Daikin EWAD 330÷520 BZS S / L, EWAD 330÷520 BZX S / L / R Operation manuals

Installation, Operation and Maintenance Manual

D - KIMAC00305-10EN

Inverter air to water cooling only chillers

EWAD 330÷520 BZS S / L

EWAD 330÷520 BZX S / L / R

50Hz – Refrigerant: R-134a

Original Instructions

IMPORTANT

This Manual is a technical aid but does not represent a binding offer for Daikin.

Daikin has drawn up this Manual to the best of its knowledge. The content cannot be held as explicitly or implicitly

guaranteed as complete, precise or reliable.

All data and specifications contained herein may be modified without notice. The data communicated at the moment

of the order shall hold firm.

Daikin shall assume no liability whatsoever for any direct or indirect damage, in the widest sense of the term,

ensuing from or connected with the use and/or interpretation of this Manual.

The entire content is protected by Daikin copyright.

WARNING

Before starting the installation of the unit, please read this manual carefully. Starting up the unit is absolutely

forbidden if all instructions contained in this manual are not clear.

Key to symbols

Important note: failure to respect the instruction can damage the unit or compromise functioning

Note regarding safety in general or respect of laws and regulations

Note regarding electrical safety

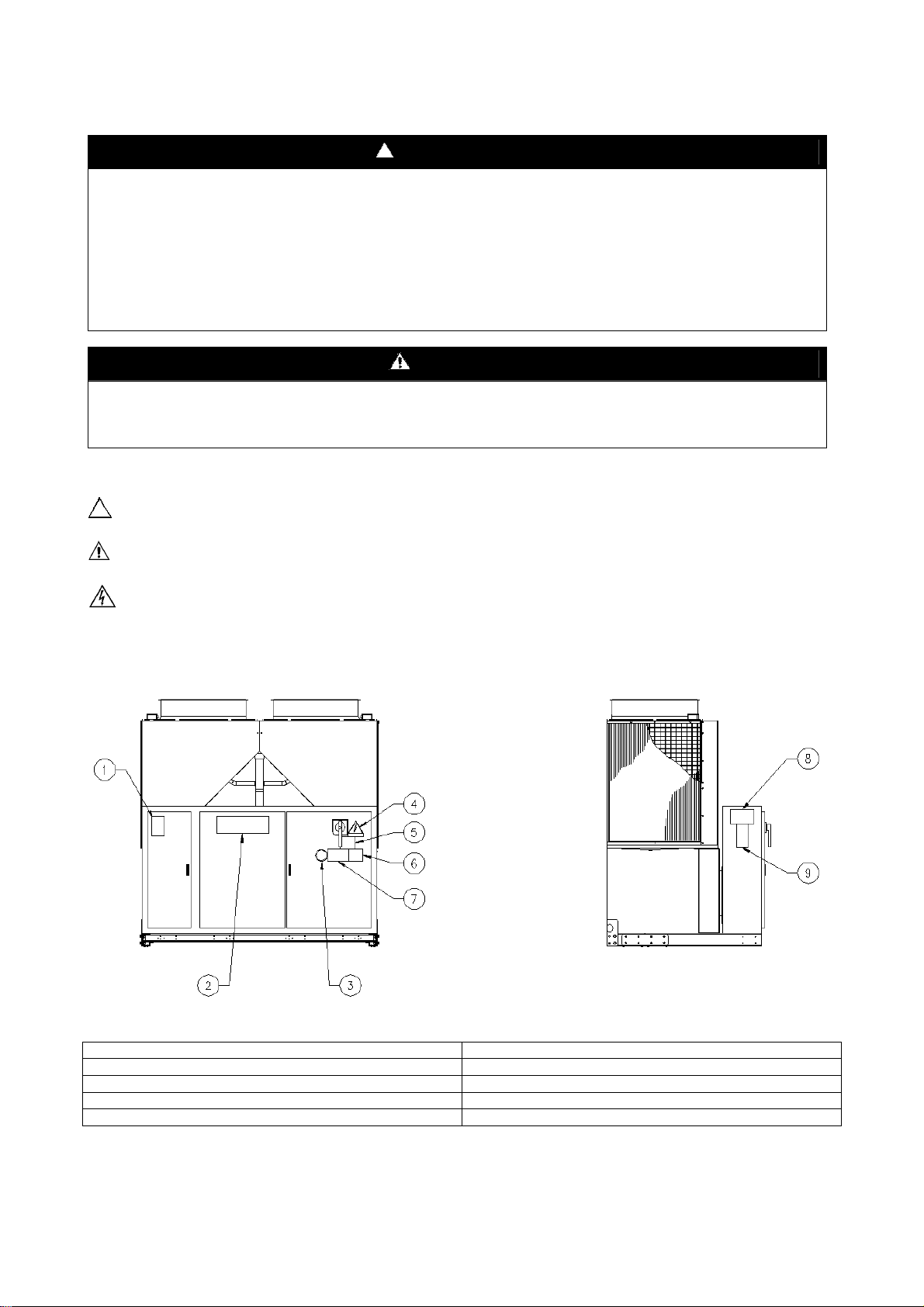

Description of the labels applied to the electrical panel

Label Identification

1 – Non flammable gas symbol 6 – Cable tightening warning

2 – Manufacturer’s logo 7 – Water circuit filling warning

3 – Gas type 8 – Lifting instructions

4 – Electrical hazard symbol 9 – Unit nameplate data

5 – Hazardous Voltage warning

D - KIMAC00305-10EN - 2/64

Contents

General Information..........................................................................................................................................................5

Acceptance of the machine............................................................................................................................................5

Checks ...........................................................................................................................................................................5

Purpose of the manual ................................................................................................................................................... 5

Nomenclature.................................................................................................................................................................6

Specifications.................................................................................................................................................................... 7

Sound pressure level...................................................................................................................................................... 13

Operating limits............................................................................................................................................................... 14

Storage......................................................................................................................................................................... 14

Operation......................................................................................................................................................................14

Mechanical installation................................................................................................................................................... 16

Transport......................................................................................................................................................................16

Responsibility...............................................................................................................................................................16

Safety...........................................................................................................................................................................16

Handling and lifting....................................................................................................................................................... 16

Positioning and assembly.............................................................................................................................................18

Minimum space requirements ...................................................................................................................................... 18

Acoustic protection.......................................................................................................................................................20

Water pipes..................................................................................................................................................................20

Water treatment............................................................................................................................................................21

Protection of the evaporator and the heat recovery exchangers against frost..............................................................21

Installation of the flow meter.........................................................................................................................................22

Hydronic kit (optional)...................................................................................................................................................23

Electrical installation ...................................................................................................................................................... 28

General specifications..................................................................................................................................................28

Electrical components ..................................................................................................................................................30

Electrical wiring ............................................................................................................................................................30

Electrical heaters.......................................................................................................................................................... 30

Electricity supply for the pumps....................................................................................................................................30

Water pump control......................................................................................................................................................31

Unit On/ Off remote control – Electrical wiring..............................................................................................................31

Overboost unit – Electrical connection .........................................................................................................................31

Double Setpoint – Electrical wiring...............................................................................................................................31

External water Setpoint Reset – Electrical wiring (Optional).........................................................................................31

Unit limitation – Electrical wiring (Optional) ..................................................................................................................31

The VFD and related problems ....................................................................................................................................33

The operating principle of the VFD .....................................................................................................................34

The problem with harmonics...............................................................................................................................34

Operation......................................................................................................................................................................... 37

Operator’s responsibility............................................................................................................................................... 37

Description of the machine........................................................................................................................................... 37

Description of the refrigeration cycle ............................................................................................................................37

Description of the refrigeration cycle with partial heat recovery....................................................................................39

Control of the partial recovery circuit and installation recommendations......................................................................39

Description of refrigeration cycle operating with total heat recovery.............................................................................41

Control of the total heat recovery circuit.......................................................................................................................41

Compressor.................................................................................................................................................................. 43

The compression process ............................................................................................................................................43

Control of refrigeration capacity....................................................................................................................................45

Pre-start-up checks.........................................................................................................................................................46

General.........................................................................................................................................................................46

Units with an external water pump ............................................................................................................................... 47

Units with a built-in water pump....................................................................................................................................47

Electrical power supply.................................................................................................................................................47

Imbalance in power supply voltage ..............................................................................................................................47

Power supply for electrical heaters...............................................................................................................................48

Start-up procedure.......................................................................................................................................................... 49

Turning on the machine................................................................................................................................................49

Seasonal shutdown......................................................................................................................................................50

Starting up after seasonal shutdown ............................................................................................................................50

System maintenance....................................................................................................................................................... 51

General.........................................................................................................................................................................51

Compressor maintenance ............................................................................................................................................51

Lubrication.................................................................................................................................................................... 52

Routine maintenance....................................................................................................................................................53

Replacement of filter dryer ...........................................................................................................................................53

D - KIMAC00305-10EN - 3/64

Procedure for replacement of the filter dryer cartridge .................................................................................................53

Replacement of the oil filter.......................................................................................................................................... 54

Refrigerant charge........................................................................................................................................................56

Refrigerant filling procedure .........................................................................................................................................57

Standard checks .............................................................................................................................................................58

Temperature and pressure sensors..............................................................................................................................58

Test sheet ........................................................................................................................................................................59

Water side measurements............................................................................................................................................59

Refrigerant side measurements ................................................................................................................................... 59

Electrical measurements..............................................................................................................................................59

Service and limited warranty.......................................................................................................................................... 60

Periodic obligatory checks and starting up of appliances under pressure...............................................................61

Important information regarding the refrigerant used................................................................................................. 62

Index of tables

Table 1 - Acceptable water quality limits ......................................................................................................................21

Table 2 - Electrical data for the EWAD-BZSS / BZSL / BZXS / BZXL / BZXR..............................................................29

Table 3 - Electrical data of optional pumps ..................................................................................................................30

Table 4 - Typical working conditions with compressors at 100%...............................................................................49

Table 5 - Routine maintenance programme..................................................................................................................53

Table 6 - Pressure/Temperature.....................................................................................................................................57

Index of Figures

Fig. 1 - Operating range – EWAD- BZSS / BZSL / BZXS / BZXL / BZXR......................................................................15

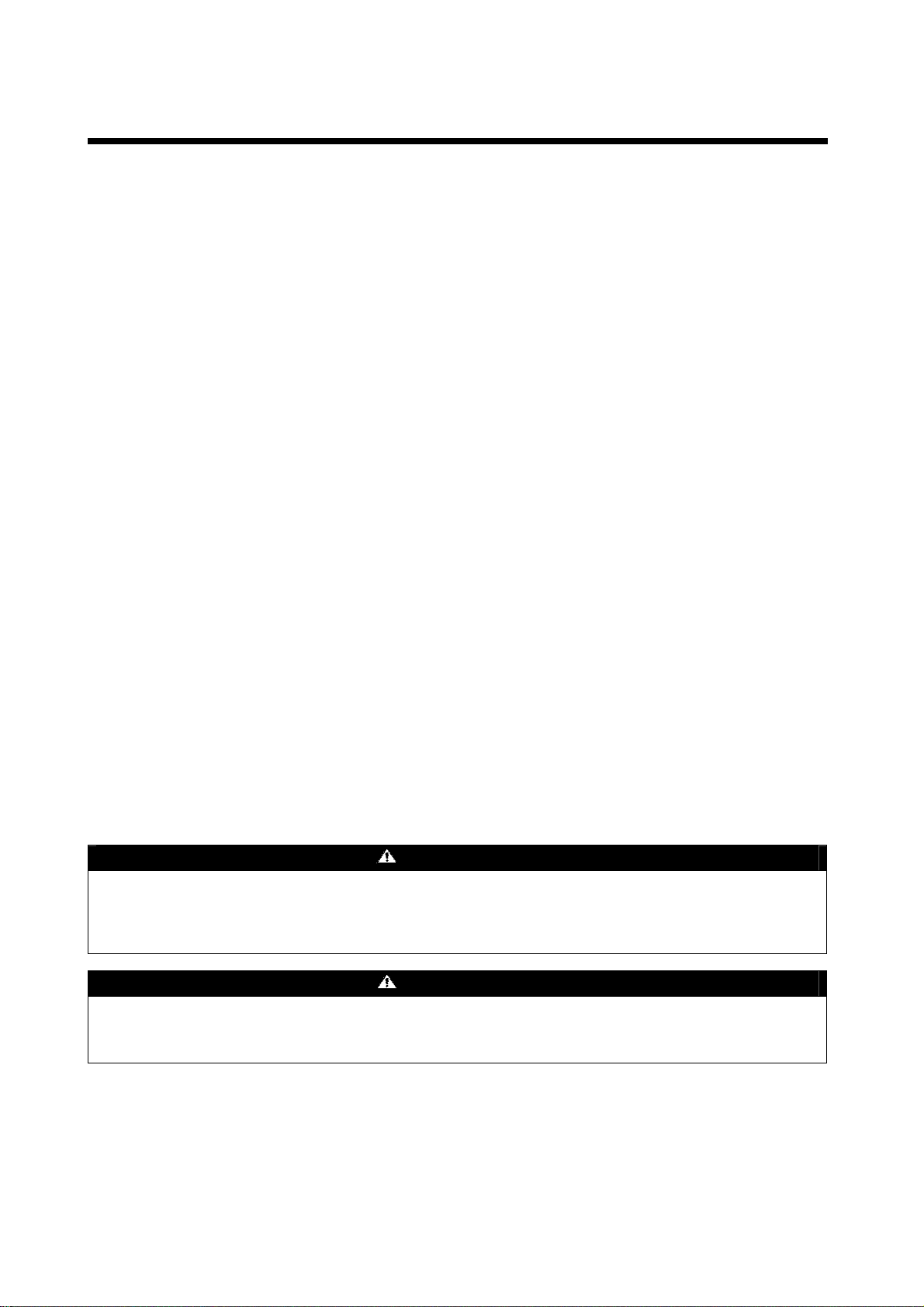

Fig. 2 - Lifting the unit.....................................................................................................................................................17

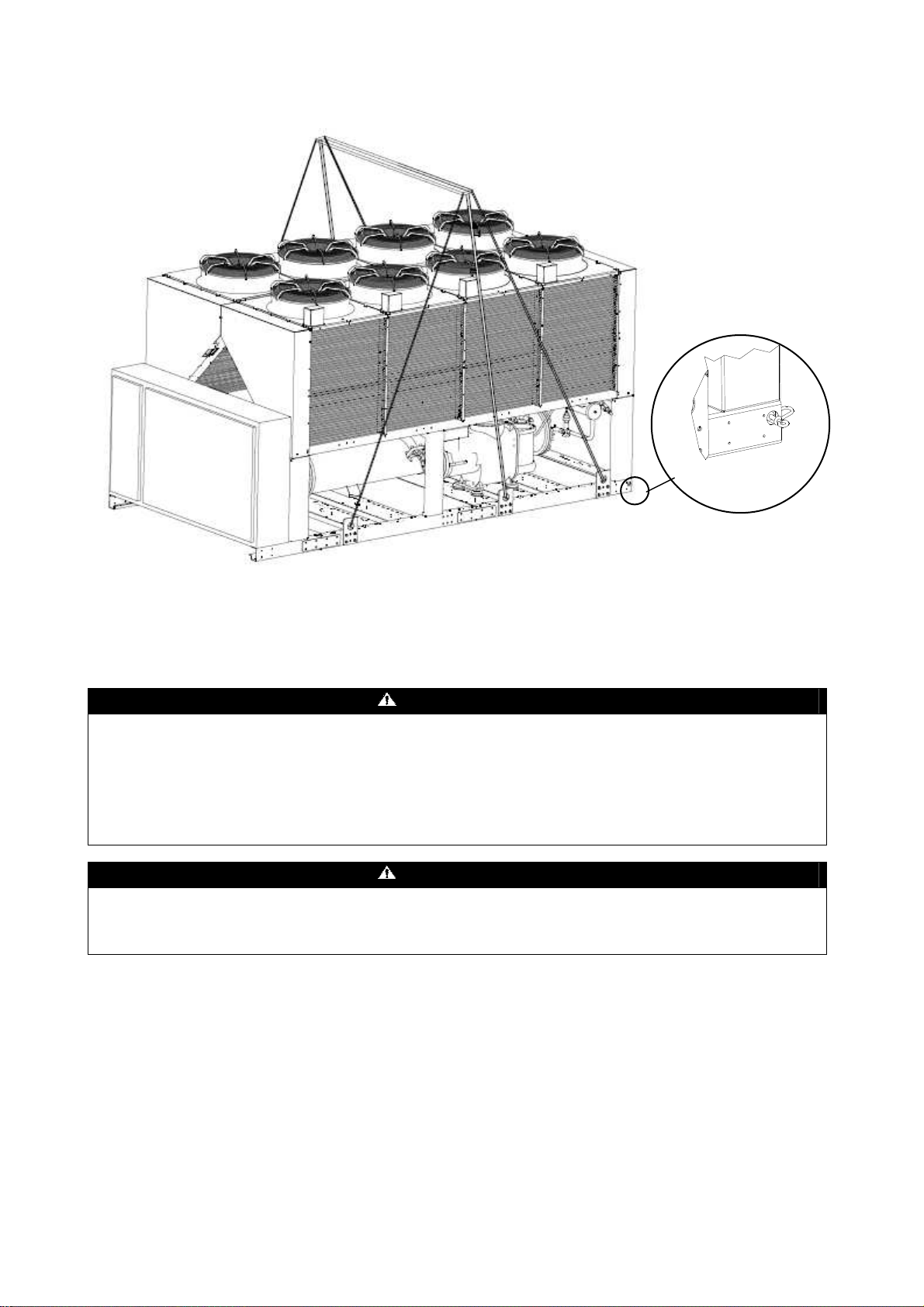

Fig. 3 - Minimum distances for machine maintenance ................................................................................................18

Fig. 4 - Minimum recommended installation distances...............................................................................................19

Fig. 5 - Water connection of the heat recovery system ...............................................................................................21

Fig. 6 - Setting the safety flow meter.............................................................................................................................22

Fig. 7 - Single or twin pump hydronic kit......................................................................................................................23

Fig. 8 - Low discharge head pump group (optional accessory) – Discharge head diagrams for EWAD- BZSS /

BZSL / BZXS / BZXL / BZXR ...........................................................................................................................................24

Fig. 9 - High discharge head pump group (optional accessory) – Discharge head diagrams for EWAD- BZSS /

BZSL / BZXS / BZXL / BZXR ...........................................................................................................................................25

Fig. 10 - Loss of evaporator load – EWAD- EWAD- BZSS / BZSL / BZXS / BZXL / BZXR..........................................27

Fig. 11 - User connection to the M3 interface terminal board .....................................................................................32

Fig. 12 - Power absorbed by the compressor depending on the load........................................................................33

Fig. 13 - Typical diagram of a VFD.................................................................................................................................34

Fig. 14 - Harmonics on the grid......................................................................................................................................35

Fig. 15 - Harmonic content with and without line inductance..................................................................................... 36

Fig. 16 – Harmonic content varying according to the percentage of non-linear loads.............................................36

Fig. 17 - Refrigeration circuit of unit EWAD-BZSS / BZSL / BZXS / BZXL / BZXR .....................................................38

Fig. 18 - Refrigeration circuit of unit EWAD-BZSS / BZSL / BZXS / BZXL / BZXR .....................................................40

Fig. 19 - Refrigeration circuit of unit EWAD-BZSS / BZSL / BZXS / BZXL / BZXR .....................................................42

Fig. 20 - Image of the compressor Fr3100.....................................................................................................................43

Fig. 21 - Compression process...................................................................................................................................... 44

Fig. 22 - Front and rear view of compressor Fr 3100 ...................................................................................................55

D - KIMAC00305-10EN - 4/64

General Information

ATTENTION

The machines described in this manual represent a valuable investment. Maximum care should be taken to ensure

correct installation and to maintain them in good running order.

Correct maintenance of the unit is indispensable for its safety and reliability. Manufacturer’s service centres are the

only having adequate technical skill for maintenance.

ATTENTION

This manual provides information about the features and standard procedures for the complete series.

All the units are delivered from factory as complete sets which include wiring diagrams, inverter manuals,

dimensional drawings with dimensions and weight, nameplate with technical characteristics attached to the unit.

WIRING DIAGRAMS, INVERTER MANUALS, DIMENSIONAL DRAWINGS AND NAMEPLATE MUST BE

CONSIDERED ESSENTIAL DOCUMENTS AND AS A PART OF THIS MANUAL

In case of any discrepancy between this manual and the equipment’s document refer to on board documents.

For any doubt ask Daikin or authorized centers

Acceptance of the machine

When the machine is delivered to the place of installation, it must immediately be inspected for damage. All components

described in the delivery note must be carefully inspected and checked; any damage must be reported to the carrier.

Before unloading the machine, check that the model and the voltage shown on the identity plate correspond to your

order. The manufacturer shall accept no liability for any damage which comes to light after acceptance of the machine.

Checks

For your own protection in case the machine is incomplete (missing parts) or has been damaged during transport, carry

out the following checks upon receipt of the machine:

a) Before accepting the machine, check every single component of the supply. Check for any damage.

b) If the machine has been damaged, do not remove the damaged parts. A series of photographs can help to

ascertain responsibility.

c) Immediately report the extent of the damage to the transport company and request them to inspect the

machine.

d) Immediately inform the dealer of the extent of the damage to allow the latter to arrange for the necessary

repairs. Under no circumstances must the damage be repaired before being inspected by a representative of

the transport company.

Purpose of the manual

The purpose of this manual is to allow the installer and the qualified operator to carry out all operations necessary to

ensure correct installation and maintenance of the machine without running the risk of harm to persons, animals or

property.

The manual is an important documentary aid to qualified persons, but cannot substitute them.

All actions must be carried out by trained and qualified personnel, in compliance with local laws and regulations.

D - KIMAC00305-10EN - 5/64

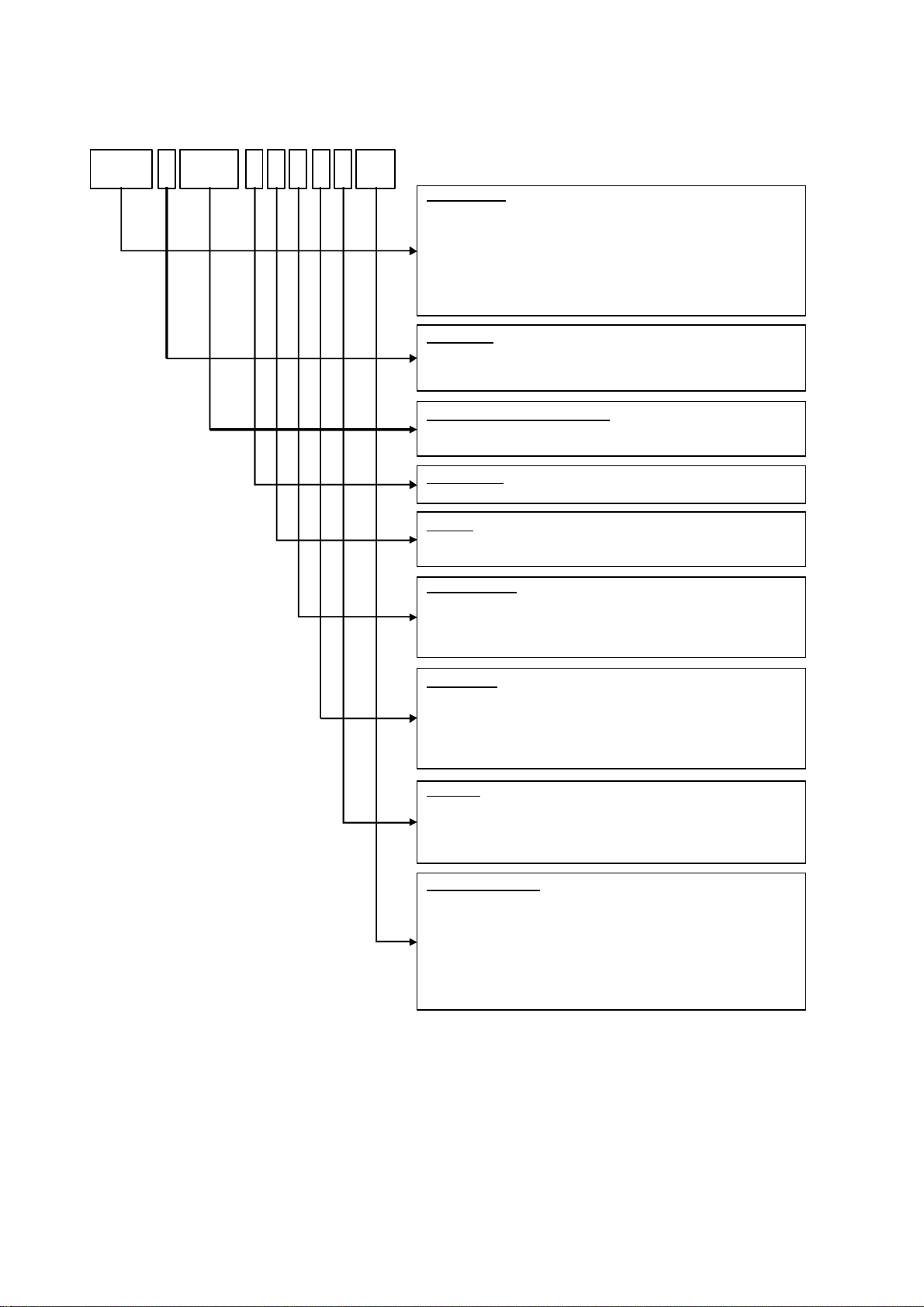

Nomenclature

Machine type

(McQuay code)

E W A D 2 0 0 B Z S S 0 0 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14

EWA = Air-cooled chiller, cooling only

EWY = Air-cooled chiller, heat pump

EWL = Remote condenser chiller

ERA = Air cooled condensing unit

EWW = Water-cooled chiller, cooling only

EWC = Air-cooled chiller, cooling only with centrifugal fan

EWT = Air-cooled chiller, cooling only with heat recovery

Refrigerant

D = R-134a

P = R-407c

Q = R-410a

Capacity class in kW (Cooling)

Always 3-digit code

Idem as previous

Model series

Letter A, B,… : major modification

Inverter

- = Non-inverter

Z = Inverter

Efficiency level

S = Standard efficiency (SE)

X = High efficiency (XE)

P = Premium efficiency (PE) (N.A for this range)

H = High ambient (HA) (N.A for this range)

Sound level

S = Standard noise (ST)

L = Low noise (LN)

R = Reduced noise (XN)

X = Extra low noise (XXN) (N.A for this range)

C = Cabinet (CN) (N.A for this range)

Warranty

0 = 1 year of warranty

B = 2 years of warranty

C = 3 years of warranty

… = ... years of warranty

Sequential number

000 = Base model

001 = First order for this model (1 or more units)

002 = Second order for this model (1 or more units)

… = ... order for this model

B01 = First order for this model + 1year warranty

B02 = Second order for this model (1 or more units)

… = ... order for this model

(McQuay code)

D - KIMAC00305-10EN - 6/64

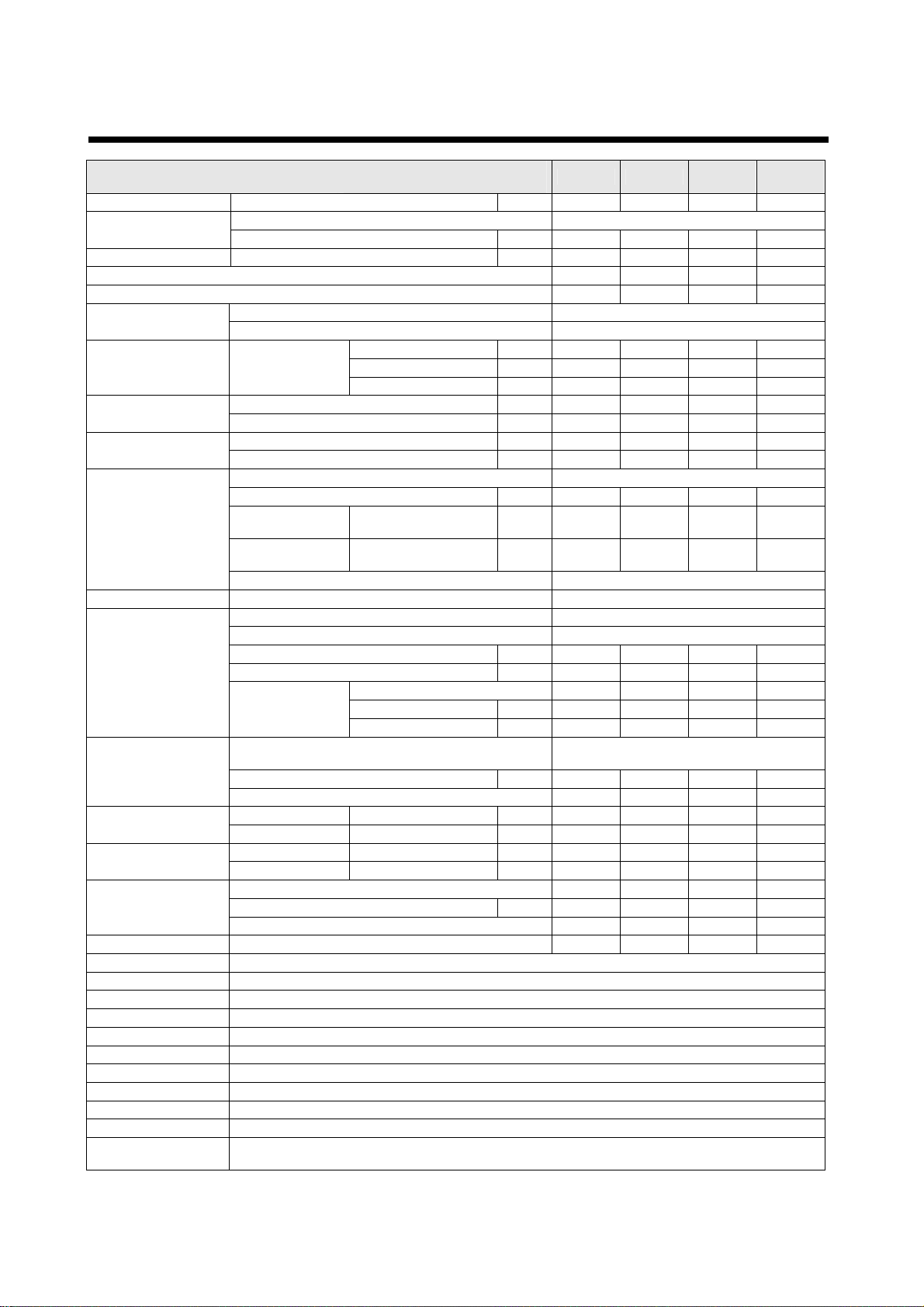

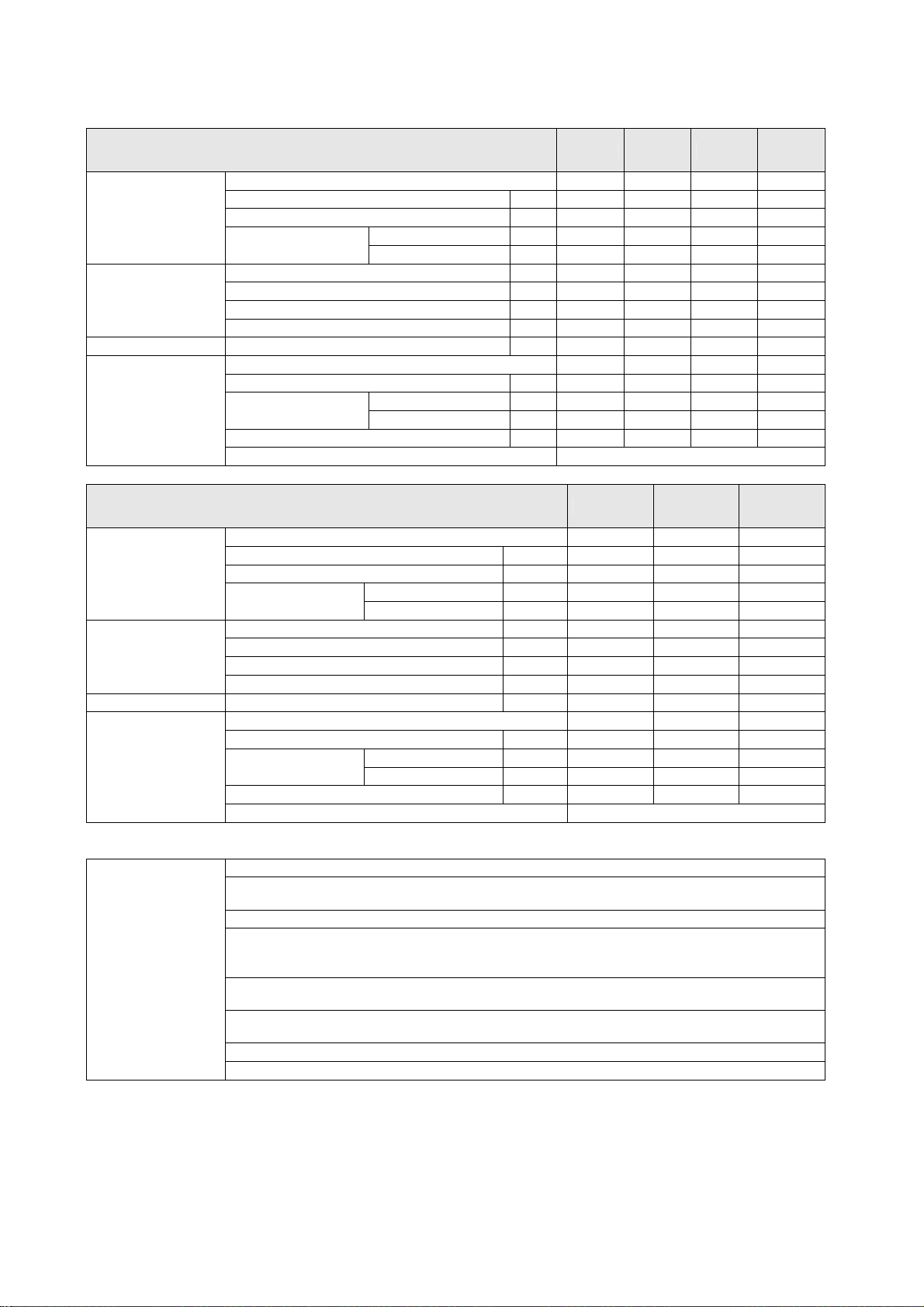

Specifications

TECHNICAL SPECIFICATIONS

Capacity Cooling

Capacity control

Unit power input Cooling kW

EER

ESEER

Casing

Dimensions Unit

Weight (BZSS)

Weight (BZSL)

Water heat

exchanger

Air heat exchanger Type Louvered fins

Fan

Compressor

Sound level (BZSS)

Sound level (BZSL)

Refrigerant circuit

Piping connections Evaporator water inlet/outlet 168,3 168,3 168,3 168,3

Safety devices High discharge pressure (pressure switch)

Safety devices High discharge pressure (transducer)

Safety devices Low suction pressure (transducer)

Safety devices Compressor overload (Kriwan)

Safety devices High discharge temperature

Safety devices Low oil pressure

Safety devices Low pressure ratio

Safety devices High oil pressure drop

Safety devices Phase monitor

Safety devices Emergency stop

Notes

Type Stepless

Minimum capacity % 13.5% 13.5% 13.5% 13.5%

Colour Ivory White

Material Galvanized and painted steel sheet

Height mm 2355 2355 2355 2355

Width mm 2224 2224 2224 2224

Depth mm 4352 4352 5252 5252

Unit kg 4190 4190 4590 4590

Operating Weight kg 4440 4440 4840 4840

Unit Kg 4340 4340 4740 4740

Operating Weight kg 4590 4590 4990 4990

Type Single Pass Shell&Tube

Water volume l 271 264 264 256

Nominal water

flow rate

Nominal Water

pressure drop

Insulation material Closed cell foam elastomer

Type Axial

Drive VFD driven

Diameter mm 800 800 800 800

Nominal air flow m³/min 1960 1960 2450 2450

Model

Type

Oil charge l 26 26 26 26

Quantity 2 2 2 2

Sound Power Cooling dBA 102,8 102,8 103,2 103,2

Sound Pressure Cooling dBA 83,0 83,0 83,0 83,0

Sound Power Cooling dBA 96,9 96,9 97,3 97,3

Sound Pressure Cooling dBA 77,0 77,0 77,0 77,0

Refrigerant type R-134a R-134a R-134a R-134a

Refrigerant charge kg 80 80 100 100

N. of circuits 2 2 2 2

Cooling capacity, unit power input in cooling and EER are based on the following conditions:

evaporator 12°C/7°C; ambient 35°C.

Cooling l/min 943

Cooling kPa 60 61 72 67

Quantity 8 8 10 10

Speed in cooling rpm 700 700 700 700

Motor output in cool. W 1133 1133 1133 1133

EWAD-BZSS

EWAD-BZSL

329 358 395 423

330 360 400 420

120 136 147 159

2,74 2,63 2,68 2,66

4,59 4,60 4,55 4,59

1026

1132

1213

Semi-hermetic single screw compressor

inverter driven

D - KIMAC00305-10EN - 7/64

TECHNICAL SPECIFICATIONS

Capacity Cooling kW

Capacity control

Unit power input Cooling kW

EER

ESEER

Casing

Dimensions Unit

Weight (BZSS)

Weight (BZSL)

Water heat

exchanger

Air heat exchanger Type Louvered fins

Fan

Compressor

Sound level (BZSS)

Sound level (BZSL)

Refrigerant circuit

Piping connections Evaporator water inlet/outlet 168.3 168.3 168.3

Safety devices High discharge pressure (pressure switch)

Safety devices High discharge pressure (transducer)

Safety devices Low suction pressure (transducer)

Safety devices Compressor overload (Kriwan)

Safety devices High discharge temperature

Safety devices Low oil pressure

Safety devices Low pressure ratio

Safety devices High oil pressure drop

Safety devices Phase monitor

Safety devices Emergency stop

Notes

Type Stepless

Minimum capacity % 13.5% 13.5% 13.5%

Colour Ivory White

Material Galvanized and painted steel sheet

Height mm 2355 2355 2355

Width mm 2224 2224 2224

Depth mm 6152 6152 6152

Unit kg 5070 5070 5070

Operating Weight kg 5320 5320 5320

Unit Kg 5220 5220 5220

Operating Weight kg 5470 5470 5470

Type Single Pass Shell&Tube

Water volume l 256 248 248

Nominal water

flow rate

Nominal Water

pressure drop

Insulation material Closed cell foam elastomer

Type Axial

Drive VFD driven

Diameter mm 800 800 800

Nominal air flow m³/min 2940 2940 2940

Model

Type

Oil charge l 26 26 26

Quantity 2 2 2

Sound Power Cooling dBA 103,6 103,6 103,6

Sound Pressure Cooling dBA 83,5 83,5 83,5

Sound Power Cooling dBA 98,2 98,2 98,2

Sound Pressure Cooling dBA 77,5 77,5 77,5

Refrigerant type R-134a R-134a R-134a

Refrigerant charge kg 120 120 120

N. of circuits 2 2 2

Cooling capacity, unit power input in cooling and EER are based on the following

conditions: evaporator 12°C/7°C; ambient 35°C.

Cooling l/min 1316

Cooling kPa 78 69 76

Quantity 12 12 12

Speed in cooling rpm 700 700 700

Motor output in cool. W 1133 1133 1133

EWAD-BZSS

EWAD-BZSL

460 490 520

459 488 515

168 181 193

2,74 2,71 2,67

4,57 4,70 4,60

Semi-hermetic single screw

compressor inverter driven

1399

1476

D - KIMAC00305-10EN - 8/64

ELECTRICAL SPECIFICATIONS

Phase 3 3 3 3

Frequency Hz 50 50 50 50

Power Supply

Unit

Fans Nominal running current in cooling A 22,4

Compressor

Voltage V 400 400 400 400

Voltage Tolerance

Maximum starting current A 232 250 251 278

Nominal running current cooling A 194 220 239 258

Maximum running current A 322 322 328 358

Maximum current for wires sizing A 355 355 361 394

Min displacement power factor at nominal

conditions

Phase 3 3 3 3

Voltage V 400 400 400 400

Voltage Tolerance

Maximum running current A 150+150 150+150 150+150 150+150

Starting method Inverter

Minimum % -10% -10% -10% -10%

Maximum % +10% +10% +10% +10%

Minimum % -10% -10% -10% -10%

Maximum % +10% +10% +10% +10%

EWAD-BZSS

EWAD-BZSL

0,98 0,98 0,98 0,98

330 360 400 420

22,4

28,0

28,0

ELECTRICAL SPECIFICATIONS

Phase 3 3 3

Frequency Hz 50 50 50

Power Supply

Unit

Fans Nominal running current in cooling A 33,6 33,6 33,6

Compressor

Voltage V 400 400 400

Voltage Tolerance

Maximum starting current A 297 311 316

Nominal running current cooling A 273 292 312

Maximum running current A 394 394 394

Maximum current for wires sizing A 433 433 433

Min displacement power factor at nominal

conditions

Phase 3 3 3

Voltage V 400 400 400

Voltage Tolerance

Maximum running current A 180+180 180+180 180+180

Starting method Inverter

Minimum % -10% -10% -10%

Maximum % +10% +10% +10%

Minimum % -10% -10% -10%

Maximum % +10% +10% +10%

EWAD-BZSS

EWAD-BZSL

0,98 0,98 0,98

460 490 520

Allowed voltage tolerance ± 10%. Voltage unbalance between phases must be within ± 3%.

Maximum starting current: starting current of biggest compressor + 75% of maximum current of

the other compressor + fans current for the circuit at 75%.

Maximum starting current referred to installation with 25kA short circuit current

Nominal current in cooling mode is referred to installation with 25kA short circuit current and is

based on the following conditions: evaporator 12°C/7°C; ambient 35°C; compressors + fans

Notes

current.

Maximum Running Current is referred to installation with 25kA short circuit and is based on

max compressor absorbed current in its envelope

Maximum unit current for wires sizing is referred to installation with 25kA short circuit current

and is based on minimum allowed voltage

Maximum current for wires sizing: (compressors full load ampere + fans current) x 1,1.

Minimum displacement power factor is referred to installation with 25kA short circuit

D - KIMAC00305-10EN - 9/64

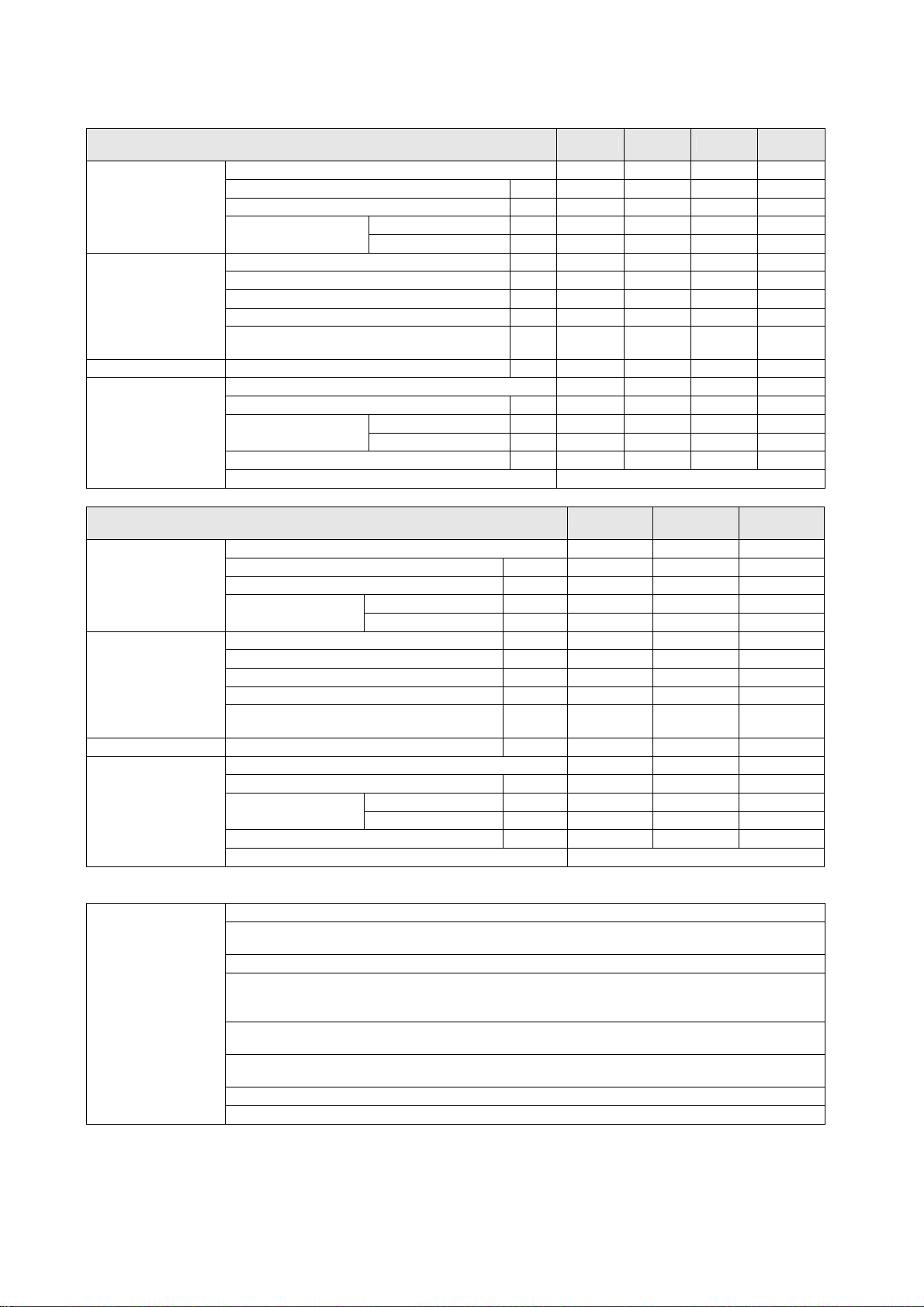

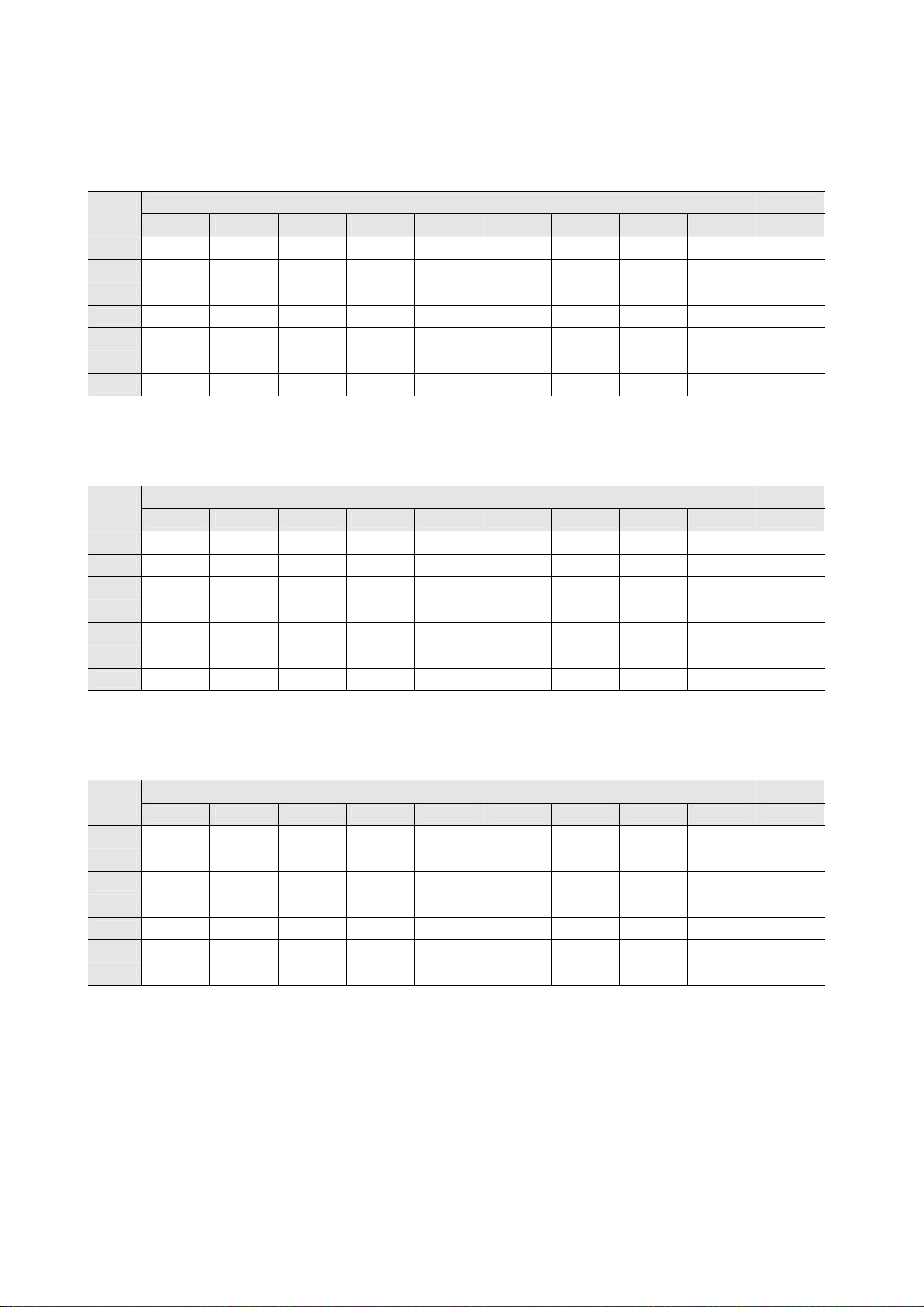

TECHNICAL SPECIFICATIONS

Capacity Cooling

Capacity control

Type Stepless

Minimum capacity % 13.5% 13.5% 13.5% 13.5%

Unit power input Cooling kW

EER

ESEER

Casing

Colour Ivory White

Material Galvanized and painted steel sheet

EWAD-BZXS

EWAD-BZXL

EWAD-BZXR

329 358 395 423

330 360 400 420

118 135 145 157

2,78 2,66 2,73 2,70

4,79 4,82 4,78 4,84

Height mm 2355 2355 2355 2355

Dimensions Unit

Width mm 2224 2224 2224 2224

Depth mm 4352 4352 5252 5252

Weight (BZXS)

Weight (BZXL)

Weight (BZXR)

Unit kg 4190

Operating Weight kg 4440

Unit Kg 4340 4340 4740 4740

Operating Weight Kg 4590 4590 4990 4990

Unit Kg 4390 4390 4790 4790

Operating Weight kg 4640 4640 5040 5040

4190

4590 4590

4440

4840 4840

Type Single Pass Shell&Tube

Water volume l 271 264 264 256

Water heat

exchanger

Nominal water

flow rate

Nominal Water

pressure drop

Cooling l/min 943

1026

1132

1213

Cooling kPa 60 61 72 67

Insulation material Closed cell foam elastomer

Air heat exchanger Type Louvered fins

Type Axial

Drive DC Inverter (Brushless)

Diameter mm 800 800 800 800

Fan

Nominal air flow m³/min 1960 1960 2450 2450

Quantity 8 8 10 10

Model

Speed in cooling rpm 700 700 700 700

Motor output in cool. W 900 900 900 900

Semi-hermetic single screw compressor

inverter driven

Compressor

Type

Oil charge l 26 26 26 26

Quantity 2 2 2 2

Sound level (BZXS)

Sound level (BZXL)

Sound level (BZXR)

Sound Power Cooling dBA 102,8 102,8 103,2 103,2

Sound Pressure Cooling dBA 83,0 83,0 83,0 83,0

Sound Power Cooling dBA 96,9 96,9 97,3 97,3

Sound Pressure Cooling dBA 77,0 77,0 77,0 77,0

Sound Power Cooling dBA 92,9 92,9 93,3 93,3

Sound Pressure Cooling dBA 73,0 73,0 73,0 73,0

Refrigerant type R-134a R-134a R-134a R-134a

Refrigerant circuit

Refrigerant charge kg 80 80 100 100

N. of circuits 2 2 2 2

Piping connections Evaporator water inlet/outlet 168.3 168.3 168.3 168.3

Safety devices High discharge pressure (pressure switch)

Safety devices High discharge pressure (transducer)

Safety devices Low suction pressure (transducer)

Safety devices Compressor overload (Kriwan)

Safety devices High discharge temperature

Safety devices Low oil pressure

Safety devices Low pressure ratio

Safety devices High oil pressure drop

Safety devices Phase monitor

Safety devices Emergency stop

Notes

Cooling capacity, unit power input in cooling and EER are based on the following conditions:

evaporator 12°C/7°C; ambient 35°C.

D - KIMAC00305-10EN - 10/64

TECHNICAL SPECIFICATIONS

EWAD-BZXL

EWAD-BZXR

Capacity Cooling kW

Capacity control

Type Stepless

Minimum capacity % 13.5% 13.5% 13.5%

Unit power input Cooling kW

EER

ESEER

Casing

Colour Ivory White

Material Galvanized and painted steel sheet

EWAD-BZXS

460 490 520

459 488 515

165 178 190

2,79 2,75 2,71

4,81 5,01 4,84

Height mm 2355 2355 2355

Dimensions Unit

Width mm 2224 2224 2224

Depth mm 6152 6152 6152

Weight ST

Weight LN

Weight XN

Unit kg 5070

Operating Weight kg 5320

Unit Kg 5220 5220 5220

Operating Weight Kg 5470 5470 5470

Unit Kg 5270 5270 5270

Operating Weight kg 5520 5520 5520

5070

5320

5070

5320

Type Single Pass Shell&Tube

Water volume l 256 248 248

Water heat

exchanger

Nominal water

flow rate

Nominal Water

pressure drop

Cooling l/min 1316

1399

1476

Cooling kPa 78 69 76

Insulation material Closed cell foam elastomer

Air heat exchanger Type Louvered fins

Type Axial

Drive DC Inverter (Brushless)

Diameter mm 800 800 800

Fan

Nominal air flow m³/min 2940 2940 2940

Quantity 12 12 12

Model

Speed in cooling rpm 700 700 700

Motor output in cool. W 900 900 900

Semi-hermetic single screw

compressor inverter driven

Compressor

Type

Oil charge l 26 26 26

Quantity 2 2 2

Sound level (ST)

Sound level (LN)

Sound level (XN)

Sound Power Cooling dBA 103,6 103,6 103,6

Sound Pressure Cooling dBA 83,5 83,5 83,5

Sound Power Cooling dBA 98,2 98,2 98,2

Sound Pressure Cooling dBA 77,5 77,5 77,5

Sound Power Cooling dBA 94,2 94,2 94,2

Sound Pressure Cooling dBA 73,5 73,5 73,5

Refrigerant type R-134a R-134a R-134a

Refrigerant circuit

Refrigerant charge kg 120 120 120

N. of circuits 2 2 2

Piping connections Evaporator water inlet/outlet 168.3 168.3 168.3

Safety devices High discharge pressure (pressure switch)

Safety devices High discharge pressure (transducer)

Safety devices Low suction pressure (transducer)

Safety devices Compressor overload (Kriwan)

Safety devices High discharge temperature

Safety devices Low oil pressure

Safety devices Low pressure ratio

Safety devices High oil pressure drop

Safety devices Phase monitor

Safety devices Emergency stop

Notes

Cooling capacity, unit power input in cooling and EER are based on the following

conditions: evaporator 12°C/7°C; ambient 35°C.

D - KIMAC00305-10EN - 11/64

EWAD-BZXS

ELECTRICAL SPECIFICATIONS

EWAD-BZXL

EWAD-BZXR

330 360 400 420

Phase 3 3 3 3

Frequency Hz 50 50 50 50

Power Supply

Voltage V 400 400 400 400

Voltage Tolerance

Minimum % -10% -10% -10% -10%

Maximum % +10% +10% +10% +10%

Maximum starting current A 232 244 251 278

Unit

Nominal running current cooling A 183 209 225 244

Maximum running current A 311 311 314 344

Maximum current for wires sizing A 342 342 345 378

Fans Nominal running current in cooling A 11.2 11.2 14.0 14.0

Phase 3 3 3 3

Voltage V 400 400 400 400

Compressor

Voltage Tolerance

Minimum % -10% -10% -10% -10%

Maximum % +10% +10% +10% +10%

Maximum running current A 150+150 150+150 150+150 150+150

Starting method Inverter

EWAD-BZXS

ELECTRICAL SPECIFICATIONS

EWAD-BZXL

EWAD-BZXR

460 490 520

Phase 3 3 3

Frequency Hz 50 50 50

Power Supply

Voltage V 400 400 400

Voltage Tolerance

Minimum % -10% -10% -10%

Maximum % +10% +10% +10%

Maximum starting current A 297 302 316

Unit

Nominal running current cooling A 256 275 295

Maximum running current A 377 377 377

Maximum current for wires sizing A 414 414 414

Fans Nominal running current in cooling A 33.6 33.6 33.6

Phase 3 3 3

Voltage V 400 400 400

Compressor

Voltage Tolerance

Minimum % -10% -10% -10%

Maximum % +10% +10% +10%

Maximum running current A 180+180 180+180 180+180

Starting method Inverter

Allowed voltage tolerance ± 10%. Voltage unbalance between phases must be within ± 3%.

Maximum starting current: starting current of biggest compressor + 75% of maximum current of

the other compressor + fans current for the circuit at 75%.

Maximum starting current referred to installation with 25kA short circuit current

Nominal current in cooling mode is referred to installation with 25kA short circuit current and is

based on the following conditions: evaporator 12°C/7°C; ambient 35°C; compressors + fans

Notes

current.

Maximum Running Current is referred to installation with 25kA short circuit and is based on

max compressor absorbed current in its envelope

Maximum unit current for wires sizing is referred to installation with 25kA short circuit current

and is based on minimum allowed voltage

Maximum current for wires sizing: (compressors full load ampere + fans current) x 1,1.

Minimum displacement power factor is referred to installation with 25kA short circuit

D - KIMAC00305-10EN - 12/64

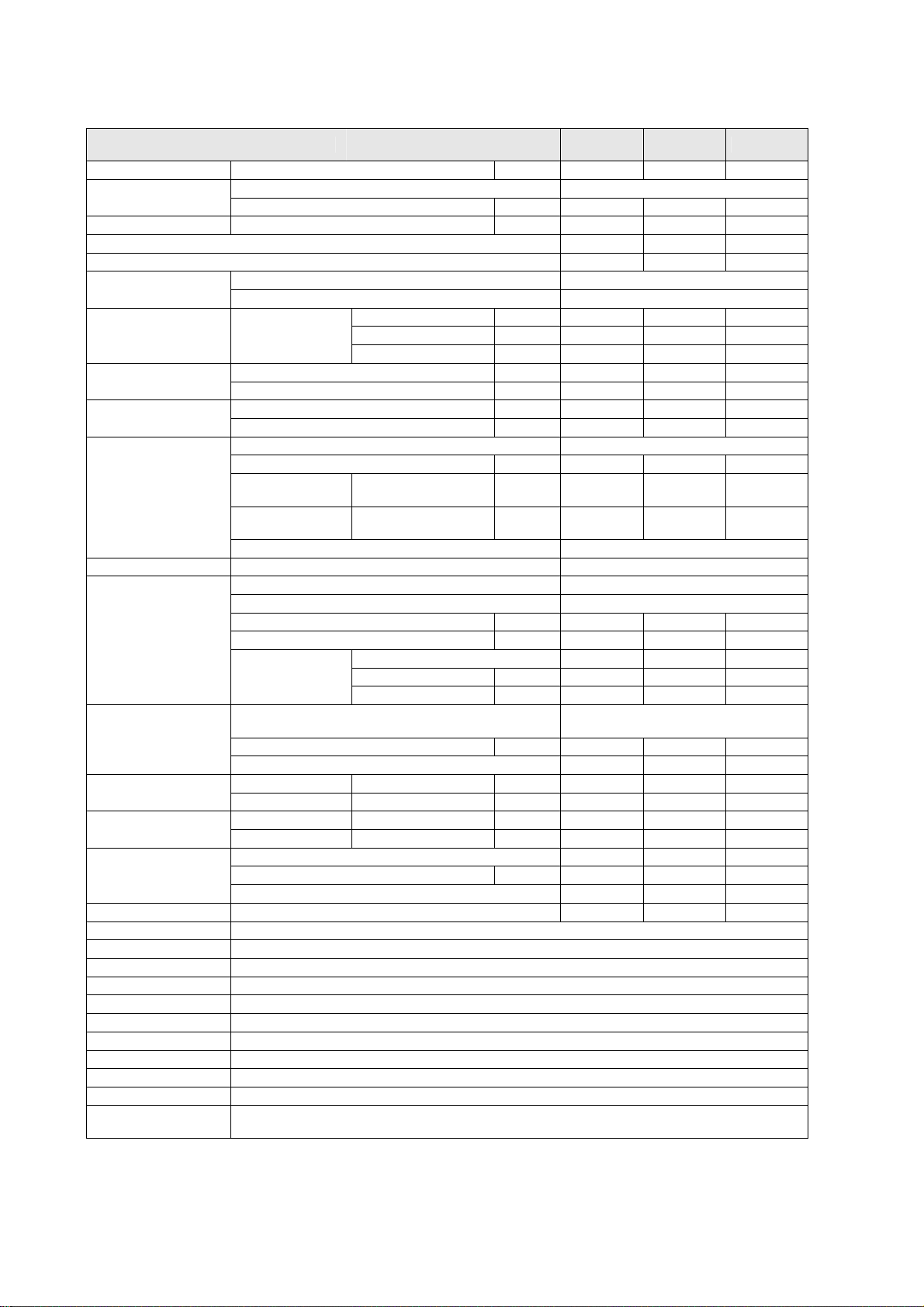

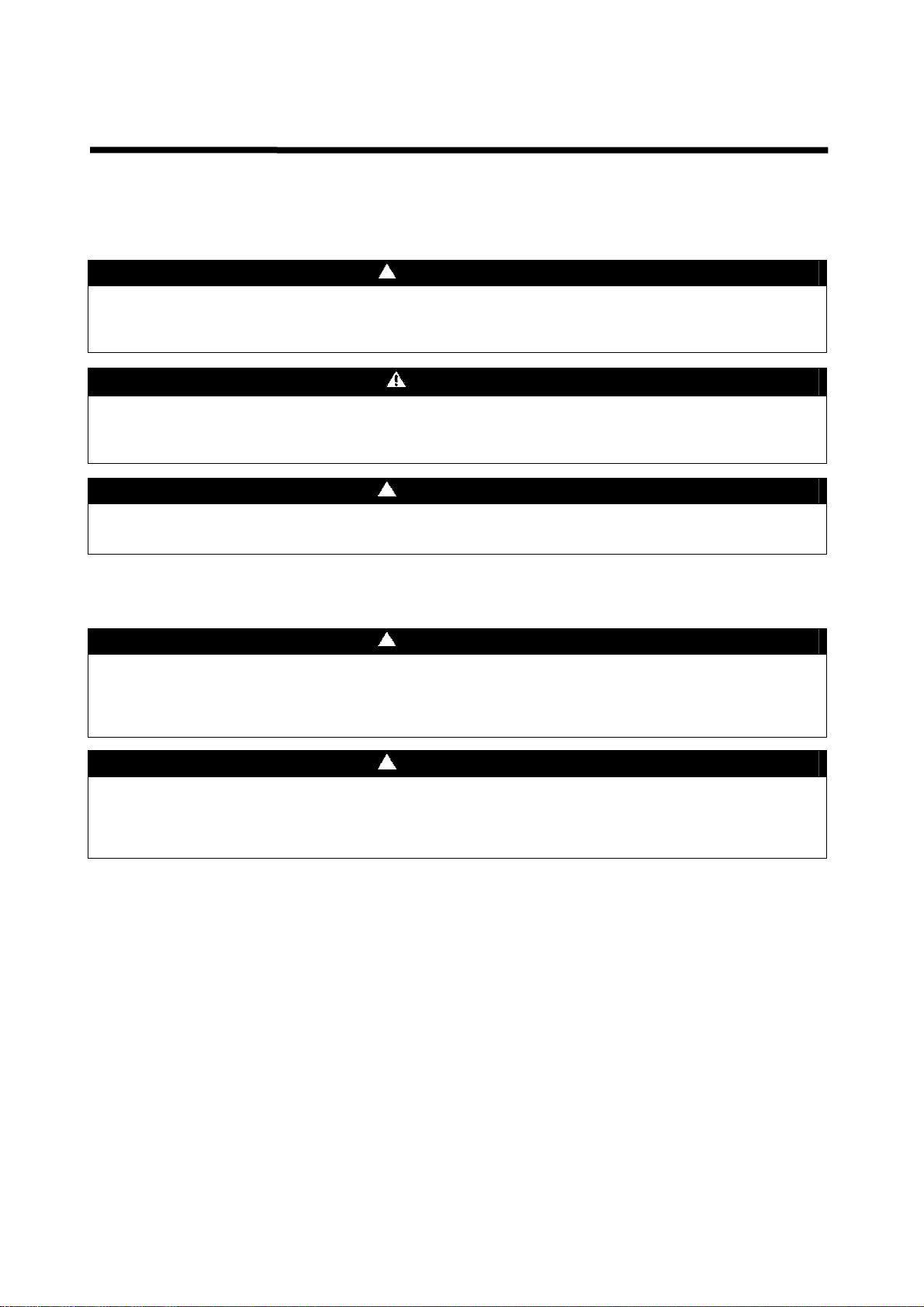

Sound pressure level

EWAD-BZSS – EWAD-BZXS

Unit

size

330

360

400

420

460

490

520

Note: The values are according to ISO 3744 and are referred to: evaporator 12/7° C, air ambient 35° C, full load operation.

EWAD-BZSL – EWAD-BZXL

Unit

size

330

360

400

420

460

490

520

Sound pressure level at 1 m from the unit in semispheric free field (rif. 2 x 10-5 Pa) Power

63 Hz 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz dB(A) dB(A)

79.1 77.8 79.0 77.6 80.0 76.1 65.6 56.6

79.1 77.8 79.0 77.6 80.0 76.1 65.6 56.6

79.1 77.8 79.0 77.6 80.0 76.1 65.6 56.6

79.1 77.8 79.0 77.6 80.0 76.1 65.6 56.6

79.6 78.3 79.5 78.1 80.6 76.6 65.6 56.6

79.6 78.3 79.5 78.1 80.6 76.6 65.6 56.6

79.6 78.3 79.5 78.1 80.6 76.6 65.6 56.6

Sound pressure level at 1 m from the unit in semispheric free field (rif. 2 x 10-5 Pa) Power

63 Hz 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz dB(A) dB(A)

78.4 73.5 73.5 71.8 73.9 69.9 59.6 50.7

78.4 73.5 73.5 71.8 73.9 69.9 59.6 50.7

78.4 73.5 73.5 71.8 73.9 69.9 59.6 50.7

78.4 73.5 73.5 71.8 73.9 69.9 59.6 50.7

78.4 74.0 74.0 72.3 74.4 70.3 60.1 50.7

78.4 74.0 74.0 72.3 74.4 70.3 60.1 50.7

78.4 74.0 74.0 72.3 74.4 70.3 60.1 50.7

83.0 102.8

83.0 102.8

83.0 103.2

83.0 103.2

83.5 103.6

83.5 103.6

83.5 103.6

77.0 96.9

77.0 96.9

77.0 97.3

77.0 97.3

77.5 98.2

77.5 98.2

77.5 98.2

Note: The values are according to ISO 3744 and are referred to: evaporator 12/7° C, air ambient 35° C, full load operation.

EWAD-BZXR

Unit

size

330

360

400

420

460

490

520

Note: The values are according to ISO 3744 and are referred to: evaporator 12/7° C, air ambient 35° C, full load operation.

Sound pressure level at 1 m from the unit in semispheric free field (rif. 2 x 10-5 Pa) Power

63 Hz 125 Hz 250 Hz 500 Hz 1000 Hz 2000 Hz 4000 Hz 8000 Hz dB(A) dB(A)

77.0 70.8 70.0 68.0 69.8 65.6 55.6 46.7

77.0 70.8 70.0 68.0 69.8 65.6 55.6 46.7

77.0 70.8 70.0 68.0 69.8 65.6 55.6 46.7

77.0 70.8 70.0 68.0 69.8 65.6 55.6 46.7

77.3 71.3 70.5 68.7 70.3 66.1 56.0 46.8

77.3 71.3 70.5 68.7 70.3 66.1 56.0 46.8

77.3 71.3 70.5 68.7 70.3 66.1 56.0 46.8

73.0 92.9

73.0 92.9

73.0 93.3

73.0 93.3

73.5 94.2

73.5 94.2

73.5 94.2

D - KIMAC00305-10EN - 13/64

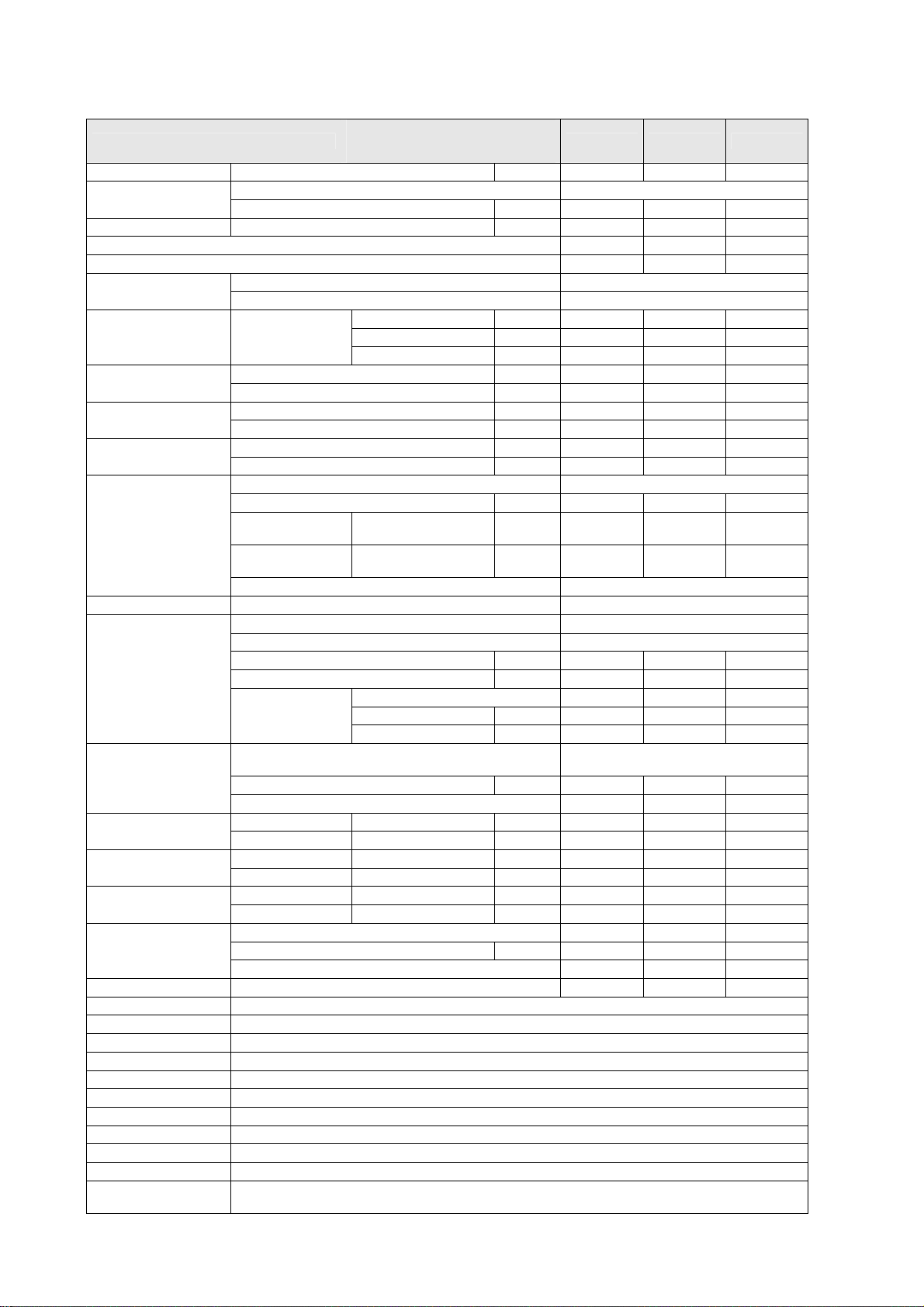

Operating limits

Storage

The units can be stored under the following environmental conditions:

Minimum ambient temperature : -10°C

Maximum ambient temperature : 53°C

Maximum relative humidity : 95% non-condensing

ATTENTION

Storage at a lower temperature than the minimum indicated can cause damage to certain parts including the

electronic control unit and its LCD display.

Storage at a higher temperature than that indicated will cause the safety valves on the suction valves of the

compressors to open.

Storage in a condensed atmosphere can damage the electronic components.

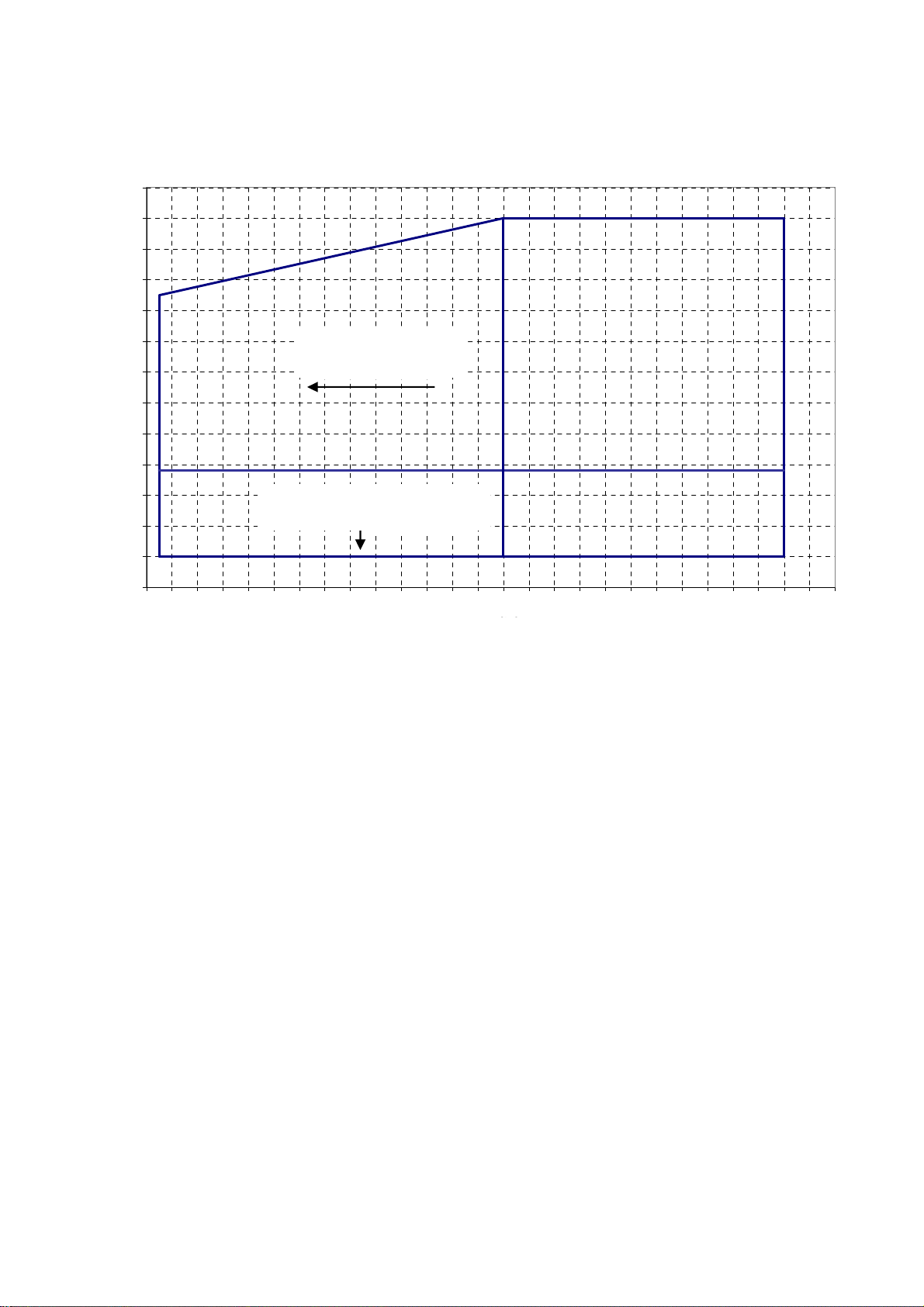

Operation

The unit must operate within the limits indicated in the following diagram.

Operating outside the limits indicated may trigger the protection devices and interrupt functioning of the unit and, in

extreme cases, may damage the unit.

For any doubts, contact the factory.

The maximum operating altitude is 2,000 m above sea level.

Please contact the factory if the equipment is to be operated at altitudes of between 1,000 and 2,000 m above sea

level.

The operating limits refer to a fully charged machine.

WARNING

ATTENTION

ATTENTION

ATTENTION

D - KIMAC00305-10EN - 14/64

REGULATION

EWAD-BZSS / BZSL / BZXS / BZXL / BZXR

50

45

40

35

30

25

20

15

Amb. Temp (°C)

10

5

0

-5

Temperature of air entering condenser

-10

-15

-10 -9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Functioning with

OPERATION

water and glycol

WITH GLYCOL

Functioning only with fan

speed regulation

FAN SPEED

ONLY

Temperature of water leaving evaporator

ELWT (°C)

Fig. 1 - Operating range –

D - KIMAC00305-10EN - 15/64

Mechanical installation

Transport

It is necessary to ensure the stability of the machine during transport. If the machine is transported with a wooden bar

placed on the machine base, this must be removed only on reaching the final destination.

Responsibility

The manufacturer declines all present and future responsibility for any harm to persons, animals or property caused by

the negligence of operators who fail to respect or who misinterpret the installation and maintenance instructions given in

this manual.

All safety appliances must be correctly and periodically checked, in compliance with local laws and regulations on safety

and environmental protection.

Safety

The machine must be firmly anchored to the ground.

It is of fundamental importance to respect the warnings given in the following list, which, however, is not to be considered

as exhaustive:

- The machine must be raised only at the lifting points on the base of the machine indicated in yellow. Only these points

can support the whole weight of the unit.

- Do not allow unauthorised and/or unqualified persons access to the machine.

- Access to the electrical components is forbidden until the main switch of the machine has been switched off and the

electricity supply has thus been cut off.

- Access to the electrical components is forbidden without the use of an insulating platform. Do not switch on the

electrical components if there is water and/or humidity.

- All action on the cooling circuit and on the components under pressure must be carried out only by qualified personnel.

- Replacement of a compressor or addition of lubricating oil must be carried out by qualified personnel only.

- Sharp corners and the surface of the condensing section can potentially cause injuries. Avoid direct contact.

- Cut off the electricity supply from the machine at the main switch before carrying out any action on the cooling fans

and/or compressors. Failure to respect this rule can cause serious bodily harm.

- Do not introduce solid bodies inside the water pipes when connecting the machine to the water supply.

- A mechanical filter must be fitted on the water pipe at the entrance of the heat exchanger.

- The machine is supplied with safety valves installed on both the high-pressure and the low-pressure sides of the

refrigerant circuit.

In case of sudden stop of the unit, follow the instructions on the Control Panel Operating Manual which is part of the

on-board documentation delivered to the end user with this manual.

It is recommended to perform installation and maintenance with other people. In case of accidental injury or unease, it is

necessary to:

- keep calm

- press the alarm button if present in the installation site

- move the injured person in a warm place far from the unit and in rest position

- contact immediately emergency rescue personnel of the building or if the Health Emergency Service

- wait without leaving the injured person alone until the rescue operators come

- give all necessary information to the the rescue operators

Before carrying out any operation on the machine, read the instruction and operating manual carefully.

Installation and maintenance must be carried out only by qualified personnel who are familiar with legal provisions

and local regulations, who have had specific training and who have experience of this type of appliance.

The machine must not be installed in any place which can be considered dangerous during maintenance, such as

(but not only) surfaces with no parapet or railings or without adequate space.

Handling and lifting

Avoid blows and/or jolts when unloading from the lorry and handling the machine. Do not push or pull any part of the

machine except the base frame. Prevent the machine from sliding on the lorry to prevent damage to the panels and the

base frame. Avoid any part of the machine from falling during unloading and/or handling; such falls can cause serious

damage.

All units of the series are provided with six lifting points marked in yellow. Use only these points for lifting the unit, as

indicated in Figure 2.

ATTENTION

ATTENTION

D - KIMAC00305-10EN - 16/64

Method for removing the

machine from the

container.

Optional Container Kit

Fig. 2 - Lifting the unit

ATTENTION

Both the lifting ropes and the spacer and/or equalizer bar must be dimensioned to safely support the weight of the

machine. Check the weight of the unit on the machine identification plate.

The weights indicated in the “Technical Data” table in the “General Information” chapter refer to standard units

without any additional optional elements.

Your particular machine could have accessories which increase the overall weight (pumps, batteries, copper/copper

parts etc.)

The machine must be lifted with maximum care and attention. Avoid sudden movements and lift the machine very

slowly, always keeping it level.

ATTENTION

D - KIMAC00305-10EN - 17/64

Positioning and assembly

All units are designed for outdoor installation on terraces or on the ground provided the area is free from obstacles which

can hinder the flow of air to the condensing batteries.

The machine must be installed on a strong, perfectly level foundation; if the machine is installed on a terrace or on the

roof, it may be necessary to place it on beams in order to distribute the weight.

For installation on the ground, prepare a strong cement base at least 250 mm wider and longer than the machine. The

foundation must also be strong enough to support the weight of the machine as declared in the technical sheet.

If the machine is installed in a place easily accessible to persons and animals, it is advisable to install protective grills

around the batteries and the compressor section.

To guarantee optimum performance of the machine in the place of installation, the following precautions and warnings

must be respected:

• Avoid recirculation of the air flow

• Make sure no obstacles hinder the air flow

• The free circulation of air is necessary to guarantee correct suction and expulsion.

• Make sure the flooring is strong and compact in order to reduce sound emissions and vibration as much as possible.

• Avoid installing the machine in particularly dusty environments in order to avoid dirtying the condensation batteries.

• The water in the plant must be particularly clean and all traces of oil or rust must be removed. A mechanical water

filter must be installed in the pipe which supplies the unit with water.

Minimum space requirements

It is of fundamental importance to respect the minimum distances for all units, in order to guarantee optimum ventilation

of the condensing batteries. Reduced installation space could reduce normal air flow with significant reduction in the

performance of the machine and a considerable increase in electricity consumption.

In deciding the position of the machine and guaranteeing correct air flow, it is important to bear in mind that the

recirculation of hot air and lack of ventilation to the air condensers must be avoided.

Both these factors can cause an increase in condensation pressure which will result in reduced energy efficiency and

reduced refrigerating capacity. Thanks to the shape of the air condensers, the unit is less sensitive to inefficient air

distribution.

In addition, the software calculates the operating conditions of the machine and optimises load in abnormal functioning

conditions.

Each side of the machine must be accessible for post-installation maintenance. Figure 8 shows the minimum space

required.

Vertical expulsion of the air must not be obstructed as this would significantly reduce capacity and efficiency.

If the machine is positioned in a place surrounded by walls or obstacles as high as the machine, these must be at least

2500 mm from the machine. If the obstacles are higher, the machine must be installed at a distance of at least 3000 mm.

If the machine is installed without respecting the recommended distances from walls and/or obstacles, the hot air may

recirculate and/or the air condensers may be insufficiently ventilated, causing reduced capacity and efficiency.

Fig. 3 - Minimum distances for machine maintenance

D - KIMAC00305-10EN - 18/64

In any case, the microprocessor will allow the machine to adapt to new conditions, producing the maximum capacity

available (which will, however, be less than the nominal capacity of the machine) even if the free space at the side of the

machine is less than that recommended.

When two or more machines are positioned one beside the other, there must be a distance of at least 3600 mm between

the condensation batteries.

For other solutions, consult the authorised technicians.

Fig. 4 - Minimum recommended installation distances

D - KIMAC00305-10EN - 19/64

Acoustic protection

When it is particularly necessary to control the sound level, pay maximum attention to insulating the machine from the

base by the suitable application of anti-vibration devices (available as an optional accessory). In addition, install flexible

joints on the water connections.

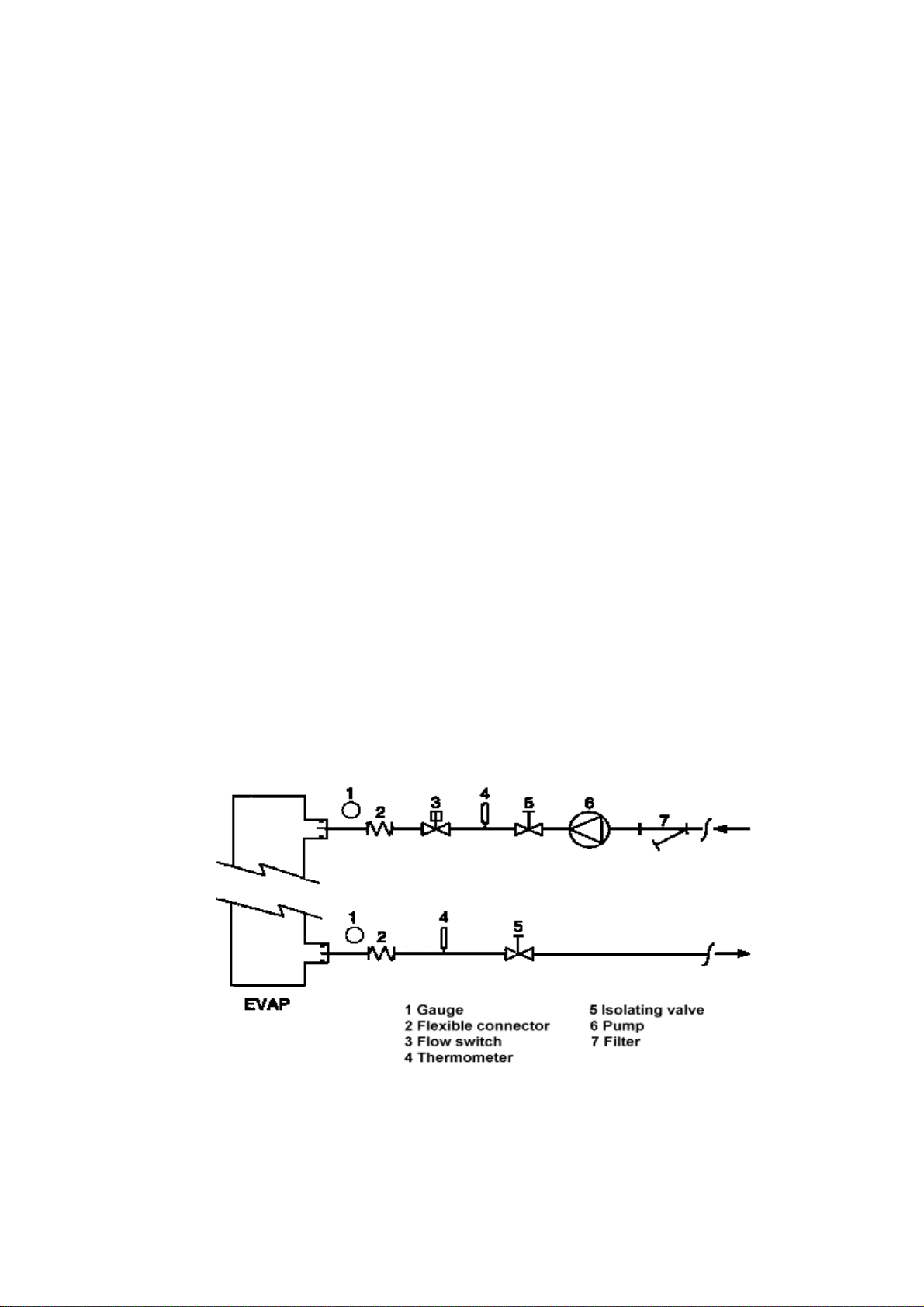

Water pipes

The piping must be designed with as few curves as possible and as few upward-flow sections as possible; in this way the

cost of the system will be considerably reduced and performance will be improved.

The water plant should contain:

1. Anti-vibration supports to reduce the transmission of the vibrations to the basic structure.

2. Cut-off valves to cut off the machine from the water system during maintenance or repairs.

3.

A manual or automatic air bleeding device at the highest point of the plant. A drainage device at the lowest point

of the plant. Neither the evaporator nor the heat recovery device must be positioned at the highest point of the

plant.

4. A device to maintain the pressure of the water system (expansion tank, etc.).

5. Water temperature and pressure indicators positioned on the machine, in aid of maintenance and servicing

operations.

6.

A filter or other device to remove extraneous particles from the water before entering the pump (consult the

pump manufacturer’s recommendations for the correct size of the filter to avoid cavitation). The use of a filter

will prolong the life of the pump and will maintain the water system in the best conditions.

7.

Another filter must be fitted on the water pipe at the machine water input point, near the evaporator and the heat

recovery device (if installed). The filter prevents solid particles from entering the heat exchanger, which could

damage it or reduce heat exchange capacity.

8. The shell and tube heat exchanger has an electrical resistance with a thermostat to prevent the water from

freezing even at temperatures as low as -25°C. All t he other water pipes outside the machine must be thermally

insulated to prevent freezing.

9. The water must be removed from the heat recovery device during the winter period unless a sufficient

percentage of an ethylene glycol mixture is introduced into the water circuit.

10.

If the machine is installed in place of another, the whole water system must be drained and cleaned before

installing the new unit. Regular analysis of the water and correct chemical treatment is recommended before

starting up the new machine.

11.

If glycol is added to the water in the circuit as an anti-freeze solution, make sure that the suction pressure is

lower; machine performance will be reduced and loss of water pressure will be greater. All machine protection

systems, such as anti-freeze and low pressure protection, must be reset.

Before thermally insulating the water pipes, make sure that there are no leaks.

D - KIMAC00305-10EN - 20/64

Loading...

Loading...