Installer reference guide

intelligent Tablet Controller

DCC601A51

Installer reference guide

intelligent Tablet Controller

English

Table of contents

Table of contents

1 About this document 2

2 Installation 2

2.1 General safety precautions ....................................................... 2

2.1.1 General ....................................................................... 3

2.1.2 Installation site ............................................................ 3

2.1.3 Electrical ..................................................................... 3

2.2 Contents of the kit and optional equipment ............................... 3

2.2.1 Contents of the kit....................................................... 3

2.2.2 Optional equipment..................................................... 4

2.3 System overview ....................................................................... 4

2.3.1 About the Daikin intelligent Tablet Controller solution 4

2.3.2 The intelligent Tablet Controller kit ............................. 4

2.3.3 Compatible (Daikin) equipment................................... 4

2.3.4 Additional components in the intelligent Tablet

Controller solution ....................................................... 4

2.4 Before installation...................................................................... 5

2.4.1 Necessary equipment ................................................. 5

2.4.2 Determining installation place ..................................... 5

2.4.3 About the location of terminals and switches.............. 6

2.5 Installation of the intelligent Tablet Controller hardware ........... 7

2.5.1 To install the 3 intelligent Tablet Controller hardware

components ................................................................ 7

2.6 About electric wiring .................................................................. 8

2.6.1 Connecting to other equipment................................... 8

2.6.2 Connecting the power supply to all modules .............. 9

2.6.3 Connecting the LAN cable .......................................... 9

2.7 About the installation of the Daikin-supplied router ................... 10

3 Commissioning 10

3.1 About commissioning the intelligent Tablet Controller setup..... 10

3.2 Minimum requirements for the commissioning.......................... 10

3.3 To turn on the data backup battery ........................................... 10

3.4 To connect to the intelligent Tablet Controller for the first time . 10

3.5 To upgrade the firmware to the latest version ........................... 11

3.6 To run the commissioning tool for the first time......................... 12

3.7 To configure the network settings (local commissioning tool) ... 13

3.8 To configure the connected devices quickly (local

commissioning tool)................................................................... 13

3.8.1 To use the stand-alone mode ..................................... 14

3.8.2 To use the cloud-connect mode.................................. 15

3.9 To configure the Avalue screen (optional)................................. 15

3.10 About Net commissioning.......................................................... 17

3.10.1 To configure and upload your configuration................ 17

3.10.2 Preparation ................................................................. 17

3.10.3 To activate the net commissioning mode.................... 17

3.10.4 To configure the login information............................... 18

3.10.5 To detect all connected equipment ............................. 18

3.10.6 To exclude equipment................................................. 18

3.10.7 To configure or correct the information of all

connected devices ...................................................... 19

3.10.8 To commission the intelligent Tablet Controller .......... 20

6.1 About known limitations.............................................................. 28

6.1.1 Compatibility with KRP928 (interface adapter for

DIII‑NET)...................................................................... 28

6.1.2 Unconnected units are listed in the local

commissioning tool ...................................................... 28

6.1.3 Finding out the IP address of the intelligent Tablet

Controller ..................................................................... 28

6.1.4 Re-applying the Net commissioning procedure ........... 28

6.2 Technical specifications ............................................................. 29

6.2.1 External dimensions..................................................... 29

6.2.2 Environmental conditions............................................. 29

6.2.3 Electrical cabinet.......................................................... 29

6.2.4 Power consumption specifications............................... 29

6.2.5 Other intelligent Tablet Controller specifications.......... 29

6.2.6 Commissioning computer requirements ...................... 29

6.2.7 Default tool passwords................................................. 30

6.2.8 Wiring requirements..................................................... 30

6.3 Disposal...................................................................................... 30

6.4 Copyright and trademarks .......................................................... 31

6.5 To set Group and AirNet addresses........................................... 31

6.5.1 About the installer menu .............................................. 31

6.5.2 To enter the installer menu .......................................... 31

6.5.3 Group address ............................................................. 31

6.5.4 AirNet address ............................................................. 32

6.6 To switch from Cloud connect Mode to Stand-alone Mode........ 34

1 About this document

Target audience

Authorised installers + service technicians

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ Installation manual:

▪ Installation instructions

▪ Format: Paper (supplied in the kit)

▪ Installer reference guide:

▪ Preparation of the installation, reference data,…

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

extranet (authentication required).

4 Operation 20

4.1 Advanced configuration of the intelligent Tablet Controller ....... 20

4.1.1 Main window overview ................................................ 20

4.1.2 Management points .................................................... 21

4.1.3 To change date and time ............................................ 24

4.1.4 To change network settings........................................ 25

4.1.5 To change the function mode ..................................... 25

5 Maintenance 26

5.1 To set equipment in and out of maintenance ............................ 26

5.2 To upgrade the firmware ........................................................... 27

5.3 To replace the data backup battery........................................... 27

6 Appendix 28

Installer reference guide

2

2 Installation

2.1 General safety precautions

Please read these general safety precautions carefully before

installing air conditioning equipment, and be sure to install the

equipment correctly.

Failure to follow these instructions properly may result in property

damage or personal injury, which may be serious depending on the

circumstances.

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

2 Installation

After completing the installation, make sure the power supply and

controller modules operate properly during the startup operation.

Meaning of warnings and symbols

These safety messages are used to attract your attention. The

meaning of each safety message is described below:

WARNING

Indicates a situation that could result in death or serious

injury.

CAUTION

Indicates a situation that could result in minor or moderate

injury.

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

INFORMATION

Indicates useful tips or additional information.

NOTICE

Indicates a situation that could result in equipment or

property damage.

2.1.1 General

If you are NOT sure how to install or operate the unit, contact your

dealer.

NOTICE

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or

approved by Daikin.

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (on top of the

instructions described in the Daikin documentation).

CAUTION

Wear adequate personal protective equipment (protective

gloves, safety glasses,…) when installing, maintaining or

servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

2.1.2 Installation site

Do NOT install the equipment in a potentially explosive atmosphere.

2.1.3 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before connecting electrical

wiring or touching electrical parts.

▪ Disconnect the power supply for more than 1 minute,

and measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

The voltage MUST be less than 50 V DC before you

can touch electrical components. For the location of the

terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service

cover is removed.

WARNING

A main switch or other means for disconnection, having a

contact separation in all poles providing full disconnection

under overvoltage category III condition, shall be installed

in the fixed wiring.

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable

legislation.

▪ All field wiring must be performed in accordance with

the wiring diagram supplied with the product.

▪ Make sure to install earth wiring. Do NOT earth the unit

to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER

use a power supply shared by another appliance.

▪ Make sure to install the required fuses or circuit

breakers.

▪ Make sure to install an earth leakage protector. Failure

to do so may cause electric shock or fire.

WARNING

▪ After finishing the electrical work, confirm that each

electrical component and terminal inside the electrical

components box is connected securely.

▪ Make sure all covers are closed before starting up the

unit.

2.2 Contents of the kit and optional equipment

2.2.1 Contents of the kit

Based on the following accessory list, check that all parts and

accessories for the intelligent Tablet Controller are included in the

kit. If there is any missing or defective part, contact the dealer where

you purchased this product.

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

Installer reference guide

3

2 Installation

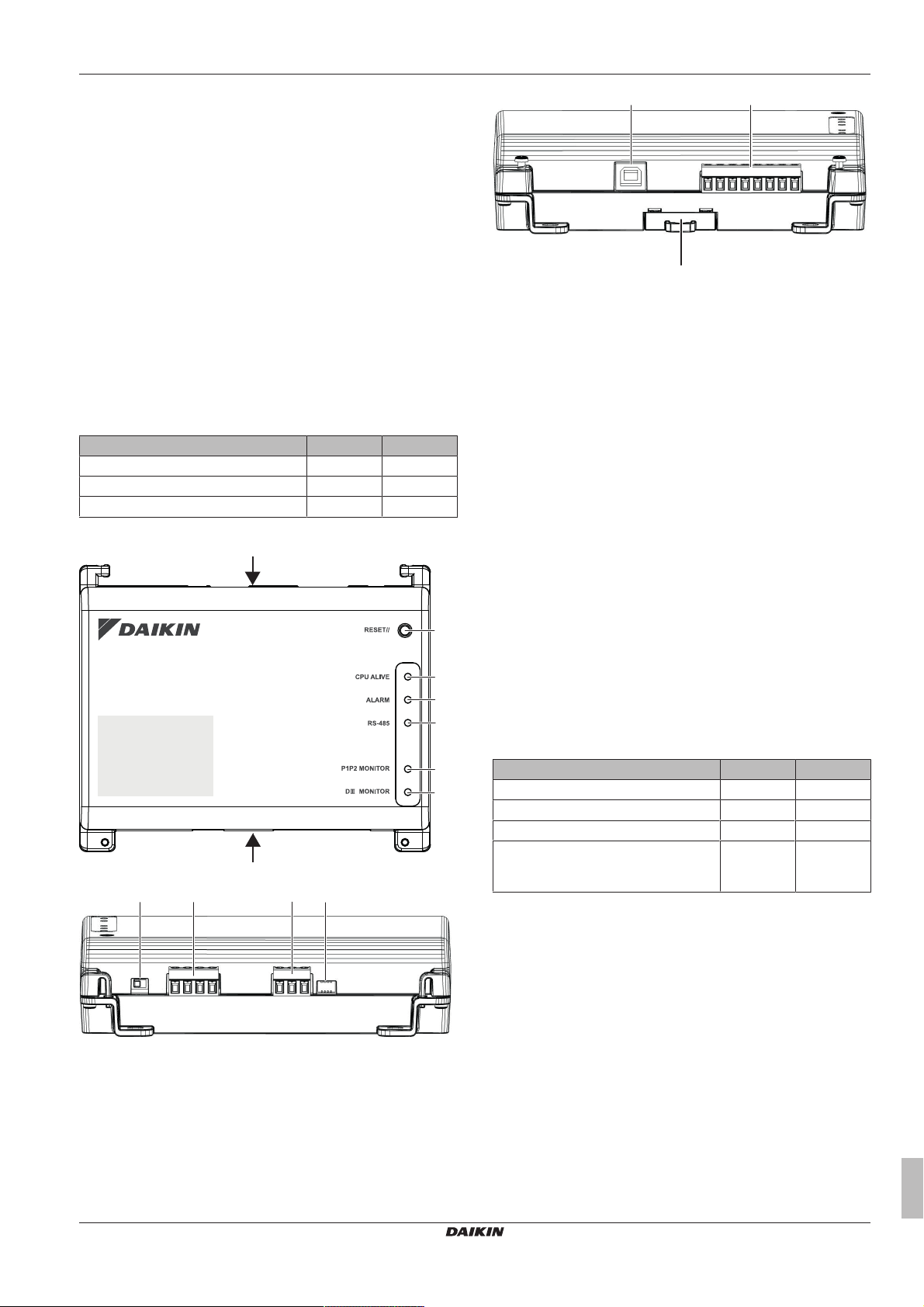

a

b

c

+ +

- -

L

N

d

e

a CPU module (1×)

b I/O module (1×)

c WAGO power supply unit (1×)

d USB cable, 0.5m (1×)

e Installation manual (1×)

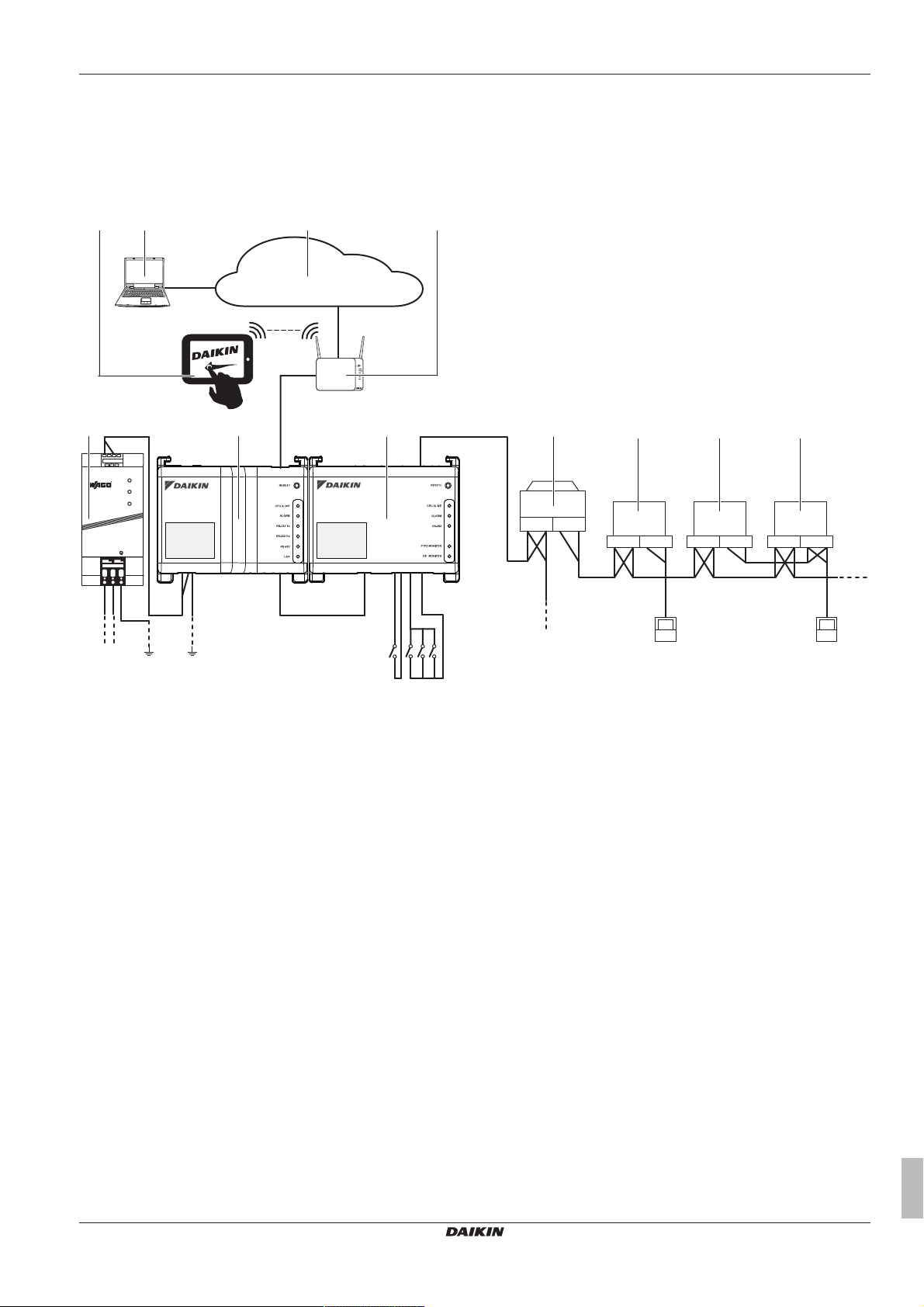

2.3.2 The intelligent Tablet Controller kit

To set up the intelligent Tablet Controller solution in your

environment, you have been given the Daikin intelligent Tablet

Controller kit. This kit provides a central controller and links the

supported Daikin equipment to a local Ethernet network and the

Daikin Cloud Service. The kit consists of the following components:

▪ a WAGO power supply unit (PSU),

▪ the CPU module,

▪ the I/O module.

For a typical setup of the intelligent Tablet Controller kit, see

"Schematic setup of the intelligent Tablet Controller" on page 5.

Before installing the intelligent Tablet Controller kit modules, draw up

an efficient plan of work, using this schematic and based on the

actual environment it needs to be installed in.

2.3.3 Compatible (Daikin) equipment

The intelligent Tablet Controller solution can connect to certain

Daikin units that provide a DIII‑NET communication interface. For an

up-to-date list of which equipment can be controlled using the

intelligent Tablet Controller, see the following site: http://

www.daikineurope.com/support-and-manuals/product-information/.

2.2.2 Optional equipment

The following optional equipment is available:

Equipment Type Material number /

Product number

Daikin-supplied router ASUS dual‑band LTE

Wi-Fi modem router

Daikin-supplied

screen

Daikin-supplied tablet ASUS ZenPad 8.0 Z380M /

For more information on this optional equipment, see

"2.3.4 Additional components in the intelligent Tablet Controller

solution"on page4.

Avalue multi touch

panel computer

4G‑AC68U /

90IG03R1‑BM200

CCD‑10W01 /

CCD‑10W01‑7V39C‑

1R

Z380M‑6A028A

2.3 System overview

2.3.1 About the Daikin intelligent Tablet

INFORMATION

The connection of the equipment that uses other

communication interfaces might be supported in future

upgrades.

NOTICE

The intelligent Tablet Controller cannot be used in

combination with other centralised controllers, such as the

intelligent Touch Manager (iTM).

In addition, a number of terminals are available on the I/O module to

connect digital inputs. The digital input on the first terminal is

hardwired as a forced stop contact input. The remaining digital

inputs can each be configured as either a normal-open or normalclosed contact input, or as a pulse input.

NOTICE

When the forced stop contact input is closed, a stop signal

is sent to all connected devices. There is no hard

guarantee that all devices are actually stopped and remain

stopped during the time the forced stop contact input is

active.

Controller solution

The Daikin intelligent Tablet Controller solution allows an end user to

control and manage a wide range of Daikin HVAC equipment from a

tablet app and web browser interface.

The intelligent Tablet Controller solution is available in one of the 2

following function modes (i.e., operation modes):

▪ Stand-alone Mode: A local function mode where you can control

your local environment from anywhere within your local area

network. This is done via the intelligent Tablet Controller app on

the Daikin-supplied tablet.

▪ Cloud-connect Mode: A cloud-based function mode where you

can control multiple environments from anywhere in the world.

This is done via a browser application by accessing the Daikin

Cloud Service at: http://cloud.daikineurope.com. Note that the

Daikin Cloud Service can also be accessed using a browser

running on the Daikin-supplied tablet. In cloud-based function

mode, local control via the intelligent Tablet Controller app is still

possible, but the provided feature set will be restricted.

Installer reference guide

4

2.3.4 Additional components in the intelligent Tablet Controller solution

The following optional equipment is available as part of the intelligent

Tablet Controller solution. Its requirements depend on your local

environment and needs. Contact your dealer for more information.

Daikin-supplied router (ASUS 4G‑AC68U)

An optional Daikin-supplied router can be used to create a WiFicapable LAN. This might be necessary if the intelligent Tablet

Controller modules cannot be connected to the locally-available

LAN, or if the locally-available LAN does not provide WiFi for access

by the Daikin-supplied tablet.

In addition, the router has mobile 4G capabilities, which can be used

to provide connection to the Daikin Cloud Service in case an internet

connection is not available using a locally-available LAN. Note that

for a mobile internet connection, a SIM card is required, which is not

supplied with the router.

Daikin-supplied screen (Avalue CCD‑10W01)

In the local function mode an optional Daikin-supplied screen can be

used to run the intelligent Tablet Controller app.

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

2 Installation

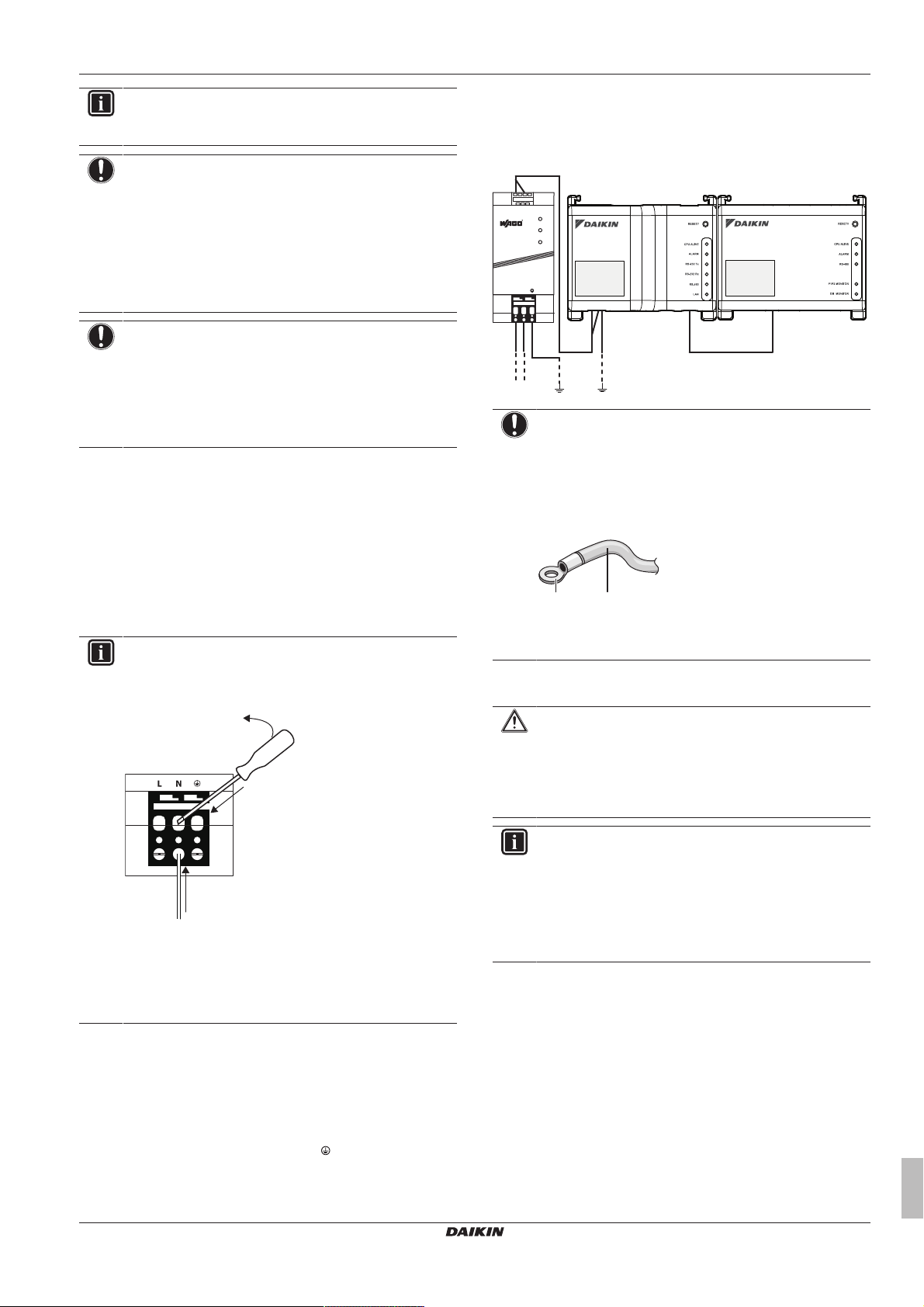

USB

230 V AC

RJ-45

F1, F2

P1, P2

F1, F2 P1, P2 F1, F2 P1, P2

F1, F2

OUT IN

F1, F2

http://cloud.daikineurope.com

DIII-NET

POWER I/O IF

CPU IF

LAN

F1/F2

Di1~Di4

d e f

i i ih

j*

k*

24 V DC c

b

g

a

l l

+ +

- -

L

N

The app will be pre-installed on the screen.

Daikin-supplied tablet (ASUS ZenPad 8.0 Z380M)

If you choose the local function mode you have to use a Daikinsupplied tablet to run the intelligent Tablet Controller app.

Schematic setup of the intelligent Tablet Controller

The intelligent Tablet Controller app can be installed from Google

Play.

a WAGO power supply unit

b CPU module

c I/O module

d Optional Daikin-supplied tablet

e Computer with connection to the Daikin Cloud Service

f Daikin Cloud Service

g LAN gateway (optional Daikin-supplied router)

h Outdoor unit connected to DIII-NET

i Indoor unit connected to DIII-NET

2.4 Before installation

j Forced stop contact input

k Digital inputs (can be configured as contact inputs or pulse inputs)

l Wired remote controller

* This is a conceptual wiring diagram, for the correct wiring of the Di1~Di4 terminals, refer to "To connect digital input and output devices"on

page8.

Before you start installing the intelligent Tablet Controller, complete

the following preparations:

▪ Check that the intelligent Tablet Controller kit comes with all

accessories, see "2.2.1Contents of the kit"on page3.

▪ Check that you have all equipment necessary to install the

intelligent Tablet Controller kit modules, see "2.4.1 Necessary

equipment"on page5.

▪ Check that an appropriate space for installing the intelligent Tablet

Controller modules is available, see "2.4.2Determining installation

place"on page5.

▪ Familiarise yourself with the location of the terminals and switches

of the intelligent Tablet Controller modules, see "2.4.3 About the

location of terminals and switches"on page6.

2.4.1 Necessary equipment

Use the following equipment to install the intelligent Tablet Controller

kit modules:

▪ A flat-blade screwdriver

▪ A Phillips screwdriver

▪ The necessary amount of electrical wires and appropriate wiring

tools. For more info on what wires to use, see "6.2.8 Wiring

requirements"on page30.

2.4.2 Determining installation place

Make sure to install the intelligent Tablet Controller components in a

place that complies with the conditions described in the following

sections.

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

Installer reference guide

5

2 Installation

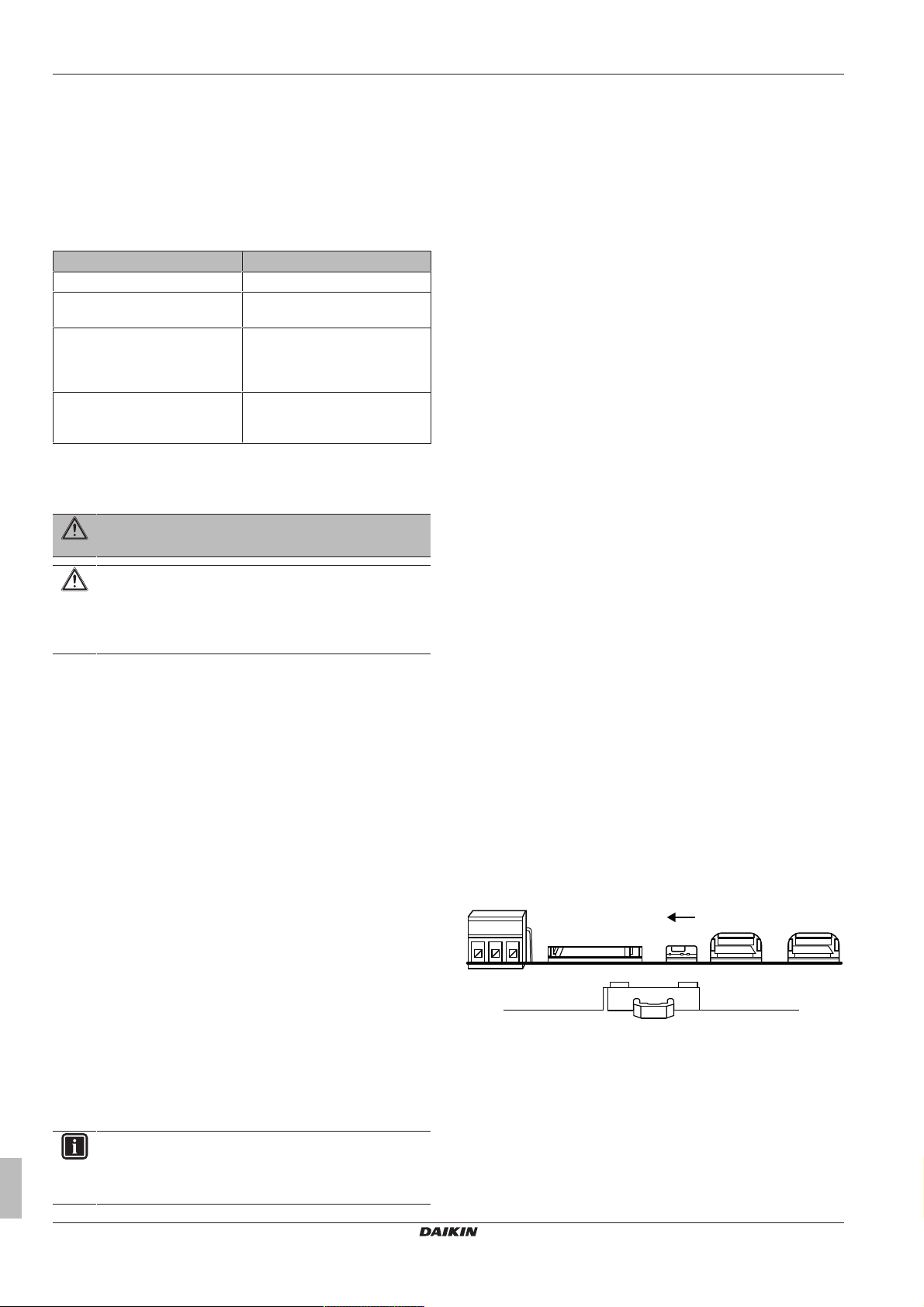

≥60

≥80

≥70

≥60

≥70

50

136

130

152≥15

≥15

152

a

b

a

≥80

≥20

I/OCPU

+ +

- -

L

N

(mm)

a

b

c

d

e

f

g

A

B

kjih

A

B

l

m n

o p

q

About installation place and mounting direction

Make sure the installation place complies with the following

requirements:

▪ Location: Indoor, inside an electrical cabinet.

▪ The electrical cabinet:

▪ must be lockable or designed to be opened only with a special

tool. The key or tool should be available only to service

personnel.

▪ must be installed in a space with no access for the general

public.

▪ must comply with the applicable legislation.

▪ must have ingress protection class of IP4X or higher (however,

make sure enough ventilation is provided to prevent

overheating of the equipment).

▪ must have impact protection class of IK07 or higher (see

international standard IEC62262‑2002).

▪ must have a minimum height of 290mm and minimum width of

410mm to allow for the clearance specified in "About required

space"on page6.

▪ Mounting direction: vertical only

▪ Make sure the installation place complies with the environmental

conditions, specified in "6.2.2 Environmental conditions" on

page29.

About required space

The following figure indicates the minimum space required for

installation.

▪ Make sure there is a minimum clearance of 60mm between both

the CPU module, the I/O module and the wiring ducts and a

minimum clearance of 80 mm between the modules and the

electrical cabinet in the vertical direction.

▪ Make sure there is a minimum vertical clearance of 70 mm

between the WAGO PSU and the wiring ducts.

▪ The CPU module and I/O module can be installed without

clearance in the horizontal direction, but make sure there is a

minimum clearance of 20 mm between the modules and the

electrical cabinet.

▪ The WAGO PSU requires a minimum clearance of 15mm on both

sides in the horizontal direction.

Module Depth

I/O module 39mm

WAGO PSU 92mm

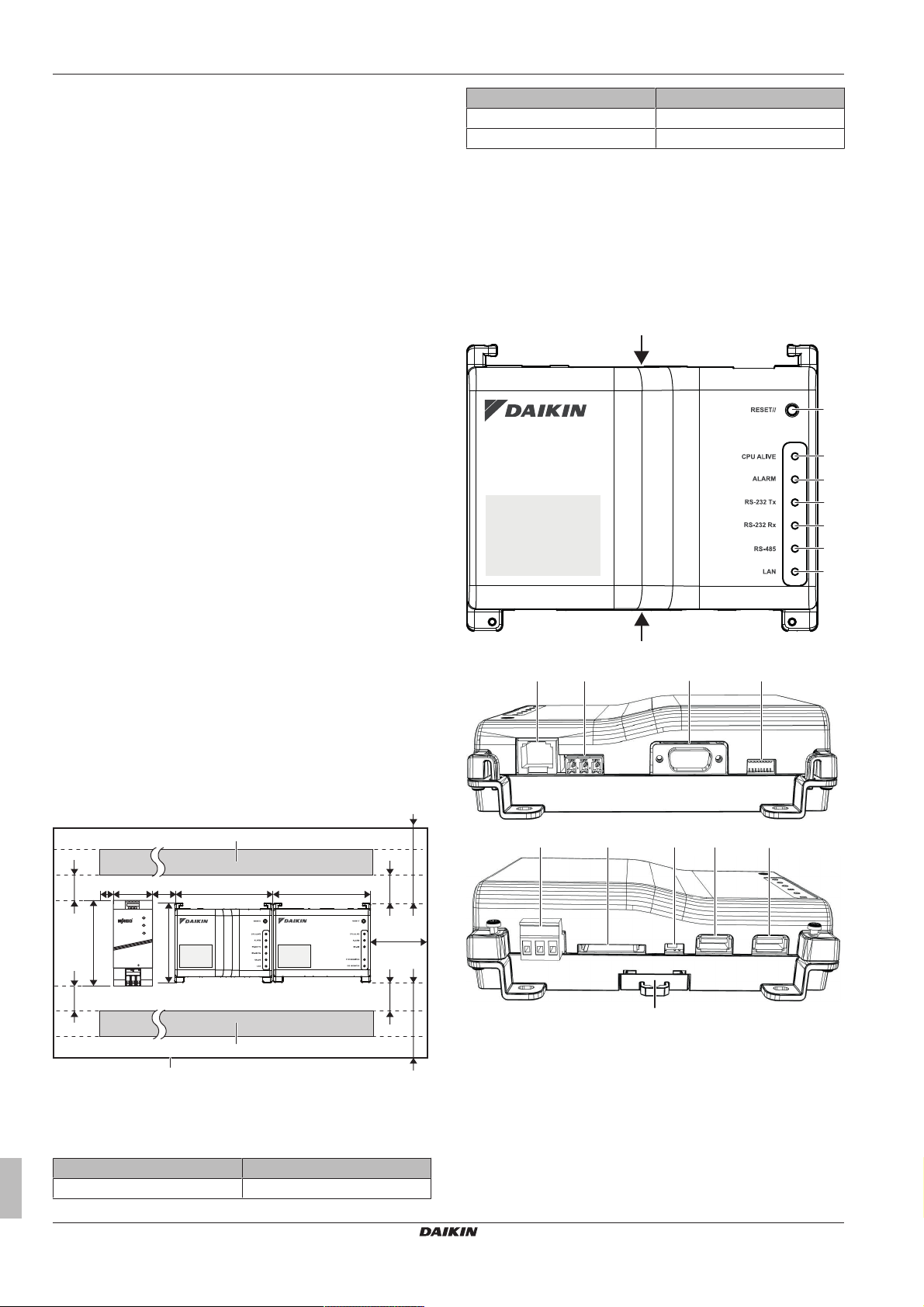

2.4.3 About the location of terminals and switches

Understand the arrangement of terminals and the location of

openings on the module and plan how to route the cable and in

which order to connect its wires to facilitate the installation

procedure.

For connection details see "2.6About electric wiring"on page8.

CPU module

a Wire duct

Observe the depth of these modules and make sure you provide the

necessary amount of space in depth in the electrical cabinet.

Module Depth

CPU module 45mm

b Electrical cabinet

Connectors and sockets

h [LAN] RJ‑45 socket for connecting the intelligent Tablet Controller to

an Ethernet network.

i [RS‑485] Reserved for future use.

j [RS‑232] Reserved for future use.

l [Power] Power connector. A power supply voltage of 24VDC is

required and will be provided when connected to the WAGO PSU.

m [SD CARD] Reserved for servicing.

o [USB] USB2.0 typeA socket, reserved for servicing. This socket

CANNOT be used to connect the CPU module and the I/O module.

p [I/O IF] USB2.0 typeA socket. Use only this USB socket to connect

the CPU module with the I/O module.

Installer reference guide

6

intelligent Tablet Controller

DCC601A51

4P420109-1E – 2018.09

Controls and switches

A

B

a

b

c

d

e

f

jihg

A

B

k

l

m

a [RESET]Button for restarting the CPU module and I/O module.

k [DIP SW]Reserved for servicing. Factory default: all switches are set

to "OFF".

n [BACKUP] Switch for turning on/off the backup power supply for

retaining the current settings (provided by the internal battery).

Factory default: "OFF". This will be set to the "ON" position during

commissioning.

q [Lever] To assist mounting/dismounting the module onto/from a DIN

rail.

LEDs

b [CPU ALIVE] (Green) This LED blinks when the CPU operates

normally. For details on LED operations, refer to the table below.

c [ALARM] (Red) This LED is lit if a failure is detected. For details on

LED operations, refer to the table below.

d [RS‑232 Tx] (Green) This LED blinks when data is being sent from the

serial port.

e [RS‑232 Rx] (Orange) This LED blinks when data is received by the

serial port.

f [RS‑485] (Orange) This LED blinks when data is being

sentorreceived over the RS‑485 port.

g [LAN] (Green) This LED is on when linked correctly. The LED will

blink when data is being sent/received.

LED status and operation table (CPU module)

Operating condition CPU ALIVE ALARM

Normal Blink OFF

Power interruption / hardware failure OFF OFF

Application software not installed Blink ON

I/O module

2 Installation

Connectors

h [DIII (F1/F2) and P1P2 (P1/P2)] 2×2 communication lines, connecting

the intelligent Tablet Controller with DIII-compatible units and P1P2compatible units respectively. The P1P2 connection is reserved for

future use.

i [RS‑485] Reserved for future use.

k [CPU IF] USB2.0 type-B socket. To connect with the CPUmodule.

Acts as a power supply and communication channel for the I/

Omodule.

l [Di1‑4 and Do] Terminals for connecting digital inputs (Di) and digital

outputs (Do). The Do connection is reserved for future use.

Controls and switches

a [RESET] Reserved for future use.

g [DIII MASTER] Switch for setting the intelligent Tablet Controller to

"MASTER" or "SLAVE" in a DIII-NET configuration. Factory default:

left position (MASTER).

j [DIP SW] Mode selector. Factory default: bit1 is set to: "ON"; bits2-4

are set to: "OFF".

m [Lever] To assist mounting/dismounting the module onto/from a

DINrail.

LEDs

b [CPU ALIVE] (Green) This LED blinks when the I/Omodule operates

normally. For details on LED operations, refer to the table below.

c [ALARM] (Red) This LED is lit or blinks if a failure is detected. For

details on LED operations, refer to the table below.

d [RS‑485] (Orange) This LED blinks when data is being

sentorreceived over the RS‑485 port.

e [P1P2 MONITOR] (Orange) This LED blinks when data is being sent

or received via the P1P2 line.

f [DIII MONITOR] (Orange) This LED blinks when DIII-NET

communication is performed.

LED status and operation table (I/O module)

Operating condition CPU ALIVE ALARM

Normal Blink OFF

Hardware failure OFF ON

Power interruption OFF OFF

Communication failure between CPU

module and I/O module (for 10seconds

or more)

ON Blink

2.5 Installation of the intelligent Tablet Controller hardware

The intelligent Tablet Controller components are to be mounted onto

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

a 35 mm DIN rail, inside an electrical cabinet. For more information

see "About installation place and mounting direction"on page6.

2.5.1 To install the 3 intelligent Tablet Controller hardware components

1 Place the module over the top of the DIN-35 rail so that the

upper hook on the rear face is hooked in.

2 Push the module in direction 'a' until the lower hook snaps into

the rail.

3 If necessary, pull the lever on the lower parts of the module in

direction 'b' to click the module onto the rail. Use a flat-blade

screwdriver if necessary.

Installer reference guide

7

2 Installation

a

b

a

b

c

d

e

f

d d d d

d d d d d

a

b

c

DIII

F2 F1

Di1 Di2 COM Di3 Di4 COM COMDo

a b c

4 Repeat the previous steps for all other modules.

2.6 About electric wiring

This chapter will describe the procedure to connect the intelligent

Tablet Controller kit components with Daikin devices and other

equipment.

WARNING

▪ Do NOT turn on the power supply before all wire

connections are completed. Not doing so may cause an

electric shock.

▪ After the wiring is completed, double-check that all

wires are connected correctly before turning on the

power supply.

▪ All field supplied parts, materials and electric works

MUST comply with the applicable legislation.

INFORMATION

At the time of writing, some connectors are NOT active, but

provided for future use.

2.6.1 Connecting to other equipment

For all wiring requirements see "6.2.8 Wiring requirements" on

page30.

To connect DIII‑NET compatible equipment

DIII‑NET is a unique air conditioning equipment communication

capability developed by Daikin. Using DIII‑NET, you can centrally

control multiple DIII‑NET-compatible air conditioning devices by

connecting them to your intelligent Tablet Controller.

1 Use the F1 and F2 terminals on the upper part of the I/O

module to connect the DIII‑NET communication line. These 2

terminals have no polarity.

An example of connecting more than 2 air conditioning devices is

shown in the following figure.

Schematic wiring diagram with DIII terminals

a Outdoor unit

b OUT – OUT

c IN – OUT

d Indoor unit

e A maximum of 7 outdoor units can be connected.

f A maximum of 32 indoor units can be connected (a unique

DIII address is required for each unit).

To connect digital input and output devices

The intelligent Tablet Controller can be connected with an external

signal input device for stopping air conditioners, with electric energy

meters for calculating the electricity usage of individual air

conditioners or other devices.

1 Connect the contact input lines or pulse input lines to the Di1,

Di2, Di3, Di4 and COM terminals of the connector on the

bottom of the I/O module. The function of each terminal is as

shown in the following figure.

Schematic wiring diagram with Di and Do terminals

Installer reference guide

8

a [Di1] Forced stop contact input (normally open).

b [Di2] [Di3] [Di4] Digital inputs. Can be configured as

normallyopen (A-type) or normallyclosed (B-type) contact

inputs, or as pulse inputs.

c [Do] Provided for future use.

You can change the function assignment at a later time. For how to

change the function assignment, refer to "About management points

attribute descriptions"on page22.

For more details on the required pulse width and interval, refer to

"6.2.8Wiring requirements"on page30.

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

2 Installation

a

b

c

USB

230 V AC

POWER I/O IF

CPU IF

24 V DC

+ +

- -

L

N

CPU I/O

b a

INFORMATION

At the time of writing, the digital output connection Do is

NOT active, but provided for future use.

NOTICE

▪ When the forced stop contact input is closed, a stop

signal is sent to all connected devices. There is no hard

guarantee that all devices are actually stopped and

remain stopped during the time the forced stop contact

input is active.

▪ When the forced stop contact input is closed, the

connected devices cannot be restarted unless the

contact input is reopened.

NOTICE

▪ The COM terminals are all connected internally. So,

you can use any one of them. However, you can only

connect up to 2 wires simultaneously to each COM

terminal.

▪ If applicable, connect the I/O module’s COM terminal to

the negative side of the device terminals.

2.6.2 Connecting the power supply to all modules

For all wiring requirements see "6.2.8 Wiring requirements" on

page30.

▪ connect the terminal to the earth rail bar of the electrical

cabinet (if provided), or

▪ connect the terminal to the M3 earthing screw on the bottom

face of the WAGO PSU.

NOTICE

If you want to connect the earth wire to the WAGO PSU,

you can only use a stranded wire with a crimp-style

terminal on the tip of the wire.

Place the round crimp-style terminal on the wire up to the

insulated part and fasten the terminal with a Phillips

screwdriver.

To connect the power supply to all modules

1 Connect the power supply to the 3 terminals, L (live), N (neutral)

and ground in the input section of the WAGO power supply unit

(PSU).

INFORMATION

Use a flat-head screwdriver to manipulate the WAGO PSU

cage clamp as described below, so that the wires are fixed

to the power supply.

a Place the screwdriver in the upper clamp entry and place

it above the clamp.

b Push the clamp downwards by pivoting the screwdriver

in direction 'b', so that the lower clamp entry opens.

c Put the wire in the respective lower clamp entry.

2 Connect the DC output of the WAGO PSU to the DC input of

the CPU module. Take the polarity of the wires into account.

3 Plug the A-type plug of the USB cable in the rightmost USB

socket on the CPU module. This socket is marked "I/O IF".

4 Plug the B-type plug of the USB cable in the B-type USB socket

on the I/O module.

5 Provide an earth connection to the terminal of the CPU

module, using one of the following 2 options:

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

a Stranded conductor wire

b Round crimp-style terminal

6 Once all wiring has been completed and double-checked, turn

on the power supply.

CAUTION

The power supply is ONLY guaranteed when the "DC OK"

LED on the WAGO PSU and the "CPU ALIVE" LEDs on

both the CPU module and the I/O module are blinking.

If 1 or more of the above LEDs are NOT lighting up, check

for faulty wiring.

INFORMATION

A new CPU module does NOT come with application

software installed. Therefore, the "ALARM" LED will be lit

red. This is as expected, see the table under "CPU

module" on page 6. Application software will be installed

during the commissioning phase, refer to "3.1 About

commissioning the intelligent Tablet Controller setup" on

page10.

2.6.3 Connecting the LAN cable

For all wiring requirements see "6.2.8 Wiring requirements" on

page30.

Do NOT connect the LAN cable until you start commissioning the

intelligent Tablet Controller. Otherwise, a network address conflict

may occur.

Installer reference guide

9

3 Commissioning

BACKUP

ON

OFF

2.7 About the installation of the Daikin-supplied router

For information on the installation, see the manual provided with the

Daikin-supplied router. For information on when to use the Daikinsupplied router, see "2.3.4 Additional components in the intelligent

Tablet Controller solution"on page4.

The following table gives an overview of the most relevant

information.

Requirement Information

Default WiFi name (SSID) ASUS

Default WiFi password (access

key)

Router configuration URL Use one of the following:

Router configuration password Not set. You will set this when

To be found on the sticker at the

back of the router.

▪ http://192.168.1.1

▪ http://router.asus.com

you start the router’s "Quick

internet setup" feature.

3 Commissioning

WARNING

Only qualified persons should conduct commissioning.

CAUTION

Preliminary electrical system checks such as earth

continuity, polarity, resistance to earth and short circuit

must be carried out by using a suitable test meter by a

competent person.

3.1 About commissioning the intelligent Tablet Controller setup

After you have verified that the intelligent Tablet Controller

components have been installed and all necessary wiring has been

completed, you can start the commissioning of your intelligent Tablet

Controller setup.

In this commissioning phase, you will do the following:

▪ Turn on the data backup battery, see "3.3 To turn on the data

backup battery"on page10.

▪ Configure your computer to be able to connect to the intelligent

Tablet Controller, see "3.4 To connect to the intelligent Tablet

Controller for the first time"on page10.

▪ Upgrade the firmware to the most recent version, see "3.5 To

upgrade the firmware to the latest version"on page11.

▪ Configure the date and time and set the function mode, see

"3.6To run the commissioning tool for the first time"on page12.

▪ Configure the LAN settings, see "3.7 To configure the network

settings (local commissioning tool)"on page13.

▪ Add all attached (Daikin) equipment to the intelligent Tablet

Controller app, see "3.8 To configure the connected devices

quickly (local commissioning tool)"on page13.

▪ If you choose the cloud-connect mode, register your devices to

the Daikin Cloud Service. See "3.10About Net commissioning"on

page17.

INFORMATION

If you choose stand-alone mode, this last step is not

required. For more information on the modes, see

"2.3System overview"on page4.

Installer reference guide

10

3.2 Minimum requirements for the commissioning

Before you start configuring the intelligent Tablet Controller,

complete the following preparations.

▪ Make sure your computer specs comply with the minimal

requirements mentioned in "6.2.6 Commissioning computer

requirements"on page29.

▪ Make sure you have both the version-up tool and the

commissioning tool.

▪ The latest version of both tools is available on https://my.daikin.eu/

content/denv/en_US/home/applications/software-finder/servicesoftware/unit-software/controls/dcc601a51.html.

▪ Contact your network administrator for the following network

information for the intelligent Tablet Controller:

▪ the desired network name for the intelligent Tablet Controller

(the controller name),

▪ a static IP address and corresponding subnet mask,

▪ the IP address of the default gateway,

▪ the IP address of the DNS server, and

▪ the IP address of the alternate DNS (if applicable).

▪ If you are going to connect the intelligent Tablet Controller to your

company WiFi, contact your network administrator for the network

name (SSID) and password.

▪ If you want to use the cloud-connect mode, check with your

network administrator that the following ports are unblocked by the

outgoing firewall:

▪ port 80 (http) and

▪ port 443 (https).

The intelligent Tablet Controller solution does not support the

use of a proxy server. If you require a proxy server for normal

internet access, it will need to be disabled or bypassed for the

intelligent Tablet Controller solution to function.

▪ Make sure the power of all connected equipment is turned on.

3.3 To turn on the data backup battery

To retain all settings, even in the event of a power outage, the CPU

module of the intelligent Tablet Controller has a built-in battery. This

battery is disabled by default.

1 Enable this battery before commissioning.

2 Look at the bottom side of the CPU module and find the

BACKUP switch.

3 Use a screwdriver to set this switch to the "ON" position.

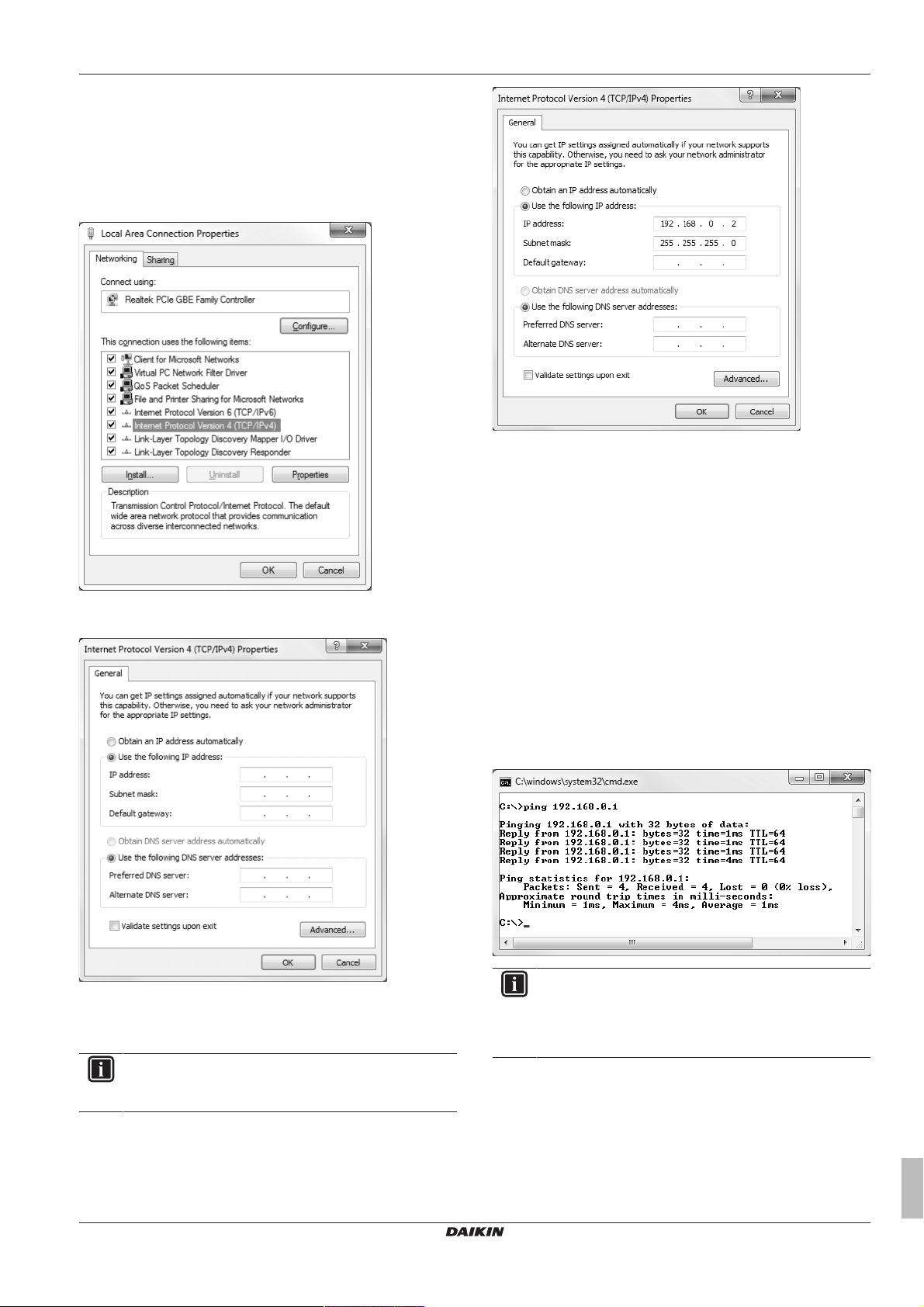

3.4 To connect to the intelligent Tablet Controller for the first time

A new CPU module has a fixed IP address 192.168.0.1 and a

subnet mask 255.255.255.0.

To connect to this device, you will have to change the IP address of

your computer to the same range as this IP address.

1 Plug a CAT 5e (or higher) Ethernet cable into the CPU module.

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

2 Connect the Ethernet cable with your computer and change

your IP address to match that of the CPU module.

3 On your computer, go to the Control Panel.

4 In the Control Panel, click Network and Sharing Center >>

Change Adapter Settings.

5 In the Network Connections window, double-click Local Area

Connection.

6 Select Internet Protocol Version 4 (TCP/IPv4) and click

Properties.

3 Commissioning

10 Click OK.

To prevent interference from any wireless network, disable all

wireless network cards on your computer as follows:

11 In the Network Connections window, right-click Wireless

Network Connection.

12 Select Disable.

13 Check if you can make a connection from your computer to the

CPU module. To do so, open the command prompt on your

computer as follows:

14 Click the Windows Start button.

15 In the Search box, type "command prompt", or alternatively

"cmd".

16 In the list of results, click Command Prompt or Cmd

respectively.

17 Ping to the IP address of the CPU module. To do so, enter:

"ping 192.168.0.1" and confirm by pressing the Enter key.

Result: You will receive an answer as the example below:

7 In the Properties window, choose Use the Following IP

Address:.

8 Set the following IP address: "192.168.0.2".

INFORMATION

This example uses 192.168.0.2, but you can choose any

address in the range of 192.168.0.2~192.168.0.254.

9 Set the following subnet mask: "255.255.255.0".

DCC601A51

intelligent Tablet Controller

4P420109-1E – 2018.09

INFORMATION

If you do NOT get replies, but time-outs instead, there

might be something wrong with the connection. Refer to

"6.2 Technical specifications" on page 29 to fix the

problem.

3.5 To upgrade the firmware to the latest version

Now that you are connected to the intelligent Tablet Controller, you

will have to upgrade the firmware to optimise the intelligent Tablet

Controller.

Installer reference guide

11

Loading...

Loading...