Daikin RQYQ8PY1B, RQYQ10PY1B, RQYQ12PY1B, RQYQ14PY1B, RQYQ16PY1B Installation manuals

...

INSTALLATION MANUAL

System air conditioner

Series

MODELS

RQYQ8PY1B

RQYQ10PY1B

RQYQ12PY1B

RQYQ14PY1B

RQYQ16PY1B

RQYQ18PY1B

RQYQ20PY1B

RQYQ22PY1B

RQYQ24PY1B

RQYQ26PY1B

RQYQ28PY1B

RQYQ30PY1B

RQYQ32PY1B

RQYQ34PY1B

RQYQ36PY1B

RQYQ38PY1B

RQYQ40PY1B

RQYQ42PY1B

RQYQ44PY1B

RQYQ46PY1B

RQYQ48PY1B

English

Deutsch

Français

Español

Italiano

ΕλληνικÜ

Nederlands

Portugues

Рóссêий

Türkçe

[Q8 · 10 · 12 type]

4

1, 2, 3

[Q14 · 16 type]

4

1, 2, 3

1, 2, 3

Top view

<

1

If installed as a single unit

(Pattern 1)

2

1

3

45

6

7

8

(Pattern 2)

≥50

(Pattern 3)

≥10

≥10

1

≥50

≥300

>

≥300 ≥300

4

≥500

3

≥100

4

≥500

3

2

(Pattern 1)

≥10

(Pattern 2)

≥50

(Pattern 3)

<

When installed in serial

≥10

1

≥20

≥100

≥20

≥100

1

≥300

>

≥500

≥50

2

4

3

≥100

≥500

4

3

9

10

11

≥200

1

≥200

1

≥400 ≥400

figure 1

2

5

figure 4

figure 7

figure 2

figure 3

1

1

2

3

≥1500

≥1000

≥1000

≥1000

4

≥1500

≥1500

≥1500

(mm)

1

243

figure 5

100

100

≥

2

3

100

≥

100

≥

1

≥

100

2

3

100

≥

≥

66(3)

figure 8

2

3

figure 6

1

2

1

2

A

B

≥66

≥66

1

2

765

722-737

1

2

4

5

3

figure 9

1

figure 10

5

10

figure 14

2

6

3

4

5

3

1

2

figure 11

12

3

67

8

9

4

6

5

11

8

7

8

12

13

14

15

16

3

figure 15

1

figure 12

5

10

2

1

4

2

5

6

3

3

figure 13

12

3

67

8

9

4

6

5

8

11

7

8

12

13

14

18-1

figure 16

figure 17

1

2

3

1

2

figure 19

12

A-arrow view

1

B-arrow view

A

B

5

4

6

3

4

7

C

1

3

4

2

1

3

4

(C-arrow view)

D

1

5

6

1

18-2

4

(D-arrow view)

18-3

figure 18

1

2

9

10

8

8

7

3

4

5

11

12

8

12

13

6

figure 20

figure 21

figure 23

3

ABC

1

2

22

5

22

ABC I/P A1P

TO IN/D UNIT

C

A

F1 F2 F1 F2 Q1 Q2

B

3

1

5

2

22

1

2

TO OUT/D UNIT TO MULTI UNIT

1

4

F1 F2 F1 F2 F1 F2

3

4

6

8

6

7

11

10

99

22

22

figure 22

5

22

22

8

6

1

23

ABC I/P A1P A1P

TO IN/D UNIT

TO OUT/D UNIT

TO MULTI UNIT

F1 F2 F1 F2

Q1 Q2

A

C

B

311

4

6

TO MULTI UNIT

Q1 Q2

2

5

2

7

ABC I/P

(A1P)

1

4

2

figure 24

1

figure 25

5

L1 L2 L3 N

1

6

3

2

3

2

4

7

4

5

4

8

8

figure 26

[In case of Q8 · 10 · 12 type] [In case of Q14 · 16 type]

11

1

10

1

13

10

11

figure 27

1

2

figure 28

2

3

4

6

3

4

5

12

5

6

7

8

13 13

9

10

11

12

9

8

7

14

15

:

16

:

17

3

2

3

15

4

14

1

2

6

5

4

12

5

6

1

2

9

8

7

3

4

5

figure 29 figure 30

3

1

2

4

5

6

7

8

9

11

10 10

13

14

12

figure 31 figure 32

1

2

figure 33

11

3

1

2

13

4

5

6

7

8

9

14

(3)

15

10 10

:

12

:

13

67

4

5

9

14

figure 34

8

9

8

10

11

12

1

3

1

4

2

1

5

4

5

6

2

3

7

3

figure 35

RQYQ8PY1B

RQYQ10PY1B

RQYQ12PY1B

RQYQ14PY1B

RQYQ16PY1B

RQYQ18PY1B

RQYQ20PY1B

RQYQ22PY1B

RQYQ24PY1B

RQYQ26PY1B

RQYQ28PY1B

RQYQ30PY1B

RQYQ32PY1B

RQYQ34PY1B

RQYQ36PY1B

RQYQ38PY1B

RQYQ40PY1B

RQYQ42PY1B

RQYQ44PY1B

RQYQ46PY1B

CONTENTS

1. FIRST OF ALL .........................................................................1

1-1 Safety precautions ........................................................... 1

1-2 Special notice of product ................................................. 2

1-3 Disposal requirements ..................................................... 2

2. INTRODUCTION...................................................................... 2

2-1 Combination..................................................................... 2

2-2 Standard supplied accessories........................................ 3

2-3 Option accessory ............................................................. 3

2-4 Technical and Electrical specifications ............................3

2-5 Main components ............................................................ 3

2-6 Installation Process.......................................................... 3

3. SELECTION OF LOCATION ...................................................4

4. INSPECTING AND HANDLING THE UNIT .............................4

5. PLACING THE UNIT................................................................ 4

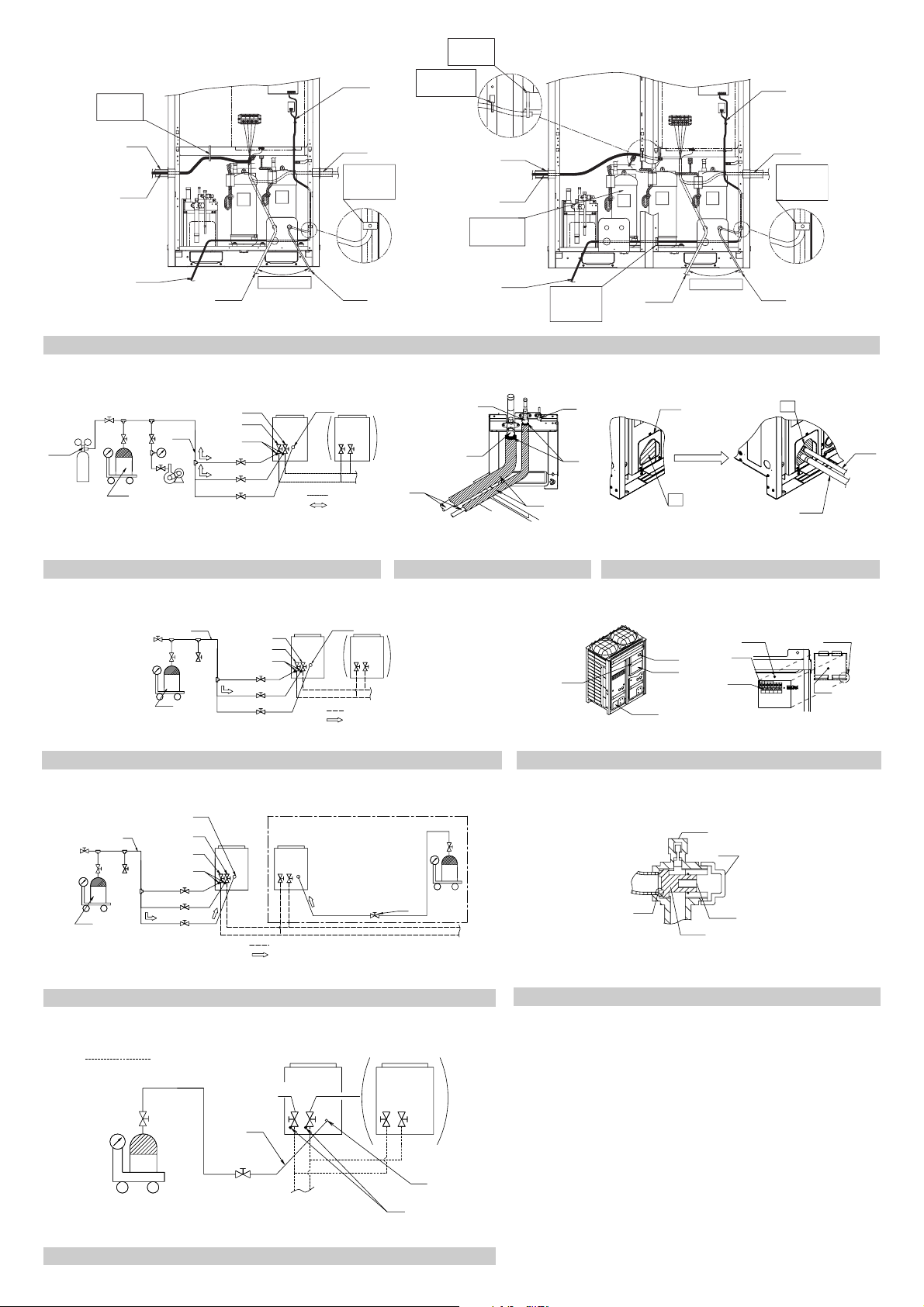

6. REFRIGERANT PIPING .......................................................... 5

6-1 Selection of piping material and Refrigerant

branching kit .................................................................... 5

6-2

Protection against contamination when installing pipes

....... 5

6-3 Pipe connection ............................................................... 5

6-4 Connecting the refrigerant piping..................................... 5

6-5 Example of connection .................................................... 8

7. FIELD WIRING ...................................................................... 10

7-1

Power circuit, safety device, and cable requirements

........ 10

7-2 Wiring Connection Example for Whole System ............. 10

7-3 Leading wire Procedure................................................. 10

7-4 Transmission Wiring Connection Procedure ................. 11

7-5 Power Wiring Connection Procedure............................. 11

7-6 Procedure for Wiring Inside Units .................................. 12

8. AIR TIGHT TEST AND VACUUM DRYING ........................... 12

8-1 Preparations .................................................................. 12

8-2 Air tight test and vacuum drying method ....................... 12

9. PIPE INSULATION ................................................................13

10. CHECKING OF DEVICE AND INSTALLATION

CONDITIONS ........................................................................ 13

11. ADDITIONAL REFRIGERANT CHARGE AND

CHECK OPERATION ............................................................ 13

11-1 Before working ............................................................... 13

11-2 Procedure of Adding Refrigerant charging and check

operation........................................................................ 15

12. ONSITE SETTINGS............................................................... 20

12-1 Onsite Settings With the Power Off ............................... 20

12-2 Onsite Settings With the Power On ............................... 20

13. TEST RUN ............................................................................. 20

13-1 Before test run ............................................................... 20

13-2 Test Run ........................................................................20

13-3 Checks After Test Run................................................... 20

14. CAUTION FOR REFRIGERANT LEAKS............................... 20

1. FIRST OF ALL

• This document is an installation manual for the Daikin “VRV

Series VRV Inverter. Before installing the unit, read this manual

thoroughly, and following the instructions contained in it. After

installation, do a test run to make sure the unit runs properly, and

then explain how to operate and take care of the unit to the customer, using the operation manual.

• Lastly, make sure the customer keeps this manual, along with the

operation manual, in a safe place.

•

This manual does not describe how to install the indoor unit.

Refer to the installation manual included with the indoor unit for that.

1-1 Safety precautions

Please read these “Safety precautions” carefully before installing air

conditioning unit and be sure to install it correctly.

After completing installation, conduct a trial operation to check for

faults and explain to the customer how to operate the air conditioner

and take care of it with the aid of the operation manual. Ask the customer to store the installation manual along with the operation manual for future reference.

This air conditioner comes under the term “appliances not

accessible to the general public”.

III

-Q”

RQYQ48PY1B

III

VRV

System air conditioner

III

VRV

-Q Series

Installation

manual

Meaning of WARNING and CAUTION notices

WARNING

..... Failure to follow these instructions properly may

result in personal injury or loss of life.

CAUTION

...... Failure to observe these instructions properly

may result in proper ty damage or personal injury,

which may be serious depending on the circumstances.

WARNI NG

• Ask your dealer or qualified personnel to carry out installation

work.

Do not attempt to install the air conditioner yourself. Improper

installation may result in water leakage, electric shocks or fire.

• Install the air conditioner in accordance with the instructions in

this installation manual.

Improper installation may result in water leakage, electric shocks

or fire.

• When installing the unit in a small room, take measures against to

keep refrigerant concentration from exceeding allowable safety

limits in the event of refrigerant leakage.

Contact the place of purchase for more information. Excessive

refrigerant in a closed ambient can lead to oxygen deficiency.

• Be sure to use only the specified accessories and parts for installation work.

Failure to use the specified parts may result in the unit falling,

water leakage, electric shocks or fire.

• Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

A foundation of insufficient strength may result in the equipment

falling and causing injury.

• Carry out the specified installation work after taking into account

strong winds, typhoons or earthquakes.

Failure to do so during installation work may result in the unit falling and causing accidents.

•

Make sure that a separate power supply circuit is provided for this

unit and that all electrical work is carried out by qualified personnel

according to local laws and regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shocks or fire.

• Make sure that all wiring is secured, the specified wires are used,

and that there is no strain on the terminal connections or wires.

Improper connections or securing of wires may result in abnormal

heat build-up or fire.

• When wiring the power supply and connecting the remote controller wiring and transmission wiring, position the wires so that the

EL.COMPO.BOX lid can be securely fastened.

Improper positioning of the EL.COMPO.BOX lid may result in

electric shocks, fire or the terminals overheating.

• If refrigerant gas leaks during installation, ventilate the area

immediately.

Toxic gas may be produced if the refrigerant comes into contact

with fire.

• After completing installation, check for refrigerant gas leakage.

Toxic gas may be produced if the refrigerant gas leaks into the

room and comes into contact with a source of fire, such as a fan

heater, stove or cooker.

• Do not directly touch refrigerant that has leaked from refrigerant

pipes or other areas, as there is a danger of frostbite.

• Be sure to switch off the unit before touching any electrical parts.

• Do not allow children to climb on the outdoor unit and avoid plac-

ing objects on the unit.

Injury may result if the unit becomes loose and falls.

• Be sure to earth the air conditioner.

Do not earth the unit to a utility pipe, lightning conductor or

telephone earth lead. Imperfect earthing may result in

electric shocks or fire.

A high surge current from lightning or other sources may cause

damage to the air conditioner.

• Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric

shocks or fire.

CAUTION

• While following the instructions in this installation manual,

install drain piping to ensure proper drainage and insulate piping to prevent condensation.

Improper drain piping may result in indoor water leakage and

property damage.

1 English

• Install the indoor and outdoor units, power cord and connecting

wires at least 1 meter away from televisions or radios to prevent

picture interference and noise.

(Depending on the incoming signal strength, a distance of 1 meter

may not be sufficient to eliminate noise.)

• Remote controller (wireless kit) transmitting distance can be

shorter than expected in rooms with electronic fluorescent lamps

(inverter or rapid start types).

Install the indoor unit as far away from fluorescent lamps as possible.

• Make sure to provide for adequate measures in order to prevent

that the outdoor unit be used as a shelter by small animals.

Small animals making contact with electrical parts can cause malfunctions, smoke or fire.

Please instruct the customer to keep the area around the unit

clean.

• Do not install the air conditioner in the following locations:

1. Where there is a high concentration of mineral oil spray or

vapour (e.g. a kitchen).

Plastic parts will deteriorate, parts may fall off and water leakage

could result.

2. Where corrosive gas, such as sulphurous acid gas, is pro-

duced.

Corroding of copper pipes or soldered parts may result in

refrigerant leakage.

3. Near machinery emitting electromagnetic radiation.

Electromagnetic radiation may disturb the operation of the

control system and result in a malfunction of the unit.

4. Where flammable gas may leak, where there is carbon fibre or

ignitable dust suspensions in the air, or where volatile flammables such as paint thinner or gasoline are handled.

Operating the unit in such conditions may result in fire.

1-2 Special notice of product

[CLASSIFICATION]

This air conditioner comes under the term “appliances not accessible

to the general public”.

[REFRIGERANT]

VRVIII System use R410A refrigerant.

• The refrigerant R410A requires that strict precautions be

observed for keeping the system clean, dry and tightly sealed.

Read the chapter “REFRIGERANT PIPING” carefully and follow

these procedures correctly.

A.Clean and dry

Strict measures must be taken to keep impurities (including

SUNISO oil and other mineral oils as well as moisture) out of

the system.

B.Tightly sealed

R410A contains no chlorine, does not destroy the ozone layer

and so does not reduce the earth’s protection against harmful

ultraviolet radiation. R410A will contribute only slightly to the

greenhouse effect if released into the atmosphere. Therefore,

sealing tightness is particularly important in installation. Carefully read the chapter “REFRIGERANT PIPING” and strictly

observe the correct procedures.

• Since design pressure is 4.0 MPa or 40 bar (for R407C units: 3.3

MPa or 33 bar), the thickness of pipes must be greater than previously. Since R410A is a mixed refrigerant, the required additional refrigerant must be charged in its liquid state. (If the system

is charged with refrigerant in its gaseous state, due to composition change, the system will not function normally). The indoor

unit is designed for R410A use. See the catalogue for indoor unit

models that can be connected. (Normal operation is not possible

when connecting units that are originally designed for other refrigerants.)

Total maximum refrigerant charge limits

The total maximum refrigerant charge of a VRV

below 100kg, this to be in accordance with CE requirement

(EN60335-2-40 standard).

This means that in case the total maximum refrigerant charge of the

system (factory and additional charge) is equal to or more than

100kg you must divide your multiple outdoor system into smaller

independent systems, each containing less than 100kg refrigerant

charge.

For factory charge, refer to the unit name plate.

III

system must be

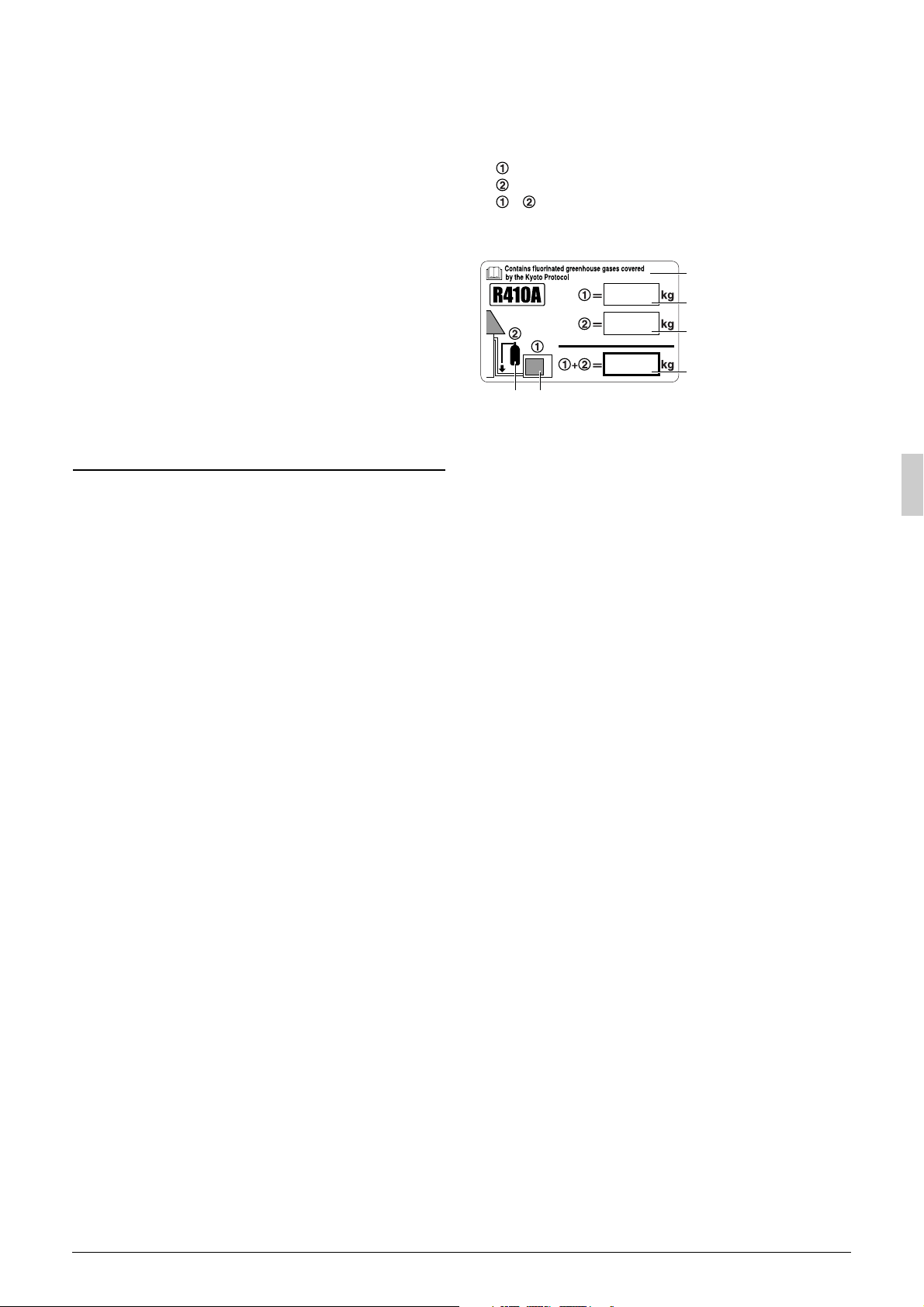

Important information regarding the refrigerant used

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type : R410A

(1)

GWP

value : 1975

(1)

GWP = global warming potential

Please fill in with indelible ink,

the factory refrigerant charge of the product,

the additional refrigerant amount charged onsite and

+ the total refrigerant charge on the refrigerant charge label

supplied with the product.

The filled out label must be adhered in the proximity of the product

charging port (e.g. onto the inside of the service cover).

4

factory refrigerant charge of

the product : see unit name

1

(2)

plate

1

additional refrigerant amount

2

2

charged in the field

3 total refrigerant charge

Contains fluorinated green-

3

4

house gases covered by the

5

6

Kyoto Protocol

5 outdoor unit

refrigerant cylinder and man-

6

ifold for charging

(2) In case of multiple outdoor systems, only 1 label must be

adhered, mentioning the total factory refrigerant charge of all outdoor

units connected on the refrigerant system.

[DESIGN PRESSURE]

Since design pressure is 4.0MPa or 40bar, the wall thickness of pipes

should be more carefully selected in accordance with the relevant

local and national regulations.

1-3 Disposal requirements

Dismantling of the unit, treatment of the refrigerant, of oil and of other parts

must be done in accordance with relevant local and national legislation.

2. INTRODUCTION

III

• “VRV

• The “VRV” units can be combined with Daikin VRV series indoor

2-1 Combination

The indoor units can be installed in the following range.

-Q” series are designed for outdoor installation and used

for cooling and heatpump applications. Outdoor units come in

three standard sizes, and with a single system through a multi

system combining up to two outdoor units, rated cooling capacity

from 22.4 kW to 118 kW and rated heating capacity from 25.0 kW

to 132 kW can be achieved.

units for air conditioning purposes. Always use appropriate indoor

units compatible with R410A. To lean which models of indoor

units are compatible with R410A, refer to the product catalogs.

To combine with other refrigerant indoor unit will cause malfunction.

〈

Outdoor unit

〉〈

Total capacity of indoor units〉〈Total quantity of indoor units

RQYQ8PY1B ....................100 ~ 260 13 units

RQYQ10PY1B .................. 125 ~ 325 16 units

RQYQ12PY1B .................. 150 ~ 390 19 units

RQYQ14PY1B .................. 175 ~ 455 22 units

RQYQ16PY1B .................. 200 ~ 520 26 units

RQYQ18PY1B .................. 225 ~ 585 29 units

RQYQ20PY1B .................. 250 ~ 650 32 units

RQYQ22PY1B .................. 275 ~ 715 35 units

RQYQ24PY1B .................. 300 ~ 780 39 units

RQYQ26PY1B .................. 325 ~ 845 42 units

RQYQ28PY1B .................. 350 ~ 910 45 units

RQYQ30PY1B .................. 375 ~ 975 48 units

RQYQ32PY1B .................. 400 ~ 1040 52 units

RQYQ34PY1B .................. 425 ~ 1105 55 units

RQYQ36PY1B .................. 450 ~ 1170 58 units

RQYQ38PY1B .................. 475 ~ 1235 61 units

RQYQ40PY1B .................. 500 ~ 1300 64 units

RQYQ42PY1B .................. 525 ~ 1365 64 units

RQYQ44PY1B .................. 550 ~ 1430 64 units

RQYQ46PY1B .................. 575 ~ 1495 64 units

RQYQ48PY1B .................. 600 ~ 1560 64 units

〉

English 2

Note

• Be sure to connect an R410A indoor unit.

See the catalog for indoor unit models which can be connected.

• At above is the total capacity and total number of units of the

indoor units when configured in a standard combination. See the

technical reference for details on total capacity and total number

of indoor units when using a configuration other than the standard

combination. The standard combination are as follows.

<Combination unit> <Independent unit>

RQYQ8PY1B RQYQ8PY1B

RQYQ10PY1B RQYQ10PY1B

RQYQ12PY1B RQYQ12PY1B

RQYQ14PY1B RQYQ14PY1B

RQYQ16PY1B RQYQ16PY1B

RQYQ18PY1B RQYQ8PY1B+ RQYQ10PY1B

RQYQ20PY1B RQYQ8PY1B+ RQYQ12PY1B

RQYQ22PY1B RQYQ10PY1B+ RQYQ12PY1B

RQYQ24PY1B RQYQ12PY1B+ RQYQ12PY1B

RQYQ26PY1B RQYQ10PY1B+ RQYQ16PY1B

RQYQ28PY1B RQYQ12PY1B+ RQYQ16PY1B

RQYQ30PY1B RQYQ14PY1B+ RQYQ16PY1B

RQYQ32PY1B RQYQ16PY1B+ RQYQ16PY1B

RQYQ34PY1B RQYQ10PY1B+ RQYQ10PY1B+ RQYQ14PY1B

RQYQ36PY1B RQYQ10PY1B+ RQYQ10PY1B+ RQYQ16PY1B

RQYQ38PY1B RQYQ10PY1B+ RQYQ12PY1B+ RQYQ16PY1B

RQYQ40PY1B RQYQ12PY1B+ RQYQ12PY1B+ RQYQ16PY1B

RQYQ42PY1B RQYQ10PY1B+ RQYQ16PY1B+ RQYQ16PY1B

RQYQ44PY1B RQYQ12PY1B+ RQYQ16PY1B+ RQYQ16PY1B

RQYQ46PY1B RQYQ14PY1B+ RQYQ16PY1B+ RQYQ16PY1B

RQYQ48PY1B RQYQ16PY1B+ RQYQ16PY1B+ RQYQ16PY1B

• If the total capacity of the connected indoor units exceeds the

capacity of the outdoor unit, cooling and heating performance

may drop when running the indoor units. See the capacity table in

the Engineering Data Book for details.

• There are restrictions on the refrigerant pipe connecting order

between outdoor unit in the case of the multi system.

Install so that the following restrictions are satisfied.

<Restrictions>

The capacities of outdoor units A,B and C must fulfill the following

conditions.

A ≥ B ≥ C

Outdoor

unit A

to indoor unit

Outdoor unit multi

connection

piping kit

Outdoor

unit B

Outdoor

unit C

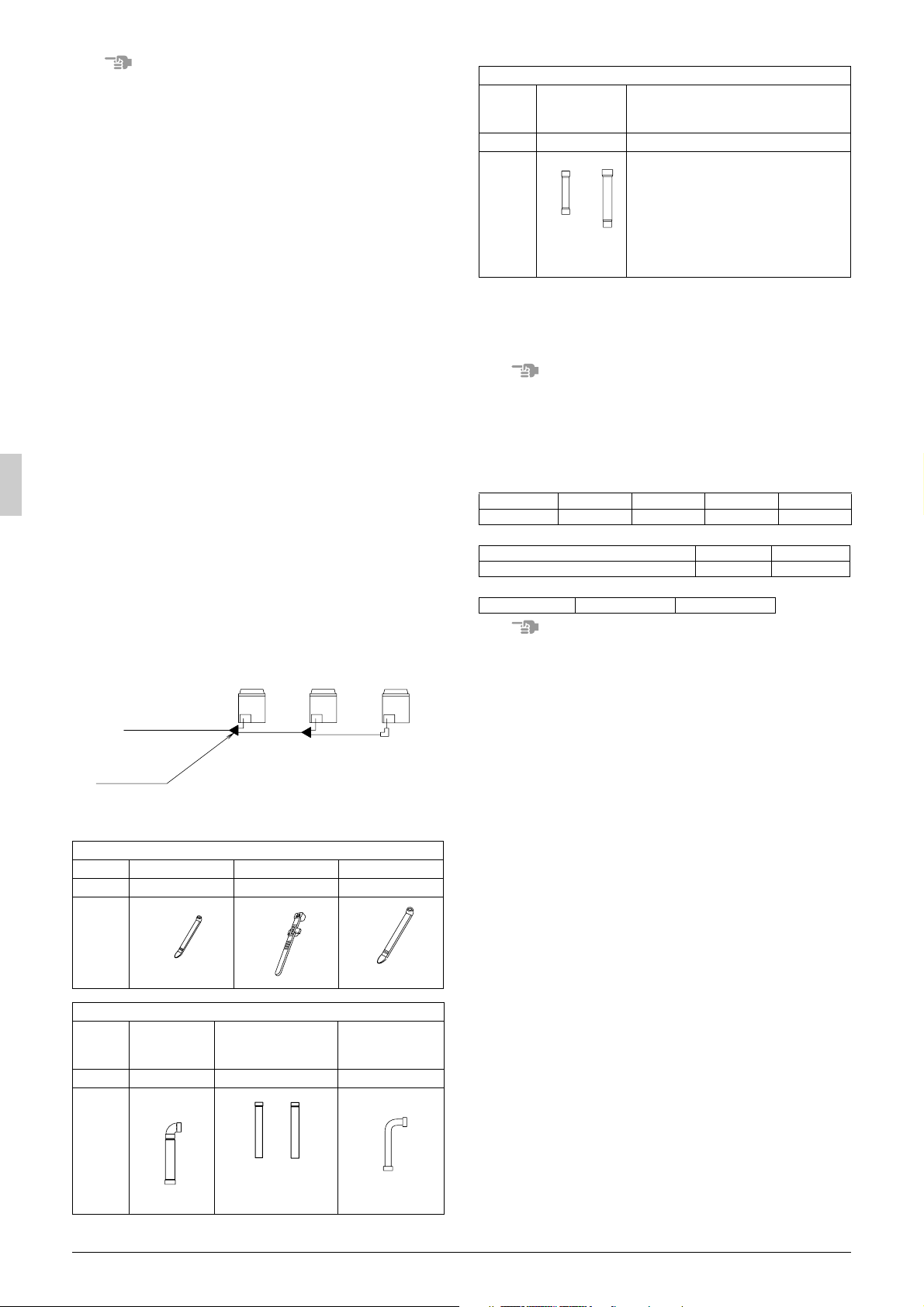

2-2 Standard supplied accessories

The following accessories are included. The storage location of the

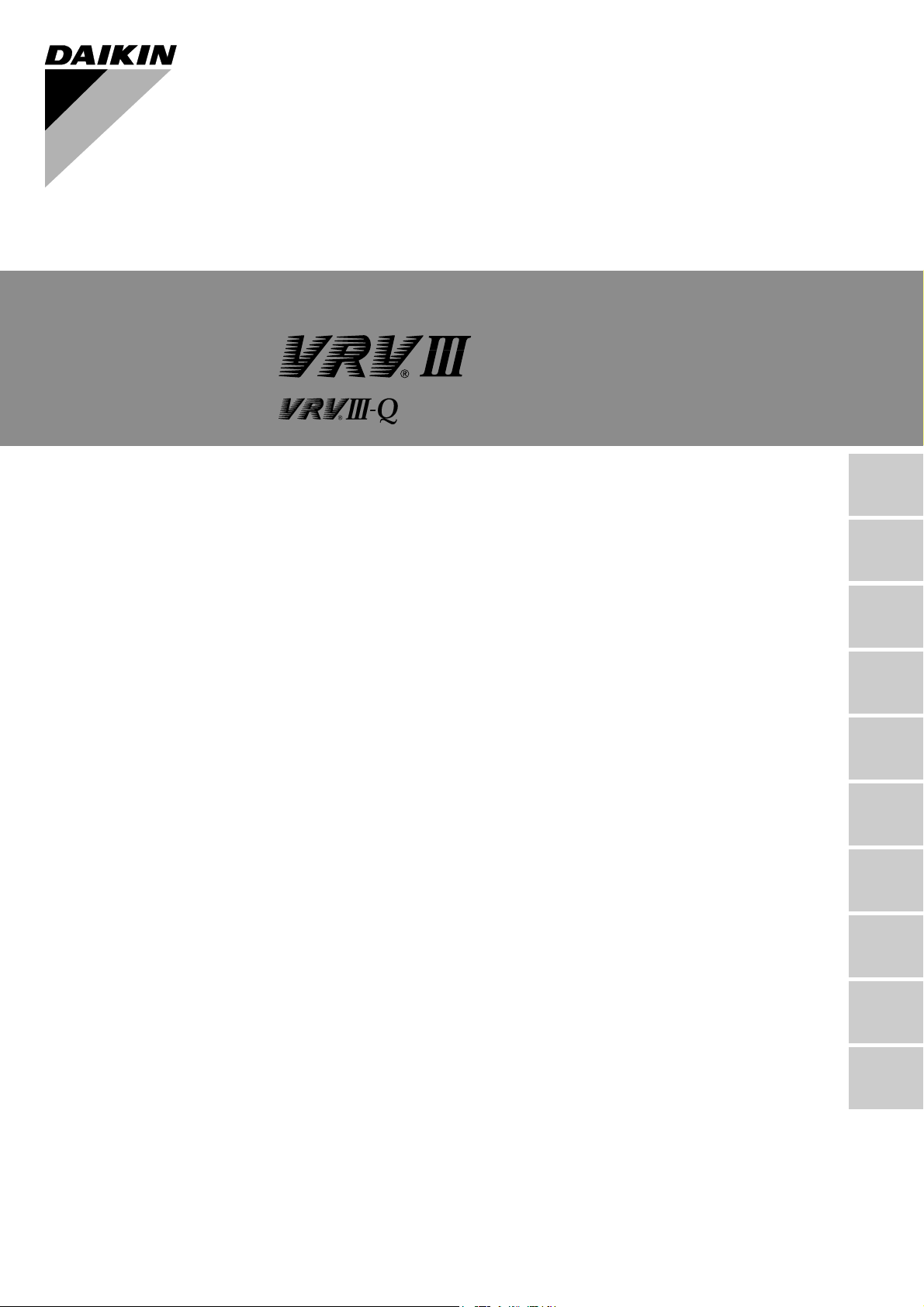

accessories is shown in figure 1.

Q8~16 type

Name

Quantity

Shape

Name

Quantity

Clamp (1) Clamp (2) Clamp (3)

9 pcs. 2 pcs. 1 pc.

Small

Q8~16 type

Gas side

accessory pipe

(1)

1 pc. 1 pc. 1 pc.

Gas side accessory

pipe (2)

Liquid side acces-

sory pipe (1)

Large

Q8~16 type

Name

Quantity

Shape

Note

Do not throw away any of the accessories until installation is complete.

Liquid side

accessory

pipe (2)

1 pc. 1 pc. each item

Q8 · 10 ·

14 · 16

(Refer to figure 1)

1. Operation manual

2. Installation manual

3. Clamps

4. Accessory pipes

type

Q12

type

Others

• Operation manual

• Installation manual

• Check list of installed system

• Declaration conformity (PED, EMC,

MD)

• “REQUEST FOR THE INDICATION”

label (Installation records)

• “ADDITIONAL REF. CHARGE” label

2-3 Option accessory

To install the outdoor units, the following optional parts are also

required. To select an optimum kit, refer to “6-5 Example of connec-

tion”.

• Refrigerant branching kit

REFNET header KHRP26M22H KHRP26M33H KHRP26M72H KHRP26M73H

REFNET joint KHRP26A22T KHRP26A33T KHRP26A72T KHRP26A73T

• Outdoor unit multi connection piping kit

Number of outdoor units connected

Kit name

• Pipe size reducer

Kit name

Note

Make sure that any separately purchased accessories are designed

for use with R410A.

KHRP26M73TP KHRP26M73HP

2 units 3 units

BHFP22P100 BHFP22P151

2-4 Technical and Electrical specifications

Refer to the Engineering Data Book for the complete list of specifications.

2-5 Main components

For main components and function of the main components, refer to

the Engineering Data Book.

2-6 Installation Process

Figure 2 shows the installation process. Install in the order of the

steps shown.

(Refer to figure 2)

1. “3. SELECTION OF LOCATION”

2. “4. INSPECTING AND HANDLING THE UNIT”

3. “5. PLACING THE UNIT”

4. “6. REFRIGERANT PIPING”

5. “7. FIELD WIRING”

6. “8. AIR TIGHT TEST AND VACUUM DRYING”

7. “9. PIPE INSULATION”

8. “10. CHECKING OF DEVICE AND INSTALLATION

CONDITIONS”

9. “11. ADDITIONAL REFRIGERANT CHARGE AND

CHECK OPERATION”

10. “13. TEST RUN”

11. Operations which require the power to be turned on.

Shape

Q8 · 10

Q12 ·

type

14 · 16

type

3 English

3. SELECTION OF LOCATION

Select a location for installation that meets the following conditions.

Get the customer’s permission.

1.

There is no danger of fire due to leakage of inflammable gas.

2.

Select the location of the unit in such a way that neither the discharged air nor the sound generated by the unit disturb anyone.

3.

The foundation is strong enough to support the weight of the unit

and the floor is flat to prevent vibration and noise generation.

4.

The piping length between the outdoor unit and the indoor unit

may not exceed the allowable piping length. (Refer to

“6. REFRIGERANT PIPING”)

5.

Locations where the unit’s suction vent and outlet vent do not generally face the wind.

Wind blowing directly into the suction or outlet vents will interfere

with the unit’s operation.

If necessary, install some kind of obstruction to block the wind.

6.

The space around the unit is adequate for servicing and the minimum space for air inlet and air outlet is available.

(See the “ Installation Space Examples” for the minimum space

requirements.)

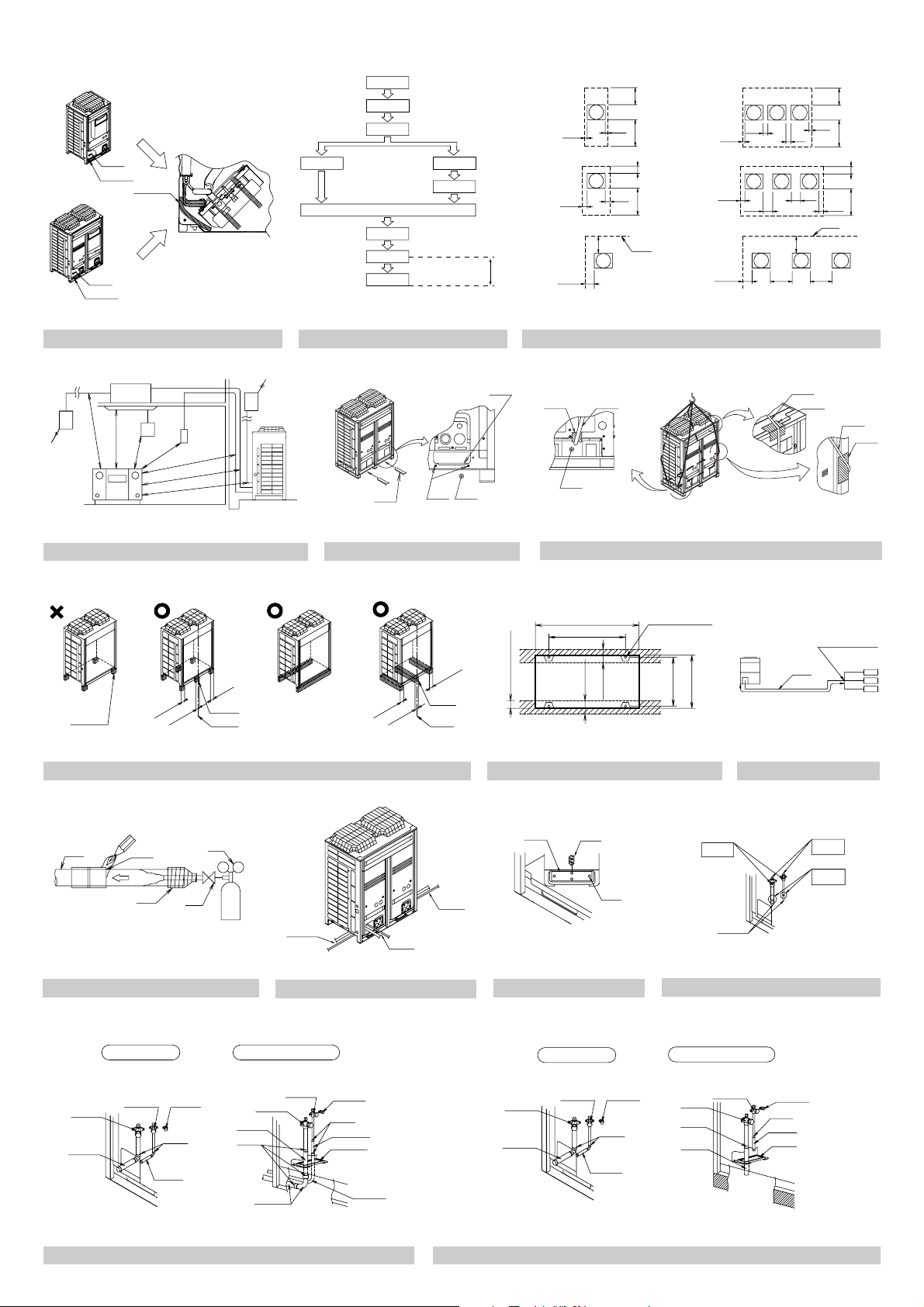

Installation Space Examples

• The installation space requirement shown in figure 3 is a refer-

ence for cooling operation when the outdoor temperature is 35°C.

If the design outdoor temperature exceeds 35°C or the heat load

exceeds maximum capacity in all the outdoor unit, take an even

large space on the intake shown in figure 3.

• During installation, install the units using the most appropriate of

the patterns shown in figure 3 for the location in question, taking

into consideration human traffic and wind.

• If the number of units installed is more than that shown in the pattern in figure 3, install the units so there are no short circuits.

• As regards space in front of the unit, consider the space needed

for the local refrigerant piping when installing the units.

• If the work conditions in figure 3 do not apply, contact your dealer

or Daikin directly.

(Refer to figure 3)

1. Front side

2. No limit to wall height

3. Service space of front side

4. Service space of suction side

For Patterns 1 and 2 in figure 3:

• Wall height for front side – no higher than 1500 mm.

• Wall height on the suction side – no higher than 500 mm.

• Wall height for sides – no limit.

• If the height is exceeded the above, calculate h1 and h2 shown

in the figure below, and add h1/2 to the service space of front

side and h2/2 to the service space of suction side.

h1

A

1500

Front side

h1 = A (Actual height) – 1500

h2 = B (Actual height) – 500

Note

1.

An inverter air conditioner may cause electronic noise generated from AM broadcasting. Examine where to install the main

air conditioner and electric wires, keeping proper distances

away from stereo equipment, personal computers, etc.

Particularly for locations with weak reception, ensure there is

a distance of at least 3 meters for indoor remote controllers,

place power wiring and transmission wiring in conduits, and

ground the conduits.

(Refer to figure 4)

1. Indoor unit

2. Branch switch, overcurrent breaker

3. Remote controller

4. COOL/HEAT selector

5. Personal computer or radio

2.

When installing in a locations where there is heavy snowfall,

implement the following snow measures.

• Ensure the base is high enough that intakes are not clogged

by snow.

• Remove the rear intake grille to prevent snow from accumulating on the fins.

h2

B

Suction side

500

3.

If condensate may drip on downstairs (or walkway) depending

on the floor condition, take a measure such as the installation of

central drain pan kit (sold separately).

4.

The refrigerant R410A itself is nontoxic, nonflammable and is

safe. If the refrigerant should leak however, its concentration

may exceed the allowable limit depending on room size. Due to

this it could be necessary to take measures against leakage.

See “14. CAUTION FOR REFRIGERANT LEAKS” for details.

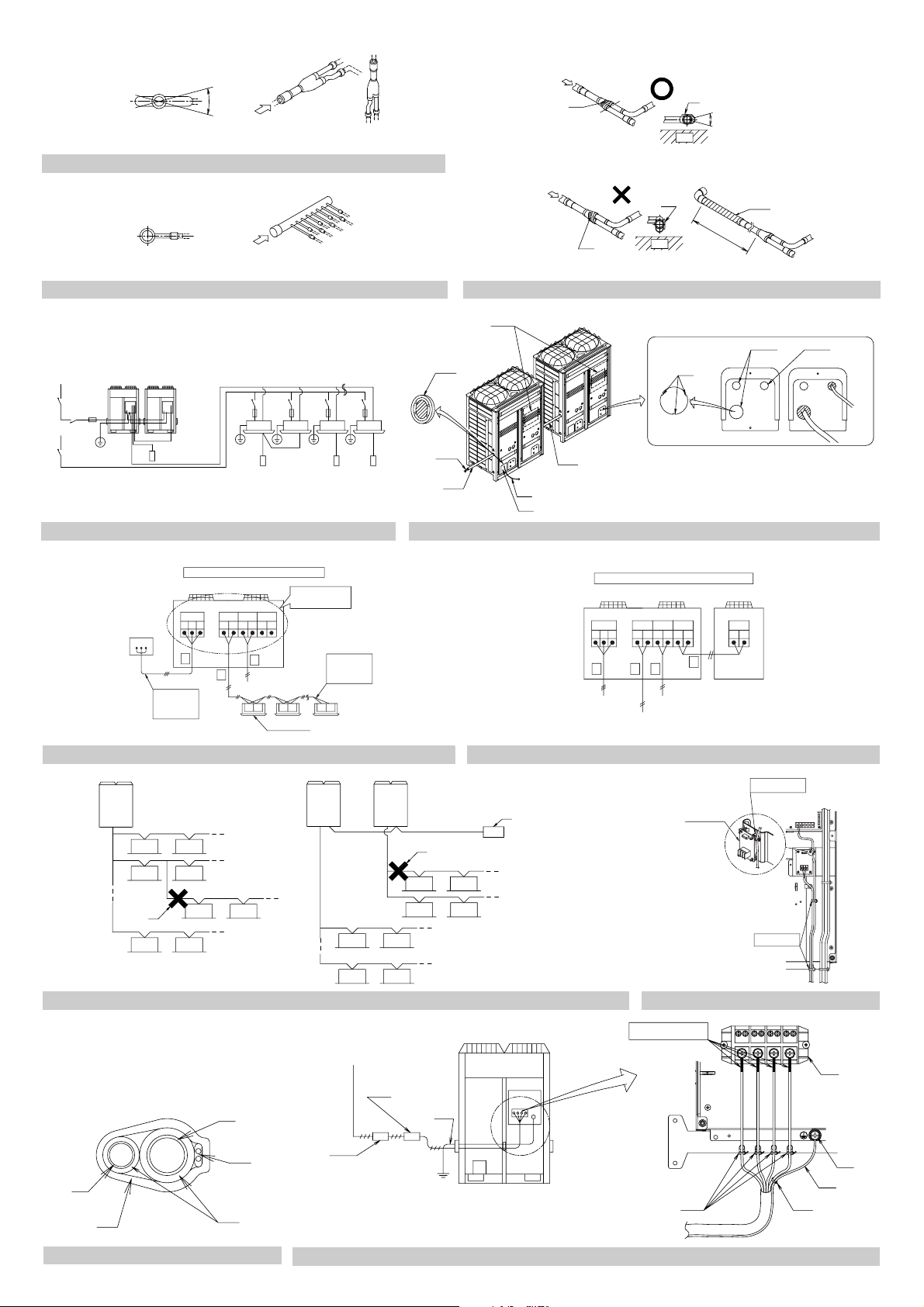

4. INSPECTING AND HANDLING THE UNIT

• At delivery, the package should be checked and any damage

should be reported immediately to the carrier claims agent.

• When handling the unit, take into account the following:

1.

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor damage.

2.

Decide on the transportation route.

3.

If a forklift is to be used, insert forks into the opening of the skid

under the unit. (Refer to figure 5)

4.

If hanging the unit, use a cloth sling to prevent damaging the unit.

Keeping the following points in mind, hang the unit following the

procedure shown in figure 6.

• Use a sling sufficiently strong to hold the mass of the unit.

• Use 2 belts of at least 8m long.

• Place extra cloth or boards in the locations where the casing

comes in contact with the sling to prevent damage.

•

Hoist the unit making sure it is being lifted at its center of gravity.

5.

After installation, remove the transportation clasp attached to the

large openings. (Refer to figure 6)

(Refer to figure 5)

1. Forklift

2. Hook

3. Skid opening

4. Transport protector (Yellow)

(Refer to figure 6)

1. Belt sling

2. Rag

3. Skid opening

Note

Apply a filler cloth on a fork to prevent coating of the bottom frame

from coming off and rust from occurring when bringing in the unit with

anti-corrosion treatment type using a forklift.

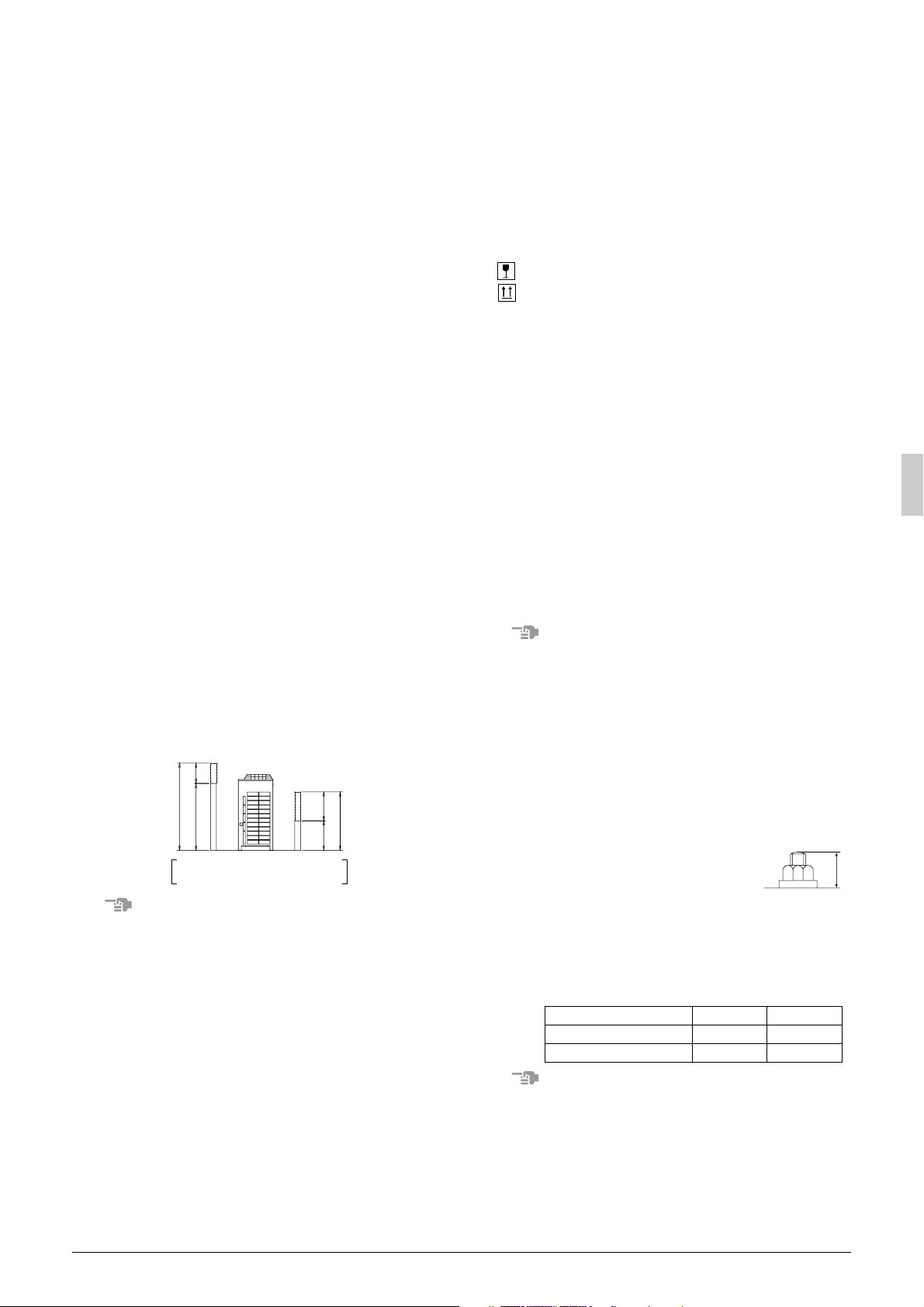

5. PLACING THE UNIT

• Make sure the unit is installed level on a sufficiently strong base to

prevent vibration and noise. (Refer to figure 7)

• The base should be bigger around than the width of the unit’s legs

(66 mm), and should support the unit. (Refer to figure 8)

If protective rubber is to be attached, attach it to the whole face of

the base.

• The height of the base should be at least 150mm from the floor.

•

Secure the unit to its base using foundation bolts. (Use four commercially available M12-type foundation bolts, nuts, and washers.)

•

The foundation bolts should be inserted 20 mm.

(Refer to figure 7)

1. Unit can not be supported with the

independent footing in four corners

only.

2, 3. Make sure to install on the base that faces four corners

and centers of the unit.

(Refer to figure 8)

1. Foundation bolt point (φ15 dia. : 4 positions)

2. Depth of product

3. Width of support leg

Model A B

Q8 · 10 · 12 type

Q14 · 16 type

Note

• There are restrictions on the refrigerant pipe connecting order

between outdoor unit in the case of the multi system.

See the Note in “2-1 Combination” for detail.

• When installing on a roof, make sure the roof floor is strong

enough and be sure to water-proof all work.

• Make sure the area around the machine drains properly by setting

up drainage grooves around the foundation.

Drain water is sometimes discharged from the outdoor unit when

it is running.

930 792

1240 1102

20

English 4

Loading...

Loading...