Daikin EKOMBG22AAV1, EKOMBG33AAV1, EKOMBG28AAV1, EKOMB22AAV1, EKOMB28AAV1 Installation Instructions And Operators Manual

...

Daikin Europe NV

EKOMBG22AAV1

EKOMBG28AAV1

EKOMBG33AAV1

Installation instructions English

Daikin Europe N.V.

CE - DECLARATION-OF-CONFORMITY

CE - KONFORMITÄTSERKLÄRUNG

CE - DECLARATION-DE-CONFORMITE

CE - CONFORMITEITSVERKLARING

CE - DECLARACION-DE-CONFORMIDAD

CE - DICHIARAZIONE-DI-CONFORMITA

CE - ∆HΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ

CE - DECLARAÇÃO-DE-CONFORMIDADE

CE - ЗАЯВЛЕНИЕ-О-СООТВЕТСТВИИ

CE - OVERENSSTEMMELSESERKLÆRING

CE - FÖRSÄKRAN-OM-ÖVERENSTÄMMELSE

CE - ERKLÆRING OM-SAMSVAR

CE - ILMOITUS-YHDENMUKAISUUDESTA

CE - PROHLÁŠENÍ-O-SHODĚ

CE - IZJAVA-O-USKLAĐENOSTI

CE - MEGFELELŐSÉGI-NYILATKOZAT

CE - DEKLARACJA-ZGODNOŚCI

CE - DECLARAŢIE-DE-CONFORMITATE

CE - IZJAVA O SKLADNOSTI

CE - VASTAVUSDEKLARATSIOON

CE - ДЕКЛАРАЦИЯ-ЗА-ϹЪОТВЕТСТВИЕ

CE - ATITIKTIES-DEKLARACIJA

CE - ATBILSTĪBAS-DEKLARĀCIJA

CE - VYHLÁSENIE-ZHODY

CE - UYGUNLUK-BEYANI

01

are in conformity with the following standard(s) or other normative document(s), provided that these are used in accordance with our

instructions:

02

der/den folgenden Norm(en) oder einem anderen Normdokument oder -dokumenten entspricht/entsprechen, unter der Voraussetzung,

daß sie gemäß unseren Anweisungen eingesetzt werden:03sont conformes à la/aux norme(s) ou autre(s) document(s) normatif(s), pour autant qu'ils soient utilisés conformément à nos instructions:04conform de volgende norm(en) of één of meer andere bindende documenten zijn, op voorwaarde dat ze worden gebruikt overeenkomstig

onze instructies:05están en conformidad con la(s) siguiente(s) norma(s) u otro(s) documento(s) normativo(s), siempre que sean utilizados de acuerdo con

nuestras instrucciones:

06

sono conformi al(i) seguente(i) standard(s) o altro(i) documento(i) a carattere normativo, a patto che vengano usati in conformità alle

nostre istruzioni:07είναι σύμφωνα με το(α) ακόλουθο(α) πρότυπο(α) ή άλλο έγγραφο(α) κανονισμών, υπό την προϋπόθεση ότι χρησιμοποιούνται σύμφωνα

με τις οδηγίες μας:

08

estão em conformidade com a(s) seguinte(s) norma(s) ou outro(s) documento(s) normativo(s), desde que estes sejam utilizados de

acordo com as nossas instruções:09соответствуют следующим стандартам или другим нормативным документам, при усл овии их использования согласно нашим

инструкциям:

10

overholder følgende standard(er) eller andet/andre retningsgivende dokument(er), forudsat at disse anvendes i henhold til vore

instrukser:11respektive utrustning är utförd i överensstämmelse med och följer följande standard(er) eller andra normgivande dokument, under

förutsättning att användning sker i överensstämmelse med våra instruktioner:12respektive utstyr er i overensstemmelse med følgende standard(er) eller andre normgivende dokument(er), under forutssetning av at

disse brukes i henhold til våre instrukser:13vastaavat seuraavien standardien ja muiden ohjeellisten dokumenttien vaatimuksia edellyttäen, että niitä käytetään ohjeidemme

mukaisesti:14za předpokladu, že jsou využívány v souladu s našimi pokyny, odpovídají následujícím normám nebo normativním dokumentům:15u skladu sa slijedećim standardom(ima) ili drugim normativnim dokumentom(ima), uz uvjet da se oni koriste u skladu s našim uputama:

16

megfelelnek az alábbi szabvány(ok)nak vagy egyéb irányadó dokumentum(ok)nak, ha azokat előírás szerint használják:17spełniają wymogi następujących norm i innych dokumentów normalizacyjnych, pod warunkiem że używane są zgodnie z naszymi

instrukcjami:

18

sunt în conformitate cu următorul (următoarele) standard(e) sau alt(e) document(e) normativ(e), cu condiţia ca acestea să fie utilizate în

conformitate cu instrucţiunile noastre:19skladni z naslednjimi standardi in drugimi normativi, pod pogojem, da se uporabljajo v skladu z našimi navodili:20on vastavuses järgmis(t)e standardi(te)ga või teiste normatiivsete dokumentidega, kui neid kasutatakse vastavalt meie juhenditele:21съответстват на следните стандарти или други нормативни документи, при условие, че се използват съгласно нашите

инструкции:

22

atitinka žemiau nurodytus standartus ir (arba) kitus norminius dokumentus su sąlyga, kad yra naudojami pagal mūsų nurodymus:23tad, ja lietoti atbilstoši ražotāja norādījumiem, atbilst sekojošiem standartiem un citiem normatīviem dokumentiem:24sú v zhode s nasledovnou(ými) normou(ami) alebo iným(i) normatívnym(i) dokumentom(ami), za predpokladu, že sa používajú v súlade

s našim návodom:25ürünün, talimatlarımıza göre kullanılması koşuluyla aşağıdaki standartlar ve norm belirten belgelerle uyumludur:

01

Directives, as amended.02Direktiven, gemäß Änderung.03Directives, telles que modifiées.04Richtlijnen, zoals geamendeerd.05Directivas, según lo enmendado.06Direttive, come da modifica.07Οδηγιών, όπως έχουν τροποποιηθεί.08Directivas, conforme alteração em.09Директив со всеми поправками.

10

Direktiver, med senere ændringer.11Direktiv, med företagna ändringar.12Direktiver, med foretatte endringer.13Direktiivejä, sellaisina kuin ne ovat muutettuina.14v platném znění.15Smjernice, kako je izmijenjeno.16irányelv(ek) és módosításaik rendelkezéseit

.

17

z późniejszymi poprawkami.18Directivelor, cu amendamentele respective.

19

Direktive z vsemi spremembami.20Direktiivid koos muudatustega.21Директиви, с техните изменения.22Direktyvose su papildymais.23Direktīvās un to papildinājumos.24Smernice, v platnom znení.25Deǧiştirilmiş halleriyle Yönetmelikler.

01

following the provisions of:02gemäß den Vorschriften der:03conformément aux stipulations des:04overeenkomstig de bepalingen van:05siguiendo las disposiciones de:06secondo le prescrizioni per:07με τήρηση των διατάξεων των:08de acordo com o previsto em:09в соответствии с положениями:

10

under iagttagelse af bestemmelserne i:11enligt villkoren i:12gitt i henhold til bestemmelsene i:13noudattaen määräyksiä:14za dodržení ustanovení předpisu:15prema odredbama:16követi a(z):17zgodnie z postanowieniami Dyrektyw:18în urma prevederilor:

19

ob upoštevanju določb:20vastavalt nõuetele:21следвайки клаузите на:22laikantis nuostatų, pateikiamų:23ievērojot prasības, kas noteiktas:24održiavajúc ustanovenia:25bunun koşullarına uygun olarak:

01 Note *

as set out in

<A>

and judged positively by

<B>

according to the

Certificate <C>

.

02 Hinweis *

wie in

<A>

aufgeführt und von

<B>

positiv beurteilt

gemäß

Zertifikat <C>

.

03 Remarque *

tel que défini dans

<A>

et évalué positivement par

<B>

conformément au

Certificat <C>

.

04 Bemerk *

zoals vermeld in

<A>

en positief beoordeeld door

<B>

overeenkomstig

Certificaat <C>

.

05 Nota *

como se establece en

<A>

y es valorado

positivamente por

<B>

de acuerdo con el

Certificado <C>

.

06 Nota *

delineato nel

<A>

e giudicato positivamente

da

<B>

secondo il

Certificato <C>

.

07 Σημείωση *

όπως καθορίζεται στο

<A>

και κρίνεται θετικά από

το

<B>

σύμφωνα με το

Πιστοποιητικό <C>

.

08 Nota *

tal como estabelecido em

<A>

e com o parecer

positivo de

<B>

de acordo com o

Certificado <C>

.

09 Примечание *

как указано в

<A>

и в соответствии

сположительным решением

<B>

согласно

Свидетельству <C>

.

10 Bemærk *

som anført i

<A>

og positivt vurderet af

<B>

i henhold til

Certifikat <C>

.

11 Information *

enligt

<A>

och godkänts av

<B>

enligt

Certifikatet <C>

.

12 Merk *

som det fremkommer i

<A>

og gjennom positiv

bedømmelse av

<B>

ifølge

Sertifikat <C>

.

13 Huom *

jotka on esitetty asiakirjassa

<A>

ja jotka

<B>

on

hyväksynyt

Sertifikaatin <C>

mukaisesti.

14 Poznámka *

jak bylo uvedeno v

<A>

a pozitivně zjištěno

<B>

v souladu s

osvědčením <C>

.

15 Napomena *

kako je izloženo u

<A>

i pozitivno ocijenjeno

od strane

<B>

prema

Certifikatu <C>

.

16 Megjegyzés *

a(z)

<A>

alapján, a(z)

<B>

igazolta a megfelelést,

a(z)

<C> tanúsítvány

szerint.

17 Uwaga *

zgodnie z dokumentacją

<A>

, pozytywną opinią

<B>

i

Świadectwem <C>

.

18 Notă *

aşa cum este stabilit în

<A>

şi apreciat pozitiv

de

<B>

în conformitate cu

Certificatul <C>

.

19 Opomba *

kot je določeno v

<A>

in odobreno s strani

<B>

v skladu s

certifikatom <C>

.

20 Märkus *

nagu on näidatud dokumendis

<A>

ja heaks

kiidetud

<B>

järgi vastavalt

sertifikaadile <C>

.

21 Забележка

* както е изложено в

<A>

и оценено положително

от

<B>

съгласно

Сертификата <C>

.

22 Pastaba *

kaip nustatyta

<A>

ir kaip teigiamai nuspręsta

<B>

pagal

Sertifikatą <C>

.

23 Piezīmes *

kā norādīts

<A>

un atbilstoši

<B>

pozitīvajam

vērtējumam saskaņā ar

sertifikātu <C>

.

24 Poznámka *

ako bolo uvedené v

<A>

a pozitívne zistené

<B>

v súlade s

osvedčením <C>

.

25 Not * <A>

’da belirtildiği gibi ve

<C> Sertifikasına

göre

<B>

tarafından olumlu olarak değerlendirildiği gibi.

<A> 177155_EMC2/03-2011

<B> KIWA (NB0063)

<C> -

01

a

declares under its sole responsibility that the equipment to which this declaration relates:

02

d

erklärt auf seine alleinige Verantwortung daß die Ausrüstung für die diese Erklärung bestimmt ist:

03

f

déclare sous sa seule responsabilité que l'équipement visé par la présente déclaration:

04

l

verklaart hierbij op eigen exclusieve verantwoordelijkheid dat de apparatuur waarop deze verklaring betrekking heeft:

05

e

declara bajo su única responsabilidad que el equipo al que hace referencia la declaración:

06

i

dichiara sotto la propria responsabilità che gli apparecchi a cui è riferita questa dichiarazione:

07

g

δηλώνει με αποκλειστική της ευθύνη ότι ο εξοπλισμός στον οποίο αναφέρεται η παρούσα δήλωση:

08

p

declara sob sua exclusiva responsabilidade que os equipamentos a que esta declaração se refere:

09

u

заявляет, исключительно под свою ответственность, что

оборудование,

к котором

у

относи тся настоящее заявление:

10

q

erklærer under eneansvarlig, at udstyret, som er omfattet af denne erklæring:

11

s

deklarerar i egenskap av huvudansvarig, att utrustningen som berörs av denna deklaration innebär att:

12

n

erklærer et fullstendig ansvar for at det utstyr som berøres av denne deklarasjon innebærer at:

13

j

ilmoittaa yksinomaan omalla vastuullaan, että tämän ilmoituksen tarkoittamat laitteet:

14

c

prohlašuje ve své plné odpovědnosti, že zařízení, k němuž se toto prohlášení vztahuje:

15

y

izjavljuje pod isključivo vlastitom odgovornošću da oprema na koju se ova izjava odnosi:

16

h

teljes felelőssége tudatában kijelenti, hogy a berendezések, melyekre e nyilatkozat vonatkozik:

17

m

deklaruje na własną i wyłączną odpowiedzialność, że urządzenia, których ta deklaracja dotyczy:

18

r

declară pe proprie răspundere că echipamentele la care se referă această declaraţie:

19

o

z vso odgovornostjo izjavlja, da je oprema naprav, na katero se izjava nanaša:

20

x

kinnitab oma täielikul vastutusel, et käesoleva deklaratsiooni alla kuuluv varustus:

21

b

декларира на своя отговорност, че оборудването, за коeто се отнася тази декларация:

22

t

visiška savo atsakomybe skelbia, kad įranga, kuriai taikoma ši deklaracija:

23

v

ar pilnu atbildību apliecina, ka tālāk aprakstītās iekārtas, uz kurām attiecas šī deklarācija:

24

k

vyhlasuje na vlastnú zodpovednosť, že zariadenie, na ktoré sa vzťahuje toto vyhlásenie:

25

w

tamamen kendi sorumluluǧunda olmak üzere bu bildirinin ilgili olduǧu donanımının aşaǧıdaki gibi olduǧunu beyan eder:

EN60335-2-40,

2P369568-1

Shigeki Morita

Director

Ostend, 3rd of March 2014

Low Voltage 2006/95/EC

Gas Appliances 2009/142/EC

Boiler Efficiency requirements 92/42/EEC

Electromagnetic Compatibility 2004/108/EC *

EKOMBG22AAV1*, EKOMBG28AAV1*, EKOMBG33AAV1*,

EKOMB22AAV1*, EKOMB28AAV1*, EKOMB33AAV1*,

* = , , 1, 2, 3, ..., 9

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9

10

11

© 2014 Daikin Europe NV

All rights reserved.

The information provided applies to the product in its standard version. Daikin Europe NV can therefore not be held liable for any damages arising from any

specifications of the product which deviate from the standard version. The available information has been compiled with the greatest possible care, but Daikin Europe

NV can not be held liable for any mistakes in the information, or for any consequences thereof. Daikin Europe NV cannot be held liable for any damage arising from

work carried out by third parties.

Subject to change.

Safety instructions 4

Unit description 5

2.1 General ............................................................................................................................................................................................ 5

2.2 Functioning ...................................................................................................................................................................................... 5

2.3 Operating modes ............................................................................................................................................................................. 5

2.4 PC Interface .................................................................................................................................................................................... 7

2.5 Test programs ................................................................................................................................................................................. 7

Main components 8

3.1 Accessories ..................................................................................................................................................................................... 9

Installation 10

4.1 Installation measurements ............................................................................................................................................................ 10

4.2 Installation space ........................................................................................................................................................................... 12

4.3 Assembly ....................................................................................................................................................................................... 13

Connecting 14

5.1 Connecting CH installation ............................................................................................................................................................ 15

5.2 Connecting DHW installation ......................................................................................................................................................... 17

5.3 Connecting electronically .............................................................................................................................................................. 18

5.4 Connect room thermostat .............................................................................................................................................................. 19

5.5 Connecting gas ............................................................................................................................................................................. 20

5.6 Flue gas output and air input ......................................................................................................................................................... 21

5.7 Outlet systems ............................................................................................................................................................................... 22

Commissioning the unit and the Installation 35

6.1 Filling and air purge of unit and installation ................................................................................................................................... 35

6.2 Commissioning the unit ................................................................................................................................................................. 36

6.3 Switching off the unit ..................................................................................................................................................................... 37

Setting and adjustment 38

7.1 Direct via operating panel .............................................................................................................................................................. 38

7.2 Parameter settings via the service code ....................................................................................................................................... 39

7.3 Setting maximum CH power .......................................................................................................................................................... 41

7.4 Set pump capacity ......................................................................................................................................................................... 41

7.5 Weather dependent regulation ...................................................................................................................................................... 41

7.6 Conversion to different type of gas................................................................................................................................................ 42

7.7 Gas/air regulation .......................................................................................................................................................................... 42

7.8 Setting gas/air regulation ............................................................................................................................................................... 43

Malfunctions 45

8.1 Show last malfunction ................................................................................................................................................................... 45

8.2 Malfunction codes ......................................................................................................................................................................... 45

Maintenance 49

Technical specifications 51

10.1 Electrical diagram .......................................................................................................................................................................... 52

10.2 NTC resistances ............................................................................................................................................................................ 53

Warranty conditions 54

Daikin Europe NV

3

These installation instructions

Description

To be referred to as

High Efficiency

HR

Daikin EKOMBG22AAV1, EKOMBG28AAV1 and

Unit

Unit with piping for central heating

CH installation

System with pipes for domestic hot water

DHW installation

CAUTION

IMPORTANT

will have a negative effect on the functioning of the

With these installation instructions, you can safely assemble, install and maintain the

unit. Carefully follow the instructions.

In case of any doubt, please contact the manufacturer.

Keep the installation instructions near the unit.

Abbreviations and terms used

EKOMBG33AAV1 wall-mounted gas boiler.

Symbols

The following symbols are used in this manual:

Procedures which - if they are not carried out with the

necessary care - may cause damage to the product, the

surroundings, the environment or injury.

Procedures and/or instructions which, if they are not

followed,

unit.

Service and technical support for the installer

For information about specific settings, installation, maintenance and repair work, as

an installer, please contact your local Daikin dealer.

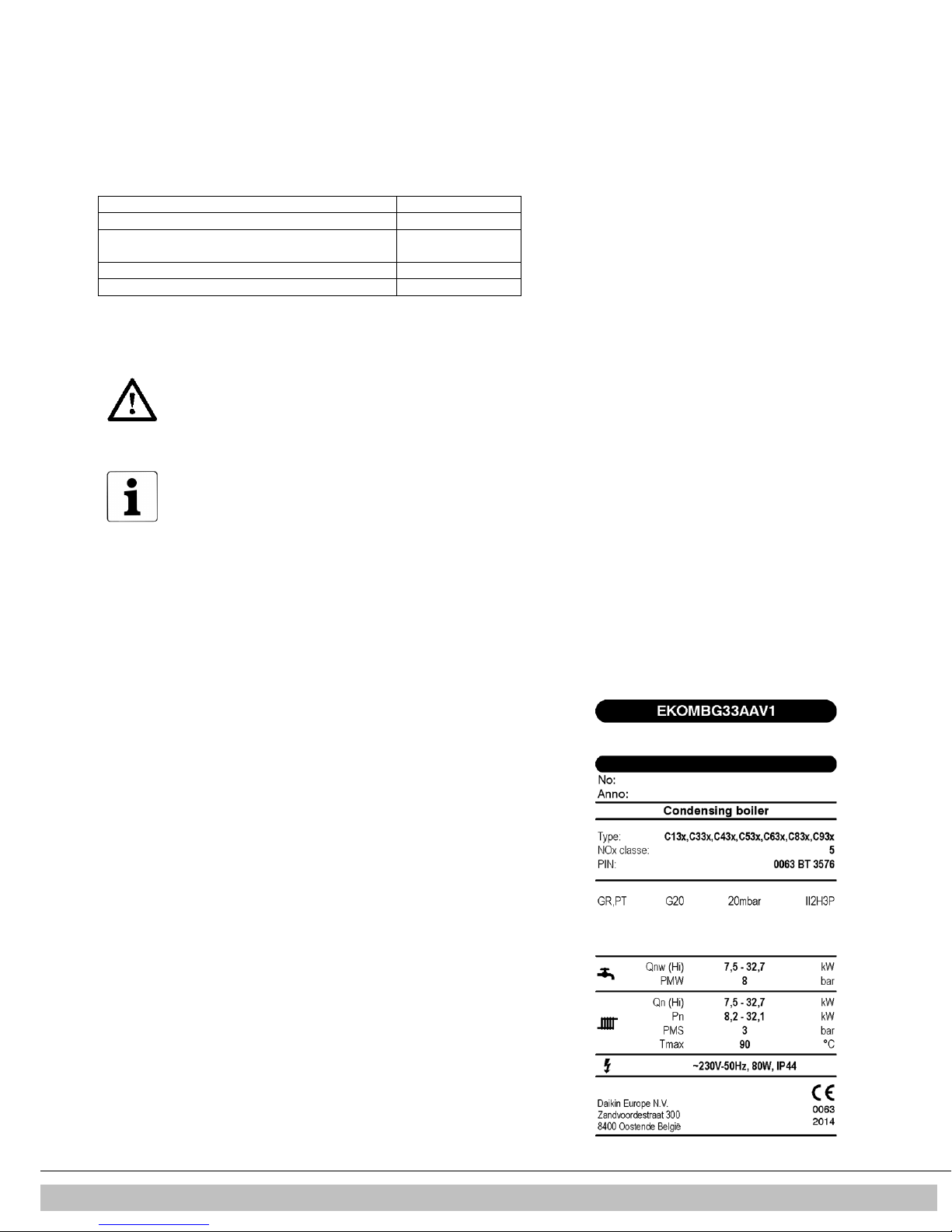

Identification of the product

You will find the unit details on the type plate on the bottom of the unit.

A. Unit type

B. Bar code with article number and serial number

C. Options

1 SAFETY INSTRUCTIONS

The manufacturer Daikin accepts no liability for damage or injury caused by the

failure to (strictly) observe the safety instructions, or negligence during the

installation of the Daikin EKOMBG*AAV1 wall-mounted gas boiler and any

associated accessories.

This device is not intended for use by people (including children) with reduced

physical, sensory or mental abilities, or lack of experience and knowledge, unless

they are given supervision or instructions on the use of the device by a person who

is responsible for their safety.

The instructions are stated separately for the various disciplines.

The entire installation must meet the applicable local technical and (safety)

instructions, for the gas installation, the electrical installation, smoke extraction

installation, drinking water installation, and central heating installation.

Daikin Europe NV 4

2 UNIT DESCRIPTION

2.1 General

The Daikin EKOMBG*AAV1 wall-mounted gas boiler is a closed unit. The unit is

intended to provide heat to the water of a CH-installation and the domestic hot water

installation.

The air supply and the combustion gas outlet of the EKOMBG*AAV1 can be connected

to the unit by two separate pipes, or by a concentric connection. The unit was tested in

combination with the combi feedthrough, but the unit may also be connected to combi

feedthroughs which meet the universal test standards for combi feedthroughs.

The unit can be connected to an assembly bracket if required, a frame with top

connection, and various installation sets. These are provided separately.

The Daikin EKOMBG*AAV1 wall-mounted gas boilers have the CE quality mark,

electrical protection class IP44.

It is possible to use the unit solely for warm water, or solely for heating. The system

which is not in use, does not need to be connected (see par. 7.2).

The unit is delivered for natural gas (G25) as a standard. On request, the unit can also

be provided for propane (G31).

2.2 Functioning

The Daikin EKOMBG*AAV1 wall-mounted gas boiler is a modulating high-efficiency

boiler. This means that the power is modulated to suit the required heat demand. In the

aluminum heat exchanger two separate copper circuits are integrated.

The separate circuits for CH and warm water allow the heating and warm water supply

to function independently. The hot water supply takes precedence over the heating.

Both cannot work at the same time.

The unit is fitted with an electronic boiler controller machine, which operates the fan

and the modulating pump at every heat requirement of the heating or the warm water

supply, opens the gas valve, ignites the boiler controller, and continuously monitors

and regulates the flame, depending on the requested power. The pump is only

operated during a heat request from the heating, depending on the requested power.

2.3 Operating modes

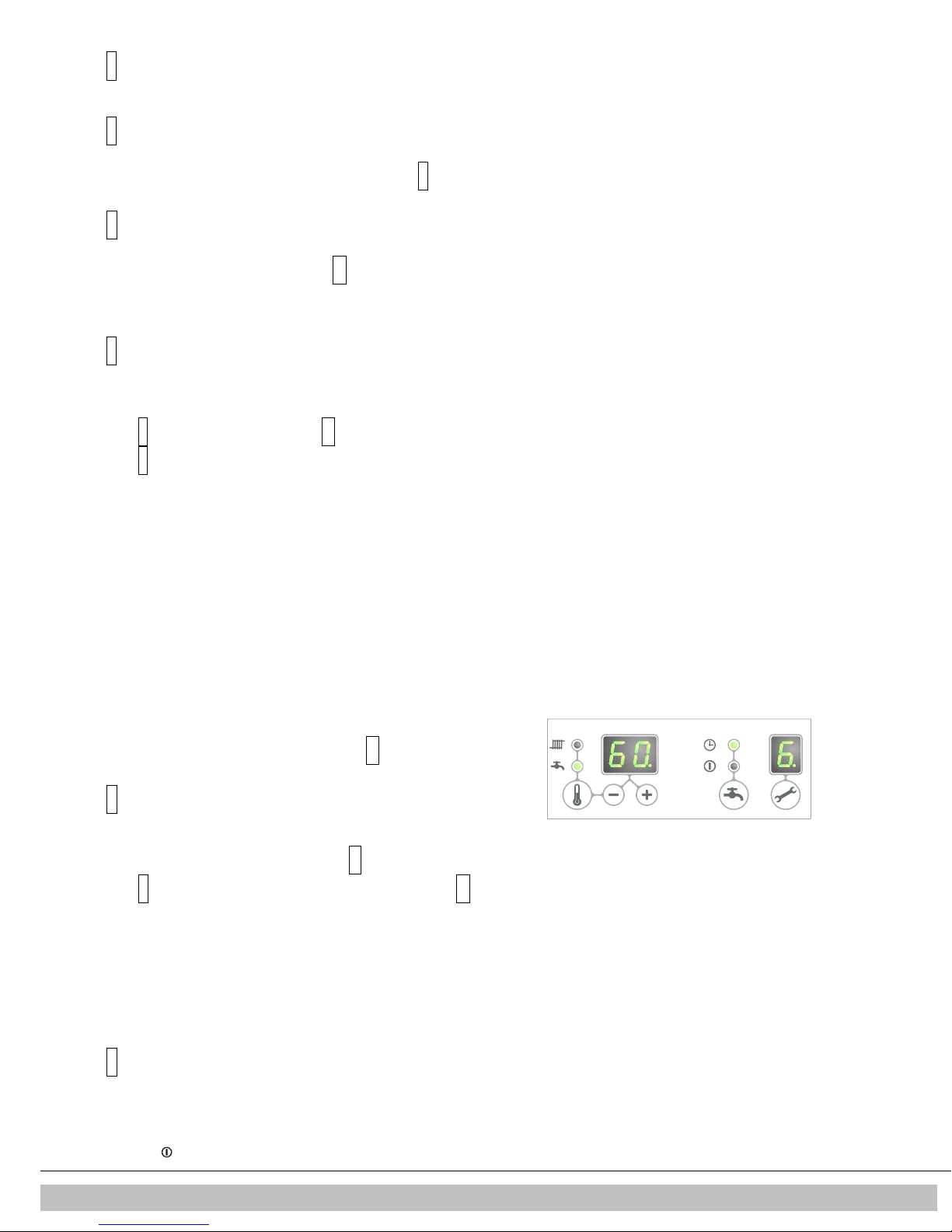

The operating mode of the unit is indicated by means of a code on the service display

of the operating panel.

-

Off

The unit is not in operation, but is connected to the electricity supply. No response is

given to requests for domestic hot water or CH water. The unit frost protection is

active. This means that the pump will start running and the exchanger will be heated

up if the temperature of the water in the system drops too far.

If the frost protection intervenes, the code

The pressure in the CH installation can also be read from the temperature display in

this operating mode (in bar).

Standby

The LED at the key is lit and possibly one of the LEDs of the tap comfort function.

The unit is ready to respond to a request for CH or tap water.

0

Post-running CH

After the end of the CH-operation, the pump will post-run. The post-pumping time is set

to the value in par. 7.2 in its factory settings. This setting can be changed. In addition

to this, the pump will run automatically 1 time per 24 hours, for 10 seconds, in order to

prevent it from getting stuck. This automatic switching on of the pump takes place at

the time of the last heating request. In order to change this, the room thermostat needs

to be set higher for a moment, at the required time of day.

1

Requested temperature reached

The boiler controller may temporarily block the heat request. The boiler controller will

then be stopped. The block occurs because the required temperature has been

reached. When the temperature has sufficiently decreased, the block will be lifted.

Daikin Europe NV

7

will be displayed (heating up exchanger).

5

2

Selftest

Once every 24 hours, the boiler controller tests the connected sensors. During the

test, the controller will not carry out any other tasks.

3

Ventilating

When the unit is started, the fan is first brought up to its correct start rpm. When the

start rpm is reached, the boiler controller will be ignited. Code 3 is also visible when

there is post-fanning after the boiler controller is stopped.

4

Igniting

When the fan has reached the start rpm, the boiler controller will be ignited by means

of electrical sparks. During the ignition, code

does not ignite, a new attempt will be made after approximately 15 seconds. If after 4

ignition attempts, the boiler controller has still not been ignited, the controller will go

into down-time.

5

CH-operation

An on/off thermostat, an OpenTherm thermostat, an outdoor sensor or a combination

thereof can be connected to the controller (see par. 10.1)

When there is a heat request from a thermostat, after the fan has started running

(code 3 ), the ignition will take place (code

(code 5 ).

During CH operation, the rpm of the fan and therefore the power of the unit can be

adjusted so the temperature of the CH water to the required CH supply temperature

can be controlled. If an on/off thermostat has been connected, this will be the CH

supply temperature set on the display. In case of an OpenTherm or wireless

thermostat, the required CH supply temperature is determined by the thermostat. In

case of an outdoor sensor, the required CH supply temperature is determined by the

fuel line programmed in the boiler controller. For the last two situations, the

temperature set on the display is the maximum.

During CH operation, the requested CH supply temperature will be displayed on the

operating panel.

The CH supply temperature can be set between 30 and 90°C (see par. 7.1). Caution:

for a low temperature system, a lower maximum setting may be required than the

standard setting of 80°C.

You can press the service button during CH operation to read the actual CH supply

temperature.

4

is displayed. If the boiler controller

4

) followed by the CH operating mode

If the tap comfort function is switched on (see code

of less than 40 degrees will be generated.

6

Domestic hot water operation

The hot water supply takes precedence over the heating. If the flow switch senses a

request for more than 2 l/min of domestic hot water, any CH requests will be

interrupted. After the fan has switched on (code

(code 4 ), the controller will switch to domestic water operation (code

domestic hot water operation, the rpm of the fan, and therefore the power of the unit,

is controlled by the controller on the basis of the set tap water temperature.

The control system ensures the tap water temperature is correct. The water

temperature can be set between 40°C and 65°C (see par. 7.1).

The set tap water temperature is displayed on the operation panel. The standard

setting is 60°C.

You can press the service button during tap water operation to read the actual tap

water temperature.

7

Heating up unit

In order to provide a fast supply of domestic hot water, a so-called tap comfort

function has been installed in the unit. This function keeps the heat exchanger at the

right temperature (it can be set, see par. 7.2). The tap comfort function has the

following settings:

•

On: ( LED on) The tap comfort function of the unit is continuously switched on.

Daikin Europe NV 6

7

), an OpenTherm heat request

3

) and there has been an ignition

6

). During

The unit always immediately provides warm water.

Description of program

Button combination

Display reading

Burner on with minimum

DHW

Burner on with set maximum CH

Burner on with maximum

DHW power

Current operation

The unit is fitted with frost protection in order to prevent it from

ntervenes, code

frost thermostat on the return pipe.

•

Eco: ( LED on) The tap comfort function of the unit is self-learning. The unit will

adjust to the usage pattern of the domestic hot water. This means the heat

exchanger will not be kept warm during the night or during longer absences.

•

Off: (Both LEDs off) The heat exchanger is not kept warm which means the supply of

domestic hot water takes a bit of time. If there is no need for fast delivery of domestic

hot water, the tap comfort function can be switched off.

In the settings "on" and "eco" , the unit meets the requirements of the Gaskeur

[Gas Inspection] CW standards.

2.4 PC Interface

The boiler controller is provided with an interface for a PC. A PC can communicate with

the CH boiler by means of a special dongle, and the associated software. This facility

enables you to follow the behavior of the boiler controller, the unit and the heat

installation over a long period.

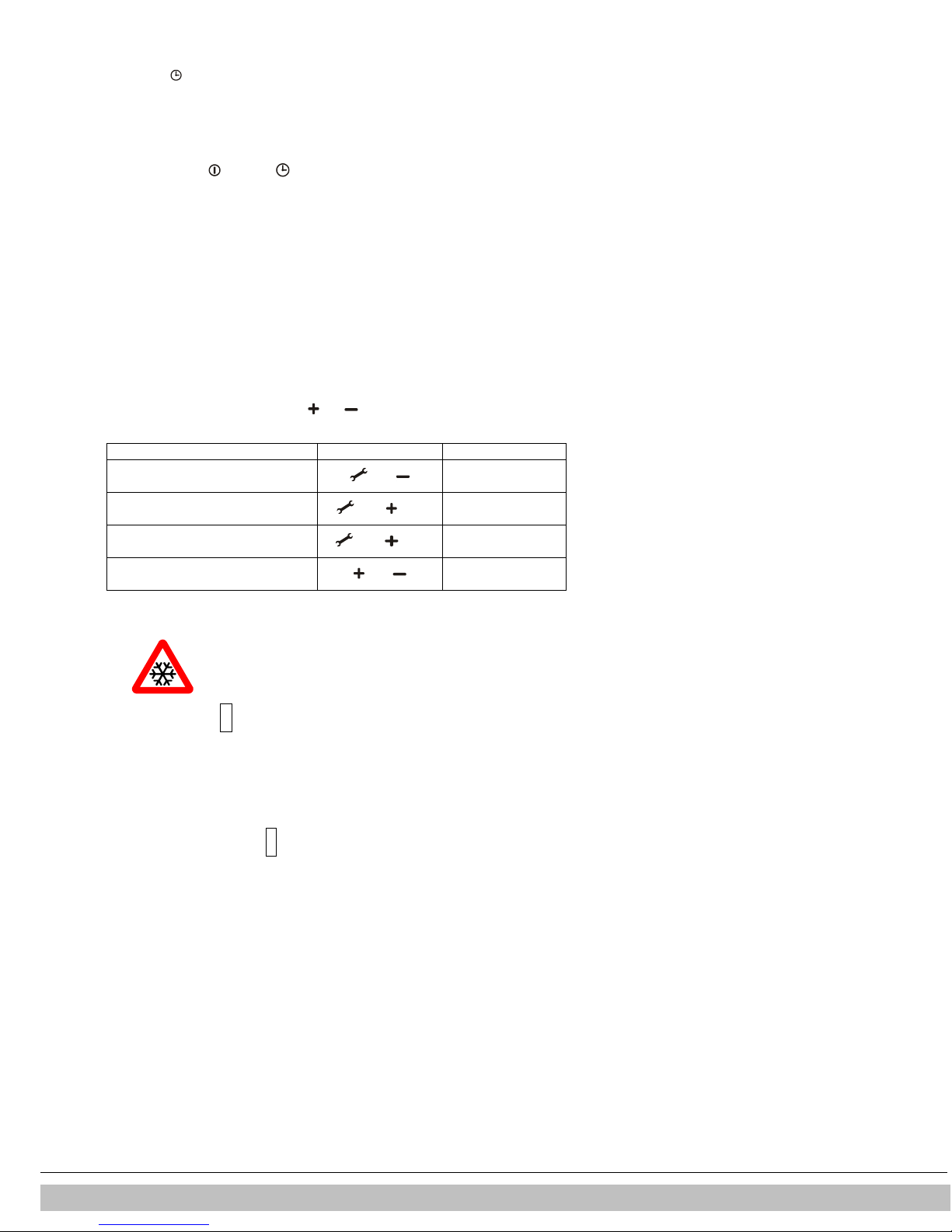

2.5 Test programs

There is an option in the boiler controller, to bring the unit into a test status.

Activating a test program, will switch on the unit with a set fan rotations per minute,

without the control functions intervening.

The safety functions do remain active.

The test program is ended by pressing and simultaneously.

Test programs

capacity (see parameter d par. 7.2)

power (see parameter 3 par. 7.2)

(see parameter 3 par. 7.2)

Switching off test program and

and

and (1x)

and (2x)

"L"

"h"

"H"

situation

2.5.1 Frost protection

•

freezing. If the temperature of the heat exchanger drops too low,

the pump will start running until the temperature of the heat

exchanger is sufficiently high. If the frost protection i

7‘

will be displayed (heating up exchanger).

•

If the installation (or a part thereof) can freeze, the coldest place

should be fitted with an (external)

This must be connected in accordance with the electrical diagram

(see par. 10.1).

Note

When the unit is switched off (

remain active, however a heat request from an (external) frost thermostat will be ignored.

-

on the service display), the unit frost protection will

Daikin Europe NV

7

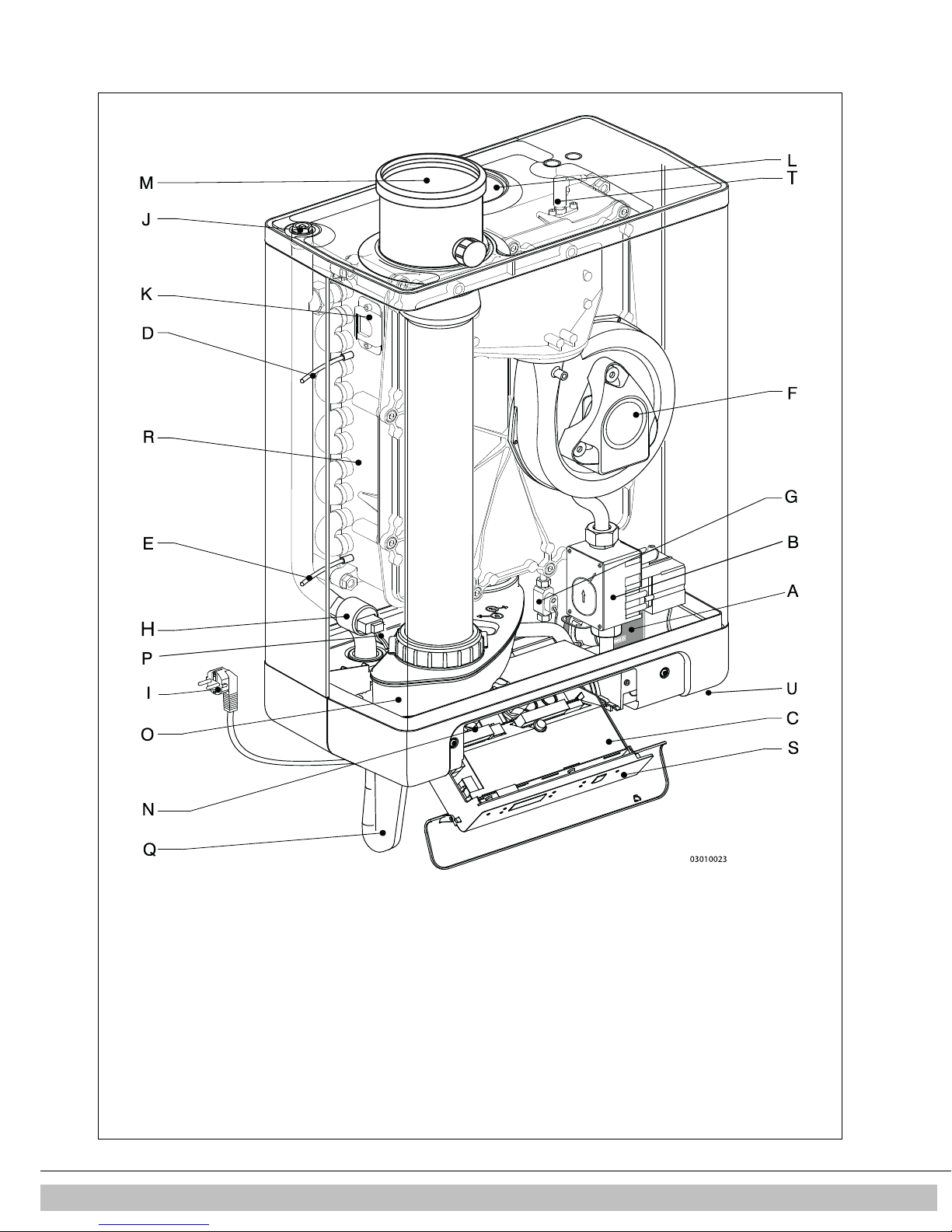

3 MAIN COMPONENTS

A. CH

pump L. Air supply (only when using twin pipe flue system)

B. Gas

valve M. Flue gas/air inlet concentric adapter

C. Burner

controller

(incl. operating panel)

N.

Connection block / terminal strip X4

D. Sensor S1 (flow)

O.

Condensate drain pan

E. Sensor S2 (return)

P.

Domestic hot water

sensor S3

F. Fan Q. Siphon

G. Flow sensor

R.

Heat exchanger

H. Pressure sensor central heating

S.

Operating panel and display

I. Connection wire 230 V ~ with earthed plug

T.

Ionization / ignition pen

J. Manual air bleed

U.

Position

of data plate

K. Sight glass

Daikin Europe NV 8

3.1 Accessories

Description

Article numbers

B-pack EKFJS*AA

EKFJS*AA

B-pack middle

EKFJM*AA

B-pack large

EKFJL*AA

Valve kit

EKVK4AA

Cover

plate EKOMBG*AAV1

EKCP1AA

O

utdoor

sensor

EKOSK1AA

3-way valve set

EK3WV1AA

Flue gas adapter Concentric

Ø

80x125

EKHY090717

Flue gas adapter Parallel 80 mm

EKHY090707

Propane set

*KOMBG22AAV1

EKPS075877

Propane set *KOMBG28AAV1

EKPS075867

Propane set *KOMBG33AAV1

EKHY075787

Daikin Europe NV

9

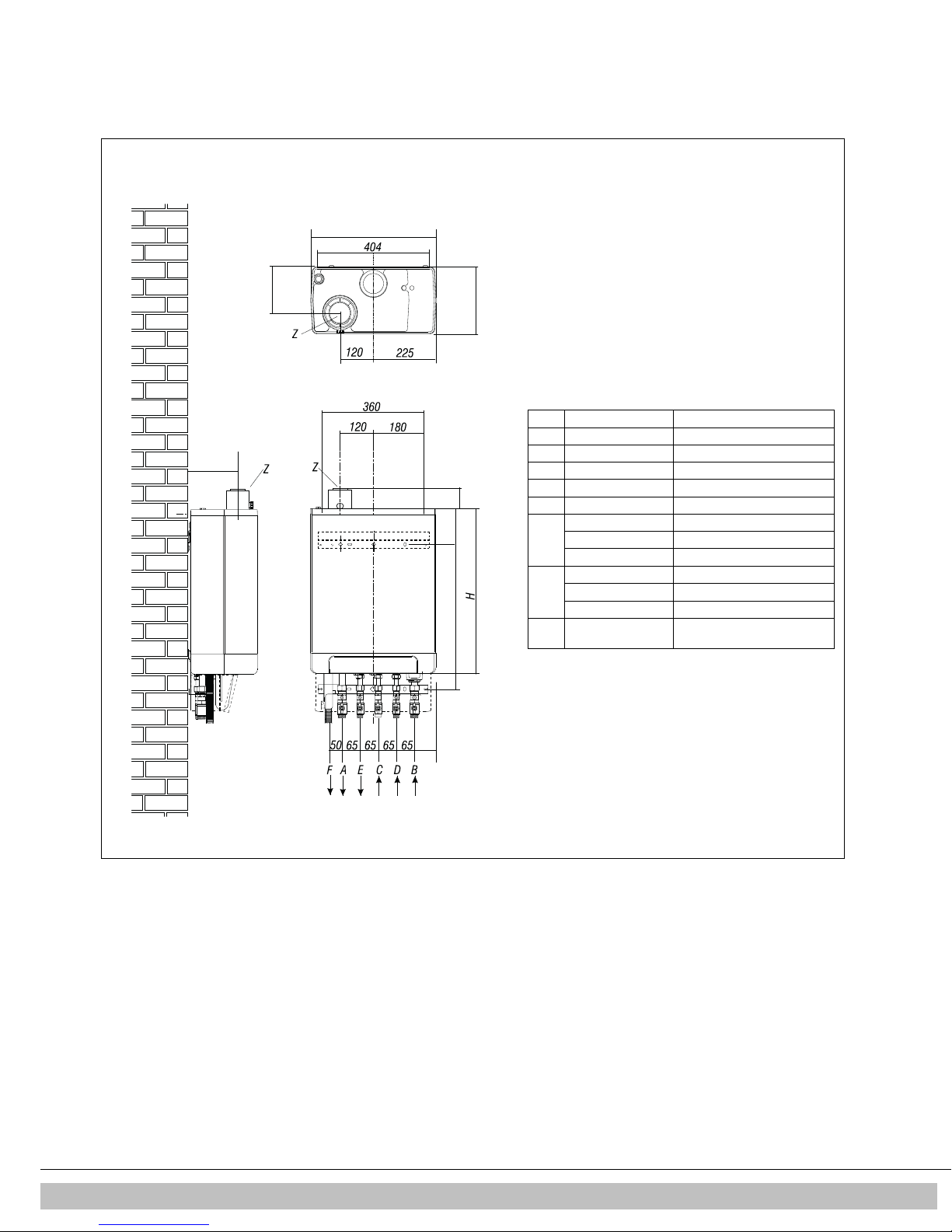

4 INSTALLATION

A = Supply CH

G ¾” (ext)

B = Return CH

G ¾” (ext)

C = Gas G ½” (int)

D = Tap water cold

G ½” (ext)

E = Tap water warm

G ½” (ext)

F = Condense outlet

Ø dn25 (flexible)

h= 517mm

EKOMBG22AAV1

577mm

EKOMBG28AAV1

637mm

EKOMBG33AAV1

H= 590mm

EKOMBG22AAV1

650mm

EKOMBG28AAV1

710mm

EKOMBG33AAV1

Z = Flue gas outlet/air

Ø60/100 (concentric)

020601002

161

161

450

240

135

h

77

75

4.1 Installation measurements

Boiler mounted directly to the wall

Connections:

inlet

Daikin Europe NV 10

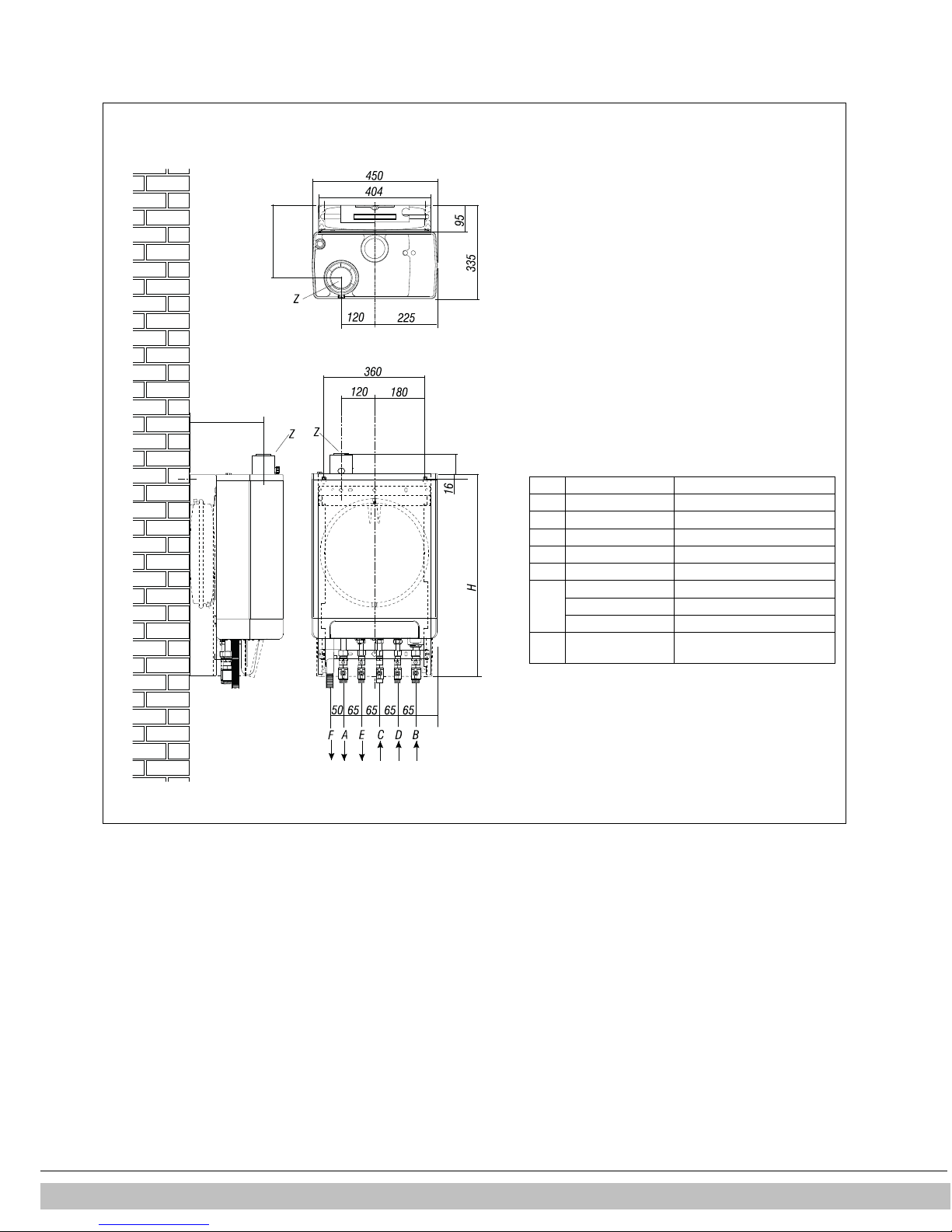

A = Supply CH

G ¾” (ext)

B = Return CH

G ¾” (ext)

C = Gas G ½” (int)

D = Tap water cold

G ½” (ext)

E = Tap water warm

G ½” (ext)

F = Condense outlet

Ø dn25 (flexible)

H= 770mm

EKOMBG22AAV1

830mm

EKOMBG28AAV1

890mm

EKOMBG33AAV1

Z = Flue gas outlet/air

Ø60/100 (concentric)

020601001

265

265

77

75

Unit connected to B-pack:

Connections:

inlet

Daikin Europe NV

11

Daikin Europe NV 12

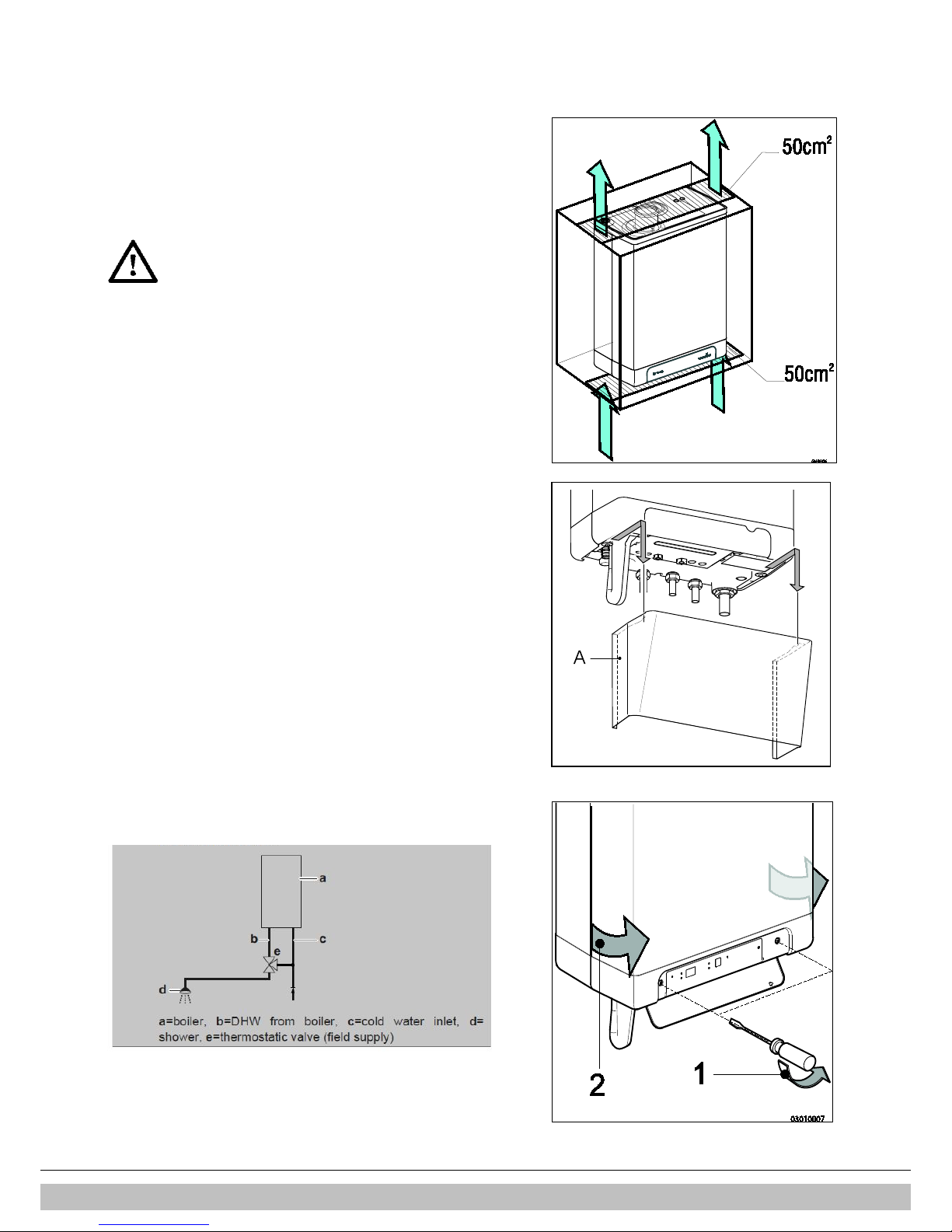

4.2 Installation spac e

The unit must be installed against a wall with sufficient load bearing capacity.

In case of light wall constructions, there is a risk of resonance noises.

Within 1 meter of the unit, there must be a earthed wall plug.

In order to prevent the condense outlet from freezing, the unit must be installed in a

frost-free room. Preferably ensure there is a space of at least 2 cm next to the boiler.

No free space is required due to danger of singeing.

IMPORTANT

The unit must not be installed in a space where work is carried out

with aggressive or corrosive gases such as hairspray.

4.2.1 Installing in kitchen cabinet

The unit can be placed between two kitchen cabinets, or inside a kitchen cabinet.

Make sure there is sufficient ventilation at the bottom and the top.

If the unit is installed inside a cabinet, ventilation openings of at least 50 cm

2

are

required.

4.2.2 Removing cover plate and front panel

For various activities on the unit, the cover plate and front panel have to be removed

from the unit, if they were installed. Do this as follows:

• If you are using the cover plate (A), remove it to the front.

• Unscrew both screws (1) behind the display window.

• Pull the bottom of the front panel (2) forwards.

Danger: risk of burning

In case of high leaving water set ponts for space heating (eighter a high fixed set point

or a high weather-dependent set point at low ambient temperatures), the heat

exchanger of the boiler can be very hot, for example 70°C.

Beware that in case of a tapping demand, the water can initially have a higher water

temperature than requested.

In this case, it is recommended to install a thermostatic valve to prevent scalding.

This can be done according to the schematics below.

4.3 Assembly

020601020

The boiler can be hung to the wall using :

•

the wall suspension strip and a the connection kit EKVK4AA

•

a B-pack including an expension vessel and a connection kit.

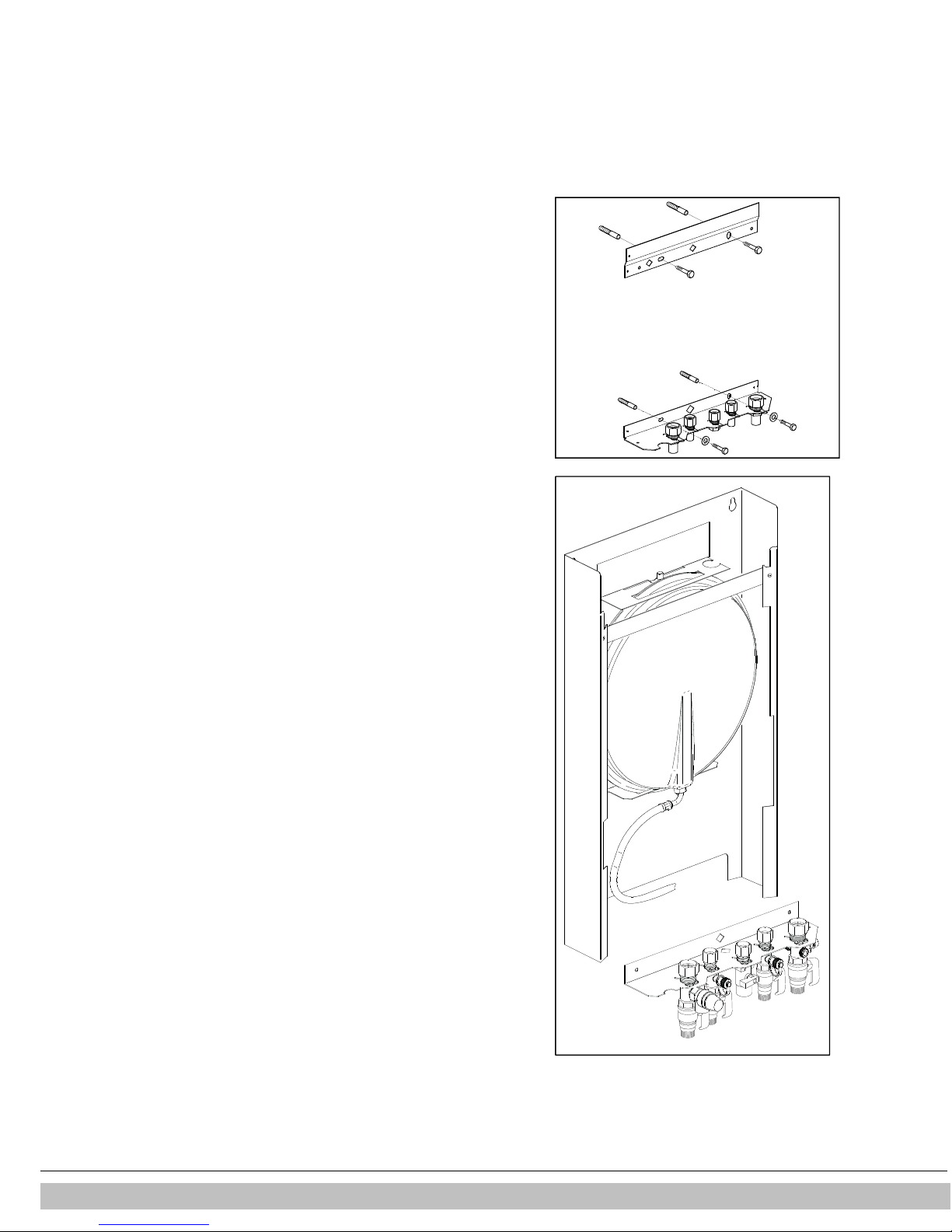

4.3.1 Assembling suspension strip and assembly bracket

• Make sure the construction of the wall is suitable for hanging the boiler.

• Drill the holes for the suspension strip and the connection kit in the wall

using the template delivered with the boiler.

• Mount the suspension strip and the assembly bracket horizontally on the

wall, using the associated attachment materials.

• Place the filling loop on the connections of the return and cold water nipple

following the connection kit installation instruction

• The boiler can now be placed on the suspension strip simultaniously sliding

the pipes of the boiler into the valves in the assembly bracket.

4.3.2 Assembling bottom connection set

• Make sure the construction of the wall is suitable for hanging the boiler and

B-pack.

• Drill the holes for the B-pack kit in the wall using the template delivered

with the boiler.

• Mount the B-pack on the wall using the associated attachment materials.

• Place the assembly bracket in the frame as described in the manual

inclued in the B-pack.

• Connect the flexible hose on the expension vessel and the conenction on

the return valve. Make sure the seal rings are placed !

• Place the filling loop on the connections of the return and cold water nipple

following the connection kit installation instruction

• The boiler can now be placed on B-pack simultaniously sliding the pipes of

the boiler into the valves in the assembly bracket

Daikin Europe NV

13

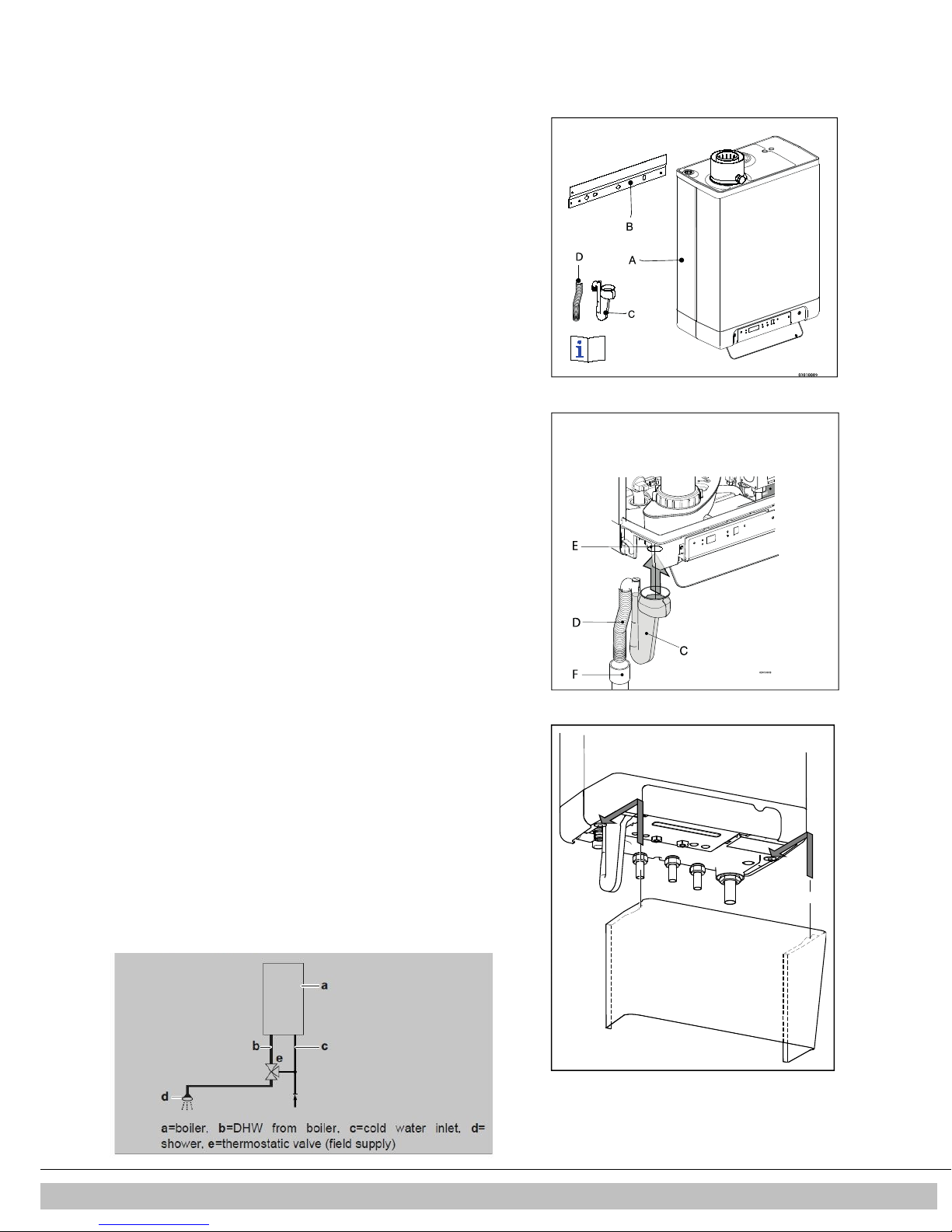

4.3.3 Assembling the unit

1. Unpack the unit.

2. Check the content of the packaging, which consists of:

• Unit (A)

• Suspension strip (B)

• Siphon (C)

• Flexible tube (D)

• Installation instructions

• Operating instructions

• Warranty card

3. Check the unit for any damage: immediately report damages to the supplier.

4. Install the suspension strip.

5. Check whether the compression rings are positioned straight in the couplings of

the assembly bracket.

6. Position the unit: slide it from top to bottom over the suspension strip (B). Make

sure the pipes slide into the compression fittings simultaneously.

7. Tighten the compression fittings onto the assembly bracket.

The nipples and pipes must not rotate with it!

8. Open the display valve and loosen the two screws on the left and right of the

display, and remove the front panel.

9. Assemble the flexible tube (D) onto the outlet of the siphon.

10. Fill the siphon with water, and slide it as far as possible on top of the condense

output connector (E) under the unit.

11. Seal flexible tube (D) of the siphon, if possible together with the overflow pipe of

the inlet combination and the overflow valve, to the sewage via open connection

(F).

12. Assemble the air supply and the burning gas outlet (see par. 5.6).

13. Assemble the cover and tighten the two screws to the left and the right of the

display, and close the display cover.

4.3.4 Apply cover plate (optional)

Suspend the converted top edge of the cover plate from the washers underneath the

bottom of the unit, and slide the cover plate as far back as possible.

Danger: risk of burning

In case of high leaving water set ponts for space heating (eighter a high fixed set point

or a high weather-dependent set point at low ambient temperatures), the heat

exchanger of the boiler can be very hot, for example 70°C.

Beware that in case of a tapping demand, the water can initially have a higher water

temperature than requested.

In this case, it is recommended to install a thermostatic valve to prevent scalding.

This can be done according to the schematics below.

5

Daikin Europe NV 14

CONNECTING

A

B

020601013

B

A

020601014

5.1 Connecting CH installation

1. Rinse the CH installation carefully.

2. Fit the supply pipe (A) and return pipe (B) to the connection set.

3. All pipes must be assembled with no electrical current, in order to prevent shocks

from the pipes.

4. Existing connections may not be rotated, in order to prevent leakages.

The CH installation must be fitted with:

•

A filling/draining tap (A) in the return pipe, immediately underneath the unit.

•

A draining tap at the lowest point of the installation.

•

An overflow valve (B) of 3 bar in the input pipe at a distance of no more than 500

mm from the unit.

Between the unit and the overflow valve there may be no valve or constriction.

•

An expansion vessel in the return pipe (in the B-pack or in the installation).

•

A check valve, if there are pipes running up, within close distance of the unit. This

prevents a thermosiphon effect from occurring during tap water operation (a non

spring-operated return valve, must be assembled vertically).

5.1.1 Thermostatic radiator taps

If all radiators are fitted with thermostatic or cable radiator taps, a minimum water

circulation must be safeguarded. See par. 7.3.

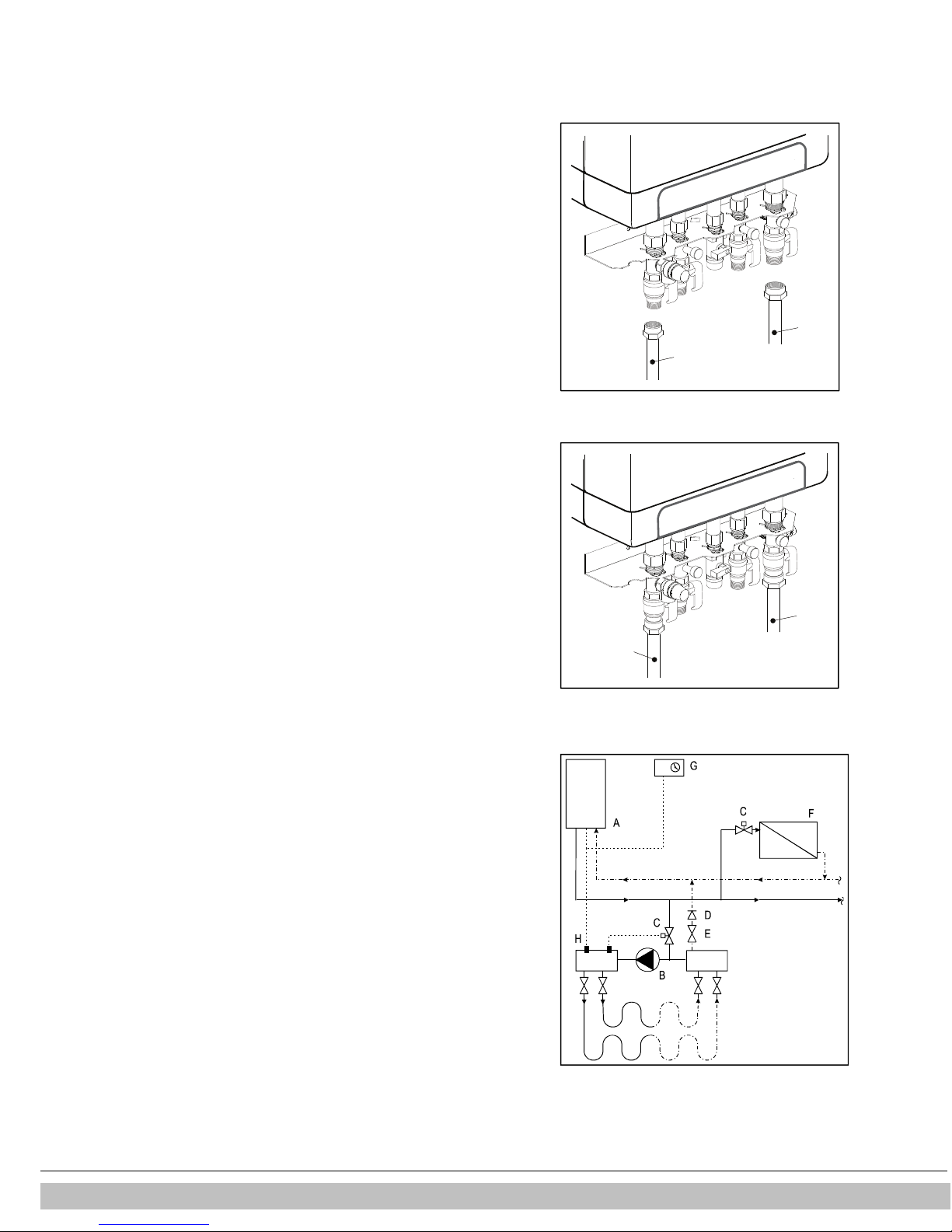

5.1.2 Underfloor heating

Underfloor heating with pump

If an underfloor heating system is not hydraulically neutral, the underfloor heating

pump may generate unwanted circulation over the CH boiler. For a good functioning of

the domestic hot water provision, unwanted circulation over the CH boiler must be

prevented.

Connect an underfloor heating system indirectly hydraulically neutrally or provide the

CH installation with a two-way valve set 230 V ~ (E). If the underfloor heating pump

absorbs heat via the return of the boiler, unwanted circulation can be prevented by

means of a check valve (D).

Make sure there is a minimal water circulation. See par. 7.3.

Connection diagram underfloor heating

A. CH boiler G. Space/clock thermostat

B. CH pump H. Maximum thermostat

C. Thermostatic control valve

D. Spring-operated check valve

E. Electrical valve 230 V ~

F. Radiators

Daikin Europe NV

15

Underfloor heating without pump

Connect the underfloor heating system (D) and set the maximum CH supply temperature of the CH boiler to the design condition. Fit a clamp

thermostat (A) onto the supply tube underneath the CH boiler. The clamp thermostat

with blind cap must be set to a maximum supply temperature of 55°C.

Fit the on/off room thermostat (B) and connect in a series with the clamp thermostat.

The boiler must be connected to X4 - 6/7.

In this situation, the pump in the boiler is used to bridge the loss of pressure of the

underfloor heating system. Using the loss of pressure graph par. 7.4, the maximum loss

of pressure of the underfloor heating system can be determined.

Make sure there is a minimal water circulation. See par. 7.3.

In case of an underfloor heating system without pump, we recommend changing the

following parameter settings:

par. o from 0 to 3.

par. P from 5 to 2.

Parameter 3 must also be set to its minimum level, or the

Transmission loss of the property, see par. 7.3.

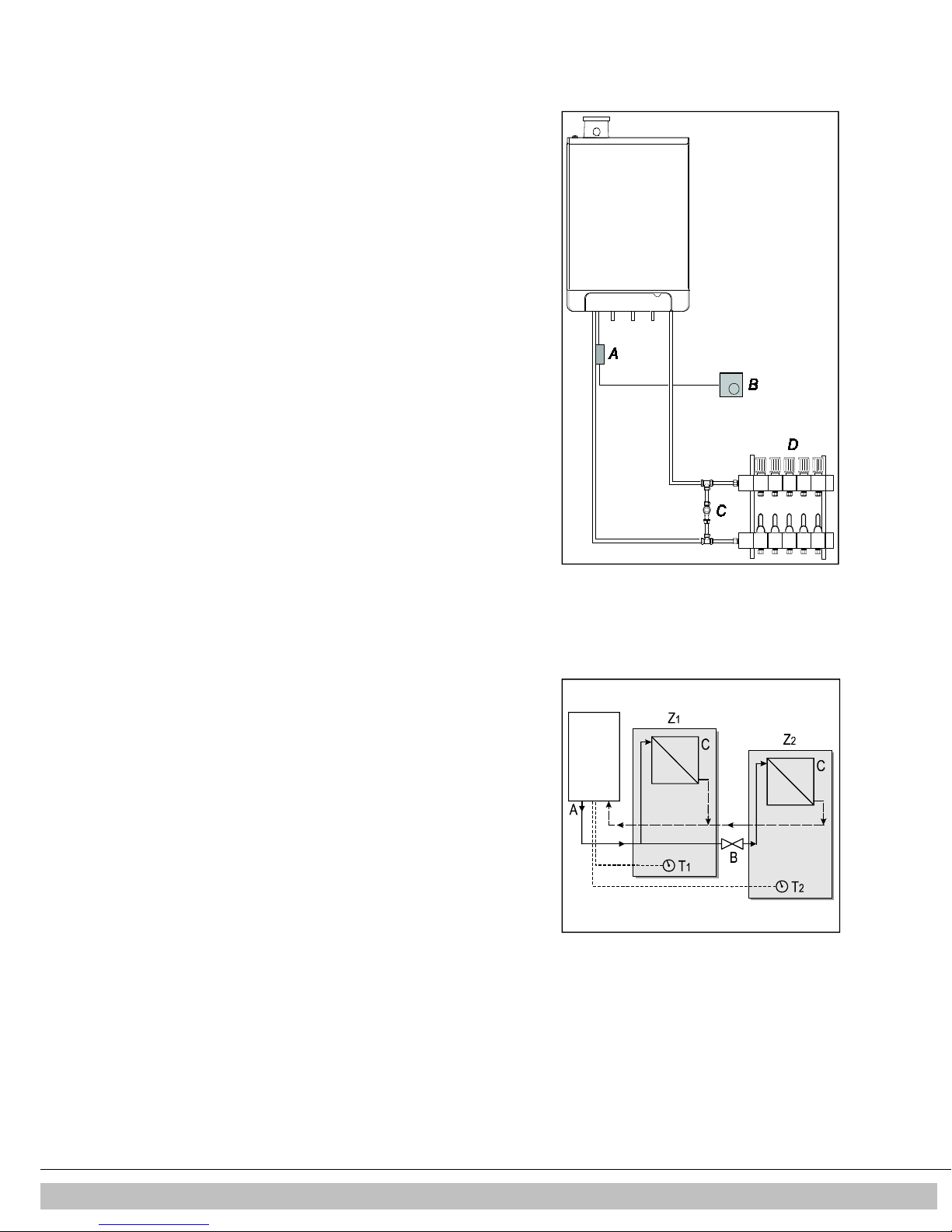

5.1.3 Dividing CH installation in groups in case of additional heat

sources

Operating principle

If the room thermostat switches off the boiler because another heat source, the other

rooms may cool down.

This can be resolved by splitting the CH installation into two groups. The group with the

external heat source (Z2) can be shut off from the main circuit by means of an electrical

shut-off valve. Both groups are fitted with their own room thermostat.

Please note: This "external heat source" regulation may only be applied if no extra

external boiler has to be heated up (installation type 1).

Installation instructions

5. Install the valve in accordance with the connection diagram.

6. Connect the room thermostat of group 1 to op X4 – 6/7.

7. Connect the room thermostat of group 2 to op X4 – 11/12.

8. Change parameter A (see Parameter settings via the service code par. 7.2).

Please note: The room thermostat in group

thermostat in group 2 may be an OpenTherm thermostat or an on/off thermostat.

Connection diagram "external heat source" regulation

A. CH boiler

B. Electrical shut-off valve 230 V ~

C. Radiators

T1. Room thermostat group 1

T2. Room thermostat group 2

Z1. Group 1

Z2. Group 2

1 MUST

be an on/off thermostat. The room

Daikin Europe NV 16

5.2 Connecting DHW installation

D

C

020601015

1. Rinse the installation carefully.

2. If required, assemble an inlet combination.

3. Assemble the cold (D) and warm water pipe (D) to the connection set.

Comments

•

If the unit is only used for warm water supply, the heating function can be switched

off using the service code on the operating panel. The CH installation does not need

to be connected or filled.

•

If the unit is switched off during winter, and is disconnected from the electricity

supply, the sanitary water must be drained in order to prevent freezing. To do so,

disconnect the tap water connections straight underneath the unit.

In case of old installations or domestic hot water circuits which can contain small particles, install

a filter in the domestic hot water circuit.

This pollution could cause a fault during domestic hot water operation.

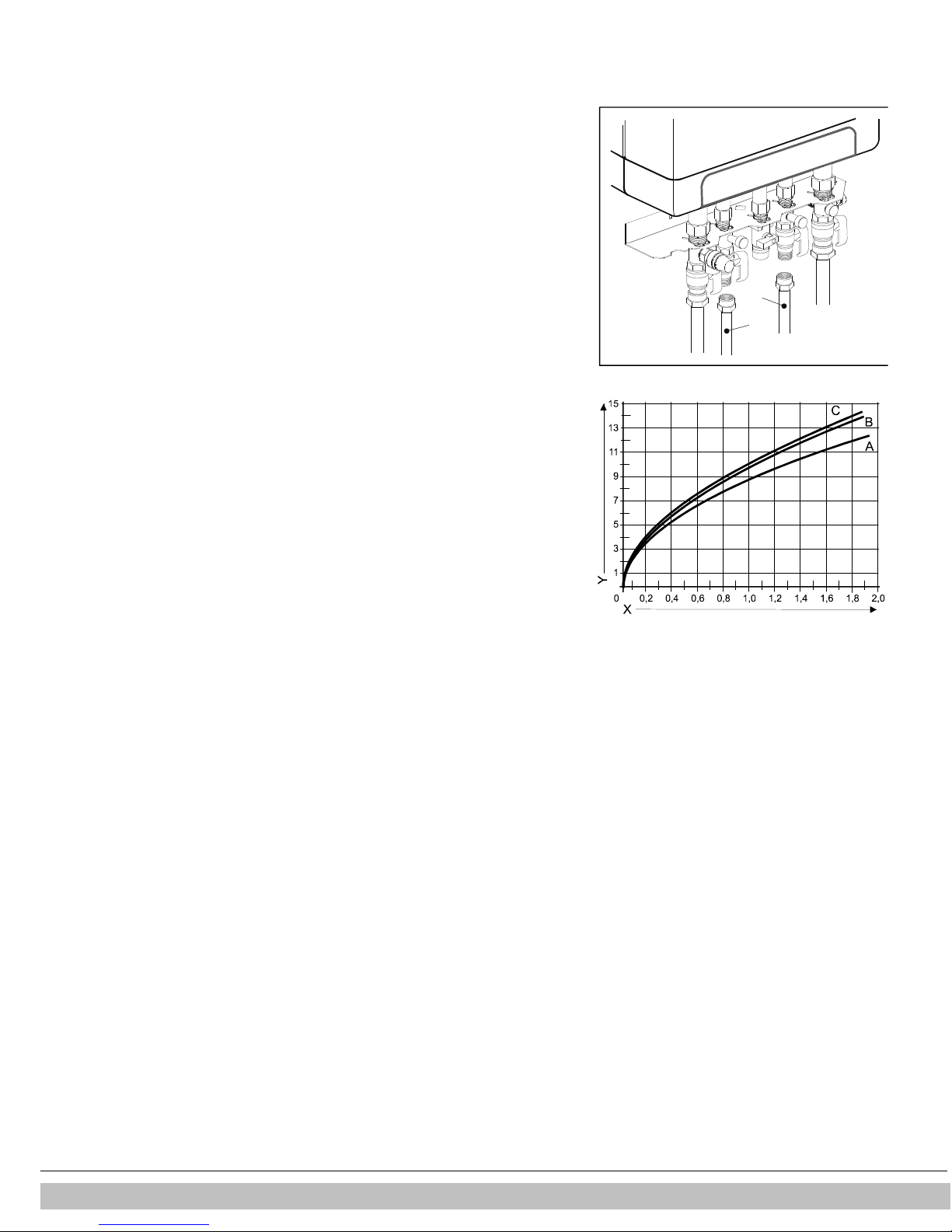

Resistance graph tap circuit unit

A. EKOMBG22AAV1

B. EKOMBG28AAV1

C. EKOMBG33AAV1

X. Water pipe pressure (Bar)

Y. Flow rate (L/min, tolerance ± 10%)

Daikin Europe NV

17

Loading...

Loading...