Daikin FWB Installation manuals

INSTALLATION AND OPERATION MANUAL

Ducted fan coil units

Installation and operation manual

Ducted fan coil units

English

M08019060001

FW B0703-A2

FWB

1

CONTENTS

Outline and dimensions-----------------------------------------------------------------------------------------------------------1

Safety Precaution-------------------------------------------------------------------------------------------------------------------2

General features and technical data -------------------------------------------------------------------------------------------3

Installation ----------------------------------------------------------------------------------------------------------------------------5

Electrical wiring connection ------------------------------------------------------------------------------------------------------7

Accessories--------------------------------------------------------------------------------------------------------------------------8

Control Features--------------------------------------------------------------------------------------------------------------------9

Service and maintenance ------------------------------------------------------------------------------------------------------10

Trouble shooting------------------------------------------------------------------------------------------------------------------11

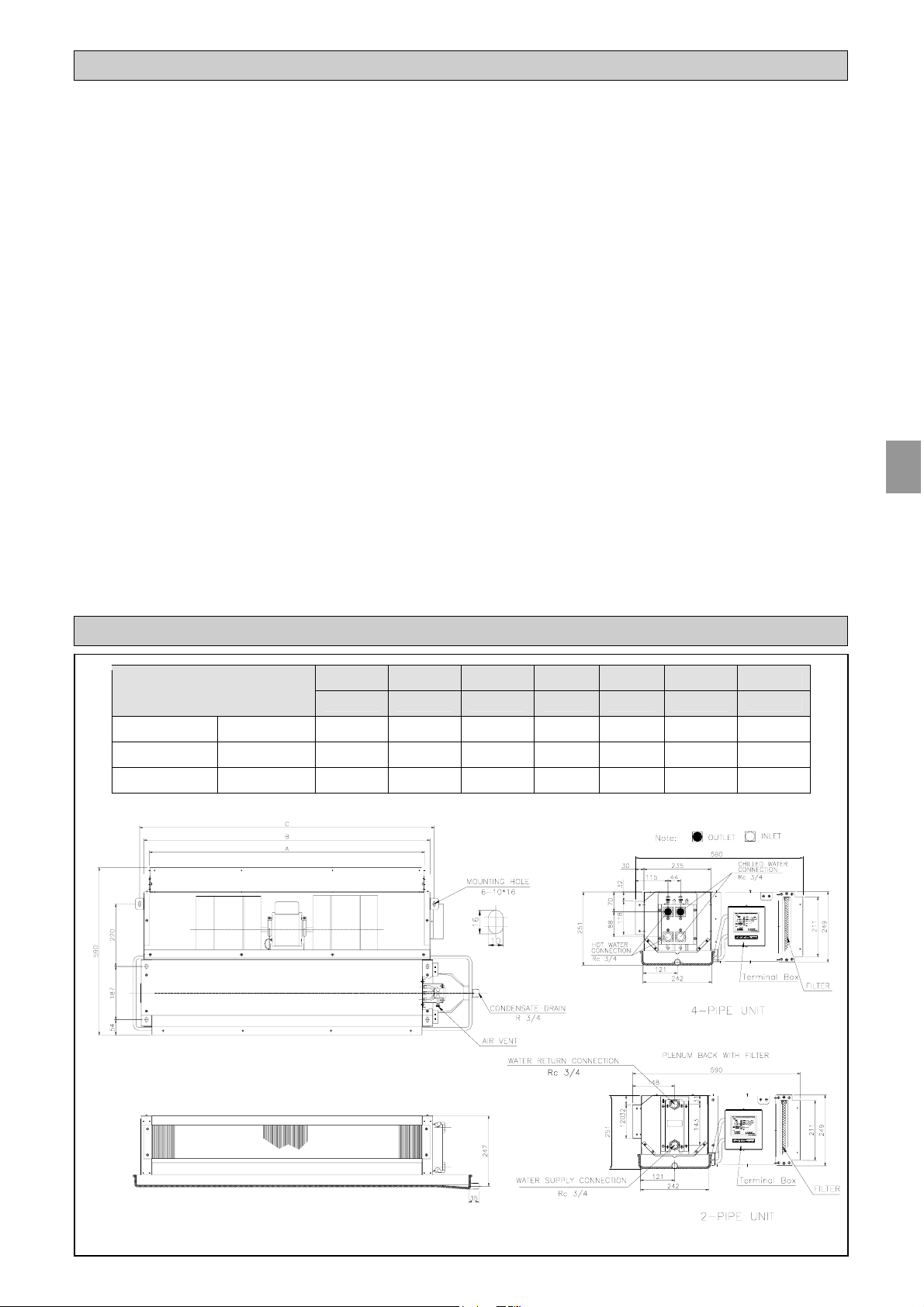

OUTLINE AND DIMENSIONS

02JT 03JT 04/05 JT 06JT 07JT 09JT 10/11 JT

MODEL FW B

02JF 03JF 04JF 06JF 07JF 08JF 10JF

A m m 467 637 767 967 1217 1317 1577

B m m 505 675 805 1005 1255 1355 1615

C m m 535 705 835 1035 1285 1385 1645

:$7(5287/(7

&211(&725:,7+7,*+7)25&(

%(&$5()8/12772'$0$*(7+(

&$87,21

:+(13,3,1*

:$7(5,1/(7

Unit:mm

2

SAFETY PRECAUTION

WARNING

z

Installation and maintenance should be performed by

qualified persons who are familiar with local code and

regulation, and experienced with this type of

appliance.

z

All field wiring must be installed in accordance with

the national wiring regulation.

z

Ensure that the rated voltage of the unit corresponds

to that of the name plate before commencing wiring

work according to the wiring diagram.

z

The unit must be GROUNDED to prevent possible

hazard due to insulation failure.

z

All electrical wiring must not touch the water piping or

any moving parts of the fan motors.

z

Confirm that the unit has been switched OFF before

installing or servicing the unit.

z

Risk of electric shock, can cause injury or death.

Disconnect all remain electric power supplies before

servicing.

z

DO NOT pull out the power cord when the power is

ON. This may cause serious electrical shocks which

may result in the fire hazards.

z

Keep the indoor and outdoor units, power cable and

transmission wiring, at least 1m from TVs and radios,

to prevent distorted pictures and static. {Depending

on the type and source of the electrical waves, static

may be heard even when more than 1m away}.

CAUTION

Please take note of the following important points when

installing.

z Ensure that the drainage piping is connected properly.

If the drainage piping is not connected properly, it may

cause water leakage which will dampen the furniture.

z Sharp edges and coil surfaces are potential locations

which may cause injury hazards. Avoid from being in

contact with these places.

z Tightening torque should not be too high when connecting

water pipes, in order to avoid brass deformation or

water-leakage by torsion split.

z W ater coil not used during winter season shall be drained,

or anti-freezing solution shall be added to the water circuit

to avoid freezing.

z Before turning off the power supply set the remote

controller’s ON/OFF switch to the “OFF” position to

prevent the nuisance tripping of the unit. If this is not

done, the unit’s fans will start turning automatically when

power resumes, posing a hazard to service personnel or

the user.

z Ensure the color of wires of the outdoor unit and the

terminal markings are same to the indoors

respectively.

z IMPORTANT: DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products

shall not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the

refrigerant, of oil and of other parts must be done by a qualified installer in accordance with relevant local

and national legislation. Air conditioners must be treated at a specialized treatment facility for re-use,

recycling and recovery. By ensuring this product is disposed of correctly, you will help to prevent potential

negative consequences for the environment and human health. Please contact the installer or local

authority for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with

relevant local and national legislation.

3

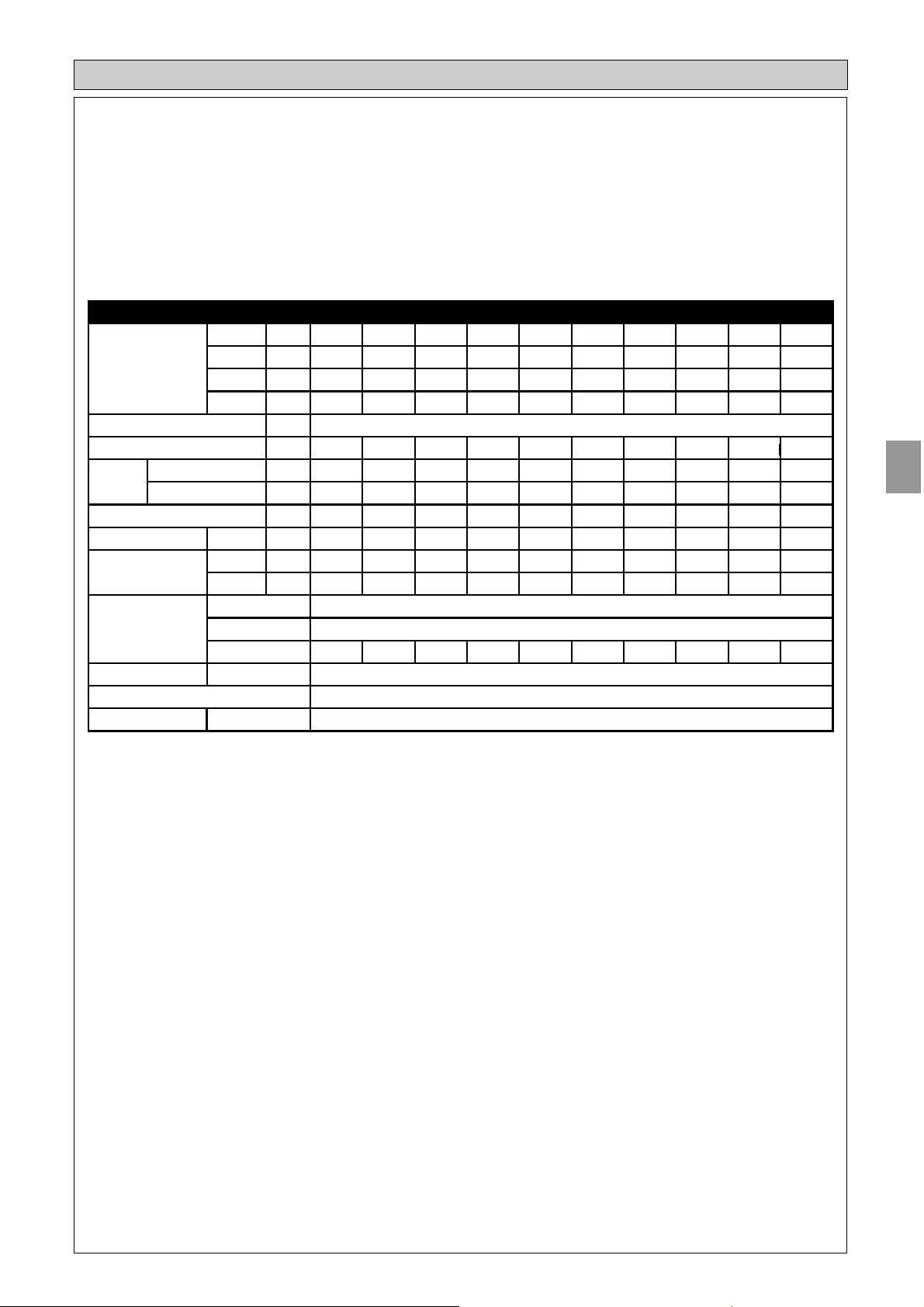

General features and technical data

Their quiet operation, compact dimensions and particularly low height, make units ideal for false ceiling

installation even in vintage buildings with narrow ceiling spaces. Units are standard supplied with sound

proofed suction plenum, air filter and extra-long drain pan. Centrifugal fans, with forwards curved blades, are

statically and dynamically balanced and moved by single-phase motor with three speeds (standard) plus one

(optional).

The availability of 2&4 pipe versions, the possibility to change connection side on field and accessories like

electronic thermostat and water on/off valves, provides the maximum flexibility and ease of installation.

02JT 03JT 04JT 05JT 06JT 07JT 08JT 09JT 10JT 11JT

S.High m³/h

331 548 715 667 982 1241 1238 1323 1837 1695

High m³/h

262 428 431 428 757 945 950 1066 1463 1341

Medium m³/h

219 357 323 325 596 756 764 882 1171 1210

Low m³/h

187 304 248 255 476 628 633 733 946 1093

Pa

W

41 61 76 73 106 144 140 157 201 203

kW

2.18 3.10 4.13 4.59 5.79 6.42 7.56 8.55 9.84 10.66

kW

1.38 2.27 2.94 3.08 4.22 5.21 5.54 6.08 7.65 7.82

kW

2.94 4.32 5.71 5.92 7.69 9.15 10.09 11.52 13.73 14.13

Cooling l/h

386 549 739 803 1022 1109 1338 1523 1764 1910

Cooling kPa

11 8 16 11 31 13 8 10 22 17

Heating kPa

9 7 13 9 26 11 7 9 19 14

1 1 2 2 2 3 3 3 4 4

MODELS FWB (2 PIPES)

Nominal Air Flow

External static pressure 30

Power Input

Cooling

capacity

Total capacity

Sensible capacity

Direct driven centrifugal fan (forward-curved blades); hot-galvanised steel

4 steps:super high, high, medium, low

Water pressure drop

Heating capacity

Fan

Water flow

Type

Fan Speed

Quantity

220-240 / 1 / 50

Single phase capacitor running

Air filter Washable Nylon in 8mm Aluminium frame

TypeMotor

Power supply V / Ph / Hz

Rating Conditions:

The nominal air flow, power input and capacity test is under the power supply of 220V/1Ph/50Hz.

Nominal Air Flow: with plenum and filter, no water supply, ambient air temperature between 10 and 30ć

Power input: S.High fan speed

Cooling capacity: 7/12ć inlet/outlet water temperature, 27ć DB/19ć WB air temperature, S.High fan speed

Heating capacity: 50ć inlet water temperature, 20ć DB inlet air temperature, water flow rate same as for the cooling test, S.High fan speed

Heating capacity for additional heat exchanger: 70ć inlet water temperature, water temperature decrease 10ć , 20ć DB inlet air temperature, S.High fan speed

Loading...

Loading...