Daikin HPSU compact 304, HPSU compact 308, HPSU compact 508, HPSU compact 516 Installation manuals

For the qualified installer

ROTEX HPSU compact (V5.2)

Installation and maintenance

manual

Solar tank with integrated interior heat pump unit

For the types

HPSU compact 304

HPSU compact 308

HPSU compact 508

HPSU compact 516

GB

Edition 07/2017

CE - DECLARATION-OF-CONFORMITY

CE - KONFORMITÄTSERKLÄRUNG

CE - DECLARATION-DE-CONFORMITE

CE - CONFORMITEITSVERKLARING

CE - DECLARACION-DE-CONFORMIDAD

CE - DICHIARAZIONE-DI-CONFORMITA

CE - ǻHȁȍȈǾ ȈȊȂȂȅȇĭȍȈǾȈ

CE - DECLARAÇÃO-DE-CONFORMIDADE

CE - ɁȺəȼɅȿɇɂȿ-Ɉ-ɋɈɈɌȼȿɌɋɌȼɂɂ

CE - OVERENSSTEMMELSESERKLÆRING

CE - FÖRSÄKRAN-OM-ÖVERENSTÄMMELSE

CE - ERKLÆRING OM-SAMSVAR

CE - ILMOITUS-YHDENMUKAISUUDESTA

CE - PROHLÁENÍ-O-SHODċ

CE - IZJAVA-O-USKLAĈENOSTI

CE - MEGFELELėSÉGI-NYILATKOZAT

CE - DEKLARACJA-ZGODNOĝCI

CE - DECLARAğIE-DE-CONFORMITATE

CE - IZJAVA O SKLADNOSTI

CE - VASTAVUSDEKLARATSIOON

CE - ȾȿɄɅȺɊȺɐɂə-ɁȺ-ɔɈɌȼȿɌɋɌȼɂȿ

CE - ATITIKTIES-DEKLARACIJA

CE - ATBILSTƮBAS-DEKLARƖCIJA

CE - VYHLÁSENIE-ZHODY

CE - UYUMLULUK-BEYANI

01

are in conformity with the following standard(s) or other normative document(s), provided that these are used in accordance with our

instructions:02der/den folgenden Norm(en) oder einem anderen Normdokument oder -dokumenten entspricht/entsprechen, unter der Voraussetzung,

daß sie gemäß unseren Anweisungen eingesetzt werden:03sont conformes à la/aux norme(s) ou autre(s) document(s) normatif(s), pour autant qu'ils soient utilisés conformément à nos instructions:04conform de volgende norm(en) of één of meer andere bindende documenten zijn, op voorwaarde dat ze worden gebruikt overeenkomstig

onze instructies:05están en conformidad con la(s) siguiente(s) norma(s) u otro(s) documento(s) normativo(s), siempre que sean utilizados de acuerdo con

nuestras instrucciones:

06

sono conformi al(i) seguente(i) standard(s) o altro(i) documento(i) a carattere normativo, a patto che vengano usati in conformità alle

nostre istruzioni:

07

İȓȞĮȚ ıȪȝijȦȞĮ ȝİ IJȠ(Į) ĮțȩȜȠȣșȠ(Į) ʌȡȩIJȣʌȠ(Į) Ȓ ȐȜȜȠ ȑȖȖȡĮijȠ(Į) țĮȞȠȞȚıȝȫȞ, ȣʌȩ IJȘȞ ʌȡȠȨʌȩșİıȘ ȩIJȚ ȤȡȘıȚȝȠʌȠȚȠȪȞIJĮȚ ıȪȝijȦȞĮ

ȝİ IJȚȢ ȠįȘȖȓİȢ ȝĮȢ:

08

estão em conformidade com a(s) seguinte(s) norma(s) ou outro(s) documento(s) normativo(s), desde que estes sejam utilizados de

acordo com as nossas instruções:09ɫɨɨɬɜɟɬɫɬɜɭɸɬ ɫɥɟɞɭɸɳɢɦ ɫɬɚɧɞɚɪɬɚɦ ɢɥɢ ɞɪɭɝɢɦ ɧɨɪɦɚɬɢɜɧɵɦ ɞɨɤɭɦɟɧɬɚɦ, ɩɪɢ ɭɫɥɨɜɢɢ ɢɯ ɢɫɩɨɥɶɡɨɜɚɧɢɹ ɫɨɝɥɚɫɧɨ ɧɚɲɢɦ

ɢɧɫɬɪɭɤɰɢɹɦ:

10

overholder følgende standard(er) eller andet/andre retningsgivende dokument(er), forudsat at disse anvendes i henhold til vore

instrukser:11respektive utrustning är utförd i överensstämmelse med och följer följande standard(er) eller andra normgivande dokument, under

förutsättning att användning sker i överensstämmelse med våra instruktioner:12respektive utstyr er i overensstemmelse med følgende standard(er) eller andre normgivende dokument(er), under forutssetning av at

disse brukes i henhold til våre instrukser:13vastaavat seuraavien standardien ja muiden ohjeellisten dokumenttien vaatimuksia edellyttäen, että niitä käytetään ohjeidemme

mukaisesti:14za pĜedpokladu, e jsou vyuívány v souladu s naimi pokyny, odpovídají následujícím normám nebo normativním dokumentĤm:15u skladu sa slijedeüim standardom(ima) ili drugim normativnim dokumentom(ima), uz uvjet da se oni koriste u skladu s naim uputama:

16

megfelelnek az alábbi szabvány(ok)nak vagy egyéb irányadó dokumentum(ok)nak, ha azokat elĘírás szerint használják:17speániają wymogi nastĊpujących norm i innych dokumentów normalizacyjnych, pod warunkiem Īe uĪywane są zgodnie z naszymi

instrukcjami:

18

sunt în conformitate cu următorul (următoarele) standard(e) sau alt(e) document(e) normativ(e), cu condiĠia ca acestea să fie utilizate în

conformitate cu instrucĠiunile noastre:19skladni z naslednjimi standardi in drugimi normativi, pod pogojem, da se uporabljajo v skladu z naimi navodili:20on vastavuses järgmis(t)e standardi(te)ga või teiste normatiivsete dokumentidega, kui neid kasutatakse vastavalt meie juhenditele:21ɫɴɨɬɜɟɬɫɬɜɚɬ ɧɚ ɫɥɟɞɧɢɬɟ ɫɬɚɧɞɚɪɬɢ ɢɥɢ ɞɪɭɝɢ ɧɨɪɦɚɬɢɜɧɢ ɞɨɤɭɦɟɧɬɢ, ɩɪɢ ɭɫɥɨɜɢɟ, ɱɟ ɫɟ ɢɡɩɨɥɡɜɚɬ ɫɴɝɥɚɫɧɨ ɧɚɲɢɬɟ

ɢɧɫɬɪɭɤɰɢɢ:

22

atitinka emiau nurodytus standartus ir (arba) kitus norminius dokumentus su sąlyga, kad yra naudojami pagal mnjsǐ nurodymus:23tad, ja lietoti atbilstoi raotƗja norƗdƯjumiem, atbilst sekojoiem standartiem un citiem normatƯviem dokumentiem:24sú v zhode s nasledovnou(ými) normou(ami) alebo iným(i) normatívnym(i) dokumentom(ami), za predpokladu, e sa pouívajú v súlade

s naim návodom:25ürünün, talimatlarmza göre kullanlmas koúuluyla aúa÷daki standartlar ve norm belirten belgelerle uyumludur:

01

Directives, as amended.02Direktiven, gemäß Änderung.03Directives, telles que modifiées.04Richtlijnen, zoals geamendeerd.05Directivas, según lo enmendado.06Direttive, come da modifica.07ȅįȘȖȚȫȞ, ȩʌȦȢ ȑȤȠȣȞ IJȡȠʌȠʌȠȚȘșİȓ.08Directivas, conforme alteração em.09Ⱦɢɪɟɤɬɢɜ ɫɨ ɜɫɟɦɢ ɩɨɩɪɚɜɤɚɦɢ.

10

Direktiver, med senere ændringer.11Direktiv, med företagna ändringar.12Direktiver, med foretatte endringer.13Direktiivejä, sellaisina kuin ne ovat muutettuina.14v platném znČní.15Smjernice, kako je izmijenjeno.16irányelv(ek) és módosításaik rendelkezéseit

.

17

z póĨniejszymi poprawkami.18Directivelor, cu amendamentele respective.

19

Direktive z vsemi spremembami.20Direktiivid koos muudatustega.21Ⱦɢɪɟɤɬɢɜɢ, ɫ ɬɟɯɧɢɬɟ ɢɡɦɟɧɟɧɢɹ.22Direktyvose su papildymais.23DirektƯvƗs un to papildinƗjumos.24Smernice, v platnom znení.25Deۜiútirilmiú halleriyle Yönetmelikler.

01

following the provisions of:02gemäß den Vorschriften der:03conformément aux stipulations des:04overeenkomstig de bepalingen van:05siguiendo las disposiciones de:06secondo le prescrizioni per:07ȝİ IJȒȡȘıȘ IJȦȞ įȚĮIJȐȟİȦȞ IJȦȞ:08de acordo com o previsto em:09ɜ ɫɨɨɬɜɟɬɫɬɜɢɢ ɫ ɩɨɥɨɠɟɧɢɹɦɢ:

10

under iagttagelse af bestemmelserne i:11enligt villkoren i:12gitt i henhold til bestemmelsene i:13noudattaen määräyksiä:14za dodrení ustanovení pĜedpisu:15prema odredbama:16követi a(z):17zgodnie z postanowieniami Dyrektyw:18în urma prevederilor:

19

ob upotevanju doloþb:20vastavalt nõuetele:21ɫɥɟɞɜɚɣɤɢ ɤɥɚɭɡɢɬɟ ɧɚ:22laikantis nuostatǐ, pateikiamǐ:23ievƝrojot prasƯbas, kas noteiktas:24odriavajúc ustanovenia:25bunun koúullarna uygun olarak:

527(;+HDWLQJ6\VWHPV*PE+

01

a

declares under its sole responsibility that the equipment to which this declaration relates:

02

d

erklärt auf seine alleinige Verantwortung daß die Ausrüstung für die diese Erklärung bestimmt ist:

03

f

déclare sous sa seule responsabilité que l'équipement visé par la présente déclaration:

04

l

verklaart hierbij op eigen exclusieve verantwoordelijkheid dat de apparatuur waarop deze verklaring betrekking heeft:

05

e

declara bajo su única responsabilidad que el equipo al que hace referencia la declaración:

06

i

dichiara sotto la propria responsabilità che gli apparecchi a cui è riferita questa dichiarazione:

07

g

įȘȜȫȞİȚ ȝİ ĮʌȠțȜİȚıIJȚțȒ IJȘȢ İȣșȪȞȘ ȩIJȚ Ƞ İȟȠʌȜȚıȝȩȢ ıIJȠȞ ȠʌȠȓȠ ĮȞĮijȑȡİIJĮȚ Ș ʌĮȡȠȪı Į įȒȜȦıȘ:

08

p

declara sob sua exclusiva responsabilidade que os equipamentos a que esta declaração se refere:

09

u

ɡɚɹɜɥɹɟɬ, ɢɫɤɥɸɱɢɬɟɥɶɧɨ ɩɨɞ ɫɜɨɸ ɨɬɜɟɬɫɬɜɟɧɧɨɫɬɶ, ɱɬɨ

ɨɛɨɪɭɞɨɜɚɧɢɟ,

ɤ ɤɨɬɨɪɨɦ

ɭ

ɨɬɧɨɫɢɬɫɹ ɧɚɫɬɨɹɳɟɟ ɡɚɹɜɥɟɧɢɟ:

10

q

erklærer under eneansvarlig, at udstyret, som er omfattet af denne erklæring:

11

s

deklarerar i egenskap av huvudansvarig, att utrustningen som berörs av denna deklaration innebär att:

12

n

erklærer et fullstendig ansvar for at det utstyr som berøres av denne deklarasjon innebærer at:

13

j

ilmoittaa yksinomaan omalla vastuullaan, että tämän ilmoituksen tarkoittamat laitteet:

14

c

prohlauje ve své plné odpovČdnosti, e zaĜízení, k nČmu se toto prohláení vztahuje:

15

y

izjavljuje pod iskljuþivo vlastitom odgovornoüu da oprema na koju se ova izjava odnosi:

16

h

teljes felelĘssége tudatában kijelenti, hogy a berendezések, melyekre e nyilatkozat vonatkozik:

17

m

deklaruje na wáasną i wyáączną odpowiedzialnoĞü, Īe urządzenia, których ta deklaracja dotyczy:

18

r

declară pe proprie răspundere că echipamentele la care se referă această declaraĠie:

19

o

z vso odgovornostjo izjavlja, da je oprema naprav, na katero se izjava nanaa:

20

x

kinnitab oma täielikul vastutusel, et käesoleva deklaratsiooni alla kuuluv varustus:

21

b

ɞɟɤɥɚɪɢɪɚ ɧɚ ɫɜɨɹ ɨɬɝɨɜɨɪɧɨɫɬ, ɱɟ ɨɛɨɪɭɞɜɚɧɟɬɨ, ɡɚ ɤɨeɬɨ ɫɟ ɨɬɧɚɫɹ ɬɚɡɢ ɞɟɤɥɚɪɚɰɢɹ:

22

t

visika savo atsakomybe skelbia, kad Ƴranga, kuriai taikoma i deklaracija:

23

v

ar pilnu atbildƯbu apliecina, ka tƗlƗk aprakstƯtƗs iekƗrtas, uz kurƗm attiecas Ư deklarƗcija:

24

k

vyhlasuje na vlastnú zodpovednosĢ, e zariadenie, na ktoré sa vzĢahuje toto vyhlásenie:

25

w

tamamen kendi sorumluluۜunda olmak üzere bu bildirinin ilgili olduۜu donanmnn aúaۜdaki gibi olduۜunu beyan eder:

EN60335-2-40,

EN55014-1: 2006 (+A1:200$),

EN55014-2: 1997 (+A1: 2001 +A2: 200),

EN61000-3-2: 20,

EN61000-3-3: 20,

EN61000-6-: 2007 (+A1: 2011),

Low Voltage 20/5/E8

Electromagnetic Compatibility 204//E8

(FRGHVLJQ(&

+368FRPSDFW+&'%+368FRPSDFW+&%LY+368FRPSDFW+'%+368FRPSDFW+%LY

+368FRPSDFW+&'%+368FRPSDFW+&%LY+368FRPSDFW+'%+368FRPSDFW+%LY

+368FRPSDFW+&'%+368FRPSDFW+&%LY+368FRPSDFW+'%+368FRPSDFW+%LY

+368FRPSDFW+&'%+368FRPSDFW+&%LY+368FRPSDFW+'%+368FRPSDFW+%LY

(1

(1

(1

&RPPLVVLRQUHJXODWLRQ

&RPPLVVLRQUHJXODWLRQ

*HRUJ%OPHO

0DQDJLQJ'LUHFWRU

*JOLQJHQWKRI$SULO

List of contents

1 General Information . . . . . . . . . . . . . . . . . . . . 4

1.1 Observing instructions . . . . . . . . . . . . . . . . . . . . .4

1.2 Warranty conditions . . . . . . . . . . . . . . . . . . . . . . .4

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Warning signs and explanation of symbols. . . . . .5

2.1.1 Meaning of the warnings . . . . . . . . . . . . . . . . . . . . . .5

2.1.2 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.3 Order number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.4 Handling instructions. . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Avoid danger. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 Instructions for operating safety . . . . . . . . . . . . . .7

2.4.1 Before working on the hydraulic system . . . . . . . . . .7

2.4.2 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . .7

2.4.3 Working on cooling systems (heat pump) . . . . . . . . .7

2.4.4 Site of installation . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.4.5 Heating system and sanitary connection. . . . . . . . . .8

2.4.6 Requirements for the heating water . . . . . . . . . . . . .8

2.4.7 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.4.8 Instructing the user/owner . . . . . . . . . . . . . . . . . . . . .9

3 Product description . . . . . . . . . . . . . . . . . . .10

3.1 Design and components . . . . . . . . . . . . . . . . . . .10

3.1.1 Top of unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.1.2 Equipment external and internal structure

ROTEX HPSU compact 304/308 DB . . . . . . . . . . .11

3.1.3 Equipment external and internal structure

ROTEX HPSU compact 304/308 BIV . . . . . . . . . . .12

3.1.4 Equipment external and internal structure

ROTEX HPSU compact 508/516 DB . . . . . . . . . . .13

3.1.5 Equipment external and internal structure

ROTEX HPSU compact 508/516 BIV . . . . . . . . . . .14

4 Set-up and installation . . . . . . . . . . . . . . . . .16

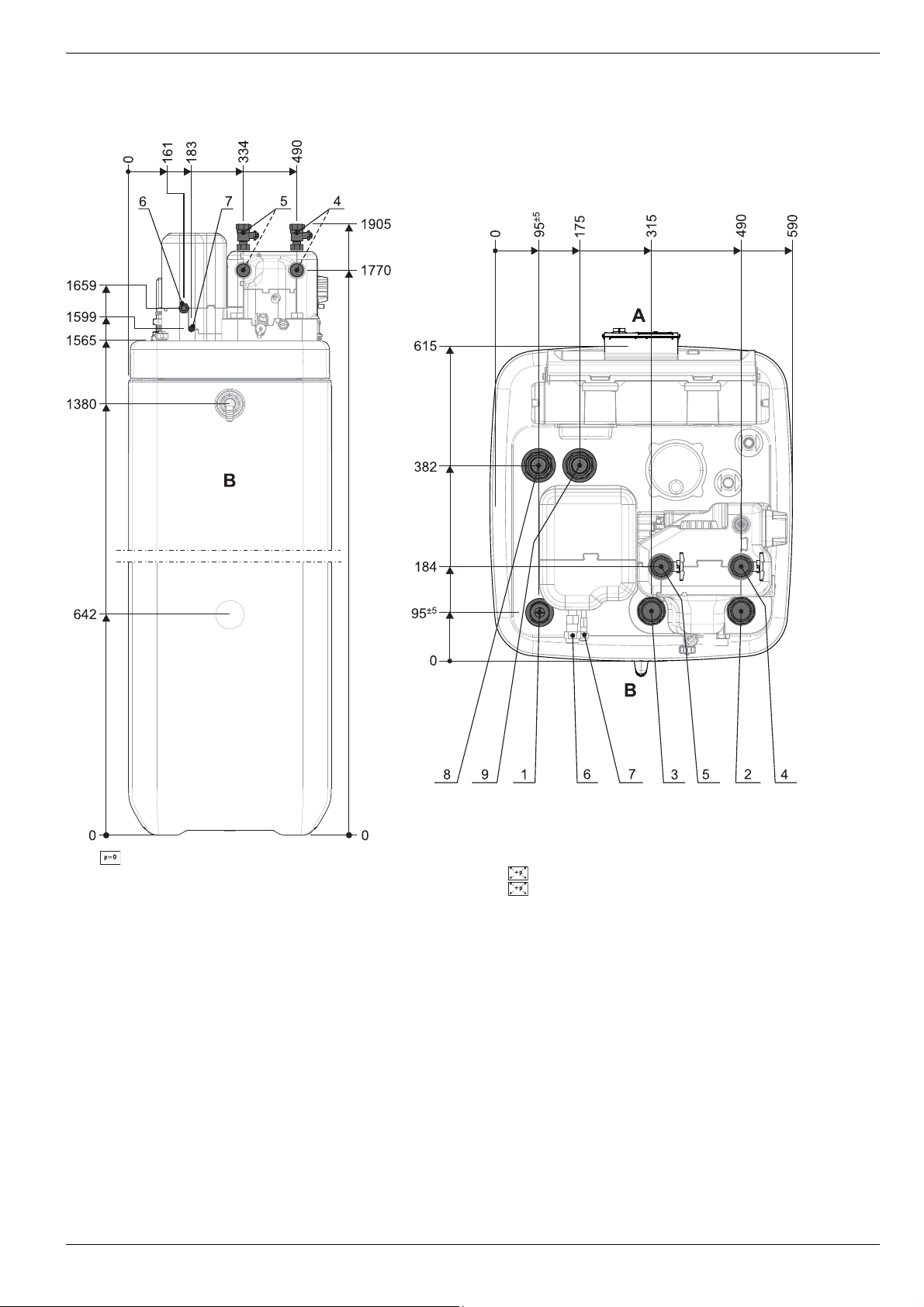

4.1 Dimensions and connections . . . . . . . . . . . . . . .17

4.1.1 ROTEX HPSU compact 304/308 . . . . . . . . . . . . . .17

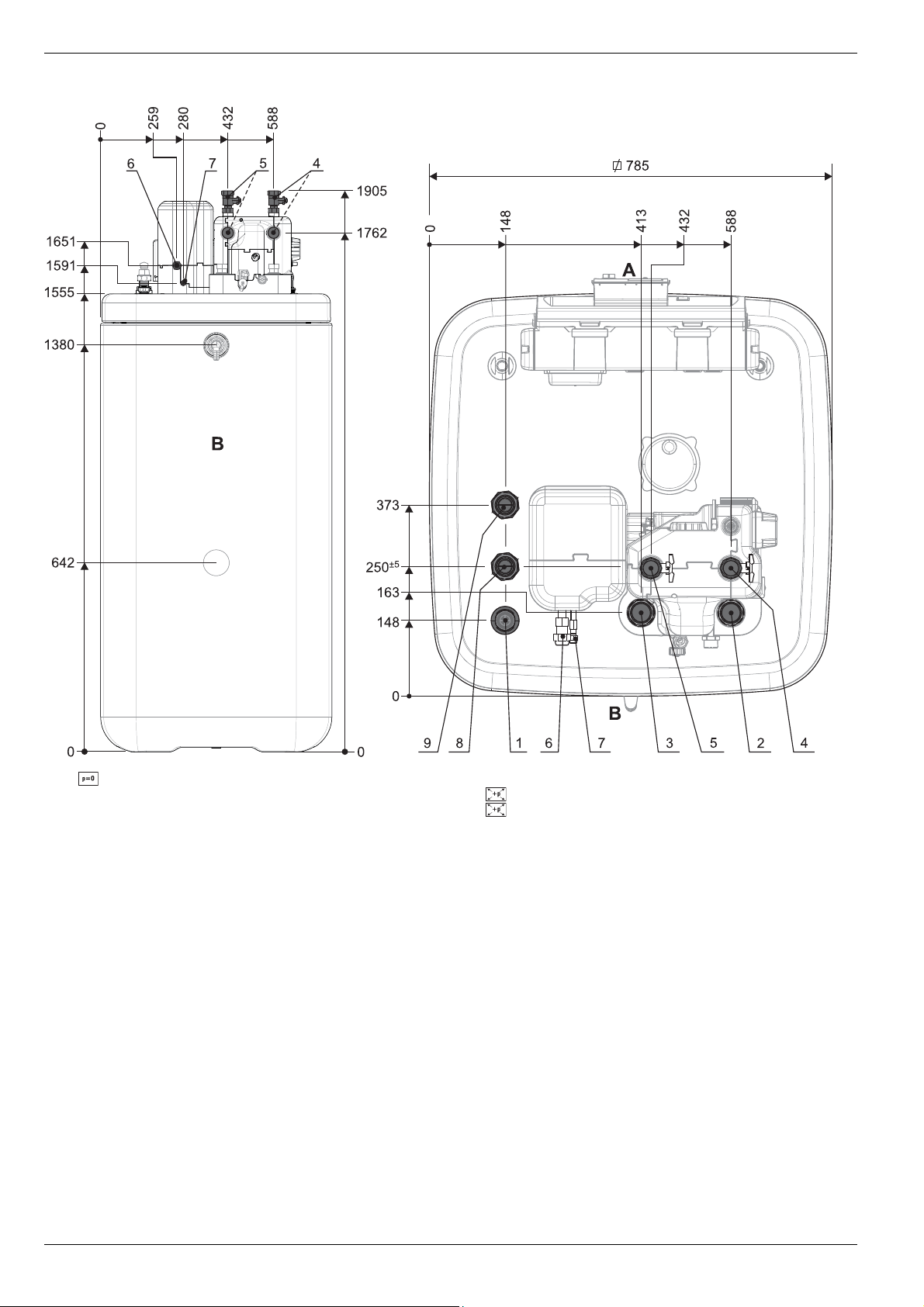

4.1.2 ROTEX HPSU compact 508/516 . . . . . . . . . . . . . .18

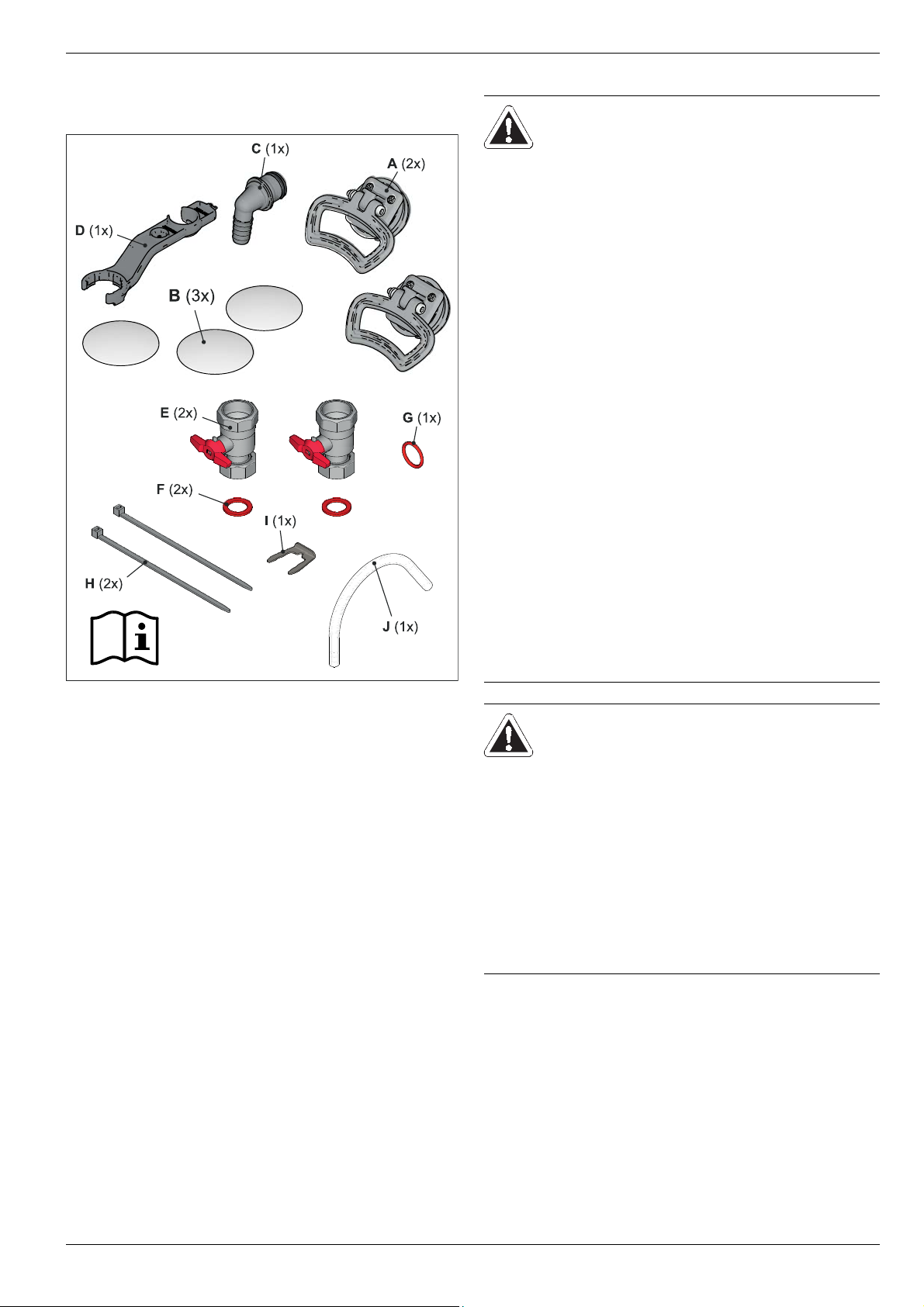

4.1.3 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.2 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.3 Remove cover hood and heat insulation. . . . . . .21

4.4 Water connection . . . . . . . . . . . . . . . . . . . . . . . .22

4.4.1 Aligning the connections of the heating feed and

return flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.4.2 Connecting hydraulic lines . . . . . . . . . . . . . . . . . . .24

4.4.3 Installation of DB connection kit ( 141590) . . . . . . .25

4.4.4 Installation of P connection kit ( 141589) . . . . . . . .25

4.5 Electrical connection . . . . . . . . . . . . . . . . . . . . . .25

4.5.1 Overall connection plan ROTEX HPSU compact . .27

4.5.2 Position of the circuit boards . . . . . . . . . . . . . . . . . .28

4.5.3 Connection assignment, circuit board A1P . . . . . . .28

4.5.4 Terminal assignment for the RTX-EHS

circuit board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4.5.5 Connection assignment, circuit board RoCon BM1.29

4.5.6 Mains connection ROTEX HPSU compact . . . . . . .29

4.5.7 Open controller housing and making the electrical

connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.5.8 Connection of exterior heat pump unit RRLQ . . . . .30

4.5.9 Connection of external temperature sensor

RoCon OT1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.5.10 Connection of an external switching contact . . . . . .31

4.5.11 External demand signal (EDS) . . . . . . . . . . . . . . . .31

4.5.12 Connection of the electrical ROTEX Backup Heater

(BUxx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.5.13 Connection of an external heat generator . . . . . . . .33

4.5.14 Connection of the ROTEX room thermostat . . . . . .34

4.5.15 Connection optional ROTEX

RoCon system components. . . . . . . . . . . . . . . . . . 35

4.5.16 Connection of the ROTEX HP convector. . . . . . . . 35

4.5.17 Connection switch contacts (AUX outputs) . . . . . . 36

4.5.18 Low tariff mains connection (HT/NT) . . . . . . . . . . . 36

4.5.19 Connection intelligent controller (Smart Grid - SG) 37

4.5.20 Symbols and legend keys on connection and

circuit diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.6 Laying coolant lines . . . . . . . . . . . . . . . . . . . . . . 40

4.7 Pressure test and filling the coolant circuit. . . . . 40

4.8 Filling the system with water . . . . . . . . . . . . . . . 40

4.8.1 Checking the water quality and adjusting the

pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.8.2 Filling the hot water heat exchanger . . . . . . . . . . . 41

4.8.3 Filling the storage tank . . . . . . . . . . . . . . . . . . . . . 41

4.8.4 Filling the heating system . . . . . . . . . . . . . . . . . . . 41

5 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.3 Set the commissioning parameters . . . . . . . . . . . . 43

5.1.4 Venting the hydraulics . . . . . . . . . . . . . . . . . . . . . . 43

5.1.5 Check the minimum flow rate . . . . . . . . . . . . . . . . 44

5.1.6 Configuring Screed Program parameters

(only if necessary) . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 Re-commissioning . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6 Decommissioning. . . . . . . . . . . . . . . . . . . . . 46

6.1 Temporary shutdown . . . . . . . . . . . . . . . . . . . . . 46

6.1.1 Draining the storage tank . . . . . . . . . . . . . . . . . . . 46

6.1.2 Draining the heating circuit and hot water circuit. . 47

6.2 Final shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . 48

7 Service and maintenance. . . . . . . . . . . . . . . 50

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2 Activities to be performed annually . . . . . . . . . . 51

7.3 Filling and topping up the storage tank . . . . . . . 53

7.4 Filling and topping up the heating system . . . . . 54

8 Errors, malfunctions and messages. . . . . . 56

8.1 Recognising errors, correcting malfunctions . . . 56

8.1.1 Current fault display. . . . . . . . . . . . . . . . . . . . . . . . 56

8.1.2 Read Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.1.3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2 Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.3 Fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.4 Monitoring and configuration DIP Switch . . . . . . 67

8.5 Emergency operation. . . . . . . . . . . . . . . . . . . . . 67

9 Hydraulic system connection . . . . . . . . . . . 68

10 Technical data. . . . . . . . . . . . . . . . . . . . . . . . 73

10.1 Equipment data . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.1.1 ROTEX HPSU compact 304/308. . . . . . . . . . . . . . 73

10.1.2 ROTEX HPSU compact 508/516. . . . . . . . . . . . . . 76

10.2 Characteristic lines. . . . . . . . . . . . . . . . . . . . . . . 78

10.2.1 Sensor characteristic lines. . . . . . . . . . . . . . . . . . . 78

10.2.2 Characteristic curves for pumps . . . . . . . . . . . . . . 80

10.3 Tightening torque . . . . . . . . . . . . . . . . . . . . . . . 80

10.4 Circuit diagram ROTEX HPSU compact . . . . . . 81

11 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12 List of keywords . . . . . . . . . . . . . . . . . . . . . . 83

FA ROTEX HPSU compact (V5.2) • 07/2017

3

1 x General Information

1 General Information

1.1 Observing instructions

Original Operating Instructions

These operating instructions are a >> Tran slation of

the Original Version << in your language.

Please read this manual carefully and thoroughly before proceeding with the installation or modification of the heating

system.

Target Group

These instructions are aimed at people who are authorised and

who have successfully completed a qualifying technical or skilled

manual training program for the particular work to be carried out

and who have participated in professional development seminars

recognised by the appropriate responsible authority. This, in par

ticular, includes heating specialists and climate control technicians who have experience, as a result of their technical training

and their knowledge of the subject, of proper and appropriate installation and maintenance of heating, climate control and

cooling installations and heat pumps.

This manual provides all the necessary information for installation, start-up and maintenance, as well as basic information on

operation and settings. All parameters needed for trouble-free

operation have been configured at the factory. Please see the at

tached documents for a detailed description of operation and

control.

1.2 Warranty conditions

The legal guarantee conditions fundamentally apply. Our warranty conditions beyond that can be found online on your sales

representative's webpage.

-

-

Relevant documents

– ROTEX HPSU compact:

– Operating instructions for the user/owner

– Commissioning checklist

– The operating manual for the user/owner

– Operating instructions for the RoCon HP control unit

– External unit for ROTEX HPSU compact; the associated

installation and operating instructions.

– When connecting to a ROTEX solar system; the associated

installation and operating instructions.

– If a ROTEX HP convector is connected; the associated instal-

lation and operating instructions.

– In the case of connection to a control component offered as

an accessory (room controller, mixer module etc.); the asso

ciated installation and operating instructions.

The guides are included in the scope of supply for the individual

units.

-

4

FA ROTEX HPSU compact (V5.2) • 07/2017

2Safety

2 x Safety

2.1 Warning signs and explanation of symbols

2.1.1 Meaning of the warnings

Warnings in this manual are classified according

into their severity and probability of occurrence.

DANGER!

Draws attention to imminent danger.

Disregarding this warning can lead to serious injury or death.

WARNING!

Indicates a potentially dangerous situation.

Disregarding this warning can result in

serious injury or death.

CAUTION!

Indicates a situation which may cause

possible damage.

Disregarding this warning can lead to

damage to property and the environment.

Health impairing or irritant materials

Prescribed temperature for continuous use

Danger of explosion

2.1.2 Validity

Some information in this manual has limited validity. The validity is highlighted by a symbol.

Exterior heat pump unit RRLQ

Heat pump indoor unit HPSU compact

HP convector

Only valid for ROTEX HPSU compact with

cooling function (see also section 2.3)

Pay attention to the stipulated tightening

torque (See chapter 10.3 "Tightening

torque")

Only applicable for the unpressurised

solar system (drain-back)

Only applicable for the pressurised solar

system.

2.1.3 Order number

This symbol identifies user tips and particularly useful information, but not

warnings or hazards.

Special warning signs

Some types of danger are represented by

special symbols:

Electric power

Risk of burning or scalding

Risk of environmental damage

Danger of local freezing up

Notes related to order numbers are identified by

the shopping cart symbol .

2.1.4 Handling instructions

● Instructions on actions are shown as a list.

Actions of which the sequential order must be

maintained are numbered.

Results of actions are identified with an

arrow.

Entry into a setting procedure

Exit from a setting procedure

FA ROTEX HPSU compact (V5.2) • 07/2017

5

2 x Safety

2.2 Avoid danger

The ROTEX HPSU compact is state-of-the-art

and is built to meet all recognised technical requirements. However, improper use may result

in serious physical injuries or death, as well as

property damage.

To prevent such risks, install and operate

ROTEX HPSU compact only:

– as stipulated and in perfect condition,

– with an awareness of the safety and hazards

involved.

This assumes knowledge and use of the contents of this manual, the relevant accident prevention regulations and the recognised safetyrelated and occupational medical rules.

WARNING!

This equipment must only be used by

children aged 8 and above and by

persons with restricted physical, sensory

or mental capabilities or with a lack of experience and knowledge, if they are

under supervision or if they have been

instructed in the safe use of the

equipment and understand the dangers

arising therefrom. Children must not

play with the equipment. Cleaning or

user maintenance must not be carried

out by children without supervision.

Internal unit External unit

HPSU compact

304 H/C DB-5 14 15 73

HPSU compact

304 H DB-5

HPSU compact

304 H/C Biv-5 14 15 77

HPSU compact

304 H Biv-5

HPSU compact

308 H/C DB-5

HPSU compact

308 H DB-5

HPSU compact

308 H/C Biv-5 14 15 78

HPSU compact

308 H Biv-5

HPSU compact

508 H/C DB-5 14 15 75

HPSU compact

508 H DB-5

HPSU compact

508 H/C Biv-5

HPSU compact

508 H Biv-5

HPSU compact

516 H/C DB-5 14 15 76

14 15 81

14 15 85

14 15 74

14 15 82

14 15 86

14 15 83

14 15 79

14 15 87

RRLQ004CAV3 14 51 51

RRLQ006CAV3

RRLQ008CAV3

RRLQ006CAV3

RRLQ008CAV3

14 51 52

14 51 53

14 51 52

14 51 53

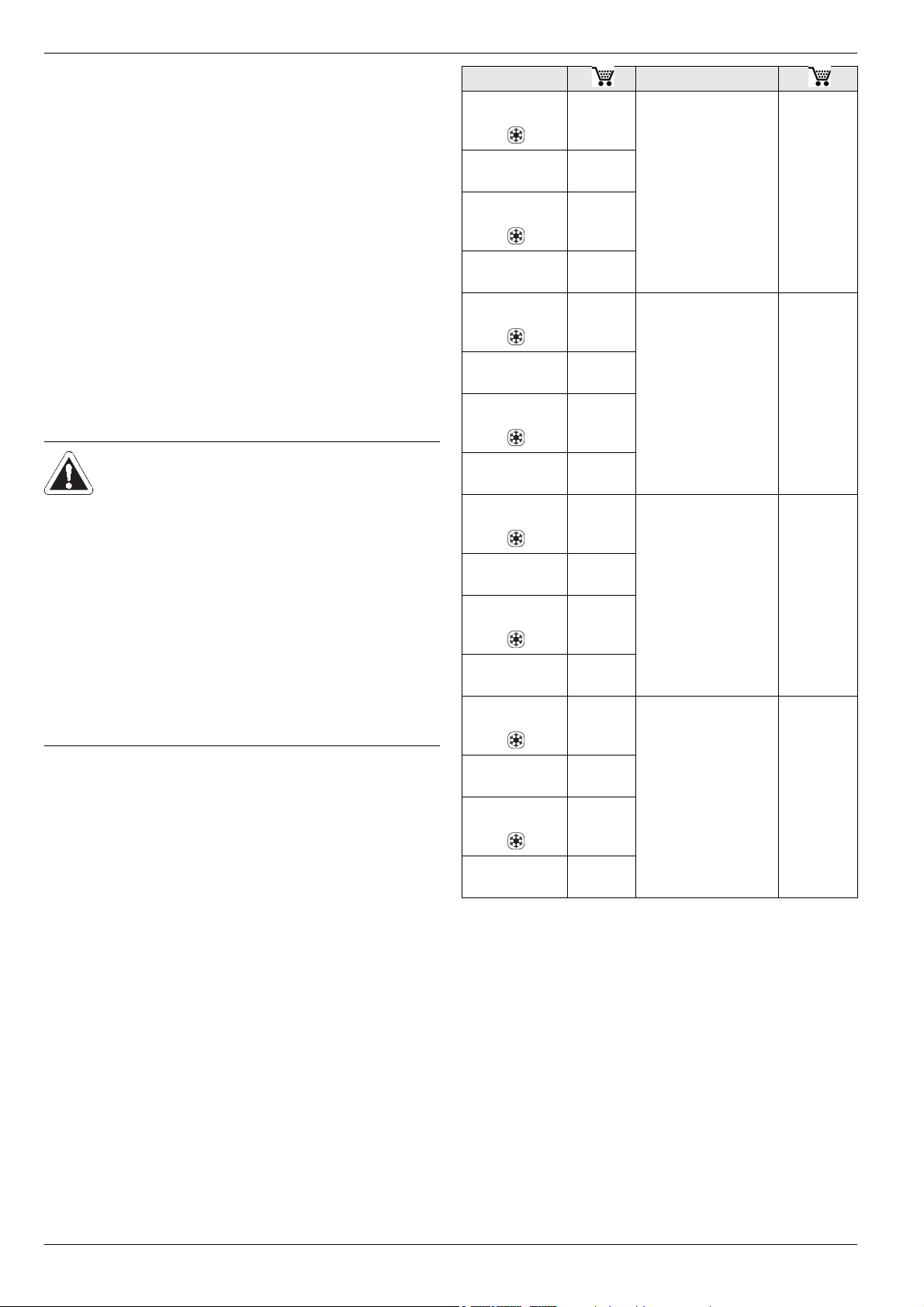

2.3 Proper use

The ROTEX HPSU compact may only be used

for preparation of warm water, as a room heating

system, and depending on its design, as a room

cooling system.

The ROTEX HPSU compact must be installed,

connected and operated only according to the indications in this manual.

Only use of a suitable external unit approved by

ROTEX is permitted. The following combinations

are permissible in this respect:

HPSU compact

516 H DB-5

HPSU compact

516 H/C Biv-5

HPSU compact

516 H Biv-5

BIV - Additional heat exxchanger for the bivalent connection

* Not all the equipment mentioned here is offered in some countries because of

the various different country-specific connection conditions.

Tab. 2-1 Permissible combinations of ROTEX HPSU compact internal

units and ROTEX heat pump external units

14 15 84

14 15 80

14 15 88

RRLQ011CA(V3/W1)*

RRLQ014CA(V3/W1)*

RRLQ016CA(V3/W1)*

14 51 45/48

14 51 46/49

14 51 47/50

Any other use outside the intended use is considered as improper. The operator alone shall

bear responsibility for any resulting damage.

Use as intended also involves compliance with

maintenance and inspection conditions. Spare

parts must at least satisfy the technical requirements defined by the manufacturer. This is the

case, for example, with original spare parts.

6

FA ROTEX HPSU compact (V5.2) • 07/2017

2 x Safety

2.4 Instructions for operating safety

2.4.1 Before working on the hydraulic system

● Work on the ROTEX HPSU compact (such as

setup, servicing, connection and initial startup) is only to be carried out by persons who

are authorised and who have successfully

completed qualifying technical or vocational

training and who have taken part in advanced

training sessions recognised by the appropriate responsible authorities for the specific

activity. This, in particular, includes heating

specialists and climate control technicians

who have experience, as a result of their

technical training and their knowledge of the

subject, of proper and appropriate installation

and maintenance of heating, climate control

and cooling installations and heat pumps.

● Switch off the external main switch before

starting any work on the ROTEX HPSU

compact and secure it against unintentional

switch-on.

● Seals must not be damaged or removed.

● Make sure that the safety valves comply with

the requirements of EN 12828 when

connecting on the heating side, and with the

requirements of EN 12897 when connecting

on the domestic water side.

● Only original ROTEX replacement parts may

be used.

● When working on the hydraulics, you must first

drain the water or release the pressure using

the internal KFE valve. Otherwise hot water

can jet out under pressure and result in injury.

2.4.3 Working on cooling systems (heat pump)

The ROTEX HPSU compact requires fluorinated

greenhouse gas for its function.

For work on stationary refrigeration

systems (heat pumps) and air conditioning systems, proof of expertise is required in the European Community according to the F-Gases Directive (EC)

No. 303/2008.

– up to 3 kg coolant fill quantity:

Expert certificate category II

– 3 kg coolant fill quantity or over:

Expert certificate category I

● Always wear safety goggles and protective

gloves.

● When working on the refrigerant circuit,

ensure that the workplace is well ventilated.

● Never carry out work on the coolant circuit in

closed rooms or work pits.

● Do not let refrigerant come into contact with

open fire, embers or hot objects.

● Never allow refrigerant to escape into the

atmosphere (high pressure at the point of the

leak).

● When removing the service pipes from the

filling connections, never hold the connections

in the direction of your body. Residual refrigerant could escape.

● Components and spare parts must at least

satisfy the technical requirements defined by

the manufacturer.

2.4.2 Electrical installation

● Electrical installation may be carried out only

by electrical engineers and in compliance with

the valid electro-technical guidelines as well as

the regulations of the relevant energy supply

company (EVU).

● Compare the mains voltage (~230 V, 50 Hz or

~400 V, 50 Hz) indicated on the type plate with

the supply voltage before connecting to the

mains.

● Before beginning work on live parts,

disconnect all of the systems circuits from the

power supply (switch off main switch,

disconnect fuse) and secure against unintentional restart.

● Equipment covers and service panels must be

replaced as soon as the work is completed.

FA ROTEX HPSU compact (V5.2) • 07/2017

2.4.4 Site of installation

For safe and fault-free operation, it is necessary

that the installation location of the ROTEX HPSU

compact fulfils certain criteria. Related information can be found in chapter 4.2.

Information on the installation site of other components can be found in the associated documentation supplied with them.

7

2 x Safety

2.4.5 Heating system and sanitary connection

● Create a heating system according to the

safety requirements of EN 12828.

● With sanitary connection, you must observe;

– EN 1717 - Protection of domestic water

from contamination in domestic water

installations and general requirements concerning safety equipment for the prevention

of domestic water contamination by backflow

– EN 806 - Technical regulations for domes-

tic water installations

– and, in addition, the country-specific legal

regulations.

The connection of a solar installation, an electric

heating rod or an alternative heat generator may

cause the storage temperature to exceed 60 °C.

● For this reason you should fit scalding

protection (e.g. VTA32 15 60 15 + Screw

connection set 1" 15 60 16).

If the ROTEX HPSU compact is connected to a

heating system with steel pipes, radiators or nondiffusion-proof floor heating pipes, slurry and

swarf could enter the hot water storage tank and

cause blockages, local overheating or corrosion.

● To prevent possible damage, fit a dirt filter or

sludge separator into the heating return flow

of the system.

– SAS 1 ( 15 60 21)

● The dirt filter must be cleaned at regular

intervals.

2.4.6 Requirements for the heating water

Observe the current technological regulations to

prevent corrosion products and deposits.

Minimum requirements regarding the quality

of filling and supplementary water:

– Water hardness (calcium and magnesium,

calculated as calcium carbonate):

≤ 3 mmol/l

– Conductivity: ≤ 1500 (ideal ≤ 100) μS/cm

–Chloride: ≤ 250 mg/l

– Sulphate: ≤ 250 mg/l

– pH value (heating water): 6,5 - 8,5

Using filling water and top-up water which does

not meet the stated quality requirements can

cause a considerably reduced service life of the

equipment. The responsibility for this is entirely

that of the operator.

2.4.7 Operation

The ROTEX HPSU compact:

● Do not operate until all installation and

connection work is completed.

● Only operate with a completely full storage

tank (Level indicator) and heating circuit.

● Operate at a maximum pressure of 3 bar.

● Only connect with a pressure reducer on the

external water supply (supply line).

● Only operate the with the specified quantity of

refrigerant and the type of refrigerant

specified.

● Only operate if the protective cover is

installed.

The prescribed maintenance intervals must

be maintained and the inspection work must

be carried out.

8

FA ROTEX HPSU compact (V5.2) • 07/2017

2.4.8 Instructing the user/owner

● Before you hand over the ROTEX HPSU

compact, explain to the user/owner how to

operate and check the system.

● Hand over the technical documentation (this

document and all supporting documents) to

the user and advise him that these documents

must be made available at all times and be

stored in the immediate vicinity of the unit.

● Make a record of the handover by filling out

and signing the installation and instruction

forms jointly with the user/owner.

2 x Safety

FA ROTEX HPSU compact (V5.2) • 07/2017

9

3 x Product description

3 Product description

3.1 Design and components

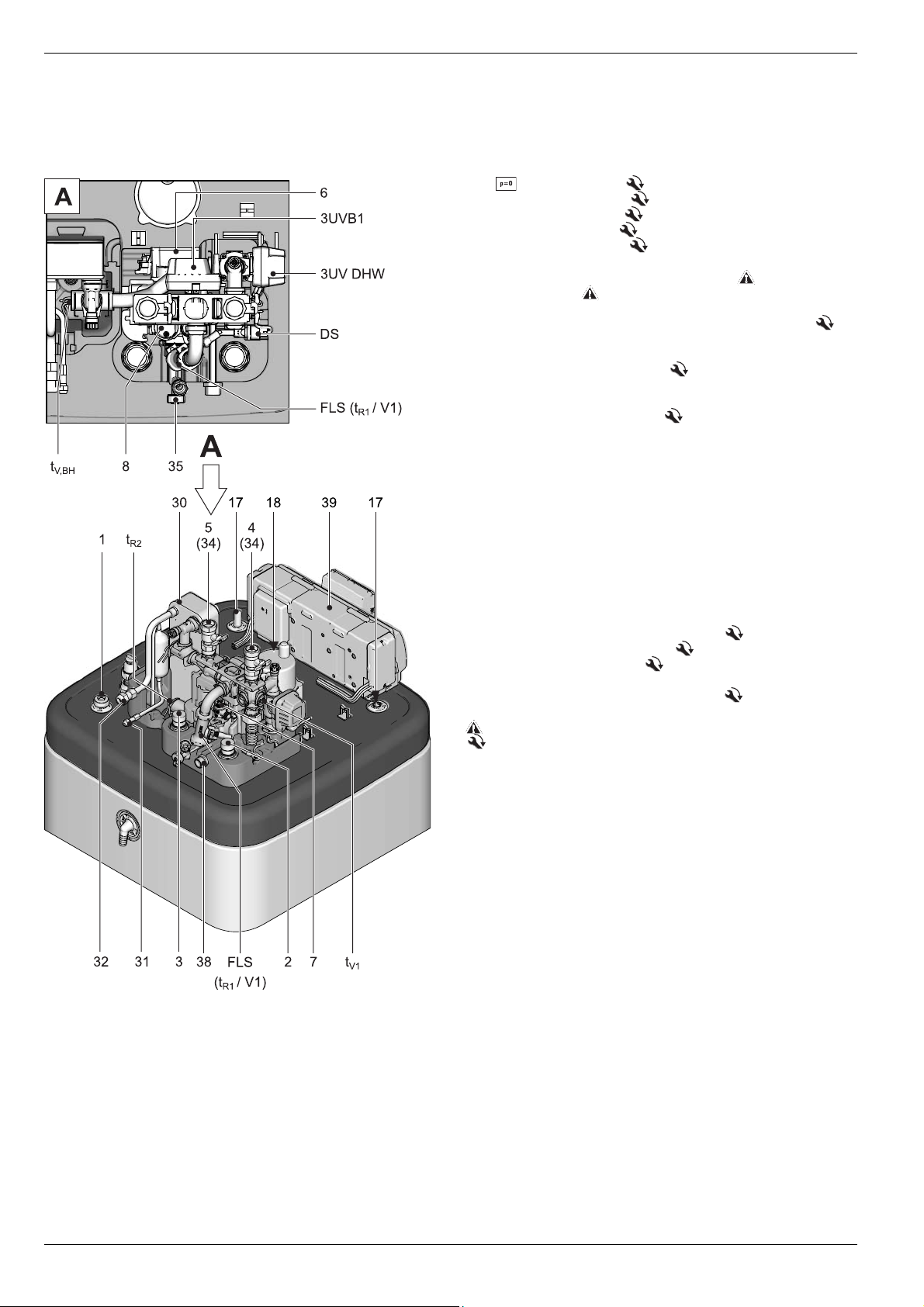

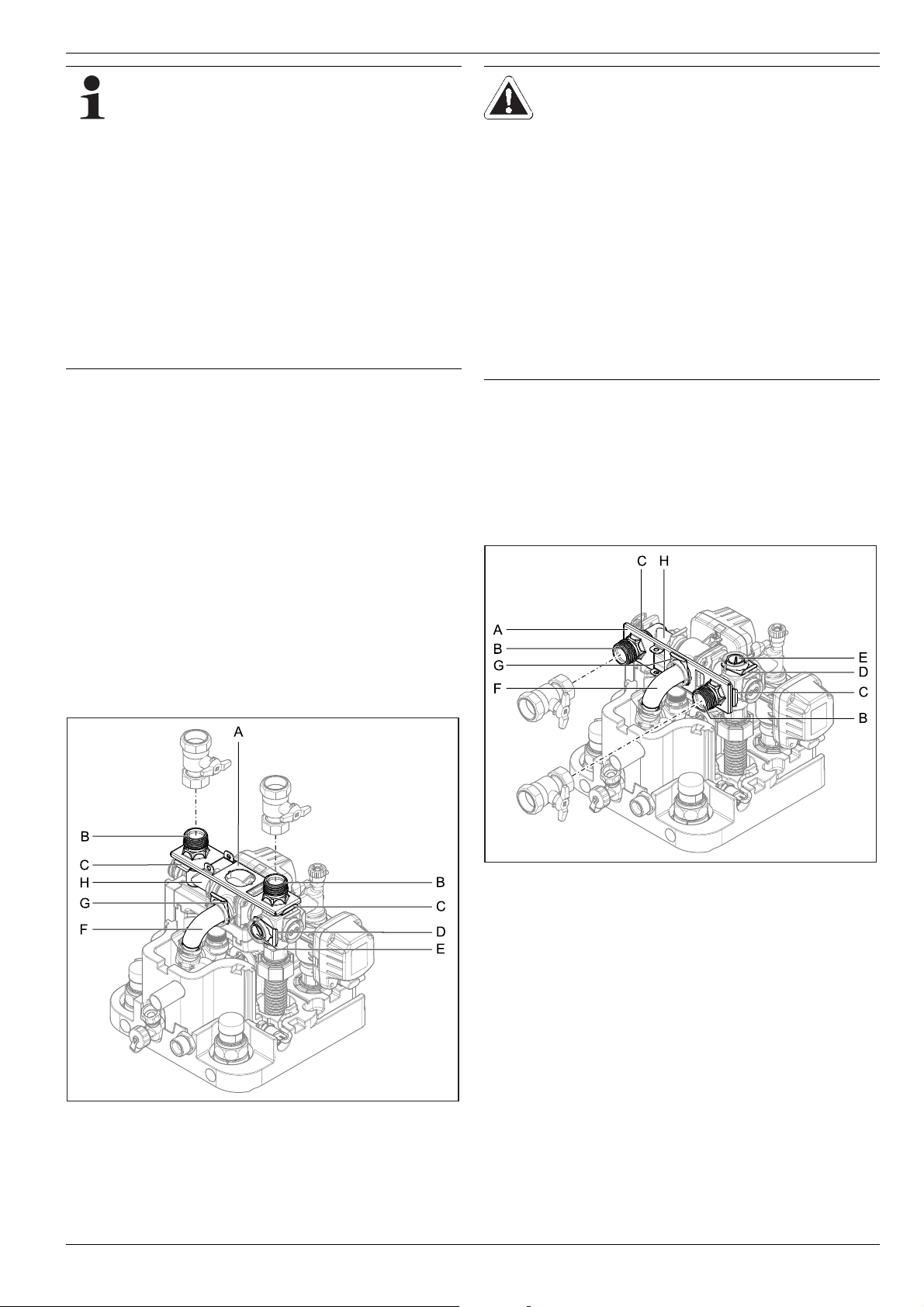

3.1.1 Top of unit

1 Solar - flow (1" IG)

2 Cold water flow (1" AG)

3 Hot water flow (1" AG)

4 Heating flow (1" AG)*

5 Heating return (1" AG)*

6 Circulation pump

7 Safety-pressure relief valve (heating circuit)

8 Automatic vent

17 Fill level indicator (tank water)

18 Connection for electrical Backup Heater BUxx (R 1½" IG)

(Accessory)

30 Plate heat exchanger (PWT)

31 Connection refrigerant fluid line

ROTEX HPSU compact 30x/508: Cu Ø 6.4 mm (1/4"),

ROTEX HPSU compact 516: Cu Ø 9.5 mm (3/8")

32 Connection to coolant gas line

Cu Ø 15,9 mm (5/8")

34 Ball cock (heating circuit)*

35 Combined filling and draining valve (heating circuit)

37 Storage tank temperature sensor t

38 Connection diaphragm expansion vessel

39 Controller housing with elect. terminal strip

DHW1

and t

DHW2

3UVB1

3-way diverter valve (internal heat generator circuit)

3UV DHW

DS Pressure sensor

FLS (t

tR2Return flow temperature sensor

t

V1

t

V, BH

AG Male thread

IG Female thread

* Ball cock (1" IG) is supplied with the equipment

Fig. 3-1 Structure and constituents ROTEX HPSU compact DB

3-way diverter valve (hot water / heating)

/ V1)

R1

Return flow temperature and flow sensor

Inflow temperature sensor

Flow temperature sensor Backup Heater

Safety devices

Observe tightening torque!

(top side of device)

10

FA ROTEX HPSU compact (V5.2) • 07/2017

3 x Product description

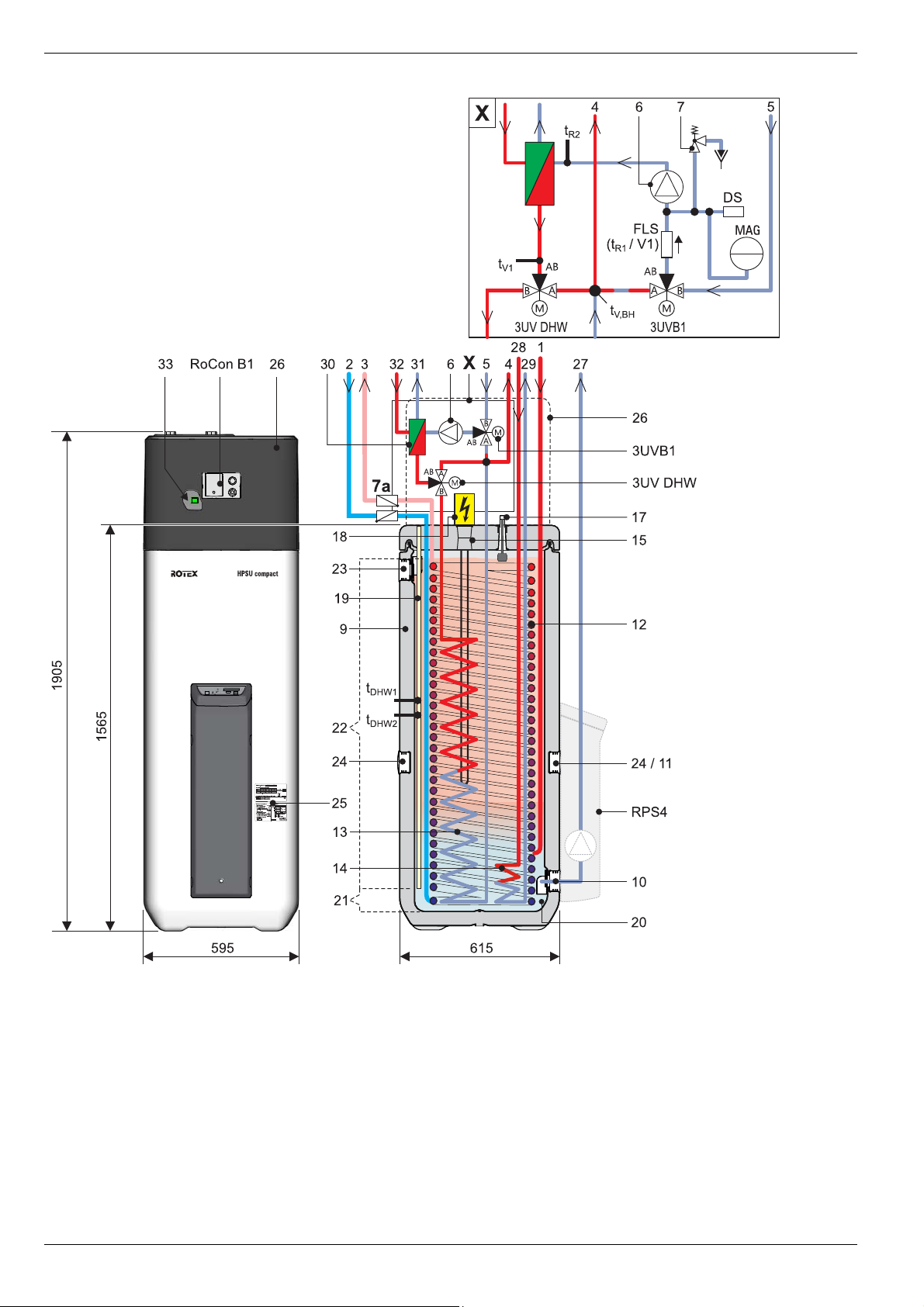

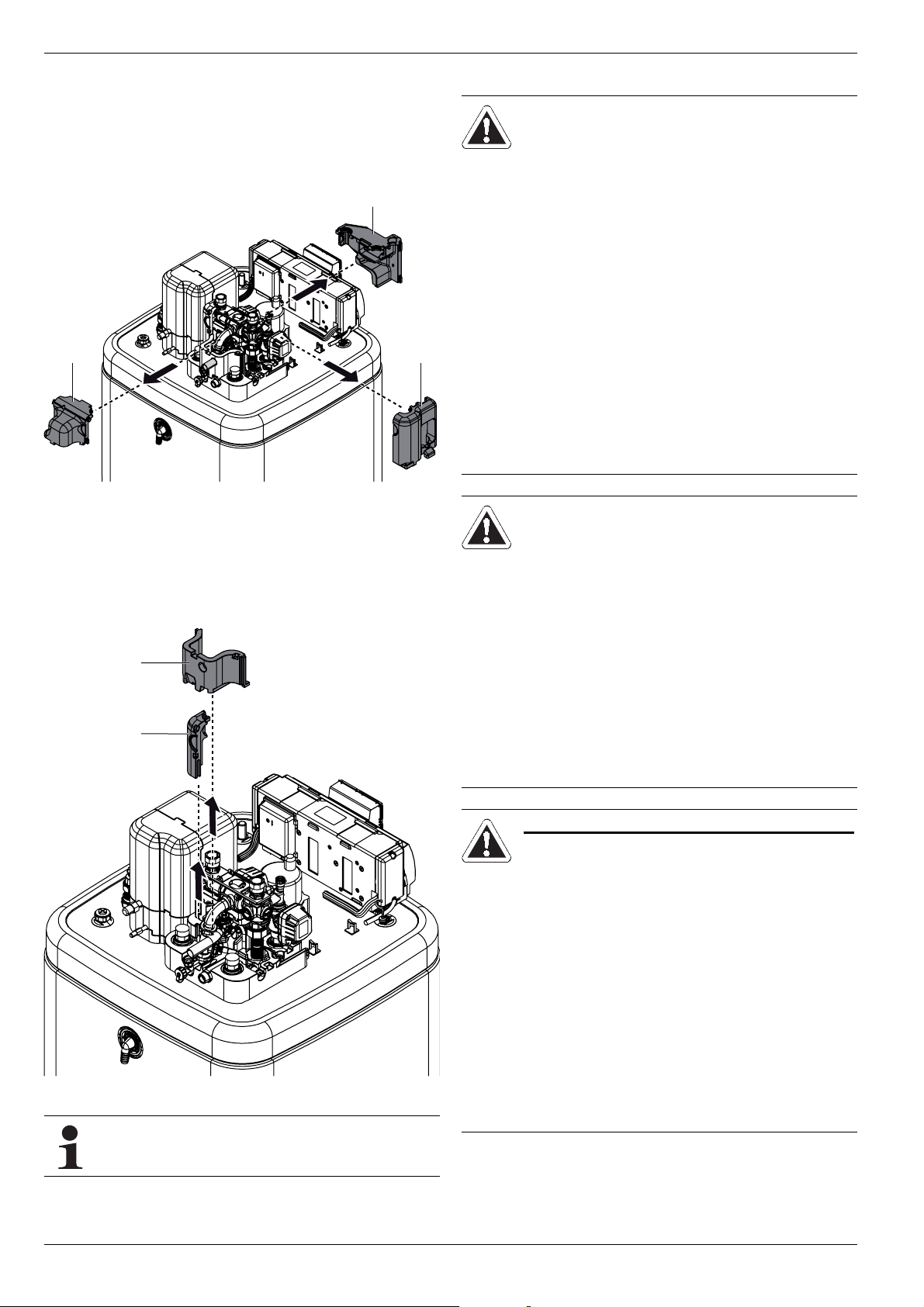

3.1.2 Equipment external and internal structure ROTEX HPSU compact 304/308 DB

Fig. 3-2 Structure and constituents ROTEX HPSU compact 304/308 DB (External appearance and internal structure)

Designations of key see tab. 3-1

FA ROTEX HPSU compact (V5.2) • 07/2017

11

3 x Product description

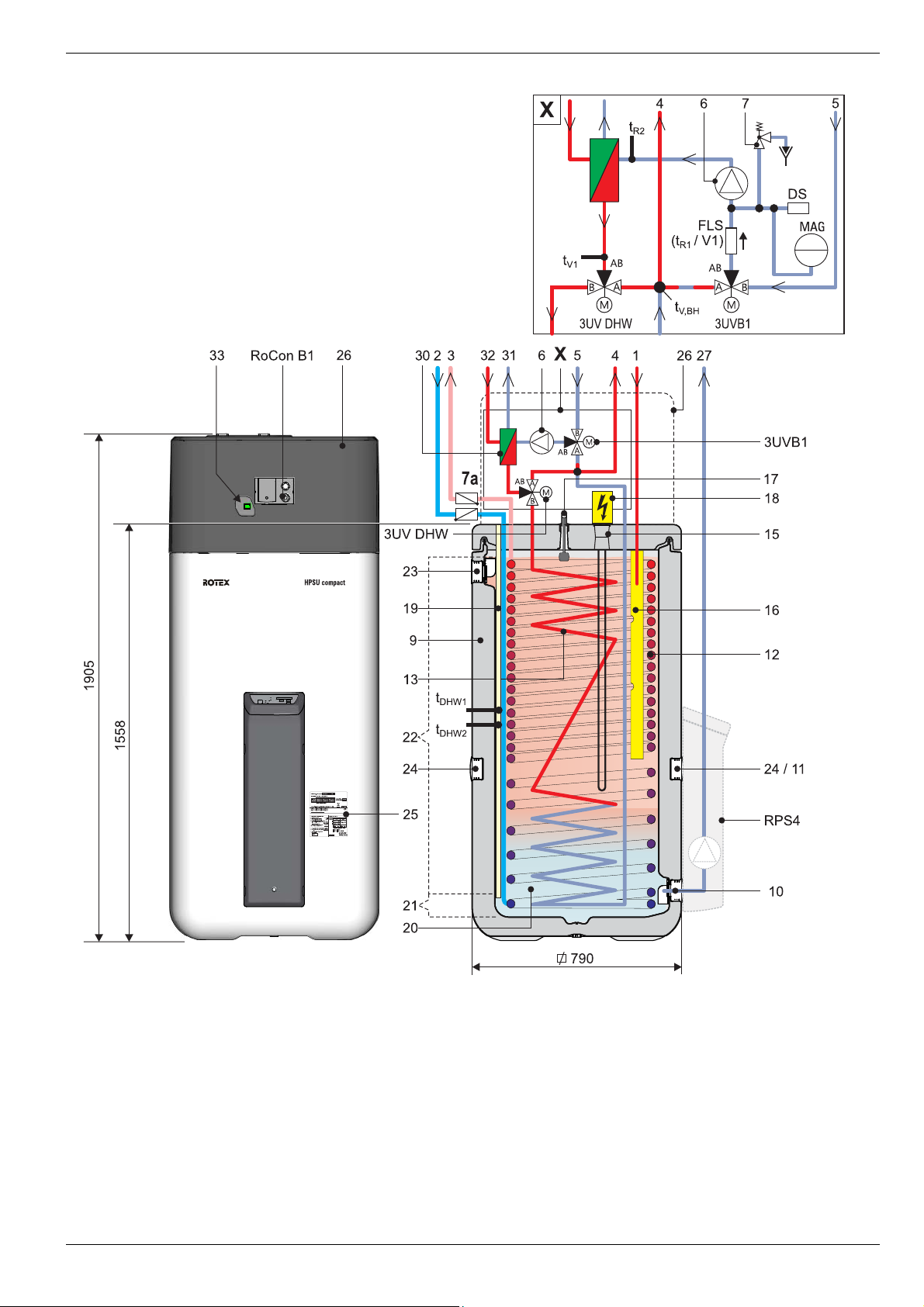

3.1.3 Equipment external and internal structure ROTEX HPSU compact 304/308 BIV

Fig. 3-3 Structure and constituents ROTEX HPSU compact 304/308 BIV (External appearance and internal structure)

Designations of key see tab. 3-1

12

FA ROTEX HPSU compact (V5.2) • 07/2017

3 x Product description

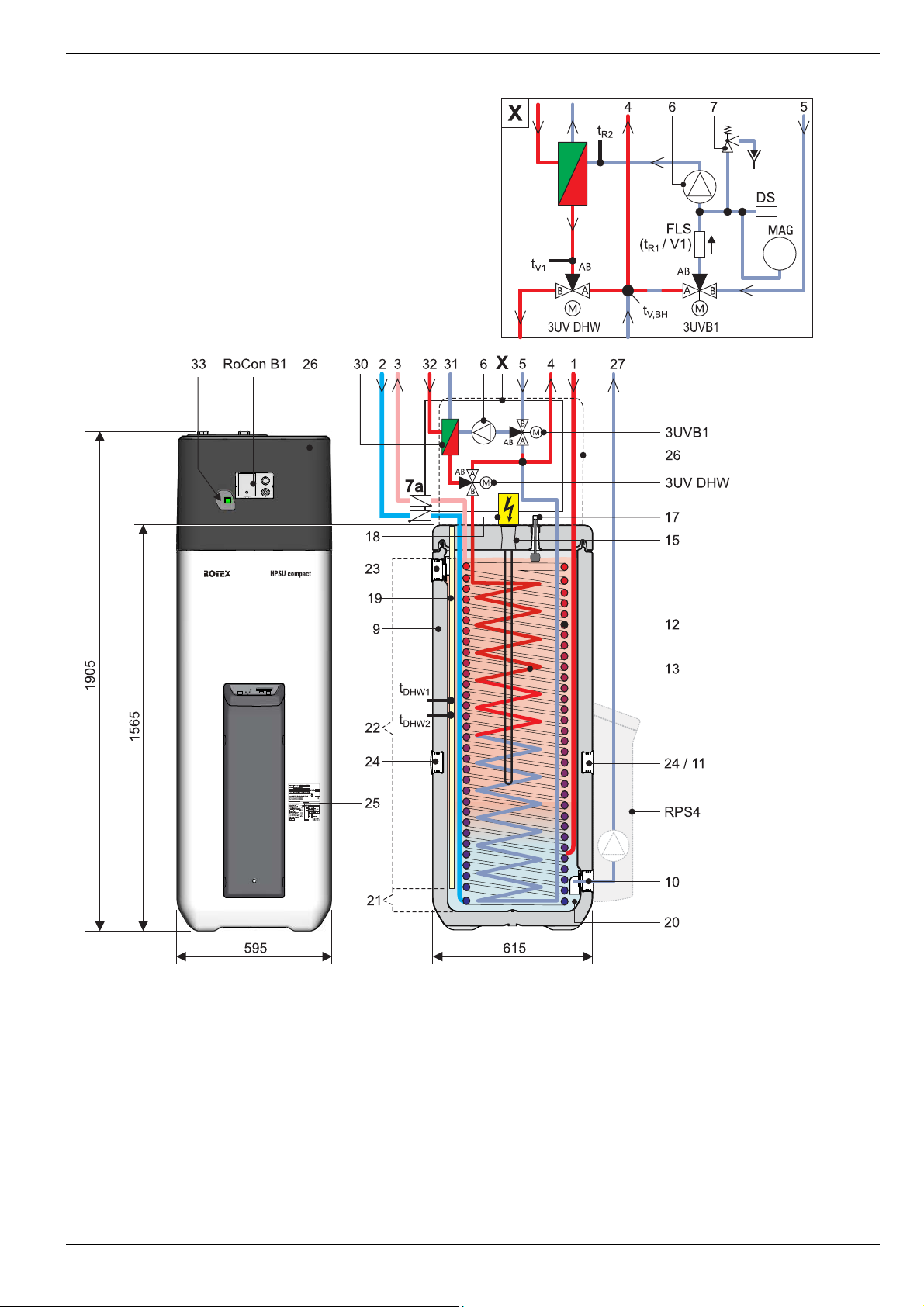

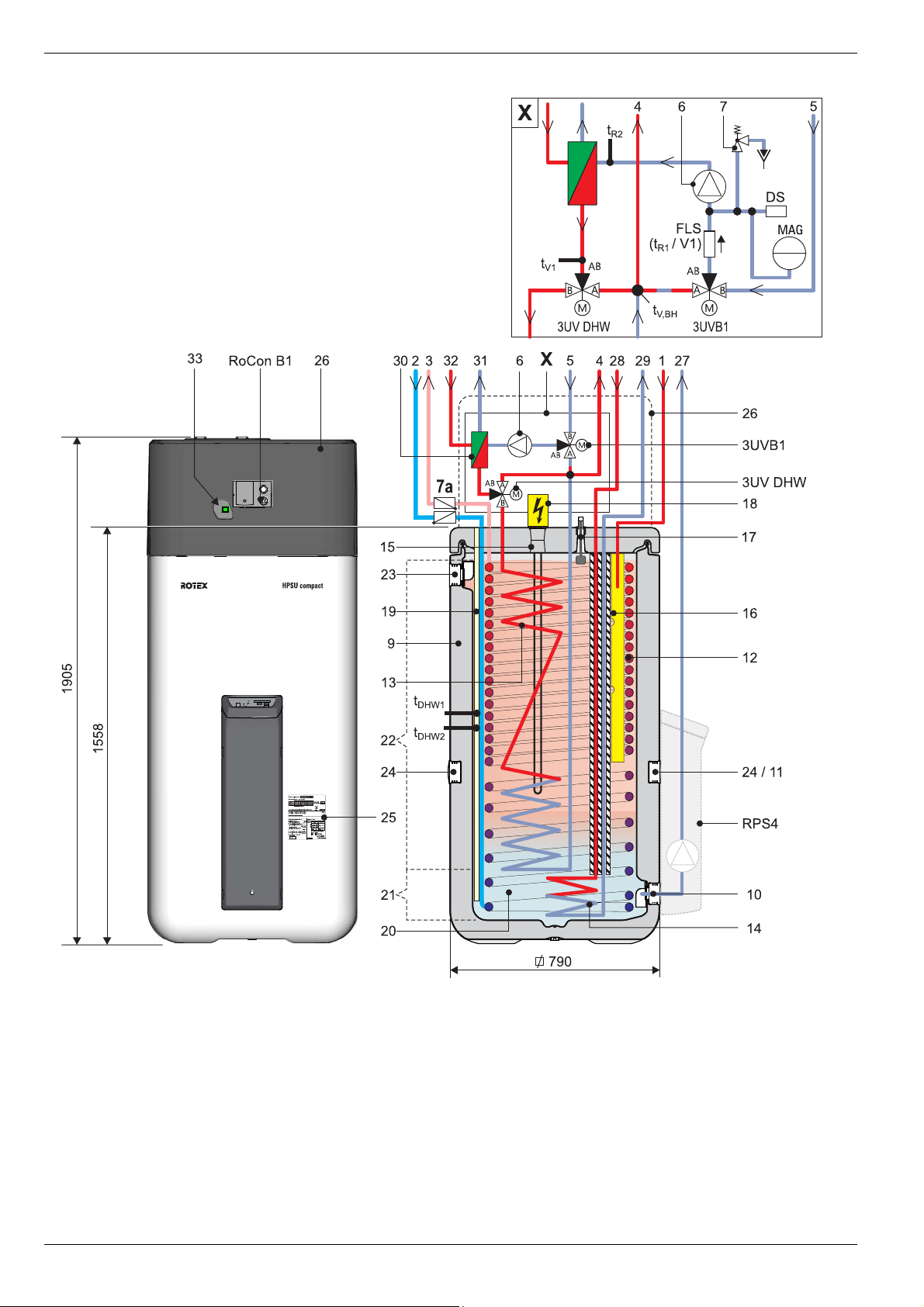

3.1.4 Equipment external and internal structure ROTEX HPSU compact 508/516 DB

Fig. 3-4 Structure and constituents ROTEX HPSU compact 508/516 DB (External appearance and internal structure)

Designations of key see tab. 3-1

FA ROTEX HPSU compact (V5.2) • 07/2017

13

3 x Product description

3.1.5 Equipment external and internal structure ROTEX HPSU compact 508/516 BIV

Fig. 3-5 Structure and constituents ROTEX HPSU compact 508/516 BIV (External appearance and internal structure)

14

Designations of key see tab. 3-1

FA ROTEX HPSU compact (V5.2) • 07/2017

3 x Product description

1 Solar - flow or connection for addition-

al heat source(1" IG)

2 Cold water flow (1" AG)

3 Hot water flow (1" AG)

4 Heating flow (1" AG)*

5 Heating return (1" AG)*

6 Circulation pump

7a Recommended accessories:

Non-return valves (2 pcs.), 16 50 70

9 Storage tank (double walled jacket made

of polypropylene with PUR hard foam heat

insulation)

10 Filling and drainage connection or

Solar - return flow connection

11 Mount for solar controller or handle

12 Heat exchanger (stainless steel) for drink-

ing water heating

13 Heat exchanger (stainless steel) for stor-

age tank charging or heating support

14 Heat exchanger (stainless steel) for pres-

surised solar storage tank charging

15 Connection for optional electrical Backup

Heater (R 1½" IG)

16 Solar inflow layering pipe

17 Fill level indicator (tank water)

18 Optional: Electrical backup heater

(BUxx)

19 Submersible sensor sleeve for storage

tank temperature sensor t

20 Unpressurised storage tank water

21 Solar zone

22 Hot water zone

23 Safety overflow connection

24 Mount for handle

25 Type plate

26 Protective cover

27 Solar - return

28 Solar - feed (3/4" IG + 1" AG)

(only type … Biv)

29 Solar - return flow (3/4" IG + 1" AG)

(only type … Biv)

30 Panel heat exchanger

31 Fluid line for connection of refrigerant

fluid

ROTEX HPSU compact 30x/508:

Cu Ø 6.4 mm (1/4"),

ROTEX HPSU compact 516:

Cu Ø 9.5 mm (3/8")

32 Connection to coolant gas line

Cu Ø 15,9 mm (5/8")

3UVB1

3-way diverter valve (internal heat genera-

tor circuit)

3UV DHW

3 way diverter valve (hot water/heating)

DHW1

and t

DHW2

DS Pressure sensor

FLS (t

t

tR2Return flow temperature sensor

tV1Inflow temperature sensor

t

RoCon B1

RPS4

AG Male thread

IG Female thread

* Ball cock (1" IG) is supplied with the equip-

/ V1)

R1

Return flow temperature and flow sensor

, t

DHW1

DHW2

Storage tank temperature sensor

V, BH

Flow temperature sensor Backup

Heater

Operating section ROTEX HPSU compact

control unit

Optional: ROTEX Solar regulation

and pump unit

Safety devices

Observe tightening torque!

ment

Tab. 3-1 Legend from fig. 3-2 to fig. 3-5

FA ROTEX HPSU compact (V5.2) • 07/2017

15

4 x Set-up and installation

4 Set-up and installation

WARNING

Cooling systems (heating pumps), climate control systems and heating devices that have

been set up and installed incorrectly can both endanger life and health of people and be impaired in their function.

● Work on the ROTEX HPSU compact (such as setup, servicing, connection and initial

start-up) is only to be carried out by persons who are authorised and who have successfully completed qualifying technical or vocational training and who have taken part in

advanced training sessions recognised by the relevant responsible authorities for the

specific activity. These include in particular certified heating engineers, qualified

electricians and HVAC specialists, who because of their professional training and

expert knowledge, have experience in the professional installation and maintenance of

heating, cooling and air conditioning systems and heat pumps.

16

FA ROTEX HPSU compact (V5.2) • 07/2017

4.1 Dimensions and connections

4.1.1 ROTEX HPSU compact 304/308

4 x Set-up and installation

1 Solar - feed

2 Cold water

3 Hot water

4 Heating feed

5 Heating return flow

6 Connection coolant gas line

Fig. 4-1 Connections and dimensions ROTEX HPSU compact 304/308 (in general)

7 Connection coolant fluid line

8 Solar - feed (only type …Biv)

9 Solar - return flow (only type …Biv)

A Front

BBack

FA ROTEX HPSU compact (V5.2) • 07/2017

17

4 x Set-up and installation

4.1.2 ROTEX HPSU compact 508/516

1 Solar - feed

2Cold water

3 Hot water

4 Heating feed

5 Heating return flow

6 Connection coolant gas line

Fig. 4-2 Connections and dimensions ROTEX HPSU compact 508/516 (in general)

7 Connection coolant fluid line

8 Solar - feed (only type …Biv)

9 Solar - return flow (only type …Biv)

A Front

BBack

18

FA ROTEX HPSU compact (V5.2) • 07/2017

4 x Set-up and installation

4.1.3 Scope of delivery

– ROTEX HPSU compact

– Bag of accessories (see fig. 4-3)

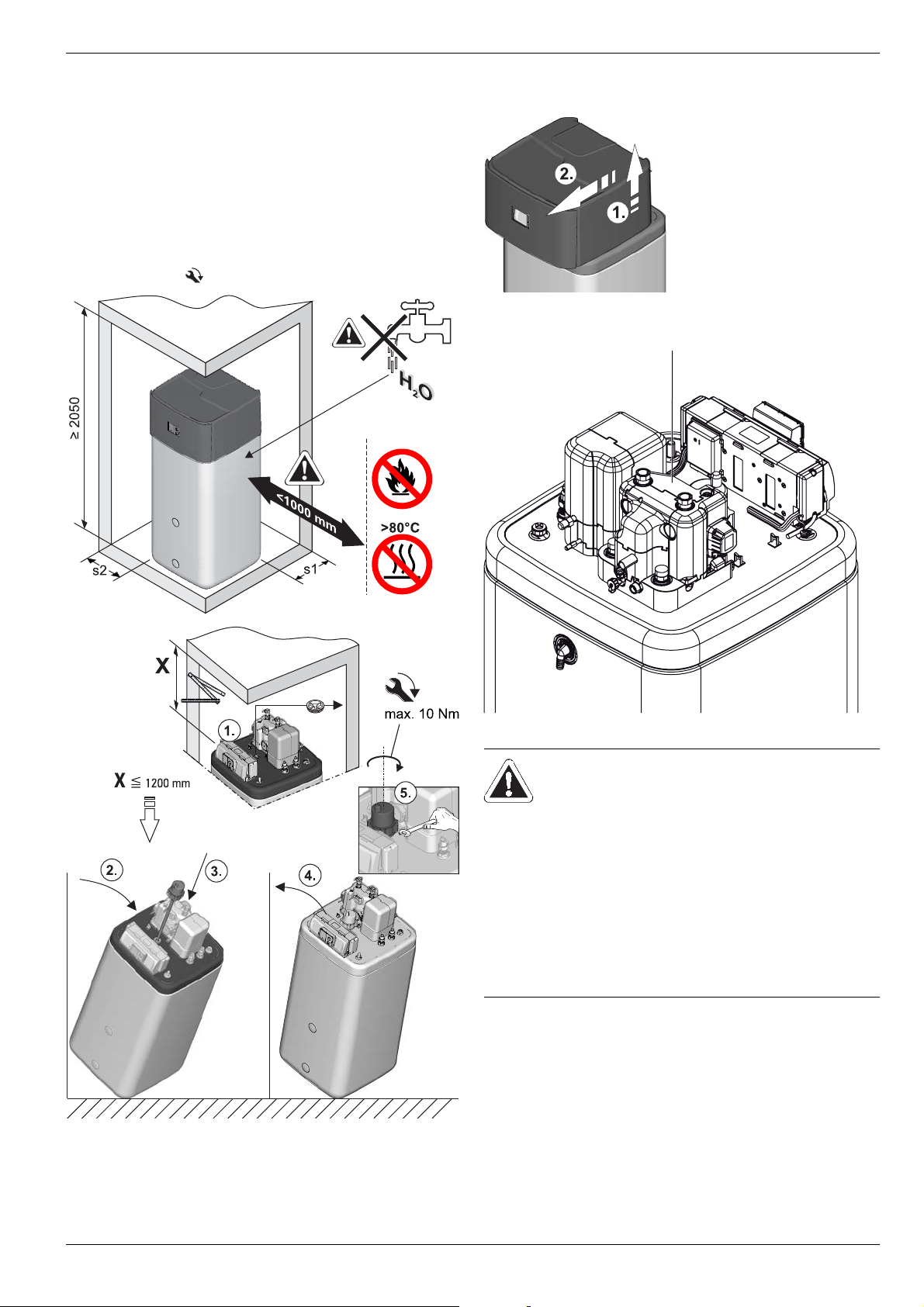

4.2 Set-up

CAUTION!

● Only erect the ROTEX HPSU

compact when a sufficient ground

load-bearing capacity, of

1050 kg/m² plus safety margin, has

been assured. The ground must be

flat and level.

● Outdoor installation is not permitted.

● Erection in explosion-risk environ-

ments is not permitted.

● The electronic control system must

not be subjected to atmospheric

factors under any circumstances.

● The storage tank must not be

exposed to continuous direct solar

radiation, since the UV radiation and

weather-influences will damage the

plastic.

● The ROTEX HPSU compact must be

installed in a manner protected from

frost.

● Make sure that the supply company

does not provide corrosive

domestic water.

– Suitable water treatment may be

required.

A Handles (only required for

transport)

B Cover screen

C Hose connection piece for

safety overflow

D Spanner

Fig. 4-3 Contents of bag of accessories

EBall cock

F Flat seal

GO-ring

H Tie wraps

I Plug bracket

J Venting tube

WARNING!

The plastic wall of the storage tank on

the ROTEX HPSU compact may melt

due to the effects of external heat

(>80 °C) and, in the extreme case, can

catch fire.

● Erect the ROTEX HPSU compact

only at a minimum distance of 1 m to

other heat sources (>80 °C) (e.g.

electric heater, gas heater, chimney)

and flammable materials.

FA ROTEX HPSU compact (V5.2) • 07/2017

19

4 x Set-up and installation

CAUTION!

ROTEX HPSU compact is not erected

adequately lower the flat solar panels

(the top edge of the of the storage tank is

higher than the bottom edge of the solar

panels), the unpressurised solar system

in the outdoor area will be unable to

drain completely.

● Erect the ROTEX HPSU compact with

a DrainBack solar connection at a

sufficient depth to the flat solar panels

(observe the minimum gradient in the

solar connecting lines).

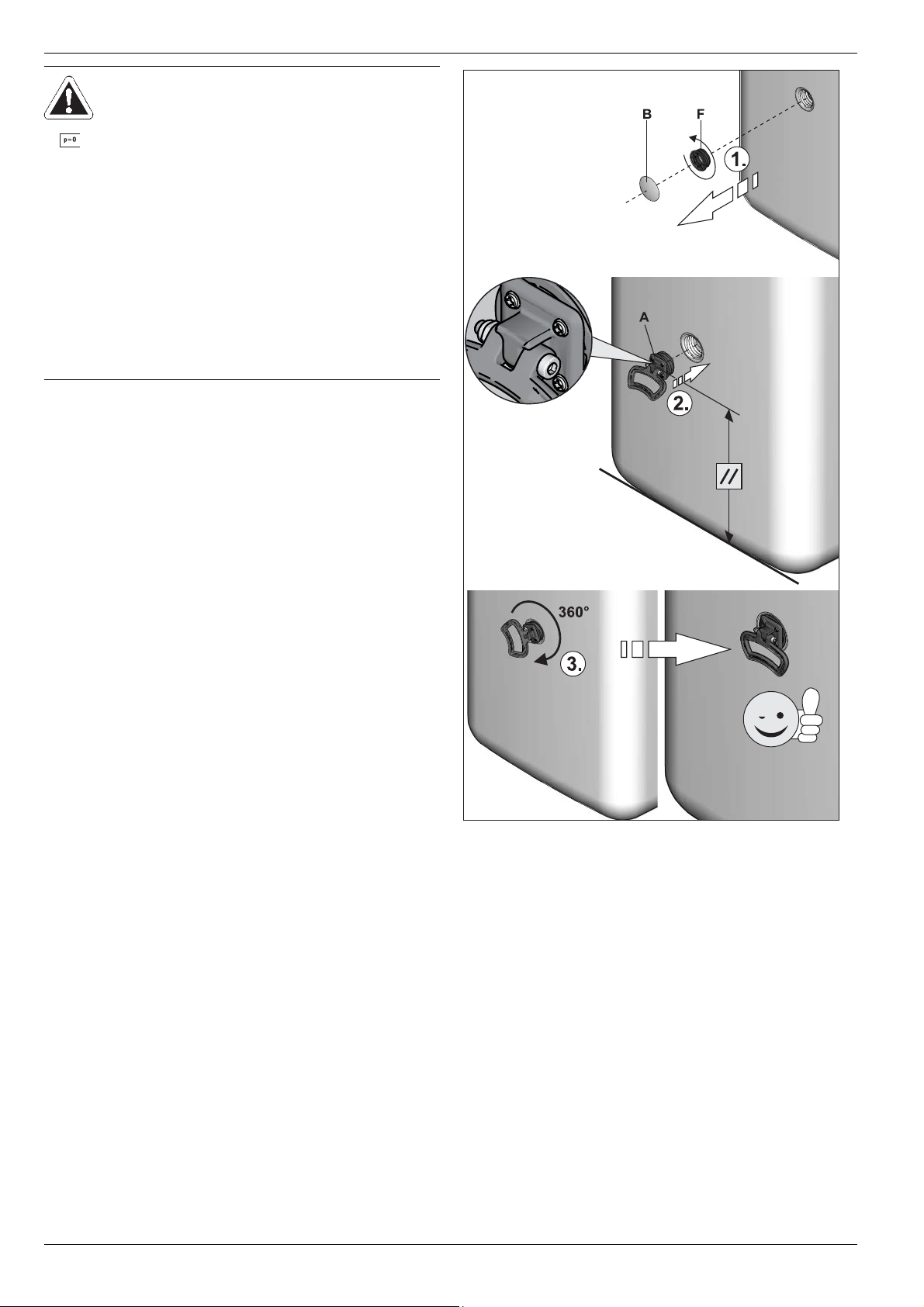

● Remove packing and dispose of it in an environment-friendly

manner.

● Remove the cover plates on the storage tank (fig. 4-4, item B)

and unscrew the threaded pieces (fig. 4-4, item F) from the

apertures on which the handles are to be mounted (fig. 3-2 to

fig. 3-5, item 24).

● Screw handles (fig. 4-4, item A) into the threaded holes that

are now free.

20

A Handle

B Cover screen

Fig. 4-4 Attach handles

FA ROTEX HPSU compact (V5.2) • 07/2017

F Threaded piece

4 x Set-up and installation

A

● Install the ROTEX HPSU compact at the installation site.

– Recommended clearances (fig. 4-5):

To the wall: (s1) ≥ 100 mm, (s2) ≥ 500 mm.

From the ceiling (X): ≥ 1200 mm, minimum 480 mm.

– Carefully transport the ROTEX HPSU compact, use the

handles.

– When setting up the unit in a cabinet, behind panels or in

other restricted conditions, sufficient ventilation (e.g.,

using ventilation gratings) must be ensured.

● If necessary, install the optional Backup Heater (BUxx) in the

ROTEX HPSU compact (

Observe the assembly and operating manual supplied with

the accessory ( for tightening torque see chapter 10.3).

fig. 4-5).

4.3 Remove cover hood and heat insulation

● Lift the cover hood at the back and remove to the front.

Fig. 4-6 Removing the protective cover

Fig. 4-5 Layout (shown on ROTEX HPSU compact 508/516 with incor-

poration of the optional Backup Heater)

Fig. 4-7 ROTEX HPSU compact without cover hood

CAUTION!

The thermal insulation (fig. 4-7, item A)

consists of pressure sensitive shaped

EPP components that can easily be

damaged by inappropriate handling.

● Carry out removal of the thermal

insulation only in the sequence and in

the directions quoted below.

● Do not use force.

● Do not use tools.

FA ROTEX HPSU compact (V5.2) • 07/2017

21

4 x Set-up and installation

A

B

C

A

B

● Remove the top thermal insulation in the following order:

– Pull away the side insulation element (fig. 4-8, item A)

horizontally.

– Pull away the rear insulation element (fig. 4-8, item B) hor-

izontally.

– Pull away the front insulation element (fig. 4-8, item C)

horizontally.

Fig. 4-8 Removing top thermal insulation

● If required: Remove the bottom thermal insulation in the

following order:

– Pull away the side insulation element (fig. 4-9, item A) ver-

tically.

– Pull away the rear insulation element (fig. 4-9, item B) ver-

tically.

4.4 Water connection

CAUTION!

If the ROTEX HPSU compact is connected to a heating system with steel

pipes, radiators or non-diffusion-proof

floor heating pipes, slurry and swarf

could enter the hot water storage tank

and cause blockages, local over-

heating or corrosion.

● Flush the feed pipes before filling the

heat exchanger.

● Rinse out the heat distribution

network (in the existing heating

system).

● Install the dirt filter or sludge

separator into the heating return flow

(see chapter 2.4.5).

CAUTION!

If the ROTEX HPSU compact is connected to a cold water line, where steel

pipes are used, chips can enter the

special steel corrugated pipe heat exchanger and remain there. This can lead

to contact corrosion damage and subsequently to leakage.

Fig. 4-9 Removing bottom thermal insulation

Installing the thermal insulation is carried out in the

reverse order.

● Flush the feed pipes before filling the

heat exchanger.

● Install contamination filter in the cold

water feed (see chapter 2.4.5).

ONLY ROTEX HPSU COMPACT …BIV

CAUTION!

If the heat exchanger for charging the

pressurised solar system (fig. 4-1 /

fig. 4-2, item 8+9) has an external

heating unit (e.g. wood-burning boiler)

connected to it, an excessive flow temperature at these connections can

damage or destroy the ROTEX HPSU

compact.

● The feed flow temperature of the

external heater should be limited to

max. 95 °C.

22

FA ROTEX HPSU compact (V5.2) • 07/2017

4 x Set-up and installation

In accordance with EN 12828 you must install a safety

valve at or in the immediate vicinity of the heat

exchanger, with which you can limit the maximum per

missible operating pressure in the heating system.

There should be no hydraulic blocking elements

between the heat generator and the safety valve.

Any steam or heating water which may escape must be

diverted by a suitable blow-off line with constant gradi

ent in a frost-protected, safe and observable manner.

A diaphragm expansion vessel of adequate dimensions

and pre-set for the heating system must be connected

to the ROTEX HPSU compact. There should be no

hydraulic blocking elements between the heat genera

tor and the diaphragm expansion vessel.

ROTEX recommends integrating a mechanical

manometer for the filling of the heating system.

● For drinking water lines, comply with the EN 806 and

DIN 1988 stipulations.

● To avoid a circulation line, install ROTEX HPSU compact

close to the draw-off location. If a circulation line is absolutely

essential, it must be installed in accordance with the

schematics in

chapter 9 "Hydraulic system connection".

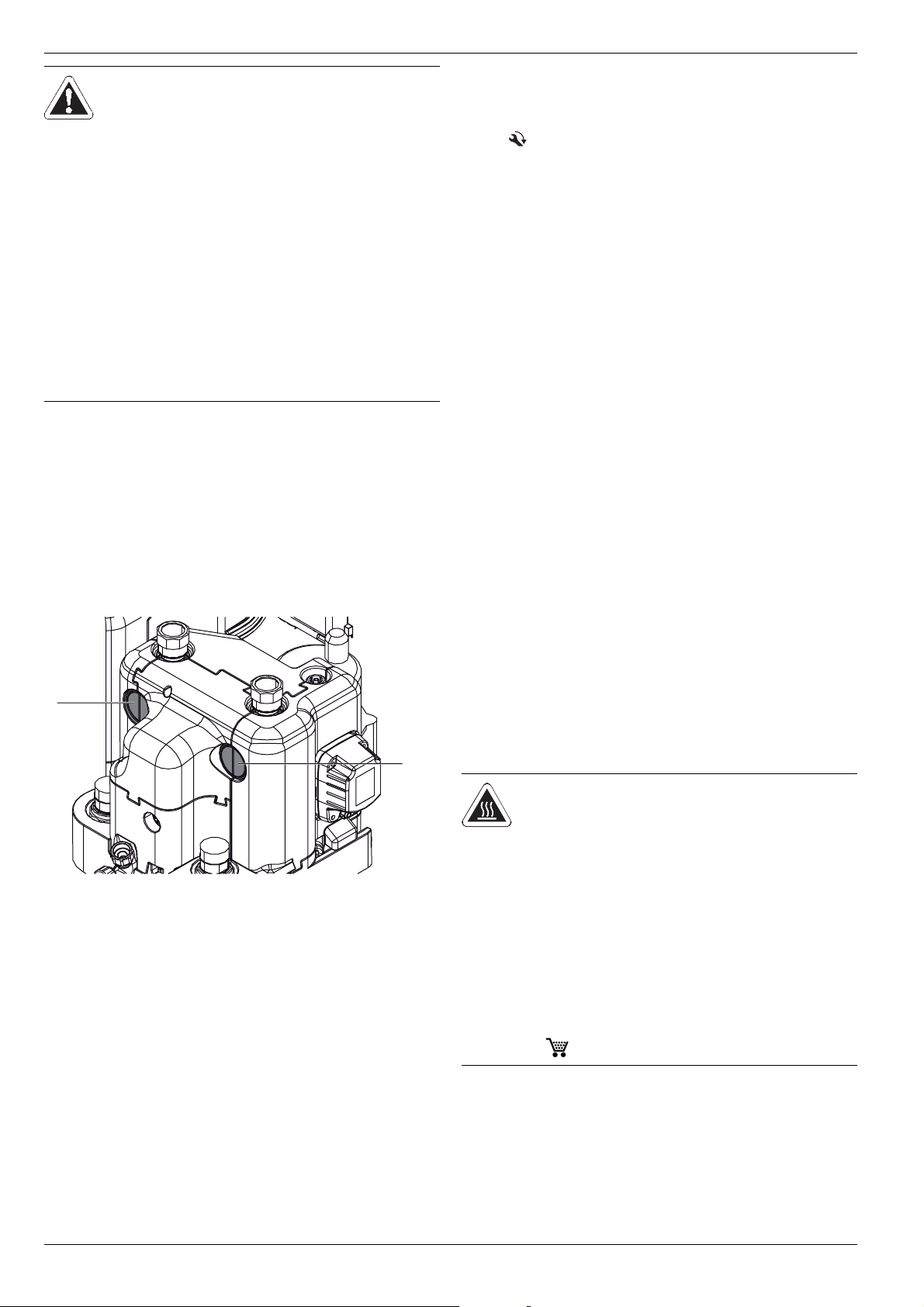

4.4.1 Aligning the connections of the heating feed

and return flow

CAUTION!

-

When working on the hydraulics you

must take care of the mounting position

of the O-rings to prevent damage to the

O-rings and consequent leaks.

-

● Always place O-rings on the part to be

inserted after a plug connection has

been removed or before it is installed.

● Connection of heating lines by plug

-

connection must be without tension.

Establish suitable tension relief particularly for connection with flexible lines

(not breathable!).

● Remove retainer plate (fig. 4-10, item A).

● Pull off the plug bracket on the closing plug (fig. 4-10, item D).

● Pull out the closing plug (fig. 4-10, item E).

● Rotate the angular piece (fig. 4-10, item H) by 90° to the back.

● Pull off the plug bracket on the elbow (fig. 4-10, item G).

● Pull the elbow (fig. 4-10, item F) carefully to the rear out of its

horizontal mount so that the retainer plate (fig. 4-11, item A)

can be inserted in the gap vertically.

The connections for the heating feed and return flow can be directed out of the unit upwards or downwards in order to adapt to

the on-site conditions in the most optimum manner.

The unit is delivered with the connections exiting upwards as

standard. In order to direct the connections out from the back of

the unit you must carry out the following conversion steps:

● Remove the cover hood and the upper thermal insulation

(see chapter 4.3).

Fig. 4-11 Heating feed and return flow connections aligned to the rear

● Slide the retainer plate between the elbow and its horizontal

mount and insert the elbow (fig. 4-11, item F) back in its

mount through the central hole in the retainer plate.

Fig. 4-10 Heating feed and return flow connections aligned upwards

● Pull off both the plug brackets on the connection couplings

(fig. 4-10, item C).

● Pull off both connection couplings (fig. 4-10, item B).

FA ROTEX HPSU compact (V5.2) • 07/2017

23

4 x Set-up and installation

A

A

CAUTION!

If the plug brackets are not inserted

properly, the couplings can come loose

in their mounts which may result in high

levels of fluid escape and continuous

fluid escape.

● Before plugging in a plug bracket,

make sure that the plug bracket

engages in the groove in the coupling.

To do this, insert the coupling into the

mount until the groove becomes

visible through the plug bracket

mount.

● Insert the plug bracket up to the stop.

● Secure the elbow back into its mount with plug bracket

(fig. 4-11, item G).

● Insert both connection couplings (fig. 4-11, item B) through

the retainer plate in the side mounts.

● Secure both connection couplings in their mounts with the

plug brackets (fig. 4-11, item C).

● Insert the closing plug (fig. 4-11, item E) in the top mount.

● Secure the closing plug with the plug bracket (fig. 4-11,

item D).

● Cut out the side transit points in the thermal insulation

(fig. 4-12, item A) using a suitable tool.

● Establish hydraulic connections at the ROTEX HPSU

compact.

– Position and dimensions of the heating connections to be

taken from fig. 4-1 / fig. 4-2 and from tab. 3-1.

– Pay attention to the stipulated tightening torque

(see chapter 10.3 "Tightening torque").

– Design the lines as such that the sound attenuation cowl

can be applied without any problem following assembly.

– Connect the water for filling or refilling the heating system

as specified by EN 1717 to avoid contamination of drinking water by backwash.

● Connect a drain line to the safety overpressure valve and

connect a diaphragm drain container in accordance with

12828.

EN

– Check the seating of the drain hose on the overpressure

valve.

– If required, attach your own hose and route accordingly.

● Carefully insulate pipe lines against heat loss and so as to

avoid the formation of condensation (insulation thickness at

least 20

– Water shortage protection: The pressure and temperature

monitoring of the control unit safely switches off the ROTEX

HPSU compact in the event of a water shortage. No addi

tional water shortage protection is needed in the construction.

– Avoid damages caused by deposits and corrosion:

Observe the relevant regulations of technology to prevent

creation of corrosion products and deposits.

Minimum requirements regarding the quality of filling and supplementary water:

– Water hardness (calcium and magnesium, calculated as

– Conductivity: ≤ 1500 (ideal ≤ 100) μS/cm

– Chloride: ≤ 250 mg/l

– Sulphate: ≤ 250 mg/l

– pH value (heating water): 6,5 - 8,5

mm).

-

calcium carbonate): ≤ 3 mmol/l

Fig. 4-12 Thermal insulation cut-out

4.4.2 Connecting hydraulic lines

Requirement: Optional accessories (e.g. Solar, backup heater)

mounted on the ROTEX HPSU compact according to the specifi

cations of the instructions included.

● Check cold water pressure (maximum 6 bar).

– At higher pressure in the drinking water line, a pressure

reducer must be installed.

In the case of filling and top-up water with a high overall hardness

or other properties that deviatte from the minimum requirements,

measures for the desalination, softening, hardness stabilisation

or other suitable conditioning measures are required to maintain

the required water quality.

WARNING!

There is a danger of scalding at hot

water temperatures over 60

°C. This is

possible, when solar energy is used, with

a connected external heating device,

when the Legionella protection is acti

vated or when the domestic hot water

target temperature is set higher than

-

60 °C.

● Install a scald protection (domestic

hot water mixing unit (e.g. VTA32

15 60 15).

● Connect the drain hose to the connection piece for the safety

overflow (

– Use transparent drain hose (draining water must be visi-

– Connect the drain hose to an adequately dimensioned

– Drain should not be lockable.

fig. 3-2 to fig. 3-5, item 23).

ble).

waste water installation.

24

FA ROTEX HPSU compact (V5.2) • 07/2017

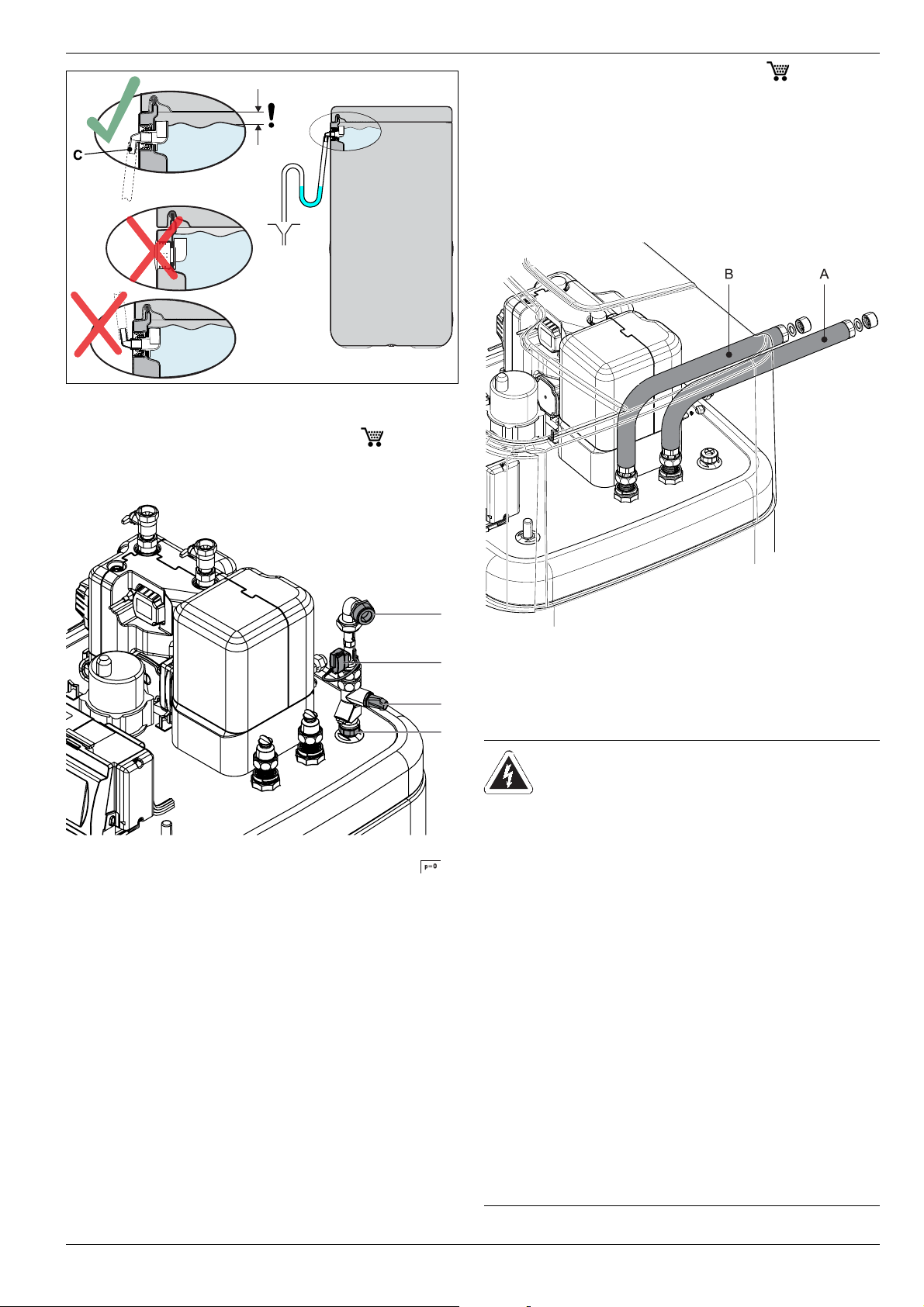

Fig. 4-13 Installation of drain hose at safety overflow

A

D

B

C

4.4.3 Installation of DB connection kit ( 141590)

The optional DB connection kit provides improved accessibility

for connecting the DrainBack line (solar feed).

4 x Set-up and installation

4.4.4 Installation of P connection kit ( 141589)

The optional P connection kit for Biv device types provides better

access for connecting the feed and return flow of a pressurised

solar system or another external heat generator to the storage

tank. The kit contains two thermally insulated corrugated pipes

that are connected to the connections on the storage tank with a

union nut. At the other end of the corrugated pipe there is an

adapter for each of the various different connection sizes of the

feed and return flow line.

A DB line connection (solar

feed)

B FlowSensor (not included in

the DB connection kit, but in

cluded in RPS4)

Fig. 4-14 DB connection kit

C Flow limiter (FlowGuard)

D Solar feed connection on

the storage tank

-

A Flow connection (red)

B Return flow connection (blue)

Fig. 4-15 P connection kit for Biv equipment types

4.5 Electrical connection

WARNING!

Touching live parts can result in an

electric shock and lead to potentially

fatal injuries and burns.

● Before beginning work on live parts,

disconnect all of the systems circuits

from the power supply (switch off

main switch, disconnect fuse) and

secure against unintentional restart.

● The electrical connection and working

on the electrical components should

only be performed by electrical

engineers in compliance with valid

standards and guidelines as well as

the specifications of the energy

supply company.

● The equipment covers and maintenance opening covers must be refitted immediately after completion of

the work.

FA ROTEX HPSU compact (V5.2) • 07/2017

25

4 x Set-up and installation

CAUTION!

In the controller housing of the

ROTEX HPSU compact, in continuous

running, elevated temperatures can be

generated. This can result in currently-

carrying wires from reaching higher

temperatures during operation due to

self-heating. For this reason, these lines

need to have a continuous use temperature of 90 °C.

● For the following connections, use

only cables with a long-term use

temperature ≥90 °C:

– Exterior heat pump unit

– Optional: Electrical Backup Heater

(BUxx)

26

FA ROTEX HPSU compact (V5.2) • 07/2017