Service guide

APP pumps

APP 0.6 - 1.0

Disassembling and assembling

hpp.danfoss.com

Service guide | Disassembling and Assembling, APP 0.6-1.0

Table of Contents

Contents

Introduction ................................................................................................................................................................................2

1. Disassembling and assembling the pump .............................................................................................................3

2. Removal of flushing valve.............................................................................................................................................6

3. Change of shaft seal .......................................................................................................................................................7

4. Exploded view APP 0.6-1.0 ........................................................................................................................................ 10

Introduction

NOTE: If the pump is disassembled within the warranty period, the pump is no longer covered

by the warranty.

This document covers the instructions for

disassembling and assembling the axial piston

pump APP 0.6-1.0

Important: It is essential that the pump is

serviced in conditions of absolute cleanliness.

To understand the pump design better, please

see exploded view on last page.

Tools needed:

• Shaft seal tool (code no. 180B4142)

• Seal set (code no. 180B4141)

• 2 Screwdrivers

WARNING: Do not reuse disassembled O-ring

or shaft seal as they might be damaged.

© Danfoss | DCS (im) | 2017.082 | 180R9092 | DKCFN.PI.013.EC5.02 | 521B0739

Service guide | Disassembling and Assembling, APP 0.6-1.0

1. Disassembling and

assembling the pump

1. Unscrew the 4 mounting screws and

remove seal SAE flange.

Do not yet unscrew the 2 lower screws.

3. Unscrew the 2 lower screws.

2. Wet the shaft and shaft seal with clean

(filtered) soap water. Gently lever the shaft

seal assembly free using 2 screwdrivers.

4. Carefully turn the whole pump over so

that the shaft is facing down. Support the

pump in a suitable hollow base so that the

pump is not supported by the shaft.

5. Remove the housing.

© Danfoss | DCS (im) | 2017.08 180R9092| DKCFN.PI.013.EC5.02 | 521B0739| 3

6. Remove the pistons, retaining plate,

retaining ball, spring guide, and spring

from the cylinder barrel.

Service guide | Disassembling and Assembling, APP 0.6-1.0

7. Remove the cylinder barrel.

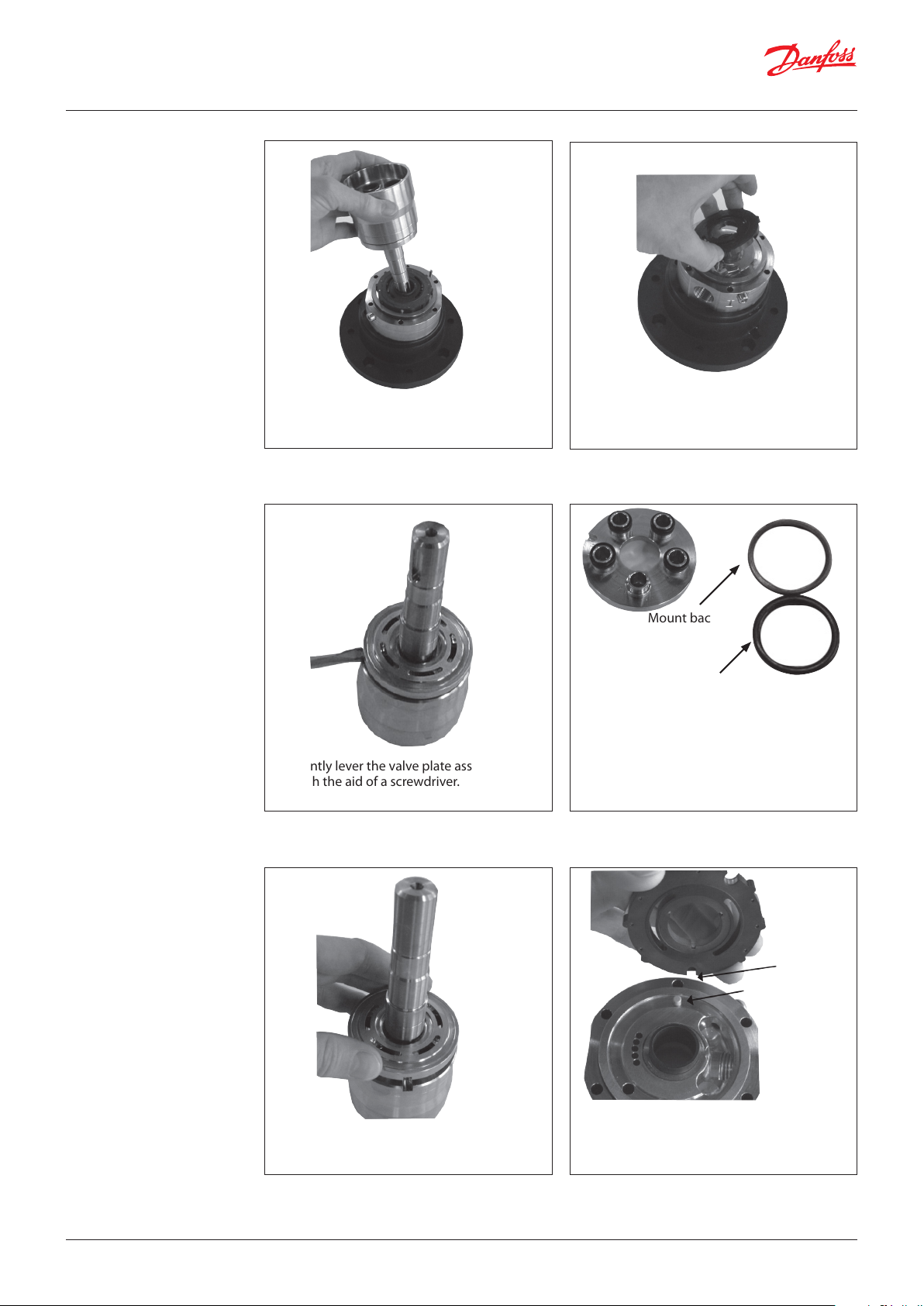

9. Gently lever the valve plate assembly free

with the aid of a screwdriver.

8. Remove the port plate and guide pin.

Mount backup

ring first

Then mount

O-ring

10. Replace the O-rings and the back-up rings

on the valve plate. Mount the new back up rings on the new valve plate first and

then mount the new O-rings.

Wet the O-rings and back-up rings with

clean (filtered) soap water.

11. Gently press, by hand, the valve onto the

cylinder barrel.

Locating hole

Guide pin

12. Position the port plate over the guide pin.

IMPORTANT: Make sure that the guide

pin is located in the locating hole in the

port plate

© Danfoss | DCS (im) | 2017.084 | 180R9092 | DKCFN.PI.013.EC5.02 | 521B0739

Service guide | Disassembling and Assembling, APP 0.6-1.0

O-ring

13. Replace O-ring on the port flange and

position the new cylinder barrel on the

port plate.

15. Position the housing on the port flange

and over the guide pin.

14. Position the new spring, new spring

guide, new retaining ball, new retainer

and new pistons.

16. Hold the pump topgether and carefully

turn it over to rest on the housing. To

prevent seizing-up, lubricate the threads

on the 2 screws and screw them into the

port flange and the housing. Use Molykote

D paste from Dow Corning or Klüber UH1

84-201 from Klüber lubrication. Tighten

the 2 flange screws accordiing to exploded

view.

18. Replace the O-ring on the SAE flange.17.Mount the new shaft seal following the

instructions on page

© Danfoss | DCS (im) | 2017.08 180R9092| DKCFN.PI.013.EC5.02 | 521B0739| 5

Service guide | Disassembling and Assembling, APP 0.6-1.0

19. Lubricate the threads on the 4 screws with

grease and screw them into the pump and

tighten by hand. Use Molykote D paste

from DOW Corning or Klüber UH1 84-201

from Klüber lubrication.

Tighten screws according to exploded

view.

2. Removal of flushing valve

1.. Use a pointed plier to remove flushing

valve. Gently grab the pin with the plier

and pull it out.

3. To assemble the valve, press new spring

onto shoulders of poppet guide and

poppet so it is stuck on both shoulders.

Then mount the new O-ring on poppet

guide.

2. Assemble the new flushing valve, or

replace parts that are worn (shoulders)

4. Turnflushing valve upside down. If it is not

properly assembled spring will fall off.

© Danfoss | DCS (im) | 2017.086 | 180R9092 | DKCFN.PI.013.EC5.02 | 521B0739

Service guide | Disassembling and Assembling, APP 0.6-1.0

5. Mount flushing valve by pressing it into

the hole.

3. Change of shaft seal

6. It must be pressed down so it levels with

the surface of the port flange (same level).

In order to find out if the valve is

working correctly, the pump needs to

be further dismantled. To work correctly

a small flat edged wire is pushed against

the flushing valve. You should be avle to

move it a couple of mm and feel the load

of the spring pressing backwards.

Recessed

screws

Tools needed

Recessed

screws

1. Unscrew the 4 mounting screws and

remove the seal SAE flange.

Do not unscrew the 2 recessed screw at

this time.

2. Wet the shaft and shaft seal with

clean (filtered) soap-water. Gently lever

the shaft seal assembly free with the aid of

2 screwdrivers.

© Danfoss | DCS (im) | 2017.08 180R9092| DKCFN.PI.013.EC5.02 | 521B0739| 7

Service guide | Disassembling and Assembling, APP 0.6-1.0

3. Fit the hollow bush (torpedo) to the shaft.

Wet the torpedo and replacement shaft

seal with soap. Do not use silicone

grease.

5. Using the plastic tool provided, large

diameter first, press the seal home against

the shoulder, by hand.

4. Slide the shaft seal over the torpedo with

the carbon seal face pointing upwards. Be

careful not to damage the carbon seal

face on the shaft seal.

6. Remove ceramic ring from the flange.

7. Push the new ceramic ring into the flange

using the plastic tool provided. Make sure

the face with the rubber seal is positioned

against the shoulder in the flange.

Wet the parts with clean (filtered) soap water before assembly.

8. Position the O-ring on the seal SAE flange.

© Danfoss | DCS (im) | 2017.088 | 180R9092 | DKCFN.PI.013.EC5.02 | 521B0739

Service guide | Disassembling and Assembling, APP 0.6-1.0

9. To prevent cold welding, lubricate

threads on the 4 screws with grease and

screw them into the pump and tighten

by hand. Use Molykote® D paste from Dow

Corning or Klüber UH1 84-201 from Klüber

lubrication. Tighten the 4 flange screws

according to exploded view.

© Danfoss | DCS (im) | 2017.08 180R9092| DKCFN.PI.013.EC5.02 | 521B0739| 9

Service guide | Disassembling and Assembling, APP 0.6-1.0

4. Exploded view

APP 0.6-1.0

© Danfoss | DCS (im) | 2017.0810 | 180R9092 | DKCFN.PI.013.EC5.02 | 521B0739

Service guide | Disassembling and Assembling, APP 0.6-1.0

© Danfoss | DCS (im) | 2017.08 180R9092| DKCFN.PI.013.EC5.02 | 521B0739| 11

Danf

already on order pro

All trademarks in this material are property of the respec

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

© Danfoss | DCS (im) | 2017.08

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

180R9092 | DKCFN.PI.013.EC5.02 | 521B0739| 12

Loading...

Loading...