Instruction

Instruction

APP pump instruction

APP pumps

APP 11 / APP 13 / APP 16 /

APP 11-13 and APP 16-22

APP 17 / APP 19 / APP 22

www.ro-solutions.com

hpp.danfoss.com

Instruction | APP 11-13 and APP 16-22

Table of Contents

1. Identication ...........................................................................2

2. System design ..........................................................................3

2.1 Open-ended systems with direct water supply ..........................................3

2.2 Preferred RO system design and P&ID ...................................................4

2.3 Reversible pumps .......................................................................4

2.4 General comments on...................................................................4

3. Building up the pump unit ..............................................................5

3.1 Mounting ..............................................................................5

3.2 Direction of rotation ....................................................................6

3.3 Orientation .............................................................................6

3.4 Protection against too high outlet pressure ..............................................7

3.5 Connections ............................................................................7

4. Initial start-up ...........................................................................9

5. Operation..............................................................................10

5.1 Temperature...........................................................................10

5.2 Pressure ...............................................................................10

5.3 Dry running............................................................................10

5.4 Disconnection .........................................................................10

5.5 Storage ................................................................................10

5.5.1 Recommended procedure .............................................................10

6. Service.................................................................................11

6.1 Warranty ..............................................................................11

6.2 Maintenance...........................................................................11

6.3 Repair .................................................................................11

1. Identication

PUMP

Type APP 16

Code no. 180BXXXX

Serial no. XXXXXXXX-XXX

MADE IN DENMARK

Danfoss A/S, 6430 Nordborg, Denmark

2

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

Instruction | APP 11-13 and APP 16-22

2. System design The design of the system must ensure that

self-emptying of the pump during standstill is

avoided.

The inlet pressure of the pump must never

exceed the outlet pressure. This may typically

occur in boosted or open-ended systems with

direct water supply.

2.1 Open-ended systems with direct

water supply

The pump is supplied with water direct from a

feed pump.

In order to eliminate the risk of cavitation, a

positive inlet pressure of at least 2 barg (29 psig)

is always to be maintained, but it must not

exceed 5 barg (72.5 psig) continuously.

1. Place the lter (1) in the water supply line in

front of the pump.

2. Place a monitoring pressure switch (3)

between lter and pump inlet - set at min.

2 barg (29 psig) inlet pressure. The

monitoring pressure switch must stop the

pump at pressures lower than 2 barg

(29 psi g) inlet pressure.

3. Install a low pressure safety valve or a low

pressure relief valve (4) in order to avoid

system or pump damage in case the pump

stops momentarily (high-pressure peaks) or

starts spinning backwards.

Note: If a non return valve (2) is mounted in the

inlet line, a low-pressure relief valve is also

required between non return valve and pump

as protection against high-pressure peaks.

1

2

3

PS

Inlet

4

Outlet

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

3

Instruction | APP 11-13 and APP 16-22

2.2 Preferred RO system design and P&ID

1. Dimension the inlet line to obtain minimum pressure loss (large ow, minimum

pipe length, minimum number of bends/

connections, and ttings with small

pressure losses).

2. Place an inlet lter (1) in front of the APP

pump (2). Please consult the Danfoss lter

data sheet for guidance (521B1009) on how

to select the right lter. Thoroughly clean

pipes and ush system prior to start-up.

3. Place a monitoring pressure switch (3) set

at min. inlet pressure between lter and

pump inlet. The monitoring switch must

stop the pump at pressures lower than

minimum pressure.

4. Use exible hoses (4) to minimize vibrations

and noise.

5. In order to eliminate the risk of damage

and cavitation, a positive pressure at the

inlet (5) is always to be maintained at min.

inlet pressure and max. inlet pressure.

Recommend to install safety valve or a

pressure relief valve (9) in order to avoid

high-pressure peaks in case the pump

stops momentarily or starts spinning

backwards.

6. For easy system bleeding and ushing, a

bypass non-return valve (6) is integrated in

the APP pump.

7. A non-return valve (7) in outlet can be

installed in order to avoid backspin of the

pump. The volume of water in the membrane vessel works as an accumulator and

will send ow backwards in case of the

pump stops momentarily.

8. A safety valve or a pressure relief valve (8)

can be installed in order to avoid system

damage as the Danfoss APP pump creates

pressure and ow immediately after

start-up, regardless of any counter

pressure.

Note: If a non-return valve is mounted in the

inlet line, a low-pressure relief valve is also

required between non return valve and pump

as protection against high-pressure peaks.

Media filter

9 3

1

PT

Feed

PI

PI

1

PI PI

5

Fresh water

permeat flush

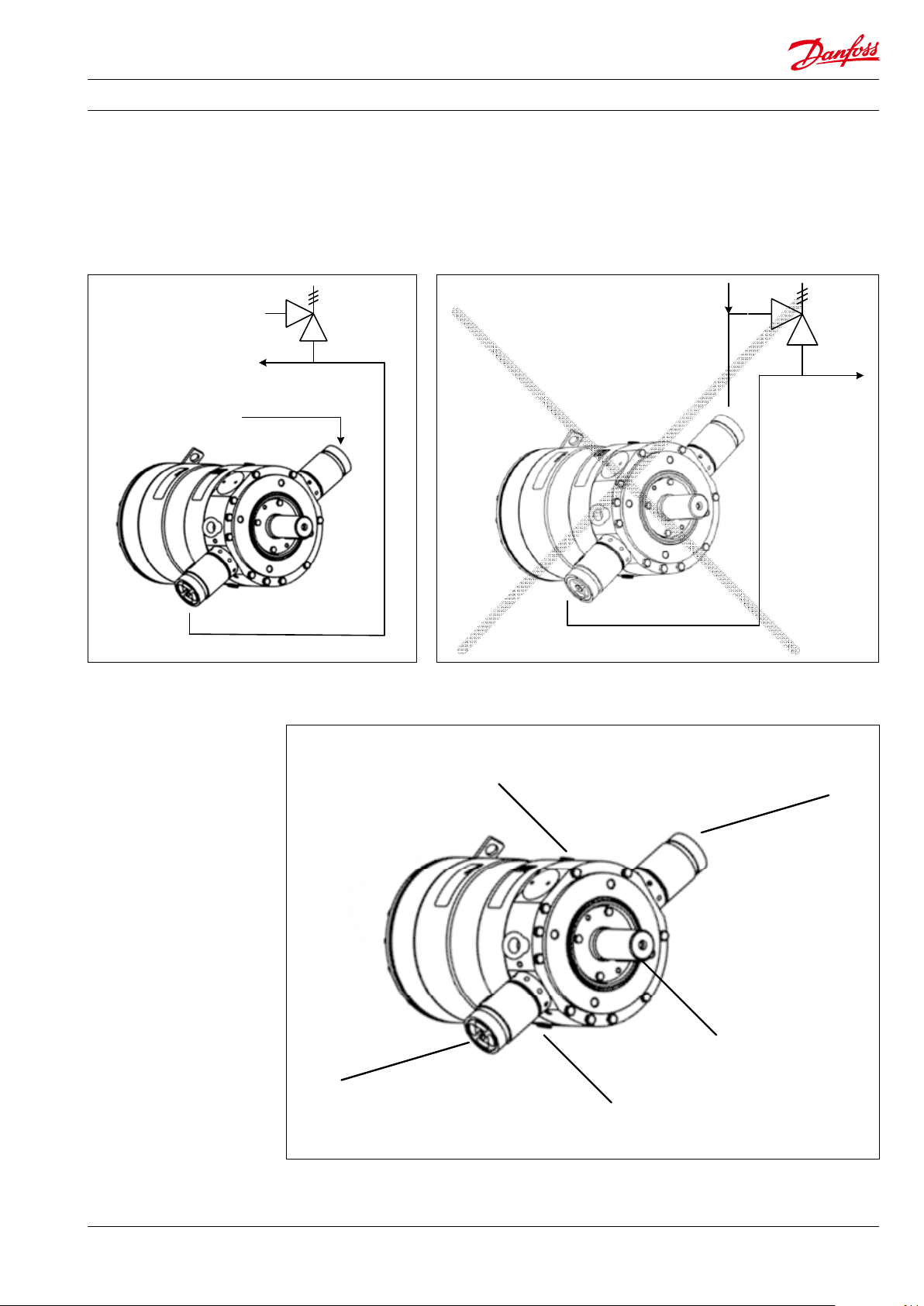

2.3 Reversible pumps

If exposed to high pressure in the outlet while the

electric motor is not energized, the pump will start

spinning backwards. This will not harm the pump

as long as the pressure in the inlet does not exceed

the max. pressure peak of 10 barg (145 psig).

If a non-return valve is mounted in the inlet line,

a low-pressure relief valve is also required as

protection against high-pressure pulses and high

pressure in general.

Alternatively a high-pressure check valve can be

mounted in the pump discharge line to prevent

the pump from reversing.

The dotted setup ensures that the inlet pressure

does not exceed 10 barg (145 psig), when a

non-return valve is mounted in the inlet.

Attention: In order to avoid the risk of cavitation, the inlet pressure at the pump must be

min. 2 barg (29 psig).

The inlet line connection must be properly

tightened, as possible entrance of air will cause

cavitation.

M

2

7

8

PI

Permeate

4

6

PI

Brine

2.4 General comments on

Filtration

A good ltration is vital to ensure a long and

trouble free life of the pump.

As water has very low viscosity, the APP pumps

have been designed with very narrow clearance

in order to control internal leakage rates and

improve component performance. Therefore it is

important that the inlet water is ltered properly

to minimize the wear of the pump.

The main lter must have a ltration eciency of

99.98% at 10 µm. We recommend to use

precision depth lter cartridges rated 10 µm abs.

≥

ß

5000 (equivalent to a ltration eciency of

10

99.98%). Bag lters and string wounded lter

cartridges typically have only 50% ltration

eciency. This means that for each 100,000

particles reaching the lter, 50,000 particles pass

through it compared to only 20 particles in a

lter with an eciency of 99.98%.

4

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

Instruction | APP 11-13 and APP 16-22

3. Building up the

pump unit

For more information on the importance of

proper ltration, please consult our data sheet

“Filtration” (521B1009), which also will provide

you with an explanation of ltration denitions

and a guidance on how to select the right lter.

3.1 Mounting

3-5 mm (0.12-0.2 inch)

1: Bolts and nuts: torque 75 Nm ± 5 Nm

2: Bolts and nuts: torque 40 Nm ± 4 Nm

3: Torque see table below

1

Monitoring

It is recommended to continuously monitor the

following conditions:

• lter clogging

• pressure (inlet- and outlet side of the pump)

A: Elastic coupling

B: Bell housing

C: Motor shaft

D: Pump ange

3

2

2

C

1

Thread

size

Torque

(Nm)

1. Mount the coupling ush or maximum

1 mm oset from the pump shaft end.

Ensure an air gap between coupling parts

of 3-5 mm (0.12-0.2 inch).

2. Mount the bell housing on pump. Secure

nuts with the right torque.

3. Measure the longest distance “A” from top

of bell housing to the button of coupling

claw.

4. Mount the coupling on motor shaft. Ensure

the coupling and motor ange are not in

contact with each other.

5. Measure from motor ange to the top of

the coupling. That measurement “B” shall

be 3-5 mm (0.12 - 0.2 inch) shorter than the

measurement “A”.

M4 M5 M6 M8 M10 M12 M16

1.5 2 4.8 10 17 40 80

6. Adjust respectively, verify the measurement, and secure both couplings with the

right torques on the locking screws (see

coupling operation & mounting instruction).

7. Mount the elastic gear ring and mount the

bell housing/pump on the motor. After

mounting it must be possible to move the

elastic gear ring 3-5 mm (0.12 - 0.2 inch)

axial “C”. The check can be done through

the inspection hole of bell housing. Secure

ange bolts with the right torque.

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

5

Instruction | APP 11-13 and APP 16-22

If alternative mounting is desired, please contact

Danfoss High Pressure Pumps.

Choose proper tolerances to ensure an easy

mounting of the elastic coupling without use of

tools.

Please take care to observe the recommended

length tolerances of the chosen coupling, as an

axial force on the pump will damage the pump.

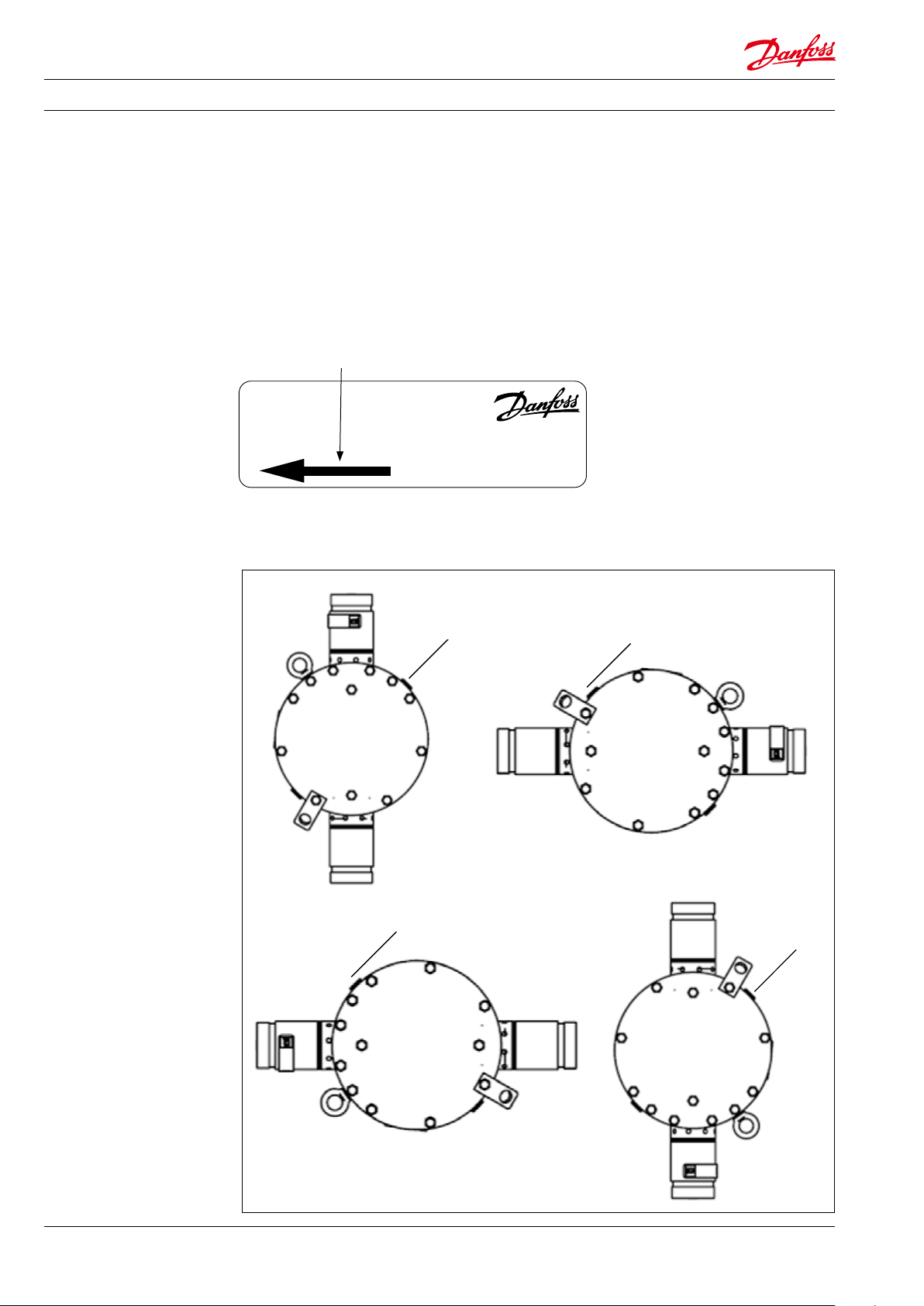

3.2 Direction of rotation

Is indicated by means of an arrow on the pump

label.

PUMP

Type APP 16

Code no. 180BXXXX

Serial no. XXXXXXXX-XXX

3.3 Orientation

The pump can be mounted/orientated in any

horizontal direction with the inlet and the outlet

pointing upwards, downwards or to either side.

MADE IN DENMARK

Danfoss A/S, 6430 Nordborg, Denmark

C

C

C

C

C - Bleeding

C

C

C

C

6

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

Instruction | APP 11-13 and APP 16-22

3.4 Protection against too high

outlet pressure

The pump should be protected against too high

outlet pressure by means of a safety valve or a

pressure relief valve. The valve should be placed

as close to the pump as possible. The opening

characteristics of the valve must not result in

peak pressures higher than 80 barg (1160 psig).

Inlet

Both the inlet and outlet lines must be exible

soft hoses.

The valve outlet must not be connected

directly to the pump suction line. It must be

connected directly to the drain.

Inlet

Outlet

3.5 Connections

I : Inlet

O : Outlet

C : Bleeding

D : Parallel key

Outlet

C

I

O

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

D

C

7

Instruction | APP 11-13 and APP 16-22

APP 11 - APP 13

Description APP 11 - APP 13

Parallel key,

DIN 6885

Bleeding

Inlet port

Outlet port

Pump mounting

ange

mm

10 × 8 × 45

inch

0.39 × 0.31 × 1.77

G ¼”, Hexagon AF = 6 mm

M42 x 1.5; depth 17 mm

M42 x 1.5; depth 17 mm

125 B 4

APP 16 – APP 22

Description APP 16 – APP 22

Parallel key,

DIN 6885

Bleeding

Inlet port

Outlet port

Pump mounting

ange

mm

12 × 8 × 70

In

0.47 × 0.31 × 2.76

G ¼”, Hexagon AF = 6 mm

M52 x 1.5; depth 21 mm

M52 x 1.5; depth 21 mm

125 B 4

Accessories Typ e Code no.

2” inlet hose kit

2 m / 79”

2” inlet Vic.

Super Duplex

Non-return

valve (outlet)

Super Duplex

2” Victaulic 180Z0298

2” Victaulic 180Z0166

1,5” Victaulic

180H0 053

(OD 48.3 mm)

For more details on the accessories, please

contact Danfoss High Pressure Pumps.

Accessories Typ e Code no.

2” inlet hose

kit 2 m/79”

2” inlet Vic.

Super Duplex

Non-return

valve (outlet)

Super Duplex

2” Victaulic 180Z0298

2” Victaulic 180Z0165

2” Victaulic

180H0256

(OD 63 mm)

For more details on the accessories, please

contact Danfoss High Pressure Pumps.

8

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

Instruction | APP 11-13 and APP 16-22

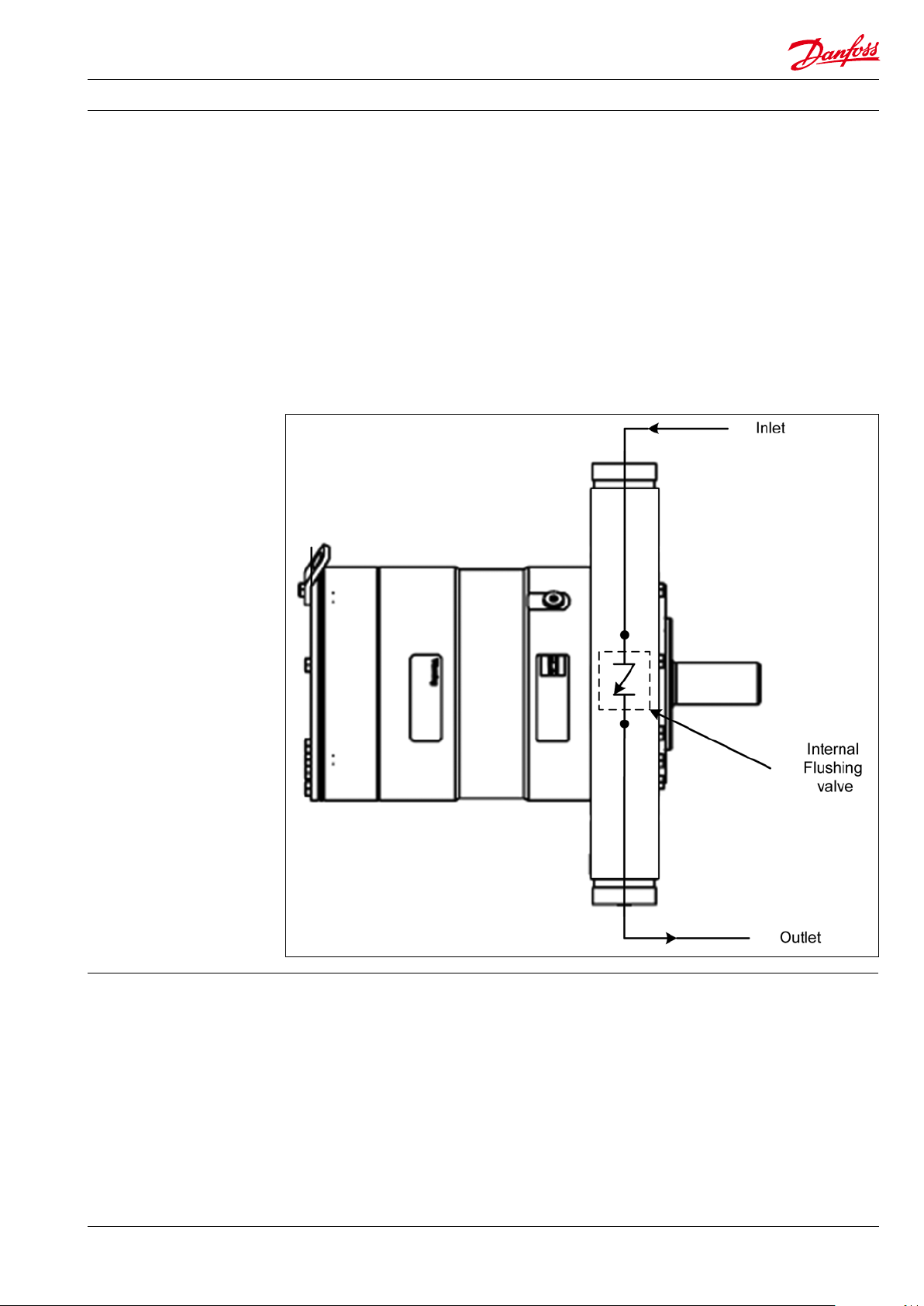

4. Initial start-up 1. Flush inlet line before connecting the

pump, to remove possible impurities from

pipes, hoses etc.

2. Connect pump inlet to inlet line and ush

the pump for 5 min. by means of the

internal ushing valve, to remove possible

impurities from pipes, hoses etc.

3. Loosen top bleeding plug “C” (see item 3.3)

using an allen key (only plugs with internal

hexagan sockets). Retighten the plug,

when water appears from the bleeding

plug.

4. Make sure that the direction of rotation of

the electric motor corresponds to the

direction of rotation of the pump (see label

on pump).

5. Now the pump is ready for start-up.

Warning:

Make sure that the direction of rotation of the

electric motor corresponds to the direction of

rotation of the pump (see label on pump).

Otherwise the pump will be damaged if a

check valve is placed between pump and feed

pump.

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

9

Instruction | APP 11-13 and APP 16-22

5. Operation

5.1 Temperature

Fluid temperature:

Min. +2° C to max. +50° C

(Min. +35.6° F to max. +122° F)

Ambient temperature:

Min. +2°C to max. +50°C

(Min. +35.6°F to max. +122°F)

In case of lower operating temperatures, please

contact the Danfoss High Pressure Pumps.

º

80

C

Duplex

70

60

50

316L

40

30

The chart below illustrates the corrosive

resistance of dierent types of stainless steel

related to NaCl concentration and temperature.

The APP water pump is made of Duplex and

Super Duplex. If the water pump is operated

above the Super Duplex line, always ush water

pump with fresh water at operation stop in order

to minimise the risk of crevice corrosion.

Super Duplex

20

100

1000

160 1600

5.2 Pressure

The inlet pressure for APP 11-13 and APP 16-22

must be min. 2 barg (29 psig) and max. 5 barg

(72.5 psig).

At lower pressures the pump will cavitate,

resulting in damage of the pump.

Max. inlet pressure peak (e.g. in case the pump

stops momentarily) up to 10 barg (145 psig) are

acceptable.

Max. pressure on the pump’s outlet line should

be limited at 80 barg (1160 psig) continuously.

NB: The pump unit should include a pressure

gauge on the high-pressure side.

5.3 Dry running

When running, the pump must always be

connected to the water supply in order to avoid

damage if it should run dry.

5.4 Disconnection

If the inlet line is disconnected from the water

supply, the pump will be emptied of water

through the disconnected inlet line. When

starting up again, follow the bleeding pro cedure

described under section 4: Initial start up.

-

10 000

16000

5.5 Storage

Storage temperature:

Min. -40°C to max. +70°C

(Min. -40°F to max. +158°F)

When preparing the pump for long-term storage

or for temperatures below the freezing point,

ush the pump with an anti-freeze medium type

monopropylene glycol to prevent internal

corrosion or frost in the pump.

For further information on anti-freeze media,

please contact Danfoss High Pressure Pumps.

5.5.1 Recommended procedure

1. Disconnect the water supply to the pump.

2. Through the lower bleeding plug, empty

the pump housing of water and close it

again.

3. Connect the pump to a tank containing

anti-freeze additive. Connect a hose to the

inlet port of the pump and via another

hose return the ow from the outlet port to

the tank with anti-freeze additives.

4. Quickly start and stop the pump. Make

sure that the pump does not run dry.

The pump is now protected against

internal corrosion and frost.

100 000

160000

CI

ppm

NaCI

ppm

10

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

Instruction | APP 11-13 and APP 16-22

Storage:

Storage of pump that have been in operation:

For shorter periods of storage ush the pump

with permeate rotating the pump for 10 sec.,

empty permeate and store.

For long term storage (more than 2 months)

Danfoss recommends sevicing the product and

clean any biological growth of the surfaces. Store

the pump dry without water inside.

6. Service 6.1 Warranty

Danfoss APP pumps are designed for long

operation, low maintenance and reduced

lifecycle costs.

Provided that the pump has been running

according to the Danfoss specications, Danfoss

guarantees 8,000 hours service-free operation,

however, max 18 months from date of production.

If Danfoss recommendations concerning

system-design are not followed, it will strongly

inuence the life of the APP pumps.

6.2 Maintenance

After 8,000 hours of operation it is strongly

recommended to inspect the pump and change

any worn parts, e.g. pistons and shaft seal. This is

done in order to prevent a potential breakdown

of the pump. If the parts are not replaced, more

frequent inspection is recommended according

to our guidelines.

Stand still

The APP pumps are made of Duplex/Super

Duplex materials with excellent corrosion

properties. It is however, always recommended

to ush the pump with freshwater when the

system is shut down.

When stopping the pump for more than 1 day

ush the pump with permeate by rotating the

pump for 10 sec. Flushing through the ushing

valve of the pump without rotating the pump is

not enough for cleaning the inside of the pump.

The pump can ushed with biocide like the

membranes. The biocide must be compatible

with the materials used in our pump (materials

can be found in the parts list in the Operating

guide).

6.3 Repair

In case of irregular function of the APP, please

contact Danfoss High Pressure Pumps.

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 10.2019

11

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2019.10

180R9223 | 521B1184 | DKCFN.PI.013.T3.02 | 12

Loading...

Loading...