Daikin D9HA2018A, D9HA2024A, D9HA2032A, R9HA2018A, R9HA2024A Operation manuals

...

Installation and

operating

instructions

Oil condensing boiler A2 F

A2 F 18H

A2 F 24H

A2 F 32H

04/2018

Daikin ROTEX

D9HA2018A

D9HA2024A

D9HA2032A

R9HA2018A

R9HA2024A

R9HA2032A

Installation and operating instructions

Oil condensing boiler A2 F

English

List of contents

List of contents

1 General safety precautions 4

1.1 Particular safety instructions ..................................................... 4

1.1.1 Observing the instructions .......................................... 5

1.1.2 Meaning of warnings and symbols.............................. 5

1.2 Safety instructions for installation and operation....................... 5

1.2.1 General ....................................................................... 5

1.2.2 Intended use ............................................................... 5

1.2.3 Device installation room.............................................. 6

1.2.4 Electrical installation ................................................... 6

1.2.5 Requirements for the heating water............................ 6

1.2.6 Heating system and sanitary connection .................... 6

1.2.7 Fuel............................................................................. 6

1.2.8 Operation .................................................................... 6

2 Handover to operator and warranty 7

2.1 Instruct the owner...................................................................... 7

2.2 Warranty conditions................................................................... 7

3 Product description 8

3.1 Design and components............................................................ 8

3.2 Brief description......................................................................... 10

4 Set-up and installation 11

4.1 Dimensions and connection dimensions ................................... 11

4.2 Different set-ups ........................................................................ 11

4.2.1 Room-air independent operation ................................ 12

4.2.2 Partial ambient air-independent mode........................ 12

4.2.3 Ambient air-dependent mode...................................... 13

4.2.4 Additional information on device type in accordance

with CEN/TR1749 ...................................................... 13

4.3 Transport and delivery............................................................... 14

4.4 Installing the oil condensing boiler ............................................ 15

4.4.1 Selecting the installation site....................................... 15

4.4.2 Installing the device .................................................... 16

4.5 Air/flue gas system (LAS).......................................................... 16

4.5.1 General instructions for the flue gas system............... 16

4.5.2 Connecting a flue gas line........................................... 17

4.5.3 Flue gas system kits ................................................... 18

4.6 Water connection ...................................................................... 19

4.6.1 Connecting hydraulic lines.......................................... 19

4.6.2 Connect the condensate drain.................................... 20

4.7 Electrical connection ................................................................. 20

4.7.1 Opening the boiler control panel and establishing

electrical connections.................................................. 20

4.7.2 Integrated heating circulation pump and 3-way valve. 22

4.7.3 Temperature sensors and further electric

components ................................................................ 22

4.7.4 Connecting the RoCon OT1 external temperature

sensor ......................................................................... 23

4.7.5 RoCon M1 mixer module (optional) ............................ 24

4.7.6 Room controller RoCon U1 (optional)......................... 24

4.7.7 Internet Gateway RoCon G1 (optional)....................... 24

4.7.8 Room thermostat (optional) ........................................ 24

4.7.9 External switching contact (optional) .......................... 24

4.8 Connect the oil line.................................................................... 25

4.8.1 Important instructions for oil connection ..................... 25

4.8.2 Connecting the oil filter ............................................... 25

4.8.3 Connect the oil line ..................................................... 26

4.9 Filling the system....................................................................... 26

4.9.1 Checking the water quality and adjusting the

pressure gauge ........................................................... 26

4.9.2 Filling the heating system ........................................... 26

4.10 Installing/Removing the boiler cladding ..................................... 26

5 Start-up 29

5.1 Initial commissioning ................................................................. 29

5.1.1 Requirements.............................................................. 29

5.1.2 Checks before start-up................................................. 29

5.1.3 Start-up ........................................................................ 29

5.1.4 After start-up ................................................................ 29

5.2 Checklists for start-up................................................................. 30

6 Controller and electronic components 31

6.1 Operating elements on the boiler control panel.......................... 31

6.2 Replacing the RoCon B1 control panel ...................................... 31

6.3 Change cables ........................................................................... 32

6.4 Changing sensors ...................................................................... 32

6.4.1 Replacing the inflow temperature sensor / return flow

temperature sensor and pressure sensor .................... 33

6.4.2 Changing the flue gas temperature sensor.................. 33

6.5 Replacing the fuse or circuit board............................................. 33

7 Oil burner 35

7.1 Design and brief description....................................................... 35

7.2 Safety function............................................................................ 36

7.3 Burner setting ............................................................................. 36

7.3.1 Setting values .............................................................. 36

7.3.2 Establishing access to the burner................................ 37

7.3.3 Checking and setting the burner.................................. 37

7.3.4 Check the vacuum at the oil pump............................... 37

7.3.5 Adjusting the flue gas quality ....................................... 37

7.3.6 Recirculation gap ......................................................... 38

7.3.7 Check and set the electrode distance and the

distance between oil nozzles and air nozzles .............. 38

7.4 Dismantling the burner ............................................................... 39

7.4.1 Move the burner to the service position....................... 39

7.4.2 Installing/removing the recirculation pipe..................... 40

7.4.3 Removing/fitting the burner.......................................... 40

7.5 Connecting the firing unit............................................................ 41

7.6 Ignition transformer with flame monitor ...................................... 41

7.7 Oil burner pump and oil filter ...................................................... 42

8 Hydraulic connection 43

8.1 Hydraulic system connection...................................................... 43

9 Service and maintenance 45

9.1 General overview of service and maintenance .......................... 45

9.2 Service and maintenance tasks ................................................. 45

9.2.1 Filling, topping up the heating system.......................... 45

9.2.2 Checking the connections and pipes ........................... 46

9.2.3 Cleaning the combustion chamber and condensate

siphon/condensate box ................................................ 46

9.2.4 Checking and cleaning the burner ............................... 48

9.2.5 Changing the ignition electrodes and oil nozzle........... 49

10 Faults and malfunctions 50

10.1 Troubleshooting.......................................................................... 50

10.2 Overview of possible malfunctions ............................................. 50

10.3 Fault codes ................................................................................. 52

10.4 Rectifying burner malfunctions and STB malfunctions ............... 53

10.5 Emergency operation ................................................................. 53

11 Taking out of operation 54

11.1 Temporary shutdown.................................................................. 54

11.2 Final decommissioning and disposal.......................................... 54

12 Technical data 55

12.1 Basic data................................................................................... 55

12.1.1 Integrated heating circulation pump, 3-way valves ...... 56

12.1.2 Information on the type plate ....................................... 57

12.1.3 Data sheets according to Ecolabel and Ecodesign

regulation (EU) 811/2013............................................. 57

12.1.4 Tightening torque ......................................................... 58

12.2 Flow rate and residual feed height ............................................. 59

12.3 Temperature sensor ................................................................... 59

12.4 Electrical connection diagram .................................................... 60

13 Notes 62

List of keywords 63

Installation and operating instructions

2

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

14 For the chimney sweep 64

14.1 Data for designing the flue gas pipe .......................................... 64

14.2 Emissions measurement ........................................................... 64

List of contents

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Installation and operating instructions

3

1 General safety precautions

1 General safety precautions

1.1 Particular safety instructions

WARNING

Heating devices that have not been set

up and installed correctly can impair

the function of the heating device and/

or cause serious or fatal injuries to the

user.

▪ Work on the device (such as set-up,

servicing, connection and initial startup) must only be carried out by persons who are authorised who are

authorised and who have successfully completed qualifying technical

or vocational training and who

have taken part in advanced training

sessions recognised by the relevant

responsible authorities for the specific activity. These include, in particular, certified heating engineers,

qualified electricians and HVAC

specialists, who, because of their

professional training and their expert knowledge, have experience in

the professional installation and

maintenance of heating systems,

gas installations and hot water tanks.

WARNING

Disregarding the following safety instructions may result in serious physical injury or death.

▪ This device must only be used by

children aged 8 and above and by

persons with restricted physical,

sensory or mental capabilities or with

a lack of experience and knowledge,

if they are under supervision or if

they have been instructed in the safe

use of the equipment and understand the dangers arising therefrom.

Children must not play with the

device. Cleaning and user mainten-

ance must not be carried out by

children without supervision.

▪ Make up the power supply in accord-

ance with IEC 60335-1, via a separator device which exhibits contact

separation in all poles with a contact

opening distance that provide full

disconnection in accordance with

overvoltage category III.

▪ All the electrical work must only be

carried out by electrically qualified

experts and with consideration of the

local and national regulations, and

the instructions in this manual.

Check that a suitable electrical circuit is being used.

Inadequate capacity of the power circuit or improperly executed connections can cause electrocution or fire.

▪ The customer must install a pressure

relief device with rated over-pressure

less than 0.6MPa (6bar) for connecting a hot water storage tank.

The connected drain line must have

a continuous gradient and a free outlet in a frost-free environment

(seeChap. 4.4).

▪ Water may drip out of the drain line

of the pressure relief device. The

drain opening must be left free to atmosphere.

▪ The pressure relief device must be

operated regularly in order to remove scale deposits and to make

sure it is not blocked.

▪ All work on oil-carrying parts must

only be carried out by heating oil-related qualified experts and with consideration of local and national regulations, and the instructions in this

manual.

▪ Improperly performed work on oil or

flue gas-carrying lines can endanger

life and health and hinder the operation of the heating device.

Installation and operating instructions

4

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

1 General safety precautions

1.1.1 Observing the instructions

▪ The original documentation is written in German. All other lan-

guages are translations.

▪ Please read this manual carefully and thoroughly before proceed-

ing with the installation or modification of the heating system.

▪ The precautionary measures described in this document cover

very important topics. Follow them meticulously.

▪ The installation of the system, and all activities described in this

manual and the applicable documents for the installer must be

carried out by an approved installer.

This manual provides all the necessary information for installation,

start-up and maintenance, as well as basic information on operation

and settings. Please see the attached documents for a detailed description of operation and control.

All heating parameters needed for smooth operation are already

factory-set. Please refer to other relevant documents for information

on setting the control.

Relevant documents

▪ A2 F :

▪ Operating manual for the operator

▪ RoCon BF: Operating instructions.

▪ When additional components are connected; the associated in-

stallation and operating instructions.

The guides are included in the scope of supply for the individual

devices.

1.1.2 Meaning of warnings and symbols

Warnings in this manual are classified according into their severity

and probability of occurrence.

DANGER

Indicates an immediate danger.

Disregarding this warning can lead to serious injury or

death

WARNING

Indicates a potentially dangerous situation

Disregarding this warning may result in serious physical injury or death.

CAUTION

Indicates a situation which may cause possible damage

Disregarding this warning can cause damage to property

and the environment, and result in minor injuries.

This symbol identifies user tips and particularly useful information, but not warnings or hazards

Special warning signs

Some types of danger are represented by special symbols:

Electric current

Danger of explosion

Risk of burning or scalding

Risk of poisoning

Validity

Some information in this manual has limited validity. The validity is

highlighted by a symbol.

Observe specified tightening torque (see )

Handling instructions

1 Handling instructions are shown as a list. Actions for which the

sequential order must be maintained are numbered.

è

Results of actions are identified with an arrow.

1.2 Safety instructions for installation and operation

1.2.1 General

WARNING

Heating devices that have not been set up and installed

correctly can impair the function of the heating device and/

or cause serious or fatal injuries to the user.

▪ Work on the A2 F (such as set-up, servicing, connection

and initial start-up) must only be carried out by persons

who are authorised and who have successfully completed qualifying technical or vocational training and

who have taken part in advanced training sessions recognised by the relevant responsible authorities for the

specific activity. These include, in particular, certified

heating engineers, qualified electricians and HVAC

specialists, who, because of their professional training and their expert knowledge, have experience in the

professional installation and maintenance of heating systems, gas installations and hot water tanks.

▪ Switch off the main switch and secure it against uninten-

ded switching on when carrying out any work on the A2

F.

▪ Do not leave any tools or other objects inside the device

after finishing installation or maintenance work.

Avoiding danger

A2 F conforms to the state-of-the-art and meets all recognised technical requirements. However, improper use may result in serious

physical injuries or death, as well as property damage. To prevent

such risks, only install and operate the devices:

▪ as stipulated and in perfect condition,

▪ with an awareness of safety and the hazards involved.

This assumes knowledge and use of the contents of this manual, of

the relevant accident prevention regulations as well as the recognised safety-related and occupational health rules.

Before working on the heating system

▪ Only authorised and trained heating technicians may work on the

heating system (such as installation, connection and initial startup).

▪ Switch off the main switch and secure it against unintended

switching on when carrying out any work on the heating system.

▪ Seals must not be damaged or removed.

▪ Make sure that the safety valves comply with the requirements of

EN12828 when connecting on the heating side, and with the re-

quirements of EN12897 when connecting on the domestic water

side.

1.2.2 Intended use

The A2 F may only be used for the heating of hot water heating systems. It must only be installed, connected and operated according to

the information in this manual.

The A2 F may only be operated with the integrated circulation pump

and in conjunction with a controller approved by the manufacturer.

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Installation and operating instructions

5

1 General safety precautions

Any other use outside the intended use is considered as improper

and will result in a loss of warranty. The operator alone shall bear responsibility for any resulting damage.

The A2 F is suitable for operation with light heating oil.

Intended use also includes compliance with the maintenance and

service conditions. Replacement parts must at least satisfy the technical requirements defined by the manufacturer. This is the case,

forexample, with original spare parts.

1.2.3 Device installation room

▪ Operate A2 F only if sufficient combustion air supply is ensured. If

the A2 F is operated as an ambient air-independent device with a

concentric air/flue gas system (LAS) dimensioned according to the

manufacturer's standard, this is automatically ensured and there

are no further conditions for the installation room. Only this

method of operation is permissible for installation in residential

rooms.

▪ Make sure that there is an outside air opening of at least 150cm

for ambient-air dependent or partial ambient-air independent operation.

▪ Do not operate the A2 F in ambient-air dependent operation in

rooms with aggressive vapours (e.g. hair spray, perchloroethylene, carbon tetrachloride), strong dust formation (e.g. workshop)

or high humidity (e.g. laundries).

▪ Avoid operating conditions that can cause heavy soiling of the

burner. Do not operate the device if temporary heavy dust deposits occur in the area of the air extraction system.

▪ Always ensure the minimum distances to walls and other objects

(see Chap. 4.4.1).

1.2.4 Electrical installation

▪ Electrical installations may only be carried out by electrical techni-

cians and in compliance with valid electrical guidelines as well as

the specifications of the responsible energy supply company.

▪ Compare the mains voltage (230V, 50Hz) indicated on the name-

plate with the supply voltage before connecting to the mains.

▪ Before beginning work on live parts, disconnect them from the

power supply (switch off main switch, remove fuse) and secure

against unintentional restart.

▪ Device covers and service panels must be replaced as soon as

the work is completed.

Using filling water and top-up water which does not meet the stated

quality requirements can cause a considerably reduced service life

of the device. The responsibility for this lies solely with the operator.

1.2.6 Heating system and sanitary connection

▪ Create a heating system according to the safety requirements of

EN12828.

▪ The sanitary connection for filling the system from the drinking wa-

ter supply network and for connection of a hot water tank must

meet the requirements of EN12897. The requirements of the following must also be observed:

▪ EN1717 – Protection against pollution of potable water installa-

tions and general requirements of devices to prevent pollution

by backflow

▪ EN61770 – Electric appliances connected to the water mains –

Avoidance of backsiphonage and failure of hose-sets

2

▪ EN806 – Specifications for installations inside buildings con-

veying water for human consumption

▪ and, in addition, the country-specific legislation.

1.2.7 Fuel

The A2 F is intended exclusively for the use of approved heating oils

(see Chap. 12).

1.2.8 Operation

▪ Do not operate the A2 F if the boiler cladding is open.

▪ Only operate the A2 F if all requirements according to the check-

list in Chap. 5.2 are satisfied.

1.2.5 Requirements for the heating water

Avoid damage caused by deposits and corrosion: Comply with the

applicable engineering regulations on prevention of corrosion

products and deposits (VDI 2035, BDH/ZVSHK technical information

"Scale formation").

Measures for desalination, softening or hardness stabilisation are

necessary if the filling and top-up water have a high total hardness

(>3mmol/l - total of the calcium and magnesium concentrations, calculated as calcium carbonate).

Minimum requirements regarding the quality of filling and supplementary water:

▪ Water hardness (calcium and magnesium, calculated as calcium

carbonate): ≤3mmol/l

▪ Conductivity: ≤1500 (ideal: ≤100) μS/cm

▪ Chloride: ≤250mg/l

▪ Sulphate: ≤250mg/l

▪ pH-values (heating water): 6.5 - 8.5

Measures for desalination, softening or hardness stabilisation or

other suitable conditioning measures are necessary to maintain the

required water quality if the filling and top-up water have a high total

hardness or other properties divergent from the minimum requirements.

Installation and operating instructions

6

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

2 Handover to operator and

warranty

2.1 Instruct the owner

▪ Before you hand over the heating system, explain to the owner

how he/she can operate and check the heating system.

▪ Hand over the technical documentation (at least the operating in-

structions and operating manual) to the operator and advise him

that these documents must be made available at all times and be

stored in the immediate vicinity of the device.

▪ Document the handover by filling out the installation and instruc-

tion forms together with the owner and sign them.

2.2 Warranty conditions

The legal guarantee conditions fundamentally apply. Our more extensive warranty conditions can be found in the Internet. Ask your

suppliers if necessary.

There is only an entitlement to warranty services when it can be certified that the annual maintenance work according to chap. 9has

been regularly completed.

2 Handover to operator and warranty

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Installation and operating instructions

7

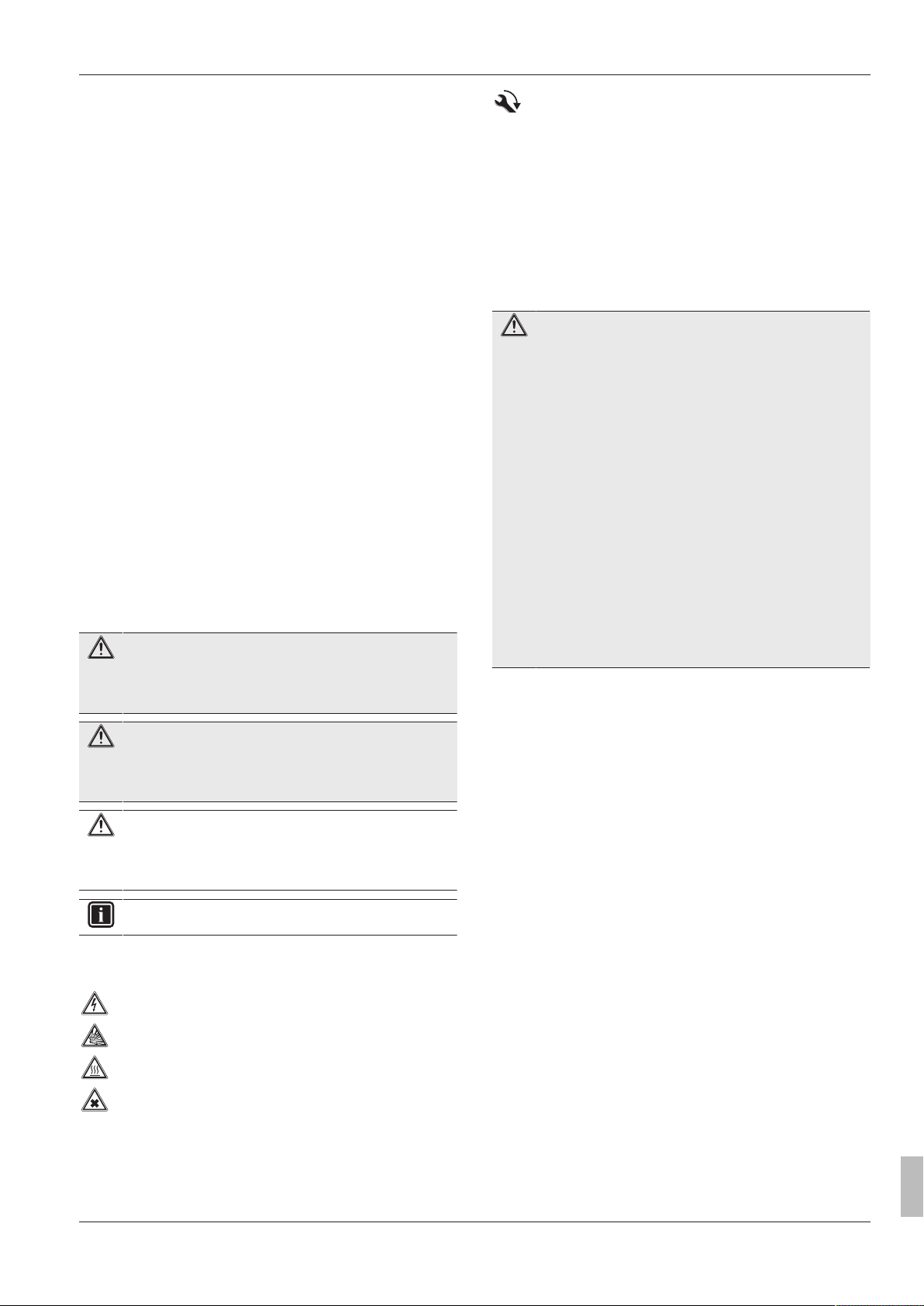

3 Product description

3 Product description

3.1 Design and components

Fig.3-1 Design and components - view from above

Fig.3-2 Design and components - front and rear view

(1)

Fig.3-3 Design and components - view without cladding

(1)

(1)

(1)

For legend, see Tab. 3-1

Installation and operating instructions

8

Fig.3-4 Design and components - view of lower part

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

(1)

3 Product description

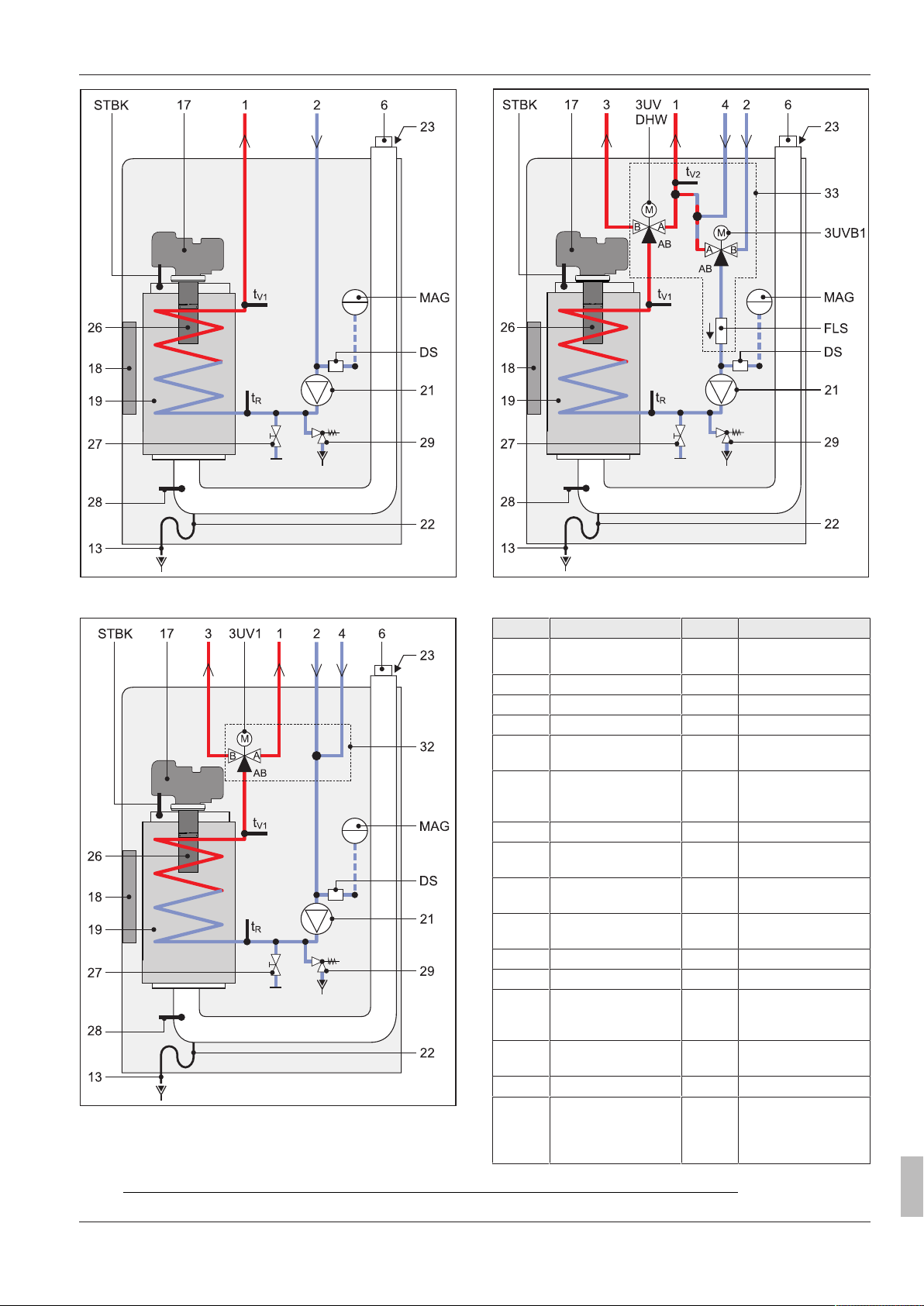

Fig.3-5 Design and components with standard equipment -

schematic drawing (hydraulic system)

Fig.3-6 Design and components with valve kit - schematic draw-

ing (hydraulic system)

(1)

(1)

Fig.3-7 Design and components with Smart start kit - schematic

drawing (hydraulic system)

(1)

Item Designation Item Designation

A View from front 21 Heating circulation

pump

B Rear view 22 Condensate siphon

1 Heating flow 23 Supply air connection

2 Heating return flow 24 oil filter

3 Storage tank – char-

25 MAG connection

ging flow (optional)

4 Storage tank – char-

26 Recirculation tube

ging return flow (optional)

5 Oil connection 27 KFE cock

6 flue gas connection 28 Flue gas temperature

sensor

7 Mains switch 29 Safety-pressure relief

valve (heating circuit)

8 Controller – control

30 Automatic vent valve

panel

9 boiler enclosure 32 Valve kit

10 Height-adjustable feet 33 Smart start kit

11 Recessed grips 3UV1 /3

UV DHW

3-way valve (distribution valve, hot water/

heating)

12 Optional flue gas con-

3UVB1 3-way mixer valve

nection

13 Condensate drain FLS FlowSensor

14 Feed-through for ex-

ternal diaphragm expansion vessel

MAG Diaphragm expansion

vessel (accessory/

provided by the customer)

(1)

For legend, see Tab. 3-1

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Installation and operating instructions

9

3 Product description

Item Designation Item Designation

15 Blow-off line from

safety valve

16 Cable penetration STBK Safety temperature

17 Burner tv1 Inflow temperature

18 Boiler control panel t

19 Boiler main body with

heat and sound insulation

20 Type plate with manu-

facturer's number

Tab.3-1 Legend for Fig. 3-1 to Fig. 3-7

DS Pressure sensor

limiter

sensor

v2

t

R

Internal mixer sensor

Return flow temperat-

ure sensor

3.2 Brief description

The A2 F is a completely pre-assembled oil condensing unit.

Operating mode

The A2 F is constructed so it can be operated independent of the

ambient air (concentric flue gas/air supply pipes). All flue gas carrying parts are surrounded by combustion air. The burner suctions the

combustion air directly in through an installation shaft or a doublewalled flue gas pipe. This operating mode is recommended by us

and has many advantages:

▪ The heating room does not need any ventilation opening into the

open air and therefore does not cool down.

▪ Lower energy consumption.

▪ Additional energy recovery in the flue gas pipe through preheating

the combustion air.

▪ Contamination from the environment of the burner are not suc-

tioned in. The heating room can thus be used as a workspace,

laundry room, etc. at the same time.

▪ Possible to install in loft areas or attic.

▪ Possible to install in garages.

The heating water is first fed into the boiler body at the lowest position. There, it is heated in counterflow via the adjacent combustion

chamber and several stainless steel heat exchanger tubes that pass

through the boiler body. The heated heating water is fed from the upper connection of the boiler body to the inflow connection of the

boiler housing. The combustion gases flow through the heat exchanger tubes into the boiler body from top to bottom after flame reversal in the combustion chamber. These tubes contain turbulators

that improve heat transfer to the heating water.

The condensate produced is fed into the sewage system via the condensate siphon and then via a plastic pipe. Optionally, it can be

neutralised via the optional condensate box.

Smart Start function

The Smart Start function was developed to avoid frequent switching

of the burner when the requirement for room heating is low.

If the optional Smart Start kit (two steplessly controllable 3-way

valves) is installed in the A2 F, the Smart Start function can be used.

The requirement for room heating is therefore temporarily covered

by the heat stored in the hot water storage tank. The Smart Start

function remains active until the next request for hot water generation is pending.

The Smart Start function is automatically controlled by the RoCon

BF controller.

Safety management

The entire safety management of the A2 F is carried out by the electronic controller. If there is water shortage, oil shortage or undefined

operating conditions, there is a safety shutdown. A corresponding

fault signal provides an engineer with all the necessary information

for troubleshooting.

Electronic controller

An electronic digital controller combined with the burner "intelligent"

firing unit automatically controls all heating and hot water functions

for the direct heating circuit and an optional storage tank charging

circuit.

One or more mixed circuits can be connected and controlled via optionally connected mixer modules RoCon M1.

All settings, displays and functions are carried out by the integrated

RoCon BF controller. The display and the operating elements make

operation easy.

A digital room controller (RoCon U1) is optionally available for

greater comfort. It can be used as a remote control and room thermostat.

The controller can be connected to the Internet via the optional gateway (RoCon G1). This enables remote control of the A2 F by mobile

phones (by app).

Condensing technology

Condensing technology makes optimum use of the energy contained

in the heating oil. The flue gas is cooled down in the boiler – and in

the flue system with ambient air-independent operation in the concentric flue gas system – to the extent that the temperature is below

the dew point. A part of the water vapour generated through combustion of the heating oil thus condenses. The condensation heat is

fed to the heating, as opposed to low-temperature boilers, which enables efficiency rates of over 100% (based on the lower heating

value).

Fuel

The A2 F can be operated with standard or low-sulphur heating oil

(sulphur content <50ppm). It is equipped for the combustion of heating oil with biogenic components. Mixing of bio-heating oil up to

10% (B10) is permitted without further conversion.

INFORMATION

We recommend using EL low sulphur heating oil, in order

to achieve the highest efficiency and to keep the maintenance expenditure low.

Condensate treatment unit

The condensate produced during combustion in an oil condensing

boiler has a pH-value of 1.8 – 3.7 when using heating oil that is not

low in sulphur.

The optional condensate preparation unit fulfils the following functions:

▪ Removal of floating particles in the settling basin

▪ Neutralisation of the condensate in the Hydrolit-MG filter material

When using low-sulphur heating oil, the condensate can usually be

drained off into the sewage network without neutralisation. Please

refer to the regulations of the local water authorities.

Installation and operating instructions

10

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

4 Set-up and installation

A

736

A

606

271

262

1360

134

263 140

140

80

0

0

110

293

368

442

516

540

50

124

R

H

≥ 40 cm

≥ 40

cm

≥ 40 cm

≥ 200 cm

CA

FG

RV

(e)

(e)

(d)

(d)

(f)

(a)

1

(a)

4

(a)

3

(b)

5

(c)

6

(a)

2

C

93

C

53

C

53

C

83

C

33

C

33

B

23

B

23P

B

33

B

53

B

53P

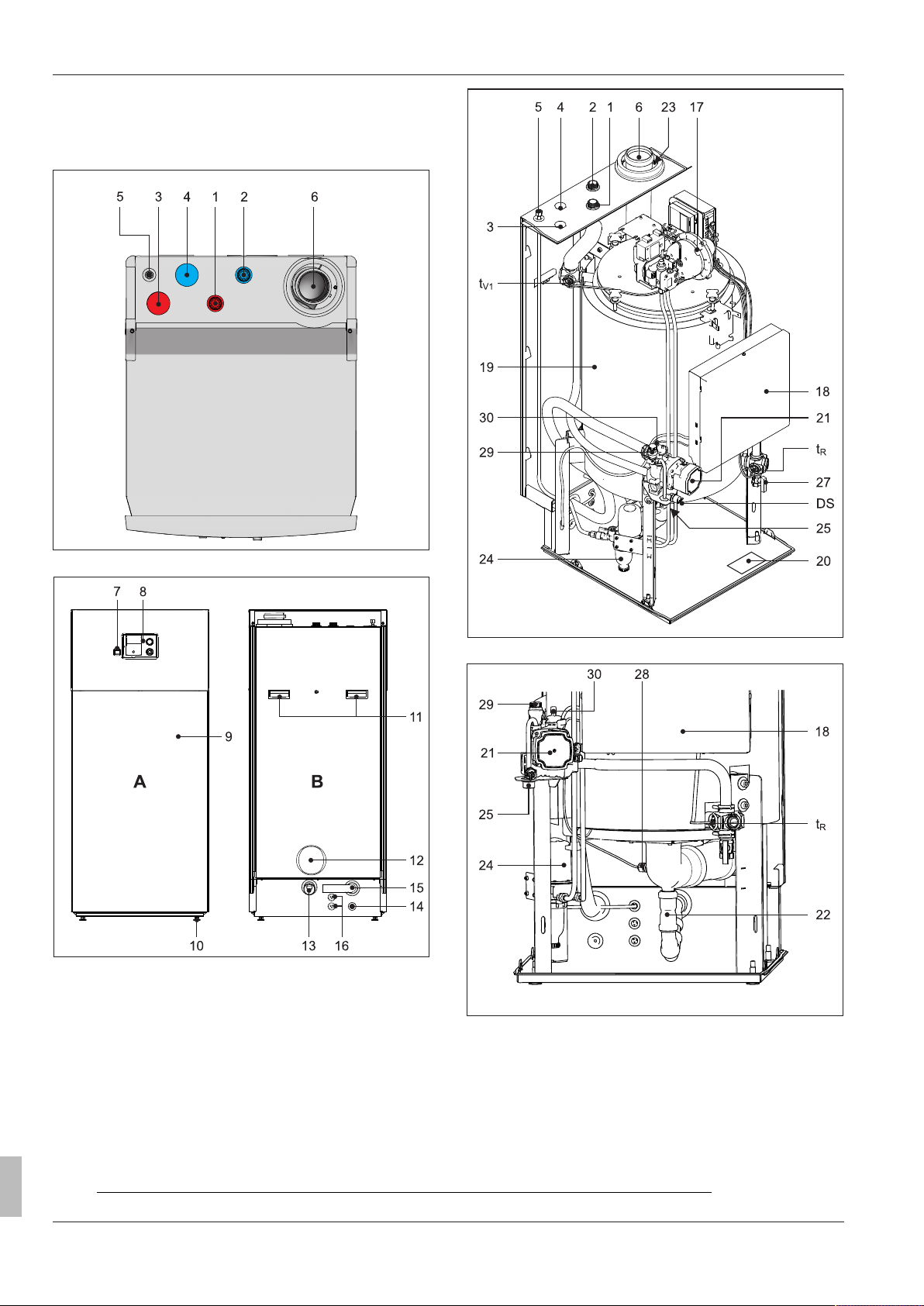

4 Set-up and installation

WARNING

Devices which have been set-up and installed incorrectly

may not operate properly and can be a health and safety

risk endangering human life.

▪ Only authorised and trained heating technicians may set

up and install the A2 F.

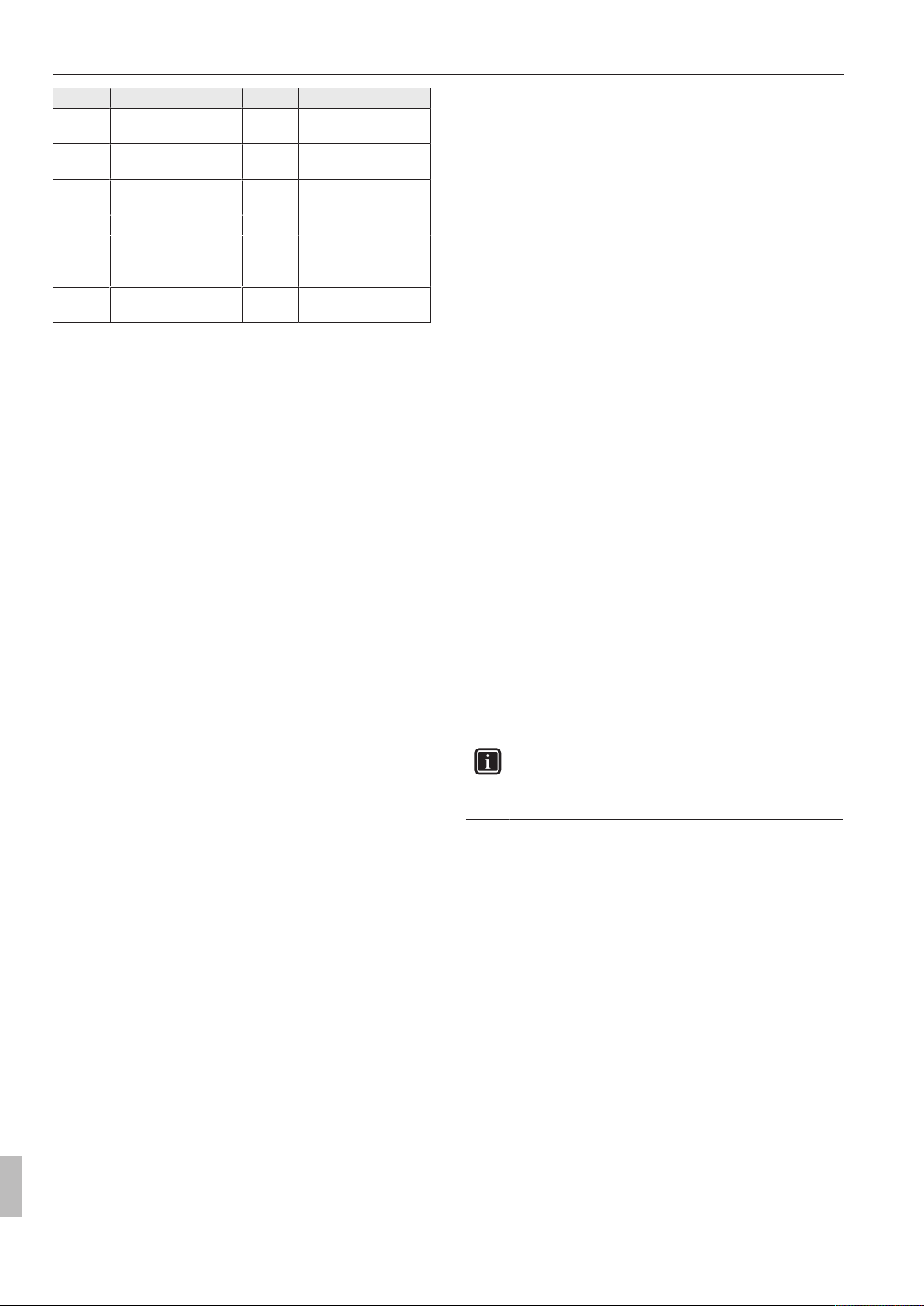

4.1 Dimensions and connection dimensions

4.2 Different set-ups

Fig.4-1 Installation dimensions

Item Designation

R

H

Tab.4-1 Legend for Fig. 4-1

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Minimum room height (see Chap. 4.4.1)

INFORMATION

To avoid increased cooling losses, we recommend the installation of SKB gravity brakes (accessory) or the syphoning of the connection line.

Fig.4-2 Different set-ups

Item Designation

1-6 Installation versions (for a description, see Chap. 4.2.1

to Chap. 4.2.3)

CA Supply air (combustion air)

FG Flue gas

RV Rear ventilation

a Installation version for ambient air-independent opera-

tion (flue gas/supply air concentric)

b Installation version for conditional ambient air-independ-

ent operation (flue gas/supply air separate)

c Installation version for ambient air-dependent mode

d Longitudinally ventilated shaft with a fire-resistance

period of 90minutes (30minutes in low height residen-

tial buildings). Observe country-specific regulations for

fire-resistance periods!

e Ventilation opening (1x150cm2 or 2x75cm²)

f Rear ventilation opening (150cm2)

Tab.4-2 Legend for Fig. 4-2

The A2 F is designed for ambient air-independent operation. It is

fitted as standard with a concentric flue gas /air supply pipe DN

80/125.

INFORMATION

In some cases, the resonance in the flue gas system can

amplify the noise at the mouth of the flue gas duct. The

noise level can be effectively reduced by using a silencer

(accessory: DN80: E8MSD or DN110: E11MSD).

Installation and operating instructions

11

4 Set-up and installation

INFORMATION

Use of the A2 F in ambient air-independent operation with

a concentric flue gas/air supply line is recommended by us.

If possible, choose this installation version!

In partial ambient air-independent operation (separate flue

gas/air supply lines with a single-walled connecting pipe)

and ambient air-dependent operation the installation room

must have a ventilation opening of at least 150cm2 to the

outside.

As such, the installation room will not be assigned the

heated building envelope under the Energy Conservation

Ordinance (EnEV), which downgrades the energy rating of

the building. This reduces the overall energy efficiency of

the building according to European Directive 2010/31/EU:

EPBD.

The following descriptions of the different set-ups includes

information regarding the possible classification of the

devices based on the type of flue gas routing (equipment

type) in accordance with EN15035 and CEN/TR1749.

Chap. 4.2.4 and Chap. 4.5 must also be observed in this

regard.

The described SETs are accompanied by separate assembly instructions.

The SETs mentioned below are recommendations for the

appropriate combination of the required individual components for the typical installation variants.

4.2.1 Room-air independent operation

INFORMATION

When devices are installed in residential rooms only one of

the installation versions 1 to 4 is permissible.

Installation version 1

The A2 F is connected to the chimney or an installation shaft with

the concentric SetK LAS connection line.

▪ The combustible air supply from the outside runs through the

chimney or through an installation shaft.

▪ The flue gas discharge to the outside runs through the same shaft

as the air supply.

▪ Minimum vertical distance between flue gas exit and roof ridge:

40cm.

▪ Device type C

Installation version 2

The A2 F is placed directly below the roof. Connection with SETL.

▪ The combustible air supply and flue gas discharge run through a

concentric dual pipe.

▪ The combustible air supply from the outside runs through the

outer ring-shaped gap of the dual pipe, and the flue gas discharge

to the outside runs through the inner tube.

▪ Minimum vertical distance between flue gas exit and roof surface:

40cm.

▪ Minimum height of the flue gas pipe: 2m.

▪ Device type C

Installation version 3

The A2 F is not placed directly below the roof. The dual pipe for the

combustible air supply and flue gas duct runs through the roof truss.

▪ The combustible air supply and the flue gas discharge run through

a concentric dual pipe (as in Installation version 2).

▪ In the area of the roof truss, the dual pipe for the combustible air

supply and the flue gas duct must be laid through a protective pipe

with sufficient fire resistance or be structurally separated from the

roof truss.

93x

33x

▪ Device type C

33x

Installation version 4

The A2 F is connected with the SETK LAS connection line to the

SETG outer wall system.

▪ The combustible air supply from the outside runs through the ring-

shaped gap in the dual pipe, through the outer wall (suction from

below).

▪ The flue gas discharge to the outside runs through a concentric

pipe, through the outer wall and then up to at least 40cm over the

roof surface. In the external area, the outer air gap serves as heat

insulation for the flue gas pipe.

▪ Device type C

53x

If the wall feed through is at a height of less than one

meter above the ground, we recommend routing the combustion air through a separate air supply pipe (mounting

height: approx. 2m). W8ZR or W11ZR

Installation version 5

If, for constructional or legal/regulatory reasons, the shaft used for

the flue gas routing is not suited for also routing the combustion air

at the same time, the combustion air must be routed through a separate line.

If the flue gas connection line to the shaft is double-walled and is

surrounded by the combustion air, there are no additional ventilation

requirements on the installation room.

▪ Combustion air supply is routed from the outside via the ad-

equately sealed supply line which is connected directly to the concentric exterior pipe of the connection line. The supply line should

be sized so that the suction resistance at nominal output is

less than 50Pa.

▪ The connection line between the A2 F and the installation shaft is

completely concentric and surrounded by combustion air.

▪ Device type C

, C

53x

83x

INFORMATION

The A2 F is suitable for installation and operation within

garages. Requirements:

▪ Ambient air-independent operation,

▪ A durable operating manual placed in a very visible

place near the device,

▪ The construction must include a protective device

against mechanical damage (vehicle!) for the entire system (e.g. bracket or deflector).

▪ Permanently frost-protected.

Installation variant 7 (not shown)

If permitted by local regulations, the A2 F can be connected to

SETW2 to the horizontal flue gas outlet.

▪ The combustible air supply and flue gas discharge run through a

concentric dual pipe.

▪ The combustible air supply runs from the outside through the

outer ring-shaped gap of the dual pipe (supply air inlet via the intake grille of the wall feed through) and the flue gas discharge to

the outside runs through the inner tube.

▪ Minimum height of the flue gas pipe: 2m

▪ Observe local regulations regarding minimum distances of win-

dows or other building openings.

▪ Device type C

13x

4.2.2 Partial ambient air-independent mode

Alternative to installation variant 5

The A2 F is operated with separately routed supply air/flue gas lines

(2-pipe system).

Installation and operating instructions

12

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

4 Set-up and installation

▪ The combustion air supply from the outside runs through an ad-

equately sealed air supply line through the external wall. The supply line should be sized so that the suction resistance at nominal

output is less than 50Pa.

▪ Flue gas discharge to the outside runs through the chimney or an

installation shaft. If the connection line between the A2 F and the

installation shaft is single-walled or not completely surrounded by

combustion air, a ventilation opening to the outside of at least

150cm2 is required.

Appropriate measures must be taken to ensure that the burner

cannot be operated if the ventilation opening is closed.

▪ The installation shaft where the flue gas line runs must be rear

ventilated. There must be a rear ventilation opening of at least

150cm2 in the lower area.

The cross-section of this installation shaft must be sized so that

between the external wall of the flue gas line and the internal

face of the installation shaft the following minimum distance

must be maintained:

▪ with a rectangular shaft cross-section: 2cm

▪ with a round shaft cross-section: 3cm.

The rear ventilation opening must not be located in rooms where a

negative pressure is generated (e.g. by controlled apartment ventilation, a tumble-drier etc.).

▪ Device type C

, C

53x

83x

4.2.3 Ambient air-dependent mode

Installation version 6

The A2 F can also be connected dependent on the ambient air.

Thereby, only the inner flue gas pipe (plastic pipe Ø 80mm) of the

concentric air-flue gas pipe is connected to the flue gas line. The

device sucks the combustible air from the installation room through

the ring-shaped gap of the jacket pipe.

The same conditions apply to the flue gas routing into the open air,

shaft dimensioning and rear ventilation as in Chap. 4.2.2. A ventila-

tion opening into the open air of at least 150cm2 is mandatory.

▪ Device type B23, B

, B33, B53, B

23P

53P

INFORMATION

In some cases, the resonance in the flue gas system can

amplify the noise at the mouth of the flue gas duct. The

noise level can be effectively reduced by using a silencer

(DN80: E8MSD or DN110: E11MSD).

4.2.4 Additional information on device type in

accordance with CEN/TR1749

INFORMATION

We basically recommend installing the A2 F regardless of

the room air (device type C) and with concentric air/flue

gas guides (see Chap. 4.2.1). Other permissible applications of the air intake and flue gas discharge are not described in detail in these instructions.

Special requirements that exist for such systems based on

EN15035 are listed below.

C13:

▪ Horizontal openings for flue gas outlet and supply air inlet

▪ Openings within a square of 50cmx50cm

C33:

▪ vertical openings for flue gas outlet and supply air inlet

▪ Openings within a square of 50cmx50cm

▪ Spacing of opening levels <50cm

C43:

▪ Connection of more than one device to a common air/flue gas sys-

tem that is part of the building

▪ vertical opening for flue gas outlet and supply air inlet

▪ Openings within a square of 50cmx50cm

▪ Spacing of opening levels <50cm

▪ Suitable calculated dimensioning verification required because va-

cuum prevails in the case of the flue gas inlet into the common air/

flue gas system. The flue gas must be discharged with a natural

draught.

▪ For data on dimensioning, see Chap. 14.1.

▪ Condensate flow from the common air/flue gas system must not

be discharged through the device.

C53:

▪ Vertical opening for flue gas outlet

▪ Opening for supply air inlet into different pressure area possible.

▪ Openings must not be installed on opposite walls of the building.

C63:

▪ Connection to a separately approved and marketed flue gas/sup-

ply air system if allowed by national law.

▪ This allows all other described installation forms to the realised for

device type C if the conditions of the respective installation form

are met.

▪ If the dimensions of the system used differ from those described in

this manual (seeChap. 4.5.1), a suitable arithmetical dimension-

ing verification is required.

▪ For data on dimensioning, see Chap. 14.1.

▪ Properties and possible applications of the pipe system:

▪ Minimum requirements according toChap. 4.5.1 fulfilled

▪ Condensate flow into the device allowed with single assign-

ment, not allowed with multiple assignment.

▪ Maximum combustion air temperature: 60°C

▪ Maximum allowed flue gas recirculation current under wind con-

ditions: 10%

C83:

▪ Connection to one or more devices to a vacuum flue gas system

that is part of the building.

▪ Vertical opening for flue gas outlet

▪ Air intake via associated second

(2)

line.

▪ Opening for supply air inlet into different pressure area possible.

▪ Suitable arithmetical dimensioning verification required because

vacuum prevails in the case of the flue gas inlet into the common

air/flue gas system.

▪ For data on dimensioning, see Chap. 14.1.

▪ Properties and application options of the flue gas system:

▪ Minimum requirements according toChap. 4.5.1 fulfilled (except

for pressure class).

▪ Condensate flow into the device allowed with single assign-

ment, not allowed with multiple assignment.

C93:

▪ as for C33, but

▪ Connection of the supply air pipe to an existing vertical shaft (e.g.

chimney) that is part of the building.

(2)

If the air supply pipe was used beforehand as a flue gas pipe or chimney of an oil or solid fuel furnace, it should be cleaned

prior to use as an air supply pipe.

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Installation and operating instructions

13

4 Set-up and installation

▪ The cross-section of this installation shaft must be sized so that

between the external wall of the flue gas line and the internal

face of the installation shaft the following minimum distance

must be maintained:

▪ with a rectangular shaft cross-section: 2cm

▪ with a round shaft cross-section: 3cm

B23:

▪ Flue gas pipe without flow safeguard - vacuum operation

▪ Properties and application options of the flue gas pipe:

▪ Minimum requirements according toChap. 4.5.1 fulfilled.

▪ Opening for flue gas outlet to the outside

▪ Supply air directly from installation room (seeChap. 4.2.3).

▪ If the dimensions of the flue gas line differ from those described in

this manual, a suitable arithmetical dimensioning verification is required.

▪ For data on dimensioning, see Chap. 14.1.

B

:

23P

▪ as for B23, but underpressure operation

B33:

▪ Connection of more than one device to a common flue gas system

(vacuum flue gas shaft).

▪ Vertical opening for flue gas outlet.

▪ Supply air directly from installation room (seeChap. 4.2.3).

▪ Suitable arithmetical dimensioning verification required because

vacuum prevails in the case of the flue gas inlet into the common

air/flue gas system.

▪ For data on dimensioning, see Chap. 14.1.

▪ Parts under overpressure of the connection pipe must be conduc-

ted as a concentric pipe system.

B53:

▪ as for B33, but connection to associated flue gas pipe including flue

gas opening.

B

:

53P

▪ as for B53, but overpressure operation.

Spacings of brackets and offsets

The distance of the supports of the flue gas line must not be more

than 2m in the vertical area.

In the horizontal area of the connecting lines, the brackets must be

installed so tightly that there is no risk of any gradient in the horizontal area in which condensate could accumulate.

If an offset is required in the vertical part of the flue gas line, the

maximum angle must not exceed 45°. In the case of external installation, the height above the last bracket must not exceed 1.5m.

4.3 Transport and delivery

WARNING

Lifting or displacing the A2 F by the panels can damage

the device.

▪ Only carry the A2 F with the cover removed, in pairs us-

ing the recessed grips provided for this purpose in the

rear panel of the device and on the boiler frame.

The A2 F is delivered on a pallet. All industrial trucks, such as lifting

trucks and forklift trucks, are suitable for transporting it.

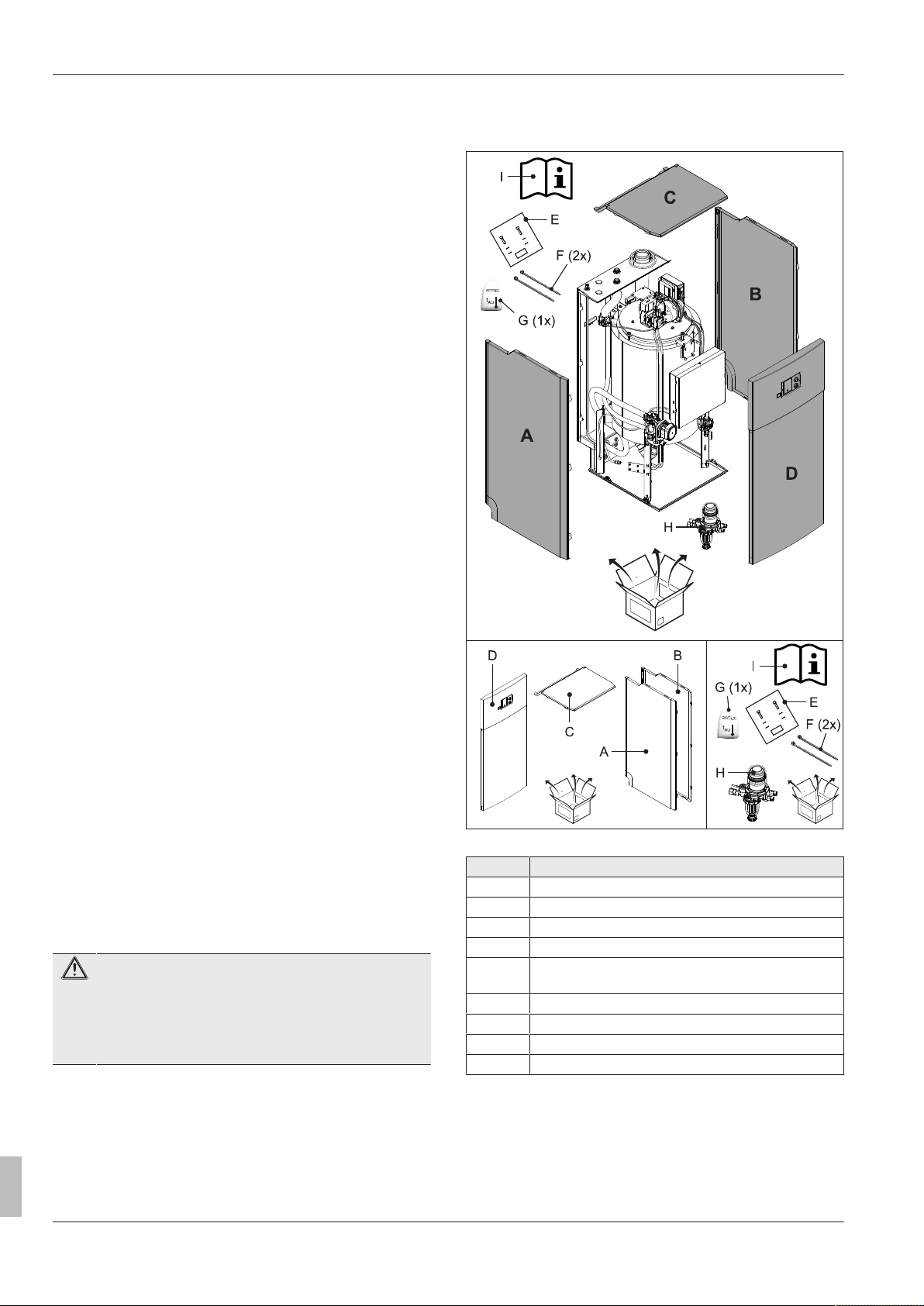

Scope of delivery

▪ A2 F (preassembled),

▪ Boiler cladding (see Fig. 4-3)

▪ Screws for boiler cladding

▪ Documentation package

▪ Cable tie

▪ oil filter

▪ External temperature sensor

Fig.4-3 Scope of delivery standard accessories package

Item Designation

A Boiler cladding – side panel

B Boiler cladding – side panel

C Boiler cladding – cover

D Boiler cladding – front panel

E Small accessories: Screws, 4-pin circuit board con-

nector, strain relief clip (3x)

F Cable tie

G External temperature sensor

H oil filter

I Documentation

Tab.4-3 Legend for Fig. 4-3

For A2 F accessories, see price list.

Installation and operating instructions

14

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

4 Set-up and installation

4.4 Installing the oil condensing boiler

4.4.1 Selecting the installation site

The installation site of the A2 F must meet the minimum requirements below (see alsoChap. 1.2.3).

Installation height

▪ The bottom edge of the condensate connection on the device

must be higher than the drain height of the condensate drain

hose, otherwise condensation can accumulate in the drain. Install

a pedestal if necessary.

▪ Small unevennesses of the installation surface can be com-

pensated using the height-adjustable feet (see Chap. 4.4.2).

Installation area

▪ The base must be level and smooth and have a sufficient ground

load-bearing capacity of 500kg/m² plus safety factor. Install a

pedestal if necessary.

▪ Observe the installation dimensions (see Chap. 4.1).

Installation room

▪ There are no special conditions for ventilation of the installation

room for ambient air-independent operations (using a concentric

air/flue gas system).

▪ In partial ambient air-independent and ambient-dependent mode,

the installation room must have a ventilation opening of at least

150cm2 to the outside. If the flue gas line is routed to the outside

through an installation shaft, it must be rear-ventilated (seeChap.

4.2.2).

▪ For partial ambient air-independent and for ambient air-dependent

mode, the installation room must be free from aggressive vapours

(e.g. hair spray, perchloroethylene, carbon tetrachloride), heavy

dust formation and high atmospheric humidity (e.g. laundry).

▪ Outdoor installation is not permissible.

▪ Installation in an explosion-risk environment is not permissible.

▪ The electronic controller may never be exposed to the effects of

the weather.

▪ The A2 F must be protected from frost.

INFORMATION: HEATING OIL STORAGE IN THE INSTALLATION ROOM

The construction specifications allow, as a rule, hot oil storage of up to 5000litres (according to the firing ordinance of

the country) if the building is a Building Class 1 construction and the installation room is not a room were people

live or work.

Installation in the attic

If the A2 F is installed in the attic and the oil is stored in the rooms

below it, the oil pump of the burner is generally not sufficient. If the

vacuum on the suction side exceeds the value 0.4bar, the oil must

be supplied to the burner through a separate pump. We strongly recommend using a suction unit.

The minimum height of the flue gas conduit must be 2m in order

to avoid malfunction at start or during operation of the burner.

WARNING

If using a pressure aggregate, oil could escape if there is a

failure. Escaping oil can cause serious damage to the environment.

▪ Install the boiler on a water-proof tray and secure by a

float switch (connection via additional plug strip).

▪ Use only a metallic filter cup (never Plexiglas).

▪ Ambient air-independent operation,

▪ A durable operating manual placed in a very visible place near the

device,

▪ The construction must include a protective device against mech-

anical damage (vehicle!) for the entire system (e.g. bracket or deflector).

▪ Permanently frost-protected.

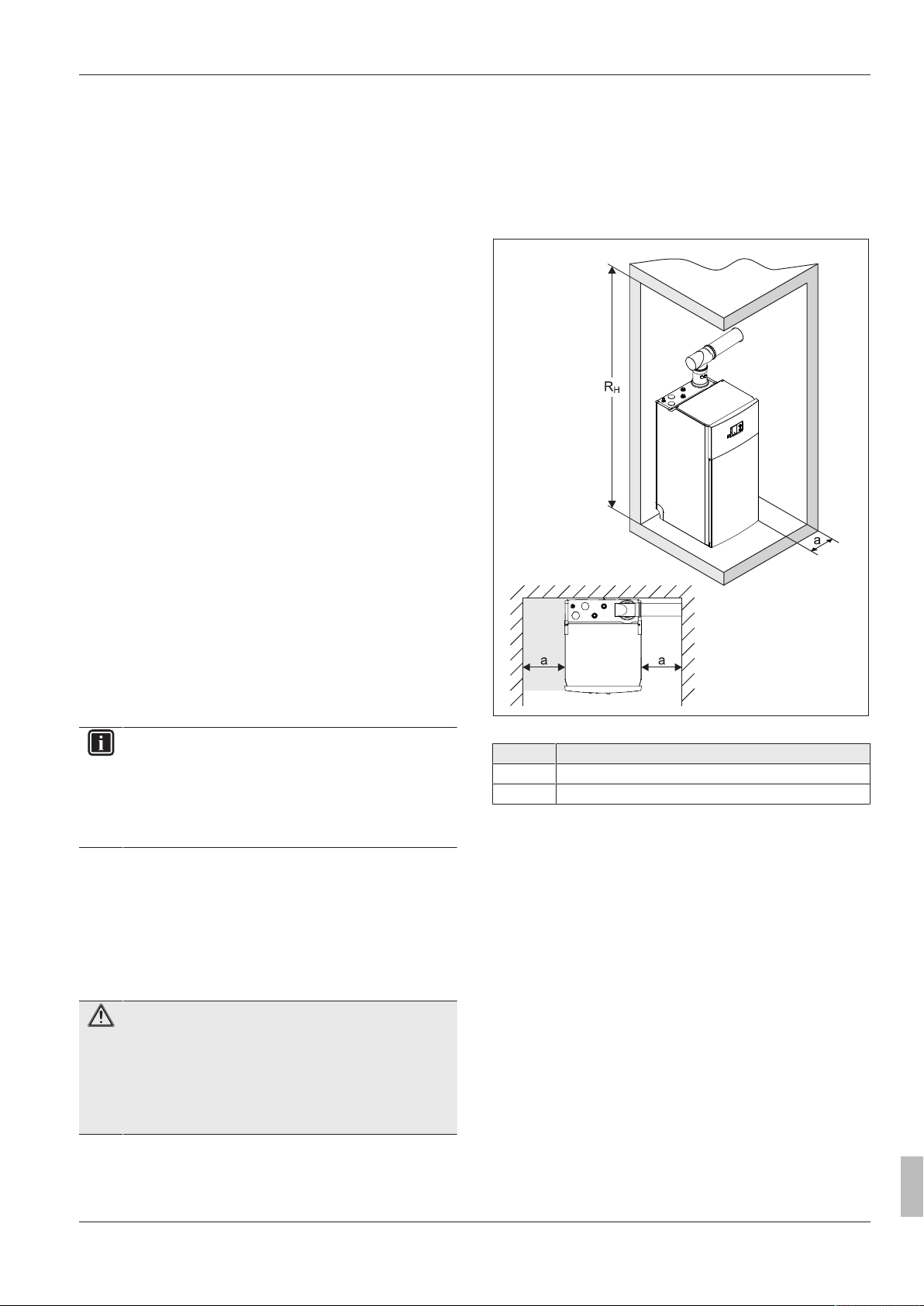

Surface temperatures, minimum distance

Fig.4-4 Minimum distances for installation

Item Designation

R

H

a Minimum lateral wall distance: 0.50m

Tab.4-4 Minimum distance dimensions

▪ In ambient air-independent mode with rated power, the design

does not allow temperatures >70°C on any component outside

the device panels. Therefore, no minimum distance is specified for

components made with flammable materials.

▪ A minimum distance of 50mm between the flue gas line and flam-

mable components should be maintained in a partial ambient airindependent and ambient air-dependent operation (separate flue

gas/air supply pipes).

▪ Do not store or use easily inflammable and highly combustible

materials in the immediate vicinity of the A2 F (minimum distance

1m).

▪ When installing the device as described in Fig. 4-4, we recom-

mend maintaining the minimum distances from walls and ceilings

in order to perform maintenance and repair work without excessive installation effort.

▪ When installing in a niche, the A2 F can be placed on the left side,

directly against the niche wall, if the area in front of the A2 F is

freely accessible.

Minimum room height: 1.80m

Installation in garages

Provided local regulations do not generally prohibit the installation of

boilers in garages, the A2 F is completely suitable for installation and

operation within garages. Requirements:

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Installation and operating instructions

15

4 Set-up and installation

4.4.2 Installing the device

Precondition

▪ The installation site complies with applicable country-specific reg-

ulations and meets the minimum requirements described in Chap.

4.4.1.

Installation

1 Remove the packaging completely (edge protection as well) and

dispose of it in an environment-friendly manner.

2 Installing the A2 F at the installation site. Only lift or move the

device by the recessed grips provided for this purpose.

3 Position the A2 F in such a way that the connection points of the

oil hoses or mounting position of the oil filter, the ducting of the

heating pipes and the flue gas pipe can be operated without restrictions.

4 Check the horizontal position and correct installation height of

the A2 F. Slight unevennesses can be compensated by four

height-adjustable feet.

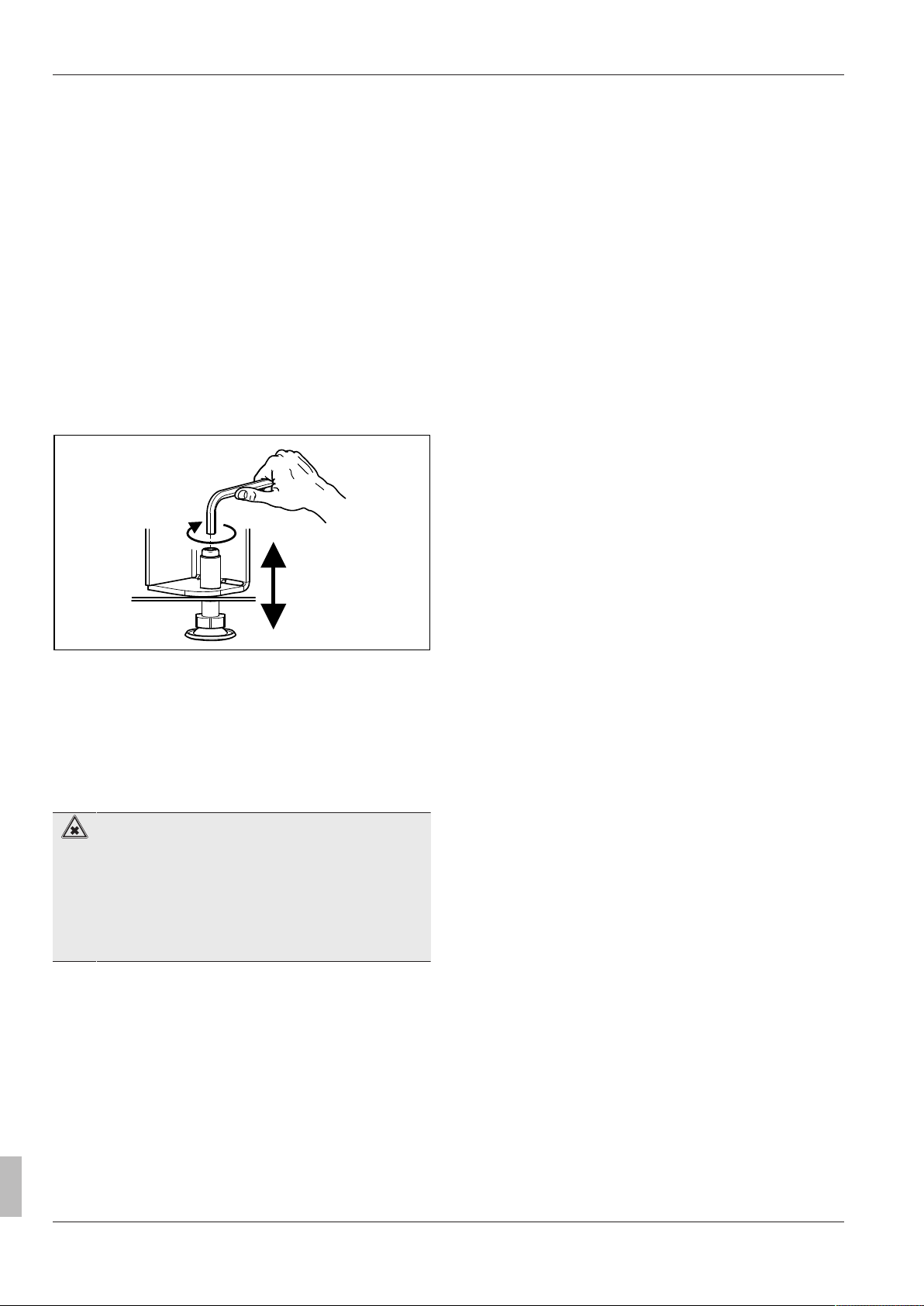

Height adjustment

Fig.4-5 Height-adjustable feet

▪ Adjust the height of the A2 F using the screw with an Allen key

SW 5mm or a 17mm open-ended spanner.

4.5 Air/flue gas system (LAS)

4.5.1 General instructions for the flue gas system

DANGER: RISK OF POISONING

There will be a risk of poisoning caused by flue gas escaping within enclosed rooms that are inadequately ventilated.

▪ Install only approved flue gas systems.

▪ Depending on the installation variant, the stipulated

ventilation and rear ventilation must be ensured (see

Chap. 4.2).

Minimum requirements

For the design and measurement of the flue gas system, the respectively valid national fire code ordinance or the country-specific

regulations and EN15287 must be observed.

Basically, for the flue gas system, you can use each flue gas pipe

according to EN14471 with EU label, which meets the following minimum requirements:

▪ Suitable for heating oil.

▪ Suitable for flue gas temperatures of at least 120°C (temperature

class T120 or higher).

▪ Suitable for at least 200Pa overpressure (pressure class P1 or

H1).

▪ Humidity-resistant (condensation resistance class W).

▪ Sufficiently corrosion-resistant (corrosion resistance class 2).

The properties of the flue gas system must be identifiable on the installed system (nameplate in the installation room).

The associated assembly instructions must be observed for installing

the flue gas and supply air holding system components or their

means of attachment.

▪ Each flue gas line must be installed with a suitable test ad-

apter for checking and setting the combustion values. The

LAS construction sets contain one test adapter each (D8PA)

▪ Depending on the local building regulations, inspection compon-

ents must be installed in the required locations.

Type of connections

▪ On the side or at the rear (SETK)

▪ Direct roof feed-through (SETL)

▪ Straight, directly at the rear (SETH), optional connection on the

back of the device

For further details and connection dimensions for the three variants

of the flue gas pipe, see Chap. 4.5.3.

Installation position and piping height

▪ The maximum permitted flue gas counter pressure is 200 Pa. The

pressure loss in the supply line must not exceed 50Pa.

▪ Angle of entry of the flue gas pipe into the chimney or installation

shaft: at least3°.

▪ Avoid horizontal sections in the connection line or keep them as

short as possible.

▪ Slope for horizontal sections of the flue gas line: at least3°.

Counter-slopes are not permissible at any point in the flue gas

line so that condensate can drain off without restriction.

▪ If the more than 3 deflections >45° are needed for the flue gas

line, the maximum height for the flue gas line reduces by at least

1m per deflection (flue gas calculations may be needed).

▪ If the horizontal connecting piece is extended to more than 2m,

the maximum permitted height of the flue gas duct is reduced by

exactly that length.

▪ Flexible flue gas lines may not be used in horizontal connection

sections.

▪ Straight pipe sections must be fastened at intervals of <2m using

suitable wall brackets. Suitable spacers must be used within vertical shafts.

Flue gas system resistance

A minimum resistance in the flue gas pipe is required for a safe

burner start and stable setting values.

1 Switch on the burner (see Chap. 14.2).

2 Measure the resistance with a differential pressure gauge on the

flue gas measurement section between the flue gas and supply

air measurement openings (differential pressure for all A2 F at

least 0.2mbar).

è

If the differential pressure is not reached at the maximum speed

of the burner blower, a silencer must be installed (E8MSD)

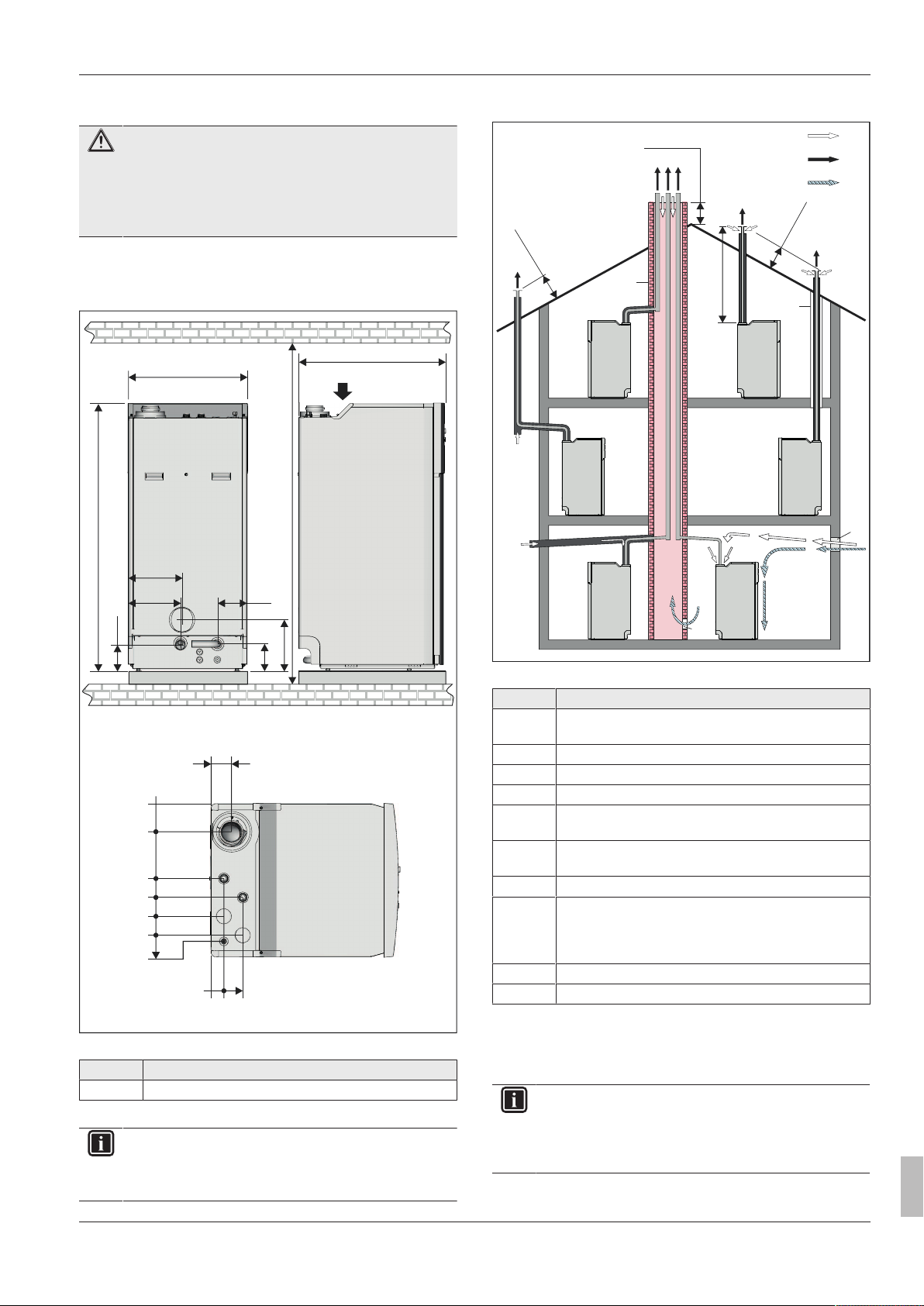

The Tab. 4-5 shows the maximum permissible height of the flue gas

line to ensure that the A2 F can be operated in the nominal output

range.

Installation and operating instructions

16

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

4 Set-up and installation

Installation ver-

sion

(according to im-

age 9)

(3) (4)

1

(5)

2

(5)

3

(5) (4)

4

(3) (4)

5

(3) (4)

6

Max. permissible height of the flue gas line

DN80

A2 F 18H A2 F 24H A2 F 32H

8 12 18

10 14 20

10 14 20

7 7 10

25 25 25

25 25 25

Tab.4-5 Maximum height for the flue gas line in m

Any restriction on the output range may require a recalculation of the

maximum permitted height for the flue gas duct. The characteristics

for the flue gas calculation can be obtained from Fig. 4-6 and the

Chap. 14.

Connection

INFORMATION

We recommend use of the associated LAS construction

sets (see Chap. 4.5.3). They satisfy all requirements and

are also fitted with special acid-proof seals.

The associated assembly instructions must be observed

for installing the flue gas and supply air holding system

components or their means of attachment.

1 Connect the A2 F to the flue gas system inside the installation

room (Fig. 4-1).

2 Place the nameplate of the flue gas duct in the installation room.

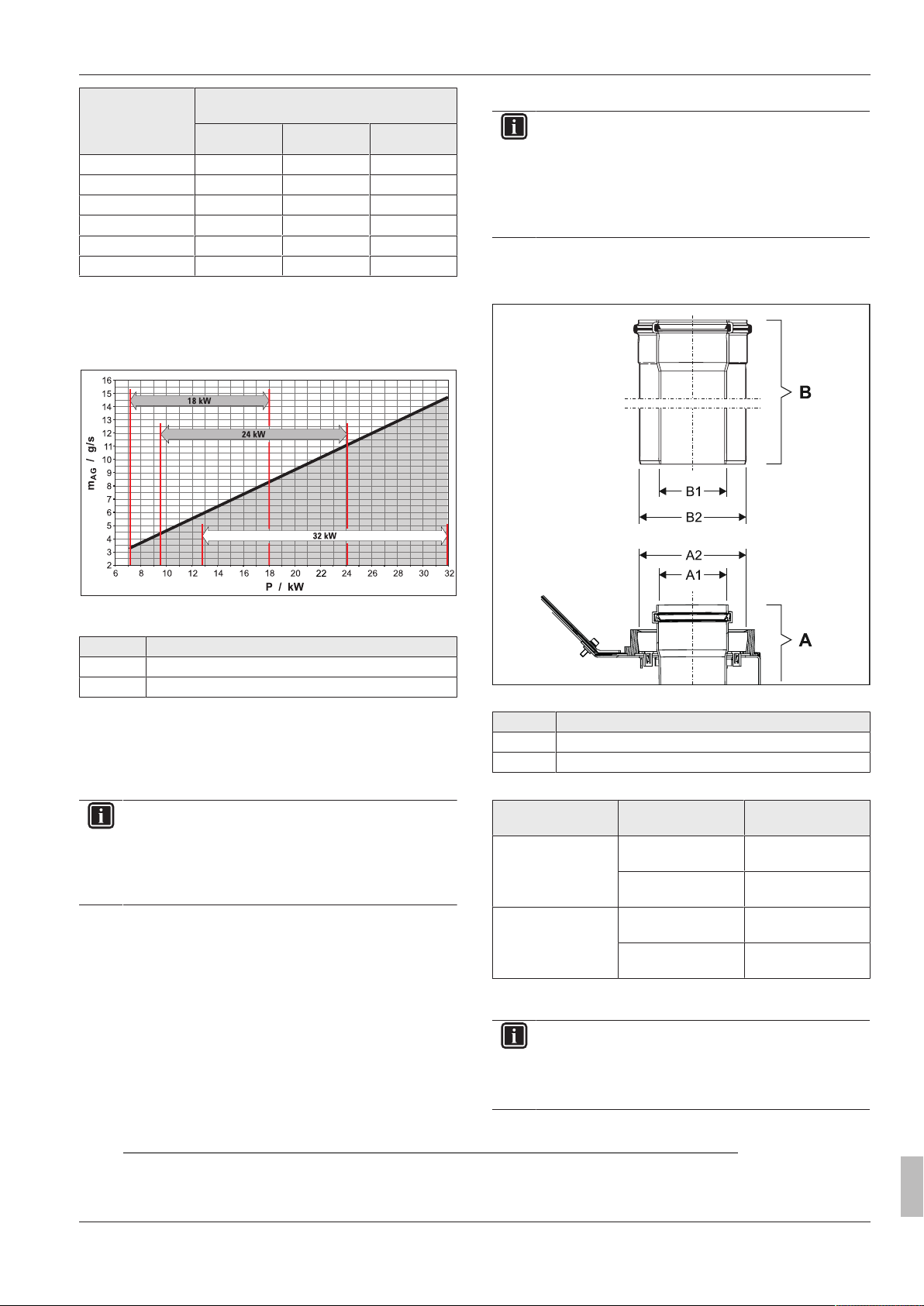

Fig.4-6 Flue gas mass flow in relation to the burner load (all

types)

Item Designation

m

AG

Flue gas mass flow

P Burner loading

Tab.4-6 Legend for Fig. 4-6

The flue gas mass flow of the system depends on the set burner output of the A2 F.

4.5.2 Connecting a flue gas line

INFORMATION

The specialised company carrying out the work must come

to an agreement with the district chimney sweep before beginning the work. Even in regions where it is not legally

specified, we recommend documenting the participation of

the district chimney sweep on a form.

Requirements

▪ The flue gas system fulfils the requirements described inChap.

4.5.1.

▪ The flue gas system fulfils any required other national or regional

safety requirements.

▪ The A2 F is installed correctly.

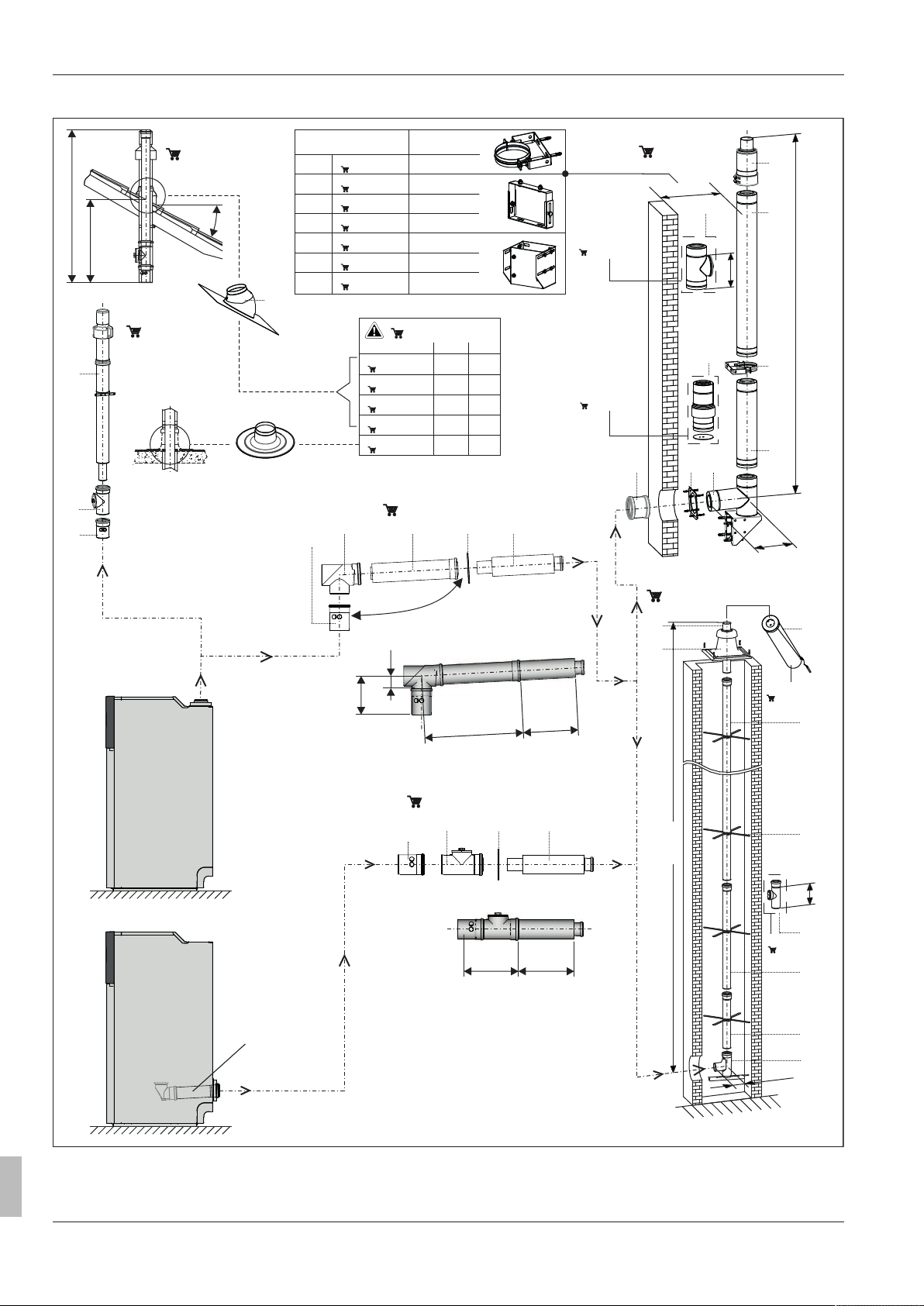

Fig.4-7 Connection dimensions - flue gas pipe

Item Designation

A Boiler connection

B Flue gas connection

Tab.4-7 Legend for Fig. 4-7

Connection side Connection Connection dimen-

sion in mm

A Boiler side A1 Flue gas DN 80

Collar

A2 Supply air DN 125

Collar

B Flue gas side B1 Flue gas DN 80 Inner diameter = 80.0

B2 Supply air DN 125 Inner diameter =

Tab.4-8

Connection dimensions for the LAS connection of the A2

Inner diameter = 80.4

+0.8

Inner diameter =

-0.5

127.0

+0.3

+0.3

126.0

F

INFORMATION

In some cases, the resonance in the flue gas system can

amplify the noise at the mouth of the flue gas duct. The

noise level can be effectively reduced by using a silencer

(E8MSD or E11MSD).

(3)

Shaft cross-section of DN80: 135mm x 135mm

(4)

A horizontal connecting cable with a length of 2m and an 87° deflection are taken into account

(5)

Concentric flue gas/supply line DN 80/125

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Installation and operating instructions

17

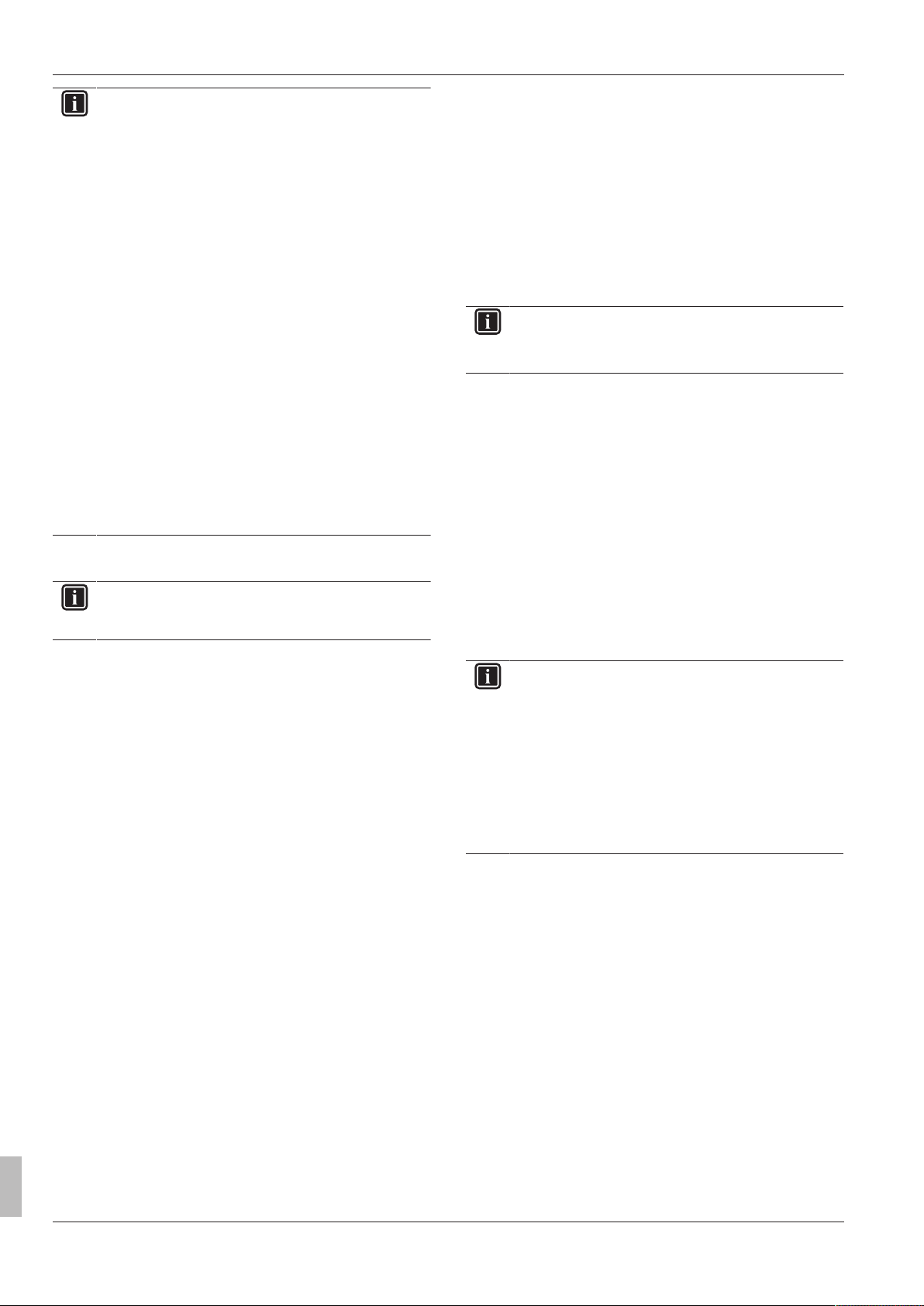

4 Set-up and installation

130

10080

215

014

009

004

013

003

002

015

016

017

040

(PA)

040

(PA)

039 052031 050

038

052050

α

1335

1835

041

040

(PA)

038

3696

082

(3x)

094

(3x)

081

090

101103

252

W

A

215

088

098

WA

094 W8 WH 40-60 mm

( 155079.0059)

095 W8 WHV14 43-137 mm

( 155079.0087)

096 W8 WHV23 137-231 mm

( 155079.0088)

097 W8 WHV32 231-325 mm

( 155079.0089)

091 W8 WKV15 55 - 147 mm

( 155079.0084)

092 W8 WKV24 147 - 239 mm

( 155079.0085)

093 W8 WKV33 239 - 331 mm

( 155079.0086)

SET-L + XXX

α XXX

D8 FD15 0-15° 049

( 155079.0082)

D8 SD25S 5-25° 045

( 155079.0014)

D8 SD45S 25-45° 046

( 155079.0037)

D8 SD55S 35-55° 047

( 155079.0012)

D8 FD 0° 048

( 155079.0040)

xxx

SET-H

( 155079.08)

DRFLUEGAKITA

SET-L

( 155079.10)

E8 RR *

( 155079.0107)

E8 MSD *

( 154578)

SET-E

( 155079.05)

SET-L

( 155079.10)

099

E8 RR *

( 155079.0107)

E8 MSD *

( 154578)

SET-E

( 155079.05)

SET-G

( 155079.07)

E8 ZR *

( 155079.0114)

W8 ZR *

( 155079.0066)

SET-K

( 155079.09)

335 350

640

350

255

85

SET-K

SET-H

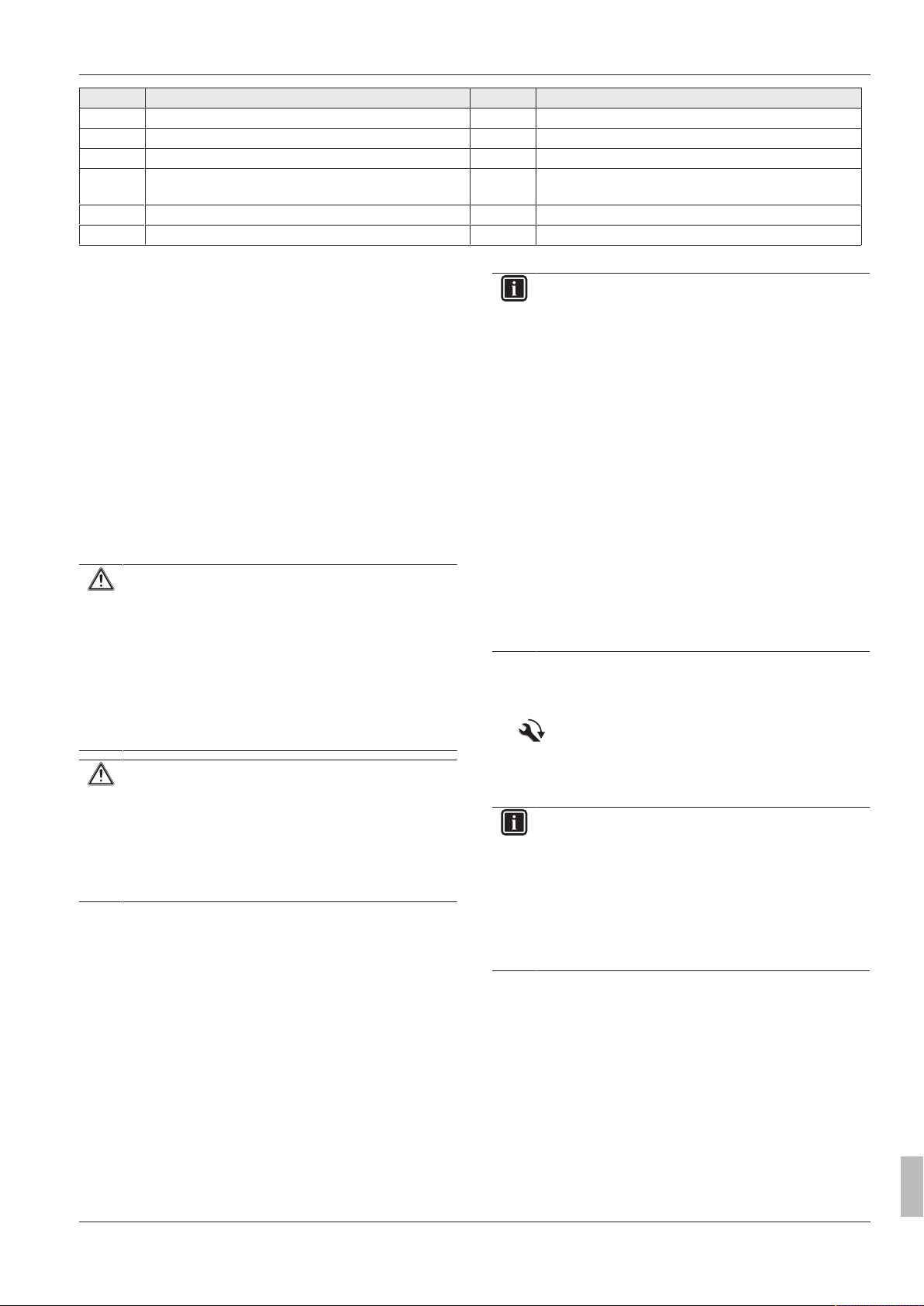

4.5.3 Flue gas system kits

Fig.4-8 Flue gas system kits

Installation and operating instructions

18

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

4 Set-up and installation

Item Designation Item Designation

* If needed WH Wall bracket

PA Test adapter WHV Extension for wall bracket

RR Inspection pipe WKV Extension for external wall bracket

SD Slanting roof cover ZR Supply air pipe (mounting height for supply air inlet ≥1m

above the ground)

FD Flat roof covering WA Wall distance

MSD Silencer

Tab.4-9 Legend for flue gas system construction sets

Additional kits

▪ Flue gas connection to a shaft system (rigid flue gas line SETE or

flexible flue gas line SET-O)

▪ Flue gas connection for external wall line (SET-G)

If necessary, additionally needed concentric LAS pipes for increased

roof or ceiling heights, single wall PP pipes for flue heights of more

than 10m or additional accessory components must be ordered.

The three-digit numbers in assist in finding individual compon-

ents in the price list.

4.6 Water connection

The connections of the A2 F are on the top of the device. Optionally,

a valve kit or a Smart Start kit can be installed in the boiler to connect a hot water tank.

Important information

CAUTION

If the A2 F is connected to a heating system with steel

pipes, radiators or non-diffusion-proof floor heating pipes,

slurry and swarf could enter the boiler body and cause

blockages, local overheating or corrosion.

▪ Rinse supply lines before filling the device.

▪ Rinse out the heat distribution network (in the existing

heating system).

▪ Install a dirt filter or sludge separator in the heating re-

turn flow (see Chap. 1.2.6).

CAUTION

Corrosion may be caused by air entering the heating water

network and by a quality of the heating water that does not

comply with the requirements in accordance with Chap.

1.2.5. Corrosion products (particles) thus created may clog

pumps and valves and cause malfunctions.

▪ Device may not be connected by permeable, flexible

lines.

INFORMATION

In accordance with EN12828 a safety valve that limits the

maximum permissible operating pressure in the heating

system must be installed on or in the immediate vicinity of

the heat generator. There may not be any hydraulic blocking elements between the heat generator and the safety

valve.

Any steam or heating water which may escape must be

drained by a suitable blow-off line with constant gradient in

a frost-protected, safe and observable manner.

A suitable safety valve is integrated in the A2 F as standard (see Fig. 3-4, item29). The blow-off line, which is led

out of the boiler as a transparent hose, must be extended

by the customer and connected to the waste water system.

A suitably-sized diaphragm expansion vessel (available as

an accessory) preset for the heating system must be connected to the A2 F. There may not be any hydraulic blocking elements between the heat generator and the diaphragm expansion vessel.

If the diaphragm expansion vessel is to be connected outside A2 F, the internal connection (Fig. 3-3 and Fig. 3-4,

item 25) must be sealed on site.

4.6.1 Connecting hydraulic lines

1 Establish hydraulic connections on the A2 F.

▪ Observe the specified tightening torque.

▪ Connect the water for filling or refilling the heating system as

specified by EN1717/EN61770 to avoid contamination of

drinking water by return flow.

INFORMATION

The A2 F is equipped with a pressure sensor. The system

pressure in monitored electronically and can be displayed

with the device switched on.

Nevertheless, we recommend installing a mechanical pressure gauge between the A2 F and the diaphragm expansion vessel, for example.

▪ Install the pressure gauge so that it is easy to see when

filling.

1 Connect the blow-off line and diaphragm expansion vessel ac-

cording to EN12828.

▪ Any steam or heating water which may escape must be drained

by a suitable blow-off line with constant gradient in a frost-protected, safe and observable manner.

▪ Connect a suitably dimensioned and preset diaphragm expan-

sion vessel for the heating system. There may not be any hydraulic blocking elements between the heat generator and the

safety valve.

▪ Position the diaphragm expansion vessel in an easily access-

ible place (maintenance, parts replacement).

▪ Lay the ducting in such a way that the housing parts of the A2 F

can be inserted easily after installation.

Daikin/ROTEX A2 F

Oil condensing boiler A2 F

008.1546499_02 – 04/2018 – EN

Installation and operating instructions

19

4 Set-up and installation

INFORMATION

There must not be any hydraulic blocking elements

between the heat generator and the diaphragm expansion

vessel that can be operated by the system operator. The

location (Fig. 3-3 and Fig. 3-4, item 25) provided for the

connection of an integrated diaphragm expansion vessel

(accessory) is not closed when delivered. If the diaphragm

expansion vessel is connected outside the heat generator,

this point must be sealed on site.

1 Carefully insulate pipework against heat loss and to avoid con-

densation (insulation thickness at least 20mm).

– Water shortage protection: The pressure and temperature

monitoring of the A2 F switches off the oil condensing boiler

safely in the event of a lack of water and locks it. No additional water shortage protection is needed in the construction.

– Avoid damage caused by deposits and corrosion: Ob-

serve the requirements on the heating water (see Chap.

1.2.5).

4.6.2 Connect the condensate drain

The condensate resulting from the cooling of the combustion gases

in the boiler and in the flue gas system has a pH-value of 1.8 – 3.7. If

necessary, it must be neutralised in accordance with the guidelines

of the German Wastewater Association (DWA A251) before being

discharged into the public sewage system.

INFORMATION

Depending on the stipulations of the community waster water regulations, the neutralisation can be dispensed with, if

the condensing boiler is operated exclusively with EL

low-sulphur heating oil.

The condensate is conducted via the condensate siphon mounted

on the flue gas elbow under the boiler body and then discharged into

the sewage system.

If the condensate has to be neutralised before discharge into the

sewage system, a condensate box (accessory) can be installed in

the boiler instead of the condensate siphon.

3 The complete outlet must not be lockable and must discharge

the condensation and any medium leaking due to damage (heating water) outwards visibly (e.g. hose to flow drain or transparent

outlet pipe).

4 In order to avoid accumulation in the flue gas connection of the

boiler, make sure that no additional siphon is formed from the

condensate drain line to the connection to the wastewater line.

5 Fill the condensate siphon or condensate box. To do so, pour in

water via the inspection opening of the flue gas pipe.

6 Check the condensate drain section for leakage.

4.7 Electrical connection

DANGER: RISK OF ELECTROCUTION

Touching live parts can result in an electric shock and

lead to potentially fatal injuries and burns.

▪ Before beginning work on live parts, disconnect all of

the systems circuits from the power supply (switch off

external main switch, disconnect fuse) and secure

against unintentional restart.

▪ Establishment of the electrical connection and work on

electrical components should only be performed by elec-

trical technicians in compliance with valid standards

and guidelines as well as the specifications of the energy supply company and the instructions in this manual.

▪ Never make constructional changes to connectors or

other electrical equipment components.

▪ Device covers and service panels must be replaced

as soon as the work is completed.

All A2 F control and safety devices are connected ready for use and

tested. Modifications on the electrical installation are dangerous and

prohibited. The operator alone shall bear responsibility for any resulting damage.

Mains connection, external temperature sensor and other optional

applications must still be connected to the boiler control panel.

4.7.1 Opening the boiler control panel and establishing electrical connections

1 Check the supply voltage (~230V, 50Hz).

2 Set the mains switch of the A2 F to "Off" (see Fig. 3-2, item 7).

3 Switch off the circuit breaker in the junction box of the domestic

power supply.

4 Remove the front panel of the boiler control panel (Fig. 4-10).

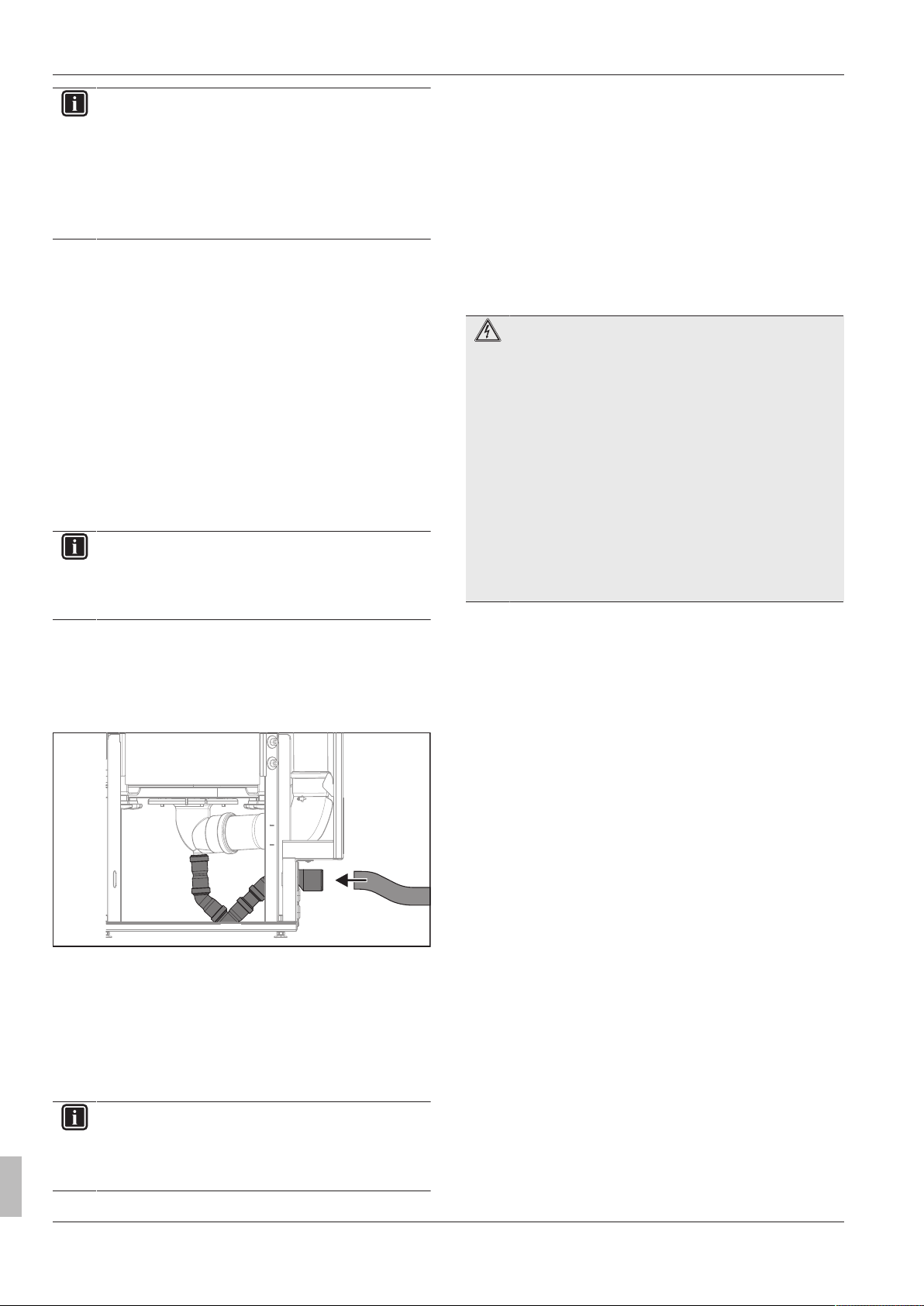

Fig.4-9 Connection of the condensate drain line

The condensate box can be mounted under the boiler frame and

connected to the flue gas connection piece of the boiler. The connection to the wastewater network is designed for HT pipe DN 50.

1 Condensation drain line (not included) with free inflow to the

drains connection.

2 Lay the condensate drain sloping down from the boiler, so that

condensation will not accumulate in the flue gas pipe.

INFORMATION

If it is not possible to connect the condensate drain to the

waste water system with a sufficient gradient in the installation room, a condensate lifting pump must be installed on

site.