Page 1

Data sheet

Actuator for modulating control

AME 445 - for industrial applications

Description

AME 445 actuator is used for industrial applications

with two and three-way valves type VRB, VRG, VF

and VL up to DN 80 diameter.

The actuator has some special features:

• it automatically adapts its stroke to the valve

end positions which reduces commissioning

time (self stroking)

• valve flow adjustment feature; flow can be

variably-adjusted from linear to logarithmic or

opposite.

• the advanced design incorporates load

related ‘switch-off’ to ensure that actuators

and valves are not exposed to overload

Combinations with other valves could be seen

under Accessories.

Not appropriate for domestic applications, for hot water

servi ce with heat exc hangers and f or applicati ons where

higher noise level is not acceptable.

Main data:

• Nominal voltage (AC or DC):

• 24 V, 50/60 Hz

• Control input signal:

• 0(4)-20 mA

• 0(2)-10 V

• Force: 400 N

• Stroke: 20 mm

• Speed: 3 s/mm

• Max. medium temperature: 130 °C

• Self stroking

• LED signalling

• External RESET button with lock option

• Output signal

• Manual operation

Ordering

© Danfoss | 2016.08

Actuator

Typ e

AME 445 24 AC/DC 082H0 053

Power supply

(V)

Accessories - Stem heater

Typ e DN Code No.

Stem heater 15 -80 065Z 0315

Code No.

Accessories - Adapter

Valves DN

Adapter for old

VRB, VRG, VF, VL

valves

max. Δp

(bar)

15 9

20 4

25 2

32 1

40 0.8

50 0.5

Code No.

06 5Z0313

VD.LF.P3.02 | 1

Page 2

Data sheet Actuator for modulating control AME 445

Technical data

Installation

Power supply V 24 AC/DC; ±10%

Power consumption VA 7.6

Frequency Hz 50/60

Control input Y

Output signal X V 0-10 (2-10); [RL = 650 Ω] (maximal load)

Close of force N 400

Max. stroke mm 20

Speed s/mm 3

Max. medium temperature

Ambient temperature 0 … 55

Storage and transport temperature –40 … 70

Protection class II

Grade of enclosure IP 54

Weight kg 0.45

- marking in accordance with standards

V

mA

°C

Low Voltage Directive (LVD) 2006/95/EC: EN 60730-1, EN 60730-2-14

EMC Directive 2004/108/EC: EN 61000- 6-2, EN 61000 -6-3

0-10 (2-10); [Ri = 95 k Ω]

0-20 (4-20); [Ri = 500 Ω]

130

Mechanical

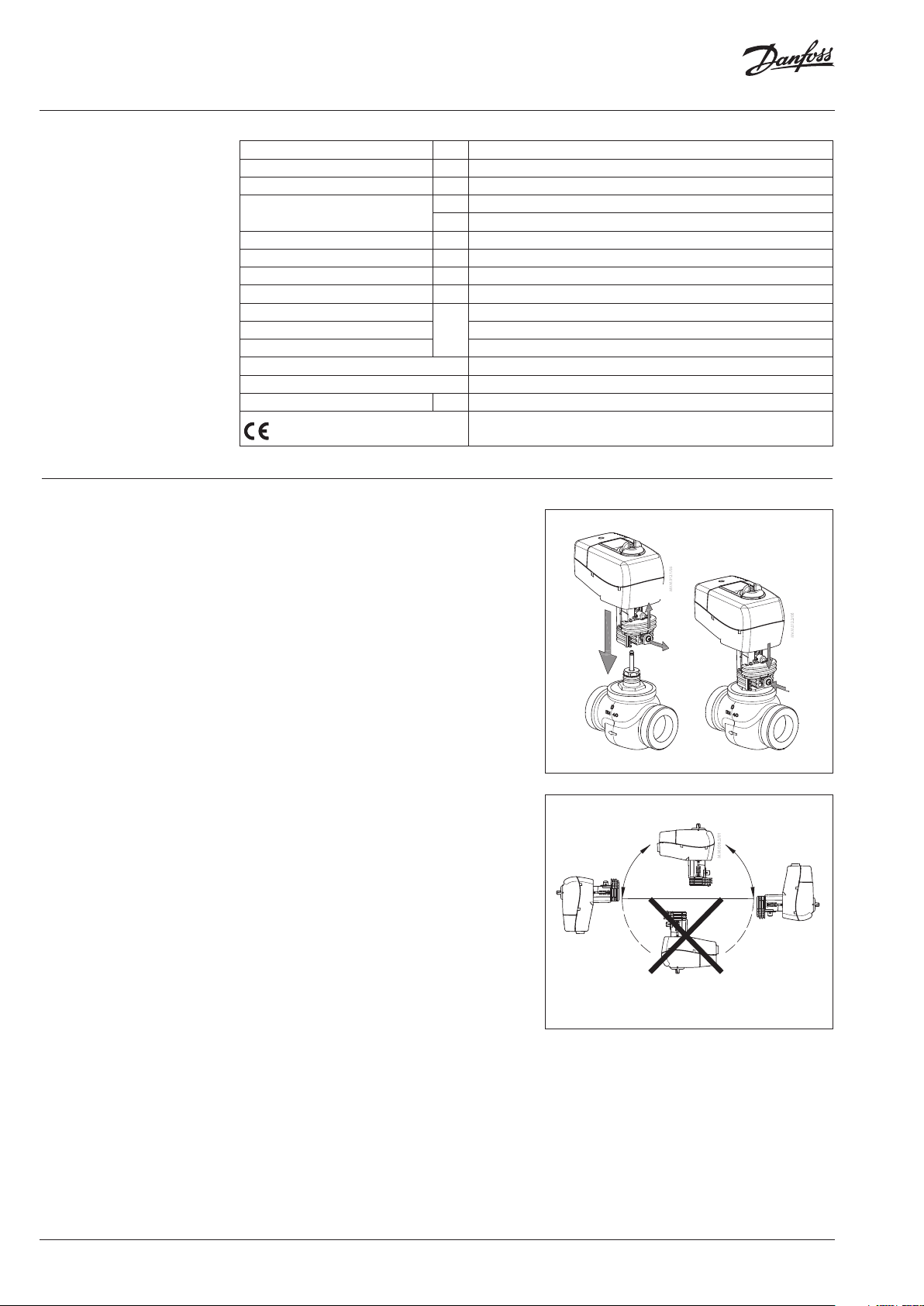

No tool is required to mount actuator on the

valve. Installation of the valve with the actuator

is allowed in horizontal position or upwards.

Installation downwards is not allowed.

The actuator must not be installed in an

③

①

②

explosive atmosphere, at ambient temperature

lower than 0 °C or at ambient temperature higher

than 55 °C. It must not be subject to steam jets,

water jets or dripping liquid as well.

⑤

④

Note:

The actuato r may be rotated up to 360° with respe ct to the valve

stem by looseni ng the retaining fixtur e. Once the actuator is

placed, retighten the fixture.

Electrical

Electrical connections can be accessed by

removing the actuator cover. Two cable gland

entries without thread (Ø 16 and combined

Ø 16/Ø 20) are prepared for cable glands. From

factory one entry is provided by rubber cable

gland and the other entry is prepared for

opening.

Note:

Cable and cable g land used must not compromise the a ctuator’s

IP rating, and must e nsure the connectors are ful ly strain relieved.

Rubber cabl e gland delivered from fac tory does not compromis e

IP rating but it doe s not provide fully strain rel ieve according to

LVD directive.

Please obser ve local rules and regulatio ns as well.

2 | © Danfoss | 2016.08

VD.LF.P3.02

Page 3

Data sheet Actuator for modulating control AME 445

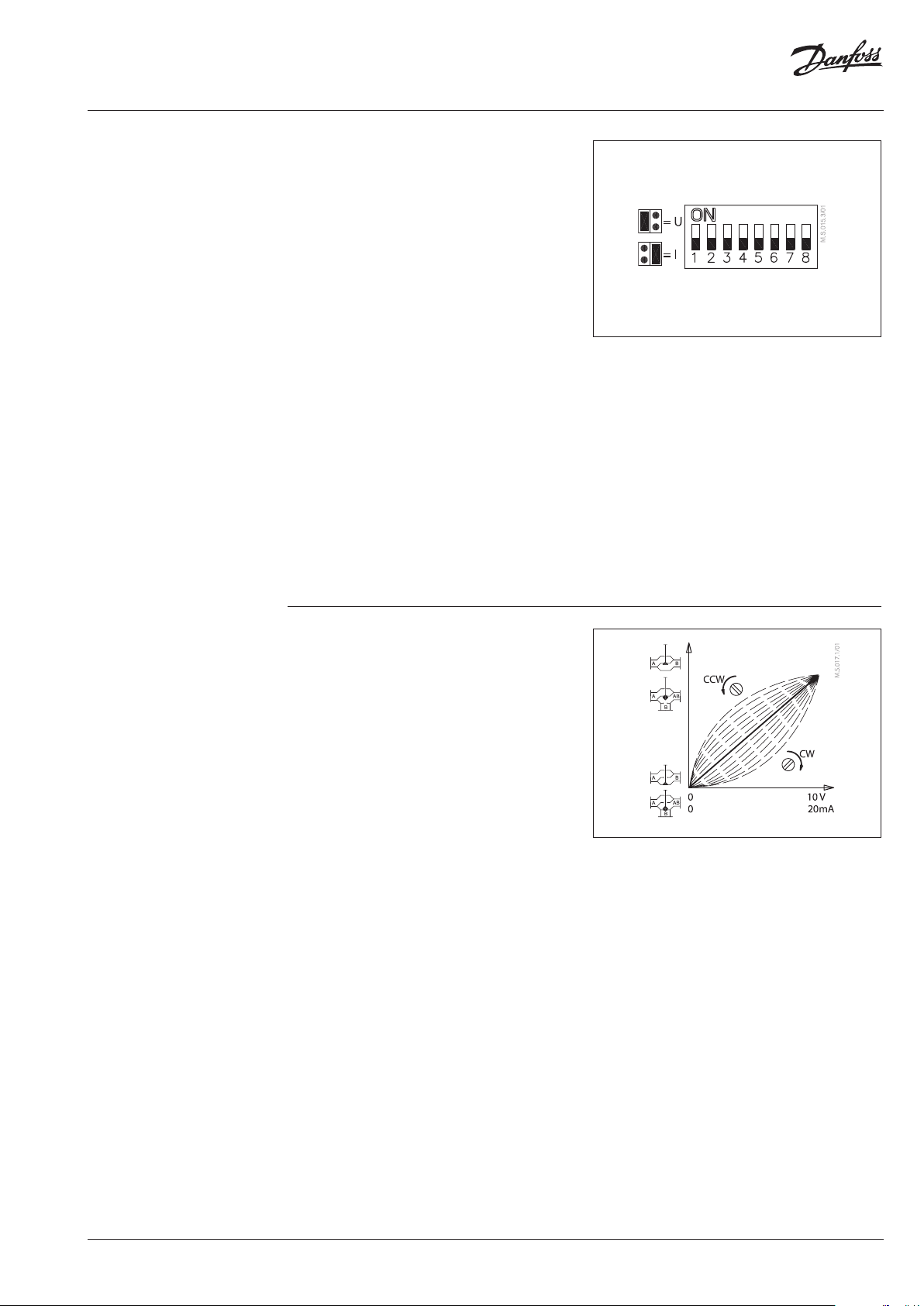

Jumper/DIP switch setting

Jumper

• U/I - Input signal type selector

• U position; voltage input is selected

• I position; current input is selected

DIP switches

• SW 1: Not used

• SW 2: Input signal range selector

• OFF position; the input signal is in the range

from 0-10 V (voltage input) or from 0-20 mA

(current input)

• ON position; the input signal is in the range

from 2-10 V (voltage input) or from 4-20 mA

(current input)

• SW 3: Direct or inverse acting selector

• OFF position; the actuator is in direct acting

mode (stem extend as voltage increases)

• ON position; the actuator is in inverse acting

mode (stem retracts as voltage increases)

• SW 4: Not used

• SW 5: Not used

• SW 6: Not used

INV

2 … 10 V

DIR

0 … 10 V

LOG

SMART

LIN

ACT

• SW 7: Linear or equal-percentage flow

through valve selector

• OFF position; the valve position is linear acc.

to the control signal

• ON position; the valve position is equalpercentage acc. to the control signal. This

relation is adjustable - see Equal-percentage

valve-flow adjustment section

• SW 8: Smart function selector

• OFF position; the actuator does not try to

detect oscillations in the system

• ON position; the actuator enables special anti

oscillations algorithm – see Anti oscillations

algorithm section

Equal-percentage valve-flow adjustment

(SW 7 in position ON)

The actuator has a special valve-flow

adjustment feature. Flow can be, by turning

the potentiometer clock wise (CW) or counter

clockwise (CCW), variably adjusted from linear

to logarithmic or opposite. For details see

Instructions.

VD.LF.P3.02

© Danfoss | 2016.08 | 3

Page 4

Data sheet Actuator for modulating control AME 445

Jumper/DIP switch setting

(continued)

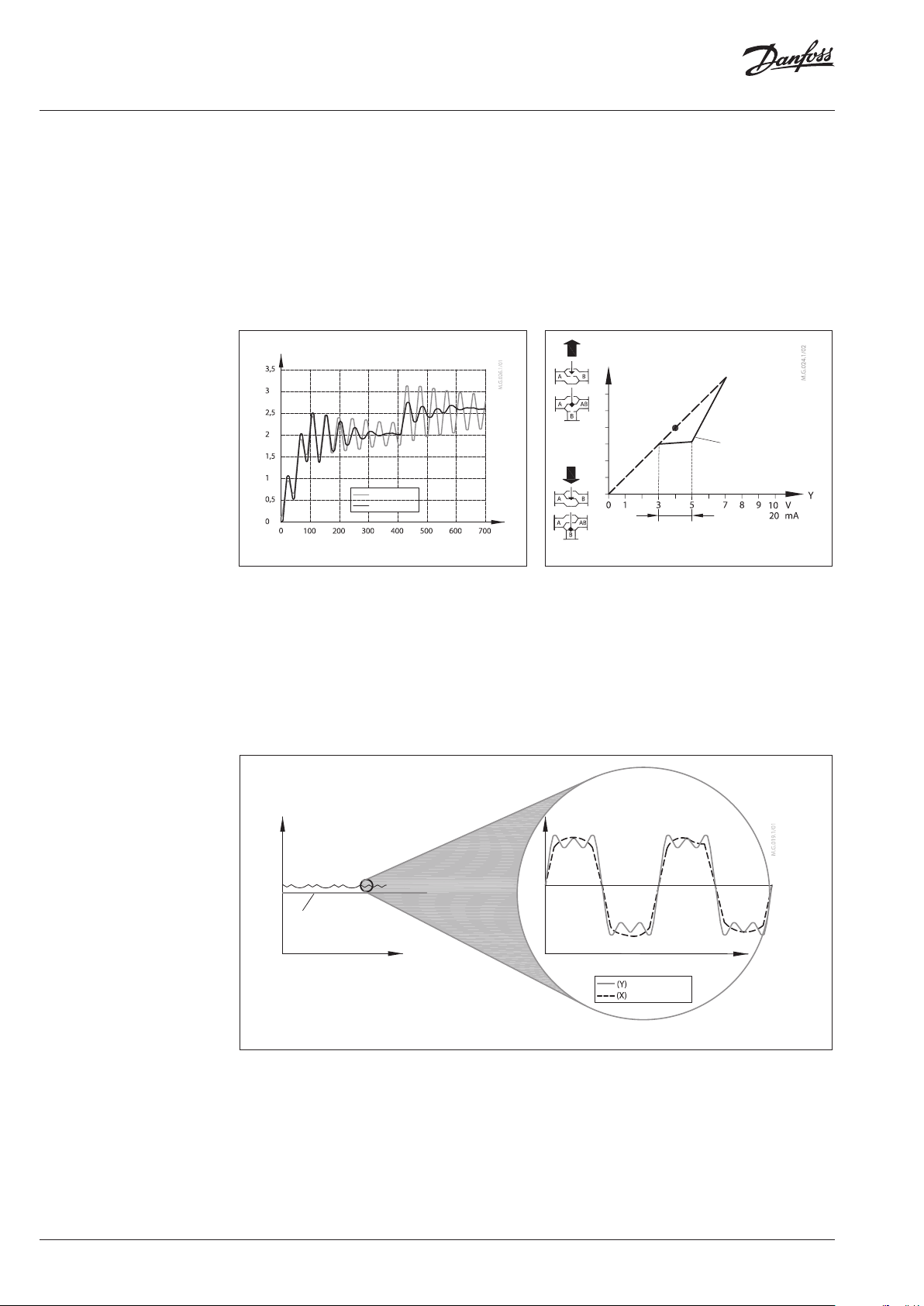

Anti oscillations algorithm

(SW 8 in position ON)

The actuator has special anti oscillations

algorithm. In case control signal Y on certain

point oscillates (Fig. 1) - looking from time

perspective, algorithm starts to lower the

amplification of the output to the valve. Instead

of having static characteristics actuator changes

to dynamic characteristics (Fig. 2) - certain

output stroke area changes to new slope

(decrease amplification).

Valve position X signal (V)

Functi on OFF

Functi on ON

Fig. 1

time (se c)

iMCV 2nd generation

Harmonic oscillations are high frequency

oscillations with low amplitude that vary around

its own equilibrium value and not around

set-point temperature. They can appear in up to

70 % of control time, even though the system is

properly commissioned. Harmonic oscillations

have negative influence on control stability, and

lifetime of the valve and actuator.

After control signal does not oscillate anymore

output to the valve slowly returns back to static

characteristics.

Stroke

static characteristic

Point A

linear area

Fig. 2

dynamic

characteristic

Smoothening function

Smoothening function implemented in New 2nd

generation of anti-oscillation function reduces

harmonic oscillations; consequently room

temperature is closer to the set-point (desired)

temperature. Smoother operation of the MCV

increases lifetime of the valve and actuator and

saves energy and reduces costs in general.

4 | © Danfoss | 2016.08

temperature

set-point

time (24 h) time (1 h)

temperature

set-point

control signal

feedback signal

VD.LF.P3.02

Page 5

Data sheet Actuator for modulating control AME 445

Commissioning

Complete the mechanical and electrical

installation, set jumper and DIP-switches, then

perform the necessary checks and tests:

• Apply power

Note that the actuator will now perform

automatic self stroking function

• Apply the appropriate control signal and

check:

• if the valve stem direction is correct for the

application and

• the actuator drives the valve over the entire

stroke length

The unit is now fully commissioned.

Automatic self stroking feature

The actuator automatically adapts its stroke to

the valve end positions:

• when power is applied for the first time or

• afterwards by pressing the STAND-BY/

RESET/LOCK-button button for 6-9 seconds.

The function gets active with releasing the

button after 2 × green LED blinks. If LOCK

MODE is activated (indicated by 1 × red LED

blink after 3 sec. and 2 × after 6 sec.) please

first unlock the button-functions by pressing

the button for 9-12 sec. and releasing it after

3 × green LED blinks. The button-functions

are unlocked now and RESET MODE can be

activated as mentioned before.

Testing entire valve stroke length

The actuator can be driven to the fully-open or

closed positions (depending on valve type) by

connecting SN to terminals 1 or 3.

VD.LF.P3.02

© Danfoss | 2016.08 | 5

Page 6

Data sheet Actuator for modulating control AME 445

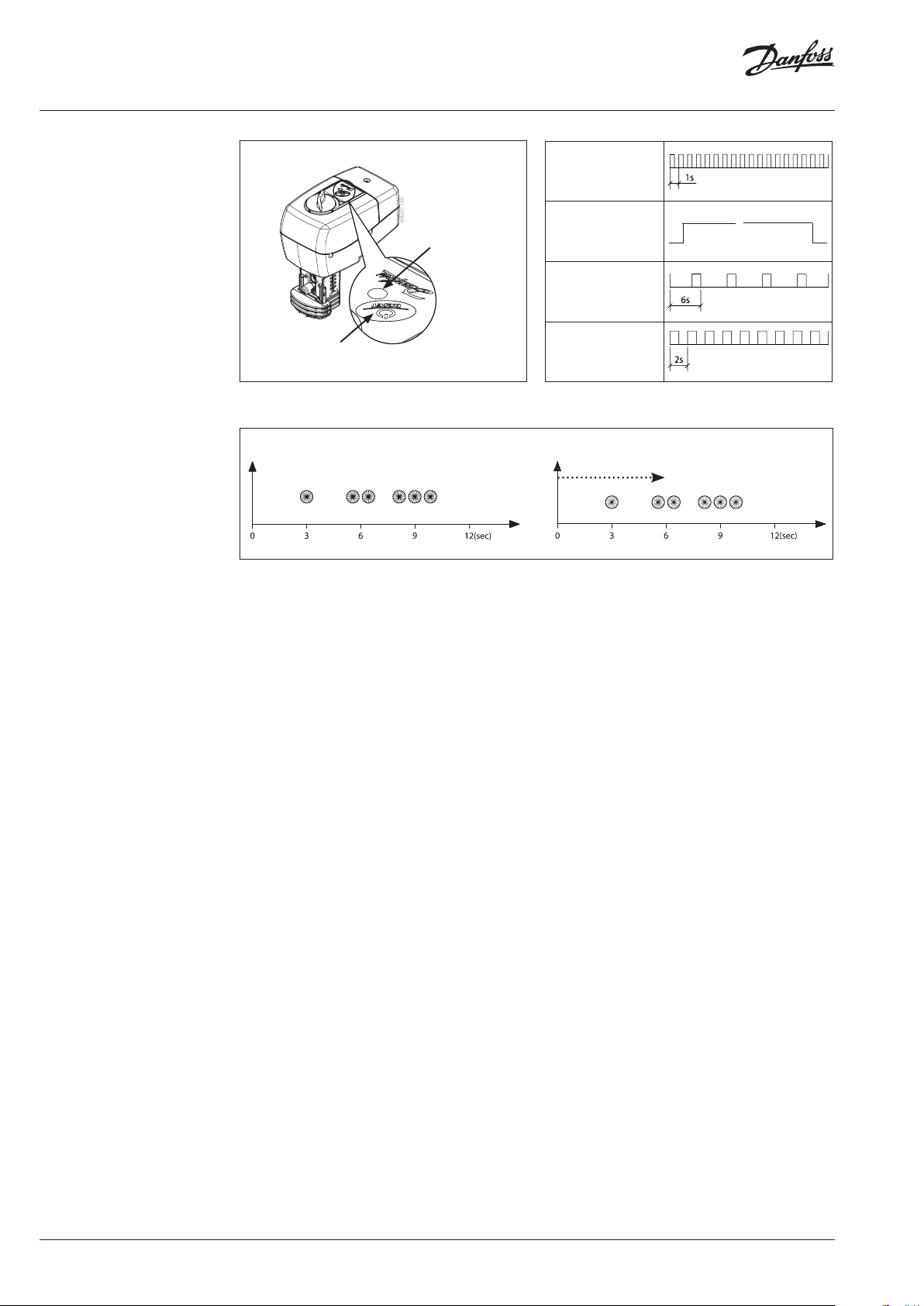

LED signalling/

Actuator operating modes

Flashing green LED:

Self stroking mode =

RESET MODE

(period is every second)

Constant green LED:

POSITIONING MODE

Flashing green LED:

Setpoint is reached

(period is every

Flashing red LED:

STAND-BY MODE

(period is every two

STA ND-B Y/RE SET/

LOCK- butto n

RED / GREEN

LED LIGHT

STAND-BY, RESET and LOCK MODE on actuator AME 445

Starting from NORMAL MODE

STAN D- BY

enabled

1 × Green 2 × Green 3 × Red

RESET

enabled

LED function indicator

LOCK MODE

activatedNoactivation

Starting from LOCK MODE

LOCK MODE is st ill activated

• STAND-BY MODE

Pressing the STAND-BY/RESET/LOCK-button

The bicolour (green/red) LED function indicator

is located on the actuator cover. It indicates the

operating modes.

for 3-6 sec. and releasing it after 1 × green

LED blink causes the actuator to activate

STAND-BY MODE. The actuator will not react

on any change of the control signal until it is

External button

switched back again to NORMAL MODE by

pressing the button as mentioned before.

Actuator has external STAND-BY/RESET/

LOCK-button which is located next to LED

indicator.

By pressing, holding and releasing this button

for/after specified time periods, different

operating modes are initiated:

During STAND-BY MODE, the actuator can be

moved manually or can be switched to RESET

MODE or LOCK MODE by pressing the button

as described in the according operating

modes.

• LOCK MODE

• Self stroking mode = RESET MODE

Pressing the STAND-BY/RESET/LOCK-button

for 6-9 sec. and releasing it after 2 × green LED

blinks causes the actuator to start

self stroking procedure:

The bicolor LED flashes green at 1 sec.

intervals during calibration procedure, which

begins by extending the stem. When the

maximum force is detected (at the valve

end position), the actuator then retracts the

stem, until the maximum force is once again

detected (on the other valve end position).

The actuator will then enter to NORMAL MODE

Pressing the STAND-BY/RESET/LOCK-button

for 9-12 sec. and releasing it after 3 × red LED

blinks causes the actuator to activate LOCK

MODE. The actuator can not be brought to

STAND-BY MODE or RESET MODE until it was

switched back again to NORMAL MODE by

pressing the button as mentioned before

(releasing the button now after 3 × green

LED blinks). During LOCK MODE, the actuator

works just as described in NORMAL or

POSITIONING MODE, but with partly locked

button-functions (shown with 1 × or 2 × red

LED blinks).

and respond to the control signal.

• REMARK

• POSITIONING MODE

The bicolour LED is green and stays on during

positioning of the actuator according to the

Pressing the STAND-BY/RESET/LOCK-button

for more than 12 sec., no activation/

deactivation occurs.

control signal

6 seconds)

seconds)

1 × Red 2 × Red

Deactivates

LOCK MODE

3 × Green

≈

activat ion /

deactivation

No

6 | © Danfoss | 2016.08

• NORMAL MODE

When the positioning of the actuator is

finished the LED flashes green every 6

seconds.

VD.LF.P3.02

Page 7

Data sheet Actuator for modulating control AME 445

Manual override

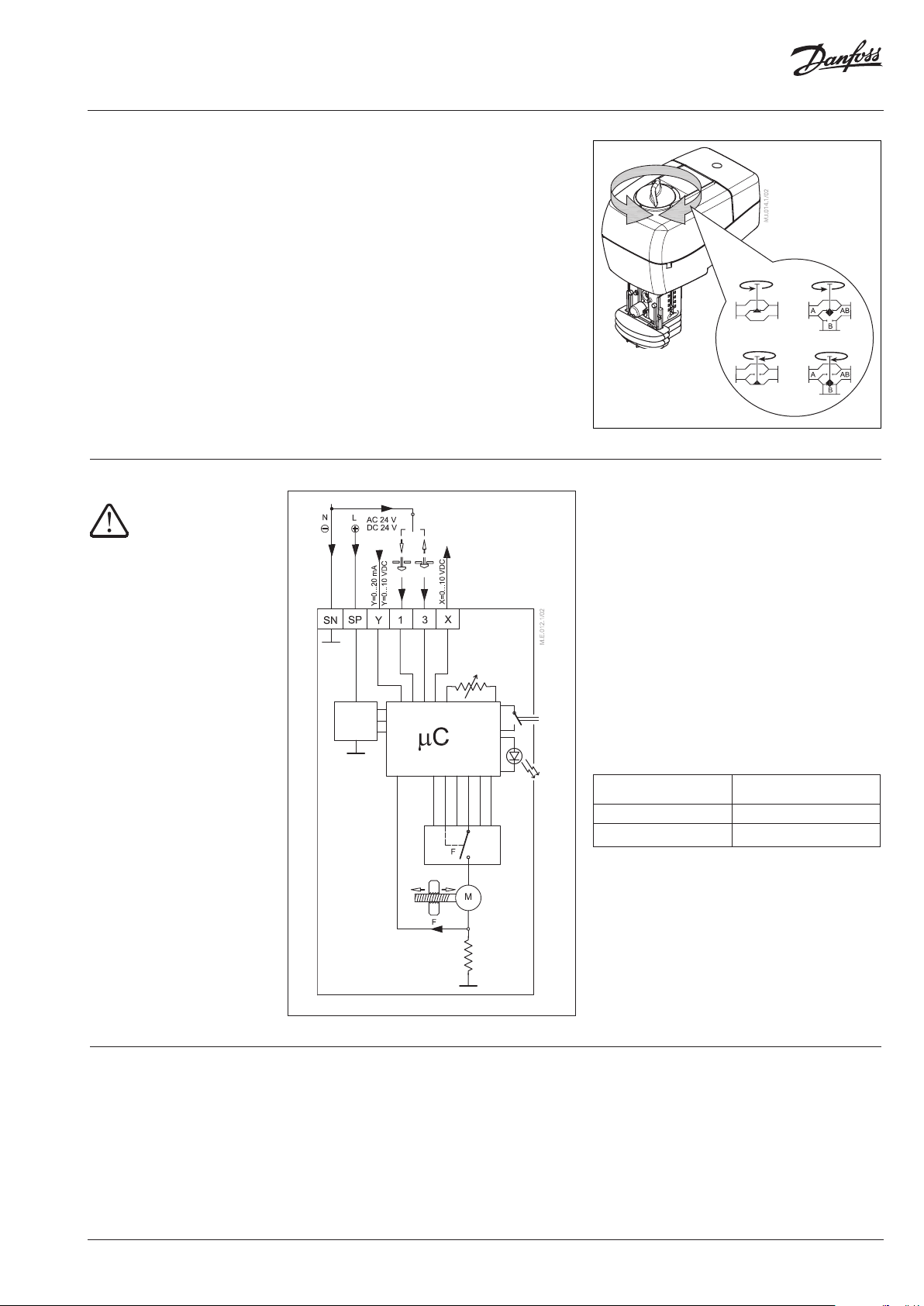

Wiring

24 V AC/DC only

Manual override is done by means of control

knob on actuator housing:

• Disconnect power supply or activate

STAND-BY MODE

• Adjust valve position using the control knob

(observe the rotation direction)

After manual override is not needed:

• Restore power supply or go to NORMAL

MODE again

Remark:

When the manua l override has been used, the o utput signal (X) is

not correct unti l the actuator reaches its e nd position.

SP 24 V AC/DC ...... Power supply

power

supply

down up

SN 0 V .............. Common

Y 0(2)-10 V ......... Input signal

0(4)-20 mA

X 0(2) -10 V ......... Output signal

1, 3 Override input signal

(can not be used for 3-point control)

Wiring length

0-50 m 0.75 mm

> 50 m 1.5 m m

Recommended cross-sectional

area of the wiring

2

2

Disposal

VD.LF.P3.02

The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

© Danfoss | 2016.08 | 7

Page 8

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Actuator for modulating control AME 445

Actuator - valve

combinations

Dimensions

AME 445 +

VRB 2, VRG 2

147

AME 445 +

VRB 3, VRG 3

AME 445 +

VF 2, VL 2

DN 15- 80

82.5

159. 5

AME 445 +

VF 3, VL 3

DN 15- 80

min . 180

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

8 | © Danfoss | DHS-SRMT/SI | 2016.08

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

VD.LF.P3.02

Loading...

Loading...