Page 1

DMCI

XF105System and component information

Page 2

Page 3

©200528 DAF Trucks N.V., Eindhoven,

The Netherlands.

In the interest of continuing product development,

DAF reserves the right to change specifications

or products at any time without prior notice.

No part of this publication may be reproduced

and/or published by printing, by photocopying, on

microfilm or in any way whatsoever without the

prior consent in writing of DAF Trucks N.V.

©

200528 DW332094

Page 4

Page 5

XF105 series

STRUCTURE

Structure

TECHNICAL DATA

0

DMCI ENGINE MANAGEMENT SYSTEM

1

©

200528

Page 6

Page 7

TECHNICAL DATA

XF105 series

Contents

CONTENTS

Page Date

1. DMCI ENGINE MANAGEMENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200528

1.1 Power supply and earth of DMCI electronic unit . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200528

1.2 DMCI electronic unit CAN connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200528

1.3 Status signals DMCI electronic unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 . . . . . 200528

1.4 Accelerator pedal sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 . . . . . 200528

1.5 Coolant temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6 . . . . . 200528

1.6 2

1.7 Inlet air boost pressure and temperature sensor. . . . . . . . . . . . . . . . . . . . 1-10 . . . . 200528

1.8 Fuel pressure and temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13 . . . . 200528

1.9 Engine oil pressure and temperature sensor. . . . . . . . . . . . . . . . . . . . . . . 1-16 . . . . 200528

1.10 Crankshaft sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19 . . . . 200528

1.11 Camshaft sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21 . . . . 200528

1.12 Engine oil level sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23 . . . . 200528

1.13 Switches (manual gearbox) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25 . . . . 200528

1.14 Switches (AS Tronic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26 . . . . 200528

1.15 Extra bulkhead lead-through functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27 . . . . 200528

1.16 Red warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28 . . . . 200528

1.17 Starter motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29 . . . . 200528

1.18 Glow components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30 . . . . 200528

1.19 Waste gate valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31 . . . . 200528

1.20 Exhaust brake valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33 . . . . 200528

1.21 DEB solenoid valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34 . . . . 200528

1.22 Pump unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36 . . . . 200528

1.23 Injector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38 . . . . 200528

1.24 Electronically controlled fan clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40 . . . . 200528

nd

coolant temperature sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8 . . . . . 200528

0

©

200528 1

Page 8

0

TECHNICAL DATA

Contents XF105 series

2

©

200528

Page 9

TECHNICAL DATA

XF105 series

DMCI engine management system

1. DMCI ENGINE MANAGEMENT SYSTEM

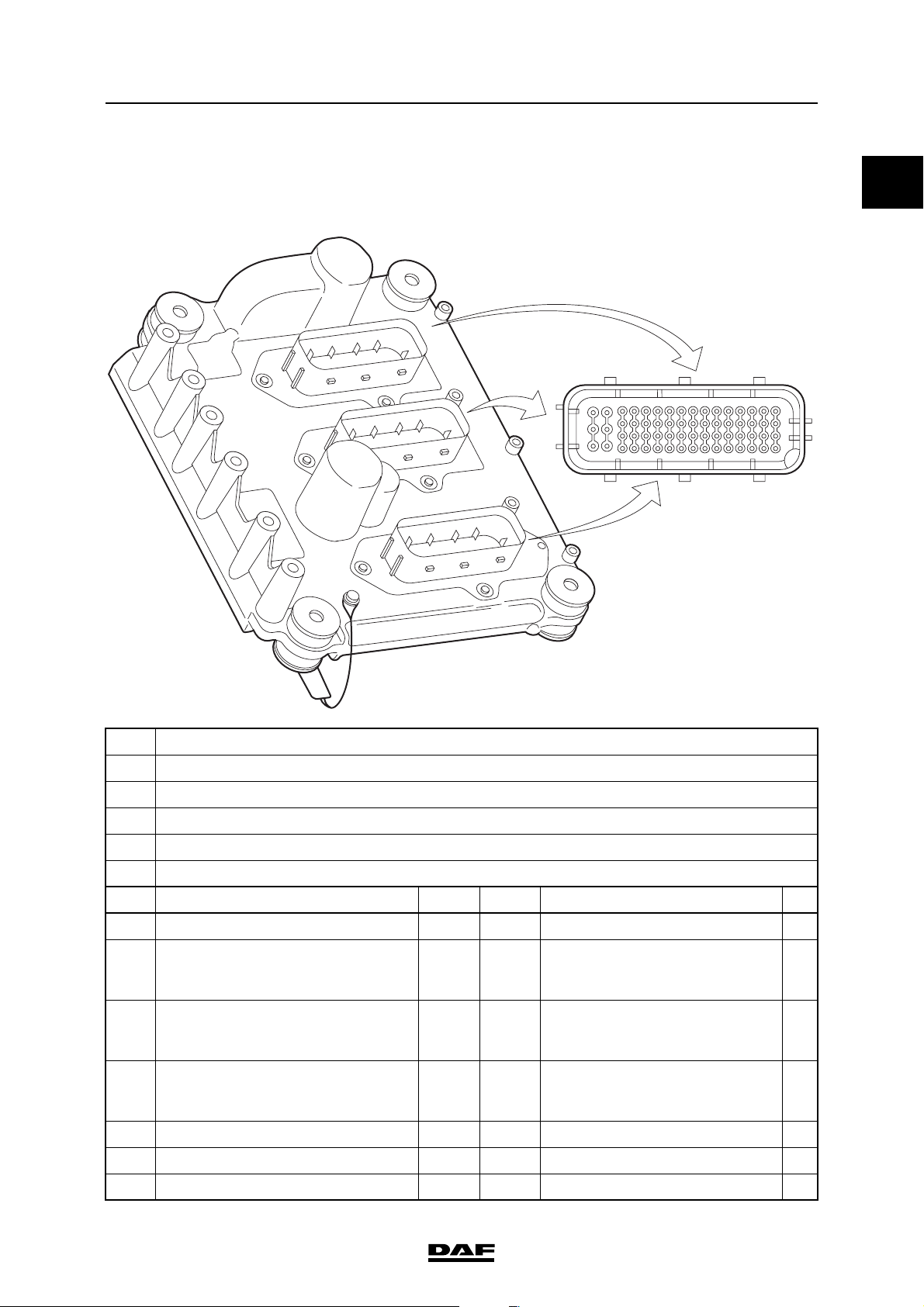

1.1 POWER SUPPLY AND EARTH OF DMCI ELECTRONIC UNIT

A

41

45

49

53

57

60 62

C

B

0

21

25

29

33

37

1 4591317

i400726

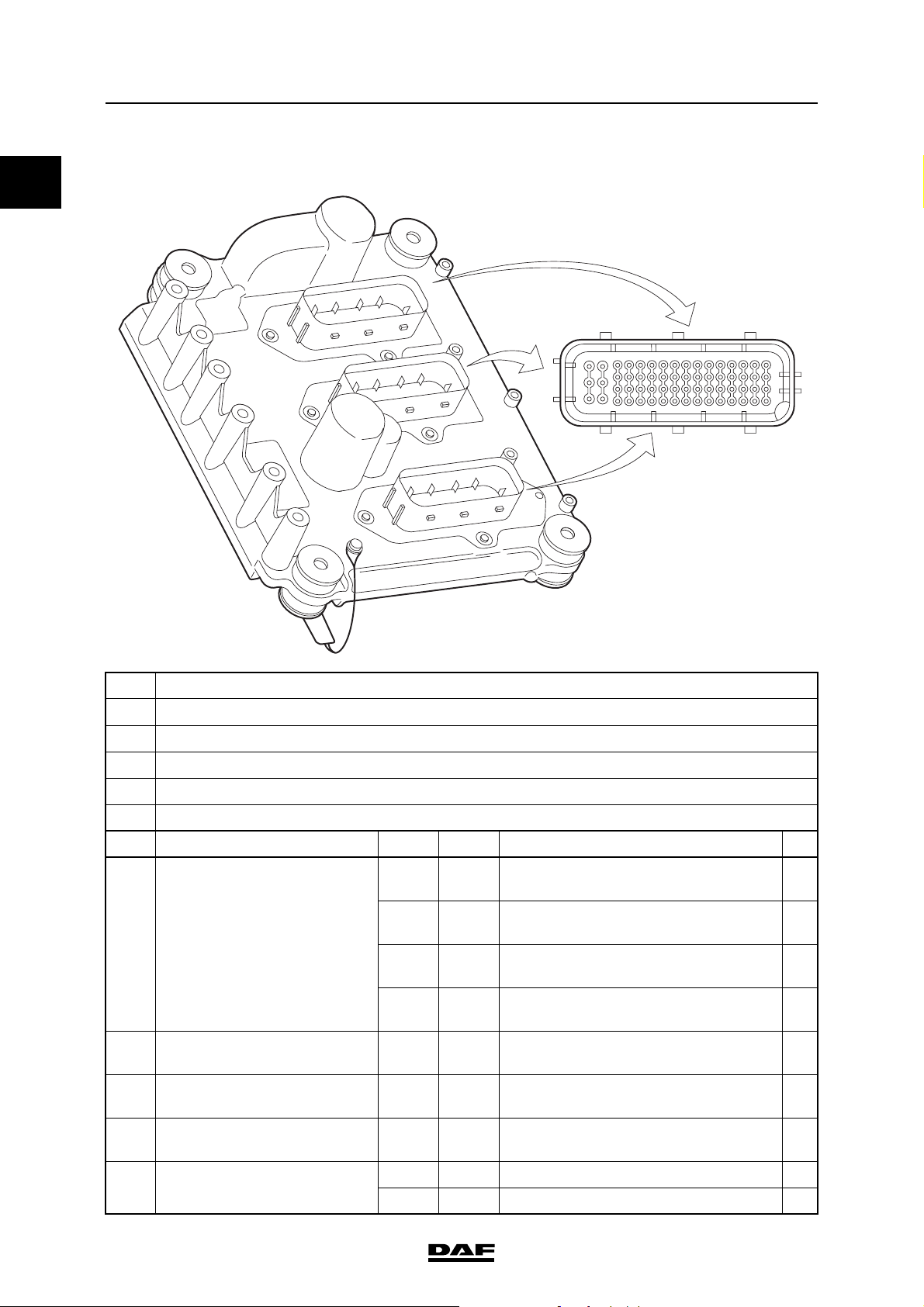

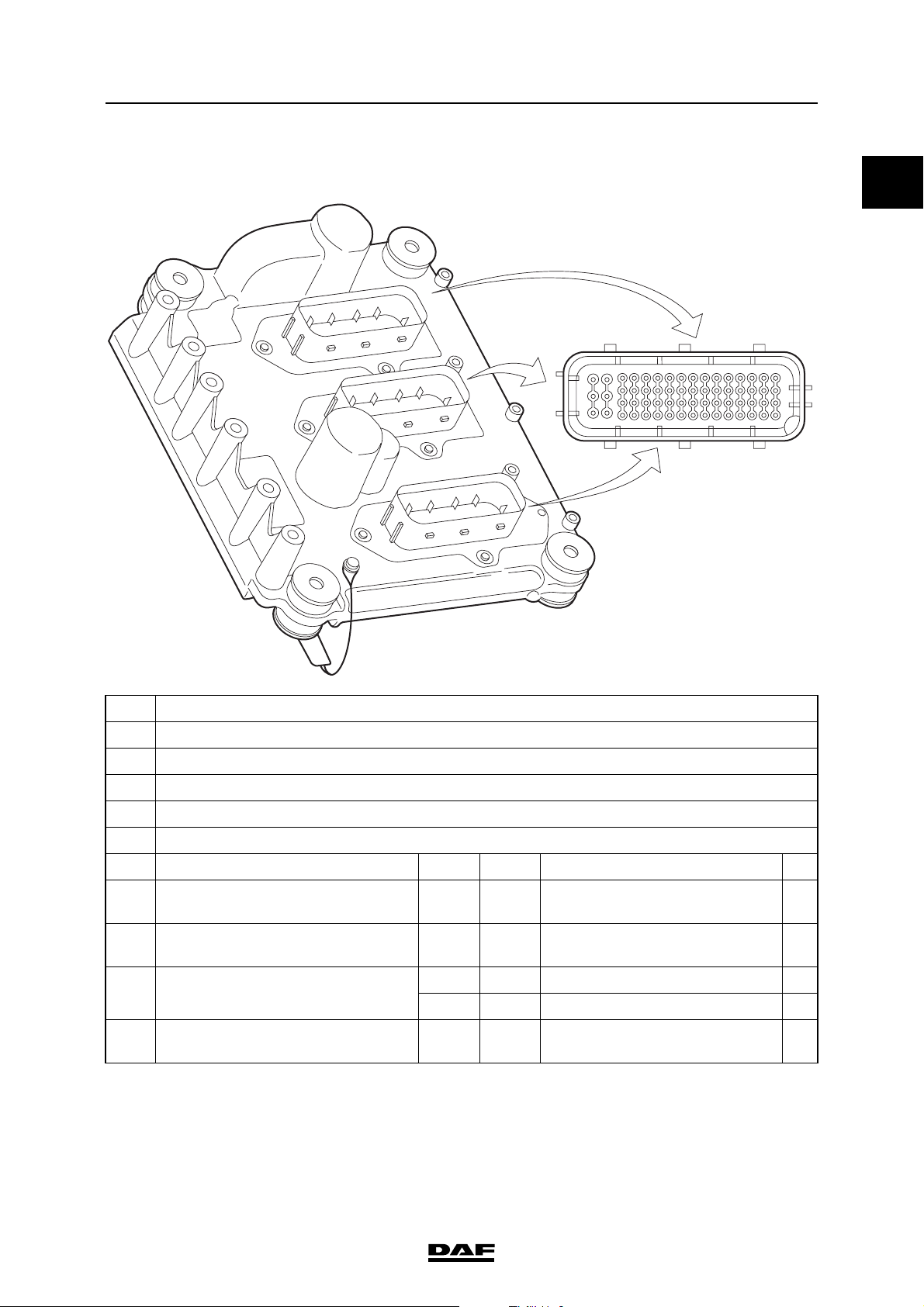

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

B44 Power supply after ignition (G426) Ubat V DC Ignition on

B57 Earth < 0.5 VDC Voltage loss measurement with

as many consumers as possible

switched on.

B58 Earth < 0.5 VDC Voltage loss measurement with

as many consumers as possible

switched on.

B59 Earth < 0.5 VDC Voltage loss measurement with

as many consumers as possible

switched on.

B60 Power supply before ignition (G126) Ubat VDC

B61 Power supply before ignition (G126) Ubat VDC

B62 Power supply before ignition (G126) Ubat VDC

©

200528 1-1

Page 10

0

TECHNICAL DATA

DMCI engine management system XF105 series

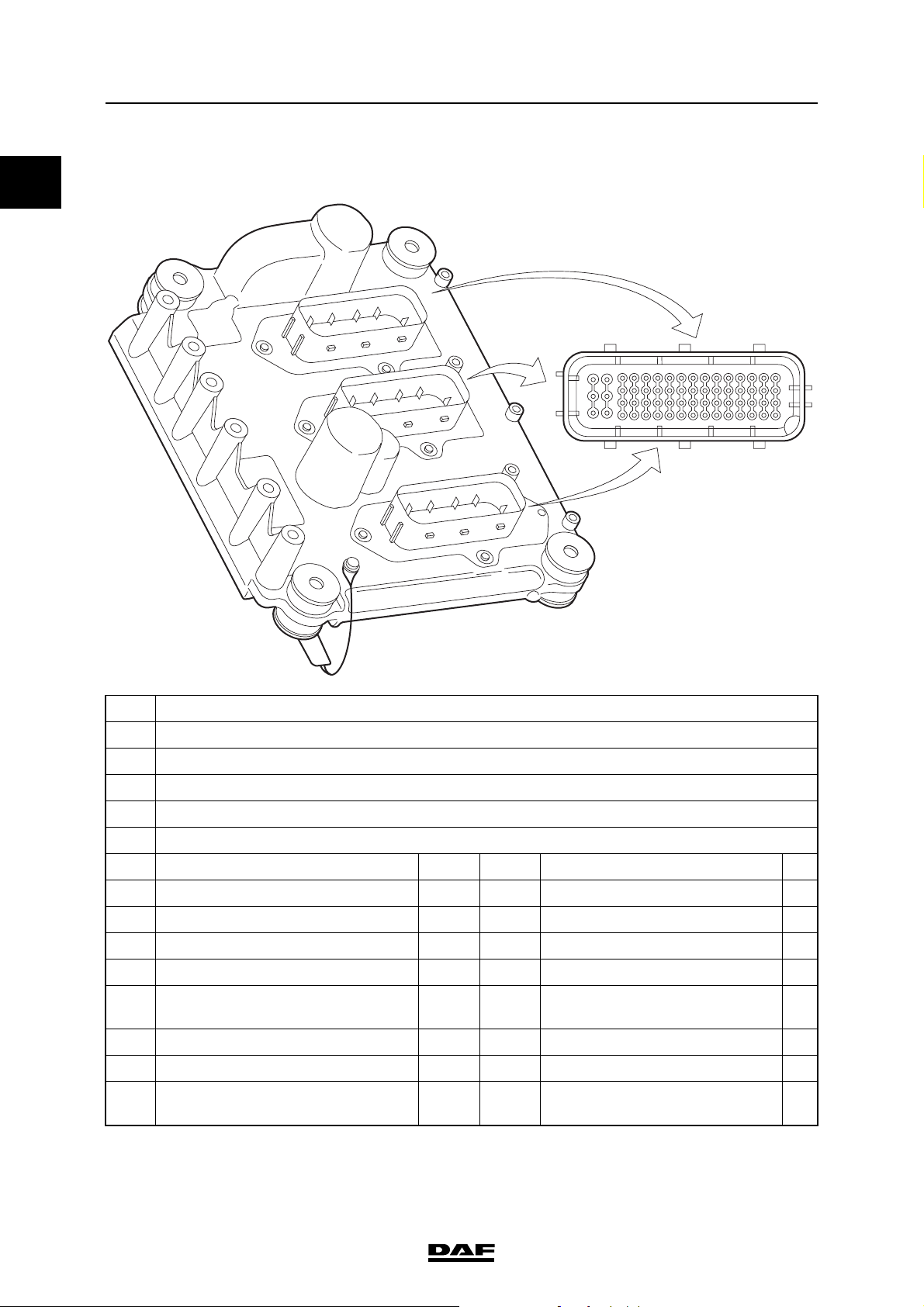

1.2 DMCI ELECTRONIC UNIT CAN CONNECTIONS

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

B27 V-CAN1-H According to ISO 11898

B35 V-CAN1-L According to ISO 11898

B42 V-CAN1 through connection According to ISO 11898

B45 V-CAN2-H According to ISO 11898 X

B46 V-CAN1 terminating resistance

According to ISO 11898 X

through connection

B50 V-CAN1 through connection According to ISO 11898 X

B53 V-CAN2-L According to ISO 11898 X

B54 V-CAN1 terminating resistance

According to ISO 11898

through connection

V-CAN1 terminating resistance ≥120

V-CAN2 terminating resistance ≥120

(1) Check the resistance by measuring at connection points B46 and B50 of the electronic unit.

(2) Check the resistance by measuring at connection points B45 and B53 of the electronic unit.

1-2

(1)

(2)

©

200528

Page 11

TECHNICAL DATA

XF105 series

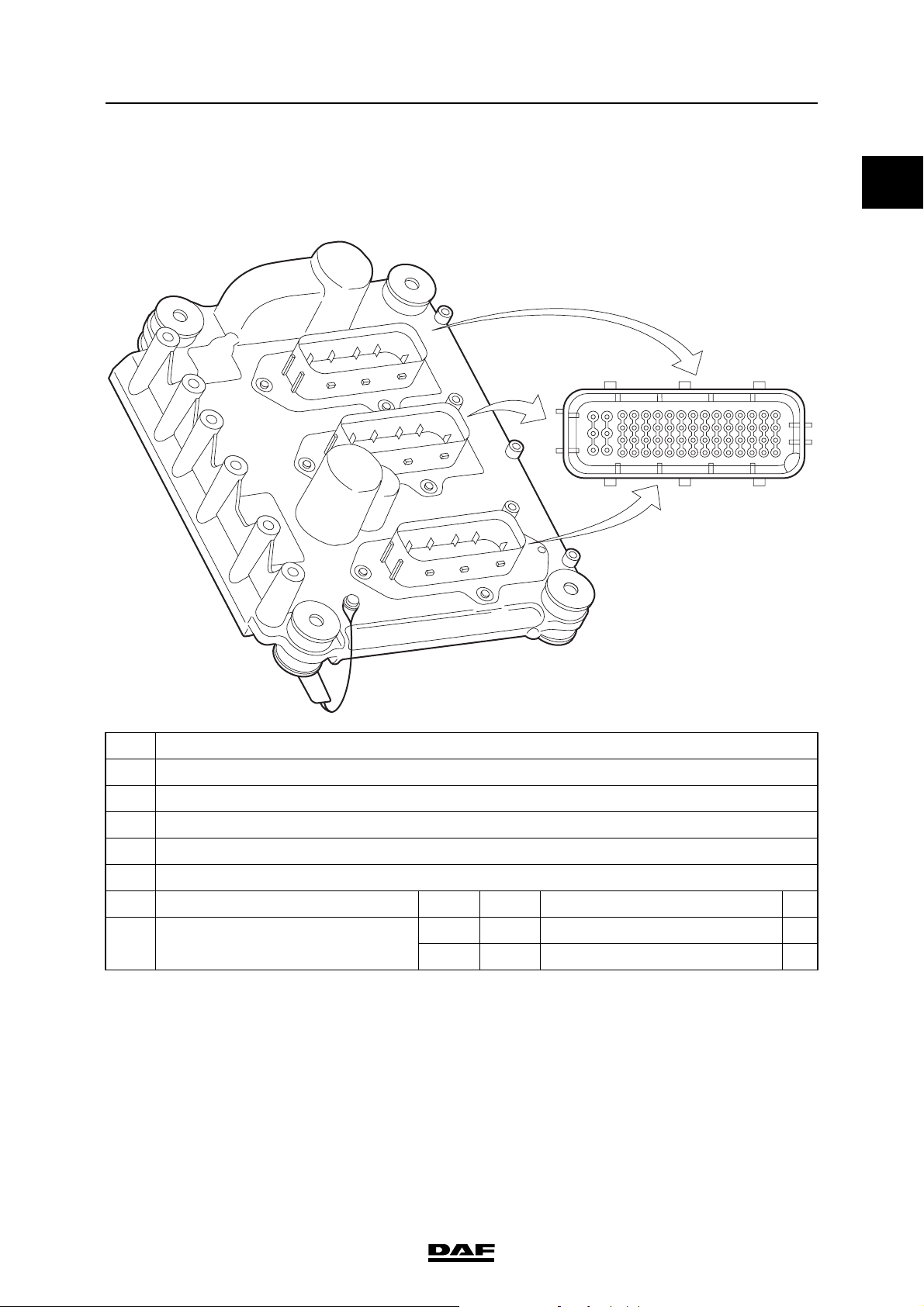

1.3 STATUS SIGNALS DMCI ELECTRONIC UNIT

A

C

B

DMCI engine management system

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

0

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

B51 Input signal, service brake (G469) Ubat V DC Brake pedal not operated

0 V DC Brake pedal operated

©

200528 1-3

Page 12

0

TECHNICAL DATA

DMCI engine management system XF105 series

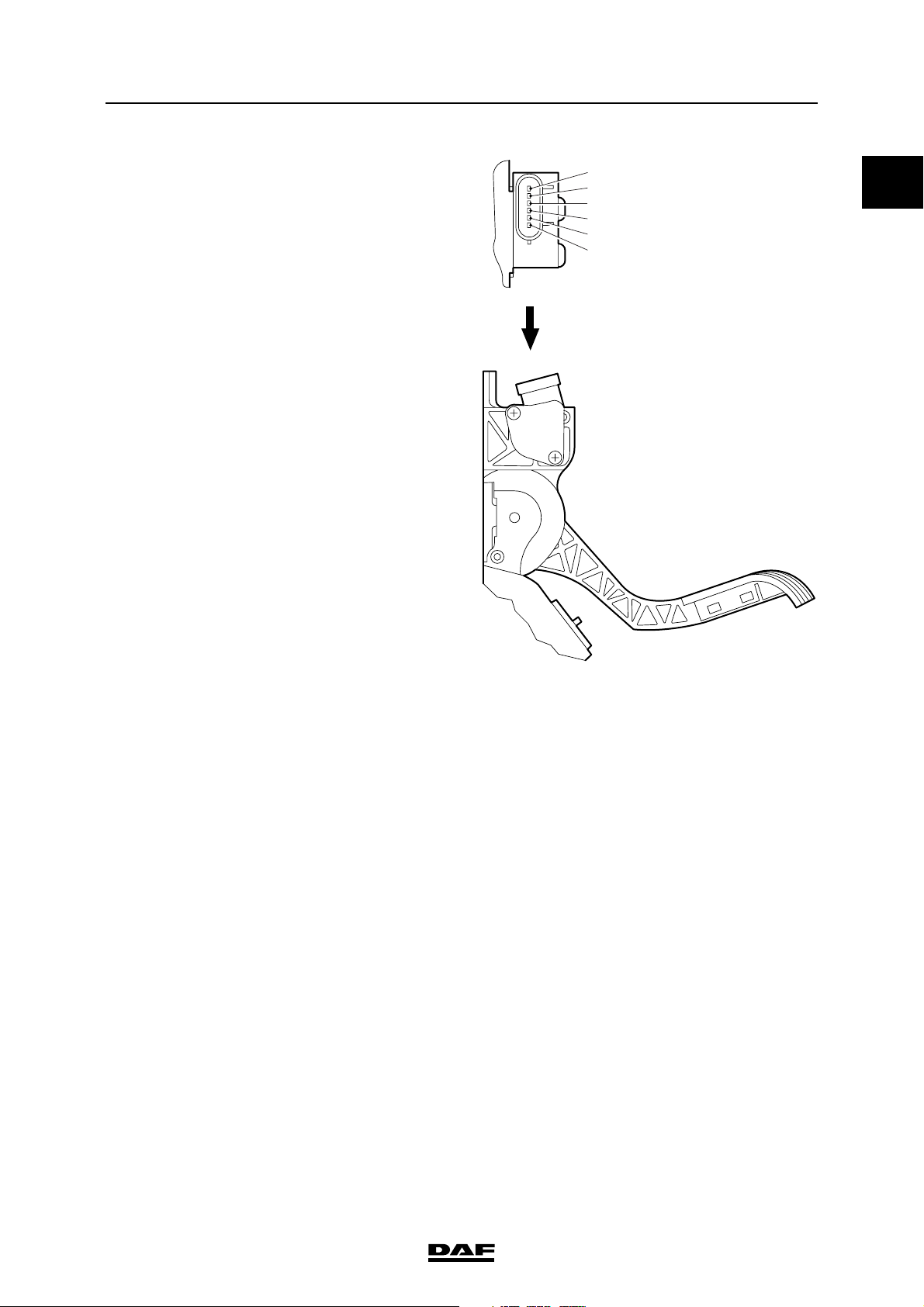

1.4 ACCELERATOR PEDAL SENSOR

A

C

B

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

29

33

37

41

45

49

53

57

60 62

1 45913172125

i400726

AB CDE F

B33 Input signal accelerator pedal

sensor (F672)

0.325 -

0.500

0.675 -

V DC Idling, accelerator pedal not operated

(0%)

V DC Switching point idling switch (circa 10%) X

X

0.875

3.000 -

V DC Full load (circa 85%) X

3.400

3.550 -

V DC Kickdown (circa 100%) X

4.265

B34 Power supply, accelerator

5V DC

pedal sensor (F672)

B37 Earth, accelerator pedal

0V DC

sensor (F672)

B38 Accelerator pedal sensor

0V DC

earth, idling switch (F672)

B41 Accelerator pedal sensor input

signal, idling switch (F672)

1-4

5 V DC Accelerator pedal not operated X

0 V DC Accelerator pedal operated circa 10% X

©

200528

Page 13

TECHNICAL DATA

XF105 series

Potentiometer resistance

value (B - C)

Potentiometer output

resistance value (A - B)

Potentiometer output

resistance value (A - C)

Resistance value across

idling switch (open position)

Resistance value across

idling switch (closed position)

(1) Accelerator pedal not operated

(2) Accelerator pedal operated

(1)

(1)

(1)

(2)

1000 ≥ 40%

1500 ≥ 40%

2500 ≥ 40%

1000 ≥ 40%

DMCI engine management system

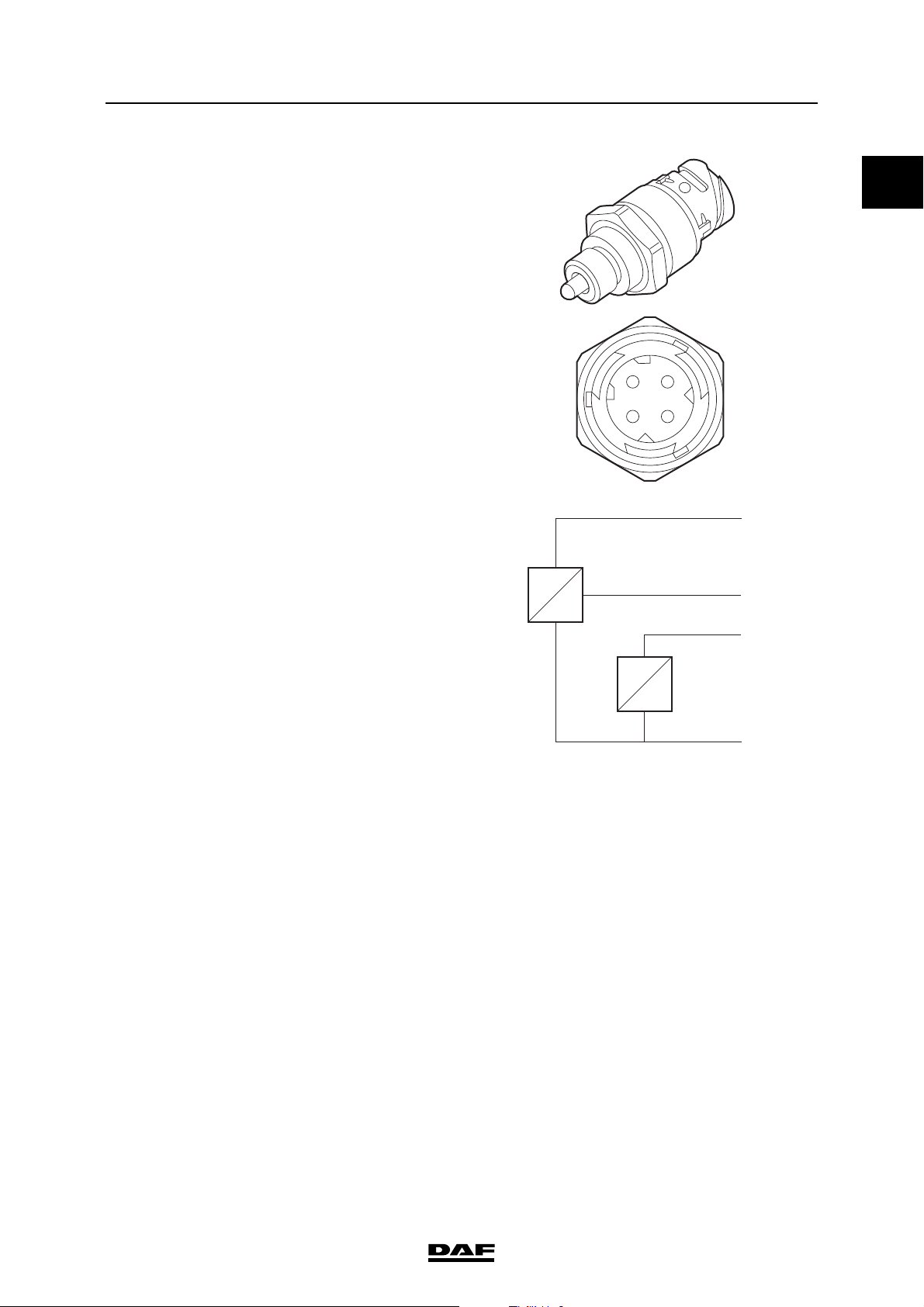

A

B

C

D

E

F

0

A. Potentiometer signal

B. Mass

C. Potentiometer supply voltage

D. Idling switch earth

E. Not in use

F. Idling switch signal

I400438

©

200528 1-5

Page 14

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.5 COOLANT TEMPERATURE SENSOR

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

C25 Input signal, coolant temperature

(F566)

C26 Earth, coolant temperature sensor

5 V DC Open voltage, with detached

connector

0V DC

X

(F566)

1-6

©

200528

Page 15

TECHNICAL DATA

XF105 series

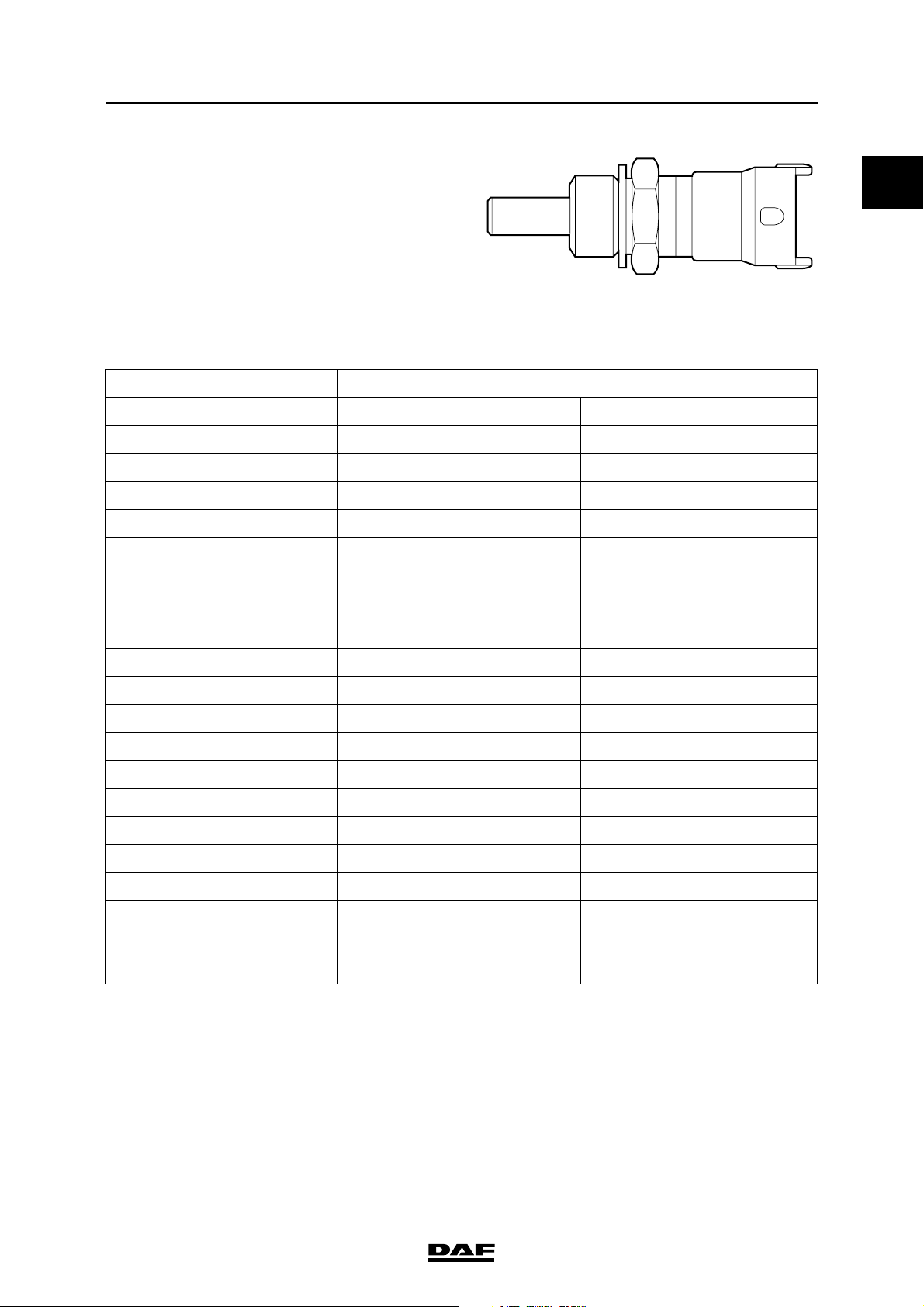

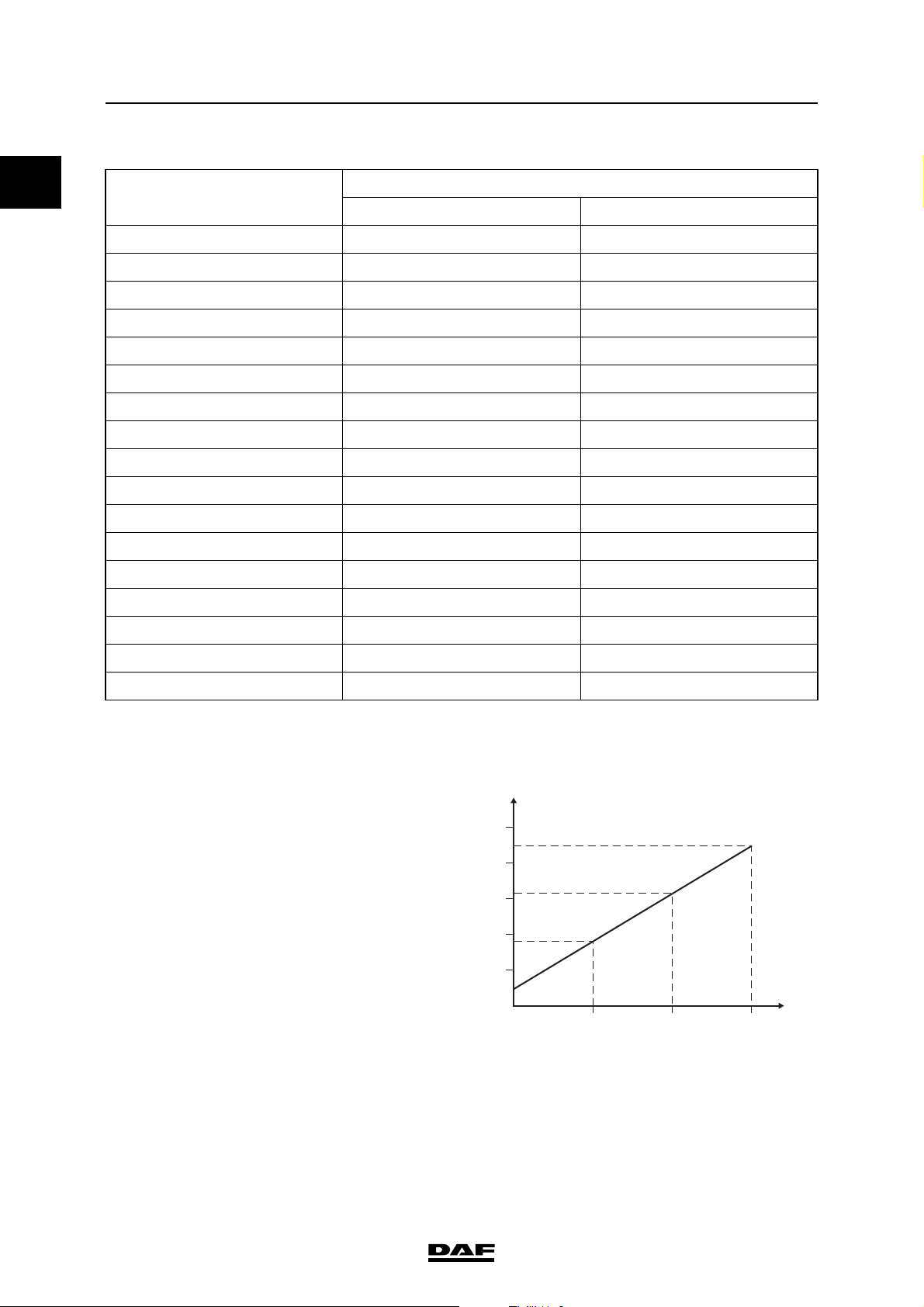

Coolant temperature sensor

Model NTC

Resistance in relation to measured temperature

Temperature (C) Resistance ()

Minimum Maximum

- 40 38313 52926

- 30 22307 30194

-20 13402 17718

-10 8244 10661

0 5227 6623

DMCI engine management system

0

i 400440

(1)

10 3390 4217

20 2262 2760

25 1870 2260

30 1553 1866

40 1080 1277

50 771 900

60 555 639

70 408 465

80 304 342

90 230 257

100 178 196

110 136 152

120 106 119

130 84 95

140 67 76

(1) Check the resistance by measuring on the connection points of the sensor.

©

200528 1-7

Page 16

TECHNICAL DATA

DMCI engine management system XF105 series

0

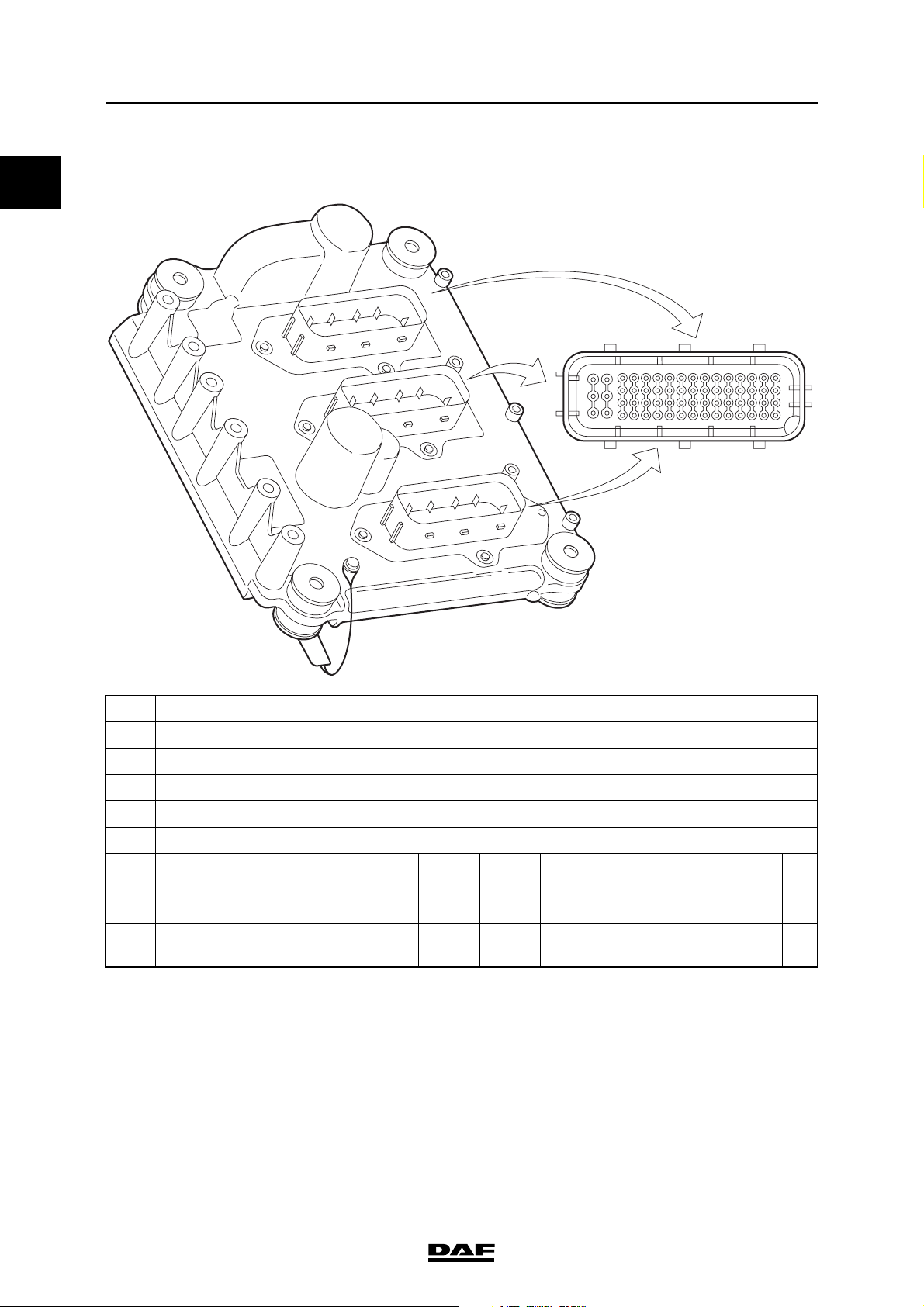

1.6 2

nd

COOLANT TEMPERATURE SENSOR

A

C

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

A37 Input signal, coolant temperature

(F743)

A38 Earth, coolant temperature sensor

5 V DC Open voltage, with detached

connector

0V DC

X

(F743)

1-8

©

200528

Page 17

TECHNICAL DATA

XF105 series

Resistance in relation to measured temperature

Temperature (C) Resistance ()

Minimum Maximum

- 40 87134 98852

- 30 44876 50910

-20 24215 27471

-10 13703 15545

0 7914 8978

10 4752 5390

20 2948 3344

40 1224 1388

50 8167 927

60 558 632

70 390 442

80 278 311

DMCI engine management system

0

90 201 227

100 148 168

110 110 124

120 83 95

Coolant temperature sensor

Model NTC

i401003

©

200528 1-9

Page 18

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.7 INLET AIR BOOST PRESSURE AND TEMPERATURE SENSOR

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

A27 Earth air inlet boost pressure and

0V DC

temperature sensor (F649)

A28 Supply voltage air inlet boost

pressure and temperature sensor

5 V DC Open voltage, with detached

connector

(F649)

A30 Input signal air inlet boost pressure

(F649)

A34 Input signal air inlet temperature

(F649)

1-10

0.5 V DC Air inlet pressure 0 bar X

4.5 V DC Air inlet pressure 4 bar X

5 V DC Open voltage, with detached

connector

©

200528

X

Page 19

TECHNICAL DATA

XF105 series

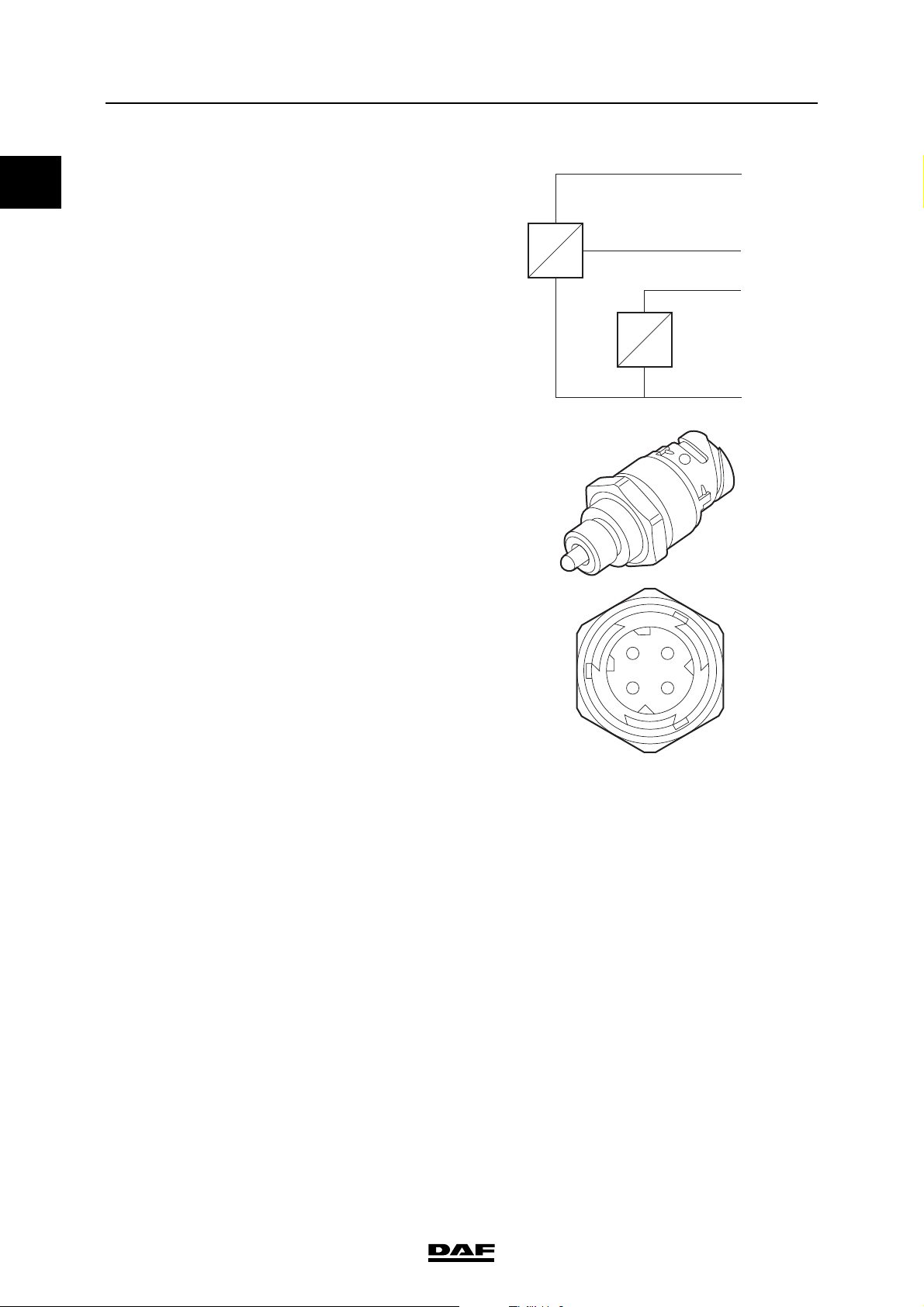

Colour of O-ring green

Type of temperature sensor NTC

Resistance value See table

DMCI engine management system

0

P

U

T

R

1. Mass

2. Temperature sensor output signal

3. Pressure sensor supply voltage

4. Pressure sensor output signal

i 400441

3

4

2

1

i400534

©

200528 1-11

Page 20

TECHNICAL DATA

DMCI engine management system XF105 series

0

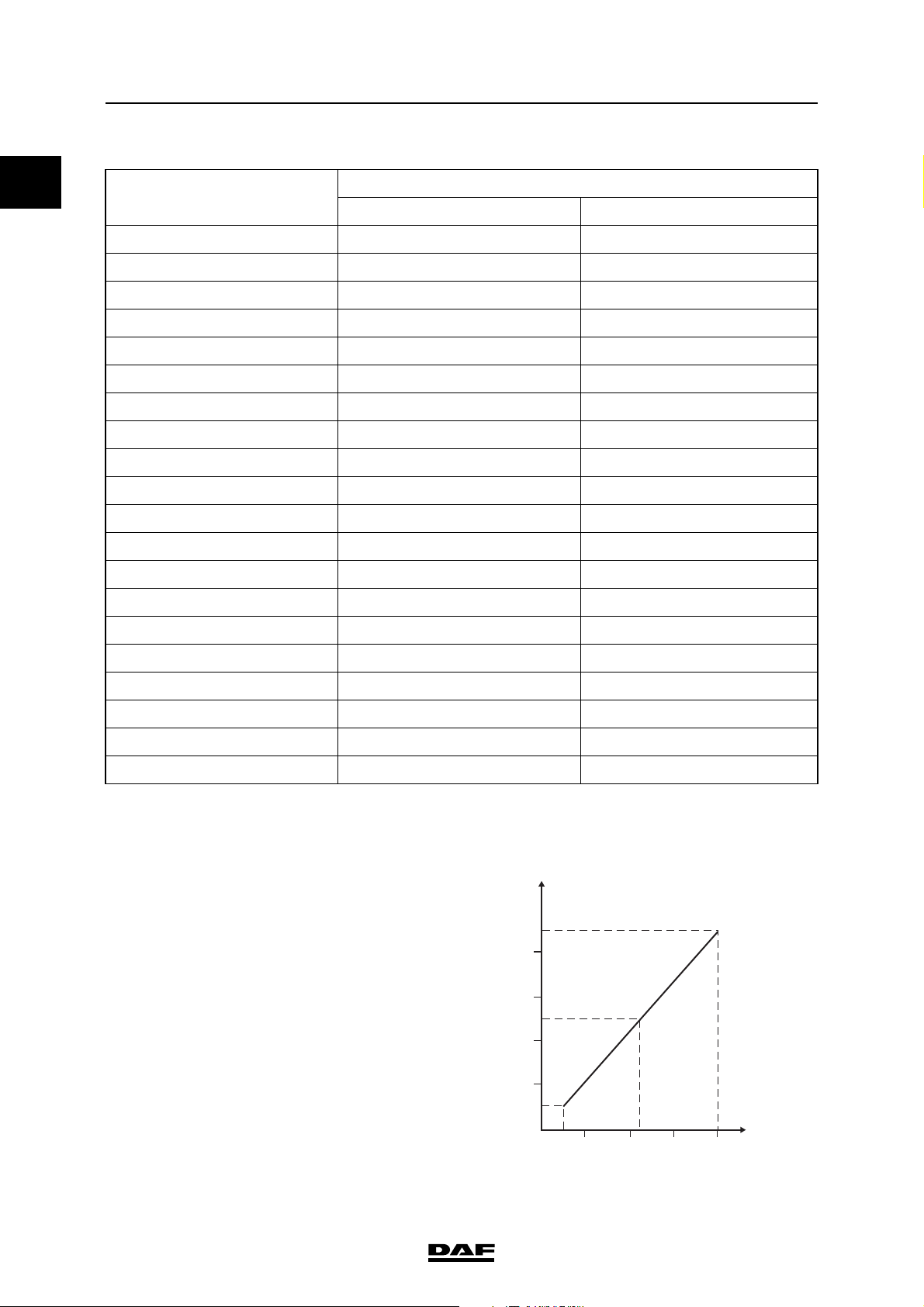

Resistance in relation to measured temperature

Temperature (C) Resistance ()

Minimum Maximum

- 40 38313 52926

- 30 22307 30194

-20 13402 17718

-10 8244 10661

0 5227 6623

10 3390 4217

20 2262 2760

25 1870 2260

30 1553 1866

40 1080 1277

50 771 900

60 555 639

70 408 465

80 304 342

(1)

90 230 257

100 178 196

110 136 152

120 106 119

130 84 95

140 67 76

(1) Check the resistance by measuring on connection points 1 and 2 of the sensor.

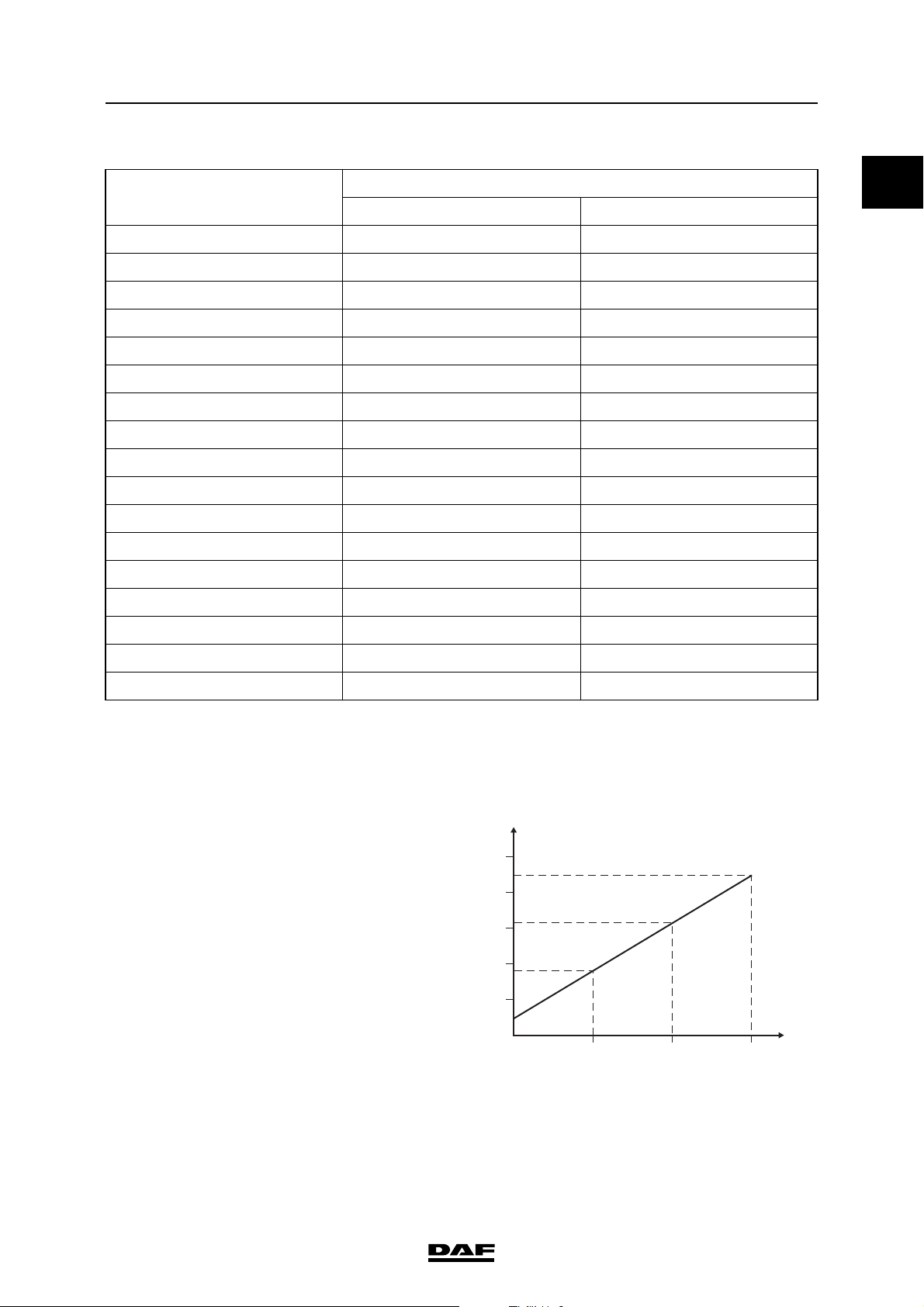

Type of pressure sensor piezoresistive

Pressure sensor output signal See graph

U

(V)

5

4

3

2

1-12

1

P

1 2 34

(bar)

i400836

©

200528

Page 21

TECHNICAL DATA

XF105 series

DMCI engine management system

1.8 FUEL PRESSURE AND TEMPERATURE SENSOR

A

C

B

0

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

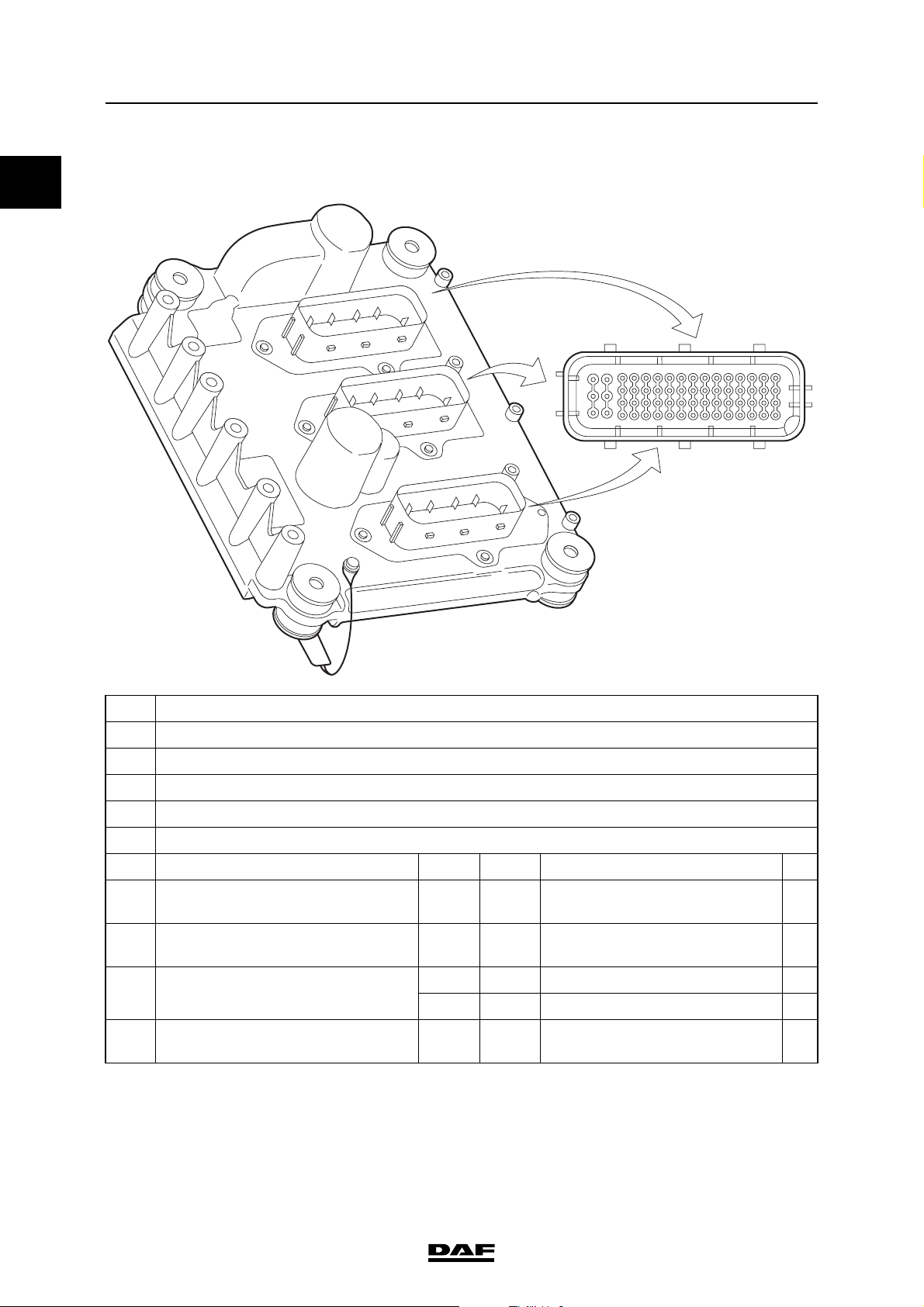

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

A41 Input signal fuel temperature (F713). 5 V DC Open voltage, with detached

X

connector

A42 Supply voltage fuel pressure and

temperature sensor (F713)

5 V DC Open voltage, with detached

connector

A45 Input signal fuel pressure (F713) 0.5 V DC Fuel pressure 0 bar X

4.5 V DC Fuel pressure 15 bar X

A46 Earth, fuel pressure and temperature

0V DC

sensor (F713)

©

200528 1-13

Page 22

TECHNICAL DATA

DMCI engine management system XF105 series

0

Gasket Copper ring

P

2

1

U

3

T

R

4

i400791

1. Pressure sensor supply voltage

2. Pressure sensor output signal

3. Temperature sensor output signal

4. Mass

Type of temperature sensor NTC

13

42

i400792

1-14

©

200528

Page 23

TECHNICAL DATA

XF105 series

Temperature sensor resistance value

Temperature (C) Resistance ()

- 30 24351 30653.2

- 20 13431 16594

- 10 7850 9095

0 4488 5372

10 2740 3236

20 1727 2010

30 1120 1291

40 746 850

50 510 574

60 355 396

70 253 279

80 185 198

DMCI engine management system

(1)

0

Minimum Maximum

90 134 145

100 100 107

110 75 81

120 57 62

130 44 48

(1) Check the resistance by measuring on connection points 3 and 4 of the sensor.

Type of pressure sensor piezo-capacitive

Voltage signal pressure sensor

U

(V)

5

4

3

2

1

5 10 15

©

200528 1-15

(bar)

P

i400835

Page 24

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.9 ENGINE OIL PRESSURE AND TEMPERATURE SENSOR

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

C29 Input signal engine oil temperature

(F744)

C30 Supply voltage engine oil pressure

and temperature sensor (F744)

C33 Input signal engine oil pressure

(F744)

C34 Earth, engine oil pressure and

5 V DC Open voltage, with detached

connector

5 V DC Open voltage, with detached

connector

0.5 V DC Engine oil pressure 0 bar X

4.5 V DC Engine oil pressure 15 bar X

0V DC

X

temperature sensor (F744)

1-16

©

200528

Page 25

TECHNICAL DATA

XF105 series

Gasket Copper ring

DMCI engine management system

0

13

42

i400792

2

1. Pressure sensor supply voltage

2. Pressure sensor output signal

3. Temperature sensor output signal

4. Mass

Type of temperature sensor NTC

P

U

1

3

T

R

4

i400791

©

200528 1-17

Page 26

TECHNICAL DATA

DMCI engine management system XF105 series

0

Resistance in relation to measured temperature

Temperature (C) Resistance ()

Minimum Maximum

- 30 24351 30653

- 20 13431 16594

- 10 7850 9095

0 4488 5372

10 2740 3236

20 1727 2010

30 1120 1295

40 746 850

50 510 574

60 355 396

70 253 279

80 185 198

90 134 145

100 100 107

(1)

110 75 81

120 57 62

130 44 48

(1) Check the resistance by measuring on connection points 3 and 4 of the sensor.

Type of pressure sensor piezo-capacitive

U

(V)

5

4

3

2

1

5 10 15

P

(bar)

i400835

1-18

©

200528

Page 27

TECHNICAL DATA

XF105 series

1.10 CRANKSHAFT SENSOR

A

C

DMCI engine management system

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

B

0

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB CDE F

A49 Input signal, crankshaft sensor (F552) - Hz /

(VAC)

Frequency depends on

engine speed

X

A50 Earth, crankshaft sensor (F552) 0 V DC

A60 Shield signal crankshaft sensor (F552) 0 V DC

Type Inductive

Signal version sine-wave alternating voltage

Total number of pulses per crankshaft revolution 54

Number of cylinder detection pulses per

crankshaft revolution 3

Effective voltage when starting approx. 1.5 V

Effective voltage when idling approx. 4.0 V

Effective voltage at 1200 rpm approx. 7.0 V

Resistance value 860 ≥ 10% at 20C

(1)

(1)

(1)

(2)

(1) Measurements taken with multimeter in "AC voltage" position (VAC).

(2) Measured on connection points 1 and 2 of the sensor.

©

200528 1-19

Page 28

TECHNICAL DATA

DMCI engine management system XF105 series

0

ab

1

2

1. Flywheel

a. Area with two holes missing

b. Segment with 18 holes

c. Area with two holes missing

2. Crankshaft sensor signal

c

I400732

1-20

©

200528

Page 29

TECHNICAL DATA

XF105 series

1.11 CAMSHAFT SENSOR

A

C

DMCI engine management system

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

B

0

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB CDE F

A53 Input signal camshaft sensor (F558) - Hz /

(VAC)

Frequency depends on the

speed

X

A54 Earth, camshaft sensor (F558) 0 V DC

A61 Shield signal camshaft sensor (F558) 0 V DC

Type Inductive

Signal version sine-wave alternating voltage

Total number of pulses for every two crankshaft

revolutions 7

Effective voltage when starting approx. 0.5 V

Effective voltage when idling approx. 2.0 V

Effective voltage at 1200 rpm approx. 4.0 V

Resistance value 860 ≥ 10% at 20C

(1)

(1)

(1)

(2)

(1) Measurements taken with multimeter in "AC voltage" position (VAC).

(2) Measured on connection points 1 and 2 of the sensor.

©

200528 1-21

Page 30

TECHNICAL DATA

DMCI engine management system XF105 series

0

624s153

a

b

0

I400762

a. Pulse wheel

b. Camshaft sensor signal

1-22

©

200528

Page 31

TECHNICAL DATA

XF105 series

1.12 ENGINE OIL LEVEL SENSOR

A

C

DMCI engine management system

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

B

0

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

B13 Output and input signal oil level

sensor (F673)

- V DC Voltage increase or decrease

depending on the oil level and the

oil temperature

B14 Earth oil level sensor (F673) 0 V DC

©

200528 1-23

Page 32

TECHNICAL DATA

DMCI engine management system XF105 series

0

Supply voltage approx. 24 V

Resistance value (at 20C) 20.5 - 23.5

(1) During the measurement of the resistance value the

current may not be more than 200mA.

(1)

E501146

1-24

©

200528

Page 33

TECHNICAL DATA

XF105 series

1.13 SWITCHES (MANUAL GEARBOX)

A

C

DMCI engine management system

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

B

0

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB CDE F

B36 Input signal clutch switch (E575) 0 V DC Clutch pedal not depressed

Ubat V DC Clutch pedal fully depressed

B40 Input signal neutral position switch (E593) Ubat V DC Gearbox in neutral:

0 V DC Gear box in gear

Clutch switch

Model Hall proximity switch

Neutral position switch

Model Normally Open

©

200528 1-25

Page 34

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.14 SWITCHES (AS TRONIC)

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

B40 Input signal neutral position switch

(E599)

0 V DC Gearbox in neutral

Ubat V DC Gear box in gear

Neutral position switch

Model Normally Closed

1-26

©

200528

Page 35

TECHNICAL DATA

XF105 series

DMCI engine management system

1.15 EXTRA BULKHEAD LEAD-THROUGH FUNCTIONS

A

C

B

0

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

B1 Output signal engine speed (bulkhead

lead-through connector 12C:3)

- Hz Frequency depends on engine

speed (30 pulses per crankshaft

revolution)

B8 Input signal torque limitation 1 (bulk-

head lead-through connector 12C:17)

B11 Input signal torque limitation 2 (bulk-

head lead-through connector 12C:20)

Ubat V DC Only active after release. Not

programmable with DAVIE XD

Ubat V DC Only active after release. Not

programmable with DAVIE XD

X

X

Connection point B8 Connection point B11 Torque limiting during engine

speed control

Ubat 0 Level 1: 1800 Nm

0 Ubat Level 2: 1200 Nm

Ubat Ubat Level 3: 600 Nm

©

200528 1-27

Page 36

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.16 RED WARNING

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

B22 Output signal red warning to VIC-2

(D310)

Ubat VDC No red warning

0 - 5 VDC Red warning active (always in

combination with a CAN

message)

1-28

©

200528

Page 37

TECHNICAL DATA

XF105 series

1.17 STARTER MOTOR

A

C

DMCI engine management system

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

B

0

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

B9 Output signal earth starter motor

(B010)

0 VDC If starter motor is active

about

VDC If engine is running

1.5

©

200528 1-29

Page 38

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.18 GLOW COMPONENTS

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

C32 Output signal glow relay (G014) 0 V DC Glow relay active

Ubat V DC Glow relay not active

C39 Input signal glow relay active (G014) Ubat V DC Glow relay activated

0 V DC Glow relay not active

Glow plug relay

Supply voltage Ubat

Resistance value of coil 21 ≥ 10%

Glow element

Supply voltage Ubat

Rated output 1.9 kW ≥ 10%

Resistance value 0.25 ≥ 10%

1-30

©

200528

Page 39

TECHNICAL DATA

XF105 series

1.19 WASTE GATE VALVE

A

C

DMCI engine management system

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

B

0

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

C8 Output signal waste gate valve

(B368)

- % Depending on the desired boost

pressure, earth-controlled duty

X

cycle

C59 Earth waste gate valve (B368) 0 V DC

©

200528 1-31

Page 40

TECHNICAL DATA

DMCI engine management system XF105 series

0

Supply voltage approx. 24 V

Air pressure approx. 10 bar

Control signal earth-controlled

duty cycle

Duty cycle voltage level approx. 12 V

Frequency of duty

cycle signal circa 160 Hz

(1) Check duty cycle with the multimeter by plus

measurement pin at C59 and less measurement pin

at C8.

Duty cycle (%) Output pressure, output

00.30.3

10 0.3 0.3

(1)

10% duty cycle, earth-controlled, plus

measurement pin C8 less measurement pin

C59

U (V)

25

20

15

10

5

0

MX375 MX410

Output pressure, output

"2" (bar)

"2" (bar)

i401021

50 1.5 2.5

90 3.0 5.0

95 3.0 5.0

100 0.3 0.3

1-32

©

200528

Page 41

TECHNICAL DATA

XF105 series

1.20 EXHAUST BRAKE VALVE

A

C

DMCI engine management system

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

B

0

i400726

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

C28 Output signal exhaust brake valve

(B192)

Ubat VDC Exhaust brake valve not active

0 VDC Exhaust brake valve active

Resistance value 56 ≥ 10%

©

200528 1-33

Page 42

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.21 DEB SOLENOID VALVE

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

A35 Earth magnetic valve DEB (B411) 0 V DC

A36 Output signal magnetic valve DEB

(B411)

Ubat V DC DEB active

0 V DC DEB not active

A39 Earth magnetic valve DEB (B415) 0 V DC

A40 Output signal magnetic valve DEB

(B415)

Ubat V DC DEB active

0 V DC DEB not active

A43 Earth magnetic valve DEB (B413) 0 V DC

A44 Output signal magnetic valve DEB

(B413)

Ubat V DC DEB active

0 V DC DEB not active

A47 Earth magnetic valve DEB (B416) 0 V DC

1-34

©

200528

Page 43

TECHNICAL DATA

XF105 series

AB C D E F

A48 Output signal magnetic valve DEB

(B416)

A51 Earth magnetic valve DEB (B412) 0 V DC

A52 Output signal magnetic valve DEB

(B412)

A55 Earth magnetic valve DEB (B414) 0 V DC

A56 Output signal magnetic valve DEB

(B414)

Resistance value 40 ≥ 10%

(1) Check the resistance by measuring at the valve connection points to the correct connection points of the in-line connectors.

Ubat V DC DEB active

0 V DC DEB not active

Ubat V DC DEB active

0 V DC DEB not active

Ubat V DC DEB active

0 V DC DEB not active

DMCI engine management system

(1)

0

©

200528 1-35

Page 44

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.22 PUMP UNIT

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

A03 Output signal high pump unit

- V DC See scope example X

cylinder 1 (B131)

A04 Output signal low pump unit

- V DC See scope example X

cylinder 1 (B131)

A07 Output signal high pump unit

- V DC See scope example X

cylinder 3 (B133)

A08 Output signal low pump unit

- V DC See scope example X

cylinder 5 (B135)

A11 Output signal high pump unit

- V DC See scope example X

cylinder 2 (B132)

A12 Output signal low pump unit

- V DC See scope example X

cylinder 3 (B133)

A15 Output signal high pump unit

- V DC See scope example X

cylinder 5 (B135)

1-36

©

200528

Page 45

TECHNICAL DATA

XF105 series

AB C D E F

A16 Output signal low pump unit

cylinder 6 (B136)

A19 Output signal high pump unit

cylinder 6 (B136)

A20 Output signal low pump unit

cylinder 2 (B132)

A23 Output signal low pump unit

cylinder 4 (B134)

A24 Output signal high pump unit

cylinder 4 (B134)

Pick-up voltage approx. 50 V

Withstand voltage approx. 24 V

- V DC See scope example X

- V DC See scope example X

- V DC See scope example X

- V DC See scope example X

- V DC See scope example X

DMCI engine management system

U (V)

60

40

20

0

0

Solenoid valve resistance value

-40C1.1

20C1.6

120C2.4

(1) Check the resistance by measuring on the connection points of the pump unit.

(1)

i400845

©

200528 1-37

Page 46

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.23 INJECTOR

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

A01 Output signal low injector cylinder 1

V DC See scope example

(B421)

A02 Output signal high injector cylinder 1

V DC See scope example

(B421)

A05 Output signal low injector cylinder 5

V DC See scope example

(B425)

A06 Output signal high injector cylinder 3

V DC See scope example

(B423)

A09 Output signal low injector cylinder 3

V DC See scope example

(B423)

A10 Output signal high injector cylinder 2

V DC See scope example

(B422)

A13 Output signal low injector cylinder 6

V DC See scope example

(B426)

1-38

©

200528

Page 47

TECHNICAL DATA

XF105 series

AB C D E F

A14 Output signal high injector cylinder 5

(B425)

A17 Output signal low injector cylinder 2

(B422)

A18 Output signal high injector cylinder 6

(B426)

A21 Output signal low injector cylinder 4

(B424)

A22 Output signal high injector cylinder 4

(B424)

Pick-up voltage approx. 50 V

Withstand voltage approx. 24 V

DMCI engine management system

V DC See scope example

V DC See scope example

V DC See scope example

V DC See scope example

V DC See scope example

U (V)

60

40

20

0

0

i400846

Solenoid valve resistance value

-40C1.1

20C1.6

120C2.4

(1) Check the resistance by measuring at the injector connection points to the correct connection points of the in-line connectors.

(1)

©

200528 1-39

Page 48

0

TECHNICAL DATA

DMCI engine management system XF105 series

1.24 ELECTRONICALLY CONTROLLED FAN CLUTCH

A

C

A Electronic unit connection point

B Description of connection point

C Reading at connection point (Ubat = battery voltage)

D Measuring unit

B

21

25

29

33

37

41

45

49

53

57

60 62

1 4591317

i400726

E Explanatory notes (if applicable)

F Additional information available in Technical Data at "X" mark

AB C D E F

C16 Output signal fan clutch control - % Earth-controlled duty cycle X

Ubat VDC Ignition on

C31 Fan clutch speed sensor earth 0 VDC

C35 Fan clutch speed sensor power

5VDC

supply

C36 Fan clutch speed sensor input signal - Hz Square wave signal X

1-40

©

200528

Page 49

TECHNICAL DATA

XF105 series

Type of speed sensor Hall

Speed sensor output signal Square-wave

signal 5 V

Frequency at 1000 rpm fan

speed 100 Hz

Pulses per fan revolution 6

Fan clutch control earth-controlled

duty cycle

(0 - 100%

Duty cycle voltage level 24 V

Frequency of duty

cycle signal 2 Hz

Duty cycle high

Duty cycle low

(1)

(1)

Decreasing fan

speed

Increasing fan

speed

DMCI engine management system

U (V)

6

4

2

0

U (V)

25

20

15

10

5

0

0

i400848

(1) Measured with plus probe on pin B60 and minus probe on

pin C16

1. Fan speed sensor output signal

2. Fan speed sensor earth

3. Fan clutch control signal

4. Fan clutch supply voltage 24V

5. Fan speed sensor supply voltage 5V

i400847

5

4

3

1

2

i 400456

©

200528 1-41

Page 50

0

TECHNICAL DATA

DMCI engine management system XF105 series

1-42

©

200528

Page 51

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

Contents

CONTENTS

Page Date

1. SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200528

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200528

1.2 Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200528

1.3 System description of fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 . . . . . 200528

2. DESCRIPTION OF COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200528

2.1 DMCI electronic unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200528

2.2 Accelerator pedal sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200528

2.3 Coolant temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4 . . . . . 200528

2.4 2

2.5 Inlet air boost pressure and temperature sensor. . . . . . . . . . . . . . . . . . . . 2-5 . . . . . 200528

2.6 Fuel pressure and temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7 . . . . . 200528

2.7 Engine oil pressure and temperature sensor. . . . . . . . . . . . . . . . . . . . . . . 2-8 . . . . . 200528

2.8 Crankshaft sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9 . . . . . 200528

2.9 Camshaft sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12 . . . . 200528

2.10 Waste gate valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15 . . . . 200528

2.11 Pump unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17 . . . . 200528

2.12 Injector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23 . . . . 200528

2.13 Electronically controlled fan clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27 . . . . 200528

nd

coolant temperature sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4 . . . . . 200528

1

3. CONTROL FUNCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200528

3.1 System status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200528

3.2 CAN controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 . . . . . 200528

3.3 Pre-glowing and after-glowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 . . . . . 200528

3.4 Immobiliser and start interruption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 . . . . . 200528

3.5 Cylinder detection and synchronisation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9 . . . . . 200528

3.6 Fuel injection when starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14 . . . . 200528

3.7 Injection timing control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15 . . . . 200528

3.8 Idling control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16 . . . . 200528

3.9 Turbocharger pressure control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17 . . . . 200528

3.10 Smoke limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19 . . . . 200528

3.11 Engine brake control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20 . . . . 200528

3.12 Fan clutch control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24 . . . . 200528

3.13 Engine protection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27 . . . . 200528

3.14 Vehicle speed limiting functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32 . . . . 200528

3.15 Cruise control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34 . . . . 200528

3.16 Downhill Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37 . . . . 200528

3.17 Engine speed control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40 . . . . 200528

4. DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200528

4.1 Key to block diagram DMCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200528

4.2 Block diagram DMCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 . . . . . 200528

©

200528 1

Page 52

1

DMCI ENGINE MANAGEMENT SYSTEM

Contents XF105 series

2

©

200528

Page 53

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

1. SYSTEM DESCRIPTION

1.1 INTRODUCTION

The design, functions and controls of the "DMCI"

engine management system are described in this

systems manual.

"DMCI" stands for DAF Multi Controlled Injection.

Fuel injection is controlled by an electronically

controlled pump unit and an electronically

controlled injector.

The pump unit is responsible for the fuel supply to

the injector. Injection timing is determined by the

injector. Injection quantity is determined by the

pump unit and injector in combination.

Of course, the DMCI electronic unit requires

various sensors to control these two components

correctly in order to determine the injection timing

and the correct quantity of fuel to be injected.

System description

1

©

200528 1-1

Page 54

1

DMCI ENGINE MANAGEMENT SYSTEM

System description XF105 series

1.2 ELECTRICAL SYSTEM

The electronic unit is the central control device of

the DMCI engine management system. The

functions can be split into engine functions and

vehicle functions.

Note:

Functions may be optional or may depend on the

vehicle configuration.

Engine functions:

- system status

-CAN controls

- pre-glowing and after-glowing

- control of fuel supply

- cylinder detection and synchronisation

- fuel injection when starting

- injection timing control

- idling control

- turbocharger pressure control

- smoke limitation

- full-load limiting and engine protection

functions

- engine brake control

- fan clutch control

Vehicle functions:

- Cruise control

- downhill speed control

- vehicle speed limiting prescribed by law

- variable vehicle speed limiting

- vehicle speed limiting for special applications

- engine speed control

-CAN controls

1-2

©

200528

Page 55

DMCI ENGINE MANAGEMENT SYSTEM

/

/

/

/

/

/

XF105 series

E575

CAN

network

F672

B335

F673G469

E593/

E599 F552F566

D965

B010

VIC

D310 D899

B368

F649F743

B192

F744

G014

System description

F713 F558

B411/

B412/

B413/

B414/

B415/

B416/

B421/

B422/

B423/

B424/

B425/

B426/

1

B131

B132

B133

B134

B135

B136

i400991

The DMCI electronic unit needs different input

signals to control engine and vehicle functions

and various components are activated by output

signals.

Input signals

The most important input signals are:

- clutch proximity switch (E575)

- service brake (G469)

- accelerator pedal sensor (F672)

- neutral position switch (F593/F599)

- oil level sensor (F673)

nd

-2

- coolant temperature sensor (F566)

- air inlet boost pressure and temperature

- engine oil pressure and temperature sensor

- fuel pressure and temperature sensor (F713)

- crankshaft sensor (F552)

- camshaft sensor (F558)

- electronically controlled fan clutch (B335)

- glow relay (G014)

coolant temperature sensor (F743)

sensor (F649)

(F744)

©

200528 1-3

Page 56

1

DMCI ENGINE MANAGEMENT SYSTEM

System description XF105 series

Output signals

After processing of the input signals, output

signals control the following components:

- electronically controlled fan clutch (B335)

- red warning VIC-2 (D310)

- waste gate valve (B368)

- starter motor (B010)

- exhaust brake valve (B192)

- DEB solenoid valves (B411 to B416)

- glow relay (G014)

- pump units (B131 to B136)

- injectors (B421 to B426)

The DMCI communicates with the various other

electronic systems in the vehicle via the CAN

network.

DAVIE XD is used to diagnose faults on the

DMCI.

1-4

©

200528

Page 57

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

1.3 SYSTEM DESCRIPTION OF FUEL SYSTEM

Fuel system

7

B

8

6

M M M M M M

A

66

77777

66

PUT

R

9

System description

6

c

b

5

a

c

4

b

a

1

d

2a2b

b

1

A Cylinder block 4 Fuel filter

B Cylinder head 4a Filter element

1 Fuel tank 4b Bleed restriction

1a Fuel-tank coarse filter 5 Fuel pressure control valve

2a Shut-off valve, supply 5a Pressure control flap

2b Shut-off valve, return 5b Throttle bleed/idling speed

3 Fuel pump 5c Fuel pressure measuring point

3a Lift pump 6 Pump units

3b Primer pump 7 Injectors

3c Pressure release valve 8 Non-return valve

3d Circulation valve 9 Fuel pressure and temperature sensor

The fuel lift pump (3a) draws fuel out of the fuel

tank (1) via a shut-off valve (2a) in the supply

pipe. The fuel goes to the fuel pump (3) via the

cylinder block (A). The fuel lift pump (3a) pumps

the fuel via the fuel filter (4) to the fuel gallery in

the cylinder block (A). The pressure in the fuel

a

a

M

3

i400749

©

200528 1-5

Page 58

DMCI ENGINE MANAGEMENT SYSTEM

System description XF105 series

gallery is controlled by the pressure control flap

(5a) in the fuel pressure control valve (5). The

valve (5a) opens at a specific pressure and

the fuel is led back to the intake side of the

fuel pump (3).

1

There is a calibrated opening (5b) in the fuel

pressure control valve (5) that ensures cooling of

the fuel system, by means of fuel flow-back, at

low engine speeds and in situations where fuel is

not injected (e.g. DEB in use). This calibrated

opening (5b) also ensures that pressure in the

fuel gallery is stable at low speeds and therefore

that pump pressures are low.

There is a test connection (5c) on the fuel

pressure control valve (5) for measuring the fuel

gallery pressure.

The fuel flows to the pump units (6) from the fuel

gallery. If the solenoid valve in the pump unit is

not activated, the pump unit pumps the fuel back

into the fuel gallery. If the solenoid valve in the

pump unit is activated, the fuel is pumped at high

pressure to the injectors (7) via the fuel injection

pipes.

If the solenoid valve in the injector is activated, an

injection takes place.

The lubricating and leak-off fuel from the pump

unit plunger is discharged to the return gallery in

the cylinder block via a bore. The return and leakoff fuel from the injectors flows to the return

gallery in the cylinder block via a bore in the

cylinder head and the fuel return pipe with nonreturn valve (8).

The return fuel flows back to the tank via a shutoff valve (2b).

The shut-off valves (2a and 2b) are opened when

the fuel pipes are connected. When the fuel pipes

between engine and chassis are disconnected,

the valves close the opening to the cylinder block.

1-6

©

200528

Page 59

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

Fuel filter

There is a coarse filter (1a) in the fuel tank (1),

which prevents any larger impurities from the

bottom of the fuel tank getting into the fuel lift

pump. From the fuel lift pump, fuel is pumped to

the fuel gallery through the fuel fine filter (4).

The fuel filter is self-bleeding. There is a throttle

(3b) at the highest point in the fuel fine filter (4)

through which air in the system is discharged to

the fuel tank.

Basic function of injection

The pump unit and injector work in tandem to

bring about fuel injection. A complete fuel

injection cycle is described in the following steps.

Filling

7

4

1

System description

2

b

c

1

a

a

P

3

6

5

Filling

The fuel lift pump (3) draws fuel out of the tank (5)

via the inlet pipe (6) and pumps it to the pump unit

(1). The pump unit has not been activated and the

pump unit valve (1a) is open. The space above

the pump unit plunger (1b) is filled. Because the

camshaft moves the pump unit plunger up, the

fuel can now flow back to the supply side.

Pressure has not yet built up in the fuel injection

pipe.

d

b

X

Y

e

i400795

©

200528 1-7

Page 60

DMCI ENGINE MANAGEMENT SYSTEM

System description XF105 series

Pressure increase

1

7

4

1

a

P

3

6

5

Pressure increase

When the pump unit (1) is activated, the pump

unit valve (1a) shuts off the fuel supply. The pump

unit plunger (1b) continues to move up, but now

pressure builds up because the fuel can no

longer flow back to the supply side. The fuel is

now pumped to the injector (2). The chamber

above the injector plunger (2d) now fills slowly via

the throttle (2c). Because the injector valve (2a)

has not been activated, the fuel cannot flow out to

the return (7). The fuel pressure and the spring

above the injector plunger (2d) ensure that the

injector needle (2e) cannot be lifted.

Curve x indicates the fuel pressure in the injector.

Curve y indicates the movement of the injector

needle.

The fuel pressure (x) now increases. The injector

needle has not yet lifted (y).

2

a

b

c

d

b

X

Y

e

i400796

1-8

©

200528

Page 61

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

Start of injection

6

4

P

3

System description

7

2

a

1

b

c

1

a

b

d

e

5

Start of injection

When the injector (2) is also activated, the

injector valve (2a) releases the path to the return

(7). The pressure above the injector plunger (2d)

is now slowly released via a throttle (2b). Now the

pressure under the injector needle (2e) is able to

lift the injector needle. Fuel is now injected.

The fuel pressure (x) now experiences a small dip

because fuel is being injected, but the pressure

immediately rises again. The needle is now

lifted (y).

X

Y

i400797

©

200528 1-9

Page 62

DMCI ENGINE MANAGEMENT SYSTEM

System description XF105 series

Pressure reduction

1

7

4

1

a

P

3

6

5

Pressure reduction

To ensure that the injector needle (2e) closes

quickly enough, the fuel pressure in the injector is

first reduced. The pump unit (1) is no longer

activated and, as a result, the pump unit valve

(1a) re-opens the supply and the pressure in the

fuel injection pipe drops. Injection still continues.

The fuel pressure (x) now decreases. The injector

needle is still lifted to its maximum extent (y).

2

a

b

c

d

b

X

Y

e

i400798

1-10

©

200528

Page 63

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

End of injection

6

5

4

P

3

System description

7

2

a

b

1

c

1

a

b

d

e

End of injection

The injector valve (2a) is now no longer

energised. In the meantime, the fuel pressure in

the injector has decreased and the injector

needle (2e) is closed by the spring above the

injector plunger (2d).

The fuel pressure (x) now decreases even

further. The injector needle is about to close (y).

X

Y

i400799

©

200528 1-11

Page 64

DMCI ENGINE MANAGEMENT SYSTEM

System description XF105 series

Closed

1

7

4

1

a

P

3

6

5

Closed

The fuel pressure has now dropped as much as

possible and the injector needle (2e) is pushed

down by the spring above the plunger (d).

The fuel pressure (x) is now at its minimum level.

The injector needle has closed (y).

2

a

b

c

d

b

X

Y

e

i400800

1-12

©

200528

Page 65

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

2. DESCRIPTION OF COMPONENTS

2.1 DMCI ELECTRONIC UNIT

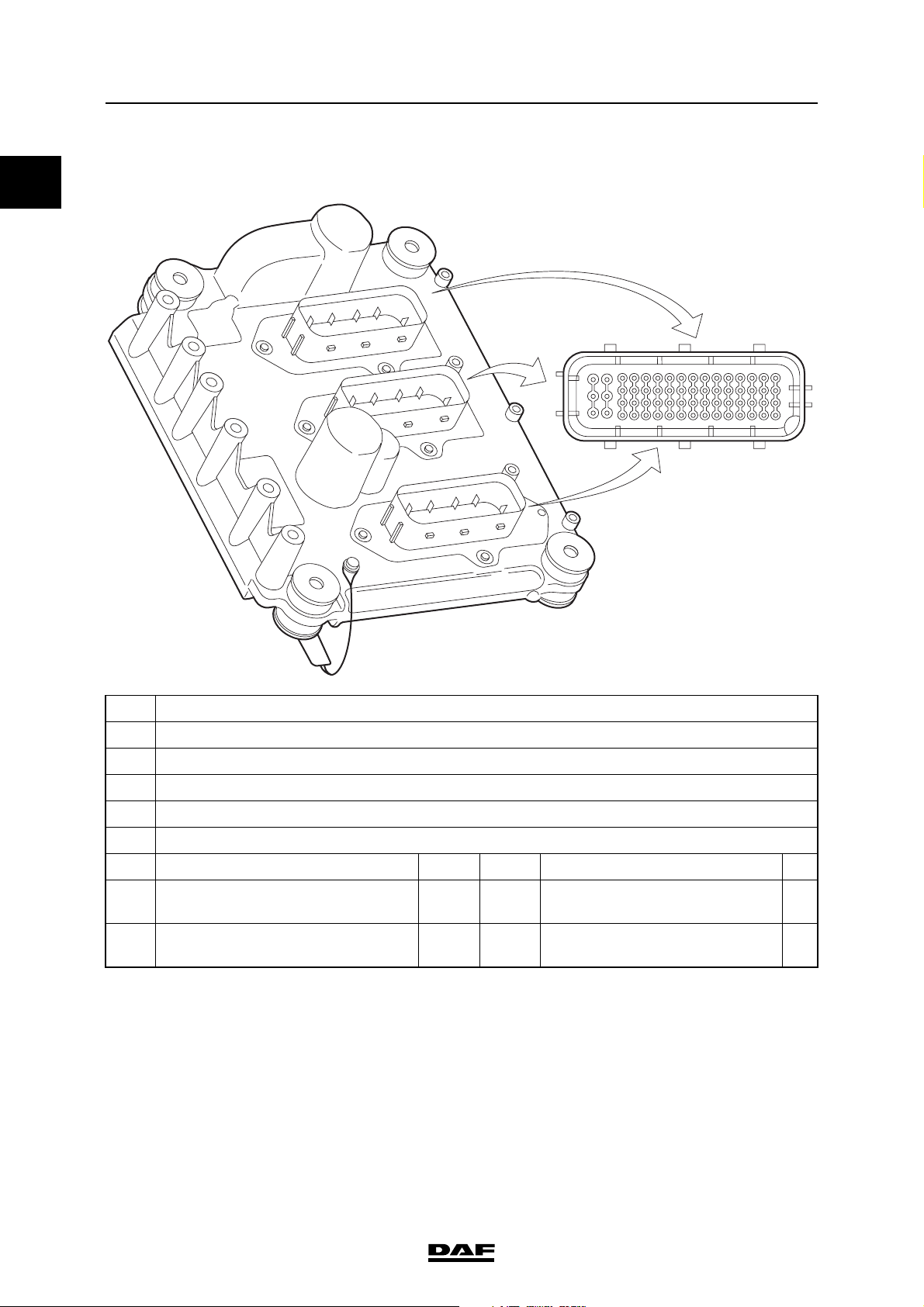

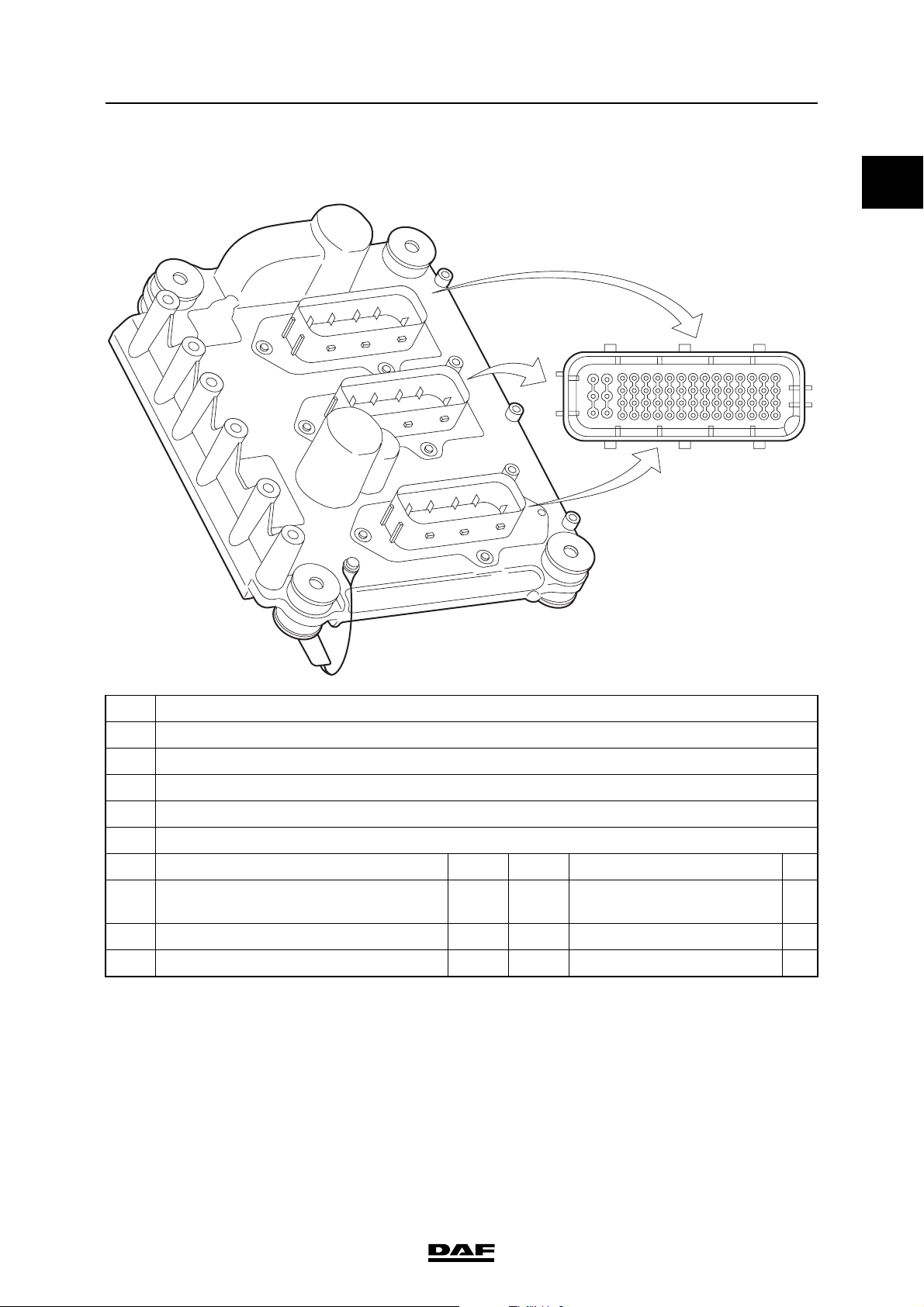

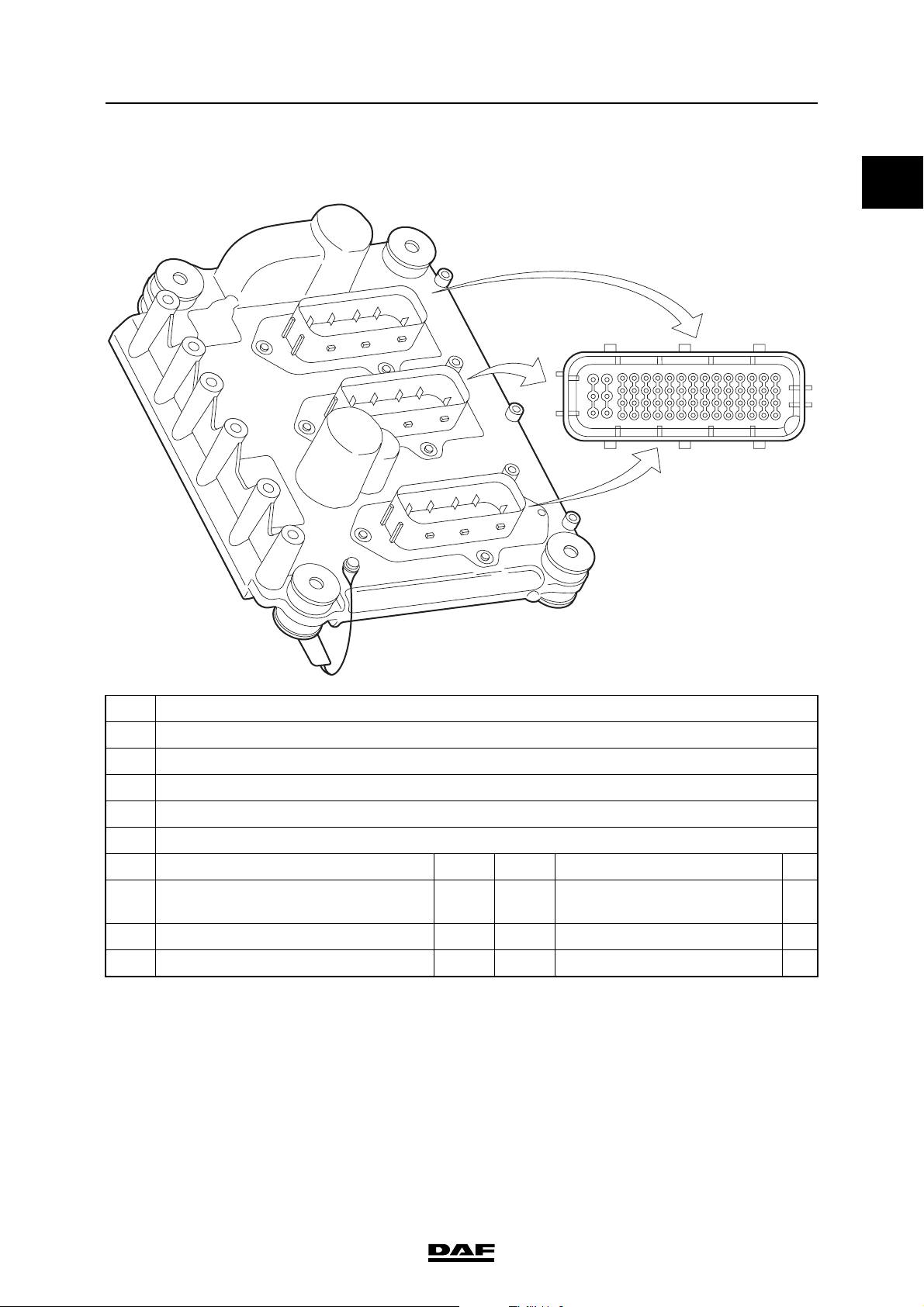

The electronic unit is mounted on the cylinder

block using rubber insulating bushes (3). The

electronic unit has three 62-pin connectors. Input

signals from various sensors are continuously

processed and compared with data stored in

various maps (tables) in the electronic unit.

Actuators are energised on the basis of the

signals received and the maps.

The housing (1) of the electronic unit is directly

connected to the engine block by an earth cable

(2). This earth connection is required because of

internal components which protect against radio

waves from outside.

The electronic unit incorporates an atmospheric

pressure sensor and a temperature sensor.

There is an air vent (4) for the atmospheric

pressure sensor in the housing of the electronic

unit.

An identification sticker (5) is attached to the

electronic unit.

Description of components

1

4

1

5

3

2

i400785

The effect of atmospheric pressure on the

system:

- the quantity of fuel injected when driving at

high altitudes (low air pressure).

If atmospheric pressure is low (in mountainous

areas), the air is thinner. When the air is thinner it

has a low density. The electronic unit uses this

information to control the turbocharger pressure

and adjust the quantity of fuel to be injected.

The effect of the internal temperature sensor

on the system:

- none.

The internal temperature sensor measures the

temperature of the electronic unit. If the

temperature becomes too high, a fault code is

stored. The system does not take any further

action on the basis of this information.

Calibration

The performance of pump units and injectors may

differ slightly from one another as a result of small

production tolerances. These small production

differences are compensated for during

production by means of calibration in order to

optimise the engine output, exhaust gas

emissions and handling characteristics. A

calibration code is used to program the pump

units and injectors into the electronic unit

individually. The electronic unit modifies the

control of the pump units and injectors on the

basis of these calibration codes.

©

200528 2-1

Page 66

1

DMCI ENGINE MANAGEMENT SYSTEM

Description of components XF105 series

2.2 ACCELERATOR PEDAL SENSOR

1 Kick-down switch

2 Accelerator pedal sensor

D965

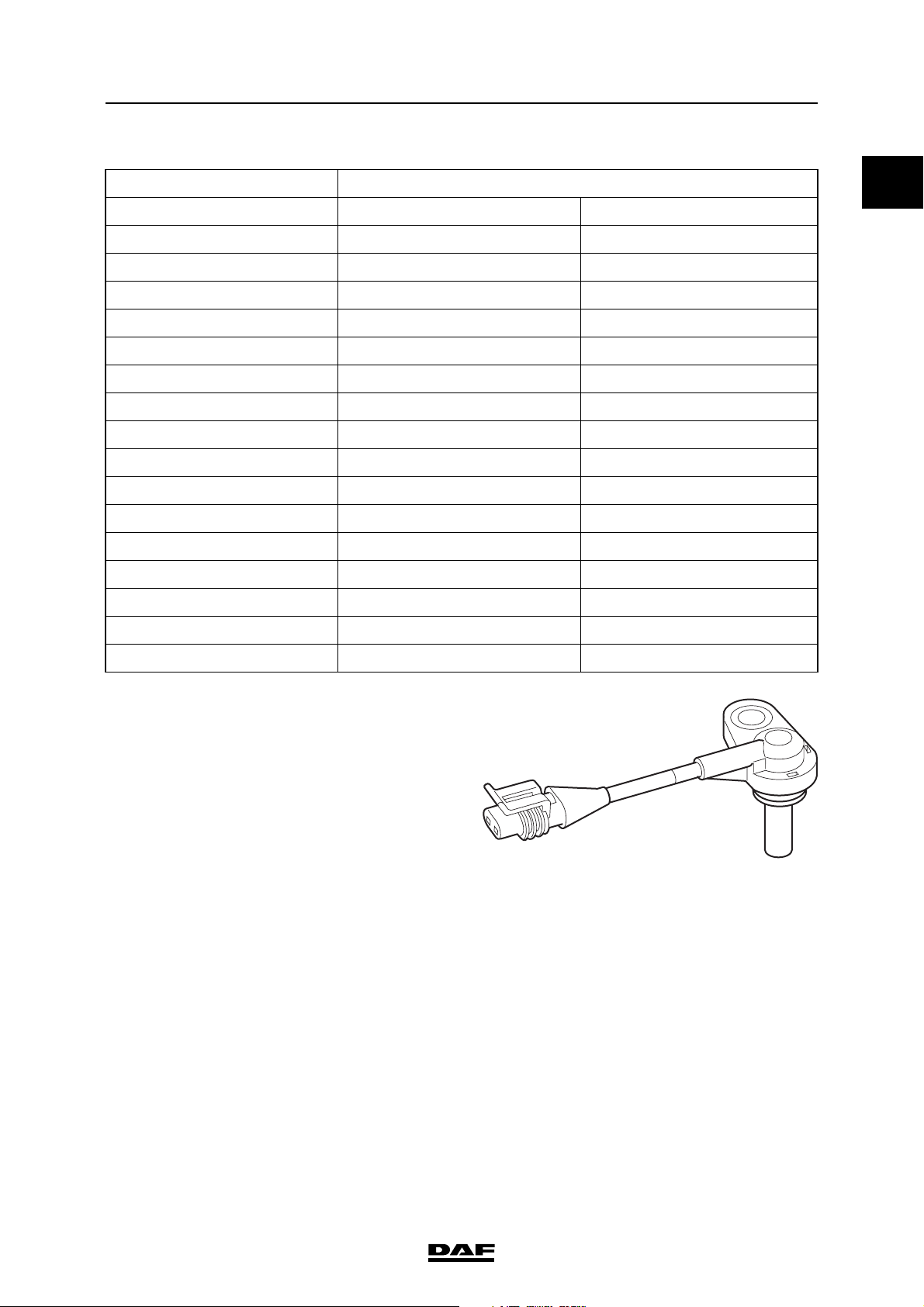

The accelerator pedal sensor (F672) is mounted

on the accelerator pedal. The sensor (2) consists

of a potentiometer and a switch.

Potentiometer

The output signal (B33) from the potentiometer is

a linear voltage that has a fixed relationship with

the position of the accelerator pedal and

therefore is determined by the driver. The

potentiometer signal is the basis for determining

the quantity of fuel to be injected. The

potentiometer has a supply voltage (B34) and an

earth (B37) via the electronic unit.

B34

B33 B37 B38 B41

4677

4679

4678

4166

4680

CABDF

Idling switch

Parallel to the potentiometer also the idling switch

is operated by depressing the accelerator pedal.

The idling switch is open in the no-load position

and is closed when the accelerator pedal is

operated. The switch is required for the

emergency function, when the potentiometer

signal is absent. This emergency function allows

the vehicle to be driven to a safe place or a

workshop if there is no potentiometer signal. One

side of the switch is connected to earth (B38) via

the electronic unit. The positive side (B41) is

connected to earth by means of the switch.

Kick-down switch

The kick-down switch (1) under the accelerator

pedal only acts to form a mechanical resistance

when the accelerator pedal is depressed. The

electronic unit detects the kick-down status

because the value of the output signal from the

potentiometer is higher than at full load. The kickdown switch is for instance used to temporarily

disengage variable vehicle speed limiting so that

an automatic/automated gearbox can shift down

(in order to accelerate).

F672

2

1

i400694

2-2

©

200528

Page 67

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

Effect of potentiometer output signal on the

system:

- the basis for determining the quantity of fuel

to be injected.

- engine brake disengaging/engaging

conditions

- disengaging conditions of Downhill Speed

Control

- CAN message accelerator pedal position,

via V-CAN1 (AS Tronic, AGC-A) and

V-CAN2 (EBS-2, VIC-2, builder module);

- CAN message kickdown position active, via

V-CAN1 (AS Tronic, AGC-A);

Effect of idling switch output signal on the

system:

- emergency function if the potentiometer is

not working.

- engine brake disengaging/engaging

conditions

- disengaging conditions of Downhill Speed

Control

- CAN message idling switch active, via

V-CAN1 (AS Tronic) and V-CAN2 (VIC-2,

ZF intarder EST-42, EBS-2, DIP-4, builder

module)

Description of components

1

©

200528 2-3

Page 68

1

DMCI ENGINE MANAGEMENT SYSTEM

Description of components XF105 series

2.3 COOLANT TEMPERATURE SENSOR

The coolant temperature sensor emits a signal

that indicates the temperature of the coolant and

therefore indirectly the engine temperature. The

sensor used is of the NTC (negative temperature

coefficient) type. The higher the temperature, the

lower the resistance of the sensor.

Effect of output signal on the system:

- calculation of glowing time;

- calculation of the quantity of fuel to be

injected and the injection timing;

- calculation of actuation of the electronically

controlled fan clutch;

- limiting of engine torque when temperature is

too high;

- CAN message engine temperature, via

V-CAN2 to VIC-2 for display on the

instrument panel;

- limitation of the maximum engine speed

when the engine is cold.

i 400440

2.4 2nd COOLANT TEMPERATURE SENSOR

The 2nd coolant temperature sensor (F743) gives

a signal of the temperature of the coolant and

therefore indirectly of the engine at the level of

cylinder 6. The signal is compared by the

electronic unit (D965) to the signal from the

coolant sensor (F566) at the level of cylinder 1.

The sensor is of the NTC (Negative Temperature

Coefficient) type. The higher the temperature, the

lower the resistance of the sensor.

Effect of the signal on the system:

- Detection of a cooling problem resulting in

engine torque limitation

i401003

2-4

©

200528

Page 69

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

Description of components

2.5 INLET AIR BOOST PRESSURE AND TEMPERATURE SENSOR

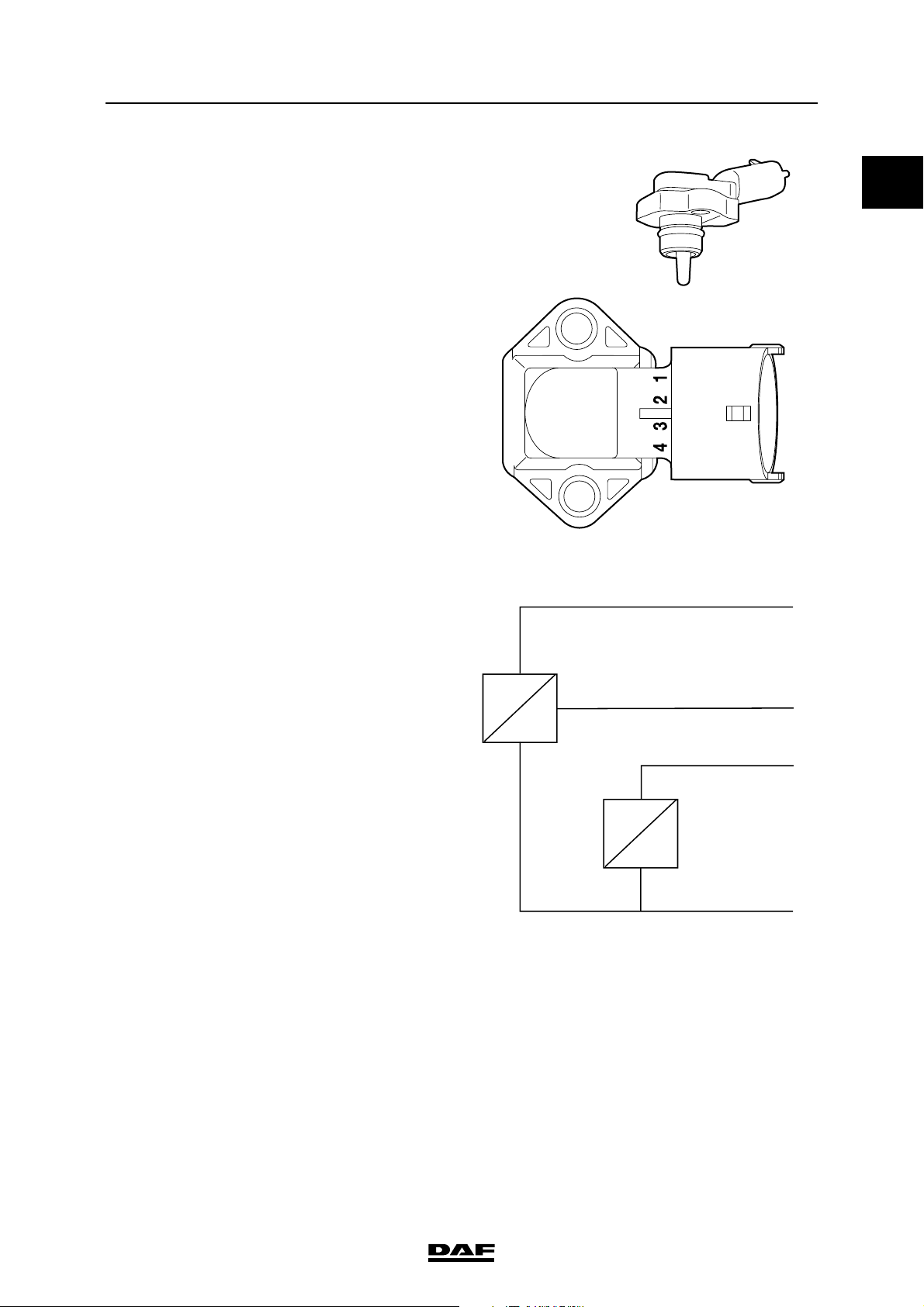

This is a combined sensor that measures the air

pressure in the inlet manifold and the

temperature of this air. The electronic unit uses

this data to calculate the quantity of air drawn in.

The quantity of intake air needs to be known in

order to calculate the quantity of injected fuel to

prevent smoke. The charge pressure is also in a

direct relationship to the turbocharger pressure

control. The waste gate valve is actuated

depending on this signal.

1

1 Air inlet pressure sensor, piezo-resistive

2 Electrical connection

3 Air inlet temperature sensor, NTC

4 Air inlet opening

5O-ring

6 Accommodation

The charge temperature sensor (3) used is of the

NTC (negative temperature coefficient) type. The

higher the temperature, the lower the resistance

of the sensor. The charge pressure sensor (1) is

a piezoresistive sensor. The inlet air is measured

via an opening (4) in the sensor. The higher the

pressure, the higher the voltage signal. The

sensor is sealed in the installation hole in the

cylinder head by an O-ring (5).

i 400441

1 2

6

5

4

3

i400742

©

200528 2-5

Page 70

DMCI ENGINE MANAGEMENT SYSTEM

Description of components XF105 series

The temperature signal is fed back to the

electronic unit via a connection (2).

A piezoresistive sensor requires a power

supply (3) and earth (1) to create a linear

voltage signal (4).

3

1

Effect of temperature signal on the system:

- calculation of glowing time;

- correction on the waste gate control;

- correction on the smoke limiting system.

Effect of pressure signal on the system:

- calculation for smoke limiting;

- calculation of the waste gate control;

- protection of turbocharger;

- CAN message to VIC for the charge boost

pressure display on the main display of

the DIP.

P

4

U

2

T

R

1

i400534

2-6

©

200528

Page 71

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

2.6 FUEL PRESSURE AND TEMPERATURE SENSOR

This is a combined sensor that measures the fuel

pressure in the fuel gallery and the temperature

of this fuel. The sensor is located in the middle of

the fuel gallery between the cylinder 3 pump unit

and the cylinder 4 pump unit. Because of this the

measured values for fuel pressure and

temperature are the most representative for the

whole fuel gallery.

The fuel temperature sensor is of the NTC

(negative temperature coefficient) type. The

higher the temperature, the lower the resistance.

The fuel pressure sensor is a Piëzo capacitive

sensor. The higher the pressure, the higher the

voltage signal.

The temperature signal is fed back to the

electronic unit via a connection (3).

A Piëzo capacitive sensor requires a power

supply (1) and earth (4) to create a linear voltage

signal (2).

P

Effect of temperature signal on the system:

- correction of quantity of fuel to be injected;

- calculation of glowing time;

U

Description of components

1

13

42

i400792

2

1

3

Effect of pressure signal on the system:

- enabling fuel pressure to be read on DAVIE;

T

R

4

i400791

©

200528 2-7

Page 72

1

DMCI ENGINE MANAGEMENT SYSTEM

Description of components XF105 series

2.7 ENGINE OIL PRESSURE AND TEMPERATURE SENSOR

This is a combined sensor that measures the

engine oil pressure in the cylinder block main

passage and the temperature of this oil.

The engine oil temperature sensor used is of the

NTC (negative temperature coefficient) type. The

higher the temperature, the lower the resistance

of the sensor. The engine oil pressure sensor is a

Piëzo capacitive sensor. The higher the pressure,

the higher the voltage signal. The engine oil

pressure is measured via an opening in the

sensor. The higher the pressure, the higher the

voltage signal.

13

42

i400792

The temperature signal is fed back to the

electronic unit via a connection (3). A piëzocapacitive sensor requires a power supply (1)

and earth (4) to create a linear voltage signal (2).

Effect of temperature signal on the system:

- none.

Effect of pressure signal on the system:

- CAN message to VIC to actuate oil pressure

indicator light and warning on the DIP main

display when engine oil pressure is too low.

P

2

1

U

3

T

R

4

i400791

2-8

©

200528

Page 73

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

2.8 CRANKSHAFT SENSOR

1 Electrical connection, earth

2 Electrical connection, signal

3 Electrical connection, shield

A Crankshaft sensor

B Flywheel housing

C Magnet

D Metal core

ECoil

F Flywheel

G Hole pattern

The crankshaft sensor (F552) registers engine

speed and is used to determine the injection

timing. The crankshaft sensor is responsible,

together with the camshaft sensor, for

synchronisation when starting the engine. If there

is no camshaft signal, the crankshaft signal is

used for cylinder detection.

The crankshaft sensor (A) is mounted on the

flywheel housing (B). It is an inductive sensor and

consists of a magnet (C), a metal core (D) and a

coil (E). Inductive means that the sensor can

generate an alternating voltage signal

independently by means of a changing magnetic

field. The pattern of holes in the flywheel (F)

means that the sensor can generate a specific

alternating signal. The pattern consists of 3

segments each with 18 holes and an area with

2 holes missing (G). Each segment is used for

calculations on two specific cylinders (1/6, 2/5

and 3/4).

The sensor has 3 connections. Pins 1 and 2 are

responsible for the signal. Pin 2 is the signal

connection and pin 1 is the earth connection. Pin

3 is connected to the shield around the signal

wires and to the earth connection (pin 1). This

prevents the engine speed signal being affected

by signals from outside.

Description of components

1

2

A

3

B

1

S

N

C

D

E

1

F

18

G

I400731

©

200528 2-9

Page 74

1

DMCI ENGINE MANAGEMENT SYSTEM

Description of components XF105 series

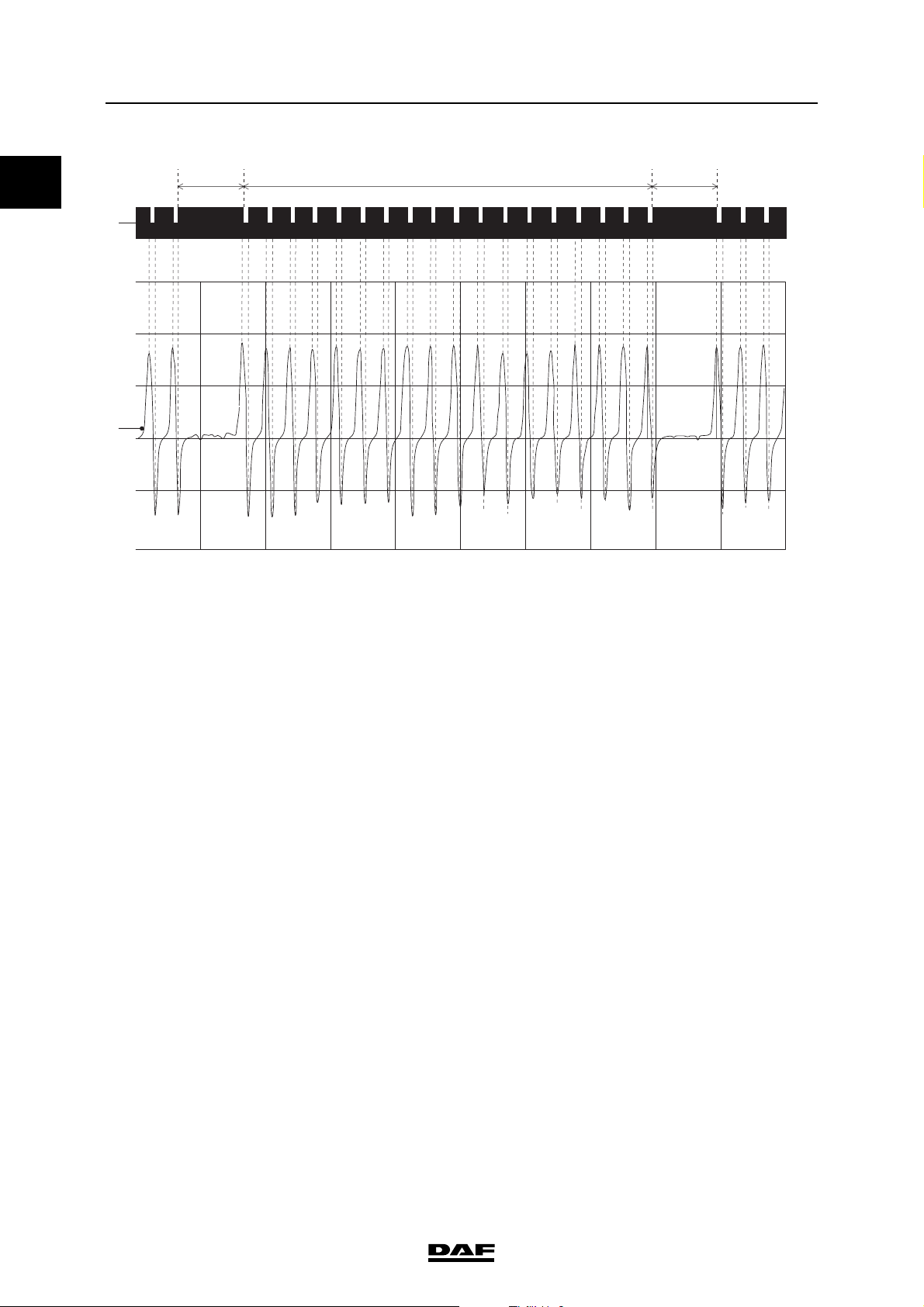

The most powerful changes in the magnetic field

of the sensor take place when the pattern of holes

(1) in the flywheel changes from a hole to a tooth

and vice versa. A sine-wave alternating voltage

(2) is generated as a result of this changing

magnetic field. As a hole approaches, the

crankshaft sensor signal must be at the maximum

positive value and then drop to the maximum

negative value as the end of the hole

approaches. This is determined by the sensor

connections to the electronic unit! The electronic

unit converts this sine-wave alternating voltage

signal to a digital signal (3) which it uses to carry

out calculations.

1

2

3

E500606

ab

c

1

2

2-10

©

200528

I400732

Page 75

DMCI ENGINE MANAGEMENT SYSTEM

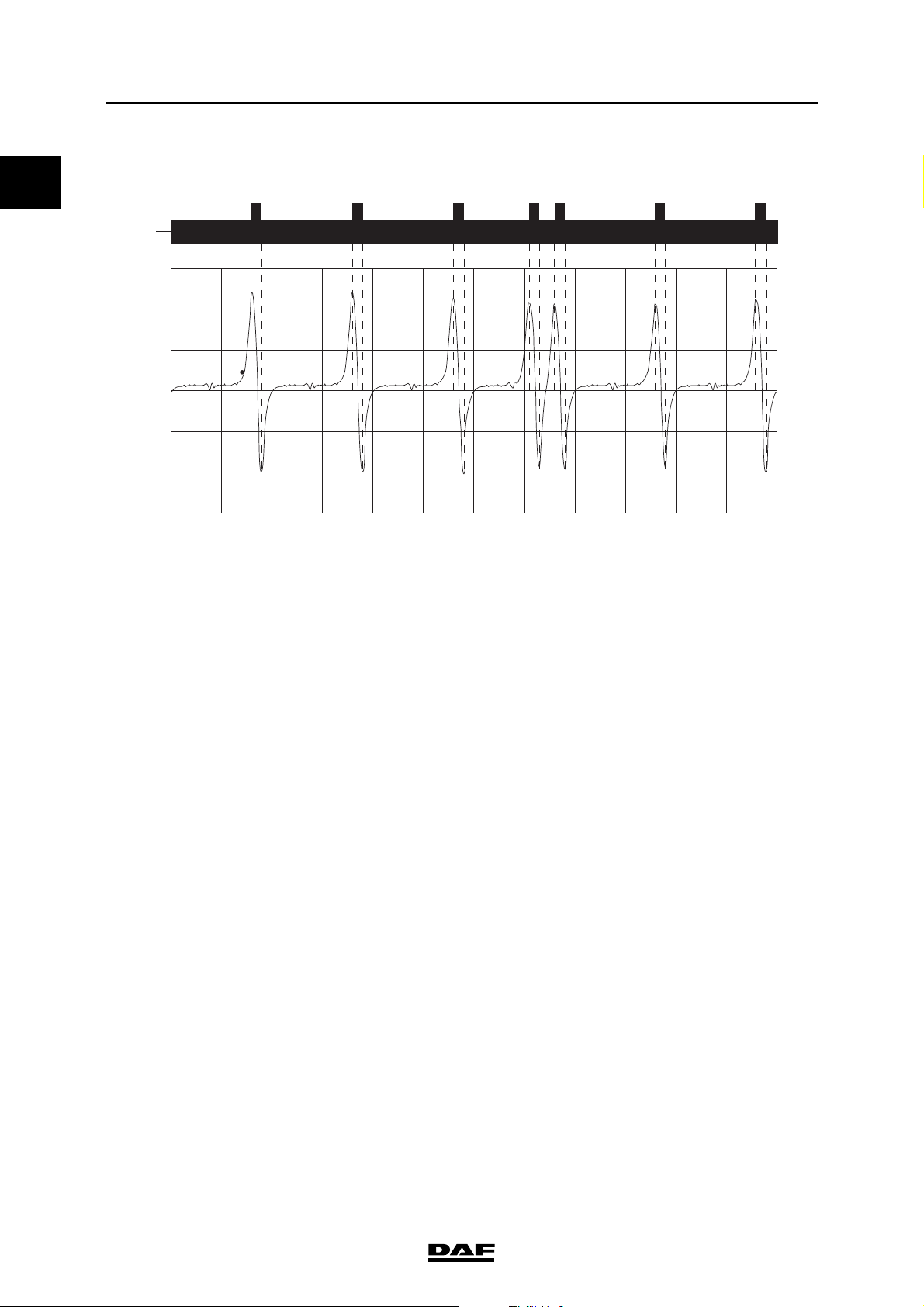

XF105 series

Sine-wave signals (2) can be measured using an

oscilloscope with the engine running using the

pattern of holes in the flywheel (1). Each hole in a

segment (b) generates a sine-wave pulse. When

the area with the two holes missing (a and c) goes

under the crankshaft sensor, the pulse pattern is

interrupted. This enables the sensor to detect the

end of the segment.

Effect of output signal on the system:

- synchronisation during starting;

- injection timing calculation;

- registration of engine speed;

- cylinder detection if there is no camshaft

signal.

- CAN message engine speed to other vehicle

systems via V-CAN1 (AS Tronic, EAS) and

V-CAN2 (VIC-2, ZF intarder EST-42, ABS-D,

EBS-2, DIP-4, ECAS-4, builder module)

- output signal engine speed (EMAS, cab

lead-through connector).

Description of components

1

©

200528 2-11

Page 76

1

DMCI ENGINE MANAGEMENT SYSTEM

Description of components XF105 series

2.9 CAMSHAFT SENSOR

The camshaft sensor (F558) is responsible,

together with the crankshaft sensor, for

synchronisation when starting the engine. The

signal also provides the information relating to

cylinder detection. If the crankshaft sensor (F552)

is defective the camshaft signal acts as a reserve

signal for registering the engine speed and

determining the correct injection timing.

1 Electrical connection, signal

2 Electrical connection, earth

3 Electrical connection, shield

A Camshaft sensor

B Flywheel housing

C Magnet

D Metal core

ECoil

F Pulse wheel

The camshaft sensor (A) is mounted on the

flywheel housing (B). It is an inductive sensor and

consists of a magnet (C), a metal core (D) and a

coil (E). Inductive means that the sensor can

generate an alternating voltage signal

independently by means of a changing magnetic

field. The sensor can generate a specific

alternating signal by means of a tooth pattern on

the pulse wheel (F). The sensor has 3

connections. Pins 1 and 2 are responsible for the

signal. Pin 1 is the signal connection and pin 2 is

the earth connection. Pin 3 is connected to the

shield around the signal wires and to the earth

connection (pin 2). This prevents the signal being

affected by signals from outside.

1

S

A B

S

N

5

4

1

2

3

C

D

E

3

F

6

2

I400761

2-12

©

200528

Page 77

DMCI ENGINE MANAGEMENT SYSTEM

XF105 series

The most powerful changes in the magnetic field

of the sensor take place when the tooth pattern

(1) on the pulse wheel changes from a tooth to a

hole and vice versa. A sine-wave alternating

voltage (2) is generated as a result of this

changing magnetic field. As a tooth approaches,

the camshaft sensor signal must be at the

maximum positive value and then drop to the

maximum negative value as the end of the tooth

approaches. This is determined by the sensor

connections to the electronic unit! The electronic

unit converts this sine-wave alternating voltage

signal to a digital signal (3) which it uses to carry

out calculations.

624s153

Description of components

1