Installation manual

Split system air conditioners

CVXM20A2V1B

FVXM25A2V1B

FVXM35A2V1B

FVXM50A2V1B

Installation manual

Split system air conditioners

English

Table of Contents

Table of Contents

1 About the documentation 2

1.1 About this document.................................................................. 2

2 Specific installer safety instructions 2

3 About the box 3

3.1 Indoor unit ................................................................................. 3

3.1.1 To remove the accessories from the indoor unit......... 3

4 About the unit 4

4.1 About the wireless LAN ............................................................. 4

4.1.1 Precautions when using the wireless LAN.................. 4

4.1.2 Basic parameters ........................................................ 4

4.1.3 Setting the wireless LAN............................................. 4

5 Unit installation 4

5.1 Preparing the installation site .................................................... 4

5.1.1 Installation site requirements of the indoor unit .......... 4

5.2 Opening the indoor unit ............................................................. 4

5.2.1 To remove the front panel........................................... 4

5.2.2 To remove the front grille ............................................ 5

5.2.3 To open the terminal block and remove the electrical

wiring box cover .......................................................... 5

5.3 Mounting the indoor unit............................................................ 5

5.3.1 To install the indoor unit.............................................. 5

5.3.2 To drill a wall hole ....................................................... 8

5.3.3 To remove the slit portions.......................................... 8

5.3.4 To provide drainage.................................................... 8

6 Piping installation 9

6.1 Preparing refrigerant piping....................................................... 9

6.1.1 Refrigerant piping requirements.................................. 9

6.1.2 Refrigerant piping insulation ....................................... 9

6.2 Connecting the refrigerant piping .............................................. 10

6.2.1 To connect the refrigerant piping to the indoor unit .... 10

7 Electrical installation 10

7.1 Specifications of standard wiring components .......................... 10

7.2 To connect the electrical wiring to the indoor unit ..................... 10

7.3 To connect optional accessories (wired user interface, central

user interface, wireless adapter, etc.) ....................................... 11

8 Finishing the indoor unit installation 11

8.1 To finish the indoor unit installation ........................................... 11

8.2 To close the indoor unit ............................................................. 11

8.2.1 To close the electrical wiring box and close the

terminal block.............................................................. 11

8.2.2 To re-install the front grille .......................................... 11

8.2.3 To re-install the front panel ......................................... 11

9 Commissioning 12

9.1 To perform a test run................................................................. 12

9.1.1 To perform a test run using the user interface............ 12

1 About the documentation

1.1 About this document

INFORMATION

Make sure that the user has the printed documentation and

ask him/her to keep it for future reference.

Target audience

Authorised installers

INFORMATION

This appliance is intended to be used by expert or trained

users in shops, in light industry, and on farms, or for

commercial and household use by lay persons.

WARNING

Make sure installation, servicing, maintenance, repair and

applied materials follow the instructions from Daikin and, in

addition, comply with applicable legislation and are

performed by qualified persons only. In Europe and areas

where IEC standards apply, EN/IEC 60335-2-40 is the

applicable standard.

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you MUST read before installing

▪ Format: Paper (in the box of the indoor unit)

▪ Indoor unit installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the indoor unit)

▪ Installer reference guide:

▪ Preparation of the installation, good practices, reference data,…

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

Business Portal (authentication required).

10 Disposal 12

11 Technical data 12

11.1 Wiring diagram .......................................................................... 12

11.1.1 Unified wiring diagram legend..................................... 12

Installation manual

2

2 Specific installer safety

instructions

Always observe the following safety instructions and regulations.

Unit installation (see "5Unit installation"[44])

WARNING

CVXM-A and FVXM-A Floor Standing range is allowed to

be combined only with systems with total refrigerant

amount <1.842 kg. Therefore in case of combination with

outdoor units 3MXM40N8 or 3MXM52N8, the total liquid

refrigerant piping length of the installation MUST be ≤30m.

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

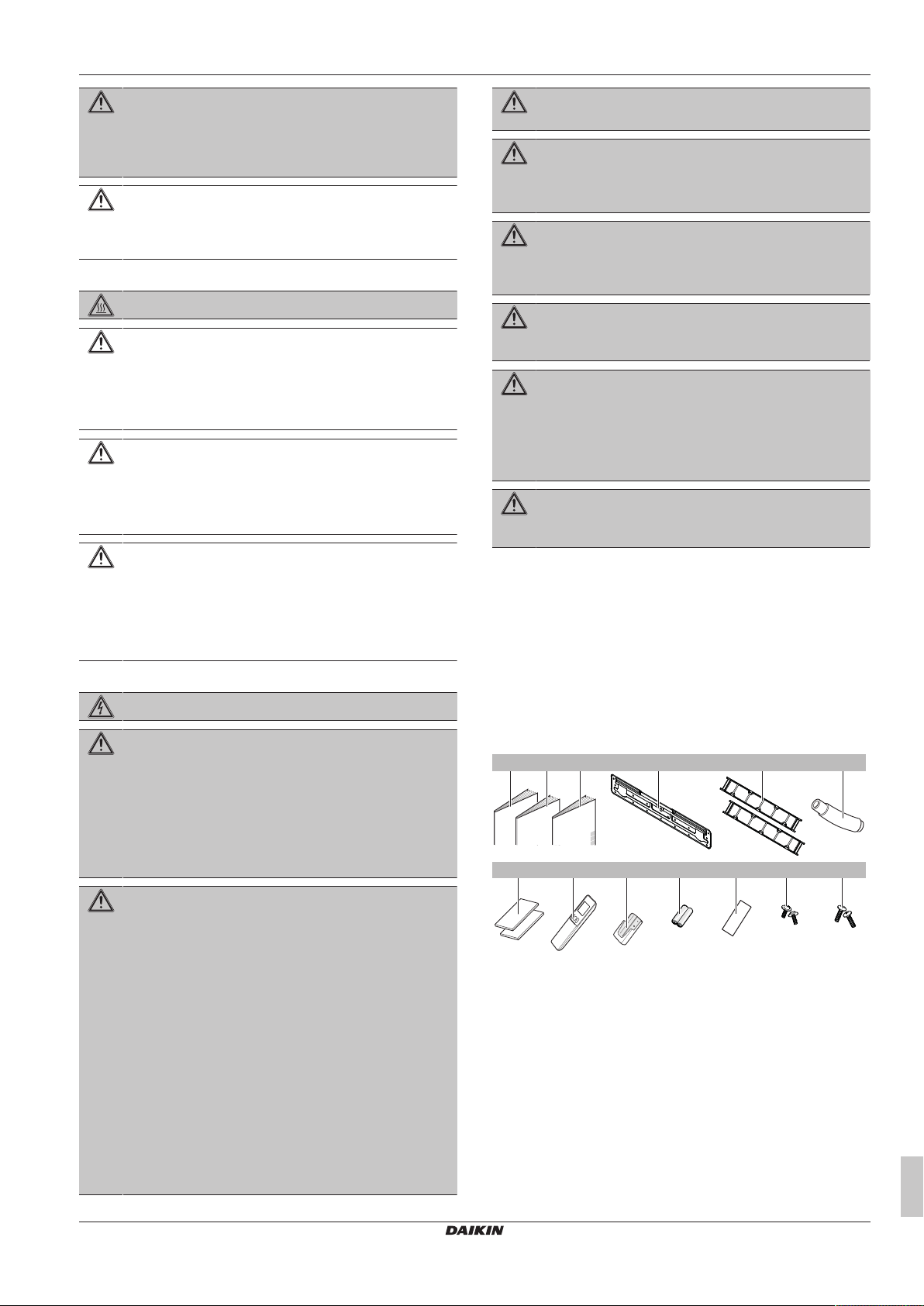

3 About the box

1× 2×1× 1× 1×1×

2× 1× 2×1×

edb ca f

1×2× 2×

j k lih

g

m

WARNING

The appliance shall be stored in a room without

continuously operating ignition sources (example: open

flames, an operating gas appliance or an operating electric

heater).

CAUTION

For walls containing a metal frame or a metal board, use a

wall embedded pipe and wall cover in the feed-through

hole to prevent possible heat, electrical shock, or fire.

Piping installation (see "6Piping installation"[49])

DANGER: RISK OF BURNING/SCALDING

CAUTION

▪ Use the flare nut fixed to the unit.

▪ To prevent gas leakage, apply refrigeration oil only to

the inside of the flare. Use refrigeration oil for R32.

▪ Do NOT reuse joints.

CAUTION

▪ Do NOT use mineral oil on flared part.

▪ NEVER install a drier to this R32 unit to guarantee its

lifetime. The drying material may dissolve and damage

the system.

CAUTION

▪ Incomplete flaring may cause refrigerant gas leakage.

▪ Do NOT re-use flares. Use new flares to prevent

refrigerant gas leakage.

▪ Use flare nuts that are included with the unit. Using

different flare nuts may cause refrigerant gas leakage.

WARNING

ALWAYS use multicore cable for power supply cables.

WARNING

Use an all-pole disconnection type breaker with at least

3 mm between the contact point gaps that provide full

disconnection under overvoltage category III.

WARNING

If the supply cord is damaged, it MUST be replaced by the

manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

WARNING

Do NOT connect the power supply to the indoor unit. This

could result in electrical shock or fire.

WARNING

▪ Do NOT use locally purchased electrical parts inside

the product.

▪ Do NOT branch the power supply for the drain pump,

etc. from the terminal block. This could result in

electrical shock or fire.

WARNING

Keep the interconnection wiring away from copper pipes

without thermal insulation as such pipes will be very hot.

3 About the box

3.1 Indoor unit

Electrical installation (see "7Electrical installation"[410])

DANGER: RISK OF ELECTROCUTION

WARNING

▪ All wiring MUST be performed by an authorised

electrician and MUST comply with the applicable

legislation.

▪ Make electrical connections to the fixed wiring.

▪ All components procured on-site and all electrical

construction MUST comply with the applicable

legislation.

WARNING

▪ If the power supply has a missing or wrong N-phase,

equipment might break down.

▪ Establish proper earthing. Do NOT earth the unit to a

utility pipe, surge absorber, or telephone earth.

Incomplete earthing may cause electrical shock.

▪ Install the required fuses or circuit breakers.

▪ Secure the electrical wiring with cable ties so that the

cables do NOT come in contact with sharp edges or

piping, particularly on the high-pressure side.

▪ Do NOT use taped wires, stranded conductor wires,

extension cords, or connections from a star system.

They can cause overheating, electrical shock or fire.

▪ Do NOT install a phase advancing capacitor, because

this unit is equipped with an inverter. A phase

advancing capacitor will reduce performance and may

cause accidents.

3.1.1 To remove the accessories from the indoor unit

1 Remove the accessories located at the bottom of the package.

Spare SSID sticker is located on the unit.

a Installation manual

b Operation manual

c General safety precautions

d Mounting plate (attached to the unit)

e Titanium apatite deodorising filter

f Drain hose

g Insulation piece

h User interface

i User interface holder

j Dry battery AAA.LR03 (alkaline) for user interface

k Spare SSID sticker (attached to the unit)

l Screws for fixing drain hose

m White head screws "To re-install the front grille"[411]

▪ Spare SSID sticker. Do NOT throw away the spare sticker. Keep

it in a safe place in case it is needed in the future (e.g. in case the

front grille is replaced, attach it to the new front grille).

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

Installation manual

3

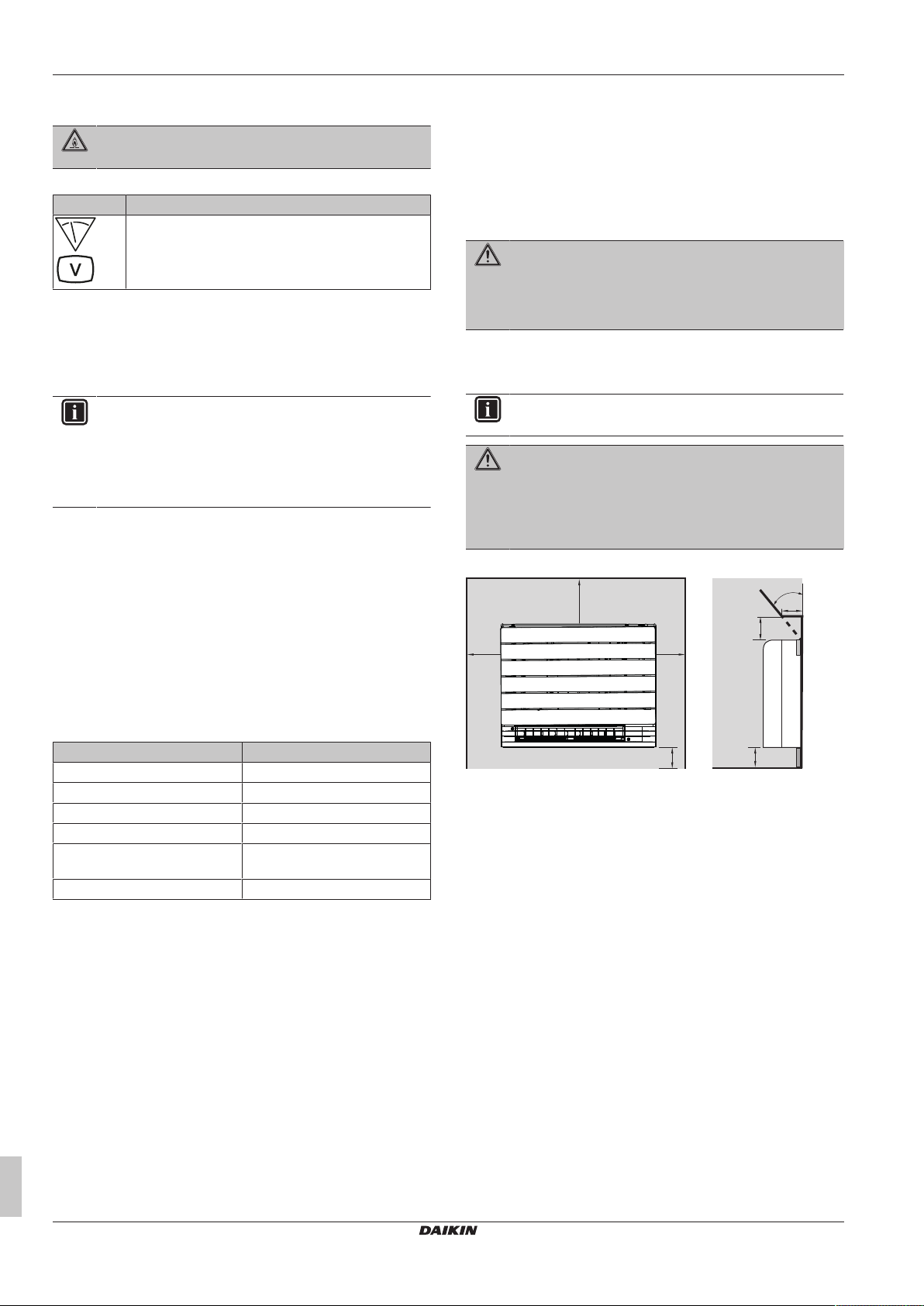

4 About the unit

≤60

(65)

≤27°

(mm)

≥467

≥50 ≥50

A B

(105)

≤60

4 About the unit

WARNING: MILDLY FLAMMABLE MATERIAL

The refrigerant inside this unit is mildly flammable.

Following symbols may occur on the indoor unit:

Symbol Explanation

Measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

4.1 About the wireless LAN

For detailed specifications, installation instructions, setting methods,

FAQ, declaration of conformity and the latest version of this manual,

visit http://www.onlinecontroller.daikineurope.com.

INFORMATION

▪ Daikin Industries Czech Republic s.r.o. declares that

the radio equipment type inside of this unit is in

compliance with Directive 2014/53/EU.

▪ This unit is considered as combined equipment

according to the definition of Directive 2014/53/EU.

4.1.1 Precautions when using the wireless LAN

Do NOT use near:

▪ Medical equipment. E.g. persons using cardiac pacemakers or

defibrillators. This product may cause electromagnetic

interference.

▪ Auto-control equipment. E.g. automatic doors or fire alarm

equipment. This product may cause faulty behaviour of the

equipment.

▪ Microwave oven. It may affect wireless LAN communications.

2 Search for Daikin Residential Controller.

3 Follow the directions on the screen to install.

5 Unit installation

5.1 Preparing the installation site

WARNING

The appliance shall be stored in a room without

continuously operating ignition sources (example: open

flames, an operating gas appliance or an operating electric

heater).

5.1.1 Installation site requirements of the indoor unit

INFORMATION

The sound pressure level is less than 70dBA.

WARNING

CVXM-A and FVXM-A Floor Standing range is allowed to

be combined only with systems with total refrigerant

amount <1.842 kg. Therefore in case of combination with

outdoor units 3MXM40N8 or 3MXM52N8, the total liquid

refrigerant piping length of the installation MUST be ≤30m.

▪ Spacing. Mind the following requirements:

4.1.2 Basic parameters

What Value

Frequency range 2400MHz~2483.5MHz

Radio protocol IEEE 802.11b/g/n

Radio frequency channel 13ch

Output power 13dBm

Effective radiated power 15dBm (11b) / 14dBm (11g) /

14dBm (11n)

Power supply DC 14 V / 100 mA

4.1.3 Setting the wireless LAN

The customer is responsible for providing:

▪ Smartphone or tablet with minimum supported version of Android

or iOS, specified on http://www.onlinecontroller.daikineurope.com

▪ Internet line and communicating device, such as modem, router,

etc.

▪ Wireless LAN access point.

▪ Installed free Daikin Residential Controller application.

To install the Daikin Residential Controller application

1 Open:

▪ Google Play for appliances using Android.

▪ App Store for appliances using iOS.

A Front view

B Side view

▪ Do not install the unit more than 60mm above the floor.

▪ Wall insulation. When conditions in the wall exceed 30°C and a

relative humidity of 80%, or when fresh air is inducted into the

wall, then additional insulation is required (minimum 10 mm

thickness, polyethylene foam).

▪ Wall or floor strength. Check whether the wall or the floor is

strong enough to support the weight of the unit. If there is a risk,

reinforce the wall or the floor before installing the unit.

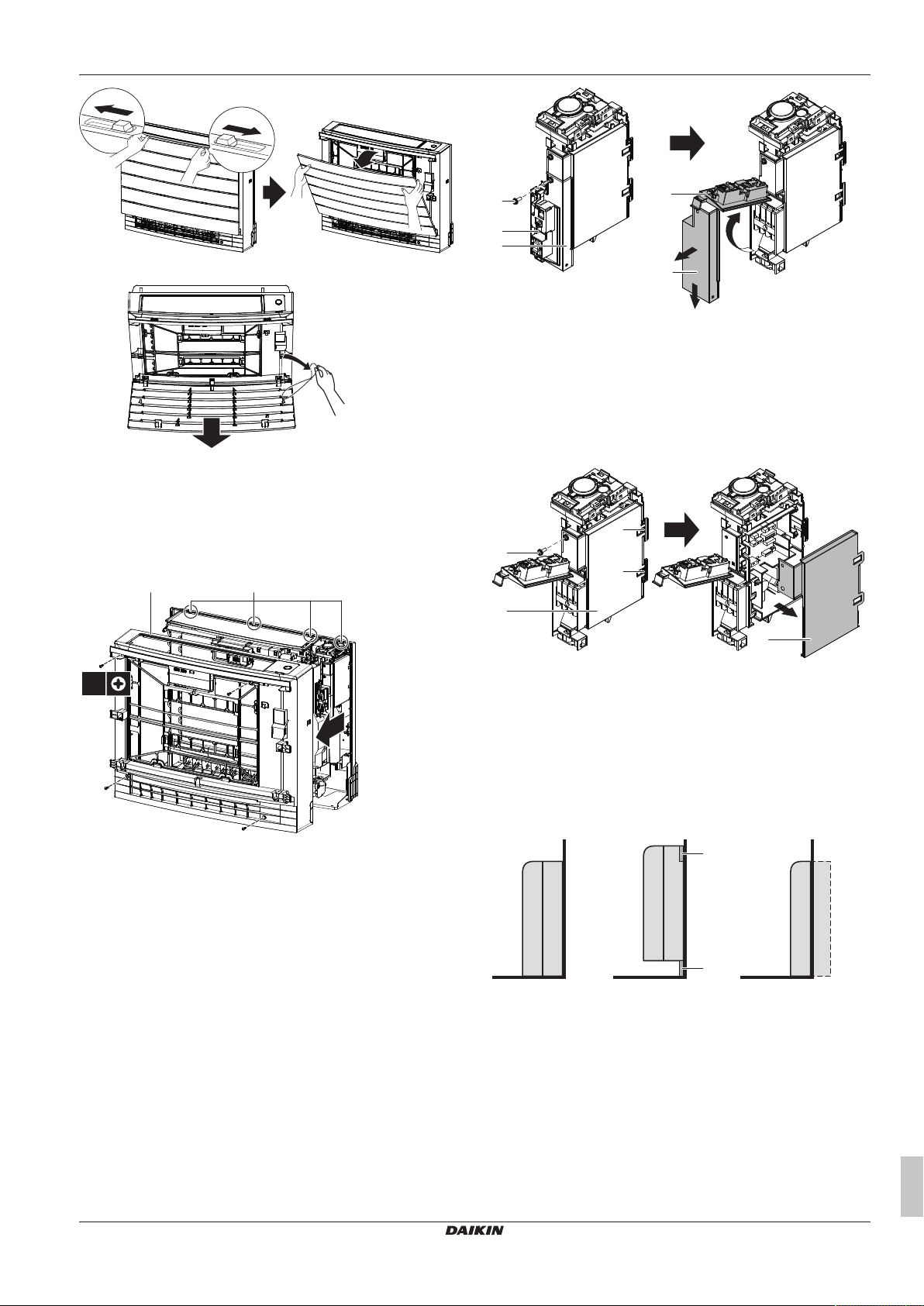

5.2 Opening the indoor unit

5.2.1 To remove the front panel

1 Slide both sliders in the direction of the arrows until they click.

Installation manual

4

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

2 Open the front panel and remove the string.

4×

b

a

c

b

c

b

a

1

2

3

b

a

c

c

b

a

b

A B C

3 Remove the front panel.

5.2.2 To remove the front grille

1 Remove the front panel. See "To remove the front panel"[44].

2 Remove the 4 screws, remove the grille from 4 tabs on the top

and remove the front grille while pulling it toward you.

5 Unit installation

a Screw

b Sensor securing plate

c Metal plate cover

To remove the electrical wiring box cover

1 Open the terminal block.

2 Remove 1 screw from the electrical wiring box.

3 Unhook the 2 tabs on the electrical wiring box cover and

remove it.

a Front grille

b Tabs

5.2.3 To open the terminal block and remove the electrical wiring box cover

To open the terminal block

1 Remove the front grille.

2 Remove 1 lower screw.

3 Lift the sensor securing plate.

4 Move the metal plate cover down and then towards you to

remove it.

a Screw

b Wiring box cover

c Tabs

5.3 Mounting the indoor unit

5.3.1 To install the indoor unit

Installation options

There are 3 possible type of installation for the indoor unit.

A Floor (exposed) installation

B Wall (exposed) installation

C Half concealed installation

a Mounting plate

b Skirting board

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

Installation manual

5

5 Unit installation

(mm)

634.5

750

006

300

200

285

115

159

238

689

a

a

a

a

159

a

a

75

06

75

45

Ø65

Ø65

45

b

c

75

75

54

f

e

A B

C

54

45

d

6×

82

166

06≤

(mm)

634.5

750

006

553

300

200

285

115

238

b

b

b

b

75

06

75

45

Ø65

Ø65

45

d

e

75

75

54

h

g

54

45

f

A B

C

c c

a

5×

Floor-standing installation

5‒1 Indoor unit installation drawing: Floor-standing installation

A Front view

B Side view

C Top view

a Screw hole 6×

b Left-back piping hole location

c Right-back piping hole location

d Left/right piping hole location

e Left-bottom piping hole location

f Right-bottom piping hole location

1 Drill a wall hole, depending on which side piping is taken out.

See "To drill a wall hole"[48].

2 Open the front panel and remove the front grille (see

"5.2Opening the indoor unit"[44]).

3 Remove the slit portions using nippers. See "To remove the slit

portions"[48].

4 Secure the unit to the wall and floor using 6 screws M4×25L

(field supply).

Wall-mounted installation

5‒2 Indoor unit installation drawing: Wall-mounted installation

A Front view

B Side view

C Top view

a Mounting plate

b Screw hole 4×

c Floor

d Left-back piping hole location

e Right-back piping hole location

f Left/right piping hole location

g Left-bottom piping hole location

h Right-bottom piping hole location

6 Temporarily secure the mounting plate on the wall.

7 Make sure the mounting plate is level.

8 Mark the centres of the drilling points on the wall.

9 Secure the mounting plate on the wall using 5 screws M4×25L

(field supply).

5 When the complete installation is finished, attach the front panel

and the front grille in their original position.

Installation manual

6

10 Drill a wall hole, depending on which side piping is taken out.

See "To drill a wall hole"[48].

11 Open the front panel and remove the front grille (see

"5.2Opening the indoor unit"[44]).

12 Remove the slit portions using nippers. See "To remove the slit

portions"[48].

13 If necessary for the skirting board, remove the slit portion on the

bottom frame.

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

a

b

a Bottom frame

≤60

4×

a

5

4

30

f

734~740

170

350

70

200

593~595

170 350

d e

c

c

a

A B

(mm)

a

a

75

54

Ø60

Ø60

54

75

C

159

238

689

159

b b

06

75

75

54

h

g

634.5

115

285

b

b

b

b

300

6×

b Slit portion

14 Align the unit using the alignment symbol on the

mounting plate: 375mm from the alignment symbol to the each

side (unit width 750mm), 487mm from the alignment symbol to

the bottom of the unit.

15 Hook the unit on the mounting plate and secure the unit to the

wall using 4 screws M4×25L (field supply).

a Alignment symbol

16 When the complete installation is finished, attach the front panel

and the front grille in their original position.

5 Unit installation

Half-concealed installation

5‒3 Indoor unit installation drawing: Half-concealed installation

A Front view

B Side view

C Top view

a Extra filler board

b Screw hole 6×

c Hole

d Left-back piping hole location

e Right-back piping hole location

f Right/left piping hole location

g Left-bottom piping hole location

h Right-bottom piping hole location

17 Make a hole in the wall as illustrated above.

18 Install the extra filler board (field supply) in accordance with the

space between the unit and the wall. Make sure there is no gap

between the unit and the wall.

19 Drill a wall hole, depending on which side piping is taken out.

See "To drill a wall hole"[48].

20 Remove the slit portions using nippers. See "To remove the slit

portions"[48].

21 Open the front panel, remove the front grille, remove the top

and side casings (see "5.2Opening the indoor unit"[44]).

22 Secure the unit to the extra filler board and to the floor using 6

screws M4×25L (field supply).

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

23 When the complete installation is finished, attach the front panel

and the front grille in their original position.

Installation manual

7

5 Unit installation

Ø65

a

b

c

a

c

d

d

b

5.3.2 To drill a wall hole

CAUTION

For walls containing a metal frame or a metal board, use a

wall embedded pipe and wall cover in the feed-through

hole to prevent possible heat, electrical shock, or fire.

NOTICE

Be sure to seal the gaps around the pipes with sealing

material (field supply), in order to prevent water leakage.

1 Bore a 65 mm large feed-through hole in the wall with a

downward slope towards the outside.

2 Insert a wall embedded pipe into the hole.

3 Insert a wall cover into the wall pipe.

a Wall embedded pipe

b Putty

c Wall hole cover

4 After completing wiring, refrigerant piping and drain piping, do

NOT forget to seal the gap with putty.

5.3.3 To remove the slit portions

For side piping (left/right) and bottom piping (left/right) slit portions

must be removed. Remove slit portions according to where the

piping is taken out.

2 Remove an burrs along the cut section using a half round

needle file.

5.3.4 To provide drainage

Make sure condensation water can be evacuated properly. This

involves:

▪ General guidelines

▪ Connecting the drain piping to the indoor unit

▪ Checking for water leaks

General guidelines

▪ Pipe length. Keep drain piping as short as possible.

▪ Pipe size. Use rigid polyvinyl chloride pipe with 20 mm nominal

diameter and 26mm outer diameter.

NOTICE

▪ Install the drain hose with a downward slope.

▪ Traps are NOT permitted.

▪ Do NOT put the end of the hose in water.

▪ Drain hose. Drain hose (accessory) is 220 mm long and with

18mm outer diameter on the connecting side.

▪ Extension hose. Use rigid polyvinyl chloride pipe (field supply)

with 20 mm nominal diameter as extension hose. When

connecting an extension hose, use a polyvinyl adhesive agent for

a Bottom frame

b Slit portion for side piping on the front grille (same on the

other side)

c Slit portion for side piping on the bottom frame (same of

the other side)

d Slit portion for the bottom piping

1 Cut off the slit portion using nippers.

Installation manual

8

glueing.

▪ Condensation. Take measures against condensation. Insulate

the complete drain piping in the building.

To connect the drain piping to the indoor unit

NOTICE

Incorrect connection of the drain hose might cause leaks,

and damage the installation space and surroundings.

1 Push the drain hose (accessory) as far as possible over the

drain socket and fix it with 1 screw (accessory).

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

d

1×

c

a

b

a Drain pan

100

a

≥50

220

150

100

(mm)

c

d

b

a

t

Ø

ØiØ

i

t

ØpØ

p

b Drain socket

c Drain hose (accessory)

d Screw (accessory)

2 Check for water leaks (see "To check for water leaks"[49]).

3 Insulate the indoor drain socket and drain hose with ≥10mm

insulation material to prevent condensation.

4 Connect the drain piping to the drain hose. Insert the drain hose

≥50mm, so it will not be pulled out of the drain pipe.

6 Piping installation

6 Piping installation

6.1 Preparing refrigerant piping

6.1.1 Refrigerant piping requirements

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

INFORMATION

Additional refrigerant charge is NOT allowed in case of

combination of the outdoor unit 3MXM40N8 or 3MXM52N8

with the indoor units CVXM-A and/or FVXM-A. The total

piping length MUST be ≤30m.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30mg/10m.

Refrigerant piping diameter

Use the same diameters as the connections on the outdoor units:

Class Pipe outer diameter (mm)

Liquid piping Gas piping

20~35 Ø6.4 Ø9.5

50 Ø6.4 Ø12.7

a Drain hose (accessory)

b Vinyl chloride drain pipe (VP-30) (field supply)

c Reducer (field supply)

d Vinyl chloride drain pipe (VP-20) (field supply)

To check for water leaks

1 Remove the air filters.

2 Gradually pour approximately 1l of water in the drain pan, and

check for water leaks.

Refrigerant piping material

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Piping temper grade and thickness:

Outer diameter

Temper grade Thickness (t)

(a)

(Ø)

6.4mm (1/4") Annealed (O) ≥0.8mm

9.5mm (3/8")

12.7mm (1/2")

(a)

Depending on the applicable legislation and the maximum

working pressure of the unit (see "PS High" on the unit name

plate), larger piping thickness might be required.

6.1.2 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052W/mK (0.035

and 0.045kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness

Pipe outer diameter

(Øp)

6.4mm (1/4") 8~10mm ≥10mm

9.5mm (3/8") 12~15mm ≥13mm

12.7mm (1/2") 14~16mm ≥13mm

Insulation inner

diameter (Øi)

Insulation thickness

(t)

If the temperature is higher than 30°C and the humidity is higher

than RH 80%, the thickness of the insulation materials should be at

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

least 20 mm to prevent condensation on the surface of the

insulation.

Installation manual

9

7 Electrical installation

a

b

c

d

a

b

a

a

e

b

e

c

b

a

d

c

d

b

a

b

c

6.2 Connecting the refrigerant piping

DANGER: RISK OF BURNING/SCALDING

6.2.1 To connect the refrigerant piping to the indoor unit

WARNING: MILDLY FLAMMABLE MATERIAL

The refrigerant inside this unit is mildly flammable.

▪ Pipe length. Keep refrigerant piping as short as possible.

1 Connect refrigerant piping to the unit using flare connections.

2 Insulate the refrigerant piping on the indoor unit as follows:

a Gas pipe

b Gas pipe insulation

c Liquid pipe

d Liquid pipe insulation

NOTICE

Make sure to insulate all refrigerant piping. Any exposed

piping might cause condensation.

3 Close the slit on the refrigerant pipe connection and secure it

with a tape (field supply). Make sure there are no gaps.

4 Wrap the slit and the end of the insulation of the connected

refrigerant piping with insulation piece (accessory). Make sure

there are no gaps.

WARNING

Do NOT connect the power supply to the indoor unit. This

could result in electrical shock or fire.

WARNING

▪ Do NOT use locally purchased electrical parts inside

the product.

▪ Do NOT branch the power supply for the drain pump,

etc. from the terminal block. This could result in

electrical shock or fire.

WARNING

Keep the interconnection wiring away from copper pipes

without thermal insulation as such pipes will be very hot.

7.1 Specifications of standard wiring components

Component

Interconnection cable

(indoor↔outdoor)

4-core cable

1.5mm²~2.5mm²

andapplicable for

220~240V

H05RN-F (60245 IEC 57)

7.2 To connect the electrical wiring to the indoor unit

1 Open the terminal block. See "5.2Opening the indoor unit"[44].

2 Strip the wire ends approximately 15mm.

3 Match wire colours with terminal numbers on indoor and

outdoor unit’s terminal blocks and firmly screw wires to the

corresponding terminals.

4 Connect the earth wires to the corresponding terminals.

a Refrigerant pipe connection

b Refrigerant piping (field supply)

c Slit

d Tape

e Insulation piece (accessory)

a Terminal block

7 Electrical installation

DANGER: RISK OF ELECTROCUTION

WARNING

ALWAYS use multicore cable for power supply cables.

WARNING

Use an all-pole disconnection type breaker with at least

3 mm between the contact point gaps that provide full

disconnection under overvoltage category III.

WARNING

If the supply cord is damaged, it MUST be replaced by the

manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Installation manual

10

5 Pull the wires to make sure that they are securely attached,

then retain the wires with the cable clamp.

6 Make sure that the wires do not come in contact with the metal

parts of the heat exchanger.

7 In case of connecting to an optional adapter, see "7.3 To

connect optional accessories (wired user interface, central user

interface, wireless adapter, etc.)"[411].

b Electrical component block

c Cable clamp

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

8 Finishing the indoor unit installation

a

b

a

b

c

e

f

2×

2×

b

a

c c

7.3 To connect optional accessories (wired user interface, central user interface, wireless adapter, etc.)

1 Remove the electrical wiring box cover. See "5.2 Opening the

indoor unit"[44].

2 Connect the optional adapter wire to the S21 connector. To

connect the optional adapter wire to the option, refer to the

installation manual of the optional adapter.

3 Lead the wire as shown in the figure below.

a S21connector

B Optional adapter wire

4 Close the electrical wiring box cover. See "8.2 To close the

indoor unit"[411].

2 Attach the front metal cover and fix it with the screw.

3 Close the sensor securing plate.

8.2.2 To re-install the front grille

1 Attach the front grille to the original position.

2 Secure the front grille in 4 tabs.

3 Secure with the 2 original screws on the top part and with the 2

white head screws (accessory) on the bottom part.

a Front grille

b 4 tabs

c White head screws (accessory)

8.2.3 To re-install the front panel

1 Insert the front panel into the grooves of the unit (3 places) and

attach the string.

8 Finishing the indoor unit

8.1 To finish the indoor unit

1 After the drain piping, refrigerant piping and the electrical wiring

are finished. Wrap the refrigerant pipes and the interconnection

cable with insulation tape. Overlap at least half the width of the

tape with each turn.

2 Pass the pipes through the wall hole and seal the gaps with

putty.

8.2 To close the indoor unit

8.2.1 To close the electrical wiring box and

1 Hook the electrical wiring box onto the 2 tabs, close it, and fix it

with 1 screw.

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

installation

installation

a Interconnection cable

b Gas pipe

c Gas pipe insulation

d Insulation tape

e Liquid pipe

f Liquid pipe insulation

close the terminal block

2 Close the front panel and slide both sliders until they click.

3 Push on the sides of the front panel to make sure the front

panel is securely fixed.

Installation manual

11

9 Commissioning

,

A

INDOOR

OUTDOOR

9 Commissioning

NOTICE

ALWAYS operate the unit with thermistors and/or pressure

sensors/switches. If NOT, burning of the compressor might

be the result.

9.1 To perform a test run

Prerequisite: Power supply MUST be in the specified range.

Prerequisite: Test run may be performed in cooling or heating

mode.

Prerequisite: Test run should be performed in accordance with the

operation manual of the indoor unit to make sure that all functions

and parts are working properly.

1 In cooling mode, select the lowest programmable temperature.

In heating mode, select the highest programmable temperature.

Test run can be disabled if necessary.

2 When the test run is finished, set the temperature to a normal

level. In cooling mode: 26~28°C, in heating mode: 20~24°C.

3 The system stops operating 3 minutes after the unit is turned

OFF.

9.1.1 To perform a test run using the user interface

1 Press to switch the system on.

Symbol Meaning Symbol Meaning

Circuit breaker Protective earth

Connection Protective earth (screw)

Connector

Earth Relay connector

Field wiring Short-circuit connector

Fuse Terminal

Indoor unit Terminal strip

Outdoor unit Wire clamp

Residual current

device

Symbol Colour Symbol Colour

BLK Black ORG Orange

BLU Blue PNK Pink

BRN Brown PRP, PPL Purple

GRN Green RED Red

GRY Grey WHT White

YLW Yellow

Rectifier

2 Press the middle of and simultaneously.

3 Press twice to choose and confirm selection by pressing

.

Result: on the display indicates that the test run is selected. Test

run operation will stop automatically after about 30 minutes.

4 To stop operation sooner, press the ON/OFF button.

10 Disposal

NOTICE

Do NOT try to dismantle the system yourself: dismantling

of the system, treatment of the refrigerant, oil and other

parts MUST comply with applicable legislation. Units

MUST be treated at a specialised treatment facility for

reuse, recycling and recovery.

11 Technical data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

Business Portal (authentication required).

11.1 Wiring diagram

11.1.1 Unified wiring diagram legend

For applied parts and numbering, refer to the wiring diagram on the

unit. Part numbering is by Arabic numbers in ascending order for

each part and is represented in the overview below by "*" in the part

code.

Symbol Meaning

A*P Printed circuit board

BS* Pushbutton ON/OFF, operation

switch

BZ, H*O Buzzer

C* Capacitor

AC*, CN*, E*, HA*, HE*, HL*,

HN*, HR*, MR*_A, MR*_B, S*, U,

V, W, X*A, K*R_*, NE

D*, V*D Diode

DB* Diode bridge

DS* DIP switch

E*H Heater

FU*, F*U, (for characteristics,

refer to PCB inside your unit)

FG* Connector (frame ground)

H* Harness

H*P, LED*, V*L Pilot lamp, light emitting diode

HAP Light emitting diode (service

HIGH VOLTAGE High voltage

IES Intelligent eye sensor

IPM* Intelligent power module

K*R, KCR, KFR, KHuR, K*M Magnetic relay

L Live

L* Coil

L*R Reactor

M* Stepper motor

M*C Compressor motor

M*F Fan motor

M*P Drain pump motor

M*S Swing motor

Connection, connector

Fuse

monitor green)

Installation manual

12

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

Symbol Meaning

MR*, MRCW*, MRM*, MRN* Magnetic relay

N Neutral

n=*, N=* Number of passes through ferrite

core

PAM Pulse-amplitude modulation

PCB* Printed circuit board

PM* Power module

PS Switching power supply

PTC* PTC thermistor

Q* Insulated gate bipolar transistor

(IGBT)

Q*C Circuit breaker

Q*DI, KLM Earth leak circuit breaker

Q*L Overload protector

Q*M Thermo switch

Q*R Residual current device

R* Resistor

R*T Thermistor

RC Receiver

S*C Limit switch

S*L Float switch

S*NG Refrigerant leak detector

S*NPH Pressure sensor (high)

S*NPL Pressure sensor (low)

S*PH, HPS* Pressure switch (high)

S*PL Pressure switch (low)

S*T Thermostat

S*RH Humidity sensor

S*W, SW* Operation switch

SA*, F1S Surge arrester

SR*, WLU Signal receiver

SS* Selector switch

SHEET METAL Terminal strip fixed plate

T*R Transformer

TC, TRC Transmitter

V*, R*V Varistor

V*R Diode bridge, Insulated-gate

bipolar transistor (IGBT) power

module

WRC Wireless remote controller

X* Terminal

X*M Terminal strip (block)

Y*E Electronic expansion valve coil

Y*R, Y*S Reversing solenoid valve coil

Z*C Ferrite core

ZF, Z*F Noise filter

11 Technical data

CVXM20+FVXM25~50A2V1B

Split system air conditioners

3P477070-2L – 2020.10

Installation manual

13

Verantwortung für Energie und Umwelt

Copyright 2020 Daikin

3P477070-2L 2020.10

Loading...

Loading...