Page 1

Data Sheet

Shut-off diaphragm valve

Type BML and BMT

With and without handwheel

The shut-o diaphragm valves BML and BMT

are designed for installation in the liquid,

suction and hot gas lines of refrigeration

circuits, in order to open and to shut o inner

refrigerant ow path by operating the

handwheel.

BML valves can be delivered with are, ODF

solder or ODF solder with extended ends.

In the same product category, BMT 6 is a threeway manual shut-o valve with similar

characteristics.

Features

• Fitted with three stainless steel diaphragms

that prevent leakage throughout the

operating life of the valve.

• Valve plate of polyamide nylon to give

complete shut-o with minimum torque.

• Valve cover with counter-seat to prevent the

ingress of moisture.

AI212386431516en-000901

Page 2

Danfoss

9G8091

Refrigerants

R134a, R22/R407C, R290, R404A/R507, R407H, R449B, R450A, R513A, R515B,

R516A, R600, R600a, R1234ze(E), R1234yf, R1270

Refrigerant oil

POE, PAG (PVE, PAO)

Technical data

Values

Max. working pressure

PS/MWP = 28 bar / 406 psig

Media Temperature range

-55 – 100 °C / -67 – 212 °F

Environmental transport/storage

temperature and humidity

-40 – 65 °C /-40 – 150 °F

Air humidity: RH≤95%

Shut-o diaphragm valve, Types BML and BMT

Applications

Application

Typical applications for BML and BMT valves are:

• Cold room

• Chiller

• Heat pump

• Transport refrigeration

Figure 1: Application

Media

Table 1: Media features

NOTE:

• For a complete list of approved refrigerants, visit http://store.danfoss.com/ and search for individual code

numbers, where refrigerants are listed as part of product details.

• This product is approved for R290, R516A, R600, R600a, R1234ze(E), R1234yf and R1270 by ignition source

assessment in accordance to standard EN ISO 80079-36.

• Flare connection is only approved for A1 and A2L refrigerants.

Product specication

Technical data

Table 2: Technical data

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 2

Page 3

Technical data

Values

Working range

Δp = -1 – 21 bar / -14 – 304 psig

Serviceable

Yes

Flow direction

Single ow

Box label

Handwheel

Danfoss

9G8092

Position

Inscription

Explanation

Box label

Shut-o diaphragm valve

Product name

Box label

BML 6s

Product type

Box label

009G0202

Code number

Box label

Straightway

Direction

Box label

With Hand wheel

Hand wheel type

Box label

¼ in Extended ends, ODF

Connection size and type

Box label

PS 28 bar/MWP 406 psig

Max. working pressure in bar and psig

Box label; Handwheel

Additional information: Relevant approval authority

logos

Box label

BE2720E

Code for production place and time

(BE = Wuqing, week 27, year 2020, weekday E =

Friday)

Box label; Handwheel

MADE IN CHINA

Manufacturing site acc. to EN standards

Box label

EAN code

Barcode for individual code no. identication according to EAN standard

Handwheel

OPEN

Open direction

Shut-o diaphragm valve, Types BML and BMT

Identication

Relevant product data is available on the product and box label. An example of a box label is shown, including an

explanation of the content.

Table 3: Box label (example)

Table 4: Product and label text

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 3

Page 4

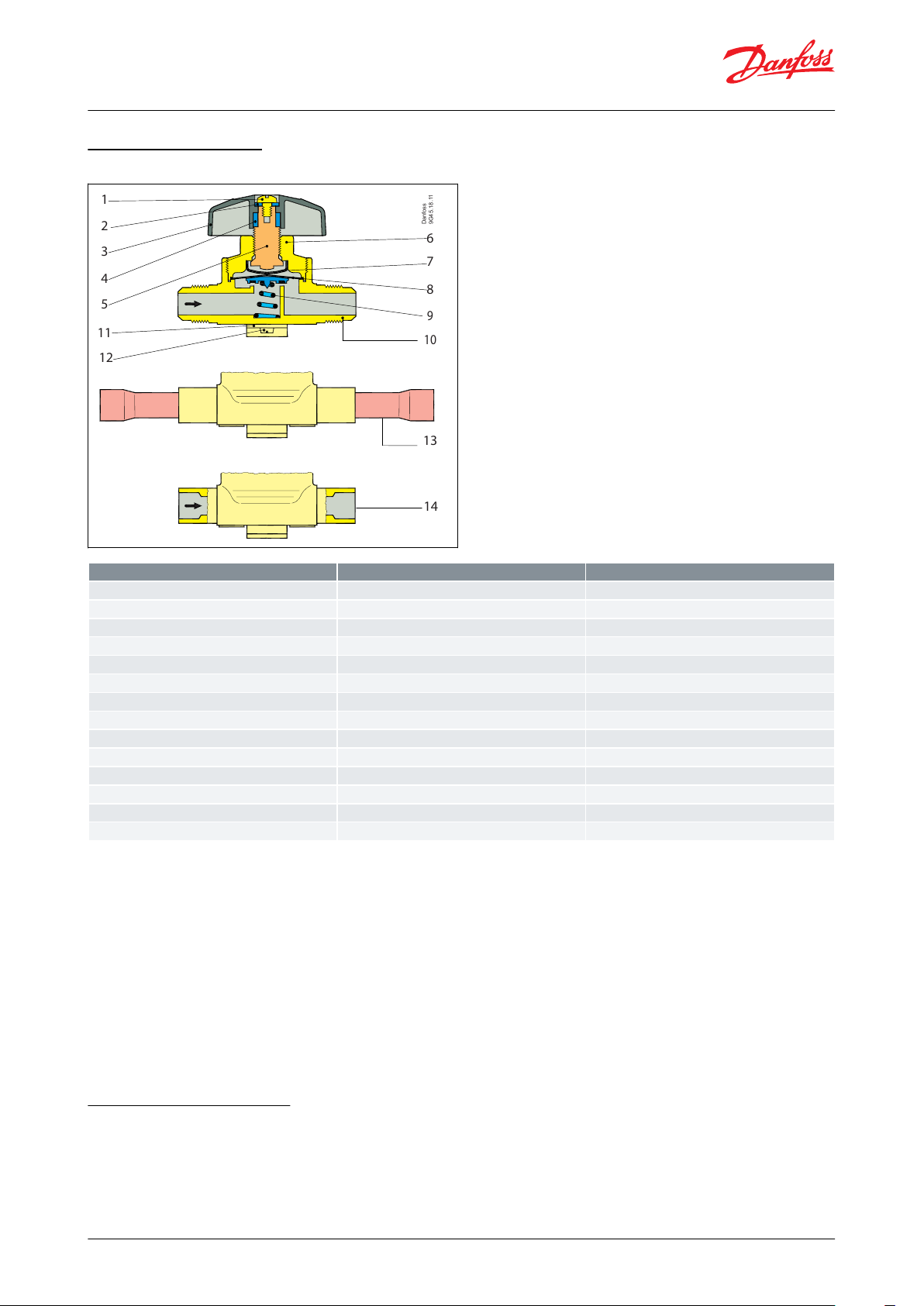

Danfoss

9G45.18

.11

13

14

8

6

7

10

9

1

2

3

4

5

11

12

Position

Description

Material

1

Screw

Steel with plating Zn

2

Lock washer

Steel with plating Zn

3

Handwheel

Plastic4Driver

Al alloy

5

Spindle

Brass6Cover

Brass7Thrust pad

Stainless steel

8

Diaphragm with sealing ring

Stainless steel + nylon

9

Spring

Steel with plating Zn

10

Flare connection

Brass11Bracket

Steel with plating Zn

12

Screw

Steel with plating Zn

13

ODF solder with extended ends

Copper

14

ODF solder connection

Brass

Shut-o diaphragm valve, Types BML and BMT

Design and Materials

Figure 2: Design and Materials

The shut-o diaphragm valves are tted with three diaphragms of stainless steel which ensure long operating life.

BM valves are available in straightway, and threeway versions (BMT). The side connection of the three-way BMT can

be shut o, but the end connections will always remain open. The BM can be tted with a mounting bracket. Valve

body, cover and spindle are made of brass, the handwheel (3) of coloured plastic. BM valves have a triple diaphragm

seal (8) which is designed in such a way that the tension in the diaphragms lift the valve plate from the seat when

the valve is opened.

The sealing ring itself is made of nylon and gives complete shut-o when the handwheel is lightly tightened. The

thrust pad (7) prevents direct contact between spindle (5) and diaphragms (8). This also contributes to increased

valve life. The spring (9) is able to hold the valve open at operating pressures down to -1 bar (pe). The counter-seat

in the cover (6) prevents the ingress of moisture in fully open position. When the valve is opened, the pressure on

the outlet side must not exceed the pressure on the inlet side by more than 1 bar.

Dimensions and weights

Dimensions and Weights

We have chosen to show dimensions of the major versions.

You will nd downloadable dimension drawings for individual code numbers on Danfoss store as part of the Visuals

tab for individual code numbers.

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 4

Page 5

BML

BMT

Type

SAE

Flare

Flare

Thread

Hand

wheel

H3H5LL3BB1B2

ød

Net

weight

Code no.

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

BML 6

1/4

7/16-20UNF-2A

Yes461577—6250505

0.3

009G0101

BML 6

1/4No471577—62—5050.3

009G0115

BMT 6

1/4

Yes46196532.56250505

0.3

009G0105

BML 10

3/8

5/8-18UNF-2A

Yes491585—6250505

0.3

009G0127

BML 12

1/2

3/4-16UNF-2A

Yes5618

102—70605660.6

009G0141

BML 15

5/8

7/8-14UNF-2A

Yes6619

118—83716960.8

009G0168

BML 18

3/4

1 1/16-14UNS-2A

Yes6624

130—83716961.3

009G0183

Shut-o diaphragm valve, Types BML and BMT

Weights also dier depending on the design of the individual code numbers. Weights are available as part of the

technical data for individual code numbers on Danfoss store.

Flare version

Table 5: Flare version

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 5

Page 6

B1

H

3

H

5

L1

L

L2

B

2

B

Ød

Danfoss

9G8094

Type

Inlet

connection

Extended ODF

solder

Outlet

connection

SAE Flare

Flare Thread

connection

Hand

wheel

H3H5LL1L2BB1B2ød

Net

weight

Code no.

[inch]

[mm]

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

BML 6

1/4-1/4

7/16-20UNF-2A

Yes45159739762505050.29

009G0119

BML 6-6

1/4No47159739762—505

0.24

009G0117

Shut-o diaphragm valve, Types BML and BMT

ODF solder extended end + are version

Figure 3: ODF solder extended end +

are version

Table 6: ODF solder extended end + are version

ODF solder extended ends version

Figure 4: ODF solder extended ends

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 6

Page 7

Type

Connection size

Connection toler‐

ance

Hand

wheel

H3H5LL2BB1B2

ød

Net

weight

Code no.

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

BML 6s

1/46+0.065/+0.155

Yes4617

117762505050.3

009G0202 /

009G0208

BML 6s-6

+0.065/+0.155

No4717

117762505050.3

009G0209

BML 10s

3/810+0.06/+0.13

Yes4916

117962505050.3

009G0222 /

009G0228

BML 10s

-10+0.06/+0.13

No5016

117962505050.3

009G0230

BML 12s

1/212+0.065/+0.155

Yes5518

1281070605660.5

009G0242 /

009G0248

BML 12s

-12+0.065/+0.155

No5718

1281070605660.5

009G0249

BML 15s

5/816+0.065/+0.155

Yes6620

1651283716960.8

009G0262

BML 22s

7/822+0.06/+0.13

Yes6622

1811783716960.9

009G0291

Type

Connection size

Connection tolerance

Hand

wheel

H3H5LL2BB1B2

ød

Net

weight

Code no.

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

BML 6s

1/4

6

+0.06/+0.13

Yes46176576250505

0.3

009G0102 /

009G0108

BML 10s

3/810Yes49167296250505

0.3

009G0122 /

009G0128

BML 12s

1/212Yes551887107060566

0.5

009G0142 /

009G0148

BML 15s

5/816Yes6520

1061283716960.8

009G0170

BML 18s

3/418Yes6622

1031483716960.8

009G0181 /

009G0184

BML 22s

7/822Yes6622

1031783716960.8

009G0191

Shut-o diaphragm valve, Types BML and BMT

Table 7: ODF solder extended ends

ODF solder version

Figure 5: ODF solder

Table 8: ODF solder

Connections

Standard BML versions are with connection types are, ODF solder or ODF solder with extended ends in a wide

variety of connection sizes. BMT versions are with are connection.For details on availability, see Ordering section.

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 7

Page 8

Connection type

Inlet

Outlet

mm connections

Inch connections

Flare

Flare

Flare

-

¼ in x ¼ in

⅜ in x ⅜ in

½ in x ½ in

⅝ in x ⅝ in

¾ in x ¾ in

ODF solder extended end +

are

ODF solder with extended end

Flare

6 mm x ¼ in

¼ in x ¼ in

ODF solder extended ends

ODF solder with extended end

ODF solder with extended end

6 mm x 6 mm

10 mm x 10 mm

12 mm x 12 mm

16 mm x 16 mm

22 mm x 22 mm

¼ in x ¼ in

⅜ in x ⅜ in

½ in x ½ in

⅝ in x ⅝ in

⅞ in x ⅞ in

ODF solder

ODF solder

ODF solder

6 mm x 6 mm

10 mm x 10 mm

12 mm x 12 mm

16 mm x 16 mm

18 mm x 18 mm

22 mm x 22 mm

¼ in x ¼ in

⅜ in x ⅜ in

½ in x ½ in

⅝ in x ⅝ in

¾ in x ¾ in

⅞ in x ⅞ in

Type

Connection

Type

SAE Flare

Kv value

Cv value

Multi pack

[in.]

[m3/h]

[gal/min]

Code no.

Qty/ pack

BML 6

Flare ext. × ext.

1/4

0.3

0.35

009G0101

20

BML 10

3/8

0.84

0.98

009G0127

20

BML 12

1/2

1.5

1.75

009G0141

12

BML 15

5/8

2.2

2.57

009G0168

12

BML 18

3/4

2.9

3.38

009G0183

12

Shut-o diaphragm valve, Types BML and BMT

Table 9: Connection diagrams

Ordering

BML code numbers described in this data sheet are standard code numbers, i.e. made to stock.Besides code

numbers made to stock

BML is also made to order. Make to order options include:

• Mechanical connection type

• Mechanical connection size

Multipack contains several items, individually packed, so that customers can purchase 1 item and receive all relevant

documentation.

Industrial pack contains several items that are not individually packed. Industrial packs cannot be broken down, and

will only contain documentation on pack level, not on item level.

Straightway version with hand wheel

Table 10: BML with are connections

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 8

Page 9

Type

Connection

Type

ODF solder connection

Kv value

Cv value

Multi pack

[in.]

[mm]

[m3/h]

[gal/min]

Code no.

Qty/ pack

BML 6s

Solder ODF × ODF

1/4-0.3

0.35

009G010220-60.3

0.35

009G0108

20

BML 10s

3/8-0.84

0.98

009G012220-100.84

0.98

009G0128

20

BML 12s

1/2-1.5

1.75

009G014212-121.5

1.75

009G0148

12

BML 15s

5/8162.2

2.57

009G0170

12

BML 18s

3/4-2.9

3.38

009G018112-182.9

3.38

009G0184

12

BML 22s

7/8222.9

3.38

009G0191

12

Type

Connection

Type

Extended ODF solder connection

Kv value

Cv value

Multi pack

[in.]

[mm]

[m3/h]

[gal/min]

Code no.

Qty/ pack

BML 6s

Solder ODF × ODF

1/4-0.3

0.35

009G020220-60.3

0.35

009G0208

20

BML 10s

3/8-0.84

0.98

009G022220-100.84

0.98

009G0228

20

BML 12s

1/2-1.5

1.75

009G024212-121.5

1.75

009G0248

12

BML 15s

5/8162.2

2.57

009G0262

12

BML 22s

7/8222.9

3.38

009G0291

12

Type

Connection

Type

Inlet connection

Extended ODF solder

Outlet

connection

SAE Flare

Kv value

Cv value

Multi pack

[in.]

[mm]

[in.]

[m3/h]

[gal/min]

Code no.

Qty/ pack

BML 6

Solder ODF ×

Flare ext.

1/4-1/4

0.3

0.35

009G0119

20

Shut-o diaphragm valve, Types BML and BMT

Table 11: BML with ODF solder connections

Table 12: BML with extended ODF solder connections

Table 13: BML with extended ODF solder + are connections

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 9

Page 10

Type

Connection

Type

SAE Flare

Kv value

Cv value

Multi pack

[in.]

[m3/h]

[gal/min]

Code no.

Qty/ pack

BMT 6

Flare ext. × ext.

1/4

0.3

0.35

009G0105

20

Type

Connection

Type

SAE Flare

Kv value

Cv value

Multi pack

[in.]

[m3/h]

[gal/min]

Code no.

Qty/ pack

BML 6

Flare ext. × ext.

1/4

0.3

0.35

009G0115

20

Type

Connection

Type

Extended ODF solder connection

Kv value

Cv value

Multi pack

[in.]

[mm]

[m3/h]

[gal/min]

Code no.

Qty/ pack

BML 6s

Solder ODF × ODF

-60.3

0.35

009G0209

20

BML 10s-10

0.84

0.98

009G0230

20

BML 12s-12

1.5

1.75

009G0249

12

Shut-o diaphragm valve, Types BML and BMT

Threeway version with hand wheel

Table 14: BML with are connections

Straightway version without hand wheel

Table 15: BML with are connections

Table 16: BML with extended ODF solder connections

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 10

Page 11

Type

Connection

T

ype

Inlet connection

Ex

tended ODF solder

Outlet

c

onnection

SAE Flare

Kv value

Cv value

Multi pack

[in.]

[mm]

[in.]

[m3/h]

[gal/min]

Code no.

Qty/ pack

BML 6

Solder ODF ×

F

lare ext.

-61/4

0.3

0.35

009G0117

20

Danfoss

9G8095

3

2

1

Position

Description

Qty.

1

Diaphragm assembly with sealing ring

12Diaphragm

2

3

Bag with grease

1

Shut-o diaphr

agm valve, Types BML and BMT

Table 17: BML with extended ODF solder + ar

Accessories

igure 6: Accessories

F

e connections

Figure 7: Diaphragm kit

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 11

Page 12

Type

Valve connection size

Multi pack

[inch]

[mm]

Code no.

Qty/ pack

BML 6 and BMT 6

1⁄4

6

009G0025

12

BML 10

3⁄8

10

009G0026

12

BML 12

1⁄2

12

009G0027

12

BML 15

5⁄8

16

009G0028

12

BML 18 and BML 22

3/4 – 7/8

18 – 22

009G0029

12

Type

Valve connection size

Industrial pack

[inch]

[mm]

Code no.

Qty/ pack

BML 6 and BMT 6

1⁄4

6

009G0020

75

File name

Document type

Document topic

Approval authority

RU Д-DK.БЛ08.B.03634

EAC Declaration

Machinery & Equipment

EAC

033F4001.AE

Manufacturers Declaration

PED

Danfoss

033F4006

Manufacturers Declaration

China RoHS

Danfoss

033F4010

Manufacturers Declaration

RoHS

Danfoss

033F4017.AA

Manufacturers Declaration

EN ISO 14903:2017 Level B1

Danfoss

UA.089.D.00188-17

UA Declaration

PED

LLC CDC EURO TYSK

UA.TR-089.0993-17

Pressure - Safety

Certicate

PED

LLC CDC EURO TYSK

UL SA7200

Mechanical - Safety

Certicate

UL

UL

Shut-o diaphragm valve, Types BML and BMT

Figure 8: Diaphragm with sealing ring

Table 18: Diaphragm with sealing ring

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 19: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 12

Page 13

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI212386431516en-000901 | 13

Loading...

Loading...