Page 1

PRINTED IN U.S.A.

Part No. 138049-000

REV 10/16/06

Daisy Outdoor Products

Rogers, AR 72757-0220 U.S.A.

800-643-3458

www.daisy.com

Page 2

Operation Manual

888

MEDALIST

WARNING:

COMPETITION OR TARGET RANGE USE. MISUSE OR CARELESS USE MAY CAUSE

SERIOUS INJURY OR DEATH. MAY BE DANGEROUS UP TO 257 YARDS (235 METERS).

THIS IS A SPECIAL CLASS OF NON-POWDERED GUNS AND NOT FOR GENERAL USE. IT IS TO BE

USED FOR TRAINING AND TARGET SHOOTING UNDER SUPERVISION. RECOMMENDED FOR USE

THOSE 16 YEARS OF AGE OR OLDER. THIS GUN SHOOTS PELLETS ONLY. THE PURCHASER

USER SHOULD CONFORM TO ALL LAWS GOVERNING THE USE AND OWNERSHIP OF AIRGUNS.

Competition Pellet Rifles

NOT A TOY. THIS AIRGUN IS DESIGNED FOR USE BY

EXPERIENCED SHOOTERS AND IS INTENDED FOR MATCH

Use .177 cal. (4.5mm) LEAD AIRGUN PELLET

887 GOLD

MEDALIST

BY

AND

Page 3

WARNING: THIS GUN CAN CAUSE DEATH. READ AND FOLLOW THE

INSTRUCTIONS CAREFULLY. DO NOT LOAD A PELLET INTO THE CHAMBER UNTIL YOU ARE

READY TO SHOOT. IF YOU DO LOAD A PELLET AND DECIDE NOT TO SHOOT, REMOVE IT

EITHER MANUALLY OR BY SHOOTING IT IN A SAFE DIRECTION. AN UNCOCKED, UNLOADED

GUN IS SAFEST. ACCIDENTS HAPPEN FAST, AND ACCIDENTALLY INJURING OR KILLING

SOMEONE IS A TERRIBLE THING. PLEASE SHOOT SAFELY.

This safety alert symbol indicates important safety messages in this manual. When you see

this symbol, be alert to the possibility of personal injury and carefully read the message that

follows.

The Avanti Models 887 and 888, Competition Pellet Rifles shoot with much more muzzle energy

than many BB and pellet guns. Use extreme caution when operating these guns. Although your

new Avanti Competition Air Rifle is not a firearm, it has lethal potential and should be treated with

the caution and respect due any conventional firearm. Like a firearm, your Avanti Competition Air

Rifle, when misused or carelessly used, can kill or seriously injure the shooter or other persons.

Always remember, the first and most important safety feature of any gun is the shooter. All safeties

are mechanical devices and the shooter is the only part of the system that can make a gun safe–or

unsafe. DON’T DEPEND ON MECHANICAL SAFETIES – think ahead and avoid situations that

might lead to accidents.

Guns differ in their operation, and you are never ready to fire any gun until you are thoroughly

familiar with it. Read the following operating instructions and, WITHOUT LOADING ANY PELLETS,

proceed through the operating steps, dry firing your gun several times at a safe target. This will

enable you to learn to operate this Competition Air Rifle properly and safely.

HOW TO OPERATE:

WARNING: BE SURE GUN IS ALWAYS POINTED IN A SAFE DIRECTION.

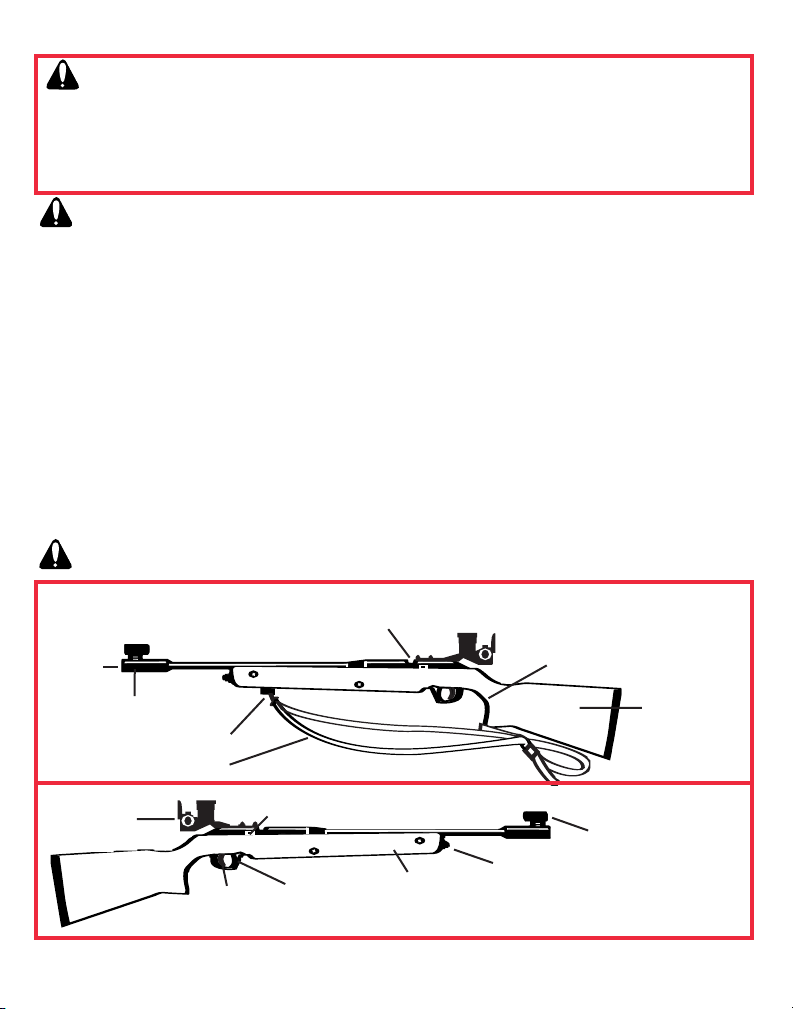

NOTE: Models 887 and 888 are identical except for Stock and Sights.

MODEL 887 SHOWN

FEED TRACK

LEFT SIDE

MUZZLE

BARREL WEIGHT

REAR SIGHT

SLING BRACKET

SLING

TRIGGER

BOLT HANDLE

TRIGGER

SAFETY

FOREARM

2

PISTOL GRIP

STOCK

RIGHT SIDE

FRONT SIGHT

CO2 BOTTLE

(CYLINDER)

FIGURE NO. 1

Page 4

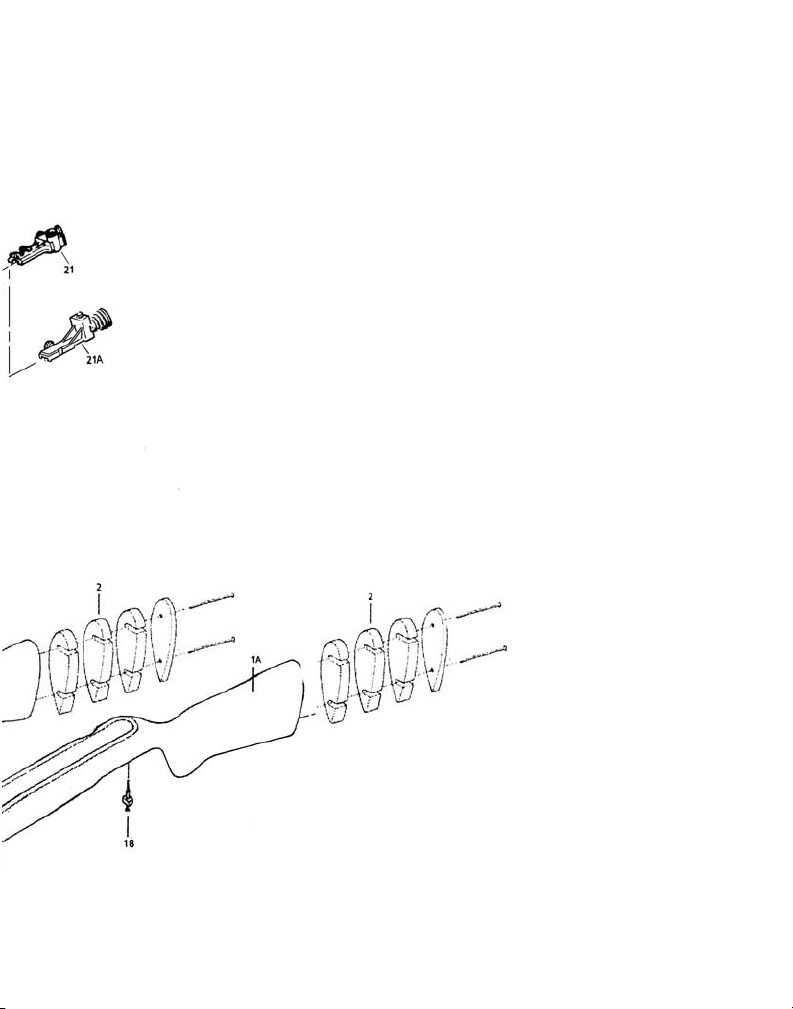

Key Part No. Description

1 888-1 888 Stock, butt plate and screws

1A 887-1 887 Stock, butt plate and screws

2 888-2 Stock spacers (3 each)

3 888-3 Trigger housing

4 888-4 Safety assembly

5 888-5 Trigger assembly

6 888-6 Hammer and spring

7 888-7 Receiver

8 888-8 Bolt handle assembly

(includes bolt, bolt handle,and spring

9 888-9 Valve body and barrel assembly

10 888-10 Right filler

11 888-11 Left filler

12 888-12 Frame

13 888-13 Barrel band

14 888-14 888 Front sight and set screws

14A 887-14 887 Front sight and set screws

15 888-15 888 Sight inserts

15A 888-15 887 Sight inserts

16 888-16 O-ring

17 888-17 Burst disk and relief valve

18 888-18 Screw assortment

screws, 1 trigger housing screw, 1 trigger

adjustment screw, 1 rear tie down valve

body screw, 2 stock screws, 1 seat screw)

19 888-19 O-ring valve group (includes o-ring,

spring, valve)

20 888-20 Adapter

21 888-21 888 Rear sight

21A 887-21 887 Rear sight

(includes ball & spring)

(includes 2 receiver

15

Page 5

AVANTI Models 887 and 888 Parts List

14

Page 6

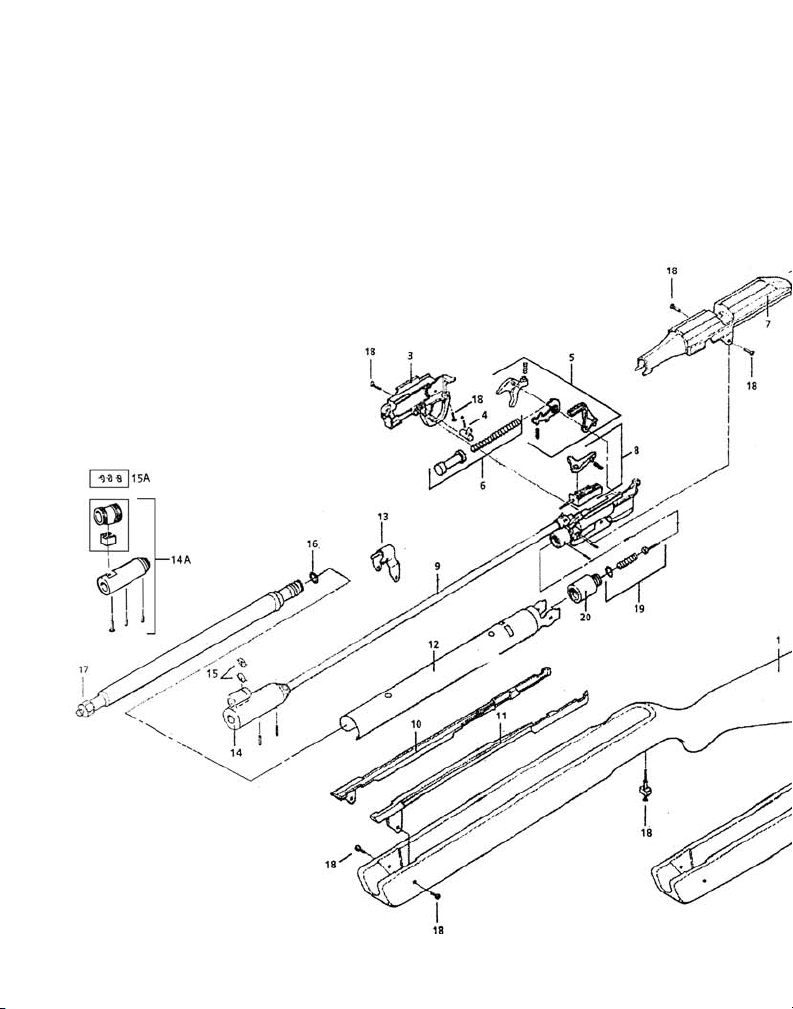

Step 1. PUT “ON” TRIGGER SAFETY

(no red showing)

Step 2. OPEN BOLT

Step 3. INSTALL CO2

Step 4. LOAD PELLET

Step 5. CLOSE BOLT

Step 6. AIM AT SAFE TARGET

Step 7. TAKE “OFF” TRIGGER SAFETY

(red showing)

Step 8. FIRE

DOVETAIL GROOVES

BOLT HANDLE

NO. 1A

TRACK FEED

TRIGGER SAFETY

TRIGGER

SAFETY ON

TRIGGER

SAFETY OFF

red showing on

opposite side

WARNING: BE SURE GUN IS ALWAYS POINTED IN A SAFE DIRECTION.

STEP 1. PUT “ON” TRIGGER SAFETY

Push the trigger safety from left to right (no red

showing). It is a good practice to get into the habit of

FEED TRACK

always keeping the trigger safety “ON” until actually ready

to fire the gun. (See Drawing No. 1A.)

BOLT HANDLE

STEP 2. OPEN BOLT

Pull the bolt handle fully to the rear. Then, release your

hold on the bolt handle, leaving the bolt open. The gun

NO. 1B

TRIGGER SAFETY

cannot fire with the bolt open. (See Drawing No. 1B.)

STEP 3. INSTALL CO2

The Model 888 CO2 Pellet Rifle is energized by CO2 only, from a refillable 2.5 ounce removable

CO2 bottle (cylinder) designed for use in this model.

WARNING: Do not attempt to use compressed air, or any gasses other than CO2 in this

model.

WARNING: Do not attempt to use any type of CO2 bottle, cylinder, or fittings that this

model is not designed to use.

A newly purchased Daisy 2.5 ounce refillable CO2 bottle (cylinder) will be empty. It will not have

CO2 in it until it has been filled. These bottles can be filled with CO2 at stores where CO2 paintball

marker cylinders are filled.

INSTALLING THE FILLED 2.5 OUNCE REFILLABLE CO2

BOTTLE (CYLINDER) INTO THE GUN: Coat the threads of

the bottle and the O-ring with 30-weight non-detergent

motor oil.

Keep the gun pointed in a safe direction. IT IS VERY

IMPORTANT TO ALWAYS KEEP THE GUN POINTED IN A

SAFE DIRECTION WHILE INSTALLING OR REMOVING THE

CO2 BOTTLE (CYLINDER).

Insert the threaded fitting end of the CO2 bottle (cylinder)

into the forearm of gun. (See Drawing No. 2A)

3

NO. 2A

NO. 2B

Page 7

Using a 5/8 inch wrench (preferably the shorter handle wrench provided with the gun, to help in

preventing the bottle from being over tightened) screw the bottle (cylinder) inward until it is seated.

Do not over tighten. (See Drawing No. 2B.)

With the gun pointed in a safe direction, it can then be dryfired, with CO2 only, to find out if the

CO2 bottle (cylinder) is installed correctly. If no CO2 shoots from the gun, the shooter should

retighten the CO2 bottle (cylinder), again being careful not to over tighten it. Never assume any gun

is unloaded–follow all safety rules.

O-RINGS: The O-ring on the refillable CO2 bottle (cylinder), should be replaced when it is found to

be damaged. The O-ring is an easily replaceable part. These O-rings are available from Daisy, and

from stores where paintball supplies are sold.

REMOVING THE CO2 SOURCE FROM THE GUN: Whenever the shooter notices that the CO2

pressure is becoming lower in the CO2 bottle (cylinder), it should be removed from the gun. When

the CO2 pressure is allowed to become very low, or completely used out, it may cause a pellet to

fail to shoot out of the gun. The pellet may remain inside the chamber or part way down the barrel

of the gun. This remaining pellet may, or may not shoot out of the gun when the gun is shot the

first time after a full CO2 source has been reinstalled. This can create a very dangerous condition,

and can be avoided by not allowing the CO2 source to become completely emptied while the gun

is being used. The shooter should always assume that a pellet may be in the gun, and the gun

should always be kept pointed in a safe direction, and should NEVER be dryfired unless the gun is

pointed in a safe direction.

REMOVING THE 2.5 OUNCE REMOVABLE CO2 BOTTLE (CYLINDER) FROM THE GUN: CO2

pressure can cause the bottle (cylinder) O-ring to seal very tightly in the gun, and can cause the

bottle (cylinder) to be harder to unscrew. To help to keep this from happening, the shooter should

always be sure to oil the O-ring and threads of the bottle (cylinder) before installing it, and should

avoid over tightening it. While the pressurized bottle (cylinder) is being unscrewed from the gun, a

small amount of CO2 can usually be heard escaping. This is normal.

Being sure to keep the gun pointed in a safe direction, and when possible, using the shorter

handle 5/8 inch wrench provided, unscrew the bottle (cylinder) and remove it from the gun.

NOTE: As the bottle (cylinder) is being unscrewed, the shooter should be observant for any

movement or loosening of the bottle (cylinder) fittings. If this is found, or if the shooter experiences

any problems when they are installing or removing the CO2 source, the gun and CO2 source

should be stored in a safe place and the shooter should call the Daisy Customer Service

Department for information on handling the problem. Only trained personnel should attempt to

work on the refillable bottle (cylinder), or on the gun.

Step 4. LOAD PELLET

With the bolt back, lower the muzzle slightly and load a pellet, solid end forward (See Drawing

No. 4A).

Step 5. CLOSE BOLT

Push the bolt handle fully forward. This will chamber a pellet and lock the bolt. (See Drawing

No. 4B.) The gun will not fire if the bolt is open.

CAUTION: The gun is now loaded and ready to fire.

Step 6. AIM AT SAFE TARGET

Aim the gun at a safe target. To be a consistent marksman, use the correct sight picture each

time you fire your gun. (See Drawing No. 5.)

4

Page 8

MODEL 887/888 SPECIFICATIONS

ACTION CO2, single shot

CALIBER .177 cal. (4.5mm)

AMMUNITION .177 cal. (4.5mm) lead air gun pellets

FRONT SIGHT Globe type with apertures

REAR SIGHT Peep sight with micrometer click, screw adjustment

BARREL Rifled steel with barrel weight

MUZZLE VELOCITY 500 fps (152mps)

MUZZLE ENERGY 4.3 ft. lb. (5.8J)

TARGET DISTANCE 33 ft. (10m)

MAXIMUM SHOOTING 257 yds. (235m)

DISTANCE*

ADD ON Standard dovetail mount in receiver to accept a

ACCESSORIES scope; nylon web sling

*With muzzle pointed upward at optimum angle

13

Page 9

MODIFICATION

WARNING: The components of this gun were engineered to deliver optimum performance.

Any modification or tampering with a gun may cause a malfunction and may make it unsafe to use.

Any change in performance, such as a lowered trigger force and shortened trigger travel, indicates

possible wear and such gun should be inspected, replaced, or properly repaired by qualified

personnel. Any gun that has been dropped should be checked by qualified personnel to insure that

its function has not been affected.

WARNING: A GUN THAT IS NOT OPERATING PROPERLY MAY BE DANGEROUS. IT

SHOULD BE KEPT SAFELY FROM USE BY ANYONE UNTIL REPAIRED OR DESTROYED. DO NOT

TRY TO TAKE THE GUN APART. IT IS DIFFICULT TO REASSEMBLE, AND IMPROPER

REASSEMBLY CAN CAUSE A HAZARDOUS CONDITION.

GUNS IN WARRANTY

LIMITED ONE-YEAR WARRANTY

For one year from date of purchase, Daisy will repair or replace and return this gun, free

of charge, if defective in material or workmanship. Service is available by returning the gun

to Daisy Outdoor Products (refer to important note below). Attach to the gun, your name,

address, and telephone number, description of problem and proof of date of purchase.

Package and send, transportation prepaid, to Daisy. This Warranty gives you specific

legal rights, and you may also have other rights which may vary from state to state.

IMPORTANT: You can return your inoperative rifle to Daisy for repair via United

Parcel Service. Be sure to put “ON” safety and unload all ammo before returning the gun

to Daisy. You must include your street address for Daisy to send your rifle directly back

to you through UPS delivery.

GUNS OUT OF WARRANTY

If your Avanti gun needs repair, please call 1-800-713-2479 for repair charges. Daisy

will repair the gun or replace it with a reconditioned gun of the same model, if available;

otherwise, with a model of equivalent quality.

Daisy Outdoor Products

Service Department

11823 Lime Kiln Rd.

Neosho, MO 64850 U.S.A.

NOTE: AVANTI air guns do not come under the provisions of the “Gun Control Act Of

1968” and can be shipped via UPS (not mailed).

12

Page 10

CAUTION: Due to the power of this air gun, use extra caution in selecting a safe target

backstop. Pellet guns should not be used with BB gun target backstops. Pick targets that cannot

BOLT TIP

FEED TRACK

PELLET

BOLT HANDLE

NO. 4A

be penetrated or that will not cause ricochet because of their hard surface. Use only targets and

traps that are designed for use with high-powered pellet guns. Do not shoot at the surface of

water.

Step 7. TAKE “OFF” TRIGGER SAFETY

When you are certain the target, backstop and surrounding

area are safe, push the trigger safety from the right, fully to the

left (red showing on left). Your gun is now cocked and ready to

shoot. In this condition, it should be handled with extreme care.

Step 8. FIRE

After making sure the gun is pointed in a safe direction,

gently but firmly squeeze the trigger. Repeat steps 1 through 8 to continue shooting.

REAR

SIGHT

NO. 5

NO. 4B

FRONT

SIGHT

BULLSEYE

FAILURE TO SHOOT CO2

If the gun does not shoot CO2, with the safety “ON” (no red showing), and with the gun pointed

in a safe direction, try retightening the 2.5 ounce bottle (cylinder). Do not over tighten.

If the gun still does not shoot CO2, the CO2 source may be empty. The 2.5 ounce refillable

bottle (cylinder) can be checked for CO2 pressure by, removing it from the gun and pushing inward

on the bottle (cylinder) valve pin. If the valve can be opened and no gas escapes, the CO2 bottle

(cylinder) is empty, and should be refilled to operate the gun.

FAILURE TO SHOOT A PELLET

If the gun does shoot CO2, but does not shoot the pellet, one or more pellets may be jammed

in the barrel of the gun. With the safety “ON” (no red showing), and with the CO2 source removed

from the gun, a brass or aluminum cleaning rod (a steel cleaning rod will damage the rifling) can be

run through the barrel of the gun to dislodge any pellets that may be jammed there.

If these steps do not correct the problem, the gun and CO2 source should be stored in a safe

place. The Daisy Customer Service Department should be called for information on correcting the

problem, or for information on how to return the gun and CO2 source for repair. Do not return the

gun to the retailer.

WARNING: If a pellet does not fire after completing the operating steps, the gun is

jammed. KEEP THE GUN POINTED IN A SAFE DIRECTION and perform the following steps:

1. Put trigger safety “ON” (no red showing).

2. Open bolt.

3. Close bolt, and with gun pointed in a safe direction, take the trigger safety “OFF” and fire.

5

Page 11

If the pellet still does not fire, follow these steps carefully:

1. Put trigger safety “ON” (no red showing).

2. Open bolt.

3. Remove CO2 source from the gun, with gun pointed in safe direction.

4. Invert the gun with the barrel held in the horizontal position.

5. Clear barrel by running cleaning rod through from the muzzle end and allow the pellet to fall

clear of the receiver through the feed track. Be careful not to damage the bolt tip by pushing the

rod through too hard. Do not reuse this pellet. Do not allow a pellet to fall into the action of the

gun.

NOTE: Should you let a pellet fall into the action of the gun, make every effort to shake it free

and get it to fall out. Otherwise, the gun will have to be returned to the Daisy Service

department. (See “Repair of Daisy Guns” section.)

6. Repeat operating Steps 1 through 8. If after following the firing procedure, a pellet is not fired,

put safety “ON” (no red showing) and return your gun to the Factory Service Department. (See

“Repair of Daisy Guns” section.)

UNLOAD PELLET

The bolt does not extract a pellet. You must shoot the pellet out if a safe target is available. If a

safe target is not available, put trigger safety “ON” (no red showing), open bolt, invert the gun with

the barrel held horizontal, insert a cleaning rod in the muzzle end and push the pellet out of the

barrel. This allows the pellet to fall clear of the action. Do not allow a pellet to fall into the action of

the gun. DO NOT use a steel cleaning rod. Use brass or aluminum only.

CAUTION: Never assume the gun is empty of projectiles. Always point the gun in a safe

direction.

AMMUNITION

Use only .177 (4.5mm) lead air gun pellets. Daisy No. 557 Match Pellets are recommended.

6

Page 12

PROPER CARE

With care, periodic cleaning and lubrication, your 887/888 will provide many years of shooting

enjoyment. As is the case with conventional firearms, abuse, neglect and continued exposure to

the elements will impair the performance of any air gun. Learn to take care of your 887/888 and it

will serve you well.

CAUTION: Never attempt to clean this gun until you put the trigger safety in the “ON”

position (no red showing), have made absolutely certain that the gun is not loaded and have the

bolt in the fully open position, and the CO2 source has been removed from the gun.

STOCK AND FOREARM: The wooden stock may be wiped clean with a damp rag, and lightly

waxed.

EXTERIOR PARTS: Exposed metal parts (i.e., receiver, barrel, etc.) should occasionally be wiped

clean using a soft, lightly oiled cloth. Use a clean 30-weight non-detergent motor oil.

BARREL: The barrel should be cleaned occasionally to maintain accuracy. We recommend using

Daisy’s No. 5878 Cleaning Kit. To clean barrel, open bolt and insert cleaning rod and oil saturated

patches into the muzzle end of the bore. Retract the rod and patch from the barrel. Repeat this

procedure several times with oiled patches, then switch to dry patches. Continue using dry

patches until most of the oil is removed from the bore

NOTE: Be careful not to damage the sealing tip on the bolt when the rod tip enters the loading

area. It may be necessary to clean the barrel approximately every 50 shots to maintain maximum

accuracy. Frequent cleaning may be necessary when the gun is new, and until excess oil is

removed.

LUBRICATION

The easiest and best way to lubricate this model is to place a drop of 30-weight non-detergent

motor oil on the CO2 source before it is installed into the gun. Using the 2.5 ounce refillable CO2

bottle (cylinder), the gun can be lubricated each time it is installed into the gun. This can be done

by placing one drop of 30-weight non-detergent motor oil onto the center of the face of the fitting

that screws into the gun. This will be on the valve pin on the 2.5 ounce refillable CO2 bottle

(cylinder). Use one drop only, more than that can cause the bottle (cylinder) or adapter to seem to

be completely screwed into place when it is not. CO2 will not feed into the gun until the bottle

(cylinder) has been retightened. Also, too much oil can flood the valve of the gun and cause the

gun to shoot low pellet velocities.

One drop of oil will lubricate the gun properly.

IMPORTANT: The only oils recommended for use in the 887/888 are 30-weight, automotive motor

oils. DO NOT use light, household type oils or aerosol type spray lubricants since they may contain

substances or additives harmful to the rubber seals and other components.

STORAGE

To make your 887/888 safe for storage or transporting, proceed through operating Steps 1

through 8, omitting Step 4 (Loading), WHILE POINTING THE GUN IN A SAFE DIRECTION FOR

THE ENTIRE TIME! Then put the trigger safety “ON” (no red showing). This will ensure that the

hammer is fired, that there is not a pellet in the chamber and that the trigger safety is “ON.”

Remove CO2 source.

Always store pellets in a place separate from the gun to keep them from untrained shooters.

Before putting your gun away, make sure it is clean, dry, oiled, unloaded and uncocked. If the gun

is to be stored for a long period of time, a light coat of oil in the barrel will help prevent corrosion.

11

Page 13

TRIGGER ADJUSTMENT

The trigger in this model is adjustable for travel. This is a

Special Purpose Match Precision Gun and is exempt from the 2 lb.

(0.9 kg) minimum trigger pull standard.

The trigger adjusting screw is located behind the trigger guard

(See Drawing No. 11). The adjusting screw can be turned outward

until it has no effect and trigger travel is at the maximum, or it can

be turned inward to shorten the trigger travel. To adjust the trigger

travel in this model, the gun should be kept pointed in a safe

direction, the safety should be at “ON” (no red showing), there

should be no pellet in the gun, and the CO2 source should be

removed from the gun.

CAUTION: The trigger should be adjusted by an experienced shooter only.

After the trigger has been adjusted the gun should be treated with caution. Shooting coaches

and instructors should make sure that inexperienced shooters use this model with the trigger

adjustment screw backed out to maximum trigger travel.

For target shooting, experienced shooters may find that the best trigger travel setting can be

obtained by [with the safety at “ON” (no red showing), no pellet in the gun, and with the CO2

source removed] carefully turning the adjusting screw inward until slight resistance is felt.

After the trigger has been adjusted, (with the gun pointed in a safe direction, and with no pellet

or CO2 in the gun) it should be dryfired several times, and the safety tried several times to make

sure that the trigger, sear, and safety are all functioning correctly. If the gun does not seem to be

functioning correctly, the adjusting screw should be turned outward 1/2 turn, and the gun tried for

function again.

As the trigger is being adjusted, the shooter should be careful that the adjusting screw is not

forced, because the sear and the safety mechanism can be damaged.

If the shooter has questions about the proper way to adjust the trigger, they can call the Daisy

Customer Service Department for information on doing this.

TRIGGER

ADJUSTMENT

SCREW

NO. 11

BURST DISK SAFETY PRESSURE RELIEF

The 2.5 ounce refillable CO2 bottle (cylinder) has a burst disk safety pressure relief on the front

fitting of the bottle (cylinder). The disk will burst, or rupture to safely relieve excess CO2 gas

pressure, to prevent the pressure from becoming too high.

The pressure inside the bottle (cylinder) could become too high from the bottle (cylinder) being

overfilled with CO2, or from the bottle (cylinder) becoming heated by being left in direct sunlight or

from some other source.

The burst disk is a replaceable part, but replacing the disk should be done by trained personnel

only. Ruptured burst disks can be replaced by personnel at stores where these CO2 bottle

(cylinders) are filled.

When a burst disk does rupture to relieve the excess pressure in the CO2 bottle (cylinder), all of

the CO2 in the bottle (cylinder) will escape rapidly from the bottle (cylinder). The rapidly emptying

CO2 bottle (cylinder) will quickly become coated with frost. The shooter should avoid contact with

the escaping CO2 and the frosted bottle (cylinder). If the disk bursts inside an automobile, or in

some other enclosed area, a window or door should be opened to allow the CO2 to dissipate.

10

Page 14

REAR SIGHT INSTALLATION AND ADJUSTMENT

(MODEL 887)

This is a universal target sight with a rubber eyepiece, which prevents light reflecting from the

sight into your eye.

ELEVATION

ADJUSTMENT

KNOB

MOUNTING

SCREW

NO. 6

ELEVATION

CALIBRATION

Installation Step 1. Loosen the bracket mounting screw and plate, and sliding the sight onto the

dovetail grooves of the receiver. Position the sight forward or to the rear until it suits your eye-sight

and/or physique.

Installation Step 2. Tighten mounting screw securely. (See drawing No. 6)

ELEVATION: To lower the point of impact, turn elevation knob to the left

(counterclockwise). To raise the point of impact, turn elevation knob to the right (clockwise), per

arrow and word “UP” (See drawing No. 7)

WINDAGE: To move the point of impact to the left, turn the windage knob counterclockwise. To

move the point of impact to the right, turn the windage knob clockwise.

FRONT SIGHT APERTURE INSERTS (MODEL 887)

WINDAGE

CALIBRATION

RING

WINDAGE

ADJUSTMENT

KNOB

NO. 7

APERTURE

INSERT

NO. 8A

NO. 8B

Your Model 887, Competition Pellet Rifle comes with four aperture inserts, 2.6mm, 3.8mm,

4.0mm, 4.4mm (4.4mm already in place). To change inserts, follow this procedure:

1. Point the muzzle up and away from you.

2. Grip the ring at the muzzle end of the sight and turn counterclockwise. If tight, a coin may be

used in the slots. (See drawing No. 8A)

3. Unscrew until aperture is free to be removed by using finger and thumb on side of sight tube,

engaging ears on aperture to pull back and upwards. (See drawing No. 8B)

Note: Apertures have ears of different sizes to ensure the proper positioning when replaced.

4. To install, make sure back locking ring is unscrewed far enough for clearance. Have ears to

proper side. Insert in groove and push forward. Tighten locking ring. A coin may be used to

assure a firm lock.

7

Page 15

REAR SIGHT INSTALLATION AND ADJUSTMENT

(MODEL 888)

WINDAGE

ADJUSTMENT KNOB

MOUNTING

SCREWS

NO. 6 NO. 7

DOVETAIL GROOVES

PEEP SIGHT

ELEVATION

ADJUSTMENT KNOB

MOUNTING SCREWS

WINDAGE

CALIBRATION

ELEVATION

ADJUSTMENT

KNOB

ELEVATION

CALIBRATION

(under knob)

Installation Step 1. Loosen bracket mounting screws and slide receiver sight onto dovetail

grooves of receiver (See Drawing No. 6). Position the sight forward or to the rear until it suits your

eye-sight and/or physique.

Installation Step 2. Tighten mounting screws securely.

ELEVATION: To lower the point of impact, turn elevation knob to the left (counterclockwise). To

raise the point of impact, turn elevation knob to the right (clockwise), per arrow and word “UP”

(See Drawing No. 7).

WINDAGE: To move the point of impact to the left, turn the windage knob counterclockwise. To

move the point of impact to the right, turn the windage knob clockwise, per arrow and letter “R”

(See Drawing No. 7).

ADJUSTMENT: This precision peep sight is fully adjustable. Each click of the micrometer

adjustment results in a .413 minute of angle (.048 inch) shift of pellet impact at 10 meters (33 feet).

FRONT SIGHT APERTURE INSERTS (MODEL 888)

WINDAGE

ADJUSTMENT

KNOB

PEEP SIGHT

NO. 8A

RELEASE PLATE

INSERT TABS

RELEASE

PLATE

SLOTS

APERTURE

INSERT

NO. 8B

Your Model 888, Competition Pellet Rifle comes with additional aperture inserts, one is already

in place. To change inserts, follow this procedure.

1. Point the muzzle up and away from you.

2. Using your index finger (or middle and index fingers if you fingers are slender), push in on the top

and bottom of the release plate (See Drawing No. 8A).

3. With insert release plate pushed in, lift out the aperture insert with thumb and index finger of

opposite hand (See Drawing No. 8B).

4. To replace aperture, depress release plate. Place desired aperture in position with insert tabs in

appropriate slots (See Drawing 8B).

5.

Front sight apertures provided with this airgun measure: .140 inch, .150 inch, .160 inch and

.170 inch. Post front sight width measures 1.7526mm (.069 inch)

8

Page 16

SLING ATTACHMENT

The sling is attached by a detachable sling swivel which connects to a sling bracket on the forward

end of the accessory rail. With the sling attached to the swivel and then pulled back along the

underside of the rifle, the tab end of the sling should be hanging down (See Drawing No. 9A).

NO. 9A

SLING SWIVEL

NO. 9B

SLING

SWIVEL

SLING

BRACKET

RIFLE LOOP

TAB END

OF SLING

LENGTH ADJUSTING KEEPER

ARM

LOOP

PUTTING SLING ON ARM:

1. Open the arm loop.

2. Turn loop one quarter turn in the direction of the sling arm (i.e., one quarter turn to the left if the

sling is going on the left arm) and slip your arm into the loop (See Drawing 9B).

3. Place sling loop on your upper arm either above the biceps near the shoulder or below the

biceps.

4. Tighten the sling loop until it is snug enough to remain in place on your arm. it should not be so

tight that it restricts the flow of blood in your arm or creates a pulse effect.

LENGTHENING SLING:

Grasp the tab end of the

NO. 9C NO. 9D

keeper with your trigger hand

and lift it up while pulling on

the top strand (not the tab

end) of the sling (See Drawing

No. 9C).

SHORTENING SLING: Pull

the tab end of the sling away

from you until sling reaches

the desired length. (See Drawing 9D).

STOCK ADJUSTMENTS

To adjust stock, loosen screws in buttplate

BUTTPLATE

SPACER

sufficiently to allow insertion of the desired number of

spacers (See Drawing No. 10). Spacers go between

stock and buttplate. Each insert will adjust stock length

5/8 inch (.625 inch). After stock adjustment inserts

have been added, tighten buttplate screws to lock

BUTTPLATE

SCREWS

inserts in place. To shorten the stock reverse this

procedure. Be certain spacers are placed so the

molded cleats nest in the molded receptacle.

NO. 10

9

STOCK

Loading...

Loading...