Daewoo D35S-2, D40S-2, D45S-2, D45SC-2, D40SC-2 Disassembly/assembly

...

Disassembly &

Assembly

Lift Trucks Vehicle Systems

D35S-2, D40S-2, D45S-2

D40SC-2, D45SC-2, D50SC-2

G35S-2, G40S-2, G45S-2

G40SC-2, G45SC-2, G50SC-2

SB2204E00

Jun. 1999

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety

rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an

accident occurs. A person must be alert to potential hazards. This person should also have the necessary

training, skills and tools to perform these functions properly.

Read and understand all safety precautions and warnings before operating or performing lubrication,

maintenance and repair on this product.

Basic safety precautions are listed in the ÒSafetyÓ section of the Service or Technical Manual. Additional safety

precautions are listed in the ÒSafetyÓ section of the owner/operation/maintenance publication.

Specific safety warnings for all these publications are provided in the description of operations where hazards

exist. WARNING labels have also been put on the product to provide instructions and to identify specific hazards.

If these hazard warnings are not heeded, bodily injury or death could occur to you or other persons. Warnings in

this publication and on the product labels are identified by the following symbol.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and

understood the operation, lubrication, maintenance and repair information.

Operations that may cause product damage are identified by NOTICE labels on the product and in this

publication.

DAEWOO cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in

this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or operating

technique not specifically recommended by DAEWOO is used, you must satisfy yourself that it is safe for you and

others. You should also ensure that the product will not be damaged or made unsafe by the operation, lubrication,

maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product. Obtain the complete

and most current information before starting any job. DAEWOO dealers have the most current information

available.

WARNING

1

Vehicle Systems Index

Index

Brake Hydraulic Booster..........................................21

Counterweight..........................................................36

Engine......................................................................39

Hood Assembly..........................................................5

Hydraulic Control Valve ...........................................27

Hydraulic Oil Filter Assembly...................................37

Hydraulic Pump .......................................................33

Overhead Guard ........................................................6

Primary Lift Cylinder ................................................12

Secondary Lift Cylinders............................................9

Steer Axle ................................................................23

Steering Cylinder .....................................................24

Steering Knuckles, Kingpins And Bearings .............22

Steering Unit ............................................................15

Steering Wheel ........................................................15

Tie Rods...................................................................21

Tilt Cylinders ..............................................................7

Tires And Rims (Steer) ............................................26

Transaxle .................................................................37

3

Vehicle Systems Disassembly & Assembly5

Disassembly & Assembly

Hood (with seat) Assembly

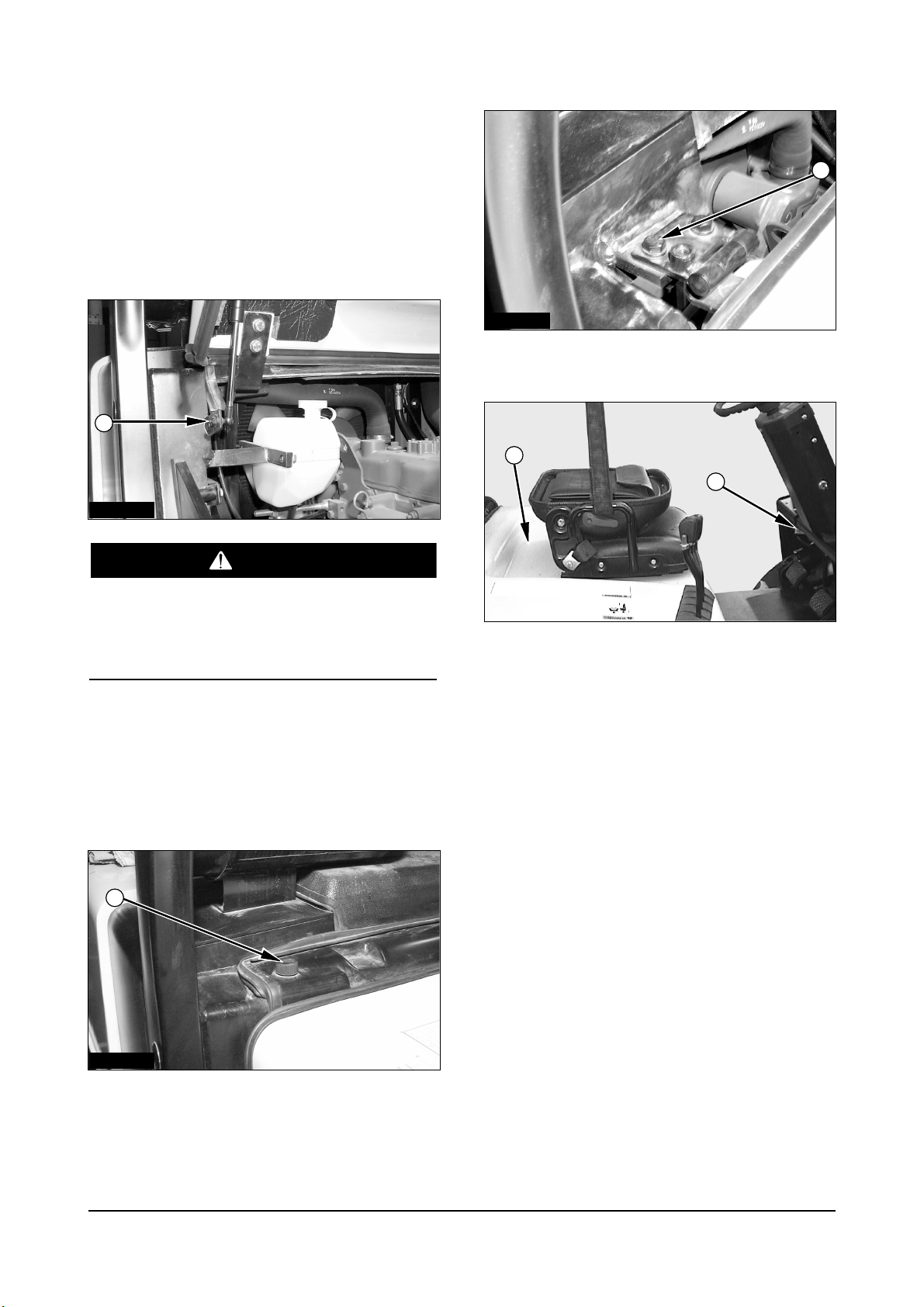

Remove & Install Hood (with seat)

Assembly

The hood and seat assembly can fall when nut (1)

is removed from the support cylinder rod. To avoid

personal injury, support the seat and hood

assembly before removing nut (1).

1. Raise the hood. Support the hood with a hoist.

2. Remove nut (1) from the support cylinder. Remove

the cylinder rod from the bracket.

3. Lower the hood.

4. Remove the bolts (2) from the cover. Remove

cover.

5. Remove the washers and four bolts (3).

6. Release latch (5). Use the hoist to remove hood

and seat assembly (4). The hood and seat

assembly weighs 52 kg (115 lb).

7. Install the hood and seat assembly in the reverse

order of removal.

IACD201P

IACD202P

IDCD054P

IACD203P

1

3

5

4

2

WARNING

Vehicle Systems Disassembly & Assembly

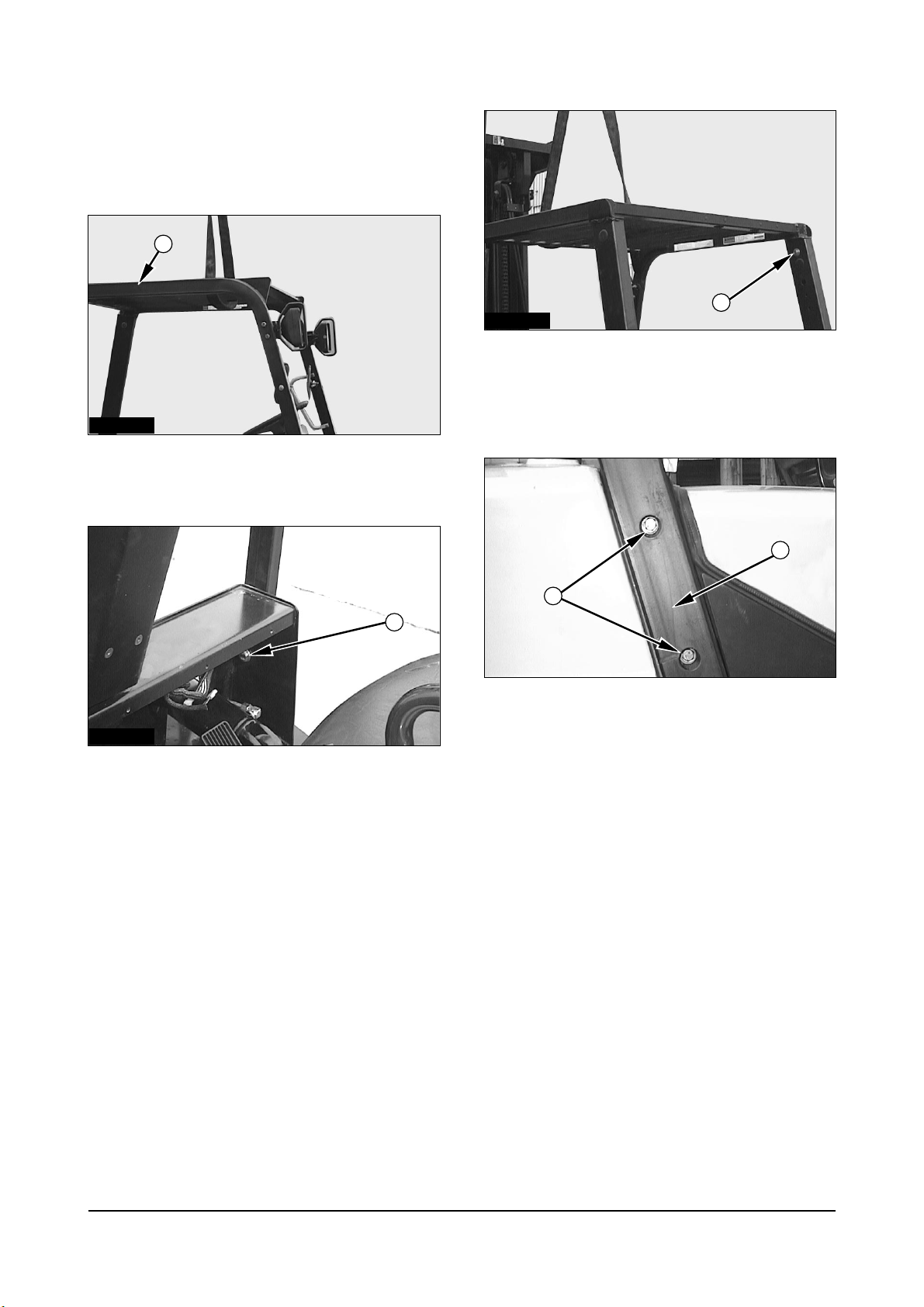

Overhead Guard

Remove & Install Overhead Guard

1. Support overhead guard (1) with lifting straps and

a hoist.

2. Remove the washers, nuts, and two bolts (2).

3. Remove the washers, nuts, and two bolts (3).

4. Remove front overhead guard (1), Front overhead

guard (1) weighs 30 kg (66 lb).

5. Remove the washers, nuts, and four bolts (4).

6. Remove rear Leg (5).

7. Install front overhead guard (1) and rear leg (5) in

the reverse order of removal.

6

IDCD055P

IDCD056P

IDCD057P

IDCD058P

1

3

4

5

2

Vehicle Systems Disassembly & Assembly

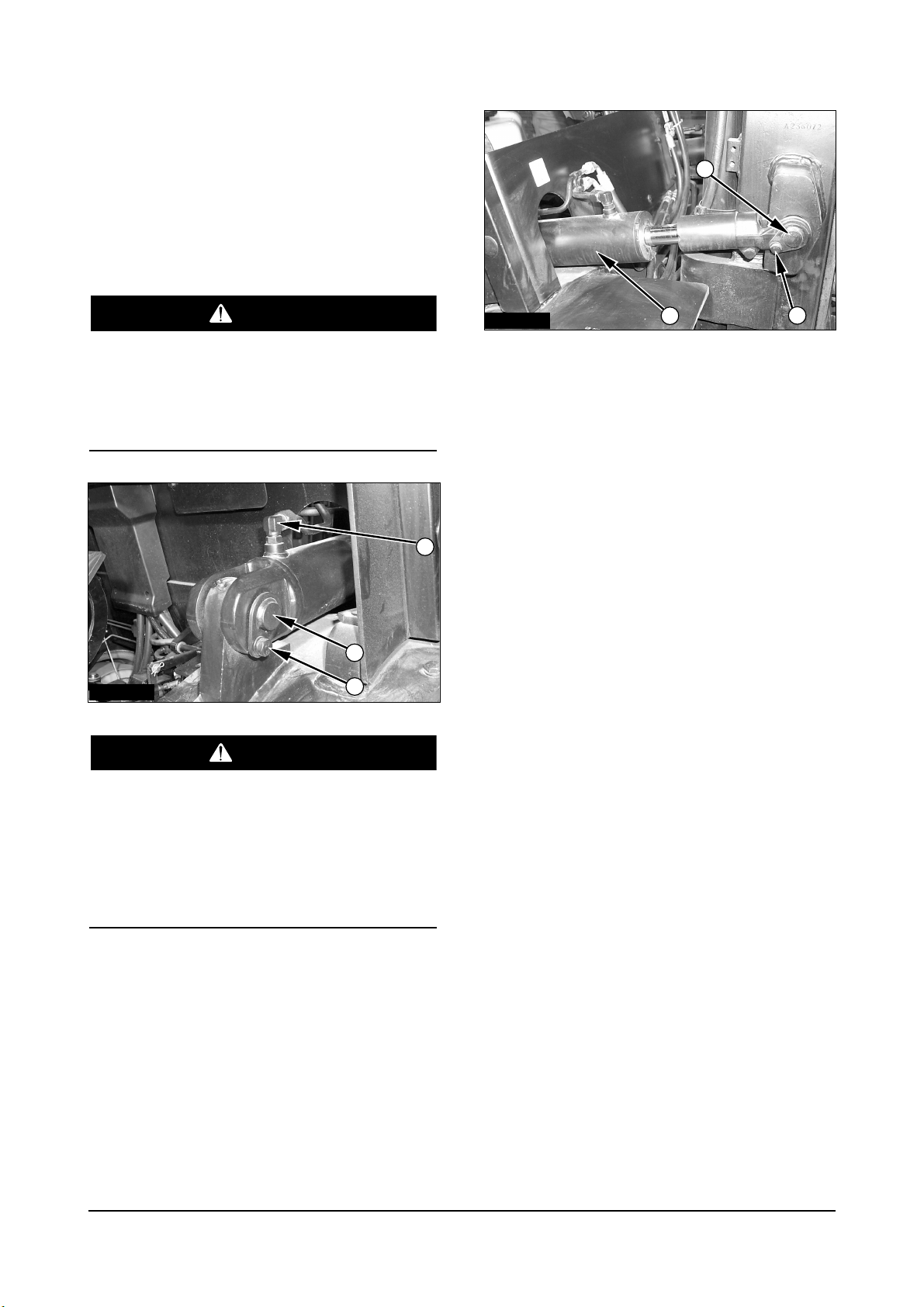

Tilt Cylinders

Remove & Install Tilt Cylinders

NOTE : The procedure for removing and installing

the tilt cylinders is the same for both cylinders.

If both tilt cylinders are removed at the same time

the mast can fall. To avoid possible personal

injury, make sure the mast is securely held in

place or supported by a hoist before removing the

tilt cylinders.

To prevent personal injury, move the control

levers backward and forward to release any

pressure in hydraulic system. Slowly loosen the

cap of the hydraulic tank to release any pressure

in the tank. Be cautious of hot hydraulic oil when

any lines are disconnected in the hydraulic

system.

1. Disconnect elbow (2). Remove retainer bolt (3)

and pin (1).

2. Remove retainer bolt (6) from pin (5). Remove pin

(5).

3. Remove tilt cylinder (4).

4. Install the tilt cylinder in the reverse order of

removal.

7

IACD204P

IACD205P

2

6

5

4

3

1

WARNING

WARNING

Vehicle Systems Disassembly & Assembly

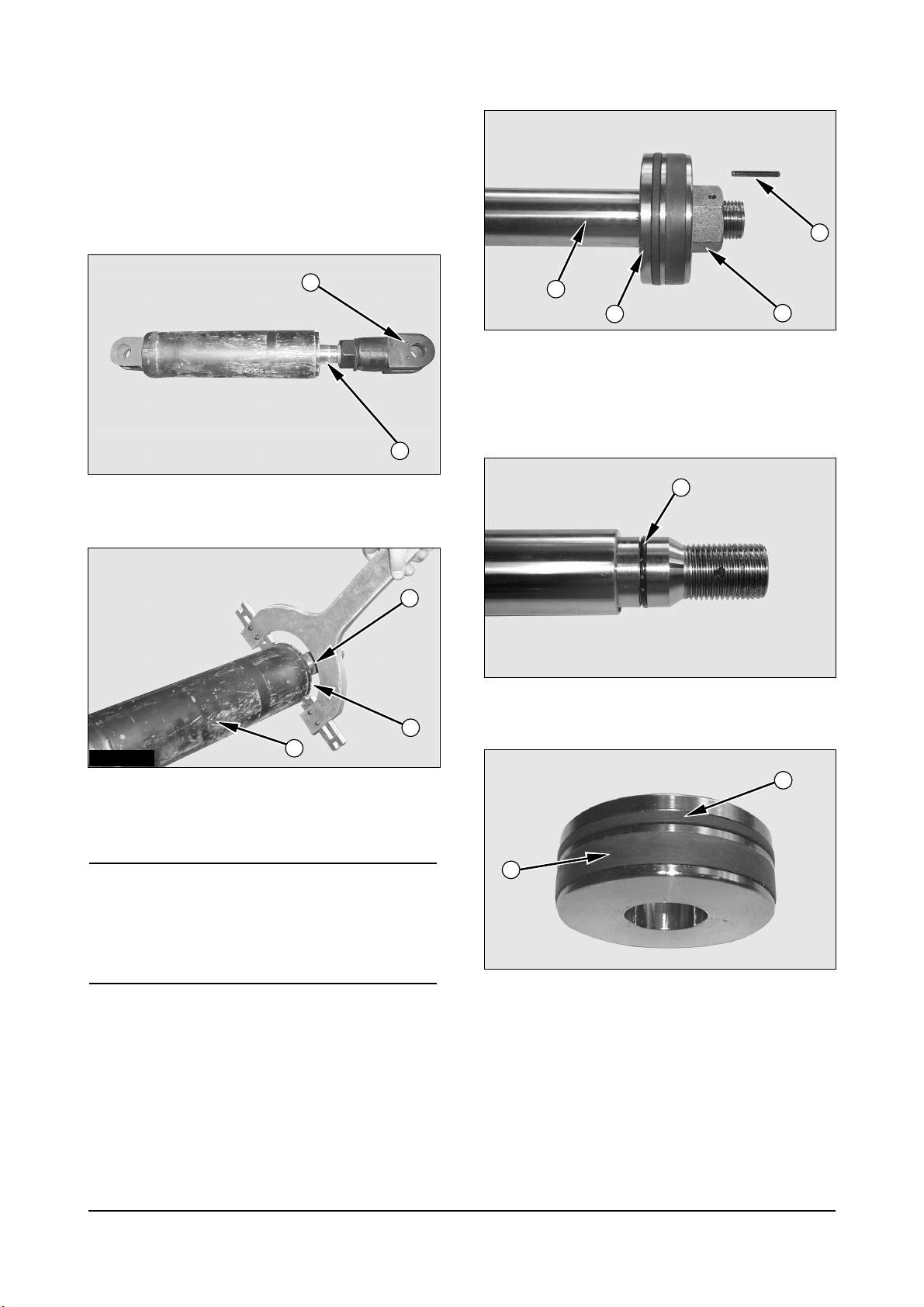

Disassemble & Assemble Tilt

Cylinders

Start By:

a. Remove tilt cylinder.

1. Remove eye (1) from the rod assembly (4).

2. Remove rod cover (2) from the cylinder tube (3)

using a spanner wrench.

NOTICE

Use extra care not to damage the highly finished

surface of the cylinder rod and the bore of the clylinder

tube during disassembly and assembly of the tilt

cylinder.

3. Remove rod assembly (4) from the cylinder body.

4. Remove pin (5) inside hole and nut (6) from the

cylinder rod (4).

5. Remove piston (7) from the cylinder rod.

6. Remove O-ring seal (8) from the cylinder rod.

7. Remove wear ring (9) and slipper seal (10) from

the piston.

8

ICCD002P

ICCD003P

ICCD005P

ICCD006P

ICCD004P

1

4

4

8

10

9

2

3

4

7

6

5

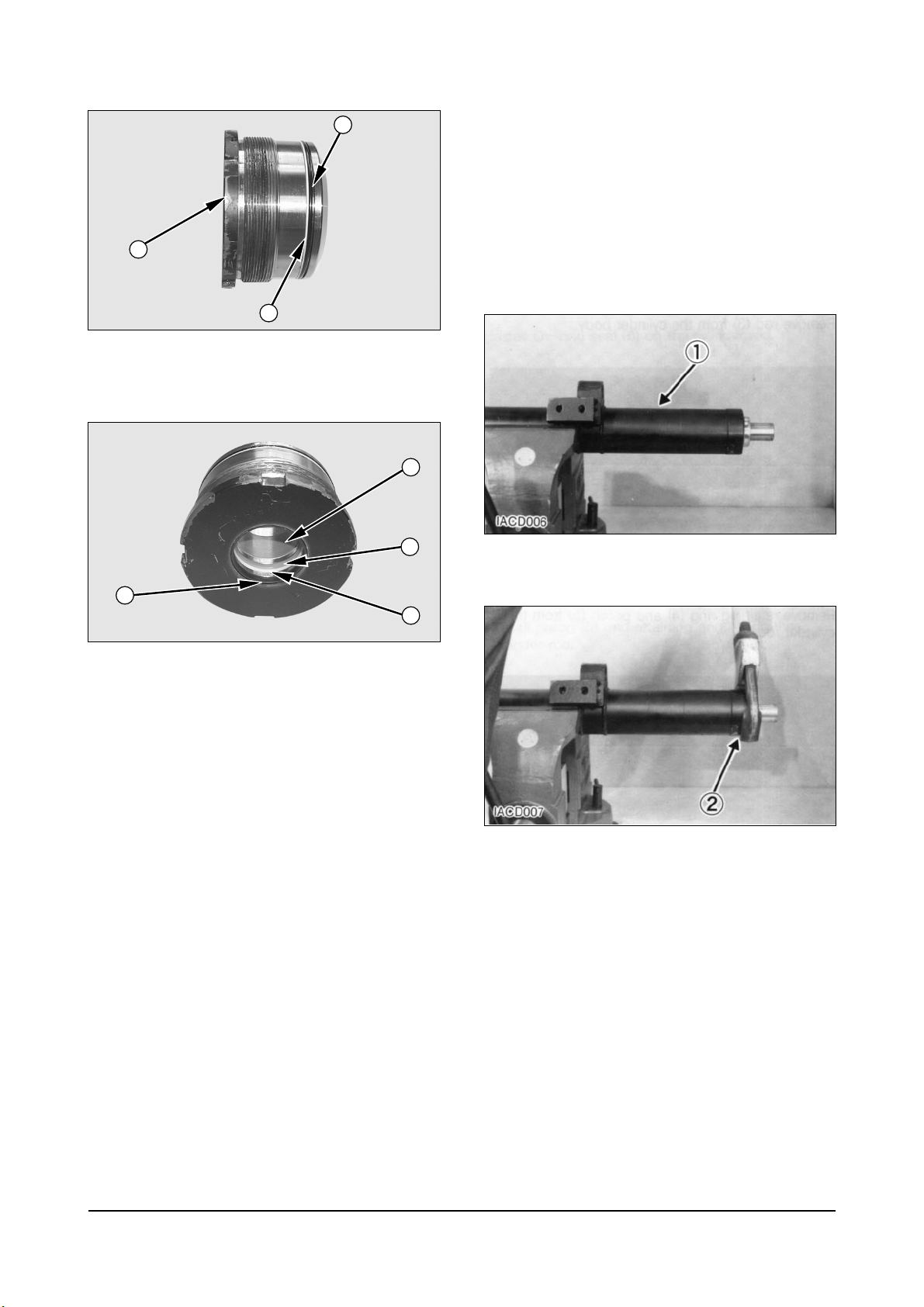

Vehicle Systems Disassembly & Assembly

8. Remove O-ring seal (11) and backup ring (12)

from the rod cover (2).

9. Remove wiper seal (13), backup ring (14), U-

packing (15) and DU-bush (16) from the rod cover.

NOTE : Assemble the tilt cylinder in the reverse

order of disassembly.

Secondary Lift Cylinders

Disassemble Secondary Lift

Cylinders

Start By :

a. Remove secondary lift cylinders.

1. Put secondary lift cylinder (1) in position as shown.

2. Remove head assembly (2) with tool.

9

ICCD007P

ICCD008P

11

2

12

13

16

15

14

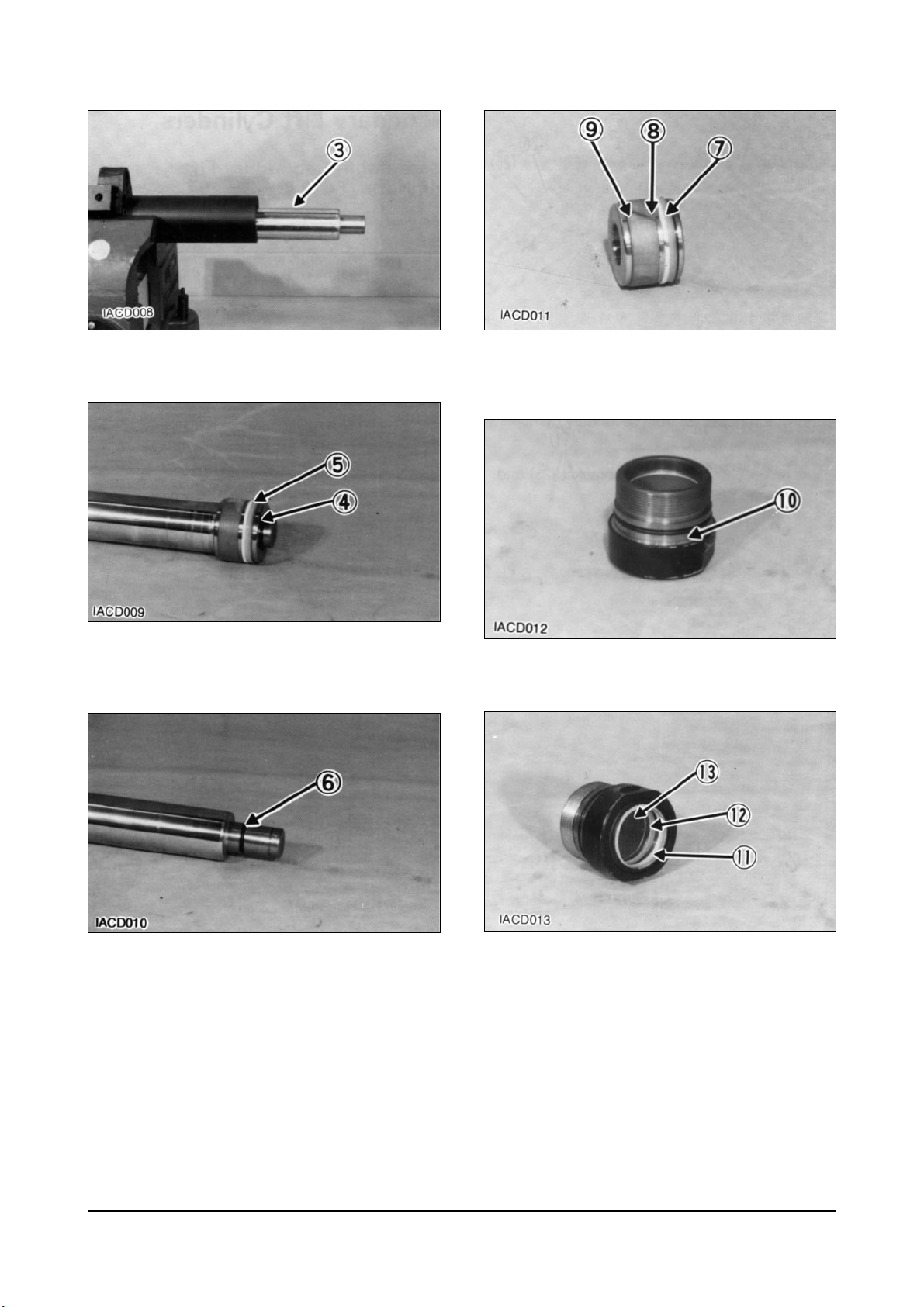

Vehicle Systems Disassembly & Assembly

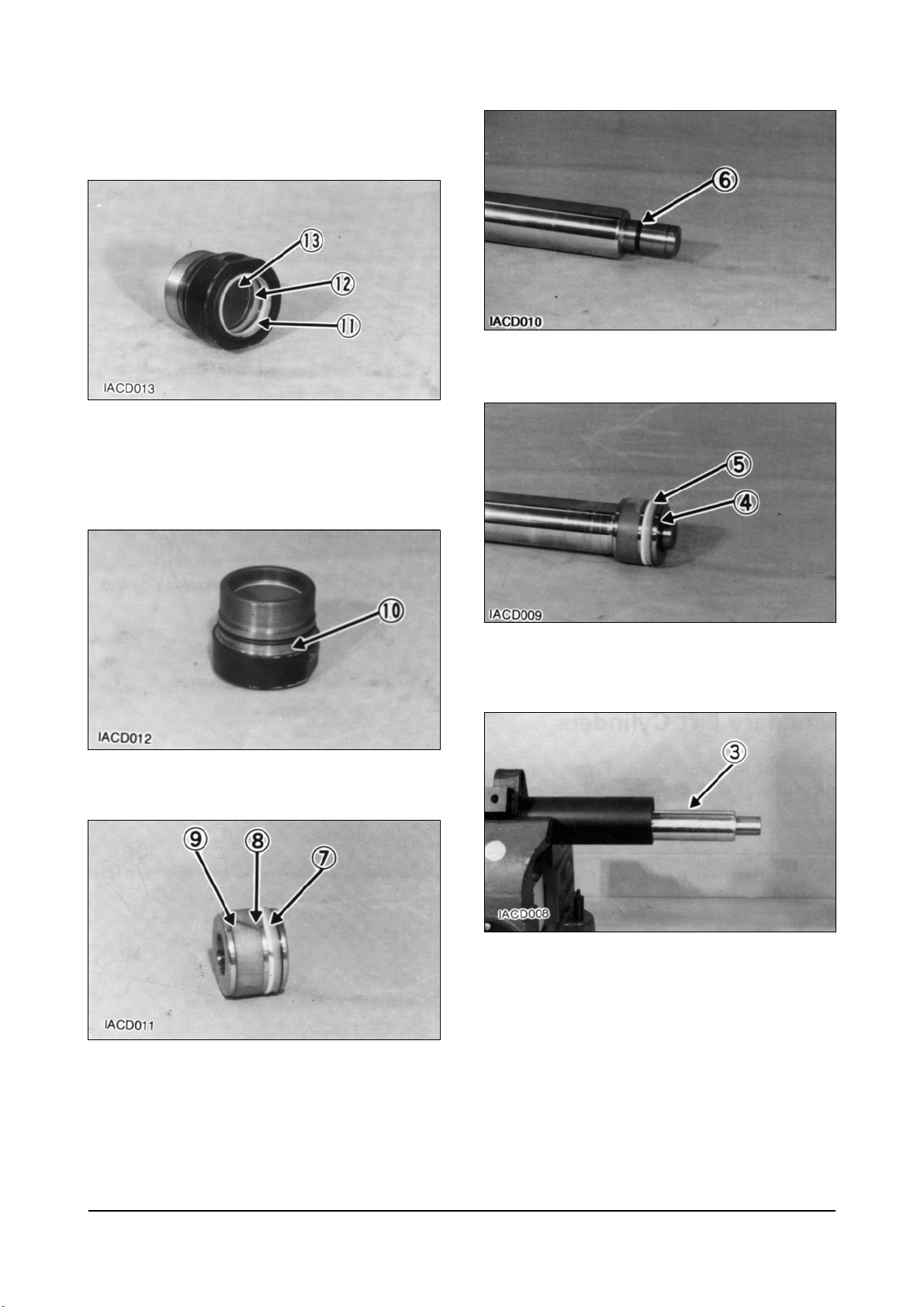

3. Remove rod (3) from the cylinder body.

4. Remove retaining ring (4) and piston (5) from the

cylinder rod.

5. Remove O-ring seal (6) from the cylinder rod.

6. Remove O-ring seal (7), back-up ring (8) and seal

(9) from the piston.

7. Remove O-ring seal (10) from the head assembly.

8. Remove wiper seal (11), seal (12) and bush (13)

from the head assembly.

10

Vehicle Systems Disassembly & Assembly

Assemble Secondary Lift

Cylinders

1. Install bush (13) and seal (12).

2. Install wiper seal (11). Install the seal with the lip

toward the outside.

3. Install O-ring seal (10) onto the head assembly.

4. Install seal (9), back-up ring (8) and O-ring seal (7)

on the piston.

5. Install O-ring seal (6) on the cylinder rod.

6. Install piston (5) and retaining ring (4) on the

cylinder rod.

7. Install cylinder rod (3) in the cylinder body.

11

Vehicle Systems Disassembly & Assembly

8. Install head assembly (2) on the cylinder rod and

tighten using tool.

End By :

a. Install secondary lift cylinders.

Primary Lift Cylinder

Remove & Install Primary Lift

Cylinder

Start By :

a. Remove carriage.

To prevent personal injury, move the control

levers backward and forward to release any

pressure in hydraulic system. Slowly loosen the

cap of the hydraulic tank to release any pressure

in the tank. Be cautious of hot hydraulic oil when

any lines are disconnected in the hydraulic

system.

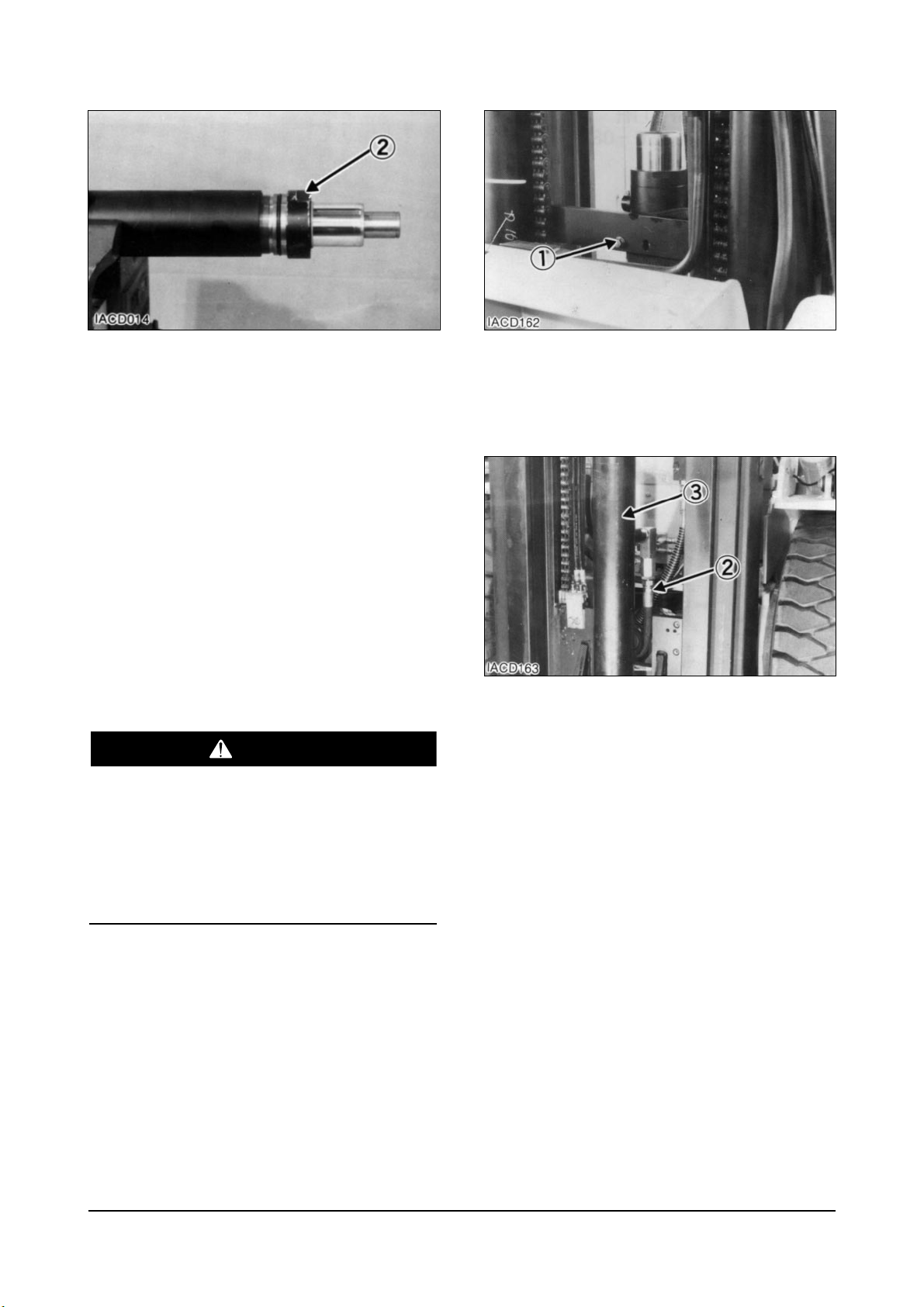

1. Fasten nylon straps and hoist to the primary lift

cylinder.

2. Remove bolt (1).

3. Pull the cylinder out far enough to disconnect

hydraulic hose (2). Remove primary lift cylinder

(3).

4. Install primary lift cylinder (3) in the reverse order

of removal.

End By :

a. Install carriage.

12

WARNING

Loading...

Loading...