Data sheet

Zone valves

AMZ 112, AMZ 113

Description

The ON/OFF zone valves type AMZ 112 and

AMZ 113 are typical used in connection with:

• Commercial central heating

applications

• Solar energy plants

• HVAC

• Priority control of hot water supply and

heating (diverting function)

• Priority control of boiler and solid fuel

installations (diverting function).

The ON/OFF zone valves can be applied

together with most Danfoss Room Thermostats,

particularly type RET 230 (single poled switch)

and programmable Room Thermostats type

RET 1000/2000. Other compatible room

thermostats are available, please see

www.danfoss.com/heating for details.

Features:

• Indication of actual valve position;

• LED indication of turning direction;

• Manual valve turning mode enabled by a

permanent clutch;

• No damage in case of valve blocking;

• Silent and reliable operation;

• Maintenance free;

• Integrated AUXILIARY switch;

• LED indication of activated AUXILIARY switch.

Main Data:

• Nominal voltage:

- 230 V AC, 50/60 Hz

- 24 V AC, 50/60 Hz

• Rotation angle 90°

•

Actuator running speed:

- DN 15-20:

30 sec / 90°

AMZ 112

- DN 25-50: 60 sec / 90°

•

Actuator running speed:

-

DN 15:

30 sec / 90°

AMZ 113

- DN 20-32: 60 sec / 90°

•

Control signal: 2-point

Ordering AMZ 112 2-port valve/actuator

k

DN

20 28 Cu-Cu 22

15 17 Rp ½ 082G5406 082G5400

20 28 Rp ¾ 082G5407 082G 5401

25 39 Rp 1 082G5408 082G5402

32 84 Rp 1¼ 082G5409 082G5403

40 156 Rp 1½ 082G5410 082G5404

50 243 Rp 2 0 82 G5411 082G5405

VS

(m3/h) 230 V 24 V

AMZ 113 3-port valve/actuator

k

DN

15 4.3 Rp ½

20 8.3 Rp ¾ 082G5 419 082 G5413

25 13 Rp 1 0 82G5420 0 82G5 414

32 21 Rp 1¼ 082G 5421 08 2G5415

VS

(m3/h) 230 V 24 V

Connection Control type

Accessories

Typ e Code No.

AUX switch ring AMZ 082G1635

Junction box 24V 082G1636

Replacement actuator AMZ 112/113 24V 15 Nm 082G1637

Replacement actuator AMZ 112/113 230V 15 Nm 082G1638

Linkage kit AMZ 112/113 082G1639

Connect. Control type

2-point

2 - point

Code No.

- 082G5427

Code No.

082G5 418 0 82G5 412

© Danfoss | 2021.08 AI192386478433en-010803 | 1

Data sheet AMZ 112, AMZ 113

Technical data Actuator

Power supply 2-point V 24 ac or 230 ac

Power consumption VA

1)

5 Nm is 30 sec/90°; 10, 15 Nm is

60 sec/90°

Frequency Hz 50/60

Running speed

Control type 2-point

Operating torque Nm 5, 10, 15

Rotation angle 90 °

Auxiliar y switch adjustable 0-90°

Auxiliar y switch max. load A 6 (24V ac, 230V ac)

Max. medium temperature

Ambient temperature 0 … 50

Storage and transport temperature −10 … 80

Protection Class II according to EN 60730-1

Grade of enclosure IP42 according to EN 60529

Weight

Color / material dark grey/PC

- marking in accordance with standards

1)

AMZ 112: 2.5

AMZ 113: 3.5

2-point sec/90° 15/60

110

°C

AMZ 112

AMZ 113 906

g

Low Voltage Directive 2006/95/EC

EMC-Directive 2004/108/EC

RoHS II: 2011/65/EU

Applied standards: EN 60730-1, EN 60730-2-14

728

Valve AMZ 112

DN 15 20 25 32 40 50

Nominal pressure PN 40 25

Flow (kVS) m3/h 17 28 39 84 156 243

Valve characteristic Logarithmic

Medium temperature °C 2 … 130 (Actuator max. 110)

Medium Water, glycol ≤50%, air, nonaggressive fluids

Max. operating Δp bar 6

Leakage according to UNI EN331 (<20cc/h)

Valve ne ck IS O 5 211

Connection Internal thread Rp ISO 7/1

Certifications and standards CE-PED – CSA - GOST

Materials

Body CW 617 N UNI EN 12165

Ball, Stem CW 614 N UNI EN 12164

Antifriction ring PTFE

Valve AMZ 113

DN 15 20 25 32

Nominal pressure PN 40

Flow (kVS) m3/h 4. 3 8.3 13 21

Medium temperature °C 2 … 130 (Actuator max. 110)

Medium Water, glycol ≤50%, air, nonaggressive fluids

Max. operating Δp bar 6

Leakage according to UNI EN331 (<20cc/h)

Valve ne ck IS O 5 211

Connection Internal thread Rp ISO 7/1

Certifications and standards CE-PED – CSA - GOST

Materials

Body CW 617 N UNI EN 12165

Ball, Stem CW 614 N UNI EN 12164

Antifriction ring PTFE

2 | AI192386478433en-010803 © Danfoss | 2021.08

Data sheet AMZ 112, AMZ 113

82G318.10

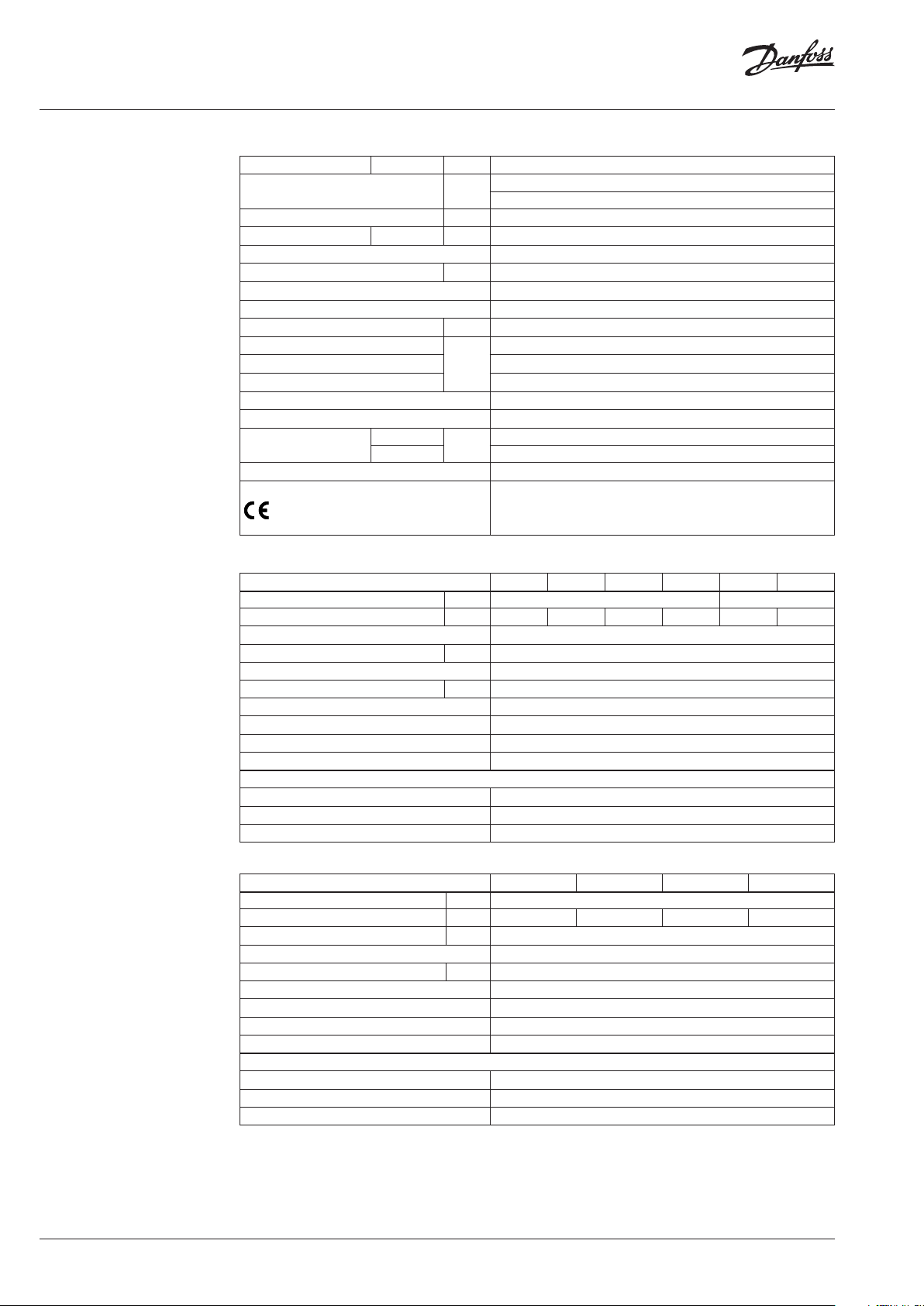

Application principles

ON/OFF control of Radiator -,

under floor heating and zone systems (night set back).

DEN-SMT

DEN-SMT

ON/OFF control of one or more heating/surfaces.

DEN-SMT

Installation positions

Hydraulic installation

Priority control of hot water supply and heating diverting function.

Recommended installation of the electric actuated ball

valve

Priority control of boiler and solid fuel installations diverting function.

1. Ball valve

2. Strainer

3. AMZ

AI192386478433en-010803 | 3© Danfoss | 2021.08

Data sheet AMZ 112, AMZ 113

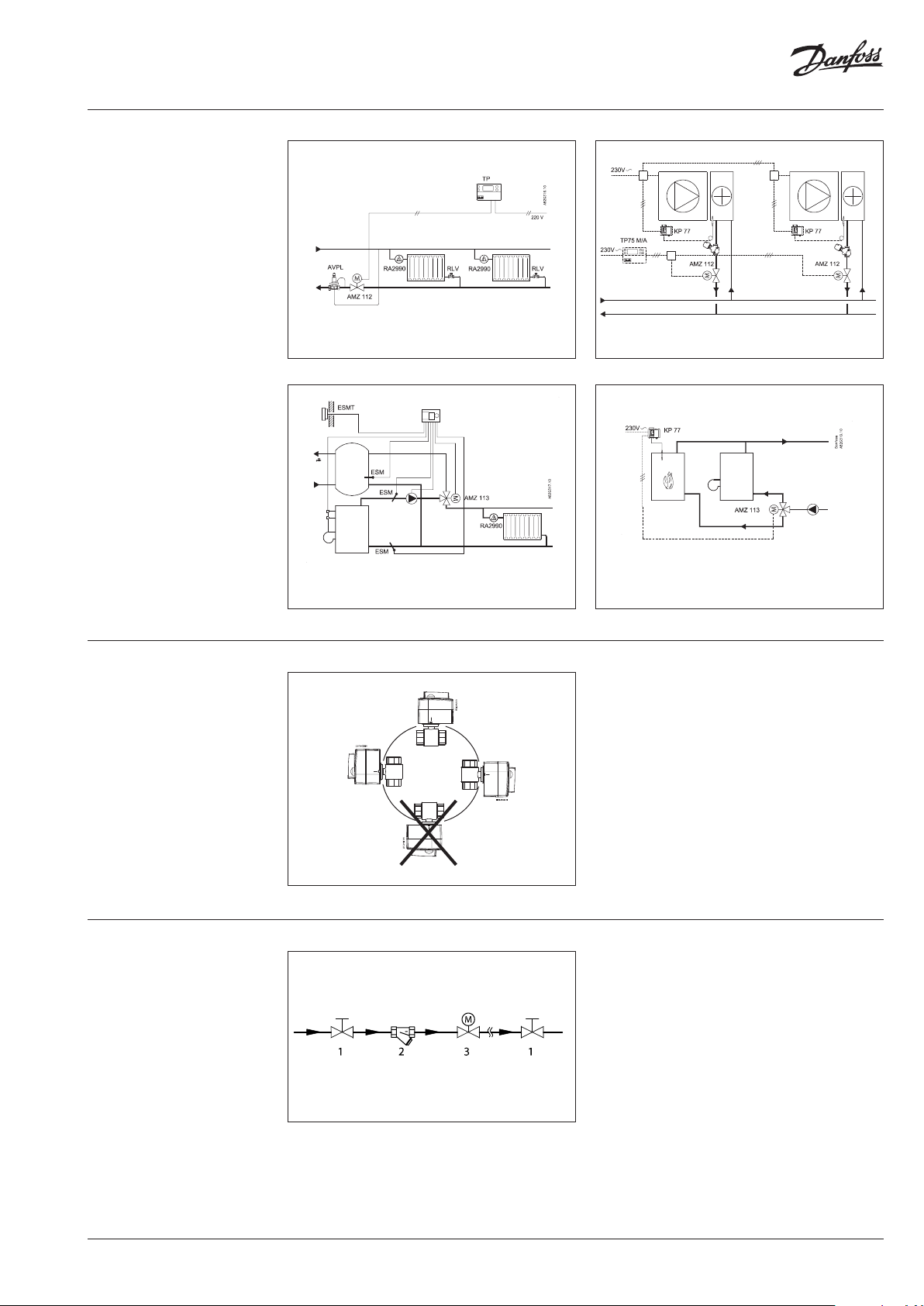

NL

230 V(24V)~

1

0

Manual override

①

②

OpenClose

A MZ 112 A MZ 113

LED signalling

Wiring

LED orange (Rotate Left)

LED green / red

LED orange (Rotate Right)

Direct/Inverse function

Jumper Wiring Open Por t

0

1

230 V(24V)~

3

12

1

2

3

2-point/2-point+switch

DIR

INV

AMZ 112/113

LED color

Orange Rotation lef t / right

Green /

Red AUX switch activation

L

5

4

6

5

4

AUX

L = 2 AB-B

L = 2 & 3

L = 2

L = 2 & 3 AB-B

Under cover

0

1

AB-A

2-point

(A MZ 112/ 113)

1

0

4 | AI192386478433en-010803 © Danfoss | 2021.08

Data sheet AMZ 112, AMZ 113

Dimensions

AMZ 112 - Copper connection

B

A MZ 112

L

AMZ 112

Connection

DN

20 Cu-Cu 22 111.5 33 37

(G)

L B N

mm

Connection

DN

15 ½” 61 29.4 37

20 ¾” 69.5 33 37

25 1” 84.5 37. 2 42

32 1¼” 98.5 47. 5 42

40 1½” 11 0 53 42

50 2” 130 64 48

(G)

L B N

mm

AI192386478433en-010803 | 5© Danfoss | 2021.08

Data sheet AMZ 112, AMZ 113

Dimensions (continuous)

A MZ 113

Connection

DN

15 ½” 64.5 38 49. 5

20 ¾” 78 42 59.5

25 1” 97 46.5 74. 5

32 1¼” 118 61. 25 95.5

(G)

L B N

mm

6 | AI192386478433en-010803 © Danfoss | 2021.08

Data sheet AMZ 112, AMZ 113

AI192386478433en-010803 | 7© Danfoss | 2021.08

Data sheet AMZ 112, AMZ 113

© Danfoss | DCS-S/SI | 2021.088 | AI192386478433en-010803

Loading...

Loading...