Page 1

Installation, use

and maintenance manual

Modular Light

Modular L

Translation of the original instructions

Page 2

Modular Light heat recovery units guarantee high quality indoor air at low energy

costs. The range consists of six sizes, customisable by adding external modules.

Armed with an extremely flexible development, Daikin air handling units are able to

satisfy all types of technical requirements.

Daikin systems guarantee respect for the environment since they are based on high

levels of energy efficiency. Reduced ecological impact and low energy consumption

make Daikin recovery units ideal for any type of market.

Page 3

Contents

Assembly instructions

Important warnings 4

Purpose of the manual 4

Intended use of the machine 4

Safety regulations 5

Residual risks 8

Safety devices 9

Machine characteristics 10

Environmental conditions 10

Environmental contamination 10

Noise 10

Ceiling and air duct specifications 11

Technical data 12

Attachments 12

Summary of machine operation 14

Receipt of the cartons 15

Transport 16

Unpacking and verification of integrity

After unpacking 17

Reading the serial number plate 18

Storage waiting for installation 19

17

Installation 20

Installation procedure 20

Maintenance 28

Safety precautions for maintenance 28

Ordinary maintenance 29

Extraordinary maintenance 33

Diagnostics 36

Troubleshooting table 37

Repair log 38

Page 4

1

Important warnings

The pictogram shows a situation of immediate danger or a dangerous situation that might cause injuries or death.

The pictogram shows that it is necessary to adopt suitable behaviour in order to avoid jeopardising staff safety and

cause damages to the equipment.

The pictogram shows particularly important technical information that should be taken into consideration by the

people installing or using the equipment.

Purpose of the manual

The purpose of this manual is to guide the installer and qualified operator in the installation,

maintenance and proper and safe use of the equipment. For this reason, it is mandatory for all

personnel involved in installation, maintenance and supervision of the machine to read this

manual.

Contact the manufacturer if any points are unclear or difficult to understand.

This manual contains information regarding:

- Technical specifications of the machine.

- Instructions for transport, handling, installation and assembly.

- Use.

- Information for instructing personnel authorised for its use.

- Maintenance activities.

All information refers in general to any unit of the Modular Light ranges. All the units are shipped

together with a technical schematic indicating the specific weight and size of the machine received.

It must be considered an integral part of this manual and therefore it must be kept with the utmost

care in all its parts.

If the manual or schematic is lost, it is important to request a copy from the manufacturer, specifying

the unit's serial number and date of purchase that can be found on the invoice.

In the case of divergent information between this manual and the schematic, the schematic will

prevail.

Intended use of the machine

This appliance has the function of treating the air intended to condition civil and industrial environments. Any other use is not in accordance with the intended use and therefore dangerous.

These ranges of units are designed for use in NON-explosive environments. For installation in

potentially explosive environments, the manufacturer can design and manufacture suitable machines

(anti-explosion) that will be identified by the mark .

If the machine is used in critical situations, by type of system or environmental context, the customer

must identify and adopt the technical and operational measures to avoid damage of any kind.

4

Page 5

Safety regulations

Skills required for the installation of the machine

Installers must perform operations according to their professional qualifications: all activities not within one's expertise

(i.e. electrical connections) must be carried out by specialised and qualified staff so as not to endanger one's safety and

the safety of the other operators interacting with the machine.

Transport and equipment handling operator: authorised person with recognised expertise in using transport

and lifting equipment.

Technical installer: expert technician, sent or authorized by the manufacturer or its representative, with adequate

skills and training to install the machine.

Assistant: technician subject to care obligations while lifting and assembling the equipment. He must be suitably

trained and informed about the operations to perform and the safety plans of the site/installation location.

In this manual, the technician competent to carry out each operation is specified.

Skills required for the use and maintenance of the machine

Generic operator: AUTHORISED to run the machine using commands placed on the keypad of the electrical control

panel. Performs only machine control operations, power on/off.

Maintenance mechanic (qualified): AUTHORISED to carry out maintenance, adjustments, replacement and repair

of mechanical parts. It must be a person competent in mechanical systems, therefore able to perform mechanical

maintenance in a satisfactory and safe manner, must possess theoretical preparation and manual experience. NOT

AUTHORISED to work on electrical systems.

Manufacturer's technician (qualified): AUTHORISED to perform complicated operations in every situation.

Operates in accordance with the user.

Maintenance electrician (qualified): AUTHORISED to perform service of an electric nature, adjustments,

maintenance and electrical repairs. AUTHORISED to operate in the presence of an active electrical connection inside

the control panels and junction boxes. It must be a person competent in electronics and electrical engineering,

therefore able to work on electrical systems satisfactorily and safely, must possess theoretical knowledge and proven

experience. NOT AUTHORISED to work on mechanical systems.

Installers, users and maintenance staff for the machine must also:

- Be responsible and experienced adults without physical impairments, in perfect psychological and physical condition.

- Master the machine's operating cycle, therefore participate in theoretical/practical training alongside an expert machine operator,

or alongside a technician of the manufacturer.

In this manual, the technician competent to carry out each operation is specified.

5

Page 6

Read this manual carefully before machine installation and maintenance and keep it for any

further future consultation by the various operators. Do not remove, tear out or rewrite any part

of this manual.

All installation, assembly, electrical connections to the mains and ordinary/extraordinary

maintenance must be performed only by qualied personnel authorised by the Retailer

or Manufacturer after turning off the unit electrically and using personal protective

equipment (i.e., gloves, protective goggles, etc.), in compliance with the regulations in force in

the country the equipment is to be used in and the laws regarding the systems and safety in

the workplace.

Installation, use or maintenance other than those specified in the manual may cause damage,

injury or death, invalidate the warranty and relieve the Manufacturer of any liability.

Use protective clothing and suitable equipment while handling or installing the equipment, in

order to prevent accidents and safeguard your own and other people's safety. Individuals not

assigned to installation or maintenance are NOT allowed to stand or pass through the work area

while the machine is assembled.

Disconnect the equipment from the mains before installing or maintaining it.

Before installing the equipment, check that the systems comply with the legal provisions in

force in the country of use and meet the specifications on the serial number plate.

It is the responsibility of the user/installer to check the static and dynamic stability relative to

the installation and to arrange environments so that people who are not competent or

authorised DO NOT have access to the machine or to its commands.

It is the responsibility of the user/installer to make sure that weather conditions do not affect

the safety of persons and property during installation, use and maintenance.

Make sure the air intake is not located near any exhausts, flue-gases or other contaminating

elements.

Do not install the equipment in places exposed to strong winds, salt air, open flames or

temperatures exceeding 40°C (104°F).

After installation is complete, instruct the user on the correct use of the machine.

If the equipment does not work or functional or structural alterations are noted, disconnect

it from the mains and contact a service centre authorised by the Manufacturer or Retailer,

without attempting to repair it on your own. For any replacements request the use of original

spare parts.

Unauthorised actions, tampering or modifications that do not follow the information provided

in this manual can cause damage, injuries or fatal accidents and void the warranty.

6

Page 7

The serial number plate on the unit provides important technical information, essential in case

of machine maintenance or repairs. We recommend that you do not remove, damage or modify

it.

In order to ensure correct and safe conditions of use, it is recommended to have the unit

maintained and checked at least annually by a service centre authorised by the manufacturer or

dealer.

Failure to follow these instructions may cause damage and injuries, even fatal, voids the

warranty and relieves the Manufacturer of any liability.

7

Page 8

Residual risks

Despite having implemented and adopted all the safety measures indicated by applicable regulations,

some residual risks remain. In particular, in some operations of replacement, adjustment and tooling maximum attention is always required in order to work in the best possible conditions.

List of operations with residual risks

Risks for qualified personnel (electrician and mechanic)

- Handling - during unloading and handling it is necessary to pay attention to all the steps listed in this manual regarding the points

of reference

- Installation - during installation it is necessary to pay attention to all the steps listed in this manual regarding the points of reference

The installer must ensure the static and dynamic stability of the machine's site of installation.

- Maintenance - during maintenance it is necessary to pay attention to all the steps listed in this manual, and in particular to high

temperatures that may be present in the heat transfer fluid lines to/from the unit.

- Cleaning - the machine must be cleaned only when it is switched off, by turning off the switch installed by the electrician and

the switch located on the unit itself. The key for interrupting the power supply must be kept by the operator until the end of the

cleaning operations. Internal cleaning of the machine must be carried out using the protections required by current regulations.

While the inside of the machine does not contain particular hazards, it is necessary to pay the utmost attention so that accidents

do not occur during cleaning. The heat exchange coils that have a potentially sharp finned pack must be cleaned using protective

glasses and gloves suitable for handling metals.

During adjustment, maintenance and cleaning there are residual risks of variable entity. Being operations

that must be performed with guards disabled, it is necessary to pay particular attention in order to avoid

damage to persons and things.

Always pay close attention when performing the operations specified above.

Remember that these operations must always be performed by authorised personnel.

All work must be completed in accordance with the legal provisions relating to work safety.

Remember that the unit in question is an integral part of a larger system that includes other components,

depending on the final characteristics of realisation and the mode of use. Therefore in the end it is

the responsibility of the user and assembler to assess the residual risks and their respective preventive

measures.

For more information about the possible risks, please refer to the RAD (Risk Assessment

Document) available from the manufacturer.

8

Page 9

Safety devices

The machine is equipped with safety devices to prevent risks of damage to persons and for

proper operation. Always pay attention to the symbols and safety devices on the machine. It

should only operate with the safety devices engaged and with fixed or movable guards

installed correctly and in the proper position.

If during installation, use or maintenance the safety devices have been temporarily removed

or disabled, the machine can be operated exclusively by the qualified technician who made

this change. It is mandatory to prevent other people's access to the machine. When finished,

restore the devices to their proper status as soon as possible.

9

Page 10

2

Machine characteristics

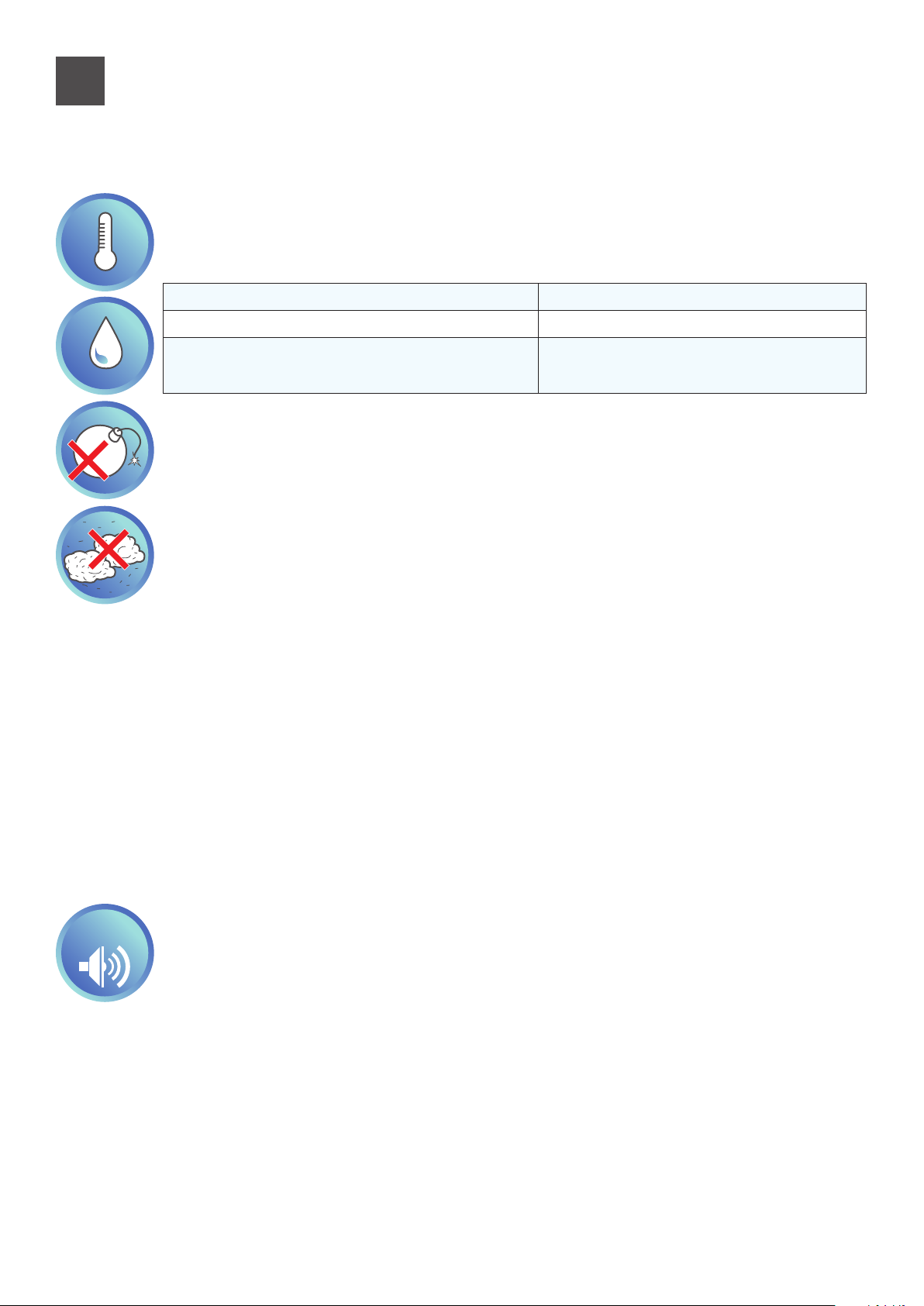

Environmental conditions

Modular Light heat recovery units are designed for use in indoor environments, installed on

the ceiling. The unit cannot operate in environments containing explosive material and with

a high concentration of dust.

Outside air temperature

Operating environment temperature

Temperature of the environment with the ma-

chine off (e.g., storage, transport, etc.)

Thanks to its modularity, each machine is able to adapt to different needs in terms of air flow

and thermodynamic treatments.

The optimised choice of every detail, the search for maximum efficiency in each

component, the adoption of specific materials and constructive solutions transform

environment friendliness and energy savings into valid and advanced technological

solutions.

-25°C to +45°C

+5°C to +45°C

-40°C to +60°C

Environmental contamination

Depending on the installation operating environment, specific regulations must be followed and all the

necessary precautions must be taken to avoid environmental issues (a system that operates in a hospital

or chemical environment can have problems different from those in other sectors, even from the point of

view of disposal of consumable parts, filters, etc.).

It is mandatory for the buyer to inform and train workers regarding proper procedures.

Noise

The machines have been designed and manufactured in such a way as to produce sound

> 80 dB(A)

during the machine's actual use.

10

emissions below the threshold of 80 dB(A). It should be noted that every environment has

its own acoustic characteristics that can greatly affect the noise perceived during operation,

therefore it is necessary to consider the noise data provided as a point of reference, while it

is up to the buyer to perform specific sound level measurements at the installation site and

Page 11

Ceiling and air duct specifications

The ceiling where you plan to install the machine must be:

- Perfectly flat and without roughness.

- Vibration resistant.

- Able to support the weight of the equipment considering an appropriate safety margin (see table of technical data on page

12).

The equipment installed on the ceiling can adapt easily to the presence of a false ceiling.

In fact, without sufficient space for up-and-over door opening, the inspection door can be transformed

into a panel able to slide on accessory guides (optional)

If provided, the air ducts must be connected directly to the machine, taking care to insert a suitable

anti-vibration system between the machine itself and the duct. When assembly is completed they must

not be taut, in order to avoid damage and transmission of vibrations.

To ensure the seal of the connections and the integrity of the machine, it is essential that the air ducts be

supported by special brackets that do not weigh directly on the machine.

11

Page 12

Technical data

TECHNICAL DATA TABLE

SIZE

2 3 4 5 6 7

Nominal air flow rate

m3/h

Heat efficiency %

FLA

FLI

W

Electrical connection

WEIGHT TABLE

Gross weight with packaging

Device weight

Door weight

Filter weight

Fan weight

Recuperator weight

Tank panel weight

kg

kg

kg

kg

kg

kg

kg

300 600 1200 1500 2500 3000

89 89 89 89 90 89

A

2.80 4.50 4.50 4.70 8.90 9.30

371 1033 1033 1033 2033 2033

200-277 V, 1 ph

SIZE

2 3 4 5 6 7

135 190 285 295 370

125 180 270 280 355

2x10,0 2x12,0 2x18,0 2x18,0 2x22,0

2x0,2 2x0,3 2x0,5 2x0,5 2x0,5

2x2,5 2x8,5 2x8,5 2x9,0 4x8,5 4x9,0

1x9,0 1x14,0 2x15,0 2x15,0 2x24,0 2x24,0

1x13,0 1x16,0 1x24,0 1x24,0 1x29,0 1x29,0

375

360

2x22,0

2x0,5

Preheating external coil

Kindly make sure that the frontal velocity through the preheating element is maintained above 1.5 m/s

for safety reasons.

Electric

panel

Electric

panel

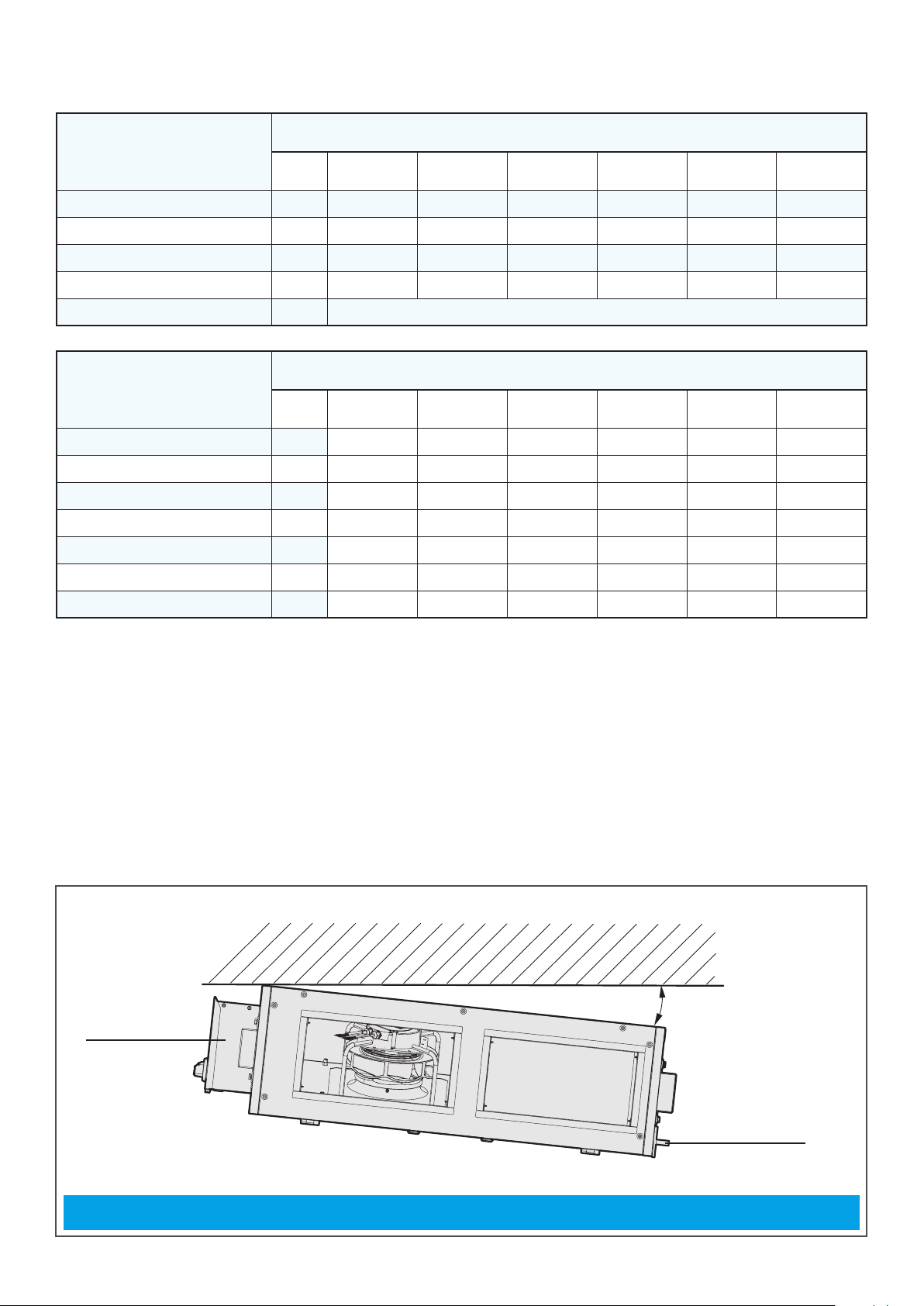

The machine must be tilted by approximately 2% of the width (B) (lifting it towards the electric panel)

1

2%

Condensation

discharge

12

Page 13

B

A

C

F

TECHNICAL DATA

TABLE

D

H

ø14 mm

ø14 mm

ø14 mm

E

G

160 mm

80 mm

SIZE

2 3 4 5 6 7

Length (A) mm

Width (B) mm

Height (C) mm

Hole distance (D) mm

Hole distance (E) mm

F (up-and-over doors)

mm 630 670 675

1660 1800 2000 2000 2000 2000

920 1100 1600 1600 2000 2000

280 350 415 415 500 500

1380

976 1156 1656 2056

F (sliding doors) mm 70

G mm 500

H mm 300

13

Page 14

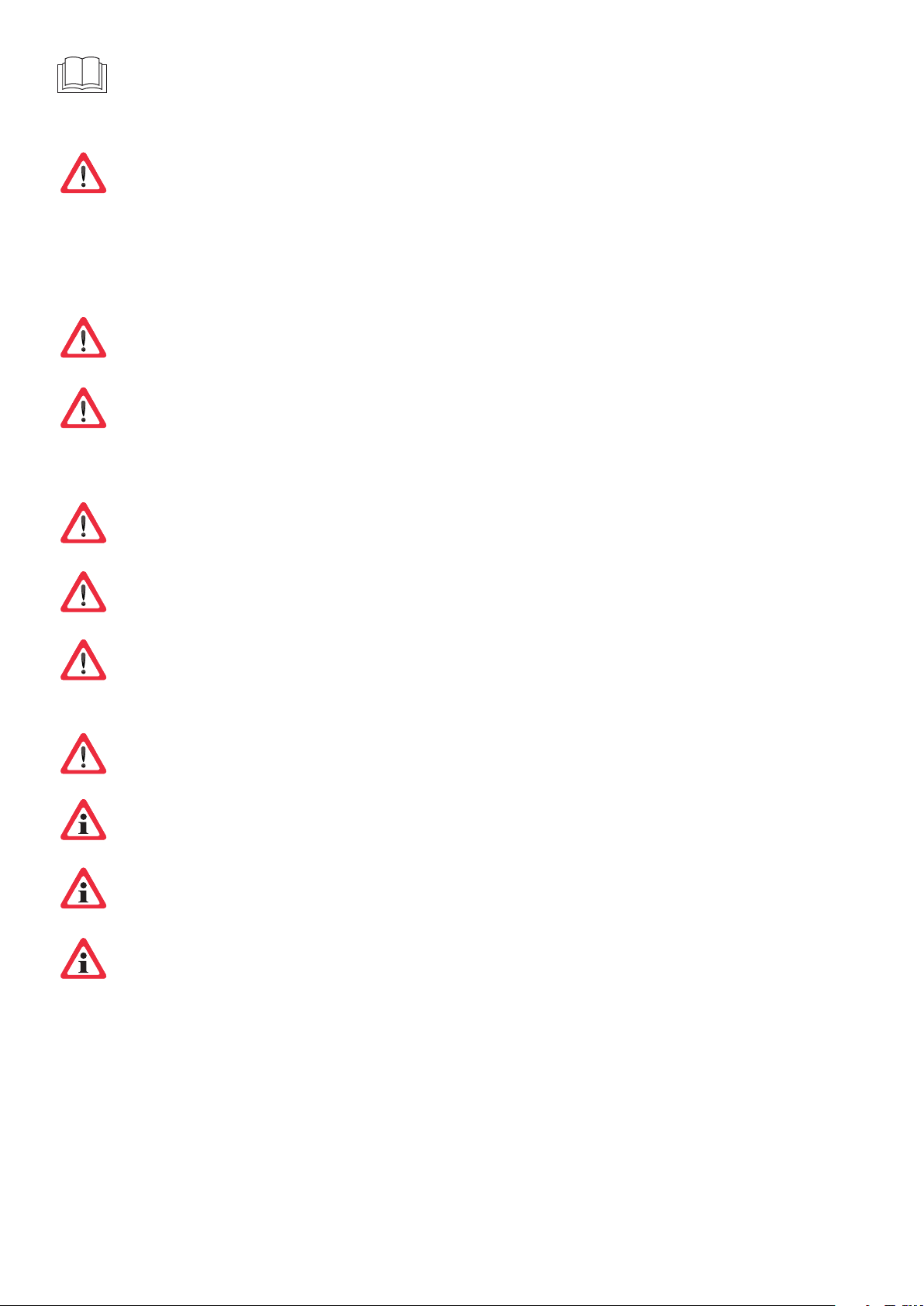

Summary of machine operation

2

5

4

A

3

6

C

D

1

B

1

air flow in a machine with orientation to the right

2

Filter and pre-filter

1

Exchanger by-pass

2

Heat exchanger

3

Delivery motor-driven fan group

4

Delivery motor-driven fan group

5

Intake motor-driven fan group

6

Pos. Component name Construction material

Supply air

A

Internal air

B

Exhaust air

C

Air from outside

B

1 Filter galvanised steel frame, fibreglass filter unit

2 Bypass aluzinc

3 Heat exchanger aluminium

4 Fan motor assembly size 2: composite board frame and impeller

size 3,4,5,6,7: steel frame, composite board impeller

5 Brackets galvanised steel

14

Page 15

3

The means and method of transport must be chosen by the transport operator according to the type, weight and size of the

machine. If necessary, draw up a "safety plan" to guarantee the safety of the people directly involved.

Receipt of the cartons

Handle the equipment following the Manufacturer's instructions on the packaging and in this manual.

Always use personal protective equipment.

Upon receipt of the machine check the integrity of the packaging

and the amount of parcels sent:

A) There is visible damage/one or more cartons is missing: do not

install, but promptly notify the Manufacturer and the carrier that

made the delivery.

Alternatively you can accept the shipment "subject to

verification": this will make it possible to open the cartons

and check if the internal components are indeed damaged.

In the latter case, as noted previously, promptly notify the

Manufacturer and the carrier that made the delivery.

Before opening the cartons, it is recommended to take good

quality pictures to document the damage.

B) There is NO visible damage: move the machine to the site of

installation.

15

Page 16

4

sudden movements.

Transport

Packages can be handled with a pallet truck of suitable capacity or with a forklift. The choice of the

most suitable means and method lies with the operator.

The operating area must be perfectly free from objects or people not involved in the transport.

If transport is done using a pallet truck make sure it is suitable for the weight and size of the

machine. Insert the forks into the points provided for handling (usually in a central position) so as

to keep the centre of gravity of the load in balance. Move the equipment carefully, avoiding

OK!

OK!

16

Page 17

A

5

Unpacking and verification of integrity

We recommend the equipment be unpacked after moving it to its installation location and only when

it is to be installed. This operation must be performed using personal protection equipment (i.e., gloves,

safety shoes, etc.).

Do not leave the packing unattended: it is potentially harmful to children and animals

(suffocation hazard).

Some packing materials must be kept for future use (wooden crates, pallets, etc.), while those that

cannot be reused (i.e., polystyrene, strapping, etc.) must be disposed of in compliance with the

regulations in force in the country of installation: this will protect the environment!

After unpacking

After unpacking, check the received contents:

- Installation and maintenance manual (IOM)

- Wiring diagram

- Declaration of conformity

Check therefore that you have received all the components and that they are undamaged

In case of damaged or missing parts.

- Do not move, install or repair damaged components and the machine in general.

- Take quality photos to document the damage.

- Find the serial number plate on the machine and note the machine's serial number.

- Immediately notify the carrier that delivered the machine.

- Promptly contact the Manufacturer (keep on hand the serial number of your machine).

Please note that complaints or claims of damage reported after 10 days of receipt of the machine

cannot be accepted.

A: Manufacturer’s name and data

Codifica

HU

Product number

Matricola

Serial number

Mandata

Supply Fan

MESSA IN FUNZIONE

All’avviamento consultare il manuale

operavo e controllare:

1) senso di rotazione del venlatore

2) l’assorbimento del motore, il quale non

deve superare il valore di targa sopraindicato

D

ALB07LBMNADBT00 A83665

I

18C0144

PORTATA ARIA /AIR FLOW

3000

F

Corrente / Current

Tensione / Voltage 230V/1Ph/50-60Hz

DAIKIN APPLIED EUROPE S.p.A

Via Piani di Santa Maria, 72 00040 Ariccia - (ROMA) IT

A

Data

Date

m3/h

H

START UP

Before the start up read carefully the operang

instrucon manual and check

1) fan rotaon direcon

2) the current input must not exceed the value

menoned on the above tag

MADE IN ITALY

POS

Code

E

Peso

4/2018 373

Weight

B

Ripresa

Return Fan

G

9.3 A

C

m3/h

B: CE markings

C: Machine weight

D: Code and POS

E: Date of manufacture

F: Supply airow rate

G: Delivery airow rate

H: Electrical specications (frequency, number of

phases, absorption in plate conditions)

I: Machine serial number

MANUFACTURER INFORMATION:

DAIKIN APPLIED EUROPE S.P.A.

Via Piani di Santa Maria, 72 - 00040 Ariccia (Roma) - Italy

Tel: (+39) 06 93 73 11 - Fax: (+39) 06 93 74 014

http://www.daikinapplied.eu

17

Page 18

Product nomenclature

A L B 07 L B M N A D B T 0 0

A AHU

L Modular Light

B Main module

02 Size 02

03 Size 03

......

07 Size 07

R right installation

L left installation

B release

M advanced controller solution

S smart controller solution

E internal electric post heating coil

W internal water post heating coil

N no internal post heating coil

A raluminium recuperator

M membrane recuperator

A Supply filter G4

B Supply filter M5

D Supply filter F7

E Supply filter F9

A Delivery filter G4

B Delivery filter M5

D Delivery filter F7

E Delivery filter F9

T Double panel thickness 50mm, mineral wool

insulation, pre-painted exterior and Aluzinc interior

0.... Production site

0.... Version

Modular Light will be produced according to customer needs.

However, we still designed a standard version indicated by only 7 digits ALB01R(L)A and that

uniquely identifies a right/left machine, aluminium counter-current exchanger, double 50mm

panel, with Microtech controller, no internal post heating coil, F7 at supply, M5 at delivery, version 01.

18

Page 19

Storage waiting for installation

Waiting for the installation, the components of the machine and the relative documents must be stored

in an area that:

- Is dedicated exclusively to the storage of the components.

- Is covered and protected from the weather (preferably prepare a closed area), with adequate temperature and humidity.

- Is accessible only to operators tasked with the assembly.

- Can support the weight of the equipment (check the load rating) and has a stable floor.

- Is free from other components, especially if they are potentially explosive/incendiary/toxic.

If you cannot proceed with the installation straight away, check periodically that the above-mentioned conditions of the storage area are maintained and cover the machine with a canvas.

While waiting for the finale installation, always provide an insulating base (e.g., wood blocks)

between the floor and the machine itself.

Correct storage awaiting installation

3

Any movement carried out after unpacking must be done with the doors closed. Do not move

the units by pulling on the doors, if present, the uprights or other protruding parts that are not

an integral part of the structure.

5÷35°C

Do not step on the units!

19

Page 20

2A

6

Installation

All installation, assembly, electrical connections to the mains and extraordinary maintenance

must be performed only by qualied personnel authorised by the Retailer or

Manufacturer, in compliance with the regulations in force in the country the equipment is to

be used and the standards on the systems and safety in the workplace.

During installation, the area must be free from people

and objects not used for the assembly.

Before starting, make sure you have all the necessary

equipment.

Use only equipment that is in good condition and

undamaged.

Installation procedure

Before installation, read the safety instructions on the first pages of this manual. Contact the Manufacturer

if any points are unclear or not perfectly understandable. A check mark next to each step will help to

confirm complete and proper installation.

Step 1: Mark the drilling points .............................................................................................................................. page 21

Step 2: Make the connections ................................................................................................................................ page 23

Step 3: Perform a trial run .......................................................................................................................................... page 26

Step 4: Safety signs .........................................................................................................................................................page 27

After installation store this manual and the assembly sheet that accompanied the machine in a place that

is dry and clean. This way it will be accessible to operators in the future who need to consult it.

Do not remove, tear out or write on any part of this manual besides the space set aside for notes:

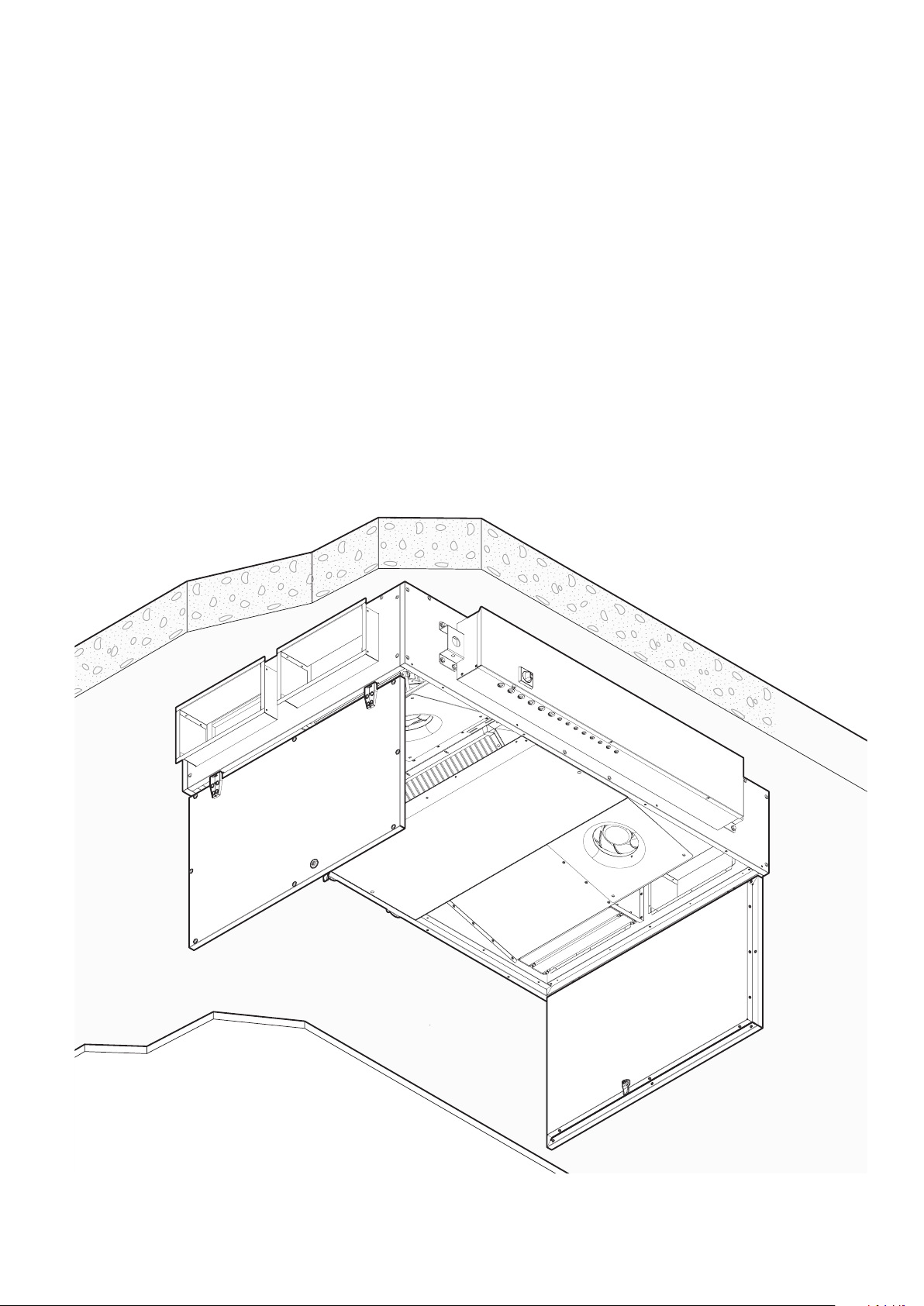

Step 0: Lift the unit to the ceiling

Lift the unit up to the ceiling.

To facilitate the operations of lifting and to ensure the safety of the installers, we recommend the

use of extensible pantograph lifts of the appropriate type and dimensions for the weight and size

of the unit to be installed.

During lifting protective apparel must be worn to prevent injury, and individuals not assigned to installation

or maintenance are NOT allowed to stand or pass through the work area.

20

Page 21

Step 1: Mark the drilling points

Make sure that the ceiling where you plan to install the machine is:

- Vibration resistant.

- Able to support the weight of the equipment (see table of technical data on page 12).

The installation site must also include (fig. 4):

• An electrical system compliant with current regulations and with specifications that meet the needs

of the machine;

• a coolant gas connection (in the case of connection to coils supplied by gas).

• A drain pipe with drain siphon connected to the sewerage system.

• An aeraulic system (ducts for the air to be conveyed to the environments).

Drill ø14 mm holes at the machine anchor holes

Insert the appropriate anchors, lift the machine and fasten it using only the brackets and screws supplied.

Electric

panel

The machine must be tilted by approximately 2% of the width (B) (lifting it towards the electric panel)

4

A

(see “technical specifications” table on page 13).

Electric

panel

2%

Condensation

discharge

Ceiling drilling

5

A

21

Page 22

x4

Install a

shockproof

rubber hose.

Ceiling drilling

6

While lifting and fastening the unit it is

mandatory to use protective clothing and

suitable equipment, in order to prevent

accidents and safeguard your own and other people's

safety.

The fastening equipment should be dimensioned

according to unit weight.

Individuals not assigned to the installation are NOT

allowed to stand or pass through the work area

during assembly.

To facilitate the operations of lifting and to

ensure the safety of the installers, we

recommend the use of extensible

pantograph lifts of the appropriate type and

dimensions for the weight and size of the unit to be

installed.

22

Page 23

Step 2: Make the connections

To operate the machine requires:

- An electrical connection.

- Drain.

- A connection to the aeraulic circuit (air ducts).

Electrical connections

For the power supply it is necessary to connect the machine to an electrical panel in compliance with

current regulations.

Always refer to the wiring diagram that is specic to the machine that you bought (it was

shipped with the unit). If it is not on the machine or has been lost, contact the salesperson of

reference who will send a copy (specify the machine's serial number).

Before connecting the machine make sure that:

• The voltage and frequency of the power supply correspond to the parameters of the machine.

• The electrical system being connected has sufficient capacity to supply the nominal electric power of

the machine to be installed and meets current regulations.

The electrical connection must be:

• Performed by qualified personnel after cutting off the facility's power supply.

• Performed in a fixed and permanent manner, without intermediate splices, in accordance with the

regulations of the country of installation.

• The power supply is sufficient for the machine (see technical specifications).

• Includes a functioning grounded plug. For multiple units it is necessary to combine them all with metal ties.

• Preferably situated in a dedicated room, locked and protected from atmospheric agents. If there is also

a key switch, the key must be removed when cutting the power supply and returned to its position

only after finishing service operations.

• install a 16A circuit breaker system or suited to machine absorption

During installation and maintenance, make sure that no other person besides the one who is

working has access to the electrical cabinets or switches.

The Manufacturer is

not responsible for

200-277 V - 1 ph

N

L

connections made in a

manner that does not comply

with regulations, with the

specifications of this manual,

and in the event of tampering

with any electrical component

of the machine.

2T1

L

N6T3

2T1 4T2 6T3

Electrical connection

7

23

Page 24

The actual supply voltage of the users must not deviate more than 10% from the normal voltage expected.

Higher voltage differences cause damage to users and to the electrical system, malfunctioning of fans, noise.

It is therefore essential to check the alignment of the actual voltage values with the nominal values.

After connecting, make sure that:

• The ground connection is sufficient (using the appropriate tool). An incorrect connection, ineffective

and lacking the grounding circuit, is contrary to safety regulations and is a source of danger and can

damage the components of the machine.

• the motor rotation direction is correct;

• The wiring and motor power draw are correct.

Ambient thermostat connection

The machine is supplied with an ambient thermostat, which must be connected to the third and fourth

terminal from the bottom, as indicated in the figure

CE+

4

3

CE-

2T1 4T2 6T3

PROG

+

-

CE-

CE+

thermostat connection

8

24

Page 25

Drain and siphon

The machines are equipped with a threaded drain (1/4” M GAS) that protrudes laterally by about 50 mmIn

order to allow a regular flow of water, each drain must be fitted with a properly sized SIPHON (see fig. 10).

IMPORTANT

HUMIDIFICATION TANK

DRAIN

Siphon

Maximum siphon level

Humidification tank

drain

Drain siphon

9

Traditional siphon with

drain valve

Siphon minimum height 100 mm

With fan prevalence greater than about 100

mm increase the height of the siphon by 10

mm every 10 mm of prevalence

To avoid overflows from the collection tank,

the siphon must have a purge valve that

allows the removal of impurities deposited on

the bottom.

In order not to affect the operation of the

drainage system, siphons operating under

pressure must NOT be connected to others

operating under vacuum.

Ball siphon with

drain valve

10

traditional and ball drain siphon

drain valve

x+20 mm

x

The drainage pipe to the sewerage network:

• Must not be connected directly to the

siphon. This in order to absorb returns

AIR GAP

min 25 mm

of air or slurry and to make the correct

outflow of waste water visible.

• Must have a larger diameter at the machine

2%

drain and a minimum inclination of 2% in order to ensure proper operation.

25

Page 26

Aeraulic connections

Air conduits are not supplied with the machine. The installer must buy and install them separately.

Coupling can occur by directly connecting the machine: we recommend installing a suitable shock absorption system between the machine and conduit.

If not using anti-vibration joints it is necessary to:

• Clean the joint surfaces between the duct and the machine/coil.

• Apply a gasket to the flange in order to prevent air infiltration.

• Carefully tighten the connecting screws.

• Use silicone on the gasket in order to optimise the seal.

If the connection is made with anti-vibration joints, when assembly is completed they should not be taut,

so as to avoid damage and the transmission of vibrations.

In order to ensure the seal of the connection and the integrity of the machine's structure, it is essential to

make sure that the ducts do not weigh on it, being supported by their own brackets.

Step 3: Perform a trial run

To commission the machine it is necessary (tick "√" the operations completed):

check accurate fluid inlet and output pipe connections to the exchange coils (if applicable)

Check that there is a suitable siphon for all the water being drained.

place a shock absorbing joint between the machine and conduits (optional);

check unit integrity;

Check the integrity of the anti-vibration supports and the various accessories.

Remove extraneous materials (e.g., assembly sheets, tools, clips, etc.) and dirt (footprints, dust, etc.)

from inside the sections.

26

Page 27

Step 4: Safety signs

The machine is supplied with the electricity-specific signs on the access doors to the fan sections.

The buyer must position other appropriate signs in the work area:

DO NOT REMOVE THE PROTECTIONS AND SAFETY DEVICES

DO NOT REPAIR OIL ADJUST CLEAN MOVING PARTS

In addition, the space where the machine is positioned must be integrated into the general signage,

specific to the characteristics of the area and workplaces:

noise - movement - dangerous areas - escape route, etc.

PERSONAL PROTECTIVE EQUIPMENT

Personal protective equipment should be used when operating the machine, suitable for use in

accordance with company criteria and rules.

During machine maintenance, other preventive measures are suggested in addition to the above: safety

shoes, gloves, suitable clothing, always compatible with the use and according to company guidelines.

TRAINING

It is the responsibility of the machine buyer/user to provide adequate instruction and training to machine

operators.

OPTIONAL

In agreed cases, additional training may be provided through the one-on-one instruction of operators by

the Manufacturer's technical staff.

27

Page 28

2A

7

Maintenance

Safety precautions for maintenance

Ordinary and extraordinary maintenance must be carried out solely by the operator

assigned to perform maintenance (mechanical and electrical maintenance staff ) according

to the regulations in force in the country of use and respecting the laws regarding systems

and work safety. Remember that, by operator assigned to perform maintenance is meant the

person who can work on the machine to perform ordinary and extraordinary maintenance,

repairs and fine tuning. This person must be an expert operator, properly instructed and

trained, given the risks involved in such operations.

Before performing any ordinary and extraordinary maintenance, the machine must always be

stopped (by disconnecting from the mains) and the EMERGENCY button engaged. The

switch must have a key that must be removed and held by the operator who will perform the

operations until the end of the maintenance itself.

It is absolutely prohibited to remove any protections from moving parts and unit

protection devices with the machine connected to the mains or operational. Adjustments

made with safety devices disengaged must be performed by a single person, expert and

authorised, and during this activity it is necessary to prevent access to the area of the machine

by other people. Upon completing the adjustments with safety devices disengaged, the

protections must be re-engaged as soon as possible.

During maintenance the operational space surrounding the machine for a distance of 1.5

metres must be free of obstacles, clean and well lit. It is prohibited for unqualified people to

pass through or remain in this space.

Use personal protective clothing (safety shoes, safety glasses, gloves, etc.) compliant with

regulations.

Before carrying out repairs or other work on the machine, always declare out loud your

intentions to other operators who are located in the machine area and make sure that they

have heard and understood the warning.

28

Page 29

Ordinary maintenance

Proper maintenance of the systems maintains efficiency (reducing costs) and consistent performance

over time, and increase the usable life of the equipment.

ACTIVITY

General cleaning of the machine. √

Check and eventual disassembly and washing of filters. √

Replacing the filters (when they have deteriorated).

Clean the finned surfaces of the heat exchange coils (if provided) with a jet of

compressed air and soft brush.

Clean the exchange surfaces of of heat recuperators with a jet of compressed air and

soft brush.

Empty and clean the condensate collection basins. √

Visual inspection for corrosion, limescale, release of fibrous substances, any damage,

abnormal vibrations, etc. (if possible, it is advisable to extract the components for a

more thorough inspection).

Check condensate drain and cleaning of siphons. √

In the case of water coils check for the presence of Legionella. √

Check the status of anti-vibration connections. √

Cleaning of the heat exchanger √

Check tightness of screws and bolts in the fan section. √

FREQUENCY

A B C D E

in case of alarm

√

√

√

Check the auger, impeller and various devices, with removal of any buildup. √

Check the integrity of piping connected to pressure gauges and pressure switches. √

Check the ground connection. √

Power connection terminal torque √

A: annual / B: six months / C: quarterly / D: monthly / E: fortnightly

29

Page 30

General information on cleaning procedures

Read the safety instructions at the beginning of this manual and page. 28

You should consult with your supplier of chemical products to choose the most suitable for

cleaning the unit components.

For the cleaning method refer to the instructions of the detergent manufacturer and carefully

read the safety data sheet (SDS).

As general guidelines, refer to the following rules:

• Always use personal protection (safety shoes, safety glasses, gloves, etc.).

• Use mild products (pH between 8 and 9) for washing and disinfecting, in normal concentrations.

Detergents must not be toxic, corrosive, flammable or abrasive.

• Use a soft cloth or bristle brushes that do not damage the stainless steel surfaces.

• If water jets are used, pressure must be under 1.5 bar and the temperature should not exceed 60°C;

• For cleaning components like motors, damper motors, bearings, pitot tubes, filters and electronic sensors (if applicable), do not spray water directly on them.

• After cleaning make sure that you have not damaged the electrical parts and the seals.

• Cleaning operations should not involve the lubricated parts, like rotation shafts, because this could

affect their good operation and create problems with durability.

• For the cleaning of finned components or dampers use an industrial vacuum cleaner and/or a

compressor. Attention, the compressed air flow must run opposite to the direction of airflow through

the unit.

Cleaning lamellar components

Remove the dust and fibres with a soft bristle brush or a vacuum cleaner.

Be careful when cleaning with compressed air because the exchanger package can be damaged.

CLEANING with pressure jets is allowed if the maximum water pressure is 3 bar and a flat nozzle

is used (40° - WEG 40/04 type).

Oils, solvents, etc. can be removed with water or hot grease solvents, by washing or immersion.

Periodically clean the condensate drain tray and fill the drain siphon with water.

Vents

Periodically check that there are no new sources of contamination near the air intake. Each component

must be checked periodically for the presence of contamination, damage and corrosion. The seal can be

protected with glycerine-based lubricants or replaced with a new one, if worn.

30

Page 31

Exchange coils

The coils must be cleaned at the slightest sign of contamination.

The coil should be cleaned and washed gently to avoid damaging the fins.

For cleaning using a mild detergent suitable for the purpose. Do not use alkaline, acidic or chlorine-based

solutions.

THE coils can be washed with a slightly pressurised water jet (max. 1.5 bar). The jet must NOT contain

chemicals or microorganisms. Also the water must be sprayed in the opposite direction to the air flow.

For the direct expansion system, all the coolant in the coils must be collected in the receiver before

washing the coil with water. This makes it possible to avoid the increase of the pressure and damage to

various parts of the pipe, keeping the airflow clean.

For pertinent accessories, refer to the enclosed documentation.

Fans

The fans can be cleaned with compressed air or by brushing them with soap and water or with a mild

detergent.

Finish the cleaning by rotating the fan by hand to verify the absence of abnormal noises.

Cleaning lters

The machine must NOT be running when the filters are removed to avoid drawing in outside air

that might be contaminated.

The filters must be cleaned often and carefully to prevent dust and microbial buildup. Usually, compact

filters can be cleaned two or three times before they are replaced. As a general rule, replacement

is required after 500-2000 hours of operation (it varies depending on the type of filter, refer to the

directions of the manufacturer), but may need to be replaced much sooner if required.

Compact lters can be cleaned using a vacuum cleaner or by blowing with compressed air or hot water

(not under pressure).

Only for versions with up-and-over doors: if the opening of the doors was difficult because of the

narrowness of the available space, it is possible to remove them by unscrewing the screws that hold the

hinges.

At the end of cleaning, it is mandatory to remount the doors.

31

Page 32

3

3

2

x16

In the absence of sufficient space for the opening of the

up-and-over doors it is possible to remove them and

transform the inspection door into a removable panel that

can slide on accessory guides (optional).

11

Removal of the hinges to make the panel removable

32

Page 33

Correct filter and pre-filter installation (in the event of replacement)

Verify proper installation of the prefilters located on special counter-frames with safety springs or guides.

After removing the filters from the packing (that they are placed in to prevent deterioration during

transport and at the installation site), insert them into the containment section, paying attention to ensure

a rigid assembly and a perfect seal of the gaskets.

Remove the filters from their packaging only when ready to install them to avoid getting them

dirty and contaminating them.

Make sure that the inside of the filter is not contaminated by external agents.

This operation should be carried out about one hour after the first start-up of the machine, the

period during which the ducts are cleaned of dust and various debris. Proceeding in this way

preserves the filtering sections that cannot be regenerated.

3

3

1

x16

3

2

4

12

filter installation

33

Page 34

Extraordinary maintenance

One can not predict extraordinary maintenance as it is normally due to effects of wear or fatigue caused

by the incorrect operation of the machine.

Replacement of parts

The replacement of parts should be performed by expert personnel:

• Qualified maintenance mechanic

• Qualified maintenance electrician

• Manufacturer technician

The machine is designed to be able to perform all the servicing necessary to maintain good efficiency of

the components. However, it sometimes happens that a component fails due to malfunction or wear, so

for replacement refer to the executive schematic.

These are the components that may need replacement:

• Filters see fig. 12

• Recovery/heating/cooling heat exchange coil see fig. 13

• Fans

• by-pass

For some of these operations of a general nature we will not enter into detail as these are operations that

fall within the abilities and professional expertise of the staff assigned to perform them.

Consumable components - Spare parts

During the operation of the machine there are particular mechanical and electrical components that are

most subject to wear. These parts must be monitored in order to carry out their replacement or repair

before they cause problems to the correct operation of the machine with consequent downtime.

34

Page 35

1

x16

13

Exchanger disassembly

35

Page 36

Disposal of used materials - waste

DEFINITION OF WASTE

Waste is any substance and object deriving from human activities or natural cycles that is abandoned or

destined to be abandoned.

SPECIAL WASTE

Special waste includes:

• Residues from industrial, agricultural, artisanal, commercial and service processes that in quality or

quantity are considered different from municipal waste.

• Deteriorated or obsolete machinery and equipment.

• Motor vehicles and their parts that can no longer be used.

HARMFUL TOXIC WASTE

Harmful toxic waste is all waste containing or contaminated by substances listed in the annex to the Italian

Presidential Decree 915/52 implementing directives 75/442/EEC, 76/442/EEC, 76/403/EEC, 768/319/EEC.

Following are described the types of waste that may be generated during the lifetime of an air handling

unit:

• Cell filters from the suction unit.

• Waste oils and greases from lubricating the fan motor assembly.

• Rags or paper soaked with substances used for the cleaning of the various parts of the machine.

• Residues from cleaning the panelling.

• Drive belts.

• TUV germicidal lamps, which must be disposed of according to current legislation.

Waste from the cell filters are to be handled as special waste or harmful toxic depending on their

use, the sector and the environment in which they are used.

Waste and scraps may cause irreparable damage if dispersed in the environment.

ELECTRICAL/ELECTRONIC WASTE

Under art. 13 of Italian Legislative Decree no. 49 of 2014 "Implementation of the WEEE Directive 2012/19/EU on electrical and

electronic equipment waste.

The logo with the crossed-out bin specifies that the product has been placed on the market after 13 August 2005 and that

at the end of its useful life it should not be disposed of with other waste but rather must be collected separately. All

equipment is made from recyclable metallic materials (stainless steel, iron, aluminium, galvanised steel, copper, etc.) in a

percentage higher than 90% by weight. Before disposal make the equipment unusable by removing the power cord and

closing any devices for closing compartments or cavities (where present). It is necessary to pay attention to the management of this

product at the end of its life by reducing its negative impact on the environment and improving the effective use of resources,

applying the principles of "he who pollutes pays", prevention, preparation for reuse, recycling and recovery. Remember that the

illegal or improper disposal of the product may result in the application of sanctions provided for by current provisions of law.

Disposal in Italy

In Italy WEEE equipment must be delivered:

- To Collection Centres (also called ecological islands or ecological platforms).

- To the dealer from whom the new equipment was purchased, which is required to collect it free of charge ("one to one" withdrawal).

Disposal in countries of the European Union

The EU Directive on WEEE equipment has been implemented differently by each country, so to dispose of this equipment we suggest

contacting local authorities or the dealer to ask for the correct method of disposal.

Diagnostics

36

Page 37

General diagnostics

The machine's electrical system includes quality electromechanical components and is therefore

extremely durable and reliable over time.

Should there be any malfunctions due to malfunctions of electrical components it will be necessary to

act as follows:

• Check the fuses of the power supply for the control circuits and if necessary replace them with fuses

having the same specifications.

• Check if the thermal protection switch for the motor has been triggered or if its fuses have blown.

If this has occurred, it may be caused by:

• Motor overload due to mechanical problems. They need to be solved.

• Incorrect supply voltage. Verify the protection trip threshold.

• Malfunction and/or short circuits in the motor. Identify and replace the failed component.

Electrical maintenance

The machine does not require routine maintenance repairs.

Do not modify the machine for any reason and do not add other devices.

The manufacturer is not liable for resulting malfunctions and problems.

Further clarification is available by contacting the manufacturer's Customer Service.

37

Page 38

Troubleshooting table

MALFUNCTION TYPE COMPONENT POSSIBLE CAUSE/SOLUTION

Impeller deformed, unbalanced or loose

NOISE

INSUFFICIENT AIR FLOW

EXCESSIVE AIR FLOW

INSUFFICIENT THERMAL

EFFICIENCY

WATER LEAK

Fan impeller

Transmission Motor or fan not attached well

Bearings Bearing worn or deteriorated

Motor

Ducts

Ducts

Filters too dirty

Heat exchange coils too dirty

Ducts

Machine

Heat exchange coil

Electric pump

Fluid

Heat exchange coil

Fan section

Nozzle damaged

Foreign bodies in the fan

Incorrect supply voltage

Worn bearings

Contact between the rotor and stator

Excessive speed in the ducts

Anti-vibration joint too taut

Load losses superior to the demand

Dampers closed

Obstructions in the ducts

Load losses inferior to the demand

Ducts too big

Terminals not installed

Filters not inserted

Access doors open

Dampers not calibrated

Incorrect connection of inlet/outlet piping

Heat exchange coil dirty

Air bubbles in the pipes

Excessive air flow

Insufficient water flow

insufficient pressure

Wrong direction of rotation

Temperature different from the project

Incorrect regulation bodies

Leak from the heat exchange coil due to

Dragging of drops due to high air velocity

Clogged "overflow" drain

corrosion

38

Page 39

Repair log

DAT E SERVICE TYPE TIME REQUIRED SIGNATURE

39

Page 40

Via Piani S. Maria, 72 - 00072 Ariccia (Rome) Italy - www.daikinapplied.eu

This publication is drawn up only as technical support and does not constitute a binding commitment

for Daikin Applied Europe S.p.A. Daikin Applied Europe S.p.A. has drawn up the content to the best of

its ability.

No explicit or implicit guarantee is given as to the completeness, precision or reliability of its

content. All the data and specifications contained herein are subject to change without notice. The

data stated at the time of the order prevail. Daikin Applied Europe S.p.A. accepts no liability whatsoever for any direct or indirect damage, in the broadest sense of the word, deriving from or associated

with the use and/or interpretation of this publication.

All content is protected by the copyright of Daikin Applied Europe S.p.A.

MI_AHU001-0518EN

Loading...

Loading...