Page 1

DESCRIPTION

The KVF Flow Control Servovalve is a precision servovalve

that provides an output flow rate proportional to a low power

electrical input signal. It features a torque motor-actuated,

double-nozzle flapper pressure control pilot valve mated to a

pressure-actuated, spring-centered boost valve module of a

unique double-spool configuration.

The design of this servovalve does not require a centering

feedback spring and ball for spool position. The servovalve's

pilot stage is a stand-alone, closed loop pressure control

valve which uses internal hydraulic pressure reactions to

achieve its closed loop control characteristics.

This combination was selected to provide fabrication

economies resulting in true servovalve performance at

proportional valve pricing. The KVF Servovalve's steady

state/dynamic response characteristics are compatible with

industrial feedback control system applications.

FEATURES

KVF

Flow Control Servovalve (FCS)

BLN-95-9061-4 Issued: February 2004

Self-contained pressure feedback, eliminates requirement

for feedback spring and ball for spool position

ISO 4406 filtration rating of 18/15 (Nominal 10 micron

filtering provides dependable performance)

Standard manual operator assists with operation and

system diagnostics

Requires low power dc current to drive rated flow;

±20 mA, ±40 mA, ±100 mA, ±150 mA, or ±220 mA, are

standard options. The ±20 mA, can be driven directly

from PLC.

Does not require PWM drive for dither but is directly

compatible with other drives

4 to 20 mA version is configured such that 4 mA = 0 flow

and 20 mA = maximum flow

Unique two spool main body design allows for factory

adjustment of null pressures at each working port

Units available in standard line-to-line or overlapped

configuration in all flows from 1 1/4 gpm to 20 gpm at no

additional cost

Installation dimensions common to all servovalves

Pricing is independent of flow capability

Four connector option: MS, 2-pin WP, 4-pin WP, or 2-2

pin WP

Easily connected for unidirectional use from 2 1/2 gpm to

35 gpm at 1000 psi rating

Adaption maniflods available for conversion to other

valve patterns

Dual spool design provides added safety shut down if

contamination causes failure of either spool

Capability of separating control source from main stage

supply to accommodate high back pressure applications

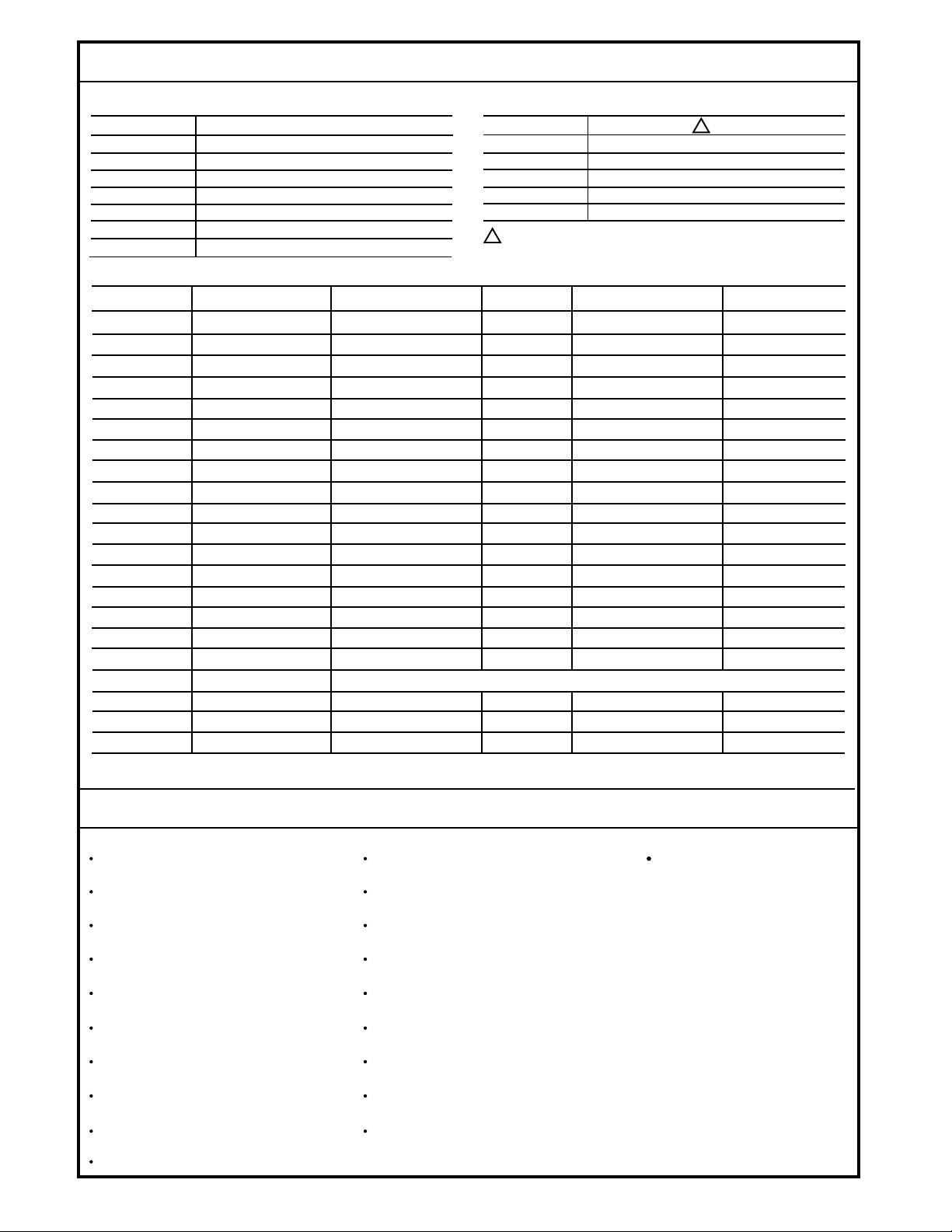

ORDERING INFORMATION

KVF X X X X X

Device Identity

Rev

Supply Pressure

Flow Rating

% Lap Split

Pilot Stage

© Danfoss, 2013-09 BLN-95-9076-2 1

Ordering specifications for standard models.

DEVICE IDENTITY

The modle code for this device is KVF.

MODEL CODE SUPPLY PRESSURE

A 500 to 3000 psi

C 200 to 1000 psi

D 500 to 3000 psi with separate pilot drain

E 2500 to 3000 psi

F 500 to 3000 psi w/o cylinder port orifices

G 500 to 3000 psi w/o cylinder port orifices

and with pilot drain

Page 2

ORDERING INFORMATION (continued)

FLOW RATING

MODEL CODE FLOW RATING

1 1.25 gpm

2 2.5 gpm

5 5 gpm

6 10 gpm

7 15 gpm

8 20 gpm

9 20 gpm with 300 lb/in springs

PILOT STAGE

PILOT STAGE DEVICE NUMBER RATED CURRENT COIL(s) CONNECTOR TYPE SCALE FACTOR

01 * MCV116A3102 ±150 mA 23 ohms Packard 1.15 psid/mA

02 * MCV116A3101 ±150 mA 23 ohms MS 1.15 psid/mA

03 * MCV116A3204 ±220 mA 16/19 ohms Packard 0.78 psid/mA

05 * MCV116A1307 ±40 mA 69 ohms MS 4.2 psid/mA

06 MCV116A1407 ±40 mA 106 ohms MS 5.5 psid/mA

07 MCV116A1402 ±40 mA 106 ohms Packard 5.5 psid/mA

08 * MCV116A1302 ±40 mA 69 ohms Packard 4.2 psid/mA

09 MCV116A1501 ±20 mA 643 ohms MS 12.6 psid/mA

10 * MCV116A3203 ±220 mA 16/19 ohms Packard (2) 0.78 psid/mA

14 MCV116A1101 ±100 mA 23 ohms MS 2.4 psid/mA

15 MCV116A3201 ±220 mA 16/19 ohms MS 0.78 psid/mA

16 MCV116A1203 ±160 mA 16/19 ohms Packard (2) 1.47 psid/mA

17 MCV116A1201 ±160 mA 16/19 ohms MS 1.47 psid/mA

18 MCV116A1102 ±100 mA 23 ohms Packard 2.4 psid/mA

19 MCV116A1502 ±20 mA 643 ohms Packard 12.6 psid/mA

20 MCV116A3214 ±220 mA 16/19 ohms Deutsch 0.78 psid/mA

21 MCV116A3100 ±150 mA 23 ohms No connector 1.15 psid/mA

22 MCV116J1407 Special, contact Danfoss

23 MCV116A1214 ±160 mA 16/19 ohms Deutsch 1.47 psid/mA

24 MCV116A1315 ±40 mA 69 ohms No connector 4.1 psid/mA

25 MCV116A1216 ±160 mA 16/19 ohms Deutsch 1.47 psid/mA

* 1.25, 2.5, and 5.0 gpm only.

% LAP SPLIT

MODEL CODE % LAP SPLIT

0 Line-to-line 50%

1 Standard overlap, 50%

2 Standard overlap, 2%

3 Heavy overlap, 50%

4 Heavy overlap, 2%

1

% of supply pressure at C1 and C2 when servo valve

is at null.

1

TYPICAL APPLICATIONS

Air cargo loading

Motion simulators

Asphalt pavers

Saw setworks positioners

Concrete pavers

Manipulator arms / industrial robots

Milling machines

Soil stabilizers

Material mixing machinery

Synchronized knife carriage servodrives

Edger in feed board positioners

Paper mill machinery

Injection molding machinery

Platform leveling

Edge guide control machinery

Product testing machinery

Marine deck machinery

Rocket motor testing equipment

Oil exploration equipment

2

For steering applications,

contact Danfoss

BLN-95-9061-4

Page 3

TECHNICAL DATA

3

3

3

3

• Electric current in torque motor coil creates a magnetic

torque on armature

• Armature/flapper rotates about torsion pivot

• Flapper repositions towards one nozzle, which creates a

differential pressure between P1 and P2

• Each spool moves in the same direction opening the

supply )Ps) to output (C1 or C2) on one spool and the

output (C1 or C2) to return (PT) on the other spool

• Differential pressure between P1 and P2 causes the

spools to move against the centering springs until the

spring force balances with the differential pressure

• Control pressure (PC1 or PC2) reflected to the flapper

produces torque on the flapper in opposition to the

magnetic torque on the armature

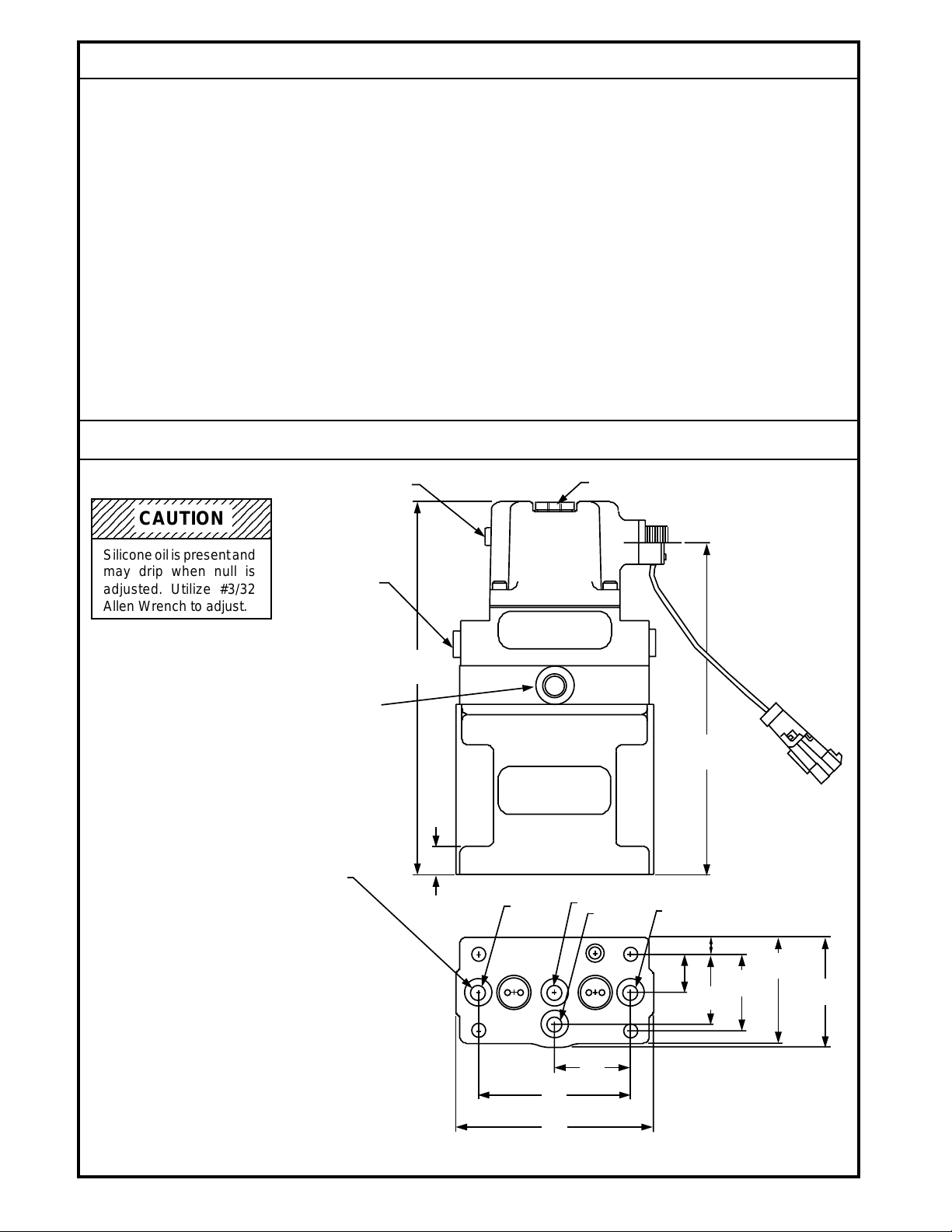

DIMENSIONS

234567890123456789012

234567890123456789012

234567890123456789012

CAUTION

234567890123456789012

NULL ADJUST ACCESS

• As the pressure torque on the flapper becomes equal to

the magnetic torque on the armature, the flapper moves

away from the closed nozzle to an equilibrium position

producing a steady-state control pressure (PC1 or PC2)

on the ends of each valve spool

• Each valve spool stops at a position where the control

pressure force on the end of each valve spool equals the

spring force on each valve spool

• Therefore, valve spool position is proportional to input

current and, with a constant pressure drop across the

spool meter-in and meter-out edges, the flow rate to the

load is proportional to spool position

MANUAL OPERATOR

Silicone oil is present and

may drip when null is

adjusted. Utilize #3/32

Allen Wrench to adjust.

3/8 O.D. TUBE

FITTING O-RING,

PORT PER SAE - J514

9/16 - 18 UNF (2 - PL)

PLUGS INSTALLED

EXTERNAL

PILOT DRAIN

ON "D" MODEL ONLY

.312 DIA

.566 O.D.

O-RING

(4-PL)

184,15

(7.32)

11,43

(.45)

C1

PT

PS

C2

19,05

(.75)

157,99

(6.22)

8,89

(.35)

34,93

(1.375)

38,1

(1.50)

53,09

(2.09)

55,37

(2.18)

BLN-95-9061-4

38,1

(1.50)

76,2

(3.00)

99,06

(3.90)

1428B

Dimensions of the KVF in Millimeters (Inches).

3

Page 4

INTERNAL WORKING SHEMATIC

PS

PT

ARMATURE

AIR GAP

PS

COIL

POLE

PIECE

PIVOT

PLATE

FLAPPER

NOZZLE

ORIFICE

PLATE

P1 P2

PERFORMANCE

RATED SUPPLY PRESSURE

3000 psi

FLOW RATINGS AT 1000 PSI VALVE DROP

1.25, 2.5, 5, 10, 15, 20 gpm

RATED INPUT SIGNAL

±20 mA dc, ±40 mA dc, ±100 mA dc,

±150 mA dc, ±220 mA dc,

FLUID

Petroleum base

P1

PS

P2

P1

PS

P2

C2C1

1289C

LINEARITY

< 5% rated signal

SYMMETRY

5% (maximum) each direction

PRESSURE RISE (BLOCKED OUTPUT PORTS)

> 80% Ps at 4% rated signal (except for 2, 3, 4 lap)

TYPICAL FREQUENCY RESPONSE

(1000 PSI VALVE DROP)

90° phase lag frequency > 30 Hz

-3 dB amplitude ratio frequency > 30 Hz

INTERNAL LEAKAGE (PILOT and BOOST STAGES)

< 1.0 gpm (< .5 gpm available on special models where

leakage requirements are primary)

THRESHOLD

< 1% rated signal (except for 2, 3, and 4 lap)

HYSTERESIS

< ±5% rated signal

RETURN PRESSURE

Atmospheric to 200 psi ("D" model provides separate

return for higher return ratings)

FLUID/AIR RATED TEMPERATURE RANGE

-20° F to 200° F

RECOMMENDED SYSTEM FILTRATION

10 micron (in-line pressure filter)

4

BLN-95-9061-4

Page 5

PERFORMANCE (continued)

ELECTRICAL CONNECTION/PHASING

Positive voltage at pin B or D with negative voltage at

pin A

Produces flow out port C1

ENVIRONMENTAL

TEMPERATURE NULL SHIFT

< 5% rated signal over rated fluid/air temperature range

PRESSURE NULL SHIFT

< 4% rated signal, 500 psi to rated supply pressure

VIBRATION

5 Hz to 2000 Hz freguency spectrum

1 g to 46 g's acceleration (varies with frequency)

FLOW SIZING FORMULAE

i

PS - ∆P

QV = Q

Q

Q

• •

r

( )

i

r

is the valve flow at an operating point

V

is the rated flow at ir and ∆PV = 1000 psi)

r

i is the operating current

i

is the rated current

r

P

is the supply pressure to the valve

S

∆P

is the load pressure between the valve's control ports (P

L

∆P

is the valve pressure drop across the valve (PS -

V

L

1000

SPACE/WEIGHT

7.25 inch high x 2.18 inch wide x 3.16 inch long; 6.6 lbs.

SHOCK

50 g's (11 millisecond duration) three mutually

perpendicular axes

SAND/DUST/HUMIDITY

Per MIL-STD-810 current issue

)

C1 - PC2

∆

P

)

L

Note:

(1) The rated flow occurs at:

∆P

V

= PS

3 (the maximum power transfer to load)

/

(2) Higher flow rates will incur some saturation

(3) The tank pressure is assumed to be zero (otherwise, substitute P

RATED SIGNAL FLOW VS.

PRESSURE DROP

LOAD FLOW VS.

LOAD PRESSURE

40

30

20

15

10

7

5

LOAD FLOW GPM

3

2

1.5

1.0

200 300 500 1000 2000 3000

20 gpm size

15 gpm size

10 gpm size

5 gpm size

2.5 gpm size

1.25 gpm size

VALVE PRESSURE DROP

PSI

S -

P

for PS )

t

- 100%

- 50%

- 75%

+100

LOAD FLOW %

-20 -40 -60 -80-100

- 25%

+80

+60

+40

+20

0

-20

-40

-60

-80

+ 75%

+ 50%

+ 25%

+20 +40

+ 100%

+80 +100

+60

LOAD PRESSURE

DROP % SUPPLY

BLN-95-9061-4

2033

-100

2034

5

Page 6

ADJUSTMENTS

The Servovalve is adjustable when re-centering of the output levels is required. The following steps are recommended while

referring to the Servovalve drawing (see drawing below). Required tools: one large slotted screw driver & one 3/32 internal

hex wrench

1. Locate the neutral adjustment access point. Using the slotted screw driver remove the access screw. See Caution # 1

2. See Caution # 2 Insert the hex wrench a short distance into the access opening and engage the adjustment setscrew.

3. Some applications require observing the system load while adjusting the servovalve and some require observing an

electrical deviation meter which measures closed loop feedback errors while adjusting the load. Adjustments are make

by turning the hex wrench very slowly either CW or CCW. Most adjustments require less than 1/3 turn from the starting

point to re-center the servovalve to achieve the desired results.

4. Upon completion ensure that the access screw is reinstalled. See Caution #3.

Caution # 1 Once the access screw is removed a small amount of silicone fluid may leak form this opening; the amount of

leakage depends on the valve orientation (see figure 1) in reference to gravity. Ensure that the screw is replaced once the

re-centering is completed

Caution # 2 To adjust neutral requires operating the hydraulic system; therefore, prior to the actual adjustment, take the

necessary safety precautions, such as having unnecessary personnel stand away form the machine as the system load will

likely move.

Caution # 3, A small amount of silicone oil leakage is acceptable (approximately 25 % of the total 45 cubic centimeters). If

excessive silicone oil is lost, restore the fluid using silicone oil replacing kit K21436 for models MCV113 & KVF. For models

MCV103, use kit K21435. Do not reuse any silicone oil that leaks from the cover due to the possibility of contamination.

NEUTRAL

ADJUSTMENT

ACCESS

ADJUSTMENT

NEUTRAL

SETSCREW

MANUAL OPERATOR

MAXIMUM/MINIMUM

OIL LEVEL

SILICONE OIL

LEVEL

SERVOVALVE

2100

6

BLN-95-9061-4

Page 7

SERVOVALVE (KVFXXXXXX) O-RING REPLACEMENT

Material

Nitrile

Pilot Stage Bottom

Viton

Viton

Viton

Viton

2

75 ± 5

75 ± 5

75 ± 5

90 ± 5

70 ± 5

Durometer

1

2

.070

.070

.070

.070

Width

.070

Boost Stage Top

2104

Boost Stage

3

.556

O.D.

.504

Dimensions

I.D.

.426 ± .005

.364 ± .005

6

Qty

6

K00830

K00829

Part Number

1

2

Item

.691

.504

.551 ± .005

.364 ± .005

2

1

K00832

K08493

3

4

.348

.208 ± .005

1

K07006

5

1

4

2

351

BLN-95-9061-4

Pilot Stage

Orifice

7

Boost

Page 8

Servovalve Manifold Options

Use this drawing and the chart listed below to

determine servovalve manifold mounting.

Top View Side View

DB

E

A

Danfoss Dimensions in Inches (Millimeters)

Part Number

K02099 3.75 2.60 1.23 1.50 3.00 0.219

Pilot Pressure Plate (95,25) (66,04) (31,24) (38,1) (76,2) (5,56)

Separate PCP Supply & Tank

K02100 3.75 2.60 1.23 1.50 3.00 0.219

Pilot Pressure Plate (95,25) (66,04) (31,24) (38,1) (76,2) (5,56)

Separate Supply to PCP

K29385 4.00 3.14 1.14 1.50 3.00 .0285

Blanking Plate (101,6) (80,0) (29,05) (38,1) (76,2) (7,26)

KK03501 4.00 2.25 1.00 NA NA NA

D01 Porting Adapter Plate (101,6) (57,15) (25,4)

KK03502 4.25 2.50 1.00 NA NA NA

D02 Porting Adapter Plate (107,95) (63,5) (25,4)

KK03503 4.00 2.25 0.50 NA NA NA

0.625 Dia. Port Circle Adapter Plate (101,6) (57,15) (12,7)

KK03504 3.90 2.00 0.75 NA NA NA

0.780 Dia. Port Circle Adapter Plate (99,06) (50,8) (19,05)

KK03505 4.25±0.06 3.25±0.03 0.875 NA NA NA

0.875 Dia. Port Circle Adapter Plate (107,95) (82,55) (22,23)

KK03506 4.00 2.00 0.75 NA NA NA

KVF to V7059 Adapter Plate (101,6) (50,8) (19,05)

KK03508 8.50 5.00 2.00 4.134 7.556 0.335

3-Valve Manifold (215,9) (127,0) (50,8) (105,0) (191,92) (8,51)

KK03509 5.00 3.00 1.00 2.24 4.24 0.281

Single Valve Manifold (127,0) (76,2) (25,4) (56,9) (107,7) (7,14)

KK03510 6.00 5.00 2.00 4.134 5.056 0.335

2-Valve Manifold (152,4) (127,0) (50,8) (105,0) (128,42) (8,51)

KK03511 11.00 5.00 2.00 4.11 10.06 0.335

4-Valve Manifold (279,4) (127,0) (50,8) (104,39) (255,52) (8,51)

KK03512 16.00 5.00 2.00 4.11 15.06 0.335

6-Valve Manifold (406,4) (127,0) (50,8) (104,39) (382,52) (8,51)

SAE Fittings on Sides

KK03513 5.00 3.00 1.50 2.50 4.50 0.281

Single Valve Manifold (127,0) (76,2) (38,1) (63,5) (114,3) (7,14)

SAE Fittings on Bottom

F

A B C D E F

C

2103

8

BLN-95-9061-4

Page 9

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair or evaluation, include a

description of the problem and what work you believe

needs to be done, along with your name, address and

telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH& Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: +49 4321 871-0

Fax: +49 4321 871-284

BLN-95-9061-4

9

Loading...

Loading...