Data sheet

Thermostat

KPU

The KPU Thermostats are temperature controlled

electrical switches, which are applied for regulation

and safety monitoring of refrigeration and air

conditioning systems.

KPU sensors are available with vapor charge or

with adsorption charge. The Thermostats with

adsorption charge are widely used to give frost

protection, while vapor charged sensors are used

where small dierential is required.

All KPU Thermostats have a single pole double

throw (SPDT) contact system. Theposition of the

switch depends on the thermostat setting and the

bulb temperature.

Features

Approvals

© Danfoss | DCS (jmn) | 2016.08 DKRCC.PD.CA0.F6.22 | 520H11320 | 1

• Wide temperature regulating range allows use in

low, medium, and high temperature refrigeration

application and air-conditioningsystems

• Snap-action electrical contacts minimize chatter,

bounce and wear, and ensure long-term electrical

and mechanical reliability

• Fingertip manual trip feature allows contact

function testing without tools

• Easily replaces other manufacturers’ thermostats

• Ultra-short bounce time

UL listed for USA and Canada, le E31024

• Long operating lifetime

• Vibration and shock resistant

• SPDT switch allows NC or NO function option as

well as alarm capability

• Automatic and manual reset versions available

Data sheet | Thermostat, KPU

Technical data

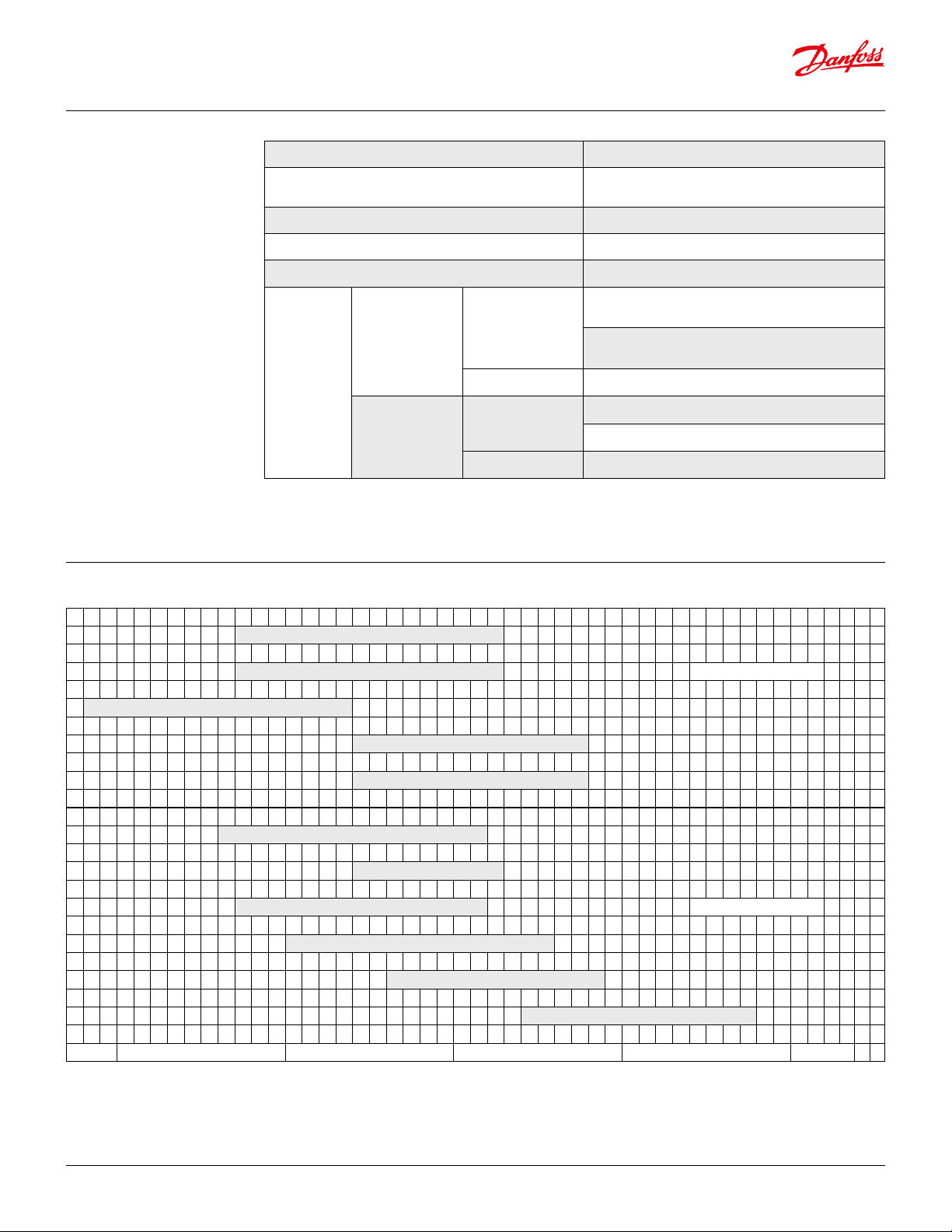

Regulating ranges in [°F]

Ambient temperature -40 – 122 °F, 175 °F up to 2 hours

Cable entry

⁄ in cable entry for ½ in male pipe thread connection

(conduit boss)

Maximum wire dimension 10 AWG

Enclosure ~NEMA 1

Switch SPDT – single pole double throw

FLA = 24 A at 120 V AC

24 A at 240 V AC

NAM rating

Alternating current

1

) = 144 A at 120 V AC

LRA

144 A at 240 V AC

Contact load

Direct current 12 W pilot duty at 240 V DC

AC1: 16 A, 400 VA

European rating

(acc. to EN 60947)

Alternating current

AC3: 16 A, 400 VA

Direct current DC13: 12 W, 220 V control current

1)

LRA is rated for make only

KPU 61

KPU 62 (room sensor) Vapor charge

KPU 63

KPU 68 (room sensor)

KPU 69

KPU 62

KPU 71

KPU 73 Adsorption charge

KP U 74

KPU 75

KPU 77

-50 0 50 100 150

© Danfoss | DCS (jmn) | 2016.082 | 520H11320 | DKRCC.PD.CA0.F6.22

Data sheet | Thermostat, KPU

Ordering

Typ e

Bulb

type

Range

Dierential

at lowest

temperature

setting

at highest

temperature

setting

Max.

bulb

temp.

Reset

function

Capillary

tube length

Code no.

[°F] [°F] [°F] [°F] [in]

Vapour 1)

KPU 61 A -20 – 60 10 – 40 2.5 – 13 250 auto. 80 060L5201

KPU 61 B -20 – 60 10 – 40 2.5 – 13 250 auto. 80 060L5203

3

KPU 61B B -20 – 60 fix e d 11 fixed 3.5 250 man.

KPU 61B B -20 – 60 fix e d 11 fixed 3.5 250 man.

) 80 060L5204

3

) 200 060L5205

KPU 62 C1 -20 – 60 10 – 40 2.5 – 13 250 auto. room sensor 060L5206

4

KPU 61 B -20 – 60 10 – 40 2.5 – 13 250 auto.

) 80 060L5210

KPU 63 A -60 – 15 18 – 125 5 – 15 250 auto. 80 060L5213

KPU 63 B -60 – 15 18 – 125 5 – 15 250 auto. 80 06 0L5214

KPU 68 C1 25 – 95 8 – 45 3 – 13 250 auto. room sensor 060 L5215

KPU 69 B 25 – 95 8 – 45 3 – 13 250 auto. 80 060 L5217

Adsorption 2)

KPU 62 C2 -20 – 60 9 – 36 3 – 14 175 auto. 4) room sensor 060L5207

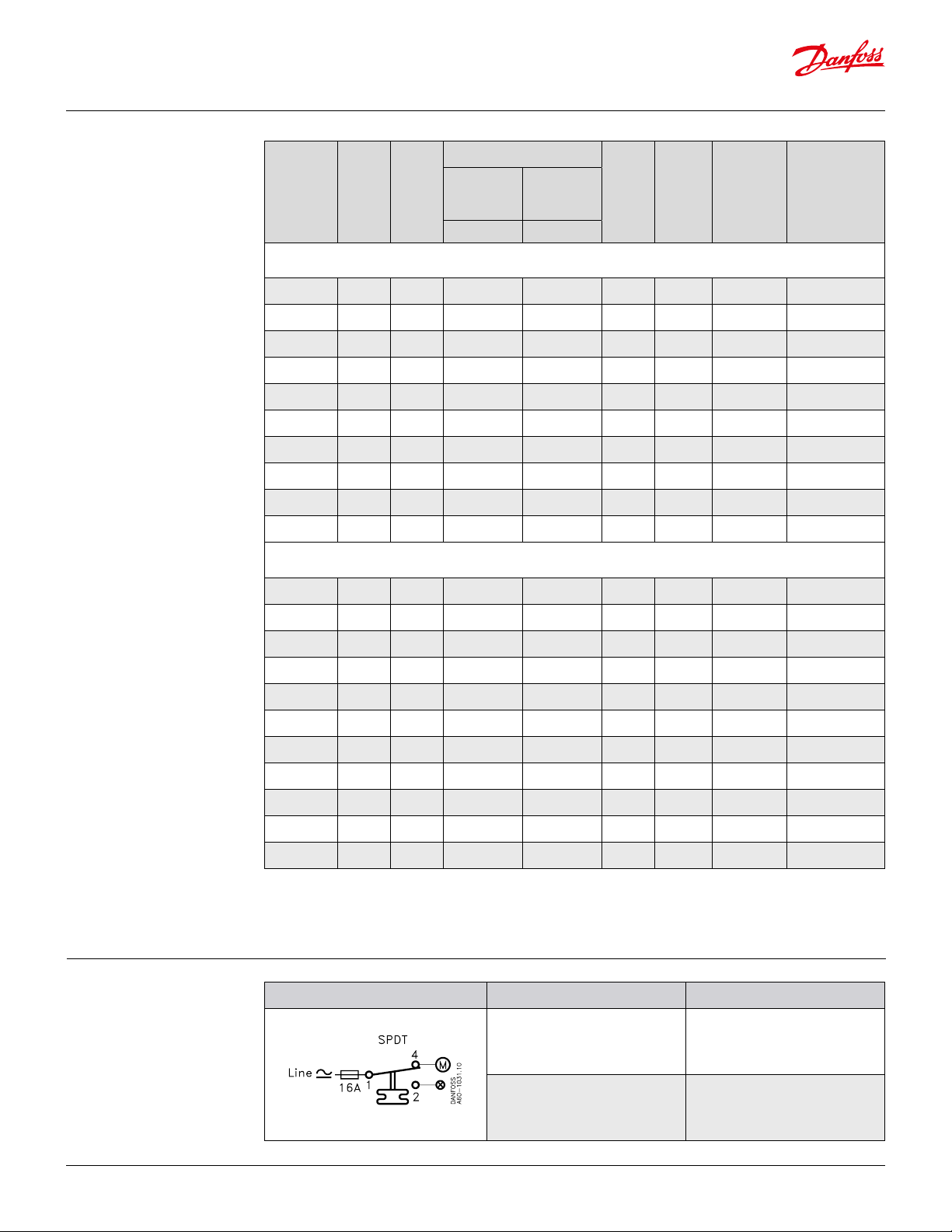

Contact system

KPU 73 E3 -15 – 60 6.5 – 32 5 – 50 175 auto. 80 060L5208

KPU 73 E1 -15 – 60 22 – 125 15 – 45 175 auto. 80 060L5209

3

KPU 73B E3 -15 – 60 fixed 6 fixed 6 175 man.

) 80 060 L52 11

KPU 73 D -15 – 60 6 – 35 5 – 32 175 auto. 80 060L 5212

KPU 71 E2 25 – 70 5.5 – 18 4 – 16 175 auto. 80 06 0L5218

3

KPU 71B E2 25 – 70 fixed 5 fixed 5 175 man.

) 80 060L 5216

KP U 74 E1 0 – 80 9 – 35 9 – 35 175 auto. 80 06 0L5219

3

KP U 74 B E1 0 – 80 fixed 10 fi xe d 10 175 man.

) 80 060L5220

KPU 75 F 30 – 95 6 – 29 4.5 – 21.5 230 auto. 80 06 0L 5221

KPU 77 E3 60 – 140 6 – 18 6.3 – 18 265 auto. 80 060L5223

1)

Bulb must be installed in colder position than thermostat

housing and capillary tube.

2

) Bulb can be placed warmer or colder than thermostat housing

and capillary tube, but variations from 70 °F

ambienttemperature will inuence the scale accuracy.

3

) Manual minimum reset. Marked with letter B. Fixed dierential.

These controls have no hand knob.

4

) With manual switch and top plate.

Switch type – singlepoledoublethrow Switch action Applicaton

1. Terminals 1 – 4 close high and

open low

Terminals 1 – 2 can be used as

1. Low temperature cut-out

low temperature alarm

2. Terminals 1 – 2 open high and

close low

Terminals 1 – 4 can be used as

2. High temperature cut-out

high temperature alarm

© Danfoss | DCS (jmn) | 2016.08 DKRCC.PD.CA0.F6.22 | 520H11320 | 3

Data sheet | Thermostat, KPU

Design / Function

1. Temperature setting spindle

2. Dierential setting spindle

3. Main spring

4. Dierential spring

5. Bellows

6. Capillary tube

7. Main arm

8. Switch

9. Cable entry

11. Temperature sensor

12. Setting knob

13. Dierential setting screw

14. Control terminals

15. Ground terminal

16. Contact housing

Key sketch of KPU Thermostat KPU Thermostat without front cover

Switches in KPU Thermostats have a snap-action

function, triggered when cut-in or cut-out

temperature is reached.

Snap-action creates anumber of advantages:

• High contact load capability

• Ultra-short bounce time

• Long mechanical and electrical life

• High resistance to pulsation and vibration

• Vibration resistance up to 4 g in range 0 – 1000 Hz

• Long mechanical and electrical service life

© Danfoss | DCS (jmn) | 2016.08 DKRCC.PD.CA0.F6.22 | 520H11320 | 4

Data sheet | Thermostat, KPU

Terminology Set point

A predetermined value to which a thermostat is

adjusted and at which it performs its

intendedfunction.

Dierential

The dierential is the dierence between the cutin

and cut-out temperatures. The dierential is

necessary for satisfactory automatic operation of

the controlled system.

Mechanical dierential (intrinsic dierential)

The mechanical dierential is the dierential set by

the dierential spindle.

Snap function

A specic contact force is maintained until snap is

initiated. The time over which contact force reaches

zero is a few milliseconds; therefore, contact

bounce due to vibration, for example, cannot occur

at cut-out. The snap-action contact system will

continue to function even when micro-welds are

created between the contacts during cut-in. The

force created to separate the contacts is strong

enough to instantly shear o all contact surface

welds that may have been created by cut-in action.

These design features ensure that the cut-out

setting of the KPU thermostat remains highly

accurate and completely independent of the

magnitude of the current load.

Reset

1. Manual reset:

A unit with manual reset can only be restored to

operational mode by activating the external reset

button.

On min. reset units the set value is equal to the

cut-out value for falling temperature. On max. reset

units the set value is equal to cut-out value for

rising temperature.

2. Automatic reset:

A unit with automatic reset is restored

tooperational mode automatically.

FLA – Motor Full Load Amperes

FLA is the largest current that a motor or other

device is designed to carry at rated voltage and

other specic conditions. Also often called current

at rated conditions.

LRA – Locked Rotor Amperes

LRA is the largest current that the motor is designed

to carry with shaft or rotor immobilized.

Setting and resets Thermostats with automatic reset

Set the cut-in temperature on the “RANGE” scale. Set

the dierential on the “DIFF” scale. Thecontrolled

system will start at the temperature set on the

RANGE scale and will be stopped when the

temperature falls the number of degrees set on the

DIFF scale.

Please note that the dierential scale is only

areference. The exact value of distances on thescale

depends on where in its range thecontrol cut-in is

set. Use the dierential scale asaguide, and if precise

function is required, establish the dierential setting

by comparing function with an accurate

thermometer in thecontrolled zone. If the

compressor does not stop at the desired low

temperature, check thedierential to ensure that it is

not set at too high avalue.

The thermostat automatically resets and

thecompressor starts once the temperature

risesabove the range scale setting.

Thermostats with manual minimum reset

Set the cut-out temperature on the range scale.

The dierential is xed.

Restart the compressor by pressing the reset

button after the temperature of the sensor rises to

a value equal to the range scale setting plus the

xed dierential.

Thermostats with manual maximum reset

Set the cut-out temperature on the range scale. The

dierential is xed.

Restart the compressor by pressing the reset button

after the temperature of the sensor falls toa value

equal to the range scale setting minus thexed

dierential.

© Danfoss | DCS (jmn) | 2016.08 DKRCC.PD.CA0.F6.22 | 520H11320 | 5

Data sheet | Thermostat, KPU

Charges

1. Vapor charge 2. Adsorption charge

Bellows

Capillary tube

Sensor

The sensor contains saturated vapor with

asmallquantity of liquid. When temperature rises,

liquidevaporates, and pressure inside

thesensorincreases.

After all of the liquid has evaporated, additional

heat results in only a small pressure rise inside the

element. Vapor charges are appropriate for low

temperature applications and others where the

bellows must be protected from deformation by

As long as the sensor is the coldest part of the

thermostat, ambient temperature has no eect on

regulating accuracy.

Sensors with adsorption charges contain

asuperheated gas together with a solid having

alarge adsorption surface. The sensor can be

placed in zones that are warmer or colder than the

control housing and capillary tube, but variations

of more than 70 °F may inuence scaleaccuracy.

ambient temperature.

The sensing element must be colder than the

bellows at all times so that condensation of

evaporated uid occurs in the element only, and

not in the bellows.

Bellows

Capillary tube

Sensor

Dimensions of KPU

withoutcapillary tube

All thermostats are supplied with universal

mountingbracket and mounting screws

asstandardaccessory.

Approximate weight of the bracket and mounting

screws: 0.615 lb

Net weight of KPU without capillary tube: ~ 0.77 lb

Net weight of 80 in capillary tube: ~ 0.17 lb

Net weight of 200 in capillary tube: ~ 0.43 lb

© Danfoss | DCS (jmn) | 2016.08 DKRCC.PD.CA0.F6.22 | 520H11320 | 6

Charges

KPU 61

KPU 63

Vapor charge

KPU 61

KPU 69

Vapor charge

KPU 62

KPU 68

Vapor charge

KPU 62

Adsorption charge

KPU 73

Adsorption charge

A

B

C

D

Straight capillary tube

Sensing length: 15 in

a = 3 1/8 in

Remote air coil

a = ⁄ in

b = 2 ¾ in

Room sensor C1

a = 1 ½ in

b = 1 ¼ in

Room sensor C2

a = 1 in

b = 3 in

Double contact remote bulb

a = ⁄ in

b = 3 ⁄ in

NOTE!

Can not be used in sensor pocket!

Remote bulb

KPU 73, KPU 74

Adsorption charge

KPU 71, KPU 75

Adsorption charge

KPU 73, KPU 77

Adsorption charge

KPU 75

Adsorption charge

E

F

E1

a = ¼ in

b = 3 ¾ in

E2

a = ⁄ in

b = 4 ½ in

E3

a = ⁄ in

b = 3 ⁄ in

Remote duct coil

a = 1 in

b = 3 ⁄ in

© Danfoss | DCS (jmn) | 2016.08 DKRCC.PD.CA0.F6.22 | 520H11320 | 7

Loading...

Loading...