Page 1

INSTALLATION MANUAL

Domestic hot water tank with option kit for air to

water heat pump system

EKHWSU150B3V3

EKHWSU200B3V3

EKHWSU300B3V3

EKUHWBB

EKUHW2WB

Page 2

EKHWSU150B3V3 EKUHWBB

1x 2x 1x1x

1x

4x

1356

2

4

EKHWSU200B3V3

EKHWSU300B3V3 EKUHW2WB

Domestic hot water tank with option kit for air to

water heat pump system

Installation manual

Contents Page

Introduction ....................................................................................... 1

General information .................................................................................. 1

Scope of this manual ................................................................................ 1

Model identification .................................................................................. 1

Accessories....................................................................................... 1

Accessories supplied with the EKHWSU domestic hot water tank .......... 1

Accessories supplied with the EKUHWBB option kit for the

domestic hot water tank ........................................................................... 2

Accessories supplied with the EKUHW2WB option kit for the

domestic hot water tank when the EKSOLHWAV1 option kit is

installed .................................................................................................... 2

Optional equipment .................................................................................. 2

Installation of the EKHWSU domestic hot water tank ....................... 2

Main components ..................................................................................... 3

Outlook diagram ....................................................................................... 4

Installation guidelines ............................................................................... 4

Installing the domestic hot water tank...................................................... 4

Connecting the water circuits ................................................................... 4

Field wiring ............................................................................................... 6

Installation of the option kit on the domestic hot water tank.............. 9

Piping requirements ................................................................................. 9

Installation procedure of the option kit.................................................... 10

Commissioning................................................................................ 10

Filling up................................................................................................. 10

Draining .................................................................................................. 10

Maintenance..................................................................................... 11

Troubleshooting................................................................................11

General guidelines ..................................................................................11

General symptoms .................................................................................. 11

Technical specifications................................................................... 12

Domestic hot water tank specifications .................................................. 12

Pressure reducing valve specifications.................................................. 13

Field wiring diagram ............................................................................... 13

READ THESE INSTRUCTIONS CAREFULLY BEFORE

INSTALLATION. KEEP THIS MANUAL IN A HANDY

PLACE FOR FUTURE REFERENCE.

PLEASE LEAVE THIS MANUAL WITH THE EKHWSU

DOMESTIC HOT WATER TANK AFTER INSTALLATION.

IMPROPER INSTALLATION OR ATTACHMENT OF

EQUIPMENT OR ACCESSORIES COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE OR

OTHER DAMAGE TO THE EQUIPMENT. BE SURE ONLY

TO USE ACCESSORIES MADE BY DAIKIN WHICH ARE

SPECIFICALLY DESIGNED FOR USE WITH THE

EQUIPMENT AND HAVE THEM INSTALLED BY A

PROFESSIONAL.

IF UNSURE OF INSTALLATION PROCEDURES OR USE,

ALWAYS CONTACT YOUR DAIKIN DEALER FOR

ADVICE AND INFORMATION.

THE UNIT DESCRIBED IN THIS MANUAL IS DESIGNED

FOR INDOOR INSTALLATION ONLY AND FOR

AMBIENT TEMPERATURES RANGING 0°C~35°C.

Introduction

General information

Thank you for purchasing this Daikin Altherma EKHWSU domestic

hot water tank.

The Daikin Altherma domestic hot water tank must be installed by a

competent person and be installed in compliance with instructions as

of subject in this manual, all current legislation, codes of practice and

regulations governing the installation of unvented hot water cylinders

in force at the date of installation.

This installation is subject to building regulation approval,

notify Local Authority of intention to install.

The domestic hot water tank is to be connected to the Daikin

Altherma unit.

The EKHWSU domestic hot water tank with integrated 3 kW

electrical booster heater is available in three types: 150, 200 and 300.

All models can be floor mounted, while the 150 type model can be

wall mounted as well via option kit EKWBSWW150.

Scope of this manual

This installation manual describes the procedures for installing and

connecting the EKHWSU domestic hot water tanks with the

EKUHWBB option kit and with the EKUHW2WB option kit in case the

EKSOLHWAV1 option kit is to be installed as well.

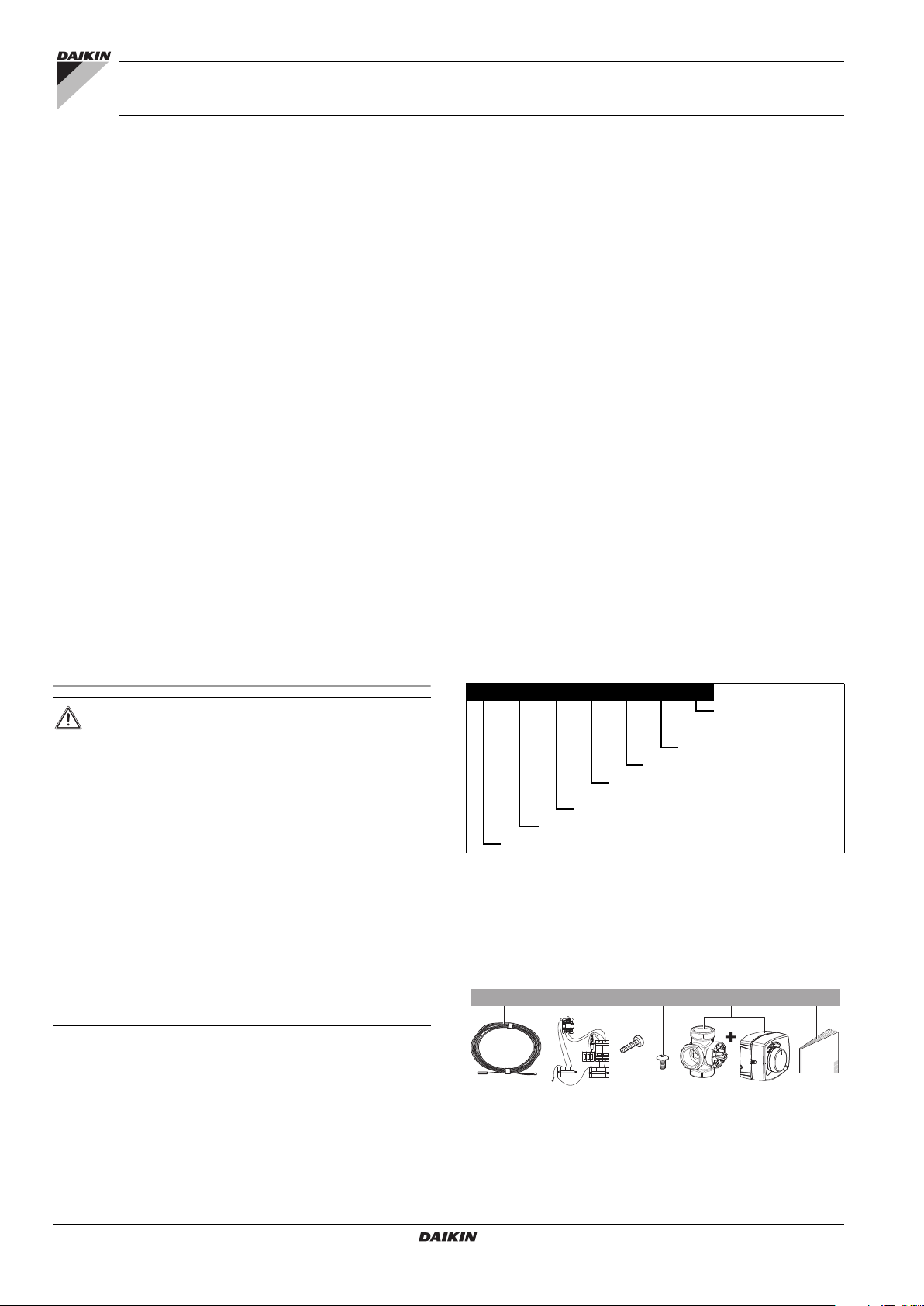

Model identification

Domestic hot water tank

EK HWS U 150 B 3 V3

Booster heater voltage

V3=1P, 230 V

Capacity booster heater: 3 kW

Series

Indication of storage capacity in litres

Special version for United Kingdom only

Standard version when no letter is mentioned

Hot Water stainless Steel tank

European Kit

Accessories

Accessories supplied with the EKHWSU domestic hot

water tank

Installation manual

1

1 Thermistor + connection wire (12 m)

2 Contactor - fuse assembly

3 Contactor fixing screw

4 Tapping screw

5 3-way valve + motor

6 Installation manual

Domestic hot water tank with option kit for air to water heat pump

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

4P344370-1 – 2013.03

system

Page 3

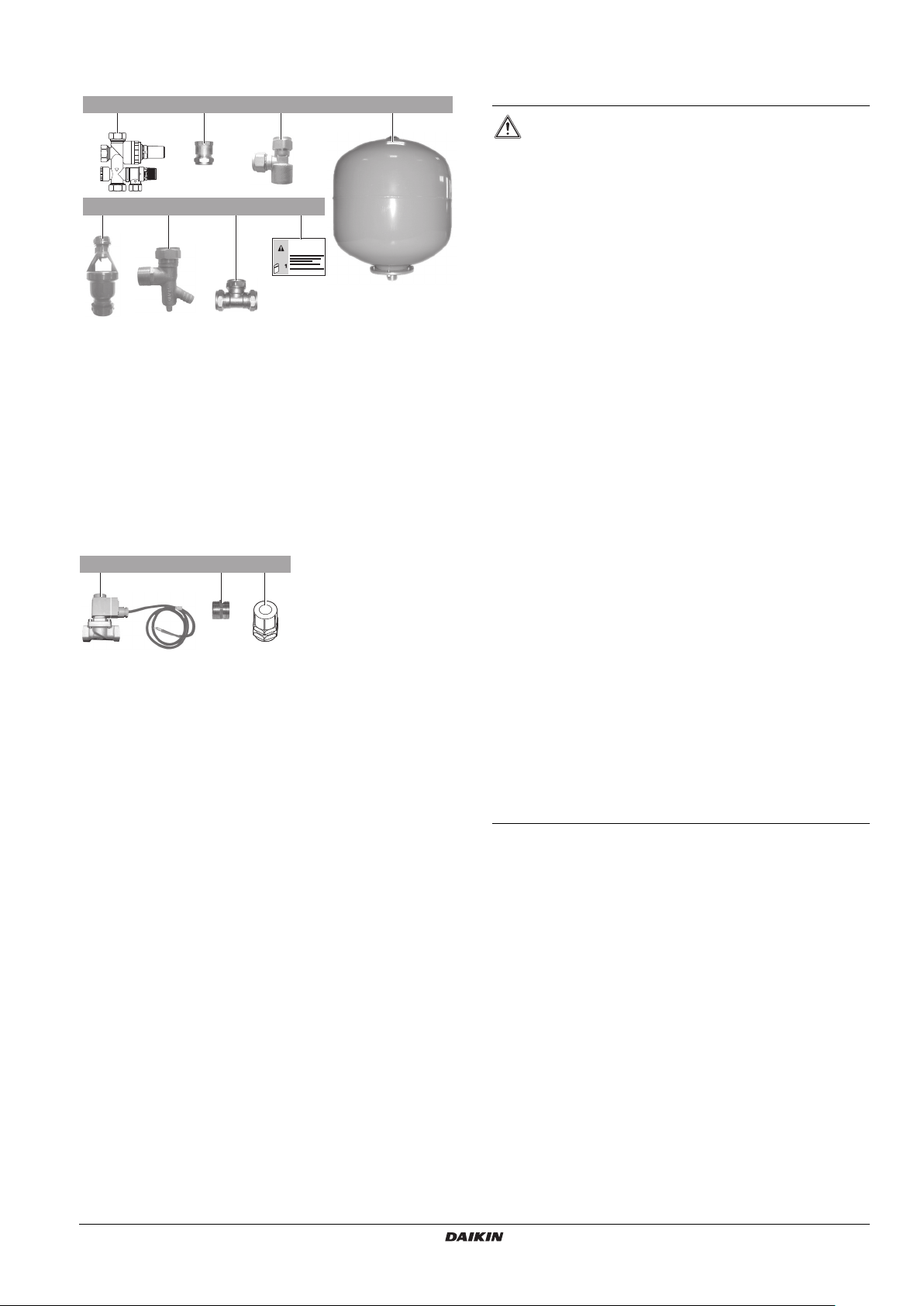

Accessories supplied with the EKUHWBB option kit for

1x

1x

1x1x

1x 1x

1x

1x

134

658

2

7

1x

2x21x

the domestic hot water tank

1 Pressure reducing valve and expansion relief valve. Water

inlet and water outlet 22 mm connection, discharge piping

connection 15 mm

2 Adaptor 22 mm×3/4" Female BSP

3 T-piece 1/2" Female BSP×15 mm×15 mm

4 Expansion vessel of 18 litres 3/4" Male BSP

5 Tundish 15 mm inlet, 22 mm outlet

6 Elbow/Drain valve 22 mm×3/4" Male BSP

7 T-piece 22 mm×22 mm×22 mm

8 Instruction sheet

Accessories supplied with the EKUHW2WB option kit for

the domestic hot water tank when the EKSOLHWAV1

option kit is installed

1

1 Solenoid 2-way valve 3/4" Female BSP×3/4" Female BSP

2 Connection nipple 3/4" Male BSP

3 PG nipple and nut

3

Optional equipment

EKWBSWW150: kit, including a wall bracket for a domestic hot water

tank of 150 litres.

Installation of the EKHWSU domestic hot

water tank

The total Daikin Altherma system is designed for

combination with a Daikin Altherma domestic hot

water tank. In case another tank or a spare part other

than native Daikin is being used in combination with

the Daikin Altherma unit, Daikin cannot guarantee

neither good operation nor reliability of the system.

For those reasons Daikin cannot give warranty of the

system in such case.

The equipment is not intended for use in a potentially

explosive atmosphere.

For safety reasons, it is not allowed to add ethylene

glycol to the water circuit. Adding ethylene glycol

might lead to contamination of the domestic water if a

leakage would occur in the heat exchanger coil.

Only this tank can be used in combination with the

solar kit option.

Domestic water quality must be according to EN

directive 98/83 EC.

Wherever possible the main supply pipe should be in

22 mm. The minimum main water supply requirement

should be 1.5 bar working pressure and 20 litres per

minute flow rate. At these values outlet flow rates may

be poor if several outlets are used simultaneously, the

higher the available pressure and flow rate the better

the system performance will be.

It is important that the storage capacity of the

domestic water tank meets normal daily fluctuations in

consumption of hot water without any fall of the water

outlet temperature during use.

Immediately after installation, the domestic hot water

tank must be flushed with fresh water. This procedure

must be repeated at least once a day the first 5

consecutive days after installation.

If applicable legislation requires a chemical

disinfection in specific situations, involving the

Altherma domestic hot water tank, please be aware

that the domestic hot water tank is a stainless steel

cylinder containing an aluminium anode. We therefore

advise in these circumstances to use a non-chloride

based disinfectant approved for use with water

intended for human consumption.

Where the secondary return circuits are used an

additional expansion vessel may be required.

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

Domestic hot water tank with option kit for air to water heat pump

system

4P344370-1 – 2013.03

Installation manual

2

Page 4

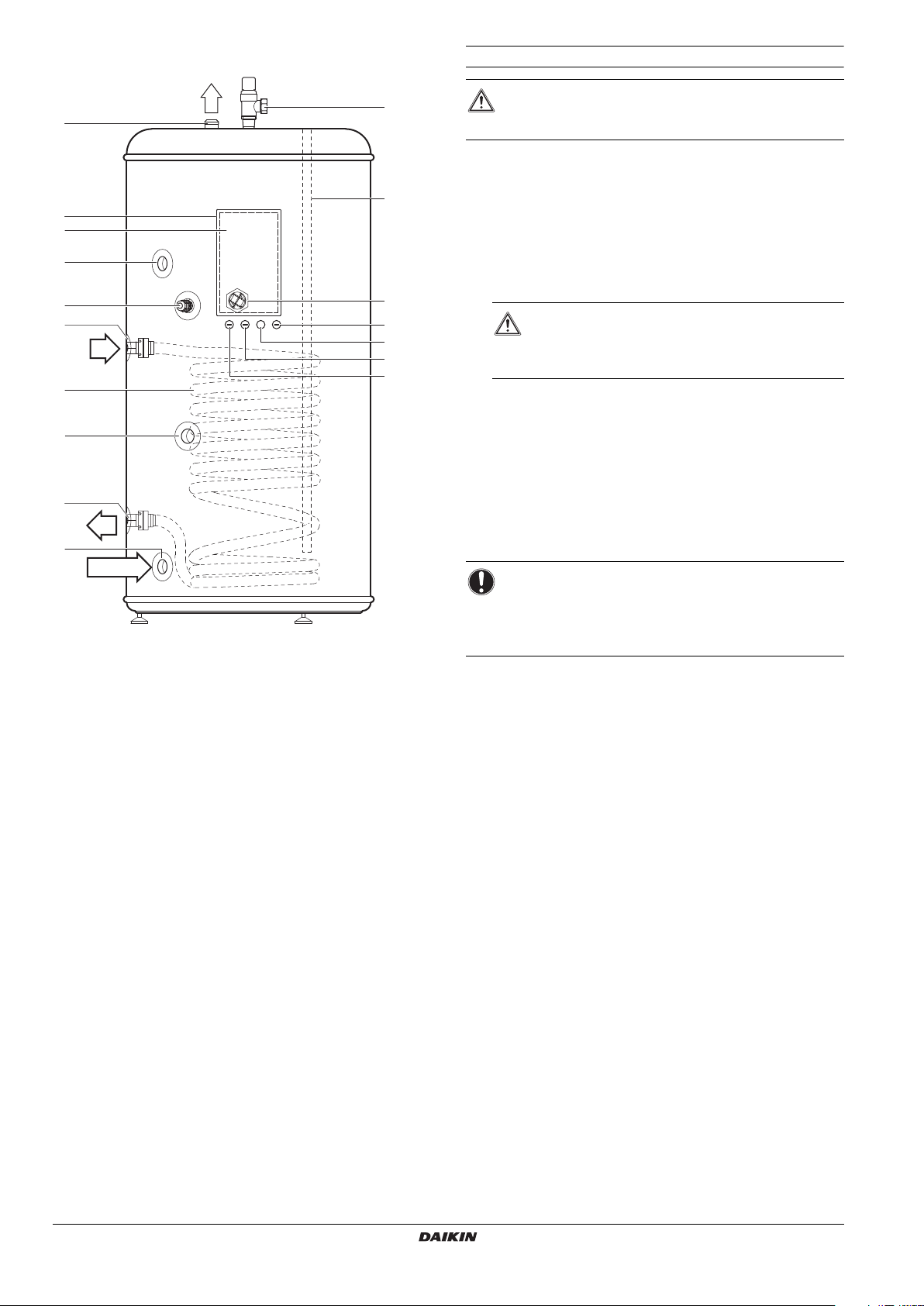

Main components

C

15

14

13

12

16

2

17

1

3

R

4

7

10

1

1

8

5

6

9

F

H

Safety devices

The domestic hot tank relief valve connections should

not be used for other purposes.

Do not install heaters without thermal cut-outs.

Thermal protector — The booster heater in the domestic hot

water tank is equipped with a thermal protector (setting 85°C).

For EKUHW2WB only: Secondary thermal protector (solenoid

2-way valve) — The thermal protector will close the solenoid

2-way valve (setting 85°C).

Both thermal protectors are activated when the temperature

becomes too high. When activated, the protectors have to be

reset on the domestic hot water tank by pressing the red button

(for access, remove the electrical box lid).

The electrical box lid must only be opened by a

licensed electrician.

Switch off the power supply before opening the

electrical box lid.

For EKUHW2WB only: Thermostat (solenoid 2-way valve)

The thermostat will close the solenoid 2-way valve when the

temperature becomes too high (setting 79°C).

Temperature and pressure relief valve

The temperature and pressure relief valve prevents excessive

water temperature (>95°C) and excessive water pressure

(≥10 bar) in the domestic hot water tank.

Expansion relief valve (option kit)

The pressure relief valve prevents excessive water pressure

(≥8 bar) in the water circuit.

NOTICE

Refer to "Installation of the option kit on the domestic hot

water tank" on page 9 for connection of other safety

1 Hot water connection

2 Temperature and pressure relief valve

3 Electrical box

4 Electrical box lid

5 Recirculation hole

6 Thermistor socket

7 Flow inlet connection

8 Heat exchanger coil

9 Threaded thermistor hole for use with solar kit option.

Refer to the installation manual of the EKSOLHWAV1

option kit.

10 Return outlet connection

11 Cold water connection

12 Only in case of installing the EKSOLHWAV1 option kit

Cable hole to fit PG nipple and nut for use with solar kit

option. Refer to the installation manual of the

EKSOLHWAV1 option kit.

13 Cable hole to fit PG nipple and nut into for cable

connections of booster heater, power supply and thermal

protection cable.

14 Only in case of installing the EKSOLHWAV1 option kit.

Cable hole to fit PG nipple and nut into for cable

connections of solenoid valve. Refer to the installation

manual of the EKSOLHWAV1 option kit.

15 Only in case of installing the EKSOLHWAV1 option kit.

Cable hole to fit PG nipple and nut into for cable

connections of solenoid valve power supply and solar

pump power supply. Refer to the installation manual of the

EKSOLHWAV1 option kit.

16 Electrical booster heater

17 Anode for corrosion protection

devices in accordance with relevant local and national

regulations.

Installation manual

3

Domestic hot water tank with option kit for air to water heat pump

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

4P344370-1 – 2013.03

system

Page 5

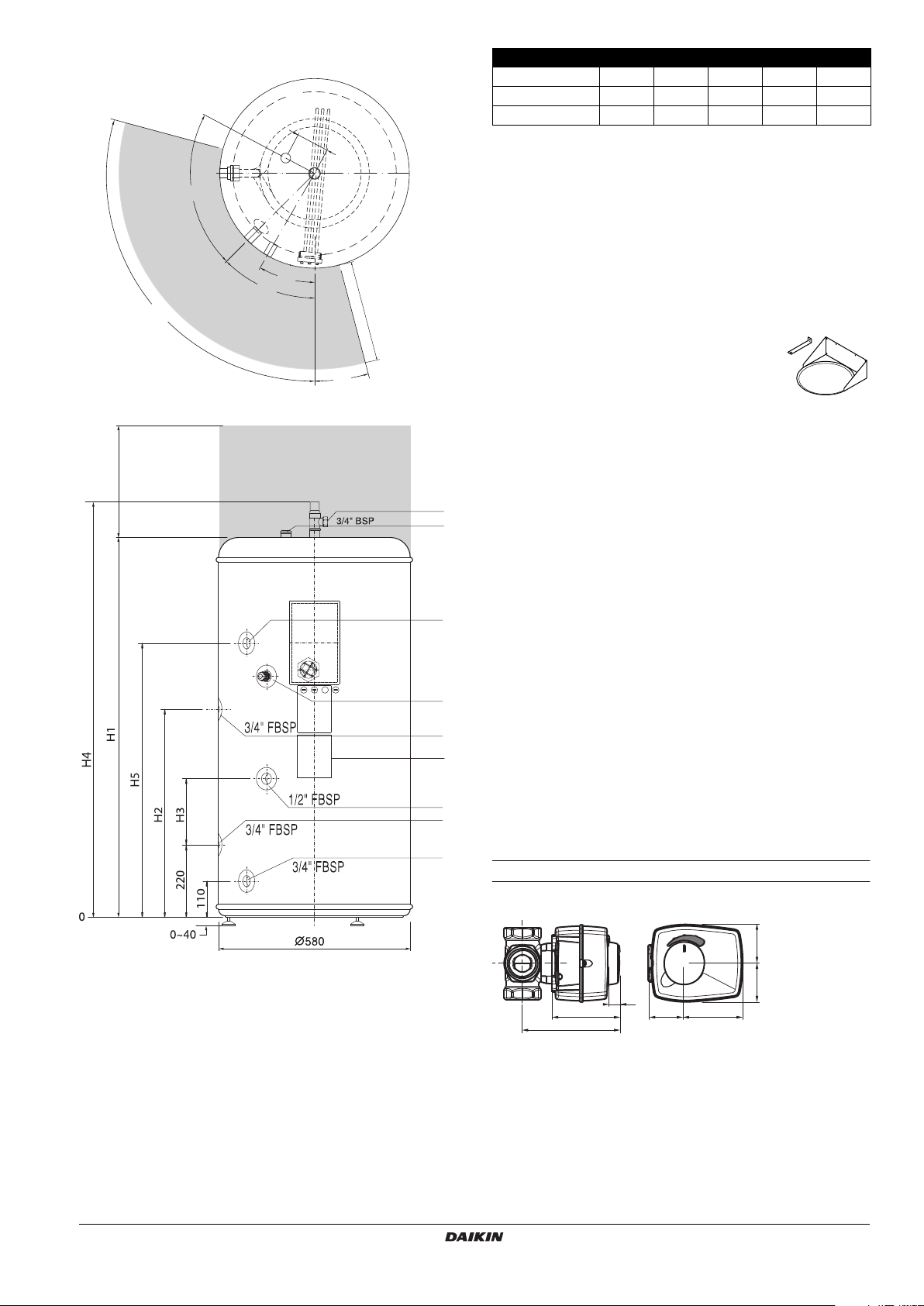

Outlook diagram

105

45

30

73

100

15

400

300

15 mm

13

77

111

38 67

44

44

H1 H2 H3 H4 H5

EKHWSU150B3V3 900 mm 475 mm 185 mm 1015 mm 605 mm

EKHWSU200B3V3 1150 mm 630 mm 200 mm 1265 mm 830 mm

EKHWSU300B3V3 1600 mm 630 mm 200 mm 1715 mm 830 mm

Installation guidelines

Keep in mind the following guidelines when installing the domestic

hot water tank:

The installation location is frost-free.

Make sure to make the piping in size 1" or more (and reduce to

3/4" at the inlet of the tank) as to have sufficient water volume in

the piping between unit and domestic hot water tank.

Locate the domestic hot water tank in a suitable position to

facilitate easy maintenance; remember access is required to the

electrical box. Refer to the grey zones in the outlook diagram.

The domestic hot water tank model

EKHWSU150B3V3 can be floor or wall

mounted. In case of wall mounting, wall

mounting kit EKWBSWW150 is required

(separate ordering).

If installing an EKHWSU* domestic hot water tank, installing the

option kit EKUHWB is obligatory. Refer to the UK Building

Regulation G3.

If installing the kit EKSOLHWAV1, installing the option kit

EKUHW2WB is obligatory.

Take care that in the event of a leak, water cannot cause any

6

1

damage to the installation space and surroundings.

Installing the domestic hot water tank

1 Hot water connection

2 Recirculation hole

3 Flow inlet connection (see also "Installation guidelines" on

page 4 regarding pipe size to use)

4 Return outlet connection (see also "Installation guidelines"

on page 4 regarding pipe size to use)

5 Cold water connection

6 Temperature and pressure relief valve connection

7 Thermistor socket

8 Threaded thermistor hole for use with solar kit option.

Refer to the installation manual of the EKSOLHWAV1

option kit.

9 Warning label

1 Check if all domestic hot water tank accessories (see

2

"Accessories" on page 1) are enclosed.

2 When floor mounting, place the domestic hot water tank on a

level surface. When wall mounting (only for EKHWSU150B3V3

model), make sure the wall is sturdy. In both cases, make sure

the tank is mounted level.

7

3 Apply thermal paste to the thermistor and insert the thermistor

as deep as possible in the thermistor socket. Fix using the nut

3

provided.

9

Connecting the water circuits

8

Refer to "Typical application examples" described in the installation

4

manual delivered with the unit for details on connecting the water

circuits and the motorised 3-way valve.

5

Connecting the 3-way valve

1 Refer to the figure below before making the connection.

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

Domestic hot water tank with option kit for air to water heat pump

system

4P344370-1 – 2013.03

Installation manual

4

Page 6

2 Installation position.

4

L

N

Y

DIR

2P

1x

It is advised to connect the 3-way valve as close as possible to

the unit. It can be installed in accordance with one of the

following four configurations.

1

1

5 When installing in accordance with figure A or figure D, open the

valve motor cover by loosening the screw and change the

jumper so as to change the rotation direction of the valve.

By default the jumper is factory set to apply for installation in

accordance with figure B and figure C.

Installation in accordance with

figure A and figure D

Installation in accordance with

figure B and figure C

2

3

figure A figure B

2

1

2

3

3

figure C figure D

1 From Daikin Altherma unit

2 To domestic hot water tank

3 To room heating

3 Unpack the 3-way valve body and 3-way valve motor.

3

1

Rotation direction of the valve

6 Push the motor on the motor sleeve.

Make sure not to rotate the sleeve during this action, so as to

maintain the valve position as set during step 4.

7

2

IP41

8 Put the scale on the valve as shown below.

Domestic hot

water tank

Installation in accordance with

figure B and figure C

Room

heating

Room

heating

Installation in accordance with

figure A and figure D

Domestic hot

water tank

2

1

1 Sleeve

2 Valve motor cover

3 Screw

4 Scale

3

4 Install the 3-way valve body in the pipework.

Make sure the shaft will be positioned in such a way that the

motor can be mounted and replaced.

Put the sleeve on the valve and turn the valve to the middle

position of the scale plate.

Check that the valve is positioned as in the figure below. It

should be blocking the outlet connection to the domestic hot

water for 50% and the outlet connection to the room heating also

for 50%.

Installation in accordance

with figure A and figure B

Installation in accordance

with figure C and figure D

9 Make sure to firmly fix the power supply cord onto the 3-way

valve body with a field supplied cable tie like in illustration below.

10 Perform the wiring in the unit in accordance with the following

figure:

8910

3-way valve

BRN

LNY

BLU

BLK

Refer also to the drawing on page 8.

See "Installation of the option kit on the domestic hot water tank" on

page 9 for details on installation in accordance with relevant local and

national regulations.

If the valve is not positioned in this way before mounting

the motor, the valve will give way to both domestic water

and room heating during operation.

Installation manual

5

Domestic hot water tank with option kit for air to water heat pump

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

4P344370-1 – 2013.03

system

Page 7

Field wiring

1x

See also "Field wiring diagram" on page 13.

A main switch or other means for disconnection,

having a contact separation in all poles, must be

incorporated in the fixed wiring in accordance with

relevant local and national legislation.

All field wiring and components must be installed by a

licensed electrician and must comply with relevant

European and national regulations.

The field wiring must be carried out in accordance

with the wiring diagram sticker supplied with the unit

and the instructions given below.

The domestic hot water tank must be earthed via the

unit.

2 Booster heater power supply

Connect the booster heater power

supply and thermal protection cable

as shown in wiring diagram sticker

on the inside of the switch box lid.

3 Solenoid valve power supply

Connect the solenoid valve power

supply cable as shown in the

following diagram sticker on the

inside of the switch box lid.

4 Solenoid valve

Connect the solenoid valve as

shown in the following diagram

sticker on the inside of the switch

box lid.

Power circuit and cable requirements

Be sure to use a dedicated power circuit. Never use a

power circuit shared by another appliance.

Use one and same dedicated power supply for the

unit(s), backup heater and domestic hot water tank.

For cable requirements and specifications, see "Field wiring" in the

unit installation manual supplied with the unit.

NOTICE

Select the power cable in accordance with relevant local

and national regulations.

Thermistor cable

The distance between the thermistor cable and power supply cable

must always be at least 5 cm to prevent electromagnetic interference

on the thermistor cable.

Procedure

Switch off the power supply before making any

connections.

Connections to be made in the domestic hot water tank

electrical box

Make sure all field wiring is insulated from the surface of

the inspection hole or can resist temperatures to 90°C.

1 Prior to upwiring

Make sure to ensure strain relief of the power cable by correctly

mounting the PG nipple and PG nut (delivered with the tank).

Connections to be made in the unit switch box

NOTICE

Only for EHBH/X:

X3M will not be installed. See figure in "For EHBH/X units

only" on page 8 for more details.

5 Mount the prewired contactor (K3M), circuit breaker (F2B) and

terminal blocks (X3M, X4M). The contactor and terminal blocks

should be fixed with the 3

6 Plug the connector connected to the contactor K3M in the socket

X13A on the PCB.

7 Plug the thermistor cable connector in the socket X9A on the

PCB.

8 Connect the prewired earth wires of the terminal block X3M and

X4M to the earthing screw.

9 Connect the booster heater power supply and thermal protection

cable (field supply) to terminal X4M earth, 1, 2, and X2M 13, 14.

10 For other models: Connect the booster heater power supply

cable to the terminal block X3M.

Only for EHBH/X: Connect the booster heater power supply

cable to the circuit breaker (F2B). The earth wire must be

connected to X4M.

11 Connect the solenoid valve power supply cable to terminal block

X7M as shown on wiring diagram B in paragraph "Connections

to be made in the domestic hot water tank electrical box" on

page 6.

12 Fix the cables to the cable tie mountings with cable ties to

ensure strain relief.

13 For other models: Set DIP switch SS2-2 on the PCB to ON.

Only for EHBH/X: Connections to the domestic hot water tank

must be enabled by installer settings on the indoor unit. Refer to

the installer reference guide.

14 When routing out cables, make sure that these do not obstruct

mounting of the unit cover.

× 2 screws supplied.

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

Domestic hot water tank with option kit for air to water heat pump

system

4P344370-1 – 2013.03

Installation manual

6

Page 8

Note: only relevant field wiring is shown.

A4P

K6M

F2B

K3M

K7M

F1B

TR1

TR1

A1P

A1P

X2M

X1M

K5M

K2M

K1M

K1M

K2M

K5M

K4M

K3M

X9A

X13A

1 2423

X4M X2M

>50 mm

X4M

X3M

3-way

valve

L

BRN

BLU

BLK

NY

A11P

K3M

F2B

X13A

X2M

X9A

X3M

X4M

8

9

10

13

14

12 423

X4M X2M

230 V AC

3 kW

LN

400 V AC

3 kW

L1L2

V3

Z2

3-way

valve

L

BRN

BLU

BLK

NY

K3M

F2B

X2M

X9A

X3M

X4M

A11P

For EKHBH/X units only

For E(D/B)(H/L)Q011-014-016 units only

Installation manual

7

Domestic hot water tank with option kit for air to water heat pump

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

4P344370-1 – 2013.03

system

Page 9

For EKCBH/X units only For EHBH/X units only

230 V AC

3 kW

LN

400 V AC

3 kW

L1L2

V3

Z2

12 423

X4M X2M

3-way

valve

L

BRN

BLU

BLK

NY

X9A

X13A

X3M

F2B

X4M

X2M

A1P

K3M

LN Y

3-way

valve

BLK

BLU

BRN

8 9 10 13 14

X2M

8,9,10

A1P

X9A

X2M

13,14

X3M

X4M

A7P

A1P

Q1L

X6M X7M

X7M

K5M K3M

F1B

F2B

X2M

X1M

X4M

X5M

X6Y

X6YA

X6YB

TR1

8 910 1413

X9A

X13A

K1M K2M

12 4

2

13 14

3

X4M X2M

>50 mm

230 V AC

3 kW

LN

400 V AC

3 kW

L1 L2

V3

Z2

M3S

M3S

L

BRN

BLU

BLK

NYL

BLK

BLU

BRN

NY

R5T

A

A

F2BF2B

X4M

X3M

K3M

X3M

1

Booster heater power supply

30

30

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

Domestic hot water tank with option kit for air to water heat pump

system

4P344370-1 – 2013.03

Installation manual

8

Page 10

Installation of the option kit on the domestic hot water tank

H

C

R

F

5

600 mm

>300 mm

D1

D1

D2

Fixed grating

Trapped

10

8

9

6

6

6

11

7

12

13

3

12

600 mm

2

4

EKUHW2WB

6

All pipework and fittings must be flushed free of all flux and debris prior to the fitting of controls of this option kit. Failure to do this

may cause irreparable damage to the controls. Flush the system by opening the hot water tap.

All cautions as under chapter "Installation of the EKHWSU domestic hot water tank" on page 2 remain of extreme importance and

are equally valid in this chapter.

Piping requirements

Tundish

The tundish should be vertical, located in the same space as the

domestic hot water tank and be fitted as close as possible to, but

lower than the temperature and pressure relief valve on the

domestic hot water tank and the expansion relief valve included

in the option kit, with no more than 600 mm of pipe between the

valve outlet and the tundish. The tundish must be visible.

Tundish pipework

Tundish pipework must be 22 mm metal pipe with a minimum

vertical length of 300 mm below the tundish before any elbows

or bends in the pipework. All pipework must have a continuous

fall of at least 1 in 200 thereafter. Maximum permitted

(equivalent) length of 22 mm pipework is 9 m. Each bend or

elbow is equivalent to 0.8 m of pipework.

Sizing of copper discharge pipe D2 for common temperature

relief valve outlet sizes

Valve

outlet

size

15 mm 15 mm 22 mm up to 9 m 0.8 m

(a) The maximum allowed resistance is expressed as a length of straight pipe

(i.e. no ellbows or bends)

Requirements to discharges

Discharge piping, tundish, drain valves, etc. must be

positioned away from any electrical components.

The discharge pipe away from the tundish must terminate in

a safe, visible position without forming any risk to persons in

the vicinity.

If in any doubt, refer to Building Regulation G3.

effluent water

(a)

Resistance

created by

each elbow

or bend

Discharge

pipe size D1

Discharge

pipe size D2

from tundish

Maximum

resistance

Do not install any valves between the domestic hot

water tank and relief valves/expansion vessel.

Installation manual

9

Domestic hot water tank with option kit for air to water heat pump

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

4P344370-1 – 2013.03

system

Page 11

Installation procedure of the option kit

1 Locate the domestic hot water tank in a suitable position to

facilitate the installation of water supply, discharge fittings and

pipework. It is therefore recommended to first read through this

whole procedure.

Refer to the figure on the facing page at the start of this chapter

for full understanding of next procedure steps.

Pre-assembly

Do not install shut-off valves between the expansion relief

valve and the domestic hot water tank.

2 Pre-assemble the T-piece and tundish (parts 3 and 5 of this kit)

so that tundish is ready for installation.

3 Pre-assemble the adaptor and expansion vessel (parts 2 and 4

of this kit) so that the expansion vessel is ready for installation.

4 Manually operate the temperature and pressure relief valve to

ensure free water flow through discharge pipe. Turn knob left.

Water main in

5 Fit the elbow/drain valve (part 6 of this kit) in the cold water

connection <C> of the domestic hot water tank.

6 Position both, the pressure reducing valve with integrated non

return valve and line strainer and the expansion relief valve

(part 1 of this kit) as high as possible and connect it to the water

mains inlet.

The pressure reducing valve and expansion relief valve must be

installed higher than the temperature and pressure relief.

Fit a length of copper tube Ø22 mm (field supply) in between the

elbow/drain valve (procedure step 5) and the pressure reducing

valve.

Make sure to provide for a connection on this pipe to the

expansion vessel (part 4 of this kit).

7 Fit a length of copper tube Ø22 mm (field supply) inbetween the

T-piece (part 7 of this kit) and the pre-assembled expansion

vessel (procedure steps 3 and 6).

Discharge

8 Install the tundish in a vertical position within a maximum of

600 mm away from the temperature and pressure relief valve

and expansion relief valve. (Procedure step 4).

Make sure that you install it so that you can still connect the

15 mm outlet of the expansion relief valve and the horizontal

inlet of the T-piece on top of the tundish. (Procedure step 11)

9 Connect a metal discharge pipe Ø15 mm (field supply) from the

temperature and pressure relief valve to the vertical inlet of the

T-piece on top of the tundish (≤600 mm).

10 Connect a metal discharge pipe Ø15 mm (field supply) from the

expansion relief valve to the horizontal inlet of the T-piece on top

of the tundish (≤600 mm).

11 Connect a metal discharge pipe from the tundish. Refer to

"Tundish pipework" on page 9.

All pipework must have a continuous fall and be fitted conform to

the requirements of the Building Regulation G3.

Only when installing the EKUHW2WB option kit

Flow inlet connection

Check direction of the flow arrow cast on the solenoid valve

body.

Do not grip the valve head while making and tightening up

connections. Either hold brass body in your hand or attach

adjustable spanner across hexagonal or flat faces in valve

body at each port’s screw thread.

13 Make sure that the solenoid 2-way valve is wired up properly as

described in "Connections to be made in the domestic hot water

tank electrical box" on page 6.

After completing the installation

14 After completing the installation, the installer has to fill in the

warning label on the tank with indelible ink. Refer to "Outlook

diagram" on page 4 for location of the warning label.

Commissioning

Filling up

Follow the next steps to fill up the tank:

1 Switch off the power supply.

2 Open each hot water tap in turn to expel air from the system

pipe work.

3 Open the cold water supply valve.

4 Check for leaks.

5 Close all water taps if all air is expelled.

6 Manually operate the temperature and pressure relief valve to

ensure free water flow through the discharge pipe (turn knob

left). Refer to "Main components" on page 3 for location of the

temperature and pressure relief valve.

Draining

Follow the next steps to drain the tank:

1 Switch off the power supply.

2 Turn off the cold water supply valve.

3 Open the hot water taps.

4 Open the drain valve.

12 Fit the solenoid 2-way valve (part 1 of this kit) using the

connection nipples (part 2 of this kit) for screwing into the 3/4"

FBSP flow inlet connection <F> of the domestic hot water tank.

Also refer to "Installation guidelines" on page 4.

The valve must be mounted so that the valve head is above

horizontal level of pipework to prevent that in the highly unlikely

event of a leak, a safety hazard results.

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

Domestic hot water tank with option kit for air to water heat pump

system

4P344370-1 – 2013.03

Installation manual

10

Page 12

Maintenance

Troubleshooting

In order to ensure optimal availability of the unit, a number of checks

and inspections on the unit and the field wiring have to be carried out

at regular intervals.

Before carrying out any maintenance or repair activity,

always switch off the circuit breaker on the supply

panel, remove the fuses or open the protection

devices of the unit.

For E(K)HBH/X units only

Make sure that before starting any maintenance or

repair activity, also the power supply to the outdoor

unit is switched off.

The described checks must be executed at least once a year.

1 Domestic hot water tank booster heater

It is advisable to remove lime buildup on the booster heater to

extend its life span, especially in regions with hard water. To do

so, drain the domestic hot water tank, remove the booster heater

from the domestic hot water tank and immerse in a bucket (or

similar) with lime-removing product for 24 hours

2 Chemical disinfection

If applicable legislation requires a chemical disinfection in

specific situations,involving the domestic hot water tank, please

be aware that the domestic hot water tank is a stainless steel

cylinder containing an aluminium anode.

We therefore advise in these circumstances to use a

non-chloride based disinfectant approved for use with water

intended for human consumption.

3 Temperature and pressure relief valve

Check for correct operation of the temperature and pressure

relief valve. Manually operate the temperature and pressure

relief valve to ensure free water flow through discharge pipe.

Turn knob left.

4 Pressure reducing valve with integrated non return valve and

line strainer

Depending on local water conditions, annual inspection of the

integral line strainer, pressure reducing valve cartridge and

seating may be necessary.

Unscrew the retaining nut of the valve. The complete

operating mechanism, including the strainer can be removed.

Clean the filter mesh and cartridge under running water.

Replace cartridge, ensuring that strainer is correctly located

and reassemble the unit.

5 Expansion relief valve

Check for correct operation of the expansion relief valve.

Manually operate the expansion relief valve to ensure free water

flow through discharge pipe. Turn knob left.

Depending on local water conditions, annual inspection of the

expansion relief valve cartridge and seating may be necessary.

Unscrew the expansion relief headwork from valve body.

Clean valve seat face and seating - do not scratch or damage

either seat face or seating.

Refit in reverse order. Do not over tighten.

6 Unit switch box

Carry out a thorough visual inspection of the switch box and

look for obvious defects such as loose connections or

defective wiring.

Check for correct operation of contactor K3M by use of an

ohmmeter. All contacts of this contactor must be in open

position.

For the anode no maintenance or replacement is required.

If it is necessary to view internal of the cylinder, the booster heater

boss can be used.

This section provides useful information for diagnosing and correcting certain troubles which may occur in the unit.

General guidelines

Before starting the trouble shooting procedure, carry out a thorough

visual inspection of the unit and look for obvious defects such as

loose connections or defective wiring.

Before contacting your local dealer, read this chapter carefully, it will

save you time and money.

When carrying out an inspection on the supply panel or on

the switch box of the unit, always make sure that the circuit

breaker of the unit is switched off.

When a safety device was activated, stop the unit and find out why

the safety device was activated before resetting it. Under no circumstances safety devices may be bridged or changed to a value other

than the factory setting. If the cause of the problem cannot be found,

call your local dealer.

General symptoms

Symptom 1: No water flow from hot taps

POSSIBLE CAUSES CORRECTIVE ACTION

The main water supply is off. The cold water inlet pressure

The strainer is blocked. Turn off the water supply, remove

The cold water inlet pressure

reducing valve is not fitted properly

Symptom 2: Water from hot taps is cold

POSSIBLE CAUSES CORRECTIVE ACTION

The thermal cut-out(s) has/have

operated

The unit is not operating. Check the unit operation. Refer to

The solenoid 2-way valve is not

operating correctly (only when option

kit EKUHW2WB is installed).

Symptom 3: Intermittent water discharge

POSSIBLE CAUSES CORRECTIVE ACTION

Thermal control failure (water will be

hot).

The expansion vessel is broken. Replace the expansion vessel.

reducing valve is not fitted properly

and clean the strainer (see

"Pressure reducing valve with

integrated non return valve and line

strainer" on page 11 on how to do

this).

Check and refit as required (see

"Pressure reducing valve with

integrated non return valve and line

strainer" on page 11 on how to do

this).

Check and reset button(s).

the manual delivered with the unit.

If any faults are suspected, contact

your local dealer.

Check the wiring, F2U and the

plumbing connections to the

solenoid 2-way valve.

Check the setting of the thermostat

(79°C).

Switch off power to the unit.

When discharge has stopped, check

the thermal controls and replace if

faulty.

Contact your local dealer.

Installation manual

11

Domestic hot water tank with option kit for air to water heat pump

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

4P344370-1 – 2013.03

system

Page 13

Symptom 4: Continuous water discharge

POSSIBLE CAUSES CORRECTIVE ACTION

Cold water inlet pressure. Check the pressure reducing valve.

Temperature and pressure relief

valve.

The expansion relief valve is not

functioning properly.

Replace the pressure reducing valve

if the measured pressure is >2.1 bar.

Check and reset button.

Check for correct operation of the

pressure relief valve by turning the

red knob on the valve counter

clockwise:

• If you do not hear a clacking

sound, contact your local dealer.

• In case the water keeps running

out of the unit, close both the

water inlet and outlet shut-off

valves first and then contact your

local dealer.

Technical specifications

Domestic hot water tank specifications

Storage capacity 150 l 200 l 285 l

Hot water capacity

(a)

EKHWSU150B3V3 EKHWSU200B3V3 EKHWSU300B3V3

136 l 175 l 252 l

Overall dimensions (Ø×H) 580×1015 mm 580×1265 mm 580×1715 mm

Booster heater

- power supply 230 V 50 Hz 1P 230 V 50 Hz 1P 230 V 50 Hz 1P

- running current 13 A 13 A 13 A

- capacity 3 kW 3 kW 3 kW

Operating pressure / set pressure of the pressure

reducing valve

3.5 bar 3.5 bar 3.5 bar

Maximum primary working pressure (heating side) 2.5 bar 2.5 bar 2.5 bar

Expansion vessel pre-charge pressure 2.5 bar 2.5 bar 2.5 bar

Preset opening pressure of expansion relief valve 8 bar 8 bar 8 bar

Maximum design pressure 10 bar 10 bar 10 bar

Preset opening temperature of temperature and

pressure relief valve

Set opening pressure of temperature

and pressure relief valve

Temperature and pressure relief valve replacement

part number

Connections 3/4" FBSP

90~95°C 90~95°C 90~95°C

10 bar 10 bar 10 bar

302810P 302810P 302810P

(b)

3/4" FBSP

(b)

3/4" FBSP

(b)

Weight

-empty 38 kg 46 kg 60 kg

- when full 188 kg 246 kg 345 kg

Mounting Wall or floor Floor Floor

Supply temperature time

Maximum water supply pressure 8 bar 8 bar 8 bar

Re-heat time

(a)(d)

Maximum operating temperature of the heating fluid

Pressure drop through the primary heater

Primary heating power input(d)

Primary flow rate

Standing heat losses

(a)(c)

(a)

(a)

(a)

(a)

(a)

41.98 min 31.96 min 46.08 min

41.61 min 31.82 min 45.68 min

80°C 80°C 80°C

20 kPa 50 kPa 50 kPa

10.1 kW 17.3 kW 17.1 kW

15 l/min 15 l/min 15 l/min

1.55 kWh/24h 1.77 kWh/24h 2.19 kWh/24h

Corrosion protection: anode Aluminium Aluminium Aluminium

(a) Values according to EN12897.

(b) FBSP = Female British Standard Pipe.

(c) The time it takes to increase the temperature from 15°C to 60°C.

(d) The time it takes to increase 70% of the vessel back up to 60°C.

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

Domestic hot water tank with option kit for air to water heat pump

system

4P344370-1 – 2013.03

Installation manual

12

Page 14

Pressure reducing valve specifications

0

1

2

3

4

5

6

10 20 30 40 50 60 70 80 90

0

Q2T

Q2L

X5M

SR

NL

T

VUW

13 14 1 2

X4M

X2M

K3M

X6M

Q3L

Q2L

E4H

F2U

X7M

F2B

3

4

3

4

domestic hot water tank

electrical box

solenoid

valve

Y1S

EKUHW2WB

unit switch box

2

1

2

1

A2

A1

The pressure drop graphic of the pressure reducing valve is

shown below.

7

A

100

B

70% back pressure

Open outlet

A Pressure drop (bar)

B Flow rate (l/min)

The outlet flow rates in function of inlet flow and inlet pressure

are shown below.

Outlet flow (l/min)

Static inlet

pressure

(bar)

10 20 30 40 50 60 70 80 90

1 10 18 25 30 34 37 39 40 42

2 10 19 27 34 40 44 48 51 53

3 10 20 28 36 42 48 53 57 60

4 10 20 28 37 44 51 56 61 65

5 10 20 29 37 46 53 60 66 71

Inlet flow (l/min)

Field wiring diagram

E4H ........................Booster heater

F2B.........................Fuse booster heater

F2U.........................Fuse 5 A/250 V

K3M ........................Contactor booster heater

L .............................Live

N.............................Neutral

Q2T ........................Thermostat domestic hot water tank

Q2L.........................Thermal protector domestic hot water tank

Q3L.........................Thermal protector booster heater

Y1S.........................Solenoid valve

X1M ........................Terminal block

X5M~X7M ..............Terminal block

..........................Protective earth

...................Field wiring

Installation manual

13

Domestic hot water tank with option kit for air to water heat pump

EKUHWBB + EKUHW2WB + EKHWSU150-300B3V3

4P344370-1 – 2013.03

system

Page 15

Page 16

*4P344370-1 0000000J*

4P344370-1 2013.03

Copyright 2013 Daikin

Loading...

Loading...