Daikin FFQ25BV1B, FFQ35BV1B, FFQ50BV1B, FFQ60BV1B Installation manuals

FFQ25BV1B

FFQ35BV1B

FFQ50BV1B

FFQ60BV1B

SPLIT SYSTEM Air Conditioners Installation manual

CONTENTS

1. SAFETY CONSIDERATIONS ....................................................................................1

2. BEFORE INSTALLATION ..........................................................................................3

3. SELECTING INSTALLATION SITE ............................................................................5

4. PREPARATIONS BEFORE INSTALLATION .............................................................6

5. INDOOR UNIT INSTALLATION ..................................................................................7

6. REFRIGERANT PIPING WORK ................................................................................9

7. DRAIN PIPING WORK ..............................................................................................11

8. WIRING EXAMPLE ..................................................................................................14

9. ELECTRIC WIRING WORK .....................................................................................15

10. FIELD SETTINGS ....................................................................................................18

11. INSTALLATION OF THE DECORATION PANEL .................................................... 19

12. TEST OPERATION ..................................................................................................19

13. WIRING DIAGRAM ..................................................................................................22

1. SAFETY CONSIDERATIONS

Please read these “SAFETY CONSIDERATIONS” carefully before installing air conditioning equipment and

be sure to install it correctly. After completing the installation, make sure that the unit operates properly during the start-up operation. Please instruct the customer how to operate the unit and keep it maintained.

Also, inform customers that they should store this installation manual along with the operation manual for

future reference.

This air conditioner comes under the term “appliances not accesible to the general public”.

Meaning of warning and caution symbols

WARNING ..........Failure to observe a warning may result in death.

CAUTION ...........Failure to observe a caution may result in injury or damage to the equipment.

WARNINGWARNING

• Ask your dealer or qualified personnel to carry out installation work. Do not try to install the machine yourself.

Improper installation may result in water leakage, electric shocks or fire.

• Perform installation work in accordance with this installation manual.

Improper installation may result in water leakage, electric shocks or fire.

• Be sure to use only the specified accessories and parts for installation work.

Failure to use the specified parts may result in water leakage, electric shocks, fire or the unit falling.

• Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

A foundation of insufficient strength may result in the equipment falling and causing injuries.

• Carry out the specified installation work after taking into account strong winds, typhoons or earthquakes.

Improper installation work may result in the equipment falling and accidents.

• Make sure that a separate power supply circuit is provided for this unit and that all electrical work is car-

ried out by qualified personnel according to local laws and regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shocks or

fire.

• Make sure that all wiring is secured, the specified wires are used, and no external forces act on the termi-

nal connections or wires.

Improper connections or installation may result in fire.

English 1

• When wiring the power supply and connecting the wiring between the indoor and outdoor units, position

the wires so that the control box lid can be securely fastened.

Improper positioning of the control box lid may result in electric shocks, fire or the terminals overheating.

• If the refrigerant gas leaks during installation, ventilate the area immediately.

Toxic gas may be produced if the refrigerant gas comes into contact with fire.

• After completing the installation work, check that the refrigerant gas does not leak.

Toxic gas may be produced if the refrigerant gas leaks into the room and comes into contact with a source

of fire, such as a fan heater, stove or cooker.

• Before touching electrical parts, turn off the unit.

CAUTION

• Ground the air conditioner.

• Do not connect the ground wire to gas or water pipes, lightning rods or telephone ground wires. Incomplete grounding may result in electric shocks.

• Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric shocks.

• While following the instructions in this installation manual, install drain piping in order to ensure proper

drainage and insulate piping in order to prevent condensation.

Improper drain piping may result in water leakage and property damage.

• Install the indoor and outdoor units, power cord and connecting wires at least 1 meter away from televisions or radios in order to prevent image interference or noise.

(Depending on the radio waves, a distance of 1 meter may not be sufficient enough to eliminate the

noise.)

• Remote controller (wireless kit) transmitting distance can result shorter than expected in rooms with electronic fluorescent lamps. (inverter or rapid start types)

Install the indoor unit as far away from fluorescent lamps as possible.

• Do not install the air conditioner in the following locations:

(a) where a mineral oil mist or an oil spray or vapor is produced, for example in a kitchen

Plastic parts may deteriorate and fall off or result in water leakage.

(b) where corrosive gas, such as sulfurous acid gas, is produced

Corroding copper pipes or soldered parts may result in refrigerant leakage.

(c) near machinery emitting electromagnetic waves

Electromagnetic waves may disturb the operation of the control system and result in a

malfunction of the equipment.

(d) where flammable gases may leak, where there are carbon fiber or ignitable dust suspensions in the

air, or where volatile flammables such as thinner or gasoline are handled.

Operating the unit in such conditions may result in fire.

2 English

2. BEFORE INSTALLATION

• When moving the unit while removing it from the carton box, be sure to lift it by holding on to the

four lifting lugs without exerting any pressure on other parts, especially, the refrigerant piping,

drain piping, and other resin parts.

• Be sure to check the type of R410A refrigerant to be used before installing the unit.(Using an incorrect

refrigerant will prevent normal operation of the unit.)

• The accessories needed for installation must be retained in your custody until the installation work is completed. Do not discard them!

• Decide upon a line of transport.

• Leave the unit inside its packaging while moving, until reaching the installation site. Where unpacking is

unavoidable, use a sling of soft material or protective plates together with a rope when lifting, to avoid

damage or scratches to the unit.

• Especially, do not unfasten packing case(top) guarding the control box until suspending the unit.

• When selecting installation site, refer to the paper pattern.

• For the installation of an outdoor unit, refer to the installation manual attached to the outdoor unit.

• Do not use the unit in locations with high salt content in the air such as beachfront property, locations

where the voltage fluctuates such as factories, or in automobiles or marine vessels.

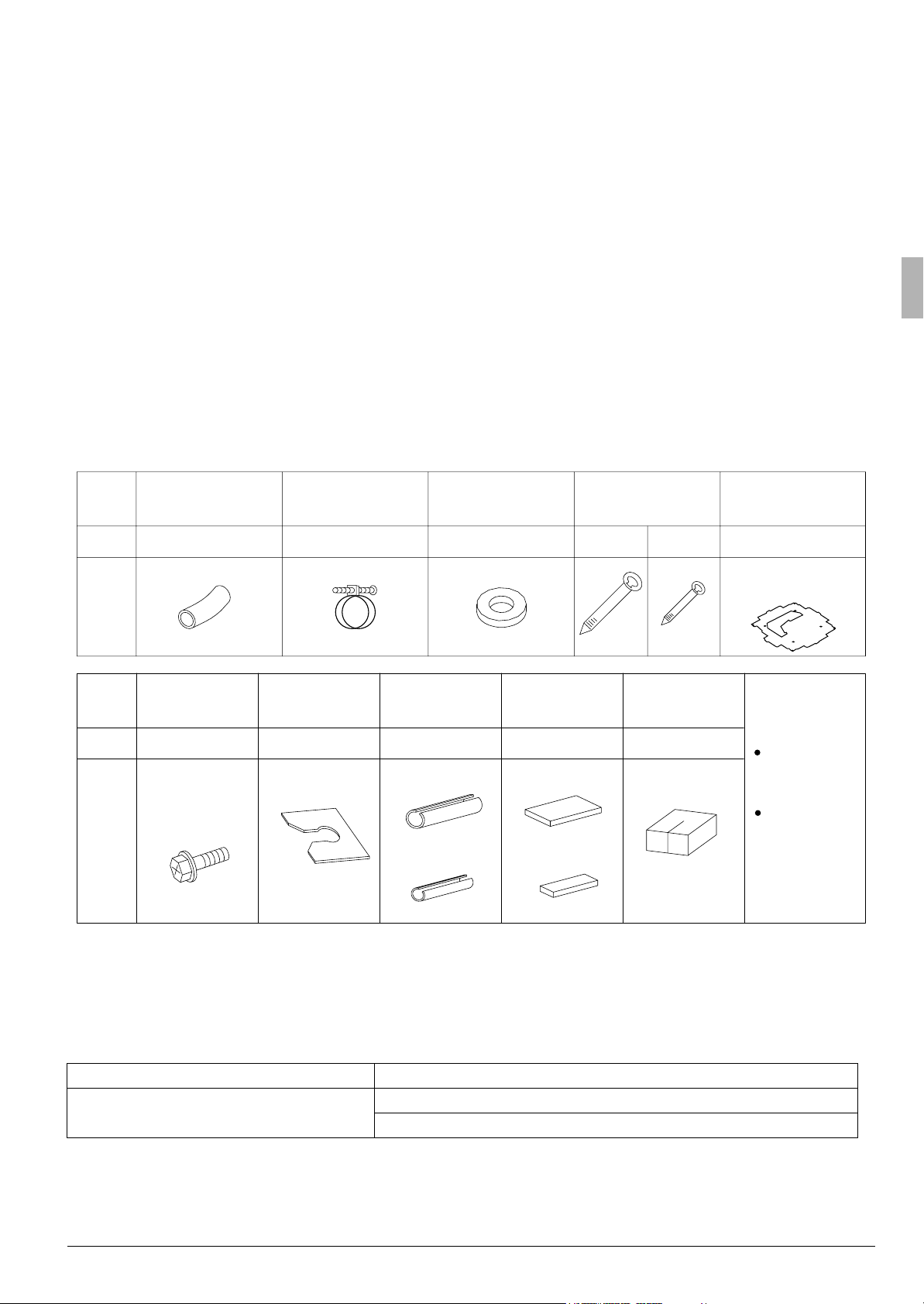

2-1 ACCESSORIES

Check the following accessories are included with your unit.

Name

Quantity

Shape

Name

Quantity

Shape

3)Washer for

(1)Drain hose

(2)Clamp (4)Clamp

1 pc. 1 pc.1 pc. 8 pcs.

(

(

6)Screws

(M5)

7)Washer

fixing plate

Insulation for fitting

4 pcs. 4 pcs. 2 pcs.

For paper pattern

for installation

(

hanging bracket

1 each.

(8)For gas pipe

(9)For liquid pipe

(Big)

6 pcs.

Sealing pad

1 each.

(

10)Large

(

11)Small

(Small)

1 pc.

(12)Sealing

material

(5)Paper pattern

for installation

Also used as

packing material

(Other)

Operation

manual

Installation

manual

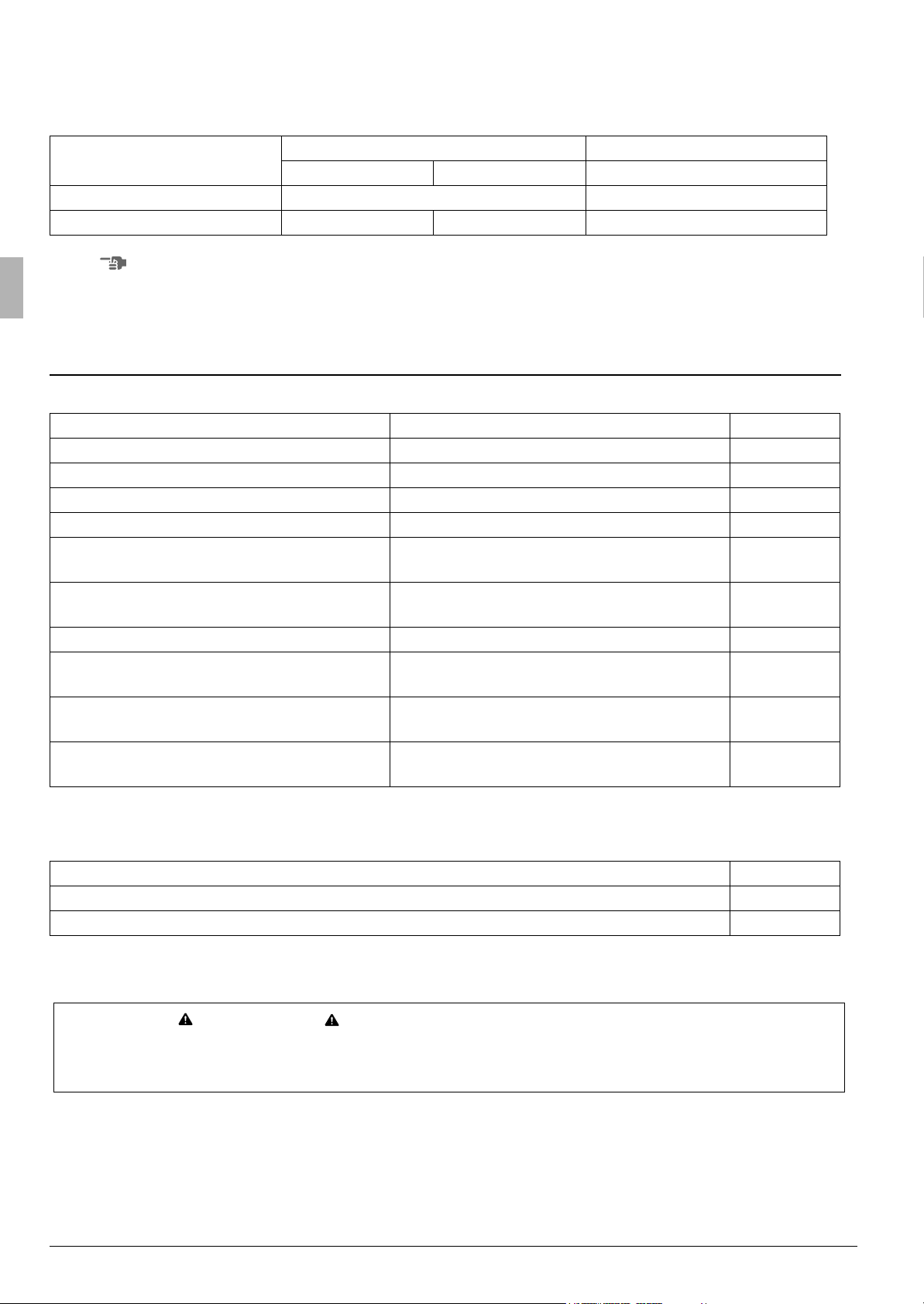

2-2 OPTIONAL ACCESSORIES

• The optional decoration panel and remote controller are required for this indoor unit.(Refer to Table 1, 2)

Table 1

Unit model Optional decoration panel

FFQ25

English 3

·35·50·

60BV1B

BYFQ60BW1

Colour : White

• These are two types of remote controllers: wired and wireless. Select a remote controller from Table 2

according to customer request and install in an appropriate place.

Table 2

Remote controller type

Cooling only type Heat Pump type Heat Pump type

Wired type BRC1C517 BRC1C61

Wireless type BRC7E531W BRC7E530W BRC7E530W

NOTE

• If you wish to use a remote controller that is not listed in

controller after consulting catalogs and technical materials

European market Australian market

“Table 2” on page 4, select a suitable remote

.

FOR THE FOLLOWING ITEMS, TAKE SPECIAL CARE DURING CONSTRUCTION AND

CHECK AFTER INSTALLATION IS FINISHED.

a. Items to be checked after completion of work

Items to be checked If not properly done, what is likely to occur Check

Are the indoor and outdoor unit fixed firmly? The units may drop, vibrate or make noise.

Is the gas leak test finished? It may result in insuffcient cooling.

Is the unit fully insulated? Condensate water may drip.

Dose drainage flow smoothly? Condensate water may drip.

Dose the power supply voltage correspond

to that shown on the name plate?

Are wiring and piping correct?

Is the unit safely grounded? Dangerous at electric leakage.

Is wiring size according to specifications?

Is something blocking the air outlet or inlet

of either the indoor or outdoor units?

Are refrigerant piping length and additional

refrigerant charge noted down?

The unit may malfunction or the components burn out.

The unit may malfunction or the components burn out.

The unit may malfunction or the components burn out.

It may result in insufficient cooling.

The refrigerant charge in the system is not

clear.

b. Items to be checked at time of delivery

Also review the “SAFETY CONSIDERATIONS”

Items to be checked Check

Did you explain about operations while showing the instruction manual to your customer?

Did you hand the instruction manual over to your customer?

c. Points for explanation about operations

The items with WARNING and CAUTION marks in the instruction manual are the items pertaining to possibillties for bodily injury and material damage in addition to the general usage of

the product. Accordingly, it is necessary that you make a full explanation about the described contents

and also ask your customers to read the instruction manual.

2-3 NOTE TO THE INSTALLER

Be sure to instruct customers how to properly operate the unit (especially cleaning filters, operating different functions, and adjusting the temperature) by having them carry out operations themselves while looking at the manual.

4 English

3. SELECTING INSTALLATION SITE

Please attach additional thermal insulation material to the unit body when it is believed that the relative

humidity in the ceiling exceeds 80%. Use glass wool, polyethylene foam, or similar with a thickness of 10

mm or more as thermal insulation material.

For this unit, you are able to select air flow direction.

To enable the discharge of air in 2 or 3 directions, it is necessary to purchase the sealing member of air discharge outlet.

(1) Select an installation site where the following conditions are fulfilled and that meets your cus-

tomer's approval.

• In the upper space (including the back of the ceiling) of the indoor unit where there is no possible dripping of water from the refrigerant pipe, drain pipe, water pipe, etc.

• Where optimum air distribution can be ensured.

• Where nothing blocks air passage.

• Where condensate can be properly drained.

• Where the ceiling is strong enough to bear the indoor unit weight.

• Where the false ceiling is not noticeably on an incline.

• Where sufficient clearance for maintenance and service can be ensured.

• Where there is no risk of flammable gas leakage.

• Where piping between indoor and outdoor units is possible within the allowable limit.

(Refer to the installation manual for the outdoor unit.)

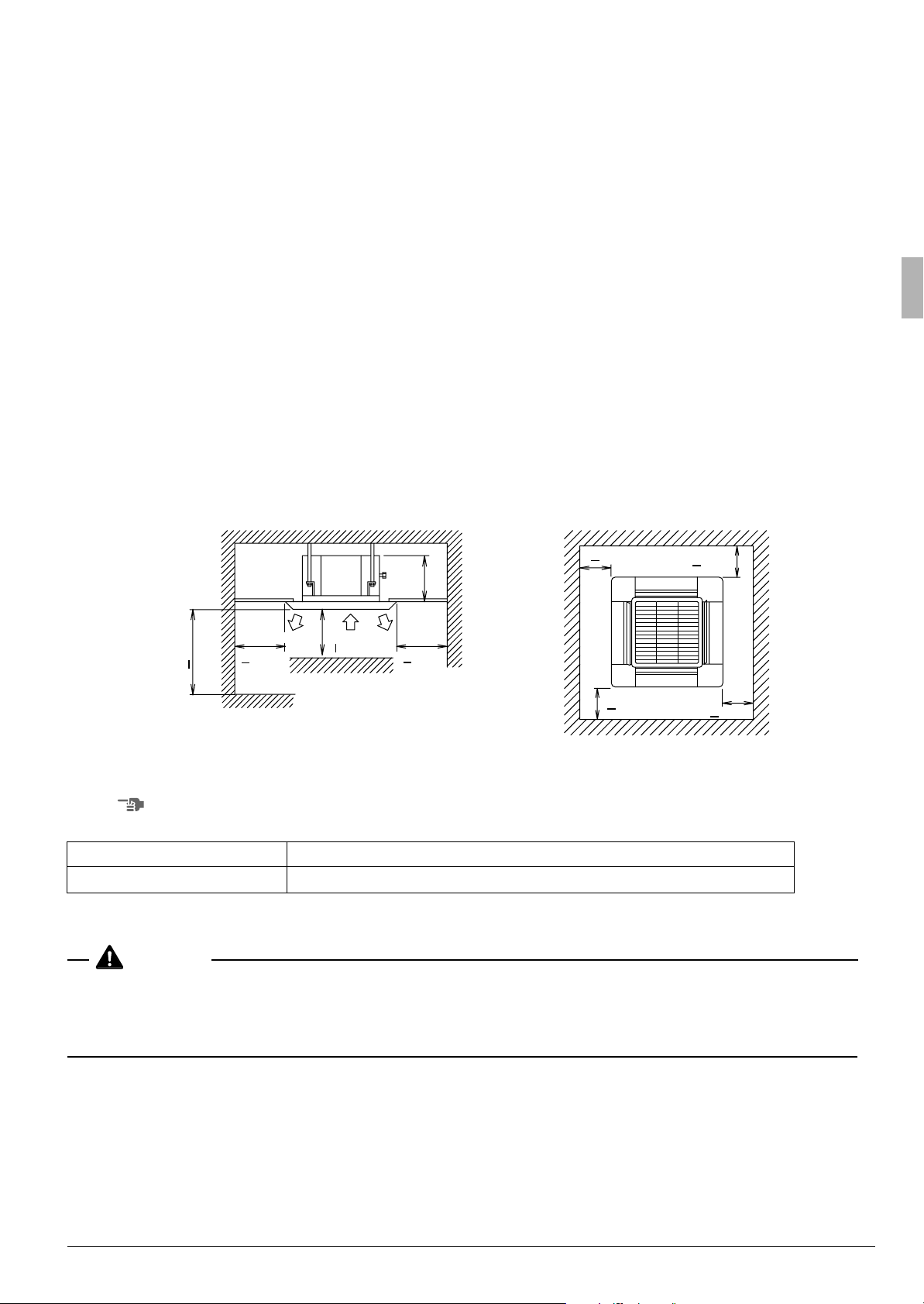

[Space required for installation] (mm)

*

>

1500

*

>

1500

H

2500

>

For installation

Air

outlet

>

*

1500

in high places

Air

1500

inlet

>

Fig. 1

Air

outlet

*

>

1500

*

>

1500

*

>

1500

Fig. 2

NOTE

• Leave 200 mm or more space where marked with the *, on sides where the air outlet is closed.

Model H

FFQ25

·35·50·

60

285 (Confirm the space of 295 or more)

CAUTION

• Install the indoor and outdoor units, power cord and connecting wires at least 1 meter away from televisions or radios in order to prevent image interference or noise.

(Depending on the radio waves, a distance of 1 meter may not be sufficient enough to eliminate the

noise.)

(2) Air flow direction

Select the air flow directions best suited to the room and point of installation. (For air outlet in 2 or 3 directions, it is necessary to make field settings by remote controller and to close the air outlet(s). Refer to the

installation manual of the sealing member of air discharge outlet and the section entitled 10. FIELD SETTING)

English 5

[Air flow direction] (Example)

Piping Piping Piping

Air outlet in

4 directions

Air outlet in

3 directions

Air outlet in

2 directions

(3) Use suspension bolts for installation. Check whether the ceiling is strong enough to support the

weight of the unit or not. If there is a risk, reinforce the ceiling before installing the unit.

(Installation pitch is maked on the paper pattern for installation. Refer to it to check for points requiring

reinforcing.)

4. PREPARATIONS BEFORE INSTALLATION

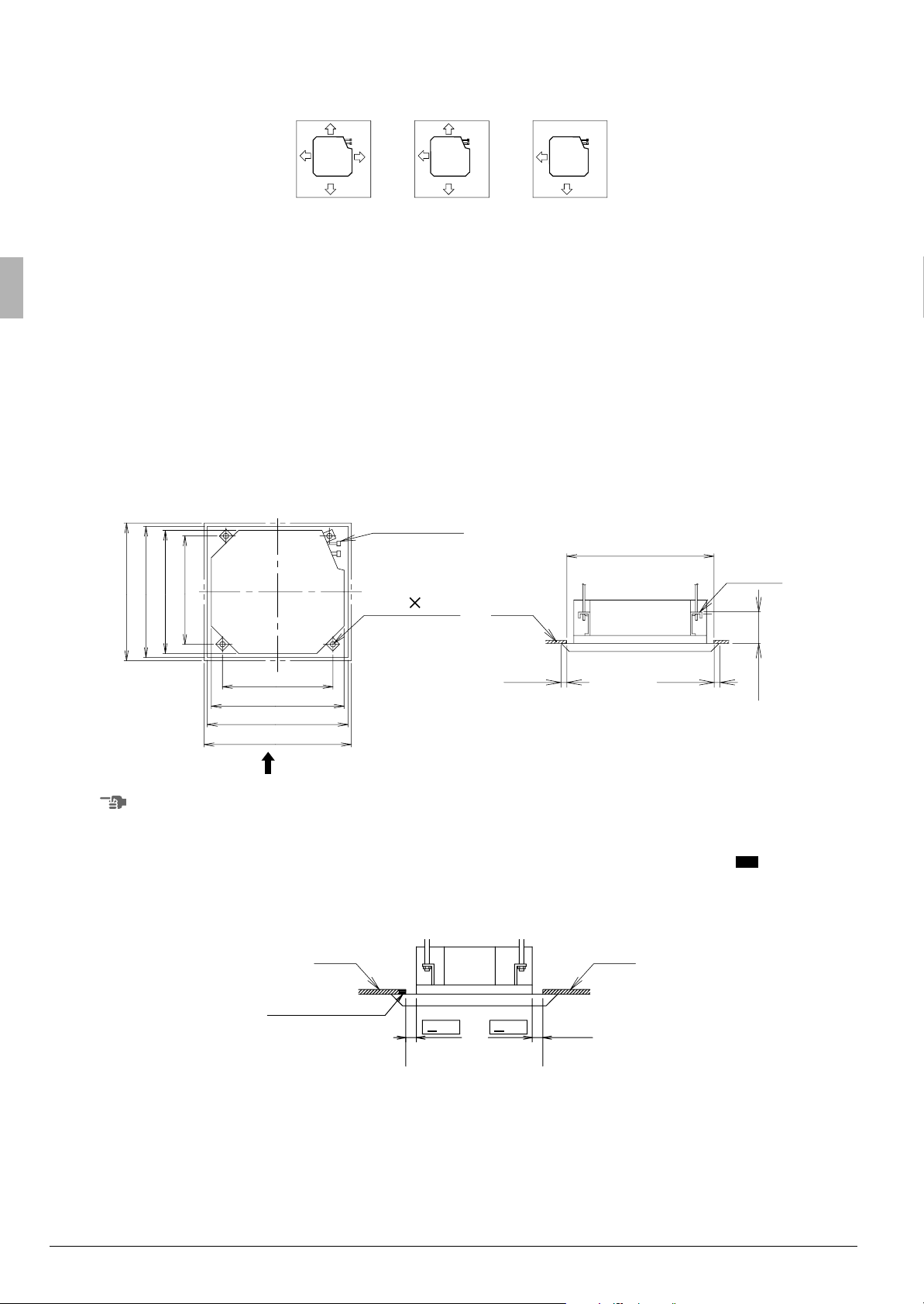

(1) Relation of ceiling opening to unit and suspension bolt position.

Refrigerant

575 (indoor unit)

533 (Suspension bolt pitch)

585-660 (Ceilimg opening)

700 (Decoration panel)

533 (Suspension bolt pitch)

575 (indoor unit)

585-660 (Ceilimg opening)

700 (Decoration panel)

piping

Suspension

bolt ( 4)

(Ceiling-panel overlapping dimension)

Fig. 3

A

(Ceiling opening dimension)

585 – *660

False

ceiling

20

≤

View as seen from A

Fig. 4

20

≤

Hanger

bracket

(mm)

(173)

NOTE

• Installation is possible with a ceiling dimension of 660 mm (marked with *). However, to achieve a ceilingpanel overlapping dimension of 20 mm, the spacing between the ceiling and the unit should be 45 mm or

less. If the spacing between ceiling and the unit is over 45 mm, attach ceiling material to part or

recover the ceiling.

False

ceiling

False

ceiling

Ceiling material

<

45

<

45

(mm)

Fig. 5

(2) Make the ceiling opening needed for installation where applicable. (For existing ceilings)

• Refer to the paper pattern for installation (5) for ceiling opening dimensions.

• Create the ceiling opening required for installation. From the side of the opening to the casing outlet,implement the refrigerant and drain piping and wiring for remote controller (unnecessary for wireless type) and wiring between units. Refer to each PIPING or WIRING section.

• After making an opening in the ceiling, it may be necessary to reinforce ceiling beams to keep the ceiling level and to prevent it from vibrating. Consult the builder for details.

6 English

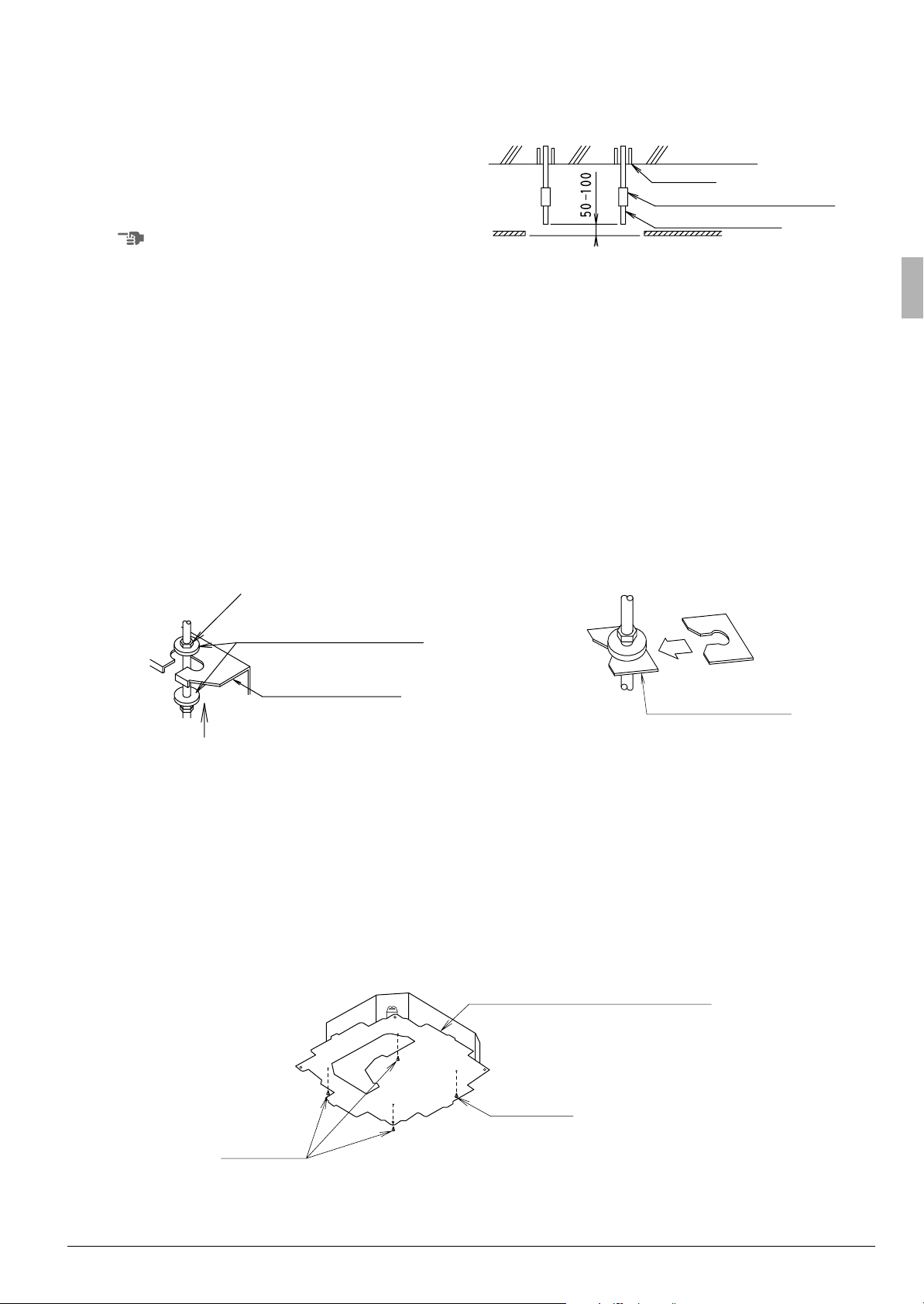

(3) Install the suspension bolts.

~

(Use either a M8

M10 size bolt)

Use a hole-in anchor for existing ceilings, and

a sunken insert, sunken anchor or other field

supplied parts for new ceilings to reinforce

the ceiling to bear the weight of the unit.

–

Adjust clearance (50

100 mm) from the

ceiling before proceeding further.

<installation example>

Ceiling slab

Anchor

Long nut or turn-buckle

Suspension bolt

NOTE

• All the above parts are field supplied.

False ceiling

(mm)

Fig. 6

5. INDOOR UNIT INSTALLATION

As for the parts to be used for installation work, be sure to use the provided accessories and specified parts

designated by our company.

(1) For new ceilings

(1-1) Install the indoor unit temporarily.

• Attach the hanger bracket to the suspension bolt. Be sure to fix it securely by using a nut and

washer (3) from the upper and lower sides of the hanger bracket.

The washer fixing plate (7) will prevent the washer from falling.

Nut (Field supplied)

Washer (3) (attached)

Hanger bracket

Washer fixing plate (7)

Tighten

(double nut)

[Securing the washer]

[Securing the hanger bracket]

Fig. 7 Fig. 8

(1-2) Refer to the paper pattern for installation (5) for ceilling opening dimension.

Consult the builder or carpenter for details.

• The center of the ceiling opening is indicated on the paper pattern for installation.

The center of the unit is indicated on the paper pattern for installation.

4

×

• Fix the paper pattern to the unit with screws (6) (

).

Paper pattern for installation (5)

(attached)

Insert

(attached)

Screws (6)

(attached)

Screws (6)

(attached)

[Installation of paper pattern for installation]

Fig. 9

English 7

Loading...

Loading...