Air-cooled single circuit screw chiller

EWAD100 ÷ 410 E

ERAD120 ÷ 490 E- (condensing unit)

50 Hz - Refrigerant R134a

Original Instructions

Installation, Operation and Maintenance Manual

D-EIMAC00704-14EN

1

6

2

7

3

8

4

9

5

IMPORTANT

This Manual is a technical aid and does not represent a binding offer for Daikin.

Daikin has drawn up this Manual to the best of its knowledge. The content cannot be held as explicitly or implicitly

guaranteed as complete, precise or reliable.

All data and specifications contained herein may be modified without notice. The data communicated at the moment

of the order shall hold firm.

Daikin shall assume no liability whatsoever for any direct or indirect damage, in the widest sense of the term,

ensuing from or connected with the use and/or interpretation of this Manual.

The entire content is protected by Daikin copyright.

WARNING

Before starting the installation of the unit, please read this manual carefully. Starting up the unit is absolutely

forbidden if all instructions contained in this manual are not clear.

Key to symbols

Important note: failure to respect the instruction can damage the unit or compromise operation

Note regarding safety in general or respect of laws and regulations

Note regarding electrical safety

Description of the labels applied to the electrical panel

2÷4 fans unit

Label Identification

– Non flammable gas symbol

– Gas type

– Unit nameplate data

– Manufacturer’s logo

– Water circuit filling warning

– Electrical hazard symbol

– Hazardous Voltage warning

– Cable tightening warning

– Lifting instructions

6 fans unit

D–EIMAC00704-14EN - 2/72

Index

General Information .......................................................................................................................................................... 6

Receiving the machine ................................................................................................................................................... 6

Checks ........................................................................................................................................................................... 6

Purpose of this Manual ................................................................................................................................................... 6

Nomenclature ................................................................................................................................................................. 7

Operating limits ............................................................................................................................................................... 17

Storing .......................................................................................................................................................................... 17

Operation ...................................................................................................................................................................... 17

Mechanical Installation ................................................................................................................................................... 19

Shipping ....................................................................................................................................................................... 19

Responsibility ............................................................................................................................................................... 19

Safety ........................................................................................................................................................................... 19

Moving and lifting ......................................................................................................................................................... 20

Positioning and assembly ............................................................................................................................................. 20

Minimum space requirements ...................................................................................................................................... 21

Sound protection .......................................................................................................................................................... 22

Water piping ................................................................................................................................................................. 22

Water treatment ..................................................................................................................................................... 23

Evaporator and recovery exchangers anti-freeze protection .................................................................................. 24

Installing the flow switch ........................................................................................................................................ 24

Hydronic kit (optional) ............................................................................................................................................ 25

Refrigerating circuit safety valves ................................................................................................................................. 28

Guidelines forERAD E- Installation ............................................................................................................................... 30

Refrigerant piping design .............................................................................................................................................. 30

Expansion valve ........................................................................................................................................................... 31

Refrigerant Chargie ...................................................................................................................................................... 31

Installation of evaporator fluid sensors ......................................................................................................................... 32

Electrical installation ...................................................................................................................................................... 33

General specifications .................................................................................................................................................. 33

Electrical components .................................................................................................................................................. 38

Power circuit wiring....................................................................................................................................................... 38

Electrical heaters .......................................................................................................................................................... 40

Electrical power supply to the pumps ........................................................................................................................... 40

Water pump control ...................................................................................................................................................... 41

Unit On/ Off remote control – Electrical wiring .............................................................................................................. 41

Double Setpoint – Electrical wiring ............................................................................................................................... 41

External water Setpoint reset – Electrical wiring (Optional) .......................................................................................... 41

Unit limitation – Electrical wiring (Optional) .................................................................................................................. 42

Operation ......................................................................................................................................................................... 44

Operator’s responsibilities ............................................................................................................................................ 44

Description of the machine ........................................................................................................................................... 44

Description of the chilling cycle .................................................................................................................................... 44

EWAD E-SS/SL ..................................................................................................................................................... 44

ERAD E-SS/SL ...................................................................................................................................................... 48

Description of the chilling cycle with heat recovery ...................................................................................................... 50

Controlling the partial recovery circuit and installation recommendations .............................................................. 50

Compressor .................................................................................................................................................................. 55

Compression process ................................................................................................................................................... 55

Cooling capacity control ............................................................................................................................................... 57

Pre-startup checks .......................................................................................................................................................... 58

Units with an external water pump ............................................................................................................................... 59

Units with a built-in water pump .................................................................................................................................... 59

Electrical power supply ................................................................................................................................................. 59

Unbalance in power supply voltage .............................................................................................................................. 59

Electrical heater power supply ...................................................................................................................................... 60

Startup procedure ........................................................................................................................................................... 61

Turning on the machine ................................................................................................................................................ 61

Seasonal shutdown ...................................................................................................................................................... 62

Starting up after seasonal shutdown ............................................................................................................................ 62

System maintenance....................................................................................................................................................... 63

General ......................................................................................................................................................................... 63

Compressor maintenance ............................................................................................................................................ 63

Lubrication .................................................................................................................................................................... 64

Routine maintenance.................................................................................................................................................... 65

Dehydration filter replacement ...................................................................................................................................... 65

Dehydration filter cartridge replacement procedure ...................................................................................................... 65

D–EIMAC00704-14EN - 3/72

Oil filter replacement..................................................................................................................................................... 66

Oil filter replacement procedure ................................................................................................................................... 66

Refrigerant charge ........................................................................................................................................................ 67

Refrigerant replenishment procedure ........................................................................................................................... 68

Standard Checks ............................................................................................................................................................. 69

Temperature and pressure transducers ....................................................................................................................... 69

Test sheet ........................................................................................................................................................................ 70

Fluid side measurements ............................................................................................................................................. 70

Refrigerant side measurements ................................................................................................................................... 70

Electrical measurements .............................................................................................................................................. 70

Service and limited warranty .......................................................................................................................................... 71

Periodic obligatory checks and starting up of appliances under pressure ............................................................... 71

Important information regarding the refrigerant used ................................................................................................. 71

Disposal ........................................................................................................................................................................ 71

Index of tables

Index of tables

Index of tablesIndex of tables

Table 1 – EWAD 100E÷180E -SS - HFC 134a - Technical Data ........................................................................................ 8

Table 2 – EWAD 210E÷410E-SS - HFC 134a - Technical Data ......................................................................................... 9

Table 3 – EWAD 100E÷180E-SL - HFC 134a - Technical Data ........................................................................................ 10

Table 4 – EWAD 210E÷400E-SL - HFC 134a - Technical Data ........................................................................................ 11

Table 5 - ERAD 120E÷220E-SS - HFC 134a - Technical Data ........................................................................................ 12

Table 6 - ERAD 250E÷490E-SS - HFC 134a - Technical Data ........................................................................................ 13

Table 7 – ERAD 120E÷210E-SL - HFC 134a - Technical Data ......................................................................................... 14

Table 8 – ERAD 240E÷460E-SL - HFC 134a - Technical Data ......................................................................................... 15

Table 9 - Sound levels EWAD E-SS – ERAD E-SS .......................................................................................................... 16

Table 10 - Sound levels EWAD E-SL – ERAD E-SL ......................................................................................................... 16

Table 11 - Acceptable water quality limits ......................................................................................................................... 24

Table 12 - Recomandend maximum equivalent length (m) for Suction line ...................................................................... 30

Table 13 - Recomandend maximum equivalent length (m) for Liquid line ......................................................................... 30

Table 14 – Refrigerant charge for (m) of Liquid ans suction line line ................................................................................ 31

Table 15 - Electrical Data EWAD 100E÷180E -SS ............................................................................................................ 34

Table 16 - Electrical Data EWAD 210E÷410E-SS ............................................................................................................. 34

Table 17 - Electrical Data EWAD 100E÷180E-SL ............................................................................................................ 35

Table 18 - Electrical Data EWAD 210E÷400E-SL ............................................................................................................ 35

Table 19 - Electrical Data ERAD 120E÷220E-SS ............................................................................................................. 36

Table 20 - Electrical Data ERAD 250E÷490E-SS ............................................................................................................. 36

Table 21 - Electrical Data ERAD 120E÷210E-SL .............................................................................................................. 37

Table 22 - Electrical Data ERAD 240E÷460E-SL .............................................................................................................. 37

Table 23 - Recommended Fuses and Field Wire Sizing ................................................................................................... 38

Table 24 - Electrical data for optional pumps .................................................................................................................... 41

Table 25 - Typical working conditions with compressors at 100% .................................................................................... 61

Table 26 - Routine maintenance programme .................................................................................................................... 65

Table 27 - Pressure/ Temperature .................................................................................................................................... 68

Index of figures

Index of figures

Index of figuresIndex of figures

Figure 1 - Nomenclature...................................................................................................................................................... 7

Figure 2 - Operating limits – EWAD E-SS/SL .................................................................................................................... 18

Figure 3 - Operating limits – ERAD E-SS/SL .................................................................................................................... 18

Figure 4 - Lifting the unit.................................................................................................................................................... 20

Figure 5 - Minimum space requirements for machine maintenance .................................................................................. 21

Figure 6 - Minimum recommended installation distances.................................................................................................. 22

Figure 7 - Water piping connection for evaporator ............................................................................................................ 23

Figure 8 - Water piping connection for heat recovery exchangers .................................................................................... 23

Figure 9 - Adjusting the safety flow switch ........................................................................................................................ 24

Figure 10 - Single- and twin-pump hydronic kit ................................................................................................................. 25

Figure 11 – EWAD E SS/SL - Available external lift for water pumps kit (option on request) - Low lift single pump ......... 26

Figure 12 – EWAD E SS/SL - Available external lift for water pumps kit (option on request) - High lift single pump ........ 26

Figure 13 – EWAD E SS/SL - Available external lift for water pumps kit (option on request) - Low lift twin pump ............ 27

Figure 14 – EWAD E SS/SL - Available external lift for water pumps kit (option on request) - High lift twin pump ........... 27

Figure 15 - Evaporator pressure drop - EWAD E SS/SL ................................................................................................... 28

Figure 16 - Heat recovery pressure drop - EWAD E SS/SL .............................................................................................. 29

D–EIMAC00704-14EN - 4/72

Figure 17 - Installation of long power supply wires ............................................................................................................ 38

Figure 18 - User connection to the interface M3 terminal boards ...................................................................................... 43

Figure 19 - EWAD E SS/SL - Not economised refrigerante circuit ................................................................................... 46

Figure 20 - EWAD E SS/SL - Economised refrigerante circuit ........................................................................................ 47

Figure 21 –ERAD E SS/SL - Not economised refrigerante circuit .................................................................................... 48

Figure 22 –ERAD E SS/SL - Economised refrigerante circuit .......................................................................................... 49

Figure 23 - EWAD E SS/SL - Heat recovery refrigerante circuit - Not Economised units ................................................ 51

Figure 24 - EWAD E SS/SL - Heat recovery refrigerante circuit - Economised units ...................................................... 52

Figure 25 –EWAD E SS/SL - Heat recovery refrigerante circuit - Not Economised units ................................................. 53

Figure 26 –ERAD E SS/SL - Heat recovery refrigerante circuit - Economised units ........................................................ 54

Figure 27 - Picture of Fr3100 compressor ......................................................................................................................... 55

Figure 28 - Picture of F3 compressor ................................................................................................................................ 55

Figure 29 - Compression process ..................................................................................................................................... 56

Figure 30 - Capacity control mechanism for Fr3100 compressor ...................................................................................... 57

Figure 31 - Capacity control mechanism for F3 compressor ............................................................................................. 57

Figure 32 - Installation of control devices for Fr3100 compressor ..................................................................................... 64

Figure 33 - Installation of control devices for F3 compressor ............................................................................................ 64

D–EIMAC00704-14EN - 5/72

General Information

ATTENTION

The units described in the present manual represent a high value investment, maximum care should be taken to

ensure correct installation and appropriate working conditions.

Installation and maintenance must be performed by qualified and specifically trained personnel only.

Correct maintenance of the unit is indispensable for its safety and reliability. Manufacturer’s service centres are the

only having adequate technical skill for maintenance.

ATTENTION

This manual provides information about the features and standard procedure for the complete series.

All units are delivered from the factory complete with wiring diagrams and dimensional drawings including size and

weight for each model.

WIRING DIAGRAMS AND DIMENSIONAL DRAWINGS MUST BE CONSIDERED ESSENTIAL DOCUMENTS OF

THIS MANUAL

In case of any discrepancy between this manual and the equipment’s document please refer to the wiring diagram

and dimensional drawings.

Receiving the machine

The machine must be inspected for any possible damage immediately upon reaching its final place of installation. All

components described in the delivery note must be carefully verified and checked; any damage must be reported to the

transporter. Check on the machine nameplate, before connecting it to earth, that the model and power supply voltage are

as ordered. Responsibility for any damage after acceptance of the machine cannot be attributed to the manufacturer.

Checks

Please perform the following checks upon receipt of the machine, for your protection in the event that it is incomplete

(any missing parts) or has incurred damage during transport:

a) Before accepting the machine, please verify every single component in the consignment. Check for any

damage.

b) In the event that the machine has been damaged, do not remove the damaged material. A set of photographs

are helpful in ascertaining responsibility.

c) Immediately report the extent of the damage to the trasnporter and immediately request that they inspect the

machine.

d) Immediately report the extent of the damage to the manufacturer representative, so that arrangements can be

made for the required repairs. In no case must the damage be repaired before the machine has been inspected

by the representative of the transportation company.

Purpose of this Manual

The purpose of this Manual is to allow the installer and the qualified operator to carry out all required operations in order

to ensure proper installation and maintenance of the machine, without risking any damage to people, animals and/or

objects.

This Manual is an important supporting document for qualified personnel but it is not intended to replace such personnel.

All activities must be carried out in compliance with local laws and regulations.

D–EIMAC00704-14EN - 6/72

Nomenclature

E W A D 1 0 0 E - S S 0 0 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Machine type

EWA = Air-cooled chiller, cooling only

EWY = Air-cooled chiller, heat pump

EWL = Remote condenser chiller

ERA = Air cooled condensing unit

EWW = Water-cooled chiller, cooling only

EWC = Air-cooled chiller, cooling only with centrifugal fan

EWT = Air-cooled chiller, cooling only with heat recovery

Refrigerant

D = R-134a

P = R-407c

Q = R-410a

Capacity class in kW (Cooling)

Always 3-digit code

Idem as previous

Model series

Letter A, B,… : major modification

Inverter

- = Non-inverter

Z = Inverter

Efficiency level

S = Standard efficiency (SE)

X = High efficiency (XE) (N.A for this range)

P = Premium efficiency (PE) (N.A for this range)

H = High ambient (HA) (N.A for this range)

Sound level

S = Standard noise (ST)

L = Low noise (LN)

R = Reduced noise (XN) (N.A for this range)

X = Extra low noise (XXN) (N.A for this range)

C = Cabinet (CN) (N.A for this range)

Warranty

0 = 1 year of warranty

B = 2 years of warranty

C = 3 years of warranty

… = ... years of warranty

Sequential number

000 = Base model

001 = First order for this model (1 or more units)

002 = Second order for this model (1 or more units)

… = ... order for this model

B01 = First order for this model + 1year warranty

B02 = Second order for this model (1 or more units)

… = ... order for this model

(McQuay code)

(McQuay code)

Figure 1 - Nomenclature

D–EIMAC00704-14EN - 7/72

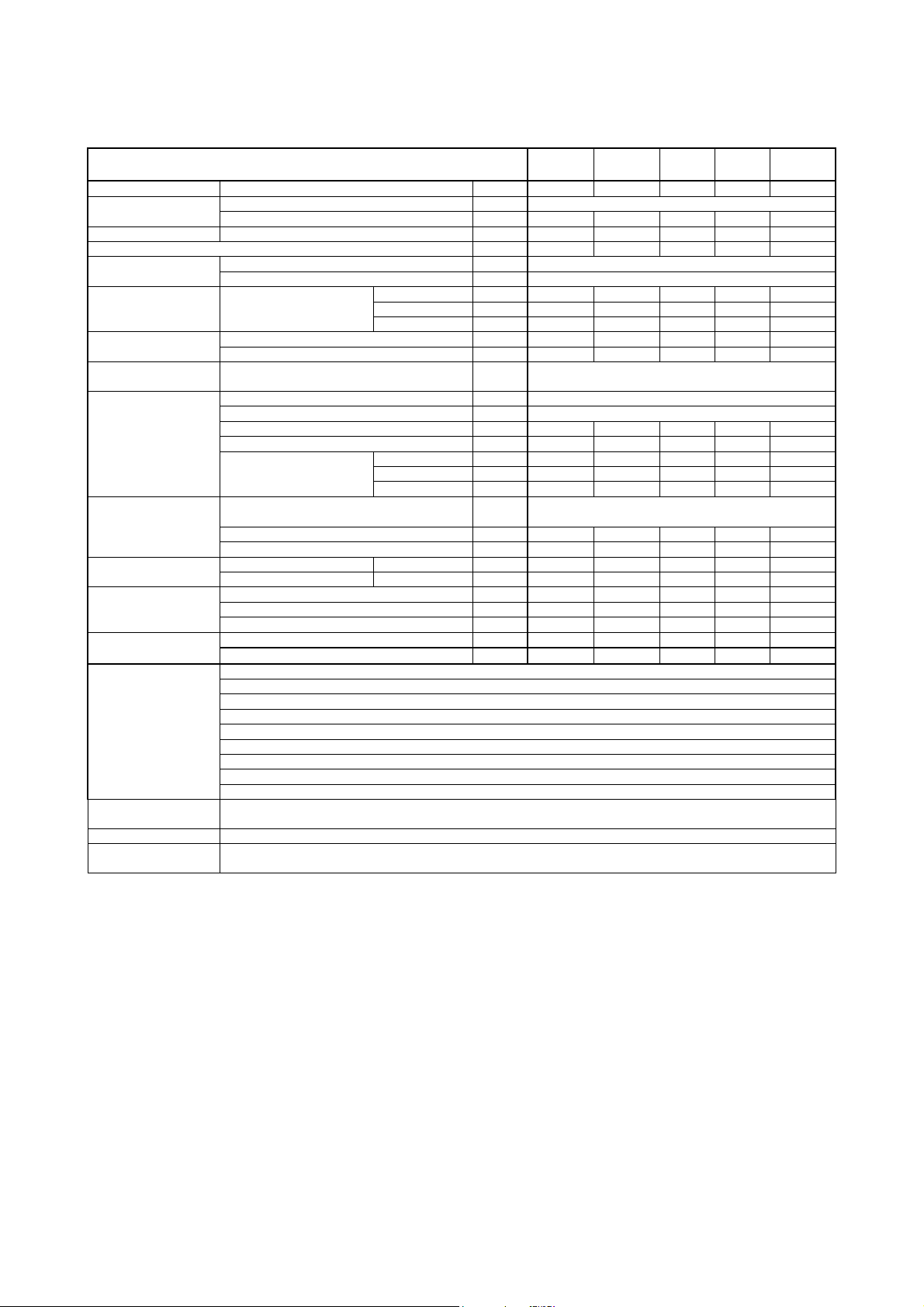

Table 1 – EWAD 100E ÷ 180E-SS - HFC 134a - Technical Data

Unit SIze 100 120 140 160 180

Capacity (1) Cooling kW 101 121 138 163 183

Capacity control

Unit power input (1) Cooling kW 38.7 46.9 53.4 60.3 68.5

EER (1) --- 2.61 2.57 2.58 2.70 2.67

ESEER --- 2.93 2.93 2.75 2.93 2.81

IPLV --- 3.36 3.25 2.98 3.13 3.25

Casing

Dimensions Unit

Weight

Water heat

exchanger

Air heat exchanger Type ---

Fan

Compressor

Sound level

Refrigerant circuit

Piping connections Evaporator water inlet/outlet " 3 3 3 3 3

Safety devices High discharge pressure (pressure switch)

High discharge pressure (pressure transducer)

Low suction pressure (pressure transducer)

Compressor motor protection

High discharge temperature

Low oil pressure

Low pressure ratio

High oil filter pressure drop

Phase monitor

Water freeze protection controller

Notes (1)

Notes (2)

Type --- Stepless

Minimum capacity % 25 25 25 25 25

Colour --- Ivory White

Material --- Galvanized and painted steel sheet

Unit kg 1651 1684 1806 1861 2023

Operating Weight kg 1663 1699 1823 1881 2047

Type --- Plate to Plate

Water volume l 12 15 17 20 24

Nominal water flow rate l/s 4.83 5.76 6.58 7.77 8.74

Nominal Water pressure drop kPa 24 25 24 24 22

Insulation material Closed cell

Type --- Direct propeller type

Drive --- DOL

Diameter mm 800 800 800 800 800

Nominal air flow l/s 10922 10575 16383 15863 21844

Model

Type --Oil charge l 13 13 13 13 13

Quantity No. 1 1 1 1 1

Sound Power Cooling dB(A) 91.5 91.5 92.3 92.3 93.0

Sound Pressure (2) Cooling dB(A) 73.5 73.5 73.7 73.7 73.9

Refrigerant type --- R-134a R-134a R-134a R-134a R-134a

Refrigerant charge kg. 18 21 23 28 30

N. of circuits No. 1 1 1 1 1

Cooling capacity, unit power input in cooling and EER are based on the following conditions: evaporator

12/7°C; ambient 35°C, unit at full load operation.

The values are according to ISO 3744 and are referred to: evaporator 12/7°C, ambient 35°C, full load

operation.

Height mm 2273 2273 2273 2273 2273

Width mm 1292 1292 1292 1292 1292

Length mm 2165 2165 3065 3065 3965

High efficiency fin and tube type

with integral subcooler

Quantity No. 2 2 3 3 4

Speed rpm 920 920 920 920 920

Motor input kW 1.75 1.75 1.75 1.75 1.75

Semi-hermetic

single screw compressor

D–EIMAC00704-14EN - 8/72

Table 2 - EWAD 210E ÷ 410E-SS - HFC 134a - Technical Data

Unit SIze 210 260 310 360 410

Capacity (1) Cooling kW 214 256 307 360 413

Capacity control

Unit power input (1) Cooling kW 71.7 86.7 111 133 146

EER (1) --- 2.98 2.95 2.77 2.71 2.84

ESEER --- 3.02 3.18 3.05 3.23 3.34

IPLV --- 3.48 3.68 3.57 3.61 3.65

Casing

Dimensions Unit

Weight

Water heat

exchanger

Air heat exchanger Type ---

Fan

Compressor

Sound level

Refrigerant circuit

Piping connections Evaporator water inlet/outlet " 3 3 3 3 3

Safety devices High discharge pressure (pressure switch)

High discharge pressure (pressure transducer)

Low suction pressure (pressure transducer)

Compressor motor protection

High discharge temperature

Low oil pressure

Low pressure ratio

High oil filter pressure drop

Phase monitor

Water freeze protection controller

Notes (1)

Notes (2)

Type --- Stepless

Minimum capacity % 25 25 25 25 25

Colour --- Ivory White

Material --- Galvanized and painted steel sheet

Unit kg 2086 2522 2745 2855 2919

Operating Weight kg 2116 2547 2775 2891 2963

Type --- Plate to Plate

Water volume l 30 25 30 36 44

Nominal water flow rate l/s 10.22 12.22 14.65 17.21 19.74

Nominal Water pressure drop kPa 21 48 48 48 45

Insulation material Closed cell

Type --- Direct propeller type

Drive --- DOL

Diameter mm 800 800 800 800 800

Nominal air flow l/s 21150 32767 32767 31725 31725

Model

Type --Oil charge l 13 16 19 19 19

Quantity No. 1 1 1 1 1

Sound Power Cooling dB(A) 94.2 94.2 94.5 94.5 95.2

Sound Pressure (2) Cooling dB(A) 75.1 75.0 75.3 75.3 76.0

Refrigerant type --- R-134a R-134a R-134a R-134a R-134a

Refrigerant charge kg. 33 46 46 56 60

N. of circuits No. 1 1 1 1 1

Cooling capacity, unit power input in cooling and EER are based on the following conditions: evaporator

12/7°C; ambient 35°C, unit at full load operation.

The values are according to ISO 3744 and are referred to: evaporator 12/7°C, ambient 35°C, full load

operation.

Height mm 2273 2223 2223 2223 2223

Width mm 1292 2236 2236 2236 2236

Length mm 3965 3070 3070 3070 3070

High efficiency fin and tube type

with integral subcooler

Quantity No. 4 6 6 6 6

Speed rpm 920 920 920 920 920

Motor input kW 1.75 1.75 1.75 1.75 1.75

Semi-hermetic

single screw compressor

D–EIMAC00704-14EN - 9/72

Table 3 – EWAD 100E ÷ 180E-SL – HFC134a - Technical Data

Units Size 100 120 130 160 180

Capacity (1) Cooling kW 97.9 116 134 157 177

Capacity control

Unit power input (1) Cooling kW 38.8 47.9 53.0 60.6 67.8

EER (1) --- 2.52 2.42 2.53 2.60 2.61

ESEER --- 3.01 2.97 2.85 3.00 3.07

IPLV --- 3.32 3.21 3.30 3.46 3.28

Casing

Dimensions Unit

Weight

Water heat

exchanger

Air heat exchanger Type ---

Fan

Compressor

Sound level

Refrigerant circuit

Piping connections Evaporator water inlet/outlet " 3 3 3 3 3

Safety devices High discharge pressure (pressure switch)

High discharge pressure (pressure transducer)

Low suction pressure (pressure transducer)

Compressor motor protection

High discharge temperature

Low oil pressure

Low pressure ratio

High oil filter pressure drop

Phase monitor

Water freeze protection controller

Notes (1)

Notes (2)

Type --- Stepless

Minimum capacity % 25 25 25 25 25

Colour --- Ivory White

Material --- Galvanized and painted steel sheet

Unit kg 1751 1784 1906 1961 2123

Operating Weight kg 1766 1799 1923 1981 2147

Type --- Plate to Plate

Water volume l 12 15 17 20 24

Nominal water flow rate l/s 4.68 5.54 6.40 7.51 8.47

Nominal Water pressure drop kPa 23 23 23 23 21

Insulation material Closed cell

Type --- Direct propeller type

Drive --- DOL

Diameter mm 800 800 800 800 800

Nominal air flow l/s 8372 8144 12558 12217 16744

Model

Type --Oil charge l 13 13 13 13 13

Quantity No. 1 1 1 1 1

Sound Power Cooling dB(A) 89.0 89.0 89.8 89.8 90.5

Sound Pressure (2) Cooling dB(A) 71.0 71.0 71.2 71.2 71.4

Refrigerant type --- R-134a R-134a R-134a R-134a R-134a

Refrigerant charge kg. 18 21 23 28 30

N. of circuits No. 1 1 1 1 1

Cooling capacity, unit power input in cooling and EER are based on the following conditions: evaporator

12/7°C; ambient 35°C, unit at full load operation.

The values are according to ISO 3744 and are referred to: evaporator 12/7°C, ambient 35°C, full load

operation.

Height mm 2273 2273 2273 2273 2273

Width mm 1292 1292 1292 1292 1292

Length mm 2165 2165 3065 3065 3965

High efficiency fin and tube type

with integral subcooler

Quantity No. 2 2 3 3 4

Speed rpm 715 715 715 715 715

Motor input kW 0.78 0.78 0.78 0.78 0.78

Semi-hermetic

single screw compressor

D–EIMAC00704-14EN - 10/72

Table 4 – EWAD 210E ÷ 400E-SL - HFC 134a - Technical Data

Units Size 210 250 300 350 400

Capacity (1) Cooling kW 209 249 296 345 398

Capacity control

Unit power input (1) Cooling kW 72.1 84.5 110 134 150

EER (1) --- 2.89 2.95 2.69 2.58 2.65

ESEER --- 3.32 3.55 3.41 3.34 3.45

IPLV --- 3.48 3.86 3.75 3.63 3.76

Casing

Dimensions Unit

Weight

Water heat

exchanger

Air heat exchanger Type ---

Fan

Compressor

Sound level

Refrigerant circuit

Piping connections Evaporator water inlet/outlet " 3 3 3 3 3

Safety devices High discharge pressure (pressure switch)

High discharge pressure (pressure transducer)

Low suction pressure (pressure transducer)

Compressor motor protection

High discharge temperature

Low oil pressure

Low pressure ratio

High oil filter pressure drop

Phase monitor

Water freeze protection controller

Notes (1)

Notes (2)

Type --- Stepless

Minimum capacity % 25 25 25 25 25

Colour --- Ivory White

Material --- Galvanized and painted steel sheet

Unit kg 2186 2633 2856 2966 3029

Operating Weight kg 2216 2658 2886 3002 3073

Type --- Plate to Plate

Water volume l 30 25 30 36 44

Nominal water flow rate l/s 9.97 11.90 14.15 16.50 19.01

Nominal Water pressure drop kPa 20 46 45 44 42

Insulation material Closed cell

Type --- Direct propeller type

Drive --- DOL

Diameter mm 800 800 800 800 800

Nominal air flow l/s 16289 25117 25117 24433 24433

Model

Type --Oil charge l 13 16 19 19 19

Quantity No. 1 1 1 1 1

Sound Power Cooling dB(A) 91.7 91.7 92.0 92.0 92.7

Sound Pressure (2) Cooling dB(A) 72.6 72.5 72.8 72.8 73.5

Refrigerant type --- R-134a R-134a R-134a R-134a R-134a

Refrigerant charge kg. 33 46 46 56 60

N. of circuits No. 1 1 1 1 1

Cooling capacity, unit power input in cooling and EER are based on the following conditions: evaporator

12/7°C; ambient 35°C, unit at full load operation.

The values are according to ISO 3744 and are referred to: evaporator 12/7°C, ambient 35°C, full load

operation.

Height mm 2273 2223 2223 2223 2223

Width mm 1292 2236 2236 2236 2236

Length mm 3965 3070 3070 3070 3070

High efficiency fin and tube type

with integral subcooler

Quantity No. 4 6 6 6 6

Speed rpm 715 715 715 715 715

Motor input kW 0.78 0.78 0.78 0.78 0.78

Semi-hermetic

single screw compressor

D–EIMAC00704-14EN - 11/72

Table 5 – ERAD 120E ÷ 220E-SS - HFC 134a - Technical Data

Units Size 120 140 170 200 220

Capacity (1) Cooling kW 121 144 165 196 219

Capacity control

Unit power input (1) Cooling kW 41.8 51.0 57.4 65.2 73.7

EER (1) --- 2.90 2.83 2.87 3.00 2.97

Casing

Dimensions Unit

Weight

Air heat exchanger Type ---

Fan

Compressor

Sound level

Refrigerant circuit

Piping connections

Safety devices High discharge pressure (pressure switch)

High discharge pressure (pressure transducer)

Low suction pressure (pressure transducer)

Compressor motor protection

High discharge temperature

Low oil pressure

Low pressure ratio

High oil filter pressure drop

Phase monitor

Notes (1)

Notes (2) The values are according to ISO 3744 and are referred to: SST 7°C, ambient 35°C, full load operation.

Notes (3)

Type --- Stepless

Minimum capacity % 25 25 25 25 25

Colour --- Ivory White

Material --- Galvanized and painted steel sheet

Unit kg 1561 1584 1700 1741 1894

Operating Weight kg 1591 1617 1768 1781 1936

Type --- Direct propeller type

Drive --- DOL

Diameter mm 800 800 800 800 800

Nominal air flow l/s 10922 10575 16383 15863 21844

Model

Type --Oil charge (3) l 13 13 13 13 13

Quantity No. 1 1 1 1 1

Sound Power Cooling dB(A) 91.5 91.5 92.3 92.3 93.0

Sound Pressure (2) Cooling dB(A) 73.5 73.5 73.7 73.7 73.9

Refrigerant type --- R-134a R-134a R-134a R-134a R-134a

Refrigerant charge (3) kg. 17 20 22 27 29

N. of circuits No. 1 1 1 1 1

Suction mm 76 76 76 76 76

Liquid mm 28 28 28 28 28

Cooling capacity, unit power input in cooling and EER are based on the following conditions: SST 7°C;

ambient 35°C, unit at full load operation.

Refrigerant and oil charge is for the unit only; doesn't include external suction and liquid line. Units are

shipped without refrigerant and oil charge; holding charge nitrogen 0.5 bar

Height mm 2273 2273 2273 2273 2273

Width mm 1292 1292 1292 1292 1292

Length mm 2165 2165 3065 3065 3965

High efficiency fin and tube type

with integral subcooler

Quantity No. 2 2 3 3 4

Speed rpm 920 920 920 920 920

Motor input kW 1.75 1.75 1.75 1.75 1.75

Semi-hermetic

single screw compressor

D–EIMAC00704-14EN - 12/72

Table 6 – ERAD 250E ÷ 490E-SS - HFC 134a - Technical Data

Units Size 250 310 370 440 490

Capacity (1) Cooling kW 252 306 370 435 488

Capacity control

Unit power input (1) Cooling kW 76.6 92.8 122 147 161

EER (1) --- 3.28 3.30 3.04 2.96 3.03

Casing

Dimensions Unit

Weight

Air heat exchanger Type ---

Fan

Compressor

Sound level

Refrigerant circuit

Piping connections

Safety devices High discharge pressure (pressure switch)

High discharge pressure (pressure transducer)

Low suction pressure (pressure transducer)

Compressor motor protection

High discharge temperature

Low oil pressure

Low pressure ratio

High oil filter pressure drop

Phase monitor

Notes (1)

Notes (2) The values are according to ISO 3744 and are referred to: SST 7°C, ambient 35°C, full load operation.

Notes (3)

Type --- Stepless

Minimum capacity % 25 25 25 25 25

Colour --- Ivory White

Material --- Galvanized and painted steel sheet

Unit kg 1936 2353 2557 2640 2679

Operating Weight kg 1981 2414 2621 2713 2756

Type --- Direct propeller type

Drive --- DOL

Diameter mm 800 800 800 800 800

Nominal air flow l/s 21150 32767 32767 31725 31725

Model

Type --Oil charge (3) l 13 16 19 19 19

Quantity No. 1 1 1 1 1

Sound Power Cooling dB(A) 94.2 94.2 94.5 94.5 95.2

Sound Pressure (2) Cooling dB(A) 75.1 75.0 75.3 75.3 76.0

Refrigerant type --- R-134a R-134a R-134a R-134a R-134a

Refrigerant charge (3) kg. 32 45 45 54 58

N. of circuits No. 1 1 1 1 1

Suction mm 76 76 139.7 139.7 139.7

Liquid mm 28 35 35 35 35

Cooling capacity, unit power input in cooling and EER are based on the following conditions: SST 7°C;

ambient 35°C, unit at full load operation.

Refrigerant and oil charge is for the unit only; doesn't include external suction and liquid line. Units are

shipped without refrigerant and oil charge; holding charge nitrogen 0.5 bar

Height mm 2273 2273 2273 2273 2273

Width mm 1292 2236 2236 2236 2236

Length mm 3965 3070 3070 3070 3070

High efficiency fin and tube type

with integral subcooler

Quantity No. 4 6 6 6 6

Speed rpm 920 920 920 920 920

Motor input kW 1.75 1.75 1.75 1.75 1.75

Semi-hermetic

single screw compressor

D–EIMAC00704-14EN - 13/72

Table 7 – ERAD 120E ÷ 210E-SL - HFC 134a - Technical Data

Units Size 120 140 160 190 210

Capacity (1) Cooling kW 116 137 159 187 209

Capacity control

Unit power input (1) Cooling kW 42.3 52.5 57.6 66.3 73.9

EER (1) --- 2.74 2.61 2.75 2.82 2.83

Casing

Dimensions Unit

Weight

Air heat exchanger Type ---

Fan

Compressor

Sound level

Refrigerant circuit

Piping connections

Safety devices High discharge pressure (pressure switch)

High discharge pressure (pressure transducer)

Low suction pressure (pressure transducer)

Compressor motor protection

High discharge temperature

Low oil pressure

Low pressure ratio

High oil filter pressure drop

Phase monitor

Notes (1)

Notes (2) The values are according to ISO 3744 and are referred to: SST 7°C, ambient 35°C, full load operation.

Notes (3)

Type --- Stepless

Minimum capacity % 25 25 25 25 25

Colour --- Ivory White

Material --- Galvanized and painted steel sheet

Unit kg 1658 1684 1795 1841 1991

Operating Weight kg 1688 1717 1830 1881 2033

Type --- Direct propeller type

Drive --- DOL

Diameter mm 800 800 800 800 800

Nominal air flow l/s 8372 8144 12558 12217 16744

Model

Type --Oil charge (3) l 13 13 13 13 13

Quantity No. 1 1 1 1 1

Sound Power Cooling dB(A) 89.0 89.0 89.8 89.8 90.5

Sound Pressure (2) Cooling dB(A) 71.0 71.0 71.2 71.2 71.4

Refrigerant type --- R-134a R-134a R-134a R-134a R-134a

Refrigerant charge (3) kg. 17 20 22 27 29

N. of circuits No. 1 1 1 1 1

Suction mm 76 76 76 76 76

Liquid mm 28 28 28 28 28

Cooling capacity, unit power input in cooling and EER are based on the following conditions: SST 7°C;

ambient 35°C, unit at full load operation.

Refrigerant and oil charge is for the unit only; doesn't include external suction and liquid line. Units are

shipped without refrigerant and oil charge; holding charge nitrogen 0.5 bar

Height mm 2273 2273 2273 2273 2273

Width mm 1292 1292 1292 1292 1292

Length mm 2165 2165 3065 3065 3965

High efficiency fin and tube type

with integral subcooler

Quantity No. 2 2 3 3 4

Speed rpm 715 715 715 715 715

Motor input kW 0.78 0.78 0.78 0.78 0.78

Semi-hermetic

single screw compressor

D–EIMAC00704-14EN - 14/72

Table 8 – ERAD 240E ÷ 460E-SL - HFC 134a - Technical Data

Units Size 240 300 350 410 460

Capacity (1) Cooling kW 243 295 352 409 462

Capacity control

Unit power input (1) Cooling kW 78.2 91.5 122.4 150.1 167.2

EER (1) --- 3.11 3.23 2.88 2.73 2.76

Casing

Dimensions Unit

Weight

Air heat exchanger Type ---

Fan

Compressor

Sound level

Refrigerant circuit

Piping connections

Safety devices High discharge pressure (pressure switch)

High discharge pressure (pressure transducer)

Low suction pressure (pressure transducer)

Compressor motor protection

High discharge temperature

Low oil pressure

Low pressure ratio

High oil filter pressure drop

Phase monitor

Notes (1)

Notes (2) The values are according to ISO 3744 and are referred to: SST 7°C, ambient 35°C, full load operation.

Notes (3)

Type --- Stepless

Minimum capacity % 25 25 25 25 25

Colour --- Ivory White

Material --- Galvanized and painted steel sheet

Unit kg 2036 2455 2662 2755 2789

Operating Weight kg 2081 2516 2726 2828 2886

Type --- Direct propeller type

Drive --- DOL

Diameter mm 800 800 800 800 800

Nominal air flow l/s 16289 25117 25117 24433 24433

Model

Type --Oil charge (3) l 13 16 19 19 19

Quantity No. 1 1 1 1 1

Sound Power Cooling dB(A) 91.7 91.7 92.0 92.0 92.7

Sound Pressure (2) Cooling dB(A) 72.6 72.5 72.8 72.8 73.5

Refrigerant type --- R-134a R-134a R-134a R-134a R-134a

Refrigerant charge (3) kg. 32 45 45 54 58

N. of circuits No. 1 1 1 1 1

Suction mm 76 76 139.7 139.7 139.7

Liquid mm 28 35 35 35 35

Cooling capacity, unit power input in cooling and EER are based on the following conditions: SST 7°C;

ambient 35°C, unit at full load operation.

Refrigerant and oil charge is for the unit only; doesn't include external suction and liquid line. Units are

shipped without refrigerant and oil charge; holding charge nitrogen 0.5 bar

Height mm 2273 2273 2273 2273 2273

Width mm 1292 2236 2236 2236 2236

Length mm 3965 3070 3070 3070 3070

High efficiency fin and tube type

with integral subcooler

Quantity No. 4 6 6 6 6

Speed rpm 715 715 715 715 715

Motor input kW 0.78 0.78 0.78 0.78 0.78

Semi-hermetic

single screw compressor

D–EIMAC00704-14EN - 15/72

Unit

Unit

-

5

Unit

Unit

Table 9 - Sound levels EWAD E-SS – ERAD E-SS

size

EWA

100 120

120 140

140 170

160 200

180 220

210 250

280 310

310 370

360 440

410 490

Note: The values are according to ISO 3744 and are referred to units without pumps kit.

D

size

ERA

D

Sound pressure level at 1 m from the unit in semispheric free field (rif. 2 x 10

63 Hz 125 Hz 250 Hz 500 Hz

75.5 70.8 68.9 75.3 64.3 61.7 53.0 47.3 73.5 91.5

75.5 70.8 68.9 75.3 64.3 61.7 53.0 47.3 73.5 91.5

75.7 71.0 69.1 75.5 64.5 61.9 53.2 47.5 73.7 92.3

75.7 71.0 69.1 75.5 64.5 61.9 53.2 47.5 73.7 92.3

75.9 71.2 69.3 75.7 64.7 62.1 53.4 47.7 73.9 93.0

77.1 72.4 70.5 76.9 65.9 63.3 54.6 48.9 75.1 94.2

77.0 72.3 70.4 76.8 65.8 63.2 54.5 48.8 75.0 94.2

77.3 72.6 70.7 77.1 66.1 63.5 54.8 49.1 75.3 94.5

77.3 72.6 70.7 77.1 66.1 63.5 54.8 49.1 75.3 94.5

78.0 73.3 71.4 77.8 66.8 64.2 55.5 49.8 76.0 95.2

1000

Hz

2000

Hz

4000

Table 10 - Sound levels EWAD E-SL – ERAD E-SL

size

EWA

100 120

120 140

130 160

160 190

180 210

210 240

250 300

300 350

350 410

400 460

Note: The values are according to ISO 3744 and are referred to units without pumps kit.

D

size

ERA

D

Sound pressure level at 1 m from the unit in semispheric free field (rif. 2 x 10-5 Pa) Power

63 Hz 125 Hz 250 Hz 500 Hz

73.0 68.3 66.4 72.8 61.8 59.2 50.5 44.8 71.0 89.0

73.0 68.3 66.4 72.8 61.8 59.2 50.5 44.8 71.0 89.0

73.2 68.5 66.6 73.0 62.0 59.4 50.7 45.0 71.2 89.8

73.2 68.5 66.6 73.0 62.0 59.4 50.7 45.0 71.2 89.8

73.4 68.7 66.8 73.2 62.2 59.6 50.9 45.2 71.4 90.5

74.6 69.9 68.0 74.4 63.4 60.8 52.1 46.4 72.6 91.7

74.5 69.8 67.9 74.3 63.3 60.7 52.0 46.3 72.5 91.7

74.8 70.1 68.2 74.6 63.6 61.0 52.3 46.6 72.8 92.0

74.8 70.1 68.2 74.6 63.6 61.0 52.3 46.6 72.8 92.0

75.5 70.8 68.9 75.3 64.3 61.7 53.0 47.3 73.5 92.7

1000

Hz

2000

Hz

4000

Hz

Hz

8000

Hz

8000

Hz

Pa) Power

dB(A) dB(A)

dB(A) dB(A)

D–EIMAC00704-14EN - 16/72

Operating limits

Storing

The environment conditions have to be in the following limits:

Minimum ambient temperature : -20°C

Maximum ambient temperature : 57°C

Maximum R.H. : 95% not condensing

ATTENTION

Storing below the minimum temperature above mentioned may cause damage to components such as the electronic

controller and its LCD display.

WARNING

Storing above the maximum temperature cause opening of the safety valves on the compressors’ suction line.

ATTENTION

Storing in condensing atmosphere may damage the electronic components.

Operation

Operation is allowed within the limits mentioned in the following diagrams.

ATTENTION

Operation out of the mentioned limits may damage the unit.

For any doubts contact the factory.

D–EIMAC00704-14EN - 17/72

Figure 2 - Operating limits – EWAD E-SS/SL

Evap Leaving Water Temperature (°C)

(below

-10°C Amb.)

Glycol

Saturated Suction Temperature (°C)

(below

-

10°C Amb.)

(below 0°C)

COMP FULL LOAD ONLY

Above this line

(ICE Mode)

Ambient Temperature (°C)

Operation with

Fan Speed

Modulation required

(below 18°C Amb.

Temp for less than

3 fans units, below

10°C for 3 or more

Figure 3 - Operating limits – ERAD E-SS/SL

COMP FULL LOAD ONLY

Above this line

(ICE Mode)

Speedtroll required

Ambient Temperature (°C)

Check on rating tables for actual operating limit at full load.

D–EIMAC00704-14EN - 18/72

Frost protection

required

Fan Speed

Modulation required

(below 18°C Amb.

Temp for less than

3 fans units, below

10°C for 3 or more

Speedtroll required

Mechanical Installation

Shipping

The stability of the machine during shipping must be ensured. If the machine is shipped with a wooden cross-plank on its

base, this cross-plank must only be removed after the final destination has been reached.

Responsibility

The manufacturer declines all present and future responsibility for any damage to persons, animals or things caused by

negligence of operators failing to follow the installation and maintenance instructions in this Manual.

All safety equipment must be regularly and periodically checked in accordance with this manual and with local laws and

regulations regarding safety and environment protection.

Safety

The machine must be securely fixed to the ground.

It is essential to observe the following instructions:

- The machine can only be lifted using the hoist points marked in yellow that are fixed to its base. These are the only

points that can support the entire weight of the unit.

- Do not allow unauthorised and/or unqualified personnel access to the machine.

- It is forbidden to access the electrical components without having opened the machine’s main switch and switched off

the power supply.

- It is forbidden to access the electrical components without using an insulating platform. Do not access the electrical

components if water and/or moisture are present.

- All operations on the refrigerant circuit and on components under pressure must be carried out only by qualified

personnel.

- Replacement of a compressor or addition of lubricating oil must be carried out only by qualified personnel.

- Sharp edges and the surface of the condenser section could cause injury. Avoid direct contact.

- Switch off the machine’s power supply, by opening the main switch, before servicing the cooling ventilators and/or

compressors. Failure to observe this rule could result in serious personal injury.

- Avoid introducing solid objects into the water pipes while the machine is connected to the system.

- A mechanical filter must be applied to the water pipe to be connected to the heat exchanger inlet.

- The machine is supplied with safety valves, that are installed both on the high-pressure and on the low-pressure sides

of the refrigerant gas circuit.

- In case of sudden stop of the unit, follow the instructions on the ControlPanelOperatingManual which is part of the

on-board documentation delivered to the end user with this manual.

- It is recommended to perform installation and maintenance with other people. In case of accidental injury or unease,

it is necessary to:

- keep calm

- press the alarm button if present in the installation site

- move the injured person in a warm place far from the unit and in rest position

- contact immediately emergency rescue personnel of the building or if the Health Emergency Service

- wait without leaving the injured person alone until the rescue operators come

- give all necessary information to the the rescue operators

WARNING

Before carrying out any operation on the machine, please read carefully the instruction and operating manual.

Installation and maintenance must be carried out solely by qualified personnel that is familiar with provisions of the

law and local regulations and has been trained properly or has experience with this type of equipment.

WARNING

Avoid to install the chiller in areas that could be dangerous during maintenance operations, like for example

platforms without parapets or railings or areas not complying with the clearance requirements around the chiller.

D–EIMAC00704-14EN - 19/72

Moving and lifting

Avoid bumping and/or jolting during unloading from the lorry and moving the machine. Do not push or pull the machine

from any part other than the base frame. Block the machine from sliding inside the lorry in order to prevent damage to

the panels and to the base frame. Avoid any part of the machine falling during unloading and/or moving, as this could

cause serious damage.

All units of the series are supplied with four lifting points marked in yellow. Only use these points for lifting the unit, as

shown in figure 2.

Procedure for extracting the unit

from the container.

(Container kit Optional)

Note: The length and the width of the unit can be different from this drawing but the lifting method remains the same

Figure 4 - Lifting the unit

WARNING

Both the lifting ropes and the spacing bar and/or scales must be of sufficient size to support the machine safely. Please

verify the unit’s weight on the machine’s nameplate.

The weights shown in the “Technical data” tables in the “General Information” chapter refer to standard units.

Specific machines could have accessories that increase their overall weight (pumps, heat recovery, copper-copper

condenser coils, etc.).

WARNING

The machine must be lifted with the utmost attention and care. Avoid jolting when lifting and lift machine very slowly,

keeping it perfectly level.

Positioning and assembly

All units are produced for installation outdoors, on balconies or on the ground, provided that the area is free from

obstacles that could hamper air flow towards the condenser batteries.

The machine must be installed on a robust and perfectly level foundation; should the machine be installed on balconies

and/or attics, it could be necessary to use weight distribution beams.

For installation on the ground, a strong cement base that is at least 250 mm wider and longer than the machine must be

foreseen. Also, this base must be able to support the weight of the machine as declared in the technical specifications.

If the machine is installed in places that are easily accessible for people and animals, it is advisable to install battery and

compressor section protection grates.

D–EIMAC00704-14EN - 20/72

Tomensure the best possible performance on the installation site, the following precautions and instructions must be

followed:

Avoid air flow recirculation

Make sure that there are no obstacles to hamper air flow.

Air must circulate freely to ensure proper intake and expulsion.

Ensure strong and solid flooring to reduce noise and vibrations as much as possible.

Avoid installation in particularly dusty environments, in order to reduce soiling of condenser batteries.

The water in the system must be particularly clean and all traces of oil and rust must be removed. Installation of a

mechanical water filter is required for the machine’s input piping.

Minimum space requirements

It is fundamental to respect minimum distances on all units, in order to ensure optimum ventilation for the condenser

batteries. Limited installation space could reduce the normal air flow, thus significantly reducing the machine’s

performance and considerably increasing consumption of electrical energy.

When deciding where to position the machine and to ensure a proper air flow, the following factors must be taken into

consideration: avoid any warm air recirculation and insufficient supply to the air-cooled condenser.

Both these conditions can cause an increase of condensing pressure, which leads to a reduction in energy efficiency and

refrigerating capacity. Thanks to the geometry of their air-cooled condensers, the units are less affected by bad air

circulation situations.

Also, the software has a particular ability for calculationg the machine’s operating conditions and for optimising the load

under abnormal operating conditions.

Every side of the machine must be accessible for post-installation maintenance operations. Figure 3 shows the minimum

space required.

Vertical air expulsion must not be obstructed as this would significantly reduce capacity and efficiency.

If the machine is positioned in such a way as to be surrounded by walls or with obstacles of the same height as the

machine, it must be installed at a distance of at least 2500 mm. If these obstacles are higher, the machine must be

installed at a distance of at least 3000 mm.

Should the machine be installed without observing the recommended minimum distances from walls and/or vertical

obstacles, there could be a combination of warm air recirculation and/or insufficient supply to the air-cooled condenser

which could cause a reduction of capacity and efficiency.

Figure 5 - Minimum space requirements for machine maintenance

In any case, the microprocessor will allow the machine to adjust to new conditions by producing the maximum available

capacity, even if the lateral distance is lower than recommended.

When two or more machines are positioned side by side, a distance of at least 3600 mm between condenser batteries is

recommended.

For further solutions, please consult Daikin technicians.

D–EIMAC00704-14EN - 21/72

THE WIDTH OF THE UNIT CAN BE DIFFERENT BUT THE MINIMUM RECOMMENDED INSTALLATION DISTANCES

REMAIN THE SAME

Figure 6 - Minimum recommended installation distances

Sound protection

When sound levels require special control, great care must be exercised in isolating the machine from its base, by

appropriately applying antivibration devices (supplied optionally). Flexible joints must be installed on the water

connections, as well.

Water piping

The following instrucrion are applicable to units supplied with the evaporator installed in the package (EWAD E-SS/SL);

that may also be considered as general guidelines for water piping in units supplied without evaporator (ERAD E-SS/SL)

when used in conjuction with refrigerant to water evaporator.

Water piping must be designed with the lowest number of curves and the lowest number of vertical changes of direction.

In this way, installation costs are reduced considerably and system performance is improved.

The water system must have:

Anti-vibration supports in order to reduce transmission of vibrations to the underlying structure.

Sectioning valves to isolate the machine from the hydraulic system during servicing.

Manual or automatic air bleeding device at the system’s highest point. Drainage device at the system’s lowest point. Both

the evaporator and the heat recovery device must not be positioned at the system’s highest point.

A device that can maintain the hydraulic system under pressure (expansion tank, etc.)

Water temperature and pressure indicators on the machine to aid servicing and maintenance operations.

A filter or device that can remove extraneous particles from the water before it enters the pump (Please consult the pump

manufacturer’s recommendations for an appropriate filter to prevent cavitation). Use of a filter prolongs the life of the

pump and helps keep the hydraulic system in best condition. Evaporator filter is supplied for EWAD E-SS/SL.

Another filter must be installed on the pipe conveying ingoing water to the machine, near the evaporator and heat

recovery (if installed). The filter avoids solid particles entering the heat exchanger, as they could damage it or reduce its

heat exchanging capacity.

The shell and tube heat exchanger has an electrical resistance with a thermostat that ensures protection against water

freezing up to an outdoor temperature of – 25°C. All the other hydraulic piping outside the machine must therefore be

protected against freezing.

The heat recovery device must be emptied of water during the winter season, unless an ethylene glycol mixture in

appropriate percentage is added to the water circuit.

If the machine is installed in order to replace another, the entire hydraulic system must be emptied and cleaned before

the new unit is installed. Regular tests and proper chemical treatment of water are recommended before starting up the

new machine.

D–EIMAC00704-14EN - 22/72

In the event that glycol is added to the hydraulic system as anti-freeze protection, pay attention to the fact that intake

pressure will be lower, the machine’s performance will be lower and water pressure drops will be greater. All machineprotection methods, such as anti-freeze, and low-pressure protection will need to be reset.

Before insulating water piping, check that there are no leaks.

1 - Pressure Gauge

2 - Flexible connector

3 - Flow switch

4 - Temperature probe

5 - Isolation Valve

6 - Pump

7 - Filter

Figure 7 - Water piping connection for evaporator

1 - Pressure Gauge

2 - Flexible connector

3 - Temperature probe

4 - Isolation Valve

5 - Pump

6 - Filter

Figure 8 - Water piping connection for heat recovery exchangers

Water treatment

Before putting the machine into operation, clean the hydraulic circuit. Dirt, scales, corrosion residue and other

extraneous material can accumulate inside the heat exchanger and reduce its heat exchanging capacity. Pressure drops

can increase, as well, thus reducing water flow. Proper water treatment therefore reduces the risk of corrosion, erosion,

scaling, etc. The most appropriate water treatment must be determined locally, according to the type of system and to

the local characteristics of the process water.

The manufacturer is not responsible for damage to or malfunctioning of equipment caused by failure to treat water or by

improperly treated water.

D–EIMAC00704-14EN - 23/72

Table 11 - Acceptable water quality limits

-

2 -

24 -

+

PH (25°C)

Electrical conductivity µS/cm (25°C) <800

Chloride ion (mg Cl

Sulphate ion (mg SO

Alkalinity (mg CaCO3 / l)

/ l)

/ l)

6,8÷8,0

<200

<200

<100

Total Hardness (mg CaCO3 / l)

Iron (mg Fe / l)

Sulphide ion (mg S

Ammonium ion (mg NH

Silica (mg SiO2 / l)

/ l) Nessuno

/ l)

4

< 200

< 1.0

< 1.0

< 50

Evaporator and recovery exchangers anti-freeze protection

All evaporators are supplied with a thermostatically controlled anti-freeze electrical resistance, which provides adequate

anti-freeze protection up to –25°C. However, this method is not the only protection system against freezing, unless the

heat exchangers are completely emptied and cleaned with anti-freeze solution.

Two or more protection methods should be foreseen when designing the system as whole:

Continuous water flow circulation inside piping and exchangers.

Addition of an appropriate amount of glycol inside the water circuit

Additional heat insulation and heating of exposed piping

Emptying and cleaning of the heat exchanger during the winter season

It is the responsibility of the installer and/or of local maintenance personnel to ensure two or more of the described antifreeze methods. Continuously verify, through routine checks, that appropriate anti-freeze protection is maintained.

Failure to follow the instructions above could result in damage to some of the machine’s components. Damage from

freezing is not covered by the warranty.

Installing the flow switch

To ensure sufficient water flow through the evaporator, it is essential that a flow switch be installed on the water circuit.

The flow switch can be installed either on the ingoing or outgoing water piping. The purpose of the flow switch is to stop

the machine in the event of interrupted water flow, thus protecting the evaporator from freezing.

If the machine is supplied with total heat recovery, install another flow switch to ensure water flow before the machine’s

functioning is modified in Heat recovery Mode.

The flow switch on the recovery circuit prevents the machine turning off because of high pressure.

The manufacturer offers an optional flow switch that has been especially selected for this purpose; its identification code

is 131035072.

This flow switch, of the palette type, is suitable for heavy-duty outdoor applications (IP67) and suitable for piping with 1”

to 6” diameter.

The flow switch is provided with a clean contact which must be electrically connected to terminals 708 and 724 of

terminal board MC24 (check the unit wiring diagram for further information).

For further information regarding device positioning and settings, please read the instruction leaflet placed inside the

apparatus’ box.

For 3” 6” piping

Use palette b = 29 mm

3” 83 mm

4” 107 mm

5” 134 mm

6” 162 mm

Adjusting the flow switch’s

trigger sensitivity

Figure 9 - Adjusting the safety flow switch

D–EIMAC00704-14EN - 24/72

Hydronic kit (optional)

The optional hydronic kit foreseen for this series of machines (except CU Model) can be composed of a single in-line

pump or a twin in-line pump. According to the choice made when ordering the machine, the kit could be configured as in

the following figure.

Single pump kit

1 Victaulic joint

2 Water safety valve

3 Connecting manifold

4 Anti-freeze electrical resistance

5 Water pump (single or twin)

6 Automatic filling unit

(*) An expansion tgank has to be installed in the plant. It is not included in the kit

N.B.: Components on some machines could be arranged differently.

N.B.: Twin pumps are available only for some models. Check the price list for available combination

Figure 10 – Single and twin pump hydronic kit

Twin pump kit

D–EIMAC00704-14EN - 25/72

Figure 11 – EWAD E SS/SL - Available external lift for water pumps kit (option on

Water flow rate (l/s)

Water flow rate (l/s)

request) - Low lift single pump

Available lift (kPa)

Figure 12 – EWAD E-SS/SL - Available external lift for water pumps kit (option on

request) - High lift single pump

Available lift (kPa)

D–EIMAC00704-14EN - 26/72

A. EWAD100E-SS / SL

B. EWAD120E-SS / SL

C. EWAD140E-SS / EWAD130E-SL

D. EWAD160E-SS / SL

E. EWAD180E-SS / SL

F. EWAD210E-SS / SL

G. EWAD260E-SS / EWAD250E-SL

H. EWAD310E-SS / EWAD300E-SL

I. EWAD360E-SS / EWAD350E-SL

L. EWAD410E-SS / EWAD400E-SL

Figure 13 – EWAD E-SS/SL - Available external lift for water pumps kit (option on

E.

L.

Water flow rate (l/s)

Water flow rate (l/s)

request) - Low lift twin pump

Available lift (kPa)

Figure 14 – EWAD E-SS/SL - Available external lift for water pumps kit (option on

request) - High lift twin pump

Available lift (kPa)

A. EWAD100E-SS / SL

B. EWAD120E-SS / SL

C. EWAD140E-SS / EWAD130E-SL

D. EWAD160E-SS / SL

EWAD180E-SS / SL

F. EWAD210E-SS / SL

G. EWAD260E-SS / EWAD250E-SL

H. EWAD310E-SS / EWAD300E-SL

I. EWAD360E-SS / EWAD350E-SL

EWAD410E-SS / EWAD400E-SL

D–EIMAC00704-14EN - 27/72

N.

M.

Water flow rate (l/s)

Refrigerating circuit safety valves

Each system comes with safety valves that are installed on each circuit, both on the evaporator and on the condenser.

The purpose of the valves is to discharge the refrigerant inside the refrigerating circuit in the event of any malfunction.

WARNING

This unit is designed for installation outdoors. However, check that there is sufficient air circulation around the machine.

If the machine is installed in closed or partly covered areas, possible damage from inhalation of refrigerant gases must

be avoided. Avoid releasing the refrigerant in the environment.

The safety valves must be connected externally. The installer is responsible for connecting the safety valves to the

discharge piping and for establishing their size.

Figure 15 - Evaporator pressure drop – EWAD E-SS/SL

Evap Pressure Drops(kPa)

J. EWAD100E-SS / SL

K. EWAD120E-SS / SL

L. EWAD140E-SS / EWAD130E-SL

M. EWAD160E-SS / SL

EWAD180E-SS / SL

D–EIMAC00704-14EN - 28/72

O. EWAD210E-SS / SL

P. EWAD260E-SS / EWAD250E-SL

Q. EWAD310E-SS / EWAD300E-SL

R. EWAD360E-SS / EWAD350E-SL

EWAD410E-SS / EWAD400E-SL

W.

N.

Water flow rate (l/s)

Figure 16 - Heat recovery pressure drop – EWAD E-SS/SL

Pressure Drops(kPa)

S. EWAD100E-SS / SL

T. EWAD120E-SS / SL

U. EWAD140E-SS / EWAD130E-SL

V. EWAD160E-SS / SL

EWAD180E-SS / SL

X. EWAD210E-SS / SL

Y. EWAD260E-SS / EWAD250E-SL

Z. EWAD310E-SS / EWAD300E-SL

Å. EWAD360E-SS / EWAD350E-SL

EWAD410E-SS / EWAD400E-SL

D–EIMAC00704-14EN - 29/72

Guidelines for ERAD E-SS/SL Installation

Full Load

Full Load

Design of condensing unit application, and, in particular, sizing of piping and piping path, is a responsibility of plant

designer. This paragraph is only focused to give suggestion to plant designer, this suggestions have to be weighted with

references to application peculiarities.

Condensing units are shipped with holding nitrogen charge. It is important to keep the unit tightly closed until the remote

evaporator is installed and piped to the unit.

Installation of the refrigerant circuit must be done by a licensed technician and must comply with all relevant European

and national regulations.

It is the contractor’s responsibility to install the interconnection piping, leak test it and the entire system, evacuate the

system and supply the refrigerant charge.

All piping must be conformed to the applicable local and state codes.

Use refrigerant grade copper tubing only and isolate the refrigeration lines from building structures to prevent transfer of

vibration.

Do not use a saw to remove end caps. This might allow copper chips to contaminate the system. Use a tube cutter or

heat to remove caps. When sweating copper joints it is important to flow dry nitrogen through the system prior to

charging with refrigerant. This prevents scale formation and the possible formation of an explosive mixture of HFC-134a

and air. This will also prevent the formation of toxic phosgene gas, which occurs when HFC-134a is exposed to open

flame.

Soft solders are not to be used. For copper-to-copper joints use a phos-copper solder with 6% to 8% silver content. A

high silver content brazing rod must be used for copper-to-brass or copper-to-steel joints. Only use oxy-acetylene

brazing.

After the equipment is correctly installed, leak tested and evacuated , it can be charged with R134a refrigerant and

started under the supervision of Daikin authorized technician.

Refrigerant piping design

In order to minimize capacity loss, it is recommended to size the lines in such a way that the pressure drop of each line

does not result in an evaporating temperature decrease of more than 1°C.

Design of refrigeant piping depends on operating condition and, in particular, on evaporating temperature and suction

superheat, so values suggested in the following table have to be considered just as a reference; no claim may be

submitted to Daikin for wrong design of piping coming from the use of tables.

Table 12 - Recomandend maximum equivalent length (m) for Suction line

Cooling

Capacity (kW)

3" 1/8

2" 5/8

2" 1/4

Piping Size

1" 5/8

1" 3/8

Table 13 - Recomandend maximum equivalent length (m) for Liquid line

Cooling

Capacity (kW)

1" 5/8

1" 3/8

1" 1/4

Piping Size

7/8

3/4