Page 1

Service Manual

Auto Washer

Model: DWF-204AY

S/M No. :

Feb. 2013

✔ Caution

: In this Manual, some parts can be changed for improving,

their performance without notice in the parts list. So, if you

need the latest parts information, please refer to PPL(Parts

Price List) in Service Information Center (http://svc.dwe.co.kr).

DWF204AY01

Page 2

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER AUTO WASHER

WASHING MACHINE

Contents

1. SPECIFICATIONS ....................................................................................................................................2

2. STRUCTURE OF THE WASHING MACHINE .......................................................................................3

3. DIRECTIONS FOR INSTALLATION AND USE ....................................................................................4

INSTALLATION OF THE COVER UNDER ...................................................................................4

HOW TO INSTALL ON AN INCLINED PLACE .............................................................................4

HOW TO CONNECT THE INLET HOSE .......................................................................................5

HOW TO CLEAN THE FILTER ......................................................................................................6

4. FEATURE AND TECHNICAL EXPLANATION .....................................................................................7

FEATURE OF THE WASHING MACHINE ....................................................................................7

WATER CURRENT TO ADJUST THE UNBALANCED LOAD ...................................................7

AUTOMATIC WATER SUPPLY SYSTEM FOR BLANKET WASH ............................................7

FUNCTIONAL PRINCIPLE OF BUBBLE WASHING MACHINE .................................................8

AUTOMATIC DRAINING TIME ADJUSTMENT ............................................................................8

AUTOMATIC UNBALANCE ADJUSTMENT .................................................................................9

CIRCULATING-WATER COURSE AND LINT FILTER ................................................................9

LINT FILTER ..................................................................................................................................10

RESIDUAL TIME DISPLAY ..........................................................................................................10

DRAIN MOTOR .............................................................................................................................10

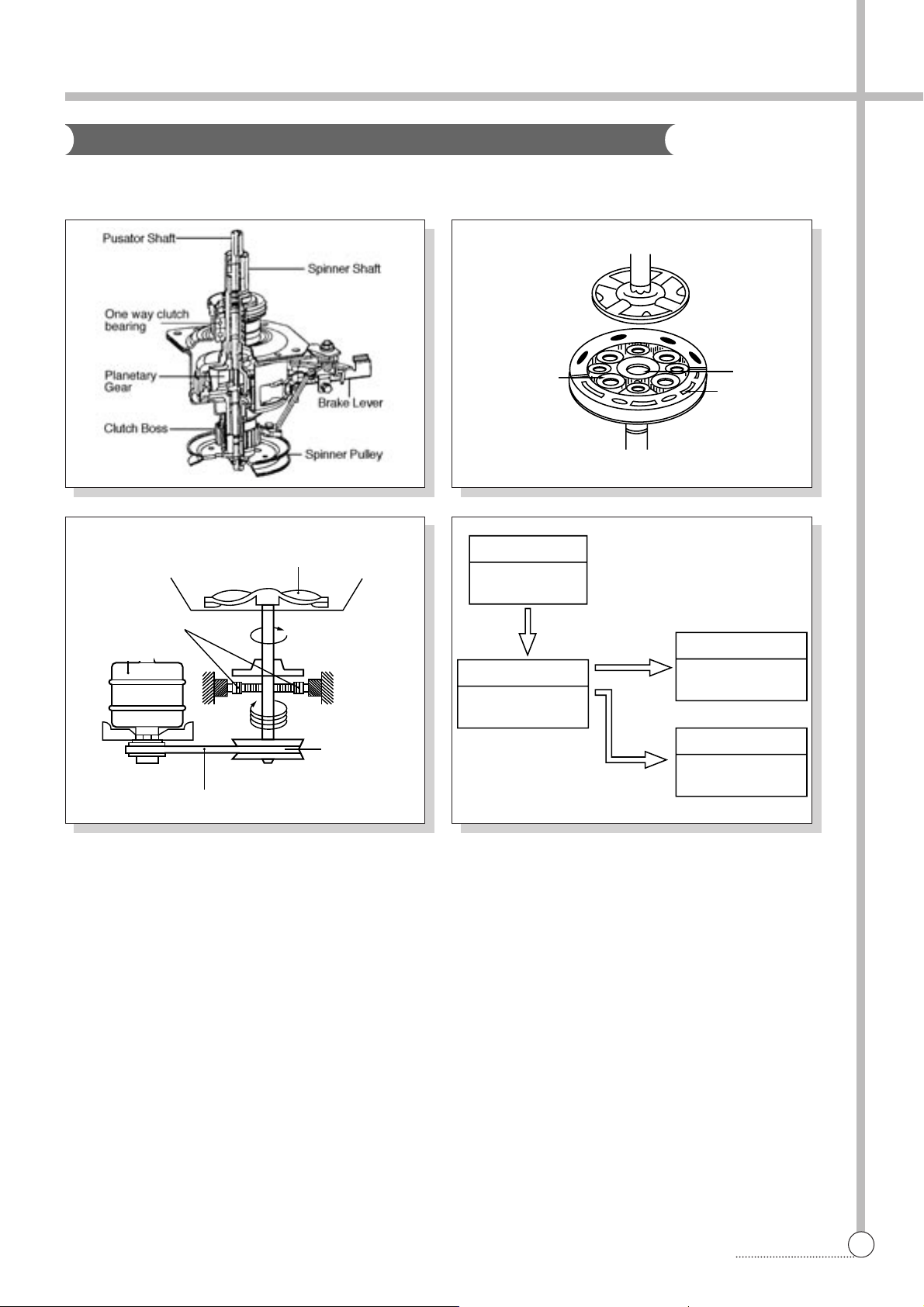

GEAR MECHANISM ASS’Y .........................................................................................................11

5. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT ................................................................12

GEAR MECHANISM ASS’Y REPLACEMENT ...........................................................................12

MOTOR SYNCHRONOUS AND VALVE REPLACEMENT .......................................................14

6. THE REPAIR METHOD OF GEAR MECHANISM FOR CLUTCH SPRING PROBLEM ................15

THE STRUCTURE OF GEAR MECHANISM ..............................................................................15

HOW TO CHECK THE CLUTCH SPRING .................................................................................16

THE PROCESS OF DISASSEMBLING .......................................................................................17

THE PROCESS OF ASSEMBLING .............................................................................................19

7. TROUBLE SHOOTING GUIDE .............................................................................................................22

CONCERNING WATER SUPPLY ...............................................................................................22

CONCERNING WASHING ...........................................................................................................23

CONCERNING DRAINING ...........................................................................................................24

CONCERNING SPINNING ...........................................................................................................25

CONCERNING OPERATING .......................................................................................................26

8. PRESENTATION OF THE P.C.B ASS’Y .............................................................................................27

CONCERNING ERROR MESSAGE ..........................................................................................27

APPENDIX

WIRING DIAGRAM .......................................................................................................................28

PARTS DIAGRAM .........................................................................................................................29

PARTS LIST ...................................................................................................................................33

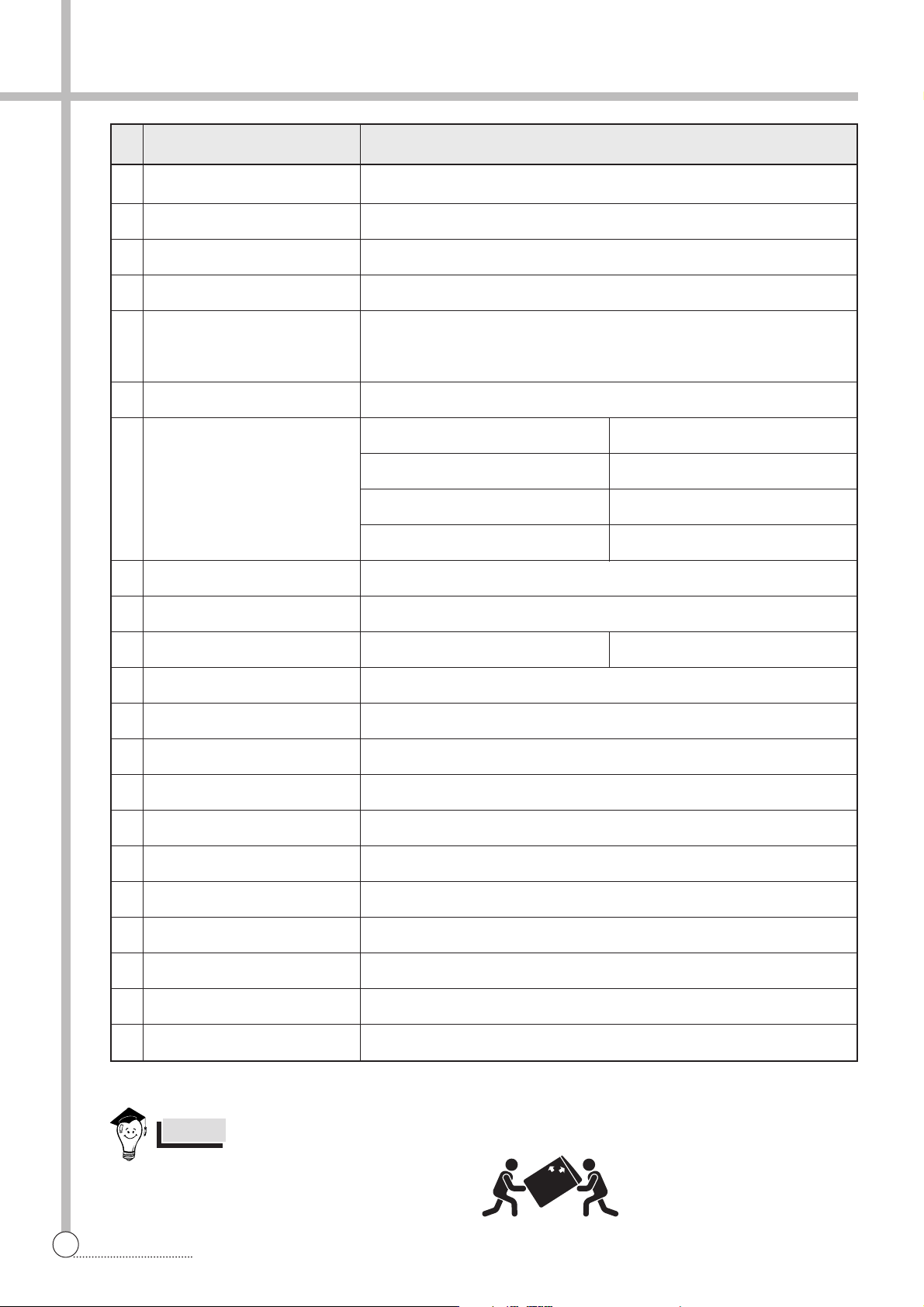

Page 3

2

SPECIFICATIONS

1 POWER SOURCE AL AC VOLTAGE AND CYCLE

2 POWER CONSUMPTION 550W

3 MACHINE WEIGHT 45Kg

4 DIMENSION (WXHXD) 630 X 1,055 X 670

5 WASHING COURSE

6 WATER CONSUMPTION 232 L

7 WATER LEVEL SELECTOR

8

OPERATING WATER PRESSURE

0.3kgf/cm2~8kgf/cm2(2.94 N/cm2~78.4N/cm2)

9 REVOLUTION PER MINUTE WASH 140~150 RPM, SPIN 675~710RPM

10 PULSATOR

11 WATER LEVEL CONTROL ELECTRONICAL SENSOR

12 GEAR MECHANISM ASS’Y HELICAL GEAR

13 MAGIC FILTER O

14 SOFTENER INLET O

15 FUNCTION FOR SOAK WASH O

16 ALARM SIGNAL O

17 RESIDUAL TIME DISPLAY O

18 AUTO. WATER SUPPLY O

19

FUNCTION FOR BUBBLE AND RADICAL

X

20 AUTO RE-FEED WATER O

21 AUTO POWER OFF O

no. item DWF-204AY

1. SPECIFICATIONS

In case of moving Washing Machine, please

follow the following picture.

NOTES

FULL AUTOMATIC 8 COURSES

(SMART CLEAN(FUZZY), JEANS, ECONOMIC, EXTRA DIRTY,

HEAVY LOAD, TUB WASH(CLEANING), COLOR, WOOL)

HIGH

MEDIUM

LOW

E.LOW

88 L

73 L

58 L

45 L

6 WINGS (ø 406mm) TBM(ø 406mm)

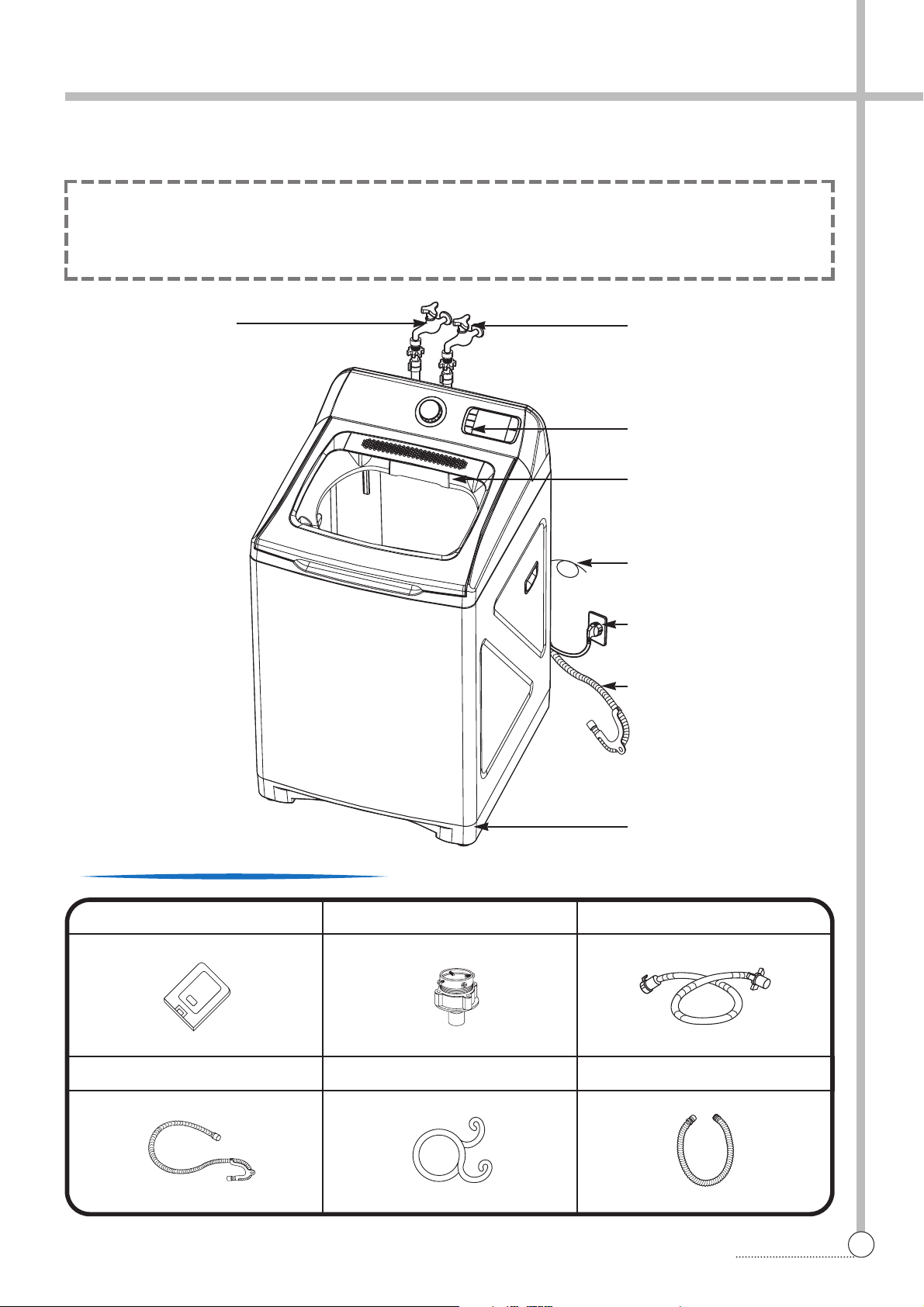

Page 4

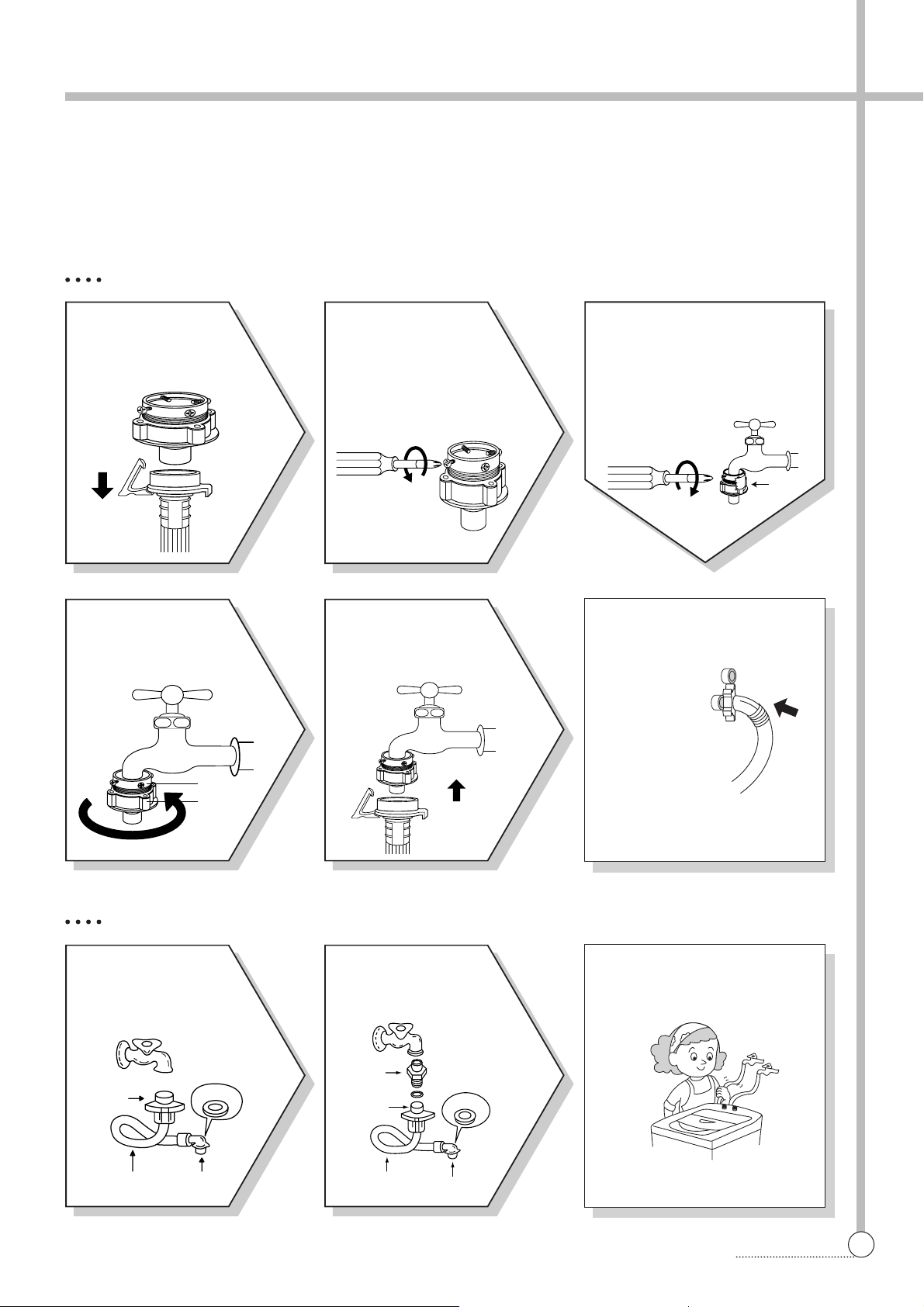

COVER UNDER (OPTION) WATER TAP ADAPTER INLET HOSE

HOSE DRAIN (FOR PUMP) HOSE DRAIN CLAMP HOSE DRAIN (FOR NON-PUMP)

2. STRUCTURE OF THE WASHING MACHINE

3

STRUCTURE

ACCESSORIES (FULL OPTION)

The parts and features of your washer are illustrated on this page.

Become familiar with all parts and features before using your washer.

NOTE

• The drawings in this book may vary from your washer model.

They are designed to show the different features of all models covered by this book, Your model may not

include all features.

UP

• COLD WATER TAP

After using the washing

machine, close the water tap.

• HOT WATER TAP

After using the washing

machine, close the water tap.

In case of the single valve

model, there is no hot water

valve.

• CONTROL PANEL

• POWER CORD

•

GROUND WIRE(OPTION)

In case of 3-wire power cord

ground wire will not be

provided.

• HOSE DRAIN

• ADJUSTABLE LEG

• CASE DETERGENT

AND SOFTENER

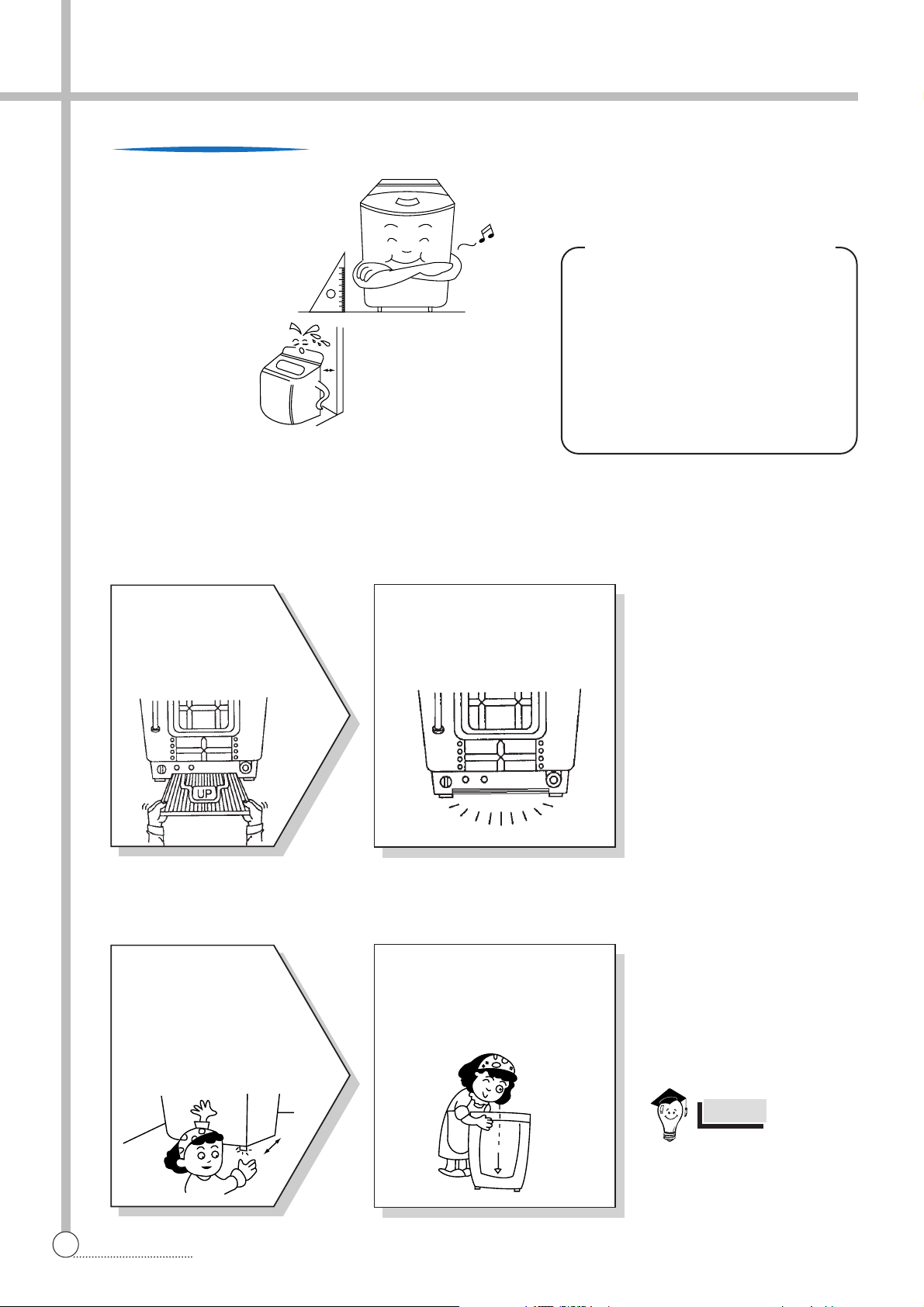

Page 5

3. DIRECTIONS FOR INSTALLATION AND USE

4

DIRECTIONS

The openings must not

be obstructed by carpeting when the washing

machine is installed on a

carpeted floor.

⏿⏿

Installation Of the COVER UNDER (Noise Insulation Plate)

⏿⏿

How To Install On An Inclined Place

ᵄ The place where it would be exposed to

direct sunlight.

ᵄ The place nearby a heater or heat

appliance.

ᵄ The place where it would be supposed

to be frozen in winter.

ᵄ The kitchen with coal gas and a damp

place like a bathroom.

NOTES

Install the washer on a horizontal

solid floor. If the washer is installed

on an unsuitable floor, it could make

considerable noise and vibration.

INSTALLING PLACE

Never install in these places

2

Push the COVER UNDER to

the end. This reduces the

noise from washing machine.

1

In the packing box or

the tub of the washer,

there is the COVER

UNDER. Put the

COVER UNDER at the

bottom of the back.

2

Check the Horizon

Status

Check the position of tub above

the center of the washer.

1

Horizon

Setting

After controlling the height

by turning the adjustable

leg, let the washer put

down to the ground.

Keep the machine body

more than 25cm apart from

the wall surface. It will

make easy cleaning the

drain filter which is equipped

at the back side of it. And if

it comes into contract

vibration may occur.

* The drawing of the COVER UNDER is variant from your model

25cm

10Cm

Page 6

5

CONNECTION

FOR ORDINARY TAP

6

Connect the inlet hose adapter

to the water inlet of the washer

by turning it clockwise to be

fixed tightly.

• Please check the rubber packing

inside the inlet hose adapter.

1

Pull down the collar

of the inlet hose to

separate it from the

water tap adapter.

2

Loosen the four

screws at the water

tap adapter, but don’t

loosen the screws until

they are separated from

the water tap adapter.

4

Remove the tape,

and screw connector

B into connector A

tightly.

5

Connect the inlet

hose to the water tap

adapter by pulling down

the collar of the hose end.

3

Connect the water tap

adapter to the water tap and

tighten the four screws evenly

with pushing up the adapter

so that the rubber packing

can stick to the water tap

tightly.

⏿⏿

How to Connect the Inlet Hose

Be careful not to mistake in supplying between the hot(maximum : 50˚C) and cold water.

In using only one water tap or in case of attached one water inlet valve, connect the inlet hose to the cold water inlet

valve.

Do not over tighten : this could cause damage to couplings.

FOR SCREW-SHAPED TAP

3

Insert the inlet hose adapter

into the water inlet of a washer

and turn it to be fixed.

• Check the packing in the inlet

1

Connect the inlet

hose to the water tap

by screwing the

connector D tightly.

2

Connect the

connector-inlet

supplied if necessary.

Inlet Hose

Connector D

Rubber

Packing

Connector C

Connector

Inlet

Rubber

Packing

Connector D

Connector C

Hose

TAPE

Connector B

Connector A

Page 7

6

CONVENIENCE

⏿

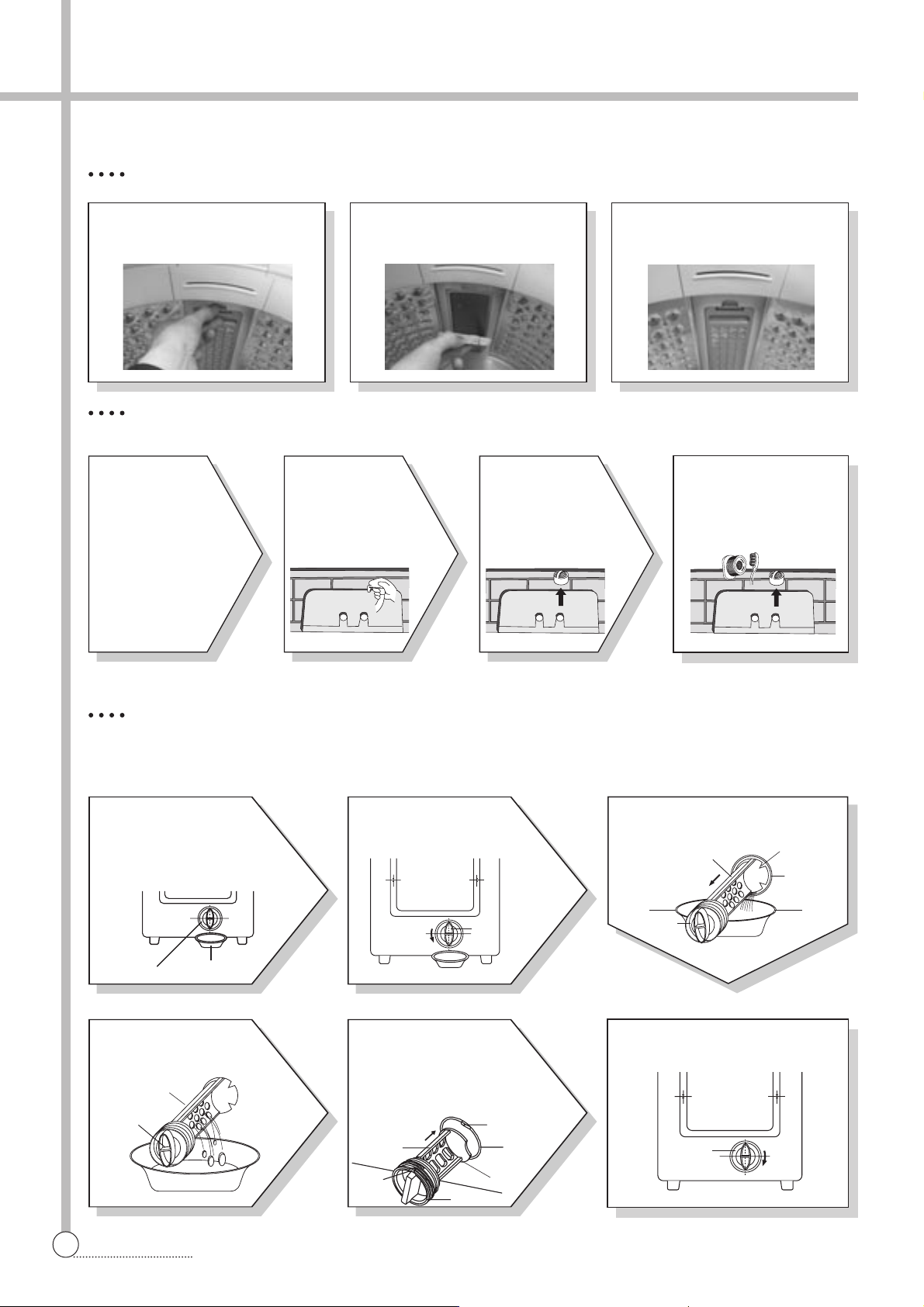

HOW TO CLEAN THE FILTER

4

Remove the dirt

from the inlet filter

with a brush.

1

Pull the

power plug

out before

cleaning it.

2

Turn off the

water supply

to the washer

and sperate the

inlet hose.

3

Pull the

inlet filter out.

CLEANING THE LINT FILTER

CLEANING THE WATER INLET FILTER

• Clean the filter when water leaks from, the water inlet.

CLEANING THE DRAIN FILTER

• In case “U” shape drain hose, this filter’s equipped at the back side of washer.

• This drain filter is to screen the foreign stuffs such as threads, coins, pins, buttons etc ...

• If the drain filter is not cleaned at proper time (every 10 times of use), Drain problem could be caused.

1

Put down the

remained water in the

hose. And put a container

under the filter to collect

water.

2

Turn the cap counter

clockwise.

3

Pull out the filter assembly off

the case of the main body.

6

Turn the cap clockwise tightly.

4

Clean the drain filter

removing the foreign

stuffs.

5

Put in the filter along the

guiding prominence of the

case. Please note the left

position of the filter adjusting

the groove to the guide rib.

FILTER

FILTER

FILTER

CAP

CAP

CAP

CAP

SLIT

CASE

CONTAINER

FILTER

CAP

CASE

SUIT

GUIDE

RIB

1

While pressing the handle of

filter, remove the filter from the

guide.

2

Remove the dirt inside the

filter and clean the filter.

3

Insert the filter into guide.

Page 8

7

FEATURE

4. FEATURE AND TECHNICAL EXPLANATION

WASH DRAIN SPIN FILL RINSE 1 DRAIN SPIN FILL RINSE 2 DRAIN •••

MOTOR C.W

SIGNAL C.C.W

TIME(SEC.) 0.3 0.3 0.3 0.3 0.3 0.3 •••••••

60 SEC.(About 50 Times)WASH

RINCE 30 SEC.(About 25 Times)

Feature of the Washing Machine

1 First applying the Radical Technology in the world ... go beyond washing, sterilize your clothes and deodorize a

bad smell.

2 The first air bubble washing system in the world.

3 Quiet washing through the innovational low-noise design.

4 Improving washing performance by more than 35%, while reducing power consumption by 40%.

5 The laundry detergent dissolves well in water because of the air bubble washing system.

6 The adoption of the water currents to adjust the unbalanced load.

7 One-touch operation system.

Water Current to Adjust the Unbalanced Load

It is a function to prevent eccentricity of the clothes after wash by rotating pulsator C.W and C.C.W for 60

seconds.(But, the SUIT course have no operation of the water currents to adjust the unbalanced load.)

EFFECT

It reduces vibration and noise effectively while spinning.

WATER FLOW

Automatic Water Supply System for Blanket Wash

The water level would be lowered because the blanket absorbs water at the beginning of washing. Therefore, after

2 minutes, the operation is interrupted to check the water level, and then the water is supplied again until the

selected water level is reached.

Page 9

8

FEATURE

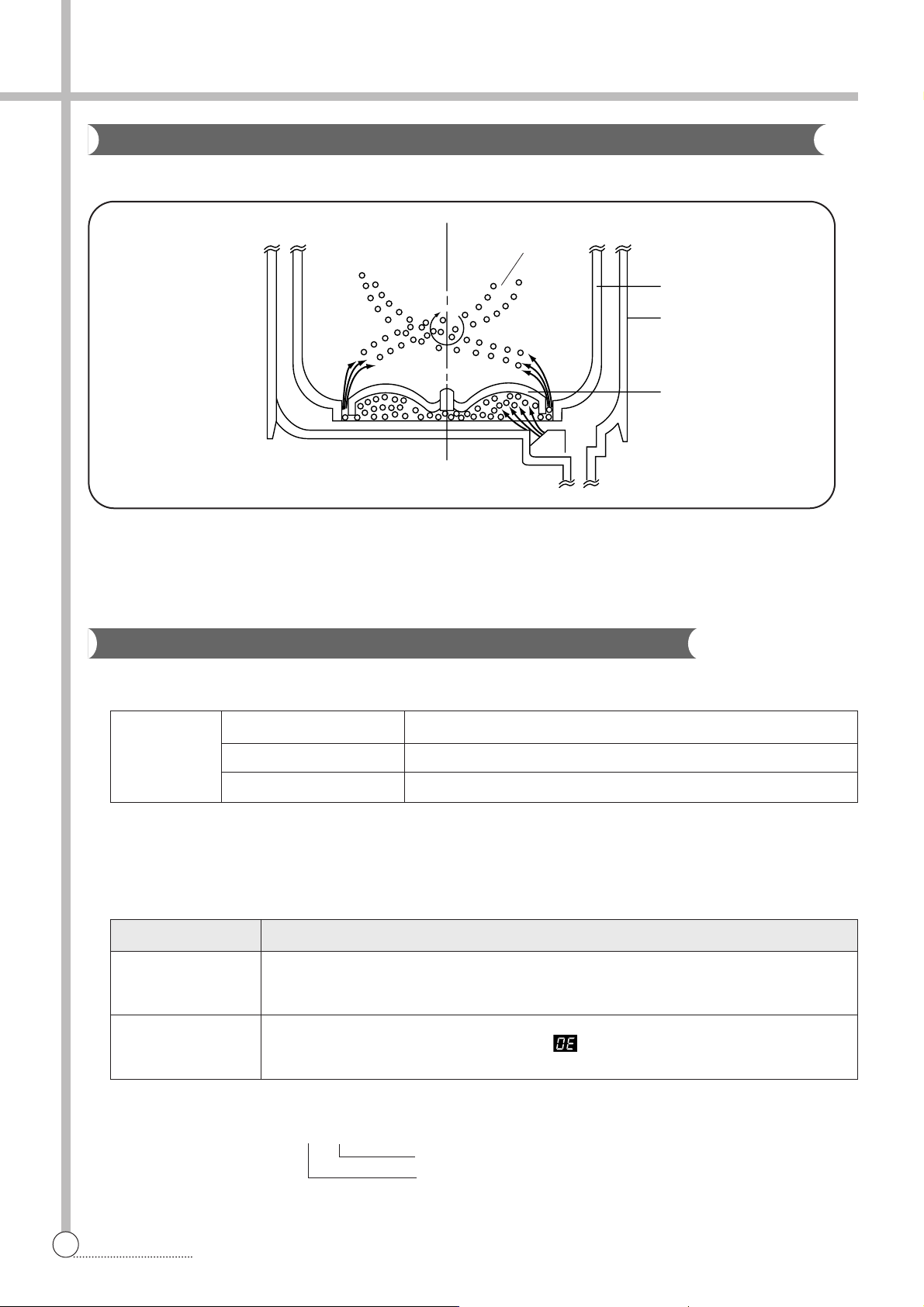

FUNCTIONAL PRINCIPLE

1 The micom can remember the time from the begining of drain to reset point when the pressure switch reaches to

“OFF” point

2 In case of continuous draining, residual drain time is determined by micom.

Draining time as a whole = D + 90

Residual drain time.

The time remembered by micom.

FUNCTIONAL PRINCIPLE

Bubble Motor supplies the air from the bottom of outer tub to the inner space of pulsator, the air is dispersed by the

rotation of pulsator. Air-bubble is created by the centrifugal force, and rises up.

Draining

Good draining The washer begins spin process after drainage.

condition

Bad draining Draininig time is prolonged.

No draining Program is stopped and gives the alarm.

Drain Time Movement of the Program

Less than

Continue draining

15 minutes

More than

Program stops and gives the alarm with blinked on display lamp.

15 minutes

Functional Principle of Bubble Washing Machine

ACROSS SECTION

Automatic Drainning time Adjustment

This system adjusts the draining time automatically according to the draining condition.

Air bubble

Tub

Outer tub

Pulsator

Page 10

9

FEATURE

Contact of safety switch

Contact lever A

Normal (ON)

Position of

unbalanced load (OFF)

Automatic Unbalance Adjustment

Circulating-Water Course and Lint Filter

The alarm finished when you close the lid after opening

it. Check the unbalance of the wash load and the

installation condition.

NOTES

Filter

Tub

Outer tub

Water

channel

Pulsator

This system is to prevent abnormal vibration during intermittent spin and spin process.

CIRCULATING-WATER

The washing and rinsing effects have been

improved by adopting the water system in

which water in the tub is circulated in a

designed pattern.

When the pulsator rotates during the washing

or rinsing process, the water below the

pulsator fans creates a water currents as

shown in figure.

The water is then discharged from the upper

part of the tub through the water channel.

About 40 L/min. water is circulated at the ‘high’

water level, standard wash load and standard

water currents.

FUNCTIONAL PRINCIPLE

1. When the lid is closed, the micro switch

contact is "ON' position.

2. In case that wash loads get uneven during

spin, the outer tub hits the safety switch due

to the serious vibration, and the spin

process is interrupted.

3. In case that P.C.B. ASS’Y gets “OFF” signal

from the safety switch, spin process is

stopped and rinse process is started

automatically.

4. If the safety switch is operated due to the

unbalance of the tub, the program is

stopped and the alarm is given.

Contact of micro switch

Lid closing

('ON' position)

Lid closing

('OFF' position)

Page 11

10

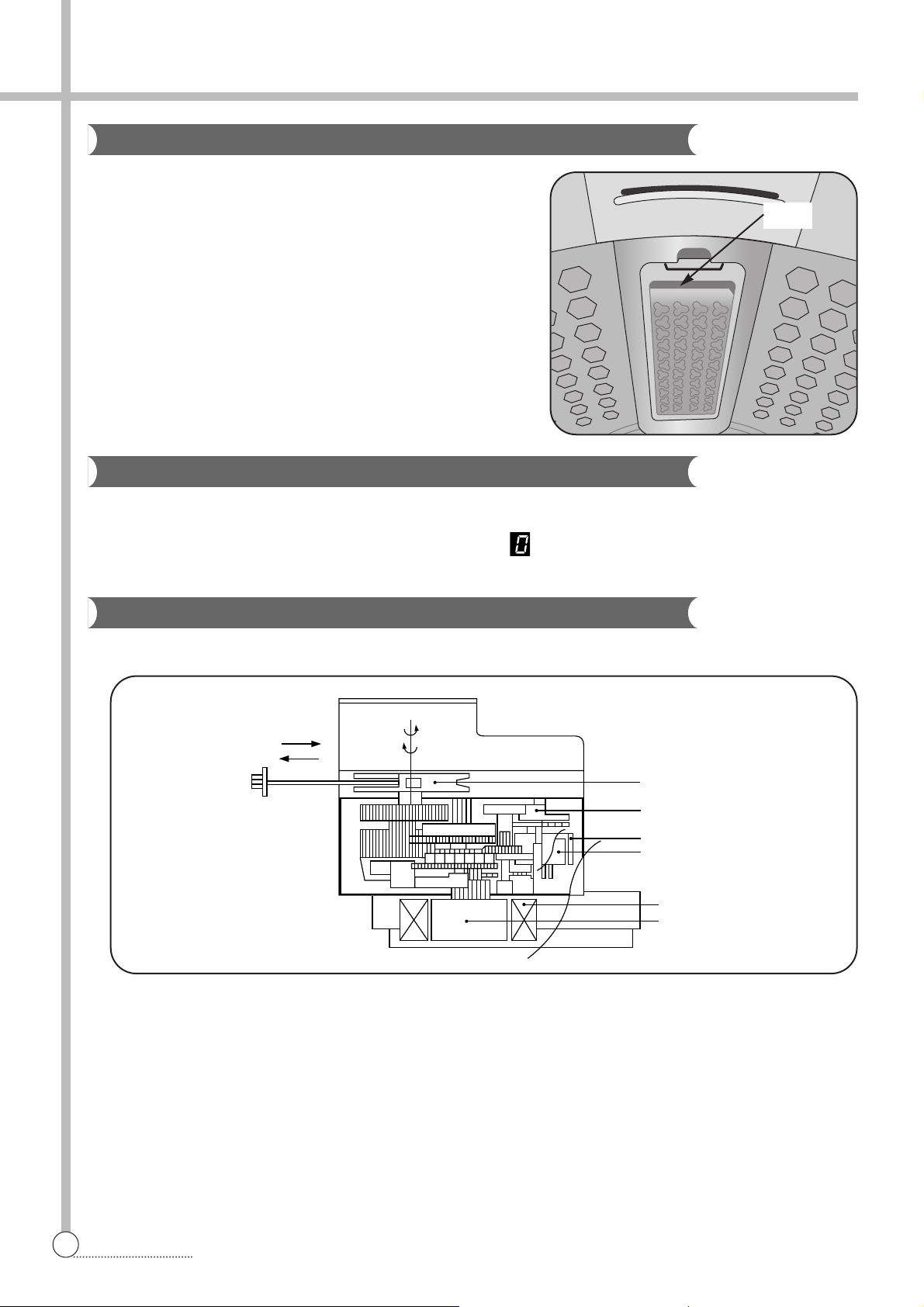

FEATURE

When the START/HOLD button is pressed, the residual time (min.) is displayed on the time indicator, and it will be

counted down according to process.

When operation is finished, the TIME INDICATOR will light up .

1 When the DRAIN MOTOR connected to the power source, the DRAIN MOTOR rotates with 900 r.p.m and revolves

the pulley by gear assembly for reducing.

2 When the pulley is rotated, the pulley winds the wire to open the drain valve.

3 Therefore, rotation of pulley changed to the linear moving of wire.

4 The wire pulls the brake lever of Gear Mechanism Ass’y within 5 seconds.

5 After the wire pulled, gear assembly is separated from motor and condition of pulling is held by operation of the

lever.

6 When the power is turned off, the drain valve is closed because the wire returns to original position.

STRUCTURE

Much lint may be obtained according to the kind of clothes

to be washed and some of the lint may also stick to the

clothes.

To minimize this possibility a lint filter is provided on the

upper part of the tub to filter the wash water as it is

discharged from the water channel. It is good to use the

lint filter during washing.

HOW TO REPLACE LINT FILTER

1 Pull the filter frame upward.

2 Turn the lint filter inside out, and wash the lint off with water.

3 Return the filter as it was, and fix the filter frame to the slot.

Pull

Loosen

Pulley

Lever

Inductive ring

Magnet

Coil of motor

Magnet of motor

Lint Filter

Residual Time Display

Drain Motor

Filter

Page 12

11

FEATURE

The proper water currents is made by the rotation of pulsator at a low speed to prevent the damage to the small

sized clothes.

Planetary gear

Sun gear

Internal gear

Pulsator

1 revolution

5 revolutions

Gear pulley

V-belt

Gear unit as

Motor

Motor

1800 r.p.m (60Hz)

1500 r.p.m (50Hz)

Gear Unit as

Directly

V-Belt

Tub

710-740r.p.m(60Hz)

640-675r.p.m(50Hz)

Pulsator

125-140r.p.m(60Hz)

130-150r.p.m(50Hz)

Spinner Pulley

710-740r.p.m(60Hz)

640-675r.p.m(50Hz)

Gear Mechanism Ass’y

Page 13

12

5. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT

12

DIRECTIONS

Gear Mechanism Ass’y Replacement

BEFORE ATTEMPTING TO SERVICE OR ADJUST ANY PART OF THE WASHING MACHINE, DISCONNECT

THE POWER CORD FROM THE ELECTRIC OUTLET.

Warning

GEAR MECHANISM ASS’Y REPLACEMENT

1 Raise the top plate on the outer cabinet.

2 Loosen four screws mounting outer tub cover and

remove outer tub cover from the tub ass’y.

4 Loosen the pulsator mounting screw and remove the

pulsator.

3 Remove the cap pulsator from the pulsator assy by

using screw driver

5 Remove the special nut by using “T” type box wrentch.

6 Remove the special washer.

Page 14

1313

DIRECTIONS

To assemble the gear mechanism ass’y, reverse the disassembly procedure.

NOTES

7 Remove the tub i assy.

q Remove four special bolt of gear mechanism assy by

using a box wrentch.

8 Lay the front of the washer on the floor.

9 Remove four special bolts of gear protect by using a box

wrentch and remove gear protect.

0 Remove the V-belt.

w Pull out the gear mechanism assy.

Page 15

14

Motor Synchronous and Valve Replacement (Non Pump Model)

DIRECTIONS

1 Lay the front of the washer on the floor.

2 Loosen two special screw of motor synchronous.

5 Turn the valve by using screw driver as shown in picture.

3 Take out the wire of motor synchronous from the braket.

4 Separate the motor synchronous from the base.

6 Remove the valve lid from the valve drain assy.

Page 16

15

6. THE REPAIR METHOD OF GEAR MECHANISM FOR CLUTCH SPRING PROBLEM

THE REPAIR

ᵄ

TOOL FOR REPLACING THE CLUTCH BOSS ASSEMBLY

ᵄ

Tool name Specification Q’ty

Fixing jig 1

Ratchet handle 1

Socket and extension bar socket : 10mm, 17mm per each

Cotton yarn some

The structure of gear mechanism

Page 17

16

THE REPAIR

NO. PARTS NAME SPECIFICATION CODE Q’TY

1 CLUTCH SPRING 1.5*1.5 3615110000 1

2 CLUTCH BOSS PP 3619301300 1

3 GREASE beacon#325 3g

PACKING PACKING THE CLUTCH BOSS ASS’Y 1

METHOD BY USING VINYL PACK

CHECKING METHOD

IN THIS CASE, YOU MUST EMPTY THE SPIN TUB FIRST.

1) TO CHECK THE REVOLUTION OF SPIN TUB.

IF THE SPIN TUB DOES NOT REVOLVE AND ONLY THE PULSATOR IS TURNING, THAT IS

CLUTCH SPRING DEFECT.

2) TO CHECK THE SPIN SPEED(RPM) BETWEEN SPIN TUB AND PULSATOR.

IF YOU FIND THE DIFFERENT SPIN SPEED BETWEEN SPIN TUB AND PULSATOR, THIS IS ALSO

CLUTCH SPRING DEFECT.

IN THIS CASE, WE ARE GOING TO SUPPLY THE CLUTCH BOSS ASSEMBLY INSTEAD OF GEAR

MECHANISM ASSEMBLY. PLEASE REFER TO FOLLOWING FIG.

THE CLUTCH BOSS ASSEMBLY

CLUTCH BOSS ASS’Y PART CORD : 3619301400

How to check the clutch spring

Page 18

17

THE REPAIR

No. Process Notice

Disassembling 1

1

2

3

4

Release screws marked 4-point

Remove the protector

Remove the v-belt

Loosen the fastening nut

Disassemble the spring washer

Use wrench or driver

- ratchet handle

- extension bar

- socket : 10mm

Use fixing jig for pulley as to

see fig 1.

and 17mm-socket for nut

Take out plain washer if it has

The Process Of Disassembling

Page 19

18

THE REPAIR

No. Process Notice

Disassembling 2

5

6

7

8

Disassemble the pulley

Disassemble the clutch boss

assembly

Separate coupling from clutch

boss ass’y

Cleaning

Catch the boss and pull

upward with spiral rotate in the

clockwise direction

Clean the drum plate, coupling

surface and contact face

between drum plate and

coupling

It is necessary to keep cotton

piece goods being dry and

clean

Page 20

19

THE REPAIR

No. Process Notice

Assembling 1

1

2

3

4

Assemble the coupling

Assemble the new clutch boss

ass’y

Assemble the pulley

Assemble the spring washer

Check the uneven face of

coupling is assembled upward

- Push in the clutch boss ass’y

with rotating on the clockwise

direction.

-

After assembling, rotate on the

clockwise more 2~3 teeth and

pull out the pulley shaft upward

If there was plain washer, you

have to assemble plain washer

the first and then assemble

spring washer

The Process Of Assembling

Page 21

20

THE REPAIR

No. Process Notice

Assembling 2

5

6

7

8

Assemble the fastening nut

Assemble the belt

Assemble the protector

Final checking

- Use fixing jig and 17mm

socket wrench

as if disassembling,

as fastening torque about

100~200kgf-cm.

- Check the end-play, up and

downward and check the

binding force, too much or not

on bi-direct of rotation.

Finally, check the interference

depth both clutch tip and clutch

boss(3.5~4.5mm)

Clutch Tip

Drain

Valve

Synchronous

Motor

3.5~4.5

Page 22

21

THE REPAIR

1 separate the back cover from

washing machine

4 turn the case filter ass’y and

separate it from the drain motor

7 assemble the case filter ass’y that

purchased

0 assemble the hose drain I to the

case filter with bond & clamp

2 remove two screws

5 separate the drain hose i from the

case filter ass’y

8 tie up three screws

q assemble the cavitation hose to

the case filter with bond & clamp

3 remove three screws

6 separate the cavitation hose from

the case filter ass’y

9 tie up two screws

w assemble the back cover to the

washing machine

REPLACE THE CASE FILTER ASS’Y

Page 23

7. TROUBLE SHOOTING GUIDE

22

TROUBLE SHOOTING

PROBLEM

WATER IS

NOT

SUPPLIED.

CHECK POINT

Do you open the water

tap?

Is the filter of the water

inlet valve clogged with

dirt?

Is the water pressure

sufficient?

(0.3~8 kgf/cm

2

)

Does the water inlet

valve make operating

sound?

Is the connector or the

terminal connected

properly?

Is the output voltage of

the P.C.B normal?

CAUSE

Water inlet valve

is defective.

Improper connection of

the connector or the

terminal.

P.C.B AS is defective.

Lead wire is defective.

SOLUTION

Change water inlet valve.

Open the water tap.

Clean the filter.

Increase the water

pressure.

Connect the connector or

the terminal properly.

Change the P.C.B AS.

Change the lead wires.

NO

YES

NO

YES

NO

YES

YES

YES

YES

NO

NO

NO

NOTE : Open the water tap fully and measure

the flow rate.

From the upper results, you know that the flow rate more than

11.5l/min. is essential for water supply.

Flow

11.5 15.0 18.0 20.3 24.1 27.4

rate(l/min.)

Water pressure

0.3 0.4 0.5 0.6 0.8 1.0

(Kgf/cm

2

)

1. When replace the P.C.B. ASS’Y do not scratch the surface of the P.C.B. ASS’Y.

2. Disconnect the power cord from the electric outlet.

NOTES

Concerning Water Supply

Page 24

23

TROUBLE SHOOTING

PROBLEM

WATER

SUPPLY IS

NOT

STOPPED.

CHECK POINT

Does the water supply

continue while the power

is turned off?

Does the water supply start

as soon as you press the

power switch?

Operate the washer after

setting the water level to

“HIGH”

Does the water supply

continue after the water

reaches to the “HIGH”

level?

Is the air tube of water

level switch kinked or

deformed?

CAUSE SOLUTION

Change the water inlet

valve.

The water inlet valve is

defective.

The triac of P.C.B is

defective.

Change the P.C.B

ASS’Y.

Normal operation.

Change the air tube.Air tube is defective.

Change the pressure

switch.

Pressure switch is

defective.

PROBLEM

THE

PULSATOR

DOES NOT

ROTATE EVEN

IF THE WATER

IS SUPPLED.

CHECK POINT

Does the motor operate after

finishing water supply?

Does the motor make

operating sound?

Is the connection

condition of capacitor

terminal good?

Does pulsator rotate in

only one direction?

Is the motor coil

disconnected?

Is the V-belt worn out?

The triac of P.C.B is

defective.

Motor is defective.

Improper connection

V-belt is defective.

Change the P.C.B

ASS’Y.

Normal

Change the motor.

Connect the terminal

properly.

Change the V-belt.

Change the motor.

CAUSE SOLUTION

YES

YES

YES

NO

NO

YES

YES

NO

YES

YES

YES

NO

YES

NO

NO

NO

NO

NO

YES

Concerning Washing

Page 25

24

TROUBLE SHOOTING

PROBLEM

THE WASHER

DOES NOT

DRAIN.

CHECK POINT

Do you install the

drain hose

properly?

Is the accumulated

foreign substance

inside the drain

housing?

Is the output voltage of

the drain motor

normal?

CAUSE SOLUTION

Install the drain hose

properly.

Remove the foreign

substance from

the drain housing

Change the drain motor.

Change the P.C.B

ASS’Y.

Improper installation

Malfunction of

drainage by the

foreign substance

The drain motor is

defective.

P.C.B ASS’Y is

defective.

YES

NO

NO

NO

YES

YES

Concerning Draining

Page 26

25

TROUBLE SHOOTING

PROBLEM

THE WASHER

DOES NOT

SPIN.

CHECK POINT

Is the lid open?

Does the micro switch

operate normally?

Does the safety switch

operate normally?

Does the pulsator rotate

while the tub does not

rotate?

Is the connector of

P.C.B ASS‘Y connected

properly?

Is the input

voltage of the drain

motor normal?

Is the V-belt worn out?

Is the input voltage of

motor normal?

Is the connection

condition of capacitor

terminal good?

CAUSE SOLUTION

Close the lid.

Change the door switch.

Change the safety

switch.

Connect the connector

properly.

Change P.C.B ASS’Y.

Change the drain motor.

Change the P.C.B

ASS’Y.

Change the V-belt.

Change the motor.

Connect the terminal

correctly.

Change the P.C.B

ASS’Y.

Door switch is defective.

Safety switch is

defective.

Improper connection of

the connector.

P.C.B. ASS’Y is

defective.

Drain motor is defective.

P.C.B ASS’Y is

defective.

V-belt is defective.

Motor is defective.

Improper connection.

P.C.B ASS’Y is

defective.

NO

YES

YES

YES

NO

NO

NO

YES

YES

YES

NO

NO

NO

NO

YES

YES

YES

NO

Concerning Spinning

Page 27

26

TROUBLE SHOOTING

NO

NO

NO

PROBLEM

THE

INDICATOR

LAMPS(L.E.D)

DO NOT LIGHT

UP WHEN THE

POWER

BUTTON IS

PRESSED.

PROGRESS

LAMPS(LED)

DO NOT LIGHT

UP.

MOTOR

ROTATES

WHEN

START/HOLD

BUTTON IS

NOT

PRESSED.

ABNORMAL

NOISE

DURING WASH

PROCESS.

CHECK POINT

Is the plug connected

to electric outlet?

Is the condition of

power button good?

Is the connector of the

P.C.B. ASS’Y

connected properly?

Is input voltage of the

transformer normal?

Do you press

START/HOLD button?

Check the output voltage

of P.C.B ASS’Y

Is the strange noise

generated when the

pulsator rotates in TEST

MODE of P.C.B ASS’Y?

Is the V-belt worn out?

CAUSE SOLUTION

Connect the plug.

Change P.C.B ASS’Y.

Change Fuse

Connect the connector

properly.

Change Transformer

Change P.C.B ASS’Y.

Press START/HOLD

button.

Replace P.C.B ASS’Y.

Change P.C.B ASS’Y.

Remove the foreign

matter.

Change the V-belt.

Power button is defective

Improper connection of

the connector.

Transformer is defective

P.C.B. ASS’Y is

defective.

P.C.B ASS’Y is

defective.

P.C.B ASS’Y is defective

There is foreign matter

between pulsator and

tub.

V-belt is defective.

NO

YES

YES

YES

YES

YES

NO

YES

YES

Abnormal

YES

NO

NO

Is Fuse opened?

Concerning Operating

Page 28

8. PRESENTATION OF THE P.C.B ASS’Y

27

PCB ASS’Y

MESSAGE CAUSE SOLUTION

Improper installation of drain hose.

The drain hose is blocked up by foreign

matter.

Drain motor is inferior.

The water tap is closed.

The water inlet filter clogged.

It passes over the 60 minutes, yet it doesn’t

come to assigned water level.

Wash loads get uneven during spin.

Poor installation of the unit.

The lid is opened.

The safety switch or micro switch is inferior.

The load sensing is inferior. After the load

sensing operates about 7 seconds, the

message is displayed during 0.5 second

and water level is always fixed ‘high’.

The water level sensing is inferior.

Install drain hose properly.

Remove foreign matter from drain hose.

Change drain motor.

Open the water tap.

Clean the water inlet filter.

Fully open the water tap and

Check the water pressure.

Re-set wash loads evenly.

Proper installation.

Close the lid.

Change the safety switch or micro switch.

Change the P.C.B. ASS’Y.

Check the water level sensor and the

contact part of the connector.

Concerning Error Message

Page 29

APPENDIX

28

PCB ASS’Y

⏿⏿

Wiring Diagram

Page 30

29

PARTS DIAGRAM

⏿⏿

Parts Diagram

A09

A01

A11

A10

A31

A30

A32

A33

A29

A34

A35

A21

A13

A14

A12

A26

A15

A25

A03

A07

A08

A16

A06

A05

A24

A02

A04

A18

A19

A20

A22

A23

A28

A27

Page 31

30

PARTS DIAGRAM

B12

B13

Page 32

31

PARTS DIAGRAM

C08

C01

C02

C03

C04

C13

C14

C13

C14

C15

C15

C07

C05

C06

C09

C10

C11

C12

Page 33

32

PARTS DIAGRAM

D02

D04

D01

D03

D05

D14

D15

D17

D16

D07

D08

D09

D10

D11

D12D13

Page 34

33

PARTS DIAGRAM

A01 36142T3400 PANEL *B ABS, DWF-260AX 1 A5, A9, M9

36142T3410 DWF-260AX SPRAY M6, M7

A02 PRPSSW4N90 PCB AS

DWF-204AY, NORMAL PUL, S, HOT, PP, NON-BB

1

A03 3613068200 HOLDER FUNCTION HIPS, DWF-204AY 1

A04 36116DAY00 DECORATOR FILM PC FILM, DWF-204AY 1

A05 3615516200 WINDOW DISPLAY TR-ABS, DWF-204AY 1

A06 3616646680 BUTTON PW/ST ABS, DWF-204AY 1 A5, A9, M9

3616646750 DWF-204AY SPRAY M6, M7

A07 3615516600 DECO WINDOW AS DWF-204AY, SPRAY 1 A5

3615516500 DWF-204AY, COATING A9, M6, M7, M9

A08 36142T3560 PANEL *F ABS, DWF-204AY 1 A5, A9, M9

36142T3570 UV_BASE, DWF-204AY SPRAY M6, M7

A09 3615516000 WINDOW COURSE TR-ABS, DWF-204AY 1

A10 3613408700 KNOB COURSE AS DWF-260AX, KNOB COURSE AS 1 A5, A9, M9

3613408720 DWF-151AX M6, M7

A11 3613068100 HOLDER COURSE HIPS, DWF-204AY 1

A12 3616646670 BUTTON FUNCTION ABS, DWF-204AY 1 A5, A9, M9

3616646720 DWF-204AY SPRAY M6, M7

A13 36190470B0 SWITCH SAFETY SF-030A31, 1

A14 3619045400 SWITCH COVER GSM-V16183A4 250V 16A 1

A15 3614801650 SENSOR PRESSURE CDL-D17N,3PIN,L=620,15DO 1

A16 3618912200 UNIT CAPACITOR AS 45.6UF 200VAC, CAN TYPE 1

A17 3611338300 CORD POWER AS 750M,201AS,EP3PIN 1

A18 3615416311 VALVE INLET

DR-12AS:C-R-H.110-130V50/60HZ NON-O.P RUBBER

1

A19 3610394400 BODY DETERGENT ABS. DWF-260AX 1

A20 3618111900 NOZZLE DETERGENT PP. DWF-260AX 1

A21 3612905300 HINGE BOSS *L ABS, DWF-26'S(HINGE DOOR) 1

A22 3612905400 HINGE BOSS *R ABS, DWF-26'S(HINGE DOOR) 1

A23 3614542400 PLATE *T ABS,DWF-260AX 1

3614542410 ABS, UV_BASE, 260A 1

A24 3612902400 HINGE DOOR POLYACETAL 2

A25 36111T2L00 CASE DETERGENT ABS, DWF-260AX 1 A5, A9, M9

36111T2L10 CASE DETERGENT ABS, UV_BASE DWF-260AX 1 M6, M7

A26 3610907800 CAP SOFTENER PP 1

A27 7112503011 SCREW TAPPING T1S,TRS,5*30 MFZN 2

A28 3611561400 CUSHION DOOR NBR, DWF-200A 2

A29 36117ADE50 DOOR *O ABS, DWF-204AY 1 A5, A9, M9

36117ADE70 UV_BASE,DWF-204AY SPRAY M6, M7

A30 361A114400 DOOR GLASS DWF-150AX 4T*479*323 1

A31 36117ADE60 DOOR *I HIPS, DWF-204AY 1

A32 7115401630 SCREW TAPPING T1 FLT 4X16 SUS WHITE PAINTING 12

A33 3611559900 CUSHION DOOR NR 2

A34 3615118300 SPRING DOOR *L DWF-260AX 1

A35 3615118400 SPRING DOOR *R DWF-260AX 1

A36 361279D430 HARNESS AS DWF-204AY LOW PUMP C-H-R,NB 1

⏿

Parts List

No. Item Code Item Materials and Sizes Q'TY Remarks

Page 35

3434

PARTS LIST

B01 DMW3200100 HOSE DRAIN O AS ELBOW 1

B02 3614514600 PLATE UPPER PP 1

B03 7122501211 SCREW TAPPING T2S TRS 5X12 MFZN 8

B04 3615302220 SUPPORTER TUB BL SPG 1.4T 1

B05 3615302320 SUPPORTER TUB BR SPG 1.4T 1

B06 3615302420 SUPPORTER TUB FL SPG 1.4T 1

B07 3615302520 SUPPORTER TUB FR SPG 1.4T 1

B08 3611413605 COVER BACK 0.35T 1

B09 3610808535 CABINET AS PCM 0.6*803.4*2146.6 1 A5

2SP06DNS30 PCM SHEET WHITE ASTY 0.6TX803.4X2146.6 A9, M9

2SP06DNS20 PCM SHEET RED ASTY 0.6TX803.4X2146.6 M6

2SP06DNS10 PCM SHEET METAL ASTY 0.6TX803.4X2146.6 M7

B10 3610310200 BASE U PP (111W) 1

B11 3617702122 LEG ADJUST AS VE 1

B12 361897360F UNIT DRAIN PUMP AS

LOW/60HZ,40W,L=1250,KET 1806 BK,BB CUT

1

B13 7122501211 SCREW TAPPING T2S TRS 5X12 MFZN 1

No. Item Code Item Materials and Sizes Q'TY Remarks

C01 3616104000 BALANCER AS DWF-1094 1

C02 3612504500 GUIDE FILTER AS 10KG MAGIC 1 PIECE 2

C03 3611911500 MAGIC FILTER AS 10KG 1 PIECE 2

C04 3616051629 SPECIAL SCREW SUS430 T2 TRS 5.5*16 12

C05 3618831410 TUB *I SUS 0.4X398.5X1636 1

C06 3616051629 SPECIAL SCREW SUS430 T2 TRS 5.5*16 12

C07 7122400829 SCREW TAPPING T2S TRS 4X8 STS430 4

C08 7122400829 SCREW TAPPING T2S TRS 4X8 STS430 4

C09 3618807003 TUB *U 94'S,-M/B,+RIB 1

C10 3616063700 SPECIAL NUT ZDC1 EU SAMWOO 1

C11 3617200600 FLANGE TUB ALDC12 VE1,6POINT 1

C12 3616007001 SPECIAL SCREW SCM24H,6.5*24 101S 6

C13 3610911200 CAP PULSATOR PP,100M 1

3610920500 PP, DWF-178W TBM

C14 3616062629 SPECIAL SCREW STS430 6X26.5 1

C15 3619705510 PULSATOR AS 100M 1

3619705520 200S TBM

No. Item Code Item Materials and Sizes Q'TY Remarks

Page 36

3535

PARTS LIST

D01 4509M83035 COVER TUB PP,100M 1

D02 4509M83012 TUB O 1098 1

D03 3619805400 SUSPENSION AS(B) 100C'S ROD=592 SPR=102 2

D04 3619805500 SUSPENSION AS(F) 100C'S ROD=592 SPR=112 2

D05 3613212120 HOSE DRAIN I EVA 100%(TRANSPARENT), L=184 1

D06 3610387400 BASE SECEN 2.0T 1

D07 3616007000 SPECIAL SCREW SCM24H,6.5*24 12

D08 3612757030 HARNESS EARTH INNER L ID=4.3,R ID=8.3,L=810 1

D09 36189L1R5L DRAIN MOTOR 110-130V (MODEL :111W) CHINA 1

D10 3617310301 GEAR MECHANISM(SP) GM-1300-WS6P0 1

D11 7341801511 BOLT HEX 6B-1 8*15 MFZN 4

D12 3618346000 PROTECTOR GEAR SGCC 1.2T 1

D13 3616590220 BELT V M20.5, AGING 1

D14 3611502700 CUSHION DOWN POM(8MM) 2

D15 3964322047 MOTOR CONDENSER

Y-W2D50CA014 110-127V 60HZ 690L #250(35955-0320)

1

3964821120

WM244XA011 120V L=1450(#1806 MG620427)

D16 7650802528 BOLT HEX 6B-1 8*25 PW(3*28) MFZN 2

D17 3618401400 PULLEY MOTOR AS M-TYPE(AL), DS=10 DP=48.5 60HZ 1

No. Item Code Item Materials and Sizes Q'TY Remarks

Page 37

S/M NO. :

DAEWOO ELECTRONICS CORP.

1-2, Jeo-dong 1(il)-ga, Jung-gu, Seoul, Korea

C.P.O. BOX 8003 SEOUL, KOREA

TELEX: DWELEC K28177-8

CABLE: “DAEWOOELEC”

PRINTED DATE: Feb. 2013

Page 38

vviissiioonn@@ccrreeaattiivveeLL@@iinnccNN

Էړ ܞĸ ࣃۉʷ

VѨݖ ێΟӂ˱ Tࠚ

ABOUT THIS MANUAL

ABOUT THIS MANUAL

ɽʁŨϊŢ ɮ

m@o@d@e@l dwfMRPTay@HsOmI

܂րRPQSNPQNRU

memo@@߭ SW

ِߏ

vision

ɽ ʁ

іОր

telZ WSPMPVVP@faxZ WSPMSWXX

QSNPQNRUMݖL@ݖ˒L@RL@SL@UL@VL@RYL@SS@֭Ŕ X

QSNPQNRYMݖL@ݖ˒L@RL@RYL@SS@ր܄@֭Ŕ U

QSNPQNSPMQL@QTL@QUL@QVL@RY@ր܄@֭Ŕ U

QSNPRNPWMRL@VL@YL@QPL@RYL@SQL@SR@ր܄@֭Ŕ W

QSNPRNQSMSQ@ր܄@֭Ŕ Q

QSNPRNQUMVL@RXL@SQ@ր܄@֭Ŕ S

QSNPRNRPMRYL@SPL@SQL@SRL@SSL@STL@SU@ր܄@֭Ŕ W

QSNPRNRQMR@ր܄@֭Ŕ Q

QSNPRNRRMRL@SR@ր܄@֭Ŕ R

Loading...

Loading...