Daikin EWYQ G XS, EWYQ G XR Operation manuals

Installation, Operation and Maintenance Manual

D–EIMHP00808-16EN

Air to Water Heat Pump Multiscroll

EWYQ~G-

XS (High Efficiency – Standard Noise)

XR (High Efficiency – Reduced Noise)

Refrigerant: R410A

Original Instructions

Table of contents

Description ................................................................................................................................................................. 3

General Information .................................................................................................................................................. 3

Receiving the unit ..................................................................................................................................................... 3

Storage ...................................................................................................................................................................... 3

Operation ................................................................................................................................................................... 3

Figure 1 - Description of the labels applied to the electrics panel ................................................................ ....... 4

Figure 2 - Operating limits in cooling mode ........................................................................................................... 4

Figure 3 - Operating limits in heating mode ........................................................................................................... 5

Figure 4 - Heating capacity correction factor for different air temperatures at the evaporator inlet with

relative humidity conditions .................................................................................................................................... 7

Safety ......................................................................................................................................................................... 7

Positioning and assembly ........................................................................................................................................ 8

Figure 5 – Positioning the unit ................................................................................................................................ 8

Figure 6 – Distances to be complied with: ............................................................................................................. 8

Noise .......................................................................................................................................................................... 8

Handling and lifting .................................................................................................................................................. 9

Figure 7 – Lifting the unit ......................................................................................................................................... 9

Sound protection ................................................................................................................................ ...................... 9

Hydraulic circuit for connection to the unit .......................................................................................................... 10

Pipe insulation ........................................................................................................................................................ 10

Installing the flow switch ....................................................................................................................................... 10

Preparing and checking the water circuit connection ......................................................................................... 10

Water treatment ...................................................................................................................................................... 11

Water flow and volume ........................................................................................................................................... 11

Anti-freeze protection for evaporators and recovery exchangers ..................................................................... 12

Electrical system General specifications ............................................................................................................. 12

Wiring at the installation site ................................................................................................................................. 12

Electric circuit and wiring requirements............................................................................................................... 12

Connection of the unit power supply .................................................................................................................... 12

Interconnecting wires ............................................................................................................................................. 13

Before start-up ........................................................................................................................................................ 13

Open the isolation and/or shut off valves............................................................................................................. 14

User responsibilities .............................................................................................................................................. 14

Periodical maintenance .......................................................................................................................................... 14

Service and limited guarantee ............................................................................................................................... 14

Mandatory periodical checks and start-up of Groups (units) ............................................................................. 14

Bleeding refrigerant gas from the safety valve .................................................................................................... 15

Important information regarding the refrigerant used ........................................................................................ 16

Product lifespan ...................................................................................................................................................... 16

Disposal ................................................................................................................................................................... 18

Figure 8 – Unit wiring in installation site .............................................................................................................. 19

D-EIMHP00808-16EN - 2/24

Thank you for purchasing this chiller

This manual is an important support document for qualified personnel but it is not intended to replace such personnel.

READ THIS MANUAL CAREFULLY BEFORE INSTALLING

AND STARTING UP THE UNIT.

IMPROPER INSTALLATION COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, COOLANT LEAKS,

FIRE OR OTHER DAMAGE TO EQUIPMENT OR INJURY.

THE UNIT MUST BE INSTALLED BY A PROFESSIONAL

OPERATOR/TECHNICIAN.

UNIT STARTUP MUST BE PERFORMED BY

AUTHORISED, TRAINED PERSONNEL.

ALL ACTIVITIES MUST BE CARRIED OUT IN

ACCORDANCE WITH LOCAL LAWS AND REGULATIONS.

IF THE INSTRUCTIONS IN THIS MANUAL ARE NOT ABSOLUTELY

CLEAR, DO NOT INSTALL AND/OR OR START UP THE UNIT.

IN CASE OF DOUBT CONTACT THE MANUFACTURER'S

REPRESENTATIVE FOR ADVICE AND INFORMATION.

Description

The unit purchased is a Water Chiller and/or a Heat

Pump, that is a machine designed to cool/heat the

water (or a water-glycol mixture) within certain limits

which will be listed below. The unit operates based on

the compression, condensation and evaporation of the

coolant gas as per the Carnot cycle, and is composed

mainly of the following parts depending on the Mode of

Operation.

Cooling or Conditioning Mode:

- One or more scroll compressors which increase the

pressure of the refrigerant gas from evaporation

pressure to condensation pressure.

- A condenser where the refrigerant gas condenses

under high pressure and transfers heat to the

water.

- An expansion valve which allows the pressure of

condensed liquid refrigerant to be reduced from

condensation pressure to evaporation pressure.

- An evaporator, where the low pressure liquid

refrigerant evaporates and chills the water.

Heating Mode or Heat Pump:

- One or more scroll compressors which increase the

pressure of the refrigerant gas from evaporation

pressure to condensation pressure.

- A condenser where the refrigerant gas condenses

under high pressure and transfers heat to the

water.

- An expansion valve which allows the pressure of

condensed liquid refrigerant to be reduced from

condensation pressure to evaporation pressure.

- An evaporator, where the low pressure liquid

refrigerant evaporates and chills the water.

- The operation of the heat exchangers can be

inverted using the 4-way valve, with which the use

of the heating/cooling unit can be seasonally

inverted.

General Information

All the units are delivered with wiring diagrams, certified

drawings, ID plate and DoC (Declaration of Conformity).

These documents list all the technical data of the unit

acquired and CONSTITUTE AN INTEGRAL AND

ESSENTIAL PART OF THIS MANUAL.

In the event of any discrepancy between this manual

and the appliance documents, please refer to the

documents that come supplied with the unit. In case of

doubt, contact the manufacturer's representative.

The aim of this manual is to make sure that the installer

and the qualified operator can properly commission,

operate and maintain the unit without creating any risk

to people, animals or things.

Receiving the unit

The unit must be inspected for any possible damage

immediately upon reaching final place of installation. All

components described in the delivery note must be

inspected and checked.

Should there be evidence of damage, do not remove

the damaged components and immediately report the

extent and type of damage both to the transportation

company, asking them to inspect it, and the

manufacturer's representative, sending if possible

photos which may be useful in identifying those

responsible.

Damage must not be repaired before inspection by the

transportation company representative and the

manufacturer's representative.

Before installing the unit, check that the model and

power supply voltage shown on the ID plate are correct.

The manufacturer will not accept responsibility for any

damage following acceptance of the unit.

Storage

The unit must be protected from dust, rain, constant

exposure to the sun and possible corrosive agents and

rodents when being stored outside before installation.

Even though it is covered by a heat-shrinking plastic

sheet, this is not intended for long-term storage and

must be removed as soon as the unit is unloaded. The

unit must be protected by tarpaulins or suchlike which

are more suitable for the long term.

Storage conditions must be within the following limits:

Minimum ambient temperature: -20°C

Maximum ambient temperature: +42°C

Maximum relative humidity: 95% without condensation.

If the unit is stored at a temperature below the minimum

ambient temperature, the components may be

damaged, while at a temperature above the maximum

ambient temperature, the safety valves could open and

discharge the refrigerant into the atmosphere.

Operation

Operation outside any of the above-mentioned limits

may damage the unit.

In case of doubt, contact manufacturer's representative.

D-EIMHP00808-16EN - 3/24

Figure 1 - Description of the labels applied to the electrics panel

1 – Slack electrical cable warning

5 – Type of gas

2 – Hazardous voltage warning

6 – Non flammable gas symbol

3 – Electrical hazard symbol

7 – Unit ID plate information

4 – Manufacturer’s logo

8 – Lifting instructions

Ambient temperature (°C)

Identification of labels

* With the exception of the unit ID plate, which is always in the same position, the other plates may be in different

positions depending on the model and options on the unit.

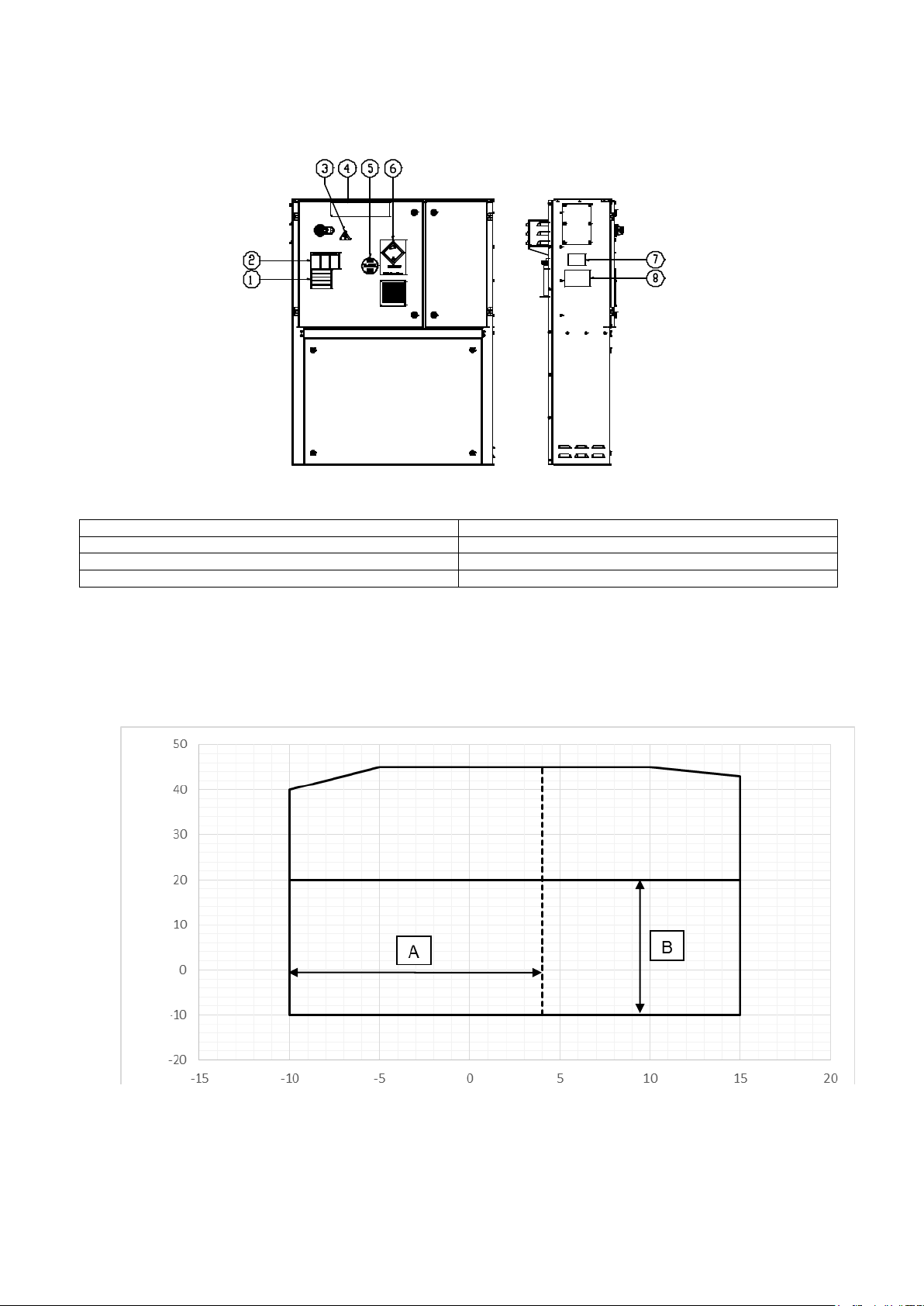

Figure 2 - Operating limits in cooling mode

EWYQ G XS (High efficiency – Standard noise)

Water temperature at outlet (°C)

Ambient temperature (°C)

Outlet wa

ter temperature

(°C)

EWYQ G XR (High efficiency - Reduced noise)

Water temperature at outlet (°C)

Legend

Ambient temperature (°C) = Air temperature at condenser inlet (°C)

Water temperature at outlet (°C) = Water temperature at evaporator outlet (°C)

A = Operating with glycol

B = Operating with fan speed mode selected

C = Operating at maximum fan speed

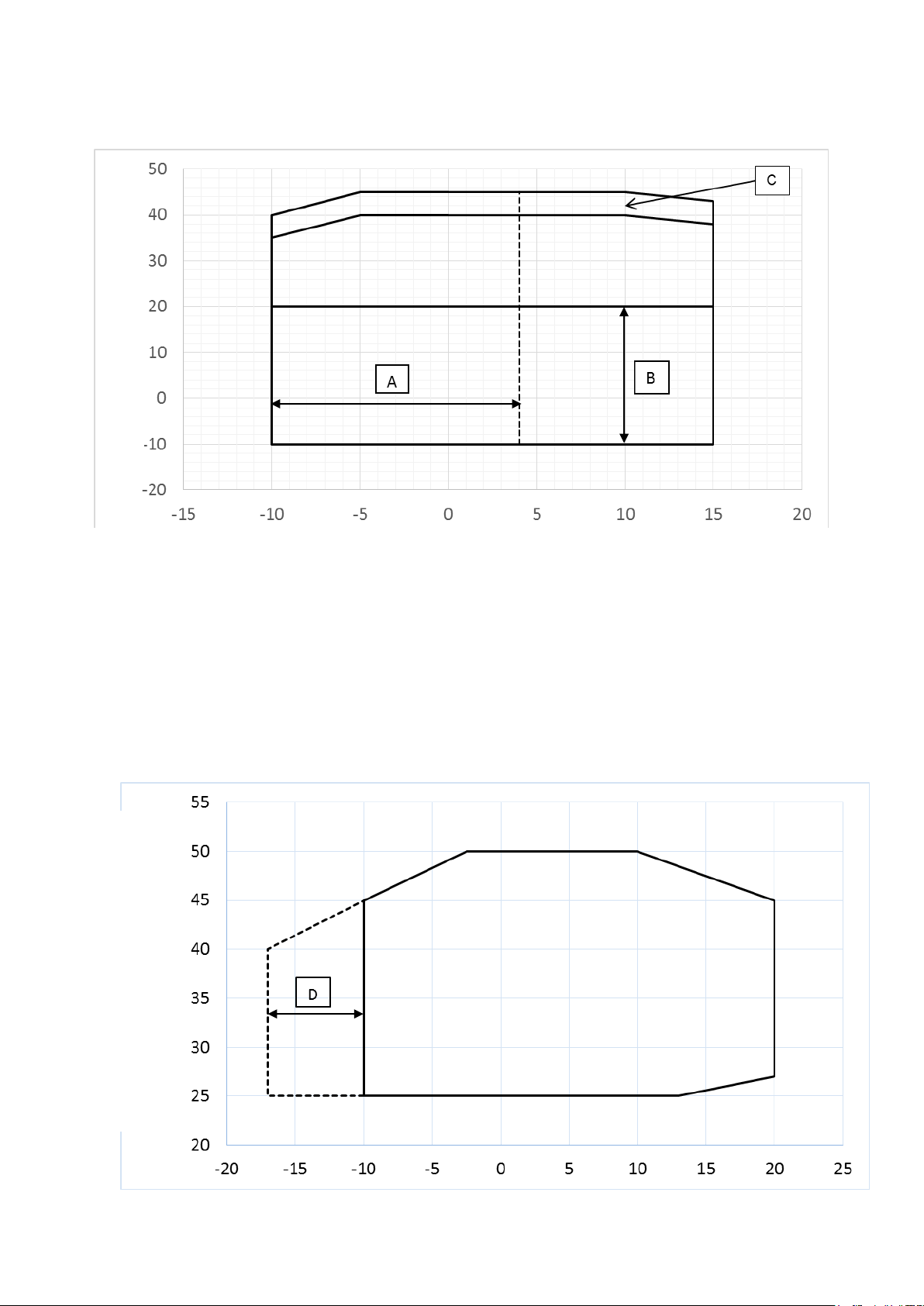

Figure 3 - Operating limits in heating mode

EWYQ G XS (High efficiency – Standard noise)

EWYQ G XR (High efficiency - Reduced noise)

External air temperature (°C)

D-EIMHP00808-16EN - 5/24

D = Operating at partial load

Notes

The diagrams show the guide lines for the range of operating limits. Refer to the Chiller Selection Software (CSS) for the

true operating limits under working conditions for each model.

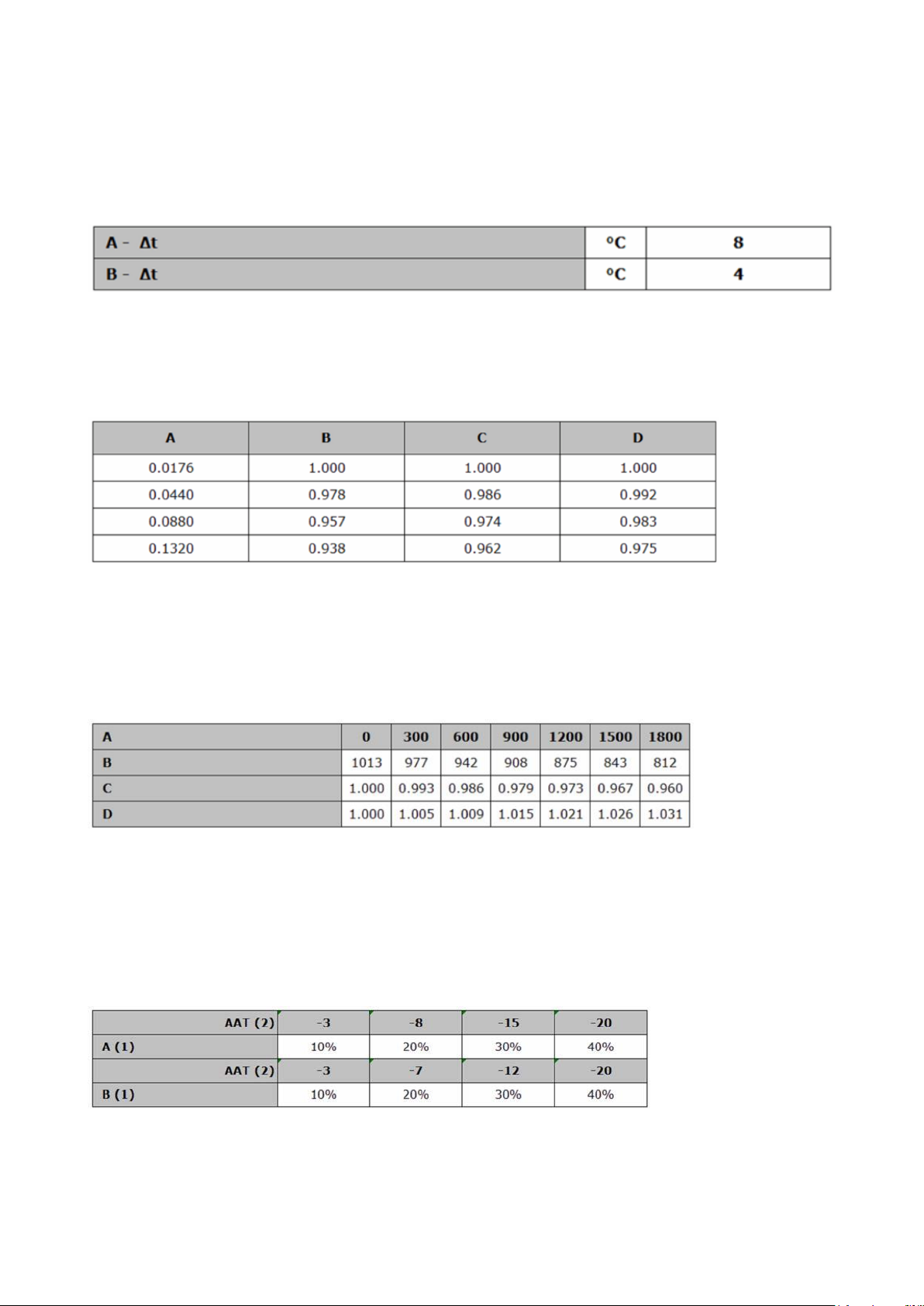

Table 1 - Evaporator – Difference in temperature Δt at Minimum and Maximum

Legend

A = Δt Maximum difference in evaporator water temperature

B = Δt Minimum difference in evaporator water temperature

Table 2 – Evaporator – Scaling factor

Legend

A = Scaling factor (m² °C / kW)

B = Refrigeration capacity correction factor

C = Power consumption correction factor

D = EER correction factor

Table 3 - Air heat exchanger - Correction factor at altitude

Legend:

A = Altitude above sea level (m)

B = Atmospheric pressure (mbar)

C = Refrigeration capacity correction factor

D = Power consumption correction factor

- The maximum operating altitude is 2000 metres above sea level

- If the unit is to be installed at an altitude of between 1000 and 2000 metres above sea level, contact manufacturer

Table 4 – Minimum percentage of glycol for low air ambient temperature

Legend:

AAT = Ambient Air Temperature (°C) (2)

A = Ethylene glycol (%) (1)

B = Propylene glycol (%) (1)

(1) Minimum percentage of glycol to prevent the water circuit from freezing at the indicated ambient air temperature

D-EIMHP00808-16EN - 6/24

(2) Ambient air temperature which exceeds unit operating limits.

Correction factor

Water circuits must also be protected in winter even if the unit is not being used.

Legend:

A = External Static Pressure (Pa)

B = Cooling capacity correction factor (kW)

C = Compressor power consumption correction factor (kW)

D = Reduction of maximum temperature of the air which passes through the condenser.

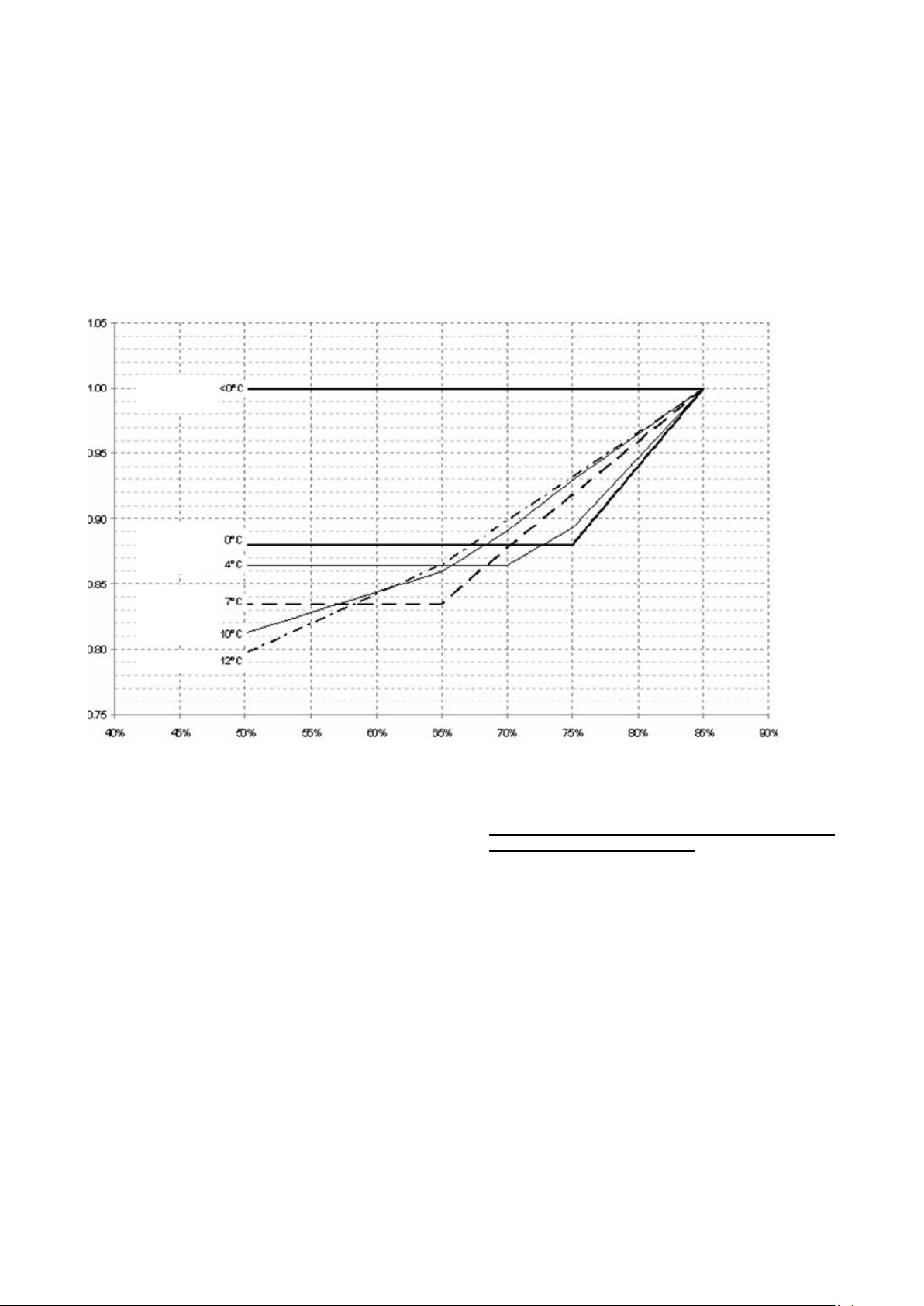

Figure 4 - Heating capacity correction factor for different air temperatures at the evaporator inlet with relative humidity

conditions

Relative Humidity (%)

Note

The following values shown in the diagram: <0 °C ; 0 °C ; 4 °C ; 7 °C ; 10 °C ; 12 °C, are for ambient temperature.

Safety

The unit must be firmly secured to the ground.

The following instructions must be followed:

Never access electrical components without having

first closed the main switch and switched off the

power supply.

Never access electrical components without some

form of insulation. Never access electrical

components if water and/or moisture are present.

Always disconnect the power supply by closing the

main switch before carrying out any work on the

cooling fans and/or compressors. Failure to do so

may result in serious injury.

Sharp edges can cause injuries. Avoid direct

contact with components and wear suitable PPE

Do not introduce solid objects into water pipes.

A mechanical filter must be fitted to the water pipe

connected to the heat exchanger inlet.

The unit is supplied with high pressure switches

and/or safety valves, that are installed on both the

high-pressure and low-pressure sides of the

refrigerant circuit: pay attention.

It is absolutely forbidden to remove any protection

system covering moving parts.

In the event of a sudden stop, follow the instructions in

the Control Panel Instruction Manual which is part of

the documentation supplied with the unit.

We strongly recommend that installation and

maintenance operations are be performed alone but

with other people present.

In the event of an accident or problem:

Keep calm

Press the alarm button, if present or close the main

switch

Move the injured person to a warm place far from

the unit and in place him or her in the recovery

position

Immediately contact any emergency personnel in

the building or the call the Emergency Services

Wait until emergency personnel arrive and do not

leave the injured person alone.

Give all necessary information to the emergency

personnel.

D-EIMHP00808-16EN - 7/24

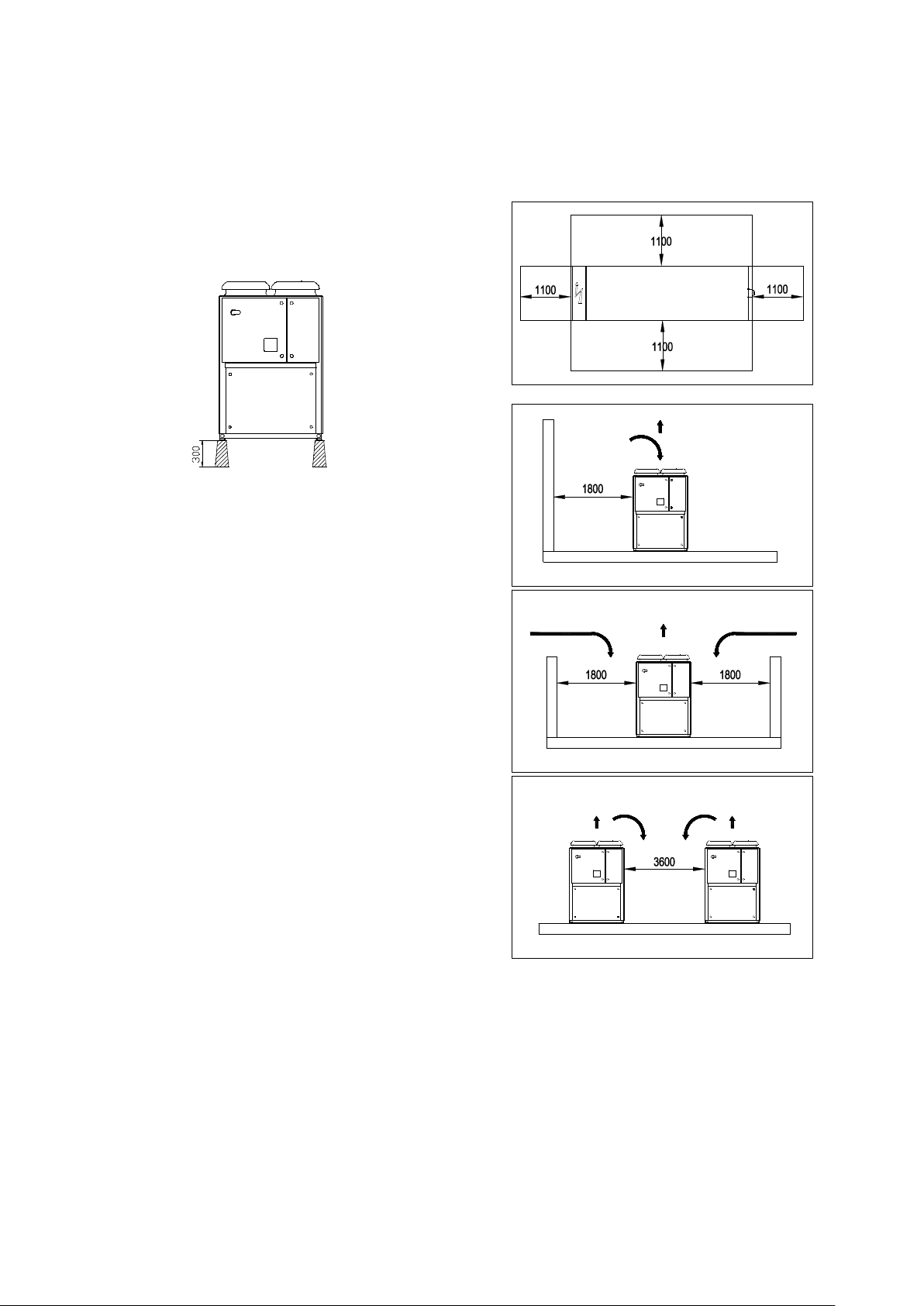

Positioning and assembly

The unit must be installed on a solid, perfectly level

base. For earthing purposes, a solid cement base, that

is wider than the unit, must be made. This base must be

able to support the weight of the unit

The anti-vibration supports must be installed between

the unit frame and the cement base or steel beam;

a distance of 300 mm must be left between the unit and

the ground as shown below.

Figure 5 – Positioning the unit

The manufacturer cannot be expected to consider all

these factors. In the unit design stage, we therefore

recommend that you consult an authorised

manufacturer representative for further solutions.

Figure 6 – Distances to be complied with:

To install the anti-vibration supports, follow the

instructions, in the dimensional diagram supplied with

the unit.

The frame must be perfectly levelled during installation,

if necessary by inserting shims under the the antivibration supports.

Before first start-up, the installation must be confirmed

as being level and horizontal using a laser level or

another suitable instrument.

Any error in the level and horizontal position must not

be greater than 5 mm per unit up to 7 metres and

10mm per unit over 7 metres.

If the unit is installed in places that are easily accessible

to people and animals, we recommend that protection

grates are fitted all round to prevent access. To ensure

optimal performance in installation site, the following

precautions and instructions must be respected:

- Make sure that there is a strong, solid foundation to

reduce noise and vibrations.

- Avoid installing the unit in areas that could be

dangerous during maintenance operations, such as

platforms without handrails, guide rails or in areas that

fail to comply with requirements as regards free space

around the unit.

The installer is responsible for calculating the best

position for the unit.

It is vital that all minimum distances for all units are

complied with to ensure there is adequate ventilation for

the condenser racks.

When deciding where to position the unit and to ensure

proper airflow, the following factors must be taken into

consideration:

avoid the recirculation of hot air

avoid insufficient air supply for the air cooling

condensers.

Both these conditions can cause an increase in

condenser pressure which can lead to poor energy

efficiency and refrigerating capacity.

If two or more units are positioned alongside each

other, we recommend leaving a space of at least 3600

millimetres between condenser racks. Each side of the

unit must be accessible for post-installation

maintenance work.

It is therefore vital that the minimum access distance in

front of the electrical panel is complied with: 1100 mm.

Noise

The noise generated by the unit is mainly due to the

rotation of compressors.

The noise level for each model size is listed in sales

documentation.

If the unit is correctly installed, operated and

maintained, noise emission levels do not require any

special protective devices to operate continuously close

to the unit without any risk.

In case of installation with special noise requirements it

may be necessary to install additional noise softening

devices.

D-EIMHP00808-16EN - 8/24

Loading...

Loading...