Daikin RXYSQ6TMYFK Operation manuals

Installation and operation

manual

VRV IV-S system air conditioner

RXYSQ6TMYFK

Installation and operation manual

VRV IV-S system air conditioner

English

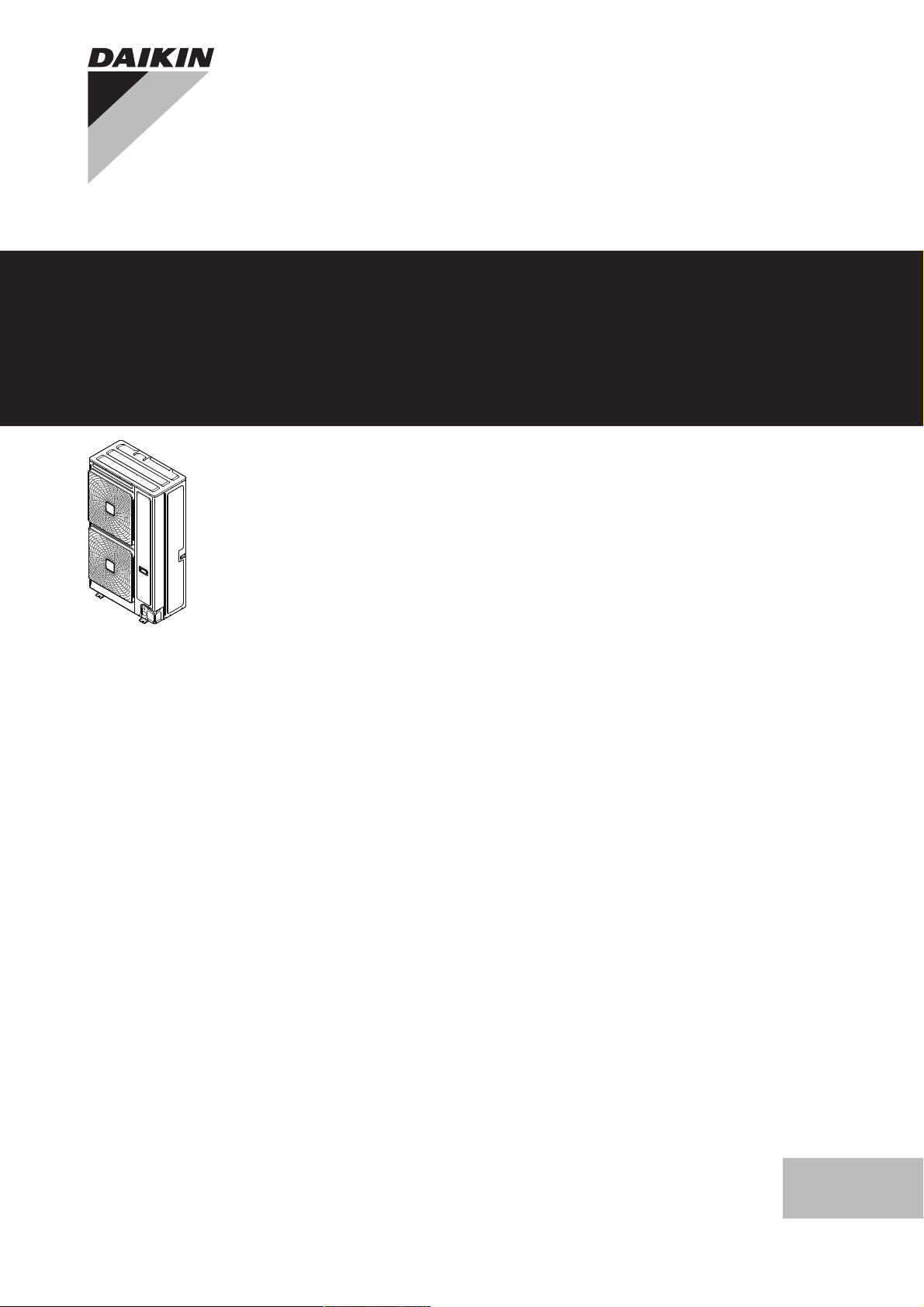

1+2

1

A~E

a b c d e e

B

e

D

HBHDH

U

(mm)

a

b

c

d

e

e

B

e

D

A

B

C

D

E

H

B

H

U

H

D

B — ≥100

A, B, C — ≥100 ≥100 ≥100

B, E — ≥100 ≥1000 ≤500

A, B, C, E — ≥150 ≥150 ≥150 ≥1000 ≤500

D — ≥500

D, E — ≥1000 ≥1000 ≤500

B, D — ≥100 ≥1000

B, D, E HB<HDHB≤½H

U

≥250 ≥1000 ≥1000 ≤500

½HU<HB≤H

U

≥250 ≥1250 ≥1000 ≤500

HB>H

U

HB>HDHD≤½H

U

≥100 ≥1000 ≥1000 ≤500

½HU<HD≤H

U

≥200 ≥1000 ≥1000 ≤500

HD>H

U

≥200 ≥1700 ≥1000 ≤500

H

U

a

b

≥100

≥100

c

d

e

e

B

e

D

A

B

C

D

E

H

B

H

D

A, B, C — ≥200 ≥300 ≥1000

A, B, C, E — ≥200 ≥300 ≥1000 ≥1000 ≤500

D — ≥1000

D, E — ≥1000 ≥1000 ≤500

B, D HD>H

U

≥300 ≥1000

HD≤½H

U

≥250 ≥1500

½HU<HD≤H

U

≥300 ≥1500

B, D, E HB<HDHB≤½H

U

≥300 ≥1000 ≥1000 ≤500

½HU<HB≤H

U

≥300 ≥1250 ≥1000 ≤500

HB>H

U

HB>HDHD≤½H

U

≥250 ≥1500 ≥1000 ≤500

½HU<HD≤H

U

≥300 ≥1500 ≥1000 ≤500

HD>H

U

≥300 ≥2200 ≥1000 ≤500

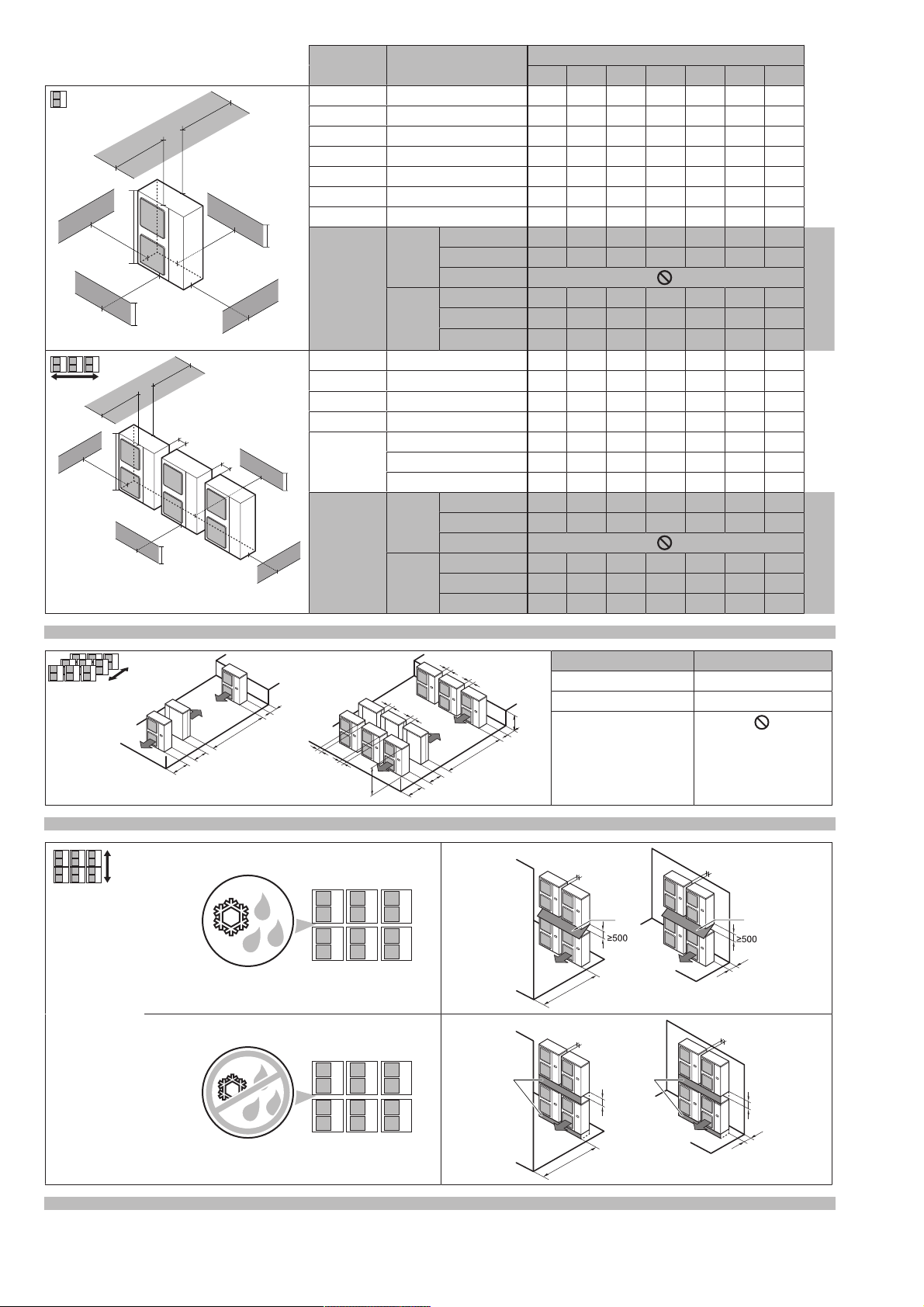

1

b (mm)

HB≤½H

U

b≥250

½HU<HB≤H

U

b≥300

HB>H

U

HBH

U

≥1000

≥200

≥2000

≥100

≥3000

≥600

≥1500

b

≥100

≥100

≥100

≥100

≥100

≥100

H

B

H

U

2

A1

B1

A2

B2

A2

≥1000

A2

≥300

≥100

≥100

≥100

≥300

≥100

≥100

B2

≥100

≥1000

B2

3

Table of contents

Table of contents

1 About the documentation 4

1.1 About this document.................................................................. 4

For the installer 4

2 About the box 4

2.1 Outdoor unit............................................................................... 4

2.1.1 To remove the accessories from the outdoor unit....... 4

2.1.2 To remove the transportation stay .............................. 4

3 About the units and options 4

3.1 About the outdoor unit ............................................................... 4

3.2 System layout............................................................................ 5

4 Preparation 5

4.1 Preparing the installation site .................................................... 5

4.1.1 Installation site requirements of the outdoor unit ........ 5

4.1.2 Additional installation site requirements of the

outdoor unit in cold climates ....................................... 5

4.2 Preparing refrigerant piping....................................................... 5

4.2.1 Refrigerant piping requirements.................................. 5

4.2.2 Refrigerant piping material.......................................... 5

4.2.3 To select the piping size ............................................. 6

4.2.4 To select refrigerant branch kits.................................. 6

4.3 Preparing electrical wiring ......................................................... 7

4.3.1 Safety device requirements ........................................ 7

5 Installation 7

5.1 Opening the units ...................................................................... 7

5.1.1 To open the outdoor unit............................................. 7

5.2 Mounting the outdoor unit.......................................................... 7

5.2.1 To provide the installation structure............................ 7

5.2.2 To install the outdoor unit............................................ 7

5.2.3 To provide drainage.................................................... 7

5.2.4 To prevent the outdoor unit from falling over .............. 8

5.3 Connecting the refrigerant piping .............................................. 8

5.3.1 Using the stop valve and service port......................... 8

5.3.2 To remove the pinched pipes...................................... 9

5.3.3 To connect the refrigerant piping to the outdoor unit .. 9

5.4 Checking the refrigerant piping ................................................. 10

5.4.1 About checking the refrigerant piping ......................... 10

5.4.2 Checking refrigerant piping: General guidelines......... 11

5.4.3 Checking refrigerant piping: Setup.............................. 11

5.4.4 To perform a leak test ................................................. 11

5.4.5 To perform vacuum drying .......................................... 11

5.5 To insulate the refrigerant piping............................................... 11

5.6 Charging refrigerant .................................................................. 12

5.6.1 Precautions when charging refrigerant ....................... 12

5.6.2 To determine the additional refrigerant amount.......... 12

5.6.3 To charge refrigerant .................................................. 12

5.6.4 Error codes when charging refrigerant........................ 13

5.6.5 To fix the fluorinated greenhouse gases label ............ 13

5.7 Connecting the electrical wiring................................................. 14

5.7.1 Field wiring: Overview................................................. 14

5.7.2 Guidelines when knocking out knockout holes ........... 14

5.7.3 Guidelines when connecting the electrical wiring ....... 14

5.7.4 To connect the electrical wiring on the outdoor unit.... 14

5.8 Finishing the outdoor unit installation ........................................ 15

5.8.1 To finish the transmission wiring................................. 15

6 Configuration 15

6.1 Making field settings.................................................................. 15

6.1.1 About making field settings......................................... 15

6.1.2 To access the field setting components...................... 16

6.1.3 Field setting components............................................ 16

6.1.4 To access mode 1 or 2 ................................................ 16

6.1.5 To use mode 1 ............................................................. 17

6.1.6 To use mode 2 ............................................................. 17

6.1.7 Mode 1 (and default situation): Monitoring settings ..... 17

6.1.8 Mode 2: Field settings.................................................. 18

6.1.9 To connect the PC configurator to the outdoor unit ..... 20

7 Commissioning 20

7.1 Precautions when commissioning .............................................. 20

7.2 Checklist before commissioning................................................. 20

7.3 Checklist during commissioning ................................................. 21

7.3.1 About the test run......................................................... 21

7.3.2 To perform a test run (7-segments display) ................. 21

7.3.3 Correcting after abnormal completion of the test run... 21

7.3.4 Operating the unit ........................................................ 21

8 Troubleshooting 21

8.1 Solving problems based on error codes..................................... 21

8.1.1 Error codes: Overview ................................................. 22

9 Technical data 23

9.1 Overview: Technical data ........................................................... 23

9.2 Dimensions: Outdoor unit........................................................... 24

9.3 Service space: Outdoor unit ....................................................... 25

9.4 Piping diagram: Outdoor unit...................................................... 26

9.5 Wiring diagram: Outdoor unit ..................................................... 27

9.6 Technical specifications: Outdoor unit........................................ 28

9.7 Capacity table: Indoor unit.......................................................... 30

For the user 31

10 About the system 31

10.1 System layout ............................................................................. 31

11 User interface 31

12 Operation 31

12.1 Operation range ......................................................................... 31

12.2 Operating the system ................................................................. 31

12.2.1 About operating the system ......................................... 31

12.2.2 About cooling, heating, fan only, and automatic

operation ...................................................................... 31

12.2.3 About the heating operation ......................................... 31

12.2.4 To operate the system ................................................. 32

12.3 Using the dry program ................................................................ 32

12.3.1 About the dry program ................................................. 32

12.3.2 To use the dry program................................................ 32

12.4 Adjusting the air flow direction.................................................... 32

12.4.1 About the air flow flap .................................................. 32

12.5 Setting the master user interface ............................................... 32

12.5.1 About setting the master user interface ....................... 32

12.5.2 To designate the master user interface (VRV DX)....... 33

12.5.3 To designate the master user interface (RA DX) ......... 33

13 Maintenance and service 33

13.1 About the refrigerant................................................................... 33

13.2 After-sales service and warranty ................................................ 33

13.2.1 Warranty period ........................................................... 33

13.2.2 Recommended maintenance and inspection ............... 33

14 Troubleshooting 34

14.1 Error codes: Overview ................................................................ 34

14.2 Symptoms that are NOT system malfunctions ........................... 35

14.2.1 Symptom: The system does not operate ..................... 35

14.2.2 Symptom: Fan operation is possible, but cooling and

heating do not work...................................................... 35

14.2.3 Symptom: The fan strength does not correspond to

the setting .................................................................... 35

14.2.4 Symptom: The fan direction does not correspond to

the setting .................................................................... 35

RXYSQ6TMYFK

VRV IV-S system air conditioner

4P524881-1 – 2018.02

Installation and operation manual

3

1 About the documentation

1

3 (12.3 N·m)3 (12.3 N·m)

2

2

1

a

b

14.2.5 Symptom: White mist comes out of a unit (Indoor

unit) ............................................................................. 35

14.2.6 Symptom: White mist comes out of a unit (Indoor

unit, outdoor unit) ........................................................ 35

14.2.7 Symptom: The user interface display reads "U4" or

"U5" and stops, but then restarts after a few minutes. 36

14.2.8 Symptom: Noise of air conditioners (Indoor unit) ........ 36

14.2.9 Symptom: Noise of air conditioners (Indoor unit,

outdoor unit)................................................................ 36

14.2.10 Symptom: Noise of air conditioners (Outdoor unit) ..... 36

14.2.11 Symptom: Dust comes out of the unit ......................... 36

14.2.12 Symptom: The units can give off odours..................... 36

14.2.13 Symptom: The outdoor unit fan does not spin ............ 36

14.2.14 Symptom: The display shows "88".............................. 36

14.2.15 Symptom: The compressor in the outdoor unit does

not stop after a short heating operation ...................... 36

14.2.16 Symptom: The inside of an outdoor unit is warm

even when the unit has stopped ................................. 36

14.2.17 Symptom: Hot air can be felt when the indoor unit is

stopped ....................................................................... 36

15 Relocation 36

16 Disposal 36

1 About the documentation

1.1 About this document

INFORMATION

Make sure that the user has the printed documentation and

ask him/her to keep it for future reference.

Target audience

Authorised installers + end users

INFORMATION

This appliance is intended to be used by expert or trained

users in shops, in light industry and on farms, or for

commercial use by lay persons.

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you must read before installing

▪ Format: Paper (in the box of the outdoor unit)

▪ Outdoor unit installation and operation manual:

▪ Installation and operation instructions

▪ Format: Paper (in the box of the outdoor unit)

▪ Installer and user reference guide:

▪ Preparation of the installation, reference data,…

▪ Detailed step-by-step instructions and background information

for basic and advanced usage

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

extranet (authentication required).

For the installer

2 About the box

2.1 Outdoor unit

2.1.1 To remove the accessories from the outdoor unit

1 Remove the service cover. See "5.1.1 To open the outdoor

unit"on page7.

2 Remove the accessories.

2.1.2 To remove the transportation stay

NOTICE

If the unit is operated with the transportation stay attached,

abnormal vibration or noise may be generated.

3 About the units and options

3.1 About the outdoor unit

This installation manual concerns the VRV IV-S, full inverter driven,

heat pump system.

This unit is intended for outdoor installation and aimed for air to air

heat pump applications.

Installation and operation manual

4

VRV IV-S system air conditioner

RXYSQ6TMYFK

4P524881-1 – 2018.02

4 Preparation

d d

c cb

a

T

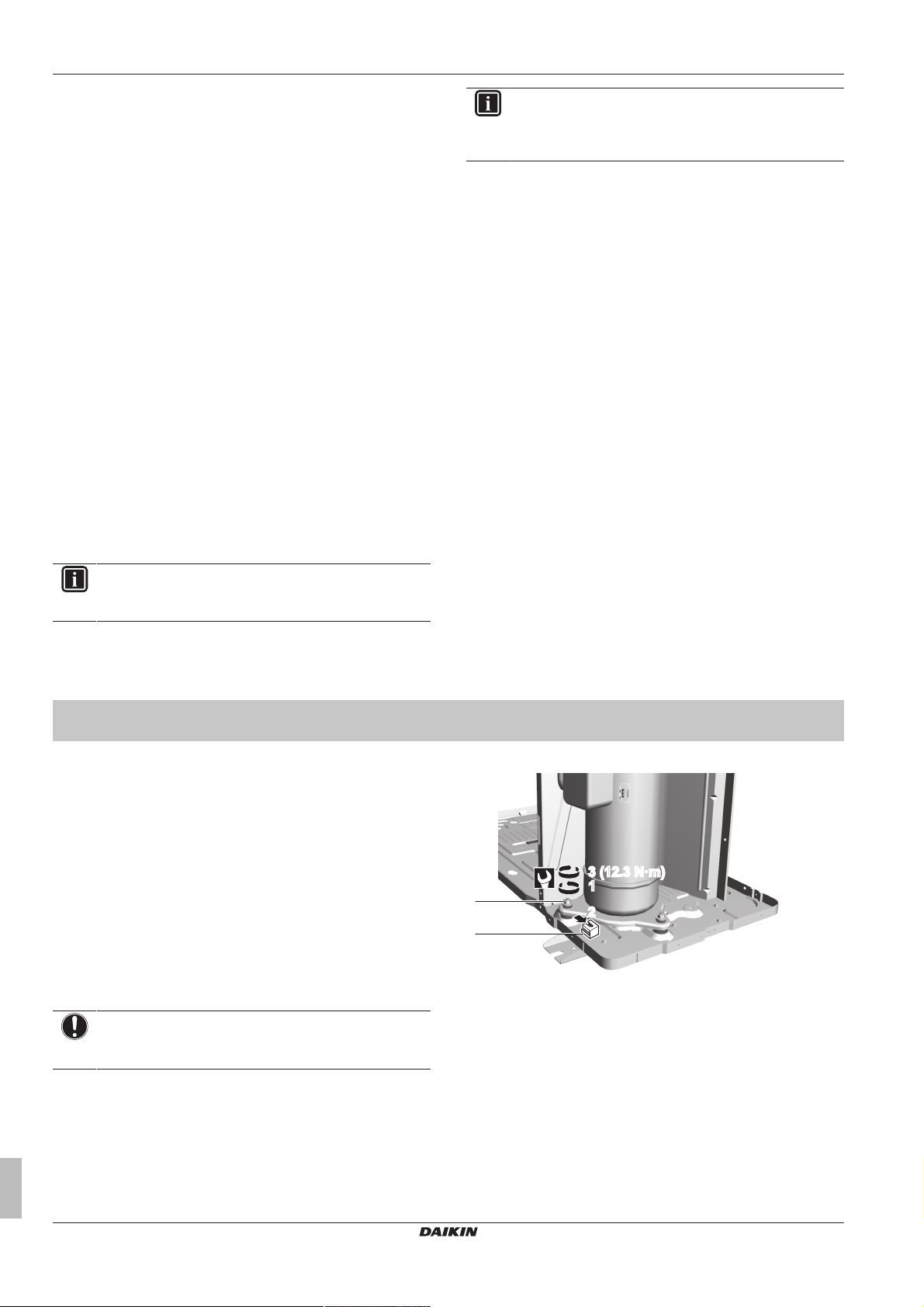

AO

(°C WB)

a b

20

15.5

15

10

5

0

–5

–10

–15

–20

10 15 20 25

27

30

T

AI

(°C DB)

Specification RXYSQ6

Capacity Heating 12.3kW

Cooling 12.8~15.1kW

Ambient design

temperature

Heating –20~15.5°CWB

Cooling –5~52°CDB

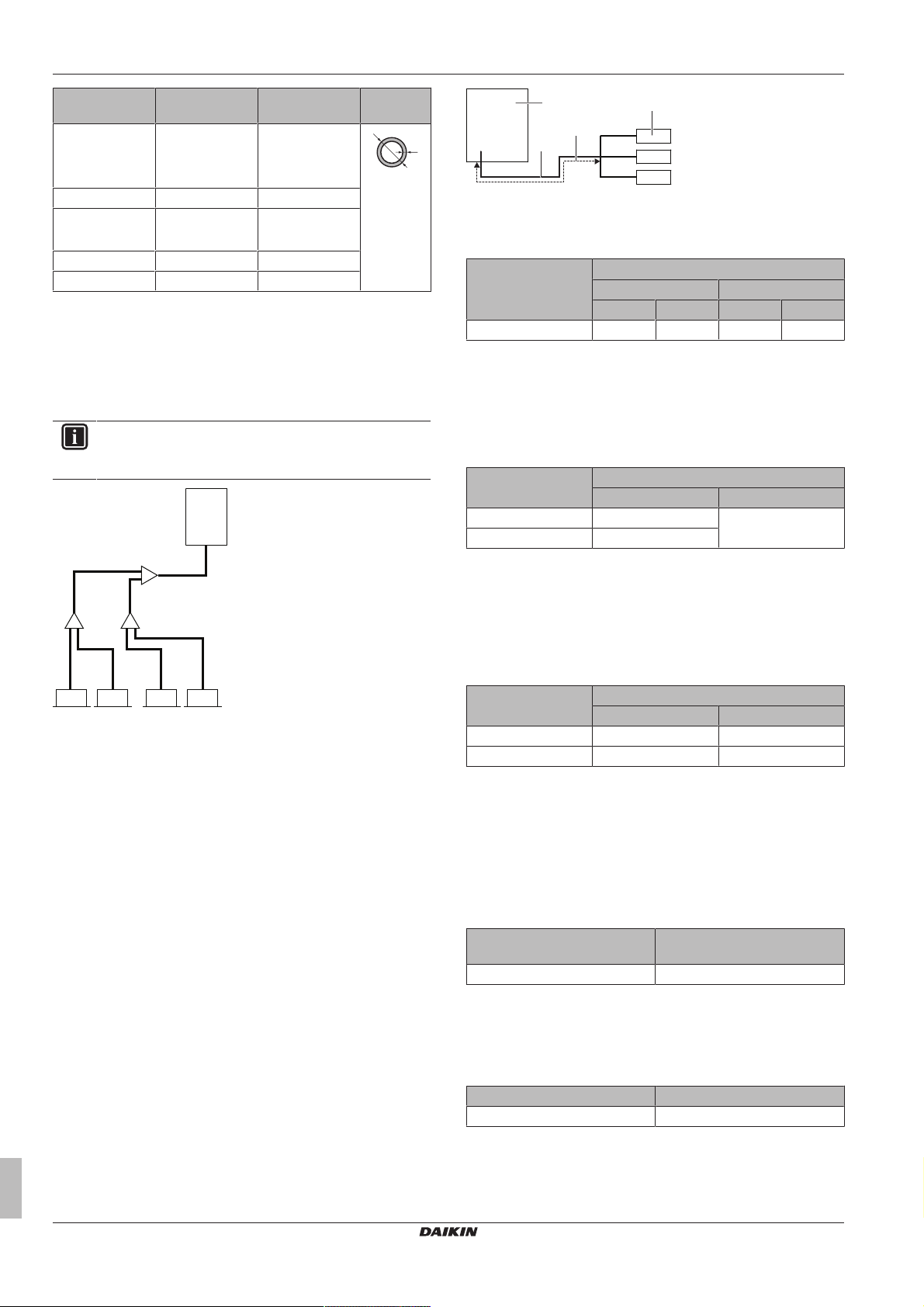

3.2 System layout

NOTICE

Design of the system must not be done at temperatures

below –15°C.

a VRV IV-S Heat pump outdoor unit

b Refrigerant piping

c VRV direct expansion (DX) indoor unit

d User interface (dedicated depending on indoor unit type)

4.1.2 Additional installation site requirements of the outdoor unit in cold climates

NOTICE

When operating the unit in heating in a low outdoor

ambient temperature with high humidity conditions, make

sure to take precautions to keep the drain holes of the unit

free by using proper equipment.

In heating:

4 Preparation

4.1 Preparing the installation site

4.1.1 Installation site requirements of the outdoor unit

Mind the spacing guidelines. See the "Technical data" chapter, and

the figures on the inside of the front cover.

CAUTION

Appliance not accessible to the general public, install it in a

secured area, protected from easy access.

This unit, both indoor and outdoor, is suitable for

installation in a commercial and light industrial

environment.

NOTICE

This is a class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

a Warming up operation range

b Operation range

TAI Ambient indoor temperature

TAO Ambient outdoor temperature

If the unit is selected to operate at ambient temperatures

lower than –5°C for 5 days or longer, with relative humidity

levels exceeding 95%, we recommend to apply a Daikin

range specifically designed for such application and/or to

contact your dealer for further advice.

4.2 Preparing refrigerant piping

4.2.1 Refrigerant piping requirements

NOTICE

Refrigerant R410A requires strict cautions for keeping the

system clean and dry. Foreign materials (including mineral

oils or moisture) should be prevented from getting mixed

into the system.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30mg/10m.

4.2.2 Refrigerant piping material

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Piping temper grade and thickness:

RXYSQ6TMYFK

VRV IV-S system air conditioner

4P524881-1 – 2018.02

Installation and operation manual

5

4 Preparation

t

Ø

A

B-1 B-2

C-1 C-2 C-3 C-4

1

3-1 3-2 3-3 3-4

VRV DX

2

2 2

a

e

b

c

d

Outer diameter

Temper grade Thickness (t)

(a)

(Ø)

6.4mm (1/4")

Annealed (O) ≥0.80mm

9.5mm (3/8")

12.7mm (1/2")

15.9mm (5/8") Annealed (O) ≥0.99mm

19.1mm (3/4")

Half hard (1/2H) ≥0.80mm

22.2mm (7/8")

25.4mm (1") Half hard (1/2H) ≥0.88mm

28.6mm (1‑1/8") Half hard (1/2H) ≥0.99mm

(a) Depending on the applicable legislation and the unit's

maximum working pressure (see "PS High" on the unit

name plate), larger piping thickness might be required.

4.2.3 To select the piping size

Determine the proper size using the following tables and reference

figure (only for indication).

INFORMATION

Combination of RA DX and aircurtain indoor units is not

allowed.

a Outdoor unit

b Main pipes

c Increase

d First refrigerant branch kit

e Indoor unit

Outdoor unit

capacity type (HP)

Piping outer diameter size (mm)

Gas pipe Liquid pipe

Standard Size-up Standard Size-up

6 22.2 25.4

(a) If size is NOT available, increase is NOT allowed.

(a)

9.5 12.7

B: Piping between refrigerant branch kits

Choose from the following table in accordance with the indoor unit

total capacity type, connected downstream. Do not let the

connection piping exceed the refrigerant piping size chosen by the

general system model name.

Indoor unit capacity

index

<150 15.9 9.5

150≤x<200 19.1

Piping outer diameter size (mm)

Gas pipe Liquid pipe

1 Outdoor unit

2 Refrigerant branch kits

3-1~3-4 VRVDX indoor units

A Piping between outdoor unit and (first) refrigerant branch

B-1 B-2 Piping between refrigerant branch kits

C-1~C-4 Piping between refrigerant branch kit and indoor unit

In case the required pipe sizes (inch sizes) are not available, it is

also allowed to use other diameters (mm sizes), taken the following

into account:

▪ Select the pipe size nearest to the required size.

▪ Use the suitable adapters for the change-over from inch to mm

pipes (field supply).

▪ The additional refrigerant calculation has to be adjusted as

mentioned in "5.6.2 To determine the additional refrigerant

amount"on page12.

A: Piping between outdoor unit and (first) refrigerant branch kit or between outdoor unit and indoor unit

When the equivalent pipe length between outdoor and indoor units is

90m or more, the size of the main pipes (both gas side and liquid

side) must be increased. Depending on the length of the piping, the

capacity may drop, but even in such a case the size of the main

pipes has to be increased. More specifications can be found in the

technical engineering data book.

Installation and operation manual

6

Example: Downstream capacity for B-1 = capacity index of unit 3-1

+ capacity index of unit 3-2

C: Piping between refrigerant branch kit and indoor unit

Use the same diameters as the connections (liquid, gas) on the

indoor units. The diameters of the indoor units are as follows:

Indoor unit capacity

index

Piping outer diameter size (mm)

Gas pipe Liquid pipe

15~50 12.7 6.4

kit

63~160 15.9 9.5

4.2.4 To select refrigerant branch kits

For piping example, refer to "4.2.3 To select the piping size" on

page6.

Refnet joint at first branch (counting from outdoor unit)

When using refnet joints at the first branch counted from the outdoor

unit side, choose from the following table in accordance with the

capacity of the outdoor unit. Example: Refnet joint A→B‑1.

Outdoor unit capacity type

(HP)

6 KHRQ22M29T9

Refnet joints at other branches

For refnet joints other than the first branch, select the proper branch

kit model based on the total capacity index of all indoor units

connected after the refrigerant branch. Example: Refnet joint

B‑1→C‑1.

Indoor unit capacity index Refrigerant branch kit

x<200 KHRQ22M20T

Refnet headers

Concerning refnet headers, choose from the following table in

accordance with the total capacity of all the indoor units connected

below the refnet header.

Refrigerant branch kit

RXYSQ6TMYFK

VRV IV-S system air conditioner

4P524881-1 – 2018.02

5 Installation

3×

(mm)

>150

620

(485-495)

490

4× M12

a

4× M12

Indoor unit capacity index Refrigerant branch kit

x<200 KHRQ22M29H

INFORMATION

Maximum 8 branches can be connected to a header.

4.3 Preparing electrical wiring

4.3.1 Safety device requirements

The power supply must be protected with the required safety

devices, i.e. a main switch, a slow blow fuse on each phase and an

earth leakage protector in accordance with the applicable legislation.

Selection and sizing of the wiring should be done in accordance with

the applicable legislation based on the information mentioned in the

table below.

Model Minimum

circuit

ampacity

RXYSQ6 22A 25A 3N~50 / 60Hz

Transmission wiring

Transmission wiring Vinyl cords with 0.75 to

Maximum wiring length

(= distance between outdoor and

furthest indoor unit)

Total wiring length

(= distance between outdoor and

all indoors)

If the total transmission wiring exceeds these limits, it may

result in communication error.

Recommended

fuses

1.25mm² sheath or cables

Power supply

380-415 / 400V

(2‑core wires)

300m

600m

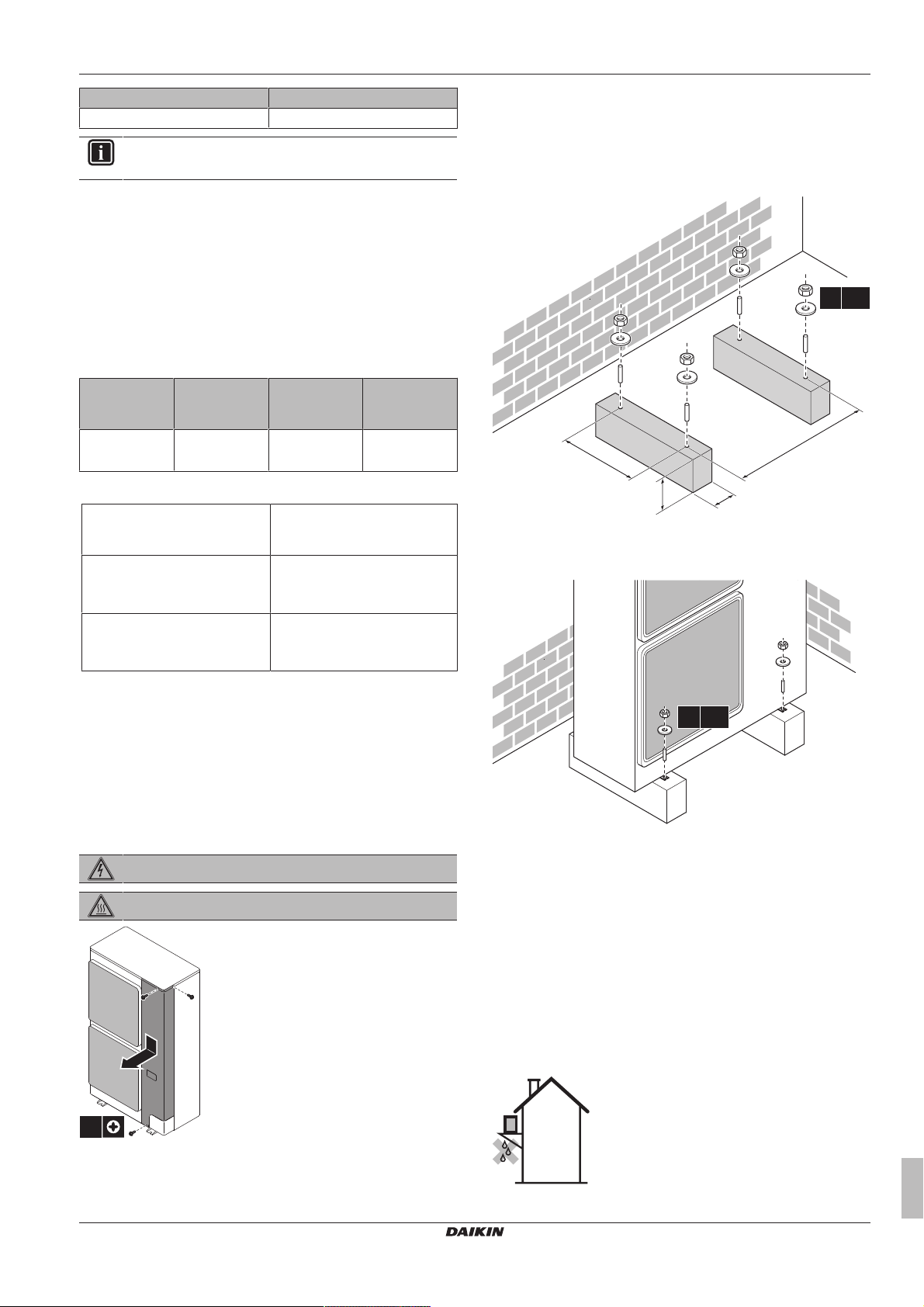

5.2 Mounting the outdoor unit

5.2.1 To provide the installation structure

Prepare 4 sets of anchor bolts, nuts and washers (field supply) as

follows:

a Make sure not to cover the drain holes.

5.2.2 To install the outdoor unit

5 Installation

5.1 Opening the units

5.1.1 To open the outdoor unit

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF BURNING

5.2.3 To provide drainage

▪ Make sure that condensation water can be evacuated properly.

▪ Install the unit on a base to make sure that there is proper

drainage in order to avoid ice accumulation.

▪ Prepare a water drainage channel around the foundation to drain

waste water away from the unit.

▪ Avoid drain water flowing over the footpath, so that it does NOT

become slippery in case of ambient freezing temperatures.

▪ If you install the unit on a frame, install a waterproof plate within

150 mm of the bottom side of the unit in order to prevent water

from getting into the unit and to avoid drain water dripping (see the

following figure).

RXYSQ6TMYFK

VRV IV-S system air conditioner

4P524881-1 – 2018.02

Installation and operation manual

7

5 Installation

≥150 mm

102

118

62

59

216

130

21

20

32

52

98

89

a

1

2

3

4

NOTICE

If drain holes of the outdoor unit are covered by a mounting

base or by floor surface, raise the unit to provide a free

space of more than 150mm under the outdoor unit.

Drain holes (dimensions in mm)

a Drain holes

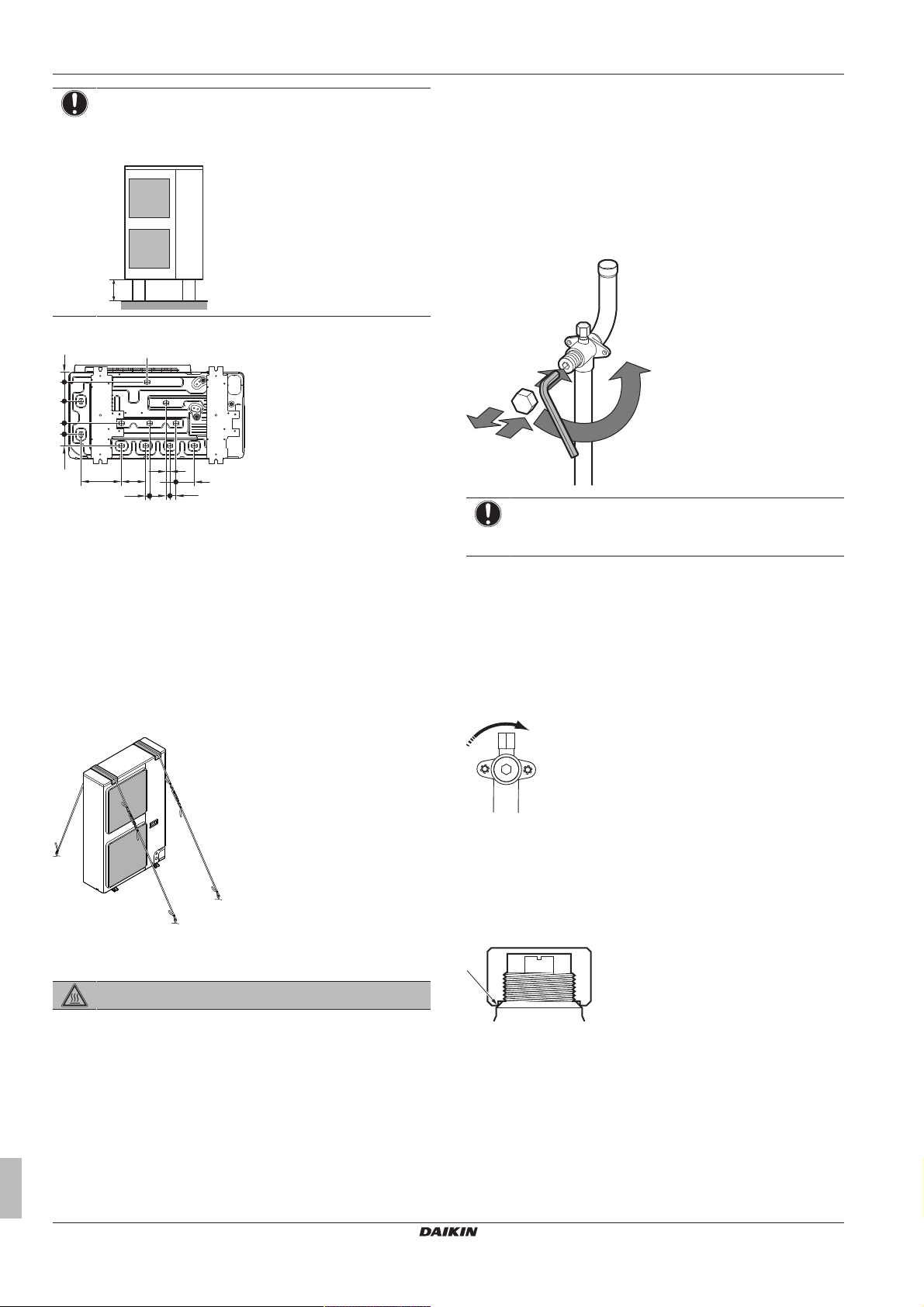

5.2.4 To prevent the outdoor unit from falling over

In case the unit is installed in places where strong wind can tilt the

unit, take following measure:

1 Prepare 2 cables as indicated in the following illustration (field

supply).

2 Place the 2 cables over the outdoor unit.

3 Insert a rubber sheet between the cables and the outdoor unit

to prevent the cables from scratching the paint (field supply).

4 Attach the ends of the cables and tighten them.

2 Insert a hexagon wrench into the stop valve and turn the stop

valve counterclockwise.

3 When the stop valve cannot be turned any further, stop turning.

Result: The valve is now open.

To fully open the Ø19.1 mm~Ø25.4 mm stop valve, turn the

hexagonal wrench until a torque between 27 and 33 N•m is

achieved.

Inadequate torque may cause leakage of refrigerant and breakage of

the stop valve cap.

NOTICE

Pay attention that mentioned torque range is applicable for

opening Ø19.1~Ø25.4mm stop valves only.

To close the stop valve

1 Remove the stop valve cover.

2 Insert a hexagon wrench into the stop valve and turn the stop

valve clockwise.

3 When the stop valve cannot be turned any further, stop turning.

Result: The valve is now closed.

Closing direction:

5.3 Connecting the refrigerant piping

DANGER: RISK OF BURNING

5.3.1 Using the stop valve and service port

To handle the stop valve

▪ Make sure to keep all stop valves open during operation.

▪ The stop valve is factory closed.

To open the stop valve

1 Remove the stop valve cover.

Installation and operation manual

8

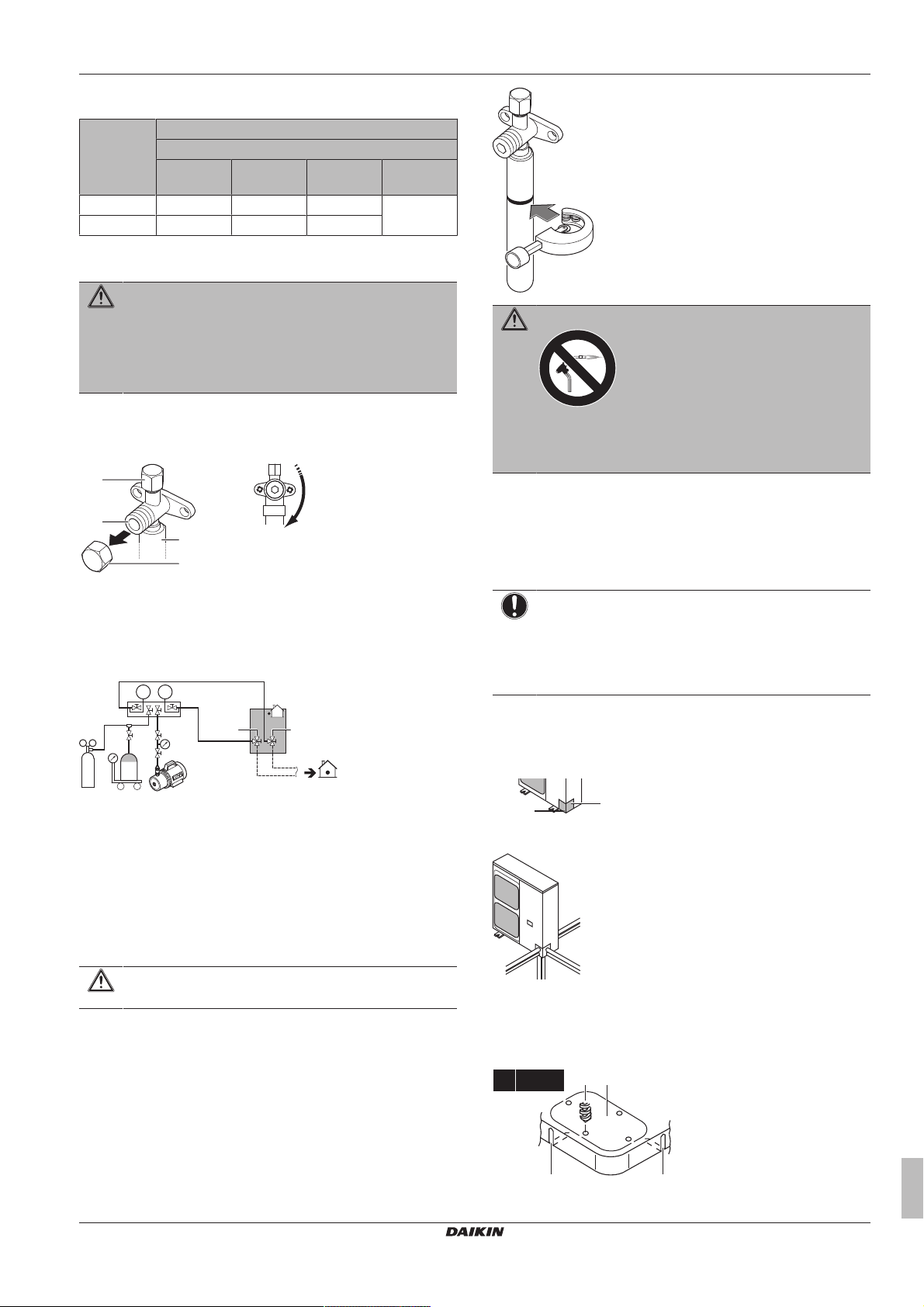

To handle the stop valve cover

▪ The stop valve cover is sealed where indicated by the arrow. Do

NOT damage it.

▪ After handling the stop valve, tighten the stop valve cover

securely, and check for refrigerant leaks. For the tightening

torque, refer to the table below.

To handle the service port

▪ Always use a charge hose equipped with a valve depressor pin,

since the service port is a Schrader type valve.

▪ After handling the service port, make sure to tighten the service

port cover securely. For the tightening torque, refer to the table

below.

▪ Check for refrigerant leaks after tightening the service port cover.

RXYSQ6TMYFK

VRV IV-S system air conditioner

4P524881-1 – 2018.02

Tightening torques

c

d

a

b

p<p

>

R410AN2

b c e

a

f g

d

A B

a

b

a

b

c

d

cc

ba

4× Ø6 mm

5 Installation

Stop valve

size (mm)

Tightening torque N•m (turn clockwise to close)

Shaft

Valve body Hexagonal

wrench

Cap (valve

lid)

Service

port

Ø12.7 8.1~9.9 4mm 18.0~22.0 11.5~13.9

Ø25.4 27.0~33.0 8mm 22.5~27.5

5.3.2 To remove the pinched pipes

WARNING

Any gas or oil remaining inside the stop valve may blow off

the pinched piping.

Failure to observe the instructions in procedure below

properly may result in property damage or personal injury,

which may be serious depending on the circumstances.

Use the following procedure to remove the pinched piping:

1 Remove the valve cover and make sure that the stop valves are

fully closed.

a Service port and service port cover

b Stop valve

c Field piping connection

d Stop valve cover

2 Connect the vacuuming/recovery unit through a manifold to the

service port of all stop valves.

WARNING

Never remove the pinched piping by brazing.

Any gas or oil remaining inside the stop valve may blow off

the pinched piping.

6 Wait until all oil is dripped out before continuing with the

connection of the field piping in case the recovery was not

complete.

5.3.3 To connect the refrigerant piping to the outdoor unit

NOTICE

Be sure that the field installed piping does not touch other

pipes, the bottom panel or side panel. Especially for the

bottom and side connection, be sure to protect the piping

with suitable insulation, to prevent it from coming into

contact with the casing.

1 Do the following:

▪ Remove the service cover. See "5.1.1 To open the outdoor

unit"on page7.

▪ Remove the piping intake plate (a) with screw (b).

a Pressure reducing valve

b Nitrogen

c Weighing scales

d Refrigerant R410A tank (siphon system)

e Vacuum pump

f Liquid line stop valve

g Gas line stop valve

A Valve A

B Valve B

3 Recover gas and oil from the pinched piping by using a

recovery unit.

CAUTION

Do not vent gases into the atmosphere.

4 When all gas and oil is recovered from the pinched piping,

disconnect the charge hose and close the service ports

5 Cut off the lower part of the gas and liquid stop valve pipes

along the black line. Use an appropriate tool (e.g. a pipe cutter,

a pair of nippers).

RXYSQ6TMYFK

VRV IV-S system air conditioner

4P524881-1 – 2018.02

2 Choose a piping route (a, b, c or d).

3 If you have chosen the downwards piping route:

▪ Drill (a, 4×) and remove the knockout hole (b).

▪ Cut out the slits (c) with a metal saw.

Installation and operation manual

9

5 Installation

a

b

a b c

a b f g

cde

A

A

cdd1

dc

c d d1

d

d1

a

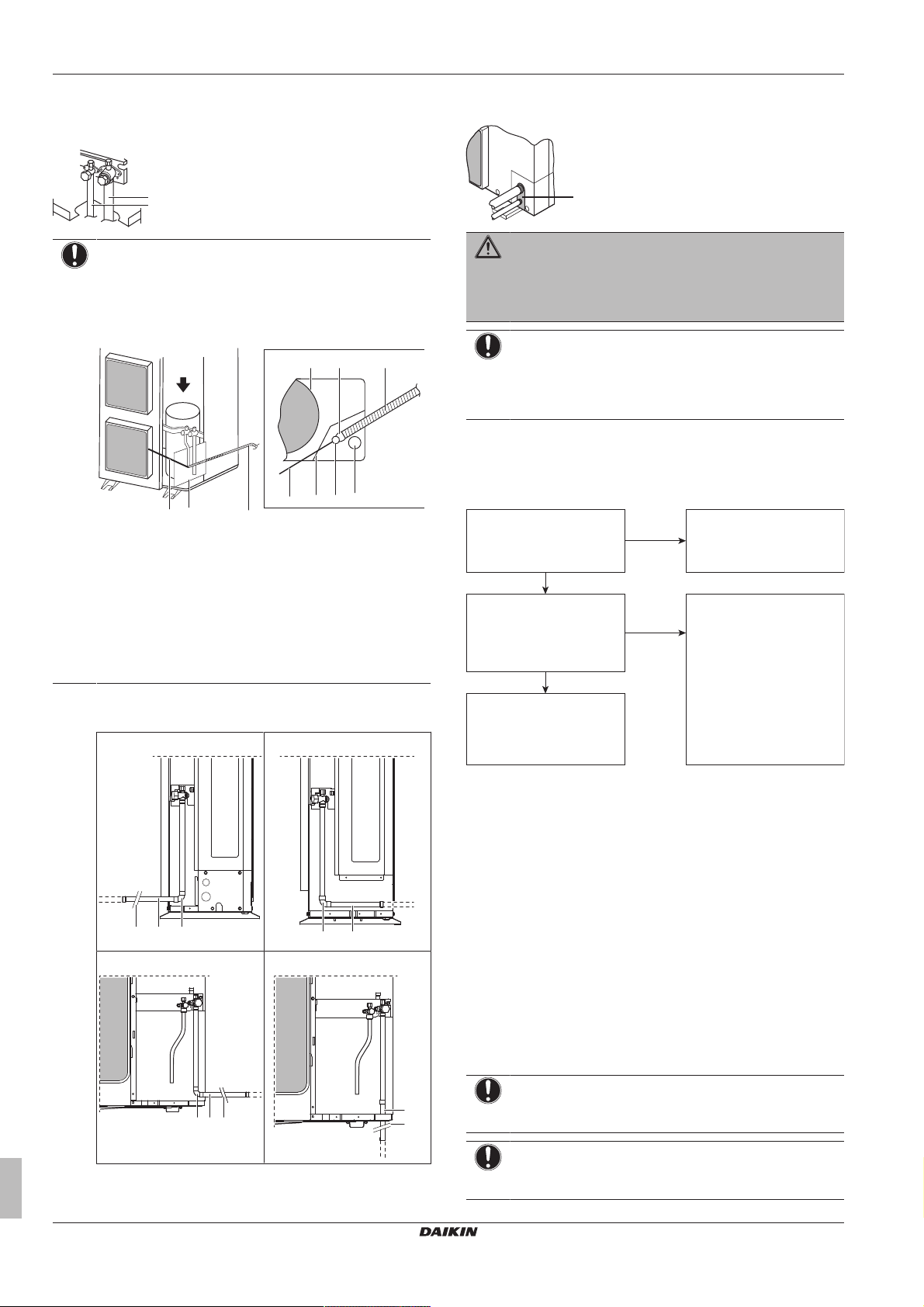

Refrigerant piping works are

finished?

The indoor units and/or

outdoor unit were already

powered ON?

Use procedure:

"Method 2: After power ON".

Finish piping work.

Use procedure:

"Method 1: Before power ON

(regular method)".

Yes

No

No

Yes

4 Do the following:

▪ Connect the liquid pipe (a) to the liquid stop valve. (brazing)

▪ Connect the gas pipe (b) to the gas stop valve. (brazing)

NOTICE

When brazing: First braze the liquid side piping, then the

gas side piping. Enter the electrode from the front of the

unit and the welding torch from the right side to braze with

the flames facing outside and avoid the compressor sound

insulation and other piping.

a Electrode

b Burning-resistant plate

c Welding torch

d Flames

e Compressor sound insulation

f Liquid side piping

g Gas side piping

▪ Connect the gas piping accessories (c, d), and cut them to

the required length (d1).

6 Seal all gaps (example: a) to prevent snow and small animals

from entering the system.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

NOTICE

Make sure to open the stop valves after installing the

refrigerant piping and performing vacuum drying. Running

the system with the stop valves closed may break the

compressor.

5.4 Checking the refrigerant piping

5.4.1 About checking the refrigerant piping

Possibility 1: To the front

Possibility 3: To the side

5 Reattach the service cover and the piping intake plate.

Possibility 2: To the back

It is very important that all refrigerant piping work is done before the

units (outdoor or indoor) are powered on.

When the units are powered on, the expansion valves will initialise.

This means that they will close. Leak test and vacuum drying of field

piping and indoor units is impossible when this happens.

Therefore, there will be explained 2 methods for initial installation,

leak test and vacuum drying.

Method 1: Before power ON

If the system has not yet been powered on, no special action is

Possibility 4: Downwards

required to perform the leak test and the vacuum drying.

Method 2: After power ON

If the system has already been powered on, activate setting [2‑21]

(refer to "6.1.4 To access mode 1 or 2" on page 16). This setting

will open field expansion valves to guarantee a R410A piping

pathway and make it possible to perform the leak test and the

vacuum drying.

NOTICE

Make sure that all indoor units connected to the outdoor

unit are powered on.

NOTICE

Wait until the outdoor unit has finished the initialisation to

apply setting [2‑21].

Installation and operation manual

10

VRV IV-S system air conditioner

RXYSQ6TMYFK

4P524881-1 – 2018.02

5 Installation

p<p

>

N2

C

b c e

a

g

f

d

A B

Leak test and vacuum drying

Checking the refrigerant piping involves:

▪ Checking for any leakages in the refrigerant piping.

▪ Performing vacuum drying to remove all moisture, air or nitrogen

in the refrigerant piping.

If there is a possibility of moisture being present in the refrigerant

piping (for example, water may have entered the piping), first carry

out the vacuum drying procedure below until all moisture has been

removed.

All piping inside the unit has been factory tested for leaks.

Only field installed refrigerant piping needs to be checked.

Therefore, make sure that all the outdoor unit stop valves are firmly

closed before performing leak test or vacuum drying.

NOTICE

Make sure that all (field supplied) field piping valves are

OPEN (not outdoor unit stop valves!) before you start leak

test and vacuuming.

For more information on the state of the valves, refer to

"5.4.3Checking refrigerant piping: Setup"on page11.

5.4.2 Checking refrigerant piping: General guidelines

Connect the vacuum pump through a manifold to the service port of

all stop valves to increase efficiency (refer to "5.4.3 Checking

refrigerant piping: Setup"on page11).

NOTICE

Use a 2-stage vacuum pump with a non-return valve or a

solenoid valve that can evacuate to a gauge pressure of

–100.7kPa (−1.007bar)(5Torr absolute).

NOTICE

Make sure the pump oil does not flow oppositely into the

system while the pump is not working.

NOTICE

Do not purge the air with refrigerants. Use a vacuum pump

to evacuate the installation.

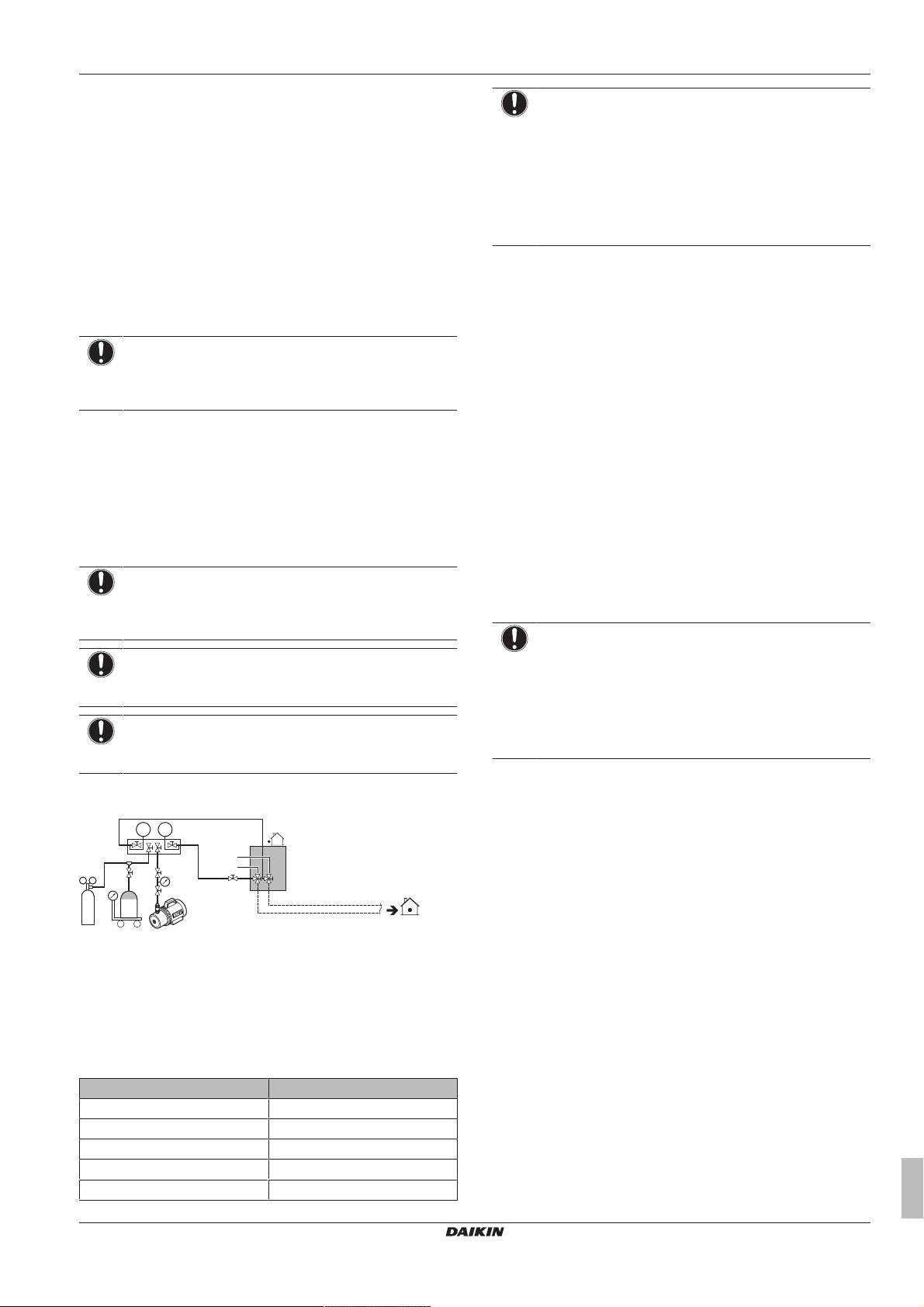

5.4.3 Checking refrigerant piping: Setup

a Pressure reducing valve

b Nitrogen

c Weighing scales

d Refrigerant R410A tank (siphon system)

e Vacuum pump

f Liquid line stop valve

g Gas line stop valve

A Valve A

B Valve B

C Valve C

Valve State of valve

Valve A Open

Valve B Open

Valve C Open

Liquid line stop valve Close

Gas line stop valve Close

RXYSQ6TMYFK

VRV IV-S system air conditioner

4P524881-1 – 2018.02

NOTICE

The connections to the indoor units and all indoor units

should also be leak and vacuum tested. Keep any possible

(field supplied) field piping valves open as well.

Refer to the indoor unit installation manual for more details.

Leak test and vacuum drying should be done before the

power supply is set to the unit. If not, see also the flow

chart earlier described in this chapter (see "5.4.1 About

checking the refrigerant piping"on page10).

5.4.4 To perform a leak test

The leak test must satisfy the specifications of EN378‑2.

To check for leaks: Vacuum leak test

1 Evacuate the system from the liquid and gas piping to

–100.7kPa (–1.007bar)(5Torr absolute) for more than 2 hours.

2 Once reached, turn off the vacuum pump and check that the

pressure does not rise for at least 1 minute.

3 Should the pressure rise, the system may either contain

moisture (see vacuum drying below) or have leaks.

To check for leaks: Pressure leak test

1 Break the vacuum by pressurising with nitrogen gas to a

minimum gauge pressure of 0.2 MPa (2 bar). Never set the

gauge pressure higher than the maximum operation pressure of

the unit, i.e. 4.0MPa (40bar).

2 Test for leaks by applying a bubble test solution to all piping

connections.

3 Discharge all nitrogen gas.

NOTICE

Make sure to use a recommended bubble test solution

from your wholesaler. Do not use soap water, which may

cause cracking of flare nuts (soap water may contain salt,

which absorbs moisture that will freeze when the piping

gets cold), and/or lead to corrosion of flared joints (soap

water may contain ammonia which causes a corrosive

effect between the brass flare nut and the copper flare).

5.4.5 To perform vacuum drying

To remove all moisture from the system, proceed as follows:

1 Evacuate the system for at least 2 hours to a target vacuum of

–100.7kPa (–1.007bar)(5Torr absolute).

2 Check that, with the vacuum pump turned off, the target

vacuum is maintained for at least 1 hour.

3 Should you fail to reach the target vacuum within 2 hours or

maintain the vacuum for 1 hour, the system may contain too

much moisture. In that case, break the vacuum by pressurising

with nitrogen gas to a gauge pressure of 0.05 MPa (0.5bar)

and repeat steps 1 to 3 until all moisture has been removed.

4 Depending on whether you want to immediately charge

refrigerant through the refrigerant charge port or first pre-charge

a portion of refrigerant through the liquid line, either open the

outdoor unit stop valves, or keep them closed. See "5.6.3 To

charge refrigerant"on page12 for more information.

5.5 To insulate the refrigerant piping

After finishing the leak test and vacuum drying, the piping must be

insulated. Take into account the following points:

▪ Make sure to insulate the connection piping and refrigerant branch

kits entirely.

▪ Be sure to insulate the liquid and gas piping (for all units).

Installation and operation manual

11

5 Installation

b

a

p<p

>

N2

C

b c e

a

g

f

d

A B

▪ Use heat resistant polyethylene foam which can withstand a

temperature of 70°C for liquid piping and polyethylene foam which

can withstand a temperature of 120°C for gas piping.

▪ Reinforce the insulation on the refrigerant piping according to the

installation environment.

Ambient

Humidity Minimum thickness

temperature

≤30°C 75% to 80% RH 15mm

>30°C ≥80% RH 20mm

Condensation might form on the surface of the insulation.

▪ If there is a possibility that condensation on the stop valve might

drip down into the indoor unit through gaps in the insulation and

piping because the outdoor unit is located higher than the indoor

unit, this must be prevented by sealing up the connections. See

below figure.

a Insulation material

b Caulking etc.

5.6 Charging refrigerant

NOTICE

Close the front panel before any refrigerant charge

operation is executed. Without the front panel attached the

unit cannot judge correctly whether it is operating properly

or not.

NOTICE

In case of maintenance and the system (outdoor unit+field

piping+indoor units) does not contain any refrigerant any

more (e.g., after refrigerant reclaim operation), the unit has

to be charged with its original amount of refrigerant (refer

to the nameplate on the unit) and the determined additional

refrigerant amount.

5.6.2 To determine the additional refrigerant amount

INFORMATION

For final charge adjustment in a test laboratory, contact

your dealer.

Formula:

R=[(X1×Ø15.9)×0.18+(X2×Ø12.7)×0.12+(X3×Ø9.5)×0.059+

(X4×Ø6.4)×0.022]

R Additional refrigerant to be charged [in kg and rounded off

to 1 decimal place]

X

Total length [m] of liquid piping size at Øa

1...4

Metric piping. When using metric piping, replace the weight factors

in the formula by the ones from the following table:

5.6.1 Precautions when charging refrigerant

Installation and operation manual

12

WARNING

▪ Only use R410A as refrigerant. Other substances may

cause explosions and accidents.

▪ R410A contains fluorinated greenhouse gases. Its

global warming potential (GWP) value is 2087.5. Do

NOT vent these gases into the atmosphere.

▪ When charging refrigerant, always use protective

gloves and safety glasses.

NOTICE

If the power of some units is turned off, the charging

procedure cannot be finished properly.

NOTICE

Be sure to turn on the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

NOTICE

If operation is performed within 12 minutes after the indoor

and outdoor units are turned on, the compressor will not

operate before the communication is established in a

correct way between outdoor unit(s) and indoor units.

NOTICE

Before starting charging procedures, check if the

7‑segment display indication of the compressor unit A1P

PCB is as normal (see "6.1.4 To access mode 1 or 2" on

page 16). If a malfunction code is present, see

"8.1Solving problems based on error codes"on page21.

NOTICE

Make sure all connected indoor units are recognised

(setting [1‑10]).

Inch piping Metric piping

Piping Weight factor Piping Weight factor

Ø6.4mm 0.022 Ø6mm 0.018

Ø9.5mm 0.059 Ø10mm 0.065

Ø12.7mm 0.12 Ø12mm 0.097

Ø15.9mm 0.18 Ø15mm 0.16

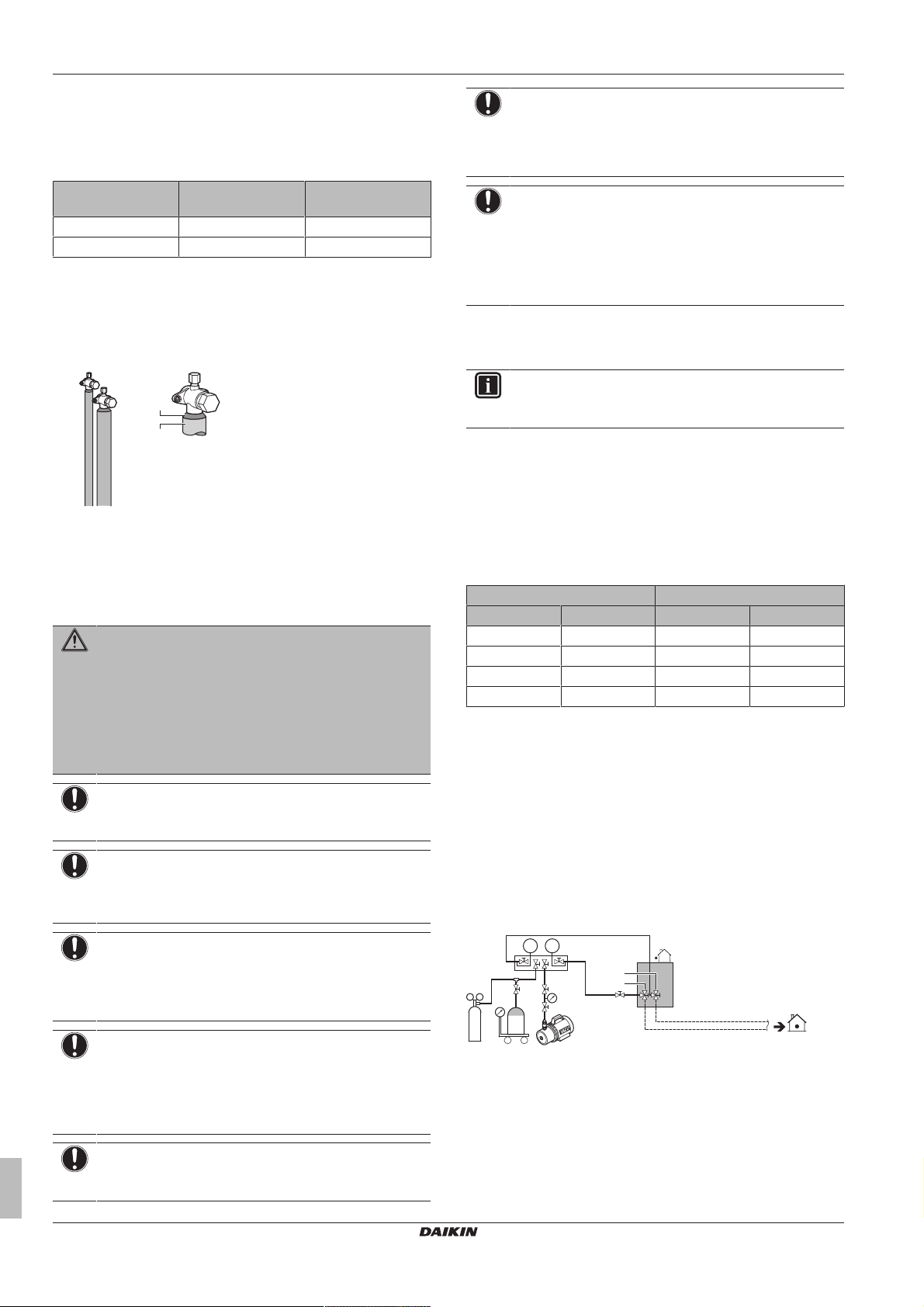

5.6.3 To charge refrigerant

To speed up the refrigerant charging process, it is in case of larger

systems recommended to first pre-charge a portion of refrigerant

through the liquid line before proceeding with the manual charging. It

can be skipped, but charging will take longer then.

Pre-charging refrigerant

Pre-charging can be done without compressor operation, by

connecting the refrigerant bottle to the service port of the liquid stop

valve.

1 Connect as shown. Make sure that all outdoor unit stop valves,

as well as valve A are closed.

a Pressure reducing valve

b Nitrogen

c Weighing scales

d Refrigerant R410A tank (siphon system)

e Vacuum pump

f Liquid line stop valve

g Gas line stop valve

A Valve A

B Valve B

C Valve C

2 Open valves C and B.

RXYSQ6TMYFK

VRV IV-S system air conditioner

4P524881-1 – 2018.02

Loading...

Loading...