Daikin EWLP012KBW1N, EWLP020KBW1N, EWLP026KBW1N, EWLP030KBW1N, EWLP040KBW1N Operation manuals

...

OPERATION MANUAL

Condenserless water-cooled water chillers

EWLP012KBW1N

EWLP020KBW1N

EWLP026KBW1N

EWLP030KBW1N

EWLP040KBW1N

EWLP055KBW1N

EWLP065KBW1N

EWLP012KBW1N EWLP040KBW1N

EWLP020KBW1N EWLP055KBW1N

EWLP026KBW1N EWLP065KBW1N

EWLP030KBW1N

Condenserless water-cooled water chillers

Operation manual

CONTENTS Page

Introduction ....................................................................................... 1

Technical specifications ............................................................................. 2

Electrical specifications ............................................................................. 2

Description ........................................................................................ 3

Function of the main components.............................................................. 4

Safety devices............................................................................................ 4

Internal wiring - Parts table........................................................................ 5

Before operation................................................................................ 6

Checks before initial start-up ..................................................................... 6

Water supply.............................................................................................. 6

Power supply connection and crankcase heating ...................................... 6

General recommendations ........................................................................ 6

Operation .......................................................................................... 6

Digital controller......................................................................................... 6

Working with the units................................................................................ 7

Advanced features of the digital controller............................................... 10

BMS connection modbus ................................................................ 13

General description of Modbus................................................................ 13

Implemented error code........................................................................... 14

Defining the BMS setting ......................................................................... 14

Var iables database.................................................................................. 14

Troubleshooting............................................................................... 15

Maintenance.................................................................................... 16

Important information regarding the refrigerant used .............................. 16

Maintenance activities ............................................................................. 16

Disposal requirements............................................................................. 16

Annex I ............................................................................................ 17

Saturated temperature............................................................................. 17

Menu overview ................................................................................ 18

INTRODUCTION

This operation manual concerns condensorless water-cooled water

chillers of the Daikin EWLP-KB series. These units are provided for

indoor installation and used for cooling applications. The EWLP units

can be combined with Daikin fan coil units or air handling units for air

conditioning purposes. They can also be used for supplying water for

process cooling.

This manual has been prepared to ensure adequate operation and

maintenance of the unit. It will tell you how to use the unit properly

and will provide help if problems occur. The unit is equipped with

safety devices, but they will not necessarily prevent all problems

caused by improper operation or inadequate maintenance.

In case of persisting problems contact your local Daikin dealer.

Before starting up the unit for the first time, make sure that

it has been properly installed. It is therefore necessary to

carefully read the installation manual supplied with the unit

and the recommendations listed in "Before starting".

READ THIS MANUAL ATTENTIVELY BEFORE STARTING

UP THE UNIT. DO NOT THROW THIS MANUAL AWAY.

KEEP IT IN YOUR FILES FOR FUTURE REFERENCE.

Read the chapter "Operation" on page 6 before changing

the parameters.

The English text is the original instruction. Other languages are

translations of the original instructions.

This appliance is not intended for use by persons, including children,

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do not play with

the appliance.

Operation manual

1

Condenserless water-cooled water chillers

EWLP012~065KBW1N

4PW61666-1 – 07.2010

Technical specifications

General EWLP 012 020 026 030

(1)

Dimensions HxWxD (mm) 600x600x600

Machine weight

(kg)

104 138 144 149

Connections

• condenser

discharge

connection

(copper)

• condenser liquid

connection

(copper)

General EWLP 040 055 065

(mm)

12.7 flare 19.1 flare 19.1 flare 19.1 flare

(mm)

9.52 flare 12.7 flare 12.7 flare 12.7 flare

Dimensions HxWxD (mm) 600x600x1200

Machine weight

(kg)

252 265 274

Connections

• condenser

discharge

connection

(copper)

• condenser liquid

connection

(copper)

Compressor EWLP 012 020 026 030

(mm)

2x 19.1 flare 2x 19.1 flare 2x 19.1 flare

(mm)

2x 12.7 flare 2x 12.7 flare 2x 12.7 flare

Model JT140BF-YE JT212DA-YE JT300DA-YE JT335DA-YE

Speed

(rpm)

2900

Oil type FVC68D

Oil charge volume

(l)

1.5 2.7 2.7 2.7

Refrigerant type R407C

Evaporator

Type brased plate heat exchanger

Min. water volume

Water flow range

Condenser

(l)

62.1 103 134 155

(l/min)

17~69 29~115 38~153 45~179

refer to engeneering specifications as published by the supplier of your

remote condenser

Compressor EWLP 040 055 065

Model 2x

Speed

(rpm)

JT212DA-YE

2x

JT300DA-YE

2900

2x

JT335DA-YE

Oil type FVC68D

Oil charge volume

(l)

2x 2.7 2x 2.7 2x 2.7

Refrigerant type R407C

Evaporator

Type brased plate heat exchanger

Min. water volume

Water flow range

Condenser

(l)

(l/min)

205 268 311

57~229 77~307 89~359

refer to engeneering specifications as published by the supplier of your

remote condenser

Electrical specifications

Model EWLP 012 020 026 030

(2)

Power supply

• Phase

•Frequency

•Voltage

•Voltage tolerance

• Recommended fuses (aM)

(Hz)

(%)

(V)

3x 16 3x 20 3x 25 3x 32

3N~

50

400

±10

Compressor

• Phase

•Frequency

•Voltage

• Nominal running current (A)

(Hz)

(V)

7.4 11.6 14.7 16.8

3~

50

400

Control

• Phase

•Frequency

•Voltage

• Recommended fuses (aM)

Model EWLP 040 055 065

(Hz)

(V)

1~

50

230

factory installed

Power supply

• Phase

•Frequency

•Voltage

•Voltage tolerance

• Recommended fuses (aM)

(Hz)

(%)

(V)

3x 40 3x 50 3x 50

3N~

50

400

±10

Compressor

• Phase

•Frequency

•Voltage

• Nominal running current (A)

(Hz)

(V)

11.6 14.7 16.8

3~

50

400

Control

• Phase

•Frequency

•Voltage

• Recommended fuses (aM)

(Hz)

(V)

1~

50

230

factory installed

(1) Refer to the engineering data book for the complete list of specifications.

EWLP012~065KBW1N

Condenserless water-cooled water chillers

4PW61666-1 – 07.2010

(2) Refer to the engineering data book for the complete list of specifications.

Operation manual

2

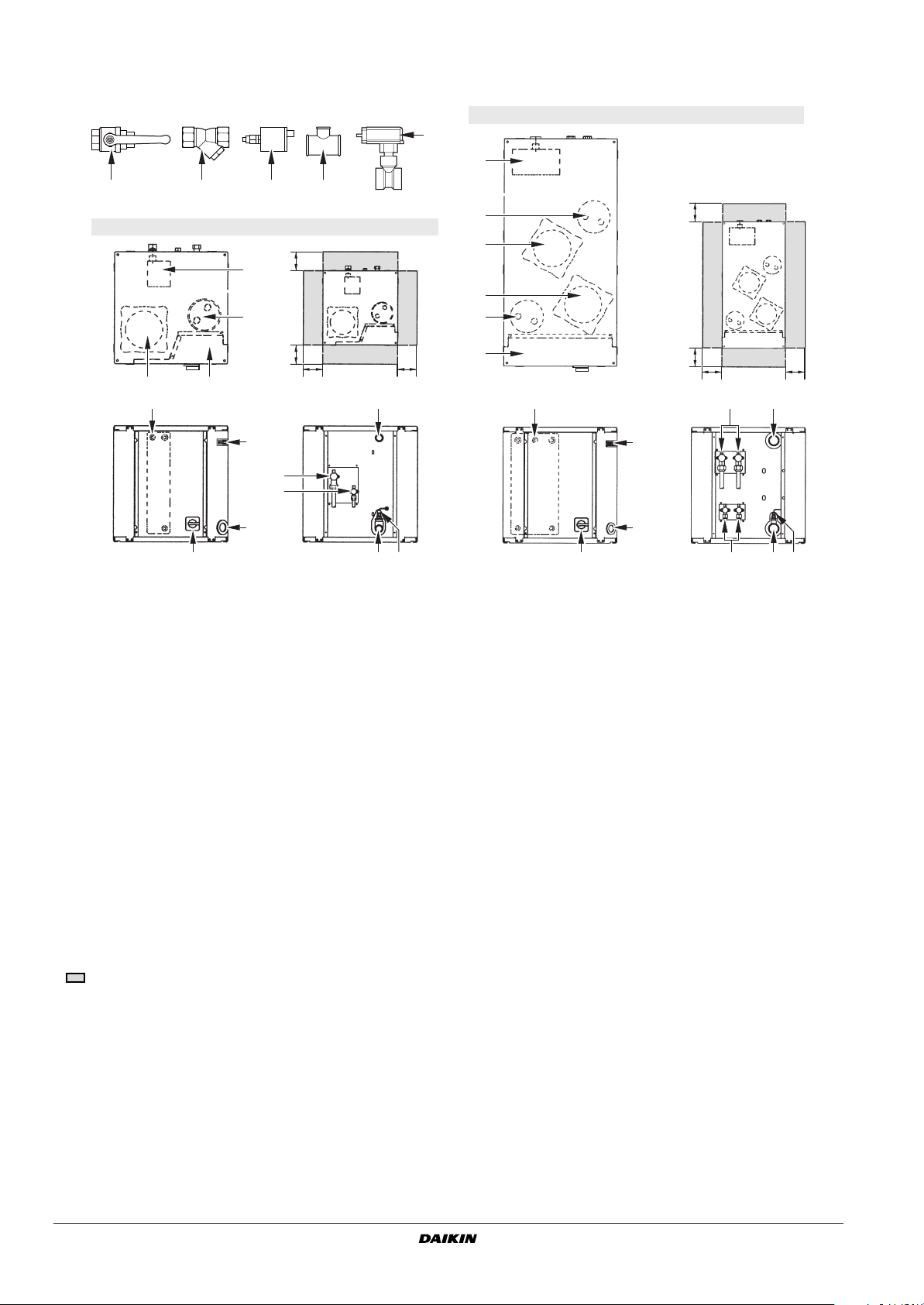

DESCRIPTION

The EWLP condenserless water-cooled water chillers are available in 7 standard sizes.

EWLP040~065KBW1N

17

2

13 14 15 16

EWLP012~030KBW1N

2

3

14

9

11

7

8

12 12

Figure: Main components

1 Compressor

2 Evaporator

3 Accumulator

4 Switchbox

5 Chilled water in

6 Chilled water out

7 Discharge stop valve

8 Liquid stop valve

9 Evaporator entering water temperature sensor

10 Freeze up sensor

11 Digital display controller

12 Power supply intake

13 Ball valve (field installed)

14 Water filter (field installed)

15 Air purge valve (field installed)

16 T-joint for air purge (field installed)

17 Flow switch (with T-joint) (field installed)

18 Main switch

500

500

500

3

1

1

3

4

500

5

11

10

500

500

500

500

759

866 1818

10

Required space around the unit for service

Operation manual

3

Condenserless water-cooled water chillers

EWLP012~065KBW1N

4PW61666-1 – 07.2010

Function of the main components

EWLP012~030KBW1N

EWLP040~065KBW1N

64

13

5

12

14

R3T

R4T

R3T

R4T

S4LP

S5LP

S4LP

1

M1C

LP

HP

3 7

M2C

LP

HP

M1C

LP

HP

S1HP

Q1D

2

8 9

S2HP

Q2D

S1HP

Q1D

10111513

Figure: Functional diagram

1 Compressor 9 Liquid stop valve

2 Filter 10 Discharge stop valve

3 Expansion valve 11 Accumulator

4 Evaporator 12 Flow switch (delivered with the unit, installed in the field)

5 Evaporator water outlet 13 Ball valve (delivered with the unit, installed in the field)

6 Evaporator water inlet 14 Water filter (delivered with the unit, installed in the field)

7 Sight glass 15 Air purge valve (delivered with the unit, installed in the field)

8 Liquid solenoid valve Field piping

As the refrigerant circulates through the unit, changes in its state or

Safety devices

condition occur. These changes are caused by the following main

components:

■ Compressor

The compressor (M*C) acts as a pump and circulates the

refrigerant in the refrigeration circuit. It compresses the

refrigerant vapour coming from the evaporator to a pressure at

which it can easily be liquified in the condenser.

■ Filter

The filter installed behind the condenser removes small particles

from the refrigerant to prevent blockage of the tubes.

■ Expansion valve

The liquid refrigerant coming from the condenser enters the

evaporator via an expansion valve. The expansion valve brings

the liquid refrigerant to a pressure at which it can easily be

evaporated in the evaporator.

■ Evaporator

The main function of the evaporator is to take heat from the

water that flows through it. This is done by turning the liquid

refrigerant, coming from the condenser, into gaseous

refrigerant.

■ Water in/outlet connections

The unit is equipped with General safety devices: shut down all

circuits and stop the whole unit.

■ I/O PCB (A2P) (input/output)

The I/O PCB (A2P) contains a reverse phase protector.

The reverse phase protector detects if the 3 phases of the power

supply are connected correctly. If a phase is not connected or if

2 phases are inverted, the unit can not start up.

■ Overcurrent relay

The overcurrent relay (K*S) is located in the switch box of the

unit and protects the compressor motor in case of overload,

phase failure or too low voltage. The relay is factory-set and may

not be adjusted. When activated, the overcurrent relay has to be

reset in the switch box and the controller needs to be reset

manually.

■ High-pressure switch

The high-pressure switch (S*HP) is installed on the discharge

pipe of the unit and measures the condenser pressure (pressure

at the outlet of the compressor). When the pressure is too high,

the pressure switch is activated and the circuit stops.

When activated, it resets automatically, but the controller needs

to be reset manually.

The water inlet and outlet connection allow an easy connection

of the unit to the water circuit of the air handling unit or industrial

equipment.

EWLP012~065KBW1N

Condenserless water-cooled water chillers

4PW61666-1 – 07.2010

Operation manual

4

■ Low pressure switch

The low-pressure switch (S*LP) is installed on the suction pipe

of the unit and measures the evaporator pressure (pressure at

the intlet of the compressor). When the pressure is too low, the

pressure switch is activated and the circuit stops.

When activated, it resets automatically, but the controller needs

to be reset manually.

■ Discharge thermal protector

The discharge thermal protector (Q*D) is activated when the

temperature of the refrigerant leaving the compressor becomes

too high. When the temperature returns to normal, the protector

resets automatically, but the controller needs to be reset

manually.

■ Freeze up sensor

The outlet water temperature sensor (R4T) measures the

temperature of the water at the water heat exchanger outlet. The

protection device shuts down the circuit when the temperature of

the chilled water becomes too low in order to prevent freezing of

the water during operation.

When the outlet water temperature returns to normal, the

protector resets automatically, but the controller needs to be

reset manually.

■ Fuse for control circuit (F1U)

The fuse for control circuit protects cables of control circuit and

controller components in case of short circuit.

■ Fuse for control circuit (F4)

The fuse for control circuit protects cables of control circuit in

case of short circuit.

■ Fuse for digital controller (F3U)

The fuse protects cables of digital controller and digital controller

in case of short circuit.

■ Flow switch (delivered with the unit, installed in the field)

The flow switch measures the flow in the water circuit. In case

the flow does not reach the minimum allowed water flow, the unit

will be shut down.

■ Ball valve (delivered with the unit, installed in the field)

A ball valve is installed in front of and behind the water filter to

allow filter cleaning without having to drain the water circuit.

■ Water filter (delivered with the unit, installed in the field)

The filter installed in front of the unit removes dirt from the water

to prevent damage to the unit or blockage of the evaporator or

condenser. The water filter should be cleaned on a regular base.

■ Air purge valve (delivered with the unit, installed in the field)

Remaining air in the chiller water system will be automatically

removed via the air purge valve.

Internal wiring - Parts table

Refer to the internal wiring diagram supplied with the unit. The

abbreviations used are listed below:

A1P.................... PCB: controller PCB

A2P.................... PCB: I/O PCB (input/output)

A3P............. ** ... PCB: Address card for BMS

A5P,A6P......** ... PCB: Softstarter for circuit 1, circuit 2

A7P............. ** ... PCB: Remote user interface

A71P.................. PCB: power supply card

A72P.................. PCB: remote user interface

E1H,E2H............ Crankcase heater circuit 1, circuit 2

F1,F2,F3 ..... # .... Main fuses for the unit

F4 ...............* ..... Fuse I/O PCB

F5 ...............## .. Surge proof fuse

F6 ...............# .... Fuse for pumpcontactor

F1U.................... Fuse I/O PCB

F3U.................... Fuse for controller PCB

H3P.............*..... Indication lamp alarm

H4P.............*..... Indication lamp operation compressor 1

H5P.............*..... Indication lamp operation compressor 2

H6P.............*..... Indication lamp general operation

K1F,K2F...... # .... Auxiliary contactor for fan motors

K1M,K2M........... Compressor contactor circuit 1, circuit 2

K4S,K5S ............ Overcurrent relay circuit 1, circuit 2

K6S............. * ..... Overcurrent relay pump

K1P............. * ..... Pumpcontactor

M1C,M2C .......... Compressor motor circuit 1, circuit 2

PE...................... Main earth terminal

Q1D,Q2D........... Discharge thermal protector circuit 1, circuit 2

R3T.................... Evaporator inlet water temperature sensor

R4T.................... Evaporator outlet water temperature sensor

R5T.................... Condenser inlet temperature sensor

S1HP,S2HP ....... High pressure switch circuit 1, circuit 2

S4LP,S5LP......... Low pressure switch circuit 1, circuit 2

S7S............. * ..... Switch for remote cooling/heating selection

dual setpoint

S9S............. * ..... Switch for remote start/stop

S10L .................. Flow switch

S12M ................. Main isolator switch

TR1.................... Transfo 230 V ➞ 24 V for supply of controller PCB

TR2.................... Transfo 230 V ➞ 24 V for supply of I/O PCB (A2P)

Y3R.................... Reversingvalve

Y1S, Y2S ........... Liquid solenoid valve

X1~3,X1~82A .... Connectors

Not included with standard unit

Not possible as option Possible as option

Obligatory # ##

Not obligatory * **

(1)

(1)

(1)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

or

(2)

or dual setpoint

Operation manual

5

(1) optional

(2) field supply

Condenserless water-cooled water chillers

EWLP012~065KBW1N

4PW61666-1 – 07.2010

Loading...

Loading...