Page 1

DAVIE XD diagnostics manual

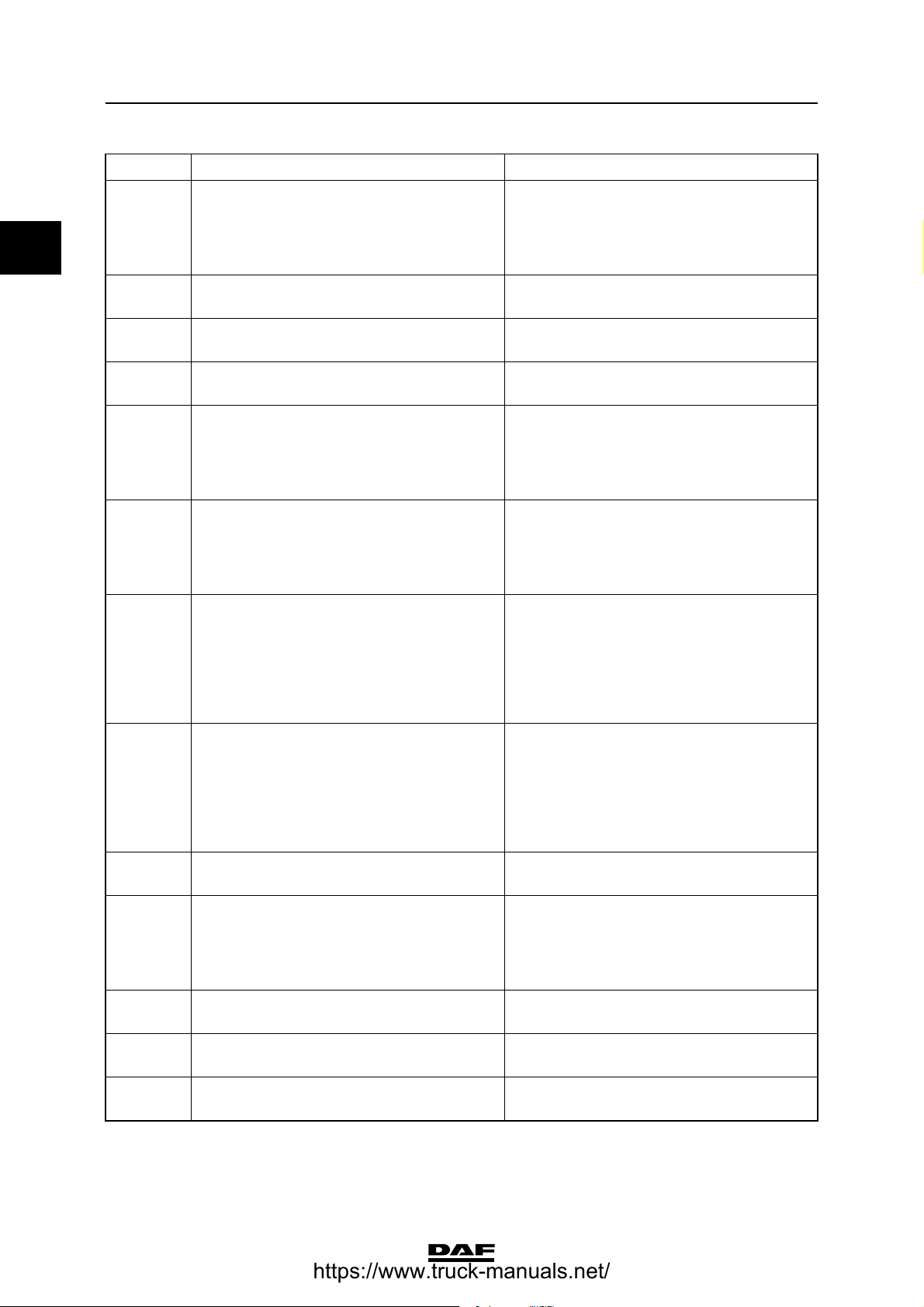

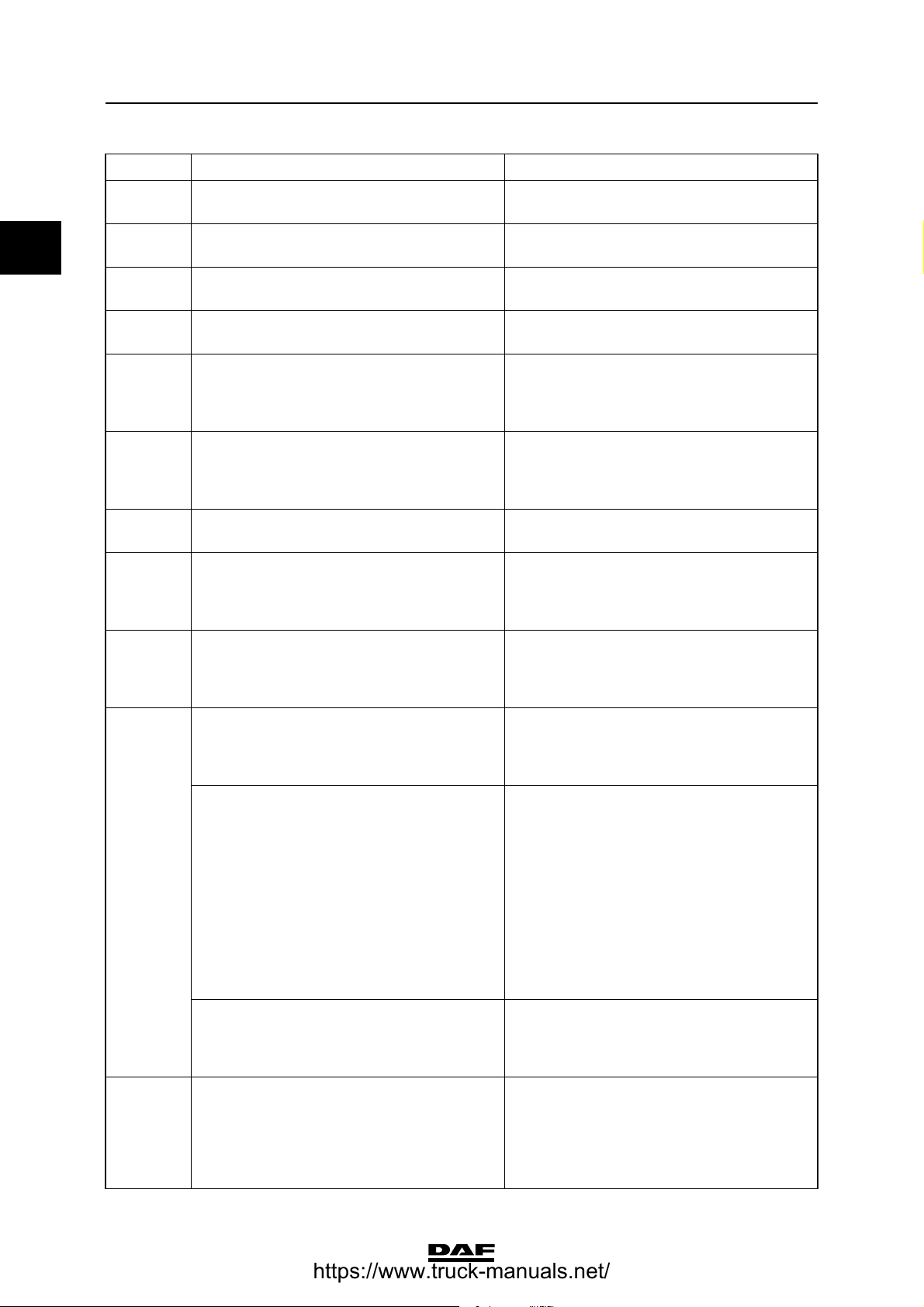

Structure

STRUCTURE

0

EBS

1

UPEC

2

AS TRONIC

3

VIC

4

EMAS

5

HYDRONIC 10 (ACH-EW)

CDS-3

ECAS-2

AIRTRONIC (ACH-EA)

ABS-D AND ABS/ASR-E

D3LC (ACH-EA)

EBS-2

6

7

8

9

10

11

12

©

200438

ECAS-3

13

AGS

14

ZF INTARDER EST42

15

Page 2

Page 3

DAVIE XD diagnostics manual

STRUCTURE

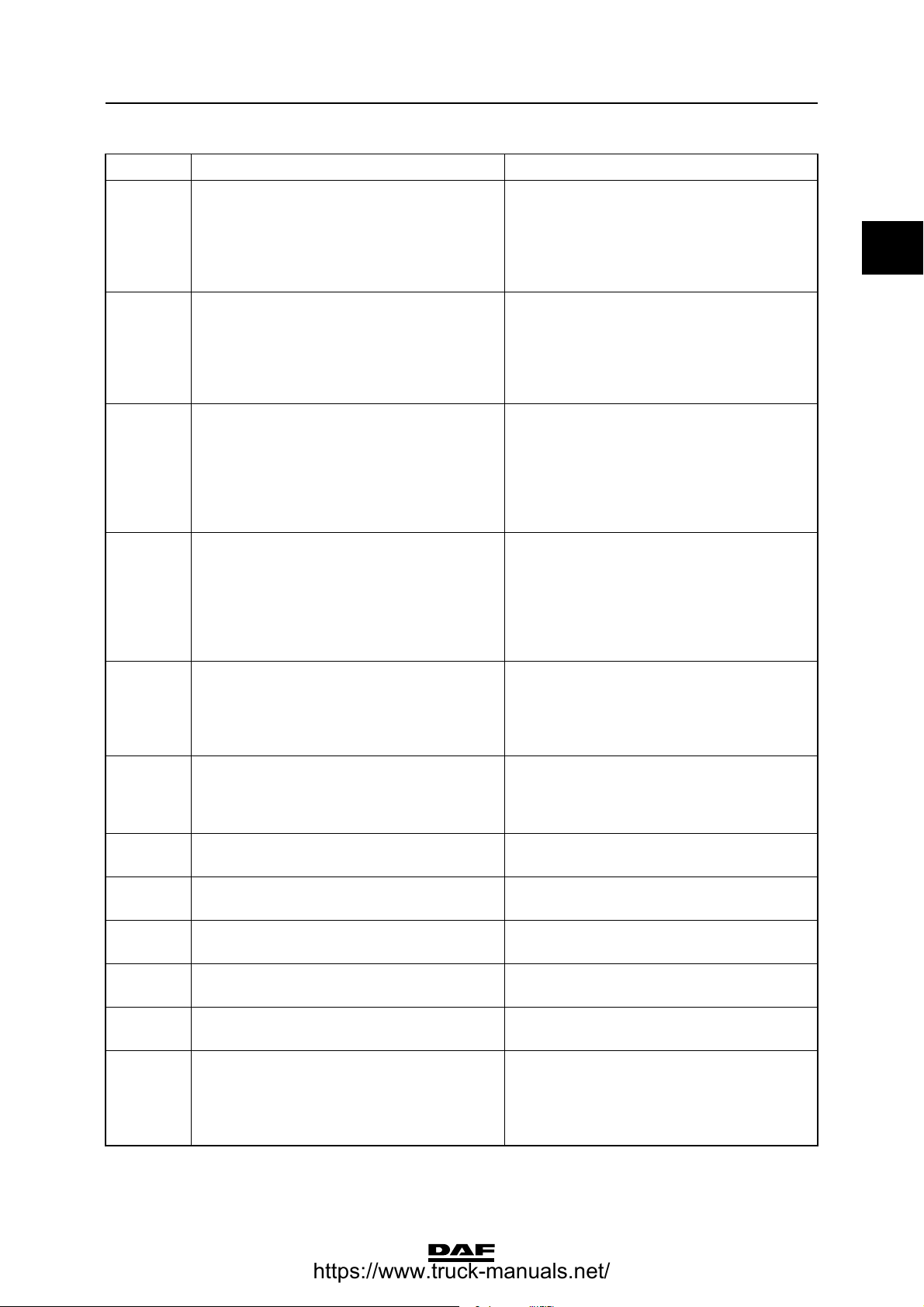

ALS-S

16

ECS-DC3

17

IMMOBILISER

18

CDM

19

©

200438

Page 4

Page 5

EBS

DAVIE XD diagnostics manual

1 EBS

CONTENTS

Page Date

1. EBS FAULT CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200438

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200438

1.2 Explanatory notes to EBS fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200438

2. EBS CUSTOMER PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200438

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200438

2.2 Explanatory notes to EBS customer parameters. . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200438

3. SYSTEM INSPECTION WITH DAVIE XD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200438

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200438

Contents

1

©

200438 1

Page 6

EBS

1

Contents

DAVIE XD diagnostics manual

2

©

200438

Page 7

EBS

DAVIE XD diagnostics manual

1. EBS FAULT CODES

1.1 INTRODUCTION

If the electronic unit detects a system fault, this

fault is usually stored in the memory of the

electronic unit as a fault code.

Most system faults will also generate a warning.

EBS fault codes

1

©

200438 1-1

Page 8

EBS

1

EBS fault codes

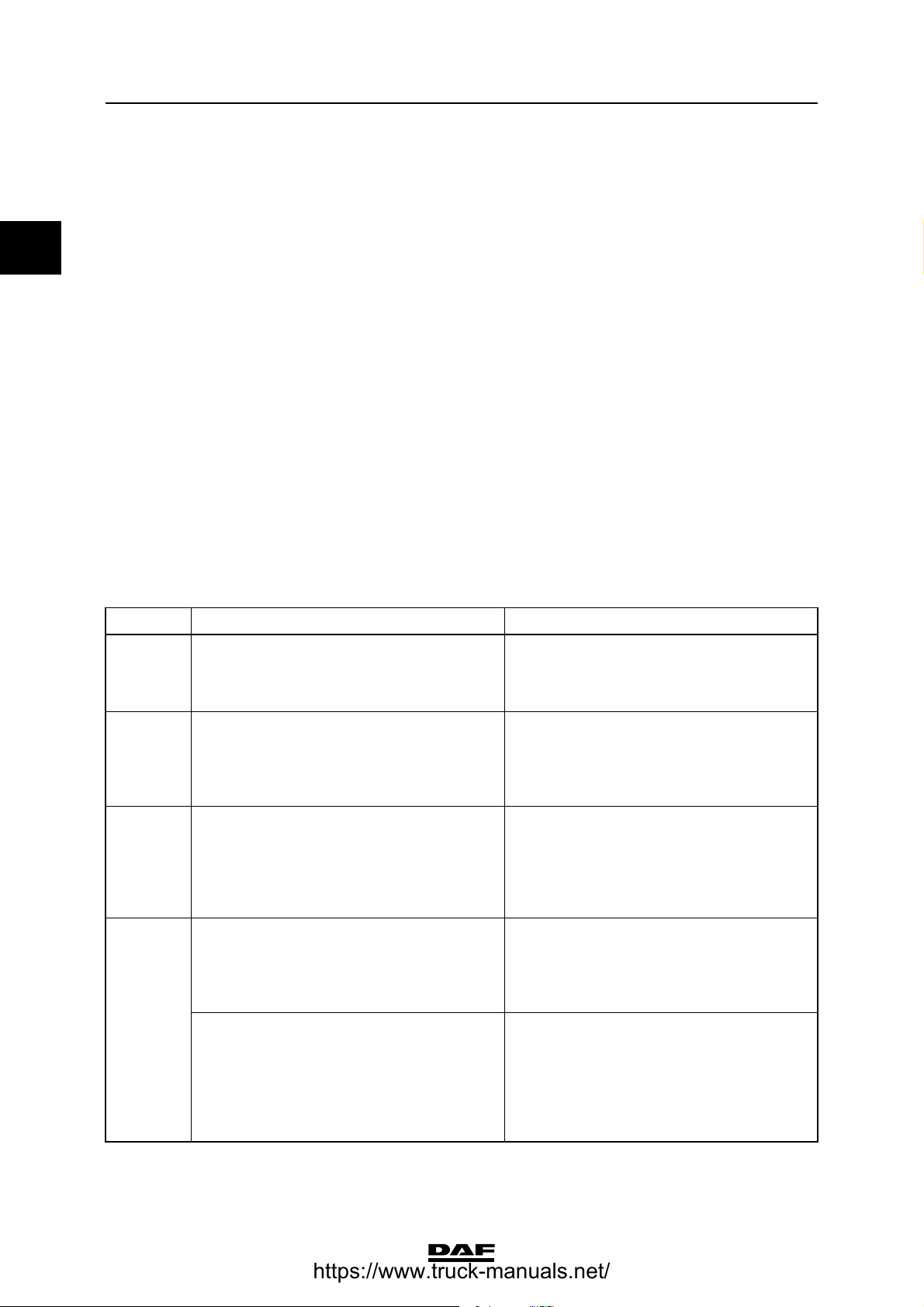

1.2 EXPLANATORY NOTES TO EBS FAULT CODES

If there is an electrical fault in the EBS system,

the symptom "open circuit in EBS pressure

control" or "deactivation of EBS pressure control"

may occur as a system reaction.

Open circuit in EBS pressure control

On application of the foot brake valve, the

electronic unit will receive information on the

desired vehicle deceleration from the brake pedal

position sensor in the foot brake valve.

In the electronic unit, this vehicle deceleration

command is converted into brake pressure to the

brake cylinders.

If there is no feedback from the output pressure

or wheel speed, there will be less accurate

electronically controlled deceleration and brake

force distribution.

Deactivation of EBS pressure control

The output pressure control in the brake cylinders

is entirely pneumatic; i.e. there is no more

electronically controlled deceleration and brake

force distribution.

DAVIE XD diagnostics manual

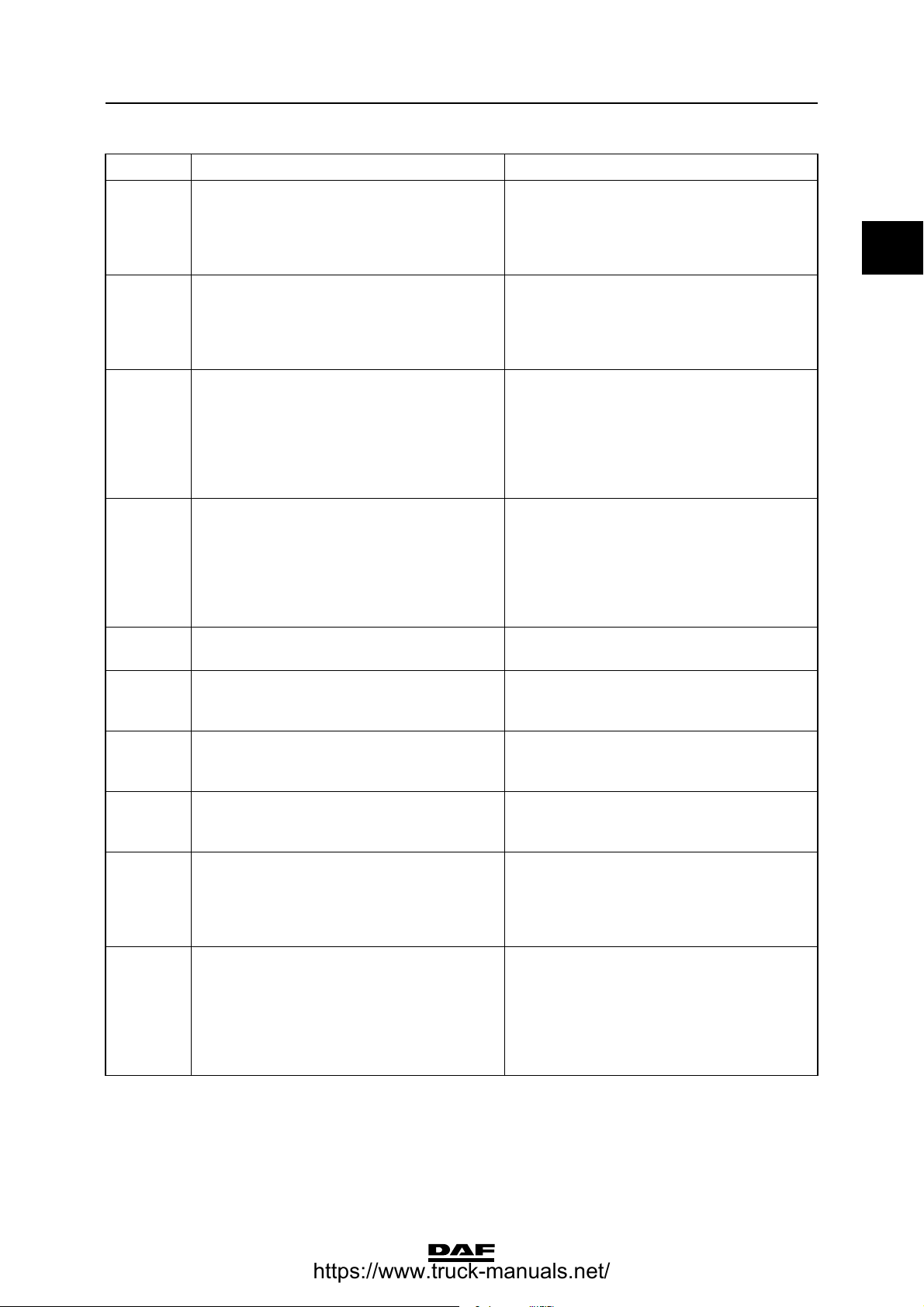

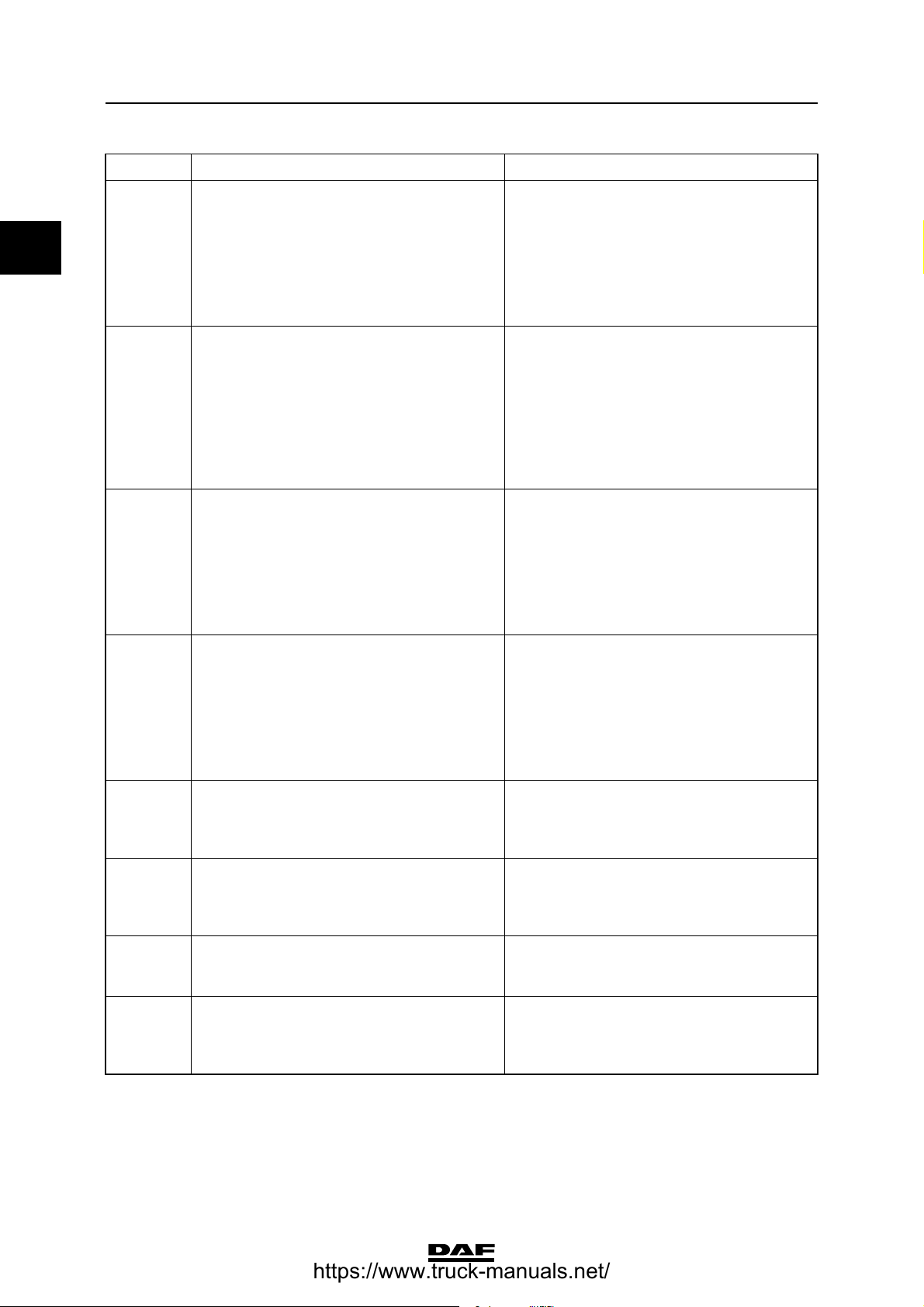

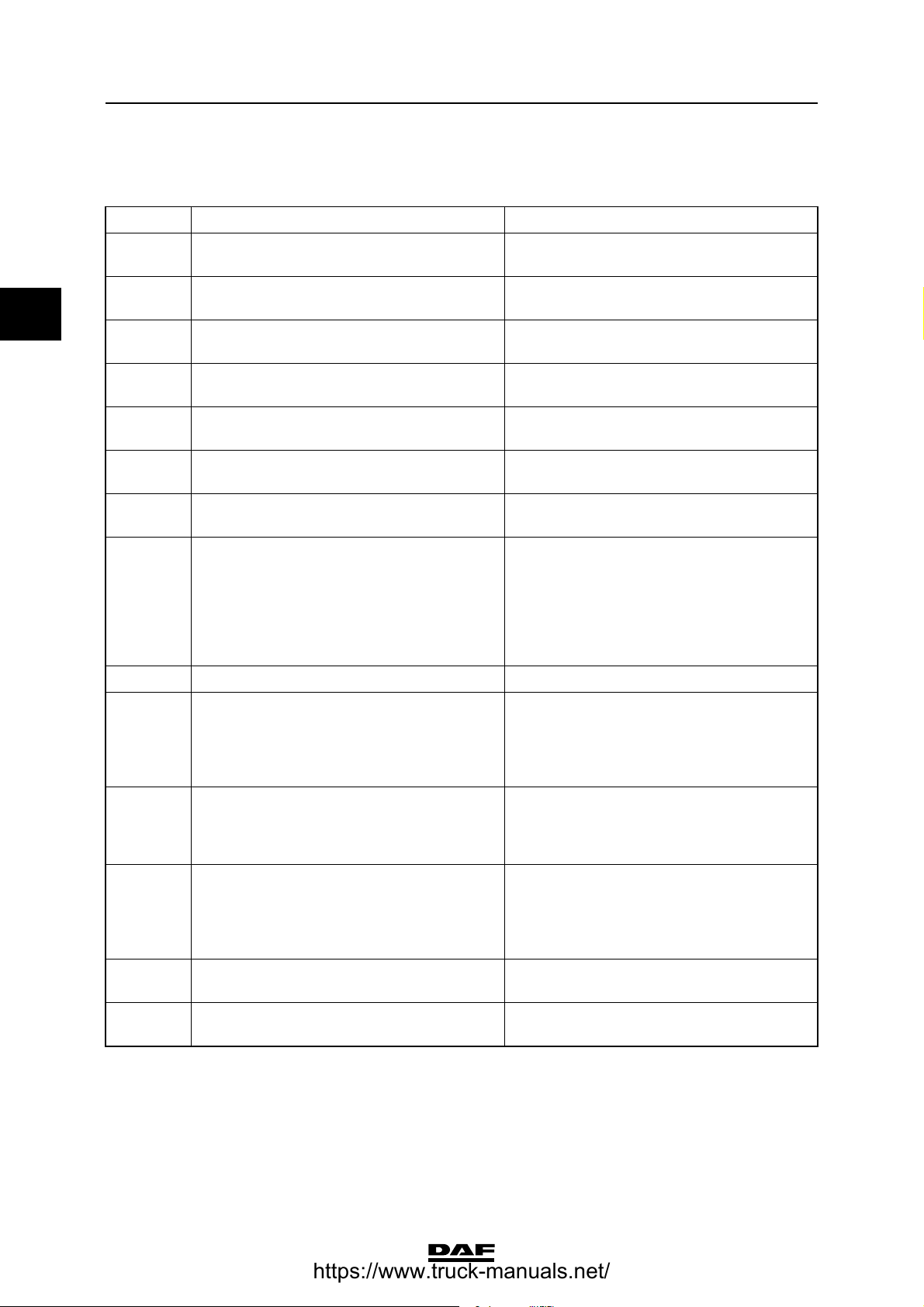

Fault code Fault code description with possible cause Symptom

11-18 Voltage on pin A8 of the EBS unit is too low due

to:

- contact resistance or poor connection to pin

A8 of the EBS unit

11-31 Extremely low voltage (<3 V) on pin A8 of the

EBS unit due to:

- excessive contact resistance on pin A8 of

the EBS unit

- interruption on pin A8 of the EBS unit

12-18 Voltage on pin A9 of the EBS unit is too low due

to:

- contact resistance or poor connection to pin

A9 of the EBS unit

- short circuit to earth on pin B7 of the EBS

unit

12-31 Extremely low voltage (<3 V) on pin A9 of the

EBS unit due to:

- excessive contact resistance on pin A9 of

the EBS unit

- interruption on pin A9 of the EBS unit

Short circuit to earth on pin E4 or B7 of the EBS

unit

- ABS on front axle deactivated

- ASR brake control deactivated

- EBS pressure control on front axle and

drawn vehicle deactivated

- ABS on front axle deactivated

- ASR brake control deactivated

- EBS pressure control on front axle and

drawn vehicle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

- Pin B7 is connected to earth inside the EBS

unit while the power supply to A9 and E4 is

interrupted inside the unit.

1-2

©

200438

Page 9

EBS

DAVIE XD diagnostics manual

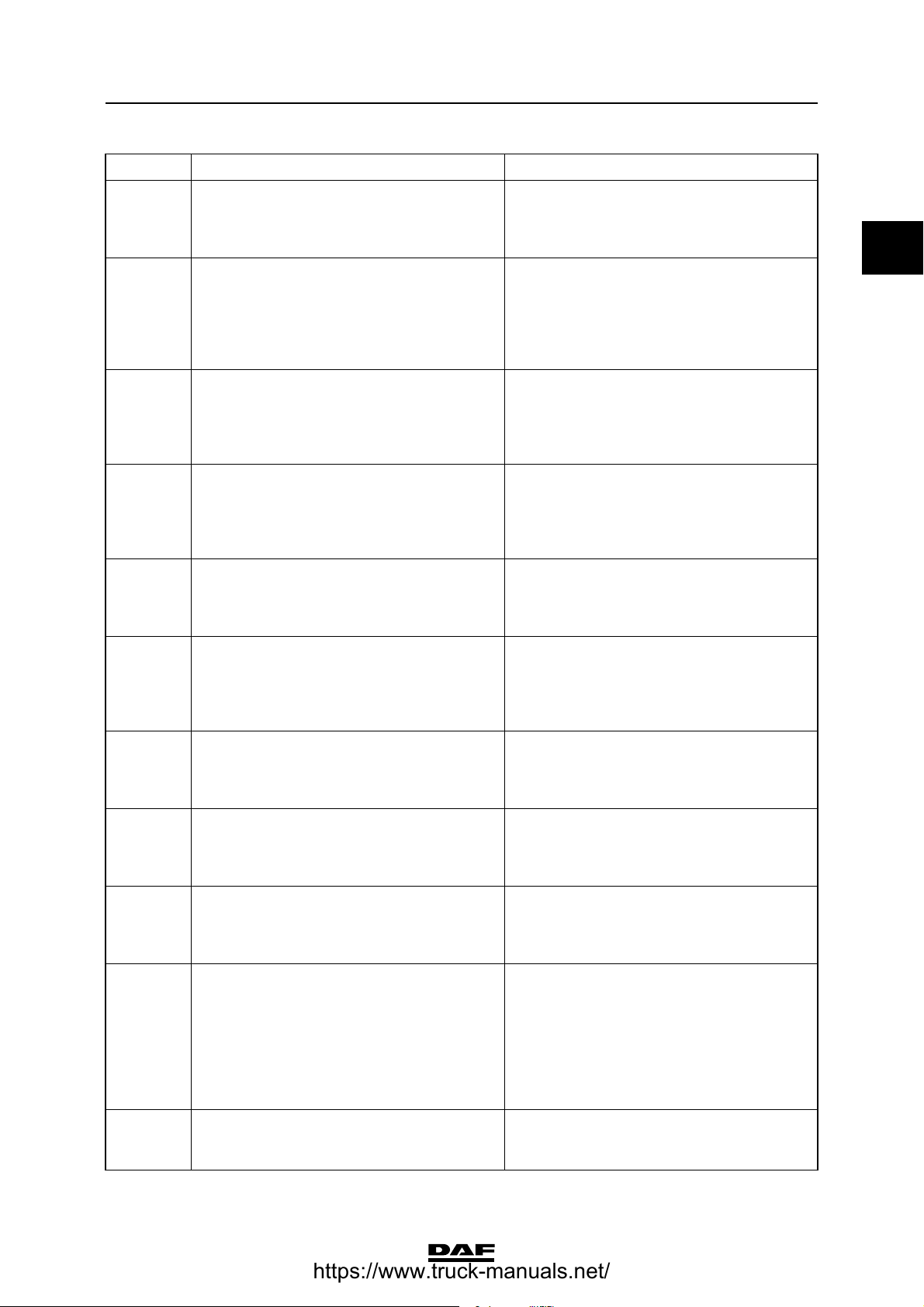

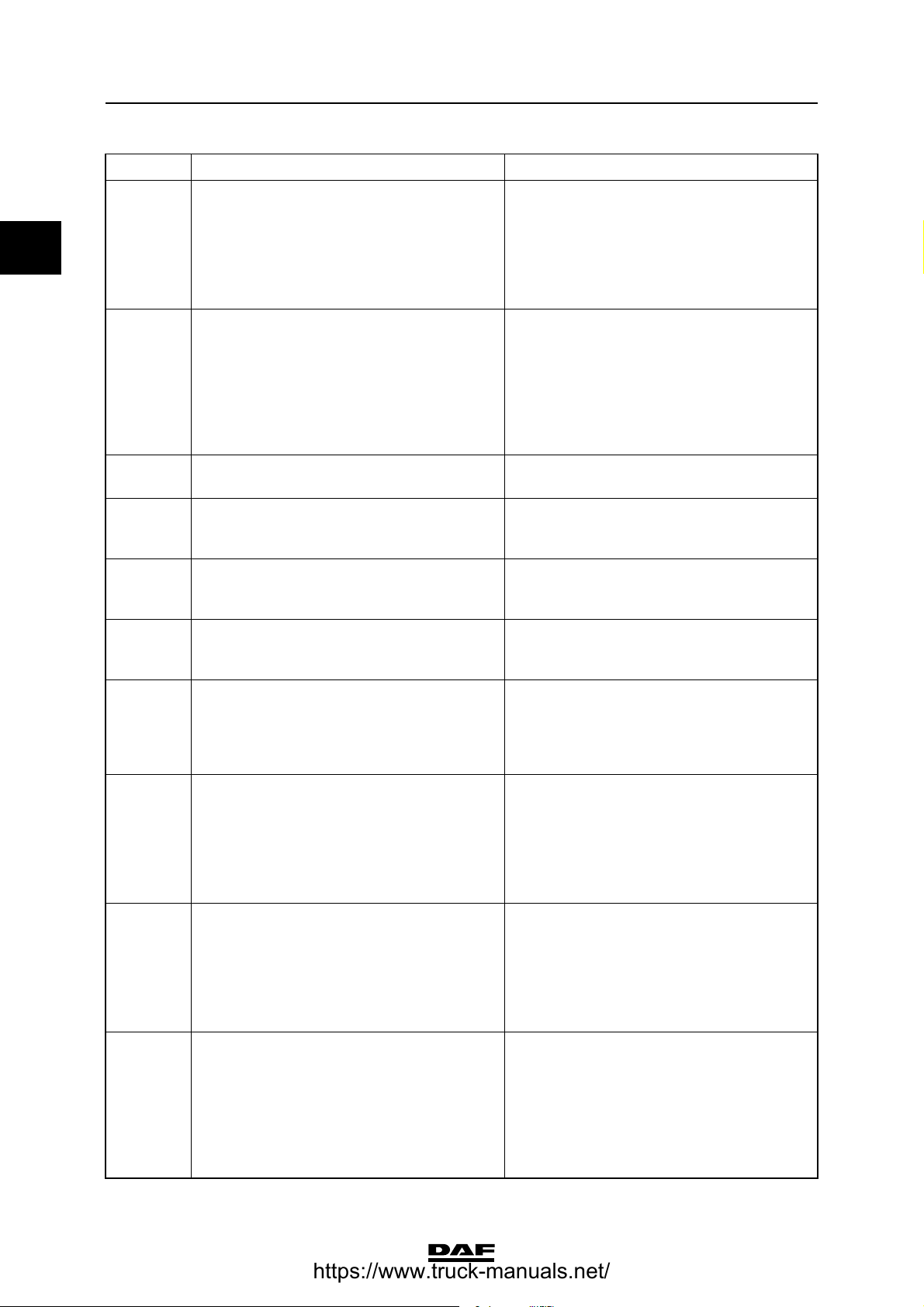

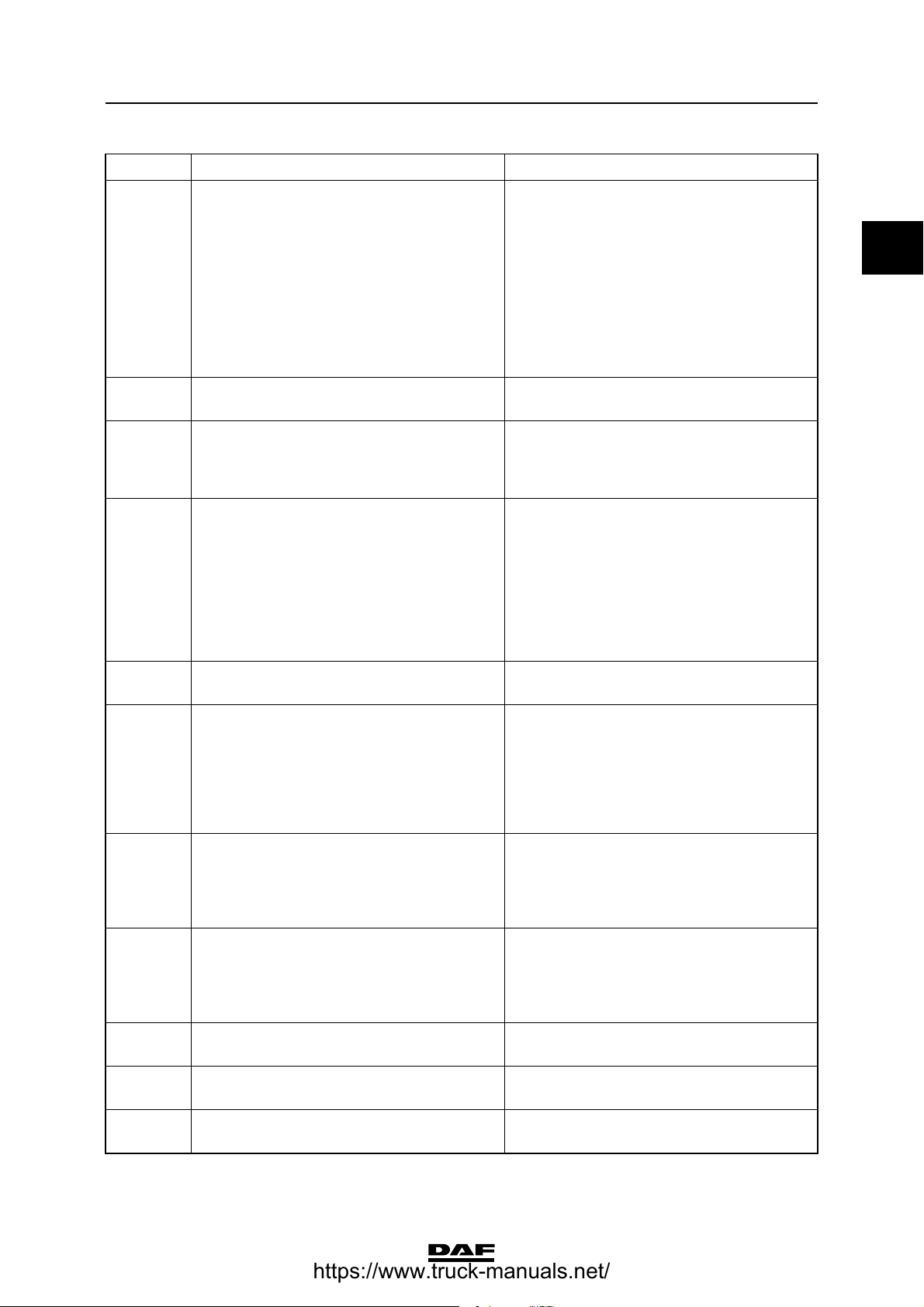

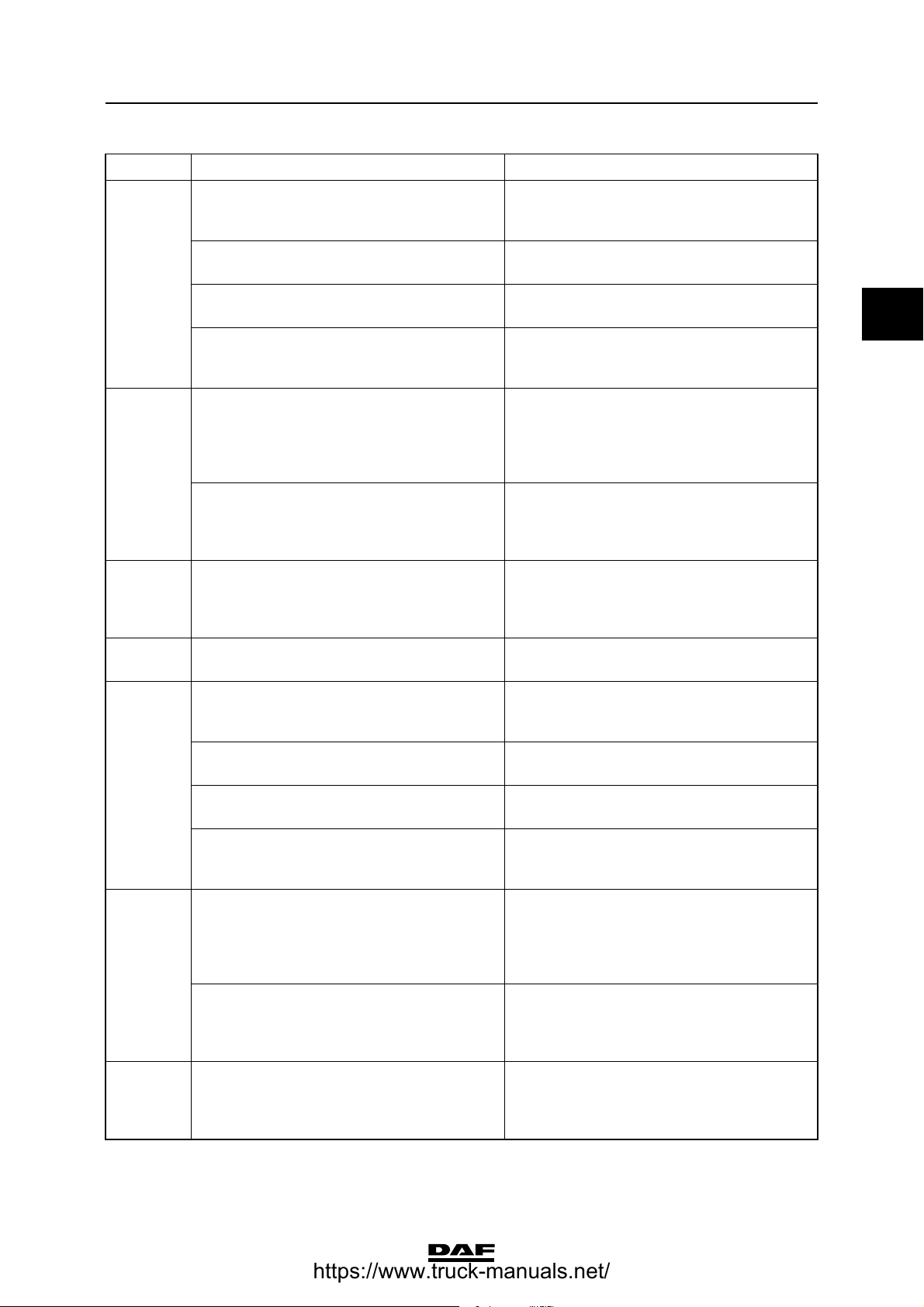

Fault code Fault code description with possible cause Symptom

13-18 Voltage on pin A7 of the EBS unit is too low due

to:

- contact resistance or poor connection to pin

A7 of the EBS unit

14-32 Sensor supply voltage on pins D9, B13 or E1 of

the EBS unit due is too low due to:

- contact resistance or poor connection on

specified connection points of the EBS unit

- short circuit to earth on specified connection

points of the EBS unit

14-33 Constant voltage, even if the ignition is turned off

and the brake is not applied, on pin D9, B13 or E1

of the EBS unit due to:

- short circuit to supply on specified

connection points of the EBS unit

15-33 Constant voltage, even if the ignition is turned off

and the brake is not applied, on pin B7 of the EBS

unit due to:

- short circuit to supply on pin B7 of the EBS

unit

16-11 Internal failure in EBS electronic unit - ABS on front and rear axles deactivated

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

EBS fault codes

1

16-12 Configuration parameters in the electronic unit

incorrect due to:

- incorrect programming

- retrofitted components without identification

card (oxford) change

16-15 Internal failure in EBS electronic unit - ABS on front and rear axles deactivated

16-17 Voltage (>32 V) on pins A7, A8 and A9 of the EBS

unit is too high due to:

- excessive alternator/battery voltage

- inductive voltage of external component

16-18 Voltage on pins A7, A8 and A9 of the EBS unit at

a speed of >2 km/h is too low due to:

- insufficient battery voltage

- poor earth connection to EBS electronic unit

16-53 Incorrect tyre size due to:

- incorrectly programmed tyre size

- tyre sizes of front and rear axles in different

tyre classes without unit having been

reprogrammed

- The difference in peripheral speed between

the left and right wheel on the same axle

exceeds 10%

21-37 Interruption on pin C4 and/or C5 of the EBS unit,

wheel speed sensor (F513)

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- ABS on front axle, right deactivated

- ASR brake/engine control deactivated

©

200438 1-3

Page 10

EBS

1

EBS fault codes

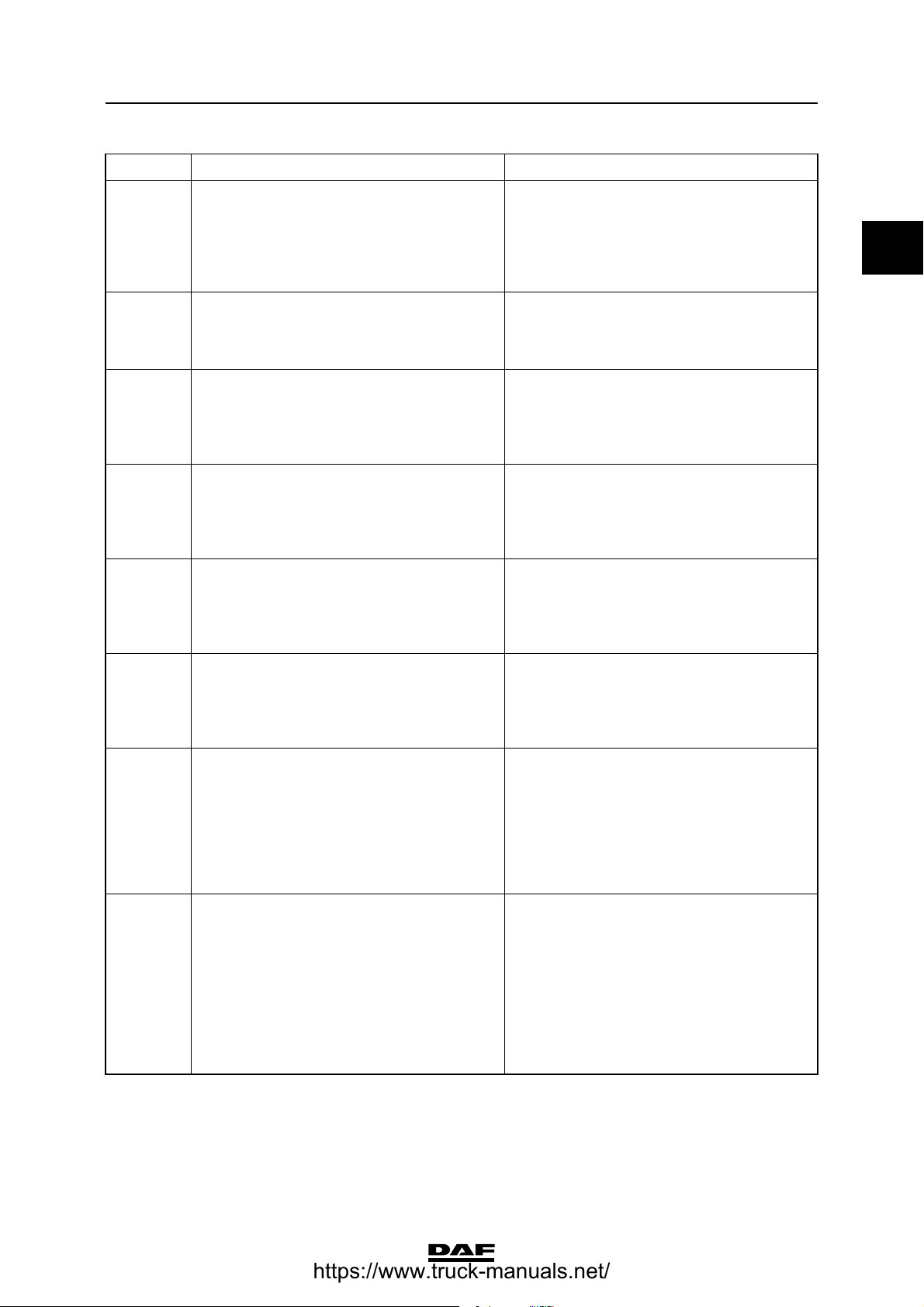

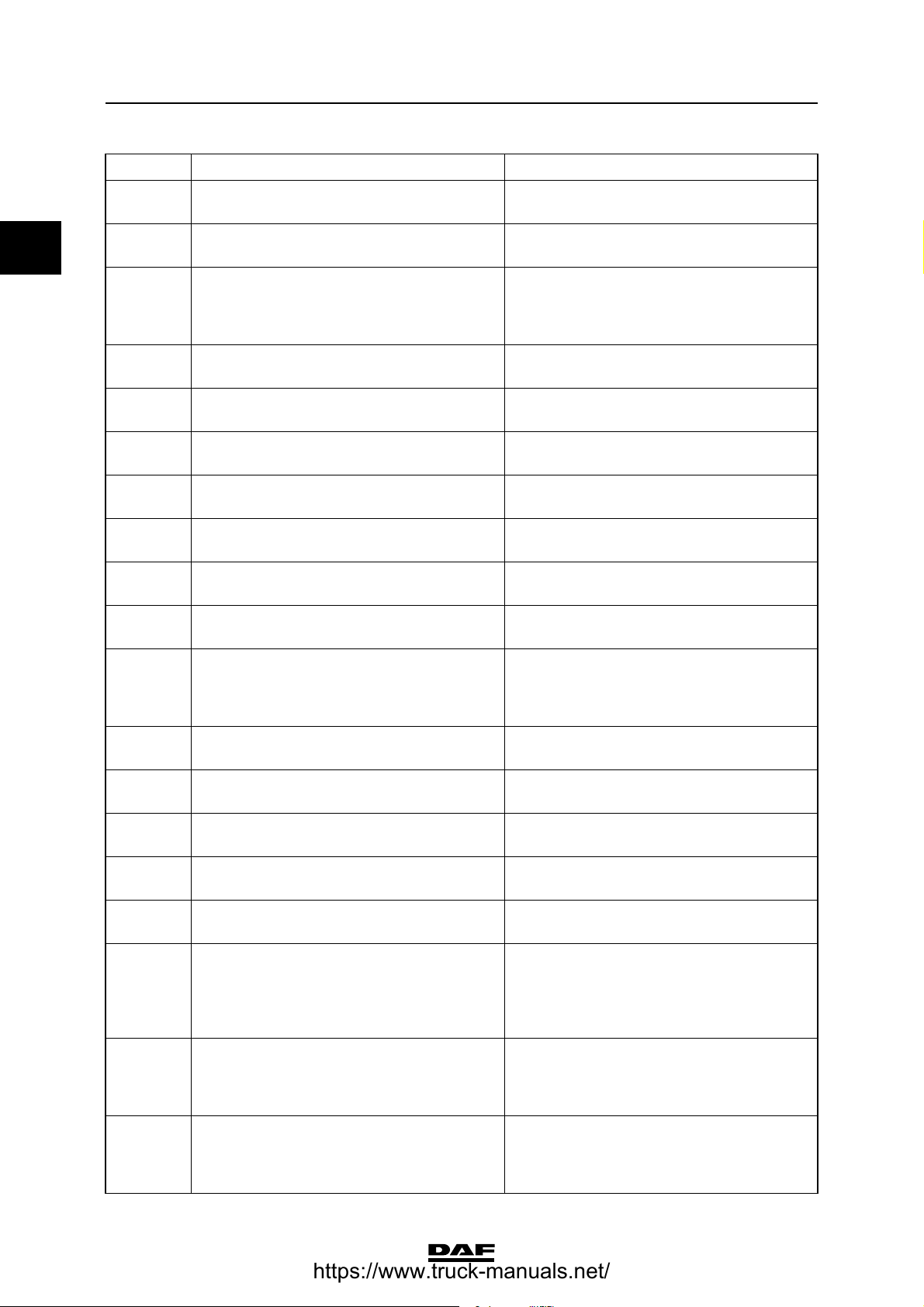

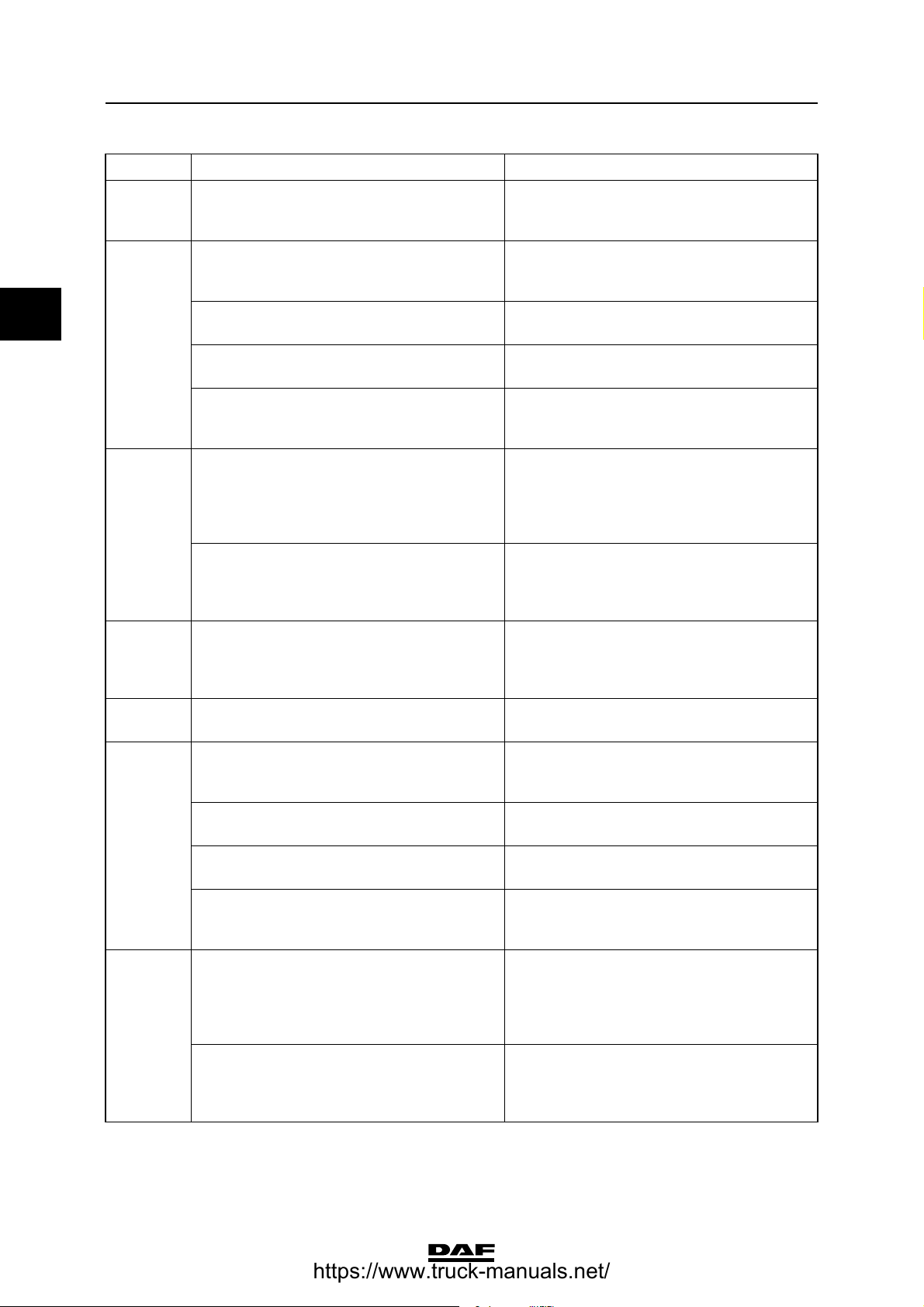

Fault code Fault code description with possible cause Symptom

21-38 Unacceptable wheel speed sensor frequency

signal from wheel speed sensor (F513) on pins

C4 and C5 of the EBS unit due to:

- loose pole ring

- wrong assessment by EBS unit

21-41 Short circuit to earth on pin C4 and/or C5 of the

EBS unit, wheel speed sensor (F513)

21-42 Short circuit to supply on pin C4 and/or C5 of the

EBS unit, wheel speed sensor (F513)

21-44 Short circuit on pin C4 and/or C5 of the EBS unit,

wheel speed sensor (F513)

21-45 Incorrect wheel speed sensor sine-wave signal

from wheel speed sensor (F513) on pins C4 and

C5 of the EBS unit due to:

- distorted wheel speed sensor ring

- damaged wheel speed sensor ring

21-46 No uniformity (frequency changes) of wheel

speed sensor signal from wheel speed sensor

(F513) on pins C4 and C5 of the EBS unit due to:

- heavy point due to brake disc wobble, for

example

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ABS on front axle, right deactivated

- ASR brake/engine control deactivated

- ABS on front axle, right deactivated

- ASR brake/engine control deactivated

- ABS on front axle, right deactivated

- ASR brake/engine control deactivated

- ABS on front axle, right deactivated

- ASR brake/engine control deactivated

- ABS on front axle, right deactivated

- ASR brake/engine control deactivated

DAVIE XD diagnostics manual

21-47 Excessive oscillation of wheel speed sensor

signal (maximum/minimum level) from wheel

speed sensor (F513) on pins C4 and C5 of the

EBS unit due to:

- excessive wheel bearing play

- incorrect mounting of wheel speed sensor

ring

21-48 Minimum value of wheel speed sensor signal

from wheel speed sensor (F513) on pins C4 and

C5 of the EBS unit is too low due to:

- too large an air gap between wheel speed

sensor ring and wheel speed sensor

- contact resistance on pin C4 and/or C5 of

the EBS unit

22-37 Interruption on pin D7 and/or D8 of the EBS unit,

wheel speed sensor (F512)

22-38 Unacceptable wheel speed sensor frequency

signal from wheel speed sensor (F512) on pins

D7 and D8 of the EBS unit due to:

- loose pole ring

- wrong assessment by EBS unit

22-41 Short circuit to earth on pin D7 and/or D8 of the

EBS unit, wheel speed sensor (F512)

22-42 Short circuit to supply on pin D7 and/or D8 of the

EBS unit, wheel speed sensor (F512)

22-44 Short circuit on pin D7 and/or D8 of the EBS unit,

wheel speed sensor (F512)

- ABS on front axle, right deactivated

- ASR brake/engine control deactivated

- ABS on front axle, right deactivated

- ASR brake/engine control deactivated

- ABS on front axle, left deactivated

- ASR brake/engine control deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ABS on front axle, left deactivated

- ASR brake/engine control deactivated

- ABS on front axle, left deactivated

- ASR brake/engine control deactivated

- ABS on front axle, left deactivated

- ASR brake/engine control deactivated

1-4

©

200438

Page 11

EBS

DAVIE XD diagnostics manual

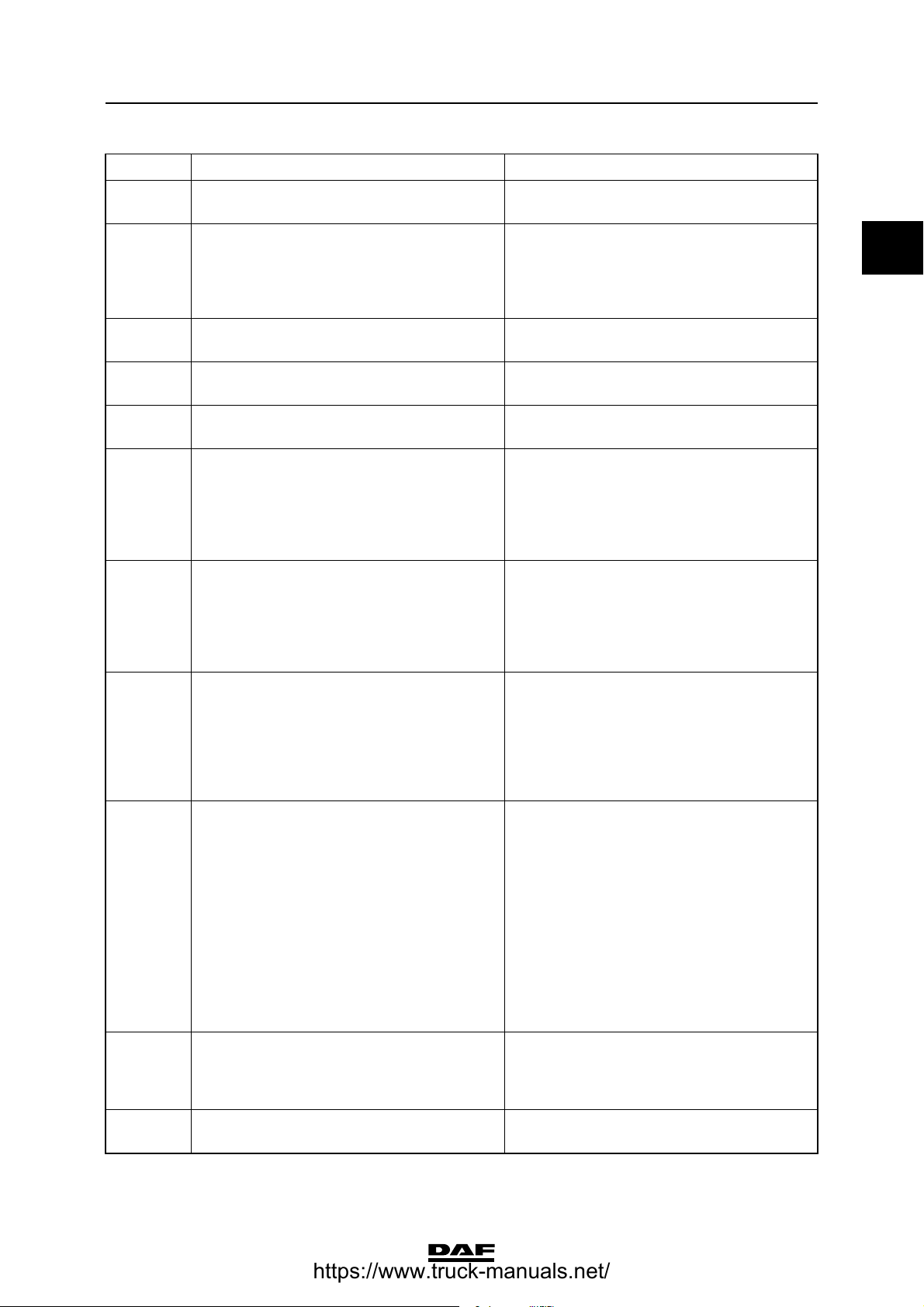

Fault code Fault code description with possible cause Symptom

22-45 Incorrect wheel speed sensor sine-wave signal

from wheel speed sensor (F512) on pins D7 and

D8 of the EBS unit due to:

- distorted wheel speed sensor ring

- damaged wheel speed sensor ring

22-46 No uniformity (frequency changes) of wheel

speed sensor signal from wheel speed sensor

(F512) on pins D7 and D8 of the EBS unit due to:

- heavy point due to brake disc wobble, for

example

22-47 Excessive oscillation of wheel speed sensor

signal (maximum/minimum level) from wheel

speed sensor (F512) on pins D7 and D8 of the

EBS unit due to:

- excessive wheel bearing play

- incorrect mounting of wheel speed sensor

ring

22-48 Minimum value of wheel speed sensor signal

from wheel speed sensor (F512) on pins D7 and

D8 of the EBS unit is too low due to:

- too large an air gap between wheel speed

sensor ring and wheel speed sensor

- contact resistance on pin D7 and/or D8 of

the EBS unit

- ABS on front axle, left deactivated

- ASR brake/engine control deactivated

- ABS on front axle, left deactivated

- ASR brake/engine control deactivated

- ABS on front axle, left deactivated

- ASR brake/engine control deactivated

- ABS on front axle, left deactivated

- ASR brake/engine control deactivated

EBS fault codes

1

23-37 Interruption on pin B1 and/or B2 of the rear axle

modulator (D879), wheel speed sensor (F515)

23-41 Short circuit to earth on pin B1 and/or B2 of the

rear axle modulator (D879), wheel speed sensor

(F515)

23-42 Short circuit to supply on pin B1 and/or B2 of the

rear axle modulator (D879), wheel speed sensor

(F515)

23-44 Short circuit between pins B1 and B2 of the rear

axle modulator (D879), wheel speed sensor

(F515)

23-45 Incorrect wheel speed sensor sine-wave signal

from wheel speed sensor (F515) on pins B1 and

B2 of the rear axle modulator (D879) due to:

- distorted wheel speed sensor ring

- damaged wheel speed sensor ring

23-46 No uniformity (frequency changes) of wheel

speed sensor signal from wheel speed sensor

(F515) on pins B1 and B2 of the rear axle

modulator (D879) due to:

- excessive wheel bearing play

- incorrect mounting of wheel speed sensor

ring

- ABS on rear axle, right deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, right deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, right deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, right deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, right deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, right deactivated

- ASR brake/engine control deactivated

©

200438 1-5

Page 12

EBS

1

EBS fault codes

Fault code Fault code description with possible cause Symptom

23-47 Excessive oscillation of wheel speed sensor

signal (maximum/minimum level) from wheel

speed sensor (F515) on pins B1 and B2 of the

rear axle modulator (D879) due to:

- excessive wheel bearing play

- incorrect mounting of wheel speed sensor

ring

23-48 Minimum value of wheel speed sensor signal

from wheel speed sensor (F515) on pins B1 and

B2 of the rear axle modulator (D879) is too low

due to:

- too large an air gap between wheel speed

sensor ring and wheel speed sensor

- contact resistance on pin B1 and/or B2 of

the rear axle modulator

24-37 Interruption in wheel speed sensor (F514) on pins

C1 and C2 of the rear axle modulator (D879)

24-41 Short circuit to earth in wheel speed sensor

(F514) on pins C1 and C2 of the rear axle

modulator (D879)

24-42 Short circuit to supply in wheel speed sensor

(F514) on pins C1 and C2 of the rear axle

modulator (D879)

24-44 Short circuit between pins C1 and C2 of the rear

axle modulator (D879), wheel speed sensor

(F514)

24-45 Incorrect wheel speed sensor sine-wave signal

from wheel speed sensor (F514) on pins C1 and

C2 of the rear axle modulator (D879) due to:

- distorted wheel speed sensor ring

- damaged wheel speed sensor ring

24-46 No uniformity (frequency changes) of wheel

speed sensor signal from wheel speed sensor

(F514) on pins C1 and C2 of the rear axle

modulator (D879) due to:

- excessive wheel bearing play

- incorrect mounting of wheel speed sensor

ring

24-47 Excessive oscillation of wheel speed sensor

signal (maximum/minimum level) from wheel

speed sensor (F514) on pins C1 and C2 of the

rear axle modulator (D879) due to:

- excessive wheel bearing play

- incorrect mounting of wheel speed sensor

ring

- ABS on rear axle, right deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, right deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, left deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, left deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, left deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, left deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, left deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, left deactivated

- ASR brake/engine control deactivated

- ABS on rear axle, left deactivated

- ASR brake/engine control deactivated

DAVIE XD diagnostics manual

24-48 Minimum value of wheel speed sensor signal

from wheel speed sensor (F514) on pins C1 and

C2 of the rear axle modulator (D879) is too low

due to:

- too large an air gap between wheel speed

sensor ring and wheel speed sensor

- contact resistance on pin C1 and/or C2 of

the rear axle modulator

1-6

- ABS on rear axle, left deactivated

- ASR brake/engine control deactivated

©

200438

Page 13

EBS

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

31-16 Large deviation between the duty cycle signals

from the foot brake valve (F628) on pins E2 and

E5 of the EBS unit due to:

- internal fault in foot brake valve

31-52 Large deviation between the duty cycle signals

from the foot brake valve (F628) on pins E2 and

E5 of the EBS unit due to:

- internal fault in foot brake valve

32-37 No signal from brake pedal position switch 1 in

foot brake valve (F628) on pin E3 of the EBS unit

due to:

- defective switch

- interruption on pin E3 of the EBS unit

32-41 Brake pedal position switch 1 remains closed in

foot brake valve (F628) or short circuit to earth on

pin E3 of the EBS unit

33-37 No signal from brake pedal position switch 2 in

foot brake valve (F628) on pin E6 of the EBS unit

due to:

- defective switch in foot brake valve

- interruption on pin E6 of the EBS unit

33-41 Brake pedal position switch 2 remains closed in

foot brake valve (F628) or short circuit to earth on

pin E6 of the EBS unit

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- Low voltage on connection point A9 inside

EBS unit

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- The actuating pressure control is active

when the brake pedal is not applied; after a

specified time (approx. 1 min.) the actuating

pressure control will automatically

disengage.

- No noticeable system limitation in EBS

- The actuating pressure control is active

when the brake pedal is not applied; after a

specified time (approx. 1 min.) the actuating

pressure control will automatically

disengage.

EBS fault codes

1

34-41 Lower signal level from brake pedal position

sensor 1 in foot brake valve (F628) on pin E2 of

the EBS unit is too low during a specified period

of time due to:

- contact resistance on pin E2 of the EBS unit

- internal fault in foot brake valve

- short circuit to earth on pin E2 of the EBS

unit

34-43 Upper signal level from brake pedal position

sensor 1 in foot brake valve (F628) on pin E2 of

the EBS unit is too high during a specified time or

the pulse width of the signal is incorrect due to:

- short circuit to supply on pin E2 of the EBS

unit

- internal fault in foot brake valve

- interruption on pin E1 of the EBS unit

- interruption on connection point E2 of the

EBS unit

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

©

200438 1-7

Page 14

EBS

1

EBS fault codes

Fault code Fault code description with possible cause Symptom

35-41 Lower signal level from brake pedal position

sensor 2 in foot brake valve (F628) on pin E5 of

the EBS unit is too low during a specified period

of time due to:

- contact resistance on pin E5 of the EBS unit

- internal fault in foot brake valve

- short circuit to earth on pin E5 of the EBS

unit

35-43 Upper signal level from brake pedal position

sensor 2 in foot brake valve (F628) on pin E5 of

the EBS unit is too high during a specified time or

the pulse width of the signal is incorrect due to:

- short circuit to supply on pin E5 of the EBS

unit

- internal fault in foot brake valve

- interruption on pin E4 of the EBS unit

- interruption on pin E5 of the EBS unit

41-61 Communication via V-CAN on pins A1 and A3 of

the EBS unit not possible when switching on

ignition due to:

- interruption on pin A1 of the EBS unit

- short circuit to earth on pin A3 of the EBS

unit

- short circuit to supply on pin A1 and/or A3 of

the EBS unit

41-63 Interrupted communication via V-CAN on pins A1

and A3 of the EBS unit due to:

- interruption on pin A1 and/or A3 of the EBS

unit

- short circuit to earth on pin A3 of the EBS

unit

- short circuit to supply on pin A1 and/or A3 of

the EBS unit

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- ASR brake/engine control deactivated

- ASR brake/engine control deactivated

DAVIE XD diagnostics manual

41-65 No CAN message "ERC1" received within a

specified period of time from the engine

management system in relation to the engine

braking torque

41-66 No CAN message "EEC1" received within a

specified period of time from the engine

management system in relation to the engine

torque and engine speed

41-67 No CAN message "ETC1" received within a

specified period of time from the gearbox

(AS Tronic) if the drive line is activated

41-68 No CAN message "CCVS" received within a

specified period of time from the engine

management system in relation to the parking

brake status, vehicle speed and clutch status

1-8

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

©

200438

Page 15

EBS

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

41-69 No CAN message "TCO1" received within a

specified period of time from the tachograph in

relation to the vehicle speed due to:

- communication problem with the tachograph

(MTCO)

- K-factor in MTCO incorrect or not there

- delayed loss of supply voltage on EBS unit

when switching off ignition (this is a common

production situation but it has been solved in

subsequent production versions by the

addition of relay G426)

41-71 No CAN message received from VIC within a

specified period of time

42-16 EBS unit does not receive correct CAN message

from the rear axle modulator (D879) on pins B1

and B4 of the EBS unit

42-61 Interrupted CAN communication with the rear

axle modulator (D879) via pins B1 and B4 of the

EBS unit due to:

- short circuit to earth on pin B4 of the EBS

unit

- short circuit to supply on pin B1 and/or pin

B4 of the EBS unit

- short circuit between pin B1 and pin B4 of

the EBS unit

43-61 CAN communication problem with the drawn

vehicle ECU via pins B3 and B6 of the EBS unit

43-63 Interrupted CAN communication, with a driving

combination, with the drawn vehicle ECU via pins

B3 and B6 of the EBS unit due to:

- interruption on pins B3 and B6 of the EBS

unit

- short circuit between pin B3 and pin B6 of

the EBS unit

43-75 Interrupted CAN communication, with a driving

combination, with the drawn vehicle ECU via pin

B3 (CAN-H) of the EBS unit due to:

- interruption on pin B3 of the EBS unit

- short circuit on pin B3 of the EBS unit

43-76 Interrupted communication, with a driving

combination, with the drawn vehicle ECU via pin

B6 (CAN-L) of the EBS unit due to:

- interruption on pin B6 of the EBS unit

- short circuit on pin B6 of the EBS unit

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

- No noticeable system limitation in EBS

EBS fault codes

1

45-16 Interruption, short circuit to earth or short circuit to

supply on pin A18 of the EBS unit

51-21 Short circuit to earth on pin D11 of the EBS unit,

ABS valve (B256)

51-22 Short circuit to supply on pin D11 of the EBS unit,

ABS valve (B256)

©

200438 1-9

- No noticeable system limitation in EBS

- ABS on front axle, left deactivated

- ABS on front axle deactivated

Page 16

EBS

1

EBS fault codes

Fault code Fault code description with possible cause Symptom

51-23 Interruption on pin D12 of the EBS unit, ABS

valve (B256)

51-24 Interruption on pin D11 of the EBS unit, ABS

valve (B256)

51-25 Continuous actuation of ABS valve (B256) via

pins D10 and D12 and/or D11 and D12 of the

EBS unit due to:

- internal short circuit in EBS unit

51-26 Interruption on pin D10 of the EBS unit, ABS

valve (B256)

51-27 Short circuit to earth on pin D10 of the EBS unit,

ABS valve (B256)

51-28 Short circuit to supply on pin D10 of the EBS unit,

ABS valve (B256)

52-21 Short circuit to earth on pin C2 of the EBS unit,

ABS valve (B257)

52-22 Short circuit to supply on pin C2 of the EBS unit,

ABS valve (B257)

- ABS on front axle, left deactivated

- ABS on front axle, left deactivated

- ABS on front axle deactivated

- EBS pressure control on front axle and

drawn vehicle deactivated

- ABS on front axle, left deactivated

- ABS on front axle, left deactivated

- ABS on front axle deactivated

- ABS on front axle, right deactivated

- ABS on front axle deactivated

DAVIE XD diagnostics manual

52-23 Interruption on pin C3 of the EBS unit, ABS valve

(B257)

52-24 Interruption on pin C2 of the EBS unit, ABS valve

(B257)

52-25 Continuous actuation of ABS valve (B527) via

pins C1 and C3 and/or C2 and C3 of the EBS unit

due to:

- internal short circuit in EBS unit

52-26 Interruption on pin C1 of the EBS unit, ABS valve

(B257)

52-27 Short circuit to earth on pin C1 of the EBS unit,

ABS valve (B257)

52-28 Short circuit to supply on pin C1 of the EBS unit,

ABS valve (B256)

53-32 Short circuit to earth on pin D12 or C3 of the EBS

unit, ABS valve (B256 or B257)

53-33 Short circuit to supply on pin D12 or C3 of the

EBS unit, ABS valve (B256 or B257)

55-12 Incorrect redundancy valve (B306) parameters

due to:

- redundancy valve connected to the EBS unit

without the EBS unit having been

programmed for a redundancy valve

55-31 Interruption in redundancy valve (B306),

measured via pin B12 of the EBS unit

- ABS on front axle, right deactivated

- ABS on front axle, right deactivated

- ABS on front axle deactivated

- EBS pressure control on front axle and

drawn vehicle deactivated

- ABS on front axle, right deactivated

- ABS on front axle, right deactivated

- ABS on front axle deactivated

- No noticeable system limitation in EBS

- ABS on front axle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

55-32 Short circuit to earth in redundancy valve (B306),

measured via pin B12 of the EBS unit

1-10

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

©

200438

Page 17

EBS

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

55-33 Short circuit to supply in redundancy valve

(B306), measured via pin B12 of the EBS unit

57-12 Incorrect ASR cut-off valve (B309) parameters

due to:

- ASR cut-off valve connected to the EBS unit

without the EBS unit having been

programmed for an ASR cut-off valve

57-31 Interruption on pin C6 of the EBS unit, ASR cut-

off valve (B309)

57-32 Short circuit to earth on pin C6 of the EBS unit,

ASR cut-off valve (B309)

57-33 Short circuit to supply on pin C6 of the EBS unit,

ASR cut-off valve (B309)

61-16 The current through the front axle modulator

(B307) magnet coil measured via pins D1 and D2

of the EBS unit is incorrect due to:

- copper short circuit in the magnet coil

- short circuit or contact resistance between

pins D1 and D2 of the EBS unit

61-55 Front axle modulator (B307) output pressure

measured on pin D6 of the EBS unit is incorrect

in relation to the current through the magnet coil

due to:

- defective pressure sensor

- too low a supply pressure

62-42 Pressure sensor failure in front axle modulator

(B307) due to:

- short circuit to supply on pin D6 of the EBS

unit

- interruption on pin D3 of the EBS unit

- short circuit to supply on pin D5 of the EBS

unit

62-43 With a nonactivated front axle modulator, the

front axle modulator (B307) pressure sensor

output signal on pin D6 of the EBS unit is too low

or too high due to:

- defective pressure sensor

- no supply voltage or supply voltage too low

on pin D9 of the EBS unit

- interruption on pin D6 of the EBS unit

- short circuit to earth on pin D6 of the EBS

unit

- air pressure at connection point 4 of the front

axle modulator (B307) if the foot brake valve

(F628) is not activated

- ABS on front axle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ASR brake control deactivated

-

- ASR brake control deactivated

-

- No noticeable system limitation in EBS

- EBS pressure control on front axle

deactivated

- EBS pressure control on front axle

deactivated

- Open circuit in EBS pressure control, front

axle

- Open circuit in EBS pressure control, front

axle

EBS fault codes

1

63-25 Permanent actuation of the front axle modulator

(B307) due to:

- short circuit to supply on one side and short

circuit to earth on the other side

63-32 Short circuit to earth on pin D1 of the EBS unit,

front axle modulator (B307)

©

200438 1-11

- Brake remains applied to front axle

- EBS pressure control on front axle

deactivated

Page 18

EBS

1

EBS fault codes

Fault code Fault code description with possible cause Symptom

63-33 Short circuit to supply on pin D1 of the EBS unit,

front axle modulator (B307)

63-34 Short circuit to earth on pin D2 of the EBS unit,

front axle modulator (B307)

63-35 Short circuit to supply on pin D2 of the EBS unit,

front axle modulator (B307)

63-36 Interruption on pin D1 and/or D2 of the EBS unit,

front axle modulator (B307)

64-13 The EBS unit parameters for the rear axle

modulator type do not correspond with the

parameters in the rear axle modulator (D879)

64-16 Fault in the solenoid valves of the rear axle

modulator (D879)

64-51 Output pressure of the rear axle modulator

(D879) is too high

64-52 Brake pressure signal difference between both

pressure sensors in rear axle modulator (D879) is

too high

64-54 No pressure sensor signal in rear axle modulator

(D879) or signal is incorrect (too high/too low)

64-64 CAN communication problem of the EBS unit with

the rear axle modulator (D879) via pins B1 and

B4 of the EBS unit

- EBS pressure control on front axle

deactivated

- EBS pressure control on front axle

deactivated

- EBS pressure control on front axle

deactivated

- EBS pressure control on front axle

deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

- ABS on rear axle deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- Open circuit in EBS pressure control, rear

axle

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

DAVIE XD diagnostics manual

Supply voltage on pin B7 of the EBS unit

interrupted

Interrupted earth connection or contact

resistance in the earth connection of the rear axle

modulator (D879)

66-12 Incorrect drawn vehicle control valve (B308)

parameters due to:

- drawn vehicle control valve connected to the

EBS unit without the EBS unit having been

programmed for a drawn vehicle control

valve

1-12

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

- With an interruption on pin B7, connection

points A9 and E4 inside the ECU will have a

low voltage, causing brake pedal position

sensor 2 to give no output signal, for

instance. If the measurement is performed

at B7, it will also turn out that B7 in this

situation will be internally connected to earth

in the ECU

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on rear axle

deactivated

- ABS on front and rear axles deactivated

- ASR brake/engine control deactivated

- EBS pressure control on front axle, rear axle

and drawn vehicle deactivated

©

200438

Page 19

EBS

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

66-16 The current measured by the drawn vehicle

control valve (B308) magnet coil via pins B10 and

B11 of the ECU is incorrect due to:

- copper short circuit in the magnet coil

- short circuit or contact resistance between

pins B10 and B11 of the EBS unit

66-55 Drawn vehicle control valve (B308) output

pressure measured on pin B14 of the ECU is

incorrect in relation to the current through the

magnet coil due to:

- defective pressure sensor

- too low a supply pressure

67-42 Pressure sensor fault in drawn vehicle control

valve (B308) due to:

- short circuit to supply on pin B14 of the EBS

unit

- interruption on pin D3 of the EBS unit

- short circuit to supply on pin D3 of the EBS

unit

67-43 With a nonactivated drawn vehicle control valve,

drawn vehicle control valve (B308) pressure

sensor output signal on pin B14 of the EBS unit is

too low or too high due to:

- defective pressure sensor

- no or too low a supply voltage to pressure

sensor

67-51 With a non-activated drawn vehicle control valve

and a speed >30 km/hour, drawn vehicle control

valve (B308) pressure sensor output signal on pin

B14 of the EBS unit is too low or too high due to:

- defective pressure sensor

68-25 Permanent actuation of the drawn vehicle control

valve (B308) due to:

- short circuit to supply on one side and short

circuit to earth on the other side

68-32 Short circuit to earth on pin B10 of the EBS unit,

drawn vehicle control valve (B308)

68-33 Short circuit to supply on pin B10 of the EBS unit,

drawn vehicle control valve (B308)

- EBS pressure control on drawn vehicle

deactivated

- EBS pressure control on drawn vehicle

deactivated

- Open circuit in EBS pressure control, drawn

vehicle

- Open circuit in EBS pressure control, drawn

vehicle

- Open circuit in EBS pressure control, drawn

vehicle

- Brake remains applied to drawn vehicle

- EBS pressure control on drawn vehicle

deactivated

- EBS pressure control on drawn vehicle

deactivated

EBS fault codes

1

68-34 Short circuit to earth on pin B11 of the EBS unit,

drawn vehicle control valve (B308)

68-35 Short circuit to supply on pin B11 of the EBS unit,

drawn vehicle control valve (B308)

68-36 Interruption on pin B10 and/or B11 of the EBS

unit, drawn vehicle control valve (B308)

73-15 If a drawn vehicle with EBS sends a CAN

message to the ECU of the prime mover,

indicating that the "serious drawn vehicle failure"

needs to be activated on DIP, this fault code will

be stored in the prime mover ECU.

©

200438 1-13

- EBS pressure control on drawn vehicle

deactivated

- EBS pressure control on drawn vehicle

deactivated

- EBS pressure control on drawn vehicle

deactivated

Page 20

EBS

1

EBS fault codes

DAVIE XD diagnostics manual

1-14

©

200438

Page 21

EBS

DAVIE XD diagnostics manual

2. EBS CUSTOMER PARAMETERS

2.1 INTRODUCTION

Customer parameters

Customer parameters are the settings of an

electronic system. The customer parameters

permit adapting control functions of a system to

the customer's particular wishes and/or needs

within certain limits. The customer parameters

are stored in a list in the memory of the electronic

unit. Customer parameters can be modified using

the programming feature of DAVIE XD.

Programming using DAVIE XD is only possible if

the logged-in user has been registered as a

"Master Technician".

Note:

Erroneous settings of customer parameters may

affect the action of control functions to such an

extent that they function eratically or not at all.

After modification of the settings the (modified)

customer parameters must be stored in the

electronic unit using the programming function in

the customer parameter overview.

EBS customer parameters

1

Customer parameter names and codes

Each customer parameter in a system has its

own name and code. The following explanation of

the customer parameters includes only the

codes. The availability of a customer parameter

in a system depends on the programmed

software in the electronic unit. The programmed

software depends on the vehicle configuration/

identity card data.

Standard values

Standard values, options and setting ranges may

vary according to the software variants of

DAVIE XD and the system. This is why they have

not been included in the following explanation of

the customer parameters.

©

200438 2-1

Page 22

1

EBS

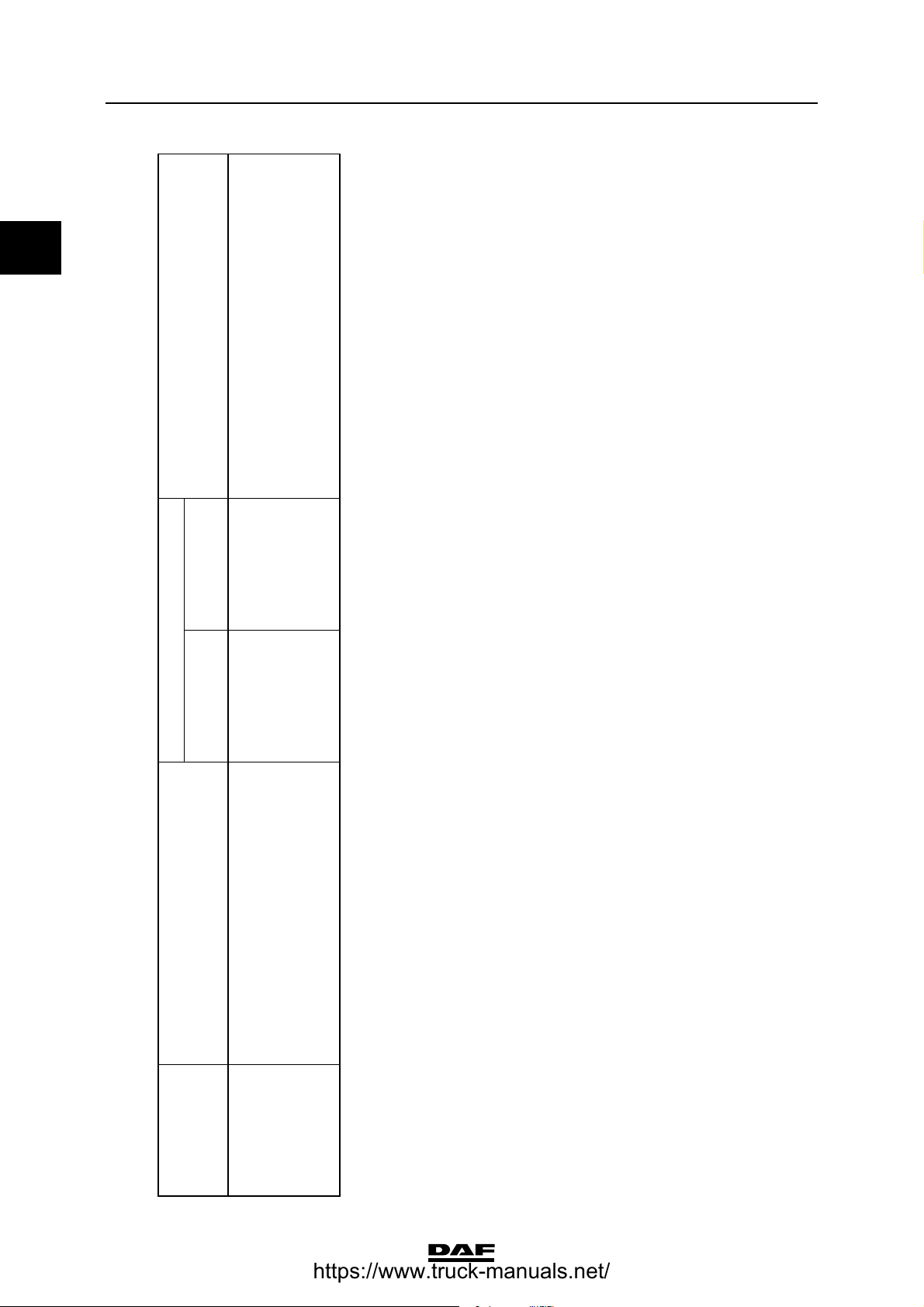

EBS customer parameters DAVIE XD diagnostics manual

drawn vehicle when braking is started.

available on FT vehicles and is only active if a drawn

vehicle without EBS system is coupled.

This setting can be changed if:

- there is a complaint relating to the towing of the

Maximum value to

be set:

Minimum value to

be set:

0 bar 3.5 bar The presssure pulse activation ‚"P inshot" is only

Explanation Dependences: Notes

determines the pulsing "P-inshot" to the drawn

vehicle.

2.2 EXPLANATORY NOTES TO EBS CUSTOMER PARAMETERS

2-2

EBS Customer

parameter code

3-01 This is a comfort parameter setting which

©

200438

Page 23

EBS

DAVIE XD diagnostics manual

3. SYSTEM INSPECTION WITH DAVIE XD

3.1 GENERAL

If the tyre size is changed or if the vehicle is

adjusted in such a way that the configuration is

changed, the electronic unit may have to be reprogrammed.

System inspection with DAVIE XD

1

©

200438 3-1

Page 24

EBS

1

System inspection with DAVIE XD

DAVIE XD diagnostics manual

3-2

©

200438

Page 25

UPEC

DAVIE XD diagnostics manual

2 UPEC

CONTENTS

Page Date

1. UPEC FAULT CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200438

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200438

1.2 Explanatory notes to UPEC fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200438

2. UPEC CUSTOMER PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200438

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200438

2.2 Explanatory notes to UPEC customer parameters . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200438

3. SYSTEM INSPECTION WITH DAVIE XD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200438

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200438

3.2 Engine brake test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200438

3.3 Speed variation control test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 . . . . . 200438

Contents

2

©

200438 1

Page 26

UPEC

2

Contents

DAVIE XD diagnostics manual

2

©

200438

Page 27

UPEC

DAVIE XD diagnostics manual

1. UPEC FAULT CODES

1.1 INTRODUCTION

If the electronic unit detects a system fault, this

fault is usually stored in the memory of the

electronic unit as a fault code.

Most system faults will also generate a warning.

UPEC fault codes

2

©

200438 1-1

Page 28

UPEC

2

UPEC fault codes

DAVIE XD diagnostics manual

1.2 EXPLANATORY NOTES TO UPEC FAULT CODES

Fault code Fault code description with possible cause Symptom

11-1 Internal communication fault in ECU - Engine stalls and/or engine starts but does

not fire

11-2 Internal communication fault in ECU - Engine stalls and/or engine starts but does

not fire

12-1 Internal fault in ECU due to:

- defective EEPROM

13-1 Internal fault in ECU during the checking

procedure after the ignition was switched off

13-2 Internal fault in ECU during the checking

procedure after the ignition was switched off

13-4 Internal fault in ECU during the checking

procedure after the ignition was switched off

13-8 Internal fault in ECU during the checking

procedure after the ignition was switched off

14-1 Voltage on pin B15 but no voltage on pins B3 and

B4 of the ECU due to:

- faulty relay G126

- no activation of relay G126

- no supply voltage on relay G126

- open connection to pin B27

- short circuit to supply on pin B27

15-1 Internal fault in ECU - No noticeable system limitation

- No noticeable system limitation in UPEC

- No noticeable system limitation in UPEC

- No noticeable system limitation in UPEC

- No noticeable system limitation in UPEC

- No noticeable system limitation in UPEC

- Engine stalls and/or engine starts but does

not fire

- Communication fault with DAVIE so that

fault code cannot be read out

- Several systems will output error messages

in connection with the CAN communication

21-8 Voltage on pins B3 and B4, with no voltage being

applied anymore on pin B15 of the ECU due to:

- faulty relay G126

- short circuit to earth on pin B27

- short circuit to supply on pin B3 and/or B4

22-1 Voltage on pins B3, B4 and B15 of the ECU is too

high (>30 V) due to:

- excessive alternator/battery voltage

- inductive voltage of external component

22-2 Voltage on pins B3, B4 and B15 of the ECU is too

low (<14 V) due to:

- insufficient supply voltage, for example

during starting

- contact resistance in power supply circuit

22-4 Internal supply voltage fault in ECU - System response depending on internal

31-1 Short circuit to supply on pump unit connections,

pin A24 and/or pin A25 of the ECU

- Engine starts but will not fire

- Communication fault with DAVIE so that

fault code cannot be read out

- Several systems will output error messages

in connection with the CAN communication

- System response depending on voltage

level

- System response depending on voltage

level

supply voltage fault

- Engine stalls and/or engine starts but does

not fire

1-2

©

200438

Page 29

UPEC

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

31-2 Short circuit to earth or interruption in the pump

unit (B131) on pin A35 of the ECU, causing the

pump unit of cylinder 1 to be switched off

Short circuit to earth on pump unit connections,

pin A24 and/or pin A25 of the ECU

Short circuit to supply of the pump unit (B131) on

pin A35 of the ECU

Interruption in the pump unit (B131) on pin A24 of

the ECU, causing the pump unit of cylinders 1, 2

and 3 to be switched off

31-4 The valve inside the pump unit (B131) does not

close due to:

- jammed valve

- internal contamination

- internal wear

The valve inside the pump unit (B131) does not

close fast enough due to:

- internal contamination

- internal wear

31-8 The valve inside the pump unit (B131) does not

open fast enough due to:

- mechanical problems

- internal contamination

32-1 Short circuit to supply on pump unit connections,

pin A24 and/or pin A25 of the ECU

32-2 Short circuit to earth or interruption in the pump

unit (B135) on pin A26 of the ECU, causing the

pump unit of cylinder 5 to be switched off

Short circuit to earth on pump unit connections,

pin A24 and/or pin A25 of the ECU

- Engine running on 5 cylinders

- Reduced engine output

- Engine stalls and/or engine starts but does

not fire

- Engine stalls and/or engine starts but does

not fire

- Engine running on 3 cylinders

- Engine does not supply power

- Engine running on 5 cylinders

- Reduced engine output

- Reduced engine output

- No noticeable system limitation in UPEC

- Engine stalls and/or engine starts but does

not fire

- Engine running on 5 cylinders

- Reduced engine output

- Engine stalls and/or engine starts but does

not fire

UPEC fault codes

2

Short circuit to supply of the pump unit (B135) on

pin A26 of the ECU

Interruption in the pump unit (B135) on pin A25 of

the ECU, causing the pump unit of cylinders 4, 5

and 6 to be switched off

32-4 The valve inside the pump unit (B135) does not

close due to:

- jammed valve

- internal contamination

- internal wear

The valve inside the pump unit (B135) does not

close fast enough due to:

- internal contamination

- internal wear

32-8 The valve inside the pump unit (B135) does not

open fast enough due to:

- mechanical problems

- internal contamination

©

200438 1-3

- Engine stalls and/or engine starts but does

not fire

- Engine running on 3 cylinders

- Engine does not supply power

- Engine running on 5 cylinders

- Reduced engine output

- Reduced engine output

- No noticeable system limitation in UPEC

Page 30

UPEC

2

UPEC fault codes

Fault code Fault code description with possible cause Symptom

33-1 Short circuit to supply on pump unit connections,

pin A24 and/or pin A25 of the ECU

33-2 Short circuit to earth or interruption in the pump

unit (B133) on pin A34 of the ECU, causing the

pump unit of cylinder 3 to be switched off

Short circuit to earth on pump unit connections,

pin A24 and/or pin A25 of the ECU

Short circuit to supply of the pump unit (B133) on

pin A34 of the ECU

Interruption in the pump unit (B133) on pin A24 of

the ECU, causing the pump unit of cylinders 1, 2

and 3 to be switched off

33-4 The valve inside the pump unit (B133) does not

close due to:

- jammed valve

- internal contamination

- internal wear

The valve inside the pump unit (B133) does not

close fast enough due to:

- internal contamination

- internal wear

33-8 The valve inside the pump unit (B133) does not

open fast enough due to:

- mechanical problems

- internal contamination

34-1 Short circuit to supply on pump unit connections,

pin A24 and/or pin A25 of the ECU

34-2 Short circuit to earth or interruption in the pump

unit (B136) on pin A27 of the ECU, causing the

pump unit of cylinder 6 to be switched off

Short circuit to earth on pump unit connections,

pin A24 and/or pin A25 of the ECU

- Engine stalls and/or engine starts but does

not fire

- Engine running on 5 cylinders

- Reduced engine output

- Engine stalls and/or engine starts but does

not fire

- Engine stalls and/or engine starts but does

not fire

- Engine running on 3 cylinders

- Engine does not supply power

- Engine running on 5 cylinders

- Reduced engine output

- Reduced engine output

- No noticeable system limitation in UPEC

- Engine stalls and/or engine starts but does

not fire

- Engine running on 5 cylinders

- Reduced engine output

- Engine stalls and/or engine starts but does

not fire

DAVIE XD diagnostics manual

Short circuit to supply of the pump unit (B136) on

pin A27 of the ECU

Interruption in the pump unit (B136) on pin A25 of

the ECU, causing the pump unit of cylinders 4, 5

and 6 to be switched off

34-4 The valve inside the pump unit (B136) does not

close due to:

- jammed valve

- internal contamination

- internal wear

The valve inside the pump unit (B136) does not

close fast enough due to:

- internal contamination

- internal wear

1-4

- Engine stalls and/or engine starts but does

not fire

- Engine running on 3 cylinders

- Engine does not supply power

- Engine running on 5 cylinders

- Reduced engine output

- Reduced engine output

©

200438

Page 31

UPEC

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

34-8 The valve inside the pump unit (B136) does not

open fast enough due to:

- mechanical problems

- internal contamination

35-1 Short circuit to supply on pump unit connections,

pin A24 and/or pin A25 of the ECU

35-2 Short circuit to earth or interruption in the pump

unit (B132) on pin A33 of the ECU, causing the

pump unit of cylinder 2 to be switched off

Short circuit to earth on pump unit connections,

pin A24 and/or pin A25 of the ECU

Short circuit to supply of the pump unit (B132) on

pin A33 of the ECU

Interruption in the pump unit (B132) on pin A24 of

the ECU, causing the pump unit of cylinders 1, 2

and 3 to be switched off

35-4 The valve inside the pump unit (B132) does not

close due to:

- jammed valve

- internal contamination

- internal wear

- No noticeable system limitation in UPEC

- Engine stalls and/or engine starts but does

not fire

- Engine running on 5 cylinders

- Reduced engine output

- Engine stalls and/or engine starts but does

not fire

- Engine stalls and/or engine starts but does

not fire

- Engine running on 3 cylinders

- Engine does not supply power

- Engine running on 5 cylinders

- Reduced engine output

UPEC fault codes

2

The valve inside the pump unit (B132) does not

close fast enough due to:

- internal contamination

- internal wear

35-8 The valve inside the pump unit (B132) does not

open fast enough due to:

- mechanical problems

- internal contamination

36-1 Short circuit to supply on pump unit connections,

pin A24 and/or pin A25 of the ECU

36-2 Short circuit to earth or interruption in the pump

unit (B134) on pin A28 of the ECU, causing the

pump unit of cylinder 4 to be switched off

Short circuit to earth on pump unit connections,

pin A24 and/or pin A25 of the ECU

Short circuit to supply of the pump unit (B134) on

pin A28 of the ECU

Interruption in the pump unit (B134) on pin A25 of

the ECU, causing the pump unit of cylinders 4, 5

and 6 to be switched off

36-4 The valve inside the pump unit (B134) does not

close due to:

- jammed valve

- internal contamination

- internal wear

The valve inside the pump unit (B134) does not

close fast enough due to:

- internal contamination

- internal wear

- Reduced engine output

- No noticeable system limitation in UPEC

- Engine stalls and/or engine starts but does

not fire

- Engine running on 5 cylinders

- Reduced engine output

- Engine stalls and/or engine starts but does

not fire

- Engine stalls and/or engine starts but does

not fire

- Engine running on 3 cylinders

- Engine does not supply power

- Engine running on 5 cylinders

- Reduced engine output

- Reduced engine output

©

200438 1-5

Page 32

UPEC

2

UPEC fault codes

Fault code Fault code description with possible cause Symptom

36-8 The valve inside the pump unit (B134) does not

open fast enough due to:

- mechanical problems

- internal contamination

41-1 Voltage level of crankshaft sensor (F552) sine-

wave signal on pins A1 and A13 of the ECU is too

low due to:

- too large an air gap between flywheel and

crankshaft sensor

- contact resistance in connection points

- short circuit or interruption

Excessive oscillation of crankshaft sensor (F552)

sine-wave signal on pin A1 of the ECU due to:

- irregularity in flywheel circumference

- faulty fitting of the flywheel

41-2 Too low a voltage level of camshaft sensor (F558)

sine-wave signal on pins A2 and A14 of the ECU

due to:

- too large an air gap between pulse disc and

camshaft sensor

- contact resistance in connection points

- short circuit or interruption

Excessive oscillation of camshaft sensor (F558)

sine-wave signal on pins A2 and A14 of the ECU

due to:

- irregularity in pulse disc circumference

- faulty fitting of the pulse disc

- No noticeable system limitation

- No engine speed signal on pin B5 of the

ECU

- No noticeable system limitation in UPEC

- Longer start time before engine fires

- Longer start time before engine fires

DAVIE XD diagnostics manual

41-8 Incorrect or unacceptable sine-wave signals of

both the crankshaft sensor (F552) and camshaft

sensor (F558) due to:

- contact resistance in connection points

- defective ECU

- interruption or short circuit in crankshaft

sensor and camshaft sensor

42-1 Signal of crankshaft sensor (F552) on pins A1 en

A13 of ECU fails due to:

- poor connection/bad contact

- faulty sensor

42-2 Synchronisation of crankshaft sensor signal and

camshaft sensor signals is not correct due to:

- loose pulse disc

- incorrect timing setting

- signal disturbance caused by external

influences

42-4 Missing or unacceptable sine-wave signal of

crankshaft sensor (F552) due to:

- interruption on pin A1 and/or A13 of the ECU

- short circuit to earth on pin A1 of the ECU

- short circuit to supply on pin A1 of the ECU

- short circuit between pins A1 and A13 of the

ECU

- Engine stalls and/or engine starts but does

not fire

- No engine speed signal on pin B5

- Engine starts but will not fire

- No engine speed signal on pin B5 of the

ECU

1-6

©

200438

Page 33

UPEC

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

42-8 Unacceptable sine-wave signal of crankshaft

sensor (F552) due to:

- missing hole in flywheel, for example due to

fouling

43-1 Interruption or short circuit/short circuit to supply/

short circuit to earth in the camshaft sensor

(F558) on pin A2 and/or A14 of the ECU

43-2 Unacceptable sine-wave signal of camshaft

sensor (F558) due to:

- loose pulse plate

43-4 Missing or unacceptable sine-wave signal of

camshaft sensor (F558) due to:

- interruption on pin A2 and/or A14 of the ECU

- short circuit to earth on pin A2 of the ECU

- short circuit to supply on pin A2 of the ECU

- short circuit between pins A2 and A14 of the

ECU

43-8 Synchronisation signal from camshaft sensor

(F558) faulty or missing under dynamic

conditions due to:

- contact resistance in connection points of

camshaft sensor

- faulty camshaft sensor

- mechanical damage of the pulse plate or

camshaft sensor

- interruption on pin A14 of the ECU

- too low a voltage level of camshaft signal

- No noticeable system limitation in UPEC

- Longer start time before engine fires

- Longer start time before engine fires

- Longer start time before engine fires

- Longer start time before engine fires

UPEC fault codes

2

44-1 Excessive engine speed caused by:

- downhill driving

- incorrect changing down into a lower gear

45-1 Signal measurement via coolant temperature

sensor (F566) not correct due to:

- interruption on pin A22 and/or A5 of the ECU

45-2 Signal measurement via coolant temperature

sensor (F566) not correct due to:

- short circuit to earth on pin A22 of the ECU

- short circuit between pins A22 and A5 of the

ECU

45-4 No signal measurement via coolant temperature

sensor (F566) due to:

- internal ECU fault

46-1 Boost pressure signal measurement via inlet air

boost pressure/temperature sensor (F649) not

correct due to:

- short circuit to supply on pin A12 and/or A23

of the ECU

46-2 Boost pressure signal measurement via inlet air

boost pressure/temperature sensor (F649) not

correct due to:

- interruption on pin A23 and/or A12 of the

ECU

- short circuit to earth on pin A23 and/or A12

of the ECU

- No noticeable system limitation in UPEC

- Thermometer gives no reading

- ECU switches to default replacement value

for engine coolant temperature

- Thermometer gives no reading

- ECU switches to default replacement value

for engine coolant temperature

- Thermometer gives no reading

- ECU switches to default replacement value

for coolant temperature

- Reduced engine output

- ECU switches to default replacement value

for boost pressure

- Reduced engine output

- ECU switches to default replacement value

for boost pressure

©

200438 1-7

Page 34

UPEC

2

UPEC fault codes

Fault code Fault code description with possible cause Symptom

46-4 No boost pressure signal measurement via inlet

air boost pressure/temperature sensor (F649)

due to:

- internal ECU fault

47-1 Inlet air temperature signal measurement via inlet

air boost pressure/temperature sensor (F649) not

correct due to:

- interruption on pin A21 and/or A17 of the

ECU

47-2 Inlet air temperature signal measurement via inlet

air boost pressure/temperature sensor (F649) not

correct due to:

- short circuit to earth on pin A21 of the ECU

- short circuit between pins A21 and A17 of

the ECU

47-4 No inlet air temperature signal measurement via

inlet air boost pressure/temperature sensor

(F649) due to:

- internal ECU fault

48-1 Signal measurement via fuel temperature sensor

(F565) not correct due to:

- interruption on pin A6 and/or A11 of the ECU

48-2 Signal measurement via fuel temperature sensor

(F565) not correct due to:

- short circuit to earth on pin A11 of the ECU

- short circuit between pins A11 and A6 of the

ECU

- Reduced engine output

- ECU switches to default replacement value

for boost pressure

- ECU switches to default replacement value

for inlet air temperature

- ECU switches to default replacement value

for inlet air temperature

- ECU switches to default replacement value

for inlet air temperature

- ECU switches to default replacement value

for fuel temperature

- ECU switches to default replacement value

for fuel temperature

DAVIE XD diagnostics manual

48-4 No fuel temperature signal measurement via fuel

temperature sensor (F565) due to:

- internal ECU fault

51-1 Signal measurement on potentiometer in

accelerator pedal sensor (F672) not correct due

to:

- short circuit to supply on pin B23 of the ECU

- interruption on pin B35 of the ECU

- short circuit between pin B16 and pin B23 of

the ECU

- moisture in connector connection

51-2 Signal measurement on potentiometer in

accelerator pedal sensor (F672) not correct due

to:

- interruption on pin B16 and/or pin B23 of the

ECU

- short circuit to earth on pin B16 and/or pin

B23 of the ECU

- short circuit between pin B16 and pin B35 of

the ECU

- short circuit between pin B23 and pin B35 of

the ECU

- moisture in connector connection

51-4 No signal measurement on potentiometer in

accelerator pedal sensor (F672) due to:

- internal ECU fault

- ECU switches to default replacement value

for fuel temperature

- Indistinct response to accelerator pedal

- Engine runs at increased idling speed

- Indistinct response to accelerator pedal

- Engine runs at increased idling speed

- Indistinct response to accelerator pedal

- Engine runs at increased idling speed

1-8

©

200438

Page 35

UPEC

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

51-8 Conflict between position of idling switch and

output signal of potentiometer in accelerator

pedal sensor (F672) due to:

- short circuit to supply on pin B16 of the ECU

- short circuit between pin B17 and pin B25 of

the ECU

- short circuit to earth on pin B17 of the ECU

- moisture in connector connection

Conflict between position of idling switch and

output signal of potentiometer in accelerator

pedal sensor (F672) due to:

- interruption on pin B17 and/or pin B25 of the

ECU

52-8 After the ignition had been switched on, the brake

pedal was operated several times (20x) while the

accelerator pedal was still being operated

53-1 Short circuit to supply of vehicle speed signal of

MTCO (B525) on pin B29 of the ECU

53-2 Short circuit to earth of vehicle speed signal of

MTCO (B525) on pin B29 of the ECU

- No response to accelerator pedal

- Engine runs at increased idling speed

- When the accelerator pedal is depressed

the idling speed of the engine increases

gradually.

- No noticeable system limitation

- Cruise control cannot be activated

- Variable vehicle speed limitation function

cannot be activated

- Engine brake can be activated with the

vehicle stationary

- Control function for engine speed control

cannot be activated

- Cruise control cannot be activated

- Variable vehicle speed limitation function

cannot be activated

- Engine brake can be activated with the

vehicle stationary

- Control function for engine speed control

cannot be activated

UPEC fault codes

2

53-8 Unacceptable vehicle speed signal of MTCO

(B525) on pin B29 of the ECU due to:

- interruption on pin B29

- excessive vehicle speed for example due to

incorrectly programmed K factor in MTCO

- loose pulse ring in gearbox

54-1 Too high a voltage on the atmospheric pressure

sensor in the ECU due to:

- internal fault in ECU

54-2 Too low a voltage on the atmospheric pressure

sensor in the ECU due to:

- internal fault in ECU

54-4 Internal ECU fault relating to the atmospheric

pressure sensor

55-8 Frequency of speed signal of electronically

controlled fan clutch (B335) on pin B30 of the

ECU is too high due to:

- mechanically blocked fan clutch

- Cruise control cannot be activated

- Variable vehicle speed limitation function

cannot be activated

- Engine brake can be activated with the

vehicle stationary

- Control function for engine speed control

cannot be activated

- No noticeable system limitation in UPEC

- No noticeable system limitation in UPEC

- No noticeable system limitation in UPEC

- No noticeable system limitation in UPEC

©

200438 1-9

Page 36

UPEC

2

UPEC fault codes

Fault code Fault code description with possible cause Symptom

55-9 Unacceptable frequency of speed signal of

electronically controlled fan clutch (B335) on pin

B30 of the ECU in relation to engine speed due

to:

- interruption on pin B30

- short circuit to supply or to earth on pin B30

- fan leakage

- no supply voltage

56-1 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipe of cylinder 1

- defective/clogged injector of cylinder 1

- air in fuel system

- internal leakage of pump unit of cylinder 1

- clogged injector pipe of cylinder 1

- too low a combustion pressure in cylinder 1

caused by a mechanical defect of the engine

(valve seal etc.)

56-2 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipe of cylinder 5

- defective/clogged injector of cylinder 5

- air in fuel system

- internal leakage of pump unit of cylinder 5

- clogged injector pipe of cylinder 5

- too low a combustion pressure in cylinder 5

caused by a mechanical defect of the engine

(valve seal etc.)

56-3 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 1 and 5

- defective/clogged injectors of cylinders 1

and 5

- air in fuel system

- internal leakage of pump units of cylinders 1

and 5

- clogged injector pipes of cylinders 1 and 5

- too low a combustion pressure in cylinders 1

and 5 caused by a mechanical defect of the

engine (valve seal etc.)

56-4 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipe of cylinder 3

- defective/clogged injector of cylinder 3

- air in fuel system

- internal leakage of pump unit of cylinder 3

- clogged injector pipe of cylinder 3

- too low a combustion pressure in cylinder 3

caused by a mechanical defect of the engine

(valve seal etc.)

- Reduced engine power (coolant

temperature may increase excessively as a

result of which the coolant overheating

safety may be activated)

- Irregular engine running and reduced

engine power

- Irregular engine running and reduced

engine power

- Irregular engine running and reduced

engine power

- Irregular engine running and reduced

engine power

DAVIE XD diagnostics manual

1-10

©

200438

Page 37

UPEC

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

56-5 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 1 and 3

- defective/clogged injectors of cylinders 1

and 3

- air in fuel system

- internal leakage of pump units of cylinders 1

and 3

- clogged injector pipes of cylinders 1 and 3

- too low a combustion pressure in cylinders 1

and 3 caused by a mechanical defect of the

engine (valve seal etc.)

56-6 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 3 and 5

- defective/clogged injectors of cylinders 3

and 5

- air in fuel system

- internal leakage of pump units of cylinders 3

and 5

- clogged injector pipes of cylinders 3 and 5

- too low a combustion pressure in cylinders 3

and 5 caused by a mechanical defect of the

engine (valve seal etc.)

- Irregular engine running and reduced

engine power

- Irregular engine running and reduced

engine power

UPEC fault codes

2

56-7 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 1, 3

and 5

- defective/clogged injectors of cylinders 1, 3

and 5

- air in fuel system

- internal leakage of pump units of cylinders 1,

3 and 5

- clogged injector pipes of cylinders 1, 3 and 5

- too low a combustion pressure in cylinders

1, 3 and 5 caused by a mechanical defect of

the engine (valve seal etc.)

56-8 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipe of cylinder 6

- defective/clogged injector of cylinder 6

- air in fuel system

- internal leakage of pump unit of cylinder 6

- clogged injector pipe of cylinder 6

- too low a combustion pressure in cylinder 6

caused by a mechanical defect of the engine

(valve seal etc.)

- Irregular engine running and reduced

engine power

- Irregular engine running and reduced

engine power

©

200438 1-11

Page 38

UPEC

2

UPEC fault codes

Fault code Fault code description with possible cause Symptom

56-9 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 1 and 6

- defective/clogged injectors of cylinders 1

and 6

- air in fuel system

- internal leakage of pump units of cylinders 1

and 6

- clogged injector pipes of cylinders 1 and 6

- too low a combustion pressure in cylinders 1

and 6 caused by a mechanical defect of the

engine (valve seal etc.)

56-10 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 5 and 6

- defective/clogged injectors of cylinders 5

and 6

- air in fuel system

- internal leakage of pump units of cylinders 5

and 6

- clogged injector pipes of cylinders 5 and 6

- too low a combustion pressure in cylinders 5

and 6 caused by a mechanical defect of the

engine (valve seal etc.)

- Irregular engine running and reduced

engine power

- Irregular engine running and reduced

engine power

DAVIE XD diagnostics manual

56-11 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 1, 5

and 6

- defective/clogged injectors of cylinders 1, 5

and 6

- air in fuel system

- internal leakage of pump units of cylinders 1,

5 and 6

- clogged injector pipes of cylinders 1, 5 and 6

- too low a combustion pressure in cylinders

1, 5 and 6 caused by a mechanical defect of

the engine (valve seal etc.)

56-12 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 3 and 6

- defective/clogged injectors of cylinders 3

and 6

- air in fuel system

- internal leakage of pump units of cylinders 3

and 6

- clogged injector pipes of cylinders 3 and 6

- too low a combustion pressure in cylinders 3

and 6 caused by a mechanical defect of the

engine (valve seal etc.)

- Irregular engine running and reduced

engine power

- Irregular engine running and reduced

engine power

1-12

©

200438

Page 39

UPEC

DAVIE XD diagnostics manual

Fault code Fault code description with possible cause Symptom

56-13 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 1, 3

and 6

- defective/clogged injectors of cylinders 1, 3

and 6

- air in fuel system

- internal leakage of pump units of cylinders 1,

3 and 6

- clogged injector pipes of cylinders 1, 3 and 6

- too low a combustion pressure in cylinders

1, 3 and 6 caused by a mechanical defect of

the engine (valve seal etc.)

56-14 Irregular engine running detected by the ECU due

to:

- fuel leak of injector pipes of cylinders 3, 5

and 6

- defective/clogged injectors of cylinders 3, 5

and 6

- air in fuel system

- internal leakage of pump units of cylinders 3,

5 and 6

- clogged injector pipes of cylinders 3, 5 and 6

- too low a combustion pressure in cylinders

3, 5 and 6 caused by a mechanical defect of

the engine (valve seal etc.)