Daikin DCG036XXX3BXXX, DCG036XXX3DXXX, DCG048XXX3DXXX, DCG048XXX1DXXX, DCG048XXX3BXXX Technical Manual

...

TECHNICAL MANUTECHNICAL MANU

TECHNICAL MANU

TECHNICAL MANUTECHNICAL MANU

ALAL

AL

ALAL

DCG Commercial Gas Units

3 - 6 Tons with R410A

• Refer to Service Manual RSD6412006 for installation, operation, and troubleshooting information.

• All safety information must be followed as provided in the Service Manual.

• Refer to the appropriate Parts Catalog for part number information.

• Models listed on page 4.

This manual is to be used by qualified, professionally trained HVAC

technicians only. Daikin does not assume any responsibility for property

damage or personal injury due to improper service procedures performed by an unqualified person.

Copyright ©2013

RTD6412016

June 2013

TABLE OF CONTENTS

PRODUCT IDENTIFIACTION...................................................3 - 4

PRODUCT DESIGN

-OVERVIEW............................................................... 5

-LOCATION AND CLEARANCES.................................. 5

-ROOFTOP INSTALLATION..........................................6

-RIGGING INFORMATION............................................ 6

-HIGH ALTITUDE DERATE........................................... 7

-BLOWER PERFORMANCE DATA CHART................... 8

ELECTRICAL DATA................................................................. 7 - 9

A* REVISION UNITS

-PRODUCT DIMENSIONS...........................................10

-CORNER WEIGHTS..................................................11

-COOLING SPECIFCIATIONS................................12 - 16

-BLOWER PERFORMACE DATA..........................17 - 22

-HIGH STATIC..........................................21 - 22

-COOLING PERFORMANCE DATA........................23 - 31

-WIRING DIAGRAMS............................................32 - 51

-ACCESSORIES.........................................................52

WARNING

WARNING

WARNING

arising from improper service or service procedures. If

you install or perform service on this unit, you assume

responsibility for any personal injury or property damage

which may result. Many jurisdictions require a license to

install or service heating and air conditioning equipment.

WARNING

WARNING

WARNING

WARNING

erty damage, personal injury, reduced unit performance

and/or hazardous conditions may result from the use of

such non-approved devices.

Disconnect ALL power before servicing or installing this unit. Multiple power

sources may be present. Failure to do so may cause property damage, personal

injury or death.

Daikin will not be responsible for

any injury or property damage

The United States Environmental Protection Agency (“EPA”) has issued various regulations regarding the introduction and disposal of refrigerants introduced into this unit. Failure to follow

these regulations may harm the environment and can lead to the imposition of substantial fines.

These regulations may vary by jurisdiction. Should questions arise, contact your local EPA office.

Do not connect or use any device

that is not design certified by Daikin

for use with this unit. Serious prop-

WARNING

HIGH VOLTAGE!

WARNING

WARNING

try level technician" as specified by the Air-Conditioning,

Heating, and Refrigeration Institute (AHRI) may use this

information. Attempting to install or repair this unit

without such background may result in product damage,

personal injury or death.

WARNING

WARNING

do not store combustible materials or use gasoline or

other flammable liquids or vapors in the vicinity of this

appliance.

ONLY individuals meeting (at a minimum) the requirements of an "en-

To prevent the risk of property

damage, personal injury, or death,

2

PRODUCT IDENTIFICATION

H

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information.

D C C 240 60 3 B * * *

1 2 3 4 , 5, 6 7, 8, 9 10 11 12 13 1 4

Brand

DDaikin

Configuration

C Commercial Pa ckage X No Options

A Non-powered convenience outlet

Applica tion

CCooling C Low A mbient Ki t

GGas Heat D Return air smoke detector

HHeat Pump E S upply air smoke de tector

Nominal Gross Cooling Capacity

036 3 Tons 102 8½ Tons Return air smoke detector

048 4 Tons 120 10 Tons H Non-powered convenience outlet;

060 5 Tons 150 12½ Ton s Supp ly air sm oke de tector

072 6 Tons 180 15 Tons J Non-powered convenience outlet;

090 7½ T ons 24 0 20 T ons Return & Supply air sm oke detectors

Nominal Heating Capacity

DCG DCC/DC

045 45,00 0 BTU/h XXX No Heat Low Ambient Kit;

090 9 0,000 BTU/h 0 10 10 kW 030 30 kW Return & Supply air sm oke detectors

115 115,000 BTU/h 015 15 kW 031 30 kW M Powered convenience outlet;

140 140,000 BT U/h 0 16 15 kW 0 45 45 kW Low A mbient Ki t

210 210,000 BTU/h 018 18 kW 046 46 kW N Powered convenience outlet;

350 350,000 BTU/h 020 20 kW 060 60 kW Return air smoke detector

400 400,000 BTU/h 025 25 kW

See p roduc t specific ation s for hea t size(s ) available for each capac ity. P P owered conveni ence outlet;

Vol tage

1 20 8V 1-Ph ase 4 4 60V 3-P hase Low Ambient Kit;

3 20 8v 3-Phase 7 5 75V 3-P haze Ret urn air smoke detect or

Supply Fan/Drive Type/Motors

B B elt D rive V 2 -Speed B elt Drive Ret urn & S upply ai r sm oke dete ctors

DDirect Drive U Non-powered convenience outlet;

Factory-In stalle d Options

XNo Options

A D ownflo w Economizer

H Disconnect Switch (non-fused)

J Do wnflo w Economi zer ; Disconnect Swit ch ( non-fused)

Note: Not all options available for all products.

Factory-Installed Options

• Stainless-Steel Heat Exchanger (DCG unit s only): A tubular heat exchanger made of 409-type

stainless steel is installed in the unit.

• Low-Ambient Kit: Allows for cooling operation at lower outdoor t emperatures. On the 3-6 ton units, cooling operation is extended for 60ºF

ambient temperatu re to 35ºF outsid e air temperature. On 7½ to 20 ton uni ts, cooling op eration is extended from 35ºF ambient temperature to 0ºF

outside air temperature.

• Economizers (D ownflow): Based on air conditions, can prov ide outside air to cool the space.

• Electric Heat Kits (DCC and DCH units only): Available in all voltage options.

• Non-powered C onvenience Outlet: A 120V,15A,GFCI outlet makes it easier for technicians to service the unit once an electrician runs power to the outlet.

• Powered Convenience Outlet: A 120V, 15A, GFCI outlet powered with a transformer built into the unit ; for use when unit is not running.

• Disconnect Switch (non-fused): A dis connect swit ch is installed in the unit and fac tory wiring w ill be complete from the switch to the unit. Please not e

that for air c onditioning (DC C units) and heat pump models (DCH units), the appropriate electric heat kit must be ordered to be factory-installed along

with the disconnect switch (non-fused) when it is ordered. Please note that for models with a powered convenience outlet option and a disconnect switch

(non-fused) opt ion, the power to the powered conv enience outlet will be shut off when the disconnect switch (non-fused) is in the off position.

• Return Air and/or Supply Air Sm oke Detectors: Return air and/or supply air smoke detectors are installed in the unit.

(Factory-Installed Electric Heat)

B P owered convenience outlet

F Non-powered convenience outlet;

G Non-powered convenience outlet;

K Non-powered convenience outlet;

L Non-powered convenience outlet;

O Power ed convenience outlet;

Q Power ed convenience outlet;

R Powered convenience outlet;

T Powered c onvenience outlet;

V L ow Ambient Kit;

W Low Ambient Kit;

Y L ow Ambient Kit;

Z Ret urn & S upply ai r smok e detec tors

X Standard A luminized Hea t Exchan ger

S Stai nless S teel He at Exchanger

*

A

15 16

Revi sion Leve ls

Major & Minor

Fac tory-In stalle d Optio ns

Low Ambient Kit

Low -ambien t kit; Su pply air s moke d etector

Return & Supply air sm oke detectors

Supp ly air sm oke de tector

Low Ambient Kit; Supp ly air sm oke d etector

Low Ambient Kit;

Low- ambient k it; Return air smok e detector

Return air smoke detector

Return & Supply air sm oke detectors

Return & Supply air sm oke detectors

Factory-Installed Options

3

PRODUCT IDENTIFICATION

The model number is used for positive identification of component parts used in manufacturing. Please use this number

when requesting service or parts information. NOTE: All unit combinations are not listed below. Models where performance

does not change are not listed individually.

DCG036XXX1DXXX

DCG036XXX3DXXX

DCG036XXX3BXXX

DCG036XXX4BXXX

DCG036XXX7BXXX

DCG048XXX1DXXX

DCG048XXX3DXXX

DCG048XXX3BXXX

DCG048XXX4BXXX

DCG048XXX7BXXX

DCG060XXX1DXXX

DCG006XXX3DXXX

DCG060XXX3BXXX

DCG060XXX4BXXX

DCG060XXX7BXXX

DCG072XXX3BXXX

DCG072XXX4BXXX

DCG072XXX7BXXX

4

PRODUCT DESIGN

DCG Light Commercial Package Gas Units are designed for

outdoor installations only, primarily in light commercial applications and are available in 208-230 volt single phase, 208230 volt three phase, 460 volt three phase and 575v three

phase in 3 thru 6 ton sizes with 1 compressor.

The connecting ductwork (Supply and Return) can be connected for either horizontal or vertical airflow. In the vertical

application, a matching Roof Curb is recommended.

The removal of condensate water from the indoor coil can be

achieved by either the 3/4" NPT female fitting on the end of

the unit or by the 3/4" NPT female fitting located on the bottom of the condensate pan. (Do not reduce the drain line

size).

Refrigerant flow control is achieved by use of flowrator type

metering device.

DCG units use the FasTest Access Fitting System which

consists of a saddle soldered to the suction and liquid lines

and then screwed into the saddle. NOTE: The core must

not be removed from the saddle until the refrigerant

charge has been removed. Failure to do so could result

in property damage or personal injury.

- Operating pressures and amp draws may differ from standard reciprocating compressors. This information may be

found in the “Cooling Performance Data” section.

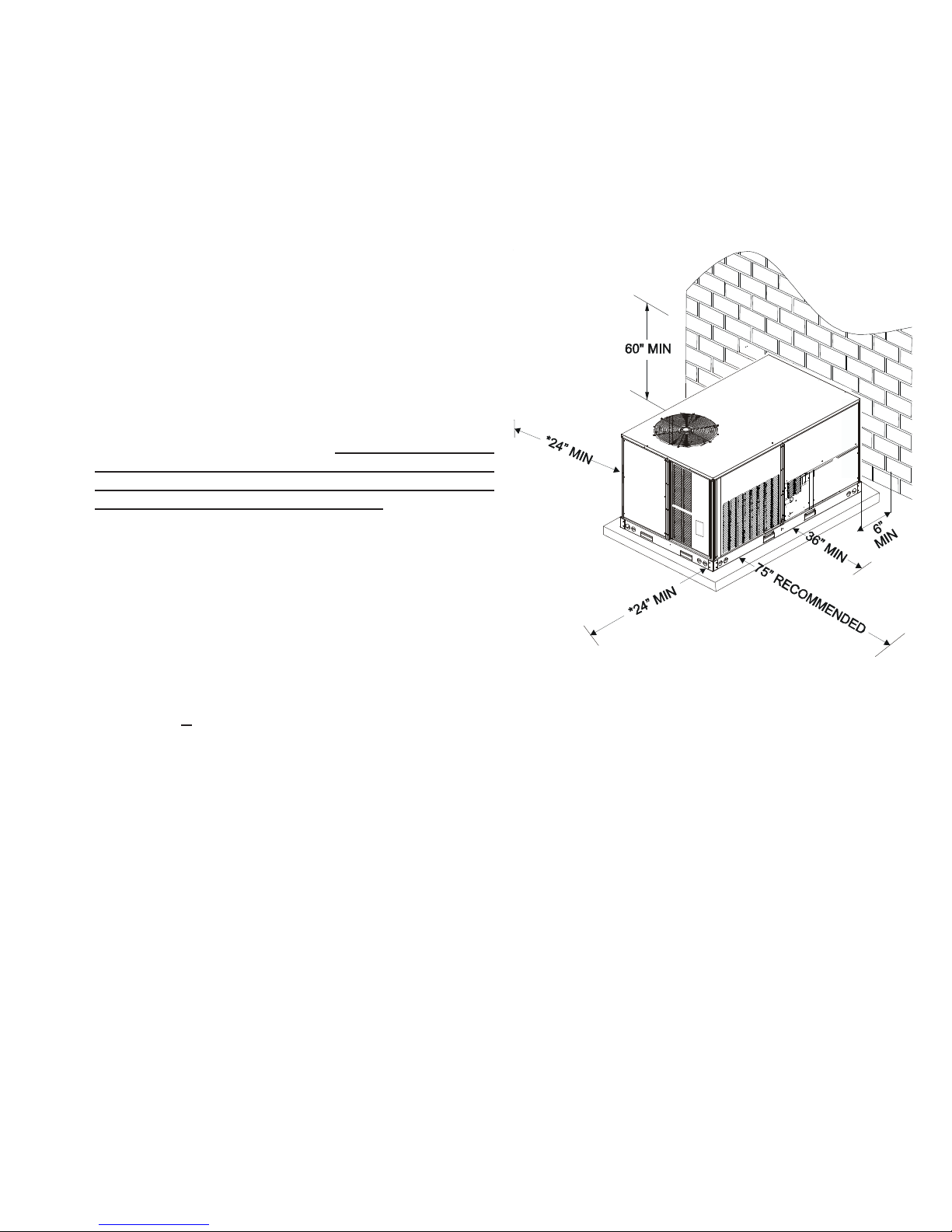

Location and Clearances

Filters are factory supplied in the return air compartment upstream from the indoor coil. The minimum filter area should

not be less than those sizes listed in the Specification Section. Under no circumstances should the unit be operated

without return air filters.

Conditioned air is drawn through the filter(s), across the coil

and back into the conditioned space by the indoor blower.

DCG***XXX*D units indoor blower motors are PSC or EEM

type motors.

DCG***XXX*B units have 3 phase belt drive indoor blower motors that are energized through the blower motor contactor.

Air for condensing (cooling cycle) is drawn through the outdoor coil by a propeller fan, and is discharged vertically out

the top of the unit. The outdoor coil is designed for .0 static.

No additional restriction (ductwork) shall be applied.

DCG series package units use the Compliant Scroll compressor; there are a number of design characteristics which

are different from the traditional reciprocating compressor.

- Due to their design Scroll compressors are inherently more

tolerant of liquid refrigerant. NOTE: Even though the compressor section of a Scroll compressor is more tolerant

of liquid refrigerant, continued flood back or flooded start

conditions may wash oil from the bearing surfaces causing premature bearing failure.

- These Scroll compressors use "POE" or polyolester oil

which is NOT compatible with mineral oil based lubricants

like 3GS. "POE" oil must be used if additional oil is required.

- Compliant scroll compressors perform “quiet” shutdowns

that allow the compressor to restart immediately without

the need for a time delay. This compressor will restart

even if the system has not equalized.

* In situations that have multiple units a minimum of 48" is

required between the condenser coils.

Outside Slab - Multi-positional

NOTE: A clearance of 48" is recommended on all sides of

the unit and 75" total clearance is recommended on the main

control panel side to facilitate possible fan shaft, coil, electric heat and gas furnace removal. See figure above.

Roof overhang should be no more than 36" and provisions

made to deflect the warm discharge air out from the overhang.

Minimum clearances are required to avoid air recirculation

and keep the unit operating at peak efficiency.

5

PRODUCT DESIGN

Rigging Information

INSULATED

PAN ELS

Rooftop Installation

IIn installations where the unit is installed above ground level

and not serviceable from the ground (Example: Roof Top installations) the installer must provide service platform for service person with rails or guards in accordance with local codes

or ordinances or in their absence with the latest edition of the

National Fuel Gas Code ANSIZ223.1.

NOTE: Unit must use roof curb or adaptor (and platform for

leveling, where necessary) to utilize bottom discharge.

WARNING

IMPORTANT: When using bottom discharge with roof curb,

ductwork should be attached to the curb prior to installing

the unit.

Refer to Roof Curb Installation Instructions for proper curb

installation. Curbing must be installed in compliance with

the National Roofing Contractors Association Manual.

1. Unit must be lifted by the four lifting holes located at the

the base frame corners.

2. Lifting cables should be attached to the unit with shackles.

3. The distance between the crane hook and the top of the

unit must not be less than 60”.

4. Two spreader bars must span over the unit to prevent

damage to the cabinet by the lift cables. Spreader bars

must be of sufficient length so that cables do not come

in contact with the unit during transport. Remove wood

struts mounted beneath unit base frame before setting

unit on roof curb. These struts are intended to protect

unit base frame from forklift damage. Removal is accomplished by extracting the sheet metal retainers and

pulling the struts through the base of the unit. Refer to

rigging label on the unit.

CAUTION

6

PRODUCT DESIGN

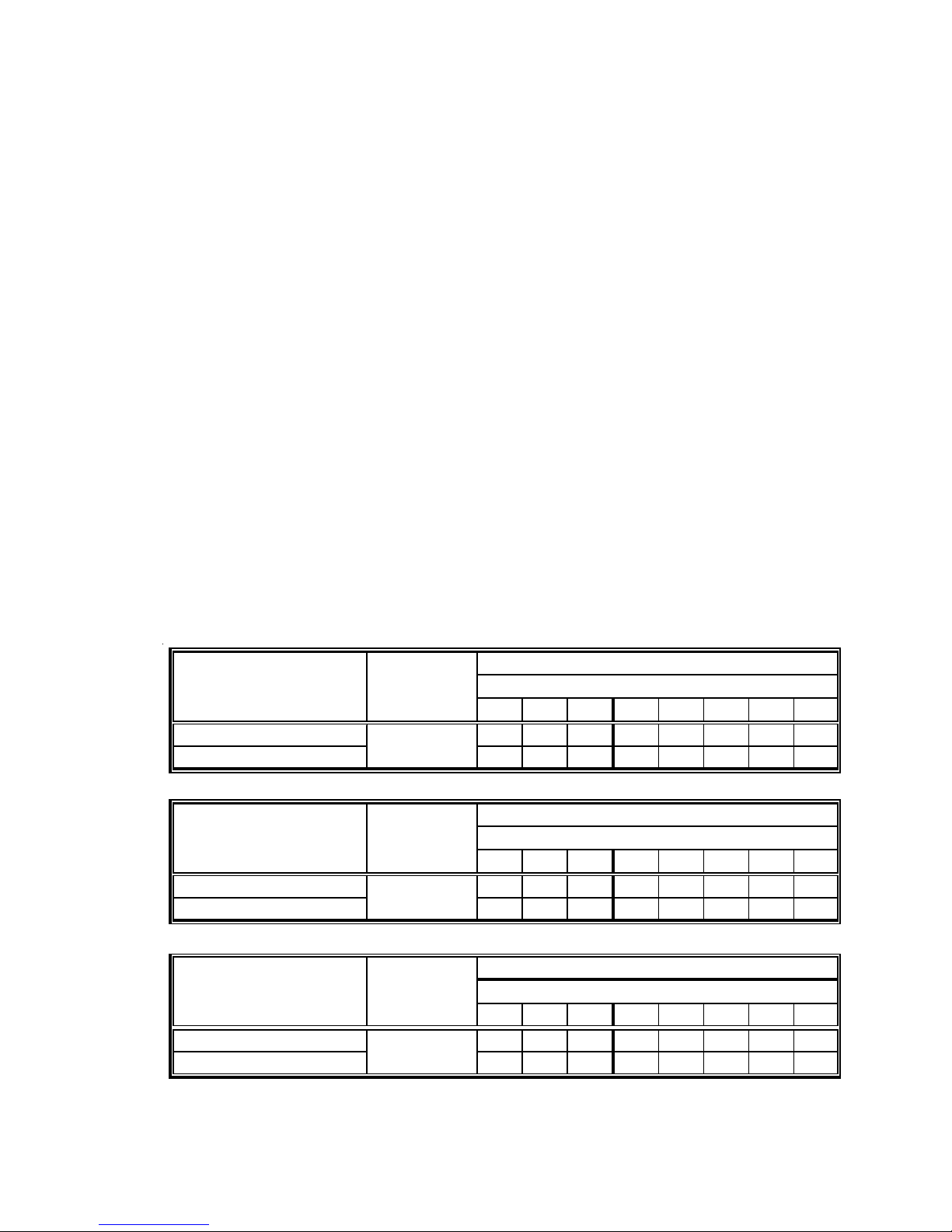

High Altitude Derate - U.S. Installations Only

IMPORTANT NOTE: The gas/electric units naturally derate with altitude. Do not attempt to increase the firing rate by

changing orifices or increasing the manifold pressure. This can cause poor combustion and equipment failure. At all

altitudes, the manifold pressure must be within 0.3 inches W.C. of that listed on the nameplate for the fuel used. At all

altitudes and with either fuel, the air temperature rise must be within the range listed on the unit nameplate. Refer to the

Installation Manual provided with the LP kit for conversion from natural gas to propane gas and for altitude adjustments.

When this package unit is installed at high altitude, the appropriate High Altitude orifice kit may be installed. As altitude

increases, there is a natural reduction in the density of both the gas fuel and combustion air. This kit will provide the proper

design certified input rate within the specified altitude range. High altitude kits are not approved for use in Canada. For

installations above 2,000 feet, use kit HA-02. The HA-02 kit is used for both Natural and LP gas at high altitudes.

For DCG036045, use LPT-00A propane conversion kit for propane conversions at altitudes below 2000 feet. Natural gas

installations below 2000 feet do not require a kit. For all other 3, 4 and 5 ton models, use LPM-05.

For propane conversion above 2000 feet, high altitude kit HA-02 is required in addition to propane conversion kit LPT-00A

or LPM-05.

INPUT/BURNER

U.S. BURNER ORIFICE 45/55 47/55 47/56 - 47/56 48/57 48/58 4 9/58

CANADA BURNER ORIFICE 45/55 - - 48/57 - - - -

INPUT/BURNER

U.S. BURNER ORIFICE 44/55 44/55 45/56 - 45/56 46/57 47/58 4 7/58

CANADA BURNER ORIFICE 44/55 - - 47/57 - - - -

INPUT/BURNER

U.S. BURNER ORIFICE 43/55 43/55 44/56 - 44/56 44/56 45/57 4 5/57

CANADA BURNER ORIFICE 43/55 - - 46/57 - - - -

HIGH ALTITUDE

KIT

2000 3000 4000 4 500 5000 6000 7000 8000

HA-02

HIGH ALTITUDE

KIT

2000 3000 4000 4 500 5000 6000 7000 8000

HA-02

HIGH ALTITUDE

KIT

2000 3000 4000 4 500 5000 6000 7000 8000

HA-02

20,000 BTUH NAT/20,000 BTUH/L. P.

ELEVATION ABOVE SEA-L EVEL ( FEET)

22,500 BTUH NAT/20,000 BTUH/L. P.

ELEVATION ABOVE SEA-L EVEL ( FEET)

25,000 BTUH NAT/20,000 BTUH/L. P.

ELEVATION ABOVE SEA-L EVEL ( FEET)

7

PRODUCT DESIGN

÷ CFM

130 140 150

FORMULAS

BTU OUTPUT = CFM x 1.08 x RISE

1.08

BTU OUTPUT

RISE =

100

2400 CFM

2200

2000

1800

1600

1400

1200

1100

1000

900

800

OUTPUT BTU/HR x 1000

90

700

80

BTU OUTPUT vs TEMPERATURE RISE CHART

600 CFM

100

8

70

60

50

30 40 50 60 70 80 90 110 120

40

30

20

10

TEMPERATURE RISE

DCG Package Gas Units

3 - 6 Tons with R410A

A* REVISION UNITS

9

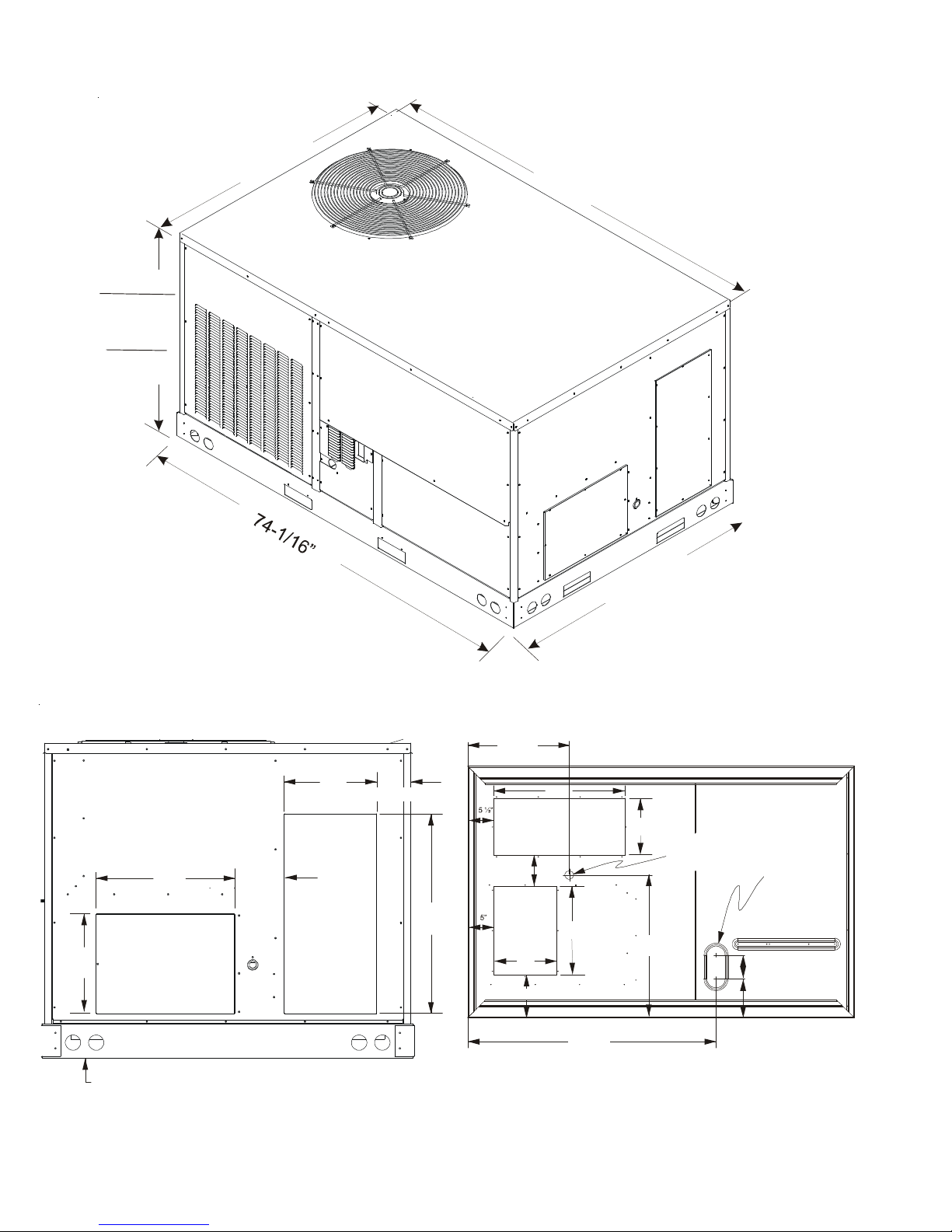

PRODUCT DIMENSIONS

V

”

2

/

1

-

7

4

3

-

5

T

O

N

S

3

8

-

1

3

1

/

6

”

6

T

O

N

S

4

2

-

1

3

/

1

6

”

DCG036-072XXX**XXXA*

7

3

-

1

/

4

”

HORIZONTAL DISCHARGE

17” 7 3/8”

12”

SUPPLY

11”

RETURN

4 7/8”

25”

”

6

1

/

3

-

8

4

ERTICAL DISCHARGE

19 7/16”

25”

RETURN

6 1/4”

SUPPLY

12”

7 13/16”

17”

11”

27 3/8”

DRAIN

THRU CURB

LOCATION

EMBOSS

FOR

THRU THE

BASE

UTILITIES

4 1/2”

7 1/2”

6 1/4”

For horizontal discharge, remove the supply and return duct covers and

place them over the vertical discharge return and supply openings. Install

with insulation facing up, using the longer screws provided in the literature package.

10

47 1/2”

BOTTOM VIEW OF UNIT

CORNER WEIGHTS

A

Corner & Center of Gravity Locations

NOTES:

1. Weights are for belt drive gas unit; no options.

2. Centers of gravity weights are for belt drive gas units

without options.

Provisions for forks have been included in the unit base frame

on three sides. If unit is moved by forklift, no other fork locations are approved.

CAUTION

3 - 6 TONS

DCG036-072XXX**XXXA*

CORNER WEIGHTS

Model

A * Rev

X

(in)Y(in)

Corner Weights ( lbs )

ABCD

DCG036045* 37 30 100 165 100 165

DCG036090* 37 30 100 170 100 170

DCG048090* 37 30 110 180 110 180

DCG048115* 37 30 110 180 110 180

DCG060090* 37 30 113 187 118 192

DCG060140* 37 30 118 192 118 192

DCG072140* 37 30 127 210 127 211

* Weights shown are belt drive with no accessories.

24 1/4”

COMPRESSOR

CONDENSER COIL

RETURN

EVAPORATER COIL

C

B

39”

CENTER OF GRAVITY 3 - 6 TONS

SUPPLY

D

11

PACKAGE GAS SPECIFICATIONS

DCG 0360451DXXA*DCG0 360901DXXXA*DCG04 80901DXXXA*DCG048 1151DXXXA*DCG 0600901D XXXA*DCG06014 01DXXX

COOLING COOLING CA PACITY , BTUH 34,60 0 34,600 45,500 45,500 58,000 58,000

CAPACITY SE ER/EER 13/11.0 13/11. 0 13/11. 3 13/11.3 13/11 .1 13/11. 1

HEATING

CAPACITY LO W HEATING I NPUT / O UTPUT BTUH --- 69,000 / 55 ,200 69,000 / 55,000 86,25 0 / 69,00 0 69,000 / 55, 000 103, 000 / 83,000

UNIT VOLTAG E (NAME PLATE) 2 08-230/1/60 20 8-230/1/60 208 -230/1/60 2 08-230/1/60 20 8-230/1/60 208 -230/1 /60

ELEC TRIC AL UNIT A MPS (TOTAL) 20.6 20.6 24 .1 24.1 35.4 35.4

SPECIFIC ATION

HEATING NUMBER OF BURNERS 244546

SECT ION ORIFICE SIZE NATURAL 43 43 43 4 3 43 43

COMPRESSOR TYP E SCROLL SCROLL SCROLL SCROLL SCR OLL SCRO LL

RATED L OAD AMP S 16.7 16.7 19.9 19.9 26.4 26 .4

CONDENSER HORSEPOWER 1/41/41/41/41/41/4

FAN MOTOR RPM 10 90 1090 1090 1090 109 0 1090

CONDENSER FAN BLAD E DIAMET ER( ") / # OF BLADES 22/4 22/4 22/4 22/4 22/ 4 22/4

CONDENSER FACE AREA - SQ. FT.

COIL NUMBER O F ROWS

EVAPORATOR HORSEPOWER - TY PE 1/3 - DIRE CT DRIVE 1/3 - DIRECT DRIVE 1/2 - DIRECT DRIVE 1/2 - DIRECT DRIVE 1.0 - DI RECT DRIVE 1.0 - DIRECT DR IVE

BLOWER NO. OF SP EEDS PSC - 3 P SC - 3 PSC - 3 PSC - 3 EE M - 5 E EM - 5

MOTOR

EVAPORATOR DIAM ETER X WIDTH (IN CHES) 10 X9 10 X9 10 x 9 10 x 9 11 X 10 11 X 10

BLOWER RATED S CFM COOLING 1200 120 0 1 600 1600 200 0 2 000

EVAPORATOR FACE AREA - SQ. FT.

COIL NUMBER O F ROWS

HEATING PRIM ARY LIMI T SETT ING (° F) 14 0 120 120 1 40 14 0 220

LIMITS AUXILIARY LI MIT SETTI NG (°F) 120 150 150 150 150 150

GENERAL FILTER SIZE - SQ. FT.

INFORMATION DRAI N SIZE (INCHES)

HIGH HEATI NG INPUT / OUTPUT BTUH 4 6,000 / 36,80 0 92 ,000 / 74,000 92,000 / 74, 000 11 5,000 / 92,0 00 92 ,000 / 74,000 1 38,000 / 110 ,400

A.F. U.E. (%) 80 80 80 80 80 80

TEMPERAT URE RISE (° F) HI/LOW 25 - 55 4 0 - 70 / 30 - 60 30 - 60 / 15 - 45 40- 70 / 25 - 55 20 - 50 / 15 - 45 35 - 65 / 25 - 55

MINI MUM CIRC UIT AMP ACITY 25 25 29 29 42 42

MAXIMUM OVERCURRENT PROTECTION

ORIFICE SIZE LP 55 55 55 55 55 55

PRESSURE SWTICH SETTING 0.340.340.340.340.340.34

LOCKED R OTOR AMPS 79 79 109 1 09 134 134

RATED L OAD AMP S 1.40 1.40 1.40 1.40 1.40 1.4 0

LOCKED R OTOR AMPS 2.9 2 .9 2. 9 2. 9 2 .9 2. 9

NOMINAL C FM 3,800 3,800 3,800 3, 800 3,800 3,800

FI NS PE R INC H

FULL LO AD AMPS 2.5 2.5 2. 9 2.9 7 .6 7. 6

LOCKE D ROTO R AMPS -- -- 5 5 --- - --

MOTOR SPEED TAP - COOLING LOW SPE ED LOW SPEED Medium Medium T4 T4

RPM 890 890 1 000 10 00 105 0 1 050

MAX EXTERNAL STATIC PRESS ("w.c.) 0.5 0.5 0.6 0.6 0.9 0.9

FI NS PE R INC H

ROLLOUT L IMIT SET TING (°F) 350 350 350 350 350 350

EXPA NSION D EVICE

REFRIGERANT CHARGE R-410A (Oz.)

POWER SUPPLY CONDUIT HOLE SIZE (") 1.97" 1.97" 1.97" 1.97" 1.97" 1.97"

KNOCKOU TSIZE (" ) 1.125 1.125 1.125 1. 125 2.56" 2.5 6"

LOW VOLTAG E CONDUIT HO LE SIZE (") 1/2" 1/ 2" 1/ 2" 1/2 " 1/ 2 1/2

LOW PRESS URE SWIT CH (OPEN/CLO SE-PSIG) 22/50 22 /50 22/ 50 22/5 0 55/95 55/ 95

HIGH PRESSURE SWITCH (OPENS-P SIG) 660 66 0 660 660 660 660

SHIPPING WEIGHT LBS.

OPERATIN G WEIGHT LBS.

(2)

40 40 45 45 60 60

17 17 17 17 1 2.5 12 .5

111122

24 24 24 24 27 27

5.45.4 7 7 7.87.8

334444

16 16 16 16 16 16

(1) 24 "X 24" x 2" (1) 24"X 24" x 2" (4) 14" X 2 0" x 2" (4) 14" X 20" x 2" (4) 1 4" X 20" x 2" (4) 14" X 20" x 2"

3/4" 3/4" 3/ 4" 3/ 4" 3 /4" 3/ 4"

Orifice (0.068) Orifice (0.068) Orifice (0.076) Orifice (0.076) Orifice (0.086) Orifice (0.086)

83 85 103 1 03 100.8 100 .8

550 560 600 605 635 645

525 535 575 580 610 620

DCG036-060XXX1DXXXA*

A*

(1) Units installed in Canada are certifed only to 4500 feet.

(2) Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

IMPORTANT: While this data is presented as a guide, it is important to electrically connect the unit and properly size wires and fuses/circuit breakers in

accordance with the National Electrical Code and/or all local codes.

12

PACKAGE GAS SPECIFICATIONS

DCG0 360453DXXXA*DCG03 60903DX XXA*DCG 0480903 DXXXA*DCG0 481153DXXXA*DCG06 00903DX XXA*DCG 0601403 DXXX

COOLING CO OLING CA PACITY, BT UH 34,600 34,600 4 5,500 45,500 58,000 58 ,000

CAPACITY SEER/ EER 13/11 .0 13/11. 0 13/1 1.3 13/11 .3 13/11. 1 13/1 1.1

HEATING HIGH HE ATING INPUT / 0UTP UT BTUH 46 ,000 / 36,800 92,0 00 / 74,000 92,00 0 / 74,000 115,000 / 92,000 92,0 00 / 74,000 138,000 / 110,4 00

CAPACITY

UNIT VOLT AGE (NAMEPLA TE) 20 8-230/3/60 208-23 0/3/60 208-230 /3/60 208-2 30/3/60 2 08-230/3/60 20 8-230/3/60

ELEC TRIC AL

SPECIFICAT ION MINIMUM CIRCUIT A MPACITY 17 17 2 1 21 29 29

HEATING NUMB ER OF BU RNERS 2 4 4 5 4 6

SECT ION

COMPRESSOR TYPE SCROLL SCROLL SC ROLL SCROLL SCROLL SCROLL

RATED L OAD AMP S 10.4 10.4 13.1 13 .1 16 16

CONDENSER HORSEPOWER 1/41/41/41/41/41/4

FAN MOTOR RPM 1090 1090 10 90 1090 1090 109 0

CONDENSER FAN

CONDENSER FACE AREA - SQ. FT.

COIL NUMB ER OF ROW S

EVAPORATOR HORSEP OWER - TY PE - STANDARD 1/3 - DIRECT DRIV E 1/3 - DIRECT DR IVE 1/2 - DIRE CT DRIVE 1/2 - DIR ECT DRIVE 1.0 - DIRECT DR IVE 1 .0 - DIREC T DRIV E

BLOWER NO. OF SPEEDS PSC - 3 PSC- 3 PSC - 3 PSC - 3 EEM - 5 EEM - 5

MOTO R RATED L OAD AMP S 2.5 2.5 2.87 2. 87 7.6 7.6

EVAPORATOR

BLOWER RATE D SCFM COO LING 1200 1200 16 00 1600 2000 200 0

EVAPORATOR FACE AREA - SQ. FT.

COIL

HEATING

LIMITS AUXILIAR Y LIMIT S ETTING (°F) 120 1 50 150 150 150 15 0

GENERAL FILTER SIZE

INFORM AT ION DRAIN S IZE (INCH ES)

LOW HEA TING INPU T / OUTPUT B TUH --- 69,000 / 55,00 0 69,00 0 / 55,000 86,250 / 69,000 6 9,000 / 55,0 00 10 3,000 / 83,00 0

STEADY STATE EFFY % 80 80 80 80 80 80

TEMPERA TURE RISE (° F) HI/LOW 25 - 55 / 40 - 70 / 30 - 60 30 - 60 / 1 5 - 45 40-70 / 25 -55 20 - 50 / 15 - 4 5 35 - 65 / 25 - 55

UNIT AMP S (TOTAL) 14.4 14. 4 17.4 17.4 25 25

MAXIMUM OVERCURRENT PROTECTION

ORIFICE SIZE NATURAL 434343434343

ORIFICE SIZE LP 55 55 55 55 55 55

PRESSURE S WITCH S ETTIN G 0.34 0.3 4 0.34 0.34 0.34 0.34

LOCKED R OTOR AMPS 73 73 83.1 83.1 1 10 110

RATED L OAD AMP S 1.4 1.4 1.40 1. 40 1.4 1. 4

LOCKED R OTOR AMPS 2.9 2.9 2.9 2 .9 2.9 2.9

BLADE DIA METER( ") / # OF BLADE S 22/4 22/ 4 22/4 22/4 22/ 4 2 2/4

NOMINAL C FM 3,800 3,800 3 ,800 3, 800 3,800 3,800

FINS PER INCH

LOCKED ROTOR AMPS 3.3 3.3 5 5 -- ---

MOTOR S PEED TAP - CO OLING LOW SPEED LOW SPEED M edium M edium T4 T4

RPM 890 8 90 10 00 1000 1050 105 0

DIAMET ER X WIDT H (INCHES) 10 x 9 10 x 9 10 X 9 10 X 9 11 X 10 11 X 10

MAX EXTERNA L STATIC PRES S ("w.c.) 0 .5 0.5 0.5 0 .5 0.9 0.9

NUMBE R OF ROWS

FINS PER INCH

PRIMAR Y LIMIT SET TING (°F) 140 120 12 0 140 1 40 220

ROLLOUT LIMIT SE TTING (° F) 350 3 50 35 0 350 3 50 35 0

EXPA NSION D EVICE

REFRI GERANT CH ARGE R-41 0A (Oz .)

POWER SUP PLY CONDUIT HO LE (") 1.125 1.125 1 .125 1. 125 1.12 5 1.125

LOW VOLTAG E CONDUIT HOLE 1 /2" 1/2" 1/ 2" 1 /2" 1/2 " 1/2"

LOW PRESSURE SWITC H ( OPEN/CLO SE-PSIG) 22/50 22/50 2 2/50 22 /50 55/95 55/95

HIGH PR ESSU RE SWITCH (OPENS-PSIG ) 660 660 66 0 660 6 60 660

SHIPPING WEIGHT LBS.

OPERATING WEIGHT LBS.

(2)

25 25 3 0 30 40 40

17 18 1 7 17 12. 5 1 2.5

111122

24 22 2 4 24 27 27

5.45.47.07.07.87.8

334444

16 16 1 6 16 16 16

(1) 24"X 24" x 2" (1) 24"X 24" x 2" (4) 14"X 20" x 2" (4) 14"X 20" x 2" (4) 14"X 20" x 2" (4) 14"X 20" x 2"

3/4" 3/4" 3/4" 3/4" 3/4" 3/4"

Ori fice (0. 072) Or ifice ( 0.068) Orifice (0.076 ) Orif ice (0.0 76) ORIFI CE (0.086) ORIFICE (0.086)

83 83 103 103 100 .8 100.8

550 5 60 600 605 6 35 645

525 5 35 575 580 6 10 620

DCG036-060XXX3DXXXA*

A*

(1) Units installed in Canada are certifed only to 4500 feet.

(2) Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

IMPORTANT: While this data is presented as a guide, it is important to electrically connect the unit and properly size wires and fuses/circuit breakers in

accordance with the National Electrical Code and/or all local codes.

13

PACKAGE GAS SPECIFICATIONS

DCG0360453BX XXA*DCG036 0903BX XXA*DC G0480 903BXXXA*DCG048 1153BXXXA*DCG060 1403BXX XA*DC G07214 03BXXX

COOL ING

CAPACITY

HEATING

CAPACITY

UNIT

ELE CTRIC AL

SPECI FICATION

HEATING

SEC TION

COMPRE SSOR

CONDE NSER

FAN MOTOR

CONDE NSER FAN

CONDE NSER

COIL

EVAPORATO R

BLOW ER

MOTOR

EVAPORATO R

BLOW ER

EVAPORATO R

COIL

HEATING

LIMITS

GENERAL

INFORM ATION

COO LING CA PACITY , BTUH 34,600 34,60 0 45,500 45,5 00 58,000 71, 000

SE ER/EER 13/11 .0 13 /11.0 13/11 .3 13 /11.3 13/11.1 11.0

H IGH HEATI NG INPU T / OUTP UT BTUH 46,0 00 / 36,800 92,00 0 / 74,0 00 92 ,000 / 74 ,000 115,0 00 / 92, 000 138,00 0 / 110,4 00 138, 000 / 11 0,400

LO W HEA TING IN PUT / OUT PUT BT UH --- 69,000 / 55,000 69 ,000 / 55 ,000 86,2 50 / 69, 000 103,00 0 / 83,0 00 103 ,000 / 83 ,000

STEADY STATE EFFY % 808080 808080

TEM PERATURE RISE (°F) H I/LOW 25 - 55 40 - 7 0 / 30 - 60 3 0 - 60 / 15 - 45 40-70 / 25-55 35 - 6 5 / 25 - 55 3 5 - 65 / 25 - 55

VO LTAGE (NA MEPLATE ) 208-2 30/3/60 2 08-230/3 /60 20 8-230/3/60 208-2 30/3/60 208- 230/3/6 0 208- 230/3/60

UNIT AMPS (TOTAL) 15.715.718.318.321.222.4

MIN IMUM C IRCUIT AMPACI TY 18 1 8 22 22 25 31

MAXIM UM OVERCURRE NT PROTEC TION

N UMBER OF BUR NER S 2 4 4 5 6 6

ORIFICE SIZE NATURAL 434343434343

ORI FICE SIZE LP 55 55 55 55 55 55

PRE SSURE S WITCH S ETTING 0. 34 0. 34 0 .34 0.3 4 0.34 0. 34

TYP E SCRO LL SCRO LL SCR OLL SCROLL SCROLL SCROL L

RATE D LOAD AMP S 10.4 10.4 1 3.1 13 .1 16 16

LO CKED ROTO R AMPS 73 7 3 83.1 83 .1 11 0 110

HORSEPOWER 1/41/4 1/41/41/41/4

R PM 1090 10 90 109 0 1 090 10 90 109 0

R ATED LOAD A MPS 1. 4 1.4 1.40 1.4 0 1.4 1. 4

LOCKED ROTOR AMPS 2.92.9 2.92.92.94.0

BLA DE DIAMET ER( ") / # OF BLA DES 22 /4 22/4 2 2/4 22 /4 22/4 22 /4

N OMINA L CFM 3,8 00 3,800 3 ,800 3,800 3 ,800 3,800

FAC E AREA - SQ. F T.

NUMBER OF ROWS

FI NS PE R INCH

HORSEPOWER - TYPE - STANDARD

NO. OF S PEEDS

R ATED LOAD A MPS 3. 8 3.8 3.8 3. 8 3.8 5

LO CKED RO TOR AM PS 10 .9 10.9 1 0.9 10 .9 24 18

MOTOR SPEED TAP - COOLING --- --- --- --- --- ---

R PM 1725 17 25 172 5 1 725 17 25 172 5

DI AMETER X WIDTH (INCH ES) 11 X 10 11 X 10 11 x 1 0 1 1 x 10 11 X 10 11 X 10

R ATED SCFM C OOLING 1200 1200 1600 1 600 20 00 2 400

MAX E XTERNAL ST ATIC PRESS ("w.c.) 0.7 0.7 1.0 1.0 1.0 1 .0

FAC E AREA - SQ. F T.

NUMBER OF ROWS

FI NS PE R INCH

PRIM ARY LI MIT SET TING (° F) 140 120 140 140 22 0 140

AUX ILIARY LI MIT S ETTI NG (°F) 120 150 145 150 14 5 150

R OLLO UT LIMIT SETT ING (°F) 350 350 350 350 350 350

FI LTER SIZE

D RAIN SI ZE (IN CHES )

EXPANSI ON DEVICE

REFRIG ERANT CHA RGE R-410 A (Oz.)

PO WER SUP PLY C ONDUIT H OLE (") 1 .125 1.12 5 1.125 1.1 25 1 .125 1.125

LO W VO LTAGE C ONDU IT HOLE 1/ 2" 1/2" 1 /2" 1/ 2" 1/2" 1 /2"

LO W PRE SSURE SWI TCH (OPEN/CL OSE-PSIG) 2 2/50 22/50 22/50 22/50 55/9 5 55/95

HI GH PRESSU RE SWITCH (OP ENS-PSIG ) 660 660 660 660 66 0 660

SHIP PING WEIGHT LBS.

OP ERATIN G WEIGH T LBS . 525 535 575 580 620 675

(2)

25 2 5 30 30 40 45

17 1 8 17 17 12.5 19

111122

24 2 2 24 24 27 27

1.0 - STD STAT IC

BELT DRIVE

11

5.45.4 7.87.87.87.8

334444

16 1 6 16 16 16 16

(1) 24" X 24" x 2 " (1) 24"X 24" x 2" (4) 14"X 20" x 2" (4 ) 14"X 20" x 2" (4) 14 "X 20" x 2" (4 ) 14"X 20 " x 2"

3/4" 3/4 " 3 /4" 3/4" 3/4" 3/4"

Orifi ce (0.0 72) Orifi ce (0.06 8) O rifice (0. 076) O rifice (0. 076) O RIFICE (0 .086) O RIFICE (0 .094)

85 8 3 105 103 1 00.8 146

550 560 600 605 645 700

1.0 - STD STATIC

BELT DR IVE

DCG036-072XXX3BXXXA*

A*

1.0 - STD S TATIC

BELT DRIVE

1111

1.0 - ST D STAT IC

BELT D RIVE

1.0 - STD STATIC

BELT DRIVE

1.5 - ST D STATIC

BELT DRIVE

(1) Units installed in Canada are certifed only to 4500 feet.

(2) Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

IMPORTANT: While this data is presented as a guide, it is important to electrically connect the unit and properly size wires and fuses/circuit breakers in

accordance with the National Electrical Code and/or all local codes.

14

PACKAGE GAS SPECIFICATIONS

(

DCG036 0454BXXXA*DCG0 360904BXX XA*DCG04 80904BXXXA*CPG04811 54BXXXA*DCG06 00904BXXXA*DCG060 1404BXXXA*DCG0 721404BXXX

COOL ING COOLING CAPACIT Y, BTUH 34, 600 34, 600 45,5 00 45,500 58,000 5 8,000 71, 000

CAPACI TY SEER/ EER 13/11.0 13/11. 0 13/11.3 13/11.3 13/11. 1 13/11.1 11 .0

HEATI NG HIGH HEAT ING INPUT / OUTPUT BTUH 4 6,000 / 3 6,800 92, 000 / 74 ,000 9 2,000 / 74,000 115,000 / 92,00 0 92,0 00 / 74,0 00 138,000 / 110,4 00 1 38,000 / 110,400

CAPACI TY LOW HEATING INPUT / OU TPUT BTUH --- 6 9,000 / 55,0 00 69,00 0 / 55,000 86 ,250 / 69,000 69, 000 / 55,0 00 10 3,000 / 83,0 00 103,000 / 83,000

UNIT VOLTA GE (NAMEPLA TE) 460/3/ 60 460/ 3/60 460/3/ 60 4 60/3/60 460/ 3/60 460/3/60 460/3/ 60

ELE CTR IC AL UNIT AMPS (T OTAL) 8.5 8.5 8.8 8 .8 10.5 10.5 13.4

SPECIFICATION MINI MUM CIRCU IT AMPACIT Y 1 0 10 1 0 10 13 1 3 16

HEATI NG NUMBER OF BURNERS 2 4 4 5 4 6 6

SEC TIO N ORIFICE SIZE NATURAL 43434343 434343

COMPRE SSOR

RATED LOAD AMPS 5.8 5.8 6.1 6.1 7.8 7.8 9.7

CONDE NSER HORSEPOWER 1/41/41/41/41/41/41/3

FAN MOTOR

CONDE NSER FAN

CONDE NSER FACE AREA - SQ. FT.

COIL NUMBE R OF ROWS

EVAPORATOR HORSEPOWER - T YPE

BLOW ER NO. OF SPEEDS 1 1 1 1 1 1 1

MOTO R RATED LOAD AMPS

EVAPORATOR DIAME TER X WIDT H (INCHES ) 11 X 10 11 X 10 1 1 X 10 11 X 1 0 11 X 10 11 X 10 11 X 10

BLOW ER RATE D SCFM COOLI NG 12 00 1200 1600 1600 2 000 2000 2,400

EVAPORATOR FACE AREA - SQ. FT.

COIL NUMBE R OF ROWS

HEATI NG PRI MARY L IMIT SETT ING (°F ) 14 0 120 1 40 14 0 160 220 140

LIMITS AUX ILIARY LIM IT SETT ING (°F) 12 0 150 1 45 15 0 145 145 150

GENERAL FILTER SIZE

INFORMATI ON DRAIN SIZE (INCHES)

A.F.U.E. (%) 80808080808080

TEMPERA TURE RIS E (°F ) HI/LOW 25 - 55 40 - 70 / 30 - 60 30 - 6 0 / 15 - 4 5 40-70 / 25 -55 20 - 50 / 15 - 4 5 35 - 65 / 25 - 55 30 - 60 / 15 - 45

MAXIMUM OVERCURRENT PROTECTION

ORIFICE SIZ E LP 55 55 5 5 55 55 5 5 55

PRESSURE SWTICH SETT ING 0. 34 0.34 0.3 4 0.34 0.3 4 0.34 0. 34

TYPE SCROLL SCROL L SCROLL SCROL L SCROLL SCRO LL S CROLL

LOCKED R OTOR AMPS 38 38 41 41 52 52 62

RPM 890 890 8 90 890 1090 1090 1075

RATED L OAD AMP S 0.8 0 .8 0.80 0. 80 0.8 0.8 1.2

LOCKED R OTOR AMPS 1.7 1 .7 1. 7 1 .7 1. 7 1.7 2.3

BLADE D IAMETER( ") / # OF B LADES 22/4 22/ 4 22/4 22/ 4 22/4 22/4 22/4

NOMINAL C FM 3,800 3, 800 3, 800 3, 800 3,8 00 3,800 4,3 00

FINS PER INCH

LOCKED R OTOR AMPS 10.9 10.9 10.9 1 0.9 13 1 3 12

MOTOR SPEED TAP - COOLING --- --- -- - --- -- -' ---' ---

RPM 1725 1725 1725 172 5 1 725 1725 1725

MAX EXTERNAL STATIC PRESS ("w.c.) 0.7 0.7 1.0 0.8 1.0 1.0 1.0

FINS PER INCH

ROLLOUT L IMIT SE TTING (° F) 350 350 3 50 35 0 350 350 350

EXPA NSION DEVIC E

REFRIGERANT CHARGE R-410A (Oz.)

POWER SUP PLY CONDUIT HO LE (") 1 .125 1.1 25 1.12 5 1.97" 1.125 1.125 1. 125

LOW VOLTAG E CONDUIT HOLE 1/ 2" 1/2" 1/2 " 2.56" 1/ 2" 1/2" 1/2"

LOW PRES SURE SWITCH ( OPEN/CLOSE - 2 2/50 22 /50 22/5 0 22/50 55/ 95 55/95 55 /95

HIGH P RESSURE SWI TCH (OPE NS-PSIG) 66 0 660 660 660 660 66 0 660

SHI PPING W EIGH T LBS.

OPERATI NG WEIGHT LBS. 525 535 5 75 58 0 610 620 675

15 15 15 15 20 2 0 25

17 18 17 17 12 .5 12.5 19

1111222

24 22 24 24 27 2 7 27

1.0 - STD STATIC

BELT DRIVE

1.9 1 .9

5.4 5 .4 7.0 7.0 7.8 7.8 8 .9

3344444

16 16 16 16 16 1 6 16

(1) 24 "X 24" x 2" (1) 24"X 24" x 2 " (4) 14"X 20" x 2" (4) 14"X 20" x 2" ( 4) 14" X 2" x 2" (4) 14" X 20" x 2" (4) 16 " X 20" x 2"

3/4" 3/4" 3/4 " 3/4" 3/ 4" 3/4" 3 /4"

ORIFIC E (0.068) ORI FICE (0.06 8) O rifice (0. 076) Or ifice (0. 076) O RIFICE (0.086 ) ORIFIC E (0.086) ORIF ICE (0.09 4)

83 85 103 103 100 .8 1 00.8 146

550 560 6 00 60 5 630 645 700

1.0 - STD STAT IC

BELT DRIVE

1.0 - ST D STATIC

DCG036-072XXX4BXXXA*

BEL T DR IVE

1.9 1 .9

1.0 - STD ST ATIC

BELT DRIVE

1.0 - STD STAT IC

BELT DRIV E

1.9 1.9 2 .5

1.0 - STD STATIC

BELT DRI VE

A*

1.5 - STD ST ATIC

BELT DRIVE

(1) Units installed in Canada are certifed only to 4500 feet.

(2) Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

IMPORTANT: While this data is presented as a guide, it is important to electrically connect the unit and properly size wires and fuses/circuit breakers in

accordance with the National Electrical Code and/or all local codes.

15

PACKAGE GAS SPECIFICATIONS DCG036-072XXX7BXXXA*

DCG03 60907BX XX

A*

COOLING C OOLING CAPACITY , BTUH 35,0 00 45,50 0 58,000 71, 000

CAPACITY SE ER/EE R 13 /11.0 13/1 1.3 13 /11.1 11.0

HEATING HIGH HEATING INPUT / O UTPUT BTUH 92,000 / 74,000 11 5,000 / 92,0 00 138,000 / 110,400 138, 000 / 110,40 0

CAPACITY LO W HEATING INPUT / OUTP UT BTUH 69,000 / 55,000 86,25 0 / 69,000 103,000 / 83,00 0 103 ,000 / 83 ,000

A.F.U.E. (%) 808080 80

T EMPERATURE R ISE (°F) HI/LOW 40 - 70 / 30 - 6 0 40 - 70 / 25-55 3 5 - 65 / 25 - 55 35 - 65 / 25 - 55

UNIT VO LTAGE (NA MEPLATE ) 575/3/6 0 575/ 3/60 575/3/60 575/3/60

ELECTRICAL UNIT AMPS (TOTAL)

SPECIFICATION MINIMUM CIRCU IT AMPACITY 7.7 8 10 10

HEATING NU MBER OF BU RNER S 4 5 6 6

SECT ION ORIFICE SIZE NATURAL 43 4 3 43 43

COMPRESSO R T YPE SCROLL SCROLL SCROLL SCROLL

RATED LOAD AMPS

CONDENSER HORSEPOWER

FAN MOTOR RPM 1075 10 75 1075 1075

CONDENSER FAN

CONDENSER FACE AREA - SQ. FT.

COIL

EVAPORATOR HORSEPOWER - TYPE

BLOWER NO. OF SPEEDS 1 1

MOTOR RATED LOAD AMPS

EVAPORATOR D IAMETE R X W IDTH (INCHES) 1 1 X 10 11 X 10 11 X 10 11 X 10

BLOWER RAT ED SCFM COOLING 1 200 1600 2000 2400

EVAPORATOR FACE AREA - SQ. FT.

COIL NUMBER OF ROWS

HEATING PRIMAR Y LIMI T SE TTING (°F ) 120 140 220 140

LIMITS AUXILIARY LIMIT SETTI NG (°F) 150 150 145 150

GENERAL FILTER SIZE

INFORMATION D RAIN SIZE (INCHES)

MAXIM UM OVERCURRE NT PROTECTION

OR IFICE SI ZE L P 55 55 55 55

PRESSURE SWTICH SETTING 0.34 0.34 0.34 0.34

LO CKED ROTO R AMPS 36.5 33 38.9 38.9

RATED LOAD AMPS

LO CKED ROTO R AMPS 1.61 1.61 1.61 2.3

BLADE DIAMETER( ") / # OF BLADES

NO MINAL CF M 3,800 3,80 0 3,800 3,800

NUMBER OF ROWS

FINS PER INCH

LOCKED RO TOR AMPS 10.9 10.9 11 12

MOTOR SPEED TAP - COOLING --- ---

RPM 1 725 1725 1725 1725

MAX EXTERNAL STATIC PRESS ("w. c.) 0.7 0.8 1.0 1.0

FINS PER INCH

RO LLOUT LIMIT SETT ING (°F) 350 350 35 0 350

EXPANSI ON DEVICE

REFRI GERANT CHARG E R-410A (Oz.)

POWER SUPPLY CONDUIT HOLE (") 1.125 1.125 1.125 1.125

LOW VOLTAGE CONDUIT HOLE 1/2" 1/2" 1/2" 1/2"

LOW PRESSURE S WITCH (O PEN/CLO SE-PSIG) 22/50 22/50 5 5/95 55/95

H IGH PRES SU RE SWIT CH (OP ENS- PSIG ) 660 6 60 66 0 660

SHIPPING WEIGHT LBS.

OP ERAT ING WE IGHT LBS . 535 580 620 675

(2)

6.7

15

3.8

1/4

0.58

22/4

13 17 12.5 19

2

16 24 27 27

1.5 - STD STATIC BELT

DRIVE

2.3

5.4 7.8 7.8 7 .8

3444

16 16 16 16

(1) 24 X 24 x 2 (4 ) 14 X 20 x 2 (4) 14" X 20" x 2" ( 4) 14" X 2 0" x 2"

3/4" 3/4 " 3/4" 3 /4"

ORI FICE (0.068 ) ORIFICE (0. 076) ORIFICE (0.086) OR IFICE (0.09 4)

ORI FICE (0.053) 1 10 100.8 146

560 605 645 700

DCG048 1157BXXX

A*

7.3

15

4.4

1/4

0.58

22/4

122

1.5 - STD STATIC BELT

DRIVE

2.3

DCG0601407BXX X

A*

8.58 8.58

15 15

5.7 5.7

1/4 1/4

.58 .58

22/4 22/4

1.5 - STD STATIC BELT

DRIVE

NA 1

2.3 2.3

--- ---

DCG0 721407BXX X

A*

1.5 - STD ST ATIC BELT

DRIVE

(1) Units installed in Canada are certifed only to 4500 feet.

(2) Maximum Overcurrent Protection Device: MUST use Time Delay Fuse or HACR type Circuit Breaker of the same size as noted.

IMPORTANT: While this data is presented as a guide, it is important to electrically connect the unit and properly size wires and fuses/circuit breakers in

accordance with the National Electrical Code and/or all local codes.

16

Loading...

Loading...