INSTALLATION MANUAL

SPLIT SYSTEM HEAT PUMP

MODELS

Air Handling Unit

FTQ18PBVJU

FTQ24PBVJU

FTQ30PBVJU

FTQ36PBVJU

FTQ42PBVJU

English

Français

Español

Read these instructions carefully before installation.

Keep this manual in a handy place for future reference.

This manual should be left with the equipment owner.

Lire soigneusement ces instructions avant l’installation.

Conserver ce manuel à portée de main pour référence ultérieure.

Ce manuel doit être donné au propriétaire de l’équipement.

Lea cuidadosamente estas instrucciones antes de instalar.

Guarde este manual en un lugar a mano para leer en caso de tener alguna duda.

Este manual debe permanecer con el propietario del equipo.

SPLIT SYSTEM HEAT PUMP Installation manual

CONTENTS

1. SAFETY CONSIDERATIONS ........................................... 1

2. BEFORE INSTALLATION .................................................. 3

3. SELECTING INSTALLATION SITE ................................... 4

4. PREPARATIONS BEFORE INSTALLATION AND

INSTALLATION .................................................................. 5

5. REFRIGERANT PIPING WORK ....................................... 6

6. DRAIN PIPING WORK ...................................................... 8

7. INSTALLING THE DUCT ................................................... 9

8. ELECTRIC WIRING WORK .............................................. 9

9. WIRING EXAMPLE ......................................................... 10

10. FIELD SETTING AND TEST RUN .................................. 13

11. WIRING DIAGRAM ......................................................... 17

SAFETY CONSIDERATIONS1.

Read these “SAFETY CONSIDERATIONS for Installation”

carefully before installing an air conditioner or heat pump. After

completing the installation, make sure that the unit operates

properly during the startup operation.

Instruct the customer on how to operate and maintain the unit.

Inform customers that they should store this Installation Manual with the Operation Manual for future reference.

Always use a licensed installer or contractor to install this

product. Improper installation can result in water or refrigerant

leakage, electrical shock, fi re, or explosion.

This air conditioner comes under the term “appliances not

accessible to the general public”.

Meanings of DANGER, WARNING, CAUTION, and NOTE

Symbols:

DANGER ................ Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING .............. Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION ............... Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury.

It may also be used to alert against

unsafe practices.

NOTE...................... Indicates situations that may result in

equipment or property-damage

accidents only.

DANGER

Refrigerant gas is heavier than air and replaces oxygen. •

A massive leak can lead to oxygen depletion, especially

in basements, and an asphyxiation hazard could occur

leading to serious injury or death.

Do not ground units to water pipes, gas pipes, tele-•

phone wires, or lightning rods as incomplete grounding

can cause a severe shock hazard resulting in severe

injury or death. Additionally, grounding to gas pipes

could cause a gas leak and potential explosion causing

severe injury or death.

If refrigerant gas leaks during installation, ventilate the •

area immediately. Refrigerant gas may produce toxic

gas if it comes in contact with fi re. Exposure to this gas

could cause severe injury or death.

After completing the installation work, check that the •

refrigerant gas does not leak throughout the system.

Do not install unit in an area where fl ammable materials •

are present due to risk of explosions that can cause

serious injury or death.

Safely dispose all packing and transportation materials •

in accordance with federal/state/local laws or ordinances. Packing materials such as nails and other metal or

wood parts, including plastic packing materials used for

transportation may cause injuries or death by suffocation.

WARNING

All phases of the fi eld-installation, including, but not •

limited to, electrical, piping, safety, etc. must be in accordance with manufacturer’s instructions and must

comply with national, state, provincial and local codes.

Only qualifi ed personnel must carry out the installation •

work. Installation must be done in accordance with this

installation manual. Improper installation may result in

water leakage, electric shock, or fi re.

When installing the unit in a small room, take measures •

to keep the refrigerant concentration from exceeding

allowable safety limits. Excessive refrigerant leaks, in

the event of an accident in a closed ambient space, can

lead to oxygen defi ciency.

Use only specifi ed accessories and parts for installation •

work. Failure to use specifi ed parts may result in water

leakage, electric shocks, fi re, or the unit falling.

Install the air conditioner or heat pump on a foundation •

strong enough that it can withstand the weight of the

unit. A foundation of insuffi cient strength may result in

the unit falling and causing injuries.

Take into account strong winds, typhoons, or earth-•

quakes when installing. Improper installation may result

in the unit falling and causing accidents.

Make sure that a separate power supply circuit is pro-•

vided for this unit and that all electrical work is carried

out by qualifi ed personnel according to local, state, and

national regulations. An insuffi cient power supply

capacity or improper electrical construction may lead to

electric shocks or fi re.

1 English

Make sure that all wiring is secured, that specifi ed wires •

are used, and that no external forces act on the terminal

connections or wires. Improper connections or installation may result in fi re.

When wiring, position the wires so that the control box

•

cover can be securely fastened. Improper positioning of

the control box cover may result in electric shocks, fi re, or

the terminals overheating.

Before touching electrical parts, turn off the unit.•

It is recommended to install a ground fault circuit inter-•

rupter if one is not already available. This helps prevent

electrical shocks or fi re.

Securely fasten the outdoor unit terminal cover (panel). •

If the terminal cover/panel is not installed properly, dust

or water may enter the outdoor unit causing fi re or

electric shock.

When installing or relocating the system, keep the •

refrigerant circuit free from substances other than the

specifi ed refrigerant (R410A) such as air. Any presence

of air or other foreign substance in the refrigerant circuit can cause an abnormal pressure rise or rupture,

resulting in injury.

Do not change the setting of the protection devices. If •

the pressure switch, thermal switch, or other protection

device is shorted and operated forcibly, or parts other

than those specifi ed by Daikin are used, fi re or explosion may occur.

Heat exchanger fi ns are sharp enough to cut. •

To avoid injury wear glove or cover the fi ns when working around them.

CAUTION

Do not touch the switch with wet fi ngers. Touching a •

switch with wet fi ngers can cause electric shock.

Do not allow children to play on or around the unit to •

prevent injury.

Do not touch the refrigerant pipes during and immedi-•

ately after operation as the refrigerant pipes may be hot

or cold, depending on the condition of the refrigerant

fl owing through the refrigerant piping, compressor, and

other refrigerant cycle parts. Your hands may suffer

burns or frostbite if you touch the refrigerant pipes. To

avoid injury, give the pipes time to return to normal

temperature or, if you must touch them, be sure to wear

proper gloves.

Install drain piping to proper drainage. Improper drain

•

piping may result in water leakage and property damage.

Insulate piping to prevent condensation.•

Be careful when transporting the product.•

Do not turn off the power immediately after stopping

•

operation. Always wait for at least 5 minutes before turning off the power. Otherwise, water leakage may occur.

Do not touch the refrigerant pipes during and immedi-•

ately after operation as the refrigerant pipes may be hot

or cold, depending on the condition of the refrigerant

fl owing through the refrigerant piping, compressor, and

other refrigerant cycle parts. Your hands may suffer

burns or frostbite if you touch the refrigerant pipes. To

avoid injury, give the pipes time to return to normal

temperature or, if you must touch them, be sure to wear

proper gloves.

Do not use a charging cylinder. Using a charging cylin-•

der may cause the refrigerant to deteriorate.

Refrigerant R410A in the system must be kept clean, •

dry, and tight.

Clean and Dry -- Foreign materials (including min-(a)

eral oils such as SUNISO oil or moisture) should be

prevented from getting into the system.

Tight -- R410A does not contain any chlorine, does (b)

not destroy the ozone layer, and does not reduce the

earth’s protection again harmful ultraviolet radiation.

R410A can contribute to the greenhouse effect if it is

released. Therefore take proper measures to check

for the tightness of the refrigerant piping installation. Read the chapter Refrigerant Piping work and

follow the procedures.

Since R410A is a blend, the required additional refriger-•

ant must be charged in its liquid state. If the refrigerant

is charged in a state of gas, its composition can change

and the system will not work properly.

The indoor unit is for R410A. See the catalog for indoor •

models that can be connected. Normal operation is not

possible when connected to other units.

Remote controller transmitting distance can be shorter •

than expected in rooms with electronic fl uorescent

lamps (inverter or rapid start types). Install the indoor

unit far away from fl uorescent lamps as much as possible.

Install in a machine room that is free of moisture. •

The unit is designed for indoor use.

Indoor units are for indoor installation only. Outdoor •

units can be installed either outdoors or indoors. This

unit is for indoor use.

Do not install the air conditioner or heat pump in the •

following locations:

Where a mineral oil mist or oil spray or vapor is (a)

produced, for example, in a kitchen.

Plastic parts may deteriorate and fall off or result in

water leakage.

Where corrosive gas, such as sulfurous acid gas, is (b)

produced.

Corroding copper pipes or soldered parts may result

in refrigerant leakage.

Near machinery emitting electromagnetic waves.(c)

Electromagnetic waves may disturb the operation of

the control system and cause the unit to malfunction.

Where fl ammable gas may leak, where there is (d)

carbon fi ber, or ignitable dust suspension in the air,

or where volatile fl ammables such as thinner or

gasoline are handled. Operating the unit in such

conditions can cause a fi re.

English 2

Take adequate measures to prevent the outdoor unit •

from being used as a shelter by small animals. Small

animals making contact with electrical parts can cause

malfunctions, smoke, or fi re. Instruct the customer to

keep the area around the unit clean.

Be sure to check the type of R410A refrigerant to be used

before installing the unit.

(Using an incorrect refrigerant will prevent normal operation of the unit.)

For the installation of an outdoor unit, refer to the installation

manual attached to the outdoor unit.

NOTE

Install the power supply and control wires for the indoor •

and outdoor units at least 3.5 feet away from televisions

or radios to prevent image interference or noise. Depending on the radio waves, a distance of 3.5 feet may

not be suffi cient to eliminate the noise.

In a domestic environment this product may cause radio •

interference in which case the user may be required to

take adequate measures.

Dismantling the unit, treatment of the refrigerant, oil and •

additional parts must be done in accordance with the

relevant local, state, and national regulations.

Do not use the following tools that are used with con-•

ventional refrigerants: gauge manifold, charge hose,

gas leak detector, reverse fl ow check valve, refrigerant

charge base, vacuum gauge, or refrigerant recovery

equipment.

If the conventional refrigerant and refrigerator oil are •

mixed in R410A, the refrigerant may deteriorate.

This air conditioner or heat pump is an appliance that •

should not be accessible to the general public.

As design pressure is 478 psi, the wall thickness of •

fi eld-installed pipes should be selected in accordance

with the relevant local, state, and national regulations.

BEFORE INSTALLATION2.

PRECAUTIONS2-1

Be sure to instruct customers how to properly operate the •

unit (operating different functions, and adjusting the temperature) by having them carry out operations themselves

while looking at the operation manual.

Do not install in locations where the air contains high levels of

•

salt such as that near the ocean and where voltage fl uctuates

greatly such as that in factories, or in vehicles or vessels.

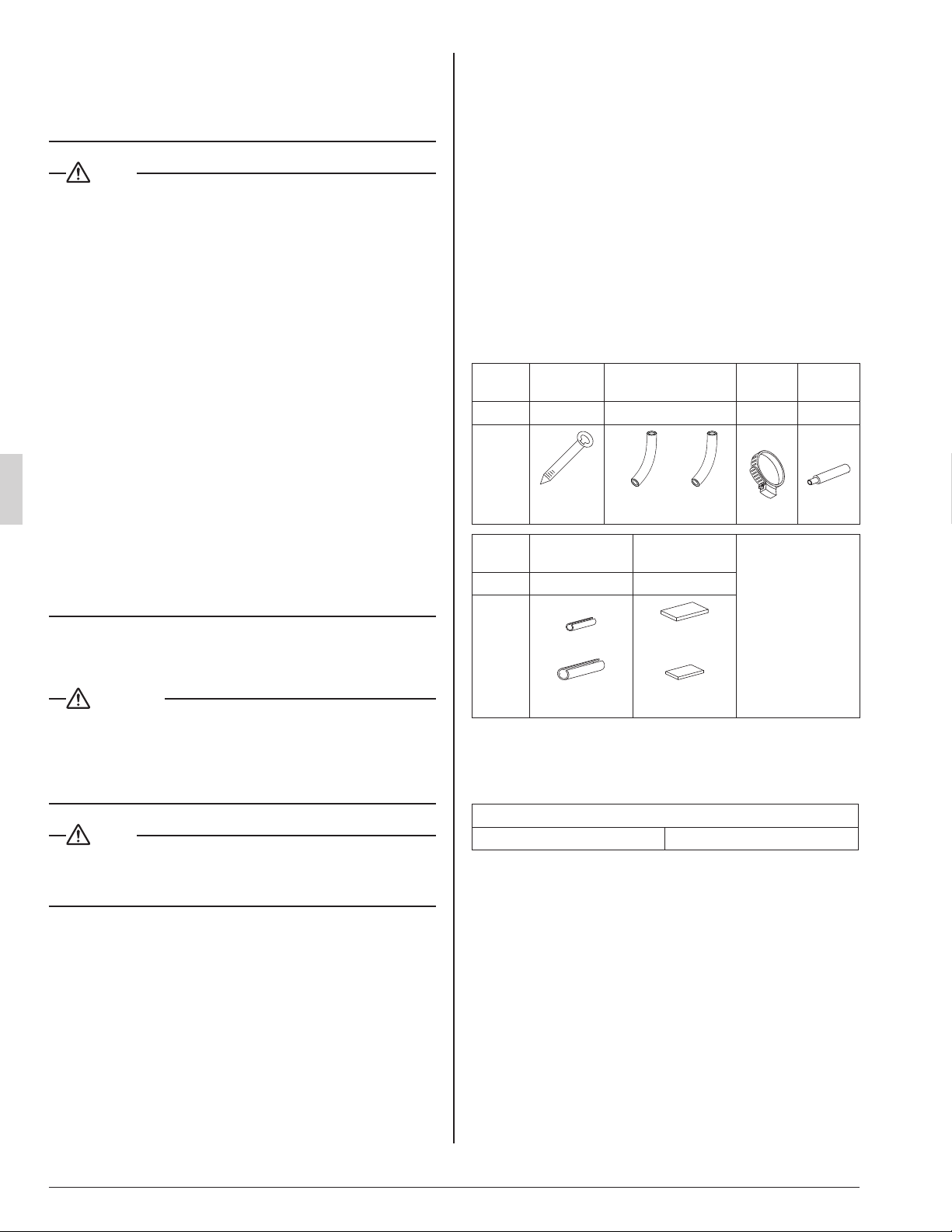

ACCESSORIES2-2

Check the following accessories are included with your unit.

Name

Quantity 6 pcs. 1 set 1 pc. 1 pc.

Shape

Name

Quantity 1 each –

Shape

Clamp

material (1)

Small (2)

Insulation for

fi tting

for liquid pipe (6)

Insulation tube

Large (3)

1 pc.

Sealing pad

1 pc.

Large (9)

1 pc.

Metal

clamp (4)

(Other)

Operation manual •

Installation manual •

Note sheet •

Drain

hose (5)

WARNING

Entrust installation to the place of purchase or a qualifi ed •

serviceman. Improper installation could lead to leaks and, in

worse cases, electric shock or fi re.

Use of unspecifi ed parts could lead to the unit falling, leaks •

and, in worse cases, electric shock or fi re.

NOTE

Be sure to read this manual before installing the indoor unit.•

Be sure to mount an air fi lter (part to be procured in the fi eld) in

•

the suction air passage in order to prevent water leaking, etc.

The accessories needed for installation must be retained

in your custody until the installation work is completed.

Do not discard them.

Decide upon a line of transport.1.

Leave the unit inside its packaging while moving, until reach-

2.

ing the installation site. Where unpacking is unavoidable, use

a sling of soft material or protective plates together with a

rope when lifting, to avoid damage or scratches to the unit.

for gas pipe (7)

2 pcs.

Small (8)

OPTIONAL ACCESSORIES2-3

This indoor unit requires one of the operation remote con-•

trols listed below.

Remote controller

Wired type BRC1E71

NOTE

If you wish to use a remote controller that is not listed in •

Table 1, select a suitable remote controller after consulting

catalogs and engineering data.

3 English

English 4

FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE

24 or more

(unit : in.)

(Top view)

DURING CONSTRUCTION AND CHECK AFTER

INSTALLATION IS FINISHED.

a. Items to be checked after completion of work

Items to be checked

Are the indoor and outdoor

unit fi xed fi rmly?

Was the installation of the

outdoor unit completed?

Is the gas leak test fi nished? No cooling or heating.

Is the unit fully insulated?

(Refrigerant piping, drain

piping, and duct)

Dose drainage fl ow

smoothly?

Does the power supply

voltage conform to the

indication on the name

plate?

Are wiring and piping

correct?

Is the air conditioner or heat

pump properly grounded?

Is wiring size according to

specifi cations?

Is something blocking the air

outlet or inlet of either the

indoor or outdoor units?

Did you set the external

static pressure?

Are refrigerant piping length

and additional refrigerant

charge noted down?

Did you check that no wiring

connection screws were

loose?

Also review the “SAFETY CONSIDERATIONS”.

b. Items to be checked at the time of delivery

Items to be checked Check

Are you sure the control box lid, air fi lter, air inlet grille,

and air outlet grille are mounted?

Did you explain about operations while showing the

operation manual to your customer?

Did you deliver the operation manual along with the

installation manual to the customer?

Did you explain the customer the handling and cleaning

methods of the fi eld supplies (e.g., the air fi lter, air inlet

grilles, and air outlet grille)?

Did you deliver instruction manual, if any, for the fi eld

supplies to the customer?

c. Points for explanation about operations

If not properly done, what is

likely to occur.

The units may drop, vibrate

or make noise.

The unit may malfunction or

the components burn out.

Condensate water may drip.

Condensate water may drip.

The unit may malfunction or

the components burn out.

The unit may malfunction or

the components burn out.

Dangerous in case of

current leakage.

The unit may malfunction or

the components burn out.

No cooling or heating.

No cooling or heating.

The refrigerant charge in

the system is not clear.

Electric shock or fi re.

Check

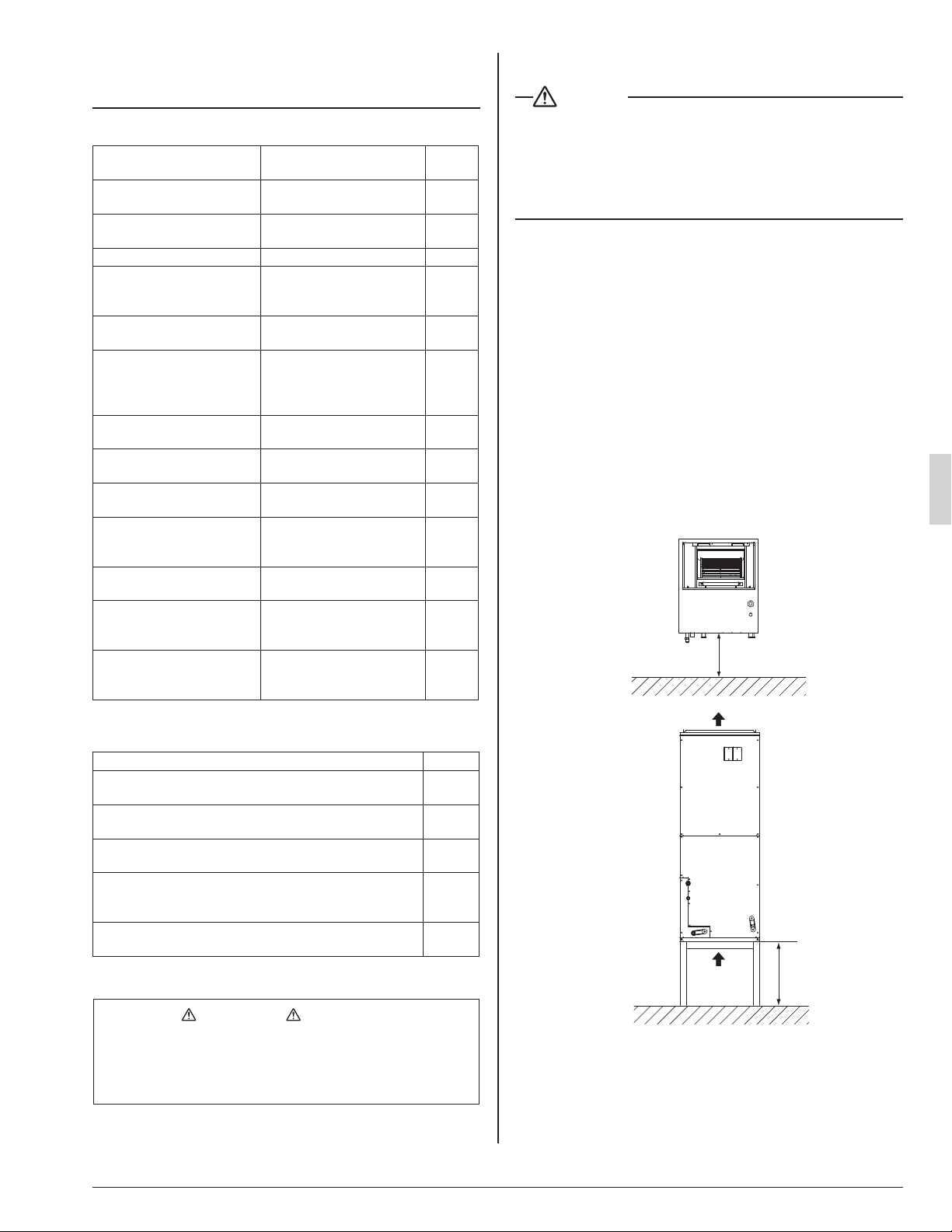

SELECTING INSTALLATION SITE3.

CAUTION

If you think the humidity inside the installation space might •

exceed 86°F and RH80%, reinforce the insulation on the

unit body.

Use glass wool or polyethylene foam as insulation so that

the thickness is more than 2 in. and fi ts inside the installation

space opening.

Select an installation site where the following conditions

(1)

are fulfi lled and that meets with your customer’s approval.

Where optimum air distribution can be ensured.•

Where nothing blocks air passage.•

Where condensate can be properly drained.•

Where the supports are strong enough to bear the •

indoor unit weight.

Where the false ceiling is not noticeably on an incline.•

Where suffi cient clearance for maintenance and service •

can be ensured. (Refer to Fig. 1-1 and Fig. 1-2)

Where piping between indoor and outdoor units is •

possible within the allowable limit. (Refer to the installation manual for the outdoor unit.)

If the a return-air duct is not installed, carefully select •

the place and method of product installation so that air

fl ow into the product will not be blocked.

If installed vertically

Air outlet

(Front view)

Fig. 1-1

Air inlet

H

The items with WARNING and CAUTION marks in the

operation manual are the items pertaining to possibilities for bodily

injury and material damage in addition to the general usage of the

product. Accordingly, it is necessary that you make a full explanation

about the described contents and also ask your customers to read

the operation manual.

If installed horizontally

20

22

13-1/16

12

26

A

B

C

1-1/4

Gas line

182 (2)

1

2-1/4

20-11/163

(2-5/16)

Liquid line

Inlet

Inlet

(Right side view)

(Front view)

(unit: in.)

Fig. 2

(Front view)

Air inlet

(Side view)

24 or

more

Air outlet

H

H

Fig. 1-2

WARNING

When installing the unit horizontally, be sure to tilt the unit in •

the direction shown in Fig. 1-2. If the unit is tilted in any other

way, water can leak.

PREPARATIONS BEFORE INSTALLA-4.

TION AND INSTALLATION

When installing the product, refer to “3. SELECTING (1)

INSTALLATION SITE” and consider the product size

as shown Fig. 2 and Table 1.

Ensure suffi cient space for the bottom of the product

•

(H dimensions) so that a downward slope of 1/100 can

be maintained for drain piping, as described for the intake

duct installation and in “6. DRAIN PIPING WORK”.

[ PRECAUTION ]

Install the indoor and outdoor units, power supply wiring •

and connecting wires at least 3.5 ft. away from televisions or radios in order to prevent image interference or

noise. (Depending on the radio waves, a distance of

3.3 ft. may not be suffi cient to eliminate the noise.)

If installing the wireless kit in a room with electronic •

fl uorescent lighting (inverter or rapid start type), the

remote controller’s transmission distance may be shortened. Indoor units should be installed as far away from

fl uorescent lighting as possible.

DANGER

Do not install unit in an area where fl ammable materials are •

present due to the risk of an explosion resulting in serious

injury or death.

WARNING

If the supporting structural members are not strong enough •

to take the unit’s weight, the unit could fall out of place and

cause serious injury.

Table 1

ABC

FTQ30 - 42

FTQ18 - 24 48-1/8 13-3/16 9-1/16

58-1/4 16-1/4 12-1/16

Make sure the range of the unit’s external static pres-(2)

sure is not exceeded. (up to 0.5 in.WG at “HH” speed.)

5 English

English 6

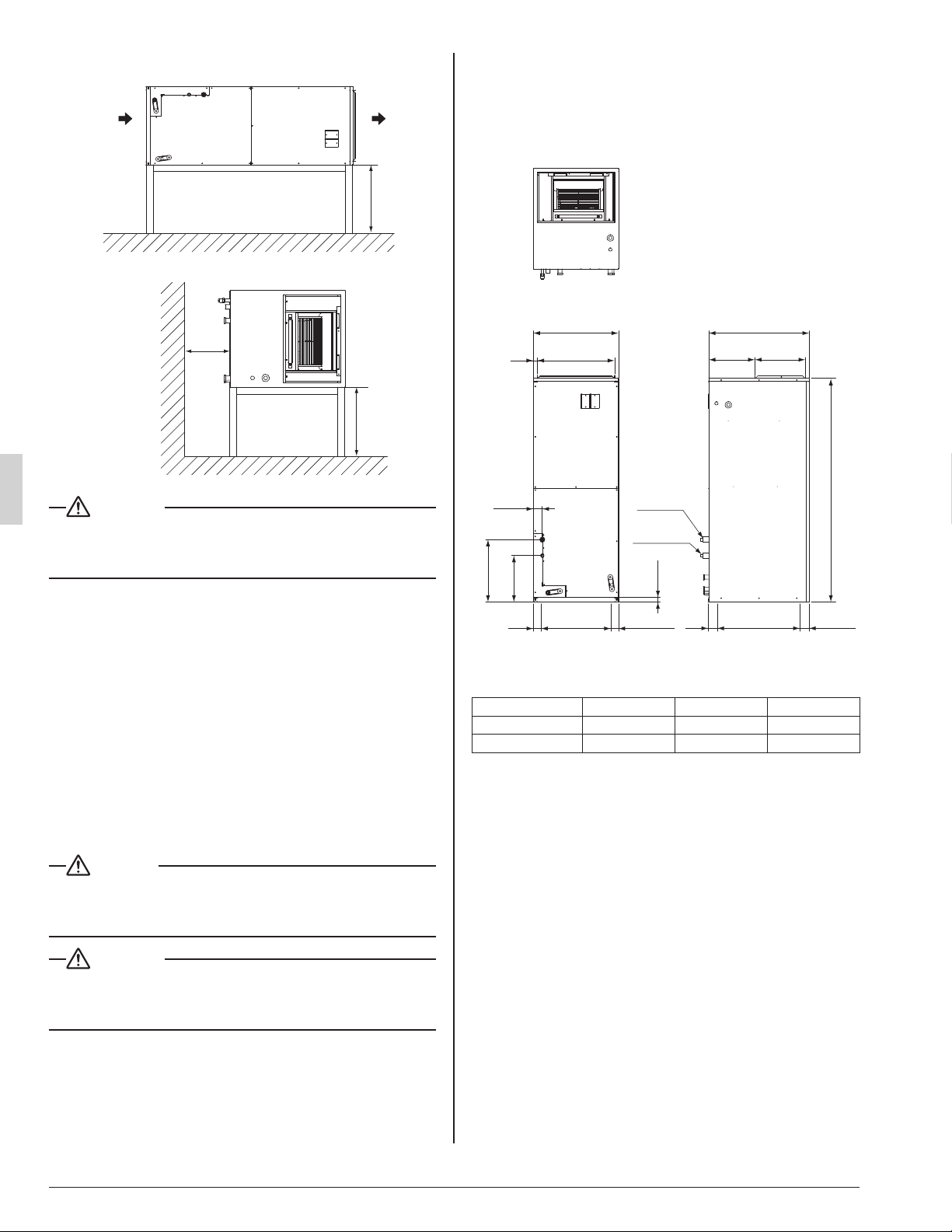

Condensation may form on the product during COOL (3)

If installed vertically

If installed horizontally

Second drain pan

Second drain pan

Drain piping

Drain piping

Level

If installed vertically

Level

If installed horizontally

operation. Be sure to provide (fi eld supplied) and

install a second drain pan.

Secure the unit fi rmly to prevent it from falling.(5)

REFRIGERANT PIPING WORK5.

〈Observe the requirements listed below for refrigerant

piping sizes.〉

Liquid Gas

3/8 in. 5/8 in.

〈Execute heat insulation work completely on both sides of

the gas piping and the liquid piping or else a water leakage might result.

Failing to insulate the pipes may cause leaking or burns.

And be sure to use the insulation which can withstand

such temperatures of 248°F or more for the gas piping.

Reinforce the insulation on the refrigerant piping according to the installation environment. If the temperature or

humidity in the product installation location might reach

86°F or 80%, respectively. Condensation may form on the

surface of the insulation.〉

Check if the unit is horizontally level.(4)

CAUTION

Make sure the unit is installed level using a level: four sides. •

(One thing to watch out for in particular is if the unit is installed so that the slope is not in the direction of the drain

piping, this might cause leaking.)

CAUTION

Follow the points at below.

Use a tube cutter and fl are suitable for the type of refriger-•

ant.

To prevent dust, moisture or other foreign matter from infi l-•

trating the piping, either pinch the end or cover it with tape.

Do not allow anything other than the designated refrigerant •

to get mixed into the refrigerant circuit, such as air. If any

refrigerant gas leaks while working on the unit, immediately

ventilate the room.

Connect the piping.(1)

The outdoor unit is fi lled with refrigerant.•

When connecting or disconnecting piping to or from the •

unit, be sure to use two spanners and two torque

wrenches. (Refer to Fig. 3)

Torque wrench

Spanner

Flare nut

Piping union

Fig. 3

Refer to Table 2 for the processing dimensions of the •

Heat insulation procedure for gas piping

Insulation material

for piping

(on unit side)

Insulation material

for piping (field supply)

Make sure that

the seam faces

upward.

Clamp

material (1)

(accessory)

Gas pipe

Liquid pipe

Flare nut joint

Attached to

the surface.

Insulation for fitting (7) (accessory)

Sealing pad (small) (8)

(accessory)

Wrap the Sealing pad (small) (8)

around the portion from the

surface of the main unit to the

upper part of the flare nut joint.

Insulation material

for piping (field supply)

Wrap the Sealing pad (small) (8)

around the portion from the

surface of the main unit to the

upper part of the flare nut joint.

Fig. 5

Heat insulation procedure for liquid piping

Insulation material

for piping

(on unit side)

Make sure that

the seam faces

upward.

Clamp

material (1)

(accessory)

Main unit

Flare nut joint

Attached to

the surface.

Insulation for fitting (6) (accessory)

Sealing pad (small) (8)

(accessory)

fl are.

Use the fl are nut provided with the unit.•

Apply ether oil or ester oil only to inner side of the •

fl are and screw in the fl are nut three to four turns fi rst

by hand at the time of connecting the fl are nut.

(Refer to Fig. 4)

Apply ester oil or ether oil

only to inner side of flare.

Refer to the illustration on the right-hand side and be sure (3)

to perform heat insulation work on the piping joints after

gas leakage checks. (Refer to Fig. 5)

•

Fig. 4

Refer to Table 2 for the corresponding tightening torque.•

Table 2

Pipe

Tightening torque

size

φ 3/8 26.7 ±2.6 lbf·ft

φ 5/8 50.6 ±5.0 lbf·ft

CAUTION

Do not excessively tighten the fl are nut.•

Doing so will break the fl are nut and refrigerant leakage may

result.

Make sure that all parts around the fl are are free of oil. •

The drain pan and the resin part may be deteriorated if oil is

attached.

If no torque wrenches are available, refer to Table 3 as a •

standard.

When the fl are nut is tightened with the spanner, the

tightening torque should increase suddenly. Tighten the

fl are nut further for the corresponding angle shown in

Table 3.

Table 3

Pipe size Further tightening angle

φ 3/8 60 to 90 degrees Approx. 7-7/8 in.

φ 5/8 30 to 60 degrees Approx. 11-13/16 in.

Flare

dimensions

A (in.)

0.504 – 0.520

0.760 – 0.776

Recommended arm length of

˚

2

±

˚

˚

5

2

4

±

˚

0

9

Flare shape

A

R0.016-0.031

tool

Use the Insulation for fi tting (6) and (7) provided to the •

liquid piping and gas piping, respectively, and conduct

heat insulation work.

(Tighten both edges of the Insulation for fi tting (6) and

(7) for each joint with the Clamp material (1).)

Make sure that the joint of the Insulation for fi tting (6) •

and (7) for the joint on the liquid piping and gas piping

side faces upward.

On completion of installation work, (2) check that there is no

gas leakage.

7 English

Wrap the Sealing pad (small) (8) around the Insulation •

for fi tting (6) and (7) for the joint (fl are nut part).

CAUTION

Be sure to insulate any fi eld piping all the way to the piping •

connection inside the unit. Any exposed piping may cause

condensation or burns if touched.

English 8

When brazing the refrigerant piping, perform nitrogen re-•

placement fi rst, or perform the brazing while feeding nitrogen into the refrigerant piping. (Refer to Fig. 6)

Pressure-reducing valve

Part to be brazed

Taping

In case of horizontal installation

Nitrogen

Refrigerant piping

hands

valve

Nitrogen

Fig. 6

CAUTION

When brazing piping while feeding nitrogen inside the •

piping, make sure to set the nitrogen pressure to 2.9 psi or

less using the pressure reducing valve.

(This pressure is such that a breeze is blown to your cheek.)

DANGER

Use of oxygen could result in an explosion resulting in •

serious injury or death. Only use dry nitrogen gas.

Refrigerant gas may produce toxic gas if it comes in contact •

with fi re such as from a fan heater, stove or cooking device.

Exposure to this gas could cause severe injury or death.

NOTE

Do not use fl ux when brazing refrigerant piping. Therefore, •

use the phosphor copper brazing fi ller metal (BCuP) which

does not require fl ux.

Flux has an extremely negative effect on refrigerant piping

systems. For instance, if chlorine based fl ux is used, it will

cause piping corrosion. Flux containing fl uorine will damage

refrigerant oil.

DRAIN PIPING WORK6.

CAUTION

Make sure all water is out before making the duct connection.

•

Fig. 7-2

Primary drain piping connection hole

Secondary drain piping

connection hole

Perform drain work so that the unit is drained thoroughly. •

(Be sure to insulate the following 2 locations since

condensation may cause water leakage.)

Be sure to use the included Drain hose (5) and Metal •

clamp (4).

Insert the Drain hose (5) up to the step on the drain

socket. Within the range of the tape section at the

end of the inserted hose, tighten the Metal clamp (4)

to the torques of 0.99 ± 0.1 lbf·ft (11.9 ± 1.2 lbf·in).

CAUTION

Do not tighten the Metal clamp (4) to torques exceeding the

•

specifi cation. Otherwise, the Drain hose (5), the socket, and

the Metal clamp (4) may become damaged.

To avoid the Sealing pad (large) (9) from tearing at the •

edge of the Metal clamp (4), either affi x a plastic tape

on the edge of the Metal clamp (4) or bend the end of

the Metal clamp (4) inward as shown in the fi gure.

<When affixing plastic tape>

Tightening

section

Approx. 90°

Install drain piping as described Fig. 7.(1)

Plastic tape

In case of vertical installation

To avoid tearing the Sealing

pad (large) (9), affix a

plastic tape.

Fig. 7-1

Cross section A-A

Secondary drain piping connection hole

Primary drain piping connection hole

Tape section

VP25 side

Metal clamp (4)

(accessory)

Drain hose (5)

(accessory)

Tightening

section

Bend the end to avoid

tearing the Sealing

pad (large) (9).

Approx. 90°

Main unit

<When bending the end>

Refer to the following fi gure and check the drain. Then, •

use the included Sealing pad (large) (9) to thermally

insulate the Metal clamp (4) and the Drain hose (5).

Sealing pad

(large) (9)

Start wrapping

from near the

tightening

section of the

Metal clamp (4)

(accessory)

Drain hose (5)

(accessory)

Do not make any gap

<Drain socket thermal insulation work>

Wrap the sealing

material around so

that the side with the

edge of the flat band is

doubly wrapped.

Sealing pad

(large) (9)

(accessory)

The drain pan has connections for a primary and sec-•

ondary drain.

The diameter of the drain piping should be greater than •

or equal to the diameter of the connecting pipe (vinyl

tube; pipe size : 25/32 in. ; outer dimension : 1-1/32 in.).

(not including a riser)

Keep piping runs short with a downward slope of at •

least 1/100 to prevent air pocket from forming.

Be sure to install a drain trap at the drain outlet since •

the inside of the unit is at negative pressure relative to

atmospheric pressure during operation.

To keep the piping from becoming clogged with dirt, •

avoid bends where possible and install so that traps can

be cleaned.

〈PRECAUTIONS〉

Drain piping connections

Do not connect the drain piping directly to sewage piping •

that smell of ammonia. The ammonia in the sewage might

enter the indoor unit through the drain piping and corrode

the heat exchanger.

Do not twist or bend the drain hose, as excessive force may •

cause it to leak.

After piping work is fi nished, check drainage fl ows (2)

smoothly.

Gradually insert approximately 1 quart of water into the •

drain pan to check drainage in the manner described

below.

INSTALLING THE DUCT7.

Exercise care regarding the following when performing duct work.

Verify that duct work does not exceed the unit’s setting range

•

of external static pressure (up to 0.5 in.WG at “HH” speed).

Install canvas ducts at air outlets and inlets so that vibrations •

from the main unit are not transmitted to ducts or the fl oor.

Additionally, line the duct with sound-absorbing material

(heat insulation material) as necessary.

Be sure to install an air fi lter to the product’s air inlet or to a •

fi eld-supplied air inlet inside the air passage on the suction

side.

Perform the curing and other work during duct welding so •

that the inside of the product is not exposed to spatter.

If the metal duct passes through a metal lath, wire lath, or •

metal plate of a wooden structure, isolate the duct from the

wall electrically.

Be sure to heat-insulate the duct to prevent the formation of •

condensation. (Material: Glass wool or polyethylene foam;

thickness: 1 inch.)

Explain to the customer how to operate and clean fi eld-•

supplied components such as air fi lters, air inlet grilles, air

outlet grilles.

To prevent drafts, locate the air outlet grille on the indoor •

side so that warm air from the outlet does not come into

direct contact with room occupants.

When an electric heater (optional) is installed, use metal •

duct and wrap the duct with a glass-wool insulation material.

At least

4 in.

At least

3 in.

Observe the following guidelines when installing con-•

centrated drain piping. Select the thickness of the

concentrated drain piping to refl ect the capacity of the

machine to which it will be connected.

CAUTION

Water accumulating in the drain piping can cause the drain •

to clog.

9 English

Air handler

ELECTRIC WIRING WORK8.

GENERAL INSTRUCTIONS8-1

Shut off the power before doing any work.•

All fi eld supplied parts and materials, electric works must •

conform to local codes.

Use copper conductors only.•

See also the “Wiring Diagram Label” located inside the unit’s •

front cover.

For details on hooking up the remote controller, refer to the •

“REMOTE CONTROLLER INSTALLATION MANUAL”.

All wiring must be performed by an authorized electrician.•

Install a wiring interrupter or ground-fault circuit interrupter •

for the power wiring.

Make sure the ground resistance is no greater than 100• Ω.

To avoid short circuiting the power supply wire, be sure to •

use insulated terminals.

Do not turn on the power supply (wiring interrupter or •

ground-fault circuit interrupter) until all other work is done.

English 10

DANGER

Do not ground units to water piping, telephone wires or •

lightning rods because incomplete grounding could cause a

severe shock hazard resulting in severe injury or death, nor

to gas piping because a gas leak could result in an explosion which could lead to severe injury or death.

LIST OF STANDARD WIRING EQUIPMENT8-2

Power supply wiring

(including ground wire)

Protective

device

15A

Size Wire Size

Must comply with

local codes.

NOTES

If the wiring is in a place where people it can be easily 1.

touched by people, install a ground-fault circuit interrupter

to prevent electric shock.

When using a ground-fault circuit interrupter, make sure to 2.

select one useful also to protection against overcurrent and

short-circuit.

When using a ground-fault circuit interrupter only for

grounding device, make sure to use a wiring interrupter

together.

The length of the transmission wiring and remote controller •

wiring are as follows.

Length of the transmission wiring and remote controller wiring

Outdoor unit – Indoor unit

Indoor unit – Remote controller Max. 1640 ft.

Transmission wiring

Remote controller wiring

2-conductor,

stranded,

non-shielded

copper/PVC or

vinyl jacket

Max. 3280 ft.

(Total wiring length: 6560 ft.)

AWG18 – 16

ELECTRICAL CHARACTERISTICS8-3

Units Power supply Fan motor

208/

230

Voltage

range

Min. 187

Max. 229/

Min. 207

Max. 253

MCA MOP HP FLA

1.5

15

1.2

350

Model Hz Volts

18 type

24 type 1.6 1.3

30 type 2.3 1.8

36 type 2.8 2.2

60

WIRING EXAMPLE9.

HOW TO CONNECT WIRINGS9-1

〈Precautions when laying power supply wiring〉

Wiring of different thicknesses cannot be connected to the •

power supply wiring terminal block. Slack in the power

supply wiring may cause abnormal heat.

Use sleeve-insulated round crimp-style terminals for con-•

nections to the power supply wiring terminal block. When

none are available, connect wires of the same diameter to

both sides, as shown in the fi gure.

Insulation sleeve

Round crimp-style terminal

Connect wires of

the same gauge to

both sides.

Do not connect

wires of the same

gauge to one side.

If the wiring gets too hot due to loose power-supply wiring, use the following precautions:

For wiring, use the designated power supply wiring and •

connect fi rmly, then secure to prevent outside pressure

being exerted on the terminal board.

Use the correct screwdriver for tightening the terminal •

screws. If the blade of screwdriver is too small, the head of

the screw might be damaged, and the screw will not be

properly tightened.

If the terminal screws are tightened too hard, screws might •

be damaged.

Refer to Table 4 for the tightening torque of the terminal •

screws.

Table 4

Terminal block Tightening torque (ft · lbf)

Remote controller / transmission

wiring terminal block (6P) (10P)

Power supply wiring terminal

block (3P)

Electric wire

Do not connect

wires of different

gauges.

0.58 – 0.72

0.87 – 1.06

42 type 3.6 400 2.8

MCA: Minimum Circuit Amps (A)

MOP: Max Overcurrent Protective Device (A)

HP: Fan motor output (W)

FLA: Full Load Amps (A)

Remove the front panel (upper).(1)

Terminal block

Terminal block

Transformer

Fig. 8

<FTQ18,24,30,36PBVJU models>

<FTQ42PBVJU model>

Terminal block

Terminal block

Transformer

Top panel

Low-voltage

hole

Remove the electric component box cover.(2)

High-voltage

hole

(3)

Pass the power supply wiring and the ground wire

through the top panel’s high-voltage hole (requires use of

conduit) and pass the remote controller wiring and transmission wiring through the top panel’s low-voltage hole.

Pass the included insulation tube through the hole in the •

panel before connecting the electric wires and the

ground wire to the terminal block shown in Fig. 8.

Pass the included insulation tube through the hole in the •

panel before connecting the remote controller wiring

and transmission wires to the terminal block shown in

Fig. 8.

Then secure them in place with the included Clamp •

material (1) as shown in Fig. 8 to protect them from

external force from outside the unit.

If the power supply voltage is 208V, change the trans-•

former wire connection from the 240V terminal to the

208V terminal. (Refer to Fig. 9)

Changing the transformer wire connection

Connector

(Connect the wire to the 208V terminal.

Be sure to insert the wire securely until

a clicking sound is produced.)

Wire (Red)

Connector

Cap

230V power supply (factory set)®208V power suppy®

240V208VCOM

Cap

(Change the

connection.)

Wire

(Red)

Fig. 9

208VCOM 240V

11 English

English 12

How to use insulation tube.

Pass through the

conduit

Clamp material (1)

(accessory)

Remote controller and

transmission wiring

Power supply wiring

and ground wire

Power supply

Main

switch

Outdoor unit

Power supply wire

Transmission wire

Switch

Overcurrent

Protective device

Indoor unit

Remote controller

Use the insulation tube to cover the wiring.•

Joint the insulation tube with the tape and cut off the tube •

sticking out of the unit.

Tape

Insulation tube large (3)

Insulation tube

small (2)

Cut off the sticking

out of the unit.

Pass the power supply wiring and the ground wire (4)

through the conduit (conduit should be fi eld supplied). The hole for running wires through should be

sealed completely to prevent air from entering.

* When installing an optional electric heater kit, run both

the power supply wiring and ground wire of the electric

heater kit through the conduit.

Outside the air conditioners, separate the low voltage wiring •

(remote controller and transmission wiring) and high voltage

wiring (ground wire and power supply wiring) by at least 5 in.

so that they do not pass through the same place together.

Proximity may cause electrical interference, malfunctions,

and breakage.

[ PRECAUTIONS ]

Refer to the “REMOTE CONTROLLER INSTALLATION •

MANUAL” on how to install and lay the wiring for the remote

controller.

See also the “Wiring Diagram Label” located inside the unit’s •

blower deck.

Connect the remote controller and transmission wiring their •

respective terminal blocks.

CAUTION

Do not, under any circumstances, connect the power supply •

wiring to the remote controller or transmission wiring terminal block. Doing so can destroy the entire system.

[ WIRING EXAMPLE ]

Fit the power supply wire of each unit with a switch and fuse •

as shown in the drawing.

COMPLETE SYSTEM EXAMPLE

Install the front panel (upper).(5)

When using 1 remote controller for 1 indoor unit. (Nor-1.

mal operation)

DANGER

Use only specifi ed wire and connect wires to terminals •

tightly. Be careful that wires do not place external stress on

terminals. Keep wires in neat order so as to not to obstruct

other equipment. Make sure that the electric component box

Power supply

208/230V

~

60Hz

L1L2

Outdoor unit

Control box

IN/D OUT/D

F

1 F2 F1 F2

cover closes tightly. Incomplete connections could result in

overheating, and in worse cases, electric shock or fi re.

WARNING

Never connect power supply wiring to the terminal block for

•

remote controller wiring as this could damage the entire system.

CAUTION

When doing the wiring, make sure the wiring is neat and

•

does not cause the electric front panel to stick up, then close

the panel fi rmly. When attaching the front panel, make sure

you do not pinch any wires.

L1L

Indoor unit

P1P

2

F1F2T1T

2

2

P1P

2

Remote controller

(option)

When using 2 remote controllers for 1 indoor unit.2.

Remote controller wiring

terminal block

Remote

controller 2

(SUB)

Remote

controller 1

(MAIN)

1P2P1F2F1T2

T

FORCED

OFF

REMOTE

CONTRL

TRANSMISSION

WIRING

Power supply

208/230V

~

60Hz

L1L2

Outdoor unit

Control box

IN/D OUT/D

F

1 F2 F1 F2

REMOTE CONTROL (FORCED OFF AND ON/9-3

OFF OPERATION)

Connect input lines from the outside to the terminals T•

T² on the terminal block (6P) for remote controller to achieve

remote control.

See the “• 10. FIELD SETTING AND TEST RUN” for details

and

¹

on operation.

F

L1L

2

P1P2F1F2T1T

1F2

P

1P2

REMOTE

TRANSMISSION

CONTRL

2

WIRING

1T2

FORCED

OFF

T

Indoor unit

P

controller

(option)

(SUB)(MAIN)

Remote

1P2

1P2

P

For use with 2

remote controllers

NOTE

A single switch can be used to supply power to units on the 1.

same system. However, branch switches and branch circuit

breakers must be selected carefully.

Do not ground the equipment on gas piping, water piping or 2.

lightning rods, or crossground with telephones. Improper

grounding could result in electric shock.

CONTROL BY 2 REMOTE CONTROLLERS (Con-9-2

trolling 1 indoor unit by 2 remote controllers)

When using 2 remote controllers, one must be set to “MAIN” •

and the other to “SUB”.

If the remote controller to be used is Model BRC1E71, read •

the installation manual supplied with the remote controller.

MAIN/SUB CHANGEOVER

Press and hold the operation switch button of the (1)

remote controller for one of the two units for four

seconds or more. When the LCD display changes

from the display as the main remote controller to the

display as the sub remote controller, the setting is

complete.

Remove the front panel.(2)

Add remote controller 2 (SUB) to the terminal block (3)

for remote controller (P¹, P²) in the electric component

box. (There is no polarity.)

Input A

Wire specifi cation Sheathed vinyl cord or cable (2 wires)

Gauge AWG18 – 16

Length Max. 328 ft.

External terminal

Contact that can ensure the minimum

applicable load of 15 V DC, 1 mA.

FIELD SETTING AND TEST RUN10.

〈Field settings may have to be performed using the remote controller, depending on the type of installation.〉

Make sure the control box covers are closed on the (1)

indoor and outdoor units.

Depending on the type of installation, make the fi eld (2)

settings from the remote controller after the power is

turned on, following the “Field Settings” manual which

came with the remote controller.

The settings can select “Mode No.”, “FIRST CODE NO.” •

and “SECOND CODE NO.”.

The “Field Settings” included with the remote controller •

lists the order of the settings and method of operation.

FIELD SET MODE

Field Settings

Unit No

0

–––

–––

1–01

–––

5

–––

9

0–01

4

8

SECOND CODE NO.

Mode

20

Setting

2–02

–––

6

–––

a

3–01

–––

7

–––

b

Mode No.

FIRST CODE NO.

Lastly, make sure the customer keeps the “Field Settings” •

manual, along with the operating manual, in a safe place.

13 English

English 14

SETTINGS WHEN USING THE OPTIONAL RE-10-1

MOTE SENSOR

This product does not include an air inlet thermistor.

It uses a remote controller thermistor for control purposes.

For this reason, it is necessary to install an optional remote

thermistor in the following cases:

When the remote controller will be installed at a location •

where it cannot accurately measure the indoor temperature.

When using a remote controller without a built-in thermistor •

(simple remote controller, wireless remote controller, no

remote controller).

When using an optional remote sensor, change the settings as

described Table 5:

(The SECOND CODE NO. is set to “03” when shipped.)

Table 5

Mode No.

To use both the remote

controller thermistor and the

remote sensor

To use only the remote sensor 02

To use only the remote

controller thermistor

* factory set

10 (20) 2

FIRST

CODE NO.

SECOND

CODE NO.

01

03*

REMOTE CONTROL SETTING10-2

Forced off and ON/OFF operation should be selected by select-

•

ing the SECOND CODE NO. as shown in the table Table 6.

Table 6

External ON/OFF input Mode No.

Forced off

ON/OFF operation 02

* factory set

12 (22) 1

FIRST

CODE NO.

Input A of forced off and ON/OFF operation work as shown •

in Table 7.

Table 7

Forced off ON/OFF operation

Input A “on” to force a stop

(remote controller reception

prohibited)

Input A “off” to allow remote

controller

Unit operated by changing input

A from “off” to “on”

Unit stopped by changing input A

from “on” to “off”

SECOND

CODE NO.

01*

SETTING THE FILTER SIGN DISPLAY INTERVAL10-3

Explain the following to the customer if the fi lter dirt settings •

have been changed.

The fi lter sign display time is set to 2500 hours (equivalent •

to 1 year’s use) when shipped.

The settings can be changed to not display.•

When installing the unit in a dusty place, set the fi lter sign •

display time to shorter intervals (1,250 hours).

Explain it to the customer that the fi lter needs to be cleaned •

regularly to prevent clogging and also the time that is set.

SECOND

Mode No. FIRST CODE NO.

0 Filter dirt low high

10 (20)

1 (low/high)

3 Filter sign display ON OFF

Displayed time

(units: hours)

CODE NO.

01 02

2500/

1250

10000/

5000

EXTERNAL STATIC PRESSURE SETTING10-4

Setting remote controller.(1)

The “SECOND CODE NO.” is set to 11 (an external static

pressure of 0.4 in.WG) at factory set.

External Static

Pressure

(in.W.G.)

0.150

0.175 02

0.200 03

0.225 04

0.250 05

0.275 06

0.300 07

0.325 08

0.350 09

0.375 10

0.400 11

0.425 12

0.450 13

0.475 14

0.500 15

Mode No.

13 (23) 06

CAUTION

Keep in mind that a shortage of airfl ow quantity or water •

leakage will result because the air conditioner will be

operated outside the rated range of airfl ow quantity if the

external static pressure is wrongly set.

FIRST

CODE NO.

SECOND

CODE NO.

01

INSTALLATION OF AN AIR FILTER10-5

Air filter

(field supply:

H r W rD (in.)

: 1 r 20 r 25)

Take off the part on the bottom of the front panel.(1)

Connect the wires(2)

Run the wires through the low-voltage hole.•

Connect the wires to the terminal block (10P) of the •

product. The terminal Nos. for wire connection are

shown below. Refer to the information as needed.

Terminal Nos. are indicated on the name plate for the

terminal block.

Terminal

block (10P)

10

9

8

7

6

5

4

3

2

1

Insert the air fi lter as far as it can go.(2)

SETTING FOR LOCAL SUPPLIED OPTION10-6

Installation of the humidifi er, economizer and air (1)

purifi er (UV lamp)

Humidifi er, economizer and air purifi er (UV lamp) are •

sold separately. For the method of installation, refer to

the manual provided with each optional product.

Terminal No.

1, 2 Outputs: indoor unit ON signal. (AC 24V)

3, 4

5, 6

7, 8

9, 10

Input/output signal

Outputs: indoor unit cooling THERMO ON signal. (AC 24V)

Receives input: Air purifi er operation ON signal. (dry contact)

Receives input: Humidifi er operation ON signal. (dry contact)

Receives input: Forced closure of Indoor Unit Electronic

Expansion Valve during cooling operation. (dry contact)

On-site setting of air purifi er/humidifi er(3)

Mode No.

14 (24) 4 FAN SPEED

14 (24) 5

FIRST CODE NO. 01 02 03

Refer to

UNDER

OPERATING

purifi er and

humidifi er

FAN RESIDUE

TIME FOR

HUMIDIFIER

remote

controller

setting

SPEED

30 [sec.] 60* [sec.] 120 [sec.]

* factory set

H*

WARNING

If the unit is installed with an electric heater, install the •

optional product at a location where it is not exposed directly

to the heat from the electric heater. Direct exposure to heat

can result in an equipment malfunction or fi re.

15 English

English 16

SETTINGS FOR SEPARATELY SOLD ACCES-10-7

SORIES

See the instruction manuals included with optional accesso-•

ries for the necessary settings.

〈When using a wireless remote controller〉

A wireless remote controller address needs to be set when •

using a wireless remote controller. See the installation

manual included with the wireless remote controller for

details on how to make the settings.

Perform a test run according to the outdoor unit’s installation manual.

The operation lamp of the remote controller will fl ash when a •

malfunction occurs. Check the malfunction code on the

liquid crystal display to identify the point of trouble. An

explanation of malfunction codes and the corresponding

trouble is provided in “CAUTION FOR SERVICING” of the

outdoor unit.

If the display shows any of the following, there is a possibility

that the wiring was done incorrectly or that the power is not

on, so check again.

Remote controller

display

“ A8 ” lit

“ C1 ” lit

“ C6 ” lit

“ U3 ” lit

“

” is lit up

“ U4 ” is lit up

“ UH ” is lit up

No display

Error in power supply voltage to indoor

•

unit.

Fan driver PCB of indoor unit • ↔ indoor

control PCB transmission error.

Improper combination of fan driver PCB •

of indoor unit or setting failure in control

PCB type.

Test operation of outdoor unit has not •

been fi nished.

There is a short circuit at the FORCED •

OFF terminals (

The power on the outdoor unit is off. •

The outdoor unit has not been wired for •

power supply.

Incorrect wiring for the transmission •

wiring and / or FORCED OFF wiring.

The power on the indoor unit is off. •

The indoor unit has not been wired for •

power supply.

Incorrect wiring for the remote controller •

wiring, the transmission wiring and / or

the FORCED OFF wiring.

Contents

T¹, T²)

CAUTION

Always stop the test run using the remote controller to stop •

operation.

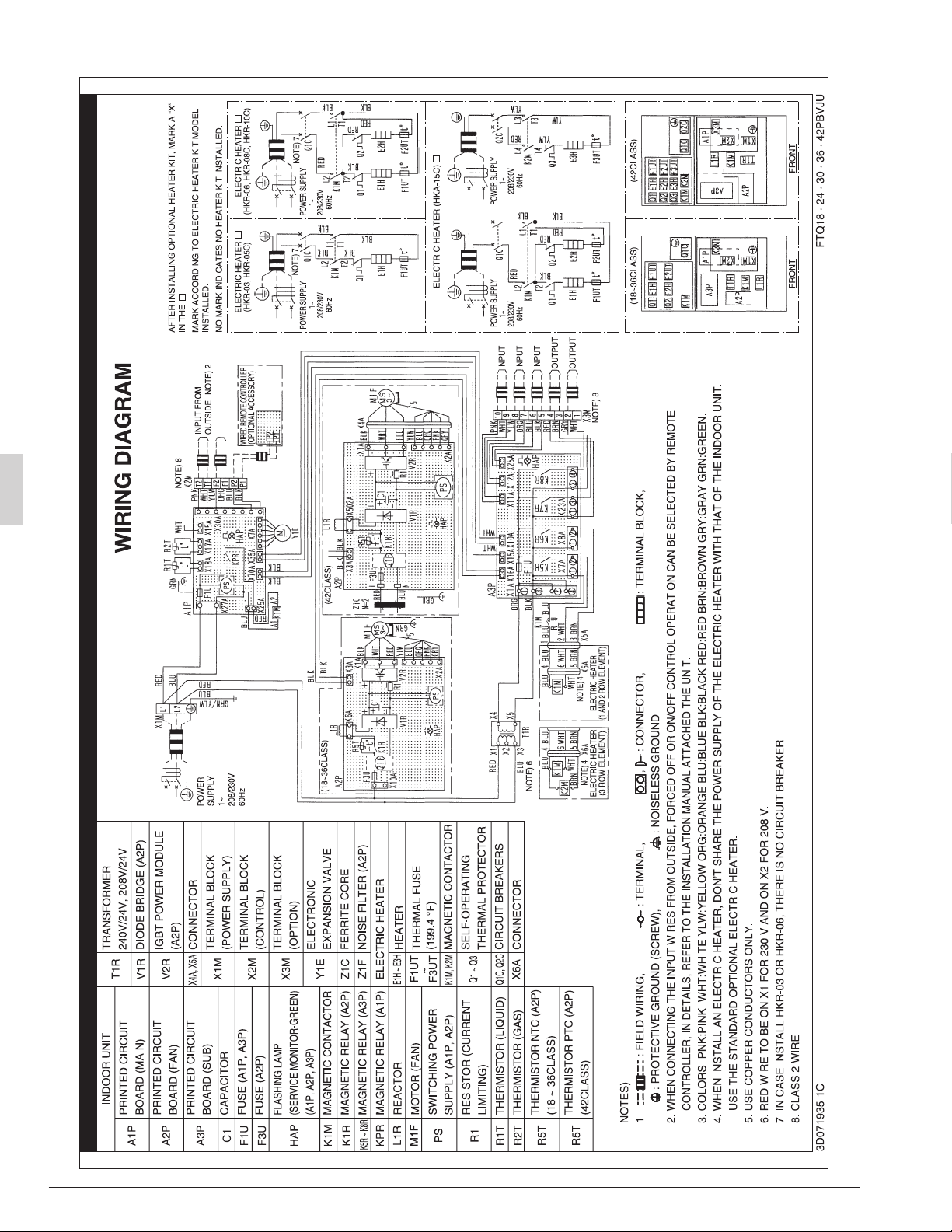

WIRING DIAGRAM11.

17 English

3P250363-4E

EM11A011A

(1609)

HT

Loading...

Loading...