Page 1

Operating Guide

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

VLT® AQUA Drive FC 202

drives.danfoss.com

Page 2

Page 3

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Contents

1

Introduction 6

1.1

Purpose of the Operating Guide 6

Trademarks 6

1.2

Additional Resources 6

1.3

1.4

Document and Software Version 6

1.5

Product Overview 6

1.5.1

Intended Use 7

Safety 8

2

Safety Symbols 8

2.1

Qualied Personnel 8

2.2

Safety Precautions 8

2.3

3

Applications 11

Contents

3.1

Application Overview 11

3.2

Supported Congurations 12

3.2.1

Hardware Conguration for Expanding of Basic Cascade 12

3.2.2

Hardware Conguration for Master/Follower Cascade Control 14

3.2.3

Hardware Conguration for Mixed Pumps 15

3.2.3.1

3.2.3.2

3.2.4

Using Soft Starters for Fixed-speed Pumps 20

3.3

Sleep Mode 20

3.3.1

Basic Cascade Controller 20

3.3.2

Master/Follower and Mixed-pump Congurations 20

3.3.3

Temporary Boost of the Setpoint Before Sleep Mode 21

4

Installation 22

4.1

Before Start 22

4.2

VLT® Extended Cascade Controller MCO 101 22

4.2.1

Installing the VLT® Extended Cascade Controller MCO 101 22

Unequal-sized Pumps Conguration 16

Mixed-pump Conguration with Alternation 18

4.2.2

Electrical Data, VLT® Extended Cascade Control MCO 101 24

4.3

VLT® Advanced Cascade Controller MCO 102 24

4.3.1

Installing the VLT® Advanced Cascade Controller MCO 102 24

4.3.2

Electrical Data, VLT® Advanced Cascade Control MCO 102 26

5

Conguration of the System 27

5.1

Conguration of the Extended and Advanced Cascade Controllers 27

AQ326832164524en-000101/130R0345 | 3Danfoss A/S © 2020.08

Page 4

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

5.2

Operation 30

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

5.2.8

Contents

Basic Conguration of the Extended and Advanced Cascade Controllers 27

Conguring Multiple Drives 28

Conguring Closed-loop Control 28

Staging/Destaging of Variable-speed Pumps 28

Staging/Destaging of Fixed-Speed Pumps 29

Checking Pump Status and Controlling Pumps 30

Manual Pump Control 30

Run-time Balancing 30

Pump Spin for Unused Pumps 31

Total Lifetime Hours 31

Alternation of the Lead Pump 31

Staging/Destaging in Mixed-pump Congurations 31

Override Staging/Destaging 32

5.2.9

Minimum Speed Destaging 32

5.2.10

Fixed-speed-only Operation 32

5.2.11

Flow Compensation for Applications with Cascade Controller 32

6

Parameter Descriptions 34

6.1

Parameter Group 27-**, Cascade CTL Option 34

6.1.1

Parameter Group 27-0*, Control & Status 34

6.1.2

Parameter Group 27-1*, Conguration 35

6.1.3

Parameter Group 27-2*, Bandwidth Settings 37

6.1.4

Parameter Group 27-3*, Staging Speed 40

6.1.5

Parameter Group 27-4*, Staging Settings 41

6.1.6

Parameter Group 27-5*, Alternation Settings 44

6.1.7

Parameter Group 27-6*, Digital Inputs 45

6.1.8

Parameter Group 27-7*, Connections 47

6.1.9

Parameter Group 27-9*, Readouts 50

6.2

Parameter Lists 51

6.2.1

25-** Cascade Controller 51

6.2.2

27-** Cascade CTL Option 53

7

Conguration Example 56

7.1

Master/Follower 56

7.1.1

Basic Settings 56

7.1.1.1

7.1.1.2

7.1.2

Master Drive Settings 57

Basic Settings, Master and Follower 56

Display Settings, Master and Follower 56

AQ326832164524en-000101/130R03454 | Danfoss A/S © 2020.08

Page 5

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

7.1.3

7.1.4

Contents

7.1.2.1

7.1.2.2

7.1.2.3

7.1.2.4

7.1.2.5

Follower Drive Settings 58

7.1.3.1

7.1.3.2

Conguring Sleep Mode 59

Conguration Settings 57

Bandwidth Settings 57

Staging Speed Settings 57

Alternate Settings 58

Connection Settings 58

Open-loop Settings 58

Digital In/Out Settings 58

AQ326832164524en-000101/130R0345 | 5Danfoss A/S © 2020.08

Page 6

•

Edition

Remarks

Software version

AQ326832164524, version 0101

Editorial update.

VLT® Extended Cascade Controller MCO 101: 2.6X

VLT® Advanced Cascade Controller MCO 102: 1.2X

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Introduction

1 Introduction

1.1 Purpose of the Operating Guide

The purpose of this Operating Guide is to describe the VLT® Extended Cascade Controller MCO 101 and VLT® Advanced Cascade

Controller MCO 102. The Operating Guide contains information about:

•

Applications for cascade control.

•

Installation.

•

Conguration of the system.

•

Parameters.

•

Conguration examples.

The Operating Guide is intended for use by qualied personnel. To use the cascade controller options safely and professionally, read

this Operating Guide thoroughly and pay particular attention to the safety instructions and general warnings.

1.2 Trademarks

VLT® is a registered trademark for Danfoss A/S.

1.3 Additional Resources

Various resources are available to understand advanced drive operation, programming, and directives compliance.

•

The VLT® AQUA FC 202 Operating Guide provides detailed information for the installation and start-up of the drive.

•

The VLT® AQUA FC 202 Programming Guide provides greater detail on how to work with parameters. It also contains application

examples.

•

The VLT® AQUA FC 202 Design Guide provides detailed information about capabilities and functionality to design motor control

systems.

•

Supplemental publications, drawings, and manuals are available at www.danfoss.com.

Contact a Danfoss supplier or visit www.danfoss.com for more information.

1.4 Document and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Document and Software Version

N O T I C E

The Cascade Controller options for the VLT® AQUA Drive FC 202 are supported in the VLT® AQUA Drive software version 1.24 and

onwards.

1.5 Product Overview

The VLT® Extended Cascade Controller MCO 101 and VLT® Advanced Cascade Controller MCO 102 are add-on options extending the

supported number of pumps and the functionalities of the built-in Cascade Controller in the VLT® AQUA Drive FC 202.

The MCO 101 consists of an option board with 3 relays and is installed in slot B. Once the options are installed, the parameters

supporting the Cascade Controller functions are available via the LCP in parameter group 27-** Cascade CTL Option.

The following options for cascade control are available in the VLT® AQUA Drive FC 202:

•

Built-in Basic Cascade Controller (standard Cascade Controller)

•

VLT® Extended Cascade Controller MCO 101

•

VLT® Advanced Cascade Controller MCO 102

The MCO 101 and MCO 102 can be used in 2 dierent modes:

AQ326832164524en-000101 / 130R03456 | Danfoss A/S © 2020.08

Page 7

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

•

With the extended features controlled by parameter group 27-** Cascade CTL Option.

•

Extending the number of available relays for the Basic Cascade Controller via parameter group 25-** Cascade Controller.

With MCO 101, a total of 5 relays can be used for cascade control. With MCO 102, a total of 8 pumps can be controlled. The options

are able to alternate the lead pump with 2 relays per pump.

Introduction

N O T I C E

If the MCO 102 is installed, the VLT® Relay Card MCB 105 can extend the number of relays to 13.

1.5.1 Intended Use

Cascade control is a common control system used to control parallel pumps or fans in an energy-ecient way.

The VLT® Extended Cascade Controller MCO 101 and the VLT® Advanced Cascade Controller MCO 102 are designed for pump appli-

cations, however, it is also possible to use Cascade Controllers in any application requiring multiple motors congured in parallel.

The MCO 101 and MCO 102 enable control of multiple pumps congured in parallel by:

•

Automatically turning individual pumps on/o.

•

Controlling the speed of the pumps.

When using Cascade Controllers, the individual pumps are automatically turned on (staged) and turned o (destaged) as needed to

meet the required system output for ow or pressure. The speed of pumps connected to the VLT® AQUA Drive FC 202 is also controlled to provide a continuous range of system output.

The Cascade Controller software runs from a single drive with a Cascade Controller option installed (master drive). It controls a set of

pumps, each controlled by a drive or connected to a contactor or a soft starter.

Other drives in the system (follower drives) do not need to have a Cascade Controller option card installed. They are operated in

open-loop mode and receive the speed reference from the master drive. Pumps connected to drives are referred to as variablespeed pumps. Pumps connected to mains through a contactor or through a soft starter are referred to as xed-speed pumps.

Each pump, variable speed or xed speed, is controlled by a relay in the drive. The MCO 101 and MCO 102 can control a mix of

variable-speed and xed-speed pumps.

N O T I C E

VLT® Digital Cascade can be used instead of MCO 101 and MCO 102 for master/follower applications for full redundant system.

The VLT® Digital Cascade control is unlocked with a license code. Installation is easy using embedded Modbus RTU and multi-

master ability makes system redundant. Example: If the master breaks down, the back-up master takes its place until a replace-

ment takes place.

AQ326832164524en-000101 / 130R0345 | 7Danfoss A/S © 2020.08

Page 8

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualied Personnel

To allow trouble-free and safe operation of the unit, only qualied personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualied electrical engineers, or persons who have received training from qualied electrical engineers and are suitably experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specic application.

2.3 Safety Precautions

W A R N I N G

HIGH VOLTAGE

AC drives contain high voltage when connected to AC mains input, DC supply, or load sharing. Failure to perform installation,

start-up, and maintenance by qualied personnel can result in death or serious injury.

Only qualied personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to the AC mains, DC supply, or load sharing, the motor may start at any time, causing risk of death,

serious injury, and equipment or property damage. The motor may start by activation of an external switch, a eldbus command,

an input reference signal from the LCP or LOP, via remote operation using MCT 10 Set-up software, or after a cleared fault condi-

tion.

Press [O] on the LCP before programming parameters.

-

Disconnect the drive from the mains whenever personal safety considerations make it necessary to avoid unintended motor

-

start.

Check that the drive, motor, and any driven equipment are in operational readiness.

-

AQ326832164524en-000101 / 130R03458 | Danfoss A/S © 2020.08

Page 9

Voltage

[V]

Minimum waiting time (minutes)

47152030

40

200–240

0.25–3.7 kW (0.34–

5 hp)

–

5.5–45 kW (7.5–60

hp)

–––

380–480

0.37–7.5 kW (0.5–

10 hp)

–

11–90 kW (15–125

hp)

110–250 kW

(150–335 hp)

–

315–1500 kW

(425–2000 hp)

525–600

0.75–7.5 kW (1.0–

10 hp)

–

11–90 kW (15–125

hp)

–––

525–690

–

1.1–7.5 kW

(1.5–10 hp)

11–90 kW (15–125

hp)

45–400 kW (60–

540 kW)

450–1200 kW

(600–1600 hp)

1400 kW

(1875 hp)

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are o.

Failure to wait the specied time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specied in the table Discharge time and is also visible

-

on the nameplate on top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 2: Discharge Time

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certied electrical installer.

-

W A R N I N G

ROTATING SHAFTS

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualied personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this guide.

-

W A R N I N G

UNINTENDED MOTOR ROTATION WINDMILLING

Unintended rotation of permanent magnet motors creates voltage and can charge the unit, resulting in death, serious injury, or

equipment damage.

Ensure that permanent magnet motors are blocked to prevent unintended rotation.

-

AQ326832164524en-000101 / 130R0345 | 9Danfoss A/S © 2020.08

Page 10

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

Safety

AQ326832164524en-000101 / 130R034510 | Danfoss A/S © 2020.08

Page 11

Built-in

MCO 101

MCO 102

100% 100% 100% 100%

e30ba594.12

Relay 1

Relay 2

Relay 10

1

1 2 3 4

1 VSP

(1)

+ 2

FSP

(2)

, pa-

rameter

group 25-**

Cascade

Controller

1 VSP + 5 FSP, parameter group 25-** Cascade Controller

1 VSP + 8 FSP, parameter group 25-** Cascade Controller

100% 100% 200% 200%

e30ba593.12

Relay 1

Relay 2

Relay 10

1

21

2 3 4

–

1–6 VSP + 1–5 FSP

(maximum 6 pumps),

parameter group 27-**

Cascade CTL Option

1–8 VSP + 1–7 FSP

(maximum 8 pumps),

parameter group 27-**

Cascade CTL Option

Builtin

MCO 101

MCO 102

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

3 Applications

3.1 Application Overview

Applications

1

VSP=Variable-speed pump (directly connected to the drive).

2

FSP=Fixed-speed pump (the motor could be connected via contactor, soft starter, or star/delta starter).

AQ326832164524en-000101 / 130R0345 | 11Danfoss A/S © 2020.08

Page 12

Line supply

R1 R2

R10

e30ba595.12

1

2

3

4

1

2

3

4

100%

100%

100%

100%

–

6 VSP, parame-

ter group 27-**

Cascade CTL

Option

8 VSP, parameter group 27-**

Cascade CTL

Option

R1

R2

Drive R10

R11

K3

K3

K5

K5

K7

K7

K2

K2

K2

K1

K1

K1

K1K5K5

K7

K7 K4

K4

K4

K3

K3

K1

K3

K1

K3

K7

K7

K6

K6

K6K5

K5

K1

K1

K3

K3

K5

K5

K8

K8

K8

K7

K7

e30ba876.11

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Applications

3.2 Supported Congurations

When setting up the system, create a hardware conguration which communicates the number of connected pumps and drives to

the master. The necessary hardware is explained in the hardware conguration examples.

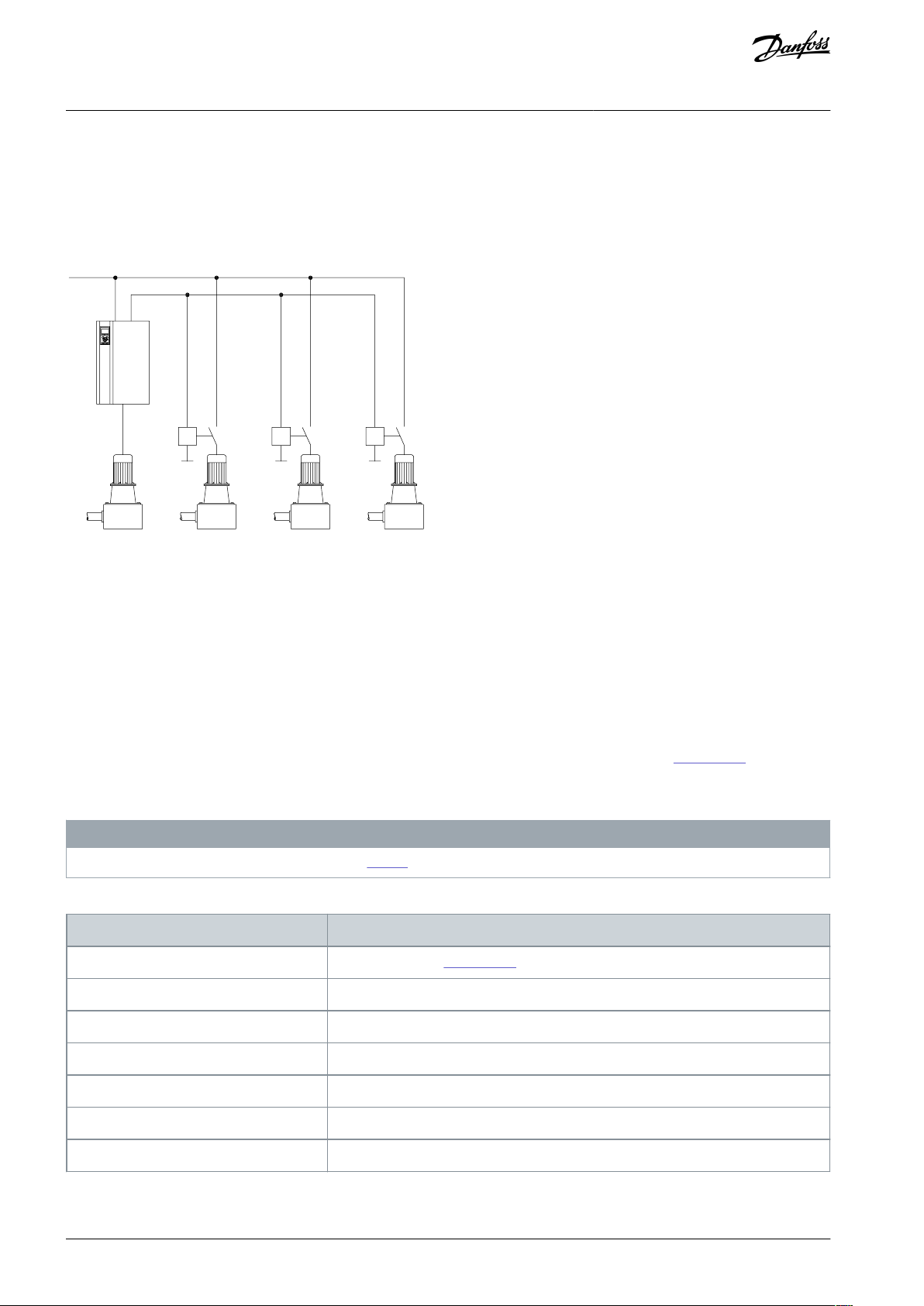

3.2.1 Hardware Conguration for Expanding of Basic Cascade

In applications already controlled by the built-in Cascade Controller in parameter group 25-** Control Mode, the option cards can be

used to extend the number of relays for cascade control, for example, if a new pump is added to the system.

To enable the basic Cascade Controller in parameter 27-10 Cascade Controller, select [3] Basic Cascade Ctrl. Refer to VLT® AQUA Drive

FC 202 Programming Guide for further programming with settings from parameter group 25-** Control Mode.

Refer to

using basic cascade and VLT® Extended Cascade Controller MCO 101 as relay extension.

Illustration 1 and Illustration 2 for examples of external wiring required for systems with alternating lead pump of 4 pumps

Illustration 1: Control Circuit Alternating Lead Pump (4 Pumps)

AQ326832164524en-000101 / 130R034512 | Danfoss A/S © 2020.08

Page 13

FC

K1

K2

K3

K4

K5

K6

K7

K8

M

M

M

M

e30ba875.11

e30ba592.13

Relay 1

Relay 2

Relay 10

1

1

2

3

4

100%

1

100% 100%

100%

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Illustration 2: Mains Circuit Alternating Lead Pump (4 Pumps)

Applications

The xed-speed pump conguration provides a cost-eective method for controlling up to 9 pumps. It is able to control system

output by controlling the number of running pumps and the speed of the single variable-speed pump.

In this conguration, the VLT® AQUA Drive FC 202 with a VLT® Advanced Cascade Controller MCO 102 controls 1 variable-speed

pump and up to 8 xed-speed pumps. The xed-speed pumps are staged and destaged as needed through contactors direct online.

The variable-speed pump provides the ner level of control needed between the stages.

The direct online pumps are staged or destaged depending on their feedback.

Illustration 3: Fixed-speed Pump Conguration Example

N O T I C E

If the pumps are not equal in size or if 2 relays per pump are used, a mixed-pump conguration must be selected in parameter

27-10 Cascade Controller. For the conguration shown in Illustration 3, relay selections in parameter group 27-7* Connections are as

follows:

27-70.0 Relay 1 → [73] Pump 2 to mains

-

27-70.1 Relay 2 → [74] Pump 3 to mains

-

27-70.9 Relay 10 → [75] Pump 4 to mains

-

27-70.10 Relay 11 → [0] Standard relay

-

27-70.11 Relay 12 → [0] Standard relay

-

AQ326832164524en-000101 / 130R0345 | 13Danfoss A/S © 2020.08

Page 14

Motor / Pump

1

Motor / Pump 2

Motor / Pump 3

DI 18

DI 18 DI

29

DI 29

DO

27

R 1

R 2

100%

100%

100%

P

U / I

T 54

T 55

T 20

2

Pressure

Transmitter

0 - 10 V

0 - 20 mA or

4 - 20 mA

T 12

DI18

2

Start

Master with

MCO 101/102

Follower 1

Follower 2

e30bd072.11

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Applications

N O T I C E

Pressure uctuations during staging/destaging transitions may occur and it may be less energy-ecient than the master/follower

congurations.

3.2.2 Hardware Conguration for Master/Follower Cascade Control

The master/follower cascade control mode oers the best performance, the most precise control, and maximum energy savings. It

controls multiple equally sized pumps in parallel, running all pumps at the same speed, and stages the pumps on and o according

to system requirements. Compared to traditional cascade control, the number of running pumps is controlled by speed instead of

feedback. To obtain the highest energy saving, staging speed on and o must be set correctly according to the system. In this example, terminal 27 of the master drive is used as pulse output for the reference, and terminals 29 of the follower drives are used as

pulse input for this reference. While the master drive is running in closed loop, the follower drives are running in open loop. All

follower drives are connected to mains and motor in the same way as the master drive.

Illustration 4: Basic Wiring Principle for a Master/Follower Conguration (Example)

AQ326832164524en-000101 / 130R034514 | Danfoss A/S © 2020.08

Page 15

100% 100% 200% 200%

e30ba593.12

Relay 1

Relay 2

Relay 10

1

21

2 3 4

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Applications

In this conguration, each pump is controlled by a drive. All pumps and drives must be of the same size. Staging and destaging

decisions are made based on the speed of the drive. The constant pressure is controlled by the master drive operating in closed

loop. The speed is the same in all running pumps.

In the master/follower mode, VLT® Extended Cascade Controller MCO 101 supports up to 6 pumps, while VLT® Advanced Cascade

Controller MCO 102 supports up to 8 pumps.

Conguring as in Illustration 4 requires the following settings in parameter group 27-7* Connections:

•

27-70.0 Relay 1 → [1] Drive 2 enable

•

27-70.1 Relay 2 → [2] Drive 3 enable

•

27-70.9 Relay 10 → [0] Standard relay

•

27-70.10 Relay 11 → [0] Standard relay

•

27-70.11 Relay 12 → [0] Standard relay

The system run-time balances all pumps automatically depending on the pump prioritization made in parameter 27-16 Runtime Bal-

ancing. The master/follower system provides a certain level of redundancy. If the master drive trips, it continues to control the follower drives.

N O T I C E

VLT® 24 V DC Supply MCB 107 can be added to increase the level of system redundancy.

Relays set to [0] Std. Relay can be used as general purpose relay controlled by parameter group 5-4* Relays.

3.2.3 Hardware Conguration for Mixed Pumps

This conguration combines some of the benets of the master/follower conguration with some of the initial cost savings of the

xed-speed congurations. It is a good choice when the extra capacity of the xed pumps is rarely needed.

The mixed-pump conguration supports a mix of variable-speed pumps connected to drives and also some xed-speed pumps.

First, the variable-speed pumps are staged and destaged based on the drive speed. The xed-speed pumps are staged and destaged last based on the feedback pressure.

N O T I C E

The variable-speed pumps and the drives must be of the same size. Fixed-speed pumps may be of dierent size.

Illustration 5: Mixed-pump Conguration Example

For this conguration, set the relays as follows in parameter group 27-7* Connections:

•

•

•

27-70.0 Relay 1 → [1] Drive 2 enable

27-70.1 Relay 2 → [74] Pump 3 to mains

27-70.9 Relay 10 → [75] Pump 4 to mains

AQ326832164524en-000101 / 130R0345 | 15Danfoss A/S © 2020.08

Page 16

100% 100% 200% 200%

e30bh880.10

Relay 1

Relay 2

Relay 10

1

1 2 3 4

Variable speed

Fixed speed

100%

100% + 200% (see Illustration 7)

100%

100% + 200% + 200%

100%

100% + 100% + 300%

100%

100% + 100% + 300% + 300%

100%

100% + 200% + 400%

100% + 100%

200%

100% + 100%

200% + 200%

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

•

27-70.10 Relay 11 → [0] Standard relay

•

27-70.11 Relay 12 → [0] Standard relay

Applications

3.2.3.1 Unequal-sized Pumps Conguration

The unequal-sized pumps conguration supports a limited mix of xed-speed pumps in dierent sizes. It provides for the largest

range of system output with the smallest number of pumps.

Illustration 6: Example of a Conguration with Unequal-sized Pumps

For this conguration, set the relays as follows in parameter group 27-7* Connections:

•

27-70.0 Relay 1 → [73] Pump 2 to mains

•

27-70.1 Relay 2 → [74] Pump 3 to mains

•

27-70.9 Relay 10 → [75] Pump 4 to mains

•

27-70.10 Relay 11 → [0] Standard relay

•

27-70.11 Relay 12 → [0] Standard relay

For a conguration to be valid, it must be possible to stage pumps in increments of 100% of the size of the variable-speed pump of

the master drive. The variable-speed pump must control the output between the xed-speed stages, see Illustration 7.

100% is dened as the maximum ow produced by the pump connected to the master drive. The xed-speed pumps must be mul-

tiples of this size.

N O T I C E

Other valid congurations than the ones shown in Table 3 are possible.

Table 3: Valid Congurations

AQ326832164524en-000101 / 130R034516 | Danfoss A/S © 2020.08

Page 17

100 %

100 %

100 %

100 %

100 %

100 %

200 % 200 %

C

1

100 %

200 %

300 %

400 %

2

3

4

e30bd073.11

Variable speed

Fixed speed

100%

200%

No control between 100% and 200%

100%

100% + 300%

No control between 200% and 300%, see Illustration 8

100%

100% + 200% + 600%

No control between 400% and 600 %

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Applications

Illustration 7: Example of a Valid Conguration

N O T I C E

Invalid congurations, as in Illustration 8, will still run, but will have a poor control performance. This allows only limited operation

if a pump fails or is interlocked.

Table 4: Invalid Congurations

AQ326832164524en-000101 / 130R0345 | 17Danfoss A/S © 2020.08

Page 18

e30bd074.11

100 %

100 %

100 %

300 %

100 %

100 %

100 %

300 %

C

1

100 %

200 %

300 %

400 %

2 3 4

e30ba602.12

Relay 10

Relay 1

Relay 2

Relay 12

1

1

2

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Applications

Illustration 8: Example of an Invalid Conguration

3.2.3.2 Mixed-pump Conguration with Alternation

In this conguration, the drive alternates between 2 pumps and controls the other as extra xed-speed pumps. The Cascade Controller attempts to balance the running hours of the pumps.

Illustration 9: Example 1

In Illustration 9, the 2 pumps are operated either as variable-speed pumps or as xed-speed pumps.

For this conguration, set the relay selection as follows in parameter group 27-7* Connections:

AQ326832164524en-000101 / 130R034518 | Danfoss A/S © 2020.08

Page 19

e30ba601.12

Relay 10

Relay 1

Relay 2

Relay 11

Relay 12

1

1

2

3

e30ba600.12

Relay 1

Relay 2

Relay 10

Relay 11

Relay 12

1

1

2

3

4

5

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

•

27-70.0 Relay 1 → [8] Pump 1 to drive 1

•

27-70.1 Relay 2 → [16] Pump 2 to drive 1

•

27-70.9 Relay 10 → [72] Pump 1 to mains

•

27-70.10 Relay 11 → [73] Pumps 2 to mains

•

27-70.11 Relay 12 → [0] Standard relay

Applications

Illustration 10: Example 2

In Illustration 10, 2 pumps are operated either as variable-speed pumps or as xed-speed pumps. The 3rd pump is an extra xedspeed pump.

For this conguration, set the relays as follows in parameter group 27-7* Connections:

•

27-70.0 Relay 1 → [8] Pump1 to drive 1

•

27-70.1 Relay 2 → [16] Pump2 to drive 1

•

27-70.9 Relay 10 → [72] Pump 1 to mains

•

27-70.10 Relay 11 → [73] Pump 2 to mains

•

27-70.11 Relay 12 → [74] Pump 3 to mains

Illustration 11: Example 3

AQ326832164524en-000101 / 130R0345 | 19Danfoss A/S © 2020.08

Page 20

Stage ON [Hz]

Stage OFF [Hz]

Stage 1

48.5 (parameter 2732.1)

30 (parameter 2734.1)

Stage 2

48.5 (parameter 2732.2)

40 (parameter 2734.2)

Stage 3

48.5 (parameter 2732.3)

42 (parameter 2734.3)

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

In Illustration 11, either pump 1 or pump 2 is connected to the drive. The pump for the connection to the drive can be selected

either automatically for balancing the running hours or forced by the congured alternation event. The xed-speed pumps 3, 4, and

5 are turned on and o as required.

For this conguration, set the relay as follows in parameter group 27-7* Connections:

•

27-70.0 Relay 1 → [8] Pump 1 to drive 1

•

27-70.1 Relay 2 → [16] Pump 2 to drive 1

•

27-70.9 Relay 10 → [74] Pump 3 to mains

•

27-70.10 Relay 11 → [75] Pump 4 to mains

•

27-70.11 Relay 12 → [76] Pump 5 to mains

Applications

3.2.4 Using Soft Starters for Fixed-speed Pumps

Soft starters can be used instead of contactors for any conguration using xed-speed pumps.

N O T I C E

Mixing soft starters and contactors prevents control of output pressure during staging and destaging transitions. The use of soft

starters delays the staging due to the ramp time of the xed-speed pump.

3.3 Sleep Mode

If the load on the multi-pump system allows it, it can be stopped by activating the sleep mode function. When in sleep mode, certain congurable conditions are monitored to nd out when load has been applied again and the system has to be restarted.

Depending on the system, sleep mode can be activated either from the low-power detection/low-speed detection or via an external

signal applied to 1 of the digital inputs (must be programmed via parameter group 5-1* Digital Inputs). Using, for example, an electromechanical ow switch to detect a no-ow condition, activates sleep mode at the raising edge of the external signal applied.

Implementation and conguration of sleep mode depend on the hardware conguration and the requirements.

3.3.1 Basic Cascade Controller

For Basic Cascade Controller applications, sleep mode can be used and congured exactly as it is described for single-pump applica-

tions in the parameter groups 22-2* to 22-4* in the VLT® AQUA Drive FC 202 Programming Guide.

Low-speed detection and low-power detection combined with the timers for minimum run-time, minimum sleep time, and the

boost feature are supported. The feedback from the pressure transducer is monitored and when this pressure has dropped with a

set percentage below the normal setpoint for pressure (parameter 22-44 Wake-up Ref./FB Dierence), the motor ramps up again, and

pressure is controlled for reaching the set value.

3.3.2 Master/Follower and Mixed-pump Congurations

In multiple-drive applications, sleep mode can be used in 2 dierent ways:

•

Low-speed detection for applications with multiple drives can be enabled by a selection in parameter 22-22 Low Speed Detection.

•

Using the Stage O-speeds in parameter group 27-3* Staging Speed.

In the following example, sleep mode is entered at 30 Hz in a master/follower application.

This mode is activated by programming the corresponding speed in parameter 27-33 Stage O Speed [RPM] or parameter 27-34 Stage

O Speed [Hz].

The value for this speed has to be higher than the minimum speed in parameter 4-11 Motor Speed Low Limit [RPM] or parameter 4-12

Motor Speed Low Limit [Hz].

The value for the override limit in parameter 27-21 Override Limit causes the drive to wake up again. The value is entered as a % of

the maximum reference as programmed in parameter 3-03 Maximum Reference.

AQ326832164524en-000101 / 130R034520 | Danfoss A/S © 2020.08

Page 21

Output speed

No/low flow detection speed

Reference and feedback

11

10

98

7654

321 0

e30bh881.10

0

System is going into a no-ow condition

1

Conditions for pulse are present

2

Pulse equals boost

3

Boost setpoint is reached

4

Pressure loss due to back-ow to close no-return

valve5No-return valve is closed and there is no load

6

PID, bring output frequency to minimum speed due

to FB>Ref

7

Delay time for no-ow has expired. Sleep mode

8

Drive stop, sleep

9

Load return to system

10

Conditions for wake-up are present

11

System running normally

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Applications

3.3.3 Temporary Boost of the Setpoint Before Sleep Mode

In some applications, it can be dicult to detect the no-ow conditions in a reliable way with a xed setpoint. This may be the case

in applications with varying inlet pressure or if the closure of a non-return valve causes a pressure loss.

In these cases, a temporary boost of the setpoint can force the PID to reduce speed. See parameter 22-22 Low Speed Detection in the

VLT® AQUA Drive FC 202 Programming Guide for further details.

Illustration 12: Temporary Boost of Setpoint

AQ326832164524en-000101 / 130R0345 | 21Danfoss A/S © 2020.08

Page 22

Voltage

[V]

Minimum waiting time (minutes)

47152030

40

200–240

0.25–3.7 kW (0.34–

5 hp)

–

5.5–45 kW (7.5–60

hp)

–––

380–480

0.37–7.5 kW (0.5–

10 hp)

–

11–90 kW (15–125

hp)

110–250 kW

(150–335 hp)

–

315–1500 kW

(425–2000 hp)

525–600

0.75–7.5 kW (1.0–

10 hp)

–

11–90 kW (15–125

hp)

–––

525–690

–

1.1–7.5 kW

(1.5–10 hp)

11–90 kW (15–125

hp)

45–400 kW (60–

540 kW)

450–1200 kW

(600–1600 hp)

1400 kW

(1875 hp)

e30ba607.11

MCO 101

1

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

4 Installation

4.1 Before Start

W A R N I N G

Never install an option card in a drive during operation.

Interrupt the power supply to the drive before starting the installation. Note that high voltage may be present, even when

-

the warning LED display lights are o.

Table 5: Discharge Time

Installation

4.2 VLT® Extended Cascade Controller MCO 101

4.2.1 Installing the VLT® Extended Cascade Controller MCO 101

The VLT® Extended Cascade Control MCO 101 includes 2 changeover contacts and can be tted into option slot B.

Illustration 13: Mounting of B Options

Procedure

1.

Disconnect power to the drive.

2.

Disconnect power to the live part connections on the relay terminals.

3.

Remove the LCP, the terminal cover, and the cradle from the drive.

AQ326832164524en-000101 / 130R034522 | Danfoss A/S © 2020.08

Page 23

Relay 10

NC NCNC

Relay 12Relay 11

1 2 3 12

e30ba606.10

754 6 8 9 10 11

e30ba177.10

8-9mm

2mm

1 1 1

1102 3

4 5 6 7 8 9 1211

2 2 3

1 1 1

1102

3

4 5

6 7 8 9 1211

3

3 3

1 1 1

1 10

2 3

4

5 6 7 8 9 1211

2

2

2

e30ba176.11

1NC2

Live part

3

PELV

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

4.5.Fit the MCO 101 option in slot B.

Connect the control cables and relieve the cables with the enclosed cable strips.

Illustration 14: Wiring of Connections

Installation

Illustration 15: Mounting of Cables

Illustration 16: Incorrect and Correct Relay Wiring

Do not combine low-voltage parts and PELV systems.

N O T I C E

AQ326832164524en-000101 / 130R0345 | 23Danfoss A/S © 2020.08

Page 24

Maximum terminal load (AC)

240 V AC, 2 A

Maximum terminal load (DC)

24 V DC, 1 A

Minimum terminal load (DC)

5 V, 10 mA

Maximum switching rate at rated load/minimum load

6 min-1/20 s

-1

Type

Description

Order number

Options

MCF 105

Mounting kit, enclosure sizes A2 and A3 (40 mm for 1 C option)

130B7530

MCF 105

Mounting kit, enclosure size A5

130B7532

MCF 105

Mounting kit, enclosure sizes B (except B3), C, D, E, F1, and F3

130B7533

MCF 105

Mounting kit, enclosure size B3 (40 mm for 1 C option)

130B1413

Accessory bag

MCO 102

Accessory bag

130B0152

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

6.

Fit the extended cradle and terminal cover.

7.

Remount the LCP.

8.

Connect power to the drive.

Installation

4.2.2 Electrical Data, VLT® Extended Cascade Control MCO 101

4.3 VLT® Advanced Cascade Controller MCO 102

4.3.1 Installing the VLT® Advanced Cascade Controller MCO 102

The VLT® Advanced Cascade Controller MCO 102 is exclusively intended for use in option slot C1.

Some items are required for the installation of a C option mounting kit. The items required depend on the drive enclosure.

Table 6: Order Numbers for Mounting Kits and Accessory Bag

A4 does not support C options. If the VLT® Advanced Cascade Controller MCO 102 is needed, select an A5 enclosure.

AQ326832164524en-000101 / 130R034524 | Danfoss A/S © 2020.08

Page 25

e30ba946.10

RemoveJumper to activate Safe Stop

12 13 18 19 27 29 32 33 20

DC

DC

e30ba945.10

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Installation

Illustration 17: Enclosure Sizes A2, A3, and B3, 40 mm (only 1 C option)

Illustration 18: Enclosure Sizes B (except B3) and C

Procedure

1.

Disconnect power to the drive.

AQ326832164524en-000101 / 130R0345 | 25Danfoss A/S © 2020.08

Page 26

e30bb025.11

e30bb026.11

Maximum terminal load (AC)

240 V AC, 2 A

Maximum terminal load (DC)

24 V DC, 1 A

Minimum terminal load (DC)

5 V, 10 mA

Maximum switching rate at rated load/minimum load

6 min-1/20 s

-1

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

2.

Disconnect power to the live part connections on the relay terminals.

3.

Remove the LCP, the terminal cover, and the cradle from the drive.

4.

Fit the MCO 102 in slot C1.

5.

Connect the control cables and relieve the cables with the enclosed cable strips.

Illustration 19: Terminal Connections, 8 Relays

Installation

Illustration 20: Terminal Connections to 7 Digital Inputs and Access to Internal 24 V DC

6.

Fit the extended cradle and terminal cover.

7.

Remount the LCP.

8.

Connect power to the drive.

4.3.2 Electrical Data, VLT® Advanced Cascade Control MCO 102

AQ326832164524en-000101 / 130R034526 | Danfoss A/S © 2020.08

Page 27

Parameter

Description

27-10 Cascade Controller

This parameter is used for enabling or disabling the Extended/Advanced Cascade Controllers. It

is also used to extend the number of pumps in Basic Cascade Control applications. In this case,

the parameters in Parameter Group 25-** Cascade Controller must be used for the conguration

details. The mixed-pump selection is the general selection for the Cascade Controller. If using 1

drive per pump, select the master/follower conguration.

27-11 Number Of

Drives

Set the number of drives.

27-12 Number Of

Pumps

Set the number of pumps. Default is the number of drives.

Parameter 27-13 Max

Number of Pumps

Running

This parameter makes it possible to force pumps to stay idle. Example: In a cascade system

where 3 pumps are necessary in normal operation, but 4 pumps are installed due to legislation,

it is possible to allow only 3 pumps running in parallel to avoid high pressure spikes. Default

always equals the number of pumps.

27-14 Pump Capacity

Pump capacity for each pump (indexed parameter). If all pumps are the same size, use the default values. To adjust the setting, select the pump, press [OK], and adjust the capacity.

27-16 Runtime Balancing

Run-time balancing for each pump (indexed parameter). If the system should balance the running hours equally between the pumps, use the default values.

27-17 Motor starters

All xed-speed pumps must be the same size.

27-18 Spin Time for

Unused Pumps

The spin time depends on the size of the pumps.

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Conguration of the System

5 Conguration of the System

5.1 Conguration of the Extended and Advanced Cascade Controllers

The Extended and Advanced Cascade Controllers, MCO 101 and MCO 102, can be congured quickly using many of the default

parameters. For more information about application types and on how to use advanced features of the Cascade Controllers, refer to

3 Applications.

N O T I C E

To avoid miscongurations, check the settings even if the parameters are set to their default values.

5.1.1 Basic Conguration of the Extended and Advanced Cascade Controllers

N O T I C E

Any unused relays are available for other functions via parameter group 5-4* Relays.

Procedure

1.

Select the values for the parameters in parameter group 27-1* Conguration.

2.

Dene the relays in parameter group 27-7* Connections.

a.

Assign 1 relay for each follower drive in the system.

b.

Assign the relays for the xed-speed pumps.

c.

If a single drive is connected to 2 pumps (alternation), congure more relays accordingly.

AQ326832164524en-000101 / 130R0345 | 27Danfoss A/S © 2020.08

Page 28

DO

Pin 27

DI

Pin 29

DI

Pin 29

1

2

3

e30ba608.11

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Conguration of the System

5.1.2 Conguring Multiple Drives

If more than 1 drive is used with the Cascade Controller, the master drive sets the speed reference for all drives via a digital pulse

signal.

Illustration 21: Multiple Drives Congured for Cascade Control

Procedure

1.

Set the basic cascade parameters, see 5.1.1 Basic Conguration of the Extended and Advanced Cascade Controllers.

2.

Set parameter 5-01 Terminal 27 Mode to [1] Output, parameter 5-30 Terminal 27 Digital Output to [55] Pulse Output, and parameter 5-60 Terminal 27 Pulse Output Variable to [116] Cascade Ref.

3.

Set each follower drive to open loop, set parameter 1-00 Conguration Mode to [0] Open Loop, parameter 3-15 Reference 1

Source to [7] Pulse Input 29, and parameter 5-13 Terminal 29 Digital Input to [32] Pulse Input.

Set the ramps fast enough to enable the PID controller to maintain control of the system.

4.

N O T I C E

Ramp-up times and ramp-down times must be the same for the master drive and for all the follower drives in the sys-

tem.

5.1.3 Conguring Closed-loop Control

The master drive is the primary controller for the system. It monitors the output pressure, adjusts the speed of the drive, and decides

when to add or remove stages.

Procedure

1.

Set up the master drive to closed-loop mode with a feedback sensor connected to an analog input of the drive.

2.

Set up the PID controller of the master drive to match the requirements of the installation.

For further information on setting up the PID parameters, see the VLT® AQUA Drive FC 202 Programming Guide.

5.1.4 Staging/Destaging of Variable-speed Pumps

Staging occurs when the speed on the drive has reached the value in parameter 27-31 Stage On Speed [RPM] (parameter 27-32 Stage

on Speed [Hz]). At this speed, the system pressure is still maintained, but the pumps start to operate outside of their peak eciency

points. Staging on another pump lowers the speed of all running pumps and provides a more energy-ecient operation.

In master/follower congurations and mixed-pump congurations, the variable-speed pumps are staged and destaged based on

the speed of the drives.

Destaging occurs when the speed of the drives drops below the value in parameter 27-33 Stage O Speed [RPM] (parameter 27-34

Stage O Speed [Hz]). At this speed, the system pressure is still maintained, but the pumps are beginning to operate below their peak

eciency points. Destaging a pump causes the speed of the drive to increase into a more energy-ecient range.

AQ326832164524en-000101 / 130R034528 | Danfoss A/S © 2020.08

Page 29

P

tot

A

B

C

1 2

t

e30bb024.11

1

1 pump running

2

2 pumps running

A

Incorrect stage on speed adjustment

B

Correct stage on speed adjustment

C

Stage on speed pump 2

Parameter

Range

Default

27-30 Auto Tune Staging Speeds

{[0] Disabled, [1] Enabled}

[1] Enabled

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Conguration of the System

Parameter 27-31 Stage On Speed [RPM] (parameter 27-32 Stage On Speed [Hz]) and parameter 27-33 Stage O Speed [RPM] (parameter

27-34 Stage O Speed [Hz]) are installation dependent. These parameters are indexed parameters with 1 set of entries for each pump

stage.

The stage on and destage o speed can be autotuned during operation or set manually. If Auto tune is enabled, the system starts

operation using default settings or the presettings programmed in parameter 27-31 Stage On Speed [RPM] (parameter 27-32 Stage on

Speed [Hz]) and parameter 27-33 Stage O Speed [RPM] (parameter 27-34 Stage O Speed [Hz]).

The tuning ensures optimum energy eciency of the system.

Illustration 22: Optimum Energy Eciency

During operation, the system monitors the actual energy consumption and optimizes every time a stage or destage takes place.

5.1.5 Staging/Destaging of Fixed-Speed Pumps

Fixed-speed pumps are staged or destaged based on system pressure.

To avoid turning on and o the pumps too often, dene an acceptable range of system pressure along with a period where the

pressure is allowed to be outside of this band before staging or destaging occurs. Set the values via:

•

Parameter 27-20 Normal Operating Range

•

Parameter 27-23 Staging Delay

•

Parameter 27-24 Destaging Delay

The parameters are installation dependent.

N O T I C E

Stage/destage threshold

The speed of the variable-speed pump at the point of staging or destaging is dened by a stage or destage threshold. These settings prevent overshoot or undershoot in the pressure at staging or destaging.

The optional auto tune of staging and destaging threshold monitors the feedback at the point of staging or destaging and adjusts

the settings every time a staging takes place.

AQ326832164524en-000101 / 130R0345 | 29Danfoss A/S © 2020.08

Page 30

Parameter

Range

Default

27-40 Auto Tune Staging Settings

{[0] Disabled, [1] Enabled}

[1] Enabled

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Conguration of the System

5.2 Operation

When the Cascade Controller is enabled, it controls system pressure by varying the speed of the drive and by staging pumps on and

o.

The Cascade Controller provides 2 stop functions. One function quickly stops the system. The other function destages the pumps in

a sequence, resulting in a pressure-controlled stop. For a VLT® AQUA Drive FC 202 equipped with STO, terminal 37 turns o all relays

and coasts the master drive. If any of the digital inputs are set to [8] Start, and the corresponding terminal is used to control start and

stop of the drive, setting the terminal to 0 V will turn o all relays and coast the master drive. Pressing [O] on the LCP causes a

sequenced destaging of running pumps.

5.2.1 Checking Pump Status and Controlling Pumps

Select parameter group 27-0* Control & Status to check on the status of the Cascade Controller and to control individual pumps.

Select a specic pump to view the status, the current running hours, and the total lifetime hours.

Procedure

1.

Navigate to parameter group 27-0* Control & Status.

Press [▵] and [▿] on the LCP to select the pump.

2.

Press [▵] and [▿] on the LCP to select the parameter.

3.

5.2.2 Manual Pump Control

Use the Extended/Advanced Cascade Controllers for complete control of each pump in the system, for example for maintenance

purposes. Use parameter 27-02 Manual Pump Control to control individual pumps through their relays.

This parameter diers from other value-related parameters as selecting 1 of these options causes the action to occur and then the

parameter reverts to its default state.

The selections are as follows:

•

[0] No Operation - Default value.

•

[1] Online - Makes the pump available to the VLT® Extended Cascade Controller MCO 101.

•

[2] Alternate On - Forces the selected pump to be the lead pump.

•

[3] Oine-O - Turns o the pump and makes it unavailable for cascading.

•

[4] Oine-On - Turns on the pump and makes it unavailable for cascading.

•

[5] Oine-Spin - Initiates a pump spin.

If any of the Oine selections are selected, the pump is no longer available to the Cascade Control until Online is selected.

If a pump is taken oine through parameter 27-02 Manual Pump Control, the Cascade Controller attempts to compensate for the

oine pumps as follows:

•

If [3] Oine-O is selected for a pump that is running, another pump is staged on to compensate for the loss of output.

•

If [4] Oine-On is selected for a pump that is o, another pump is staged o to compensate for the excess output.

5.2.3 Run-time Balancing

The Extended/Advanced Cascade Controllers are designed to balance the running hours of the available pumps, but parameter

27-16 Runtime Balancing also provides an optional balancing priority for each pump in the system.

Three levels of priority are available:

•

[0] Balanced Priority 1

•

[1] Balanced Priority 2

•

[2] Spare Pump

The Cascade Controller selects a pump to be staged or destaged based on the maximum capacity of the pump (parameter 27-14

Pump Capacity), parameter 27-03 Current Runtime Hours, and parameter 27-16 Runtime Balancing.

During staging, the Cascade Controller balances the current running hours for all pumps set to [0] Balanced Priority 1 in parameter

27-16 Runtime Balancing.

If all priority 1 pumps are running, the Cascade Controller balances the pumps set to [1] Balanced Priority 2.

AQ326832164524en-000101 / 130R034530 | Danfoss A/S © 2020.08

Page 31

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

If all priority 1 and 2 pumps are running, pumps set to [2] Spare Pump are selected.

During destaging, the reverse occurs. Spare pumps are destaged rst, followed by priority 2 pumps, followed by priority 1 pumps. At

each priority level, the pump with the highest current run-time hours is destaged rst.

Conguration of the System

N O T I C E

In mixed-pump congurations with more than 1 drive, all variable-speed pumps are staged or destaged before xed-speed

pumps.

Select parameter 27-19 Reset Current Runtime Hours to reset the current run-time hours and restart the balancing process. This parameter does not aect the total lifetime hours (parameter 27-04 Pump Total Lifetime Hours) for each pump. The total lifetime hours-

function is not used for run-time balancing.

5.2.4 Pump Spin for Unused Pumps

If a pump is used only occasionally, the Cascade Controller balances the running hours of the pumps via alternation. If a pump is not

used for 72 hours, a pump spin can be triggered.

The spin time can be set in parameter 27-18 Spin Time for Unused Pumps. The spin time should be long enough to ensure that the

pump stays in good working condition, but short enough not to overpressure the system. To disable the function, set parameter

27-18 Spin Time for Unused Pumps to 0.

N O T I C E

The Cascade Controller does not compensate for the extra pressure generated during a pump spin. Keep the spin time as short as

possible to prevent damage caused by overpressuring the output.

5.2.5 Total Lifetime Hours

The VLT® Extended Cascade Controller MCO 101 and the VLT® Advanced Cascade Controller MCO 102 track the total lifetime hours

for each controlled pump.

Parameter 27-04 Pump Total Lifetime Hours shows a running total of the operating hours for each pump. The total lifetime hours are

saved in the non-volatile memory once every hour.

This parameter can also be set to an initial value that reects the hours of operation for a pump before it was added to the system.

5.2.6 Alternation of the Lead Pump

The Cascade Controller can be congured for lead pump alternation, see also examples in 3.2.3.2 Mixed-pump Conguration with

Alternation.

In a conguration with multiple drives, the lead pump is dened as the last variable-speed pump running.

In a conguration with only 1 drive, the lead pump is dened as the pump connected to the drive.

During start-up and normal staging/destaging, the Cascade Controller balances the running hours by alternating the lead pump.

Alternation of lead pumps can also be forced manually, for example, via parameter 27-54 Alternation At Time of Day, via a digital

input, or by alternation time parameters.

5.2.7 Staging/Destaging in Mixed-pump Congurations

Two methods are used to decide when pumps should be staged or destaged:

Speed of the drives.

•

Feedback pressure exceeding the normal operating range.

•

In a mixed-pump conguration with more than 1 drive, both methods are used. In the following example, feedback is referred to as

pressure.

Staging

When the master drive receives a start command, a variable-speed pump is selected and starts using 1 of the available drives.

If the system pressure drops, the speed of the drive increases to meet the demand for more ow. While maintaining the pressure, if

the drive exceeds parameter 27-31 Stage On Speed [RPM] (or parameter 27-32 Stage On Speed [Hz]) and remains above that speed for

the time specied in parameter 27-33 Stage O Speed [RPM] (parameter 27-34 Stage O Speed [Hz], the next variable-speed pump is

staged on.

If the Cascade Controller is unable to maintain the system pressure with all variable-speed pumps running at maximum, it stages on

xed-speed pumps. If pressure goes below the setpoint with the percentage set in parameter 27-20 Normal Operating Range and

stays below the setpoint for the time specied in parameter 27-23 Staging Delay, a xed-speed pump stages on.

AQ326832164524en-000101 / 130R0345 | 31Danfoss A/S © 2020.08

Page 32

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Destaging

If the system pressure increases, the speed of the drive decreases. If the drive drops below the values specied in parameter 27-33

Stage O Speed [RPM] (or parameter 27-32 Stage O Speed [Hz] and stays there for the time specied in parameter 27-24 Destaging

Delay, a variable-speed pump is staged o.

If the system pressure is still too high with only 1 drive running at minimum speed, it destages xed-speed pumps. A xed-speed

pump is destaged when the pressure exceeds the setpoint in parameter 27-20 Normal Operating Range and stays there for the time

specied in parameter 27-24 Destaging Delay. If the system demand continues to drop, the system enters sleep mode.

Conguration of the System

5.2.8 Override Staging/Destaging

Normal staging and destaging handle most of the situations in typical applications. However, when rapid response to changes in

system pressure is required, the Cascade Controller is equipped to stage and destage pumps immediately.

Staging

When the system pressure drops below the override limit (parameter 27-21 Override Limit), the Cascade Controller immediately

stages on a pump to meet the demand.

If the system pressure continues to stay below parameter 27-21 Override Limit for the time specied in parameter 27-25 Override Hold

Time, the Cascade Controller stages on the next pump. This behavior is repeated until all pumps are on or until system pressure

drops below the override limit.

Destaging

When the system pressure exceeds parameter 27-21 Override Limit, the Cascade Controller immediately destages a pump to reduce

the pressure.

If the system pressure continues to stay above the value in parameter 27-21 Override for the time specied in parameter 27-25 Over-

ride Hold Time, the Cascade Controller destages another pump. This behavior is repeated until only the lead pump is left on or until

the pressure stabilizes.

Parameter 27-21 Override Limit is set as a % of the maximum reference. It denes a point above and below the system setpoint where

override staging and destaging occur.

5.2.9 Minimum Speed Destaging

To reduce energy usage, the Cascade Controller can destage a xed-speed pump if the lead pump is running at minimum speed for

the time set in parameter 27-27 Min Speed Destage Delay.

5.2.10 Fixed-speed-only Operation

Fixed-speed-only operation keeps critical systems operating even if all variable-speed pumps are unavailable to the Cascade Controller. In this situation, the Cascade Controller maintains system pressure by turning on and o xed-speed pumps.

Staging

If all the variable-speed pumps are unavailable and the system pressure drops below the limit in parameter 27-22 Fixed Speed Only

Operating Range for the time specied in parameter 27-23 Staging Delay, a xed-speed pump is turned on.

Destaging

If all variable-speed pumps are unavailable and the system pressure exceeds the limit set in parameter 27-22 Fixed Speed Only Oper-

ating Range for the time specied in parameter 27-24 Destaging Delay, a xed-speed pump is turned o.

5.2.11 Flow Compensation for Applications with Cascade Controller

Flow compensation allows placing the pressure sensor close to the drive, even if it is not the place for the wanted pressure setpoint.

It adjusts the setpoint automatically according to the pressure drop in the system which depends on the system ow. In Cascade

Controller applications, this is done step-wise based on the number of pumps in operation.

It uses the feedback to estimate the setpoint required at various rates of ow. The calculation of the theoretical curve results in step-

wise adjusted setpoints following this curve. Setpoint 1 is the minimum pressure required when the system is running with only 1

pump operating and under minimum load conditions. Setpoint 2 is used when all pumps are running.

AQ326832164524en-000101 / 130R034532 | Danfoss A/S © 2020.08

Page 33

Theoretical

Setpoint

Setpoint

Pump 1

2 3

4

5

e75za642.11

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Illustration 23: Calculation of Theoretical Curve

Conguration of the System

The range of the curve is determined by the no/low ow point and the uncompensated setpoint (for example, in parameter 20-21

Setpoint 1).

Besides the conguration of the Cascade Controller, the required programming steps are:

•

Enable ow compensation in parameter 22-80 Flow Compensation.

•

Program the pressure at no-ow speed in parameter 22-87 Pressure at No-Flow Speed.

•

Program the uncompensated setpoint (for example, in parameter 20-21 Setpoint 1).

If the pressure feedback signal originates at the far end of the system, the drive does not need to compensate for system pressure

changes due to ow, and the default feedback process can be used.

AQ326832164524en-000101 / 130R0345 | 33Danfoss A/S © 2020.08

Page 34

Option

Function

Pump Status is a readout parameter showing the status of each pump in the system.

[0]

Ready

The pump is available for use by the Cascade Controller.

[1]

On Drive

The pump is controlled by the Cascade Controller, the pump is connected to a drive and running.

[2]

On Mains

The pump is controlled by the Cascade Controller, the pump is connected to mains and running.

[3]

Oine - O

The pump is not available for use by the Cascade Controller, and the pump is o.

[4]

Oine - On Mains

The pump is not available for use by the Cascade Controller, and the pump is connected to mains

and running.

[5]

Oine - On Drive

The pump is not available for use by the Cascade Controller, and the pump is connected to mains

and running.

[6]

Oine - Fault

The pump is not available for use by the Cascade Controller, and the pump is connected to mains

and running.

[7]

Oine - Hand

The pump is not available for use by the Cascade Controller, and the pump is connected to mains

and running.

[8]

Oine - External Interlock

The pump has been externally interlocked and is o.

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Parameter Descriptions

6 Parameter Descriptions

6.1 Parameter Group 27-**, Cascade CTL Option

N O T I C E

If 1 of the Cascade Controller options is used to extend the number of pumps in a Basic Cascade, use the parameters in parameter

group 25-** Cascade Controller. See VLT® AQUA Drive FC 202 Programming Guide for further information.

For the following array parameters, the index refers to the number of the (specic) pump. For stage on/stage o speeds, the index

reects the number of pumps in operation.

•

Parameter 27-01 Pump Status

•

Parameter 27-02 Manual Pump Control

•

Parameter 27-03 Current Runtime Hours

•

Parameter 27-04 Pump Total Lifetime Hours

•

Parameter 27-14 Pump Capacity

•

Parameter 27-16 Runtime Balancing

•

Parameter 27-31 Stage On Speed [RPM]

•

Parameter 27-32 Stage On Speed [Hz]

•

Parameter 27-33 Stage O Speed [RPM]

•

Parameter 27-34 Stage O Speed [Hz]

N O T I C E

For parameter 27-70 Relay, index 0 refers to relay 1, index 1 refers to relay 2, index 2 refers to relay 3 … index 19 refers to relay 20.

6.1.1 Parameter Group 27-0*, Control & Status

Control and status parameters are for monitoring and manual control of the pumps.

Press [▵] and [▿] to select a pump. Press [▵] and [▿] to change settings.

Table 7: Parameter 27-01 Pump Status

AQ326832164524en-000101 / 130R034534 | Danfoss A/S © 2020.08

Page 35

•••

•

Option

Function

[9]

Spinning

The Cascade Controller is executing a spin cycle for the pump.

[10]

No Relay Connection

The pump is not directly connected to a drive, and no relay has been assigned to the pump.

Range

Function

0 h*

[0-2147483647 h]

Current Runtime Hours is a readout parameter showing the total number of hours each pump has been

running since the last reset. This time is used to balance the running hours between the pumps. The

times may all be reset to 0 via parameter 27-91 Cascade Reference.

Range

Function

0 h*

[0-2147483647 h]

N O T I C E

This parameter may be set individually to any value for maintenance purposes.

Pump Total Lifetime Hours is the total operating hours for each connected pump.

Option

Function

Cascade Controller Mode sets the operating mode.

[0]

Disabled

[1]

Master/Follower

[2]

Mixed Pumps

[3]

Basic Cascade Ctrl

Range

Function

Size related*

[1-8]

Number of drives to be controlled by the Cascade Controller.

MCO 101: 1–6

MCO 102: 1–8

Range

Function

0*

[0-Number of Drives]

Number of pumps to be controlled by the Cascade Controller.

MCO 101: 0–6

MCO 102: 0–8

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Table 8: Parameter 27-03 Current Runtime Hours

Table 9: Parameter 27-04 Pump Total Lifetime Hours

Parameter Descriptions

6.1.2 Parameter Group 27-1*, Conguration

Use the conguration parameters for setting, for example, cascade control mode, number of pumps, number of drives, and pump

capacity.

Table 10: Parameter 27-10 Cascade Controller Mode

Table 11: Parameter 27-11 Number of Drives

Table 12: Parameter 27-12 Number of Pumps

AQ326832164524en-000101 / 130R0345 | 35Danfoss A/S © 2020.08

Page 36

Range

Function

Parameter 27-12

Number of Pumps*

[1-8]

Limit the maximum number of pumps running simultaneously to prevent overpressure. Default is

always equal to parameter 27-12 Number of Pumps. Any change to parameter 27-12 Number of

Pumps forces a change to parameter 27-13 Max Number of Pumps Running.

Range

Function

100%*

[10-800%]

Pump Capacity sets the capacity of each pump in the system relative to the 1st pump. This is an indexed

parameter with 1 entry per pump. The capacity fo the 1st pump is always considered to be 100%.

Option

Function

Runtime Balancing sets the priority of each pump for balancing its running hours. The pumps with the

higest priority are operated before the lower-prioritized pumps. Pumps with the same priority are staged/destaged based on the running hours.

[0]

Balanced Priority 1

Turned on rst, turned o last.

[1]

Balanced Priority 2

Turned on if no priority 1 pumps are available. Turned o before priority 1 pumps are turned o.

[2]

Spare Pump

Turned on last, turned o rst.

Option

Function

Motor Starters selects the type of mains starters used on the xed-speed pumps. All xed-speed pumps

must be congured in the same way.

[0]

Direct Online

[1]

Soft Starter

Adds a delay when staging and destaging corresponding to the soft starter ramp time, see parameter 27-41

Ramp Down Delay and parameter 27-42 Ramp Up Delay.

[2]

Star/Delta

Adds a delay at staging, controlled by parameter 27-42 Ramp Up Delay.

Range

Function

Size related*

[0-99 s]

N O T I C E

Setting this parameter too high may cause overpressure to some systems.

Spin Time for Unused Pumps

sets the length of time to spin unused pumps. If a xed-speed pump has not

been run in the last 72 hours, it is turned on for the time set in this parameter. This is to prevent damage

caused by leaving the pump o too long. The spin feature may be disabled by setting the value of this parameter to 0.

Option

Function

Reset Current Runtime Hours is used for resetting all current runtime hours to 0. This time is used for runtime

balancing.

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Table 13: Parameter 27-13 Max Number of Pumps Running

Table 14: Parameter 27-14 Pump Capacity

Table 15: Parameter 27-16 Runtime Balancing

Parameter Descriptions

Table 16: Parameter 27-17 Motor Starters

Table 17: Parameter 27-18 Spin Time for Unused Pumps

Table 18: Parameter 27-19 Reset Current Runtime Hours

AQ326832164524en-000101 / 130R034536 | Danfoss A/S © 2020.08

Page 37

Option

Function

[0]

Do not reset

[1]

Do reset

Range

Function

Size related*

[1-100%]

Normal Operating Range is the allowed oset from the setpoint before a pump may be added or removed.

The system must be outside this limit for the time specied in parameter 27-23 Staging Delay or in parameter

27-24 Destaging Delay before a cascade operation takes place. Normal refers to the system operating with at

least 1 variable-speed pump available. This value is entered as a % of maximum reference, see parameter

21-12 Ext. 1 Maximum Reference in the VLT® AQUA Drive FC 202 Programming Guide for further information.

SBW (27-20)

SBW (27-20)

Setpoint

SBW staging delay (27-23)

e75za672.13

e75za671.12

(27-24) SBW destage delay

SBW

SBW

Setpoint

(27-20)

(27-20)

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

6.1.3 Parameter Group 27-2*, Bandwidth Settings

Parameters for conguring control response.

Table 19: Parameter 27-20 Normal Operating Range

Parameter Descriptions

Illustration 24: SBW Staging Delay

Illustration 25: SBW Destage Delay

AQ326832164524en-000101 / 130R0345 | 37Danfoss A/S © 2020.08

Page 38

Range

Function

100%*

[1-100%]

Override Limit is the allowed oset from the setpoint before a pump immediately is added or removed (for

example, if a re tab is turned on). Normal operating range includes a delay that limits the system response

to transients. This makes the system respond too slowly to large demand changes. The override limit causes

the drive to respond immediately. The value is entered as a % of maximum reference (parameter 21-12 Ext. 1

Maximum Reference). Override operation may be disabled by setting this parameter to 100%.

N O T I C E

In master/follower applications, the override limit is used as wake-up condition.

Setpoint

SBW (27-70)

OBW (27-71)

SBW (27-70)

OBW (27-71)

Actual head

OBW timer (27-25)

e30ba370.12

Range

Function

Size related*

[0- Par

27-21 %]

Fixed Speed Only Operating Range is the allowed oset from the setpoint before a pump may be added or

removed when there are no operational variable-speed pumps. The system must be outside this limit for

the time specied in parameter 27-23 Staging Delay or parameter 27-24 Destaging Delay before a cascade

operation may take place. The value is entered as a % of maximum reference. When there are no operational variable-speed pumps, the system tries to maintain control with the remaining xed-speed pumps.

SBW (27-20)

SBW (27-20)

Setpoint

SBW staging delay (27-23)

e75za672.13

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Table 20: Parameter 27-21 Override Limit

Parameter Descriptions

Illustration 26: Override Bandwidth

Table 21: Parameter 27-22 Fixed Speed Only Operating Range

Illustration 27: SBW Staging Delay

AQ326832164524en-000101 / 130R034538 | Danfoss A/S © 2020.08

Page 39

e75za671.12

(27-24) SBW destage delay

SBW

SBW

Setpoint

(27-20)

(27-20)

Range

Function

15 s*

[0-3000 s]

Staging Delay is the time that the system feedback must remain below the operating range before a pump

may be turned on. If the system is operating with at least 1 variable-speed pump available, parameter 27-20

Normal Operating Range is used. If there are no variable-speed pumps available, parameter 27-22 Fixed Speed

Only Operating Range is used.

Range

Function

15 s*

[0-3000 s]

Destaging Delay is the time that the system feedback must remain above the operating range before a pump

may be turned o. If the system is operating with at least 1 variable-speed pump available, parameter 27-20

Normal Operating Range is used. If there are no variable-speed pumps available, parameter 27-22 Fixed Speed

Only Operating Range is used.

Range

Function

10 s*

[0-300 s]

Override Hold Time is the minimum time that must elapse after a stage or destage before a stage or destage

may take place due to the system exceeding the override limit (parameter 27-21 Override Limit). The override

hold time is designed to allow the system to stabilize after a pump is turned on or o. If this delay is not long

enough, the transients caused by turning a pump on or o may cause the system to add or remove another

pump when it should not.

Range

Function

15s*[0-300 s]

Min-Speed Destage Delay is the time that the lead pump must be running at minimum speed while the system

feedback is still inside the normal operating band before a pump is turned o to save energy. Energy savings

may be realized by turning o a pump if the variable-speed pumps are operating at minimum speed but the

feedback is still in band. Under these conditions, a pump may be turned o and the system is still able to maintain control. The pumps that remain on will then be operating more eciently.

VLT® Extended/Advanced Cascade Controllers MCO 101/MCO 102

Operating Guide

Illustration 28: SBW Destage Delay

Table 22: Parameter 27-23 Staging Delay

Parameter Descriptions

Table 23: Parameter 27-24 Destaging Delay

Table 24: Parameter 27-25 Override Hold Time

Table 25: Parameter 27-27 Min-Speed Destage Delay

AQ326832164524en-000101 / 130R0345 | 39Danfoss A/S © 2020.08

Page 40

e75za640.12

(4-12)

(27-27)

F

min

F

VLT pump

Destage

timer period

Pump

switch-off

Option

Function

[0]

Disabled

[1]

Enabled