Inverter air to water heat pumps

EWYD_BZ

50Hz – Refrigerant: R-134A

Original Instructions

Installation, Operation and Maintenance Manual

D–EIMHP00508-16_01EN

D-EIMHP00508-16_01EN - 2/50

IMPORTANT

This Manual is a technical aid and does not represent a binding offer for Daikin.

Daikin has drawn up this Manual to the best of its knowledge. The content cannot be held as explicitly or implicitly

guaranteed as complete, precise or reliable.

All data and specifications contained herein may be modified without notice. The data communicated at the moment

of the order shall hold firm.

Daikin shall assume no liability whatsoever for any direct or indirect damage, in the widest sense of the term, ensuing

from or connected with the use and/or interpretation of this Manual.

The entire content is protected by Daikin copyright.

WARNING

Before starting the installation of the unit, please read this manual carefully. Starting up the unit is absolutely forbidden

if all instructions contained in this manual are not clear.

Key to symbols

Important note: failure to respect the instruction can damage the unit or compromise operation

Note regarding safety in general or respect of laws and regulations

Note regarding electrical safety

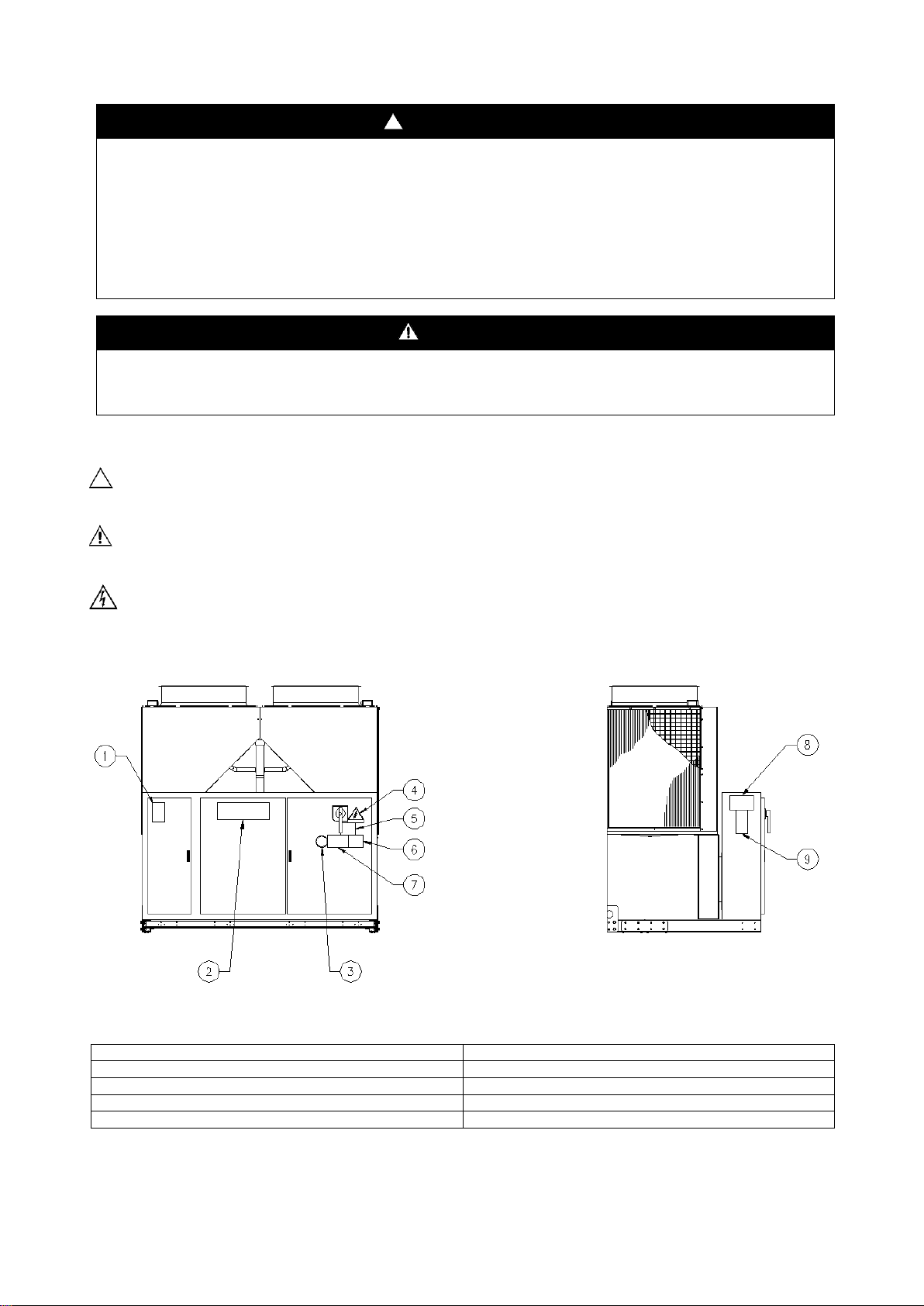

Description of the labels applied to the electrical panel

Label Identification

1 – Non flammable gas symbol

6 – Cable tightening warning

2 – Manufacturer’s logo

7 – Water circuit filling warning

3 – Gas type

8 – Lifting instructions

4 – Electrical hazard symbol

9 – Unit nameplate data

5 – Hazardous Voltage warning

D-EIMHP00508-16_01EN - 3/50

Index

1. GENERAL INFORMATION ........................................................................................................................................... 5

Purpose of this manual ................................................................................................................................................... 5

Receiving the machine ................................................................................................................................................... 5

Checks ........................................................................................................................................................................... 5

Nomenclature ................................................................................................................................................................. 6

2. OPERATING LIMITS .................................................................................................................................................... 7

Storage ........................................................................................................................................................................... 7

Operation ........................................................................................................................................................................ 7

3. MECHANICAL INSTALLATION ................................................................................................................................... 9

Shipping ......................................................................................................................................................................... 9

Responsibility ................................................................................................................................................................. 9

Safety ............................................................................................................................................................................. 9

Moving and lifting............................................................................................................................................................ 9

Positioning and assembly ............................................................................................................................................. 10

Minimum space requirements ...................................................................................................................................... 11

Sound protection .......................................................................................................................................................... 12

Water piping ................................................................................................................................................................. 12

Water treatment ............................................................................................................................................................ 14

Evaporator and recovery exchangers anti-freeze protection ........................................................................................ 14

Installing the flow switch ................................................................ ............................................................................... 14

Hydronic kit (optional) ................................................................................................................................................... 16

4. ELECTRICAL INSTALLATION ................................................................................................................................... 18

General specifications .................................................................................................................................................. 18

Electrical components .................................................................................................................................................. 18

Electrical wiring............................................................................................................................................................. 18

Electrical heaters .......................................................................................................................................................... 18

Water pump control ...................................................................................................................................................... 19

Alarm relays – Electrical wiring ..................................................................................................................................... 19

Unit On/ Off remote control – Electrical wiring .............................................................................................................. 19

Double Setpoint – Electrical wiring ............................................................................................................................... 19

External water Setpoint reset – Electrical wiring (Optional) .......................................................................................... 19

Unit limitation – Electrical wiring (Optional) .................................................................................................................. 19

The VFD and related problems .................................................................................................................................... 20

The operating principle of the VFD ............................................................................................................................... 21

The problem with harmonics ........................................................................................................................................ 21

5. OPERATION ............................................................................................................................................................... 24

Operator’s responsibilities ............................................................................................................................................ 24

Description of the machine ........................................................................................................................................... 24

Description of the refrigeration cycle ............................................................................................................................ 24

Description of the refrigeration cycle with heat recovery .............................................................................................. 26

Controlling the heat recovery circuit and installation recommendations ....................................................................... 26

Compressor .................................................................................................................................................................. 28

Compression process ................................................................................................................................................... 28

Cooling capacity control ............................................................................................................................................... 30

6. PRE-STARTUP CHECKS ........................................................................................................................................... 32

Units with an external water pump................................................................................................................................ 33

Units with a built-in water pump .................................................................................................................................... 33

Electrical power supply ................................................................................................................................................. 33

Unbalance in power supply voltage .............................................................................................................................. 33

Power supply of electrical heaters ................................................................................................................................ 34

7. STARTUP PROCEDURE ............................................................................................................................................ 35

Turning on the machine ................................................................................................................................................ 35

Selecting an operating mode ........................................................................................................................................ 36

Shutdown for a long time .............................................................................................................................................. 36

Starting up after seasonal shutdown ............................................................................................................................ 36

8. SYSTEM MAINTENANCE .......................................................................................................................................... 37

General ......................................................................................................................................................................... 37

Compressor maintenance ............................................................................................................................................ 37

Lubrication .................................................................................................................................................................... 37

Routine maintenance .................................................................................................................................................... 38

Replacement of filter dryer ........................................................................................................................................... 39

Procedure to replace the filter dryer cartridge .............................................................................................................. 39

Replacement of the oil filter .......................................................................................................................................... 40

Procedure to replace oil filter ........................................................................................................................................ 40

Procedure to replenish refrigerant ................................................................................................................................ 42

9. STANDARD CHECKS ................................................................................................................................................ 43

Temperature and pressure sensors .............................................................................................................................. 43

D-EIMHP00508-16_01EN - 4/50

10. TEST SHEET .............................................................................................................................................................. 44

Water side measurements ............................................................................................................................................ 44

Refrigerant side measurements ................................................................................................................................... 44

Electrical measurements .............................................................................................................................................. 44

11. SERVICE AND LIMITED WARRANTY ....................................................................................................................... 45

12. PERIODIC OBLIGATORY CHECKS AND STARTING UP OF APPLIANCES UNDER PRESSURE ........................ 46

13. IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED ................................................................ 47

14. FACTORY AND FIELD CHARGED UNITS INSTRUCTIONS ..................................................................................... 48

15. DISMISSION AND DISPOSAL ................................................................................................................................... 49

Index of tables

Table 1 - Acceptable water quality limits ........................................................................................................................... 14

Table 2 - Typical working conditions with compressors at 100% ...................................................................................... 35

Table 3 - Routine maintenance programme ...................................................................................................................... 38

Table 4 - Pressure/ Temperature ...................................................................................................................................... 42

Index of figures

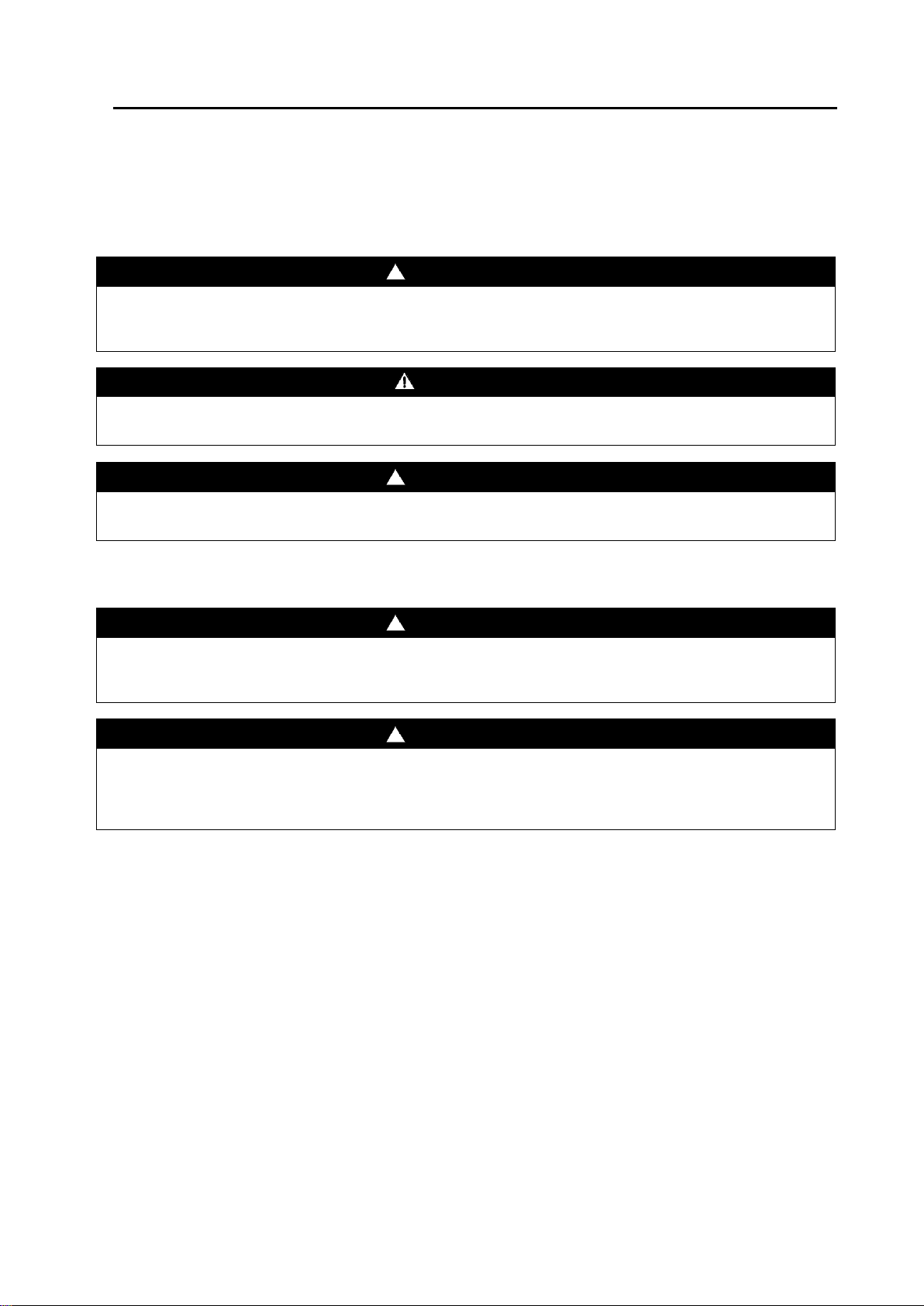

Figure 1 - Operating limits in cooling mode - EWYD~BZSS / EWYD~BZSL ....................................................................... 8

Figure 2 - Operating limits in heating mode - EWYD~BZSS / EWYD~BZSL....................................................................... 8

Figure 3 - Lifting the unit.................................................................................................................................................... 10

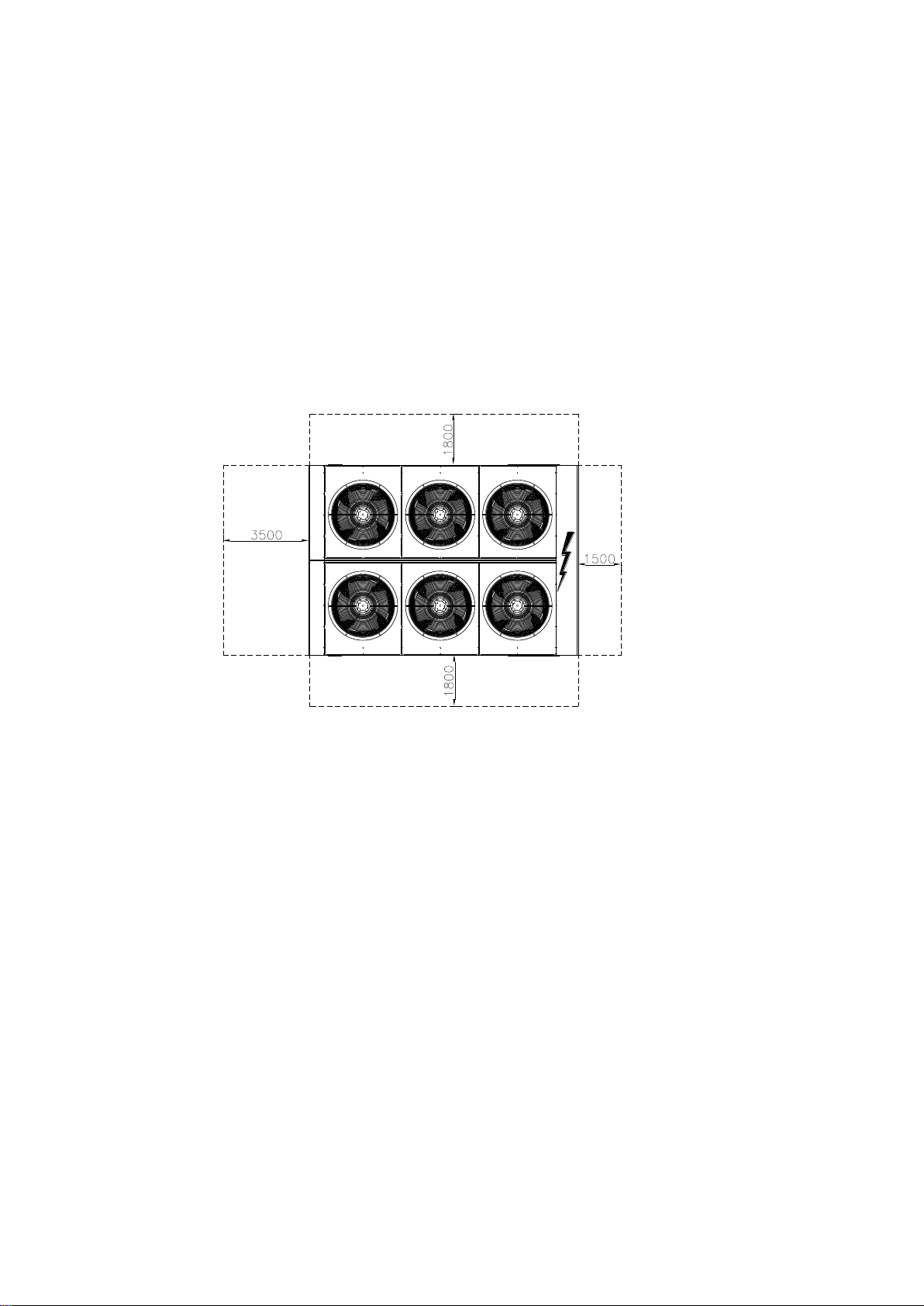

Figure 4 - Minimum clearance requirements for machine maintenance ............................................................................ 11

Figure 5 - Minimum recommended installation clearances ............................................................................................... 12

Figure 6 - Water piping connection for evaporator ............................................................................................................ 13

Figure 7 - Water piping connection for heat recovery exchangers .................................................................................... 13

Figure 8 - Adjusting the safety flow switch ........................................................................................................................ 16

Figure 9 - Single- and twin-pump hydronic kit ................................................................................................................... 16

Figure 10 - User connection to the interface M3 terminal boards ...................................................................................... 20

Figure 11 - Power absorbed by the compressor depending on the load ........................................................................... 21

Figure 12 - Typical diagram of a VFD ............................................................................................................................... 22

Figure 13 - Harmonics on the grid ..................................................................................................................................... 22

Figure 14 - Harmonic content with and without line inductance ........................................................................................ 23

Figure 15 - Harmonic content varying according to the percentage of non-linear loads .................................................... 23

Figure 16 - Refrigeration cycle .......................................................................................................................................... 25

Figure 17 - Refrigeration cycle with partial heat recovery ................................................................................................. 27

Figure 18 - Picture of Fr3100 compressor ........................................................................................................................ 28

Figure 19 - Compression process ..................................................................................................................................... 29

Figure 20 - Capacity control mechanism for Fr3100 compressor ...................................................................................... 30

Figure 21 - Continuously variable capacity control for Fr3100 compressor ....................................................................... 31

Figure 22 - Installation of control devices for Fr3100 compressor ..................................................................................... 38

Figure 23 - Front and back views for Fr3100..................................................................................................................... 41

D-EIMHP00508-16_01EN - 5/50

1. GENERAL INFORMATION

ATTENTION

The units described in the present manual represent a high value investment, maximum care should be taken to ensure

correct installation and appropriate working conditions.

Installation and maintenance must be performed by qualified and specifically trained personnel only.

Correct maintenance of the unit is indispensable for its safety and reliability. Manufacturer’s service centres are the

only having adequate technical skill for maintenance.

ATTENTION

This manual provides information about the features and standard procedures for the complete series.

All the units are delivered from factory as complete sets which include wiring diagrams, inverter manuals, dimensional

drawings with dimensions and weight, nameplate with technical characteristics attached to the unit.

WIRING DIAGRAMS, INVERTER MANUALS, DIMENSIONAL DRAWINGS AND NAMEPLATE MUST BE

CONSIDERED ESSENTIAL DOCUMENTS AND AS A PART OF THIS MANUAL

In case of any discrepancy between this manual and the equipment’s document refer to on board documents.

For any doubt ask Daikin or authorized centers

Purpose of this manual

The purpose of this manual is to allow the installer and the qualified operator to carry out required operations in order to

ensure proper installation and maintenance of the machine, without any risk to people, animals and/or objects.

This manual is an important supporting document for qualified and trained personnel but it is not intended to replace such

personnel.

All activities must be carried out in compliance with local laws and regulations.

Receiving the machine

The machine must be inspected for any possible damage immediately upon reaching its final place of installation. All

components described in the delivery note must be carefully inspected and checked; any damage must be reported to the

carrier. Before connecting the machine to earth, check that the model and power supply voltage shown on the nameplate

are correct. Responsibility for any damage after acceptance of the machine cannot be attributed to the manufacturer.

Checks

To prevent the possibility of incomplete delivery (missing parts) or transportation damage, please perform the following

checks upon receipt of the machine:

a) Before accepting the machine, please verify shipment documensts and chechs the number of shipped items

b) Check every single component in the consignment for missing parts or for any damage.

c) In the event that the machine has been damaged, do not remove the damaged material. A set of photographs are

helpful in ascertaining responsibility.

d) Immediately report the extent of the damage to the transportation company and request that they inspect the

machine.

e) Immediately report the extent of the damage to the manufacturer representative, so that arrangements can be made

for the required repairs. In no case must the damage be repaired before the machine has been inspected by the

representative of the transportation company.

D-EIMHP00508-16_01EN - 6/50

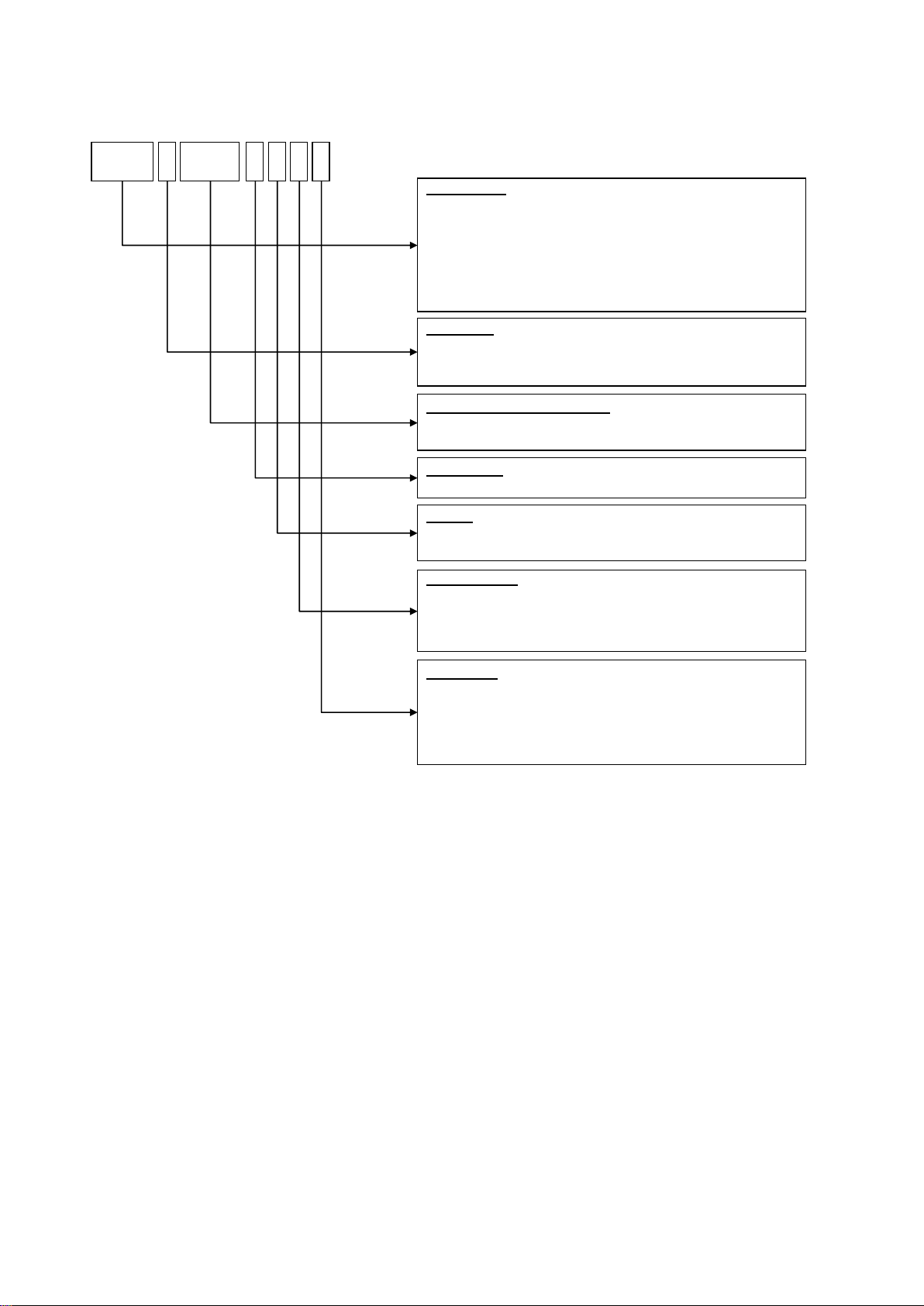

Nomenclature

E W Y D 2 0 0 B Z S L

1 2 3 4 5 6 7 8 9 10 11

Machine type

EWA = Air-cooled chiller, cooling only

EWY = Air-cooled chiller, heat pump

EWL = Remote condenser chiller

ERA = Air cooled condensing unit

EWW = Water-cooled chiller, cooling only

EWC = Air-cooled chiller, cooling only with centrifugal fan

EWT = Air-cooled chiller, cooling only with heat recovery

Refrigerant

D = R-134a

P = R-407c

Q = R-410a

Capacity class in kW (Cooling)

Always 3-digit code

Idem as previous

Model series

Letter A, B,… : major modification

Inverter

- = Non-inverter

Z = Inverter

Efficiency level

(McQuay code)

S = Standard efficiency (SE)

X = High efficiency (XE) (N.A for this range)

P = Premium efficiency (PE) (N.A for this range)

H = High ambient (HA) (N.A for this range)

Sound level

(McQuay code)

S = Standard noise (ST)

L = Low noise (LN)

R = Reduced noise (XN) (N.A for this range)

X = Extra low noise (XXN) (N.A for this range)

C = Cabinet (CN) (N.A for this range)

D-EIMHP00508-16_01EN - 7/50

2. OPERATING LIMITS

Storage

The environmental conditions must be within the following limits:

Minimum ambient temperature : -20°C

Maximum ambient temperature : 57°C

Maximum R.H. : 95% not condensing

ATTENTION

Storing below the minimum temperature mentioned above may cause damage to components such as the electronic

controller and its LCD display.

WARNING

Storing above the maximum temperature may cause opening of the safety valves on the compressors’ suction line.

ATTENTION

Storing in condensing atmosphere may damage the electronic components.

Operation

Operation is allowed within the limits mentioned in the following diagrams

.

ATTENTION

Operation out of the mentioned limits may damage the unit.

For any doubts contact the factory.

ATTENTION

The maximum operating altitude is 2,000 m above sea level.

Please contact the factory if the equipment is to be operated at altitudes of between 1,000 and 2,000 m above sea

level.

D-EIMHP00508-16_01EN - 8/50

Figure 1 - Operating limits in cooling mode - EWYD~BZSS / EWYD~BZSL

Figure 2 - Operating limits in heating mode - EWYD~BZSS / EWYD~BZSL

D-EIMHP00508-16_01EN - 9/50

3. MECHANICAL INSTALLATION

Shipping

The stability and the absence of any kind of deformation of the unit during shipping must be ensured. If the machine is

shipped with a wooden cross-plank on its base, this cross-plank must only be removed after the final destination has been

reached.

Responsibility

The manufacturer declines all present and future responsibility for any damage to persons, animals or things caused by

negligence of operators failing to follow the installation and maintenance instructions in this manual and/or the rules of

good technical practice.

All safety equipment must be regularly and periodically checked in accordance with this manual and with local laws and

regulations regarding safety and environment protection.

Safety

The machine must be secured to the ground.

It is essential to observe the following instructions:

- The machine can only be lifted using the lifting points marked in yellow that are fixed to its base. These are the only

points that can support the entire weight of the unit.

- Do not allow unauthorised and/or unqualified personnel to access the unit.

- It is forbidden to access the electrical components without having opened the unit’s main switch and switched off the

power supply.

- It is forbidden to access the electrical components without using an insulating platform. Do not access the electrical

components if water and/or moisture are present.

- All operations on the refrigerant circuit and on components under pressure must be carried out by qualified personnel

only.

- Replacement of a compressor or addition of lubricating oil must be carried out by qualified personnel only.

- Sharp edges and the surface of the condenser section could cause injury. Avoid direct contact.

- Switch off the unit’s power supply, by opening the main switch, before servicing the cooling fans and/or compressors.

Failure to observe this rule could result in serious personal injury.

- Avoid introducing solid objects into the water pipes while the machine is connected to the system.

- A mechanical filter must be installed on the water pipe connected to the heat exchanger inlet.

- The machine is supplied with safety valves, that are installed both on the high-pressure and on the low-pressure sides

of the refrigerant circuit.

In case of sudden stop of the unit, follow the instructions on the Control Panel Operating Manual which is part of the onboard documentation delivered to the end user with this manual.

It is recommended to perform installation and maintenance with other people. In case of accidental injury or unease, it is

necessary to:

- keep calm

- press the alarm button if present in the installation site

- move the injured person in a warm place far from the unit and in rest position

- contact immediately emergency rescue personnel of the building or if the Health Emergency Service

- wait without leaving the injured person alone until the rescue operators come

- give all necessary information to the the rescue operators

WARNING

Before carrying out any operation on the machine, please read carefully the instruction and operating manual.

Installation and maintenance must be carried out by qualified personnel that is familiar with provisions of the law and

local regulations and has been trained properly or has experience with this type of equipment.

WARNING

Avoid installing the chiller in areas that could be dangerous during maintenance operations, such as platforms without

parapets or railings or areas not complying with the clearance requirements around the chiller.

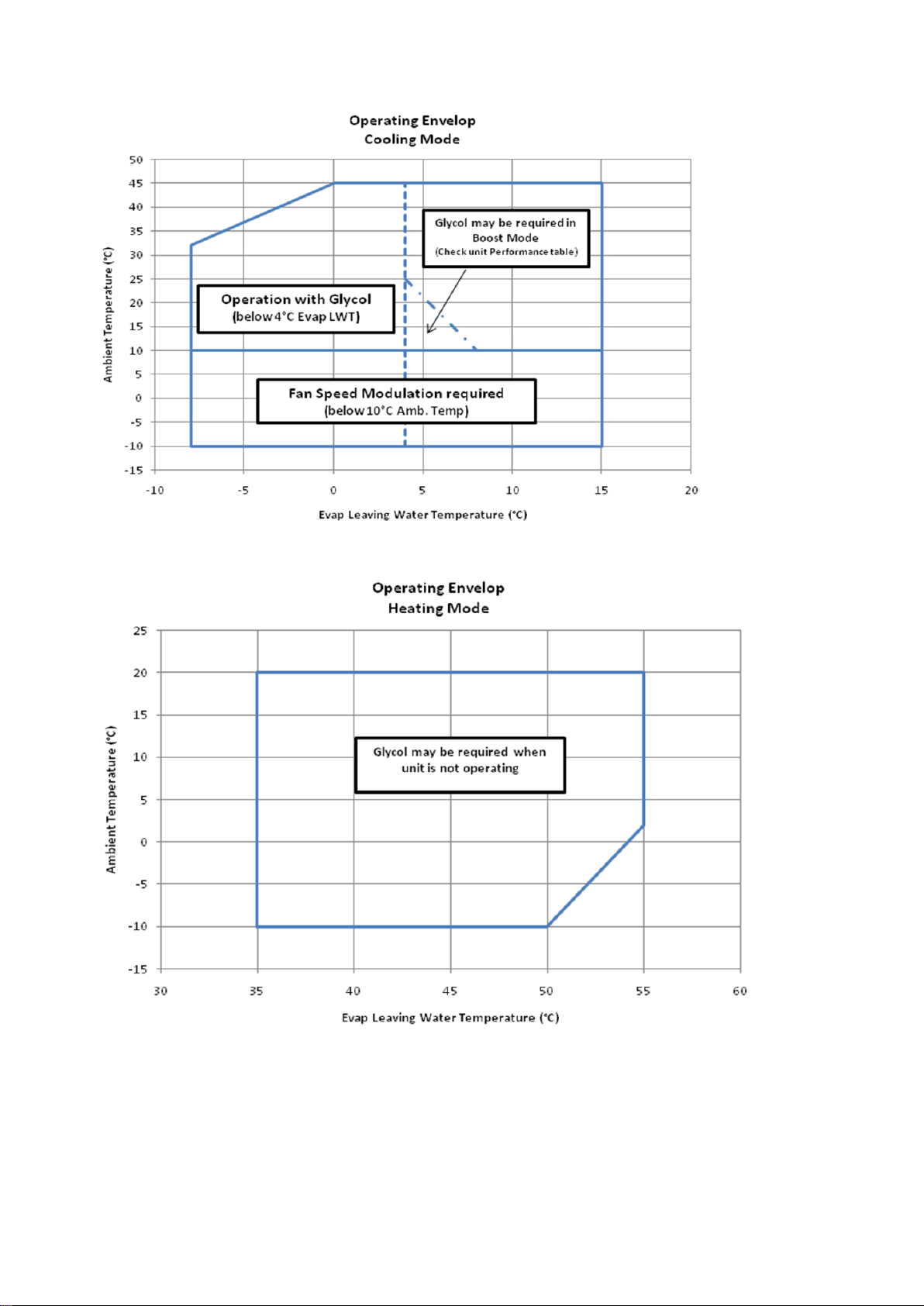

Moving and lifting

Avoid bumping and/or jolting during unloading from the lorry and moving the unit. Do not push or pull the machine from

any part other than the base frame. Secure the machine inside the lorry to prevent it from moving and causing damage to

the panels and to the base frame. Do not allow any part of the unit to fall during transportation or unloading, as this could

cause serious damage.

All units of the series are supplied with lifting points marked in yellow. Only these points may be used for lifting the unit, as

shown in the following figure.

D-EIMHP00508-16_01EN - 10/50

Procedure for extracting the machine from the container.

Container Kit Optional

Figure 3 - Lifting the unit

The number and the location of lifting points changes from model to model. This picture is for reference only. Lifting tools

(bars, ropes, etc) are not supplied.

WARNING

Both the lifting ropes and the spacing bar and/or scales must be strong enough to support the machine safely. Please

check the unit’s weight on the machine’s nameplate.

The weights shown in the “Technical specifications” tables in the “Specifications” chapter refer to standard units.

Specific units might have accessories that increase overall weight (pumps, heat recovery, copper condenser coils, etc.).

WARNING

The unit must be lifted with the utmost attention and care. Avoid jolting when lifting and lift unit very slowly, keeping it

perfectly orizzontal.

Positioning and assembly

All units are designed for installation outdoors, either on roofs or on the ground, provided that the installation area is free

of obstacles that could reduce air flow to the condensers bank.

The unit must be installed on a robust and perfectly plan foundation; should the machine be installed on balconies or roofs,

it might be necessary to use weight distribution beams.

For installation on the ground, a strong cement base that is at least 250 mm wider and longer than the machine must be

provided. Also, this base must be able to support the weight of the machine as stated in the technical specifications.

If the machine is installed in places that are easily accessible to people and animals, it is advisable to install protection

grids for the condenser and compressor sections.

To ensure the best possible performance on the installation site, the following precautions and instructions must be

followed:

• Avoid air flow recirculation.

• Make sure that there are no obstacles to hamper air flow.

• Air must circulate freely to ensure proper flow in and flow out.

• Make sure to provide a strong and solid foundation to reduce noise and vibrations as much as possible.

• Avoid installation in particularly dusty environments, in order to reduce soiling of condensers.

• The water in the system must be particularly clean and all traces of oil and rust must be removed. A mechanical water

filter must be installed on the machine’s inlet piping.

D-EIMHP00508-16_01EN - 11/50

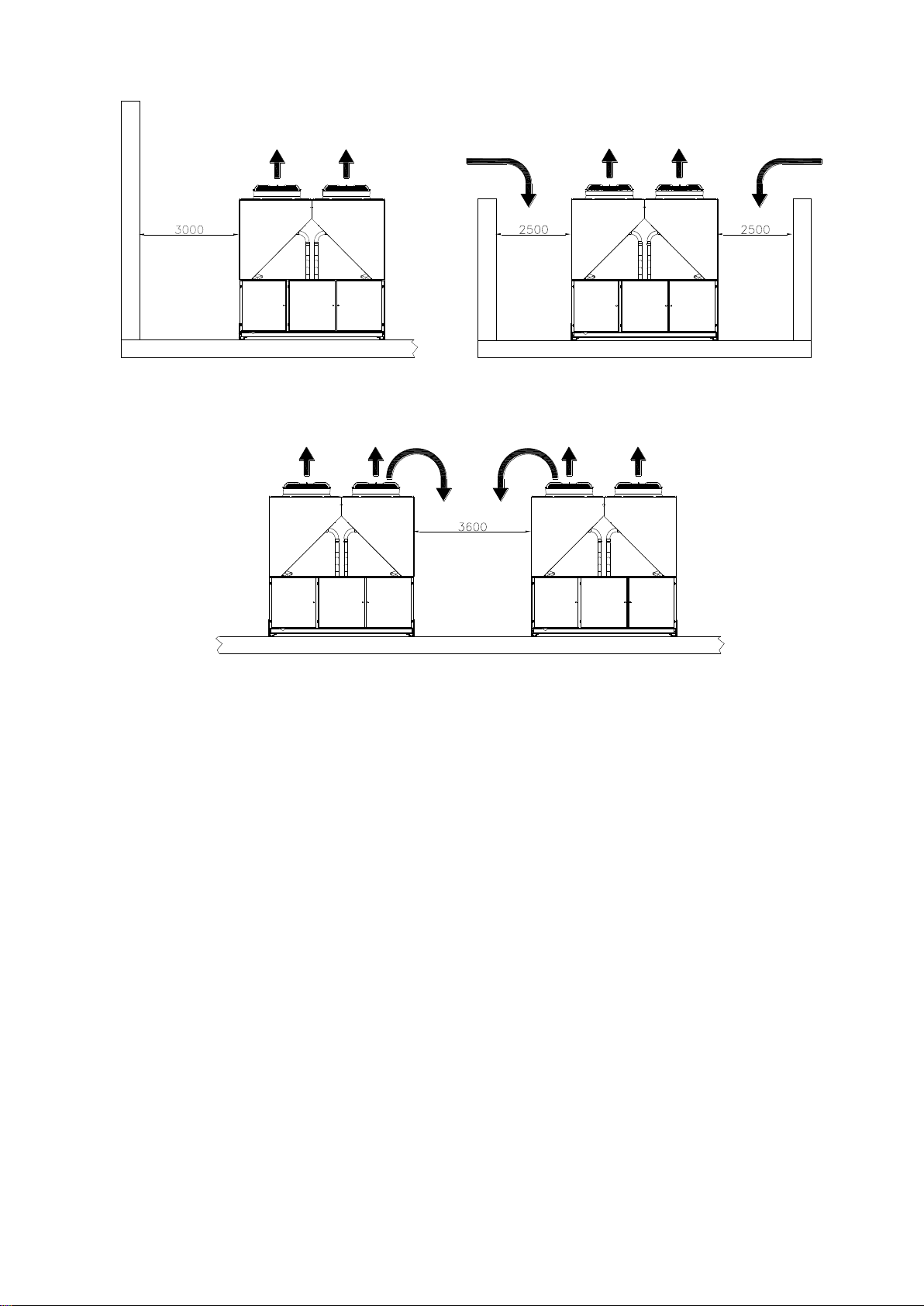

Minimum space requirements

It is fundamental to respect minimum distances on all units in order to ensure optimum ventilation to the condenser. Limited

installation space could reduce the normal air flow, thus significantly reducing the machine’s performance and considerably

increasing consumption of electrical energy.

When deciding where to position the machine and to ensure a proper air flow, the following factors must be taken into

consideration: avoid any warm air recirculation and insufficient air supply to the air-cooled condenser.

Both these conditions can cause an increase of condensing pressure, which leads to a reduction in energy efficiency and

refrigerating capacity. Thanks to the geometry of their air-cooled condensers, the units are less affected by poor air

circulation conditions.

Also, the software has particularly the ability to compute the machine’s operating conditions to optimise the load under

abnormal operating circumstances.

Every side of the machine must be accessible for post-installation maintenance operations. Figure 4 shows the minimum

space required.

Vertical air discharge must not be obstructed as this would significantly reduce capacity and efficiency.

If the machine is surrounded by walls or obstacles of the same height as the machine, it must be installed at a distance of

at least 2500 mm. If these obstacles are higher, the machine must be installed at a distance of at least 3000 mm.

Should the machine be installed without observing the recommended minimum distances from walls and/or vertical

obstacles, there could be a combination of warm air recirculation and/or insufficient supply to the air-cooled condenser

which could cause a reduction of capacity and efficiency.

Figure 4 - Minimum clearance requirements for machine maintenance

In any case, the microprocessor will allow the machine to adapt itself to new operating conditions and deliver the maximum

capacity available under any given circumstances, even if the lateral distance is lower than recommended.

When two or more machines are positioned side by side, a distance of at least 3600 mm between the respective condenser

banks is recommended.

For further solutions, please consult Daikin technicians.

D-EIMHP00508-16_01EN - 12/50

Figure 5 - Minimum recommended installation clearances

Distances shown in previous figures have not be considered a warranty for good installation; particular conditions (like

venturi effects due to wind, very tall buildings, etc.) may cause air recirculation so affecting unit performances. It is a

responsibility of the installer to assure that the unit condenser is fed with fresh air in any condistions

Sound protection

When sound levels require special control, great care must be exercised to isolate the machine from its base by

appropriately applying anti-vibration elements (supplied as an option). Flexible joints must be installed on the water

connections, as well.

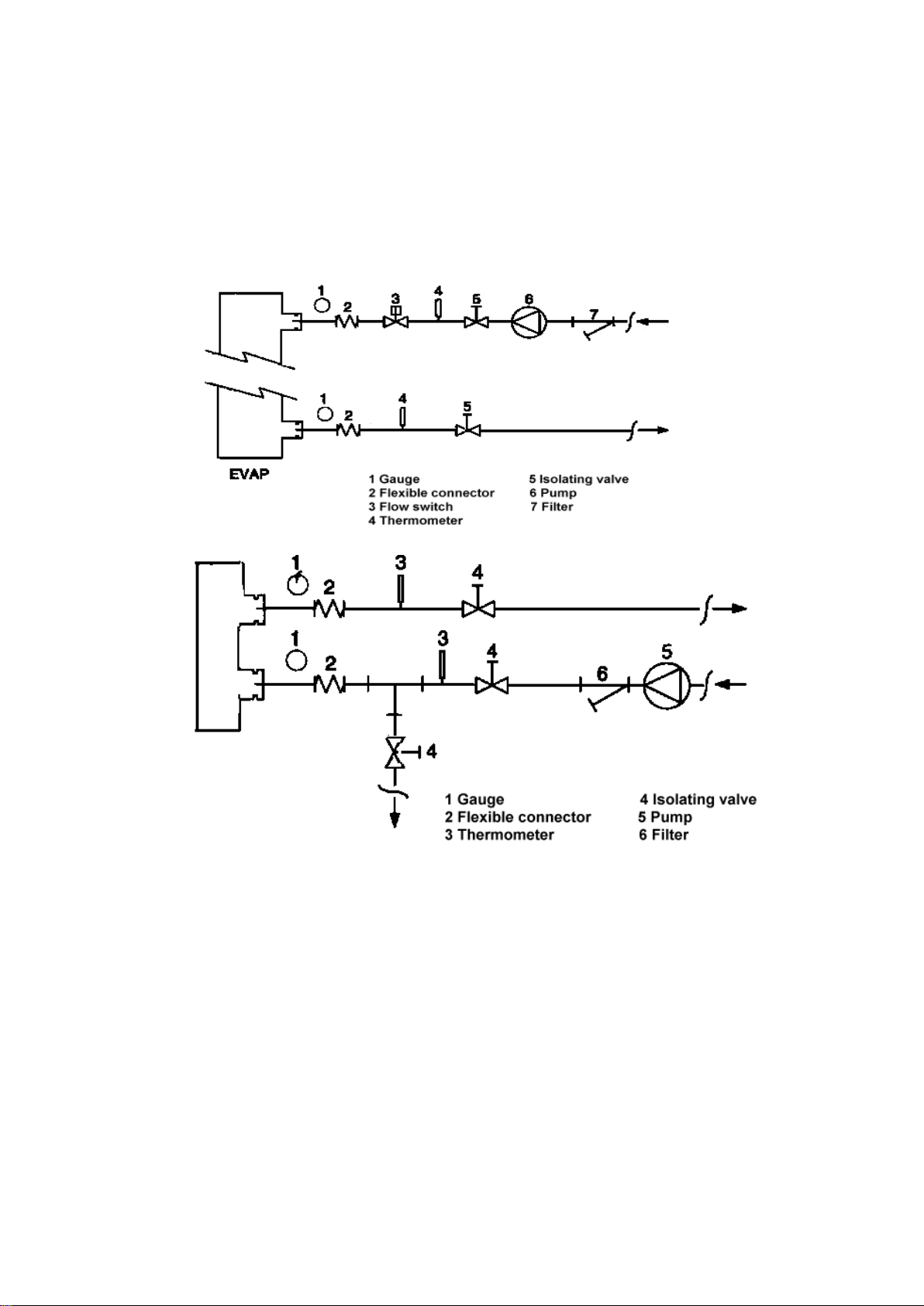

Water piping

Piping must be designed with the lowest number of elbows and the lowest number of vertical changes of direction. In this

way, installation costs are reduced considerably and system performance is improved.

The water system should have:

1 Anti-vibration mountings in order to reduce transmission of vibrations to the underlying structure.

2 Isolating valves to isolate the machine from the water system during service.

3 Manual or automatic air venting device at the system’s highest point; drain device at the system’s lowest point.

Neither the evaporator nor the heat recovery device must be positioned at the system’s highest point.

4 A suitable device that can maintain the water system under pressure (expansion tank, etc.).

5 Water temperature and pressure indicators on the machine to assist the operator during service and maintenance.

6 A filter or device that can remove foreign particles from the water before it enters the pump (in order to prevent

cavitation, please consult the pump manufacturer for the recommended type of filter). The use of a filter prolongs

the life of the pump and helps keep the water system in a better condition.

7 Another filter must be installed on the machine inlet water pipe, near the evaporator and heat recovery (if installed).

The filter prevents solid particles from entering the heat exchanger, as they could damage it or reduce its heat

exchanging capacity.

8 The shell and tube heat exchanger has an electrical resistance with a thermostat that ensures protection against

water freezing at ambient temperatures as low as –25°C. All the other water piping outside the machine must

therefore be protected against freezing.

9 The heat recovery device must be emptied of water during the winter season, unless an ethylene glycol mixture in

appropriate percentage is added to the water circuit.

D-EIMHP00508-16_01EN - 13/50

10 If the machine is intended to replace another, the entire water system must be emptied and cleaned before the new

unit is installed. Regular tests and proper chemical treatment of water are recommended before starting up the new

machine.

11 In the event that glycol is added to the water system as anti-freeze protection, pay attention to the fact that suction

pressure will be lower, the machine’s performance will be lower and water pressure drops will be greater. All

machine-protection systems, such as anti-freeze, and low-pressure protection will need to be readjusted.

Before insulating water piping, check that there are no leaks.

Figure 6 - Water piping connection for evaporator

Figure 7 - Water piping connection for heat recovery exchangers

Legend translation

Gauge

Gauge

Flexible connector

Flexible connector

Flow switch

Flow switch

Thermometer

Thermometer

Isolating valve

Isolating valve

Pump

Pump

Filter

Filter

D-EIMHP00508-16_01EN - 14/50

ATTENTION

Install a mechanical filter on the inlet to each heat exchanger. Failure to install a mechanical filter allows solid particles

and/or welding slag to enter the exchanger. Installation of a filter having a mesh size not exceeding 0,5 – 1 mm is advised.

The manufacturer cannot be held responsible for any damage to exchangers ensuing from the lack of a mechanical filter.

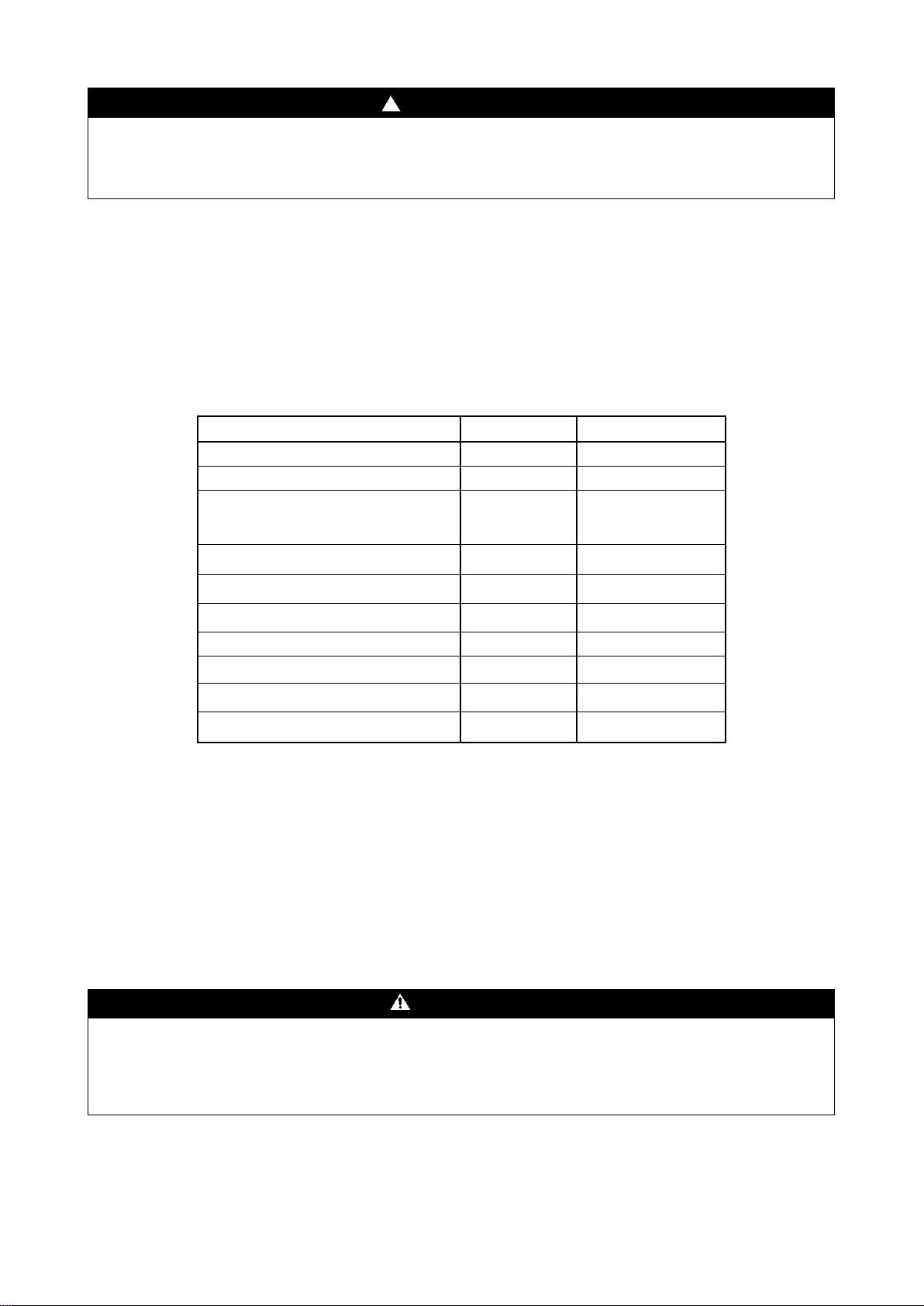

Water treatment

Before putting the machine into operation, clean the water circuit. Dirt, scale, corrosion residue and other foreign material

can accumulate inside the heat exchanger and reduce its heat exchanging capacity. Pressure drop can increase as well,

thus reducing water flow. Proper water treatment therefore reduces the risk of corrosion, erosion, scaling, etc. The most

appropriate water treatment must be determined locally, according to the type of system and local characteristics of the

process water.

The manufacturer is not responsible for damage to or malfunctioning of equipment caused by failure to treat water or by

improperly treated water.

Table 1 - Acceptable water quality limits

DAE Water quality requirements

Shell&tube

BPHE

Ph (25 °C)

6.8 ÷ 8.4

7.5 – 9.0

Electrical conductivity [μS/cm] (25°C)

< 800

< 500

Chloride ion [mg Cl- / l]

< 150

< 70 (HP1);

< 300 (CO2)

Sulphate ion [mg SO42- / l]

< 100

< 100

Alkalinity [mg CaCO3 / l]

< 100

< 200

Total Hardness [mg CaCO3 / l]

< 200

75 ÷ 150

Iron [mg Fe / l]

< 1

< 0.2

Ammonium ion [mg NH4+ / l]

< 1

< 0.5

Silica [mg SiO2 / l]

< 50

NO

Chlorine molecular (mg Cl2/l)

< 5

< 0.5

Evaporator and recovery exchangers anti-freeze protection

All evaporators are supplied with a thermostatically controlled anti-freeze electrical resistance, which provides adequate

anti-freeze protection at temperatures as low as –25°C. However, unless the heat exchangers are completely emptied and

cleaned with anti-freeze solution, additional methods should also be used against freezing.

Two or more of below protection methods should be considered when designing the system as a whole:

12 Continuous water flow circulation inside piping and exchangers

13 Addition of an appropriate amount of glycol inside the water circuit

14 Additional heat insulation and heating of exposed piping

15 Emptying and cleaning of the heat exchanger during the winter season

Partial heat recovery heat exchangers (desuperheters) are not protected against freezing (no heater is installed).

WARNING

It is the responsibility of the installer and/or of local maintenance personnel to ensure that two or more of the described

anti-freeze methods are used. Make sure that appropriate anti-freeze protection is maintained at all times. Failure to

follow the instructions above could result in damage to some of the machine’s components. Damage caused by freezing

is not covered by the warranty.

Installing the flow switch

To ensure sufficient water flow through the evaporator, it is essential that a flow switch be installed on the water circuit.

The flow switch can be installed either on the inlet or outlet water piping. The purpose of the flow switch is to stop the

machine in the event of interrupted water flow, thus protecting the evaporator from freezing.

D-EIMHP00508-16_01EN - 15/50

The flow switch on the heat recovery circuit prevents the machine from shutting down due to high pressure.

The flow switch must be a paddle-type flow switch that is suitable for heavy-duty outdoor applications (IP67) and pipe

diameters in the range of 1” to 6”.

The flow switch is provided with a clean contact which must be electrically connected to terminals 8 and 23 of terminal

board M3 (check the machine’s wiring diagram for further information).

The flow switch must be adjusted to intervene (switch off the unit) when the flow rater is lower than no less than 50% of

nominal flow rate.

For further information regarding device installation and settings, please read the instruction leaflet in the device box.

Loading...

Loading...