off the motor immediately with the EMERGENCY STOP

button if it vibrates heavily or sets off uncontrolled.

....the motor sets off uncontrolled, but the encoder test

previously was successful, then decrease 32-60 Proportional

factor. (See Optimizing the PID controller).

....the motor doesn't move?

If the motor doesn’t move at all, then the Proportional Factor

of the PID filter is probably too low or the VLT

AutomationDrive has not been enabled.

18 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 19

Optimizing the PID controll... MCO 305 Operating Instructions

4 Optimizing the PID controller

4.1 How to Control Process Works

How the Control Process Works

The Testrun explained in the chapter PC Software interface in

the APOSS Online help can be used as a tool to optimize the

MCO 305 controller settings, thereby optimizing system

performance. To do that you only need to know a few things

about the control scheme of MCO 305:

The APOSS position controller has two parts:

1.

The Setpoint Generator interprets the various

positioning commands in APOSS and generates a

series of setpoint positions that eventually ends

with the desired position. Normally, all positioning

processes have a trapeze-shaped velocity curve.

That means that after a phase of constant

acceleration there is a phase with constant velocity

and finally a phase with constant deceleration,

which ends at the desired target position.

2.

The PID controller receives the setpoint positions

from the Setpoint Generator and in turn calculates

the speed reference needed for the motor to follow

the current setpoint position. By setting the PID

control parameters you can directly influence to

what degree and how quickly a deviation from a

theoretical set path (as specified by the setpoint

series) should be counteracted.

The following behavior indicate that the control parameters

are not optimally adjusted:

4.2

Significance and Influence of the

Controller Parameters

The PID control unit of the MCO 305 motion controller

transfers the necessary output frequency via an internal

speed reference to the VLT AutomationDrive. This set value

is periodically recalculated with an interval of one

millisecond (interval is programmable by the TIMER

parameter). The MCO 305 is by default set with soft “fit for

all” controller parameters.

4 4

- Frequency converter vibrates

- Frequency converter is loud

- Frequent occurrence of position errors

- Poor control accuracy

NOTE

The control parameters are load-dependent. Thus the

frequency converter must be optimized under the actual

conditions of use.

In exceptional cases it may be necessary to determine

various sets of control parameters while working with

heavily changing load conditions and to re-program them in

subsequent application programs depending on the motion

process.

MG.33.K3.02 - VLT® is a registered Danfoss trademark 19

Page 20

Motor and

FC300

FFVEL

FFACC

KDER

Setpoint

generator

Position

Reference

CA

CV

CP

AP

KPROP

KINT

KILIM

BANDWIDTH

+

+

+

+

+

+

–

–

130BB809.10

Optimizing the PID controll... MCO 305 Operating Instructions

44

AP is the actual position (calculated from encoder feedback) in

qc (Quad Counts)

CP is the current position set point in qc

CV is the velocity set point in qc/ms (position deviation) is

calculated by CP-AP

CA is the acceleration set point

The PID filter works according to the following formula:

1 = FFVEL * (Setpoint Velocity)

2 = FFACC * (Setpoint Acceleration)

3 = KPROP * (Position Deviation)

4 = KINT * (Sum of all previous Position Deviations) (limited

by KILIM)

5 = KDER * (Difference of Position Deviation)

6 = 3 + 4 + 5 (Limited by BANDWIDTH)

NOTE

In SYNCV mode the PID controller is working with speed

deviation instead of position deviation. Speed deviation is

calculated by CV–AV. (AV is the Actual Velocity)

The controller in the MCO 305 utilizes two control strategies

at the same time:

1. An open-loop feed-forward control. Since the

asynchronous motor inherently has a good open

loop performance the feed-forward control is a

very important part of the controller in most

applications. Benefits from using feed-forwards

control is a very fast and accurate response to

changes in the setpoint reference.

2. A closed-loop PID control. The PID controller

monitors the difference between the actual

position and the setpoint position. Based on this

information it calculates a control signal to

minimize the position deviance. Thus the MCO is

able to compensate for changes in load or friction.

The PID controller is also necessary to compensate

for any position deviance caused by inaccurate

setting of the open-loop feedforward controller.

In short: The feed-forward control is used to handle changes

in the setpoint reference (especially important in synchronization applications), while the PID control is used to handle

changes in load conditions or inaccuracies of the feedforward control.

4.3 PID Factors

The32-60 Proportional factor is multiplied with the position

deviance and the result is added to the control signal (the

internal speed-reference to the VLT AutomationDrive). Since

the calculated control signal is proportional to the position

deviance (or error) this kind of control is called proportional

control. The behavior of the proportional control is similar to

that of a spring – the further the spring is extended the

stronger the counter-force it produces.

20 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 21

Optimizing the PID controll... MCO 305 Operating Instructions

Influence of the Proportional Factor:

KPROP too small large position deviation due to non-

compensatable load and frictional

moment

KPROP larger quicker reaction, smaller steady-state

deviation, larger overshoot, lesser

damping

KPROP too great heavy vibrations, instability

4.3.1 Derivative Value for PID Control

The 32-61 Derivative factor is multiplied with the derivative of

the position deviance (the 'velocity' of the position deviance)

and the result is added to the control signal. The behavior of

the derivative control is similar to that of an absorber – the

faster the absorber is extended the stronger the counterforce it produces. Thus using the Derivative Value increases

damping in your system.

Influence of the Derivative Value:

KDER small no effect

KDER larger better dampening, lesser overshoot; if

KPROP is increased simultaneously: faster

reaction to control deviation at the same

level of vibration;

KDER too large heavy vibrations, instability

overall control signal (the internal speed-reference) is maxed

out for long periods of time.

This feature is also very helpful in applications where the

power to the motor is turned off and on while the option

card is controlling the VLT AutomationDrive. Cutting of

power to the motor (by setting terminal 27 low) while little

positioning deviance is present in the controller, could result

in an enormous control signal being generated once the

power is turned back on.

4 4

4.3.4 Velocity Feed-forward: FFVEL

The 32-65 Velocity Feed-Forward is a scaling factor that is

multiplied with the derivative of the setpoint position (the

velocity of the setpoint). The result of this operation is added

to the overall control signal. This feature is especially useful

in applications where there is a good correlation between

the control signal (the VLT AutomationDrive speed

reference), and the speed of the motor. This is indeed the

case with most applications.

NOTE

The scaling of the FFVEL parameter is dependent on the

correct setting of the Maximum Reference (3-03 Maximum

Reference) as well as the32-80 Maximum Velocity (Encoder)

and 32-01 Incremental Resolution.

4.3.2 Integral Factor: KINT

The sum of all error is calculated every time the control

signal is updated. The 32-62 Integral factor is then multiplied

with the sum of all positioning errors and added to the

overall control signal.

Thus in case that steady-state position errors occurs in your

application, make sure to use the integral part of the

controller. Steady-state errors will be leveled out as the

summed error increases over time until the control signal

eventually matches the load.

It is possible to set a limit for the control signal generated by

the integral part of the controller (anti-windup).

Influence of the Integral factor:

KINT very small steady-state position deviance is very

slowly regulated to zero

KINT larger faster regulation towards zero steady-state

position deviance, larger overshoot

KINT too large heavy vibrations, instability

4.3.3 Limit Value for Integral Sum: KILIM

The32-63 Limit Value for Integral Sum sets a limit for the

control signal generated by the integral part of the

controller. This helps to prevent the so called "wind-up"

problem which typically occurs in applications where the

4.3.5 Acceleration Feed-forward: FFACC

The 32-66 Acceleration Feed-Forward is multiplied with the

2nd derivative of the setpoint position (the acceleration of

the setpoint) and the result is added to the control signal.

This feature should be used to compensate for the torque

used to accelerate/decelerate the system inertia.

NOTE

Scaling of the Acceleration Feed-forward factor is depending

on the setting of the Shortest Ramp. Increase

32-66 Acceleration Feed-Forward accordingly when

decreasing 32-81 Shortest Ramp and vice versa.

4.3.6 Sampling Time for PID Control: TIMER

For particularly slow systems, slow down the entire control

system by entering multiples of 1 ms as the sampling time.

However, it is important to remember that such a change

influences all the control parameters!

Therefore, normally you should not deviate from the value of

1 ms in 32-69 Sampling Time for PID Control.

MG.33.K3.02 - VLT® is a registered Danfoss trademark 21

Page 22

Optimizing the PID controll... MCO 305 Operating Instructions

4.3.7 PID Bandwidth

A Bandwidth of 1000 means that the set value is being

executed 100%, thus Derivative, Proportional and Integral

Factors are effective as defined. But if operating a system

which could be jeopardized by vibrations, for example, a

crane with a heavy load then you can limit the bandwidth in

which the PID controller should function.32-64 PID

Bandwidth of 300 makes a limitation of 30% possible. The

44

build-up of a vibration is thus prevented since the control is

only moved to with 30% of the calculated set value.

However, then it is necessary also to use the feed-forward

part of the controller in order to achieve the corresponding

control.

Par. # Typical Settings

3-03

32-80

32-00

32-01

32-81

4.4 Optimizing your Controller Settings

as well as

encoder type and resolution in 32-00 Incremental

Signal Type and 32-01 Incremental Resolution, and

32-81 Shortest Ramp. If these settings change again

at a later point, the controller may need optimizing

again.

Maximum Reference

Max. Velocity (Encoder)

Incremental Signal Type

Incremental Resolution

Incremental Resolution

2.

Set 32-67 Max. Tolerated Position Error to a very high

value e.g. 1000000 to avoid getting the error 108

during the following tests.

32-80 Maximum Velocity (Encoder), the

1500,000

1500

[1] RS422

1024

1.000

Step-by-Step

NOTE

Before adjusting the controller parameters it is important to

determine which controller behavior is to be achieved.

NOTE

The drive elements must never be operated outside of the

technical specifications. Thus the maximum acceleration is

determined by the “weakest” drive element.

- “Stiff” axis: the fastest reaction possible is mainly

influenced by the Proportional Factor. You can

judge the results on the basis of the velocity graph.

- Damping of vibrations is mainly influenced by the

Derivative Value. The results can best be assessed in

the velocity graph.

- Temporary (static) deviations in position are mainly

reduced by the Integral Factor and can best be

judged on the basis of the positioning graph.

For best results use the functions in the Tune Oscilloscope for

this purpose; these help you to evaluate and optimize the

PID controller on the basis of graphs of the set and actual

curves.

However, it is recommended only to change one value at a

time and subsequently determining the improvement with a

Testrun.

Click on Controller → Parameter → Axis and select the

frequency converter, of which you are currently adjusting

the settings.

4.4.1

Ten Steps for Optimum Control

The following procedure will optimize your controller

settings in most applications:

1. Make sure that you have specified correct values

for VLT AutomationDrive 3-03 Maximum Reference,

To avoid damaging the system, make sure to set 32-67 Max.

Tolerated Position Error within the limits of the system,

because the position error monitoring is not active with

extremely high values.

3. Optimize the Velocity Feed-forward control: Click

on Execute Testrun and Start a testrun with

following parameter settings:

32-6* PID-Controller

32-60 Proportional factor

32-61 Derivative factor

32-65 Velocity Feed-Forward

32-66 Acceleration Feed-Forward

View the velocity profiles: If the Actual Velocity profile is

lower than the Commanded Velocity profile, increase

Velocity Feed-forward and → Start the testrun again. Of course

if the Actual Velocity profile is

Commanded Velocity you should decrease Velocity Feed-

forward.

Run successive test runs until the two velocity profiles shown

in the Testrun graph have the same maximum value.

Velocity Feed-forward is now optimized, save the current

value.

4. In systems with large inertia and/or rapid changes

in the reference velocity it is a good idea to use and

optimize the Acceleration Feed-forward control

(make sure the inertial load is connected when

optimizing this parameter):

Execute a Testrun with KPROP=0, KDER=0, KINT=0,

FFACC=0, and FFVEL at the optimized value found

above. Use the highest possible acceleration

setting. If 32-81 Shortest Ramp is adjusted properly

an acceleration value of 100 and a deceleration

value of 100 should be sufficient. Start out with a

low setting of Acceleration Feed-forward approx. 10.

higher than the specified

0

0

100

0

22 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 23

Optimizing the PID controll... MCO 305 Operating Instructions

View the velocity profiles: If during acceleration the

actual velocity is constantly lower than the

reference velocity profile, then set a higher value of

Acceleration Feed-forward and → Start the Testrun

again.

Run successive test runs until the two velocity

profiles shown in the Testrun graph have similar

rampup and ramp-down curves.

Acceleration Feed-forward is now optimized, save

the current value.

32-6* PID-Controller

32-60 Proportional factor

32-61 Derivative factor

32-62 Integral factor

32-65 Velocity Feed-Forward

32-66 Acceleration Feed-Forward

0

0

0

result of step 3

10

5. Next step is finding the maximum stable value of

the Proportional Factor in the PID controller.

Execute a Testrun with KPROP=0, KDER=0, KINT=0.

Set FFVEL and FFACC at the optimized values

found above.

View the velocity profile. If the velocity profile is

not oscillating then increase the Proportional

Factor. Run successive testruns until the actual

velocity profile is oscillating mildly.

Decrease this "mildly" unstable Proportional Factor

value to about 70 %. Save this new value.

32-6* PID-Controller

32-60 Proportional factor

32-61 Derivative factor

32-62 Integral factor

32-65 Velocity Feed-Forward

32-66 Acceleration Feed-Forward

KPROP 0

KDER 0

KINT 0

FFVEL result of step 3

FFACC result of step 4

6. In order to dampen the oscillations created by the

Proportional part of the controller, the Derivative

Value should now be optimized. Start a Testrun

with KINT=0 and KDER=200. Set FFVEL, FFACC and

KPROP at the optimized values found above.

Run successive test runs with increasing values of

the Derivative Value. At first the oscillations will

gradually reduce. Stop increasing Derivative Value

when the oscillations begin to increase.

Save the last value of Derivative.

32-6* PID-Controller

32-60 Proportional factor

32-61 Derivative factor

32-62 Integral factor

32-65 Velocity Feed-Forward

32-66 Acceleration Feed-Forward

KPROP result of step 5

KDER 200

KINT 0

FFVEL result of step 3

FFACC result of step 4

7. In any system that requires a zero steady-state

error, the Integral part of the controller must be

used. Setting this parameter though is a trade-off

between achieving zero steady-state error fast

(which is good) and increasing overshoot and

oscillations in the system (which is bad).

If you are using the Integral part of the PID

controller, remember to reduce the 32-63 Limit

Value for Integral Sum as much as possible (without

losing the Integral Factor effect of course) in order

to reduce oscillations and overshoot as much as

possible.

8.

Reduce the 32-64 PID Bandwidth as much as

possible. With a properly optimized open-loop

control Bandwidth could be reduced to as little as 6

or 12 % (60 – 120).

9.

Set the 32-67 Max. Tolerated Position Error back to

normal e.g. 20,000.

10.

Once the Testrun is concluded, then → Save the

new parameters as the user parameters. Thus,

these parameters are saved in the controller and in

the future will be used for all programs.

What to do if....

....there is a tendency towards instability?

In the event of a strong tendency towards instability reduce

32-60 Proportional factor and 32-61 Derivative factor again, or

reset 32-62 Integral factor.

....stationary precision is required?

If stationary precision is required, increase 32-62 Integral

factor.

....the tolerated position error is exceeded?

If the test run is constantly interrupted with the message

“position error” set 32-67 Max. Tolerated Position Error –

within the tolerable limits – as large as possible.

If the position error occurs during the acceleration phase

that suggests that the set acceleration cannot be achieved

under the existing load conditions. Increase 32-67 Max.

Tolerated Position Error or determine a Maximum Acceleration

suitable for the entire system.

If position errors do not occur until after the acceleration

phase and they can be delayed but not eliminated by

increasing 32-67 Max. Tolerated Position Error, this suggests

that the Maximum Velocity (RPM) chosen is too high.

Determine a maximum velocity suitable for the entire

system.

....the maximum acceleration is not achieved?

In general, the technical data for a frequency converter are

only valid for a freely rotating axle end. If the frequency

converter is carrying a load the maximum acceleration is

reduced.

The theoretical maximum acceleration will also not be

achieved if, for example, the PID controller output is too

small, or the FC 300/motor is not sized correctly and

therefore does not provide enough energy for peak

consumption during acceleration.

4 4

MG.33.K3.02 - VLT® is a registered Danfoss trademark 23

Page 24

How to Install the Applicat... MCO 305 Operating Instructions

5 How to Install the Application

3. When copy is completed, paste the drive in-to a

5.1 Download Application Program and

Configuration

Follow these steps to create and download MCO 305

program and configuration using MCT 10 and APOSS

55

1. Open MCT 10.

2. Open the folder “Project – Drive – MCO 305 –

programs”.

3. Right click in the right hand view and select:

a. “Import program file” if using an existing program

“outside” the project file or,

b. “New MCO 305 program” when writing a new

program. Right click the program file and double

click or right click and select “Edit”. Program editor

will open.

4. Repeat step 3 if more programs are required.

5. One program must be set as Autostart program:

Right click the program file and select “Set as

Autostart”.

6. Open the folder “Project – Drive – MCO 305 –

Arrays”.

7. Right click on the file and select “Import” or “Edit”.

8. Right click on the MCO 305 folder in the tree

structure in the left-hand view of MCT 10 and select

“Write to drive”.

9. “Write MCO 305 Program Source Files to the Drive”

must be ticked if it should be possible to read the

program from the frequency converter.

Now parameters and MCO 305 data is stored in the project

file, restore by the following steps:

Now both parameters and MCO 305 data is restored in the

drive.

Backup and Restore via LCP

Both parameters and MCO 305 data can be stored in the LCP

and thus restored from the LCP to another frequency

converter.

Use the following steps to back-up parameters data in the

LCP:

Now parameters and MCO 305 data is stored in the LCP,

restore by the following steps:

Now both parameters and MCO 305 data are restored in the

frequency converter.

project folder.

4. Save the project.

1. Open the project file with MCT 10 Set-up

Software.

2. Go on-line with the drive via the Network folder.

3. Open the project folder, Right click on the drive

folder and select “Write to drive”.

1.

Select “All to LCP” [1] in 0-50 LCP Copy.

2.

Select “File from MCO to LCP” [4] in 0-50 LCP Copy.

1.

Select “All from LCP” [2] in 0-50 LCP Copy.

2.

Select “File from LCP to MCO” [5] in 0-50 LCP Copy.

5.2

Backup and Restore

All parameters and MCO 305 data can be read out and stored

in an MCT 10 project and thus restored to the frequency

converter.

NOTE

MCO 305 programs can only be read-out when they have be

downloaded including source code!

Use the following steps to back-up parameters and data by

PC:

1. Go on-line with the drive via the Network folder.

2. Right click on the drive folder and select copy.

“Include programs” must be ticked.

24 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 25

How to Install the Applicat... MCO 305 Operating Instructions

5.3 How to Connect and Run Multiple

Frequency Converters

Use MCT 10 Networking or start APOSS directly by clicking on

the application's icon. This stand-alone operation mode

allows APOSS to switch frequency converters or connect to

multiple frequency converters. In stand-alone mode, all file

and parameter handling is done via APOSS. Thus the File

menu also provides the functions for File → New, → Open, and

→ Save As. The Settings menu allows selecting the interface.

Run programs in several frequency converters

If you want to load the program into several controllers, link

the program with the corresponding VLT AutomationDrive

and click on → Execute.

If you want to load a different program in each controller,

open a different edit window for each VLT AutomationDrive,

then open the desired program file and connect it to the VLT

AutomationDrive with → Select Controller. Then start each

program, one after the other, with → Execute.

5 5

MG.33.K3.02 - VLT® is a registered Danfoss trademark 25

Page 26

General Specifications MCO 305 Operating Instructions

6 General Specifications

1) Selected in parameter 5-00 Digital I/O mode. The digital

6.1 Protection and Features

inputs are galvanic isolated from the internal electronics and

can be sourced by an external 24V power supply.

6

- All inputs, outputs and supply voltages are

protected against short circuit.

- All inputs, outputs and supply voltages are galvanic

isolated from high voltages such as mains supply

and motor voltage (PELV).

- Encoder signals are monitored during operation

and standstill.

- Customer specific application programs can be

copy protected.

- All MCO 305 parameters including user defined

application parameters are accessible via the VLT

AutomationDrive LCP.

- MCO 305 can be combined with other VLT

AutomationDrive options e.g. PROFIBUS and

DeviceNet interface.

- All digital inputs and outputs are galvanic isolated

from the internal electronics and can be sourced

from an external 24V power supply.

6.2

Technical Data

Type Plug connectors with screw

terminals.

Maximum cross section, rigid wire

Maximum cross section, flexible

wire

Maximum cross section, wire with

enclosed core

Minimum cross section

Table 6.1 Connection Terminals

of programmable digital inputs 10

Number

Terminal block X57

Terminal number 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

Logic

Voltage level 0 - 24V DC

Voltage level, logic.0. PNP < 5V DC

Voltage level, logic.1. PNP > 10V DC

Voltage level, logic.0. NPN > 19V DC

Voltage level, logic.1. NPN < 14V DC

Maximum voltage on input 28V DC

1.5mm2 / AWG 16

1.5mm2 / AWG 16

1.5mm2 / AWG 16

0.08mm2 / AWG 28

PNP or NPN ¹

Number of programmable digital outputs

Terminal block X59

Terminal number

Driver type Push/Pull

Logic

Voltage level 0 - 24V DC

Max. output current (sink or source) with

internal power supply (total )

Max. output current (sink or source) with

external power supply (per output)

Table 6.3 Digital Outputs

1

8 (6)

11, 21, 3, 4, 5, 6, 7, 8

PNP or NPN

40mA

100mA

2

1) Terminals X59-1 and X59-2 can be programmed as input,

33-60 Terminal X59/1 and X59/2 Mode.

2) Selected in 5-00 Digital I/O Mode.

Number of digital outputs which can be used as

digital inputs

Terminal block X59

Terminal number 1, 2

Logic

Voltage level 0 - 24V DC

Voltage level, logic.0. PNP < 10V DC

Voltage level, logic.1. PNP > 17V DC

Voltage level, logic.0. NPN > 13V DC

Voltage level, logic.1. NPN < 6V DC

Maximum voltage on input 28V DC

Table 6.4 Combined Digital Inputs/Outputs

1

2

PNP or NPN

1) Terminals X59-1 and X59-2 can be programmed as input,

33-60 Terminal X59/1 and X59/2 Mode.

2) Selected in 5-00 Digital I/O Mode.

Terminal block

Terminal number 1, 2

Maximum load 65mA

Table 6.5 24V DC Supply Output

X58

The internal 24V power supply can be disconnected via

parameter 33-85, an external 24V power supply must then

be connected to X58-1 and X58-2.

2

Table 6.2 Digital Inputs

26 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 27

General Specifications MCO 305 Operating Instructions

General specifications:

Number of encoder inputs 2

Terminal block X55 and X56

Terminal number 5, 6, 7, 8, 9, 10, 11, 12

Input impedance

Maximum voltage on inputs 5V DC

Cable type Screened cable with a twisted pair of

Table 6.6 Encoder Inputs

Incremental encoder type RS422/TTL

Maximum frequency 410kHz

Phase displacement between A and B 90°± 30°

Maximum cable length

Table 6.7 Incremental Encoder Specifications

Absolute encoder type SSI

Data coding Gray

Data length 12 – 32 bit

Clock frequency

Maximum cable length

120Ω

wires for each encoder channel

2

300m

78kHz – 2MHz

2

150m

1

1

Sample time of position PID loop

Positioning accuracy

Synchronizing accuracy

Table 6.11 Control Characteristics

1ms

± 1 increment ¹

± 1 increment ¹

1) This is the static accuracy; dynamic accuracy depends on

many “external” factors such as encoder resolution, moment

of inertia, mechanical backlash and elasticity.

Program memory size 100 Kbytes

Maximum number of application programs 90

Average command execution time 0.3ms

Maximum reaction time on interrupt input ms

Table 6.12 Application Program

6.3 Supply Voltage Overview

6

6

Table 6.8 Absolute Encoder Specifications

1) Always observe specifications/limitations prescribed by

the encoder supplier.

2) 150m cable is possible up to 500kHz clock frequency,

above 500kHz cable length must be limited further.

Number of encoder outputs

Terminal block X56

Terminal number 5, 6, 7, 8, 9, 10, 11, 12

Signal type RS422

Maximum frequency 410kHz

Maximum number of slaves 31 (more with repeater)

Maximum cable length 400m

Table 6.9 Encoder Output

Number of supply voltages

Terminal block X55 and X56

Terminal number 1, 2, 3, 4

24V, max. load

8V, max. load

5V, max. load

1

3

1

250mA

12

250mA

1

400mA

Table 6.10 Encoder Voltage Supply

1) This is maximum load when only one supply voltage is

used; when 2 or 3 supply voltages are used simultaneously

the load must be reduced accordingly. The following must

be observed: load24V + load8V + load5V 6W and load8V +

load5V 2W.

2) 8V is only available at terminal block X55.

MG.33.K3.02 - VLT® is a registered Danfoss trademark 27

Page 28

Troubleshooting MCO 305 Operating Instructions

7 Troubleshooting

You can find brief information on the error messages in the

7.1 Warnings and Error Messages

All messages are shown in the LCP display of the VLT

AutomationDrive in short and in the APOSS software in plain

text.

Error no. LCP display Error text

102 Too many CAN objects There are no more CAN objects available (CANINI).

103 Illegal axis num. Axis not in system.

105 Error not reset Error not cleared.

106 Home not done Failed to move to HOME position.

107 Home vel. zero Home velocity 0

77

108 Position error Position error.

109 Index not found Index pulse (encoder) not found.

110 Unknown com. Unknown command.

111 SW end limit Software end limit activated.

112 Unknown param. Illegal parameter number.

113 FC not enabled VLT Error Status

114 Too many loops. Too many nested loops.

115 Par. save failed INLONG command got an illegal string

116 Param. memory Parameters in memory are corrupted.

117 Progr. Memory Programs in memory are corrupted.

118 Reset by CPU Reset by CPU.

119 User abort User abort.

121 No more SDO chn Number of SDO channels exceeded.

125 HW end limit Limit switch activated.

149 Too many inter. Too many interrupt functions.

150 No ext. 24V External supply is missing.

151 Too many gosub Too many nested GOSUB commands

152 Too many return Too many RETURN commands.

154 D. out overload Digital output overloaded.

155 LINK failed LINKGPAR failed.

156 Illegal double arg. A floating point function was called with an invalid argument.

160 Internal Intr. error Interrupt happened, but interrupt address is no longer valid.

162 Memory error Error in verifying

170 Too many DIM arrays Too many DIM arrays defined.

171 Array too small Array too small

175 Out of array mem. No more memory space for the new array defined by DIM.

176 Array size wrong Array size does not correspond to the size of the existing array.

179 Waitndx timeout Timeout while waiting for index.

184 Too many ontime Too many ONTIME or ONPERIODS interrupts.

187 Out of memory Not enough memory for variables

188 CAN guarding error A guarding error happened.

189 CAN send-receive error CAN send or receive error.

190 Memory locked Memory locked

191 Illegal cam array Illegal curve array in SETCURVE.

192 Encoder error Encoder error

193 Stack overflow Stack overflow: Too many local variables or nested function calls.

194 Out of dyn. mem Out of dynamic memory.

table or detailed information in the following section.

The tables contain the messages in numerical order. Letters

following a % sign represent variables which can be used in

plain text at the corresponding locations.

28 MG.33.K3.02 - VLT® is a registered Danfoss trademark

Page 29

Troubleshooting MCO 305 Operating Instructions

Error no. LCP display Error text

195 Too many testindices Too many test indices in data logging command.

196 Code too old Code is too old for the current firmware.

198 Limit sw. violation rong direction after limit switch tripped and error reset.

199 Internal MCO fault Internal MCO fault

Error 102

Too many CAN objects have been used and there are no more CAN objects available. The optional error information (see Error

History) is used as follows:

CN_TIMEOUT -2 // timeout of CAN commands when sending or reading telegrams

NO_HARDWARE -6 // no CAN hardware present

NO_MEMORY -7 // no more entries available (mailboxes or lists)

NO_CANMEMORY -10 // no more mailboxes available for define command

NO_MOBJ -11 // the demanded mailbox is not available

CN_CANERROR -12 // a CAN bus error is detected (low level bus error)

CN_MOBJ_DIRERR -13 // direction of mailbox is wrong (try to read a write box or vice versa)

NO_USER -33 // return value for sdo state (SDOSTATE).

SDO_ABORT -50 // has to be higher than the CN_ error messages

SDO_ID_NOT_IN_USE -33 // return value for sdo state (SDOSTATE )

SDO_SEG_ARRAY_TOO_SMALL -51

SDO_SEG_TOGGLE_ERROR -52

SDO_SEG_TOO_MUCH_DATA -53

SDO_SEG_NOT_ENOUGH_DATA -54

SDO_SEG_ARRAY_WRITE_ERROR -55

7 7

GUARD_ERROR_NOT_OPERATIONAL -101

GUARD_ERROR_TOGGLE -102

GUARD_ERROR_MODULE_NOT_RESPONSE -103

GUARD_ERROR_NO_MODULE -104

Error 103

Illegal axis number

An attempt has been made to find an axis which does not

exist in the controller.

Check to see if the program axis command has an invalid

number or a general axis command (...X(*)).

Error 105

Error 108

Position error

HOME was executed with HOME_VEL set to zero.

The distance between the set and the real position was

greater than the Maximum Tolerated Position Error defined in

32-67 Max. Tolerated Position Error.

Causes:

Error not reset

An attempt has been made to execute a motion command,

although an actual error message has not been cleared.

Error 106

Home not done

Failed to move to HOME position. According to the axis

33-00 Force HOME, a forced move to the machine zero-point

is demanded, before other motion commands can be

executed. This move to the machine zero-point has not been

executed.

Error 107

Home velocity zero

An attempt was made to execute the HOME command but

the motor is set to 0 in 33-03 Velocity of Home Motion.

- Mechanically blocked or overloaded frequency

converter,

-

32-67 Max. Tolerated Position Error too small,

- commanded speed greater than VLT

AutomationDrive 4-13 Motor Speed High Limit [RPM]

and 3-03 Maximum Reference,

- commanded acceleration too great,

-

32-60 Proportional factor too small, or

- VLT AutomationDrive not enabled.

MG.33.K3.02 - VLT® is a registered Danfoss trademark 29

Page 30

Troubleshooting MCO 305 Operating Instructions

Error 109

Index not found

At reference or index search, the encoder index pulse could

not be found within a motor rotation.

Causes:

- An encoder without an index pulse has been used,

- index pulse not connected,

- index pulse incorrect (all three channels must have

a simultaneous low), or

-

32-01 Incremental Resolution (ENCODER) is set too

low.

Error 110

Unknown command

Cause is a Communication or program error. The program

must be re-compiled and re-loaded.

Error 111

77

Software end limit

A motion command will cause or has caused the software

end limit to be activated.

Identification of attainment of software limit at a motion in

the speed mode will only be made after the current position

is identical to the software limit switch.

Starting with MCO 5.00 it is possible to clear a software limit

error and then drive in the opposite direction. If you try again

to move in the wrong direction, then a new error is

generated.

Handling of hardware limit switches is the same as software

limit switches. That means that the error you can clear and

drive in the opposite direction. But if you try to move in the

wrong direction, then the error 198 occurs.

In positioning mode, it is known before motion start that the

target position lies outside the path. In this case, the

movement will not be executed and the error message can

be cleared.

The control unit will be switched off and the frequency

converter must be manually moved back to within the

admissible area, or the monitoring of the software limit

switch must be temporarily de-activated via 33-43 Negative

Software End Limit Active and 33-44 Positive Software End Limit

Active. Only then is it possible to clear the error.

Limit switches and reference switches allow the usage of any

input. That means not only 1..8 are supported but also larger

numbers as well as virtual inputs or outputs.

NOTE

Using virtual inputs as limit switches is dangerous because it