Page 1

INSTALLATION MANUAL

SPLIT SYSTEM Air Conditioners

English

Deutsch

MODELS

(Floor standing type)

FVQ71BV1B

FVQ100BV1B

FVQ125BV1B

READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

LESEN SIE DIESE ANWEISUNGEN VOR DER INSTALLATION SORGFÄLTIG DURCH.

BEWAHREN SIE DIESE ANLEITUNG FÜR SPÄTERE BEZUGNAHME GRIFFBEREIT AUF.

LIRE SOIGNEUSEMENT CES INSTRUCTIONS AVANT L’INSTALLATION.

CONSERVER CE MANUEL A PORTEE DE MAIN POUR REFERENCE ULTERIEURE.

LEA CUIDADOSAMENTE ESTAS INSTRUCCIONES ANTES DE INSTALAR.

GUARDE ESTE MANUAL EN UN LUGAR A MANO PARA LEER EN CASO DE TENER

ALGUNA DUDA.

PRIMA DELL’INSTALLAZIONE LEGGERE ATTENTAMENTE QUESTE ISTRUZIONI.

TENERE QUESTO MANUALE A PORTATA DI MANO PER RIFERIMENTI FUTURI.

ÄΙΑΒΑΣΤΕ ΠΡΟΣΕΚΤΙΚΑ ΑΥΤΕΣ ΤΙΣ ΟÄΗΓΙΕΣ ΠΡΙΝ ΑΠΟ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ ΕΧΕΤΕ ΑΥΤΟ

ΤΟ ΕΓΧΕΙΡΙÄΙΟ ΕΥΚΑΙΡΟ ΓΙΑ ΝΑ ΤΟ ΣΥΜΒΟΥΛΕΥΕΣΤΕ ΣΤΟ ΜΕΛΛΟΝ.

Français

Español

Italiano

ЕллзнйкЬ

Nederlands

Portugues

Русский

LEES DEZE INSTRUCTIES ZORGVULDIG DOOR VOOR INSTALLATIE. BEWAAR DEZE HANDLEINDING WAAR U HEM KUNT TERUGVINDEN VOOR LATERE NASLAG.

LEIA COM ATENÇÃO ESTAS INSTRUÇÕES ANTES DE REALIZAR A INSTALAÇÃO.

MANTENHA ESTE MANUAL AO SEU ALCANCE PARA FUTURAS CONSULTAS.

ПЕРЕД НАЧАЛОМ МОНТАЖА ВНИМАТЕЛЬНО ОЗНАКОМЬТЕСЬ С ДАННЫМИ

ИНСТРУКЦИЯМИ. СОХРАНИТЕ ДАННОЕ РУКОВОДСТВО В МЕСТЕ, УДОБНОМ ДЛЯ

ОБРАЩЕНИЯ В БУДУЩЕМ.

MONTAJDAN ÖNCE BU TALÝMATLARI DÝKKATLÝ BÝR BÝÇÝMDE OKUYUN.

GELECEKTE BAÞVURMAK ÜZERE BU ELKÝTABINI KOLAY ULAÞABÝLECEÐÝNÝZ BÝR YERDE

MUHAFAZA EDÝN.

Page 2

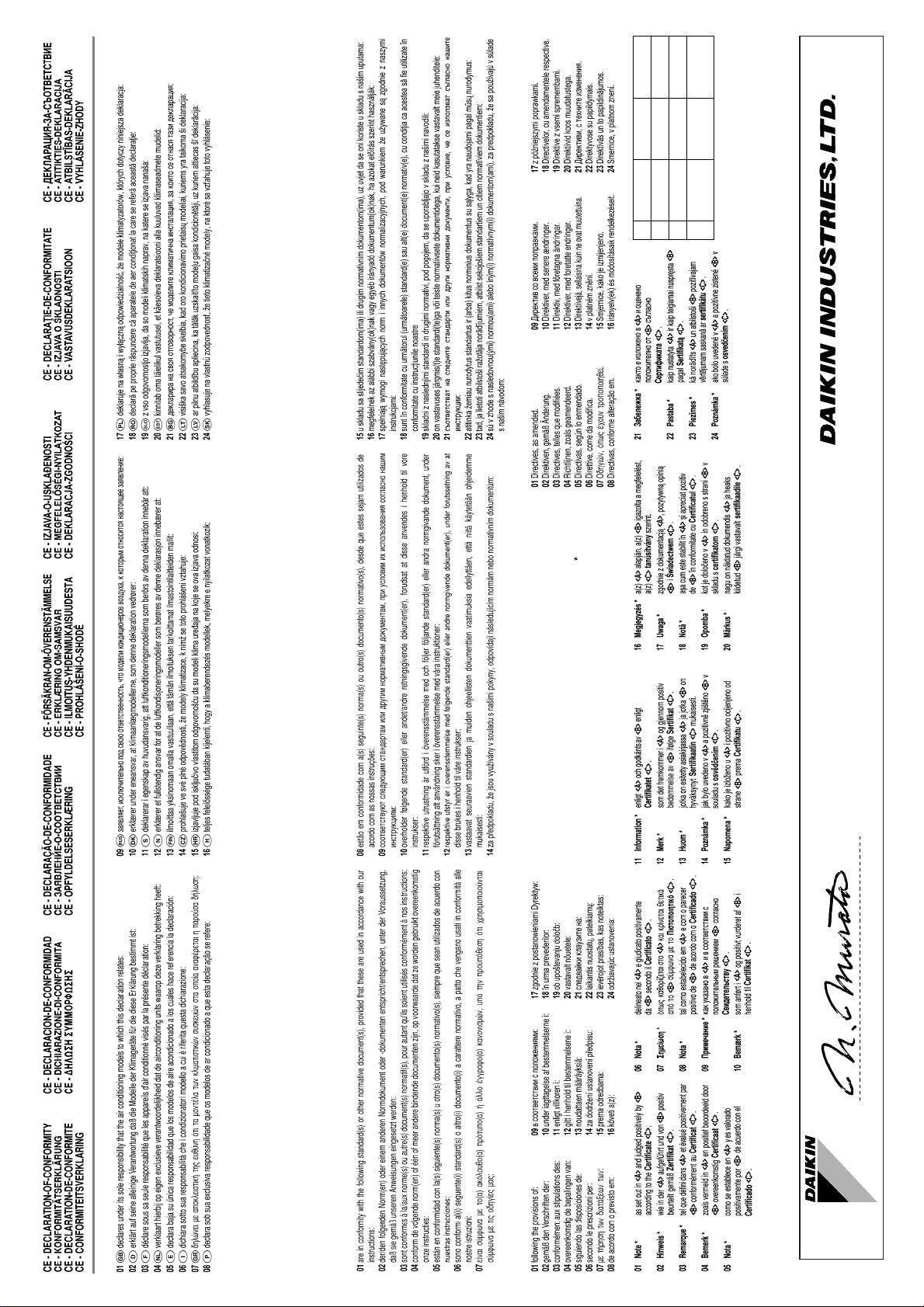

(III)

DAIKIN.TCF.021

KEMA

(II)

DAIKIN.TCF.016

KEMA

(I)

DAIKIN.TCF.004

KEMA

<A>

<B>

2024351-QUA/

EMC02-4565

81728-KRQ/

ECM98-4341

59277-KRQ/

ECM95-4233

<C>

Umeda Center Bldg., 4-12, Nakazaki-Nishi 2-chome,

Kita-ku, Osaka, 530-8323 Japan

Low Voltage 2006/95/EC

Machinery Safety 98/37/EC

Electromagnetic Compatibility 2004/108/EC

Noboru Murata

Manager Quality Control Department

Sakai, 1st of January 2008

(I) FHY35BJV1, FHY45BJV1, FHY60BJV1, FHY71BJV1, FHY100BJV1, FHY125BJV1, FH35BJV1, FH45BJV1, FH60BJV1

DAIKIN INDUSTRIES, LTD.

(II) FHYP35BV1, FHYP45BV1, FHYP60BV1, FHYP71BV1, FHYP100BV1, FHYP125BV1, FH35BZV1, FH45BZV1, FH60BZV1

FHQ35BVV1B, FHQ50BVV1B, FHQ60BVV1B, FHQ71BVV1B, FHQ100BVV1B, FHQ125BVV1B

(III) FHQ35BUV1B, FHQ50BUV1B, FHQ60BUV1B, FHQ71BUV1B, FHQ100BUV1B, FHQ125BUV1B

FVQ71BV1B, FVQ100BV1B, FVQ125BV1B

FUQ71BUV1B, FUQ100BUV1B, FUQ125BUV1B, FUQ71BVV1B, FUQ100BVV1B, FUQ125BVV1B

FAQ71BUV1B, FAQ100BUV1B, FAQ71BVV1B, FAQ100BVV1B

EN60335-2-40,

3P104327-1E

Page 3

FVQ71BV1B

FVQ100BV1B

FVQ125BV1B

SPLIT SYSTEM Air Conditioner Installation manual

CONTENTS

1. SAFETY PRECAUTIONS.....................................................................................1

2. BEFORE INSTALLATION ....................................................................................3

3. SELECTING INSTALLATION SITE......................................................................5

4. INDOOR UNIT INSTALLATION ...........................................................................5

5. REFRIGERANT PIPING WORK...........................................................................6

6. DRAIN PIPING WORK .........................................................................................9

7. SEPARATE INSTALLATION OF THE CONTROL PANEL ................................10

8. ELECTRIC WIRING WORK ...............................................................................12

9. WIRING EXAMPLE ............................................................................................13

10. INSTALLATION OF AIR INTAKE GRILLE .........................................................15

11. FIELD SETTING.................................................................................................16

12. TEST OPERATION ............................................................................................17

13. WIRING DIAGRAM.............................................................................................20

1. SAFETY PRECAUTIONS

Please read these “SAFETY PRECAUTIONS” carefully before installing air conditioning equipment and be

sure to install it correctly.

After completing installation, conduct a trial operation to check for faults and explain to the customer how to

operate the air conditioner and take care of it with the aid of the operation manual. Ask the customer to store

the installation manual along with the operation manual for future reference.

This air conditioner comes under the term “appliances not accessible to the general public”.

Meaning of WARNING and CAUTION notices.

WARNING

CAUTION ........... Failure to observe these instructions properly may result in property damage or

WARNING

• Ask your dealer or qualified personnel to carry out installation work.

Do not attempt to install the air conditioner yourself. Improper installation may result in water leakage,

electric shocks or fire.

• Install the air conditioner in accordance with the instructions in this installation manual.

Improper installation may result in water leakage, electric shocks or fire.

• Be sure to use only the specified accessories and parts for installation work.

Failure to use the specified parts may result in the unit falling, water leakage, electric shocks or fire.

• Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

A foundation of insufficient strength may result in the equipment falling and causing injury.

• Carry out the specified installation work after taking into account strong winds, typhoons or earthquakes.

Failure to do so during installation work may result in the unit falling and causing accidents.

• Make sure that a separate power supply circuit is provided for this unit and that all electrical work is carried

out by qualified personnel according to local laws and regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shocks or fire.

........... Failure to follow these instructions properly may result in personal injury or loss of life.

personal injury, which may be serious depending on the circumstances.

English 1

Page 4

•

Make sure that all wiring is secured, the specified wires are used, and that there is no strain on the terminal

connections or wires.

Improper connections or securing of wires may result in abnormal heat build-up or fire.

• When wiring the power supply and connecting the wiring between the indoor and outdoor units, position the

wires so that the terminal box lid can be securely fastened.

Improper positioning of the terminal box lid may result in electric shocks, fire or overheating terminals.

• If refrigerant gas leaks during installation, ventilate the area immediately.

Toxic gas may be produced if the refrigerant comes into contact with fire.

• After completing installation, check for refrigerant gas leakage.

Toxic gas may be produced if the refrigerant gas leaks into the room and comes into contact with a source

of fire, such as a fan heater, stove or cooker.

• Be sure to switch off the unit before touching any electrical parts.

• Do not directly touch refrigerant that has leaked from refrigerant pipes or other areas, as there is a danger

of frostbite.

• Be sure to earth the air conditioner.

Do not earth the unit to a utility pipe, lightning conductor or telephone earth lead.

Imperfect earthing may result in electric shocks or fire.

A high surge current from lightning or other sources may cause damage to the air conditioner.

• Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric shocks or fire.

CAUTION

• While following the instructions in this installation manual, install drain piping to ensure proper drainage and

insulate piping to prevent condensation.

Improper drain piping may result in indoor water leakage and property damage.

• Install the indoor and outdoor units, power cord and connecting wires at least 1 meter away from televisions

or radios to prevent picture interference and noise.

(Depending on the incoming signal strength, a distance of 1 meter may not be sufficient to eliminate noise.)

• Remote controller (wireless kit) transmitting distance can be shorter than expected in rooms with electronic

fluorescent lamps (inverter or rapid start types).

Install the indoor unit as far away from fluorescent lamps as possible.

• Do not install the air conditioner in the following locations:

1. Where there is a high concentration of mineral oil spray or vapour (e.g. a kitchen).

Plastic parts will deteriorate, parts may fall off and water leakage could result.

2. Where corrosive gas, such as sulphurous acid gas, is produced.

Corroding of copper pipes or soldered parts may result in refrigerant leakage.

3. Near machinery emitting electromagnetic radiation.

Electromagnetic radiation may disturb the operation of the control system and result in a malfunction of

the unit.

4. Where flammable gas may leak, where there is carbon fibre or ignitable dust suspensions in the air, or

where volatile flammables such as paint thinner or gasoline are handled.

Operating the unit in such conditions may result in fire.

2 English

Page 5

2. BEFORE INSTALLATION

• The accessories needed for installation must be retained in your custody until the installation work is

completed. Do not discard them!

• Decide upon a line of transport.

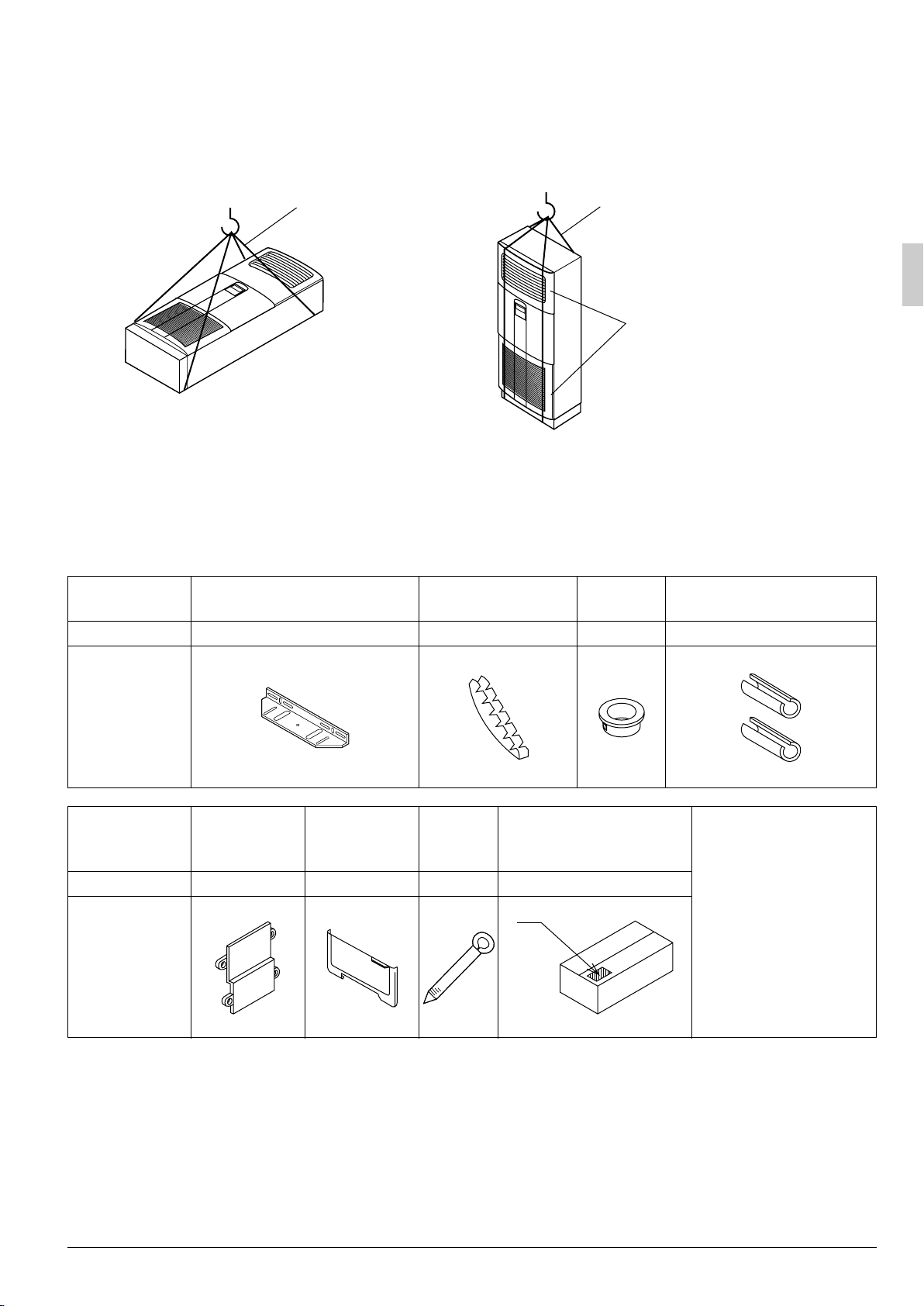

• When transporting by hanging the unit, use a sling of soft material as shown below.

(1) Horizontal hanging (2) Vertical hanging

Sling

*Be sure that the sling

does not slide in the

direction of the arrow.

• When moving the unit at or after opening, do not apply force to plastic parts.

• When selecting installation site, refer to the paper pattern (part of packaging material).

• For the installation of an outdoor unit, refer to the installation manual attached to the outdoor unit.

Sling

Apply cloth or corrugated

fibreboard so that the air

discharge grille and air inlet

grille are not damaged

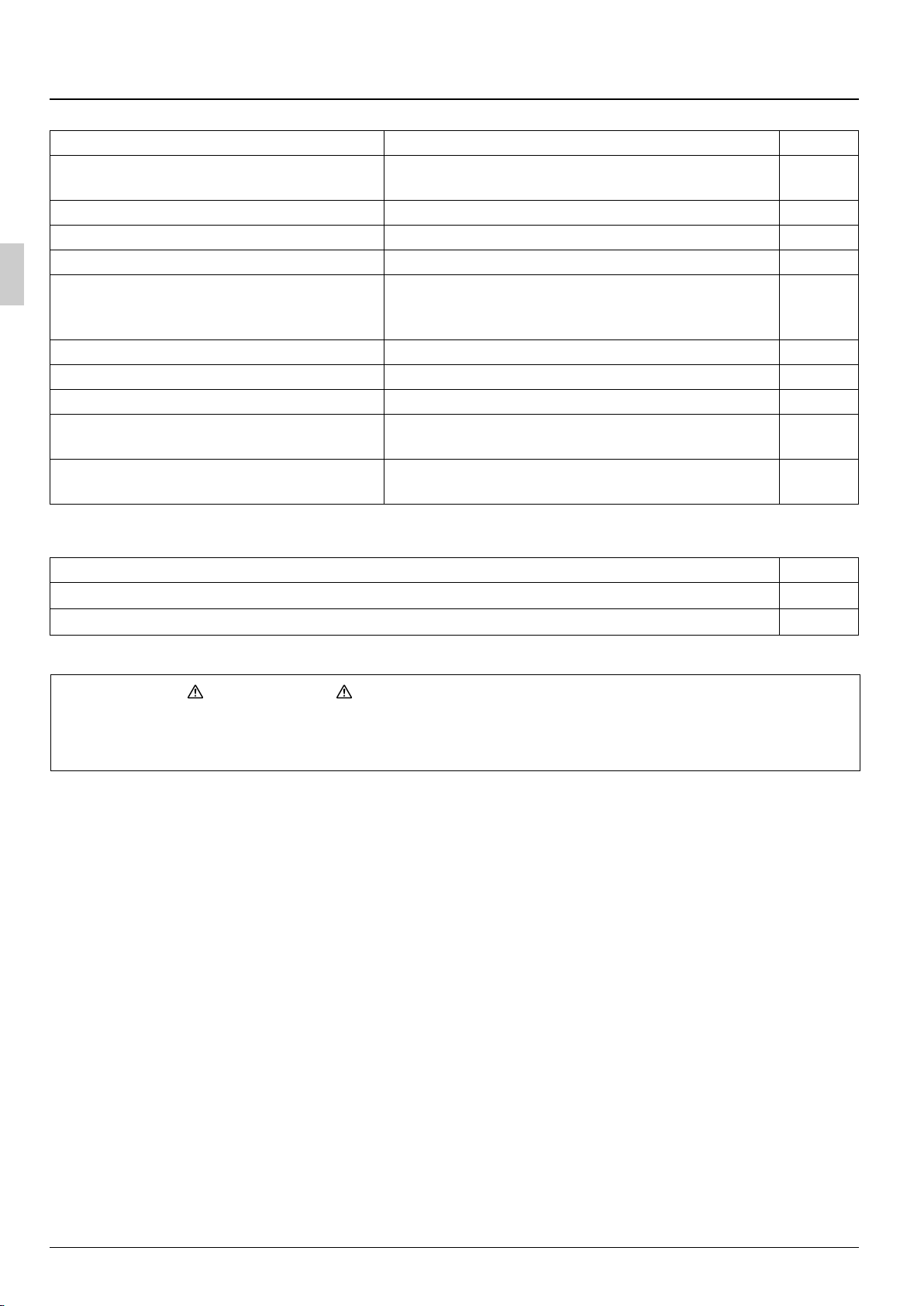

1. ACCESSORIES

Check the following accessories are included with the unit.

Name Bracket for installation

Quantity 1 set 2 pcs. 1 pc. 1 each

(1)

Shape

(Attached to the top

Control

Name

Quantity 1 pc. 1 pc. 5 pcs. 1 pc.

Shape

panel patch

plate

(6) (7) (8) (9)

panel)

Remote

controller lid

Through hole

protecting rubber

(2) (3) (4) For gas pipe

Clamp Installation pattern

Bush Insulation for fitting

(5) For liquid pipe

(Other)

(10) Operation

manual

(11) Installation

manual

(12) Screws

(M5 × 12, 2 pcs.)

(Part of packing material)

2. OPTIONAL ACCESSARIES

• When the indoor unit is to be controlled by two remote controllers (refer to “FIELD SETTING”), install

them on an adequate place, referring to the related technical information.

(As for the installation procedure, follow the instruction in “Remote controller installation procedure”

attached to the remote controller.)

English 3

Page 6

FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE DURING CONSTRUCTION AND

CHECK AFTER INSTALLATION IS FINISHED.

1. Items to be checked after completion of work

Items to be checked If not properly done, what is likely to occur Check

Are the indoor and outdoor unit fixed

firmly?

Is the gas leak test finished? It may result in insufficient cooling.

Is the unit fully insulated? Condensate water may drip.

Does drainage flow smoothly? Condensate water may drip.

Does the power supply voltage

correspond to that shown on the name

plate?

Are wiring and piping correct?

Is the unit safely grounded? Dangerous at electric leakage.

Is wiring size according to specifications?

Is something blocking the air outlet or inlet

of either the indoor or outdoor units?

Are refrigerant piping length and

additional refrigerant charge noted down?

The unit may drop, vibrate or make noise.

The unit may malfunction or the components burn out.

The unit may malfunction or the components burn out.

The unit may malfunction or the components burn out.

It may result in insufficient cooling.

The refrigerant charge in the system is not clear.

2. Items to be checked at time of delivery *Also review the “SAFETY PRECAUTIONS”

Items to be checked Check

Did you explain about operations while showing the instruction manual to your customer?

Did you hand the instruction manual over to your customer?

Points for explanation about operations

The items with WARNING and CAUTION marks in the instruction manual are the items

pertaining to possibilities for bodily injury and material damage in addition to the general usage of

the product. Accordingly, it is necessary that you make a full explanation about the described

contents and also ask your customers to read the instruction manual.

3. NOTE TO THE INSTALLER

Be sure to instruct customers how to properly operate the unit (especially operating different functions,

and adjusting the temperature) by having them carry out operations themselves while looking at the

manual.

4 English

Page 7

3. SELECTING INSTALLATION SITE

Select an installation site where the following conditions are satisfied after obtaining your customer’s

approval.

• Where optimum air distribution can be ensured.

• Where nothing blocks the air inlet and outlet, and

where sufficient clearance for maintenance and

service can be ensured.

• Where condensate can be properly drained.

• Where the floor is strong enough to bear the indoor

unit weight.

• Make sure that the floor is not remarkably tilted.

• Where there is no risk of flammable gas leakage.

• Where piping between indoor and outdoor units is

possible within the allowable limit. (Refer to the

installation manual for the outdoor unit.)

• Keep indoor unit, outdoor unit, power supply wiring

and transmission wiring at least 1 meter away from

televisions and radio receivers. This is to prevent

image interference and noise in those electrical

appliances.

(Noise may be generated depending on the

conditions under which the electric wave is generated, even if 1 meter is kept.)

50mm

or more

50mm

or more

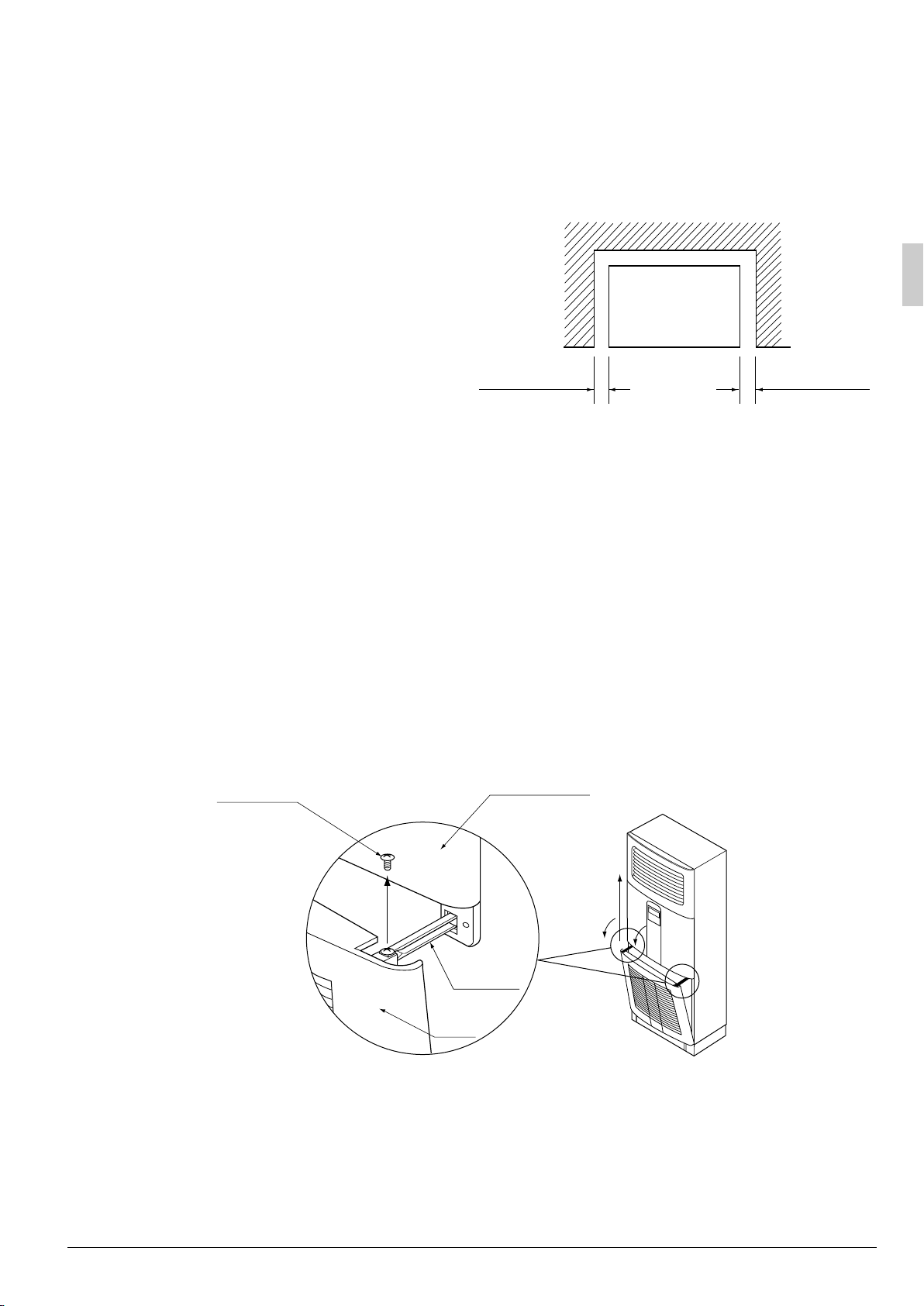

4. INDOOR UNIT INSTALLATION

As for the parts to be used for installation work, be sure to use the provided accessories and specified parts

designated by our company.

〈Fixing procedure〉

• Fix the indoor unit by using embedded bolt, etc. to prevent falling down of the vertically-long shaped unit.

1. Detach the air intake grille.

Remove the screws (R & L, total 2) locking the grille stopper. Then, (1) lean the grille forward you, and

(2) lift upward and out.

M4 × 12

Screw

Air intake

grille

Front panel

(2)

(1)

Grille

stopper

English 5

Page 8

2. In case of normal installation site.

Loosen the fixed screw and remove the bracket for installation (1) tentatively attached to the top panel.

Fix the bracket with the attached screws (12) to the top panel as shown in the figure. Then fix the indoor

unit to the wall surface with wood screws (field supply).

Fixing screw

Screw (12)

Bracket for

installation (1)

(attached)

Bracket for

installation (1)

(attached)

330

2-7 × 15 slot

(For locking with

wood screw:

field supply)

18

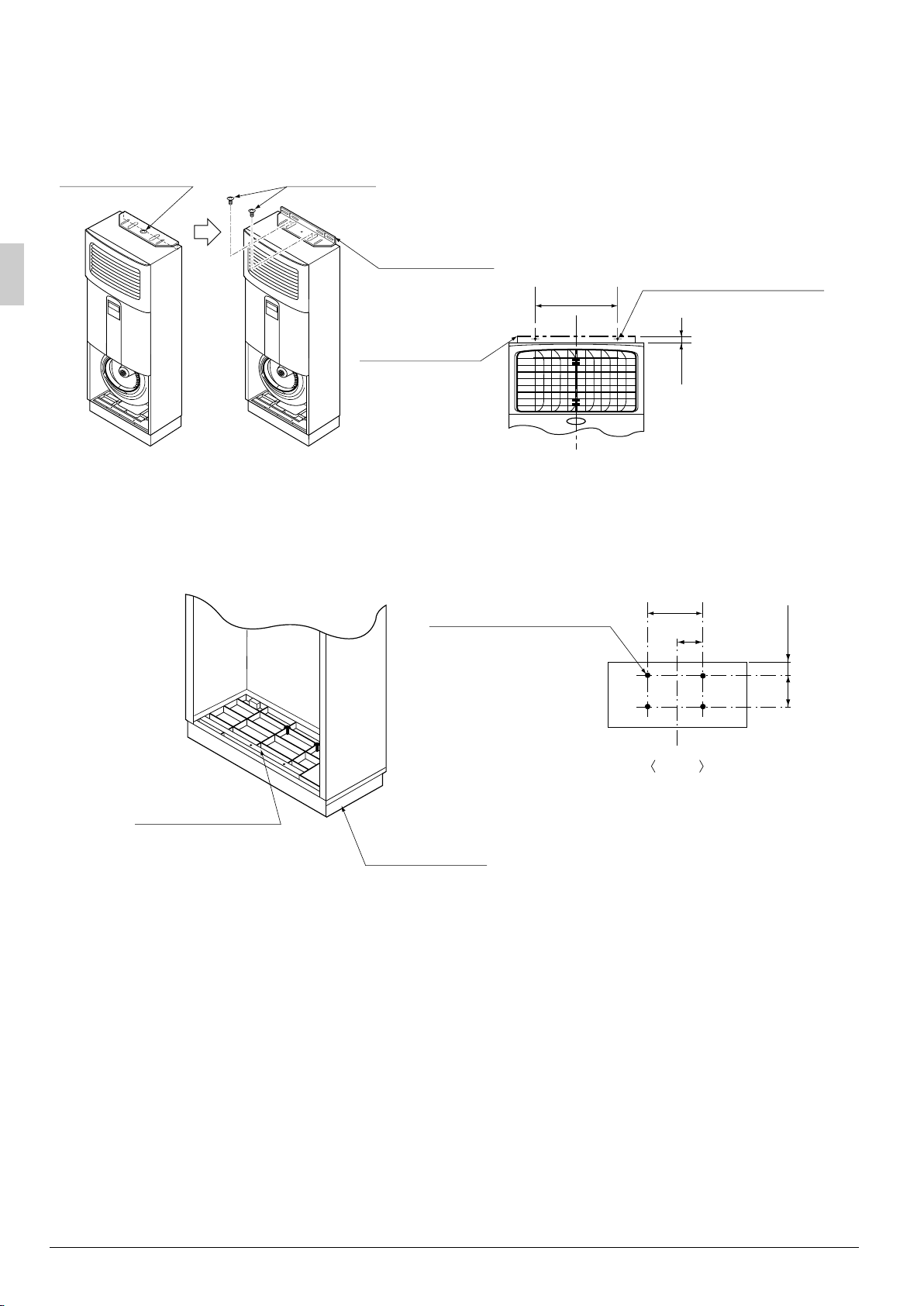

3. In the case of earthquake endurance installation site.

Perform the fixing procedure above and also fix the bottom frame. Fix the indoor unit to the floor with

anchor bolts (to be locally procured) using fixing holes (×4) on the bottom frame.

• Use the locations indicated on the installation pattern (9) (part of packing material).

4 - φ14 hole, Depth: 30

(For locking with bolt)

260

130

57

(79)

144

(202)

Front

Fixing hole (× 4)

Bottom frame

• Dimensions in ( ) for 100 - 125 models

• Unit [mm]

5. REFRIGERANT PIPING WORK

〈For refrigerant piping of outdoor units, see the installation manual attached to the outdoor unit.〉

〈Execute heat insulation work completely on both sides of the gas piping and the liquid piping.

Otherwise, a water leakage can result sometimes.〉

(When using a heat pump, the temperature of the gas piping can reach up to approximately 120°C, so use

insulation which is sufficiently resistant.)

〈Also, in cases where the temperature and humidity of the refrigerant piping sections might exceed

30°C or RH80%, reinforce the refrigerant insulation. (20mm or thicker) Condensation may form on the

surface of the insulating material.〉

〈Before refrigerant piping work, check which type of refrigerant is used. Proper operation is not

possible if the types of refrigerant are not the same.〉

6 English

Page 9

CAUTION

• Use a pipe cutter and flare suitable for the type of refrigerant.

• Apply ester oil or ether oil around the flare section before connecting.

• To prevent dust, moisture or other foreign matter from infiltrating the tube, either pinch the end or

cover it with tape.

• Do not allow anything other than the designated refrigerant to get mixed into the refrigerant circuit,

such as air, etc. If any refrigerant gas leaks while working on the unit, ventilate the room thoroughly

right away.

• The outdoor unit is charged with refrigerant.

• Use copper alloy seamless pipes (ISO 1337).

• Be sure to use both a spanner and torque wrench together, as

shown in the drawing, when connecting or disconnecting pipes

to/from the unit. (Refer to Fig. 1)

• Refer to “Table 1” for the dimensions of flare nut spaces.

• When connecting the flare nut, coat the flare section (both

inside and outside) with ester oil or ether oil, rotate three or four

times first, then screw in. (Refer to Fig. 2)

NOTE

• Use the flare nut included with the unit main body.

CAUTION

Do not let oil get on the screw holders on the dressing board.

Oil can weaken the screw holders.

Ta b le 1

Pipe size Tightening torque Flare dimensions A (mm) Flare

φ9.5 (3/8”) 32.7 - 39.9 N·m 12.8 - 13.2

φ15.9 (5/8”) 61.8 - 75.4 N·m 19.3 - 19.7

Fig. 1

Torque wrench

Flare nut

Fig. 2

Ester oil or ether oil

Piping union

45˚Ⳳ2˚

A

90˚Ⳳ0.5˚

Spanner

R0.4-0.8

• Refer to “Table 1” to determine the proper tightening torque.

CAUTION

Overtightening may damage the flare and cause a refrigerant leakage.

Not recommendable but in case of emergency

You must use a torque wrench but if you are obliged to install the unit without a torque wrench, you may

follow the installation method mentioned below.

After the work is finished, make sure to check that there is no gas leak.

When you keep on tightening the flare nut with a spanner, there is a point where the tightening torque

suddenly increases. From that position, further tighten the flare nut the angle shown below:

Pipe size Further tightening angle Recommended arm length of tool

φ9.5 (3/8”) 60 to 90 degrees Approx. 200mm

φ15.9 (5/8”) 30 to 60 degrees Approx. 300mm

English 7

Page 10

1. How to rig refrigerant piping.

• Detach the pipe retainer.

〈 In the case of left or right piping 〉

1. Open the holes on the right (left) side panel. (Refer to Fig. 3)

2. Pass refrigerant pipes, drain pipes, and unit wiring through the hole on the side panel.

Fig. 3

Bottom frame

〈 In the case of rear piping 〉

1. Open the holes on the rear panel. (Refer to Fig. 5)

2. Pass refrigerant pipes, drain pipes, and unit wiring through the hole on the rear panel.

〈 In case of downward piping 〉

1. Cut holes in the indicated area of the bottom frame. (Refer to Fig. 5)

2. Pass refrigerant pipes, drain pipes, and unit wiring through the hole on the bottom frame.

Side panel

Through hole (Select either one)

(left and right side panels and rear panel)

∗ Attach the through hole protection (2) ( )

after making the opening.

Through hole for wiring (Select either one)

(left and right side panels)

∗ Attach the bush (3) ( ) after making the opening.

Fig. 4

Insulation for fitting (4)(5)

(attached)

Drain hose

inside the unit

Pipe retainer

Knock-out hole

Fig. 5

Cut holes here.

Fix using

the clamp (8)

Rear panel

Bottom frame

• After rigging pipes and wiring, lock down the refrigerant pipes, drain hose inside the unit, indooroutdoor unit transmission wiring and grounding line, in the piping guide. (For electrical wiring work,

see “ELECTRIC WIRING WORK”.)

8 English

Page 11

6. DRAIN PIPING WORK

1. Rig the drain piping.

Rig the drain line to ensure proper drainage. Also, observe the following to prevent leaks.

Drain hose

inside the unit

Fan housing

Liquid pipe

Gas pipe

CAUTION

• Bundle the drain pipe to the refrigerant pipes as shown at right or take other means to anchor it down, so

as not to apply pressure to the hose inside the unit. This is necessary to prevent the drain pipe from

disconnecting and to ensure proper insulation. Keep the drain pipe sloping at a minimum 1/100 gradient, to

prevent air pockets.

• The drain pipe may be clogged if water accumulates in the drain pipe.

• Condensate can form on the pipe and leak from the unit. Therefore, definitely insulate the pipe in at least

the below two places.

• All pipe in the room and inside the unit.

• At connection between the unit’s drain hose and building drain pipe.

Drain pipes (Procure in field.)

Vinyl tube (pipe size I.D. 20mm)

Bottom frame

Anchor hose here.

2. After rigging the drain hose, check that drainage flows smoothly and that water does

not leak from connections.

• Carefully pour approximately

1,000cc of water through the air

discharge outlet so that it falls

directly onto the heat

exchanger at an angle without

splashing. (See figure at right.)

* If water is poured too fast or if

water pressure is too high, the

water will pass through the

heat exchanger and drip on

the fan motor below it.

* If water gets on the inner front

wall, it will leak onto the floor.

Air discharge

outlet

Heat

exchanger

CAUTION

• In order to prevent the intrusion of small animals, seal the pipe penetration hole with putty or heat insulating

material (field supply).

• Drain piping connections

Do not connect the drain piping directly to sewage pipes that smell of ammonia. The ammonia in the

sewage might enter the indoor unit through the drain pipes and corrode the heat exchanger.

English 9

Page 12

7. SEPARATE INSTALLATION OF THE CONTROL PANEL

• For this unit, remote controller (operation part) attached to the control panel can be installed separately by

using the field supplied remote controller cord.

Refer to section of ELECTRIC WIRING WORK (p. 12) for specifications of remote controller cord.

1. Detach the terminal box lid and detach the remote controller cable from the remote

controller terminal board.

Remote controller wiring

Front plate

panel

Remote controller

Screw

(M4 × 2)

terminal board

Terminal box lid

2. Remove the remote controller

holding plate on the back side of

the front plate panel.

3. Fix the attached hole covering

plate on the front plate panel where

the remote controller was set.

Screw (M4)

Front plate panel

Remote

controller

Remote controller

holding plate

Screw (M4 × 4)

Front plate panel

Hole covering plate (6)

(attached)

Screw (M4 × 4)

10 English

Page 13

4. Connect the remote controller

wiring (field supplied) to the

Terminal box lid

Remote controller

terminal board

remote controller terminal board

and lead the wiring out of the unit

as shown below.

• Lock the remote controller wiring to the

piping guide.

Remote controller wiring

5. Open the remote controller and attach the remote controller wiring (field supplied).

(Remote controller wiring has no polarity)

1. Remove the upper part of the remote

controller.

Remove the upper part of the remote

controller with screw drivers, etc.

2. Attach the remote controller wiring.

3. Reassemble the remote controller in

the opposite order of 1. and at last,

install the attached remote controller

lid (7).

Upper part of

remote controller

Remote controller wiring

Remote

controller

PC board

Upper part of

remote controller

Upper part of

remote controller

Insert the latch on

the bottom first.

Remote controller

lid (7) (attached)

6. After the remote controller wiring, reassemble the indoor unit referring to procedures

1. ~ 4.

English 11

Page 14

8. ELECTRIC WIRING WORK

• All field supplied parts and materials and electric works must conform to local codes.

• Use copper wire only.

• For electric wiring work, refer also to “WIRING DIAGRAM” attached to the unit body.

• For remote controller wiring details, refer to the installation manual attached to the remote controller.

• All wiring must be performed by an authorized electrician.

• A circuit breaker capable of shutting down power supply to the entire system must be installed.

• Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric shocks.

• Refer to the installation manual attached to the outdoor unit for the size of power supply electric wire

connected to the outdoor unit, the capacity of the circuit breaker and switch, and wiring instructions.

• Be sure to ground the air conditioner.

• Do not connect the ground wire to gas pipes, plumbing pipes, lightning rods, or telephone ground wires.

• Gas pipes: could explode and cause fires if there was a gas leak.

• Plumbing pipes: no grounding effect if hard vinyl pipes are used.

• Telephone ground wires or lightning rods: the ground potential could rise dangerously high if hit by

lightning.

• Specifications for field wire

Wiring the units

Remote controller cord

(In case of installing the

control panel separately)

Wire

H05VV-U4G

(NOTE 1)

Vinyl cord with sheath or

cable (2 wire) (NOTE 2)

2

Size (mm

)

2.5 –

0.75 - 1.25 Max. 500m

Length

NOTE

1. Shows only in case of protected pipes. Use H07RN-F in case of no protection.

2. Insulated thickness : 1mm or more.

How to connect wiring

Earth terminal

Earth terminal

Clamp

Power supply

321

terminal board (3P)

Wiring the units

Earth wire

Wiring

Pipe retainer

diagram

Terminal box lid

〈 Methods of wiring units and connecting remote controller cords 〉

• Detach the Terminal box lid as shown in the figure and connect the wires to the unit wiring terminal board

(3P) on the right side of the unit matching phase. Then, fix the wire using the clamp.

• Arrange the wires and fix a lid firmly so that the lid does not float during wiring work.

• Lock wires connecting the units and the grounding line to the pipe retainer.

[ PRECAUTIONS ]

• Do not clamp remote controller cords together with wires connecting the units. Doing so may cause

malfunction.

• Remote controller cords and wires connecting the units should be located at least 50mm from other electric

wires. Not following this guideline may result in malfunction due to electrical noise.

12 English

Page 15

• In order to prevent the intrusion of small creatures, seal the wiring outlet with putty or heat insulating

material (field supply). (If small creatures, such as insects, intrude into the unit, the creatures may cause

short-circuiting in the terminal box.)

CAUTION

• Observe the notes mentioned below when wiring to the power supply terminal board.

Precautions to be taken for power supply wiring

(Use a round crimp-style terminal for connection to the power supply terminal board. In case it cannot be

used due to unavoidable reasons, be sure to observe the following instructions.)

• Do not connect wires of different gauge to the same power supply terminal.

(Looseness in the connection may cause overheating.)

• When connecting wires of the same gauge, connect them according to the below figure.

• In wiring, make certain that prescribed wires are used, carry out complete connections, and fix the wires

so that outside forces are not applied to the terminals.

• Do not tighten the terminal screw excessively, or

otherwise the screw may be damaged.

• The tightening torque of each terminal screw is shown

in the table on the right-hand side.

Terminal block for remote controller wiring 0.79~0.97

Terminal block for wiring between units

Earth terminal

Tightening torque (N·m)

1.18~1.44

1.44~1.94

Do not connect wires

of different gauges.

(WRONG)

Round crimp-style

terminal

Connect wires of the

same gauge to both

side. (GOOD)

Do not connect wires

of the same gauge to

one side. (WRONG)

Electric wire

GOOD WRONG WRONG

9. WIRING EXAMPLE

(For the wiring of outdoor units, refer to the installation manual attached to the outdoor unit.)

Confirm the system type.

• Pair type: 1 control panel controls 1 indoor unit (standard system).

• 2 remote controller control: 1 control panel and 1 remote controller control 1 indoor unit.

• Group control: 1 control panel controls up to 16 indoor units (All indoor units operate according to the

control panel).

Pair type 2 remote controller control

Main power supply Main power supply

Main switch

Fuse

Main switch

Fuse

Outdoor unit

123

Outdoor unit

123

Indoor unit

Control

Panel

1

2

3

P1P2

P1P2

Control

Panel

1

2

3

P1P2

P1P2

(NOTE 2)

Indoor unitIndoor unit

English 13

Page 16

Group control

Main power supply Main power supply Main power supply

Main switch Main switch Main switch

FuseFuseFuse

Outdoor unitOutdoor unitOutdoor unit

123

Control

Panel

1

2

3

P1P2

P1P2

123

Control

Panel

1

2

3

P1P2

P1P2

123

Control

Panel

(NOTE 3)(NOTE 3)

1

2

3

P1P2

P1P2

Indoor unitIndoor unitIndoor unit

NOTE

1. All transmission wiring except for the remote controller wires must match the terminal symbol.

2. If the unit is under 2 remote controller control, perform additional wiring of the remote controller to the

remote controller terminal board. (Refer to the section entitled SEPARATE INSTALLATION OF THE

CONTROL PANEL)

3. If the unit is under group control, detach the remote controller cord connecting the remote controller

terminal board and the control panel. (Refer to the section entitled SEPARATE INSTALLATION OF THE

CONTROL PANEL)

Control by 2 Remote Controllers (controlling 1 indoor unit with 2 remote controllers)

• When using 2 remote controllers, one of either the control panel or the separate remote controller

must be set to “MAIN” and the other to “SUB”.

〈 MAIN/SUB CHANGEOVER 〉

1. Insert a screwdriver into the

Upper part of

remote controller

recess between the upper and

lower part of remote controller

and, working from the 2 positions,

pry off the upper part.

Lower part of

remote controller

Insert the screwdriver here and gentry work off

the upper part of remote controller.

14 English

Page 17

2. Turn the MAIN/SUB CHANGEOVER SWITCH on one of the two remote controller PC boards to “S”.

(Leave the switch to the other remote controller set to “M”.)

(Factory setting)

S

M

Remote controller

PC board

Only one remote controller

needs to be charged.

S

M

10. INSTALLATION OF AIR INTAKE GRILLE

1. Hook the air intake grille on the groove on the unit’s bottom frame in the order of (1) →

(2). (See below figure.)

(2)

(2)

(1)

Air intake

grille

(1)

Air intake grille

Bottom frame

Bottom frame

2. Fit the grille stopper (front panel) into the groove on the air intake grille and lock the

grille down in its original place by screw. (See below figure)

* Be careful not to overtighten screws.

M4 × 12

Screw

Front panel

Grille stopper

Air intake grille

Air intake grille

Bottom frame

English 15

Page 18

11. FIELD SETTING

Field setting

〈

Field setting must be made from the remote controller in accordance with the installation conditions.

• Setting can be made by changing the “Mode No.”, “FIRST CODE NO.”, and “

SECOND CODE NO

.”.

• Refer to the following procedure for Field setting.

〈 Procedure 〉

(1) Press the INSPECTION/TEST OPERATION button ( ) for 4 seconds or more in normal mode to

TEST

change to “FIELD SETTING MODE”.

(2) Press the TEMPERATURE SETTING button ( ) and choose the desired “Mode No.”.

(3) Under group control, if setting on each indoor unit is to be performed, press the TIMER MODE

START/STOP button ( ) and select the indoor unit number.

(Unnecessary in case of unified setting of group control)

(4) Press the PROGRAMING TIME upper part of the button ( ) and select the “FIRST CODE NO.”.

(5) Press the part of the button ( ) and select the “

SECOND CODE NO

.”.

(6) Press the TIMER ON/OFF button ( ) once to fix the change of the setting.

(7) Press the INSPECTION/TEST OPERATION button ( ) to return to the “NORMAL MODE”.

TEST

NOTE

• Setting is performed by a group as a seto when individual setting of each indoor unit is required, or when

the setting results must be checked, use the mode number is ( ).

UNIT NO.

Mode No.

〉

FIRST CODE NO.

UNIT NO.

SETTING

SECOND CODE NO.

(3)

TEST

(1)(7)

(4)

(6)

(5)

(2)

1. Setting air filter sign

• Control panels are equiped with the liquid crystal display of air filter signs to display the time to clean

air filters.

• Change the “

SECOND CODE NO

room.

(“

SECOND CODE NO.”

is factory set to “01” for filter contamination-light)

.” according to Table 2 depending on the amount of dirt or dust in the

16 English

Page 19

Ta b le 2

Setting

Air filter

contamination-light

Air filter

contamination-heavy

Filter cleaning period

(long life type)

Mode No.

Approx. 2500 hrs.

10 (20) 0

Approx. 1250 hrs. 02

FIRST

CODE NO.

CODE NO

2. Setting indoor unit number of simultaneous operation system

• When using in simultaneous operation system mode, change the SECOND CODE NO. as shown in

Table 3.

(SECOND CODE NO. is factory set to “01” for Pair system.)

Ta b le 3

Setting Mode No. FIRST CODE NO.

Pair system (1 unit)

Simultaneous operation

system (2-unit)

Simultaneous operation

system (3-unit)

11 (21) 0

SECOND CODE NO

01

02

03

SECOND

.

01

.

12. TEST OPERATION

Refer to the section of “FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE DURING

CONSTRUCTION AND CHECK AFTER INSTALLATION IS FINISHED” .

• After finishing the construction of refrigerant piping, drain piping, and electric wiring, conduct test operation

accordingly to protect the unit.

1. HOW TO TEST OPERATION

1 Open the gas side stop valve.

2 Open the liquid side stop valve.

Electrify crank case heater for 6 hours (Not required in case of a unit exclusively designed for cooling only).

3

Set to cooling operation with control panel and start operation by pushing ON/OFF button ( ).

4

5 Press INSPECTION/TEST OPERATION button ( ) 4 times (2 times for wireless remote controller)

and operate at Test Operation mode for 3 minutes.

6 Push AIR FLOW DIRECTION ADJUST button ( ) to make sure the unit is in operation.

7 Press INSPECTION/TEST OPERATION button ( ) and operate normally.

8 Confirm function of unit according to the operation manual.

PRECAUTIONS

• Refer to the diagnoses below if the unit does not operate properly.

• After completing the test run, press the INSPECTION/TEST OPERATION button once to put the unit

in inspection mode, and make sure the malfunction code is “00” (=normal).

If the code reads anything other than “00”, refer to the malfunction diagnoses below.

TEST

TEST

English 17

Page 20

2. HOW TO DIAGNOSE FOR PROBLEMS

With the power on. Troubles can be monitored on the

■ Trouble shooting with the display on the liquid crystal display

1 With the

When the operation stops due to trouble, operation lamp flashed, and “ ” and the error code are

indicated on the liquid crystal display . In such a case, diagnose the fault contents by referning to

the table on the Error code list it case of group control, the unit No. is displayed so that the indoor

unit no with the trouble can be recognized. (NOTE 2)

2 With the wireless remote controller.

(Refer also to the operation manual attached to the wireless remote controller)

When the operation stops due to trouble. the display on the indoor unit flashes. In such a case,

diagnose the fault contents with the table on the Error code list looking for the error code which can

be found by following procedures. (NOTE 2)

(1) Press the INSPECTION /TEST OPERATION button, “ ” is displayed and “ 0 ” flashes.

(2) Press the PROGRAMMING TIME button and find the unit No. which stopped due to trouble.

Number of beeps 3 short beeps...............Perform all the following operations

(3) Press the OPERATION MODE SELECTOR button and upper figure of the error code flashes.

(4) Continue pressing the PROGRAMMING TIME button unit it makes 2 short beeps and find the upper

code.

(5) Press the OPERATION MODE SELECTOR button and lower figure of the error code flashes.

Continue pressing the PROGRAMMING TIME button unit it makes a long beep and find the lower code.

(6)

• A long beep indicate the error code.

NOTE

1. Press the INSPECTION /TEST OPERATION button on control panel, “ ” starts flashing.

2. Keep down the ON/OFF button for 5 seconds or longer in the inspection mode and the above trouble

history disappears, after the trouble code goes on and off twice, followed by the code “00”(normal).

The display changes from the inspection mode to the normal mode.

control panel

. (NOTE 1)

1 short beep ................Perform (3) and (6)

1 long beep..................No trouble

control panel

control panel

.

.

3. Malfunction code

• For places where the error code is left blank, the “ ” indication is not displayed. Though the system

continues operating, be sure to inspect the system and make repairs as necessary.

• Depending on the type of indoor or outdoor unit, the malfunction code may or may not be displayed.

Code Malfunction/Remarks

A1 Indoor unit’s PC board faulty

A3 Drain water level abnormal

A6 Indoor fan motor overloaded, overcurrent or locked

A7 Swing flap motor locked

AF

AH

AJ

C4 Sensor for heat exchanger lamp is fault

C9 Sensor for suction air lamp is fault

CC

CJ

E0 Action of safety device (outdoor unit)

E1 Outdoor unit’s PC board faulty (outdoor unit)

E3 High pressure abnormal (outdoor unit)

E4 Low pressure abnormal (outdoor unit)

Humidifier faulty

Air cleaner faulty

Only the air cleaner does not function.

Type set improper

Capacity data is wrongly preset. Or there is nothing programmed in the data hold IC.

Temperature sensor system faulty

Sensor for remote controller is fault

The remote controller thermistor does not function, but the system thermo run is possible.

18 English

Page 21

E5 Compressor motor lock malfunction (outdoor unit)

E7

E9 Electronic expansion valve faulty (outdoor unit)

F3 Discharge pipe temperature abnormal (outdoor unit)

H3 High pressure switch faulty (outdoor unit)

H7 Outdoor motor position signal malfunction (outdoor unit)

H9

J2

J3

J5 Suction pipe thermistor faulty (outdoor unit)

J6

J9 Suction temperature sensor faulty (outdoor unit)

JA Pressure sensor for discharge pipe faulty (outdoor unit)

JC Pressure sensor for suction pipe faulty (outdoor unit)

L4

L5

L8

L9

LC Transmission malfunction between the outdoor control units’ inverters (outdoor unit)

P1 Open-phase (outdoor unit)

P3 PC board temperature sensor malfunction (outdoor unit)

P4 Heat-radiating fin temperature sensor malfunction (outdoor unit)

PJ

U0

U1

U2

U4

UF

U5

Outdoor fan motor lock malfunction

Outdoor fan instantaneous overcurrent malfunction (outdoor unit)

Outdoor air thermistor faulty (outdoor unit)

The air conditioner comes to a stop due to an error depending on the model or operating

conditions.

Current sensor faulty

Discharge pipe thermistor faulty (outdoor unit)

The air conditioner comes to a stop due to an error depending on the model or operating

conditions.

Heat exchanger thermistor faulty (outdoor unit)

The air conditioner comes to a stop due to an error depending on the model or operating

conditions.

Overheated heat-radiating fin (outdoor unit)

Inverter cooling defect.

Instantaneous overcurrent (outdoor unit)

Possible earth fault or short circuit in the compressor motor.

Electric thermal (outdoor unit)

Possible electrical overload in the compressor or cut line in the compressor motor.

Stall prevention (outdoor unit)

Compressor possibly locked.

Type set improper (outdoor unit)

Capacity data is wrongly preset. Or there is nothing programmed in the data hold IC.

Suction pipe temperature abnormal

The quantity of refrigerant may be insufficient.

Reverse phase

Reverse two of the L1,L2 and L3 leads.

Power source voltage malfunction (outdoor unit)

Inverter phase loss or a failure in the main circuit capacitor may be resulting.

Transmission error (indoor unit – outdoor unit)

Wrong wiring between indoor and outdoor units or malfunction of the PC board mounted

on the indoor and the outdoor units.

If UF is shown, the wiring between the indoor and outdoor units is not properly wired.

Therefore, immediately disconnect the power supply and correct the wiring. (The

compressor and the fan mounted on the outdoor unit may start operation independent of

the remote controller operation.)

Transmission error (indoor unit – remote controller)

Transmission is improper between the indoor unit and the remote controller.

English 19

Page 22

U8

UA

UC

UJ Transmission failure in accessory equipment

Malfunction in transmission between main and sub remote controllers.

(Malfunction in sub remote controller.)

Miss setting for multi system

Error in multi-system settings for simultaneous ON/OFF operation.

Central control address overlapping

13. WIRING DIAGRAM

(Refer to Fig. 6)

1 TO OUTDOOR UNIT 2

3 TERMINAL BOX 4 INDOOR UNIT

5NOTE) 7

CONTROL PANEL

20 English

Page 23

WIRING DIAGRAM

2

3

FVQ71 · 100 · 125BV1B3D058900-1

4

CONNECTOR

(ADAPTOR FOR WIRING)

CONNECTOR FOR OPTIONAL PARTS

X33A

INDOOR UNIT

CAPACITOR

C1

A1P PRINTED CIRCUIT BOARD

(INTERFACE

CONNECTOR

CONNECTOR

ADAPTOR FOR SKY AIR SERIES)

(POWER SUPPLY FOR ADAPTOR)

X35A

X60A

X61A

LIGHT EMITTING DIODE

(SERVICE MONITOR GREEN)

MAGNETIC RELAY (M1F)

MAGNETIC RELAY (M1S)

MOTOR (INDOOR FAN)M1F

MOTOR (SWING FLAP)M1S

HAP

KAR

K1R-K4R

1

TEMPERATURE SWITCHQ1M

THERMISTOR (AIR)

THERMISTOR (COIL)

R1T

R2T

5

TRANSFORMER

(220-240V/22V)

SELECTOR SWITCH (EMERGENCY)

LIMIT SWITCH (SWING FLAP)S1Q

SS1

T1R

TERMINAL STRIP

X1M

NOTES)

CONTROL PANEL

SIGNAL TRANSMISSION

SIGNAL RECEIVER CIRCUIT

(REMOTE CONTROLLER)

TC

RC

SELECTOR SWITCH (MAIN/SUB)

CIRCUIT

SS1

: SHORT CIRCUIT CONNECTOR : FIELD WIRING

THE ATTACHED INSTALLATION MANUAL.

ENGINEERING DATA AND CATALOGS, ETC. BEFORE CONNECTING.

ENGINEERING DATA, ETC.

BRN: BROWN BLU: BLUE

1. : TERMINAL , : CONNECTOR

2. IN CASE USING CENTRAL REMOTE CONTROLLER, CONNECT IT TO THE UNIT IN ACCORDANCE WITH

3. X33A, X35A, X60A, X61A ARE CONNECTED WHEN THE OPTIONAL ACCESSORIES ARE BEING USED.

4. REMOTE CONTROLLER MODEL VARIES ACCORDING TO THE COMBINATION SYSTEM, CONFIRM

5. CONFIRM THE METHOD OF SETTING THE SELECTOR SWITCH (SS1) BY INSTALLATION MANUAL AND

THERMISTOR (AIR)R1T

USE H07RN-F IN CASE OF NO PROTECTION.

6. SYMBOLS SHOWS AS FOLLOWS: RED: RED BLK:BLACK WHT: WHITE ORG:ORANGE

7. SHOWS ONLY IN CASE OF PROTECTED PIPES.

Fig. 6

English 21

Page 24

3PA60136-8Y EM07A043A

(0802) HT

Loading...

Loading...