Daewoo DWF-750, DWF-752, DWF-800, DWF-802, DWF-8000 Service Manual

...

Service Manual

Washing Machine

Model: DWF-750/752/800/802

DWF-8000/8001/8002

S/M No. :

✔ Caution

: In this Manual, some parts can be changed for improving, their per-

formance without notice in the parts list. So, if you need the latest

parts information, please refer to PPL(Parts Price List) in Service

Information Center (http://svc.dwe.co.kr).

DAEWOO ELECTRONICS CORP.

http : //svc.dwe.co.kr Sep. 2011

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

WASHING MACHINE

Contents

1. SPECIFICATIONS................................................................................................................... 2

2. STRUCTURE OF THE W ASHING MACHINE........................................................................ 3

3. FUNCTIONS OF THE CONTROL PANEL............................................................................. 4

4. WASHING PR OCEDURE AND PROGRAM SELECTION

FULL AUTOMATIC PROGRAM ..................................................................................................... 5

RESERVED WASHING.................................................................................................................. 7

PARTIAL PROCESS & COMBINATION ........................................................................................ 7

5. DIRECTIONS FOR INSTALLATION AND USE

LOCATION OF WASHER............................................................................................................... 8

DRAIN SYSTEM.............................................................................................................................. 8

HOW TO CONNECT THE INLET HOSE ....................................................................................... 9

HOW TO CLEAN THE FILTER..................................................................................................... 10

6. FEATURE AND TECHNICAL EXPLANATION

FEATURE OF THE WASHING MACHINE................................................................................... 11

WATER CURRENT TO ADJUST THE UNBALANCED LOAD.................................................... 11

AUTOMATIC WATER SUPPLY SYSTEM .................................................................................. 11

AUTOMATIC DRAINING TIME ADJUSTMENT...........................................................................12

SOFTENER DISPENSER............................................................................................................. 13

AUTOMATIC UNBALANCE ADJUSTMENT................................................................................ 14

CIRCULATING-WATER................................................................................................................ 14

LINT FILTER ................................................................................................................................. 15

RESIDUAL TIME DISPLAY .......................................................................................................... 15

DRAIN MOTOR.............................................................................................................................15

GEAR MECHANISM ASS’Y ......................................................................................................... 16

PRINCIPLE OF BUBBLE GENERATOR...................................................................................... 16

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MACHINE.................................................17

7. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT

GEAR MECHANISM ASS’Y REPLACEMENT............................................................................. 18

MOTOR SYNCHRONOUS AND VALVE REPLACEMENT......................................................... 20

BRAKE ADJUSTMENT................................................................................................................. 20

8. THE REPAIR METHOD OF GEAR MECHANISM FOR CLUTCH SPRING PROBLEM

THE STRUCTURE OF GEAR MECHANISM............................................................................... 21

HOW TO CHECK THE CLUTCH SPRING PROBLEM................................................................ 22

THE PROCESS OF DISASSEMBLE............................................................................................ 23

THE PROCESS OF ASSEMBLE.................................................................................................. 25

9. TROUBLE SHOOTING GUIDE

CONCERNING WATER SUPPLY.................................................................................................27

CONCERNING WASHING........................................................................................................... 28

CONCERNING DRAINING........................................................................................................... 29

CONCERNING SPINNING........................................................................................................... 30

CONCERNING OPERATION....................................................................................................... 31

10. PRESENTATION OF THE P.C.B ASS’Y............................................................................ 32

APPENDIX

WIRING DIAGRAM....................................................................................................................... 33

PARTS DIAGRAM & PARTS LIST............................................................................................... 37

CIRCUIT DIAGRAM...................................................................................................................... 47

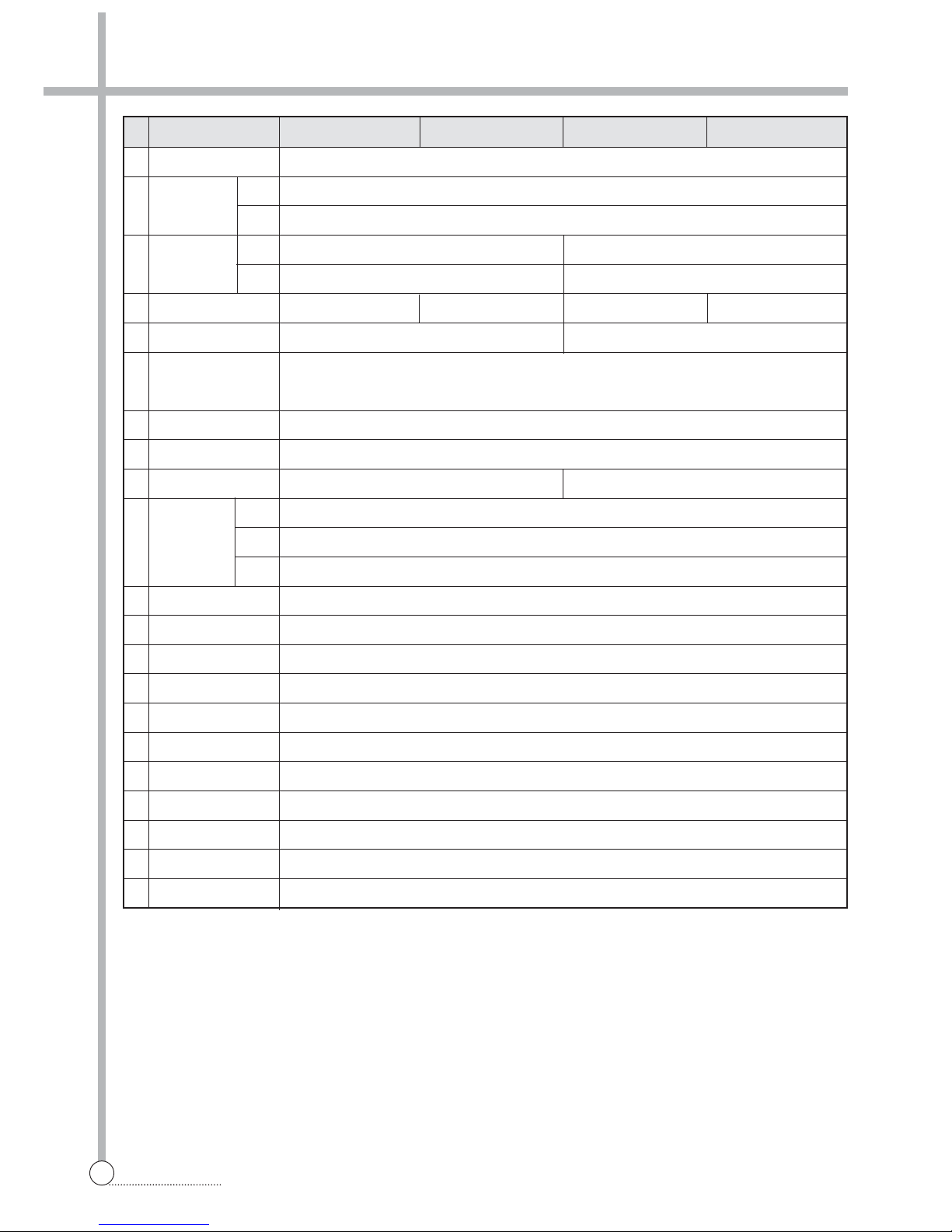

1. SPECIFICATIONS

2

SPECIFICATIONS

NO. ITEM

1 POWER SOURCE AVAILABLE IN ALL LOCAL AC VOLTAGE

2

POWER

50Hz 320W

CONSUMPTION

60Hz 300W(110~127V) / 340W(220V)

3

MACHINE NET

WEIGHT

GROSS

4 DIMENSION (WXHXD)

5

MATERIAL OF INTERNAL TUB

PLASTIC STAINLESS STEEL

6

WASHING PROGRAM

FULL AUTOMATIC 6 PROGRAMS

(FUZZY, FUZZY+SOAK, HEAVY, HEAVY+SOAK, SPEEDY, WOOL/SUIT)

7

WATER LEVEL SELECTOR

HIGH(55l), MID(45l), LOW(31l)

8

OPERATING WATER PRESSURE

0.3kgf/cm2~8kgf/cm

2

(2.94 N/cm2~78.4N/cm2)

9

MAXIMUM MASS OF TEXTILE

5.5kg 6.0kg

REVOLUTION

WASH 125~145(50Hz), 130~150(60Hz)

10 SPIN 710~725(50Hz), 760~785(60Hz)

PER MINUTE

SUIT 50(50Hz), 60(60Hz)

11

WATER CONSUMPTION

APPROX. 130l/CYCLE

12

WATER LEVEL CONTROL

ELECTRONICAL SENSOR

13 ANTI NOISE PLATE OPTION

14

GEAR MECHANISM ASS’Y

SPUR GEAR

15 LINT FILTER O

16 SOFTENER INLET O

17 ALARM SIGNAL O

18 AUTO. WATER SUPPLY O

19

FUNCTION FOR BUBBLE

OPTION

20

AUTO RE-FEED WATER

O

21 AUTO POWER OFF O

DWF-750 DWF-752 DWF-800/8000 DWF-802/8002

525X858X535 525X948X535 525X858X535 525X948X535

28kg/28.5kg(pump)

31.5kg/32kg(pump)

28.5kg/29kg(pump)

32kg/32.5kg(pump)

DRYTEN(OPTION) HOSE ADAPTER UNDER COVER(OPTION)

INLET HOSE(OPTION)

HOSE CONNECTOR(OPTION)

CONNECTOR INLET(OPTION)

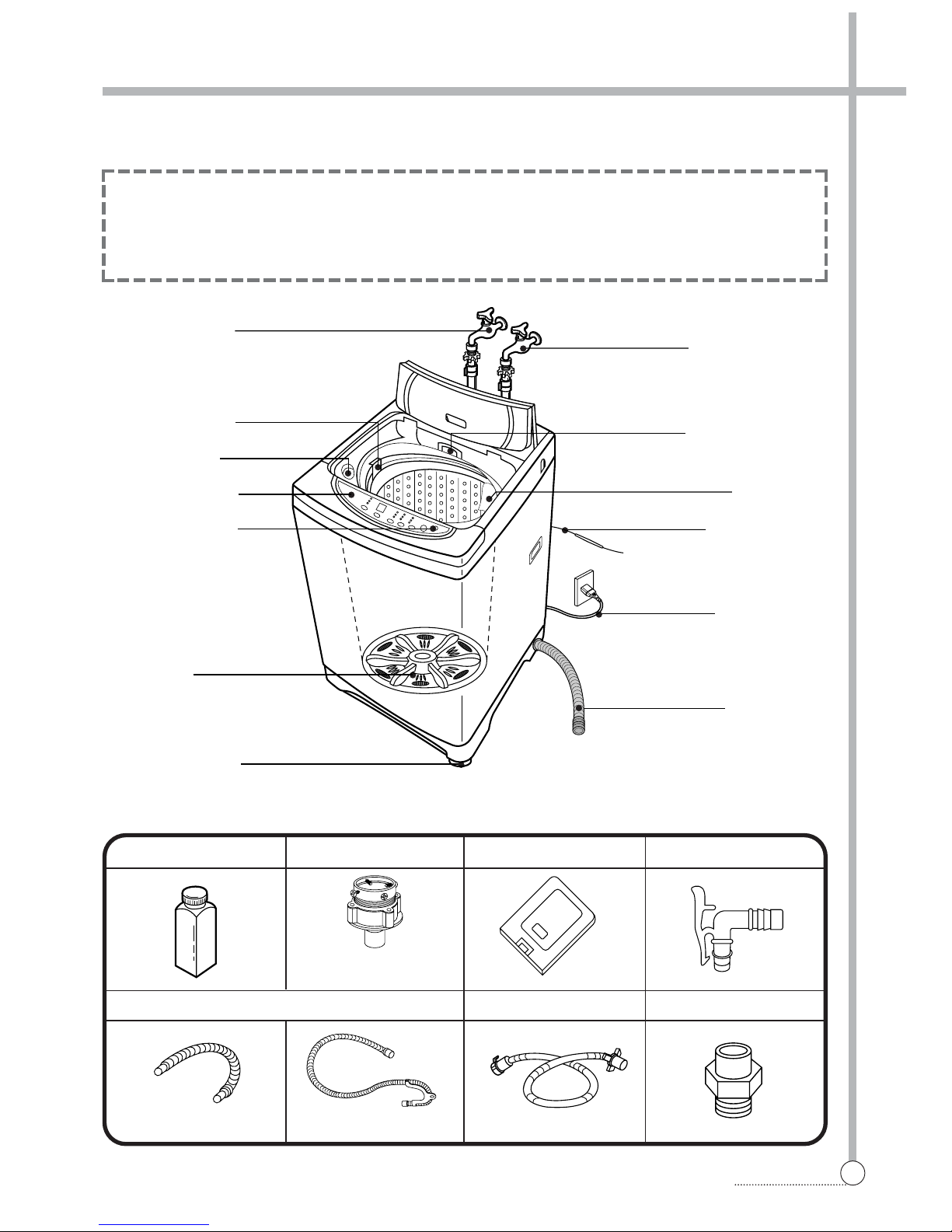

2. STRUCTURE OF THE WASHING MACHINE

3

STRUCTURE

• GROUND WIRE

In case of 3-wire

power cord, ground

wire will not be

provided

• POWER CORD

• DRAIN HOSE

• LINT FILTER

• COLD WATER TAP

After using the washer,

close the water tap

• DETERGENT CASE

• ADJUSTABLE LEG

• SOFTENER INLET

• BLEACH INLET

• CONTROL PANEL

• POWER SWITCH

• PULSATOR

• HOT WATER TAP

After using the washer, close the water tap.

In case of the single valve model,

there is no hot water valve.

UP

The parts and features of your washer are illustrated on this page.

Become familiar with all parts and features before using your washer.

NOTE

• The drawing in this book may vary from your washer model. They are designed to show the different features of all models covered by this book, Your model may not include all features.

• Page references are included next to same features.

Refer to those pages for more information about the features.

DRAIN HOSE

In case of screw shaped inlet hoses

water tap adapters will not be provided.

NON PUMP MODEL PUMP MODEL

■

Accessories

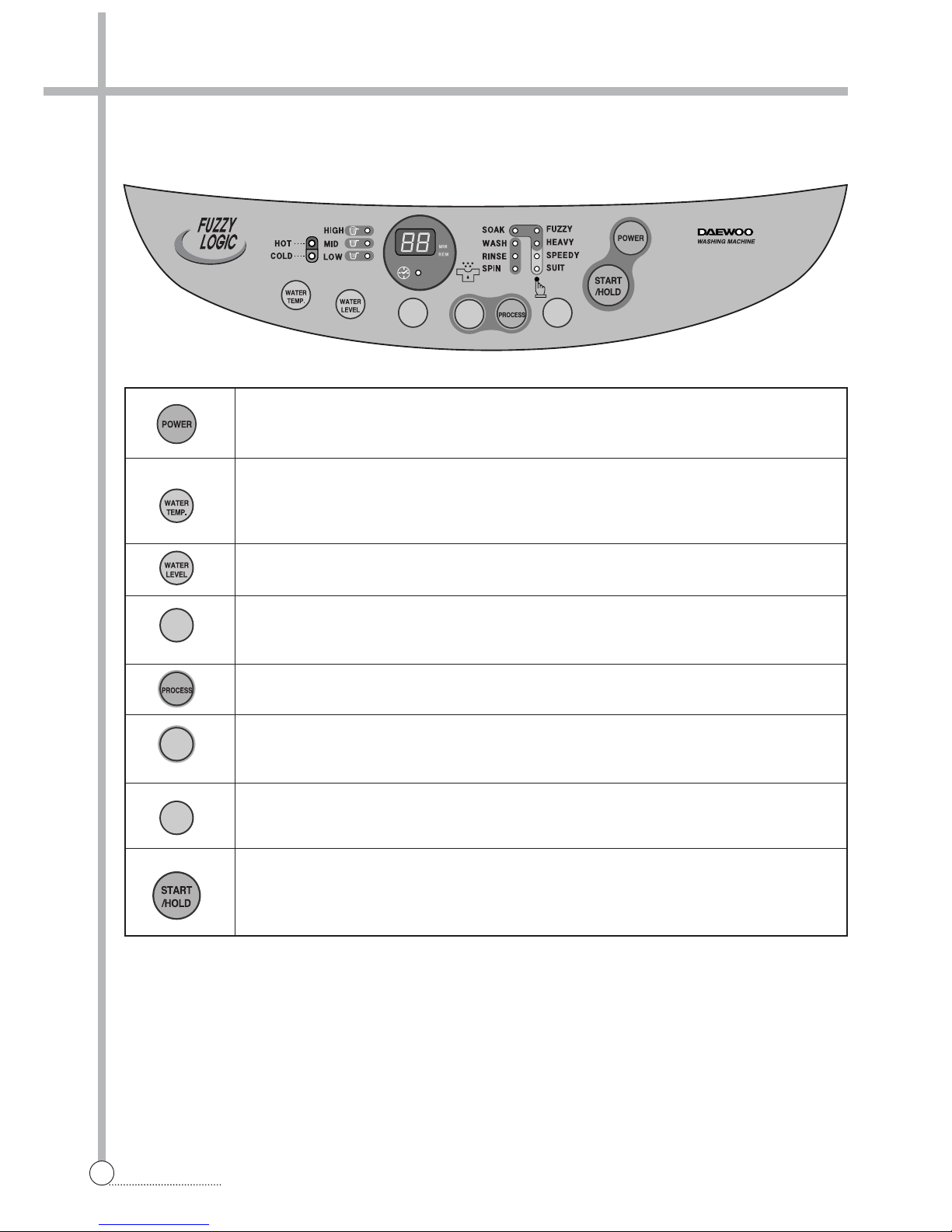

3. FUNCTIONS OF THE CONTROL PANEL

4

CONTROL PANEL

• Press this switch to turn the power on or off.

• It can be used to choose water temperature to be supplied.

• As the button is pressed, water temperature will be repeated.

COLD → COLD+HOT → HOT

• In case of the single valve model, there is no wash temperature selector function.

• It can be used to adjust amount of water according to the size of the load to be washed.

• As the button is pressed, water level is selected by MID → HIGH → LOW

• It can be used to pre-engage time for wash.

• It is the button for the partial process or the combination of each process (wash, rinse,

spin) (See page 7)

• If you want to change wash time, rinse times, spin time, you must press this button after

selecting each process by the process button. Also, this button can be used to spin only.

(See page 7)

• It can be used to select the full-automatic program.

• As the button is pressed, program will be selected by following order :

FUZZY → FUZZY+SOAK → HEAVY → HEAVY+SOAK → SPEEDY → SUIT(WOOL)

• Operation and temporary stop is repeated as it is pressed.

• When you want to change program in operating;

press the “START/HOLD” button → Select the program that you want to change → press

the “START/HOLD” button again.

RES.

HOURS

CONTROL

PROGRAM

Control panel has micom sensor.

As the buttons are pressed, the lamps indicating the selection of your desired washing program will light up.

RES.

CONTROL

PROGRAM

4. WASHING PROCEDURE AND PROGRAM SELECTION

5

PROCEDURE

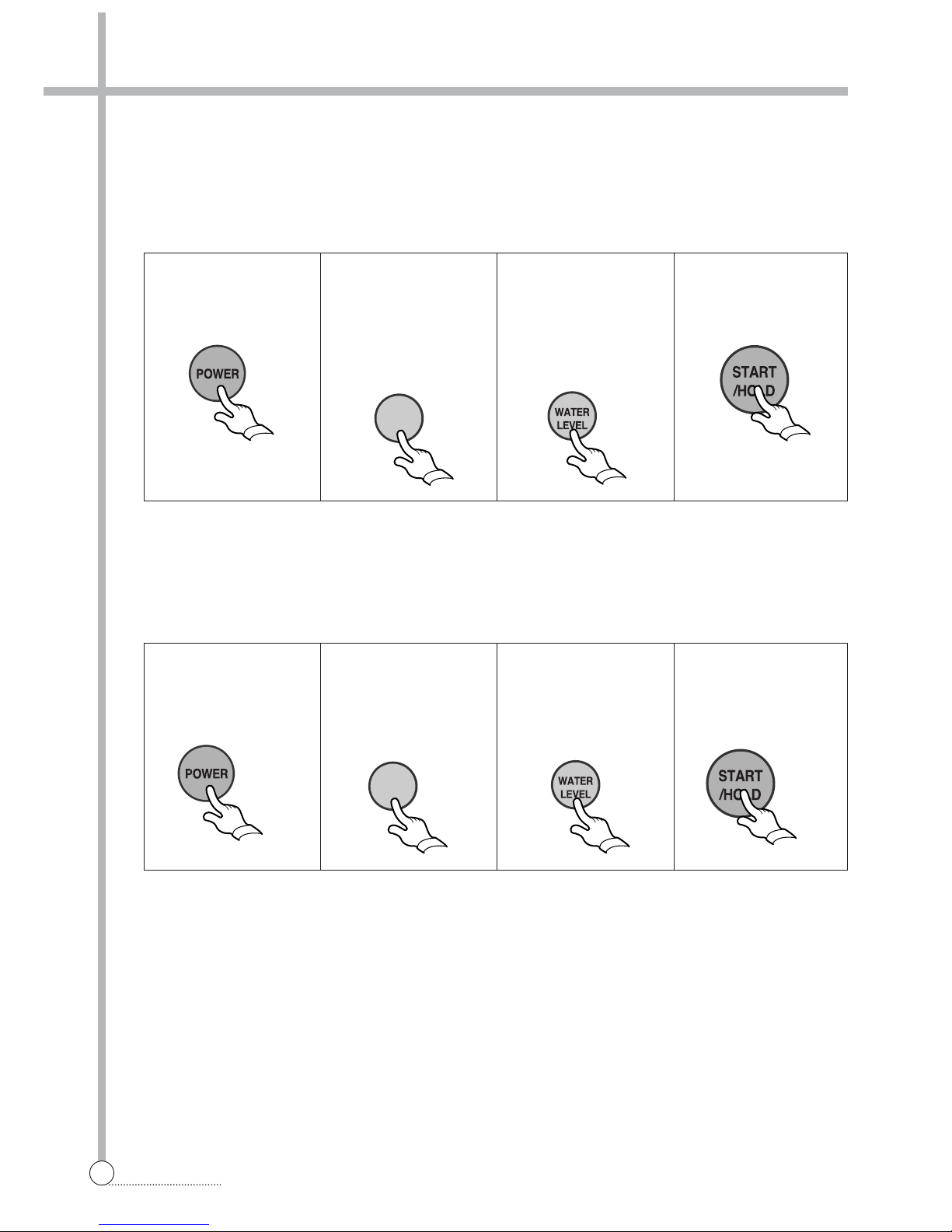

1. FUZZY PROGRAM (SENSOR);

• This selection is for general washing except extraordinary clothes.

• Artificial brain sensor selects properly the various kind of washing condition such as washing time, rinse times,

spin time and water level. Procedure to press the button;

3. SPEEDY PR OGRAM;

• This selection is useful to reduce water consumption and washing time for less dirty clothes. Procedure to press

the button;

2. HEA VY PR OGRAM;

• This selection is effective for blue-jean, climbing clothes, rucksack, sports wear etc..

• Procedure to press the button;

■■

Full Automatic Pr ogram

1 Put in the clothes 2 Press the power switch. 3 Press the Start/Hold button, and

close the lid.

1 Press the power switch. 2

Press the program selection button for “SPEEDY

”

○ FUZZY

○ HEAVY

● SPEEDY

○ WOOL/SUIT

3 Select the water level

proper to the wash

load.

○ HIGH

● MID

○ LOW

4 Press the Start/Hold

button and close the lid.

PROGRAM

1 Press the power switch. 2

Press the program selection button for “HEAVY”

○ FUZZY

● HEAVY

○ SPEEDY

○ WOOL/SUIT

3 Select the water level

proper to the wash

load.

○ HIGH

● MID

○ LOW

4 Press the Start/Hold

button and close the lid.

PROGRAM

4. SUIT(WOOL) PROGRAM;

• This selection is effective for suit/wool clothes. (1.2kg’s limitation for 1-time wash)

• Do not put leather clothes, or chamios clothes into the washing tub for washing. It may cause shrinkage or deformation to the clothes.

• Please use the neutral detergents only.

• The water temperature is fixed to “COLD”.

• The water level “LOW” is not selected. Procedure to press the button;

6

PROCEDURE

1 Press the power switch. 2

Press the program selection

button for “WOOL

” or “SUIT”.

○ FUZZY

○ HEAVY

○ SPEEDY

● WOOL/SUIT

3 Select the water level

proper to the wash

load.

○ HIGH

● MID

○ LOW

4 Press the Start/Hold

button and close the lid.

PROGRAM

1 Press the power switch. 2

Press the program selection

button for “SOAK”

SOAK ●●FUZZY

WASH ○○HEAVY

RINSE ○○SPEEDY

SPIN ○○

WOOL/SUIT

3 Select the water level

proper to the wash

load.

○ HIGH

● MID

○ LOW

4 Press the Start/Hold

button and close the lid.

PROGRAM

5. SOAK PROGRAM;

• This selection is effective for heavily soiled clothes.

• If you want to soak, press the program button to adjust to “FUZZY + SOAK” or “HEAVY + SOAK”. Precedure to

press the button;

7

PROCEDURE

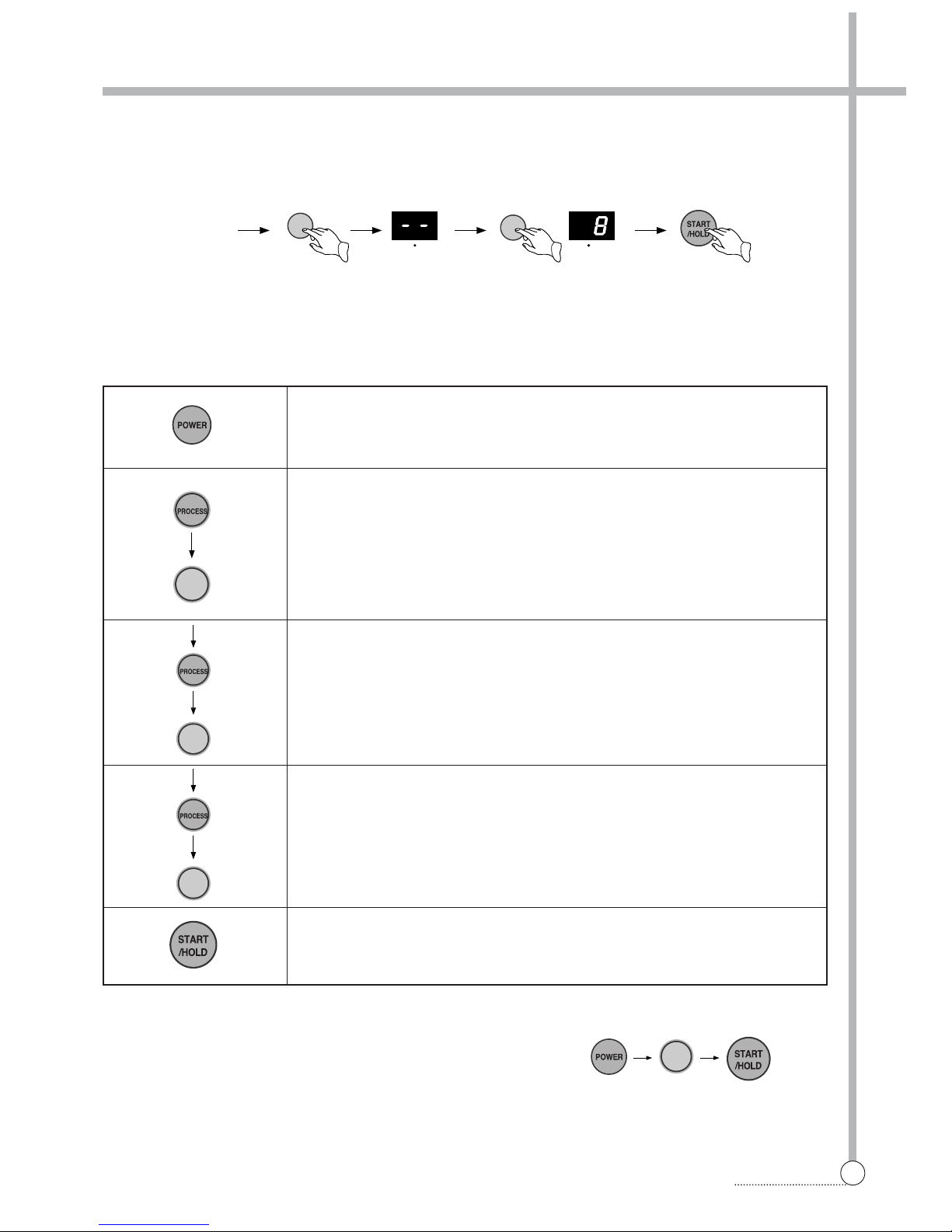

■■

Reserved Washing

■■

Partial Process & Combination

WASH TIME CONTROL

• As the control button is pressed, wash time will be repeated as following;

12 → 15 → 18 → 0 → 6 → 9min.

• If you don’t want wash process, you must adjust wash time to 0 min..

RINSE TIMES CONTROL

• As the control button is pressed, rinse times will be repeated as following;

2 → 3 → 4 → 0 → 1 time(s)

• If you don’t want rinse process, you must adjust rinse times to 0 times.

SPIN TIME CONTROL

• As the control button is pressed, spin times will be repeated as following;

5 → 7 → 9 → 0 → 1 → 3 min.

• If you don’t want spin process, you must adjust spin time to 0 min..

• Reservation can be made from 2 hours to 48 hours.

• To make reservation to complete washing in 8 hours.

• Now the reservation is made.

• If you want to check the selected program, press the “START/HOLD” button again.

RES.

RES.

adjust to "8""--" shall blink

Select the program.

Adjust to water level

and water temperature.

HOURS

MIN

HOURS

MIN

■■

Convenient Operation For Spin Onl y

• If you want spin oly, it is convenient to operate the button as following;

CONTROL

CONTROL

CONTROL

CONTROL

8

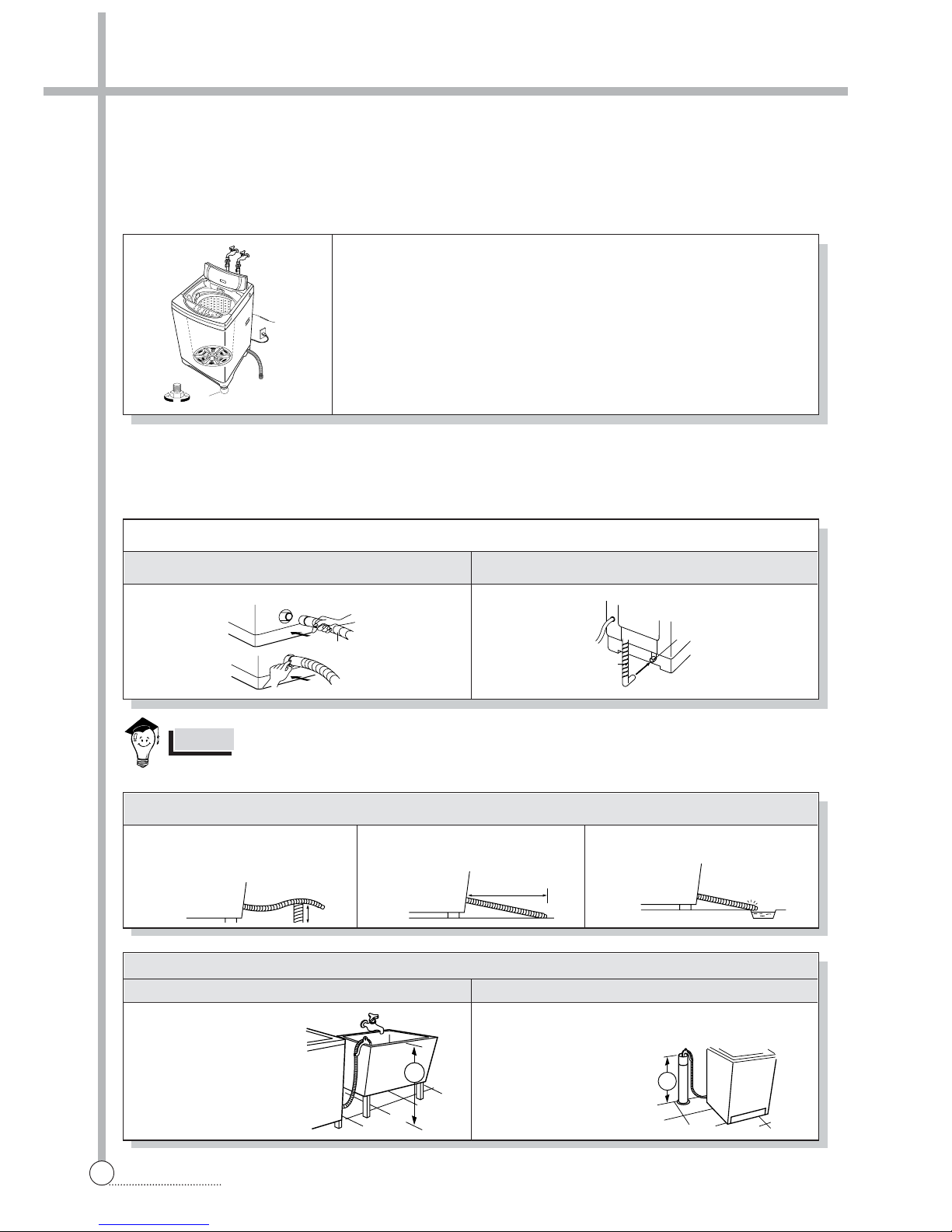

5. DIRECTIONS FOR INSTALLATION AND USE

DIRECTIONS

The opening must not be obstructed by carpeting when the washing machine is installed on a carpeted floor.

■■

Location Of Washer

Check location where washer will be installed. Make sure you have everything necessary for correct installation.

Proper installation is your responsibility.

• Do not place or store your washer below 0˚C(32˚F) to avoid any damage from freezing.

• Install the washer on the horizontal sold foor.

NOTES

If the washer is installed on an unsuitable floor, it could make considerable noise, vibrate and cause a malfunction.

If washer is not level, adjust the front leg(A) up or down for horizontal setting.

• Earthed electrical outlet(B) is required with 20cm of bottom back of

washer cabinet.

• Hot and cold water faucets (C) must be within 1M of the upper back of

the washer cabinet and provide water pressure 0.3kgf/cm

2

-

8kgf/cm

2

(2.94N/cm2-78.4N/cm2).

■■

Drain System

Never forget to install drain hose before operating your washer.

The packing box is opened, there are a drain hose.

• Conect the drain hose to the drain outlet at the back side of the washer.

Non-Pump Model Pump Model

1 In case that it goes over a door sill.

Don’t let the height of the drain

hose exceed 20cm from the bottom

of washer.

2 In case of extending the drain hose.

Don’t let the total length exceed 3m.

3 Be careful that the end of the drain

hose is not immersed in water.

Non-Pump Model

• Top of tub must be at

least 86cm (34inches)

high and no higher than

130cm from bottom of

washer (A)

• Needs a 3cm minimum diameter standpipe with minimum

carry away capacity of 30liters per minute.

• Top of tub must be at

least 86cm(34inches)

high and no higher than

130cm from bottom of

washer (B)

Pump Model

Laundry tub drain system Standpipe drain system

C

UP DOWN

B

A

Drain hose

Drain Outlet

Drain hose

20Cm

3m

A

B

9

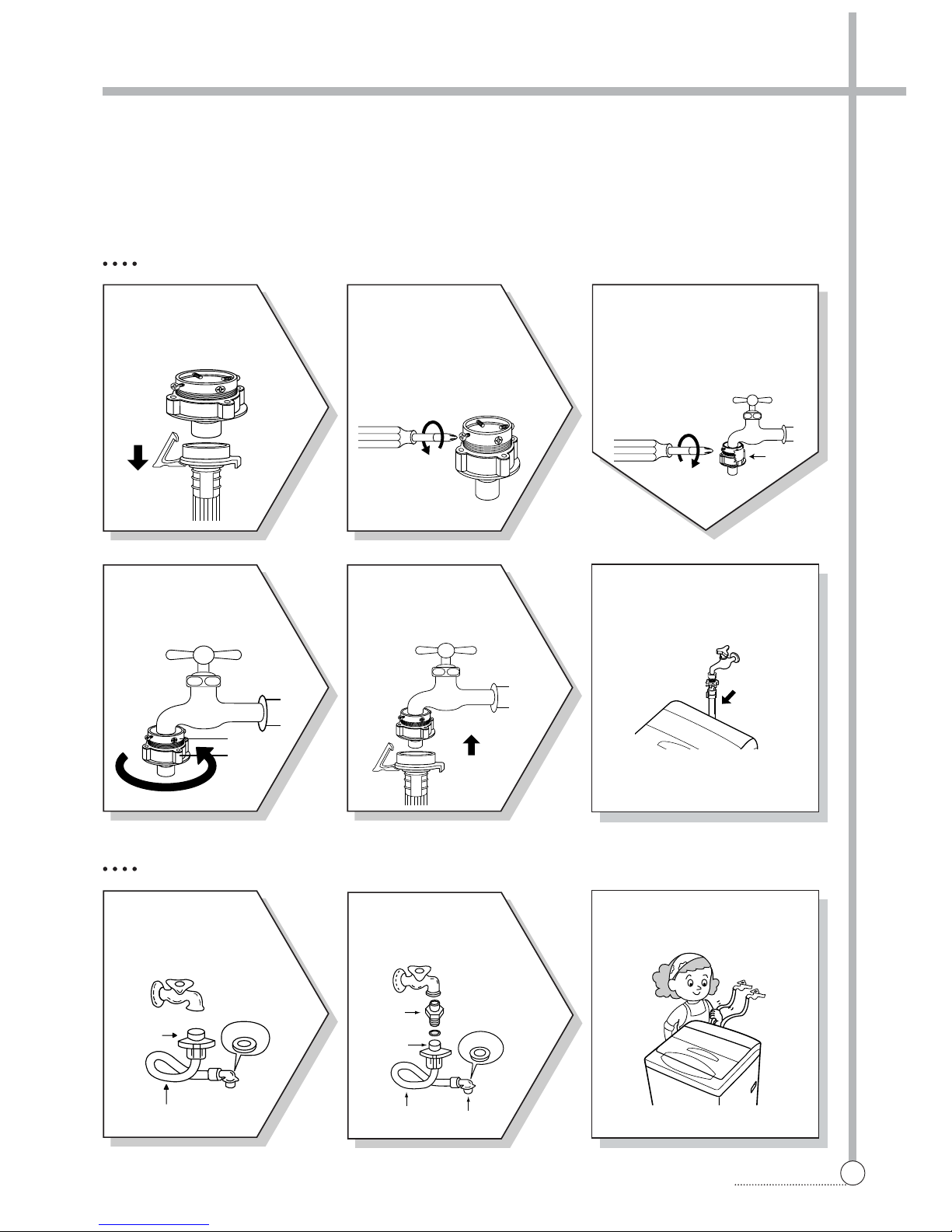

CONNECTION

FOR ORDINARY TAP

6

Connect the inlet hose adapter

of the hose to the water inlet of

the washer by turning it clockwise to be fixed tightly.

• Please check the rubber packing

inside the inlet hose adapter of

the hose.

1

Pull down the collar

of the inlet hose to

separate it from the

water tap adapter.

2

Loosen the four

screws at the water

tap adapter, but don’t

loosen the screws until

they are separated from

the water tap adapter.

4

Remove the tape,

and screw connector

B into connect A tightly.

5

Connect the inlet

hose to the water tap

adapter by pulling down

the collar of the hose end.

3

Connect the water tap

adapter to the water tap and

tighten the four screws evenly

while pushing up the adapter

so that the rubber packing

can stick to the water tap

tightly.

■■

How to Connect the Inlet Hose

Be careful not to mistake in supplying between the hot(maximum : 50˚C) and cold water.

In using only one water tap or in case of attached one water inlet valve, connect the inlet hose to the cold water inlet

valve.

Do not over tighten : this could cause damage to couplings.

FOR SCREW-SHAPED TAP

3

Insert the inlet hose adapter

into the water inlet of washer

and turn it to be fixed.

• Assert the packing in the inlet

1

Connect the inlet

hose to the water tap

by screwing the connector D tightly.

Inlet Hose

Connector D

Rubber

Packing

Connector C

TAPE

Connector B

Connector A

← collar

2

Connect the connector-inlet supplied if

necessary.

Connector

Inlet

Rubber

Packing

Connector D

Connector C

Hose

10

CONVENIENCE

■■

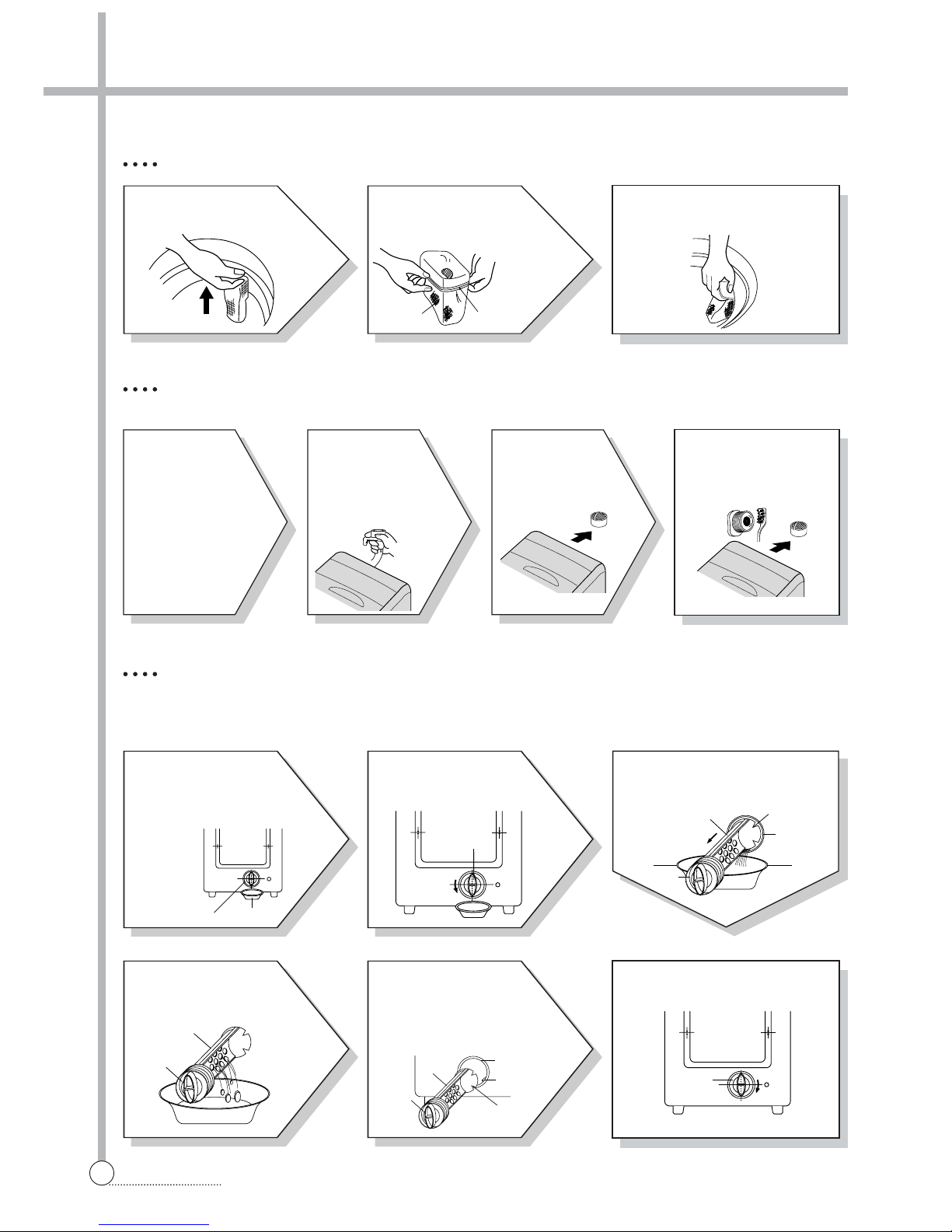

How To Clean The Filter

4

Remove the dirt

from the inlet filter

with a brush.

1

Pull the

power plug

out before

cleaning it.

2

Turn off the

water supply

to the washer

and separate

the inlet hose.

3

Pull the

inlet filter out.

CLEANING THE LINT FIL TER

CLEANING THE WATER INLET FIL TER

• Clean the filter when water leaks from the water inlet.

CLEANING THE DRAIN FIL TER

• In case of “U” shaped drain hose, this filter’s equipped at the back side of washer.

• This drain filter is to screen the foreign stuffs such as threads, coins, pins, buttons etc ..

• If the drain filter is not cleaned at proper time (every 10 times of use), drain problem could be caused.

3

Return the filter as it was, and

insert the filter frame into the

slot.

1

Pull the Filter frame

upward.

2

Turn the lint filter

inside out, wash the

lint off with water.

1

Put down the

remained water in the

hose. And put a container

under the filter to collect

water.

2

Turn the cap counterclockwise.

3

Pull out the filter assembly off

the case of the main body.

6

Turn the cap clockwise tightly.

4

Clean the drain filter

removing the foreign

stuffs.

5

Put in the filter along the

guiding prominence of the

case. Please note the left

position of the filter adjusting

the groove to the guide rib.

FILTER

CONTAINER

CAP

SLIT

CASE

FILTER

CAP

CAP

FILTER

CAP

FILTER

CASE

GUIDE

RIB

SLIT

CAP

Filter Frame

Lint Filter

11

6. FEATURE AND TECHNICAL EXPLANATION

EXPLANATION

WASH DRAIN SPIN FILL RINSE 1 DRAIN SPIN FILL RINSE 2 DRAIN •••

MOTOR C.W

SINGAL C.C.W

TIME(SEC.) 0.4 0.4 0.4 0.4 0.4 0.4 •••••••

40 SEC. (About 25 Times)

* When the water level is “HIGH”

Feature of the Washing Mac hine

1 The first air bubble washing system in the world.

2 Quiet washing through the innovational low-noise design.

3 The wash effectiveness is much more enhanced because of the air bubble washing system.

4 The laundry detergent dissolves well in water because of the air bubble washing system.

5 The adoption of the water currents to adjust the unbalanced load.

6 One-touch operation system.

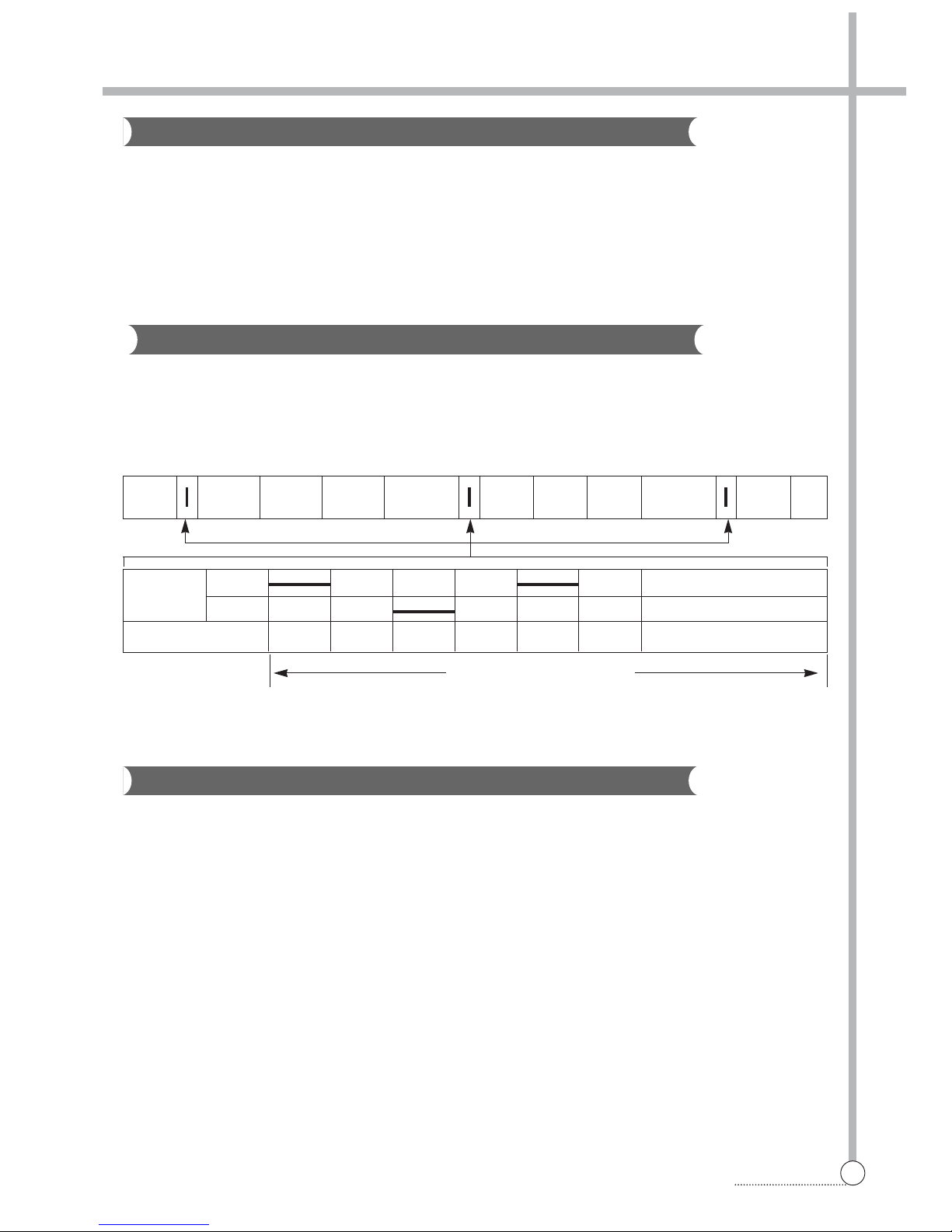

Water Current to Adjust the Unbalanced Load

It is a function to prevent eccentricity of the clothes after wash by rotating pulsator C.W and C.C.W for 35

seconds.(But, the SUIT course have no operation of the water currents to adjust the unbalnced load.)

EFFECT

It reduces vibration and noise effectively while spinning.

WATER FLO W

Automatic Water Supply System

The water level would be lowered because the clothes absorbs water at the beginning of washing. Therefore, after

60 seconds, the operation is interrupted to check the water level, and then the water is supplied again until the selected water level is reached.

12

EXPLANATION

FUNCTIONAL PRINCIPLE

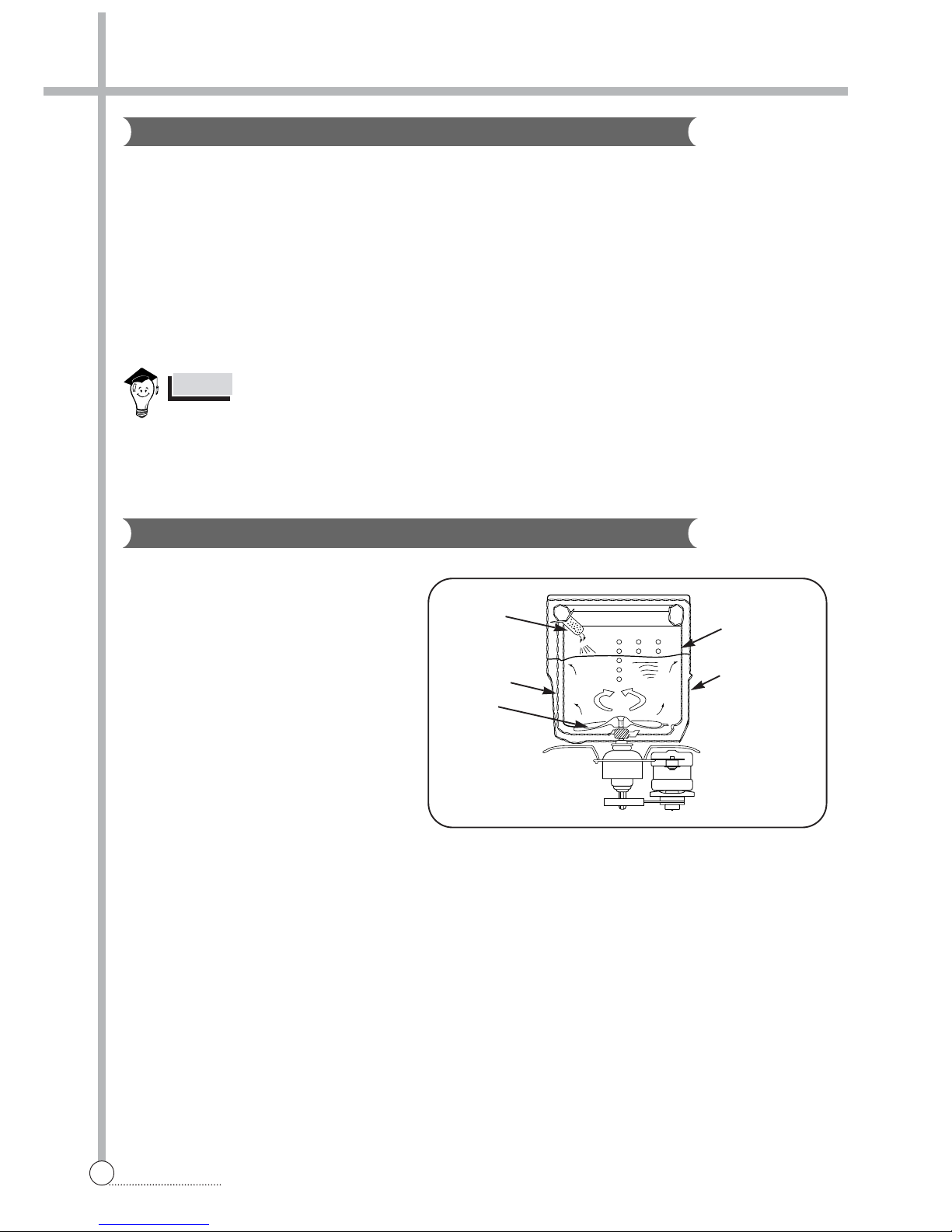

1 The micom can remember the time from the begining of drain to reset point when the pressure switch reaches to

“OFF” point

2 In case of continuous draining, residual drain time is determined by micom.

Draining time as a whole = D + 40

Residual drain time.

The time remembered by micom.

Draining

Good draining The washer begins spin process after drainage.

condition

Bad draining Draininig time is prolonged.

No draining Program is stopped and gives the alarm.

Drain Time Movement of the Program

Less than

Continue draining

10 minutes

More than

Program stops and gives the alarm with blinked on display lamp.

10 minutes

Automatic Drainning time Adjustment

This system adjusts the draining time automatically according to the draining condition.

13

EXPLANATION

This is the device to dispense the softener automatically by centrifugal force.

This is installed inside the auto-balancer.

FUNCTIONAL PRINCIPLE

1 Softener stays in room (A) when poured into softener inlet.

2 Softener moves from (A) to (B) by centrifugal force during intermittent spin process.

3 Softener flows from (B) to (C) during rinse process next to intermittent spin.

4 Softener moves from (C) to (D) by centrigfugal force during second intermittent spin.

After spin process is finished, the softener is added into the tub through softener outlet.

FLOW OF THE SOFTENER

FLOW OF THE SOFTENER INSIDE OF THE BALANCER

HOW TO CHECK MOVEMENT

Pour a reasonable amount of “MILK” into softener dispenser and operate the washer with no load. In final

rinse cycle, make sure that the milk is added into the

tub through softener outlet.

A

B

C

D

Wash Intermittent Hold Intermittent Rinse Spin

Spin Spin

Normal Centrifugal Flow in Centrifugal Flow in

force force

Program (A) (B) (C) (D)

A

B

C D

Room inside

the balancer

Centrifugal force

Flowing by weight

Balancer

Softener

outlet

Softener inlet

Softener Dispenser

Softener moves into the next room when r.p.m of the tub is more than 100 r.p.m.

NOTES

14

EXPLANATION

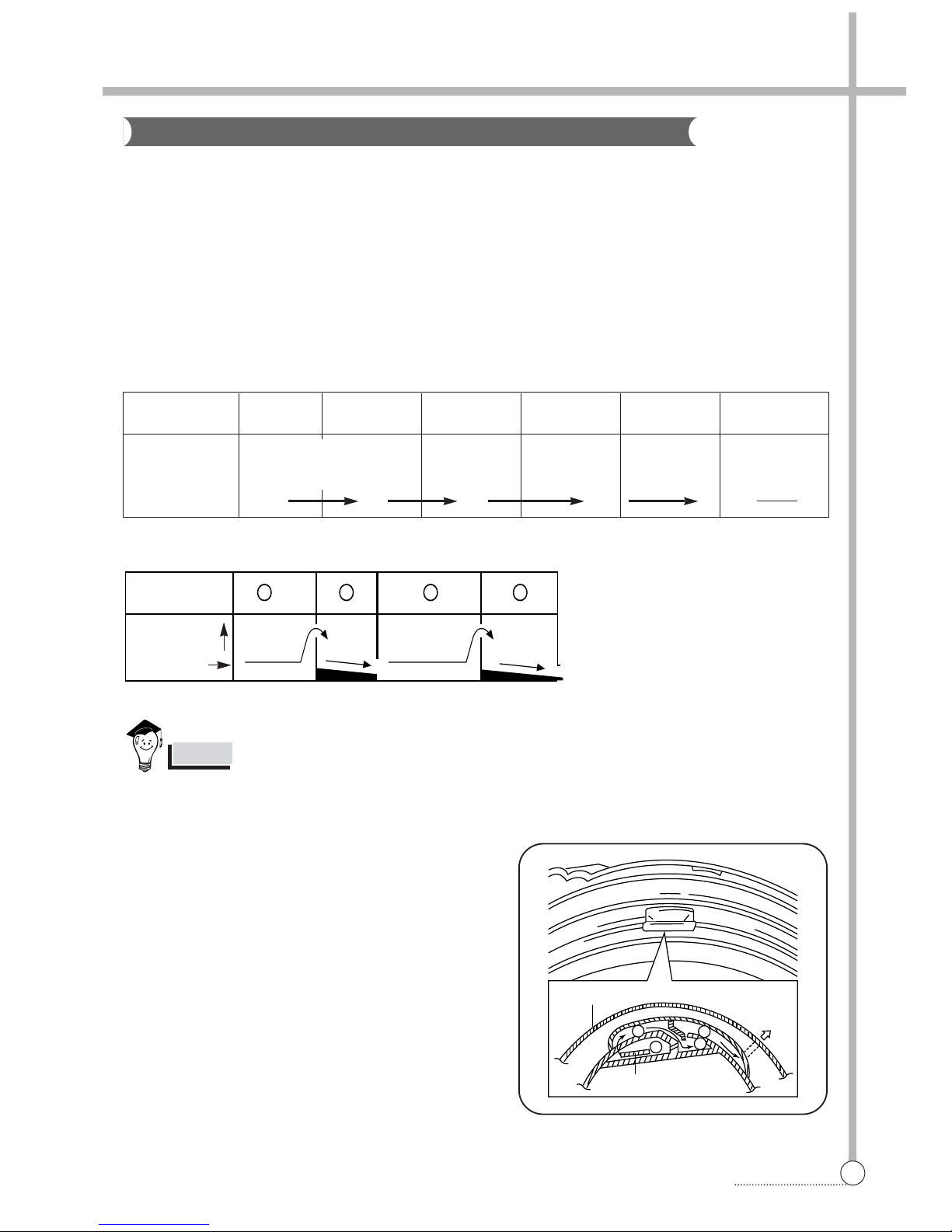

Automatic Unbalance Adjustment

Circulating-W ater

The alarm finished when you close the lid after opening it. Check the unbalance of the wash load and the

installation condition.

NOTES

Filter

Tub

Outer tub

Water

channel

Pulsator

This system is to prevent abnormal vibration during intermittent spin and spin process.

FUNCTIONAL PRINCIPLE

1 When the lid is closed, the safety switch contact is “ON” position.

2 In case that wash loads get uneven during spin, the outer tub hits the safety switch due to the serious vibration,

and the spin process is interrupted.

3 In case that P.C.B. ASS’Y gets “OFF” signal from the safety switch, spin process are stopped and rinse process

is started automatically by P.C.B. ASS’Y.

4 If the safety switch is operated due to the unbalance of the tub, the program is stopped and the alarm is given.

CIRCULA TING-WA TER

The washing and rinsing effects have been

improved by adopting the water system in

which water in the tub is circulated in a

designed pattern.

When the pulsator rotates during the washing

or rinsing process, the water below the pulsator vanes creates a water currents as shown

in figure.

The water is then discharged from the upper

part of the tub through the water channel.

About 40 L/min. water is circulated at the ‘high’

water level, standard wash load and standard

water currents.

Loading...

Loading...