Service Manual

Programmable W ahing Machine

DWF-7588TE/NE/ME

8088TE/NE/ME

9288TE/NE/ME

1088TE/NE/ME

DAEWOO ELECTRONICS CO., LTD.

S/M NO.: WF 10880100

DAEWOO ELECTRONICS CO., L TD.

686, AHYEON-DONG, MAPO-GU,

SEOUL, KOREA

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

FAX: 02) 364-5588/5305

TEL: 02) 360-7114/7315~7

PRINTED DATE: MAR.1996

TABLE OF CONTENTS

1

1. SPECIFICA TIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. FEA TURE AND TECHNICAL EXPLANATION

FEA TURE OF THE WASHING MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

WATER CURRENTS RENTS TO ADJUST THE UNBALANCED LOAD . . . . . . . . . . . . . . . . . . . 3

FUNCTION FOR SOAK WASH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AUTOMATIC WATER SUPPLY SYSTEM FOR BLANKET WASH . . . . . . . . . . . . . . . . . . . . . . . . 3

PULSA TOR SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

AUTOMATIC DRAINING TIME ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SOFTENER DISPENSER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

AUTOMATIC UNBALANCE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CIRCULA TING-WATER COURSE AND LINT FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RESIDUAL TIME DISPLA Y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

DRAIN MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GEAR MECHANISM ASS’Y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

PRINCIPLE OF BUBBLE GENERA T OR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . 9

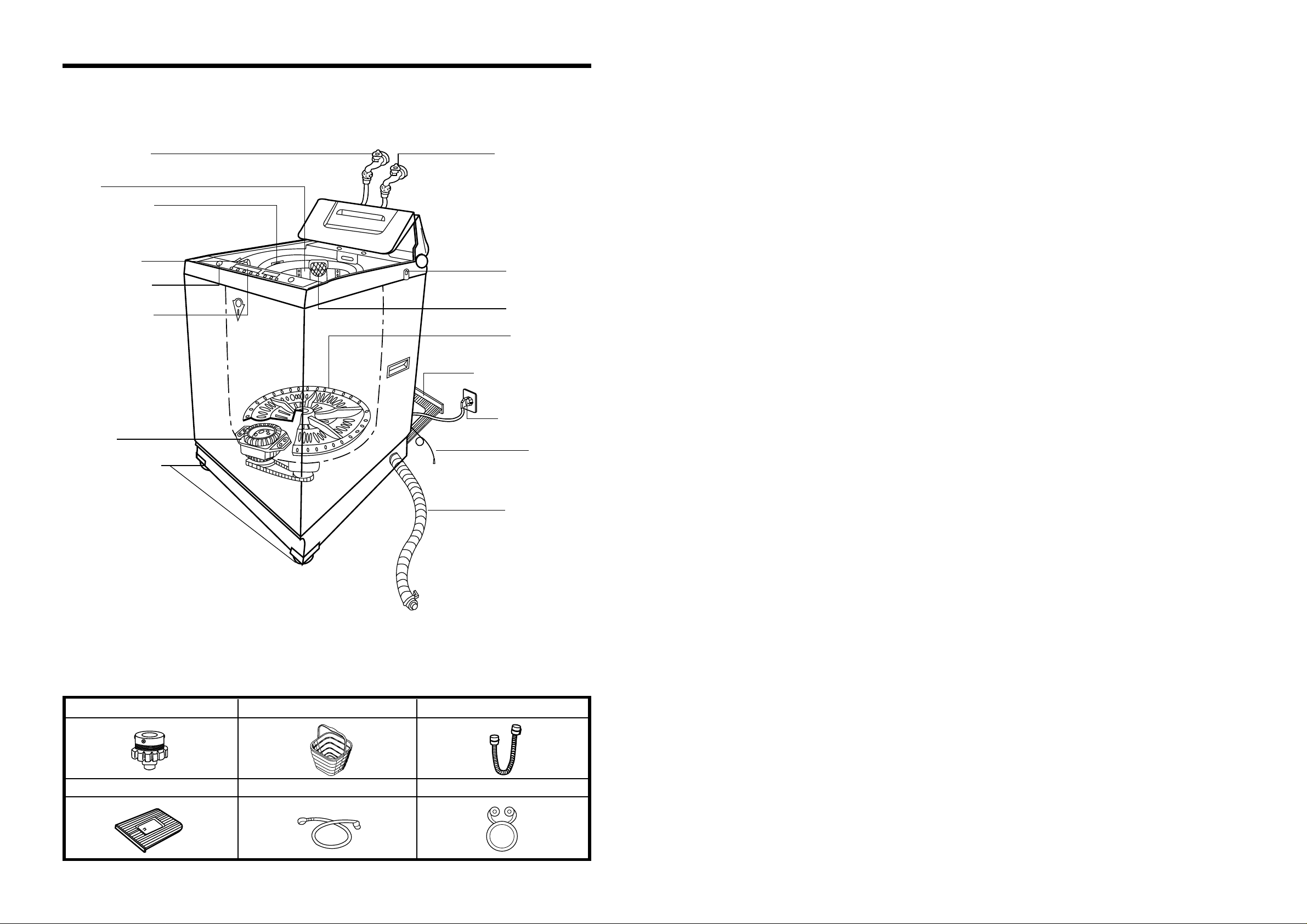

3. STRUCTURE OF THE WASHING MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

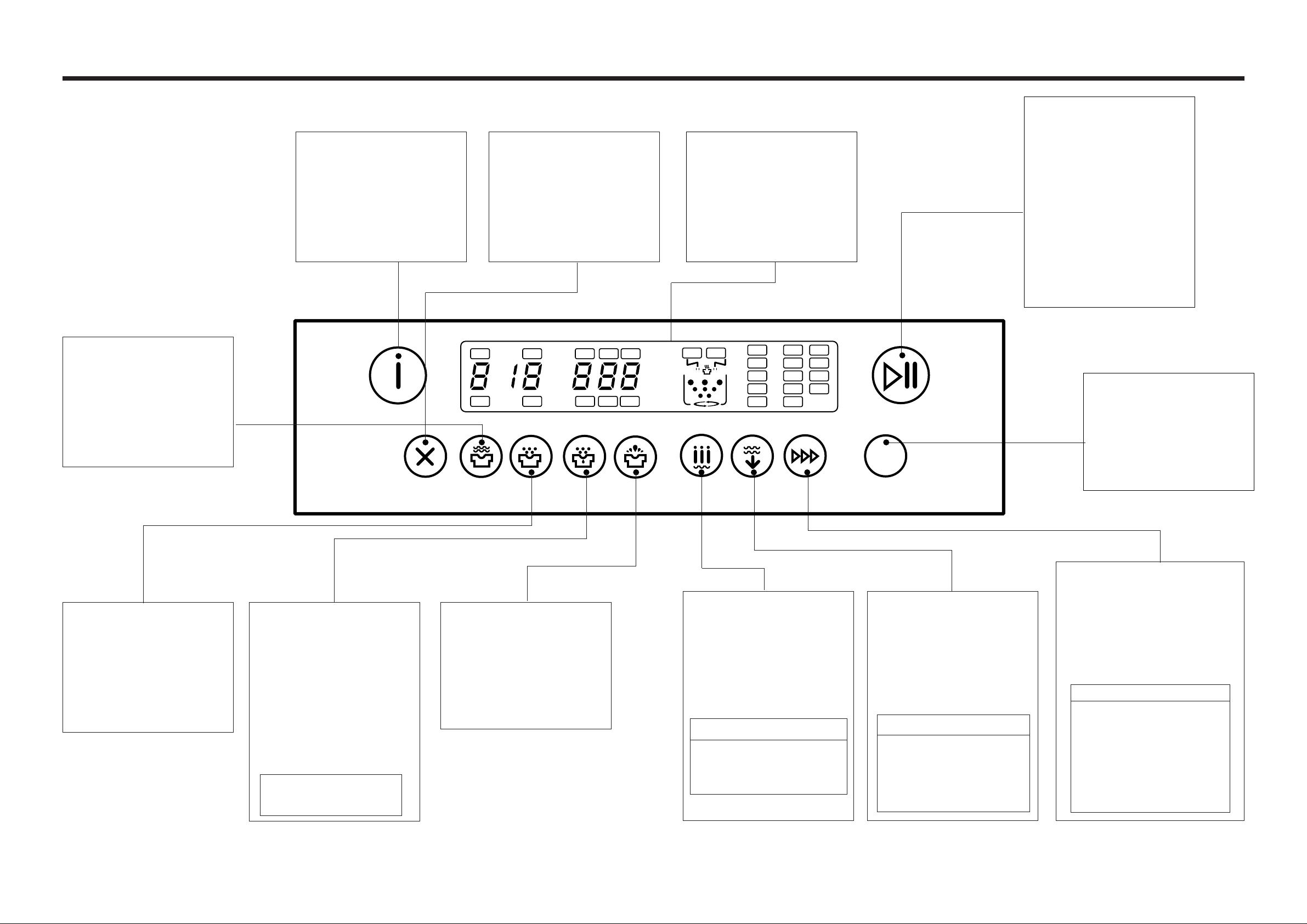

4. FUNCTIONS OF THE CONTROL P ANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5. DIRECTIONS FOR INST ALLATION AND USE

HOW TO INSTALL THE WASHING MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HOW TO CONNECT THE INLET HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PREP ARATION FOR WASHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HOW TO USE AND JOIN DRAIN HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HOW TO REROUTE THE DRAIN HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6. PROCEDURE OF FULL-AUTOMATIC WASHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT

GEAR MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DRAIN MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

BRAKE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8. TROUBLE SHOOTING GUIDE

CONCERNING WATER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CONCERNING WASHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CONCERNING DRAINING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CONCERNING SPINING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

CONCERNING OPERA TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9. PRESENT ATION OF THE P.C.B. ASS’Y

CONCERNING ERROR MESSAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CONFIGURA TION OF FULL CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

MINUTE EXPLANA TION DIAGRAM FOR EACH PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

APPENDIX

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

P ARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

P ART DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

P.C.B. PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

BARE PCB(TOP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

BARE PCB (BOTTOM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

3

2. FEATURE AND TECHNICAL EXPLANATION

2

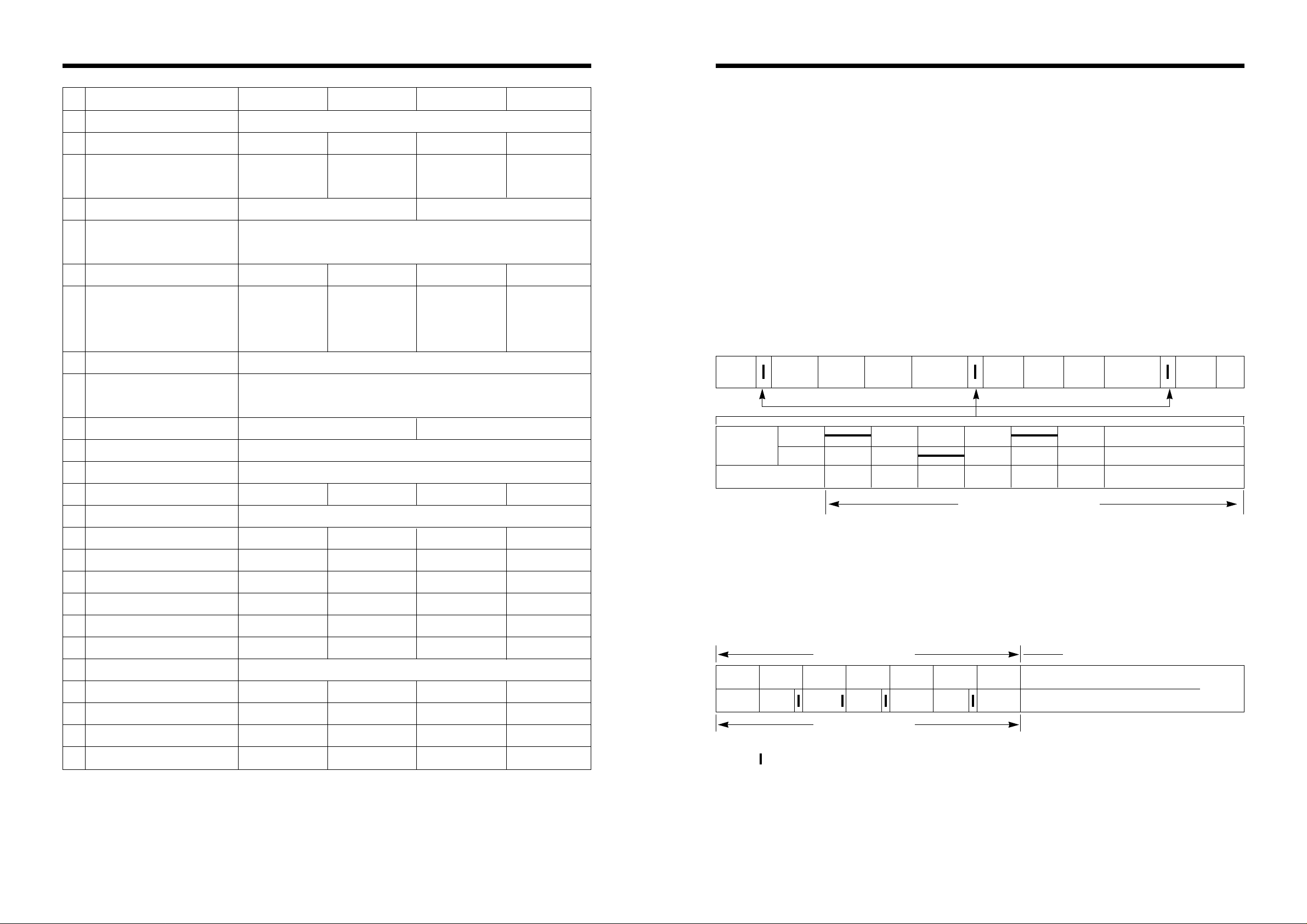

1.SPECIFICATIONS

NO. ITEM

DWF-7588TE/NE/ME DWF-8088TE/NE/ME DWF/9288TE/NE/ME DWF-1088TE/NE/ME

1 POWER SOURCE

A VAILABLE IN ALL LOCAL AC VOLTAGE AND CYCLE

2 POWER CONSUMPTION INPUT : 400W OUTPUT : 210W INPUT:460W OUTPUT:280W

3 MACHINE WEIGHT 49KG 50KG 54KG 55KG

(GROSS WEIGHT:59KG) (GROSS WEIGHT:60KG) (GROSS WEIGHT:63KG) (GROSS WEIGHT:64KG)

4 DIMENSION (WXHXD) 610 X 962 X 655mm 628 X 1005 X 673mm

5 WASHING COURSE FULL AUTOMATIC 9 OF COURSE (FUZZY, MEMORY, SOAK, DRY, SILK,

ECONOMIC, HEA VY, NIGHT , BLANAKET)

6 WATER CONSUMPTION NORMAL 259L NORMAL 265L NORMAL 304L NORMAL 315L

7 WATER LEVEL SELECTOR

8 OPERA TING W ATER PRESSURE 0.3kg/cm

2

~8kg/cm

2

(2.94 N/cm2~78.4N/cm2)

9 REVOLUTION PER MINUTE

SPIN :780r.p.m., W ASH : 140 r .p.m.(60Hz); SPIN : 680 r .p.m., W ASH : 130r .p.m.(50Hz)

A T DRY, SILK COURSE 60 r.p.m. (60Hz), 70 r.p.m.(50Hz)

10 PULSA TOR 6 WINGS (Ø 376mm) 6 WINGS (Ø 396mm)

1 1 WATER LEVEL CONTROL ELECTRONICAL SENSOR

12 OUTER CABINET PCM (PRE-COA TED METAL) SHEET

13 ANT-NOISE PLATE O O O O

14 GEAR MECHANISM ASS’Y HELICAL GEAR FOR LOW NOISE

15 LINT FIL TER O O O O

16 SOFTENER INLET O O O O

17 FUNCTION FOR SOAK WASH O O O O

18 ALARM SIGNAL O O O O

19 RESIDUAL TIME DISPLA Y O O O O

20 AUTO. WATER SUPPL Y O O O O

21 NEW WATER FLOW WATER FLOW FOR ADJUST THE UNBALANCED LOAD

22 ECONOMIC COURSE O O O O

23 FUNCTION FOR BUBBLE O

24 AUTO RE-FEED WATER O O O O

25 AUTO POWER OFF O O O O

FEATURE OF THE WASHING MACHINE

1) The first air bubble washing system in the world.

2) Quiet washing through the innovational low-noise design.

3) The wash effectiveness is much more enhanced because of the air bubble washing system.

4) The laundry detergent dissolves well in water because of the air bubble washing system.

5) The adoption of the water currents to adjust the unbalanced load.

6) One-touch operation system.

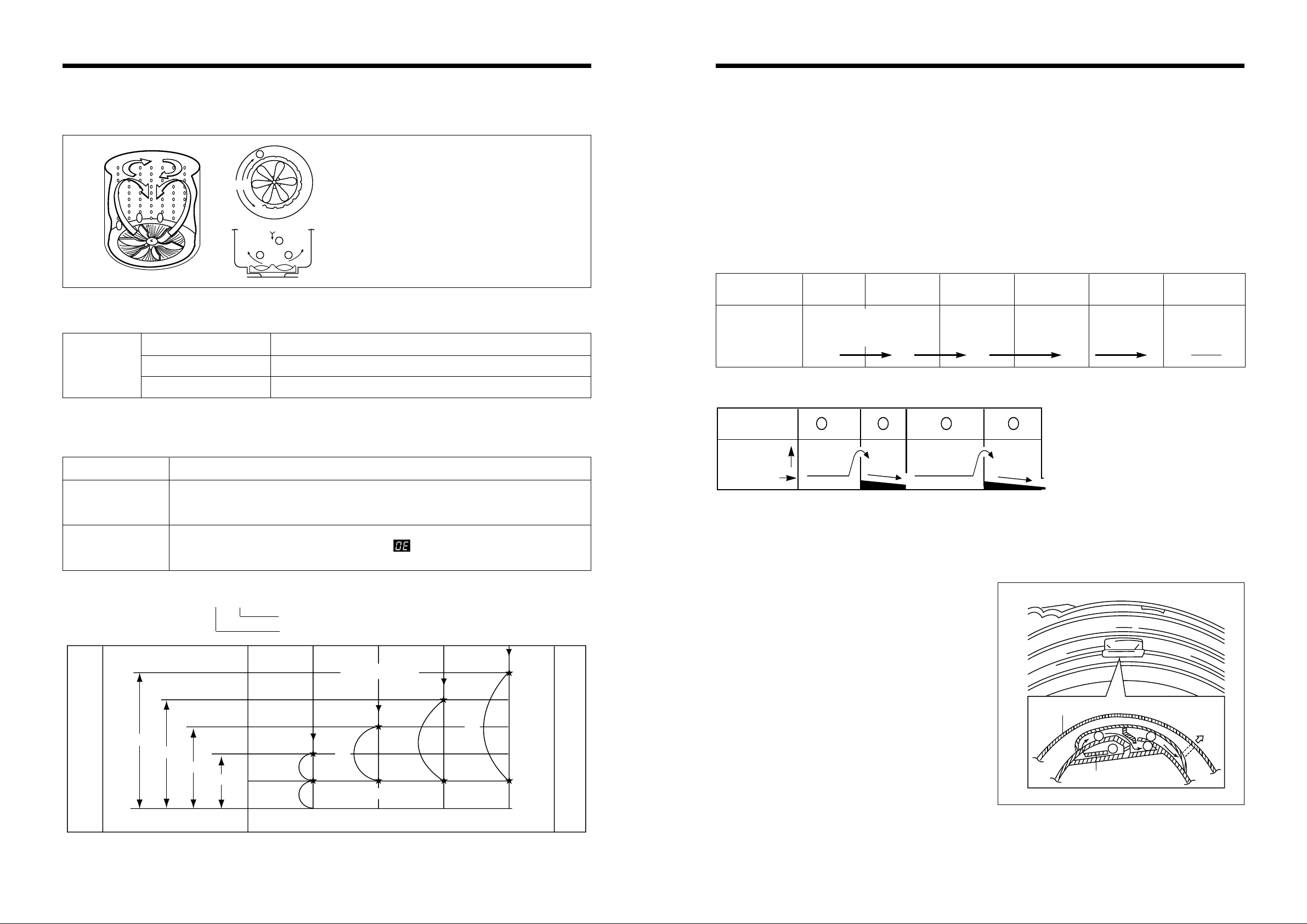

W ATER CURRENT TO ADJUST THE UNBALANCED LOAD

It is a function to prevent eccentricity of the clothes after wash by rotating pulsator C.W and C.C.W for 20

seconds.(But, the DRY & SILK course have no operation of the water currents to adjust the unbalnced

load.)

EFFECT

It reduces vibration and noise effectively while spinning.

WATER FLOW

FUNCTION FOR SOAK WASH

DISPLAY THE RESIDUAL TIME

When the SOAK WASH is selected, the total wash time increases because 60 minutes for soak process

are added to the time of main process.

PROGRESS

NOTE: ‘ ’ mark indicates the operation of the water currents to adjust the unbalanced load.

AUTOMATIC WATER SUPPLY SYSTEM FOR BLANKET WASH

The water level would be lowered because the blanket absorbs water at the beginning of washing.

Therefore, after 30 seconds, the operation is interrupted to check the water level, and then the water is

supplied again until the selected water level is reached.

WASH DRAIN SPIN FILL RINSE 1 DRAIN SPIN FILL RINSE 2 DRAIN •••

MOTOR C.W

SINGAL C.C.W

TIME(SEC.) 0.3 0.5 0.3 0.5 0.3 0.5 •••••••

20 SEC. (About 13 Times)

FILL WASH STOP WASH STOP WASH STOP

• 1’ 19’ 1’ 19’ 1’ 19’

SOAK PROCESS MAIN PROCESS

60 Minutes

HIGH(80L), MID(68L),

LOW(55L), SMALL(42L),

E.SMALL(30.5L)

HIGH(82L), MID(70L),

LOW(57L), SMALL(43L),

E.SMALL(31.5L)

HIGH(93L), MID(78L),

LOW(61L), SMALL(48L),

E.SMALL(33L)

HIGH(96L), MID(81L),

LOW(65L), SMALL(49L),

E.SMALL(36L)

54

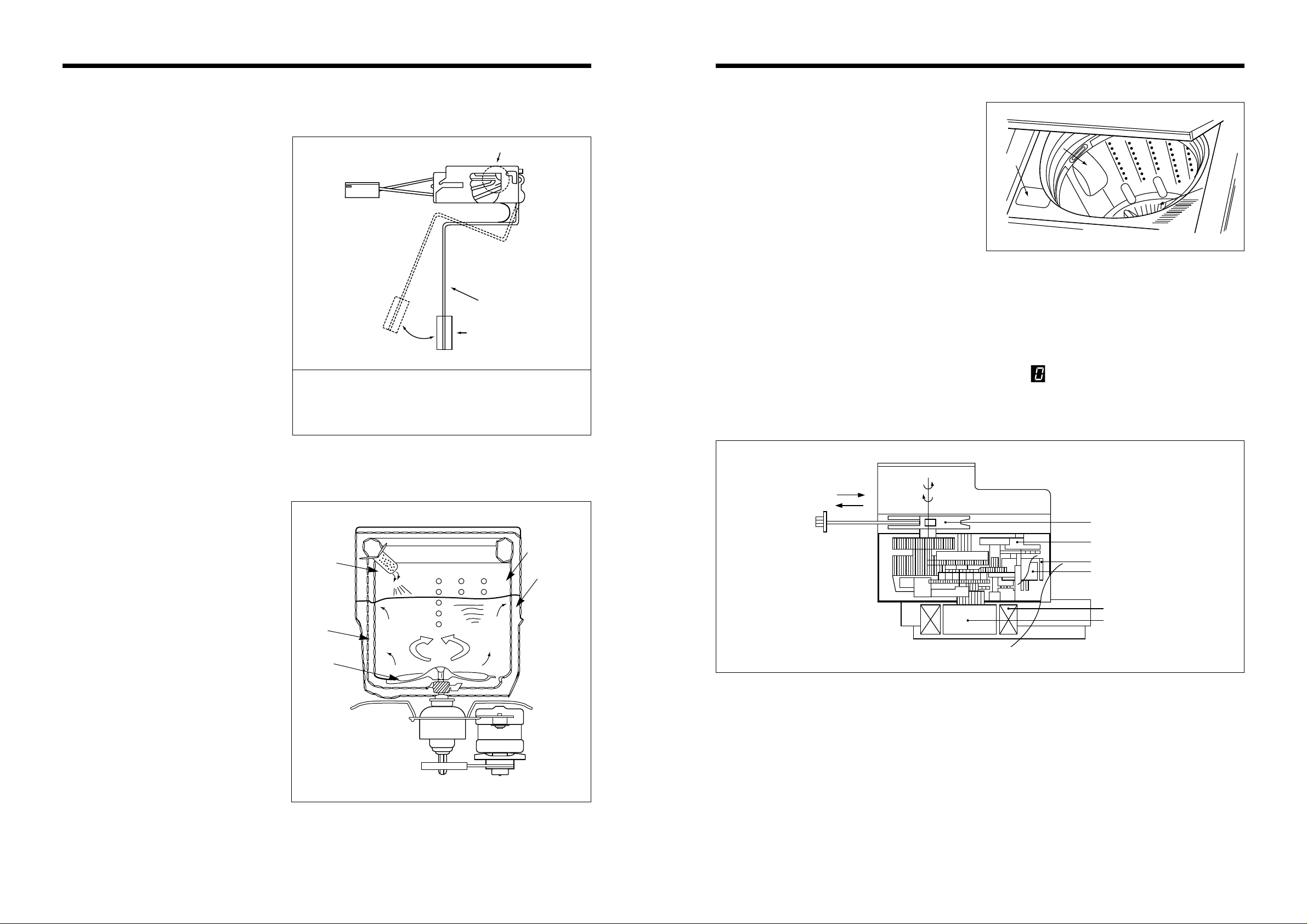

SOFTENER DISPENSER

This is the device to dispense the softener automatically by centrifugal force.

This is installed inside the auto-balancer.

FUNCTIONAL PRINCIPLE

1) Softener stays in room (A) when poured into softener inlet.

2) Softener moves from (A) to (B) by centrifugal force during intermittent spin process.

3) Softener flows from (B) to (C) during rinse process next to intermittent spin.

4) Softener moves from (C) to (D) by centrigfugal force during second intermittent spin.

After spin process is finished, the softener is added into the tub through softener outlet.

FLOW OF THE SOFTENER

FLOW OF THE SOFTENER INSIDE OF THE BALANCER

NOTE : Softener moves into the next room when r.p.m of the tub is more than 100 r.p.m.

HOW TO CHECK MOVEMENT

Pour a reasonable amount of “MILK” into softener

dispenser and operate the washer with no load. In

final rinse cycle, make sure that the milk is added into

the tub through softener outler.

PULSATOR SYSTEM

When the new shaped pulsator is rotated C.W or C.C.W at a high speed, it makes the ‘heart-shaped’

water currents as shown below.

AUTOMATIC DRAINING TIME ADJUSTMENT

This system adjusts the draining time automatically according to the draining condition.

FUNCTIONAL PRINCIPLE

1) The micom can remember the time from the begining of drain to reset point when the pressure switch

reaches to “OFF” point

2) In case of continuous draining, residual drain time is determined by micom.

Draining time as a whole = D + 60

Residual drain time.

The time remembered by micom.

T1=D1+60 (Sec.) T2=D2+60(Sec.) T3=D3+60(Sec.) T4=D4+60(Sec.)

W ATER CURRENTS

A Water is pushed up near the tub

wall by rotation of the pulsator.

B Water is pulled down in the

middle of the tub by rotation of

the pulsator.

C Water currents is generated by

rotation of the pulsator.

Draining

Good draining The washer begins spin process after drainage.

condition

Bad draining Draininig time is prolonged.

No draining Program is stopped and gives the alarm.

Drain Time Movement of the Program

Less than

Continue draining

4 minutes

More than

Program stops and gives the alarm with blinked on display lamp.

4 minutes

Wash Intermittent Hold Intermittent Rinse Spin

Spin Spin

Normal Centrifugal Flow in Centrifugal Flow in

force force

Course (A) (B) (C) (D)

Room inside

the balancer

Centrifugal force

Flowing by weight

Balancer

Softener

outlet

Softener inlet

(T sec.)

C

Rotate

B

A

A

A

B

C D

D

R

TRIP POINTS

A

I

N

I

N

G

T

I

M

E

T4

T3

T2

T1

D3

D2

D1

60

E.LOW LOW MID HIGH

RESET POINTS

D4

(mm)

400

340

280

220

60

0

W

A

T

E

R

L

E

V

E

L

B

A

D

C

76

AUTOMATIC UNBALANCE ADJUSTMENT

This system is to prevent abnormal vibration during intermittent spin and spin process.

FUNCTIONAL PRINCIPLE

1) Always the safety switch contact is “ON”

position.

2) In case that wash loads get uneven

during spin, the outer tub hits the safety

switch due to the serious vibration, and

the spin process is interrupted.

3) In case that P.C.B. ASS’Y gets “OFF”

signal from the safety switch, spin

process are stopped and rinse process

is started automatically by P.C.B.

ASS’Y.

4) If the safety switch is operated due to

the unbalance of the tub, the program is

stopped and the alarm is given.

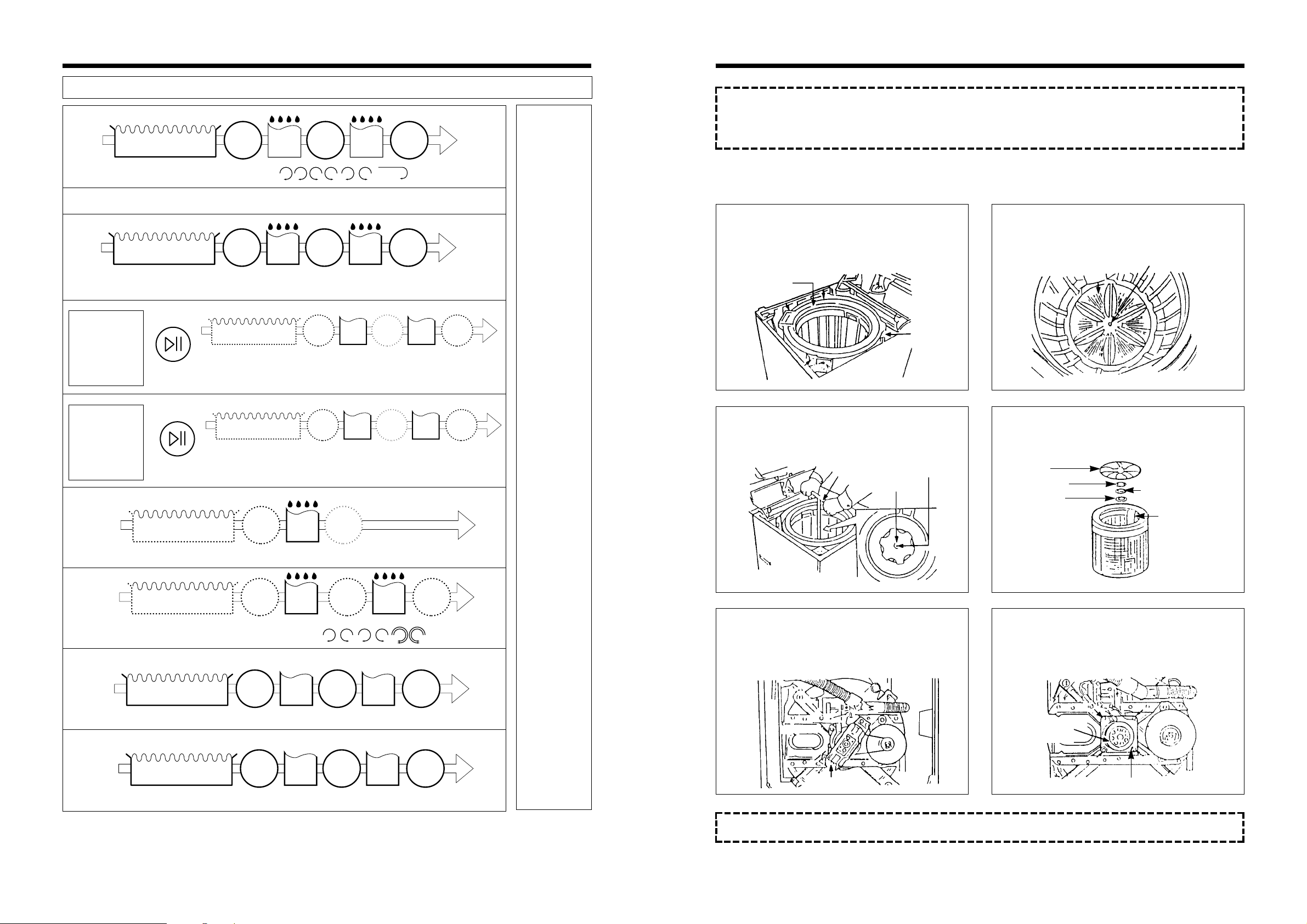

CIRCULATING-WATER COURSE AND LINT FILTER

CIRCULA TING-WATER

The washing and rinsing effects have

been improved by adopting the water

system in which water in the tub is

circulated in a designed pattern.

When the pulsator rotates during the

washing or rinsing process, the water

below the pulsator vanes creates a water

currents as shown in figure.

The water is then discharged from the

upper part of the tub through the water

channel. About 40 L/min. water is

circulated at the ‘high’ water level,

standard wash load and standard water

currents.

LINT FILTER

Much lint may be obtained according to the kind of

clothes to be washed and some of the lint may also

sticks to the clothes.

To minimize this possibility a lint filter is provided on

the upper part of the tub to filter the wash water as it

is discharged from the water channel. It is good to

use the lint filter during washing.

HOW TO REPLACE LINT FILTER

1) Pull the filter frame upward.

2) Turn the lint filter inside out, and wash the lint off with water.

3) Return the filter as it was, and fix the filter frame to the slot.

RESIDUAL TIME DISPLAY

When the START/HOLD button is pressed, the residual time (min.) is displayed on the time indicator, and

it will be counted down according to process.

When operation is finished, the TIME INDICATOR will light up .

DRAIN MOTOR

STRUCTURE

FUNCTIONAL PRINCIPLE

1) When the DRAIN MOTOR connected to the power source(A.C 220V), the DRAIN MOTOR rotates with

900 r.p.m and revolves the pulley by gear assembly for reducing.

2) When the pulley is rotated, the pulley winds the wire to open the drain valve.

3) Therefore, rotation of pulley changed to the linear moving of wire.

4) The wire pulls the brake lever of Gear Mechanism Ass’y within 5 seconds.

5) After the wire pulled, gear assembly is separated from motor and condition of pulling is held by

operation of the lever.

6) When the power is turned off, the drain valve is closed because the wire returns to original position.

NOTE:

The alarm finished when you close the lid after opening

it. Check the unbalance of the wash load and the

installation condition.

Contact of safety switch

Contact lever A

Normal (ON)

Position of

unbalanced load

(OFF)

Pull

Loosen

Pulley

Lever

Inductive ring

Magnet

Coil of motor

Magnet of motor

Tub

Filter

Water

channel

Pulsator

Outer tub

Bleach Inlet

Filter

Pulsator

98

GEAR EMCHANISM ASS’Y

The proper water currents is made by the rotation of pulsator at a low speed (about 140 r.p.m) to prevent

the damage to the small sized clothes.

PRINCIPLE OF BUBBLE GENERA T OR

STRUCTURE

PRINCIPLE OF INT AKE & OUTLET OF THE AIR

INT AKE : ARMATURE moves up, and BELLOWS inhales the air. At the same time, protector B is open

and A is close.

OUTLET : ARMATURE moves down, and BELLOWS exhausts the air. At the same time, protector B is

close and A is opend.

FUNCTIONAL PRINCIPLE OF TRANS & MAGNET

•

The phase of A.C electric power changes to 60 cycle/second.

•

The magnetic pole of trans core is changed by the change of the phase of A.C electric power.

•

The core repeats push and pull (3600 times/min.) of the at mature magnet.

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MACHINE

ACROSS SECTION

FUNCTIONAL PRINCIPLE

Bubble generator supplies the air from the bottom of outer tub to the inner space of pulsator, the air is

dispersed by the rotation of pulsator. Air-bubble is created by the centrifugal force, and rises up.

Pulsator shaft

Inner clutch spring

Brake lever

Spinner shaft

Planetary gear

Clutch spring

Clutch boss

Spinner pulley

Planetary gear

Sun gear

Internal gear

Pulsator

1 revolution

5.2 revolutions

Spinner

pulley

V-belt

Planetary gear

Motor

Motor

1490 r.p.m

(50Hz)

Planetary Gear

1/5.2

Directly

Tub

750 r.p.m

Pulsator

130 r.p.m

Spinner Pulley

750 r.p.m

Bobbin & coil

Magnet

Armature

Bellows

Air out hole

Protector A

Protector B

Air in hole

Air

Air

Trans core

A.C A.C

Air bubble

Tub

Outer tub

Pulsator

Nozzle

N

NS NS

LEAF SPRING

TRANS CORE

S

MAGNET

S

N

10

3. STRUCTURE OF THE W ASHING MACHINE

After using the washer, close the water

tap and turn off the power

• HOT WATER TAP

After using the washer, close the water

tap and turn off the power.

• COLD WATER TAP

• TUB

• BLEACH INLET

• POWER SWITCH

• CONTROL PANEL

• MOTOR

• ADJUSTABLE LEGS

Pour softener into the softener inlet just

before wash and it will be added into

the tub automatically just before the

the final rinse.

• SOFTNER INLET

•HOOK HOLE

•LINT FILTER

•PULSATOR

•UNDER BASE COVER

•POWER CORD

•EARTH

•HOSE DRAIN

WATER TAP ADAPTER(2PCS)

UNDER BASE COVER

BASKET

INLET HOSE(2 PCS)

HOSE DRAIN

HOSE DRAIN CLAMP

ACCESSORIES

Time Display

• The lamps easily indicate the

option selection of washing

program and process by

letters.

Start/Hold Button

• Operation and temporary

stop are repeated as it is

pressed it will be repeated

‘Operation’, ‘Temporary stop’

according to the one time

pressing or two times

pressing.

When you want to change

course in operating;

- Press the S/H button.

- Select the course that you

want to change.

- Press the S/H button again.

Wash Time

Pre-engagement

• It can be used to pre-engage

time for wash.

Water Temperature Selector

• It can be used to choose

water temperature to be

supplied.

• As the button is pressed, it

will be repeated following

sings ;

COLD

➜WARM➜HOT

TEMP. : TEMPERA TURE

HOT : HOT WATER

WARM : WARM WATER

COLD : COLD WATER

Water Level Selector

• It can be used to adjust

amount of water according to

the size of the load to be

washed.

• As the button is pressed.

Water level is selected by

H➜M➜L➜S➜E.S

LEVEL. : WATER LEVEL

H. : HIGH LEVEL

M. : MIDDLE LEVEL

L. : LOW LEVEL

S. : SMALL LOW LEVEL

E.S. : EXTRA SMALL LEVEL

Course Selector

• It can be used to select the fullautomatic course.

• As the button is pressed, it will

be selected following order:

MEM.➜SOAK➜ DRY➜ SILK➜ECO

.➜HEA VY➜ NIGHT➜ BLAN➜FUZ.

COURSE

MEM : MEMORY

SOAK : SOAK

DRY : DRY

SILK : SILK

ECO. : ECONOMIC

HEA VY : HEAVY

NIGHT : NIGHT

BLAN : BLANKET

FUZ. : FUZZY

1 1

CANCEL SOAK WASH RINSE SPIN COURSE

RES

WASH TEMP.

WATER LEVEL

POWER

START/HOLD

SOAK

HOUR

WASH RINSE MILD SPIN

HOT COLD

H.

M.

L.

S.

ES.

SILK

FUZZY

MEM.

SOAK.

DRY

ECO.

SUPER

NIGHT

BLAN

TIME MIN. REM.MIN.

How to use Switch

• Press this to turn the power

ON or Off. After turning OFF

the power, wait for more then

3 seconds and then turn it

On again.

Soak Time Selector

• It can be used to adjust soak

time

• As the button is pressed

you’ll see repeated.

1➜2➜3➜4 signs.

Button for Program Cancel

• It can be used to cancel the

full-automatic course.

• When the button is pressed

the display will be light down.

If you want to wash, rinse or

spin, you can press one of

the button.

4. FUNCTION OF THE CONTROL PANEL

Washing Time

• It can be used to adjust

washing time

• As the button is pressed,

you’ll see the repeated.

2➜4➜6➜8➜10➜12➜14

➜16➜18 signs.

Rinse Time Selector

• This button selects the

number or times you want to

rinse.

• As the button is pressed, it

will be repeated

➜1 time rinse ➜1 time feed

➜2 times rinse ➜2 times feed

➜3 times rinse ➜3 times feed

➜4 times rinse ➜4 times feed

➜5 times rinse ➜5 times feed

Spin Time Selector

• It can be used to change

spin time.

• As the button is pressed, it

will be repeated

1➜2➜3➜4➜5➜6➜7➜8➜9

signs.

RINS : RINSE

Rinse : Normal Rinse

Feed : Feed Rinse

1312

5. DIRECTIONS FOR INSTALLA TION AND USE

HOW TO INSTALL THE WASHING MACHINE

SELECTION OF THE INSTALLING PLACE

Install the washer on a horizontal solid floor.

If the washer is installed on an unsuitable floor, it

could make considerable noise and vibration.

•

The proper installation of the washing

machine can increase the wash

effectiveness and the life of it.

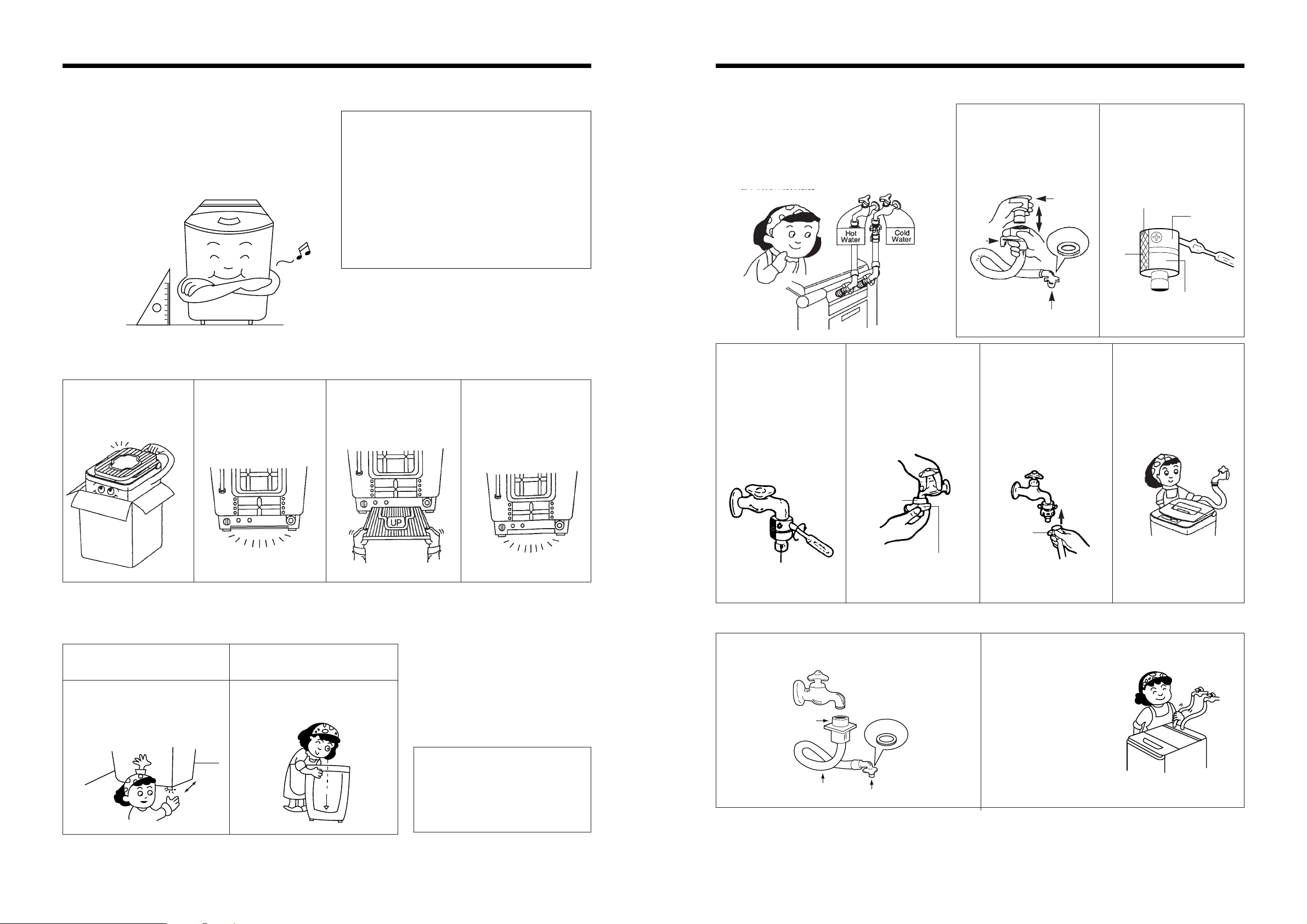

INST ALLATION OF THE UNDER BASE COVER

HOW TO INSTALL ON AN INCLINED PLACE

Never install in these places

•

The place where it would be exposed to

direct sunlight.

•

The place nearby a heater or heat appliance.

•

The place where it would be supposed to be

frozen in winter.

•

The kitchen with coal gas and a damp place

like a bathroom.

1

\ Separate under

base cover from

the unit.

2

\ There is a

inserting place

under of the back

side on the

washer.

3

let the base cover

that can be shown

the “UP” sign.

4

Insert the base

cover into the slot

of under base until

come to the end

of the slot.

1

\

Height Setting

•

After controlling the height by

turning the adjustable leg, let the

washer put down to the ground.

2

Check the

Horizontal Status

•

Check the position of tub above the

center of the washer.

After installing the washing machine,

close the under-base cover.

If the washer is installed on an unsuitable floor, it could make

considerable noise and vibration, and could cause a

malfunction.

NOTES :

The openings must not be

obstructed by carpeting when

the washing machine is installed

on a carpeted floor.

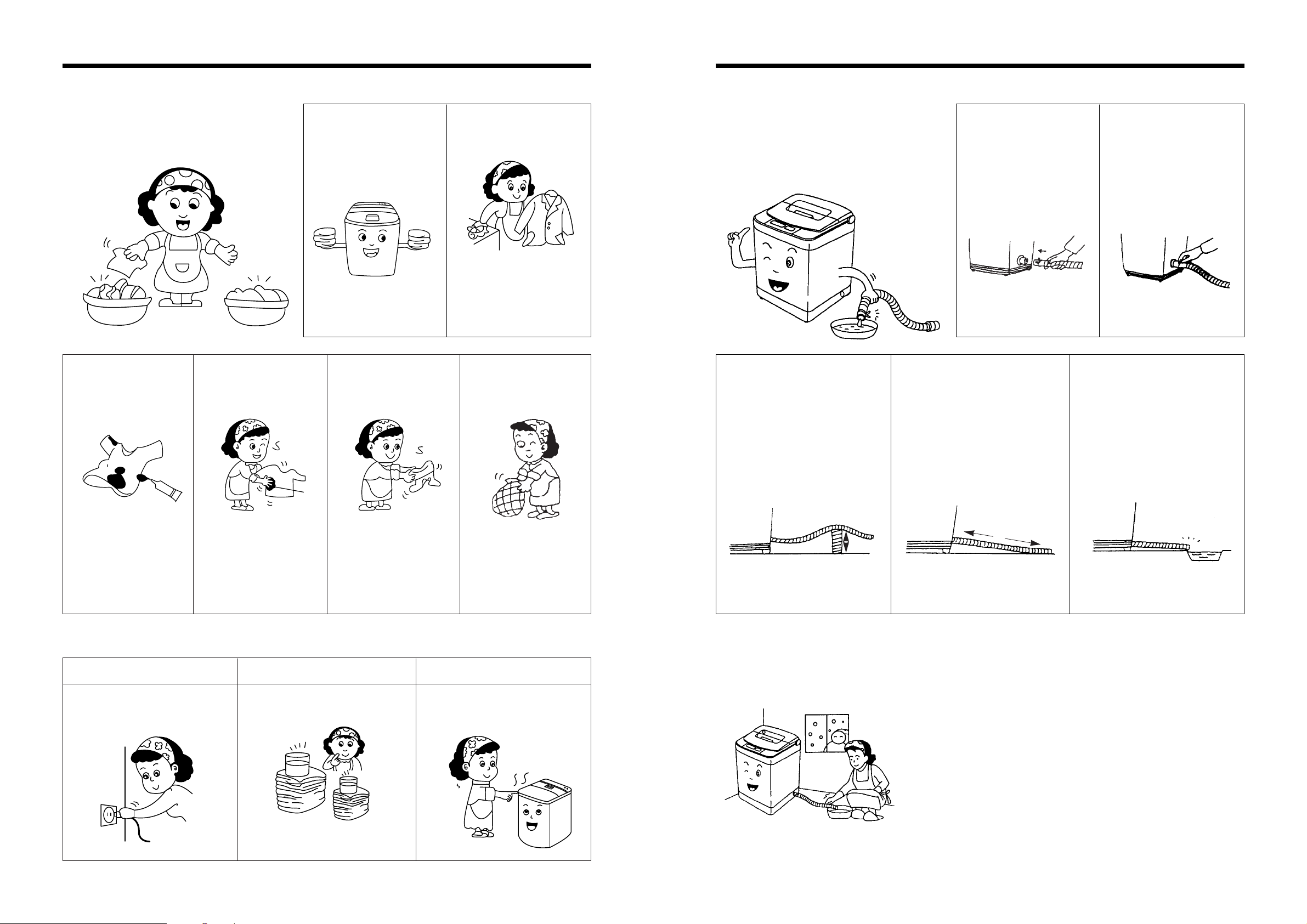

HOW TO CONNECT THE INLET HOSE

IN INST ALLING THE INLET HOSE

Be careful not to mistake in supplying hot

and cold water.

In using only one water tap, connect the

inlet hose to the cold water inlet.

•

FOR SCREW-SHAPED TAP

NOTE

In a high water pressure, when start with a set-up of WARM-temperature WASH, it is desirable not to turn

the faucet on. High pressure may cause on overflow rinse.

1

\ Pull down the collar

of the inlet hose to

separate it from the

water tap adapter.

2

\ Loosen the four

screws at the water

tap adapter, but

don’t loosen the

screw until they are

separated from the

water tap adapter.

1

\ Connect the inlet hose to the water tap by

screwing the connector D tightly.

2

\ Connect the connector C of the inlet hose to

the water inlet of the washer by turning it

clockwise to fix it tightly.

• Please check the rubber

packing inside

the connector C

of the inlet hose

3

Connect the water

tap adapter to the

water tap, and

tighten the four

screws evenly

while pushing up

the adapter so

that the rubber

packing can stick

to the water tap

tightly.

4

\ Remove the

tape, and screw

connector B into

connector A

tightly.

5

\ Connect the inlet

hose to the

water tap

adapter by

pulling down the

collar of the hose

end.

6

\ Connect the inlet

hose adapter of

the hose to the

water inlet of the

washer by

turning is

clockwise to be

fixed tightly.

Water Tap

Adapter

Connector C

Rubber

packing

Connector D

Connector C

Inlet Hose

Rubber

Packing

Water

Tap

Adapter

Connector A

Connector B

Water Tap Adapter

Connector B

Collar

Connector A

Collar

•For Ordinary Top

Tape

• Please check the rubber

packing inside the inlet

hose adapter of the

hose.

1514

PREPARATION FOR WASHING

WASHING ARRANGEMENT

Please start washing after reading these

instructions.

WASHING PREPARATION

•

Is the clothes washable

with water?

Arrange the clothes

•

Does the clothes contain

your things in the

pockets?

Remove your things from

the pockets of the clothes,

and then button up and zip

11

Power Cord

•

Connect the power cord •to the

electric outlet

22

Detergent

•

Prepare the detergent according

to the size of the wash load.

(Put the bleach and the softner into

the inlet if necessary.)

33

Clothes

•

After putting the clothes into the

tub, close the lid.

•

Is the clothes stained

with oil or paint?

Wash the clothes after

separating it from other

clothes.

•

Is the clothes stained

with the dust?

Wash the clothes after

rubbing it from other dust.

•

Is the clothes napped?

Wash the clothes after

turning it inside out.

•

Is the clothes soft one?

Wash the clothes after

putting it in the nylon-bag.

Arrange

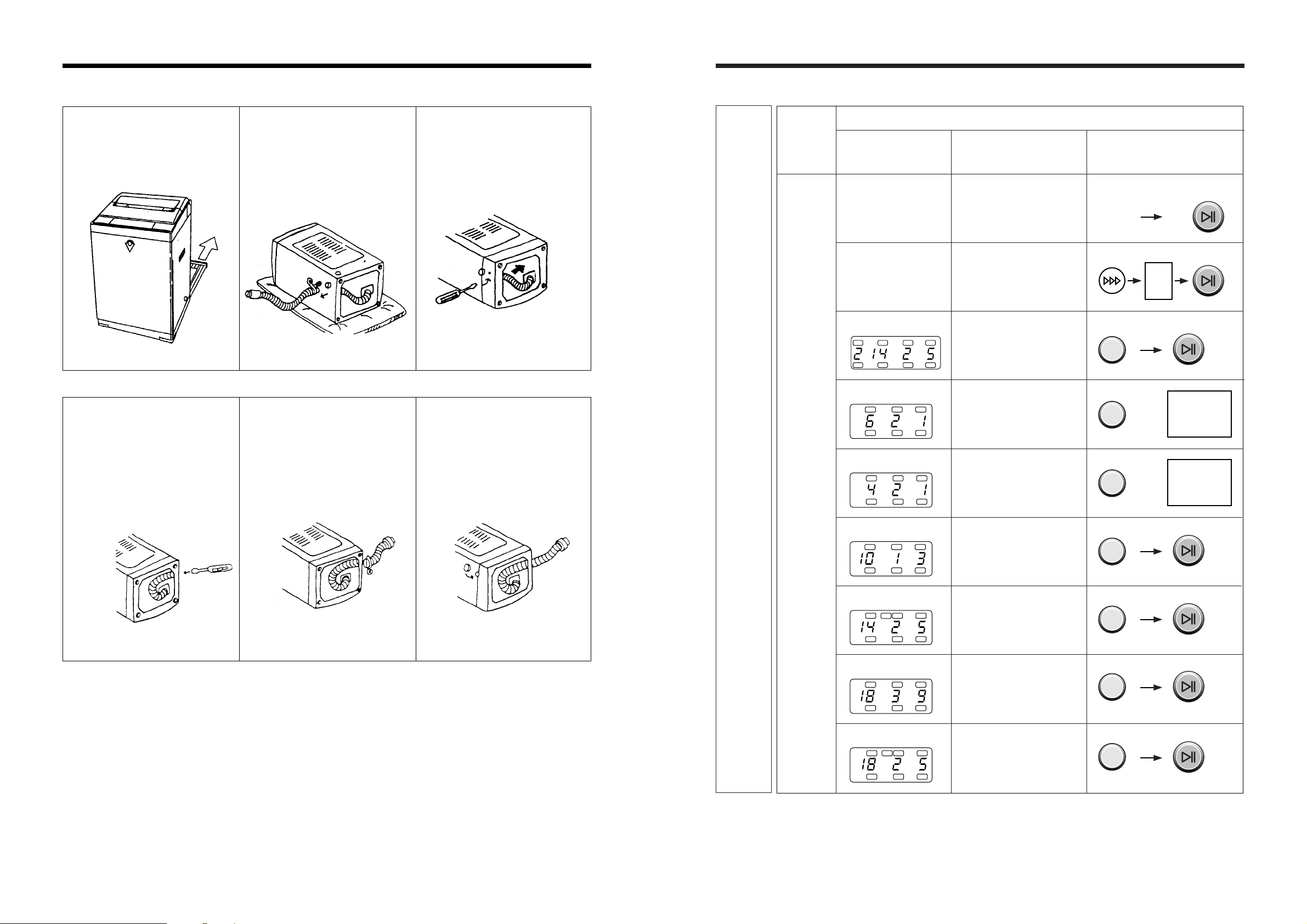

HOW TO USE AND JOIN DRAIN HOSE

INST ALLING DRAIN HOSE

Widen the drain clip and insert the drain

hose into the drain tap together with drain

hose. Dipping the end of the drain hose in

warm water makes easy to insert the drain

hose.

HOW TO USE IN WINTER

1

\ Insert the drain

hose into the drain

tap.

2

\ Secure the hose

clip around the end

of the drain hose.

•

In case that it goes over a doorsill water flow will be restricted if

any portion of the drain hose is

raised more than 20 cm from the

ground.

•

In case that it is connected when

the drain hose is extended, it

may not exceed 3 meters.

•

Take care the end of the drain

hose. Do not sink the end of the

drain hose.

•

To avoid the washing machine’s being frozen.

- Remove the inside water of the washing machine completely.

- Remove the inside water of the inlet-hose and drain hose completely.

•

In case of being frozen.

- Dip the detached inlet-hose in the hot water (about 50°C) (* Don’t use

above 50°C surely)

- Leave the tub alone for 10 minutes with pouring the hot water. (about

50 °C)

- Check the drain and inlet’s operation after attaching the inlet-hose.

20cm

3m

22

Selecting Course

Selecting Course Kinds of the Laundry

1716

HOW TO REROUTE THE DRAIN HOSE

1

\ Pull out the under base

cover to the arrow

direction.

2

\ After spreading blanket or

unit box, lay the washer as

the below figure. And

detach the outside drain

hose with widening drain

clip.

3

\ Detach the inside drain

hose fixing screw with

O

±

driver.

4

\ After detaching the drain

hole cover of the hoping

direction insert the inside

drain hose.

And then fasten the fixing

screw tightly.

5

\ Insert the outside drain

hose together with the

hose-fixing clip.

6

\ Insert the detached drain

holecover instead of the

original one.

6. PROCEDURE OF FULL-AUTOMATIC W ASHING

Prepare

for

washing.

Pressing

the

power

switch

Put the

clothes

wash in.

Select

the

washing

course.

This selection is for general

washing.

This selection is washing course

by your desire. (The memory

items are washing time, rinsing

times, spin time, water level,

water temperature)

This course is used to increase

the wash effect by keeping the

clothes soaked suffciently in the

wash water.

This selection is effective for

delicate clothes

• Just follow the washing procedure.

• 1.5 kg limitation for one-time-wash.

This selection is effective for

some clothes made of silk.

• Do not put in the wash marked with

dry-cleaning.

• 1 kg’s limitation for one-time-wash.

This selection is effective for

water saving and energy saving.

The selection is effective for

blue-jean, climbing clothes,

ruck-sack, sports wear(heavy

dirty clothes), etc...

This selection is for a nightwashing housewife who has no

opportunity at day time.

This selection is effective for

blanket, curtain, carpet, etc...

•4 kg’s limitation for one-time-wash.

Procedure to

press the Button

FUZZY

(SENSOR)

MEMORY

(USE ONLY FUZZY

COURSE)

SOAK

DRY

SILK

ECO.

HEA VY

NIGHT

BLANKET

START/HOLD

START/HOLD

FUZZY

MEMORY

MEMORY

COURSE

Select

your

desired

items.

Pull the exclusive

detergent. Dry-10.

of 26g into the tub

for dilution with

water.

Pull the exclusive

detergent. Dry-10.

of 26g into the tub

for dilution with

water.

START/HOLD

DRY

SILK

START/HOLD

START/HOLD

STONG

START/HOLD

NIGHT

START/HOLD

BLANKET

COURSE

COURSE

COURSE

COURSE

COURSE

COURSE

COURSE

WASH RINS

RES

MIN. TIME

HOUR

WASH RINS

RES

MIN. TIME

HOUR

WASH RINS

RES

MIN. TIME

HOUR

WASH RINS

RES

MIN. TIME

HOUR

WASH RINS

RES

MIN. TIME

HOUR

WASH RINSFEED

RES

MIN. TIME

HOUR

FEED

SOAK WASH RINS

RES

HOUR MIN. TIME

HOUR

11

Pressing

the Power

Switch

➜ ➜ ➜

1918

33

Procedure of Washing (Washing machine does it automatically).

Buzzer signal to

notify you can put

the sensible

clothes into the

diluted water with

Dry-10.

The washing program is processed by your desired items.

Artificial brain computer controls full procedure proper to wash load automatically.

A part of dotted line is decreasing rotation velocity.

Because protect clothes from damage.

RINSE RINSESPIN SPIN SPIN

Water inlet and

wash for 4 minutes

START/HOLD

SPIN SPIN

Water inlet and

wash for 10 minutes

RINSE

SPIN

Water inlet and

wash for 18 minutes

RINSE SPIN SPINRINSE

SPIN SPIN SPIN

Water inlet and

wash for 18 minutes

RINSE RINSE

SPIN SPIN SPIN

Water inlet and

wash for 14 minutes

RINSE RINSE

R L R L R L

Buzzer signal to

notify you can put

the sensible

clothes into the

diluted water with

Dry-10.

After Washing : Close the water tap and separate it from the inlet-hose.

If not so, the autovalve is out of order by the water pressure.

Take off plug.

A part of dotted line is decreasing rotation velocity.

Because protect clothes from damage.

A heavy course‘s water flow is

A blanket course‘s water flow

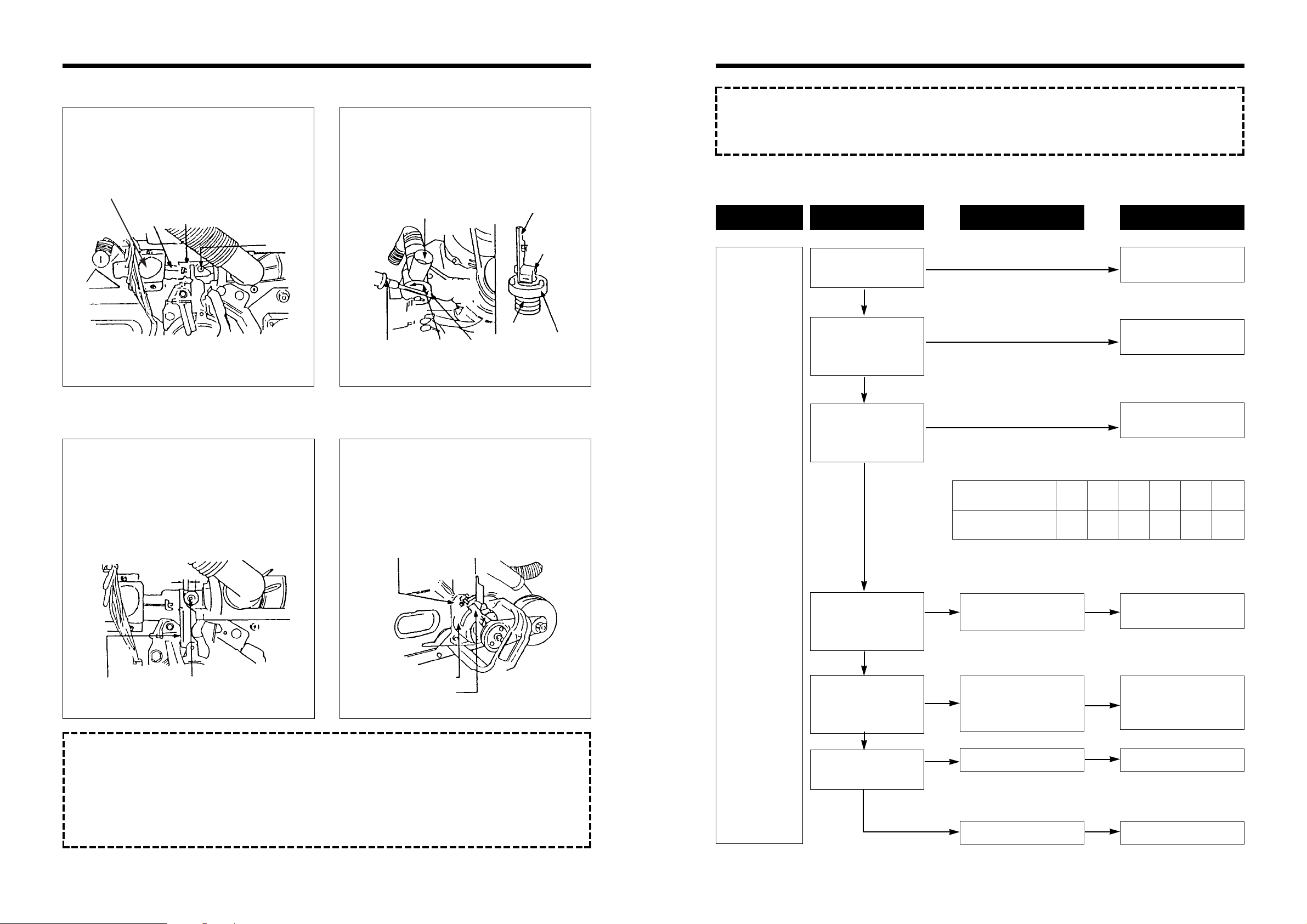

7. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT

GEAR MECHANISM ASS’Y REPLACEMENT

WARNING

BEFORE ATTEMPTING TO SERVICE OR ADJUST ANY PART OF THE WASHING MACHINE,

DISCONNECT THE POWER CORD FROM THE ELECTRIC OUTLET .

NOTE : To assemble the gear mechanism ass’y, reverse the disassembly procedure.

•

Raise the top plate on the outer cabinet.

•

Loosen four screws mounting outer tub cover and

remove outer tub cover from the tub ass’y.

•

Remove the spinner shaft flange nut by using ‘T’

type box wrench.

•

Lay the front of the washer on the floor.

•

Remove four bolts mounting the plate-gear protect

by using a box wrench and remove plate-gear

protect.

•

Remove the V-belt.

•

Loosen the pulsator mounting screw and remove

the pulsator.

•

Remove the tub ass’y.

•

Remove four bolts mounting the gear mechanism

ass’y by using a box wrench.

•

Pull out the gear mechanism ass’y.

Outer tub cover

Pulsator

Mounting screw

Mounting

screw

“T” type box

wrench

Mouting bolt

Gear mechanism

ass’y

Mounting bolt

Washer

Pulsator

Insert-pulsator

Washer-spin

shaft fixing

Nut-spin

shaft fixing

Nut-spin shaft fixing

Tub ass’y

End of

washing

informed by

buzzer.

After 10

minutes

later from

the end of

the washing

the power

switch is

turned off

automatically.

Water inlet and

wash for 18 minutes

SPIN SPIN SPIN

R R RL L L

RINSERINSE

Water inlet and

wash for 14 minutes

SPIN SPIN SPIN

RINSERINSE

START/HOLD

Water inlet and

wash for 6 minutes

SPIN SPIN SPIN

RINSE RINSE

2120

DRAIN MOTOR AND VAL VE

BRAKE ADJUSTMENT

NOTE :

1. The brake adjustment has been made at the factory, so that it is not to re-adjust. However, in case

of insufficient brake operation, perform the upper procedure.

2. Overtightening of the adjustment bolt will cause poor brake performance.

3. Undertightening of the adjustment bolt will cause continuous bracking and, thereby, cause the

problems of the motor during the spin cycle.

•

Lay the front of the washer on the floor.

•

Loosen the adjustment screw and four bolts

mounting the drain motor.

•

Take out the wire of drain motor from the bracket.

•

Loosen the adjustment screw fastening the bracket

and place the adjustment screw to the brake lever

as shown in figure.

•

Tighten the adjustment screw completely .

•

Loosen the adjustment bolt and turn the

adjustment bolt until the end of the bolt touches to

the brake lever.

•

Tighten the lock nut and apply a small amount of

paint-lock.

•

Separate the drain motor from the bracket.

•

Turn the valve lid by using screw driver as shown

in figure and remove the valve lid from the valve

frame.

Wire Bracket

Drain motor

Adjustment

screw

Valve frame

Screw driver

V alve lid

3mm

Brake lever

Adjustment screw

Adjustment bolt

Brake lever

Clutch lever

Gear mechanism ass‘y

Pin

V alve

packing

V alve lid

Adjustment

screw

Bracket

8. TROUBLE SHOOTING GUIDE

CONCERNING W ATER SUPPLY

NOTES :

1. When replace the P.C.B. ASS’Y do not scratch the surface of the P.C.B. ASS’Y.

2. Disconnect the power cord from the electric outlet.

PROBLEM

WATER IS

NOT

SUPPLIED.

CHECK POINT

Do you open the

water tap?

Is the filter of the

water inlet valve

clogged with dirt?

Is the water pressure

sufficient?

(0.3~8 kg/cm

2

)

Does the water inlet

valve make operating

sound?

Is the connector or

the terminal

connected properly?

Is the output voltage

of the P.C.B normal?

CAUSE

Water inlet valve

is defective.

Improper connection

of the connector or the

terminal.

P.C.B AS is defective.

Lead wire is defective.

SOLUTION

Change water inlet

valve.

Open the water tap.

Clean the filter.

Increase the water

pressure.

Connect the connector

or the terminal

properly .

Change the P.C.B AS.

Change the lead wires.

NO

YES

NO

YES

NO

YES

YES

YES

YES

NO

NO

NO

NOTE : Open the water tap fully and measure

the flow rate.

From the upper results, you know that the flow rate more

than 1 1.5

l/min. is essential for water supply.

Flow

1 1.5 15.0 18.0 20.3 24.1 27.4

rate(l/min.)

Water pressure

0.3 0.4 0.5 0.6 0.8 1.0

(Kg/cm

2

)

2322

PROBLEM

THE

WASHER

DOES NOT

DRAIN.

CHECK POINT

Do you put down

the drain hose?

Does the drain

motor operate

normally?

Is the input voltage

of drain motor

normal?

CAUSE SOLUTION

Install drain hose

properly .

Remove the foreign

matter.

Change the drain

motor.

Change the P.C.B

ASS’Y.

Improper installation

Drain problem by the

foreign matter

accumulated inside

drain valve housing.

Drain motor is

defective.

P.C.B ASS’Y is

defective.

CONCERNING DRAINING

YES

NO

NO

NO

YES

YES

CONCERNING W ASHING

PROBLEM

WATER

SUPPL Y IS

NOT

STOPPED.

CHECK POINT

Does the water supply

continue while the

power is turned off?

Does the water supply

start as soon as you

press the power switch?

Operate the washer

after setting the water

level to “HIGH”

Does the water supply

continue after the

water reaches to the

“HIGH” level?

Is the air tube of water

level switch kinked or

deformed?

CAUSE SOLUTION

Change the water inlet

valve.

The water inlet valve is

defective.

The triac of P.C.B is

defective.

Change the P.C.B

ASS’Y.

Normal operation.

Change the air tube.Air tube is defective.

Change the pressure

switch.

Pressure switch is

defective.

PROBLEM

THE

PULSATOR

DOES NOT

ROT ATE

EVEN IF THE

WATER IS

SUPPLED.

CHECK POINT

Does the motor operate after

finishing water supply?

Does the motor make

operating sound?

Is the connection

condition of capacitor

terminal good?

Does pulsator rotate

in only one direction?

Is the motor coil

disconnected?

Is the V-belt worn out?

The triac of P.C.B is

defective.

Motor is defective.

Improper connection

V-belt is defective.

Change the P.C.B

ASS’Y.

Normal

Change the motor.

Connect the terminal

properly .

Change the V-belt.

Change the motor.

CAUSE SOLUTION

YES

YES

YES

NO

NO

YES

YES

NO

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

2524

CONCERNING OPERATION

PROBLEM

THE

INDICA T OR

LAMP(L.E.D)

DOES NOT

LIGHT UP

WHEN THE

POWER

BUTTON IS

PRESSED.

PROGRESS

LAMPS(LED)

DO NOT

LIGHT UP.

MOTOR

ROT ATES

WHEN

START/HOLD

BUTTON IS

NOT

PRESSED.

ABNORMAL

NOISE

DURING

WASH

PROCESS.

CHECK POINT

Is the plug connected to electric outlet?

Is the condition of

power button good?

Is the connector of

the P.C.B. ASS’Y

connected properly?

Is input voltage of

the transformer

normal?

Do you press

START/HOLD button?

Does the pressure switch

operate normally?

Check the output

voltage of P.C.B ASS’Y

Is the strange noise

generated when the

pulsator rotates in

TEST MODE of P.C.B

ASS’Y?

Is the V-belt worn

out?

CAUSE SOLUTION

Connect the plug.

Change P.C.B ASS’Y.

Connect the connector

properly .

Change the

transformer.

Change P.C.B ASS’Y.

Press ST AR T/HOLD

button.

Replace P.C.B ASS’Y.

Change the pressure

switch.

Change P.C.B ASS’Y.

Remove the foreign

matter.

Change the V-belt.

Power button is

defective

Improper connection

of the connector.

Transformer is

defective

P.C.B. ASS’Y is

defective.

P.C.B ASS’Y is

defective.

Pressure switch is

defective.

P.C.B ASS’Y is

defective

There is foreign matter

between pulsator and

tub.

V-belt is defective.

YES

YES

YES

NO

NO

NO

NO

NO

NO

YES

YES

Abnormal

YES

YES

NO

NO

CONCERNING SPINNING

PROBLEM

THE

WASHER

DOES NOT

SPIN.

CHECK POINT

Is the lid open?

Does the door switch

operate normally?

Does the safety switch

operate normally?

Does the pulsator

rotate while the tub

does not rotate?

Is the connector of

P.C.B ASS‘Y

connected properly?

Is the input

voltage of the drain

motor normal?

Is the V-belt worn out?

Is the input voltage of

motor normal?

Is the connection

condition of capacitor

terminal good?

CAUSE SOLUTION

Close the lid.

Change the door

switch.

Change the safety

switch.

Connect the connector

properly .

Change P.C.B ASS’Y.

Change the drain

motor.

Change the P.C.B

ASS’Y.

Change the V-belt.

Change the motor.

Connect the terminal

correctly .

Change the P.C.B

ASS’Y.

Door switch is

defective.

Safety switch is

defective.

Improper connection

of the connector.

P.C.B. ASS’Y is

defective.

Drain motor is

defective.

P.C.B ASS’Y is

defective.

V-belt is defective.

Motor is defective.

Improper connection.

P.C.B ASS’Y is

defective.

NO

YES

YES

NO

NO

YES

YES

YES

NO

NO

NO

NO

YES

YES

NO YES

2726

CONFIGURATION OF FULL CIRCUITS

M

I

C

O

M

I.C

(5943)

DWF-1088

9288

8088

7588

DISPLA Y UNIT

CUSTOM

L.E.D

DISPLA Y

SAFETY SWITCH

UNIT

EEPROM UNIT

BUZZER UNIT

RESET UNIT

SUB OSC

(32.768 KHz)

MAIN OSC (12 MHz)

POWER SUPPLY UNIT

TEMPERA TURE

SENSOR UNIT

INTERRUPT UNIT

LOAD SENSOR UNIT

WATER LEVEL

SENSOR UNIT

LOAD DRIVE

UNIT(MOTOR, WATER

INLET, DRAIN,

BUBBLE, POWER

SWITCH AUTO OFF)

KEY INPUT UNIT

RELA Y DRIVE

UNIT

9. PRESENTA TION OF THE P.C.B ASS’Y

CONCERNING ERROR MESSAGE

MESSAGE CAUSE SOLUTION

Improper installation of drain hose.

The drain hose is blocked up by foreign

matter.

Drain motor is inferior.

The water tap is closed.

The water inlet filter clogged.

It passes over the 30 minutes, yet it

doesn’t come to assigned water level.

Wash loads get uneven during spin.

Poor installation of the unit.

The lid is opened.

The safety switch is inferior.

The load sensing is inferior. After the

load sensing operates about 20

seconds, the message is displayed

during 0.5 second and water level is

always fixed ‘high’.

The water level sensing is inferior.

This condition shows that (S/H) button

is pressed with the door being open

after reservation washing time is set.

Install drain hose properly.

Remove foreign matter from drain

hose.

Change drain motor.

Open the water tap.

Clean the water inlet filter.

Check whether or not is comes to

the assigned water level.

Re-set wash loads evenly.

Proper installation.

Close the lid.

Change the safety switch.

Change the P.C.B. ASS’Y.

Check the water level sensor and

the contact part of the connector.

Close the door.

2928

LOAD DRIVE UNIT

(cw wash, ccw wash, drainage, hot water, cold water , bubble)

1) CIRCUIT DIAGRAM AND EXPLANATION

• Controlling load of button input in MICOM terminal, it is selected to ‘L’ or ‘H’. It is selected to ‘H’ in

running load case and in ‘L’ case, load driving is finished, In clockwise rotation of washing motor, as

MICOM No. 31 is changed 0V to 5.4V, TR Q1(KTN2222S) is turn on. And then, the TRIAC1(SM

12JZ47) is turn on, the source of electric power is supplyed to washing motor for clockwise rotation.The

TRIAC as switching element, force to ‘ON’ or ‘OFF’ by use of the Q1 (KTN2222S) in the rest loads,

when the MICOM terminal voltage change 0V to 5.4v, each TRIAC DRIVE TR is active, and then TRIAC

switches the source of electric power to loads.

• The purpose of using the MICOM terminal No. 6 Q2(KTA 1664) is that the Q2 prevents the instant

supply of electric power supply to loads, in case MICOM’s action is wrong by means of pushing initial

power switch.

25

26

27

28

29

30

31

3.9KΩ

C28,683

C30,683

TRIAC1

TRIAC2

62Ω

62Ω

C18,223

TRIAC4

C21,223

TRIAC5

SM12JZ47

SM12JZ47

BCR1AM

SM3JZ47

SM3JZ47

3.9KΩ

103Z

C26

104Z

R58,100Ω,1W

C24

104Z

R57,100Ω,1W

C20

104Z

R56,100Ω,1W

C17

104Z

R60,100Ω,1W

C19

104Z

R62,100Ω,1W

C23

104Z

R63,100Ω,1W

C29

104Z

SM8JZ47

R39, 100Ω, 1W

330Ω

62KΩ

20

19

18

15

14

16

17

KTN

2222S

10KΩ

TRIAC7

C27, 103

C25, 103

TRIAC6

BCR1AM

C22,103

TRIAC3

M

I

C

O

M

HYBRID IC (IC9)

1

3

4

5

6

7

9

10

2

6

Q1

62Ω

62Ω

330Ω

11

1KΩ

10KΩ

103z

104z

Q2

KTA1664

PUMP

BL/WH

PK

BUBBLE

RD/BL

COLD WA TER

YW

HOT WA TER

YW/BK

DRAINAGE

BL

CCW WASH

VT

CW WASH

BL/YW

AC COMMON

MINUTE EXPLANATION DIAGRAM FOR EACH P ARTS

MICOM IC (64 DIP)

1 64

2 63

3 62

4 61

5 60

6 59

7 58

8 57

9 56

10 55

1 1 54

12 53

13 52

14 51

15 50

16 49

17 48

18 47

19 46

21 45

21 44

22 43

23 42

24 41

25 40

26 39

27 38

28 37

29 36

30 35

31 34

32 33

P10/S00

P1 1/SI0/SB0

P12/SCK0

P13/S01

P14/SI1/SB1

P15/SKC1

P16/BUZ

P17/PWM

TEST1

RES

XT1

XT2

VSS

CF1

CF2

VDD

P80/AN0

P81/AN1

P82/AN2

P83/AN3

P7/INT0

P71/INT1

P72/INT2/T0IN

P73/INT3/T0IN

S0/T0

S1/T1

S2/T2

S3/T3

S4/T4

S5/T5

S6/T6

S7/T7

P07

P06

P05

P04

P03

P02

P01

P00

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19

S18

S17

S16

VP

VDDVPP

S15/T15

S14/T14

S13/T13

S12/T12

S1 1/T11

S10/T10

S9/S9

S8/T8

LC866020Y

SANYO

ROM : 16384X 8 bit

RAM : 384X 8 bit

3130

3) CAUTION AND CHECKING FOR A/S

• If load is active as soon as the power switch is ‘ON’, check the driving TRIAC of load.

• Check the MICOM output terminal, if the load doesn’t act although the TRIAC isn’t anything wrong.

• Soemtimes it is happened that TRIAC DRIVE TR has circuit or an open circuit. In this case, being

measured the resistance between the TR E & C with tester, the resistance value should be near the

∞Ω. If not, the DRIVE TR is out of order.

• If the ceramic condenser(C17, C19, C20, C23, C24, C29) using by protecting the noise between the

GATE & T1 of each TRIAC has a short circuit, it has no voltage drop between the T1 and GATE.

Therefore, the TRIAC is not turn on.

• If MICOM terminal No. 6 is not active from 5.4V to 0V, all DRIVE TR of the TRIAC are not turn on.

Therefore, the TRIAC is not out of order, to begin with, check the micom terminal No. 6 and TR Q2(KTA

1664) necessarily.

• The TRIAC’s names and values of the snubber & resistance of the total parts.

SM12JZ47(12A), SM8JZ47(8A), SM3JZ47(3A)

• CHECK the resistance of the T1 &

T2 of TRIAC. (∞Ω).

• CHECK the total parts without fail,

in case the TRIAC has a short

circuit.

BCR1AM-12L

• CHECK the resistance of the T1 &

T2 of TRIAC.(∞Ω).

• CHECK the total parts without fail,

in case the TRIAC has a short

circuit.

shape

T1 T2 G

shape

T1 GT2

LOAD

CW WASH

CCW WASH

DRAINAGE

HOT & COLD

WATER

BUBBLE

GENERA T OR

PUMP

TRIAC’S NAME

SM12JZ47

BCR12PM-14L

SM12JZ47

BCR12PM-14L

BCR1AM-12L

SM3JZ47

BCR1AM-12L

SM8JZ47

BCR8PM-14L

GA TE’S

RESIST ANCES OF

LIMITED

CURRENTS

62Ω, 1/2W

62Ω, 1/2W

330Ω, 1/4W

62Ω, 1/2W

330Ω, 1/4W

62Ω, 1/2W

V ALUES OF THE

SNUBBER

100Ω, 1W+683K

AC 250V

100Ω, 1W+683K

AC 250V

100Ω, 1W+103K

AC 250V

100Ω, 1W+223K

AC 250V

100Ω, 1W+103K

AC 250V

100Ω, 1W+103K

AC 250V

RESIST ANCES OF

TOTAL PARTS

2) DETAIL EXPLANATION OF CIRCUIT ACTION (ACTION OF CW WASH)

• In case MICOM terminal No. 31 is ‘H’ and No. 6 is ‘L’ the Q1 (KTN2222S) & the Q2 (KTA1664) turn on

and control the TRIAC. The resistance, as 62Ω & 1/2W, of the R52 is used to limit the GATE current of

the TRIAC.

• The resistance R1(3.9K Ω, 1/4W) and the R5(1KΩ, 1/4W) control the base current of the Q1 & Q2 in

order as TR forces to turn on sufficiently.

• The ceramic condenser C29 between the T1 and the GATE of the TRIAC8 is used for preventing the

wrong action by means of the noise.

• The R63(100Ω, 1W) and C28(683K) between the T1 and T2 of the TRIAC is used for protecting the

TRIAC, it usually called SNUBBER CIRCUIT.

• The waveform of MICOM No. 31 & 6.

R1

3.9kΩ

AC COMMON

C29

104Z

Q1

R3

10KΩ

R4

10KΩ

R5,1KΩ

Q2

11

R2,62Ω

HYBRID IC(IC9)

R63,100Ω,1W

TRIAC1

C28,683

M

I

C

O

M

6

9

10

7

31

action

action

stop

5.4V

0V

Terminal No. 31

t

t

Terminal No. 6

5.4V

0V

action

1 The gray & red (The waveform in

secondary part of the transformer)

2 Measuring the wave form in case of the

removing condenser by the removal ripple

C33

3 It is removed the ripple with attaching the

C33(2200µF).

4 The waveform of output in the

REGULA T OR I.C 7806.

5 The waveform after passing the D2.

ELECTRIC POWER SUPPLY UNIT

1) CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

• The primary voltage of the transformer sets 220V, the secondary voltage of the transformer is full

wave rectified by use of the D7 (1N4003) & D8(1N4003).

3332

16

C3 6

104Z

104Z C31

3300µF

10V

470µF

16V

2200µF

35V

104Z

C13 C34

C32

D1,1N4003

7806

REGULATOR

D8,1N4003

C33

COMMON

220V

D7,1N4003

f=60Hz

Vpeak=11.4V

Vrms=8V

12V

W ATER LEVEL SENSOR UNIT

1) CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

• Push the power switch. And, in order to carry on the action of course selection, input the selection of

frequency according to each water level selection.

• The frequency of water level sensor in each water level becomes square wave and is sended to the

MICOM.

If the water level is selected ‘HIGH’ in washing, water suppply proceeds until inputing the frequency 22.70

KHz of ‘HIGH’ in the MICOM terminal No. 24. Being finished the water supply, washing process is

proceeded. After the washing process, water level reaches to RESET point, and then after the (D) + 60

seconds, the spin process begins.

• The value of the frequency between the MICOM terminal No. 24 and the GND.

3) CAUTION FOR A/S

• The output of the frequency in the WATER LEVEL SENSOR varies in accordance with temperature and

using condition. If it doesn’t input the output of the WATER LEVEL SENSOR in the MICOM, the error

message is displayed as ‘E9’. In case of proceeding the water supply continuously in ‘HIGH’ water level,

it is desirable to change the WATER LEVEL SENSOR because of the defect in the WATER LEVEL

SENSOR.

• Check the TR Q4(A1270Y)

• Being checked with tester, the value of the voltage reaches about 4V.

• As the frequency is low, the water level is higher.

M

I

C

O

M

24

R18,220Ω

Q4

A1270

R20,10KΩ

R21,10KΩ

R22, 3.9KΩ

WATER LEVEL NAME FREQUENCY WATER LEVEL DWF-7588 DWF-9288 DWF-1088

HIGH 22.52KHz 400± 15 80L 98L 96L

MIDDLE 23.04KHz 340+10, -15 68L 78L 81L

LOW 23.56KHz 280±15 55L 61L 65L

SMALL 24.05KHz 220±15 42L 48L 49L

E.SMALL 24.33KHz 180± 15 30.5L 33L 36L

RESET 25.02KHz

0 25.40KHz

60 ±20

6V

0V

12V

5.4V

0V

5.4V

0V

f=22~25KHz KHz

0V

0V

3534

The waveform of the secondary part in transformer passes through the diode D6, D9(1N4003), and then

the voltage is divided by means of the resistance R64 & R65. This voltage gives force to input the pulse to

the MICOM terminal No. 21 on the ground of action of the TR Q17(C3202Y).

3) CAUTION FOR A/S

• The phenomenon of no electric power supply happens, to begin with check the electric power supply

unit, and then check the INTERRUPT UNIT. It is desirable to measure the Q17(C3202Y) with tester and

the C10(C103Z).

RESET UNIT

1) CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

• The RESET unit is a hardware circuit, of which all programs are initialized, when the power switch is

‘ON’, Here, the reason why uses RESET I.C. is that the RESET UNIT prevents the MICOM from

incorrect action. Also, the R11 & C7(104Z) as a RC filter, is used in order to absorb the noise.

• The waveform measurement of the part 1

with being ‘ON’ the power switch.

3) CAUTION FOR A/S

• Check the output of the RESET I.C. and judge whether or not it is something wrong,

1. OUTPUT

2. INPUT(VDD)

3. GROUND

• The R12 and C8 turn on the accurate RESET value with controlling the RC time constant.

• After connecting the part of the dotted line &

waveform measurement

• The waveform measurement in the MICOM

No. 21

0V

0V

8.35ms

5.4V

10

R12,10K

IC3

RESET I.C.

S-8054HN

C8

47µF

16V

3300µF

10V

C7

104Z

R11,220

D2, 1N4003

M

I

C

O

M

1

• The Electrolytic condenser C13(3300µF, 10V) and diode D2 is used in order that at instant power supply

failure circuit should remember the contents of the program. It happens that the MICOM terminal NO, 16

has instant interruption of electric power, yet the MICOM is not discharged electricity because of the

diode D2.

• The measurement of voltage is as follows.

3) CAUTION FOR A/S

• Measure the voltage of input terminal REGULATOR I.C of 7806 with

tester. And, compare the measuring value with the voltage table.

• Check the condendser in case the electrolytic condenser and

ceramic condenser have short circuit. The reason is that it happens

no electric power supply.

INTERRUPT UNIT

1) CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

The INTERRUPT UNIT is necessary to reduce the generation of surge, by use of being voltage ‘ON’ from

the zero voltage.

• The waveform of the part 1

1

EFFECTIVE VALUE

2 3 4 5

82.5V 5.2V 7.9V 7.9V 5.97V 5.4V

110V 7.2V 11V 11V 5.97V 5.4V

137.5V 9.3V 14.1V 14.1V 5.98V 5.4V

165V 5.3V 7.6V 7.6V 5.96V 5.4V

220V 7.6V 10.6V 10.6V 5.98V 5.4V

275V 9.7V 13.7V 13.7V 5.98V 5.4V

• The waveform of the part 2 (in case of cutting

the part of the dotted line)

7806

INPUT OUTPUT

GND

M

I

C

O

21

C10

103Z

R19,220

Q17

C1959

R23, 3.9K

C35

103Z

R64,10K

R65

22K

D9,1N4003

2

D6,1N4003

M

0V

0V

1

POWER SWITCH ON

RESET TIME

500ms

POWER OFF

190ms

5.4V

4.9V

1

3

2

3736

• Part of the button scan

The system of the BUTTON SCAN is in wide use for the method of the DUTY output part in L.E.D DRIVE,

yet here, it is in use for the method of the segmental output.

• Though the period of the DUTY part is 1/9, the last 9th part does not generate the waveform and checks

the button input with getting out the segmental output at the same time.

• The RA1(473J, 47KΩ) is a ‘PULL DOWN’ resistance for preventing floating action.

• The D15 prevents the L.E.D from turning on unnecessarily with forming the closed loop like a threaden

line at the time of button push.

IC6

ULN

2004A

6

5

4

3

SW2 SW6

SW7SW3

R66,220

R67,220

RA1

4X473J

58

57

59

60

M

I

C

O

M

Duty Part

Segment Part

Waveform

No Generation

Segmental Waveform

for Button Input

BUZZER UNIT

1)CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

• After the button action and total process ends, BUZZER is active.

• It is active directly with offering an output the frequency waveform of 2 KHz from the MICOM terminal

No.7.

• The R7 is ‘PULL UP’ resistance, and the R8 is restrict resistor of the Q1 base current, and the R5 is

resistance of excess current under phenomenon of short circuit, when the electric current changes

abruptly according to the condenser component of piezoeletric element, and the R8 remove the

phenomenon of abnormal oscillation by preventing the collector floating state of the Q1.

• The waveform in the part of the BUZZER DRIVE TR Q1 collector.

BUTTON INPUT UNIT

1) CIRCUIT DIAGRAM

M

I

C

O

M

R7, 10K

R6,1K

Q1

C3202Y

R5, 220

BUZZER

WES27-20P

R8, 620

12V

12V

0V

f=2KHz

t

0V

6V

0V

5.4V

0V

3938

SAFETY SWITCH UNIT

1)CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

• The MICOM terminal No. 63 gets into ‘L’ at the state of the closed lid. If lid is open in spinning state,

the MICOM generates error signal as ‘LE’ .

• Case of range 40mSEC~300mSEC in spinning time: It is regarded that washing clothes should be

inclined. Accordingly washing time increases 8 minutes and rinsing action takes place another one

time. Case of above 300 mSEC : It is regarded that lid should be open. Therefore it is displayed as

‘LE’.

3) CAUTION FOR A/S

• Be level with the ground.

• The ‘UE’ error occurs in case of not being level with the ground.

• The waveform between the MICOM terminal No. 63 and the GND.

LOAD SENSOR UNIT

1) CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

• Detecting the voltage of running condenser, it sends the sensing data to the MICOM terminal No. 22

& 23. That is, as charging & discharging time of runing condenser becames different according to the

loads, in fuzzy course the washing time is determined by sensing the quantity of washing clothes.

• The waveform between the part of 1 and the GND(waveform of pulse).

R4, 3.9KΩ

Door S/W

Unbalance

S/W

C1

104Z

R3,220Ω

Lid is closed Lid is open

M

I

C

O

M

PC817

D5

IN4148

IC4

R53,10K

R55,10K

R54,3.9K

R17,10K

Q16,C1959

R39,10K

Q3

A562

5.4V

R13, 220

R14, 220

C12

104Z

23

22

6V

1

OSCILLATION UNIT

1)CIRCUIT DIAGRAM

2)EXPLANATION OF CIRCUIT

• As the OSCILLATION UNIT is a basic part of the MICOM DRIVE. If the oscillation doesn’t generate, we

able to consider that the MICOM is destroyed.

• The waveform between the part of 1 The waveform between the part of 2

and the GND and the GND

• Specification of oscillator

It is general use for the MICOM maker’s recommendatory value of condenser which is fit for MICOM’ s

characteristics.

• The R82(10MΩ, 1/6W) is in use to get rid of the initial abnormal oscillatory phenomenon of the 32.768

KHz crystal oscillator.

1

2

M

I

C

O

M

CF2,15

CF1,14

XT2, 12

XT1, 11

R17

10MΩ

1/6W

C5,18PF

C4,18PF

33PF

33PF

Murata 3 Terminal

Ceramic Resonator

(CST 12.00MTW)

Kyocera 32.768 KHz

Crystal Oscillator

(KF-38G-13P0200)

CONDENSER

TYPE OF OSCILLA T OR MAKER NAME OF OSCILLA T OR

C1 C2

12 MHZ

MURA TA CST 12.00 MTW 33 PF 33PF

CERAMIC RESONATOR

32.768KHZ

KYOCERA KF-38G-13P0200 18PF 18PF

CRYSTAL OSCILLATOR

5.4V

0V

t

6V

0V

t

4140

2) EXPLANA TION OF CIRCUIT

• The MICOM terminal No. 33~40 amplifies the source current to produce the ‘H’ by use of the buf fer

UDX-2981A. And the MICOM terminal No. 43~54 sufficiently amplifies the sink current by use of the

DRIVE I.C. ULN-2004A.

• The waveform between the part of 1 and the GND(part of the DUTY)

• The division rate of the DUTY is 1/9. And as part of the DUTY treats the black time between the square

waves, it prevents the phenomenon of faint lighting of L.E.D unnecessarily due to the phenomenon of

fold in delay time of the IC 8 between the input and output.

• The equivalent circuit of DRIVE IC & BUFFER IC

• If the light of the DISPLAY unit is does not appear, check the circuit using the oscilloscope.

0V

3.085mSEC

5.4V

INPUT

10.5KΩ

7.2KΩ

GND

OUTPUT

COMMON

INPUT

GND

1.5KΩ

2983/84 Only

20KΩ

VD

7.2KΩ

3KΩ

OUTPUT

ULN-2004A

UDN-2981A

• The element which has an effect on data of LOAD SENSOR

DISPLAY UNIT

1) CIRCUIT DIAGRAM

CONDITION SPECIFICA TION

VOLTAGE 220V AC

CAP ACITY OF CONDENSER 13.5µF

TENSION OF BELT 450gf

17 13 2 3 4

a1 a2 a3 a4 a5

b1 b2 b3 b4 b5

c1 c2 c3 c4 c5

d1 d2 d3 d4 d5

e1 e2 e3 e4 e5

f1 f2 f3 f4 f5

g1 g2 g3 g4 g5

DH RS M2

RN FE TM RM

WS IL1 M1

SK IL2 HR1 HR2

a6 b6 c6 d6

a7 b7 c7 d7

G1 B1 FZ

12 5

G2 B2 MM

G3 B3 SAK

10 7

G4 B4 DRY

G5 B5 SLK

G6 B6 QK

G7 B7 ST

G8 B8 NG

CD8

MI BL

CD1 CD2 LT LO

HTB ME

HT1 HT2 DR2 HI

e6 f6 g6

e7 f7 g7 DRY

6V

R62.43

R61.43

R60.43

R59.43

R58.43

R57.43

R56.43

R65.43

R64.43

R63.43

R67.43

R66.43

R69,43

R68,43

6V

10

11

12

13

14

I.C8

15

ULN-2981

16

17

18

9

10

11

12

13

I.C7

14

ULN-2004

15

16

10

11

12

13

14

I.C6

15

ULN-2004

16

9

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

7

6

5

4

3

2

1

8

CH4 26 CH2

13 CH1CH3

6V6V

A

RA4(4X103J)

RA3(4X103J)

C36

104Z

B

5.4V

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

S8

S9

S10

S11

S12

S13

S14

S15

VddVpp

VP

S16

S17

S18

S19

S20

S21

LC866020Y

S22

S23

S24

S25

S25

S27

S28

S29

P00

P01

I.C1

WM 7

FRONT P.C.B FRONT P.C.B

SK WS FE RN RS DH

SOAK

g1

g1

ef d1

d1

HOUR

HR1 M1 TM M2 RM

c1 b1

IL2 IL1

CUSTOM LED1 CUSTOM LED2

WASH

g2

g2

c2 b2

d2

MIN TIME MIN REM

RINSE

g3

g3

e3 f3

d3

MILD SPIN HOT COLD

g4

g4

c3 b3

c4 b4

e4 f4

d4

g5

g5

e5 f5

d5

c5 b5

HT1

HT2

G1

G2

G3

HTB

DR1, DR2

B7

B4

B3

B1

G4 G5

H.

M.

L.

S.

ES.

FZ

FUZZY

MM

SAK

SOAK.

DRY

SLK

MEH.

DRY

SILK.

HI

CD1

CD2

ME

CDB

LO

G8

B8B6

G7

MI

B5

B2

G6

LT

ECO

SUPER

NIGHT

ß LAN

QK

ST

NG

BL

4342

EEPROM UNIT

1)CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

In contrast with mask ROM, EEPROM which enable WRITE/READ by program, memorize data even

during POWER is OFF.

• EEPROM PIN FUNCTION

EEPROM stores the selected contents in MEMORY course and LOAD SENSING data.

If you press MEMORY button, MICOM read the contents in MEMORY course and L.E.D displays the

selected contents in MEMORY course.

3) CAUTION FOR A/S

1. When the selected contents of MEMORY course in EEPROM can not memorize, EEPROM is

defective.

M

I

C

O

M

SO0,1

SI0,2

SCK0,3

SO1,4

RA4 103J

1,CS

R9

10KΩ

C6,104Z

2,CLK

4,DO

3,DI

GND,5

6

VDD,8

BUSY,7

IC2 EEPROM

TC89101P

PIN NAME FUNCTION

Chip selector

CS Chip is enabled when CS is at ‘L’ level.

Set CS to ‘H’ level before executing instruction.

Clock input

CLK The DI data is latched at the rising edge of CLK.

The data is out from DO at the falling edge of CLK.

CLK is enable when CS is at ‘L’ level.

DI Serial data input

The address, command and data input pin.

DO Serial data output

The data output pin

Organization select

ORG The 16-bit organization is selected when ORG is ‘H’ level.

The 8-bit organization is selected when ORG is ‘L’ level.

Status output

RDY/BUSY ‘L’ level is output during program or chip eraise operation.

‘H’ level is output when program or chip eraise operation is completed.

TEMPERATURE SENSOR UNIT

1) CIRCUIT DIAGRAM

2) EXPLANA TION OF CIRCUIT

• To use resistor for temperature detection, the value of R43 was decided to the center value of

temperature bandwidth (-20~70°C), that is, resistance of temperature sensor is 51.35 KΩ at 25°C.

Therefore the value of R43 was decided to 51.5 KΩ, F(1%).

• C15 used electrolytic condensor (1µF) to remove noise and to stabilize the voltage.

3) CAUTION FOR A/S

1. HOW TO CHECK TEMPERATURE SENSOR.( Reference to TEST MODE)

If the L.E.D displays ‘LO’ or ‘HI’, there is some trouble with the temperature sensor.

In this case, the processing is designed to perform normal processing. Before change temperature

sensor, check the connector and temperature sensor.

2. There is function to give up role of temperature sensor forcibly.

At the first condition in TEST MODE press the RESERVATION button. And after change data by

SOAK button, press STAR T/HOLD button.

If so, data input. (11 : perform to temperature sensor, 22 : give up temperature sensor)

3. In the FUZZY course (WASH:14min, RINSE : 2Times, SPIN:5min, COOL WATER SELECTION) the

total processing time can be changed by water temperature.

M

I

C

O

M

R81,1KΩ

18

C32

1uF

R31

5.4V

SENSOR

51.1KΩ

4544

APPENDIX

WIRING DIAGRAM

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9

2 1

2 1

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

2 12 1

2 1

2 1

2 1

3 2 1

3 2 1

1 2 3

1 2 3

1 2 3

1 2 3

BL/YW

VT

BL

RD/BL

YW

WH/RD

YW/BK

PK

WH/RD

BL/WH

BL/YW

VT

BL

RD/BL

YW

WH/RD

YW/BK

PK

WH/RD

BL/WH

WH/RD

WH/RD

WH/RD

WH/RD

WH/RD

WH/RD

BR

YW

WH/RD

BR

BRBR

TRANS

GNWHGNWH

WH/RD

FUSE

YW/BK

BL/WH

BR/WH

GN/WH

BR

BK/WH

WH

GY

RD

OR

BR/WH

GN/WH

BR

BK/WH

WH

GY

RD

OR

1

1

GY

RD

OR

GY

RD

OR

BR

BR

BK/WH

WH

BR

BK/WH

WH

WH/RD

BL/YW

WH/RD

WH

BL/YW

BL/YW

BR

or

VT

BR

or

VT

BL/YW

TEMP

SENSOR

WATER

LEVEL

S/W

SAFETY

S/W

SAFETY

S/W

BR/WH

BR/WH

MOTOR

DRAIN

MOTOR

HOT

W/S VALVE

COLD

WS VALVE

BUBBLE

GENERATOR

B

C

RD/BL

EARTH

POWER CORD

AC SOURCE

BK

GN

WH

WH

BL/YW

WH

BL/YW

15µH

BK

FUSE

BL/.YW

YW/BK

YW/BK

WH/RD

WH/RD

BL/WH

WH/RD

WH.RD

WH.RDWH/RD

VT

BL

VT

VT

BL

60µH

BL

VT

BL

BL

WH/RD

BL/YW

L/F

BL/YW

BL/YW

VT

VT

VT

BL/YW

BL

BL

BL

VT

VT

VT

BL

VT

CONDENSER AS

PK

WH

PK

WH/RD

A

15µH

WH

GN

F-P.C.B. M-P.C.B.

SYMBOL RATING (V) SPEC

100~127

220~240

100~127

220~240

110

127

220

230

240

250V/8A

250V/4A OR 5A

600mA

315mA OR

300mA

R 50µF

B 54µF

41.6µF

R

12.5µF or

13.5µF

B

12.5µF or

13.5µF

12.5µF

11.4µF

• RATING : REFER TO RATING PLASTE

• RESIN MOTOR

• BRACKET MOTOR

A

B

C

HOW TO CHECK THE P.C.B. ASS’Y

COURSE 1

Keep pushing three button (WASH, RINSE, SPIN SELECTOR) together and turn on the power switch.

COURSE 2

Processign COURSE 1, Push the spin selector onceor three times according to desire check mode.

No. TIME DISPLAY FUNCTION

1 SEC State of first lighting.

Temperature which sensing t

hermistor.

2 SEC

LO : Thermistor open.

HI : thermistor short.

3 SEC

All LED light 8 times and go

back to first stage.

TIME TO PUSH

DISPLAY FUNCTION

THE SPIN BUTTON

1st Time

2nd Time

3rd Time

drain

`➜`

spin

`➜`

cold water

`➜`

hot

water

`➜`

pulsator rotae(right) ➜bubble

➜`

pulsator rotae(left)

➜`

fan

`➜`

heater

` ➜`

door

check(dc/do)

`➜`

off

Repeat drive without “off” in “d2”

FUZ

FUZ

FUZ

SOAK

HOUR

WASH RINSE MILD SPIN

HOT COLD

H.

M.

L.

S.

ES.

SILK

FUZZY

MEM.

SOAK.

DRY

ECO.

SUPER

NIGHT

BLAN

TIME MIN. REM.MIN.

4746

NO. PARTS CODE PARTS NAME DESCRIPTION Q’TY REMARK

P36 3611105400 CASE DETERGENT ABS 1

P37 3610902600 CAP REAR CR 4

B1 3610076030 ASS’Y CONDENSER 50µF+60µF, CONN 1 TE MODEL

3610031930 12.5µF+60µF, CONN 1 NE MODEL

3610045630 11.4µF+60µF, CONN 1 ME MODEL

B2 3612200100 FRAME TOP PP 1

B3 3610801800 CABINET PCM 0.7T 1

B4 3610300900 BASE UNDER PP 1

B5 3611404400 COVER BACK PP 1

B6 3617700400 LEG FIX BUTLY RUBBER 2

B7 4509M10032 FIXTURE PP 2

B8 7122502011 SCREW TAPPING T2S TRS 5X20 MFZN 2

B9 3612000200 FIXTURE LEG PPG 2

B10 3618900700 UNIT LEG RUBBER +BOLT INSERT 2

B11 3613000600 HOLDER LEG ABS 2

B12 3610901700 CAP LEG L ABS 1