Page 1

Data sheet

CI-tronic™ Soft Start Motor Controller

Type MCI 25B with Brake

MCI 25B motor controller with brake is designed

for soft starting and braking of 3 phase AC

motors.

The digital controlled soft starter features

accurate settings and several monitoring

functions. Acceleration time and initial torque are

along with the braking torque easily adjusted.

During braking the MCI 25B will apply a DC

current to all the windings of the motor,

thus providing a powerful brake function.

The automatic stop detection ensures a safe

operation. For positioning applications the

unique slow speed function can be applied.

The MCI 25B controller is typically applied on

demanding braking applications such as saws,

cranes, automatic doors, etc.

Features

y Adjustable acceleration time, 0 – 10 seconds

y Initial torque adjustable from 0 – 85%, with or

without kick start (break-away)

y Adjustable DC injection brake, 0 – 50 A DC

y Fast acting brake mode with automatic motor

field reduction

y Automatic stop detection

y Universal control voltage 24 – 480 V AC/DC

y Slow speed function, 7.5% or 10% of nom.

speed

y SCR aux. contacts for external control of

by-pass, I-O and mechanical brake

y Automatic detection of missing phase(s)

y Automatic adaptation to 50/60 Hz

y Unlimited start and stop per hour

y IP 20 protection

y Compact DIN rail mountable design

y EN 60947-4-2

y CE, C-tick

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 1

Page 2

Data sheet | Soft Start Motor Controller, Type MCI 25B

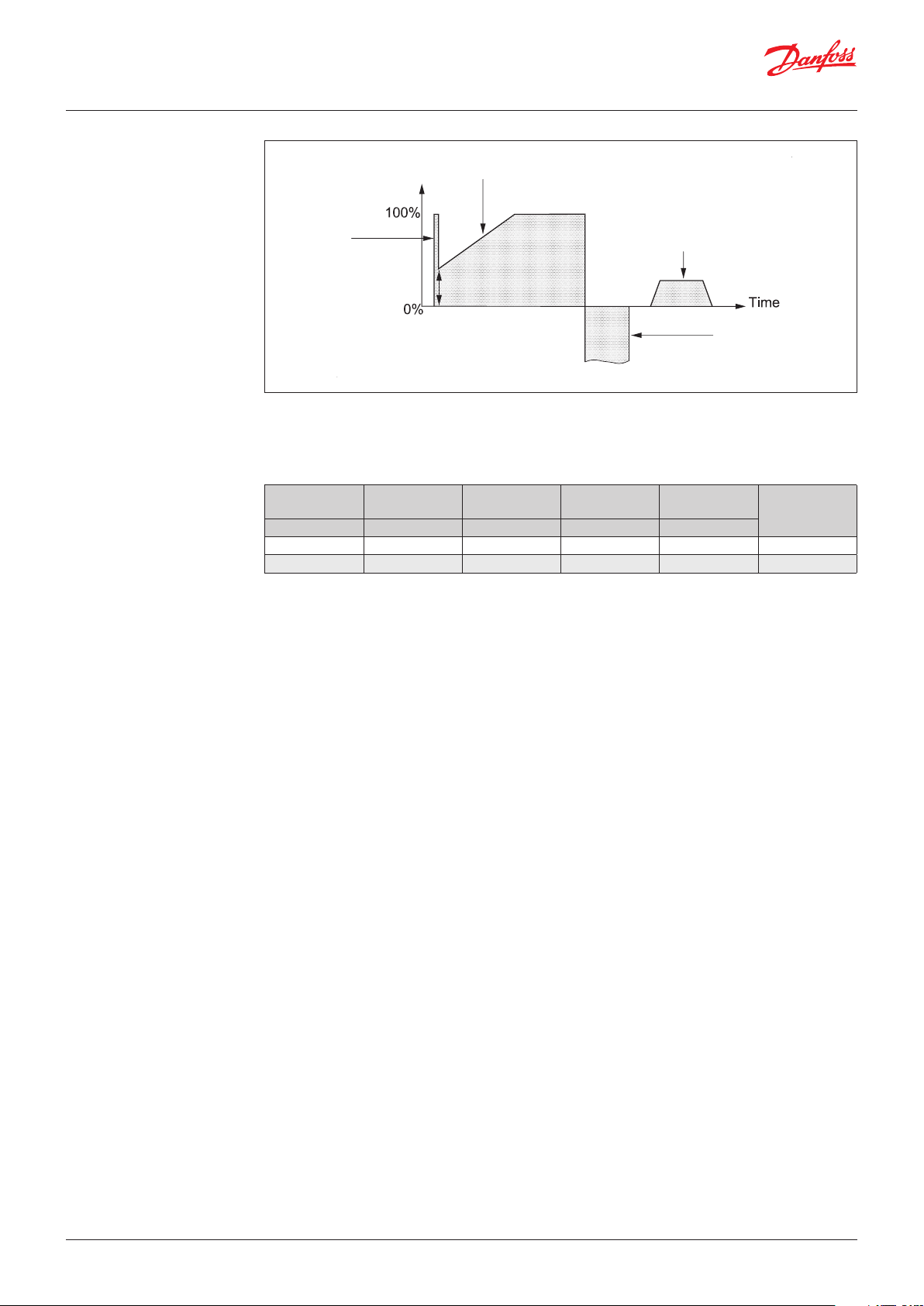

Adjustments

Motor torque

(voltage)

Ramp-up time

0 – 10 sec.

Danfoss

A37-217.20

Selection guide

Kick Start

selectable

Slow speed

7.5% or 10%

Initial torque up to

85% of nom. torque

Braking torque

0 – 50 A

Operational

voltage

[V AC] [A] [kW/HP] [V AC/DC] [mm]

208 – 240 25 7.5/10 24 – 480 90 037N0061

380 – 480 25 1/15 25 – 480 90 037N0062

Motor

current

Motor

power

Control

voltage

Module

dimensions

Code no.

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 2

Page 3

Data sheet | Soft Start Motor Controller, Type MCI 25B

Technical data Control circuit specifications

Control voltage range 24 – 480 V AC/DC

Pick-up voltage max. 20.4 V AC/DC

Drop-out voltage min. 5 V AC/DC

Max. control current for no operation 1 mA

Control current / power max. 15 mA / 2 VA

Response time max. 70 ms

Ramp-up time Adjustable from 0 to 10 Sec.

Brake current Adjustable from 0 to 50 A

Initial torque

SCR aux. contacts, voltage/current max. 24 – 480 V AC / 0.5 A (AC-14, AC-15)

SCR aux. contacts, max. fuse 10 A gL/gG, I2t max. 72 A2s

Design standard CE marked according to EN 60947-4-2

EMC immunity Meets requirements of EN 50082-1 and EN 50082-2

Output Specifications

Operational current max. (AC-3, AC-53a) 25 A

Motor size at:

208 – 240 V AC

380 – 480 V AC

Leakage current max. 5 mA

Minimum operational current 50 mA

Overload relay trip class Class 10

Semiconductor protection fusing

Type 1 co-ordination

Type 2 co-ordination I2t (t = 10 ms)

Rating index Slip ring motors: 25A: AC-52a: 4-13: 100-3000

Adjustable from 0 to 85 % of nominal torque with

optional kick start

0.7 – 7.5 kW (1 – 10 HP)

1 – 11 kW (1.5 – 15 HP)

80 A gL/gG

6300 A2 S

Asynchronous motors: 25A: AC-53a: 8-3: 100-3000

Insulation

Rated insulation voltage, U

Rated impulse withstand voltage, U

Installation category III

i

imp

660 V AC

4 kV

Thermal Specification

Power dissipation for continuous duty Pd max. 2 W/A

Power dissipation for Intermittent duty Pd max. 2 W/A x Duty cycle

Ambient temperature range -5 °C – 40 °C

Cooling method Natural convection

Mounting Vertical +/- 30 °C

Max. ambient temperature with limited rating 60 °C, see derating for high temperatures in chart below

Storage temp. range -20 °C – 80 °C

Protection degree/pollution degree IP 20 / 3

Materials

Housing Self extinguishing PPO UL94V1

Heatsink Aluminum black anodized

Base Electroplated steel

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 3

Page 4

Data sheet | Soft Start Motor Controller, Type MCI 25B

Functions

Control inputs

Operating mode selector,

select slow speed and auxiliary

contact function

Ramp up setting, accurately

adjustable from 0 – 10 seconds

Initial torque setting, adjustable from

0 – 85%, with or without kick start

Brake torque setting, adjustable on a

relative scale from 0 – 15

LED for status and error indication

Auxiliary contacts (SCR)

Functional diagram

Line voltage L1, L2, L3

Run command

Slow speed command

Brake command

Motor voltage T1, T2, T3

Brake on

Aux. contacts:

23-24 by-pass

13-14 I-O

13-14 ( M )

1. When line voltage is applied the brake will automatically stop a rotating motor.

2. The function of auxiliary contact 13-14 is selectable; “start - stop” or “mechanical brake”

Soft start function Ramp up

During ramp-up the controller will gradually

increase the voltage to the motor until it reach

full line voltage. The motor speed will depend on

the actual load on the motor shaft.

A motor with little or no load will reach full speed

before the voltage has reached its maximum

value.

The actual ramp time is digitally calculated and

will not be influenced by other settings, net

frequency or load variations.

Initial torque

The initial torque is used to set the initial starting

voltage. This way it is possible to adapt the

controller to an application requiring a higher

starting torque. In some cases on application

with very high break-away torque the initial

torque can be combined with a kick start

function. The kick start is a period of 200 ms

where the motor receives full voltage.

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 4

Page 5

Data sheet | Soft Start Motor Controller, Type MCI 25B

Brake function Braking is achieved by injecting a DC current,

adjustable from 0 – 50 A, onto all the windings

of the motor. The brake can be used on both star

and delta connected motors, but is most efficient

if the motor is connected in star.

Adjustment

The actual braking torque is controlled

indirectly by adjusting the braking voltage. The

braking voltage can be set for 0 – 15. For small

motors a relatively high braking voltage is

necessary contrary to larger motors where a

relatively low voltage is sufficient. For this

reason the braking voltage must be adjusted to

the actual application. Before starting up a new

application set the Braking torque to 1.

Increase incrementally until desired braking time

is reached.

Automatic stop detection

When the brake function is applied the MCI-B will

bring the motor to a stop before releasing the

brake current.

Note: If a contactor is placed between motor

and the MCI-B, do not open during braking as it

can cause the contactor to fail.

If the motor does not stop within 30 seconds the

DC brake will disengage and the controller will

show a “brake failure” condition.

The automatic stop detection is accomplished

by sensing the DC brake current on the motor,

and as so the accuracy of the stop detection will

depend on a correctly adjusted brake. The point

of “no rotation” depends on the motor size and

the brake voltage setting. If the motor voltage

is set to low the brake will be switched off

before the motor has come to a complete stop.

However, if the brake voltage is set to high, out of

detection range, it will not switch off the motor

before the brake failure conditions occurs after

30 seconds.

Slow speed function The slow speed function is intended for short

time operation in applications where an exact

positioning is needed, for example cranes. The

function has two selectable slow speeds: 7.5% or

10% of nominal speed.

Auxiliary contacts The auxiliary contacts are made possible by

means of SCR technology and will only switch

correctly on AC current.

Contact 13-14

The contact 13-14 is selectable for two different

functions; “I-O” or “Mechanical brake”. If the “I-O”

is selected, the contact will be closed as long as a

RUN command is given, see functional diagram

LED status indication

LED status indication:

The torque level will depend on the motor

and selected slow speed, typically 25 – 40% of

nominal torque. During slow speed the motor

current will increase, typically 2 – 2.5 times the

nominal current.

If “Mechanical brake” is selected, the contact

will be closed as long as the motor is rotating.

The “Mechanical brake” setting is intended for

operating an external mechanical brake.

Contact 23-24

The contact 23-24 is intended for operating an

external by-pass contactor. The contact will close

when the controller is in steady state operation,

see functional diagram.

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 5

Page 6

Data sheet | Soft Start Motor Controller, Type MCI 25B

Wiring

Overload and short

circuit protection

Run / brake command

Slow speed command

Forced brake command

MCI 25B

By-pass

I-O or mechanical brake

Common

Overload and short circuit protection is easily

achieved by installing a circuit breaker on the

line side of the motor controller. Select circuit

breaker from the table according to motor full

load current.

380 – 415 V AC

Type

CTI 25M

CTI 25M

CTI 25M

CTI 25M

CTI 25M

1

) Values based on let-through curves for appropriate circuit breaker

Motor full load current

[A] [kA]

4.0 – 6.3

6.3 – 10

10 – 16

14.5 – 20

18 – 25

Code number 037N0061 037N0062

Mains

L1, L2, L3

Inputs

(C, R, S, B)

Outputs

(13/14, 23/24)

208 – 240 V AC 380 – 480 V AC

24 – 480

V AC/DC

24 – 480 V AC

max. 0.5 A

Be aware of the maxium prospective short

circuit current breaking capacity. For further

information please refer to data sheet for the

circuit breaker.

Max. prospective short-circuit current Icc

100

100

40

1.8

1.5

24 – 480

V AC/DC

24 – 480 V AC

max. 0.5 A

Code no.Co-ordination 1)

047B3148

047B3149

047B3150

047B3151

047B3152

Dimensions

mm (inches)

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 6

Page 7

Data sheet | Soft Start Motor Controller, Type MCI 25B

Operating at high

temperatures

Operating on heavy loads

Overheat protection

Operation in temperatures from 40 °C up to 60

°C is possible if the power dissipation is limited

Ambient temperature Continuous operation

[°C] [A]

50 20 25 A with 80% duty cycle, max. on-time 15 min

60 15 25 A with 65% duty cycle, max. on-time 15 min

Load data is given for normal starts. If applied on

heavy starts please derate according to table.

If required the controller can be protected

against overheating by inserting a thermostat in

the slot on the right-hand side of the controller.

Order: UP 62 thermostat 037N0050

either by reducing the current or by reducing the

ON-time of the controller. Refer to table.

Duty-cycle rating

Overload relay trip class

10 (Light starts) 25

10 (Normal starts) 25

20 (Heavy starts) 20

30 (Very Heavy starts) 15

Max. current

[A]

For wiring connections see application

examples.

Mounting instructions The controller is designed for vertical mounting.

If the controller is mounted horizontally the load

current must be reduced by 50%.

The controller needs no side clearance.

Clearance between two vertical mounted

controller must be minimum 80 mm (3.15”).

Clearance between controller and top and

bottom walls must be minimum 30 mm (1.2”).

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 7

Page 8

37-218.20

Data sheet | Soft Start Motor Controller, Type MCI 25B

Application examples Overheat protection

Example 1

The thermostat can be connected in series

with the control input of the Motor Controller.

When the temperature of the heat sink

exceeds 100 °C the Motor Controller will be

switched OFF.

Note: when the temp. has dropped approx.

30 °C the Controller will automatically be

switched ON again. This is not acceptable in

some applications

Example 2

The thermostat is connected in series with the

control circuit of the main contactor. When the

temp. of the heat sink exceeds 100 °C the main

contactor will be switched OFF. This circuit

requires manual reset to restart the motor.

Standard start – brake wiring

If only the soft start and braking function is

required it is easily achieved by wiring the

control voltage to “R”. When control voltage

is applied the controller will begin the soft

start procedure. To brake the load the control

voltage is disconnected.

Danfoss circuit breaker CTI 25M is in this

example providing overload and short circuit

protection.

MCI 25B

Danfoss

CTI 25M

Danfoss

24 – 480 V AC

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 8

Page 9

A37-220.20

Application examples

(continued)

Direct wired start-stop with bypass

By wiring the auxiliary contact function

13-14 into the control circuit start and stop

can be achieved by means of push buttons.

Note that the operating mode selector must

be set for “I-0” control.

Auxiliary contact 23-24 is used to control and

external by-pass contactor during steady state

operation.

Danfoss circuit breaker CTI 25M is in this

example providing overload and short circuit

protection.

Wired for control of mechanical brake and bypass

The auxiliary contact function 13-14 is in this

example used to control a mechanical brake.

The brake is released when the

controller is applying voltage to the motor.

MCI 25B

Danfoss

CTI 25M

Danfoss

CTI 25M

24 – 480 V AC

Danfoss

A37-219.20

Danfoss

Note that the operating mode selector must

be set for “mechanical brake” control.

Auxiliary contact 23-24 is used to control an

external by-pass contactor during steady state

operation.

Danfoss circuit breaker CTI 25M is in this

example providing overload and short circuit

protection.

MCI 25B

24 – 480 V AC

24 – 480 V AC

Max. 0.5 A

© Danfoss | DCS (az) | 2018.02

IC.PD.C50.H3.02 | 9

Loading...

Loading...