Page 1

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

1

Operating Manual

Air Handling Unit

Application Software name: Airstream

D-EOMAH00006-20EN

Page 2

Operation Manual

Air Handling Unit

Operation Manual

2

Air Handling Unit

D-EOMAH00006-20EN

Table of Contents

1. Revision History..................................................................................................................... 4

2. Air Handling Unit Safety Information...................................................................................... 5

3. Introduction .......................................................................................................................... 6

4. User interface........................................................................................................................ 8

4.1 Controller POL687/638 Interfaces ...................................................................................................................... 8

4.2 External Human Machine Interfaces .................................................................................................................. 9

4.2.1 6-Button LCD HMI (POL871) ................................................................................................................................................ 9

4.2.2 Push & Roll key HMI (POL895) ............................................................................................................................................. 9

4.3 WEB-Human Machine Interface ....................................................................................................................... 11

4.4 Communication Modules .................................................................................................................................. 15

4.4.1 Modbus module installation .............................................................................................................................................. 16

4.4.2 BACnet IP module installation ........................................................................................................................................... 16

4.5 Basic Control System Diagnostic ....................................................................................................................... 16

5. Control Functions ................................................................................................................ 19

5.1 Air Quality Control Function ............................................................................................................................. 20

5.2 Humidity Control Function ................................................................................................................................ 20

5.3 Summer/Winter mode changeover functions .................................................................................................. 21

6. Main Menu screen .............................................................................................................. 22

7. Control Source .................................................................................................................... 24

8. Actual Mode........................................................................................................................ 25

9. Unit State ............................................................................................................................ 26

10. Active Setpoint .................................................................................................................... 28

11. Local Switch ........................................................................................................................ 29

12. Summer/Winter state .......................................................................................................... 30

13. Setpoints ............................................................................................................................. 32

14. I/O Overview ....................................................................................................................... 35

15. Time Scheduler.................................................................................................................... 36

15.1 Day Scheduler.................................................................................................................................................... 37

15.2 Calendar exception and Calendar fix off........................................................................................................... 38

16. Status/Settings .................................................................................................................... 40

16.1 Temperature Control ........................................................................................................................................ 41

16.2 Air Quality Control............................................................................................................................................. 42

16.3 Humidity Control ............................................................................................................................................... 43

16.4 Fans Control ...................................................................................................................................................... 44

16.4.1 Fast Heating/Cooling .......................................................................................................................................................... 48

16.5 Dampers Control ............................................................................................................................................... 49

16.6 Heat Recovery Control ...................................................................................................................................... 50

16.7 Cooling Coil Control........................................................................................................................................... 50

16.8 Heating Coil Control .......................................................................................................................................... 51

16.9 Pumps Control ................................................................................................................................................... 53

Page 3

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

3

16.10 ERQ Control ....................................................................................................................................................... 53

16.10.1 ERQ Status ........................................................................................................................................................................... 53

16.10.2 ERQ Settings ........................................................................................................................................................................ 54

16.11 Post-Heating Control ......................................................................................................................................... 56

16.12 Pre-Heating Electrical Control ........................................................................................................................... 57

16.13 Pre-Heating Water Control ............................................................................................................................... 58

17. Alarm handling .................................................................................................................... 60

17.1 Alarm restore .................................................................................................................................................... 60

17.2 Alarm list............................................................................................................................................................ 61

18. About Unit .......................................................................................................................... 71

Appendix A: Room Unit Module - POL822 ................................................................................. 73

Buttons Overview .......................................................................................................................................73

Display Overview ........................................................................................................................................74

AHU On-Off (1) ...........................................................................................................................................75

Occupancy On-Off (2) ..................................................................................................................................75

Date and time (3) ........................................................................................................................................76

Temperature Setpoint Offset (4 & 5) .............................................................................................................76

Fan Speed Display (7) ..................................................................................................................................76

Summer/Winter changeover (8) ...................................................................................................................76

Mounting instructions .................................................................................................................................77

Appendix B: iTM Installation & Configuration ............................................................................ 78

Page 4

Operation Manual

Air Handling Unit

Operation Manual

4

Air Handling Unit

D-EOMAH00006-20EN

1. Revision History

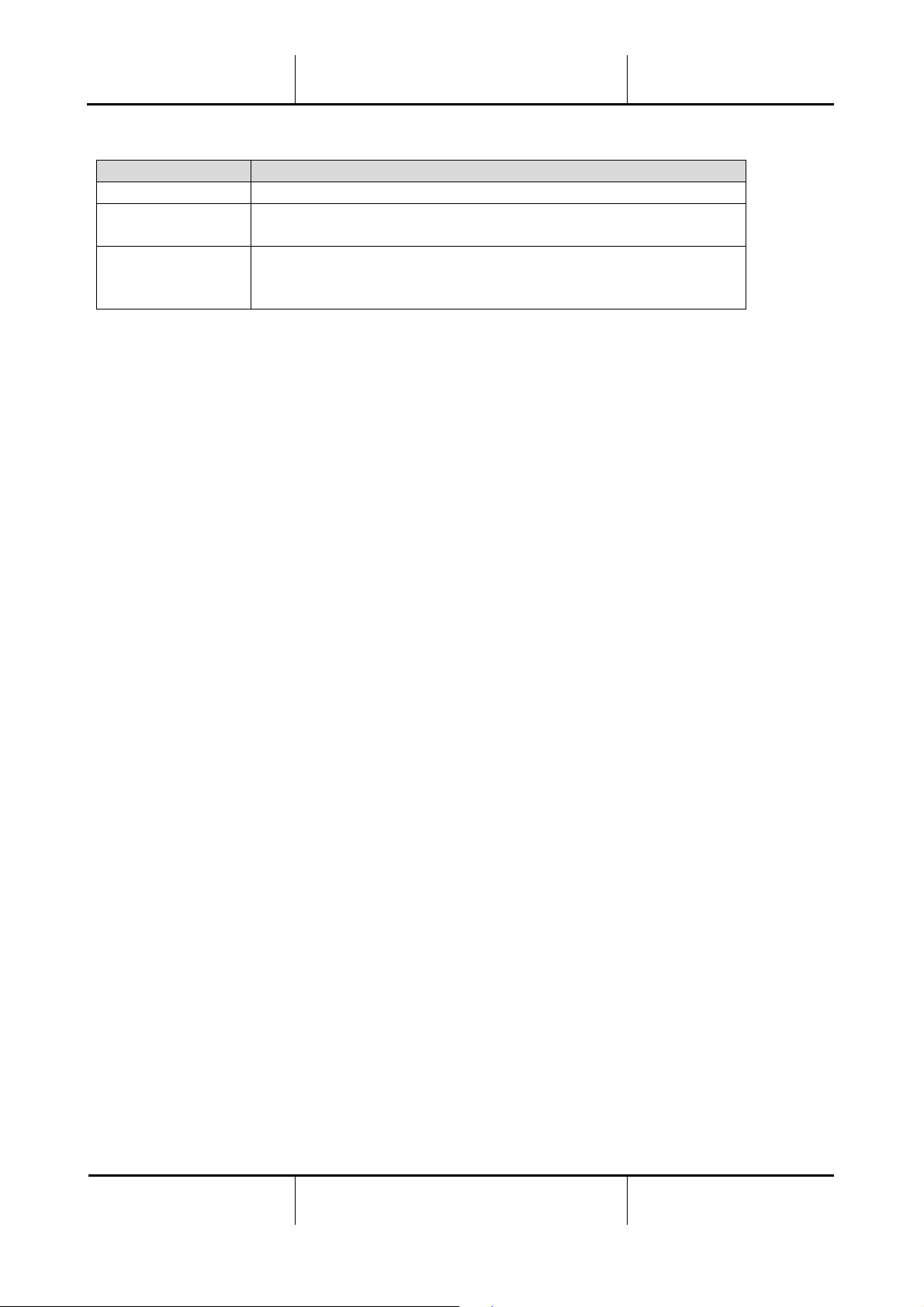

Name

Revision

Date

Scope

D-ECCAH00006-20EN

2

June 2020

The following sections have been upgraded with

the software modifications introduced by software

Airstream 3.15.A.:

• 16.12 Pre-Heating Electrical Control

D-EOMAH00006-20EN

1

January

2020

Scope of this document is to update the Operation

instructions for Units with application software

3.10.A and later.

Old versions

For Units with application software 2.90.A and

earlier.

Page 5

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

5

2. Air Handling Unit Safety Information

Observe all safety directions and comply with the corresponding general safety regulations in order to

prevent personal injury and damage to property.

• Safety devices may not be removed, bypassed or taken out of operation.

• Apparatus and system components may only be used in a technically fault-free state. Faults that can

affect safety must be rectified immediately.

• Observe the required safety instructions against excessively high contact voltages.

• The plant may not be in operation if the standard safety devices are out of operation or if their effects

are influenced in some other way.

• All handling that affects the prescribed disconnection of the protective extra-low voltage (AC 24 V)

must be avoided.

• Disconnect the supply voltage before opening the apparatus cabinet. Never work when the power

is on!

• Avoid electromagnetic and other interference voltages in signal and connection cables.

• Assembly and installation of system and plant components may only be performed in accordance

with corresponding installation instructions and instructions for use.

• Every electric part of the system must be protected against static charging: electronic components,

open printed circuit boards, freely accessible connectors and apparatus components that are

connected with the internal connection.

• All equipment that is connected to the system must be CE marked and comply with the Machine

Safety Directive.

Page 6

Operation Manual

Air Handling Unit

Operation Manual

6

Air Handling Unit

D-EOMAH00006-20EN

3. Introduction

This operating manual provides the basic information that allows the control of the Daikin Air Handling Unit

(AHU).

AHUs are used for air conditioning and air handling in terms of temperature, humidity and CO2 level control.

There are four types of AHU, based on the external devices used to produce cooling or heating:

1. AH-ERQ-U

The AH-(ERQ)-U is connected with the Daikin ERQ condensing unit;

2. AH-W-U

The AH-(Water)-U is connected with an external device that provides hot water or cold water used

in a water heat exchanger;

3. AH-DX-U

The AH-(Direct eXpansion)-U is connected with an external condenserless unit;

4. AH-WDX-U

This type of AH-(Water Direct eXpansion)-U can be connected to both water and direct expansion

devices.

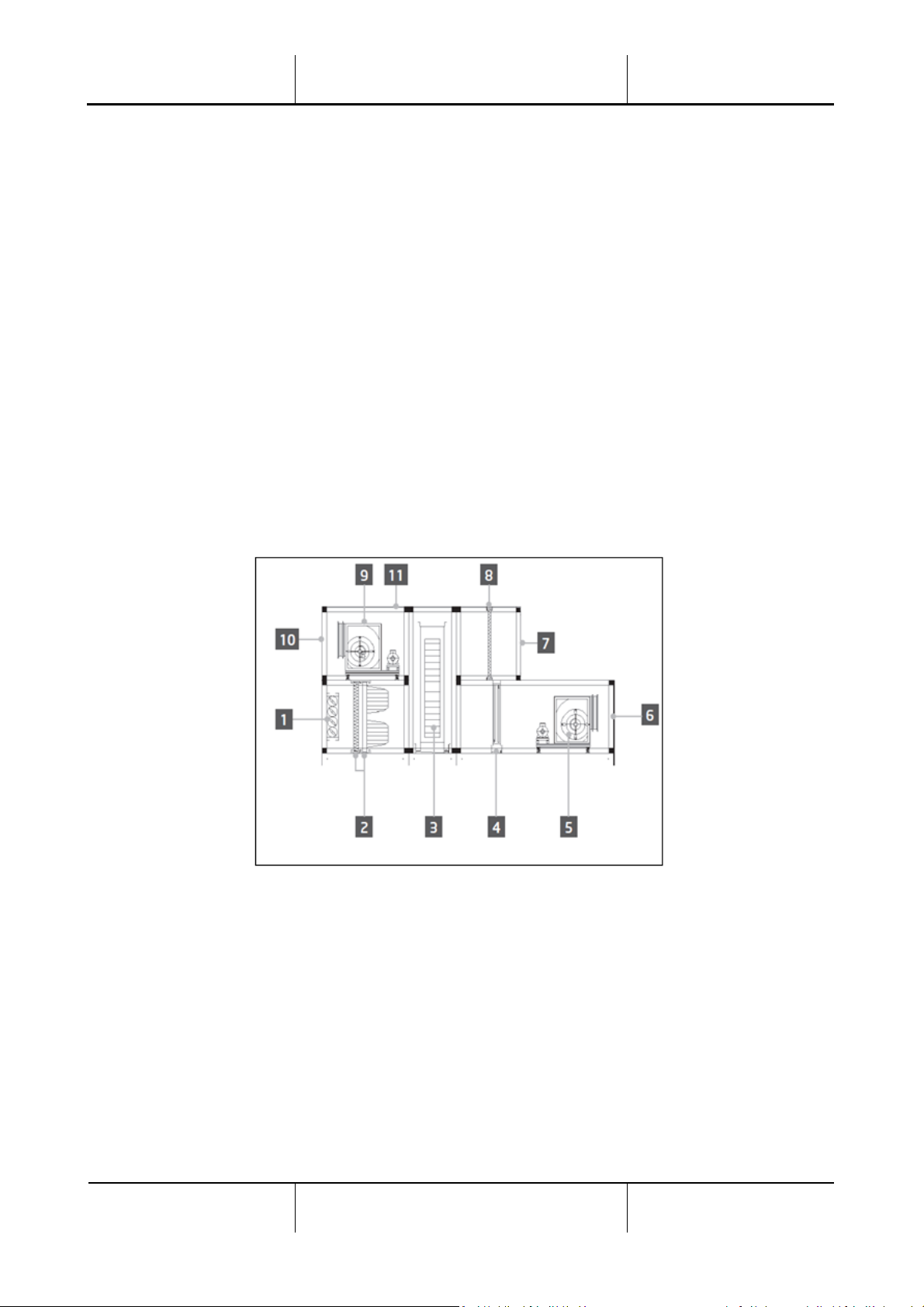

The diagrams in Figures 1 and 2 show two possible AHU layouts:

Figure 1: AHU example layout #1

1. Fresh air inlet / damper

2. Bag filter

3. Heat wheel

4. Dx coil

5. Supply fan

6. Supply air outlet

7. Return air inlet

8. Filter

9. Return fan

10. Exhaust air outlet

11. Roof for outdoor installation

Page 7

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

7

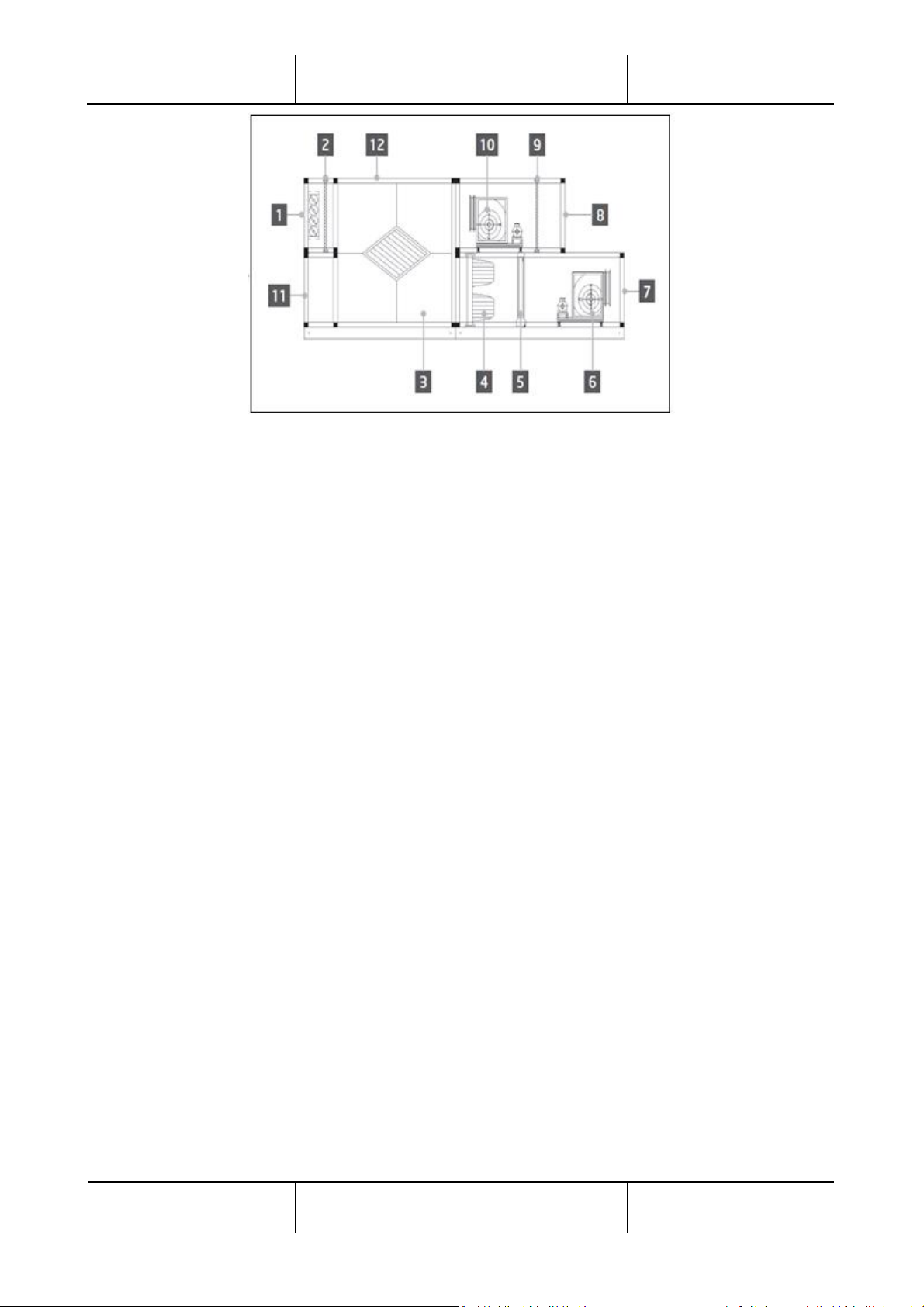

Figure 2: AHU example layout #2

1. Fresh air inlet / damper

2. Panel-filter

3. Heat recovery plate exchanger

4. Bag filter

5. Dx coil

6. Supply fan

7. Supply air outlet

8. Return air inlet

9. Panel filter

10. Return fan

11. Return air outlet

12. Roof for outdoor installation

The main components of a Daikin AHU are:

- Air filters: pre-filter, fine filter, bag filter, HEPA filter.

Every AHU unit can be equipped with several types of filters used to clean the air from little particles

of dust, pollen etc.

- Device for heat/cool recovery: Wheel, Cube Plate Exchanger, RAR coil or Mixing Damper.

These devices are used to recover cooling or heating from the return air. Part of the exhaust air is

mixed with fresh air so that the inlet air temperature is closer to the desired one.

- Water/Electrical/Dx coils.

These are the devices used for air temperature conditioning.

- Supply and return Fan.

These devices are used to regulate the air volume, and often they are controlled via an inverter.

- Supply and return air dampers.

These devices allow the air flow through the AHU when being activated.

Page 8

Operation Manual

Air Handling Unit

Operation Manual

8

Air Handling Unit

D-EOMAH00006-20EN

4. User interface

In this chapter are explained the different operative modes available to the user for AHU control.

4.1 Controller POL687/638 Interfaces

Two different controllers are available for AHU control, depending on the chosen model: POL687 for AHUModular (or Compact for software version previous to Airstream 0.10.B), POL638 for AHU-Professional.

Next figure shows POL687 controller interface schematic.

1 2

3

4

5

Controller POL687

With reference to figure above, it is possible to identify:

1) Alarm button: this button allows the user to directly access the Alarms menu.

2) Main Menu button: this button is used to return to the Main Menu screen at all times.

3) Return button: this button allows the user to go back to the previous screen.

4) Wheel select button: this button allows the user to surf through the menus; pressing the button will

enter to the next page, turning it allows the user to scroll up or down through the current page.

5) BSP/BUS LED: these LEDs allow the user to monitor POL687 controller status.

Next figure shows POL638 controller interface.

4

5

2 1 3

Page 9

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

9

Controller POL638

The differences between POL687 and POL638 interfaces are the “Main Menu” and “Return” buttons, which

are mapped respectively to “INFO” and “ESC” buttons.

4.2 External Human Machine Interfaces

The Human Machine Interfaces (HMI) are devices that can be connected to the main controller (POL687/638)

in order to create a remote interface between the controller and the user.

Two different remote interfaces are available: POL871 and POL895. Both will replicate exactly the same page

that is seen on the principal controller and must be connected to the “T-HI” output of the controller.

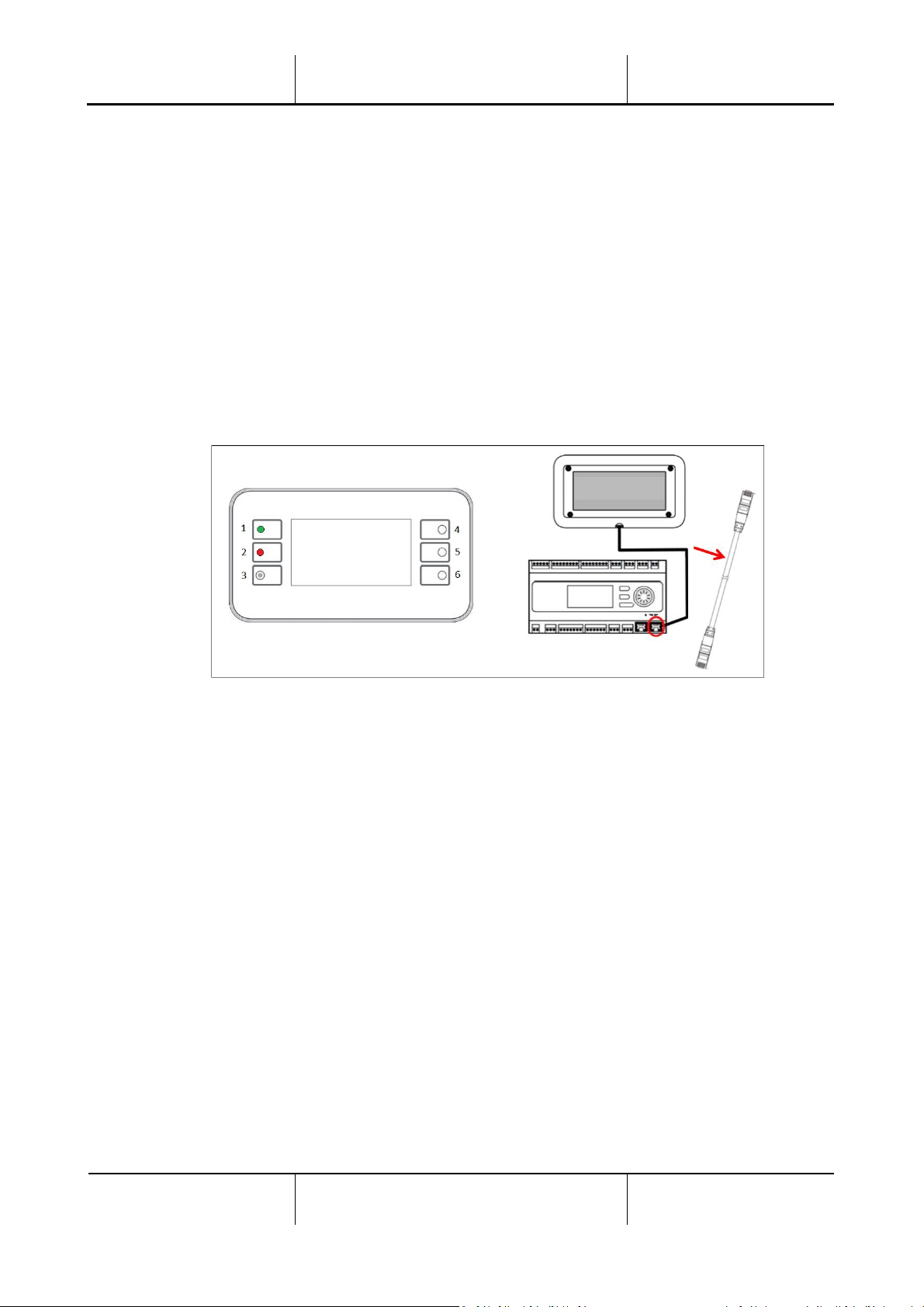

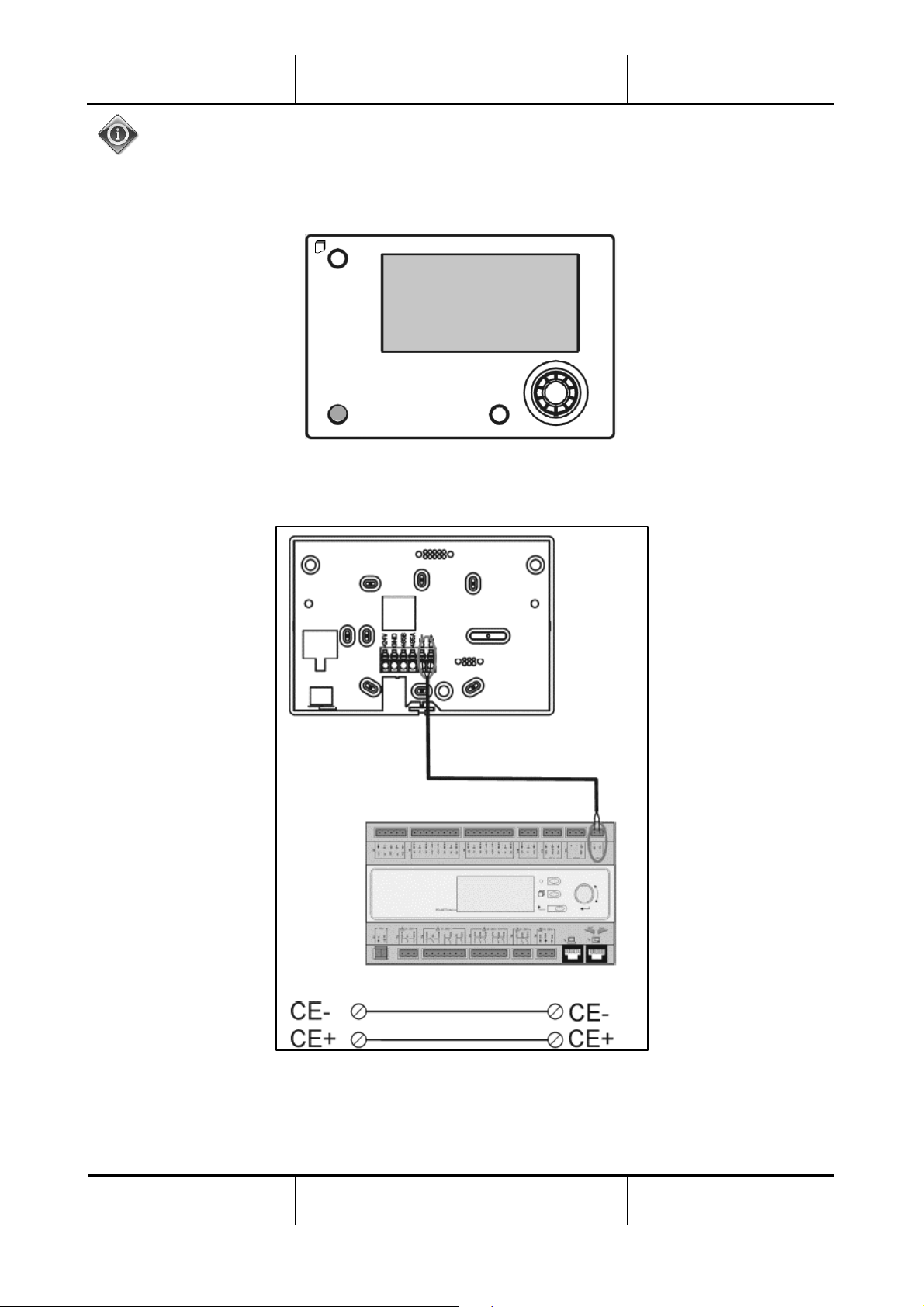

4.2.1 6-Button LCD HMI (POL871)

The following figure shows the POL871, a 6-buttons LCD interface, and how to connect to it to the main

controller through a simple Ethernet cable:

With reference to the above, it is possible to identify the following buttons:

1. Button 1: Main menu.

This button has an internal LED that indicates the status of the AHU:

- LED green: AHU running

- LED blinking orange: AHU Alarm

2. Button 2: Use this button to go directly to the alarms page.

3. Button 3: Back button.

4. Button 4: Scroll up button / increase values.

5. Button 5: Scroll down button / decrease value.

6. Button 6: Enter / validate button.

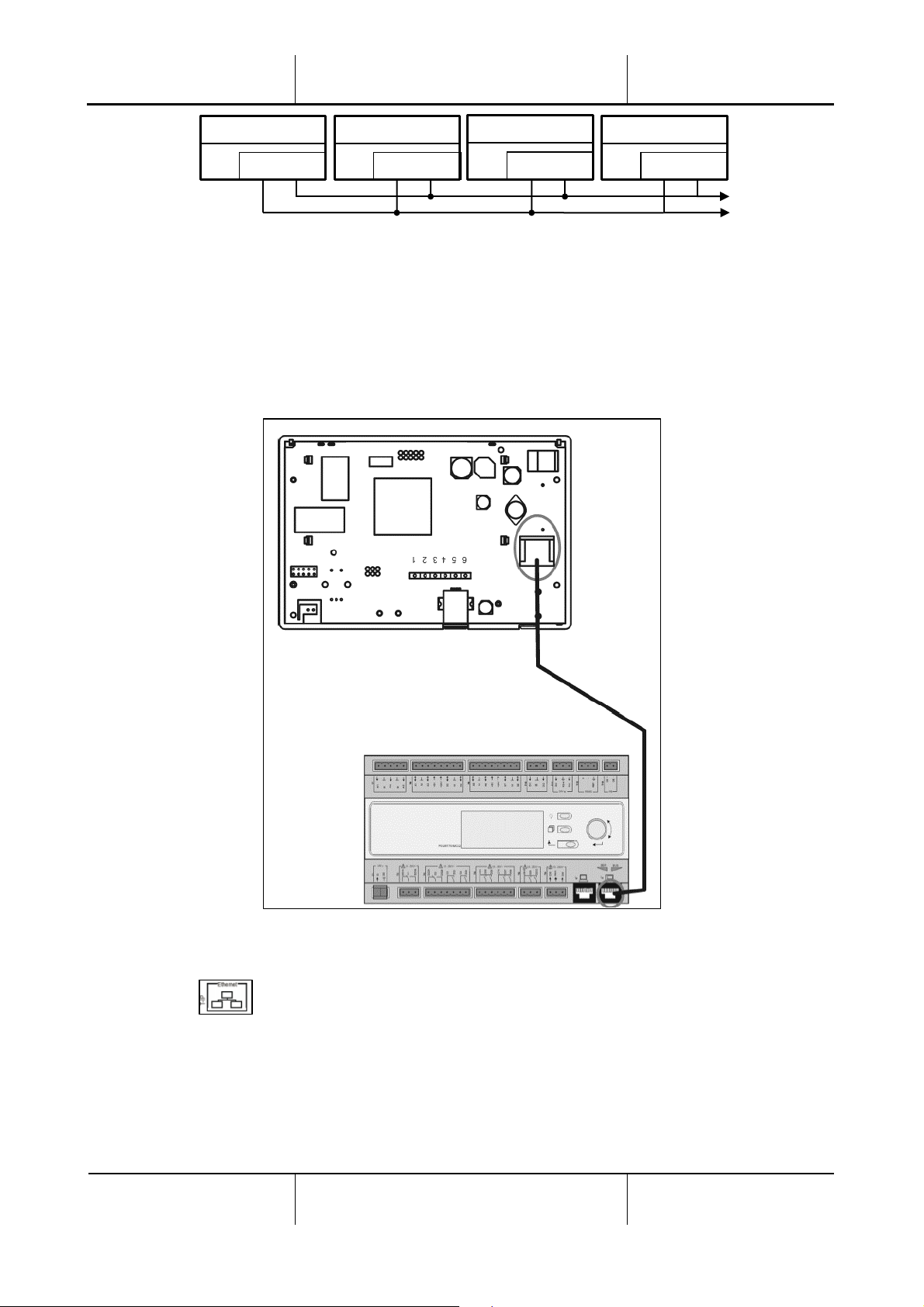

4.2.2 Push & Roll key HMI (POL895)

The POL895 is an external interfaces with a push & roll key which replicates the integrated controller HMI

navigation (if provided). All views, data and setpoint adjustments available on main controller HMIs are

available on the remote panel. Navigation is identical to the main controller as described in this manual.

The initial screen when the remote is turned on shows the units connected to it. Highlight the desired unit

and press the wheel to access it.

Page 10

Operation Manual

Air Handling Unit

Operation Manual

10

Air Handling Unit

D-EOMAH00006-20EN

Long press of the ESC button will show the list of the connected controllers. Use the wheel to select the

desired controller.

The Remote HMI can be extended up to 700m using the Process Bus connection (PB) available on the main

controller.

With a daisy-chain connection as below, a single HMI can be connected up to 8 units. Refer to the specific

HMI manual for additional details.

Page 11

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

11

The Remote interface can be also connected with an Ethernet cable (twisted pair). Maximum length changes

depending on cable characteristic:

• Shielded cable: max length 50m,

• Non-shielded cable: max length 3m.

Connection in this case has to be executed as shown in the following image.

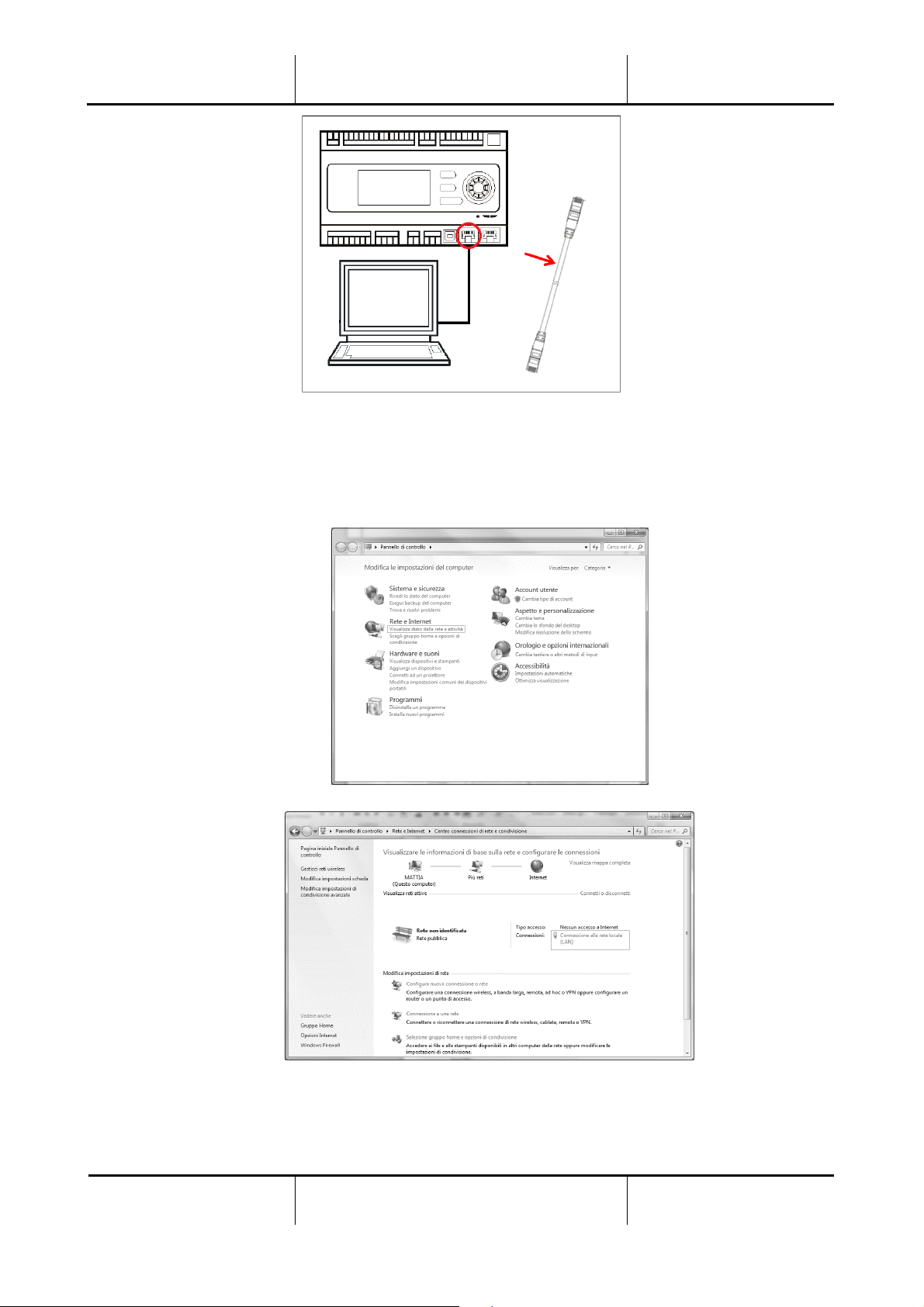

4.3 WEB-Human Machine Interface

The main controller can be connected to a PC using an Ethernet cable on the “Ethernet” output of the

controller itself .

CE- CE+

Remote HMI

CE- CE+

Unit 1

CE- CE+

Unit 2

CE- CE+

Unit 3

Page 12

Operation Manual

Air Handling Unit

Operation Manual

12

Air Handling Unit

D-EOMAH00006-20EN

To access to the controller menu through the WEB-HMI it is necessary to follow the following steps:

1. Set a static IP (Windows 7):

Start -> Control Panel -> View network status and tasks -> Local Area Connection

Properties -> Internet Protocol 4(TCP/IPv4) -> Properties

Page 13

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

13

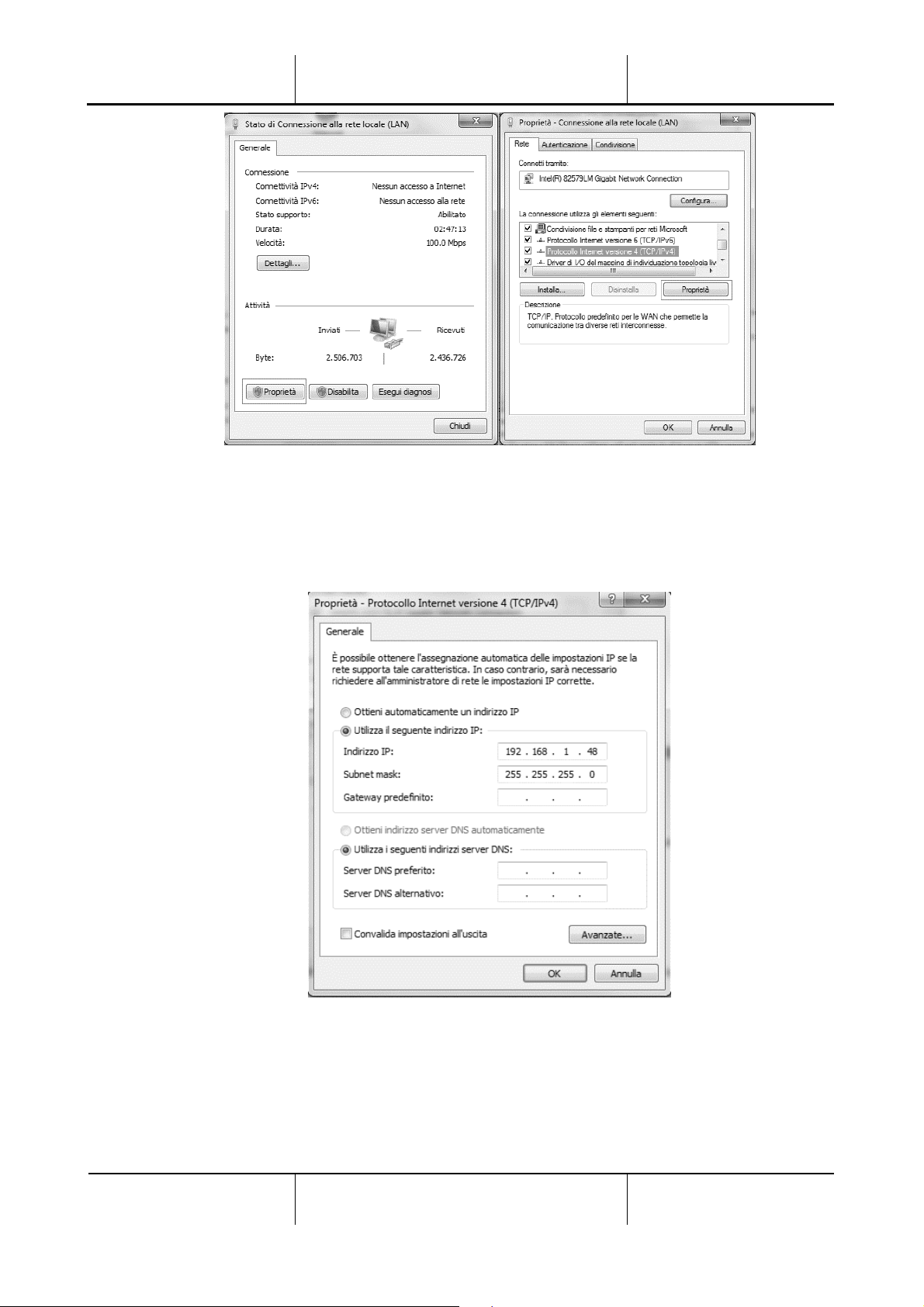

2. Set “Use the following IP address” and “Use the following DNS server addresses” and manually insert:

- IP address = 192.168.1.xxx, where xxx indicates any number between 1 and 254, except 42

- Subnet mask = 255.255.255.0

3. Press Ok

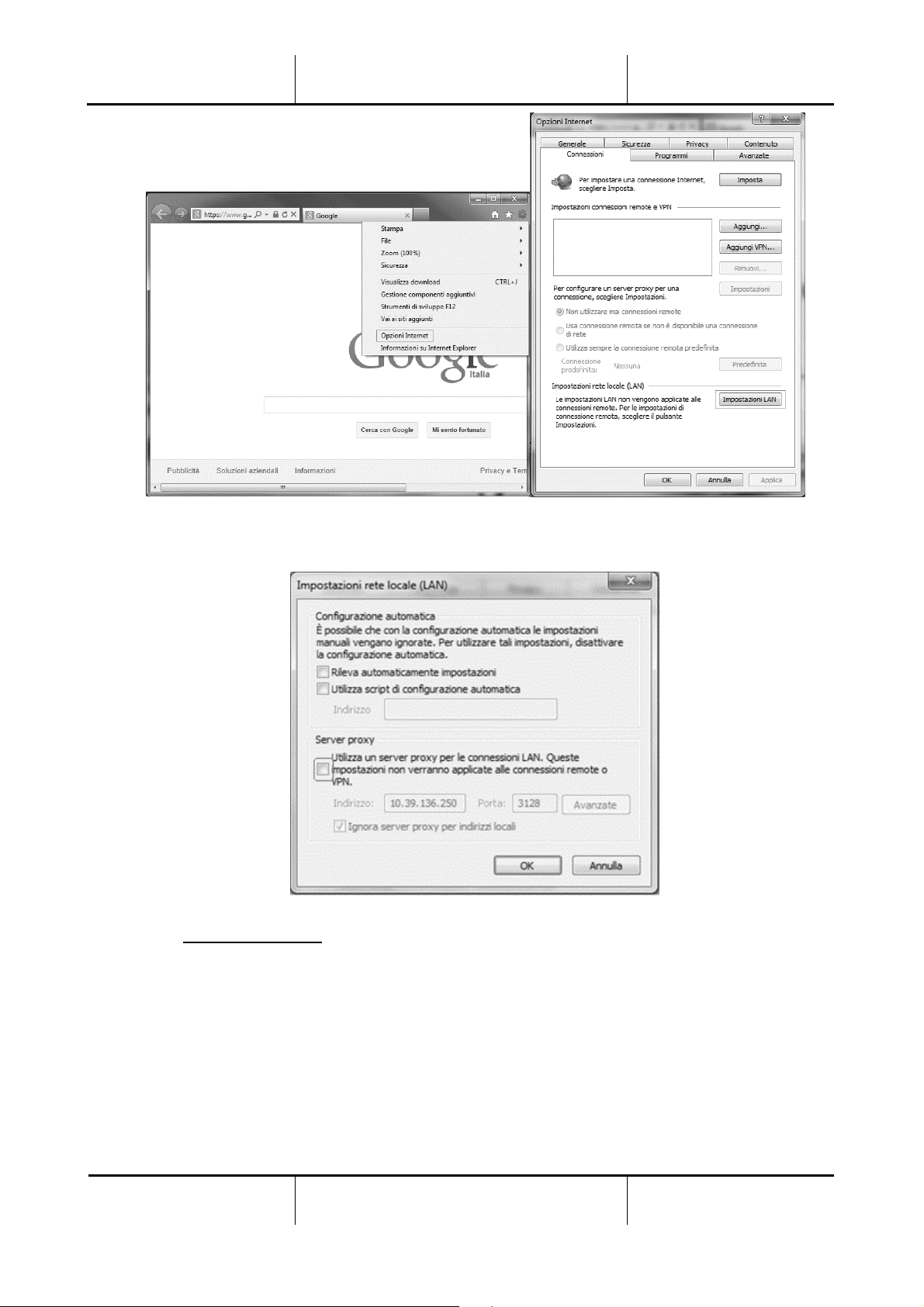

Before launching the WEB-HMI, the user must check if any proxy servers are disabled on the internet

browser:

1. For Internet Explorer select:

Tools -> Internet Options -> Connections -> Lan settings

Page 14

Operation Manual

Air Handling Unit

Operation Manual

14

Air Handling Unit

D-EOMAH00006-20EN

2. Disable “Use a proxy server for your LAN (These settings will not apply to dial-up or VPN

connections)”

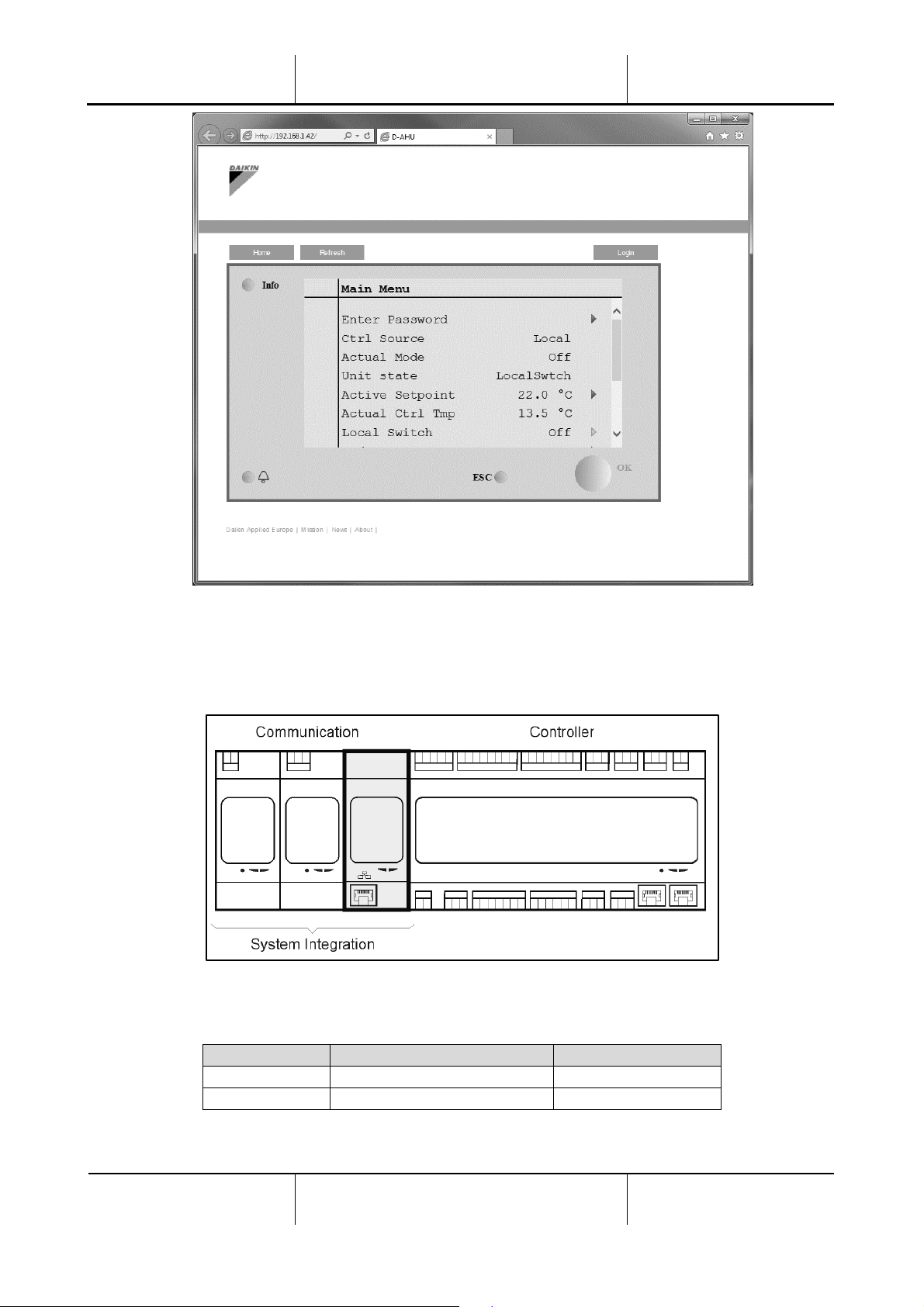

3. Type http://192.168.1.42 in the internet browser bar and, when asked, insert the following user

name and password:

- User name: ADMIN

- Password: SBTAdmin!

The following page should appear.

Page 15

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

15

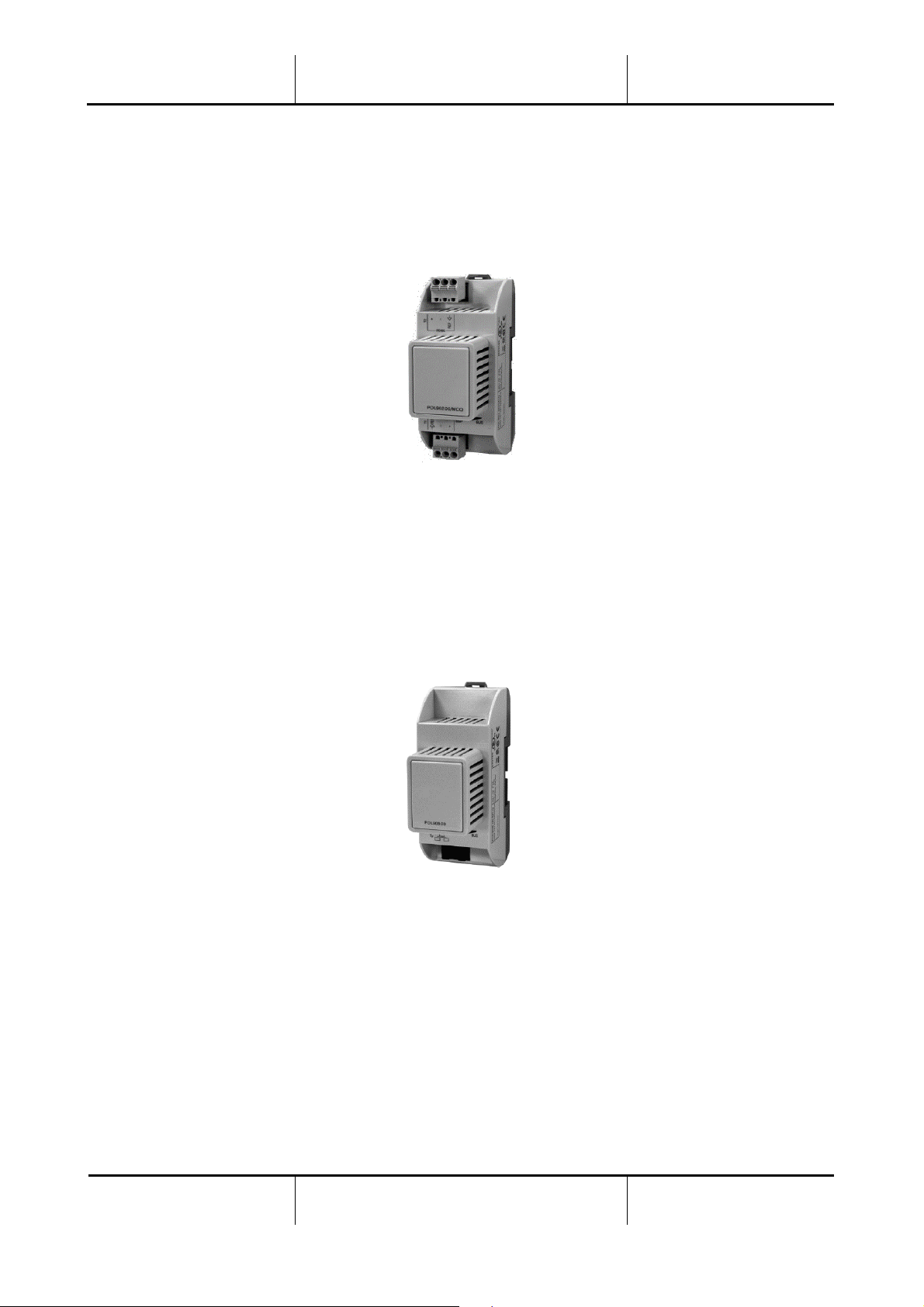

4.4 Communication Modules

Any of the modules described in this section can be connected directly to the left side of the main controller

to allow a BAS or other remote interface to function. To make the connection is required to remove the

knockout covers on both unit controller and communication module, so the installation will results as follows:

The controller should automatically detect new modules after booting up. The configuration strictly depends

on the communication protocol used.

Module

Part Number

Usage

Modbus

POL902.00/MCQ

Optional

BACnet/IP

POL908.00/MCQ

Optional

Page 16

Operation Manual

Air Handling Unit

Operation Manual

16

Air Handling Unit

D-EOMAH00006-20EN

Separate documents contains all the information about the different protocols supported and a full list of

available variables.

4.4.1 Modbus module installation

In case of Modbus connection with a BMS, the corresponding module has to be installed on the unit (POL902).

It has to be connected to the Unit Controller as indicated in the previous section.

The module has two different ports available but only the top port is programmed and operational. A

dedicated menu allows to properly setup the communication parameters.

4.4.2 BACnet IP module installation

In case of BACnet connection with a BMS, the corresponding module has to be installed on the unit (POL908).

It has to be connected to the Unit Controller as indicated in the previous section.

A dedicated menu allows to properly setup the communication parameters.

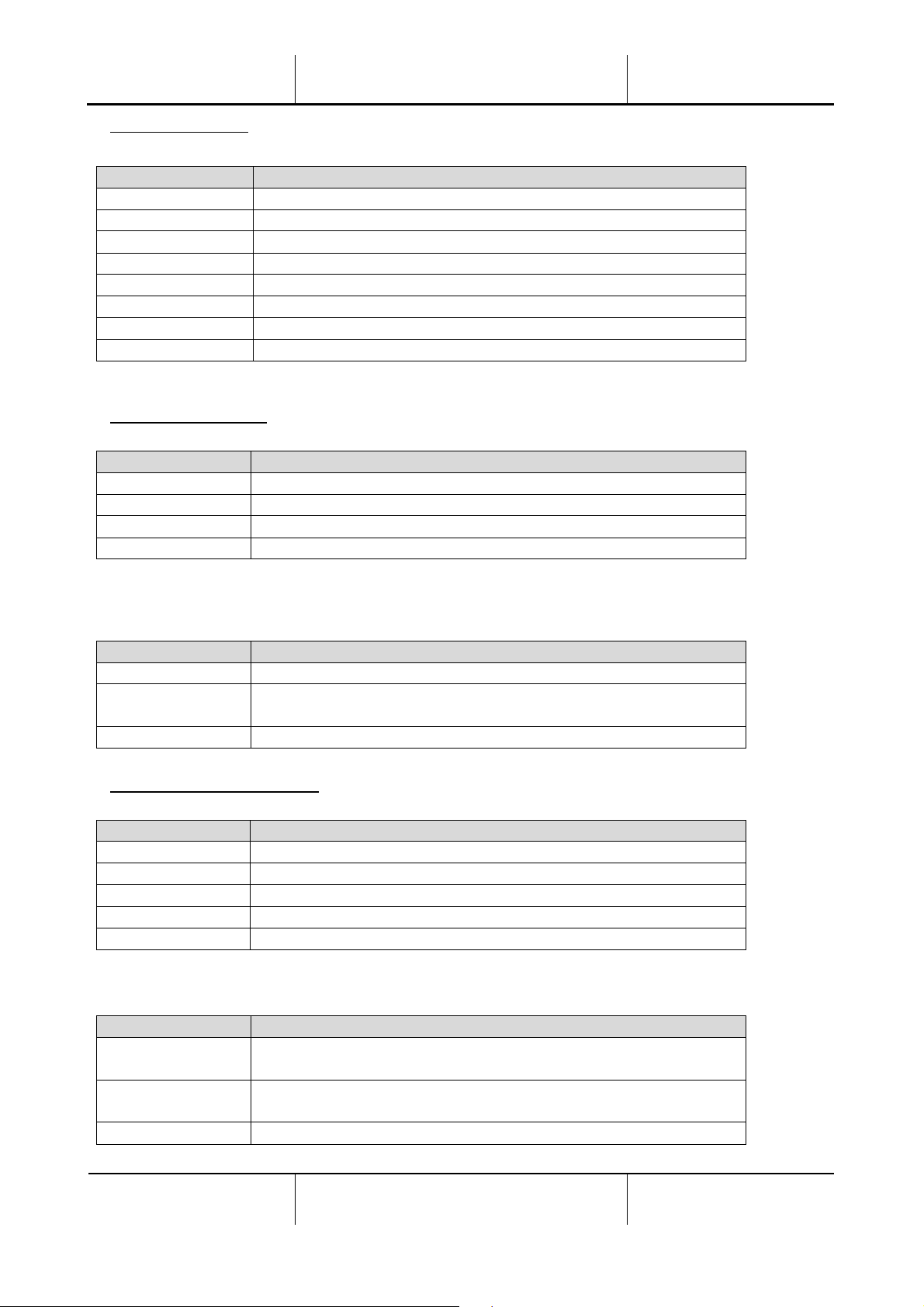

4.5 Basic Control System Diagnostic

Unit controller, extension modules and communication modules are equipped with two status LED, BSP and

BUS, to indicate the operational status of the devices (see section 3.1 for their location). The “BUS” LED

indicates the status of the communication with the controller. The meaning of the two status LED is indicated

below.

Page 17

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

17

- MAIN CONTROLLER

- BSP LED

LED Color

Mode

Solid Green

Application running

Solid Yellow

Application loaded but not running (*) or BSP Upgrade mode active

Solid Red

Hardware Error (*)

Flashing Green

BSP startup phase. The controller needs time for starting.

Flashing Yellow

Application not loaded (*)

Flashing Yellow/Red

Fail safe mode (in case that the BSP upgrade was interrupted)

Flashing Red

BSP Error (software error*)

Flashing Red/Green

Application/BSP update or initialization

(*) Contact Service.

- EXTENSION MODULES

- BSP LED

LED Color

Mode

Solid Green

BSP running

Solid Red

Hardware Error (*)

Flashing Red

BSP Error (*)

Flashing Red/Green

BSP upgrade mode

- BUS LED

LED Color

Mode

Solid Green

Communication running, I/O working

Solid Yellow

Communication running but parameter from the application wrong

or missing, or uncorrect factory calibration

Solid Red

Communication down (*)

- COMMUNICATION MODULES

- BSP LED (same for all modules)

LED Color

Mode

Solid Green

BPS running, communication with controller

Solid Yellow

BSP running, no communication with controller (*)

Solid Red

Hardware Error (*)

Flashing Red

BSP Error (*)

Flashing Red/Green

Application/BSP update

(*) Contact Service.

- BUS LED (BACnet IP)

LED Color

Mode

Solid Green

Ready for Communication. The BACnet Server is started. It doesn't

indicate an active communication

Solid Yellow

Startup. The LED stays yellow until the module receives an IP

Address, therefore a link must be established.

Solid Red

BACnet Server down. Automatic restart after 3 seconds is initiated.

Page 18

Operation Manual

Air Handling Unit

Operation Manual

18

Air Handling Unit

D-EOMAH00006-20EN

- BUS LED (Modbus)

LED Color

Mode

Solid Green

All Communication running

Solid Yellow

Startup, or one configured channel not communicating to the

Master

Solid Red

All configured Communications down (no communication to the

Master). The timeout can be configured. In case that the timeout is

zero, the timeout is disabled.

Page 19

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

19

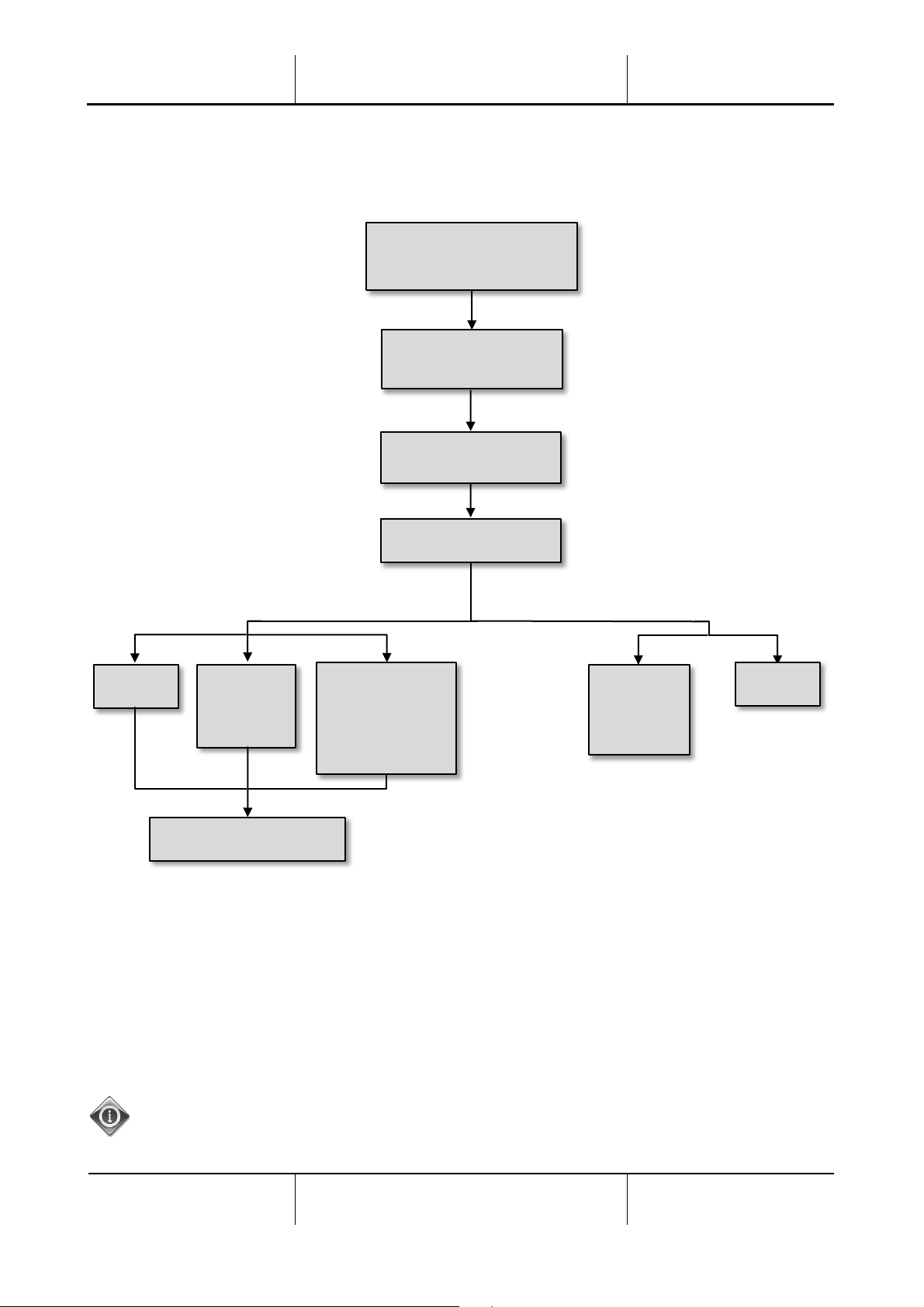

5. Control Functions

This section describes the main control functions available in Daikin Air Handling Units. A typical activation

sequence of the devices installed in Daikin AHU for thermoregulation control is showed below.

The starting sequence is performed according to an energy saving management logic, in order to satisfy the

desired temperature setpoint.

As soon as a device is fully operational (i.e. operates at 100%), the next device starts according to the

sequence shown in the figure above. The same sequence describes also the devices turn-off order by

following the opposite direction, ensuring that the upper devices are directly controlled only when the lowest

ones are not working. This ensure that the temperature setpoint is always satisfied with the lowest energy

consumption.

The activation sequence strictly depends on the devices actually installed in your AHU, so it may changes

accordingly.

Mixing Damper

Supply/Return

Fan Start

Fresh/Exhaust

Air Damper Opening

Heat Recovery Device

ERQ

+

Heating Water

Coil

ERQ

Heating

Water Coil

Electric Coil

Cooling

Water Coil

ERQ

Heating

Cooling

Page 20

Operation Manual

Air Handling Unit

Operation Manual

20

Air Handling Unit

D-EOMAH00006-20EN

5.1 Air Quality Control Function

The Air Quality control function provides the AHU with the capability of monitoring and control the actual

level of CO2 concentration in the environment by modulating the devices that control the air flow (fans and

dampers) in order to facilitate the air exchange between inside and outside, while ensuring in the meantime

the respect of the temperature setpoint selected.

In particular, when the CO2 level (in ppm) is higher than the desired setpoint, the actual fan setpoint is

increased proportionally in order to increment clean air volume coming from the outside (Supply air duct)

and at the same time extract more rapidly the environment exhaust air (Return air duct). During this state,

the dampers (both mixing and external) are modulated in order to increase fresh air flow.

For additional information on air quality control logic and parameters configuration refer to Air Quality

Control section (15.2).

The Air Quality control function is available only if the AHU is provided with a CO2 sensor.

5.2 Humidity Control Function

The AHU software is provided with both humidification and dehumidification functions in order to control

the environment relative humidity and satisfy the desired humidity setpoint. These functions may be both

available or not, depending on the configuration of the AHU.

- Humidification Control

During AHU winter mode, the controller monitors the humidity sensor readings and activates the

control of the humidifier as soon as this value drops below the desired setpoint.

The humidification function can be configured to be active also during AHU summer mode.

The humidifier can also be used to refresh the return air during AHU summer mode in order to

increase the effectiveness of the heat recovery device by enabling the adiabatic recovery function

(via AHU configuration).

- Dehumidification Control

During AHU summer mode, the controller monitors the humidity sensor readings and activates the

dehumidification control when these values becomes higher than the desired setpoint. The control

acts differently based on the cooling coil installed.

- ERQ: the dehumidification control is activated only if the cooling temperature setpoint has already

been reached. At this state, if the dehumidification is needed, the control continues to increase

the ERQs load in order to lower the air humidity value, while activating the post-heating coil

(electric or water) to prevent the air temperature to become too low.

- Water coil or DX: the cooling coil signal consists of the maximum value coming from the cooling

controller and the dehumidification controller. When the dehumidification logic is controlling, the

post-heating coil is activated to prevent the air temperature to become too low.

The dehumidification function can be configured to be active also during AHU winter mode.

Page 21

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

21

For additional information on humidity control monitoring and parameters configuration refer to Humidity

Control section (15.3).

The Humidity control function is available only if the AHU is equipped with all the necessary devices.

5.3 Summer/Winter mode changeover functions

The AHU software provides several options for summer/winter changeover control:

- Auto Mode

The controller monitors one of the several temperatures available on the AHU (Room, Return or

Outside). The value of this temperature is compared with two limits (one for summer and one for

winter) and, depending on the result of this comparison, the controller chooses the cool/heat state

for the next period.

- Manual Mode

The changeover is managed via controller interface or through the Room Unit device (if installed).

- Pursuit Mode

This logic can be used when it is desired to follow a temperature setpoint, regardless of the actual

heating/cooling mode of the unit.

The unit will automatically switch to Summer/Winter state when the actual controlled temperature

has passed respectively the to Summer/to Winter thresholds, which are calculated based on the

actual temperature setpoint selected.

- BMS

The changeover is managed via a Building Management System (BMS) through BACnet or Modbus

protocol communication.

For additional information on summer/winter changeover logics and settings refer to Summer/Winter state

section (11).

The available summer/winter changeover modes depend on the components and functions configured in the

AHU, so the number and configuration may changes accordingly.

Page 22

Operation Manual

Air Handling Unit

Operation Manual

22

Air Handling Unit

D-EOMAH00006-20EN

6. Main Menu screen

IMPORTANT! This manual refers to the user interface implemented in software version “Airstream

2.00.A” and later, so for previous software versions the presence and arrangement of some menu items

may be different.

Through Main Menu screen the user can access to all the information necessary for monitoring the AHU

status, in addition to managing the unit operative mode.

In particular, the user can:

- Control the AHU operative mode

- Change the AHU Setpoint

- Change the Summer/Winter state

- Access to the I/O overview menu

- Program the time scheduler

- Restore alarm conditions

Next chapters will describe any item of the main menu. In the following table the user can find all the items

of the main menu screen and the section where it is described.

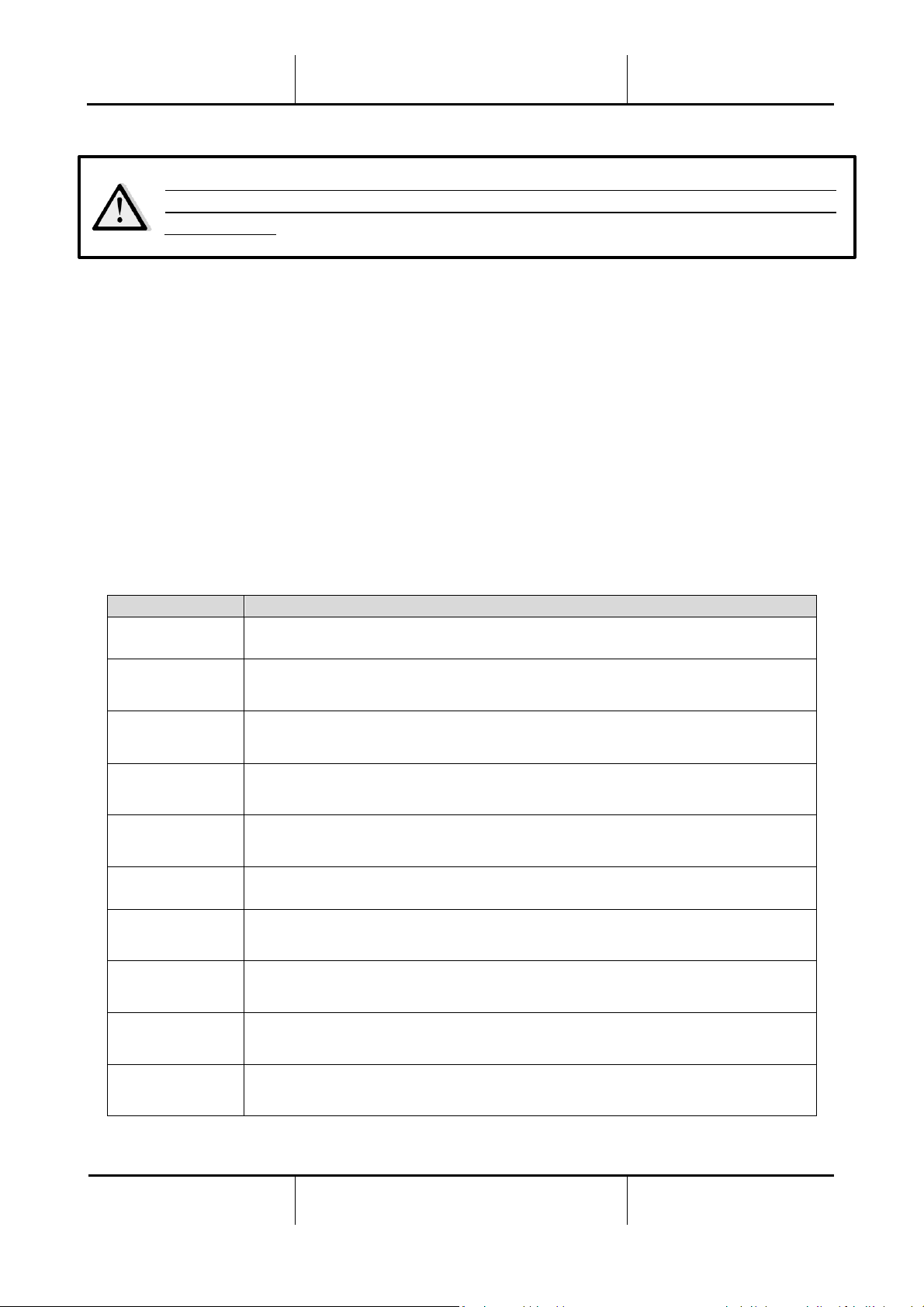

Main Menu item

Section

Enter Password

Insert the password to gain service level access.

Control Source

Display the actual control source of the AHU.

(Section 7)

Actual mode

Display the actual operating mode of the AHU.

(Section 8)

Unit State

Display the actual state of the AHU.

(Section 9)

Active Setpoint

Display all active setpoints of the AHU.

(Section 10)

Actual Ctrl Tmp

Display the actual value of the controlled temperature.

Local Switch

Display/change locally the operating mode of the AHU.

(Section 11)

Su/Wi state

Display actual AHU state and change summer/winter changeover options.

(Section 12)

Setpoints

Change AHU setpoints.

(Section 13)

I/O overview

Monitor all inputs and outputs of the controller.

(Section 14)

Page 23

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

23

Time Scheduler

Set the time slots for AHU On/Off turning.

(Section 15)

Status/Settings*

Display actual status and manage settings for the devices installed in the AHU.

(Section 16)

Commissioning*

Set the configuration parameters of the AHU.

(See commissioning manual D-ECCAH00002-20EN)

Alarm handling

Visualize and manage every alarm occurrence.

(Section 17)

About Unit

Visualize useful information about the controller.

(Section 18)

*Only visible with service password entered.

Page 24

Operation Manual

Air Handling Unit

Operation Manual

24

Air Handling Unit

D-EOMAH00006-20EN

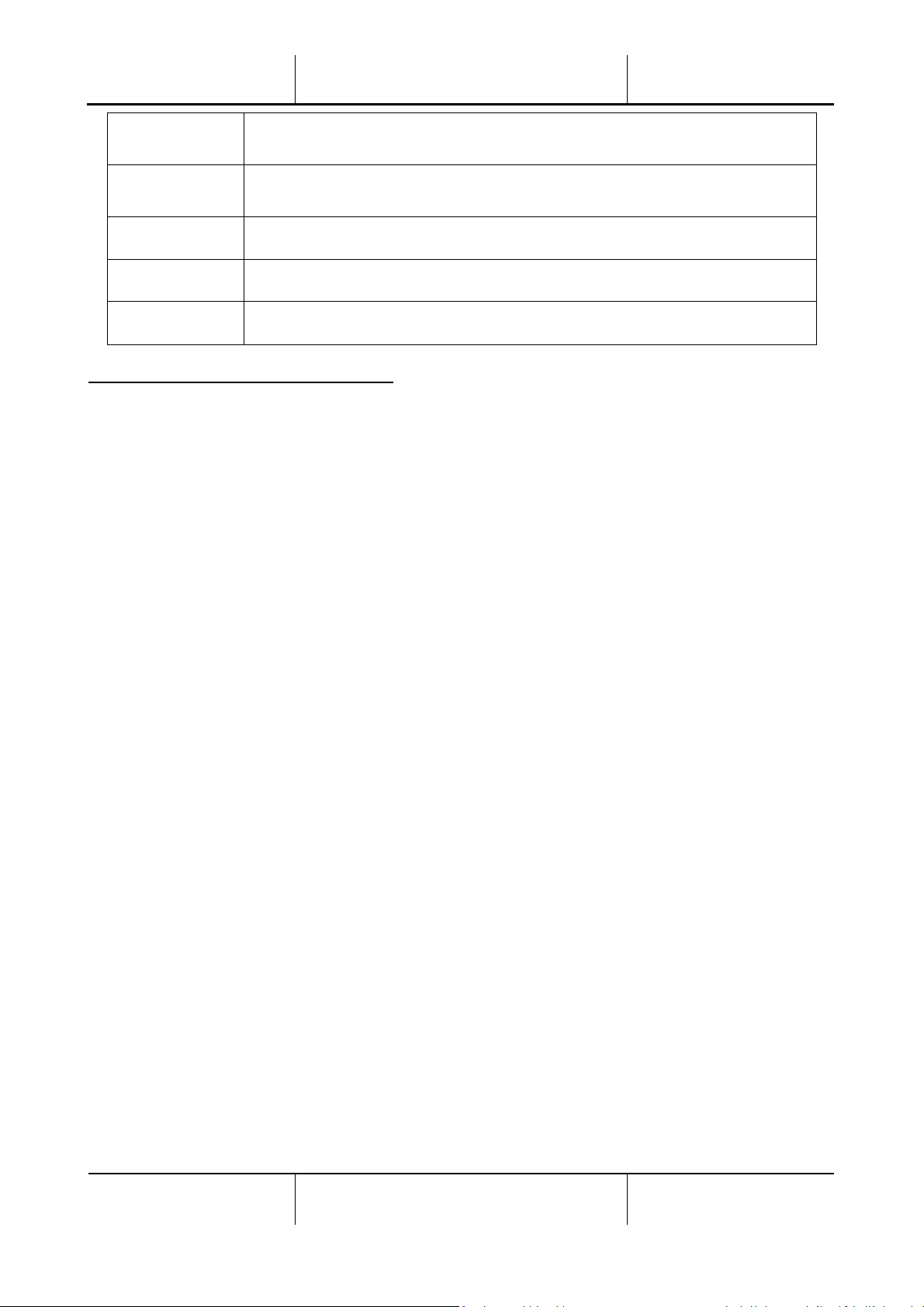

7. Control Source

This item displays the actual control source of the AHU. All possible control source are reported in the table

below.

HMI Path: Main Menu -> Ctrl Source

Main Menu item

Value

Description

Control Source

- Local

- BMS

− Local:

a. HMI: unit control managed directly from the controller

interface or automatically via time scheduler. Refer to Local

Switch page (Section 10) for more details.

b. Room Unit: when Control Source is set to Local, the unit can be

controlled also through the Room Unit device (POL822), if

installed. Refer to Appendix A for more details on Room Unit

control.

− BMS:

a. Modbus: the unit can be controlled by a Modbus Master

device through Modbus protocol, if the corresponding

communication module is installed (POL902). Refer to DEOMOCAH202-18EN for more details.

b. BACnet: the unit can be controlled through BACnet

communication if the corresponding communication module

is installed (POL904/POL908). Refer to D-EOMOCAH10009

for more details.

Page 25

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

25

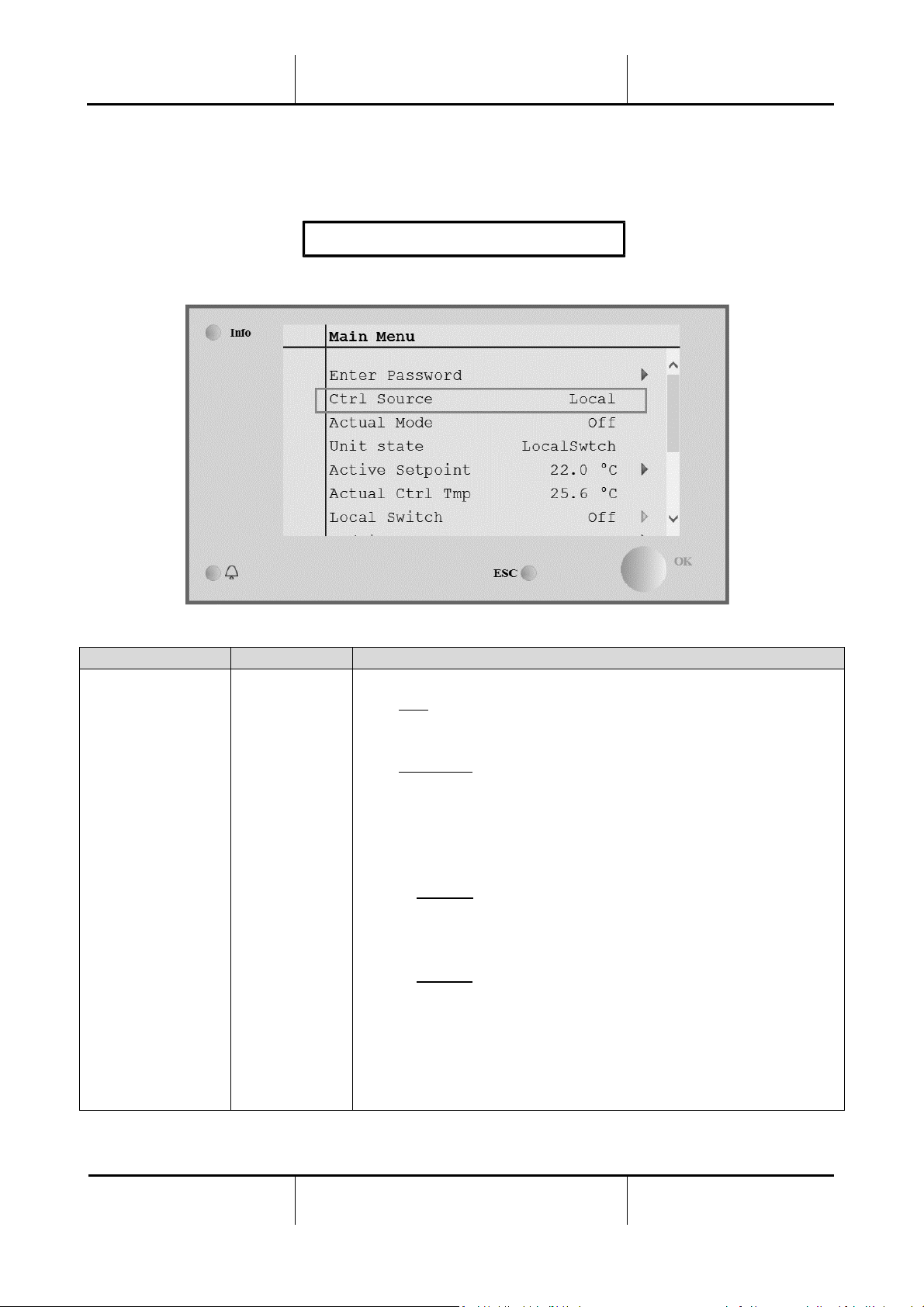

8. Actual Mode

This item (read-only) displays the actual operating mode of the AHU. All possible operating mode are reported

in the table below.

HMI Path: Main Menu -> Actual Mode

Main Menu item

Value

Description

Actual Mode

- Off

- On

- Ventilation

- Economy

Off: AHU in Off mode.

All devices installed on the AHU (fans, cooling/heating coil,

dampers, etc..) are Off.

On: AHU in On mode.

Normal functioning: all controls are active.

Ventilation: AHU in Ventilation mode.

In this mode only fans are running.

Economy: AHU in Economy mode.

Normal functioning: all controls are active, but the AHU works

referring to the Economy set points.

Refer to Setpoints page (Section 12) for more details.

Page 26

Operation Manual

Air Handling Unit

Operation Manual

26

Air Handling Unit

D-EOMAH00006-20EN

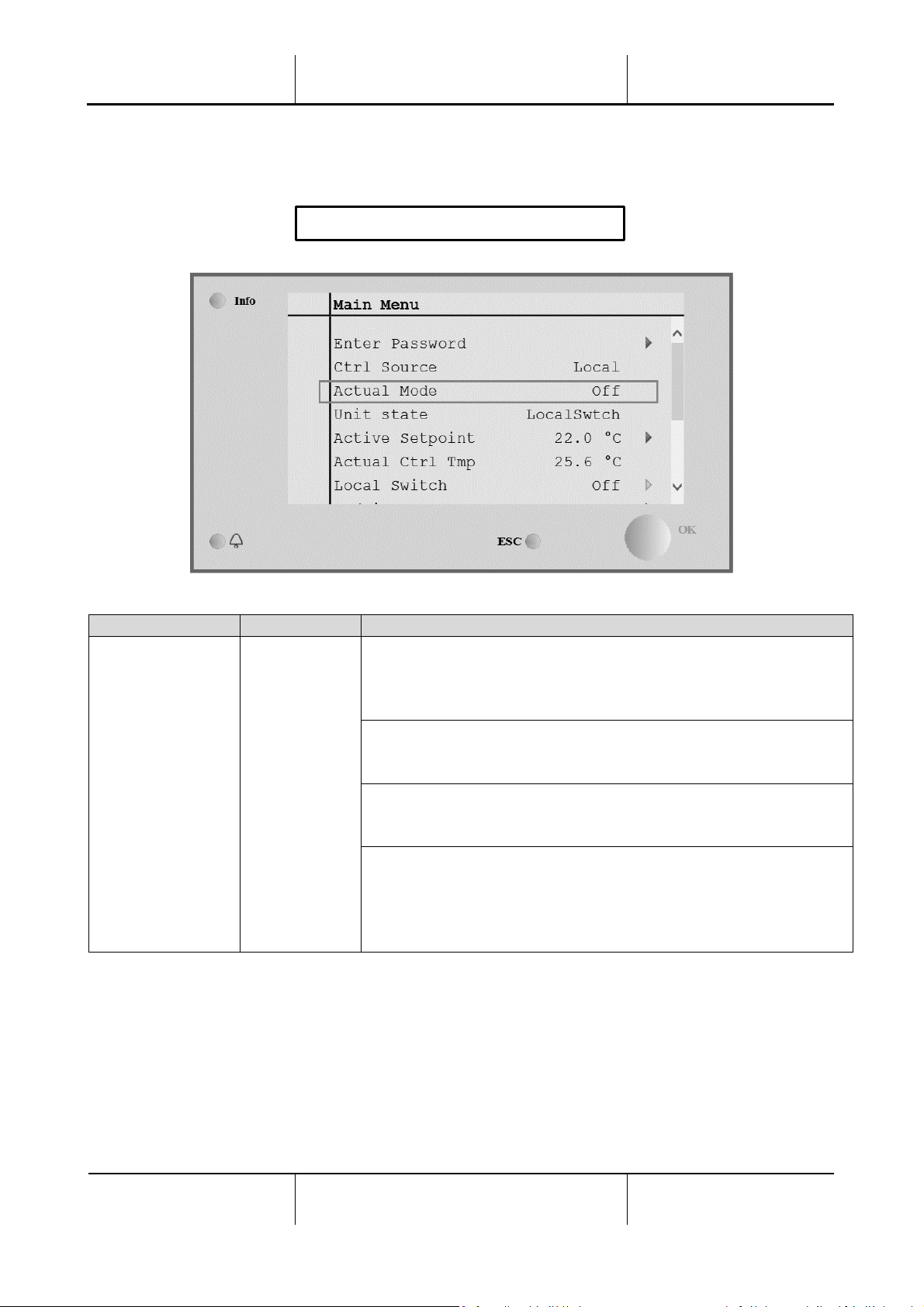

9. Unit State

This item (read-only) displays the actual state of the AHU. All possible states are reported in the table below.

HMI Path: Main Menu -> Unit State

Main Menu item

Value

Description

Unit State

- Fire

- Emergency

- Alarm

- Manual

- Panel Switch

- Local Switch

- BMS

- Scheduler

- Ready

- Occupancy

Fire: AHU in Fire alarm state.

The AHU is in this state when a “Fire Alarm” digital input is

detected.

Emergency: AHU in Emergency state

This state indicates that the Emergency button has been pressed.

Alarm: AHU in alarm state.

This state is displayed when an alarm has been detected.

Manual: AHU in Test mode.

The AHU is in this state when Local Switch is set to Test.

Refer to Local Switch page (Section 10) for more details.

Panel Switch: Switch labeled “Enable Switch” located on the

Electrical Box is set to zero.

Local Switch: AHU controlled manually from interface Room Unit or

a Modbus Master device.

Refer to Local Switch (Section 10) and Control Source (Section 6)

pages for more details.

BMS: AHU controlled via Modbus or BACnet.

Scheduler: AHU in On state by Time Scheduler.

Page 27

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

27

Main Menu item

Value

Description

Refer to Time Scheduler (Section 14) page for more details

Ready: AHU in Off state by Time Scheduler.

Refer to Time Scheduler (Section 14) page for more details.

Occupancy: AHU in On state by Occupancy function.

Refer to Room Unit page for more details. (Appendix A)

Page 28

Operation Manual

Air Handling Unit

Operation Manual

28

Air Handling Unit

D-EOMAH00006-20EN

10. Active Setpoint

All actual setpoints used by the software to control AHU devices are reported in the Active Setpoint page.

In the Main Menu screen is displayed the actual setpoint used for controlled temperature.

HMI Path: Main Menu -> Active Setpoint

Parameters

Description

Temperature

Display the actual setpoint used for the controlled temperature.

This value is the sum of the basic setpoint (given by Summer/Winter

state) plus the offset set through the Room unit (R.U.), if present.

- Summer mode

Temperature = Cool (+ R.U. Offset, if present)

- Winter mode

Temperature = Heat (+ R.U. Offset, if present)

Supply Fan

Display the actual setpoint value for the supply fan.

This value is the sum of the basic setpoint plus the offset evaluated

by the software for compensation (if a compensation function is

active).

Supply Fan = Supply Fan (+ Comp. Offset, if active)

Return Fan

Display the actual setpoint value for the return fan.

This value is the sum of the basic setpoint plus the offset evaluated

by the software for compensation (if a compensation function is

active).

Return Fan = Return Fan (+ Comp. Offset, if active)

Humidification

Display the actual humidification setpoint.

Dehumidification

Display the actual dehumidification setpoint.

Air Quality

Display the actual air quality setpoint.

Page 29

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

29

11. Local Switch

This item is used to control locally the operating mode of the AHU.

NOTE! Any change on this item does not have any effect if the AHU is configured to be controlled by

BMS (i.e. Ctrl Source = BACnet).

HMI Path: Main Menu -> Local Switch

Main Menu item

Value

Description

Local Switch

- Auto

- Off

- On

- Ventilation

- Economy

- Test

Auto: AHU On-Off state is managed by the time scheduler.

Refer to Time Scheduler page for more details.

Off: turn off the AHU.

On: turn on the AHU.

In this mode all controls are active and setpoints related to

temperature regulation and fans control are the normal setpoints.

Refer to Setpoints page (Section 12) to change normal setpoints.

Ventilation: Switch the AHU in ventilation mode.

In this mode only fans are running.

No temperature control is performed.

Economy: Switch the AHU in economy mode.

In this mode all controls are active, but the setpoints related to

temperature regulation and fans control switch from normal

setpoints to economy setpoints.

Refer to Setpoints page (Section 12) to change economy setpoints.

Test: AHU in Test mode.

In this mode every device of the AHU can be manually controlled.

NOTE! This function is only available with service password

entered and the item is visible only if the AHU is OFF.

Page 30

Operation Manual

Air Handling Unit

Operation Manual

30

Air Handling Unit

D-EOMAH00006-20EN

12. Summer/Winter state

The AHU software provides three different options for summer/winter changeover control:

- Automatic changeover based on temperature.

The controller monitors one of the several temperatures available on the AHU (Room, Return or

Outside). The value of this temperature is after compared with two limits (one for summer and one

for winter) and, depending on the result of this comparison, the controller chooses the cool/heat

state for the next period.

- Manually changeover via HMI or Room Unit.

- Changeover managed via BMS.

All information and settings for this control are available in the following HMI page:

HMI Path: Main Menu -> Su/Wi State

The following table explains all items present in the Su/Wi state page and how configure them to obtain the

desired control.

Parameters

Value

Description

Su/Wi chg source

1. Auto

2. HMI

3. BMS

4. Pursuit*

This parameter defines which mode is used to control the

Summer/Winter switch:

1. Auto: changeover is done automatically by the AHU

based on the auto mode configuration

2. HMI: Summer/Winter state is set manually by the HMI

3. BMS: Summer/Winter state is set via BMS

communication.

4. Pursuit*: changeover is performed automatically in

order to reach and maintain the desired temperature

setpoint. Refer to Setpoints page (Section 12) to

change Pursuit mode setpoints.

*Available from Airstream 1.00.A software version and only if

Return or Room temperature control has been selected.

Page 31

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

31

Parameters

Value

Description

HMI changeover

- Summer

- Winter

Set actual mode of the AHU if Su/Wi chg source = HMI

Network

changeover

- Summer

- Winter

Display the mode set via BMS.

If the Su/Wi chg source = BMS, this value is the current state of

the AHU.

Current State

- Summer

- Winter

Display the current state in which the AHU is operating.

Auto mode settings:

Tmp Used

- Return

- Room

- Outside

Select the temperature monitored to determine the

Summer/Winter state changeover.

Time constant

0…36000 [h]

Define the frequency at which the check is being performed for

the Summer/Winter changeover in Auto Mode.

Example:

If this parameter is set equal to 6 hours, the controller

maintains the same state (Summer or Winter) for six hours.

After six hours, the controller performs again the check to

determine the next state that will be maintained for next six

hours.

Tmp Damped

-64...64 [°C]

Display the value of temperature stored when automatic

changeover happened.

Su tmp

-64...64 [°C]

Changes over to summer operation when the selected

temperature is greater than this value.

Wi tmp

-64...64 [°C]

Changes over to winter operation when the selected

temperature is less than this value.

Page 32

Operation Manual

Air Handling Unit

Operation Manual

32

Air Handling Unit

D-EOMAH00006-20EN

13. Setpoints

All setpoints of the AHU can be set from the HMI. Depending on the AHU configuration some setpoints can

be available or not.

HMI Path: Main Menu -> Setpoints

Parameters

Value Range

Description

Temperature:

Cool

10..40 [°C]

Cooling temperature setpoint.

(Available when direct Htg/Clg setpoint

control selected)

Heat

10..40 [°C]

Heating temperature setpoint.

(Available when direct Htg/Clg setpoint

control selected)

Cool Economy

Cool..40 [°C]

Cooling temperature setpoint in

Economy mode.

(Available when direct Htg/Clg setpoint

control selected)

Heat Economy

10..Heat [°C]

Heating temperature setpoint in

Economy mode.

(Available when direct Htg/Clg setpoint

control selected)

Central Temp

10..40 [°C]

Central temperature setpoint.

(Available only when temperature

regulation with deadzone control

selected)

Page 33

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

33

Band Temp

0..20 [°C]

Deadzone temperature setpoint.

(Available only when temperature

regulation with deadzone control

selected)

Central Temp

Economy

Cool..40 [°C]

Central temperature setpoint in

Economy mode.

(Available only when temperature

regulation with deadzone control

selected)

Band Temp

Economy

10..Heat [°C]

Deadzone temperature setpoint in

Economy mode.

(Available only when temperature

regulation with deadzone control

selected)

Pursuit

10..40 [°C]

Pursuit mode temperature setpoint.

Refer to Summer/Winter state (Section

11) for more details.

(Available from Airstream 0.10.B SW

version and only if Return or Room

temperature control has been selected)

Pursuit Eco

10..40 [°C]

Pursuit mode temperature economy

setpoint.

Refer to Summer/Winter state (Section

11) for more details.

(Available from Airstream 0.10.B SW

version and only if Return or Room

temperature control has been selected)

Pursuit Band

3,5..10 [°C]

Pursuit mode offset temperature

setpoint. This value is

added/subtracted from actual Pursuit

setpoint in order to estimate

Summer/Winter changeover tresholds.

Refer to Summer/Winter state (Section

11) for more details.

(Available from Airstream 0.10.B SW

version and only if Return or Room

temperature control has been selected)

R.U. Offset

-6…6 [°C]

Display the actual offset set through

the room unit.

(Available only with room unit)

Pre-Heating

0..30 [°C]

Temperature threshold for Pre-Heating

control activation.

(Available only if pre-heating control

enabled)

Page 34

Operation Manual

Air Handling Unit

Operation Manual

34

Air Handling Unit

D-EOMAH00006-20EN

Fan Ventilation:

Supply

0..100 [%]

0..5000[Pa]

0..140000[m3/h]

Fans setpoints.

Depending on the control type of the

fan, the setpoint can be expressed in

Percentage [%], Pascal [Pa], Cube

meter per hour [m3/h].

(Not available if fans are controlled in

On/Off mode)

Return

0..100 [%]

0..5000[Pa]

0..140000[m3/h]

Supply Economy

0..100 [%]

0..5000[Pa]

0..140000[m3/h]

Return Economy

0..100 [%]

0..5000[Pa]

0..140000[m3/h]

Supply Defrost

0..100 [%]

0..5000[Pa]

0..140000[m3/h]

Supply fan setpoint in case of defrost of

the condensing unit ERQ

(Available only if fan-defrost limitation

control enabled)

Return Defrost

0..100 [%]

0..5000[Pa]

0..140000[m3/h]

Return fan setpoint in case of defrost of

the condensing unit ERQ

(Available only if fan-defrost limitation

control enabled)

Others:

Dehumidification

- 0…100 [%rH]

- Humidification…100 [%rH] (if

humidification control enabled)

Dehumidification setpoint

(Available only if dehumidification

control enabled)

Humidification

- 0…100 [%rH]

- 0…Dehumidification [%rH] ] (if

dehumidification control enabled)

Humidification setpoint.

(Available only if humidification control

enabled)

Air Quality

0..3000 [ppm]

Air control quality setpoint. Limit of ppm

(parts per million) for the CO2.

(Available only if CO2 control enabled)

Fan fire setpoint

0..100 [%]

Fans setpoints when fire alarm

detected.

(Available only if Fire Alarm enabled)

Page 35

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

35

14. I/O Overview

This menu allows the user to monitor all analog/digital inputs and outputs of the controller. The list can be

different for each specific AHU as it depends on the installed components of the unit which are activated

during the commissioning.

HMI Path: Main Menu -> I/O overview

Parameters

Description

Digital inputs

Monitor all digital inputs of the controller.

Digital inputs can be connected to alarm signals coming from different

installed devices in the AHU (Fan, Damper, Pressure Switch, Water

Pump, etc…), or to external switches (Emergency stop, Unit enable).

Analog inputs

Contains the values of all installed sensors: temperature, pressure, air

flow, CO2, humidity.

Digital outputs

Contains the values of all digital outputs used to command the several

devices of the AHU (ERQ on/off, Pump on/off, Fan on/off, etc…).

Analog outputs

Contains the values of all analog outputs used to command different

devices of the AHU (Fan speed, damper opening, percentage of heat

recovery, etc…).

Page 36

Operation Manual

Air Handling Unit

Operation Manual

36

Air Handling Unit

D-EOMAH00006-20EN

15. Time Scheduler

The time scheduler is a function that allows the user to set the time slots at which the AHU can be turned ON

or OFF. If the scheduler is set, the AHU will be turned On/Off automatically by following the time slot

configuration. In the next tables are reported the items of the time scheduler menu and their description.

The time scheduler page contains also the configuration pages for single day time scheduling.

HMI Path: Main Menu -> Time Scheduler

Parameter

Value

Function

TS actual

state

- Off

- On

- Ventilation

- Economy

Actual operating mode from time scheduler function.

Monday

- Active

- Passive

Active if the present day is Monday.

Refer to Day Scheduler (Section 14.1) for more details.

Copy schedule

- Off

- On

Copy Monday schedule to all weekdays.

Tuesday

- Active

- Passive

Active if the present day is Tuesday.

Refer to Day Scheduler (Section 14.1) for more details.

….

….

….

Sunday

- Active

- Passive

Active if the present day is Sunday.

Refer to Day Scheduler (Section 14.1) for more details.

Exception

- Passive

- Active

Active if the present day is an exception day.

Refer to both Day Scheduler (Section 14.1) and Calendar Exception and

Calendar Fix off (Section 14.2) for more details.

Period: Start

Start date for the weekly schedule.

If equals to *,* *.00, weekly schedules is always enabled.

Period: End

End date for the weekly schedule.

If equals to *,* *.00, weekly schedules is never disabled.

Calendar

exception

- Passive

- Active

Active if the present day is an exception day.

Refer to Calendar Exception/Fix off (Section 14.2) for more details.

Page 37

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

37

Calendar fix

off

- Passive

- Active

Active if the present day is a fix off day.

Refer to Calendar Exception/Fix off (Section 14.2) for more details.

15.1 Day Scheduler

By entering in each day page, normal or exception, it is possible to set up to 6 time slots.

Parameter

Range

Function

Time 1

00:00

SPECIAL CASE: this entry must always be set to 00:00!

Value 1

- Off

- On

- Ventilation

- Economy

Switching command for Time 1.

Time 2

00:00 - 23:59

Switching time 2

(*:*-> Entry disabled)

Value 2

- Off

- On

- Ventilation

- Economy

Switching command for Time 2.

…

Time 6

00:00 - 23:59

Switching time 6

(*:*-> Entry disabled)

Value 6

- Off

- On

- Ventilation

- Economy

Switching command for Time 6

Below is an example of a day scheduler setting. In this case the AHU will be turned ON from 9.30 until 13.00

and in Economy mode from 14:00 until to 18:40.

Parameter

Value

Time 1

00:00

Value 1

Off

Time 2

09:30

Value 2

On

Time 3

13:00

Value 3

Off

Time 4

14:00

Value 4

Economy

Time 5

18:40

Value 5

Off

Time 6

*:*

Value 6

Off

Page 38

Operation Manual

Air Handling Unit

Operation Manual

38

Air Handling Unit

D-EOMAH00006-20EN

ATTENTION! If a time value is set incorrectly (i.e. it is less than the previous) the AHU will not work properly

and it could be always keep ON or OFF.

15.2 Calendar exception and Calendar fix off

Exception days are defined in the calendar items. These may include a specific date, periods or certain days

of the week.

When an exception day occurs, the “Exception” day scheduler configuration override the weekly schedule.

The time slots at which occurs the exception days can be configured in the “Calendar exception” page. The

“Calendar fix Off” page is a special exception day configuration that allows to switch off the plant at specific

time slots.

Entering in the “Calendar exception” or “Calendar fix off” page allows the user to find the items reported in

the table below.

Parameter

Range

Function

Present value

- Passive

- Active

Displays whether a calendar entry is currently enabled:

− No calendar entry is currently enabled.

− A calendar entry is currently enabled.

Choice-x

- Date

- Range

- Week Day

- Passive

Specifies the entry for the exception:

− Date: a certain day (e.g. Friday).

− Range: a period (e.g. vacation).

− Week Day: a certain day of the week (e.g. every Monday).

− Passive: entries are ignored.

This value should be set last, after the date is entered.

(Start) date

If Choice-x = date -> Enter data for a single day.

If Choice-x = range -> Enter start date for the period.

End date

For Choice-x = range only -> Enter end date for the period.

End date must always be after the start date.

Weekday

For Choice-x = weekday only -> Enter the day of the week.

Example 1: Choice = Date

Only the entry in (start) is relevant:

- (start) date = *,01.01.09

Result: January 1, 2009 is an exception date.

- (Start) date = Mo,*.*.00

Every Monday is an exception day.

- (Start) date = *,*.Evn.00

The days for the entire month are exception day for each even month (February, April, June, August, etc.).

Page 39

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

39

Example 2: Choice = Range

The entries in (start) date and end date are relevant:

- (start) date = *,23.06.09 / end date = *,12.07.09.

June 23, 2009 through July 12, 2009 are exception days (e.g. vacation).

- (start) date = *,23.12.00 / end date = *,31.12.00.

December 23 through 31 are exceptions for each year. The entry end date =*,01.01.00 does not work

here, since January 1 is before December 23.

- (start) date = *,23.12.09 / end date = *,01.01.10.

23. December 23, 2009 through January 1, 2010 are exception days.

- (Start) date = *,*.*.00 / -End date = *,*.*.00

Attention! This entry is always enabled! The plant is continuously on exception or off.

Example 3: Choice = Weekday

The entries for week day are relevant.

- Week day = *,Fr,*

Every Friday is an exception day.

- Week day = *,Fr,Evn

Each Friday in even months (February, April, June, August, etc.) is an exception day.

- Week day = *,*,*

Attention! This settings always enables “calendar exception” or “calendar off” days.

Page 40

Operation Manual

Air Handling Unit

Operation Manual

40

Air Handling Unit

D-EOMAH00006-20EN

16. Status/Settings

This menu allows the user to display the actual status and change settings for all the devices available in the

AHU. Depending on AHU configuration some menu item may be available or not.

NOTE! This menu item is only visible with service password entered.

HMI Path: Main Menu -> Status / Settings

Menu item

Description

AHU Device Monitor

Monitor the actual status and load percentage of all devices installed

in the AHU (Dampers, Heat Recovery, Cooling/Heating coils, etc…).

Temperature Control

Contains the specific parameters for general thermoregulation control.

Refer to Temperature Control (Section 15.1) for more details.

Air Quality Control*

Contains all parameters for air quality control monitoring and

parameter settings.

Refer to Air Quality Control (Section 15.2) for more details.

Humidity Control*

Contains all parameters for humidity control monitoring and settings,

for both humidification and dehumidification.

Refer to Humidity Control (Section 15.3) for more details.

Fans

Contains all parameters for fans control monitoring and related

functions.

Refer to Fans Control (Section 15.4) for more details.

Dampers*

Contains all parameters for dampers control monitoring and settings,

for both fresh air and mixing (if installed).

Refer to Dampers Control (Section 15.5) for more details.

Page 41

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

41

Menu item

Description

Recovery*

Contains all parameters for the heat recovery device control

monitoring and settings.

Refer to Heat Recovery Control (Section 15.6) for more details.

Cooling*

Contains all parameters for water and generic direct expansion (DX)

cooling coils monitoring and settings.

Refer to Cooling Coil Control (Section 15.7) for more details.

Heating*

Contains all parameters for water and generic direct expansion (DX)

heating coils monitoring and settings.

Refer to Heating Coil Control (Section 15.8) for more details.

Pumps*

Contains all parameters for water pumps monitoring and settings.

Refer to Pumps Control (Section 15.9) for more details.

ERQ*

Contains all parameters for ERQ devices monitoring and settings.

Refer to ERQ Control (Section 15.10) for more details.

Electrical Htg*

Contains all parameters for post-heating control monitoring and

related functions (Electric coil).

Refer to Post-Heating Electrical Control (Section 15.11) for more

details.

Pre-Htg Electrical*

Contains all parameters for pre-heating control monitoring and related

functions (Electric coil).

Refer to Pre-Heating Electrical Control (Section 15.12) for more

details.

Pre-Heating Water*

Contains all parameters for pre-heating control monitoring and related

functions (Water coil).

Refer to Pre-Heating Water Coil Control (Section 15.13) for more

details.

Sensor Settings

Check the status of all sensor installed and set an offset correction on

sensors readings if needed.

Occupancy Time

Set the time value for which the occupancy function is active. This

function will take effect only if the AHU is provided with a room unit

device.

Refer to Appendix A - Room Unit Module for more details.

*Different menu items will be visible depending on AHU configuration.

16.1 Temperature Control

This menu contains the parameters for general thermoregulation control.

HMI Path: Main Menu -> Status / Settings -> Temperature Control

Page 42

Operation Manual

Air Handling Unit

Operation Manual

42

Air Handling Unit

D-EOMAH00006-20EN

Parameter

Default

Range

Description

Active Setpoint

-

-

Display the actual temperature setpoint used for

thermoregulation control.

Actual Ctrl Tmp

-

-

Display the actual controlled temperature value.

Su/Wi state

-

-

Display the actual AHU summer/winter state.

Setpoints

-

-

Contains all AHU temperature setpoints.

Refer to Setpoint page menu (Section 12) for more

details.

Temperatures

-

-

Contains all AHU temperature readings.

Gen Deadzone

1 °C

0.5 - 10 °C

Deadband value between temperature setpoint

and actual controlled temperature for

thermoregulation logics activation.

Max Supply

Tmp

40 °C

20 - 80 °C

Maximum supply temperature value above which

the control starts to limit the load of installed

heating coils.

Min Supply

Tmp

17 °C

0 - 30 °C

Minimum supply temperature value below which

the control starts to limit the load of installed

cooling coils.

Max Supply

Tmp

− Summer = 37 °C

− Winter = 40 °C

20 - 80 °C

Maximum supply temperature value above which

the control starts to limit the load of installed coils.

Min Supply

Tmp

− Summer = 17 °C

− Winter = 17 °C

0 - 30 °C

Minimum supply temperature value below which

the control starts to limit the load of installed coils.

16.2 Air Quality Control

This menu contains all parameters for air quality control monitoring and parameter settings. This function

increases the fan setpoint value by “Max forcing” value in order to reach the air quality setpoint selected.

NOTE! This menu is not visible if no air quality control function is enabled.

HMI Path: Main Menu -> Status / Settings -> Air Quality Control

Parameters

Default

Range

Description

CO2 Conc.

-

- Display the CO2 concentration measured.

Setpoint

800 ppm

0 - 3000 ppm

Set the air quality control setpoint.

Supply fan

Page 43

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

43

Parameters

Default

Range

Description

Max forcing

- 0 %

- 0 Pa

- 0 m3/h

- 0..100 %

- 0..9900 Pa

- 0..139900 m3/h

Set the maximum compensation value that will be

added to fan setpoint when air quality control

function is active.

NOTE! This value strictly depends on AHU

application site and desired setpoint, so it must

be changed accordingly from default value if it

is needed to activate the compensation

function.

Measure unit depends on fan control mode

selected.

Actual Comp

-

0 - 100 %

Display the actual fan compensation action

percentage:

- 0% -> No fan SP increasing;

- 50% -> Fan SP increased by “Max forcing”/2;

- 100% -> Fan SP increased by “Max forcing”.

Return fan

Max forcing

- 0 %

- 0 Pa

- 0 m3/h

- 0..100 %

- 0..9900 Pa

- 0..139900 m3/h

Set the maximum compensation value that will be

added to fan setpoint when air quality control

function is active.

NOTE! This value strictly depends on AHU

application site and desired setpoint, so it

must be changed accordingly from default

value if it is needed to activate the

compensation function.

Measure unit depends on fan control mode

selected.

Actual Comp

-

0 - 100 %

Display the actual fan compensation action

percentage:

- 0% -> No fan SP increasing;

- 50% -> Fan SP increased by “Max forcing”/2;

- 100% -> Fan SP increased by “Max forcing”

value.

16.3 Humidity Control

This menu contains all parameters for both humidification and dehumidification control monitoring and

settings.

Page 44

Operation Manual

Air Handling Unit

Operation Manual

44

Air Handling Unit

D-EOMAH00006-20EN

NOTE! This menu is not visible if no humidity control function is enabled.

HMI Path: Main Menu -> Status / Settings -> Humidity Control

Parameters

Default

Range

Description

Relative Hum

- - Display the value coming from the humidity sensor

readings.

Dehum Setpoint*

60 %rH

0 - 100 %rH

Set the dehumidification control setpoint.

Dehum*

-

- Off

- Active

Display the actual state of the dehumidification control

logic.

Win Dehum En*

No

- No

- Yes

Specify if the dehumidification control must be activated

also during “Winter” AHU mode.

Hum Setpoint*

40 %rH

0 - 100 %rH

Set the humidification control setpoint.

Humidifier*

-

0 - 100%

Display the actual controller load command for the

humidification device.

Adiabatic

Recovery*

-

- Off

- On

Display the actual state of the adiabatic recovery function.

Sum Hum En*

No

- No

- Yes

Specify if the humidification control must be activated also

during “Summer” AHU mode.

*Different menu items will be visible depending on AHU configuration.

16.4 Fans Control

This menu contains all parameters and settings for fans control monitoring and related functions.

HMI Path: Main Menu -> Status / Settings -> Fans

Parameters

Default

Range

Description

Setpoints

- - Contains all AHU setpoints related to fan control.

Refer to Setpoint page menu (Section 12) for more details.

Fan Data*

- - Contains additional supply/return fans data.

This menu item is available only for Modular AHU.

Fan

Compensation

-

- None

- Temp.

Display the actual compensation function selected during

AHU commissioning for fans control logic.

Page 45

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

45

Parameters

Default

Range

Description

- Co2

- None: no fan compensation function selected;

- Temperature: temperature compensation function

selected.

This function starts to decrease the fan setpoint value

selected by “Max forcing” value only if both heat recovery

and mixing damper devices are at full load, in order to

increase the thermal exchange between airflow and

heating/cooling coils and reach the desired temperature

setpoint.

- Co2: air quality compensation function selected.

This function increases the fan setpoint value selected by

“Max forcing” value in order to reach the air quality

setpoint selected.

Refer to Air Quality Control (Section 15.2) for more

details.

Supply fan

Active Setpoint

- - Display the actual supply fan setpoint that is used in the

control logic (this value represents the sum of all functions

that affect the supply fan setpoint).

Supply

Pressure*

- - Display the value read from the supply fan pressure

sensor.

Supply Air

Flow*

- - Display the value read from the supply fan air flow sensor.

State

-

- Off

- On

Display the actual fan state.

Speed

-

0 - 100 %

Display the actual fan speed.

Delay On Tm

60 s

0 - 36000 s

Set the time delay between fresh/exhaust dampers

opening and fan activation.

Over Run Tm*

180 s

0 - 36000 s

Set the time period after AHU turn off for supply fan postventilation, in order to cool down the electric coils.

This setpoint is available only if an electric coil is installed.

The controller will activate the post-ventilation

function only if the electric coil has been turned on

during AHU operation.

Max forcing*

- 0 %

- 0 Pa

- 0 m3/h

- 0..100 %

- 0..9900 Pa

- 0..139900

m3/h

Set the maximum compensation value that will be added

(Co2 compensation) or subtracted (Temp. compensation)

to fan setpoint when fan compensation function is active.

Page 46

Operation Manual

Air Handling Unit

Operation Manual

46

Air Handling Unit

D-EOMAH00006-20EN

Parameters

Default

Range

Description

Refer to “Fan Compensation” parameter for additional

details.

This value is available only if a fan compensation function

has been selected in configuration.

NOTE! This value strictly depends on AHU

application site and desired setpoint, so it must be

changed accordingly from default value if it is

needed to activate the compensation function.

Measure unit depends on fan control mode selected.

Actual Comp*

-

0 - 100 %

Display the actual fan compensation action percentage:

- 0% -> No fan SP inc/dec;

- 100% -> Fan SP inc/dec by “Max forcing” value.

Refer to “Fan Compensation” parameter for additional

details.

This value is available only if a fan compensation function

has been selected in configuration.

Max Setpnt

Devtn*

30 %

0 - 100 %

Set the percentage deviation between fan setpoint and

sensor reading above which the controller generates a

warning, if this condition is verified for more than “Setpnt

Devtn On Tm” value.

This setpoint is available only if fan deviation alarm

function has been enabled in configuration.

Setpnt Devtn

On Tm*

30 min

0 - 1000 m

Set the time period after which the controller generates a

warning if “Max Setpnt Devtn” condition is verified.

This setpoint is available only if fan deviation alarm

function has been enabled in configuration.

Defrost Setpnt*

- 80 %

Pa

m3/h

- 0..100 %

- 0..5500 Pa

- 0..139900

m3/h

Set fan setpoint in case of ERQ defrost state.

This setpoint is available only if fan-defrost limitation

control has been enabled in configuration.

Return fan

Active Setpoint

- - Display the actual return fan setpoint that is used in the

control logic (this value represents the sum of all functions

that affect the return fan setpoint).

Return

Pressure*

- - Display the value read from the return fan pressure

sensor.

Page 47

Air Handling Unit

Operation Manual

Air Handling Unit

D-EOMAH00006-20EN

Operation Manual

47

Parameters

Default

Range

Description

Return Air

Flow*

- - Display the value read from the return fan air flow sensor.

State

-

- Off

- On

Display the actual fan state.

Speed

-

0 - 100 %

Display the actual fan speed.

Delay On Tm

60 s

0 - 36000 s

Set the time delay between fresh/exhaust dampers

opening and fan activation.

Max forcing*

- 0 %

- 0 Pa

- 0 m3/h

- 0..100 %

- 0..9900 Pa

- 0..139900

m3/h

Set the maximum compensation value that will be added

(Co2 compensation) or subtracted (Temp. compensation)

to fan setpoint when fan compensation function is active.

Refer to “Fan Compensation” parameter for additional

details.

This value is available only if a fan compensation function

has been selected.

NOTE! This value strictly depends on AHU

application site and desired setpoint, so it must be

changed accordingly from default value if it is

needed to activate the compensation function.

Measure unit depends on fan control mode selected.

Actual Comp*

-

0 - 100 %

Display the actual fan compensation action percentage:

- 0% -> No fan SP inc/dec;

- 100% -> Fan SP inc/dec by “Max forcing” value.

Refer to “Fan Compensation” parameter for additional

details.

This value is available only if a fan compensation function

has been selected.

Max Setpnt

Devtn*

30 %

0 - 100 %

Set the percentage deviation between fan setpoint and

sensor reading above which the controller generates a

warning, if this condition is verified for more than “Setpnt

Devtn On Tm” value.

This setpoint is available only if fan deviation alarm

function has been enabled.

Page 48

Operation Manual

Air Handling Unit

Operation Manual

48

Air Handling Unit

D-EOMAH00006-20EN

Parameters

Default

Range

Description

Setpnt Devtn

On Tm*

30 min

0 - 1000 m

Set the time period after which the controller generates a

warning if “Max Setpnt Devtn” condition is verified.

This setpoint is available only if fan deviation alarm

function has been enabled.

Defrost Setpnt*

- 80 %

Pa

m3/h

- 0..100 %

- 0..5500 Pa

- 0..139900

m3/h

Set fan setpoint in case of ERQ defrost state.

This setpoint is available only if fan-defrost limitation

control has been enabled.

Fan fire stpt*

80 %

0 - 100 %

Set fans load when a fire alarm is detected.

This setpoint is available only if the fire alarm function

has been enabled.

Fan fire mode*

Stop

- Stop

- Run Sply

- Run Exh

- Run both

Specify fans state in case of fire alarm.

- Stop: stops both fan;

- Run Supply: only supply fan will be in on state;

- Run Exhaust: only return fan will be in on state;

- Run Supply: both fan will be in on state.

This setpoint is available only if the fire alarm function

has been enabled.

Fast Htg/Clg*

- - Contains all parameters for configuring the fast

heating/cooling function.

Refer to Fast Heating/Cooling (Section 15.4.1) for more

details.

This menu item is available only if the fast heating/cooling

function has been enabled.