Page 1

Installation, Operation and Maintenance Manual

D–EIMAC00907-16EN

Inverter

Installation, Operation and Maintenance Manual

Air cooled chiller with inverter

driven screw compressor

EWAD~TZ

Refrigerant: R-134a

Original Instructions

D–EIMAC00907–16EN - 1/20

Page 2

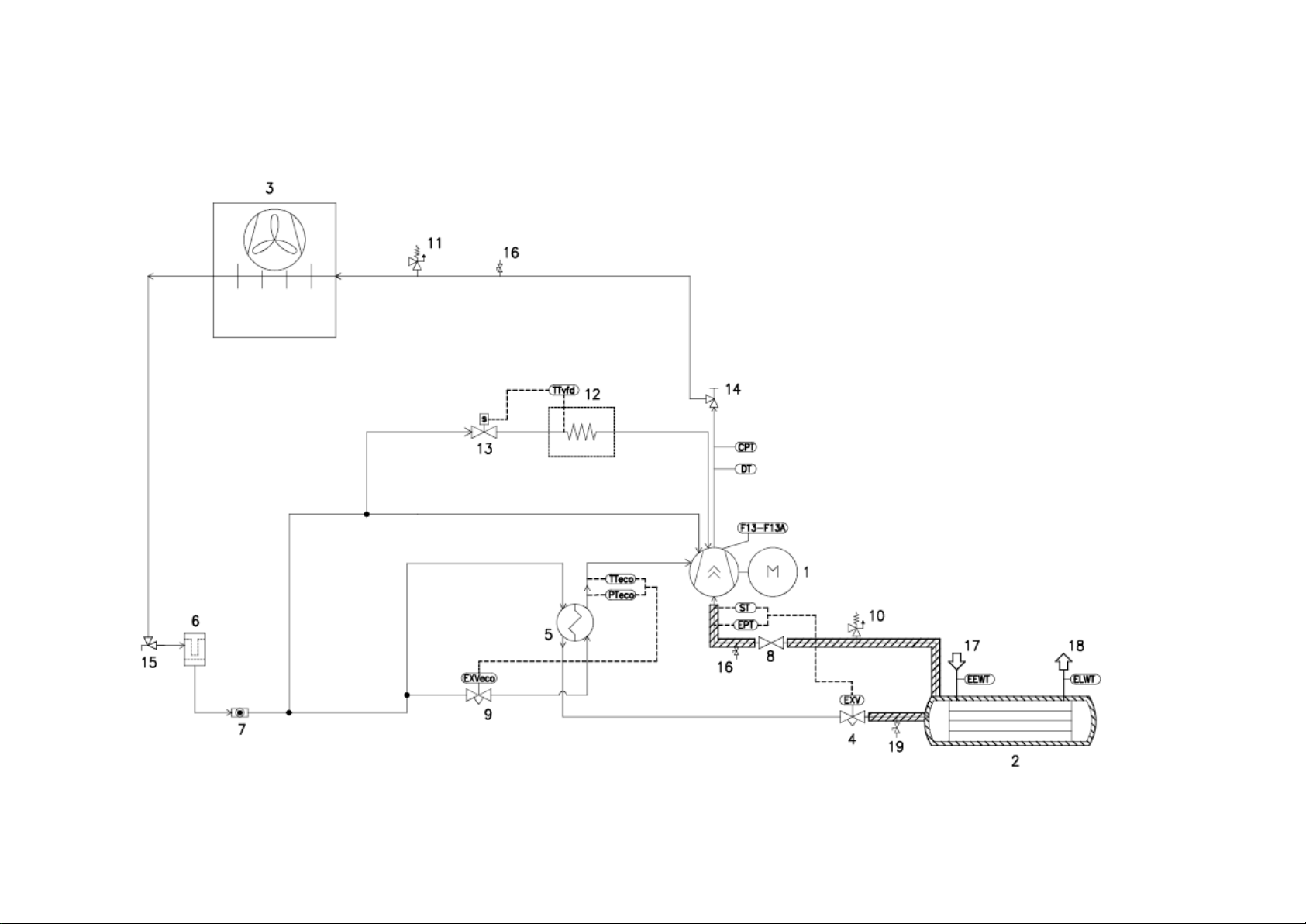

A

Typical refrigerant circuit - Water inlet and outlet are indicative. Please refer to the machine dimensional diagrams for exact water connections.

D–EIMAC00907–16EN - 2/20

Page 3

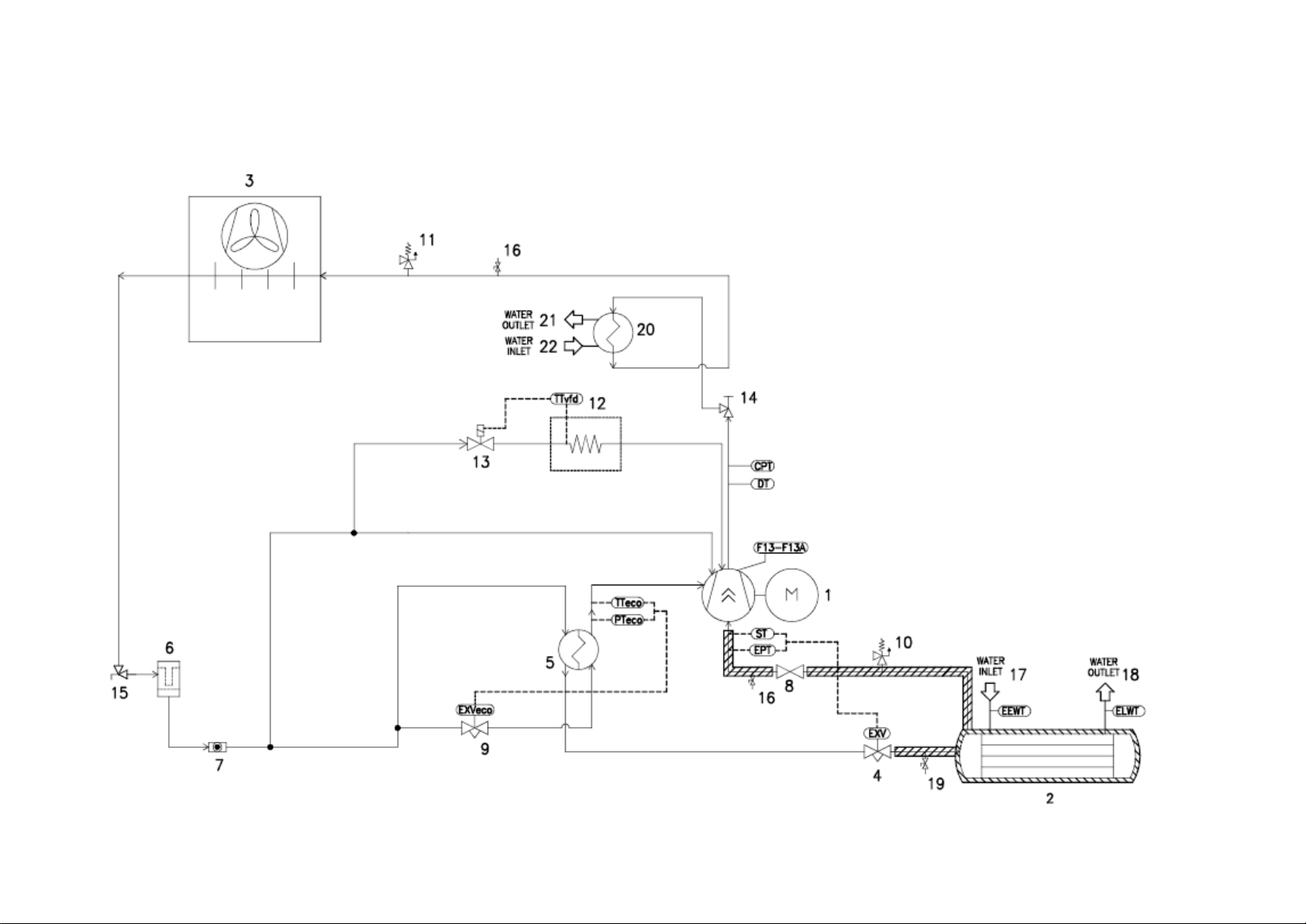

B

Typical refrigerant circuit with heat recovery - Water inlet and outlet are indicative. Please refer to the machine dimensional diagrams for exact water connections.

D-EIMAC00907-16EN - 3/20

Page 4

Legend

1

Compressor

2

Evaporator

3

Condenser coil & Axial fan

4

Electronic expansion valve

5

Economizer

6

Dehydration filter

7

Liquid and humidity indicator

8

Sution valve

9

Economizer electronic expansion

valve

10

Low-pressure safety valve

11

High-pressure safety valve

12

Heat exchanger (VFD cooling)

13

Heat exchanger (VFD cooling)

solenoid valve

14

Discharge shut off valve

15

Liquid line isolating valve

16

¼” SAE Flare valve

17

Evaporator water inlet connection

18

Evaporator water outlet connection

19

2 Way charging valve

20

Heat Recovery (Optional)

21

Heat Recovery water outlet

connection

22

Heat Recovery water inlet

connection

F13-F13A

High pressure switch

DT

Discharge temperature sensor

CPT

Condenser pressure transducer

EPT

Evaporator pressure transducer

ST

Suction temperature sensor

PTeco

Economizer pressure transducer

TTeco

Economizer temperature

transducer

TTvfd

VFD Temperature transducer

EEWT

Evaporator Entering Water

Temperature probe

ELWT

Evaporator Leaving Water

Temperature probe

D-EIMAC00907-16EN - 4/20

Page 5

This manual is an important supporting document for qualified personnel but it is not intended to replace such personnel.

READ THIS MANUAL CAREFULLY BEFORE

INSTALLING AND STARTING UP THE UNIT.

IMPROPER INSTALLATION COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE

OR OTHER DAMAGE TO THE EQUIPMENT OR

INJURE TO PEOPLE.

THE UNIT MUST BE INSTALLED BY A

PROFESSIONAL OPERATOR/TECHNICIAN

UNIT STARTUP HAS TO BE PERFORMED BY

AUTHORIZED AND TRAINED PROFESSIONAL

ALL ACTIVITIES HAVE TO BE PERFORMED

ACCORDING TO LOCAL LAWS AND REGULATION.

UNIT INSTALLATION AND START UP IS

ABOSOLUTELY FORBIDDEN IF ALL INSTRUCTION

CONTAINED IN THIS MANUAL ARE NOT CLEAR.

IF CASE OF DOUBT CONTACT THE

MANUFACTURER REPRESENTATIVE FOR ADVICE

AND INFORMATION.

Description

The unit you bought is an “air cooled chiller”, a machine aimed

to cool water (or water-glycol mixture) within the limits

described in the following. The unit operation is based on

vapour compression, condensation and evaporation according

to reverse Carnot cycle. The main components are:

- Screw compressor to rise the refrigerant vapour pressure

from evaporation pressure to condensation pressure

- Evaporator, where the low pressure liquid refrigerant

evaporates to cool the water

- Condenser, where high pressure vapour condensate

rejecting heat removed from the chilled water in the

atmosphere thanks to an air cooled heat exchanger.

- Expansion valve allowing to reduced the pressure of

condensed liquid from condensation pressure to

evaporation pressure.

General Information

All units are delivered with wiring diagrams, certified

drawings, nameplate; and DOC (Declaration Of

Conformity); these documents show all technical data

for the unit you have bought and they MUST BE

CONSIDERED ESSENTIAL DOCUMENTS OF THIS

MANUAL

In case of any discrepancy between this manual and the

equipment’s documents please refer to on board documents.

In case of any doubt contact the manufacturer representative.

The purpose of this manual is to allow the installer and the

qualified operator to ensure proper installation, commissioning

and maintenance of the unit, without any risk to people,

animals and/or objects.

Thank you for purchasing this chiller

Receiving the unit

The unit must be inspected for any possible damage

immediately upon reaching final place of installation. All

components described in the delivery note must be inspected

and checked.

Should the unit be damaged, do not remove the damaged

material and immediately report the damage to the

transportation company and request they inspect the unit..

Immediately report the damage to the manufacturer

representative, a set of photographs are helpful in recognizing

responsibility

Damage must not be repaired before the inspection of the

transportation company representative.

Before installing the unit, check that the model and power

supply voltage shown on the nameplate are correct.

Responsibility for any damage after acceptance of the unit

cannot be attributed to the manufacturer.

Operating limits

Storing Storage

Environmental conditions must be within the following limits:

Minimum ambient temperature : -20°C

Maximum ambient temperature : 57°C

Maximum R.H. : 95% not condensing

Storing below the minimum temperature may cause damage to

components. Storing above the maximum temperature causes

opening of safety valves. Storing in condensing atmosphere

may damage electronic components.

Operation

Operation is allowed within the following limits:

Evaporator Leaving Water Temperature: 4…18°C (Cool

Mode), -8…18°C (Cool with glycol, Ice Mode)

Outside Ambient Temperature @ full load:

Silver Efficiency Version: 10…47°C

Gold Efficiency Version: -18…50°C

Platinum Efficiency Version: -18…52°C

Operational envelope can be extended through selection of

specific options (such as high ambient kit, brine version, etc)

which allow the unit to operate down to -8°C evaporator

leaving temperature and/or up to 52°C ambient temperature at

full load.

The above mentioned values represent a guideline, please

refer to the chiller selection software for real operating limits for

the specific model.

As a general rule, The unit should be operated with an

evaporator water flow rate between 50% and 140% of nominal

flow rate (at standard operating conditions), however check

with the chiller selection software the correct minimum and

maximum allowed values for the specific model.

Operation out of the mentioned limits may damage the unit.

In case of doubts contact manufacturer representative.

D–EIMAC00907–16EN - 5/20

Page 6

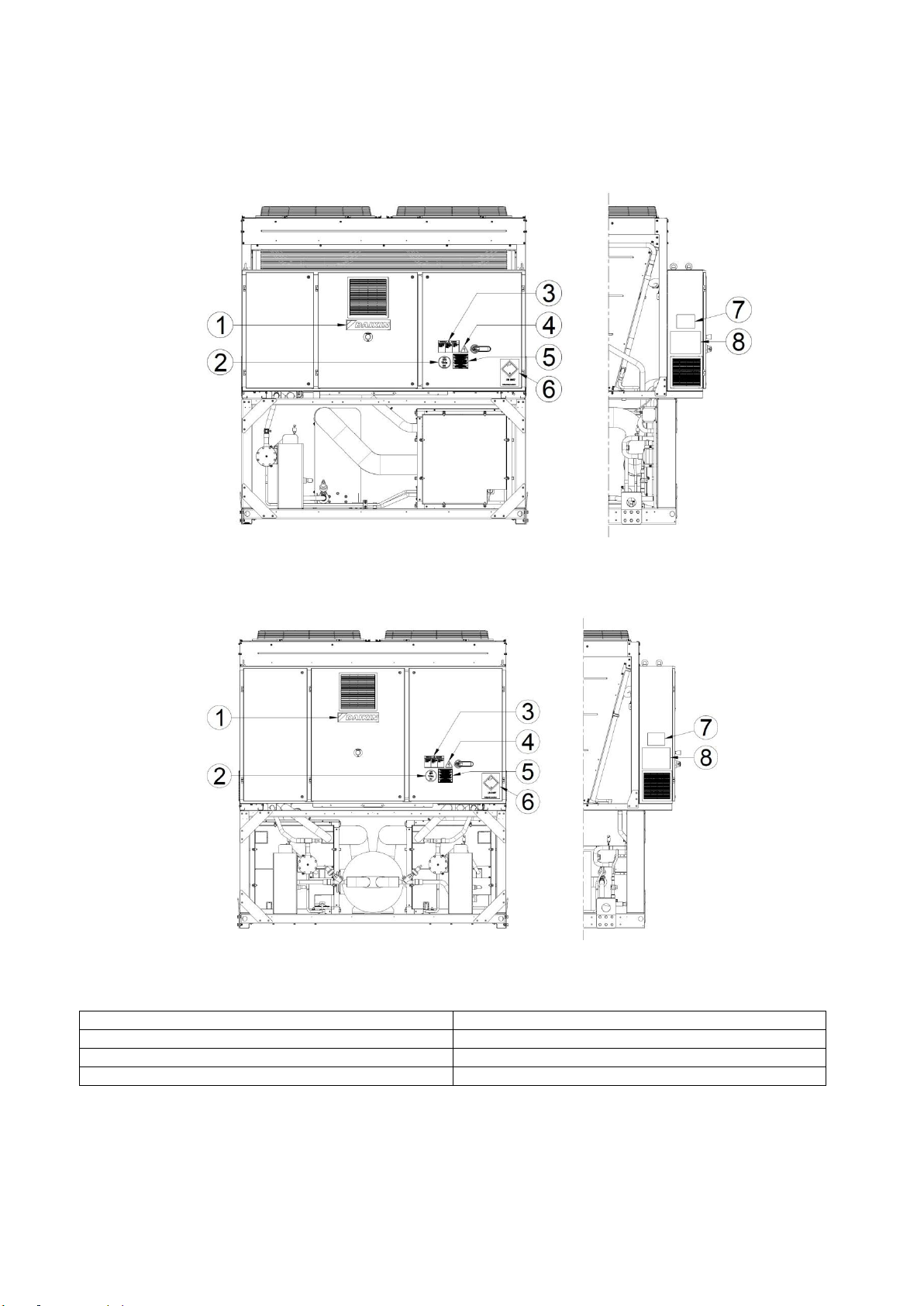

1 – Manufacturer’s logo

5 – Cable tightening warning

2 – Gas type

6 – Non flammable gas symbol

3 – Hazardous Voltage warning

7 – Unit nameplate data

4 – Electrical hazard symbol

8 – Lifting instruction

Figure 1 - Description of the labels applied to the electrical panel

Label Identification

Single circuit unit

Double circuits unit

D-EIMAC00907-16EN - 6/20

Page 7

Safety

The unit must be firmly secured to the soil.

It is essential to observe the following instructions:

The unit can only be lifted using the lifting points marked

in yellow fixed to its base.

It is forbidden to access the electrical components without

having opened the unit main switch and switched off the

power supply.

It is forbidden to access the electrical components without

using an insulating platform. Do not access the electrical

components if water and/or moisture are present.

Sharp edges and the surface of the condenser section

could cause injury. Avoid direct contact and use adeguate

protection device

Switch off power supply, by opening the main switch,

before servicing the cooling fans and/or compressors.

Failure to observe this rule could result in serious

personal injury.

Do not introduce solid objects into the water pipes while

the unit is connected to the system.

A mechanical filter must be installed on the water pipe

connected to the heat exchanger inlet.

The unit is supplied with safety valves, that are installed

both on the high-pressure and on the low-pressure sides

of the refrigerant circuit.

It is absolutely forbidden to remove all protections of

moving parts.

In case of sudden stop of the unit, follow the instructions on the

Control Panel Operating Manual which is part of the onboard documentation delivered to the end user.

It is strongly recommended to perform installation and

maintenance with other people. In case of accidental injury or

unease, it is necessary to:

- keep calm

- press the alarm button if present in the installation site

- move the injured person in a warm place far from the unit

and in rest position

- contact immediately emergency rescue personnel of the

building or the Health Emergency Service

- wait without leaving the injured person alone until the

rescue operators come

- give all necessary information to the rescue operators

Avoid installing the chiller in areas that could be

dangerous during maintenance operations, such as

platforms without parapets or railings or areas not

complying with the clearance requirements around the

chiller.

Noise

The unit is a source of noise mainly due to rotation of

compressors and fans.

The noise level for each model size is listed in sales

documentation.

If the unit is correctly installed, operated and manteined the

noise emission level do not require any special protection

device to operate continuosly close to the unit without any risk.

In case of installation with special noise requirements it could

be necessary to install additional sound attenuation devices.

Moving and lifting

Avoid bumping and/or jolting during loading/unloading unit

from the truck and moving it. Do not push or pull the unit from

any part other than the base frame. Secure the unit inside the

truck to prevent it from moving and causing damages. Do not

allow any part of the unit to fall during transportation or

loading/unloading.

All units of the series are supplied with lifting points marked in

yellow. Only these points may be used for lifting the unit, as

shown in the following figure.

Use spacing bars to prevent damage to the condensation

bank. Position these above the fan grills at a distance of at

least 2.5 metres.

Both the lifting ropes and the spacing bars must be

strong enough to support the unit safely. Please check

the unit’s weight on the unit nameplate.

The unit must be lifted with the utmost attention and care

following lifting label instructions; lift unit very slowly, keeping it

perfectly level.

Positioning and assembly

All units are designed for installation outdoors, either on

balconies or on the ground, provided that the installation area

is free of obstacles that could reduce air flow to the

condensers coil.

The unit must be installed on a robust and perfectly level

foundation; should the unit be installed on balconies or roofs, it

might be necessary to use weight distribution beams.

Figure 2 - Lifting

Unit with 4 lifting points

(The drawing shows only the 6 fans version. For the 4 fans version the lifting mode is the same)

D–EIMAC00907–16EN - 7/20

Page 8

Unit with 6 lifting points

(The drawing shows only the 12 fans version. The lifting mode is the same for the different number of fans)

Figure 3 – Unit Levelling

For installation on the ground, a strong concrete base, at least

250 mm thickness and wider than the unit must be provided.

This base must be able to support the weight of the unit.

The unit must be installed above antivibrating mounts (AVM),

rubber or spring types. The unit frame must be perfectly

levelled above the AVM.

Installation such as in the figure above must always be

avoided. In case the AVM’s are not adjustable (spring type are

normally not adjustable) the flatness of the unit frame must be

guaranteed by using metal plate spacers.

Before unit commissioning, the flatness must be verified by

using a laser levelling device or other similar devices. The

flatness shall not be over 5 mm for units within 7 m length and

10 mm for units over 7 m.

If the unit is installed in places that are easily accessible to

people and animals, it is advisable to install protection grids for

the condenser and compressor sections.

To ensure best performance on the installation site, the

following precautions and instructions must be followed:

Avoid air flow recirculation.

Make sure that there are no obstacles to hamper air flow.

D-EIMAC00907-16EN - 8/20

Page 9

Make sure to provide a strong and solid foundation to

reduce noise and vibrations.

Avoid installation in particularly dusty environments, in

order to reduce soiling of condensers coils.

The water in the system must be particularly clean and all

traces of oil and rust must be removed. A mechanical

water filter must be installed on the unit’s inlet piping.

Minimum space requirements

It is fundamental to respect minimum distances on all units in

order to ensure optimum ventilation to the condenser coils.

When deciding where to position the unit and to ensure a

proper air flow, the following factors must be taken into

consideration:

avoid any warm air recirculation

avoid insufficient air supply to the air-cooled condenser.

Both these conditions can cause an increase of condensing

pressure, which leads to a reduction in energy efficiency and

refrigerating capacity.

Any side of the unit must be accessible for post-installation

maintenance operations. Figure 3 shows the minimum space

required.

Figure 4 – Minimum clearance requirements

Vertical air discharge must not be obstructed.

If the unit is surrounded by walls or obstacles of the same

height as the unit, this must be installed at a distance no lower

than 3000 mm.

In case of two chillers installed in free field, minimum

recommended distance between them is 3600 mm; in case of

two chillers in a row, minimum distance is 1500 mm. The

pictures below show example of recommended installations.

Should the unit be installed without observing the

recommended minimum distances from walls and/or vertical

obstacles, there could be a combination of warm air

recirculation and/or insufficient supply to the air-cooled

condenser which could cause a reduction of capacity and

efficiency.

In any case, the microprocessor will allow the unit to adapt

itself to new operating conditions and deliver the maximum

available capacity under any given circumstances, even if the

lateral distance is lower than recommended, unless the

operating conditions should affect personel safety or unit

reliability.

D-EIMAC00907-16EN - 9/20

Page 10

The minimum distances, reported above, ensure functionality

of the chiller in most applications. However, there are specific

situations which include multiple chiller installations: in this

case the following recommendations are to be followed:

Multiple chiller installed side by side in a free field with

dominant wind.

Considering an installation in areas with a dominant wind from

a specific direction (as shown in the Fig.5):

Chiller N°1: is performing normally without any

ambient over-temperature

Chiller N° 2: is working in a warmed ambient. The

first circuit (from the left) is working with air

recirculating from Chiller 1 and the second circuit to

the recirculating air from the chiller N°1 and

recirculation from itself.

Chiller N° 3: circuit on the left is working in a over-

temperature ambient due to the recirculating air from

the other two chillers, circuit on the right is working

quite normally.

Figure 5 – Multiple Chiller Installation

In order to avoid the hot air recirculation due to dominant

winds, the installation where all chillers are aligned to the

dominant wind is preferred (see figure below):

Multiple chiller installed side by side in a compound.

In case of compounds with walls of the same height of the

chillers or higher, the installation is not recommended. Chiller 2

and chiller 3 work with sensible higher temperature due to the

enhanced recirculation. In this case special precautions must

be taken in to account according to the specific installation (eg:

louvered walls, install the unit on base frame in order to

increase the height, ducts on the discharge of the fans, high lift

fans, etc).

All the above cases are even more sensitive in case of design

conditions close to the limits of the unit operating envelope.

NOTE: Daikin cannot be considered responsible in case of

malfunctions generated by hot air recirculation or insufficient

airflow as result of improper installation if the above

recommendations are ignored.

D-EIMAC00907-16EN - 10/20

Page 11

pH (25°C)

6,88,0

Total Hardness (mg CaCO3 / l)

200

Electrical conductivity S/cm (25°C)

800

Iron (mg Fe / l)

1.0

Chloride ion (mg Cl - / l)

200

Sulphide ion (mg S

2 -

/ l)

None

Sulphate ion (mg SO

24 -

/ l)

200

Ammonium ion (mg NH

4

+

/ l)

1.0

Alkalinity (mg CaCO3 / l)

100

Silica (mg SiO2 / l)

50

Sound protection

When sound levels require special control, great care must be

exercised to isolate the unit from its base by appropriately

applying anti-vibration elements (supplied as an option).

Flexible joints must be installed on the water connections, as

well.

Water piping

Piping must be designed with the lowest number of elbows

and the lowest number of vertical changes of direction. In this

way, installation costs are reduced considerably and system

performance is improved.

The water system must have:

1. Anti-vibration mountings in order to reduce transmission of

vibrations to the structures.

2. Isolating valves to isolate the unit from the water system

during maintenance.

3. Flow switch, in order to protect the chiller must be

protected against freezing by continuous monitoring of the

water flow in the evaporator. In most cases, on-site the

flow switch is set to produce an alarm only when the water

pump switches OFF and the water flow fall to zero. it is

recommended to adjust the flow switch in order to produce

a “Water Loss Alarm” when the water flow reaches 50% of

the nominal value, in this case the evaporator is protected

against the freezing and the flow switch can detect the

water filter clogging.

4. Manual or automatic air venting device at the system’s

highest point.; drain device at the system’s lowest point.

5. Neither the evaporator nor the heat recovery device must

be positioned at the system’s highest point.

6. A suitable device that can maintain the water system under

pressure (expansion tank, etc.).

7. Water temperature and pressure indicators to assist the

operator during service and maintenance.

8. A filter or device that can remove particles from the fluid.

The use of a filter extends the life of the evaporator and

pump and helps to keep the water system in a better

condition. The water filter must be installed as close as

Table 1 - Acceptable water quality limits

possible to the chiller, as in Figs. 6 and 7. If the water

filter is installed in another part of the water system, the

Installer has to guarantee the cleaning of the water pipes

between the water filter and the evaporator.

9. Evaporator has an electrical resistance with a thermostat

that ensures protection against water freezing at ambient

temperatures as low as –25°C.

All the other water piping/devices outside the unit must

therefore be protected against freezing.

10. The heat recovery device must be emptied of water during

the winter season, unless an ethylene glycol mixture in

appropriate percentage is added to the water circuit.

11. If case of unit substitution, the entire water system must be

emptied and cleaned before the new unit is installed.

Regular tests and proper chemical treatment of water are

recommended before starting up the new unit.

12. In the event that glycol is added to the water system as

anti-freeze protection, pay attention to the fact that suction

pressure will be lower, the unit’s performance will be lower

and water pressure drops will be greater. All unit-protection

systems, such as anti-freeze, and low-pressure protection

will need to be readjusted.

13. Before insulating water piping, check that there are no

leaks.

Water treatment

Before putting the unit into operation, clean the water circuit.

Any damage due to the presence of foreign bodies or debris in

the evaporator will not be covered by warranty. Dirt, scales,

corrosion debrits and other material can accumulate inside the

heat exchanger and reduce its heat exchanging capacity.

Pressure drop can increase as well, thus reducing water flow.

Proper water treatment therefore reduces the risk of corrosion,

erosion, scaling, etc.. The most appropriate water treatment

must be determined locally, according to the type of system

and water characteristics.

The manufacturer is not responsible for damage to or

malfunctioning of equipment caused by failure to treat water or

by improperly treated water.

D-EIMAC00907-16EN - 11/20

Page 12

1. Pressure Gauge

2. Flexible connector

3. Flow switch

4. Temperature probe

5. Isolation Valve

6. Pump

7. Filter

1. Pressure Gauge

2. Flexible connector

3. Temperature probe

4. Isolation Valve

5. Pump

6. Filter

Evaporator and recovery exchangers anti-freeze

protection

All evaporators are supplied with a thermostatically controlled

anti-freeze electrical resistance, which provides adequate antifreeze protection at temperatures as low as –25°C.

However, unless the heat exchangers are completely empty

and cleaned with anti-freeze solution, additional methods

should also be used against freezing.

Two or more of below protection methods should be

considered when designing the system as a whole:

Continuous water flow circulation inside piping and

exchangers

Addition of an appropriate amount of glycol inside the

water circuit

Additional heat insulation and heating of exposed piping

Emptying and cleaning of the heat exchanger during the

winter season

It is the responsibility of the installer and/or of local

maintenance personnel to ensure that described anti-freeze

methods are used. Make sure that appropriate anti-freeze

protection is maintained at all times. Failing to follow the

instructions above could result in unit damage. Damage

caused by freezing is not covered by the warranty.

Installing the flow switch

To ensure sufficient water flow through the evaporator, it is

essential that a flow switch be installed on the water circuit.

Figure 6 - Water piping connection for evaporator

The flow switch can be installed either on the inlet or outlet

water piping. The purpose of the flow switch is to stop the unit

in the event of interrupted water flow, thus protecting the

evaporator from freezing.

The manufacturer offers, as optional, a flow switch that has

been selected for this purpose.

This paddle-type flow switch is suitable for heavy-duty outdoor

applications (IP67) and pipe diameters in the range of 1” to 6”.

The flow switch is provided with a clean contact which must be

electrically connected to terminals shown in the wiring

diagram.

Flow switch has to be tune to intervene when the evaporator

water flow is lower than 50% of nominal flow rate.

Heat recovery

Units may be optionally equipped with heat recovery system.

This system in made by a water cooled heat exchanger

located on the compressors discharge pipe and a dedicated

management of condensing pressure.

To guarantee compressor operation within its envelope, units

with heat recovery cannot operate with water temperature of

the heat recovery water lower than 28°C.

It is a responsibility of plant designer and chiller installer to

guarantee the respect of this value (e.g. using recirculating

bypass valve)

Figure 7 - Water piping connection for heat recovery exchangers

D–EIMAC00907–16EN - 12/20

Page 13

List of Activities

Weekly

Monthly

(Note 1)

Yearly/Seas

Onal (Note 2)

General:

Reading of operating data (Note 3)

X

Visual inspection of unit for any damage and/or loosening

X

Verification of thermal insulation integrity

X

Clean and paint where necessary

X

Analysis of water (6)

X

Check of flow switch operation

X

Electrical:

Verification of control sequence

X

Verify contactor wear – Replace if necessary

X

Verify that all electrical terminals are tight – Tighten if necessary

X

Clean inside the electrical control board

X

Visual inspection of components for any signs of overheating

X

Verify operation of compressor and oil heater

X

Measure compressor motor insulation using the Megger

X

Clean air intake filters of the electrical panel

X

Electrical Installation

General specifications

All electrical connections to the unit must be carried out

in compliance with laws and regulations in force.

All installation, management and maintenance activities

must be carried out by qualified personnel.

Refer to the specific wiring diagram for the unit you have

bougth. Should the wiring diagram not be on the unit or

should it have been lost, please contact your

manufacturer representative, who will send you a copy.

In case of discrepance between wiring diagram and

electrical panel/cables, please contact the manufacturer

representative.

Only use copper conductors. Failure to use copper conductors

could result in overheating or corrosion at connection points

and could damage the unit.

To avoid interference, all control wires must be connected

separately from the power cables. Use different electrical

passage ducts for this purpose.

Particular care must be taken when realizing wire connections

to the switchbox; if not properly sealed, cable entries may

allow ingress of water into the switchbox which may cause

damage to the equipment inside.

Before any installation and connection works, the unit

must be switched off and secured. Since this unit

includes inverters, the intermediate circuit of the

capacitors remains charged with high voltage for a short

period of time after being switched off. Do not operate to

the unit before 5 minutes after the unit has been

switched off.

This unit includes non-linear loads such as inverters, which

have a natural current leakage to earth. If an Earth Leakage

Detector is installed upstream the unit, a type B device with a

minimum threshold of 300 mA must be used.

This product complies with EMC standards for industrial

environments. Therefore it is not intended for use in residential

areas, e.g. installations where the product is connected to a

low voltage public distribution system. Should this product

need to be connected to a low voltage public distribution

system, specific additional measures will have to be taken to

avoid interference with other sensitive equipment.

Operation

Operator’s responsibilities

It is essential that the operator is appropriately trained and

becomes familiar with the system before operating the unit. In

Table 2 – Standard Routine Maintenance Plan

addition to reading this manual, the operator must study the

microprocessor operating manual and the wiring diagram in

order to understand start-up sequence, operation, shutdown

sequence and operation of all the safety devices.

During the unit’s initial start-up phase, a technician authorized

by the manufacturer is available to answer any questions and

to give instructions as to the correct operating procedures.

The operator must keep a record of operating data for every

installed unit. Another record should also be kept of all the

periodical maintenance and servicing activities.

If the operator notes abnormal or unusual operating conditions,

he is advised to consult the technical service authorized by the

manufacturer.

Maintenance

Routine maintenance

This chiller must be maintained by qualified technicians.

Before beginning any work on the system the personnel

shall assure that all security precautions have been taken.

Neglecting unit maintenance in these environments, could

degrade all parts of the units (coils, compressors, frames,

pipes, etc..) with negative effect on performances and

functionality.

There are two different levels of maintenance, which can be

chosen according to the type of application (critical/non critical)

or to the installation environment (highly aggressive).

Examples of critical applications are process cooling, data

centres, etc.

Highly Aggressive Environments can be defined as the follows:

Industrial environment (with possible concentration

of fumes result of combustion and chemical process)

Costal environment;

Highly polluted urban environment;

Rural environment close to of animal excrement and

fertilizers, and high concentration of exhaust gas

from diesel generators.

Desert areas with risk of sandstorms;

Combinations of the above

Table 2 lists all Maintenance activities for standard applications

and standard environment.

Table 3 lists all Maintenance activities for critical applications

or highly aggressive environment.

Following below instructions is mandatory for cases listed

above, but also advised for units installed in standard

environments.

D-EIMAC00907-16EN - 13/20

Page 14

Verify operation of all ventilation fans in the electrical panel

X

Verify operation of inverter cooling valve and heater

X

Verify status of capacitors in the inverter (signs of damage, leaks, etc)

X

List of Activities

Weekly

Monthly

(Note 1)

Yearly/Seas

Onal (Note 2)

Refrigeration circuit:

Check for any refrigerant leakage

X

Verify refrigerant flow using the liquid sight glass – Sight glass full

X

Verify filter dryer pressure drop

X

Verify oil filter pressure drop (Note 5)

X

Analyse compressor vibrations

X

Analyse compressor oil acidity (7)

X

Condenser section:

Clean water rinse condenser banks (Note 4)

X

Verify that fans are well tightened

X

Verify condenser bank fins – Comb if necessary

X

Notes:

List of Activities (Note 8)

Weekly

Monthly

(Note 1)

Yearly/Seas

Onal (Note 2)

General:

Reading of operating data (Note 3)

X

Visual inspection of unit for any damage and/or loosening

X

Verification of thermal insulation integrity

X

Clean

X

Paint where necessary

X

Clean and paint where necessary

X

Analysis of water (6)

X

Check of flow switch operation

X

Electrical:

Verification of control sequence

X

Verify contactor wear – Replace if necessary

X

Verify that all electrical terminals are tight – Tighten if necessary

X

Clean inside the electrical control board

X

Visual inspection of components for any signs of overheating

X

Verify operation of compressor and oil heater

X

Measure compressor motor insulation using the Megger

X

Clean air intake filters of the electrical panel

X

Verify operation of all ventilation fans in the electrical panel

X

Verify operation of inverter cooling valve and heater

X

Verify status of capacitors in the inverter (signs of damage, leaks, etc)

X

Refrigeration circuit:

Check for any refrigerant leakage

X

Verify refrigerant flow using the liquid sight glass – Sight glass full

X

Verify filter dryer pressure drop

X

Verify oil filter pressure drop (Note 5)

X

Analyse compressor vibrations

X

Analyse compressor oil acidity (7)

X

Condenser section:

Clean water rinse condenser coils (Note 4)

X

Quarterly clean condenser coils (E-coated only)

X

Verify that fans are well tightened

X

Verify condenser coil fins – Comb if necessary

X

1. Monthly activities include all the weekly ones.

2. The annual (or early season) activities include all weekly and monthly activities.

3. Unit operating values should be read on a daily basis thus keeping high observation standards.

4. In environments with a high concentration of air-borne particles, it might be necessary to clean the condenser bank more often.

5. Replace the oil filter when the pressure drop across it reaches 2.0 bar.

6. Check for any dissolved metals.

7. TAN (Total Acid Number) : 0,10 : No action

Between 0.10 and 0.19 : Replace anti-acid filters and re-check after 1000 running hours. Continue to replace filters until the TAN is lower

than 0.10.

0,19 : Replace oil, oil filter and filter dryer. Verify at regular intervals.

Table 3 –Routine Maintenance Plan for Critical Application and/or Highly Aggressive Environment

Notes:

8. Units placed or stored in a Highly Aggressive Environment for long time without operation are still subject to those routine maintenance steps.

D-EIMAC00907-16EN - 14/20

Page 15

Unit Maintenance and Cleaning

Unit exposed to a highly aggressive environment can face

corrosion in a shorter time than ones installed on a standard

environment. Corrosion causes a rapid rusting of the frame

core, consequently decreases unit structure life time. To avoid

that, it is necessary to wash periodically the frame surfaces

with water and suitable detergents.

In case of part of unit frame paint came off, it is important to

stop its progressive deterioration by repainting the exposed

parts using proper products. Please contact factory to get the

required products specifications.

Note: in case of just salt deposits are present, it is enough to

rinse the parts with fresh water.

Microchannel Coil Maintenance

Routine cleaning of coil surfaces is essential to maintain

proper operation of the unit, avoid corrosion and rusting.

Elimination of contamination and removal of harmful residues

will greatly increase the life of the coil and extend the life of the

unit.

Relative to fin and tube heat exchangers, microchannel coils

tend to accumulate more of the dirt on the surface and of the

less dirt inside which can make them easier to clean.

The following maintenance and cleaning procedure are

recommended as part of the routine maintenance activities.

1. Remove surface dirt, leaves, fibers, etc. with a vacuum

cleaner (preferably with a brush or other soft attachment

rather than a metal tube), compressed air blown from the

inside out, and/or a soft bristle (not wire!) brush. Do not

impact or scrape the coil with the vacuum tube, air

nozzle, etc..

NOTE: Use of a water stream, such as a garden hose, against

a surface loaded coil will drive the fibers and dirt into the coil.

This will make cleaning efforts more difficult. Surface loaded

fibers must be completely removed prior to using low velocity

clean water rinse.

2. Rinse. Do not use any chemicals (including those

advertised as coil cleaners) to wash microchannel heat

exchangers. They can cause corrosion. Rinse only. Hose

the MCHE off gently, preferably from the inside out and

top to bottom, running the water through every fin

passage until it comes out clean. Microchannels fins are

stronger than traditional tube & fin coil fins but still need to

be handled with care.

It is possible to clean a coil with a high pressure washer

(max 62 barg) only if a flat shape of the water spray is

used and direction of the spay is kept perpendicular to the

fin edge. If this direction is not respected the coil may

be destroyed if using a pressure washer so we do not

recommend their use.

NOTE: A monthly clean water rinse is recommended for coils

that are applied in coastal or industrial environments to help to

remove chlorides, dirt and debris. It is very important when

rinsing, to water temperature is less than 550. An elevated

water temperature (not to exceed 550 C) will reduce surface

tension, increasing the ability to remove chlorides and dirt.

3. Quarterly cleaning is essential to extend the life of an E-

coated coil and is required to maintain warranty coverage.

Failure to clean an E-coated coil will void the warranty

and may result in reduced efficiency and durability in the

environment. For routine quarterly cleaning, first clean the

coil with an approved coil cleaner. After cleaning the coils

with the approved cleaning agent, use the approved

chloride remover to remove soluble salts and revitalize

the unit.

NOTE: Harsh chemicals, household bleach or acid cleaners

should not be used to clean E-coated coils. These cleaners

can be very difficult to rinse out of the coil and can accelerate

corrosion and attack the E-coating. If there is dirt below the

surface of the coil, use the recommended coil cleaners as

described above.

Inverter Electrolytic Capacitors

Compressor Inverters include electrolytic capacitors which

have been designed to last a minimum of 15 years in normal

use. Heavy duty conditions may reduce the actual life of

capacitors.

The chiller calculates capacitor residual life based on actual

operation. When residual life gets below a give threshold, a

warning is issued by the controller. In this case replacement of

capacitors is recommended. This operation must be done only

by qualified technicians. Replacement must be carried out

through the following procedure:

Power off the chiller

Wait for 5 minutes before opening the inverter case

Check that residual dc voltage in the dc link is zero.

Open the inverter case and replace old capacitors

with new ones.

Reset the chiller controller through the maintenance

menu. This will allow the controller to recalculate the

new estimated life of the capacitors.

Capacitor Reforming after long shut-off period

Electrolytic capacitors may lose part of their original

characteristics if they are not powered for more than 1 year. If

chiller has been shut off for a longer period a “reforming”

procedure as follows is necessary:

Power on the inverter

Keep it powered on without starting the compressor

for at least 30 minutes

After 30 minutes the compressor can be started

Low Ambient Start-up

Inverters include a temperature control which allows them to

withstand ambient temperatures down to -20°C. However they

should not be switched on at temperatures lower than 0°C

unless the following procedure is executed:

Open the switchbox (only trained technicians should

perform this operation)

Open compressor fuses (by pulling the fuse holders)

or compressor circuit breakers

Power on the chiller

Keep the chiller powered on for 1 hour at least (this

allows inverter heaters to warm-up the inverter).

Close fuse holders

Close the switchbox

Service and limited warranty

All units are factory-tested and guaranteed for 12 months as of

the first start-up or 18 months as of delivery.

These units have been developed and constructed according

to high quality standards ensuring years of failure-free

operation. It is important, however, to ensure proper and

periodical maintenance in accordance with all the procedures

listed in this manual and with good practice of machines

maintenance.

We strongly advise stipulating a maintenance contract with a

service authorized by the manufacturer in order to ensure

efficient and problem-free service, thanks to the expertise and

experience of our personnel.

It must also be taken into consideration that the unit requires

maintenance also during the warranty period.

It must be borne in mind that operating the unit in an

inappropriate manner, beyond its operating limits or not

performing proper maintenance according to this manual can

void the warranty.

Observe the following points in particular, in order to conform

to warranty limits:

1. The unit cannot function beyond the specified limits

2. The electrical power supply must be within the voltage

limits and without voltage harmonics or sudden changes.

3. The three-phase power supply must not have un

unbalance between phases exceeding 3%. The unit must

stay turned off until the electrical problem has been

solved.

4. No safety device, either mechanical, electrical or

electronic must be disabled or overridden.

D–EIMAC00907–16EN - 15/20

Page 16

5. The water used for filling the water circuit must be clean

and suitably treated. A mechanical filter must be installed

at the point closest to the evaporator inlet.

6. Unless there is a specific agreement at the time of

ordering, the evaporator water flow rate must never be

above 120% and below 80% of the nominal flow rate.

Important information regarding the refrigerant

used

This product contains fluorinated greenhouse gases. Do not

vent gases into the atmosphere.

Refrigerant type: R134a

GWP(1) value: 1300

(1)GWP = global warming potential

The refrigerant quantity necessary for standard operation is

indicated on the unit name plate.

Real refrigerant quantity charged in the unit is listed on a silver

sticker inside the electrical panel.

Periodical inspections for refrigerant leaks may be required

depending on European or local legislation.

Please contact your local dealer for more information.

This manual is a technical aid and does not represent a binding offer. The content cannot be held as explicitly or implicitly guaranteed as complete, precise or reliable. All data and

specifications contained herein may be modified without notice. The data communicated at the moment of the order shall hold firm.

The manufacturer shall assume no liability whatsoever for any direct or indirect damage, in the widest sense of the term, ensuing from or connected with the use and/or interpretation

of this manual.

We reserve the right to make changes in design and construction at any time without notice, thus the cover picture is not binding.

Periodic obligatory checks and starting up of

appliances under pressure

The units are included in category I → III of the classification

established by the European Directive 2014/68/EU (PED).

For chillers belonging to this category, some local regulations

require a periodic inspection by an authorized agency. Please

check with your local requirements.

Disposal

The unit is made of metal, plastic and electronic parts. All

these parts must be disposed of in accordance with the local

regulations in terms of disposal.

Lead batteries must be collected and sent to specific refuse

collection centres.

Oil must be collected and sent to specific refuse collection

centres.

D-EIMAC00907-16EN - 16/20

Page 17

D-EIMAC00907-16EN - 17/20

Page 18

D-EIMAC00907-16EN - 18/20

Page 19

D-EIMAC00907-16EN - 19/20

Page 20

The present publication is drawn up by of information only and does not constitute an offer binding upon Daikin Applied Europe S.p.A..

Daikin Applied Europe S.p.A. has compiled the content of this publication to the best of its knowledge. No express or implied warranty is

given for the completeness, accuracy, reliability or fitness for particular purpose of its content, and the products and services presented

therein. Specification are subject to change without prior notice. Refer to the data communicated at the time of the order. Daikin Applied

Europe S.p.A. explicitly rejects any liability for any direct or indirect damage, in the broadest sense, arising from or related to the use

and/or interpretation of this publication. All content is copyrighted by Daikin Applied Europe S.p.A..

DAIKIN APPLIED EUROPE S.p.A.

Via Piani di Santa Maria, 72 - 00072 Ariccia (Roma) - Italia

Tel: (+39) 06 93 73 11 - Fax: (+39) 06 93 74 014

http://www.daikinapplied.eu

D-EIMAC00907-16EN - 20/20

Loading...

Loading...