Page 1

Manual de servicio

DSB-070L/DSB-071L

DSB-091L/DSB-092L

DSB-121L/DSB-122L

DSB-123L/DSA-123L

DSA-181L

DSB-181L

DSB-182L/L-R

DSB-183L-R

DSA-182L/DSA-183L-R

DSA-183L

DSB-240L-R

DSA-240L-R

DSA-240L

Acondicionador de Aire Tipo Split

Modelo :

Page 2

CONTENTS

1. Specifications..........................................................................................................2

2. Outline and Dimensions.......................................................................................13

3. Operation ..............................................................................................................23

4. Wiring Diagram.....................................................................................................47

5. Refrigerant Cycle..................................................................................................53

6. Control Block Diagram.........................................................................................54

7. Trouble Shooting..................................................................................................56

8. Key Components of Electronic Circuit.................................................................85

9. Disassembly Instructions .....................................................................................88

1) Indoor Unit........................................................................................................88

2) Outdoor Unit.....................................................................................................95

3) Exploded Diagram (Indoor Unit)......................................................................98

4) Exploded Diagram (Outdoor Unit).................................................................114

5) Control Box Assembly ...................................................................................122

Contents

Page 3

2

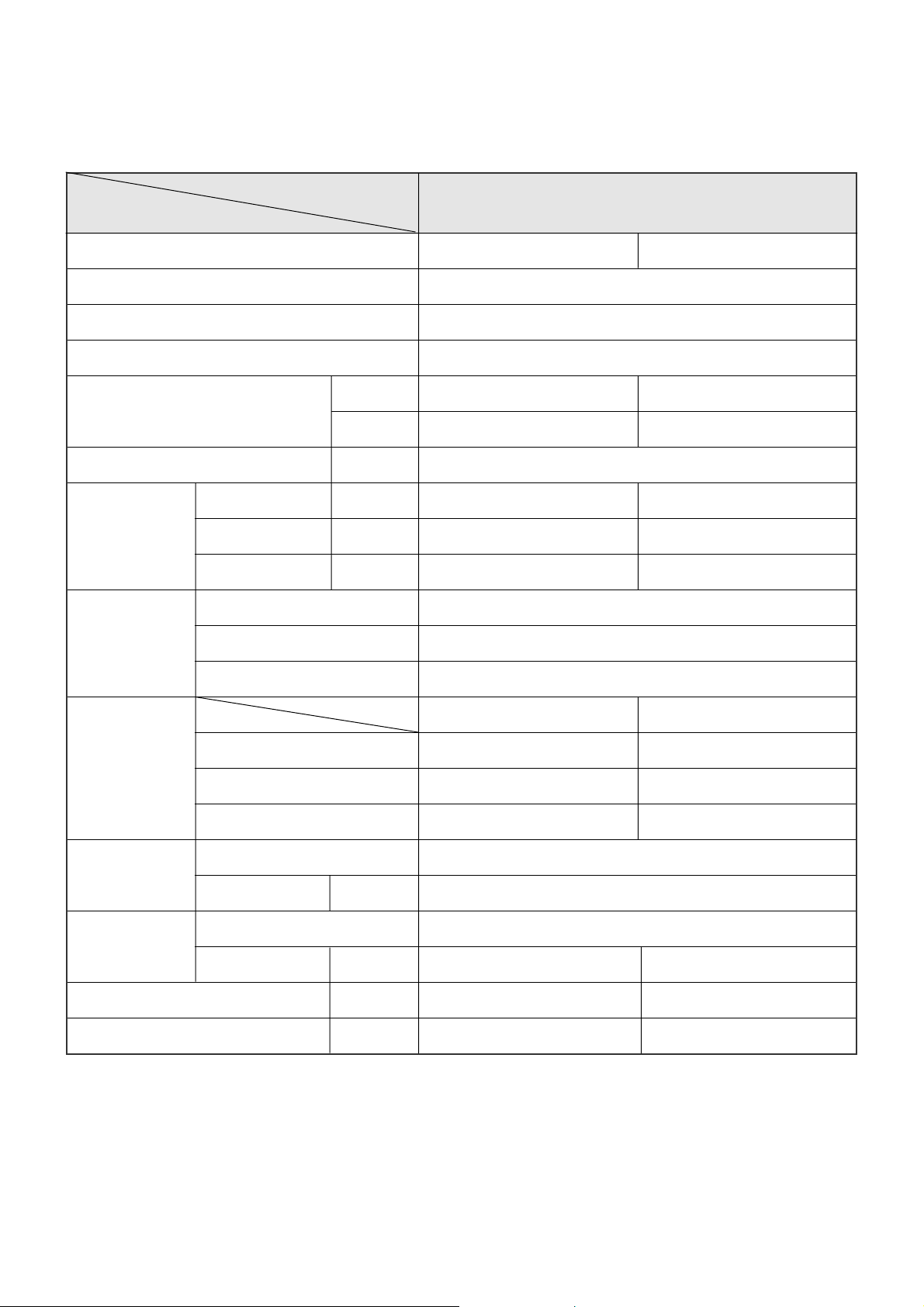

1. SPECIFICATIONS

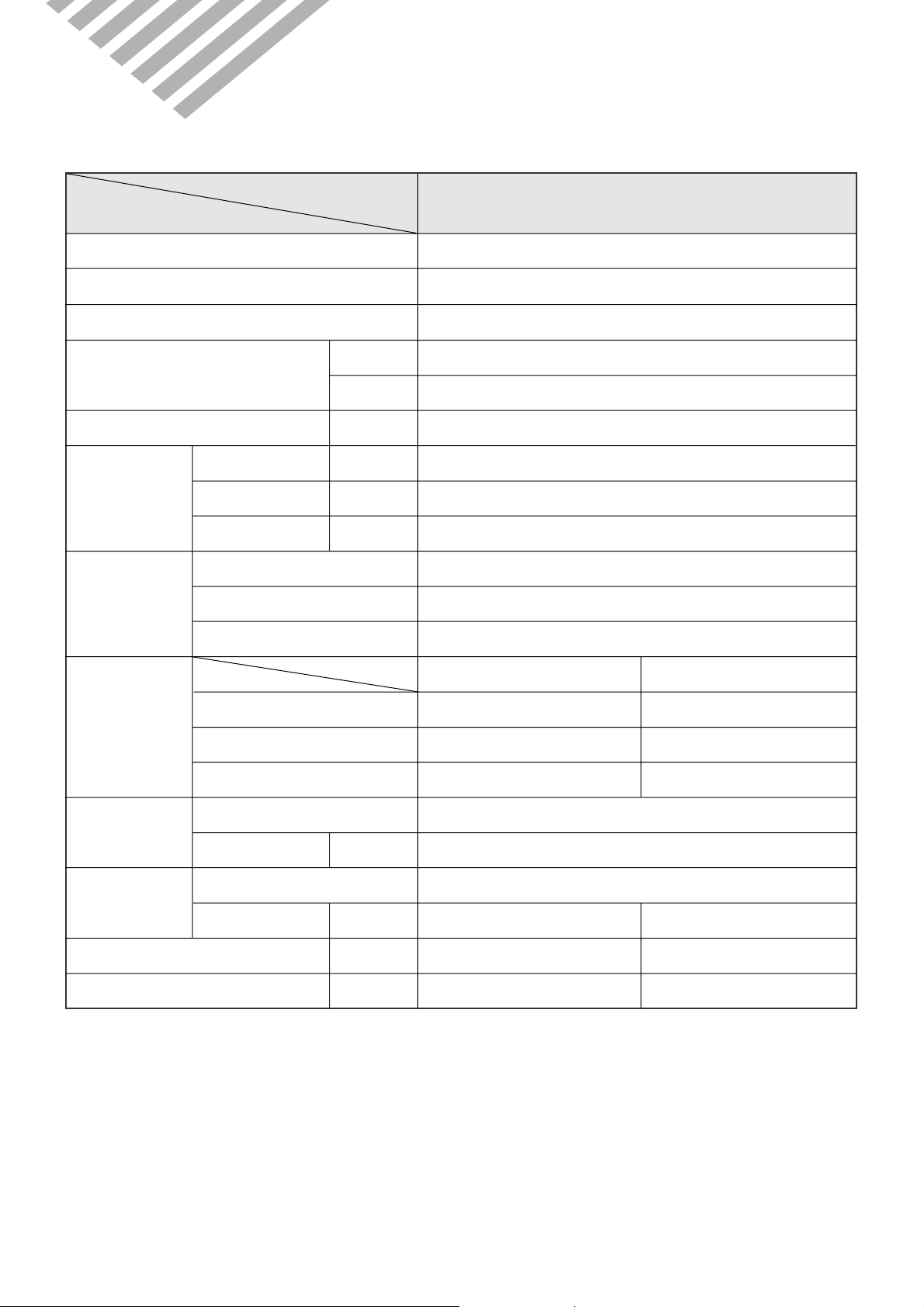

MODEL

DSB-070L/071L

ITEM

Function Cooling

Class T

1

Power AC 220~ 240V/ 50Hz

Capacity W 2,051

Btu/h 7,000

Dehumidification l/h 0.89

Running Current A 2.7

Power Input W 650

Starting Current A 18

Type Rotary

Model RBB070A011

Capacitor 25µF / 400VAC

Indoor Unit Outdoor Unit

Type Cross flow fan Propeller fan

Capacitor 1.0µF 400VAC 1.8µF 400VAC

Motor Model Number YDK-8-4B A9525BD010 / YDK-30-6B

Control Capillary

Charge Q'ty g 530

Type Flare

OD (Liquid/Gas) in(mm) 1/4 (6.35) 3/8 (9.52)

Dimensions (W x H x D) mm 750 x 245 x 179 654 x 549 x 256

Net Weight kg 7.0 32.5

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSB-070L/071L

Page 4

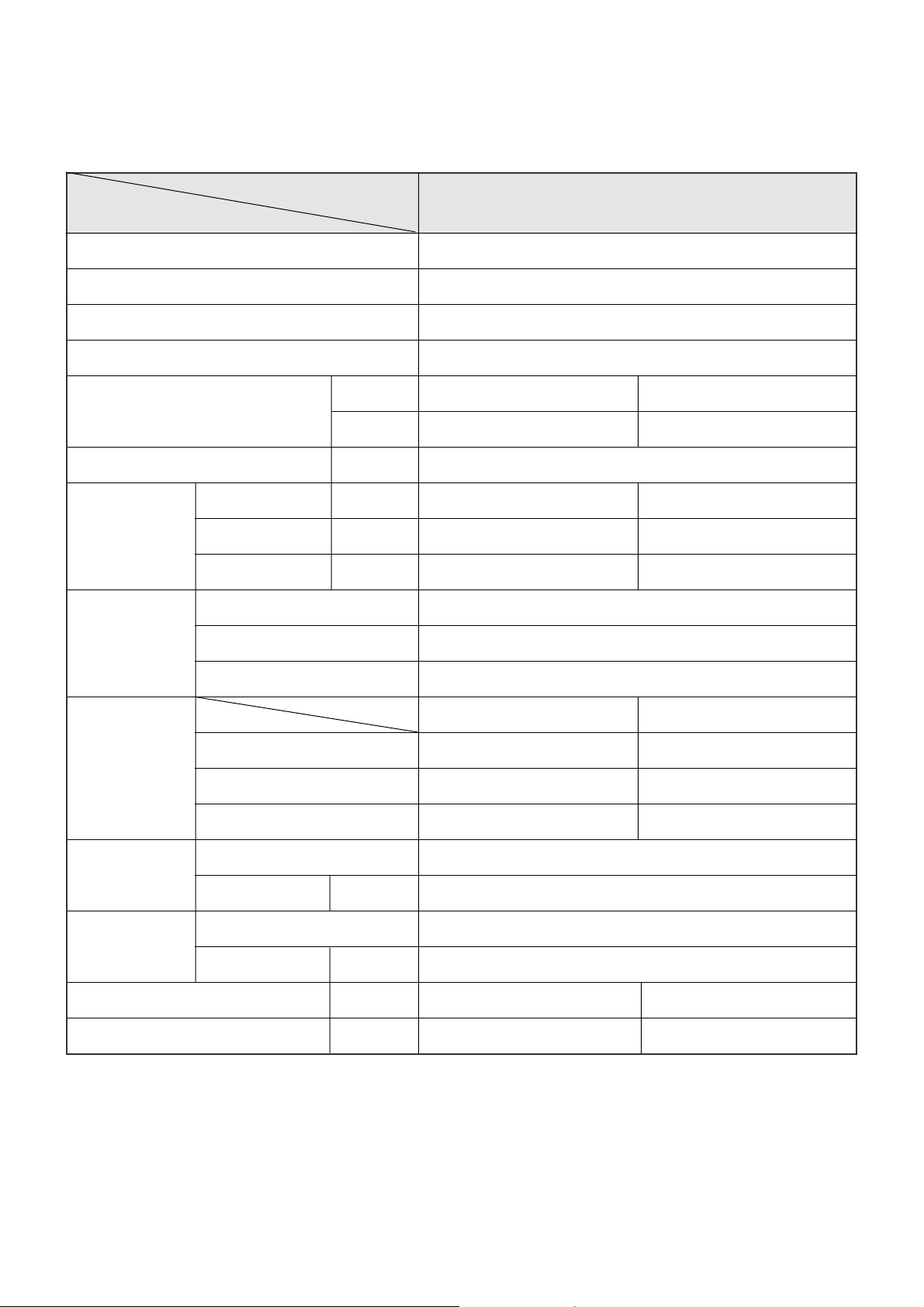

3

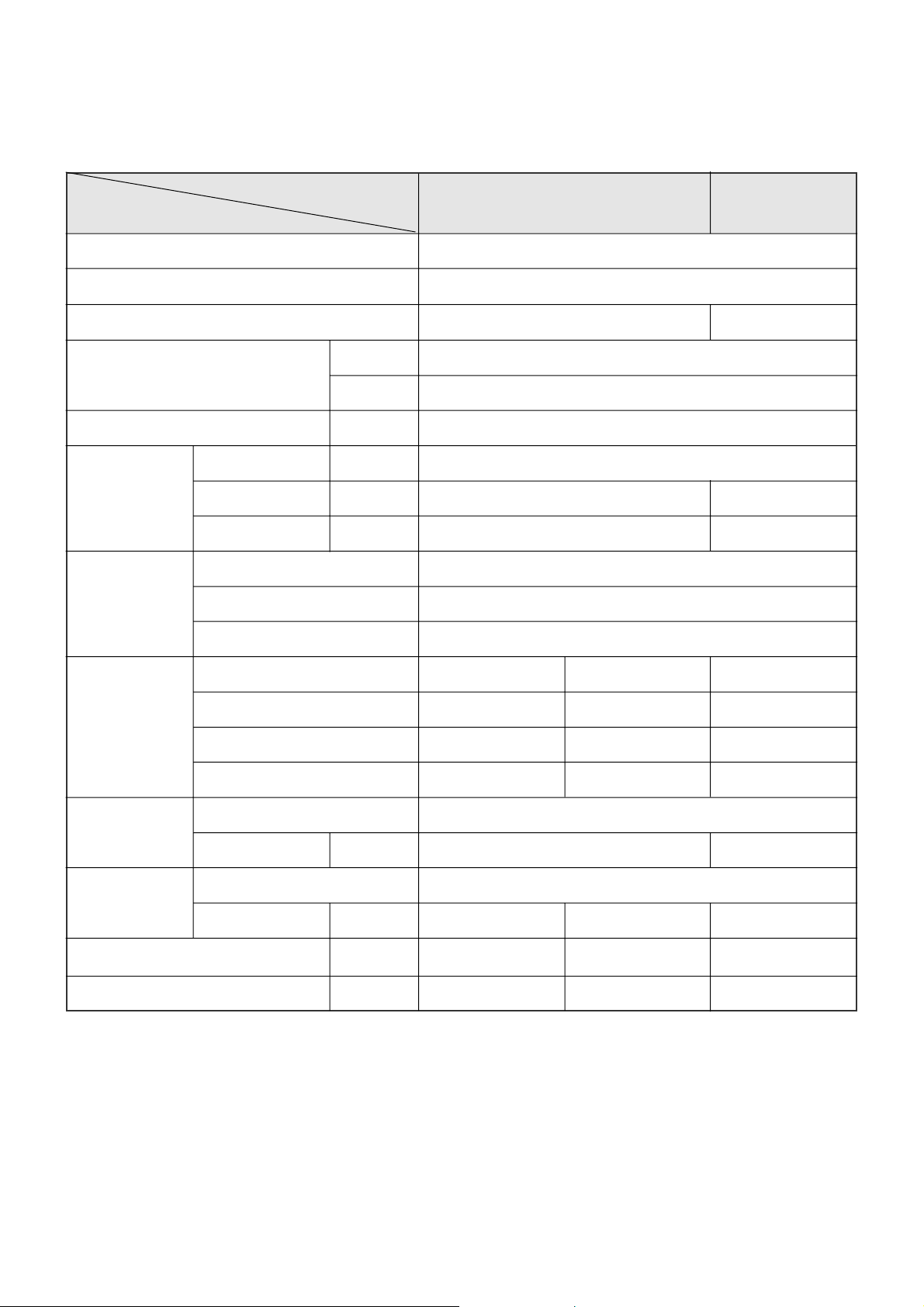

MODEL

DSB-091L/092L

ITEM

Function Cooling

Class T

1

Power AC 220~240V/ 50Hz

Capacity W 2,637

Btu/h 9,000

Dehumidification l/h 1.15

Running Current A 4.0

Power Input W 900

Starting Current A 21

Type Rotary

Model RBB095A011

Capacitor 25µF / 370VAC

Indoor Unit Outdoor Unit

Type Cross flow fan Propeller fan

Capacitor 1.0µF 400VAC 1.8µF 400VAC

Motor Model Number YDK-8-4B A9530BD010 / YDK-30-6B

Control Capillary

Charge Q'ty g 630

Type Flare

OD (Liquid/Gas) in(mm) 1/4 (6.35) 3/8 (9.52)

Dimensions (W x H x D) mm 750 x 245 x 179 654 x 549 x 256

Net Weight kg 7.0 32.5

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSB-091L/092L

Page 5

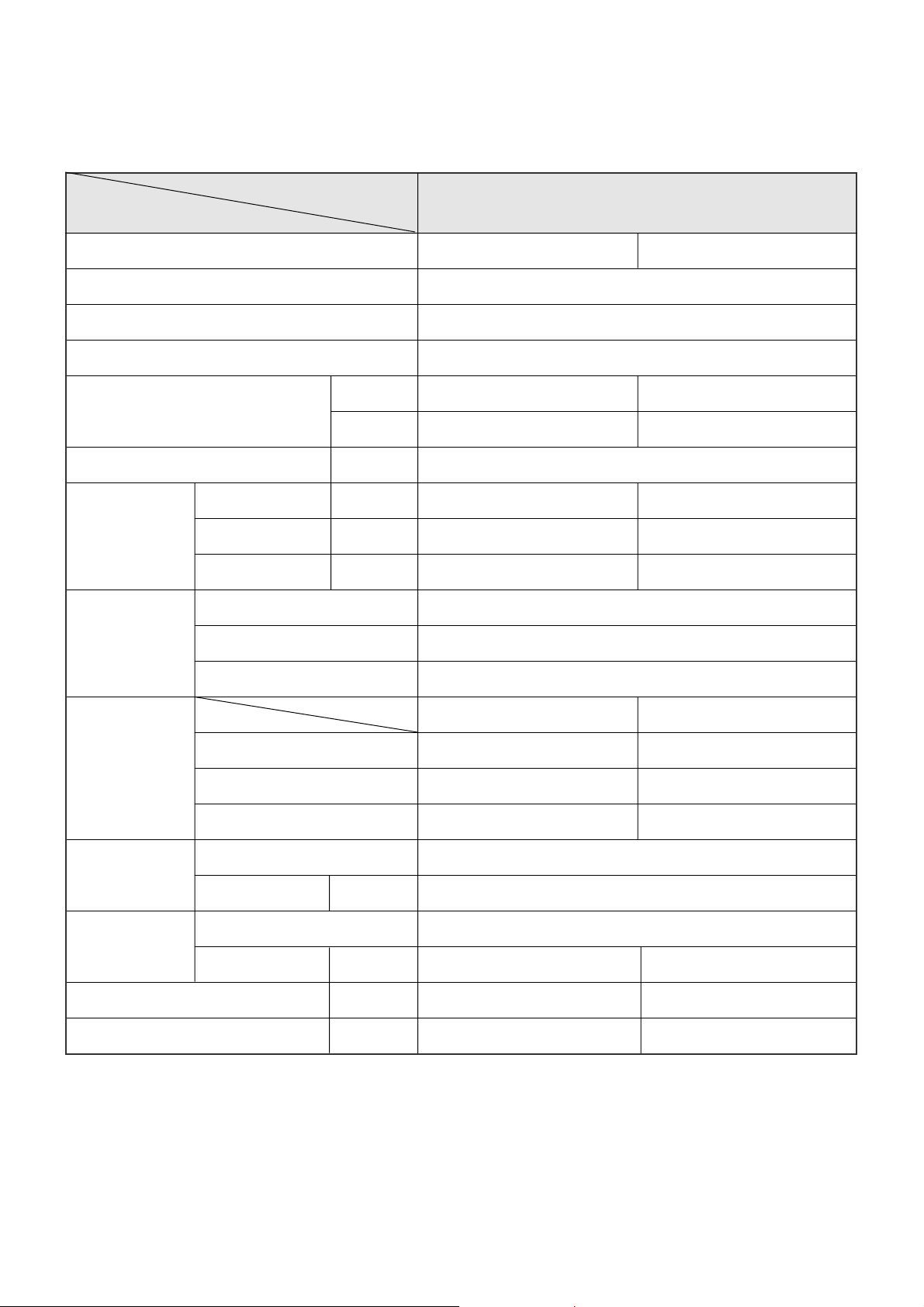

4

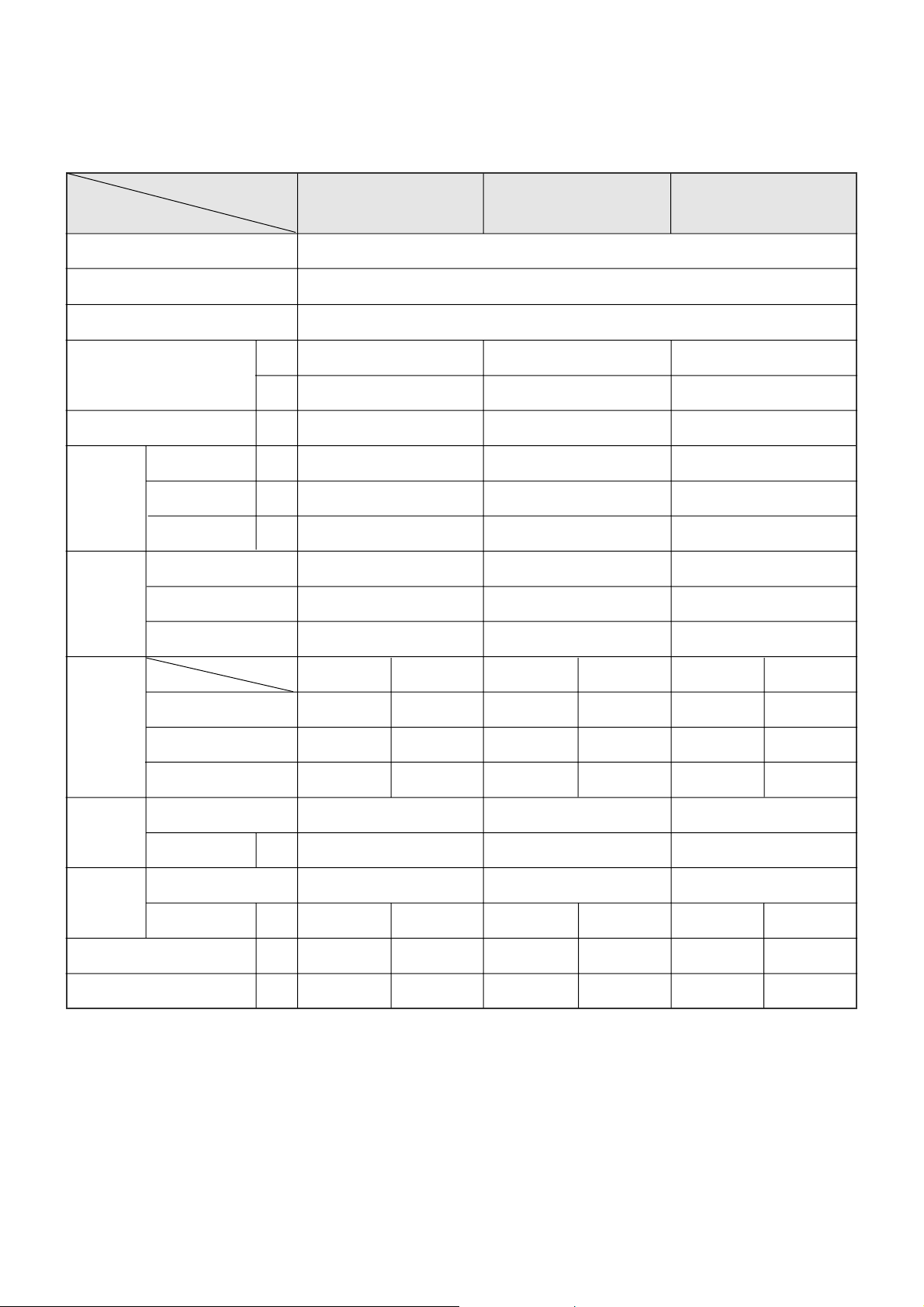

MODEL

DSB-121L/122L

ITEM

Function Cooling

Class T

1

Power AC 220~240V/ 50Hz

Capacity W 3,517

Btu/h 12,000

Dehumidification l/h 1.53

Running Current A 5.7

Power Input W 1,250

Starting Current A 34

Type Rotary

Model RCB 120A001

Capacitor 25µF/ 370VAC

Division Indoor Unit Outdoor Unit

Type Cross flow fan Propeller fan

Capacitor 1.0µF 400VAC 3.5µF 400VAC

Motor Model Number YDK-8-4B/A YDK-40-4B

Control Capillary

Charge Q'ty g 1,310

Type Flare

OD (Liquid/Gas) in(mm) 1/4 (6.35) 1/2 (12.7)

Dimensions (W x H x D) mm 925 x 285 x 194 654 x 549 x 256

Net Weight kg 9.7 34

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSB-121L/122L

Page 6

5

MODEL

DSB-123L DSA-123L

ITEM

Function Cooling

Class T

1

Power AC 220~240V/ 50Hz AC 208~230V/60Hz

Capacity W 3,517

Btu/h 12,000

Dehumidification l/h 1.35

Running Current A 5.7

Power Input W 1,300 1,200

Starting Current A 34 29

Type Rotary

Model RCB 120A001 QK173KAJ

Capacitor 25µF/ 370VAC 25µF/ 400VAC

Division Indoor Unit Outdoor Unit Outdoor Unit

Type Cross flow fan Propeller fan Propeller fan

Capacitor 1.5µF 400VAC 3.5µF 400VAC 2.0µF 400VAC

Motor Model Number RP-13B YDK-40-4B YDK-35-6A

Control Capillary

Charge Q'ty g 1,250 860

Type Flare

OD (Liquid/Gas) in(mm) 1/4 (6.35) 3/8 (9.52) 3/8 (9.52)

Dimensions (W x H x D) mm 815 x 285 x 195 654 x 549 x 256 654 x 549 x 256

Net Weight kg 9.2 34 34

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSB-123L/DSA-123L

Page 7

6

MODEL

DSA-181L DSB-181L

ITEM

Function Cooling

Class T

1

Power Supply

AC 220V, 60Hz AC 220~240V, 50Hz

Capacity W 5,129 5,100

Btu/h 18,000 17,500

Dehumidification 2.3l/h 2.3l/h

Running Current 8.0A 9.8A

Power Input 1,750W 1,950W

Starting Current 42A 46A

Type Rotary RECIPRO

Model RCA180U001 CRDQ-0200-PFJ

Capacitor 35µF/370 VAC 30µF/400 VAC

Type Indoor Cross Flow Fan

Outdoor Propeller Fan

Capacitor Indoor 1.2µF/400 VAC

Outdoor 3µF/400 VAC

Motor Model Indoor IC-9425DWKH6A IC-9425DWKC5A

Outdoor YDK-50-6A AM12DPD04

Control Capillary

Charge Q'ty 1,430g 1,150g

Type Flare

OD Indoor 1/4”(6.35mm)

(Liquid/Suction) Outdoor 1/2”(12.7mm)

Dimensions Indoor 1,035 x 322 x 205

Outdoor 800 x 615 x 320

Net Weight Indoor 11.7Kg 11.7Kg

Outdoor 50Kg 55.8Kg

Electrical

Data

Compressor

Fan

Refrigerant

(R-22)

Connection

◆DSA-181L/DSB-181L

Page 8

7

MODEL

DSB-182L DSB-182L-R DSB-183L-R

ITEM

Function Cooling

Class T1

Power AC 220~240V/ 50Hz

Capacity W 5,129 5,275 5,275

Btu/h 17,500 18,000 18,000

Dehumidification l/h 2.3 2.3 2.3

Running Current A 9.6 9.2 9.5

Power Input W 2,134 2,000 2,000

Starting Current A 49 54 54

Type Rotary Recipro Recipro

Model SHW33TC4-U AWG5524EXC AWG5524EXC

Capacitor 50µF / 370VAC 35µF / 370VAC 35µF / 370VAC

Indoor Unit Outdoor Unit Indoor Unit Outdoor Unit Indoor Unit Outdoor Unit

Type Cross flow fan Propeller fan Cross flow fan Propeller fan Cross flow fan Propeller fan

Capacitor 1.2µF 450VAC 3µF 400V 1.2µF 450VAC 3.0µF 400V 1.2µF 450VAC 3.0µF 400V

Motor Model Number IC-9625DWKC5C YDK-50-6B IC-9625DWKC5C YDK-50-6B IC-9625DWKC5C YDK-50-6B

Control Capillary Capillary Capillary

Charge Q'ty g 1,600 1,350 1,400

Type Flare Flare Flare

OD (Liquid/Gas) in(mm) 1/4 (6.35) 1/2 (12.7) 1/4 (6.35) 1/2 (12.7) 1/4 (6.35) 1/2 (12.7)

Dimensions (W x H x D) mm 1035 x 322 x 205 800 x 615 x 320 1035 x 322 x 205 800 x 615 x 320 1080 x 298 x 320 800 x 615 x 320

Net Weight kg 11.7 52.5 11.7 62 14.7 62

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSB-182L/182L-R/183L-R

Page 9

MODEL

DSA-182L DSA-183L-R

ITEM

Remark

JIS C9812 SAA 385, 386

Function Cooling

Class T1

Power AC 220V/ 60Hz

Capacity W 5,129 5,275 4,500

Btu/h 17,500 18,000 15,354

Dehumidification l/h 2.3 2.3

Running Current A 8.3 9.4 10.4

Power Input W 1,785 2,000 2,200

Starting Current A 44 52 52

Type Rotary Recipro

Model ECB185211A AWG5519EXN

Capacitor 30µF / 370VAC 25µF / 400VAC

Indoor Unit Outdoor Unit Indoor Unit Outdoor Unit

Type Cross flow fan Propeller fan Cross flow fan Propeller fan

Capacitor 1.2µF 450VAC 3µF 400V 2µF / 400VAC 2µF / 400VAC

Motor Model Number IC-9625DWKC5C YDK-50-6B IC-9430DWKF7A IC-1625DWCF6B

Control Capillary Capillary

Charge Q'ty g 1,450 1,400

Type Flare Flare

OD (Liquid/Gas) in(mm) 1/4 (6.35) 1/2 (12.7) 1/4 (6.35) 1/2 (12.7)

Dimensions (W x H x D) mm 1035 x 322 x 205 800 x 615 x 320 1080 x 298 x 200 800 x 615 x 320

Net Weight kg 11.7 50 14.7 62

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSA-182L/183L-R

8

Page 10

9

MODEL

DSA-183L

ITEM

Remark JIS C9812 SAA 385, 386

Function Cooling

Class T1

Power AC 220V / 60Hz

Capacity

W 5,270 4,450

Btu/h 18,000 15,200

Dehumidification l/h 2.5

Running Current A 10.4 11.8

Power Input W 2,000 2,300

Starting Current A 60 60

Type Rotary

Model RCA280T001

Capacitor 30µF / 440VAC

Indoor Unit Outdoor Unit

Type Cross flow fan Propeller fan

Capacitor 2µF / 400VAC 4µF / 400VAC

Motor Model Number IC-9430DWKF7A IC-1625DWCF6B

Control Capillary

Charge Q'ty g 1,350

Type Flare

OD (Liquid/Gas) in(mm) 1/4 (6.35) 1/2 (12.7)

Dimensions (W x H x D) mm 1080 x 298 x 200 800 x 615 x 320

Net Weight kg 14.7 60.5

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSA-183L

Page 11

10

MODEL

DSB-240L-R

ITEM

Function Cooling

Class T1

Power AC 220~240V/ 50Hz

Capacity

W 6,594

Btu/h 22,500

Dehumidification l/h 3.2

Running Current A 13.4

Power Input W 2,400

Starting Current A 83

Type Recipro

Model AWG5530EXC

Capacitor 45µF/ 400VAC

Division Indoor Unit Outdoor Unit

Type Cross flow fan Propeller fan

Capacitor 2µF 400VAC 5µF 400VAC

Motor Model Number IC-9430DWKF7A OSME-806DERC

Control Capillary

Charge Q'ty g 2,050

Type Flare

OD (Liquid/GAS) in(mm) 3/8 (9.52) 5/8 (15.9)

Dimensions (W x H x D) mm 1080 x 298 x 200 872 x 675 x 325

Net Weight kg 14.7 64

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSB-240L-R

Page 12

◆DSA-240L-R

MODEL

ITEM

Remark AHAM

Function Cooling

Class T1

Power AC 220V / 60Hz

W 7,034 5,129

Capacity

Btu/h 24,000 17,500

Dehumidification l/h 2.86

Running Current A 11.7 13

Electrical

Data

Compressor

Power Input W 2,500 2,850

Starting Current A 60 60

Type Recipro

Model AWG5524EXN

DSA-240L-R

Capacitor 35µF / 400VAC

Indoor Unit Outdoor Unit

Fan

Motor

Refrigerant

(R-22)

Connection

Dimensions (W x H x D) mm 1080 x 298 x 200 875 x 675 x 325

Net Weight kg 14.7 64

Type Cross flow fan Propeller fan

Capacitor 2µF / 400VAC 5µF / 400VAC

Motor Model Number IC-9430DWKF7A A2929GS010

Control Capillary

Charge Q'ty g 2100

Type Flare

OD (Liquid/Gas) in(mm) 5/8” (15.88)

11

Page 13

12

MODEL

DSA-240L

ITEM

Remark JIS C9812 SAA 385, 386

Function Cooling

Class T1

Power AC 220V / 60Hz

Capacity

W 7,030 5,860

Btu/h 24,000 20,000

Dehumidification l/h 2.86

Running Current A 10.8 13.5

Power Input W 2,320 2,750

Starting Current A 60 60

Type Rotary

Model 55A240IT1JM

Capacitor 45µF / 450VAC

Indoor Unit Outdoor Unit

Type Cross flow fan Propeller fan

Capacitor 2µF / 400VAC 5µF / 400VAC

Motor Model Number IC-9430DWKF7A A2929GS01B

Control Capillary

Charge Q'ty g 2,100

Type Flare

OD (Liquid/Gas) in(mm) 3/8 (9.52) 5/8 (15.88)

Dimensions (W x H x D) mm 1080 x 298 x 200 875 x 675 x 325

Net Weight kg 14.7 64

Electrical

Data

Compressor

Fan

Motor

Refrigerant

(R-22)

Connection

◆DSA-240L

Page 14

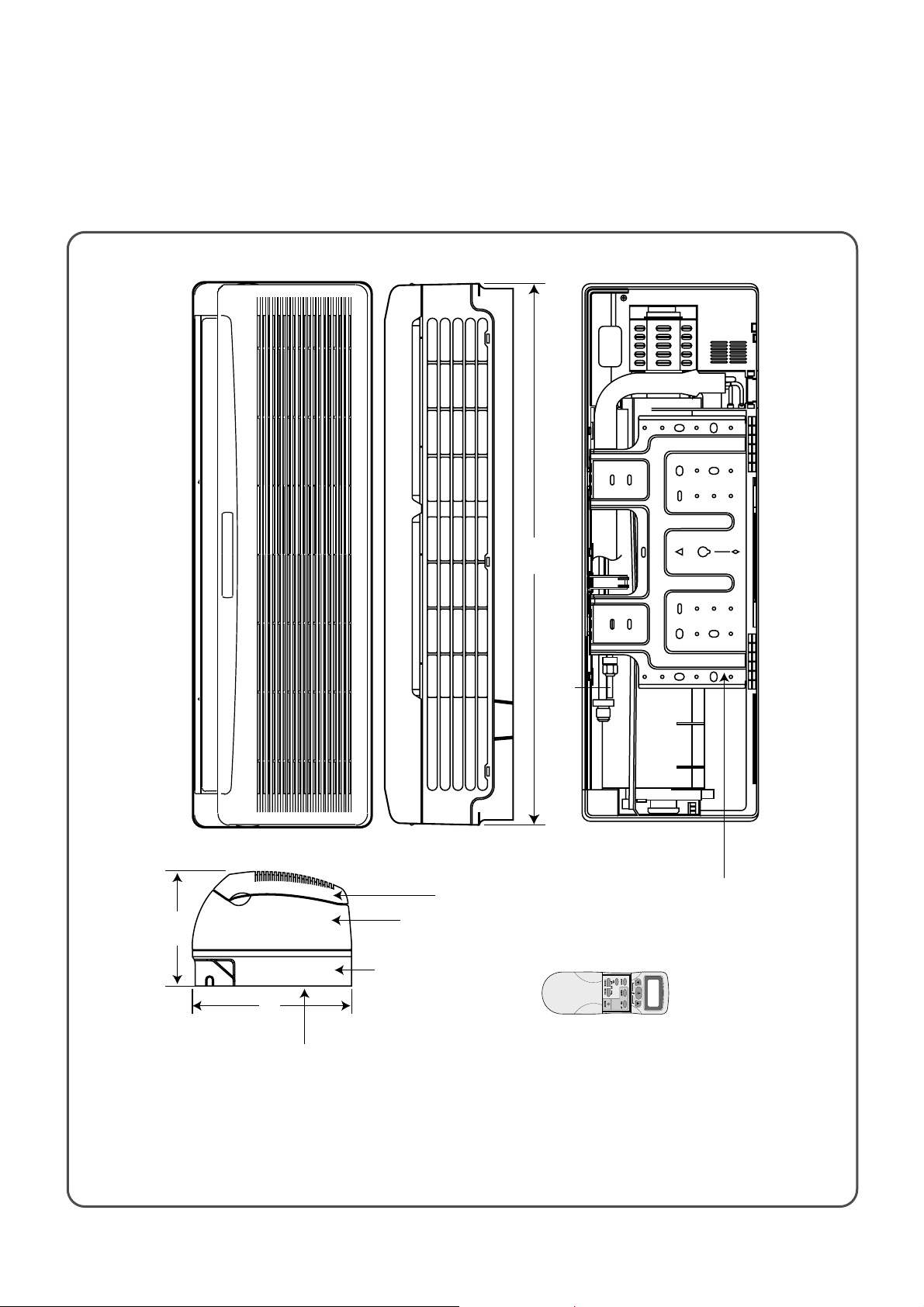

13

750

Plate Mounting

REMOCON

Connecting Pipe

Grille Insert

174

245

Frame Grille

Body

Plate Mounting

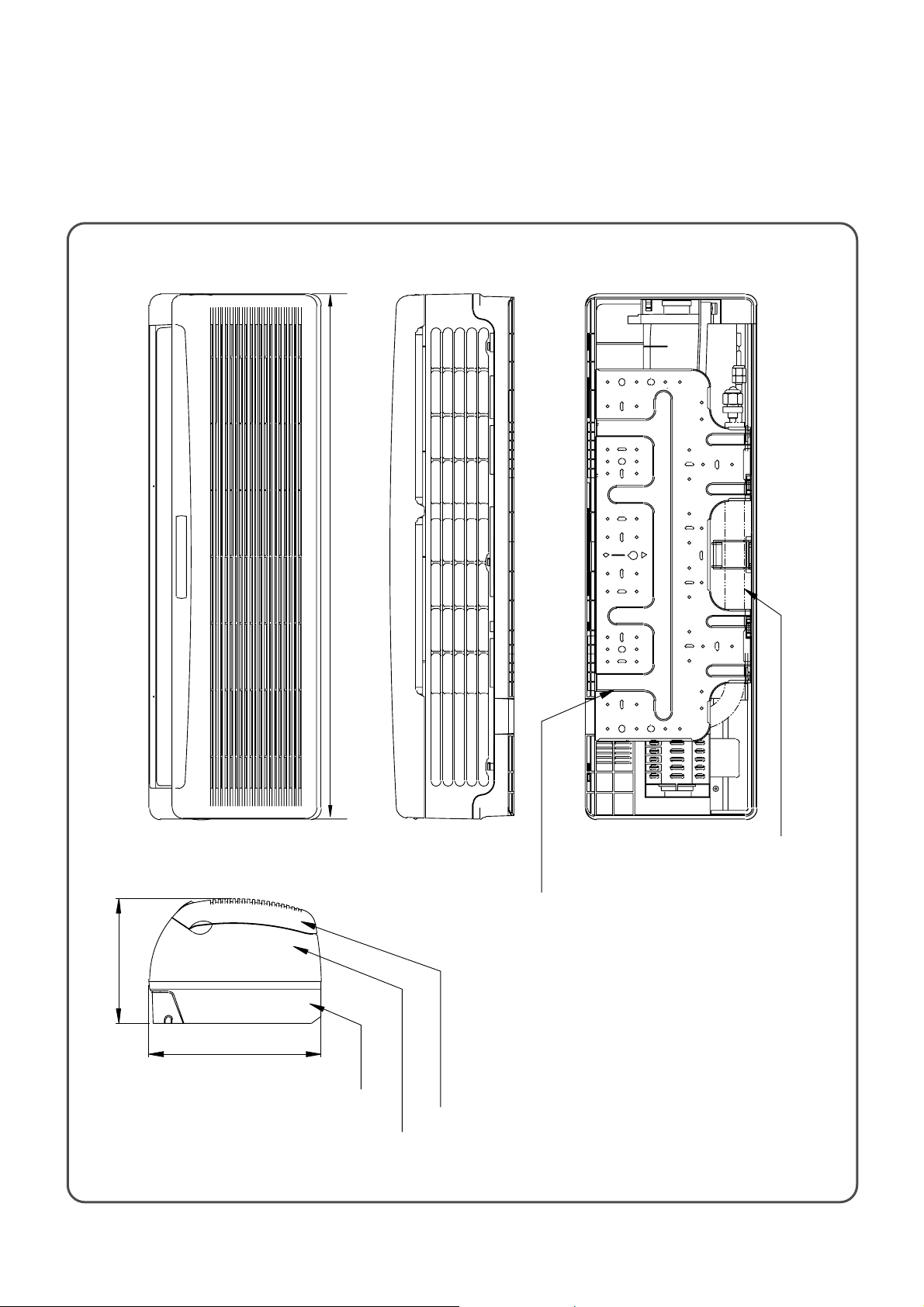

2. OUTLINE AND DIMENSIONS

1

INDOOR UNIT

◆DSB-070L/DSB-091L

179

Page 15

14

750

Plate Mounting

REMOCON

Connecting Pipe

Grille Insert

179

245

Frame Grille

Body

Plate Mounting

◆DSB-071L/DSB-092L

Page 16

15

REMOCON

Filter - L Filter - R

Grille Insert

Frame Grille

Body

Plate Mounting

Connecting Pipe

Plate Mounting

406

194

285

925

◆DSB-121L/122L

Page 17

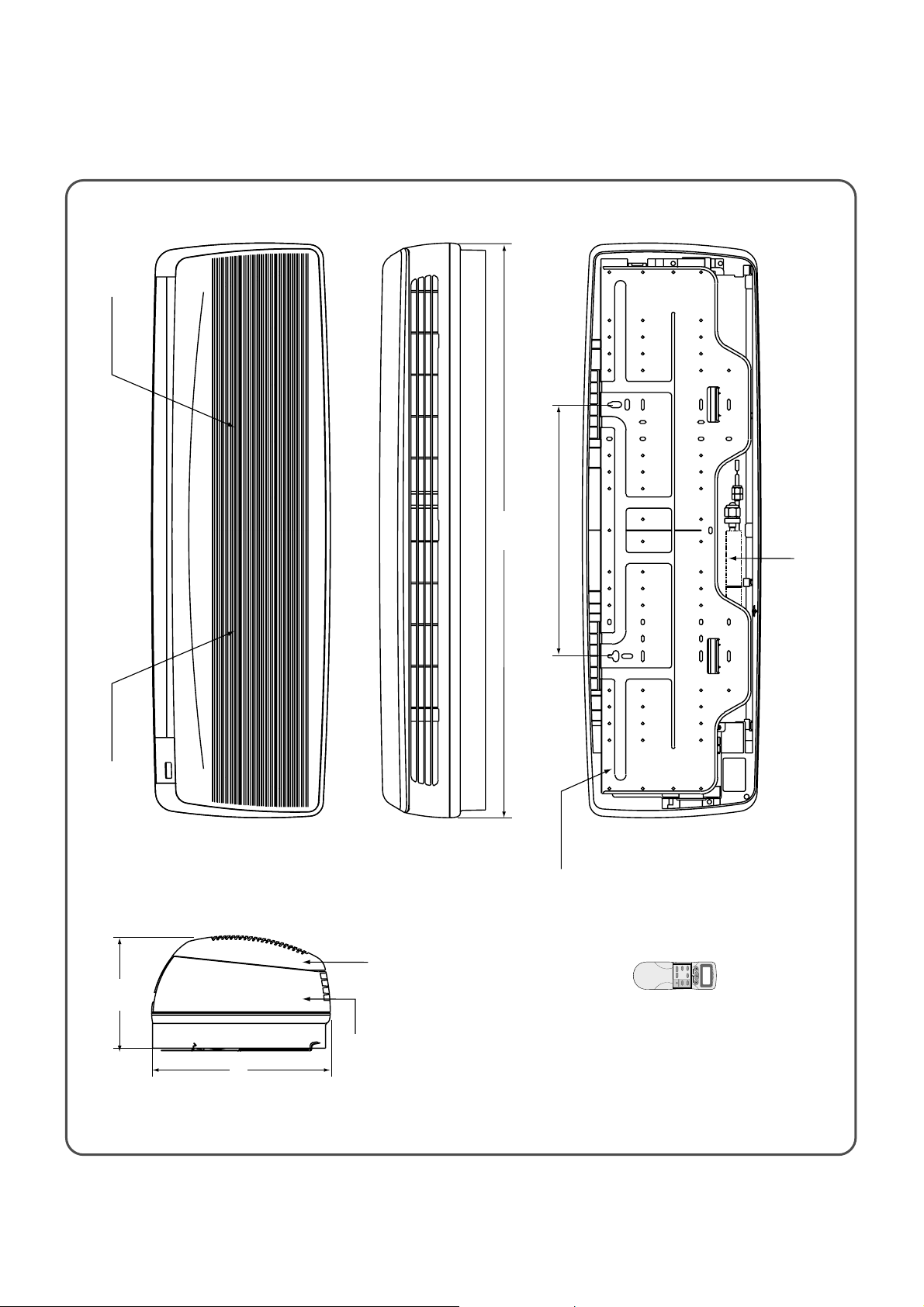

16

Insert Grille

Frame Grille

Body

Connecting Pipe

Plate Mounting

815

195

285

◆DSB-123L/DSA-123L

Page 18

17

◆ DSA-181L/DSB-181L

1035

205

322

453

¿‹ Æ˘˜ ˙`

”fi `⁄˘˙

`⁄„«…–‚fi‚ ˜

‰˙‡»– ‚Ø– ‚–

‰˙‡»– ‚ ˆ…

Connecting Pipe

Filter-L

Filter-R

Grille Insert

Body

Plate Mounting

REMOCON

453

1035

Page 19

18

Connecting Pipe

Body

Grille Insert

Plate Mounting

453

Filter-L Filter-R

REMOCON

1035

322

1035

◆DSB-182L/182L-R, DSA-182L

Page 20

19

Connecting Pipe

Body

Frame Grille

Grille Insert

Plate Mounting

430

710

1080

Filter-L Filter-R

REMOCON

◆DSA-183L-R/DSA-240L-R, DSB-183L-R/240L-R, DSA-183L/240L

200

298

Page 21

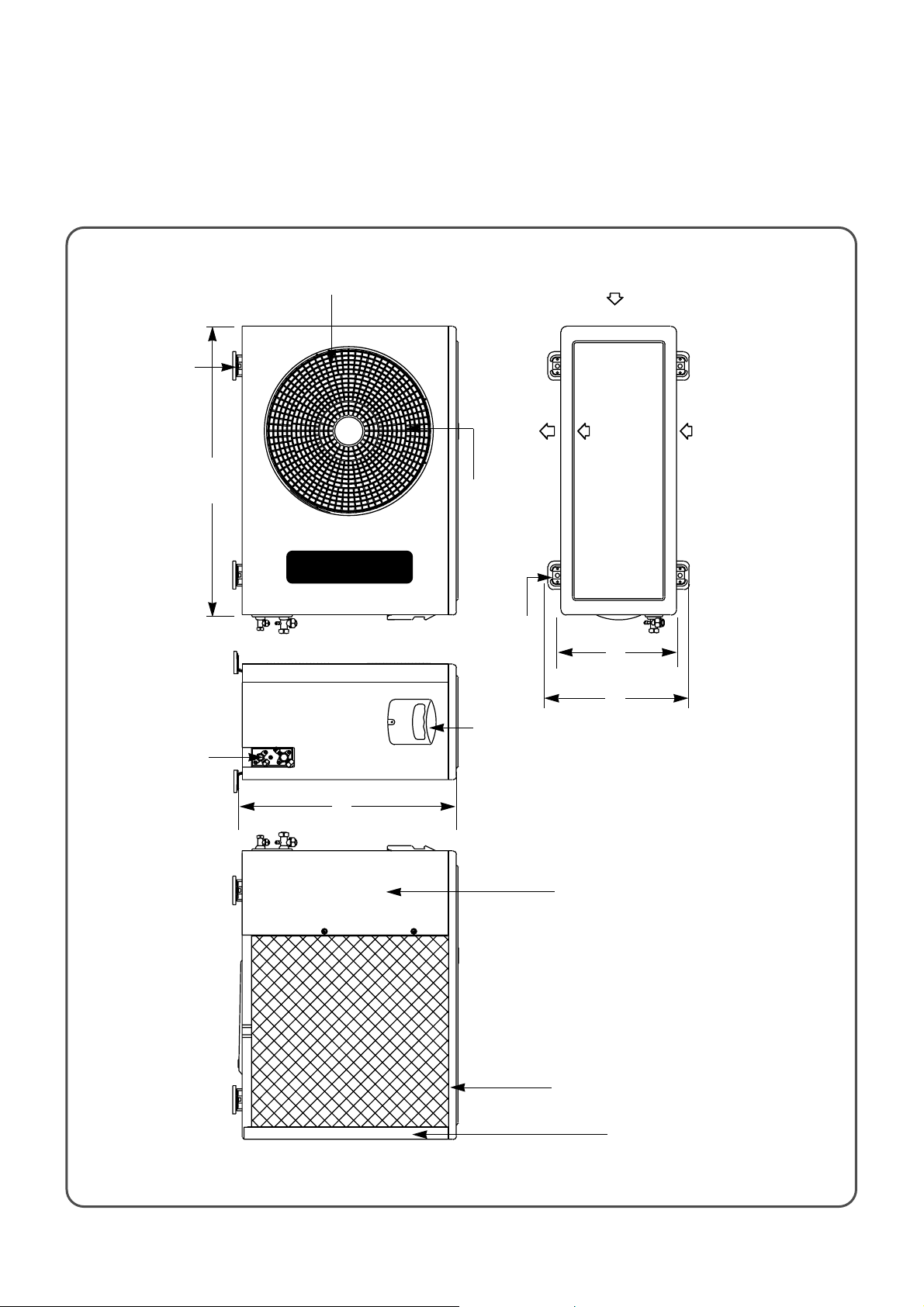

20

2

OUTDOOR UNIT

Inlet

Fot

Outlet

Foot Cushion

Ssrvice Valve

Ssrvice Valve

654

Outlet

Cabinet Front

Cabinet Side Guide Support

Panel Top

256

549

Inlet

◆DSB-070L/071L/DSB-091L/092L/DSB-121L/122L/123L

Page 22

21

◆DSB-181L/182L/182L-R/183L-R, DSA-181L/182L/183L/183L-R

Inlet

Inlet

Outlet

Outlet

Foot

Foot Cushion

Handle

Cabinet Side

Panel Top

Guide Support

Service Valve

Cabinet Front

320

380

615

800

Page 23

Inlet

380

699

323

foot

Service valve

873

Cabinet front

Service Cover

Cabinet Side

◆DSB-240L-R/DSA-240L-R/DSA-240L

22

Page 24

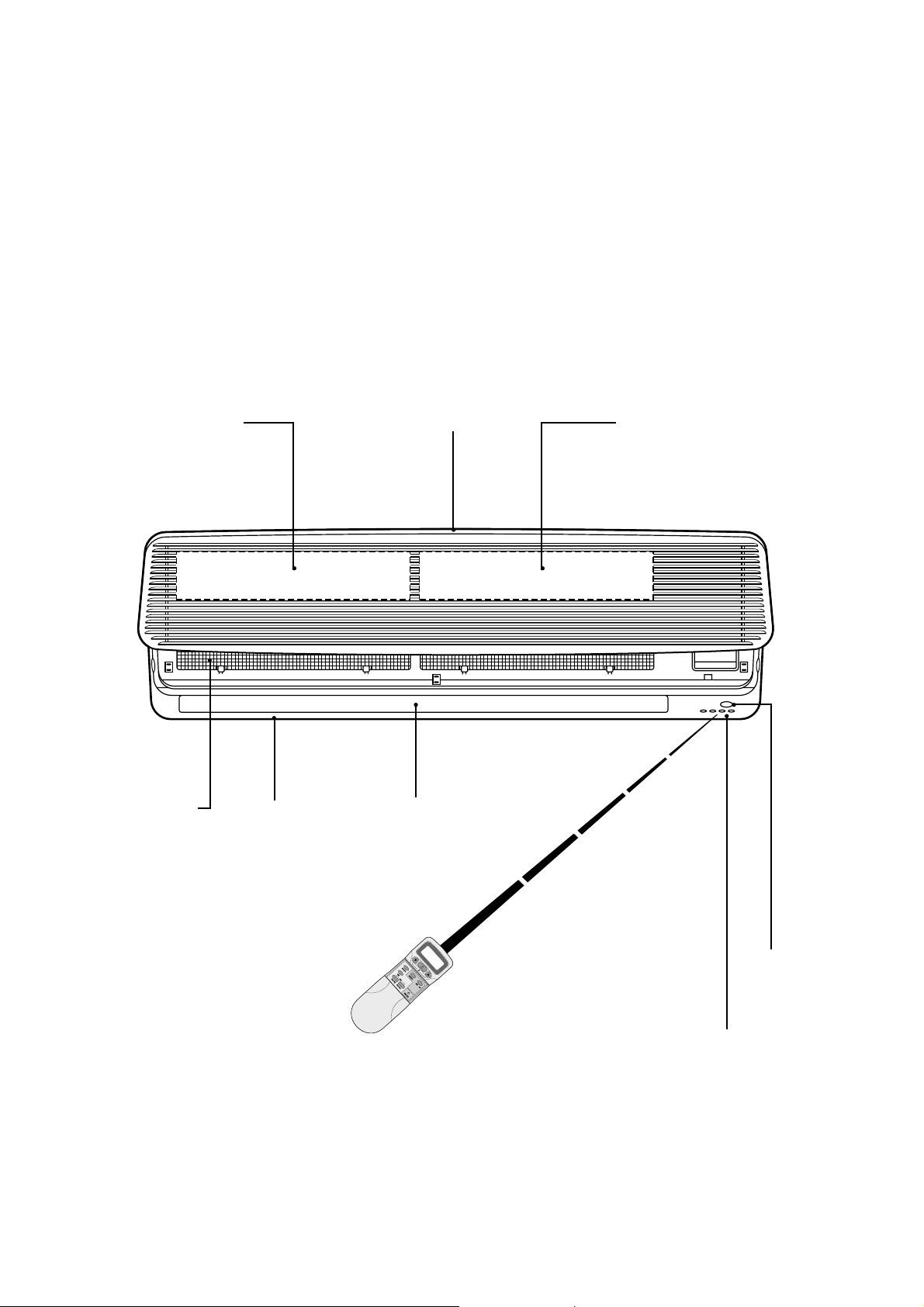

23

1

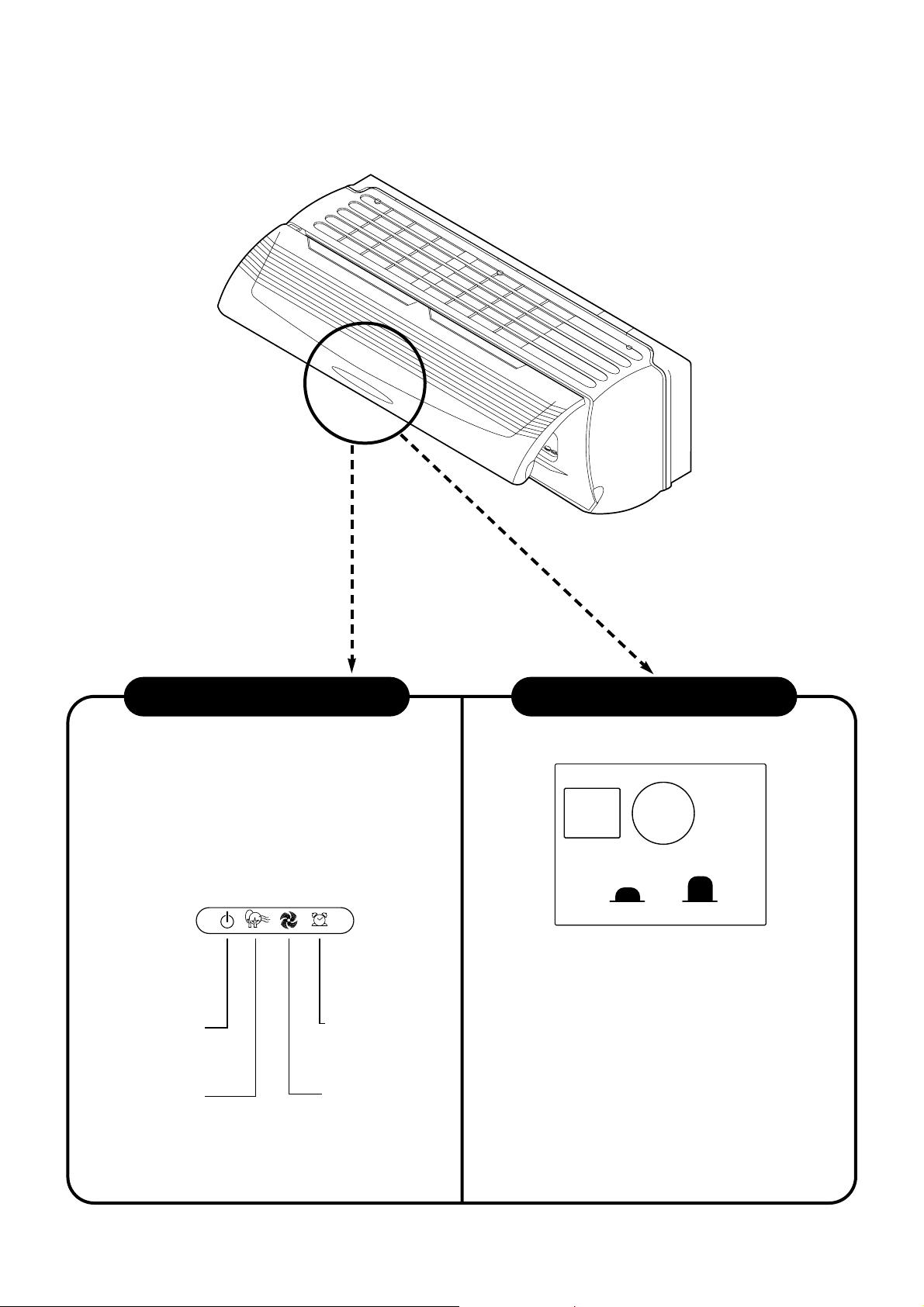

NAME AND FUNCTION OF PARTS

Indoor Unit

3. OPERATION

◆DSB-070L/DSB-091L

Electrostatic Filter(Option)

Removes dust and particles

from the air

Deodorizing Filter(Option)

Removes bad smells from

the air.

Air Inlet

Remote

Controller

Receiver

Power Plug

Remote Controller

Fan Direction

(Up, Down)

Air Outlet

Antibacterial Filter

Removes dust and

prohibits germs.

Lamp

Page 25

24

◆DSB-071L/DSB-092L

Electrostatic Filter(Option)

Removes dust and particles

from the air

Deodorizing Filter(Option)

Removes bad smells from

the air.

Air Inlet

Remote

Controller

Receiver

Power Plug

Remote Controller

Fan Direction

(Up, Down)

Air Outlet

Antibacterial Filter

Removes dust and

prohibits germs.

Lamp

Page 26

25

◆DSB-121L/122L

Electrostatic Filter Deodorizing FilterAir Inlet

Antibacterial

Filter

Air Outlet Fan Direction

(Up, Down)

Remote Controller

Remote

Controller

Receiver

Lamp

Removes dust and

particles from the air

Removes dust and

prohibits germs.

Removes bad smells

from the air.

Page 27

26

◆DSB-123L/DSA-123L

Electrostatic Filter

Removes dust and

particles from the air

Deodorizing Filter

Removes bad smells

from the air.

Air Inlet

Remote

Controller

Receiver

Remote Controller

Fan Direction

(Up, Down)

Air

Outlet

Antibacterial Filter

Removes dust and

prohibits germs.

Lamp

Page 28

27

◆ DSB-181L/182L/182L-R, DSA-181L/182L

Indoor Cover

Electrostatic Filter

Removes dust

particles from the air.

Deodorizing Filter

Removes bad

smells from the air.

Test/Emergency/

Remote Switch

Slide to select

the desired position.

Indicators

Indicate the

AC setting.

Remote Sensor

Power PlugLCD Remote Controller

Air Cleaning

Filters

Removes dust

and prohibits

germs.

Cold Air

Air In

Fan Direction

(Up/Down)

O

N

O

F

F

E

N

T

E

R

C

A

N

C

E

L

T

I

M

E

R

R

E

S

E

T

F

A

N

D

I

R

.

F

A

N

S

P

E

E

D

M

O

D

E

S

L

E

E

P

O

N

/

O

F

F

T

E

M

P

.

Page 29

28

Indoor Cover

Electrostatic Filter

Removes dust

particles from the air.

Deodorizing Filter

Removes bad

smells from the air.

Emergency/Remote Switch

Indicators

Indicate the

AC setting.

Remote

Sensor

Power Plug

LCD Remote

Controller

Air Cleaning Filters

Removes dust and

prohibits germs.

AIR OUT

AIR IN

Fan Direction

(Up/Down)

M

O

D

E

S

L

E

E

P

O

N

/

O

F

F

T

I

M

E

R

E

N

T

E

R

/

C

A

N

C

E

L

F

A

N

S

P

E

E

D

T

U

R

B

O

/

M

I

L

D

F

A

N

D

I

R

.

◆ DSA-183L-R/DSA-240L-R, DSB-183L-R/240L-R, DSA-183L/240L

Page 30

29

◆DSB-070L/DSB-091L

■

Remote Control Signal Receiver

This place is the part to receive the signal if it

receives the signal, you can hear the signal

“beep. “beep. beep.”

■

There is a switch panel at inside of Front

Panel. At the time of operating, open the

Front Panel.

Emergency switch can be used when the remote

controller is lost or Testing.

Remote switch is usually used by remote

controller.

Indoor Unit Display Switch Panel

Timer (Yellow)

Lights during the time

reservation mode.

Quick (Red)

ON (Red)

Lights when the

operation is going on.

Air clean (Green)

EMR. REMOCON

Page 31

30

◆DSB-071L/DSB-092L

■

Remote Control Signal Receiver

This place is the part to receive the signal if it

receives the signal, you can hear the signal

“beep. “beep. beep.”

■

There is a switch panel at inside of Front

Panel. At the time of operating, open the

Front Panel.

Emergency switch can be used when the remote

controller is lost or Testing.

Remote switch is usually used by remote

controller.

Indoor Unit Display Switch Panel

Timer (Yellow)

Lights during the time

reservation mode.

Quick (Red)

ON (Red)

Lights when the

operation is going on.

Air clean (Green)

EMR. REMOCON

Page 32

31

Remote Control Signal Receiver

This place is the part to receive the signal if it

receives the signal, you can hear the signal

"beep, beep".

Timer (Y ellow)

Lights during the time

reservation mode.

ON (Red)

Lights when the

operation is

going on.

■ There is a switch panel at inside of Front

Panel. At the time of operating, open the

Front Panel.

Air clean (Green)

Quick(Red)

EMERGENCY REMOTE

ON AIR CLEAN QUICK TIMER

Remote switch is usally used by Remote

Controller.

Emergency switch can be used when the remote

controller is lost or testing.

◆DSB-121L/122L

Indoor Unit Display Switch Panel

Page 33

32

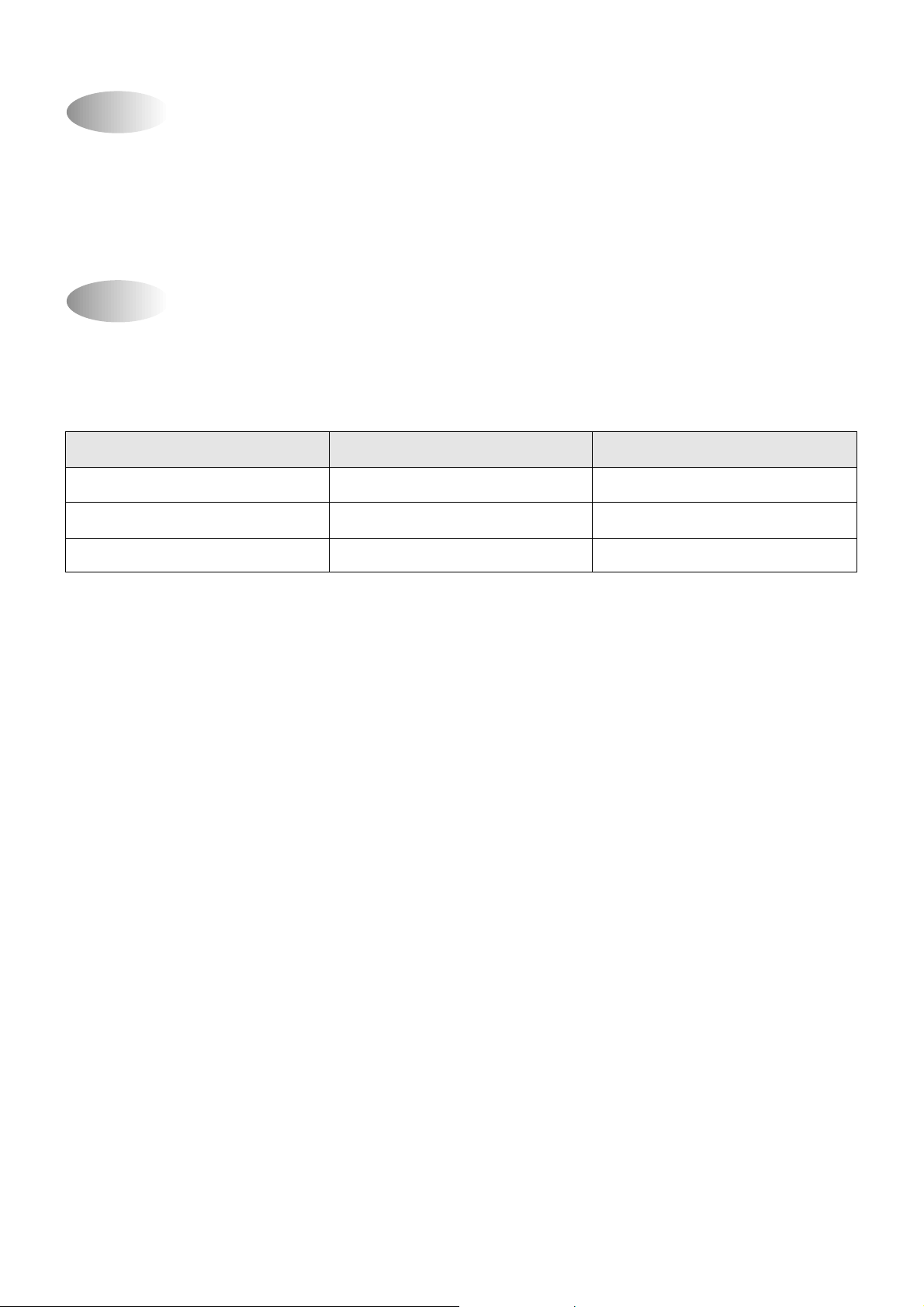

◆DSB-123L/DSA-123L

■Remote Control Signal Receiver

This place is the part to receive the signal if it receives the

signal, you can hear the signal “beep. beep”.

■There is a switch panel at inside of Front Panel. At the

time of operating, open the Front Panel.

Emergency switch can be used when the remote controller

is lost or Testing.

Remote switch is usually used by remote controller.

Indoor Unit Display Switch Panel

ON (Red)

Lights when the

operation is going on.

Air clean

(Green)

Timer (Yellow)

Lights during the time

reservation mode.

Quick (Red)

Lights during the

time Quick

Mode.

EMERGENCY

REMOCON

REMOCON

EMERGENCY

Page 34

33

◆

DSB-181L/182L/182L-R, DSA-181L/182L

■ Remote Control Signal Receiver

This place is the part to receive the signal if it receives

the signal, you can hear the signal “beep. beep”.

■ There is a switch panel at inside of Front Panel.

At the time of operating, open the Front Panel.

Emergency switch can be used when the remote

controller is lost or Testing.

Remote switch is usually used by remote controller.

Indoor Unit Display Switch Panel

ON (Red)

Lights when the

operation is going on.

Air clean (Green)

Timer (Yellow)

Lights during the time

reservation mode.

Quick (Red)

Lights during the

time Quick

Mode.

Timer

Quick

Airclean

ON

EMERGENCY REMOTE

Page 35

34

◆DSA-183L-R/240L-R, DSB-183L-R/240L-R, DSA-183L/240L

■

Remote Control Signal Receiver

This place is the part to receive the signal if it

receives the signal, you can hear the signal

“beep. “beep, beep.”

■

There is a switch panel at inside of

Front Panel. At the time of operating,

open the Front Panel.

Emergency switch can be used when the remote

controller is lost or Testing.

Remote switch is usually used by remote

controller.

Indoor Unit Display Switch Panel

Timer (Yellow)

Lights-on during the time

of reservation mode.

Quick (Red)

Lights-on during the time

of Quick Mode.

ON (Red)

Lights-on

during the operation

Air clean (Green)

Lights-on

during the operation

EMERGENCY

REMOCON

REMOCON

EMERGENCY

Page 36

35

◆DSB-070L/071L/DSB-091L/092L/DSB-121L/122L/123L/DSA-123L

AIR IN

AIR OUT

Connection Cover

Remove cover to access the

AC connection

to the indoor unit.

Service Valves

The indoor and outdoor units

are connected by copper tubes

which are connected here.

Outdoor Unit

Page 37

36

◆

DSB-181L/182L/182L-R/183L-R, DSA-181L/182L/183L/183L-R

AIR IN

AIR OUT

AC Cover

Remove cover to

access the AC

connection from

this unit to the

indoor unit.

Connection Wire

Drain Hose

COPPER TUBING

Service Valves

The indoor and outdoor

units are connected by

copper tubes which are

connected here.

Grounding Screw

Ground the unit here.

Ground Wire

(Not supplied)

Page 38

37

◆DSB-240L-R / DSA-240L-R / DSA-240L

Air Inlet

Air Outlet

Connection Pipe

Connection wire

Drain Hose

Page 39

38

MODE

SLEEP

ON/OFF

TIMER

ENTER/

CANCEL

FAN SPEED

TURBO/MILD

Display

Displays information

pertaining to unit.

TURBO/MILD

Press to select super power

operation (Turbo) mode.

TIMER ENTER/CANCEL Button

Press to enter a timer setting or

to cancel timer setting

TIMER ON/OFF Button

Press to set the unit off or on time.

(0.5, 1, 1.5, 2, 2.5, 3, 4, 5, 6, 8,

10, 12, 16, 20, 24hr)

MODE Button

Press to cycle through the modes

(Auto/Quick/Cool/Fan/Dehumidifier)

SLEEP Button

Press to set the unit for the

sleep mode.

FAN DIR.

FAN DIR. Button

Press to select up/down

direction for fan.

ON/OFF Button

Press to turn the unit

on or off.

TEMPERATURE Buttons

Press to raise or lower

the desired temperature.

FAN SPEED Button

Press to select the fan speed

(High " ", Middle " ", Low " ",

Natural).

COVER

Slide down to access most

of the remote buttons.

Slide down further to

access the battery

compartment.

AUTO

Name of Each Button

2

REMOTE CONTROLLER

◆ DSB-070L/DSB-071L/DSB-091L/DSB-092L/DSB-121L/DSB-122L/DSB-123L/DSA-123L

DSB-183L-R/DSA-183L-R/DSB-240L-R/DSA-240L-R

Page 40

39

◆DSB-182L/182L-R, DSA-182L/DSA-181L

MODE

SLEEP

ON/OFF

TIMER

ENTER/

CANCEL

FAN SPEED

TURBO/MILD

Display

Displays information

pertaining to unit.

TURBO/MILD

Press to select super power

operation (Turbo) mode.

TIMER ENTER/CANCEL Button

Press to enter a timer setting or

to cancel timer setting

TIMER ON/OFF Button

Press to set the unit off or on time.

(0.5, 1, 1.5, 2, 2.5, 3, 4, 5, 6, 8,

10, 12, 16, 20, 24hr)

MODE Button

Press to cycle through the modes

(Auto/Quick/Cool/Fan/Dehumidifier)

SLEEP Button

Press to set the unit for the

sleep mode.

FAN DIR.

FAN DIR.

FAN DIR. Button

Press to select up/down

direction for fan.

FAN DIR. Button

Press to select left/right

direction for fan.

ON/OFF Button

Press to turn the unit

on or off.

TEMPERATURE Buttons

Press to raise or lower

the desired temperature.

FAN SPEED Button

Press to select the fan speed

(High " ", Middle " ", Low " ",

Natural).

COVER

Slide down to access most

of the remote buttons.

Slide down further to

access the battery

compartment.

AUTO

Page 41

40

Replacing Batteries

3

REMOTE CONTROLLER DISPLAY

Open the cover after

pressing the arrow

direction and pulling out.

Put the drycell by

⊕⊖

direction.

Close the cover after

pushing into arrow

direction.

1

2

3

+—

+—

MODE Indicators (Auto/Quick/Cool/Fan/Dehumidifier)

Lights to indicate the mode selected.

TIMER Indicators (Include sleep)

Lights to indicate the timer function mode.

TEMPERATURE & RESERVATION TIME lndicator

Lights to indicate the temperature or time.

FAN DIRECTION Indicators

Lights to indicate the

fan direction.

NATURAL Indicator

Lights to indicate the

speeds simulating a loreeze.

FAN Indicators

Lights to indicate

the fan speed.

AUTO

Page 42

41

If you set time in OFF-Timer Mode, the unit will stop at the set time.

If you set time in ON-Timer Mode, the unit will run at the set time.

(1) Range of setting temperature: 18~32°C

(2) Setting temperature: Operating temperature of compressor

(3) During the time of test operating, Fan (Indoor, Outdoor) and Compressor is running regardless of room

temperature.

If the Indoor Unit Display receive the signal of Remote Controller, you can hear the signal "beep –" or "beep,

beep".

(1) In the case of receiving ON/OFF signal-"beep" "beep"

(2) And so on-"beep"

OFF-Timer

4

DESCRIPTION OF FUNCTIONS

Unit ON

Unit OFF

SET Time

HOUR

ON

OFF

ON-Timer

Unit ON

Unit OFF

SET Time

HOUR

ON

OFF

Control of Room Temperature

Buzzer

COMP (ON)

*RT: ROOM TEMPERATURE

DT: DESIRED TEMPERATURE

COMP (OFF)

-1°C0°C

(COOLING)

(RT-DT)

+1°C

Page 43

42

Fan Speed (Indoor Unit)

(1) Motor speed (high speed, middle speed, low speed).

(2) Remote controller setting fan speed. (Auto, L, M, H, Natural)

(3) Relation of operating mode between fan speed.

(4) Automatic Operation

If the unit is set in 'AUTO' mode, the unit operates automatically according to the room temperature to keep the

room temperature comfortable.

0°C

L

M

H

1°C2°C

(R.T-D.T)

(D.T)

(COOLING)

FAN ONLY COOL

DEHUMI-

AUTO QUICK

DIFICATION

H HHLHH

M MMLMH

L LLLLH

Auto X Auto L Auto H

Natural Natural Natural L Natural H

Page 44

43

(1) When the remote controller is lost, damaged or the battery is discharged, the Emergency operation can be

used to run the unit.

(2) The setting conditions of Emergency operation are as follows.

• Operation mode: Quick

• Preset temperature:18°C: Cooling

• Fan speed: High

*You cannot operate with remote controller.

(1) When you are going to sleep, select sleep switch and the unit controls the room to the desired temperature.

(The unit will not operate after 4 hour)

(2) For changing the temperature.

(3) To cancel sleep mode, press the SLEEP button again or press the MODE button once.: the SLEEP

indicator will disappear in the display.

Sleep Mode

Emergency Operation

0 0.5 1.0 HOUR

(COOLING CYCLE)

DT

+0.5°C

+0.5°C

+0.5°C

Frost Prevention of Indoor Unit

When the unit operates at low ambient temperature, frost may appear on the Evaporator. When the indoor coil

temperature is lower than 0°C at the end of 10 minutes of continuous compressor operation from the start, the

microcomputer of the unit stops the compressor to protect the unit from the frost. The control procedure for

indoor coil freeze protection.

1) The compressor and outdoor fan turn off.

2) Indoor fan operates according to user set speed.

3) The normal operation returns when the indoor coil

temperature is higher than 7°C or equal to 7°C.

-1°C+7°C

Compressor and

Outdoor Fan

ON ON

OFF

Indoor Fan

Set speed

(Indoor coil temperature)

Page 45

44

Auto Mode

(1) In Auto Mode

After the indoor fan is operated for 20 seconds in the Auto Mode the unit will operate automatically by selecting

operating Mode according to the room temperature

(2) Selecting Operating Mode Again

Room temperature meets desired temperature and the compressor stops running over 30 minutes, then the unit

selects operating Mode again.

3 min. Time Delay of Compressor

In normal operation, there is a time delay of three minutes between turn off and turning back on including initial

power up.

ROOM TEMPERA TURE

DT-2°C RT

DT-2°C

≤

RT ≤DT+3°C

DT+3°C RT

OPERA TING MODE

Cooling

Dehumidifier

Cooling

FLAP POSITION

Cooling Position

Cooling Position

Cooling Position

(RT: Room temperature)

>

<

Page 46

45

1) Cooling Mode

* When the room temperature is higher than 22°C

1Fan Speed: Super high speed

2Air discharge direction: Fixed

3Set temperature: 18°C (Fixed)

4Compressor and Outdoor Fan

The air discharge direction procedure is below

Fixed Up/Down

Up/Down Fixed

Dehumidification Mode

Air Discharge Direction(only remocon operation)

Quick Mode(Powerful Cooling)

The air discharge direction procedure is below.

Fixed Up/Down Fixed

Up/Down

1Desired temperature < Room temperature

Outdoor Fan, Compressor : ON

Indoor Fan : Low speed

2Desired temperature ≥ Room temperature

Compressor : 3 min/ON, 5 min/OFF

Fan Speed : low speed

3Room temperature ≤ 18°C

Compressor : OFF

Fan speed : Low speed

COOLING POSITION

Page 47

46

Self-Diagnostic Function

The control will contain diagnostic test to verify the integrity of the system.

(1)Error Code Display Pattern

1 ON LAMP: Blink

LED BLINK PATTERN CASE NOTE

Room Sensor open or Short • Continuously woorking to fix room

temperature 32°C in cooling mode

• I/D coil sensor open or short Do not woorking

1 times blink • O/D coil sensor open or short

• Compressor or electrical parts Continuously workiug

of compressor error.

3 times blink • Gas leak

0.5s

8s

Page 48

47

4. WIRING DIAGRAM

Indoor Unit

◆DSB-070L/091L ◆DSB-071L/092L

◆DSA-121L/122L, DSB-121L/122L ◆DSB-123L/DSA-123L

Page 49

48

◆DSA-181L/182L

DSB-181L/182L/182L-R

◆DSA-183L-R, DSB-183L-R, DSA-183L

DSA-240L-R, DSB-240L-R, DSA-240L

Page 50

49

Outdoor Unit

◆DSA-121L/122L, DSB-070L/071L

DSB-091L/092L/121L/122L

◆DSB-123L/DSA-123L

◆DSA-240L-R/240L, DSB-240L-R

◆DSA-181L/182L, DSB-181L/182L/182L-R, DSA-183L-R, DSB-183L-R, DSA-183L

Page 51

50

◆DSB-070L/071L

◆DSB-091L/092L

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108008700 YDK-8-4B 1

Fan Motor Capacitor 3106900300 1.0µF 400VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Stepping Motor 3108003910 24BYJ48-S1 1

Terminal Block 3108914100 JXO-CH-3P 1

Compressor 3RC0020GE1 RBB070A011 1

Fan Motor 3108004000 YDK-30-6B 1

Dual Capacitor 3109501201 1.8+25µF 400VAC 1

Terminal Block 3108914100 JXO-CH-3P 1

Outdoor

Unit

1

MAIN ELECTRIC PARTS

Indoor

Unit

◆DSB-121L/122L

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108001220 YDK-8-4B/A 1

Fan Motor Capacitor 3106900300 1.0uF 400VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Transformer 5EPV050100 220V/18V 1

Stepping Motor 3108000200 28BYJ48-V2 1

Terminal Block 3108914100 JXO-CH-3P 1

Compressor 3100030CE0 RCB120A001 1

Fan Motor 3108000800 YDK-40-4B 1

Dual Capacitor 3109500700 3.5+25µF 400VAC 1

Terminal Block 3108914100 JXO-CH-3P 1

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108008700 YDK-8-4B 1

Fan Motor Capacitor 3106900300 1.0uF 400VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Stepping Motor 3108003910 24BYJ48-S1 1

Terminal Block 3108914100 JXO-CH-3P 1

Compressor 3RC0020KE0 RBB095A011 1

Fan Motor 3108004100 YDK-30-6B 1

Dual Capacitor 3109501201 1.8+25µF 400VAC 1

Terminal Block 3108914100 JXO-CH-3P 1

Indoor

Unit

Outdoor

Unit

Outdoor

Unit

Indoor

Unit

Page 52

51

◆DSB-181L/182L/182L-R

◆DSA-183L/183L-R

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108000311 IC-9425DWKC5C 1

Fan Motor Capacitor 3106900200 1.2µF 450VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Transformer 5EPV633110 220V 50Hz 1

Stepping Motor 3108000200 28BYJ48-V2 2

Terminal Block 3108914100 JXO-CH-3P 1

Compressor

3107140100 SHW-33TC4-U 1 DSB-181L/182L

3100068010 AWG5524EXC 1 DSB-182L-R

Fan Motor 3108009100 YDK-50-6B 1

Dual Capacitor 3116901800 3+50µF 400VAC 1

Terminal Block 3118900210 JXO-CH-3P 1

Outdoor

Unit

Indoor

Unit

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108007500 IC-9430DWKG7A 1

Fan Motor Capacitor 3106902400 2uF 400VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Transformer 5EPV050120 DWA220B 1

Stepping Motor 3108007600 GSP-24RW-062 1

Terminal Block 3108914100 JXO-CH-3P 1

Compressor

3100091700 RCA180T001 1 DSA-183L

3100068110 AWG5519EXN 1 DSA-183L-R

Fan Motor 3108000521 IC-1625DWLF6B 1

Dual Capacitor 3116902500 4+25µF 440VAC 1

Terminal Block 3118900210 JXO-CH-2P 1

Indoor

Unit

Outdoor

Unit

◆DSB-123L/DSA-123L

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3118003500 RP13B 1

Fan Motor Capacitor CMXW2G155K 1.5uF, 400VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Stepping Motor 3108003910 24BYJ48-S1 1

Terminal Block 3118900200 JXO-CH-2P 1

Compressor

3100030CE0 RCB120A001 1 DSB-123L

3117148500 QK164KAJ 1 DSA-123L

Fan Motor

3108000800 YDK-40-4B 1 DSB-123L

3118007300 KDK-35-6A 1 DSA-123L

Dual Capacitor

3109500700 3.5+25µF 400VAC 1 DSB-123L

3109502010 2+25µF 400VAC 1 DSA-123L

Terminal Block 3108914100 JXO-CH-3P 1

Outdoor

Unit

Indoor

Unit

Page 53

52

◆DSB-240L-R

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108003800 220/50/60Hz 1

Fan Motor Capacitor 3106902400 2.0uF 400VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Stepping Motor 3108007600 GSP-24RW-062 1

Terminal Block 3108914100 JXO-CH-3P 1

Compressor 3100068201 AWG-5530EXC 1

Fan Motor 3108001500 220V/60Hz 1

Dual Capacitor 3100902500 5/30µF 400VAC 1

Terminal Block 3118900210 JXO-CH-2P 1

Outdoor

Unit

Indoor

Unit

◆DSA-240L/240L-R

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108007500 IC-9430DWKF7A 1

Fan Motor Capacitor 3106902400 2µF 400VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Stepping Motor 3108007600 GSP-24RW-062 1

Terminal Block 3108914100 JXO-CH-3P 1

Compressor

3117147300 55A240IT1JM 1 DSA-240L

3100068300 AWG5524EXN 1 DSA-240L-R

Fan Motor 3108005800 OSME986DERC 1

Dual Capacitor 3109504810 5/35µF 400VAC 1

Terminal Block 3118900210 JXO-CH-2P 1

Outdoor

Unit

Indoor

Unit

◆DSB-183L-R

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108003800 220/50/60Hz 1

Fan Motor Capacitor 3106902400 2.0uF 400VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Stepping Motor 3108007600 GSP-24RW-062 1

Terminal Block 3108914100 JXO-CH-3P 1

Compressor 3100068010 AWG5524EXC 1

Fan Motor 3108009100 YDK-50-6B 1

Dual Capacitor 3116901800 3+50µF 400VAC 1

Terminal Block 3108914100 JXO-CH-3P 1

Outdoor

Unit

Indoor

Unit

◆DSA-181L/182L

PART NAME PART CODE SPEC. QUANTITY REMARK

Fan Motor 3108000311 IC-9625DWKC5C 1

Fan Motor Capacitor 3106900200 1.2uF 450VAC 1

Fuse 5FVLB3152L 250V 3.15A 1

Transformer 5EPV633110 220V, 60Hz 1

Stepping Motor

3108004300 DC 12V, 400mm 2

3108004310 DC 12V, 1300mm 1

Terminal Block 3108912320 JXO-CH-3P 1

Compressor

3107140100 ECB185211A 1

3100068010 RCA180U001 1

Fan Motor 3108009100 YDK-50-6A 1

Dual Capacitor 3116901800 3+35 400VAC 1

Terminal Block 3118900210 JXO-CH-3P 1

Indoor

Unit

Outdoor

Unit

Page 54

53

5. REFRIGERANT CYCLE

INDOOR UNIT

Evaporator

Cross flow fan

Connecting pipe

Capillary tube

Dryer

Condenser

Propeller fan

OUTDOOR UNIT

Refrigerant flow

Service valve

Service valve

Accumulator

Compressor

Note) If the pipe length exceeds the standard length, add 30g of refrigerant per extra meter.

Contents

Model Name

Capillary Tube

Charge Quantity

DSA-123L

IDØ1.6 x L800

860 g

DSB-181L

IDØ2.0 x L650

1,150 g

DSB-182L

IDØ1.8 x L600

1,600 g

DSB-182L-R

IDØ2.0 x L1000

1,350 g

DSA-182L

IDØ1.8 x L600

1,450 g

DSA-183L-R

IDØ2.0 x L800

1,400 g

DSB-183L-R

IDØ2.0 x L1000

1,400 g

DSA-240L-R

IDØ2.0 x L400

1,550 g

Contents

Model Name

Capillary Tube

Charge Quantity

DSB-070L/071L

IDØ1.6xODØ3.2x900L

530 g

DSB-091L/092L

IDØ1.6xODØ3.2x1200L

630 g

DSB-121L/122L

IDØ1.6xODØ3.2x600L

1,310 g

DSB-123L

IDØ1.6xODØ3.2x600L

1,250 g

DSA-181L

IDØ2.0xL1000

1,430 g

DSB-240L-R

IDØ2.0xL500

2,050g

DSA-240L

IDØ2.0xL400

2,100g

Page 55

54

6. CONTROL BLOCK DIAGRAM

Relay RL1

Stepping

Motor

Indoor fan

motor

Compressor

outdoor fan

motor

TRIAC

DC12V

Operating Mode

Fan Speed

Timer Selection

Flap Position

Unit on lamp

Room air temp.

Indoor coil temp.

Air clean lamp

Quick lamp

Remote

Emergency

Operation

Signal

receiver

Timer lamp

A/D converter lnitialization

Clock generation

DC power supply

Circuit for

motor driving

Circuit for

relay driving

Circuit for

TRIAC control

SMPS

Circuit for signal receiver

MICRO

CONTROLLER

Beeper

Temp. Setting

ON/OFF

SLEEP

REMOCON

AC220V

50Hz

STEPPING MOTOR

ON/OFF

COMPRESSOR

ON/OFF

DC5V

◆DSB-071L, 092L, 123L/DSA-123L

Page 56

55

Relay RL1

Stepping

Motor

Indoor fan

motor

Compressor

outdoor fan

motor

TRIAC

DC12V

Operating Mode

Fan Speed

Timer Selection

Flap Position

Unit on lamp

Room air temp.

Indoor coil temp.

Air clean lamp

Quick lamp

Remote

Emergency

Operation

Signal

receiver

Timer lamp

A/D converter lnitialization

Clock generation

DC power supply

Circuit for

motor driving

Circuit for

relay driving

Circuit for

TRIAC control

Transformer

Circuit for signal receiver

MICRO

CONTROLLER

Beeper

Temp. Setting

ON/OFF

SLEEP

REMOCON

AC220V

50Hz

STEPPING MOTOR

ON/OFF

COMPRESSOR

ON/OFF

DC5V

◆DSB-121L/DSB-122L/DSA-181L/DSB-181L/DSB-182L/182L-R/183L-R/DSA-183L-R/

DSA-183L/DSB-240L-R/DSA-240L-R/DSA-240L

Page 57

56

7. TROUBLE SHOOTING

Outdoor unit does

not run?(note. 1)

Does

the compressor run

normally?

Indoor unit does

not run(note 1)

Check the failure

code according to

the self diagnostic

(note 2)

Is the unit

display

mormal?

check the failure

code according to

the self-diagonostic

(note 2)

Normal

check the

connecting

point of

magnetic

contactor

YES

YES

YES

YES

NO

NO

YES

Trouble

Is the power

applied to the

unit

Is the

power normal?

check the voltage between

L & N of terminal

block

press the power ON/OFF

button on remote controller

Does the

beeper beep two

times?

Is the display

all off?

• Check the connector on display

PCB connected to control PCB

• Check the display PCB itself

Check power supply mains

or interconnection wires

Check the wiring of indoor

Is the

switch position

on switch pannel at

"Remote"

Does

control PCB

status LED repeat one

second "on and

off"?

• control PCB fault

• Micom or reset

IC fault

• Check the remote signal receiver

• Check the connection between signal

receiver and control PCB

Place the switch

position to the

"Remote" and then

Check it once

more

YES

NO

YES

NO

NO

NO

NO

YES

YES

YES

YES

YES

NO

NO

NO

Is the

unit display

normal?

Page 58

57

Note 1)

1 Neither indoor unit nor outdoor unit runs.

Check the following points first. (There are following case in normal operation)

a. Is the timer mode set the "timer ON".

b. Is the timer mode set the "timer-OFF" and the time had passed?

2 Neither outdoor fan nor compressor runs while indoor fan runs.

Check following points first. (There are following cases in normal operation)

a. Is the temperature set point suitable?

b. Has the 3 minutes time guard for compressor operated?

• Error Code •

1 When the compressor do not run.

i) Check the voltage between and of terminal block.

(Indoor Unit, Outdoor Unit)

ii) Check connecting wire of indoor unit and outdoor unit.

iii)Check relay RL1 on power P.C.B

2 Check fixing of indoor coil thermistor.

3 Check the GAS LEAKAGE of the pipe.

Y

L

Self-Diagnostic Function

Page 59

58

Confirm following statement.

When the unit operate normally , Sometimes the outdoor unit and indoor unit cannot operate.

1 Check the function select switch. Is it timer mode?

2 The function select switch locate the sleep mode and is the setting time over?

3 Is the setting mode DEHUMIDIFIER mode?

4 When the unit is DEHUMIDIFIER mode while in the auto mode, the outdoor unit and indoor unit does

not run.

The power is applied to the unit

Check the voltge between and

of terminal block

Y

L

Check the

Breaker or Fuse

Self Diagnostic

function is ON

Check according to

self Diagnostic function

Control P.C.B defect

Check the indoor unit display

is the display all off?

Press the ON/OFF switch of

Remote Control

Is the indoor unit display all off?

Pull out the power plug

and then insert the power plug

after 5 second

Control P.C.B is normal

Recheck from the beginning

Rating voltage more than 90%

Rating voltage

under 90%

No No

No

Yes

Yes

Neither Indoor Unit nor Outdoor Unit Runs

Page 60

59

Check rotation of indoor fan

Rotate indoor fan by hand

Check input Voltage of Fan

Motor connector at power P.C.B

Check the winding resistance of

Indoor unit fan motor

Check the fan motor capacitor

Check the connecting wire of

indoor fan motor

Run again

Check the starting of indoor fan motor

Run again

Check the Fan Motor

bearing and fan

Check the power P.C.B.

The circuit for triac control

Change of fan motor

Normal

NO

Rating voltage

under 90%

Open or short

No

YES

Rating Voltage more than 90%

Normal

Outdoor Unit Runs but Indoor Fan Does Not Run

Page 61

60

Confirm following statement.

When the unit operate normally , Sometimes the outdoor unit and indoor unit cannot operate.

1 Is the setting temperature proper?

2 Is the unit during 3min. Time delay of compressor.

3 During frost prevention of lndoor unit.

4 During dehumidifier mode.

Outdoor Fan and Compressor Do Not Run

Check the voltge between and

of indoor unit terminal

Y

L

Check the voltge between and

of outdoor unit terminal

Y

L

Check compressor,

outdoor fan motor individually

Check the

connecting wire

Check the wiring

and voltage

within doors

Rating voltage

under 90%

Rating voltage

under 90%

Page 62

61

- Check the following at cooling mode

Check the voltge between and

of indoor unit terminal

Y

L

Check the voltge between and

of outdoor unit terminal

Y

L

Check the wiring of outdoor unit

Check the compressor

(Check the winding resistance)

Check the compressor capacitor

Check the connecting

wire between indoor

and outdoor.

Change the control

P.C.B

Change the

compressor.

Check the control P.C.B

the circuit for relay

driving.

Rating voltage

less than 90%

NG

Open or Short

Rating voltage

less than 90%

Rating voltage more than 90%

Rating voltage more than 90%

OK

Only Compressor Does not Run

Page 63

PCB DRIVING DESCRIPTION

Page 64

63

1

PCB CIRCUIT DIAGRAM

◆DSB-070L, 071L, 091L, 092L, 123L/DSA-123L

Page 65

64

◆DSB-121L, 122L, 181L, 182L, DSA-181L, 182L

Page 66

◆DSB-183L, 240L, DSA-183L, 240L, DSA-181L

54

Page 67

66

◆DSB-071L, DSB-092L PART LIST (INDOOR UNIT)

PART NAME SPEC QTY LOC.

FUSE 250V 50T 3.15A 1 FUSE

FUSE CLIP AFC-520 2 FUSE

VARISTOR 15G561K 1 VAR

WAFER YW396-05AVD 1 CN2

WAFER YW396-03AVD 1 CN1

C-CERA 104Z,50VDC 5 CC1,2,5,6,7

C-CERA 103Z,50VDC 5 CC3,4,9,10,,12

C-MULTI 104Z,CR0561B-Z5U 1 CC8

C-ELEC 470uF 35V SD 1 CE1

C-ELEC 10uF 450V SD 2 CE3,CE4

C-ELEC 100uF 16V SD 1 CE2

C-ELEC 10uF 16V SS 1 CE5

C-ELEC 4.7uF 50V SS 1 CE6

C-ARRAY F3 104Z 1 CA3

C-ARRAY F4 104Z 1 CA2

C-ARRAY F5 104Z 1 CA1

RESISTOR 1/4W-12.7KF 2 R28,29

RESISTOR 1/4W-1KJ 21

R5,12,13,14,15,16,17,18,19,20,

R21,23,30,31,32,33,34,35,36,37,43

RESISTOR 1/4W-10KJ 1 R11

RESISTOR 1/4W-5.6KJ 1 R22

RESISTOR 1/4W-330J 2 R25,26

RESISTOR 1/4W-100J 2 R1,R4

RESISTOR 1/4W-68KJ 2 R8,R9

RESISTOR 1/4W-51KJ 1 R6

RESISTOR 1/4W-2KJ 1 R7

RESISTOR 1/2W-1KJ 1 R2

RESISTOR 1W-47J 1 R3

RESISTOR 1/4W-3.24KF 1 R41

RESISTOR 1/4W-24.9KF 1 R39

RESISTOR ARRAY 4A 103J 1 RA3

RESISTOR ARRAY 5A 103J 1 RA2

RESISTOR ARRAY 6A 103J 1 RA1

C-LINE ACROSS 275V 104K 2 CL1,CL2

WAFER SMAW250-06(WHITE) 1 CN6

WAFER SMAW250-08 1 CN5

WAFER YMAW250-04 1 CN7

DIODE 1N4007 TAPE 1 D3

DIODE UF203 1 D2

DIODE ZENOR 1N5241B 1 ZD1

DIODE ST01D-200 1 D1

C-CERA 2200pF, 250V 1 CY1

CHOKE COIL 1mH, 0.5A 1 L1

FILTER EMI 0.6*10*3TURN 1 L2

BUZZER BM-20K 1 BZ1

COIL 130uH, 3A 1 L3

IC REGULATOR KIA7805P 1 IC3

TR KRC102M 1 TR1

IC RESET KIA7042P 1 IC5

RELAY UKH-12S 1 RL1

SW TRANS 264P,1916 1 TRS1

CAPACITOR 1uF,400VAC 1 CAP1

PCB CONTROL 162.5X140X1.6T 1 PCB

IC SWITCHING TNY264P 1 IC2

DIODE BRIDGE S1NB80 1 BD1

TRIAC SM3JZ47 1 T1

PHOTO COUPLER TLP560J 1 PT1

IC DRIVE TD62004AP 2 IC4,IC6

RESONATOR CST8.00MGW 1 OSC

IC MICOM TMP87C846AN 1 IC1

PHOTO COUPLER TLP421 2 PC1,PC2

Page 68

67

◆DSB-123L PART LIST (INDOOR UNIT)

PART NAME SPEC QTY LOC.

FUSE 250V 50T 3.15A 1 FUSE

FUSE CLIP AFC-520 2 FUSE

VARISTOR 15G561K 1 VAR

WAFER YW396-05AVD 1 CN2

WAFER YW396-03AVD 1 CN1

C-CERA 104Z,50VDC 5 CC1,2,5,6,7

C-CERA 103Z,50VDC 5 CC3,4,9,10,12

C-MULTI 104Z,CR0561B-Z5U 1 CC8

C-ELEC 470uF 35V SD 1 CE1

C-ELEC 10uF 450V SD 2 CE3,CE4

C-ELEC 100uF 16V SD 1 CE2

C-ELEC 10uF 16V SS 1 CE5

C-ELEC 4.7uF 50V SS 1 CE6

C-ARRAY F3 104Z 1 CA3

C-ARRAY F4 104Z 1 CA2

C-ARRAY F5 104Z 1 CA1

RESISTOR 1/4W-12.7KF 2 R28,29

RESISTOR 1/4W-1KJ 22

R5,12,13,14,15,16,17,18,19,20,21,

R23,30,31,32,33,34,35,36,37,43,44

RESISTOR 1/4W-10KJ 1 R11

RESISTOR 1/4W-5.6KJ 1 R22

RESISTOR 1/4W-330J 2 R25,26

RESISTOR 1/4W-100J 2 R1,R4

RESISTOR 1/4W-68KJ 2 R8,R9

RESISTOR 1/4W-51KJ 1 R6

RESISTOR 1/4W-2KJ 1 R7

RESISTOR 1/2W-1KJ 1 R2

RESISTOR 1W-47J 1 R3

RESISTOR 1/4W-8.45KF 1 R41

RESISTOR 1/4W-11.1KF 1 R39

RESISTOR ARRAY 4A 103J 1 RA3

RESISTOR ARRAY 5A 103J 1 RA2

RESISTOR ARRAY 6A 103J 1 RA1

C-LINE ACROSS 275V 104K 2 CL1,CL2

WAFER SMAW250-06(WHITE) 1 CN6

WAFER SMAW250-08 1 CN5

WAFER YMAW250-04 1 CN7

DIODE 1N4007 TAPE 1 D3

DIODE UF203 1 D2

DIODE ZENOR 1N5241B 1 ZD1

DIODE ST01D-200 1 D1

C-CERA 4700pF, 250V 2 CY1,CY2

CHOKE COIL 1mH, 0.5A 2 L1,L2,L4

BUZZER BM-20K 1 BZ1

COIL 130uH, 3A 1 L3

IC REGULATOR KIA7805P 1 IC3

TR KRC102M 1 TR1

IC RESET KIA7042P 1 IC5

RELAY UKH-12S 1 RL1

SW TRANS 264P,1916 1 TRS1

CAPACITOR 1.5uF,400VAC 1 CAP1

PCB CONTROL 165.5X140X1.6T 1

IC SWITCHING TNY264P 1 IC2

DIODE BRIDGE S1NB80 1 BD1

TRIAC SM3JZ47 1 T1

PHOTO COUPLER TLP560J 1 PT1

IC DRIVE TD62004AP 2 IC4,IC6

RESONATOR CST8.00MGW 1 OSC

IC MICOM TMP87C846AN 1 IC1

PHOTO COUPLER TLP421 2 PC1,PC2

Page 69

◆183L-R/DSA-183L-R/DSB-240L-R/DSA-240L-R PART LIST(INDOOR UNIT)

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

BZ1 3105698200 BUZZER DP-2520BA 1 EA

CA1 CN5XD104M- C-ARRAY F5 104Z 1 EA

CA2 CN4XD104M- C-ARRAY F4 104Z 1 EA

CA3 CN3XD104M- C-ARRAY F3 104Z 1 EA

CC 3108803500 PIN GP881206-2(250) 1 EA

CC1 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC10 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC11 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC13 CDXE1H104M C-MULTI CR501B-Z5U,104Z,50V 1 EA

CC2 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC3 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC4 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CC5 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CC6 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CC7 CCXE1H103M C-CERA 103Z 50VDC 1 EA

183LH-R,240LH-R

CC8 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC9 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CE1 CEXE1V108C C-ELEC 1000MF 35V SD 1 EA

CE2 CEXE1E477C C-ELEC 470MF 25V SD 1 EA

CE3 CEXE1C107C C-ELEC 100MF 16V SD 1 EA

183LH-R,240LH-R

CE4 CEXE1C475A C-ELEC 4.7MF 50V SS 1 EA

CE5 CEXE1C106A C-ELEC 10MF 16V SS 1 EA

CL 3108803500 PIN GP881206-2(250) 1 EA

CL1 CLV-B3104M C-LINE ACROSS 275V 104K(PILKOR) 1 EA

CL2 CLV-B3104M C-LINE ACROSS 275V 104K(PILKOR) 1 EA

CLIP 3107000600 FUSE CLIP AFC-520 2 EA

CN1 3108803900 WAFER YW396-05AV(RED) 1 EA

CN10 3108801100 WAFER 5267-02A 1 EA

183LH-R,240LH-R

CN11 3108804000 WAFER SMAW250-08 1 EA

CN13 3108802000 WAFER SMW250-06(WHITE) 1 EA

CN2 3108803800 WAFER YFW800-02 1 EA

CN3 3108802900 WAFER YW396-05AV 1 EA

CN4 3108802500 WAFER YW396-03AV 1 EA

CN6 3108800320 WAFER 5281-02A 1 EA

CN7 3108803400 PIN GP881205-2(187) 1 EA

CN8 3108803600 WAFER YFW800-01 1 EA

CN9 3108804500 WAFER 5267-04A 1 EA

D1 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D2 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D3 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D4 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D5 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D6 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

FUSE 5FVLB3152L FUSE GLASS TUBE 250V/50T 3.15A 1 EA

HS1 3105797200 HEAT SHINK 22(H)*23*17 1 EA

IC1 13GS1H13-- IC MICOM TMP87C846-1H13 1 EA

IC2 1KA7812AP- IC REGULATOR KIA 7812AP 1 EA

IC3 1KA7805AP- IC REGULATOR KIA 7805AP TO-220IS 1 EA

IC4 1KD65004AP IC DRIVER KID65004AP 1 EA

68

Page 70

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

IC5 1KA7042P-- IC RESET KIA7042P 5L 1 EA

IC6 1KD65004AP IC DRIVER KID65004AP 1 EA

L1 52C1374001 COIL 130UH 3A 1 EA

OSC 4850103610 RESONATOR CST8.00MTW,8MHZ 1 EA

PCB 3104398102 PCB CONTROL 160.5*140*1.6T.1(42) 1 EA

PT1 1TLP560J-- IC PHOTO COUPLER TLP 560J 1 EA

R-OPT 3104810000 RESISTOR OPTION NOTE OPTION TABLE 1 ST

R1 RD-4K101J- R CARBON FILM 1/4 100 OHM J 1 EA

R10 RN-4K1272F R METAL FILM 1/4 12.7K OHM F 1 EA

R11 RN-4K1272F R METAL FILM 1/4 12.7K OHM F 1 EA

R12 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R13 RD-4K562J- R CARBON FILM 1/4 5.6K OHM J 1 EA

R14 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R15 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R16 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R17 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R18 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R19 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R2 RD-4K562J- R CARBON FILM 1/4 5.6K OHM J 1 EA

R20 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R21 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R23 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R24 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R25 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R26 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R27 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R28 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R29 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R3 RD-4K103J- R CARBON FILM 1/4 10K OHM J 1 EA

R30 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R31 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R32 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R38 RS01F121J- R M-OXIDE FILM 1W 120 OHM J 1 EA

R4 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R5 RD-2K102J- RESISTOR 1/2W - 1K 1 EA

R6 RD-4K331J- R CARBON FILM 1/4 330 OHM J 1 EA

R7 RD-4K331J- R CARBON FILM 1/4 330 OHM J 1 EA

R8 RD-4K331J- R CARBON FILM 1/4 330 OHM J 1 EA

183LH-R,240LH-R

R9 RN-4K1272F R METAL FILM 1/4 12.7K OHM F 1 EA

183LH-R,240LH-R

RA1 RA8K5103J- RESISTOR ARRAY 6A 103J 1 EA

RA2 RA8K4103J- RESISTOR ARRAY 5A 103J 1 EA

RA3 RA8K3103J- RESISTOR ARRAY 4A 103J 1 EA

RL1 5SC0101220 RELAY UKH-12SP 1 EA

RL1 5SC0101128 RELAY CS11-12SH 1C 1P 1 EA 183L-R/LH-R,240L-R/LH-R

RL2 5SC0101128 SW RELAY CS11-12SH 1C 1P 1 EA

RL3 5SC0101128 SW RELAY CS11-12SH 1C 1P 1 EA

SCRW 7122401211 SCREW TAPPING T2S TRS 4*12 MFZN 1 EA

T1 TSM3JZ47-- TRIAC SM3JZ47 1 EA

TEST 3108804300 WAFER YF254S-02 1 EA

TR1 TKRC102M-- TR KRC 102-M (TAPPING) 1 EA

VAR D15G561K-- VARISTOR 15G561K/350V 1 EA

WSHR 3106002900 WASHER 3*6 1 EA

69

Page 71

◆CONTROL PCB ASS`Y (MODEL : 122L/LH,182L/L-R/LH/LH-R)

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

CA1 CN4XD104M- C-ARRAY F4 104Z 1 EA

CA2 CN3XD104M- C-ARRAY F3 104Z 1 EA

CC1 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC10 CCXE1H103M C-CERA 103Z 50VDC 1 EA 122LH,182LH/LH-R

CC13 CDXE1H104M C-MULTI CR501B-Z5U,104Z,50V 1 EA

CC2 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC3 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CC4 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CC5 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CC6 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CC7 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC8 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CC9 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CE1 CEXE1C475A C-ELEC 4.7MF 50V SS 1 EA

CE2 CEXE1C106A C-ELEC 10MF 16V SS 1 EA

CN1 3108802400 WAFER SMAW250-10 1 EA

CN2 3108804100 WAFER SMW250-07 1 EA

CN3 3108804200 WAFER SMW250-02 1 EA

CN4 3108802010 WAFER SMW250-06(RED) 1 EA 182L/L-R/LH/LH-R

CN5 3108802000 WAFER SMW250-06(WHITE) 1 EA

CN6 3108802000 WAFER SMW250-06(WHITE) 1 EA 182L/L-R/LH/LH-R

CN7 3108801100 WAFER 5267-02A 1 EA 182L/L-R/LH/LH-R

CN8 3108804500 WAFER 5267-04A 1 EA

D1 DZN4148FTB DIODE 1N4148 AUTO 26MM 1 EA 182L/L-R/LH/LH-R

F1 52F6010100 FILTER EMI 0.6*10*3TUTN 1 EA 182LH/LH-R

IC1 13GS1H13-- IC MICOM TMP87C846-1H13 1 EA

IC2 1KA7042P-- IC RESET KIA7042P 5L 1 EA

IC3 1KD65004AP IC DRIVER KID65004AP 1 EA

IC4 1KD65004AP IC DRIVER KID65004AP 1 EA

OSC1 4850103610 RESONATOR CST8.00MTW,8MHZ 1 EA

PCB 3104397162 PCB CONTROL 110*90.5*1.6T(99) 1 EA

R-OPT 3104810000 RESISTOR OPTION NOTE OPTION TABLE 1 ST

R1 RD-4K103J- R CARBON FILM 1/4 10K OHM J 1 EA

R10 RD-4K562J- R CARBON FILM 1/4 5.6K OHM J 1 EA

R11 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R12 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R13 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R14 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R16 RD-4K103J- R CARBON FILM 1/4 10K OHM J 1 EA

R17 RD-4K103J- R CARBON FILM 1/4 10K OHM J 1 EA 182L/L-R/LH/LH-R

R18 RN-4K1272F R METAL FILM 1/4 12.7K OHM F 1 EA

R19 RD-4K331J- R CARBON FILM 1/4 330 OHM J 1 EA

70

Page 72

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

R2 RD-4K103J- R CARBON FILM 1/4 10K OHM J 1 EA

R20 RN-4K1272F R METAL FILM 1/4 12.7K OHM F 1 EA

R21 RD-4K331J- R CARBON FILM 1/4 330 OHM J 1 EA

R22 RN-4K1272F R METAL FILM 1/4 12.7K OHM F 1 EA 122LH,182LH/LH-R

R23 RD-4K331J- R CARBON FILM 1/4 330 OHM J 1 EA 122LH,182LH/LH-R

R26 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R3 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R32 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R33 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R34 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R4 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R5 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R6 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R7 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R8 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R9 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

RA1 RA8K5103J- RESISTOR ARRAY 6A 103J 1 EA

RA2 RA8K3103J- RESISTOR ARRAY 4A 103J 1 EA

TEST 3108804300 WAFER YF254S-02 1 EA

TR1 TZTC3198Y- TRANSISTOR KTC3198Y-(1815Y) 1 EA 182L/L-R/LH/LH-R

TR2 TKRC102M-- TR KRC 102-M (TAPPING) 1 EA 182L/L-R/LH/LH-R

71

◆R-OPT. DETAIL LIST

MODEL R28 R30 MODEL R41 R39 MODEL R33 R35

DSB-121L, 122L 2.87 K 28.0 K DSB-070L, 071L

3.24 K 24.9 K

DSB-183L, 240L 5.76 K 12.4 K

DSB-181L, 182L 3.65 K 22.6 K DSB-091L, 092L DSA-183L, 240L 0.332 K 1.78 K

DSA-181L, 182L 1.47 K 6.34 K

Page 73

◆POWER PCB ASS`Y (MODEL : 122L/LH,182L/L-R/LH/LH-R)

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

BZ1 3105698200 BUZZER DP-2520BA 1 EA

C1 CLV-B3104M C-LINE ACROSS 275V 104K(PILKOR) 1 EA

C2 CLV-B3104M C-LINE ACROSS 275V 104K(PILKOR) 1 EA

CC 3108803500 PIN GP881206-2(250) 1 EA

CC1 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC2 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC3 CCXE1E104M C-CERA 104Z 25VDC 1 EA

CC4 CCXE1H103M C-CERA 103Z 50VDC 1 EA

CE1 CEXE1V108C C-ELEC 1000MF 35V SD 1 EA

CE2 CEXE1E477C C-ELEC 470MF 25V SD 1 EA

CE3 CEXE1C107C C-ELEC 100MF 16V SD 1 EA

CL 3108803500 PIN GP881206-2(250) 1 EA

CLIP 3107000600 FUSE CLIP AFC-520 2 EA

CN1 3108803900 WAFER YW396-05AV(RED) 1 EA

CN2 3108803800 WAFER YFW800-02 1 EA

CN3 3108802900 WAFER YW396-05AV 1 EA

CN4 3108802500 WAFER YW396-03AV 1 EA

CN5 3108802800 WAFER YW396-04AV(BLUE) 1 EA 082H,102H,122H

CN6 3108802100 WAFER SMW250-10 1 EA

CN7 3108800320 WAFER 5281-02A 1 EA

CN8 3108803400 PIN GP881205-2(187) 1 EA 122LH,182LH/LH-R

CN9 3108803600 WAFER YFW800-01 1 EA 122LH,182LH/LH-R

D1 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D2 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D3 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D4 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D5 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

D6 DZN4004A-- DIODE KN4004A AUTO 52MM 1 EA

FUSE 5FVLB3152L FUSE GLASS TUBE 250V/50T 3.15A 1 EA

HS1 3105797200 HEAT SHINK 22(H)*23*17 1 EA

IC1 1KA7812AP- IC REGULATOR KIA 7812AP 1 EA

IC2 1KA7805AP- IC REGULATOR KIA 7805AP TO-220IS 1 EA

L1 52C1374001 COIL 130UH 3A 1 EA

PCB 3104396142 PCB POWER 130*81*1.6T(84) 1 EA

PT1 1TLP560J-- IC PHOTO COUPLER TLP 560J 1 EA

R1 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R2 RD-4K103J- R CARBON FILM 1/4 10K OHM J 1 EA

R3 RD-4K562J- R CARBON FILM 1/4 5.6K OHM J 1 EA

R4 RD-2K102J- RESISTOR 1/2W - 1K 1 EA

R5 RD-4K101J- R CARBON FILM 1/4 100 OHM J 1 EA

R6 RD-4K102J- R CARBON FILM 1/4 1K OHM J 1 EA

R7 RS01F121J- R M-OXIDE FILM 1W 120 OHM J 1 EA

RL1 5SC0101220 RELAY UKH-12SP 1 EA 122L/LH,082M/H

RL1 5SC0101220 SW RELAY CS11-12SH 1C 1P 1 EA

RL2 5SC0101128 SW RELAY CS11-12SH 1C 1P 1 EA 122LH,182LH/LH-R

RL3 5SC0101128 SW RELAY CS11-12SH 1C 1P 1 EA 122LH,182LH/LH-R

RL4 5SC0101128 SW RELAY CS11-12SH 1C 1P 1 EA 082H,102H,122H

SCRW 7122401211 SCREW TAPPING T2S TRS 4*12 MFZN 1 EA

T1 TSM3JZ47-- TRIAC SM3JZ47 1 EA

TR1 TKRC102M-- TR KRC 102-M (TAPPING) 1 EA

VAR D15G561K-- VARISTOR 15G561K/350V 1 EA

WSHR 3106002900 WASHER 3*6 1 EA

72

Page 74

◆LED PCB ASS`Y (MODEL : 070L/LH, 071L/LH, 091L/LH,092L/LH)

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

CC1 CDXE1H104M C-MULTI CR501B-Z5U,104Z,50V 1 EA

CN1 3108804800 WAFER SMAW250-08 1 EA

HOLD 3103002700 HOLDER LED ABS 1 EA

L1 DDLS05031D LED DLSO-5031D(RED) 1 EA

L2 DDLG05031D LED DLG-5031D(GRN) 1 EA

L3 DDLS05031D LED DLSO-5031D(RED) 1 EA

L4 DDLY05031D LED DLY-5031D(YLW) 1 EA

PCB 3104398201 PCB LED 110*31*1.6T.10(288) 1 EA

RCV 1TSP1838YA RECEIVER MODULE TSOP-1838YA1(HOLDER) 1 EA

SW1 5S40202000 S/W PUSH JPS2281 1 EA

◆LED PCB ASS`Y (MODEL : 123L, 183L-R/LH-R, 240L-R/LH-R)

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

CC1 CDXE1H104M C-MULTI CR501B-Z5U,104Z,50V 1 EA

CN1 3108804800 WAFER SMAW250-08 1 EA

HOLD 3103004100 HOLDER LED 1 EA

L1 DDLS05031D LED DLSO-5031D(RED) 1 EA

L2 DDLG05031D LED DLG-5031D(GRN) 1 EA

L3 DDLS05031D LED DLSO-5031D(RED) 1 EA

L4 DDLY05031D LED DLY-5031D(YLW) 1 EA

PCB 3104398202 PCB LED 150*24.5*1.6T(240) 1 EA

RCV 1TSP1838YA RECEIVER MODULE TSOP-1838YA1(HOLDER) 1 EA

SW1 5S40202000 S/W PUSH JPS2281 1 EA

◆LED PCB ASS`Y (MODEL : 122L/LH,121L)

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

CC1 CXCH1H103M C CERA 103J/50 20% 1 EA

CN1 3108804600 WAFER SMAW250-07 1 EA

HOLD 3103001900 LED HOLDER ABS(VO) T2.0 1 EA

L1 DDSR302D-- LED DLSR-302D(RED) 1 EA

L2 DDLG302D-- LED DLG-302D 1 EA

L3 DDSR302D-- LED DLSR-302D(RED) 1 EA

L4 DDLY302D-- LED DLY-302D 1 EA

PCB 3104397402 LED PCB 72*50*1.6T(247) 1 EA

RCV 1TSP1838YA RECEIVER MODULE TSOP-1838YA1(HOLDER) 1 EA

◆LED PCB ASS`Y (MODEL : 182L/L-R/LH/LH-R,151L/LH,181L)

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

CC1 CXCH1H103M C CERA 103J/50 20% 1 EA

CN1 3108804600 WAFER SMAW250-07 1 EA

HOLD 3103001100 LED HOLDER ABS (BLK) 1 EA

L1 DDSR302D-- LED DLSR-302D(RED) 1 EA

L2 DDLG302D-- LED DLG-302D 1 EA

L3 DDSR302D-- LED DLSR-302D(RED) 1 EA

L4 DDLY302D-- LED DLY-302D 1 EA

PCB 3104395412 LED PCB 67.5*40*1.6T(350) 1 EA

RCV 1TSP1838YA RECEIVER MODULE TSOP-1838YA1(HOLDER) 1 EA

◆SWITCH PCB ASS`Y (MODEL : 182L/L-R/LH/LH-R, 181L)

No PART CODE PART NAME SPEC Q'TY UNIT REMARK

CN1 3108804700 WAFER SMAW250-02 1 EA

PCB 3104395311 S/W PCB 36*29.5*1.6T(891) 1 EA

SW1 5S30101330 SWITCH SLIDE KSA-2340B 1 EA

73

Page 75

74

Power Supply(1)

DESCRIPTION

DC Power Supply in circuit needs +12V and +5V . +12V is used for Compressor Driving Relay, Triac Driving

Photo Triac, Buzzer Driving Swing, Sweep Motor . AC voltage of secondary Power T ransformer is rectified by

Bridge Diode, and it is filtering by Main Condensor CE1.

Filtered DC voltage is about +18V , is regulated +12V DC by Regulator IC7812.

And it is regulated +5V DC by Regulator IC7805.

V AR is serge filter and CC1, CC2, CC3 is Noise filter .

AC 220V

CL1

275V

104K

VAR

FUSE1

3.15A

POWER TRANS

D2

CC1 CE1

D3

D1

D4

104

+

35V

1000µF

IC2

7812

VI VO

G

IC3

7805

VI VO

G

+

25V

470µF

CC2 CC3 CE3CE2

104

+

16V

100µF

104

12V 5V

Oscillator(2)

19

OSC

CC13

104

5V

8M

20

Page 76

75

Room temperature and Evaporator temperature Sensor Input

DESCRIPTION

Number 24, 25 of Micom is Terminal of A/D convertor Input.

Room temperature and Evaporator temperature is sensing by change of Thermister Resistance, Micom is put

in 5V by ratio between R10 (12.7KΩ) and R1 1 (12.7KΩ).

Relation between temperature and voltage is following Table 3-1.

CC5, 6 is Noise filter.

Temperature

(°C)

No. 1 No. 3

-5 1.127 1.127

0 1.378 1.378

5 1.650 1.650

10 1.936 1.936

15 2.228 2.228

Voltage (V)

Table 3-1

Sensor(3)

070LH,091LH

182LH, 240LH

O/C SENSOR

I/C SENSOR

ROOM SENSOR

CN10

330 R8

R7R6330

330

CC5

103

R9

12.7kF

CC7

103

103

CC6

23

24

25

MICOM

CN9

R10

12.7KF

R11

12.7KF

VDD-10%

V

SS+10%

Fig 2-1

DESCRIPTION

Oscillatory Frequency drive Micom, it is made up 8MHz resonator oscillatory Freqency.

Ocillatory wave is as following Fig 2-1.

Page 77

76

T riac Driving(4)

DESCRIPTION

Number 38 Terminal of Micom is put out Pulse Output, by way of Buffer it is driving Photo Triac is supplied

Trigger Signal.

Trigger Test of T riac is detected Zero Cross Part of AC input and it is triggered from Zero Cross part to Time

delay part according to Fan Speed. (Ref. Fig 4-1) SN1 is Snubber.

N

L

AC 220V

TO MOTOR

T1

SM3JZ47

L1

12

130µH

3A

SN1

0.1µF

120Ohm

TLP561

PT1

12V

R5

1K

1/2W

IC4

KID 65004

MICOM

38

215

AC220V

TRIGGER

MOTOR

INPUT

LOW SPEED MEDIUM SPEED HIGH SPEED

Fig 4-1

LOW SPEED

MEDIUM SPEED

HIGH SPEED

Page 78

77

DESCRIPTION

Signal from Remote Controller put in only Control Data Signal at Micom T erminal of Number 33, which is gotten

fid of Carrier (38KHz) from Receive Module. Signal Wave repeat third as following Fig 5-1.

But in Secondary Wave Custom Code is Reversed Face.

LEADER CODE

CUSTOM

CODE

DATA

CODE

CHECK

SUM

TAILER

9ms 4.5ms 16bit 16bit24bit 8bit

Fig 5-1

Fig 5-2

BIT STRUCTURE

Remote Controller(5)

0.56ms 0.56ms1.69ms

1.12ms 2.25ms

bit 0 bit 1

Selecting Mode(6)

(SELECT S/W INPUT, OUTPUT)

MICOM

13

R14

1K

RA1

5V

CA1

F4104Z

P2

MODE

SELECT

PUSH S/W

DESCRIPTION

There are Mode according to SW position as

following Table 6-1.

According as port of fixed Micom is Low, the unit is

operating as following Table 6-1.

Table 6-1

POSITION MODE

OPEN REMOCON

GND EMERGENCY

Page 79

78

DESCRIPTION

MICOM Power is supplied 5V at Number 42 using VDD, Number 19, 20 Vsing Oscillator, CC13 is noise filter .

Micom Power Supply(7)

VDD 42

CE5

10µF

16V

CC11

104

CC13

104

+

5V

41

40

39

22

21

19

OSC

8MHz

20

VSS

MICOM

Page 80

79

DESCRIPTION

Voltage less than about 0.8V put in Micom Terminal of Number 18 and then Micom reset. Reset IC detect

Power ON and Voltage less than 4.25V, and then send Reset Signal.

Reset(8)

R13 5.6K

1K R12

18

CC9

CE4

4.7uF/50V

IC5

7042P

10.3

MICOM

4.25V

H

L

t

t

POWER

ON

Vcc (+5V)

DELAY TIME

FOR POWER ON

RESET

Page 81

80

DESCRIPTION

Micom 34 Terminal put out Buzzer Driving Pulse,

its output is driving Buzzer through Buffer.

Ocillatory Frequency of buzzer is selected by

internal Micom.

This unit is setting at 4KHz.

VCC

12V

KID 65004

MICOM

34

611

R4

1K

BZ1

Buzzer Driving(10)

DESCRIPTION

* When power source is put at fist, Funtion selection input is recognized.

And when the unit is running the microcomputer ignore variation of funtion selection input.

model

JS3

JS2

JS1

1K

14

15

16

30

29

28

41

40

39

27

26

1K

1K

1K

1K

JS5

JS4

1K

1K

1K

1K

1K

R28

R32

R31

R30

R25

R24

R23

R35

R34

R33

R37

R29

1K

R17

MICOM

R16

R15

CA2

CA1

F5 104Z

RA1 R36

heat/low

heat/high

cool/low

MILD/HIGH

HEAT/COOL

cool/high

monitoring

6A

RA3

RA3

4A 103J

CA3

F3 104Z

103J

RA2

Function Selecting(9)

Page 82

81

DESCRIPTION

It defect Zero Cross part of Trans output voltage, Transistor TR1 is used to put in the Micom.

Detail Driving is as following Fig 11-1.

R19 is Resistance to limit current.

MICOM

TRANS

OUTPUT

D5

D6

R2

5.6K

12

CC4

103

TR1

KRC120M

12 1

23

21

R3

10K

R27

1K

VCC

31

DETECT POINT

H

The

Number

31 of

Micom

terminal

AC18V

L

Fig 11-1

Zero Crossing Detect(11)

Page 83

82

DESCRIPTION

There are one Stepping Motor for Flap (up and down) and it is used 4 face Drive Method.

It is driving as following Fig 12-1. (Ring Count Method of 8 Status)

Ø 4

Ø 3

Ø 2

Ø 1

B

+

6

5

4

3

2

1

12V

IC6

KID65004

CN13

1

MICOM

2

3

4

M1

FOR SWING

Fig 12-1

(Normal Rotating) (Reversed Rotating)

Stepping Motor Driving(12)

Ø 4

Ø 3

Ø 2

Ø 1

Page 84

ERROR

No

ERROR

No

ERROR

No

No

No

No

Yes

Select ON/OFF button

Select Mode button

Select FAN SPEEDbutton

Select FAN DIR. button

Power Supply

TEST ST ART

Power supply again

Check the Following

BA TTER Y SPRING

MICOM

PCB

LCD

Is Display at the

beginning ON?

Is Display at the

beginning ON?

Is it normal?

Is it normal?

Is it normal?

2

REMOTE CONTROLLER ASSMBLY FUNCTIONAL TEST METHOD

83

ERROR

No

ERROR

No

(Whenever you selectted Temp.

Button, it is changed by 1°C (18~32°C)

▲

( ▼)

Select TEMP. Button (▲,▼)

Select ON/OFF button

Is display at the

begining ON?

Is it normal?

Page 85

84

(0.5~24 HOUR)

ERROR

No

Select TIMER ON Button

Select Timer Enter Button

Select CANCEL Button

Select ON/OFF Button

Select OFF (Timer) Button

Select SLEEP Button

Select SLEEP Button

TEST OK!

Is LCD display OFF?

Is it normal

display?

TIMER

Is all display OFF?

Is it normal?

SLEEP MODE

Display ON?

Is display at the

beginning ON?

ERROR

No

ERROR

No

ERROR

No

ERROR

No

ERROR

No

ERROR

No

Page 86

85

(1) U1 (MICOM)

1