Page 1

Culligan

Water Tower

™

Drinking Water

System

Owners

Guide

Page 2

NOTICE: This system is intended for use on potable water supplies or disinfected water

containing cysts. Do not use where water is microbiologically unsafe or with water of

unknown quality. If bacterial contamination is present, a recognized method of water

disinfection is required.

Check with your public works department for applicable local plumbing and sanitation codes.

Follow your local codes if they differ from the standards used in this manual.

Operational, maintenance and replacement requirements are essential for this product to perform properly. The Culligan Water Tower

contains replaceable particulate and activated carbon

™

filters. It also includes a replaceable reverse osmosis membrane filter which is critical for the

effective reduction of Total Dissolved Solids. The filtered water should be tested periodically to

verify that the system is performing properly.

Culligan International Company

One Culligan Parkway

Northbrook, Illinois USA 60062-6209

847/205-6000

http:\\www. culligan.com

i

Page 3

Table of Contents

Safety/Warnings ...................................................................................................... i

System Specifications ............................................................................................. 2

Introduction

About Your System ................................................................................. 3

System Component Description...........................................................3

Application Guidelines .......................................................................................... 4

Certified Performance ...........................................................................................5

Installation ............................................................................................................... 6

Servicing Your System ........................................................................................... 7

Cartridge Replacement, Cleaning and Sanitizing Procedure ........................... 8

Troubleshooting Guide ....................................................................................... 14

Parts List ................................................................................................................16

Service Log ............................................................................................................17

Warranty.................................................................................................................18

1

Page 4

System Specifications

System Flow Sequences............................... Sediment Filter, Activated Carbon Filter,

Reverse Osmosis Membrane, Storage Tank,

Polishing Filter, Dispensing Faucet.

Sediment Filter.............................................. Spun Polypropylene Type

Carbon Filter ................................................. Activated Carbon Block

Reverse Osmosis Membrane ...................... Thin Film Composite Type

System Daily Production Rate

to Pressurized Storage Tank

1

...................... 11 gpd

Product Production Rate without

Storage Tank to Atmosphere

Ratio of Product to Flush Flow

2

................................... 35 gpd

3

Soft Water Applications ....................... 1:1

Hard Water Applications ..................... 1:3 - 1:5

Polishing Filter .............................................. Activated Carbon Block

Dispensing Faucet ........................................ Culligan® Smartap® Rotary Operation,

Stainless Steel and Resin Flow Passages, with

Built-in Siphon Break and Quality Monitor

Color Options ....................................... Polished Chrome, Satin Chrome, White, Black,

Black/Chrome, Almond

Storage Capacity ........................................... 3 gallons (max.)

2.4 gallons (nom.)

Dimensions

Filter Assembly...................................... 15.5”W x 6”D x 15”H

Storage Tank .......................................... 11” Diameter x 15.5”H

1 Rating at 50 psi, 77°F, 500 mg/L TDS influent.

2 This is a factory specification for membrane production. Actual production rate and TDS

reduction will depend on temperature, water pressure, TDS level, membrane variation and usage

pattern.

3 May vary with pressure. See Technical Manual for all hard water applications and applications

where TDS exceeds 1000 mg/L (ppm).

2

Page 5

Introduction

Thank you for choosing a Culligan Water Tower

drinking water system. Your new system is

™

designed to bring you years of healthful, deliciously crystal-clear Culligan® water. With its special

faucet installed on your sink, it’s like getting bottled water straight from your kitchen tap.

With the Culligan Water Tower drinking water system, you’ll get a continuous supply of clear,

refreshing water for drinking and cooking. But Culligan improves a lot more than just water.

Crystal clear Culligan water is ideal for:

• coffee • recipes • pasta • tea • baby formula

• ice cubes • soup • houseplants • steam irons

• juice • pets • drink mixes

• everything you make with water

With three separate water treatment technologies and its unique space-saving design, the

Culligan Water Tower drinking water system is the most advanced drinking water system available from Culligan today.

About Your System

The reverse osmosis method of water treatment has long been regarded as one of the most

efficient and effective ways to reduce impurities. It’s the technology we’ve used to build your

new Culligan Water Tower drinking water system. In addition, we’ve incorporated activated

carbon and fine particle filtration to bring you one of the most effective systems available today.

Culligan Water Tower System Components

Refer to Figure 2, page 6

Sediment Filter

The sediment filter screens out dirt, sand, rust, and other microscopic par ticles 15 times smaller

than a grain of sand.

Activated Carbon Filter

The activated carbon filter gets rid of bad tastes and odors, including chlorine, if present in your

untreated water supply.

Reverse Osmosis Membrane Cartridge

The reverse osmosis (RO) membrane squeezes out dissolved substances, including radium, lead,

and many others. These substances may not be in your water. See Performance Data Sheet for

list of substances and removal percentages.

Manifold Assembly

The manifold serves as the functional hub of the system, directing and regulating the flow

through each of the system’s components. It makes the Culligan Water Tower drinking water

system extremely space efficient and simplifies filter changes.

Storage Tank

The storage tank holds Culligan® water under pressure for rapid delivery.

3

Page 6

Polishing Filter

The Culligan Water Tower

drinking water system includes a second activated carbon filter in

™

the manifold as added assurance that your water will be crystal clear.

Culligan

Smartap® Water Quality Monitor and Faucet

®

The special drinking water faucet mounts conveniently on your kitchen sink. A simple twist of

the handle is all it takes to enjoy refreshing Culligan drinking water.

Your Cullig an Water Tower incorporates a proven performance indicator. The patented

Smartap

Water Quality Monitor uses dual probe LOGIC PULSE MEMORY

®

technology to accurately indicate membrane performance. A split-second power pulse compares

feed water Total Dissolved Solids (TDS) level with that of the product water. Then, by reversing

the polarity of the electronic pulse, the probes are cleaned and kept free of chemical plating.

Electronics from the Culligan Water Tower connected to the Smartap faucet provides feedback

on system operation.

Indications appear in a light bar integrated into the faucet body

front cover (Figure 1). Power is provided through a nine-volt

alkaline battery. To prolong battery life, indicator lights selfextinguish after a few seconds even if water is being dispensed.

- Green means quality Culligan water

- Orange tells you that a service check is necessary

- Yellow means a filter change is required

FIG. 1

Application Guidelines

The Culligan Water Tower drinking water system is designed for use on potable water supplies

meeting the guidelines outlined in Table 1. The system should be installed on your home’s cold

water line. The flushing stream should discharge through an approved siphon break as illustrated

in Figure 2, page 6. Installation of this system must comply with state and local laws and regulations.

4

Page 7

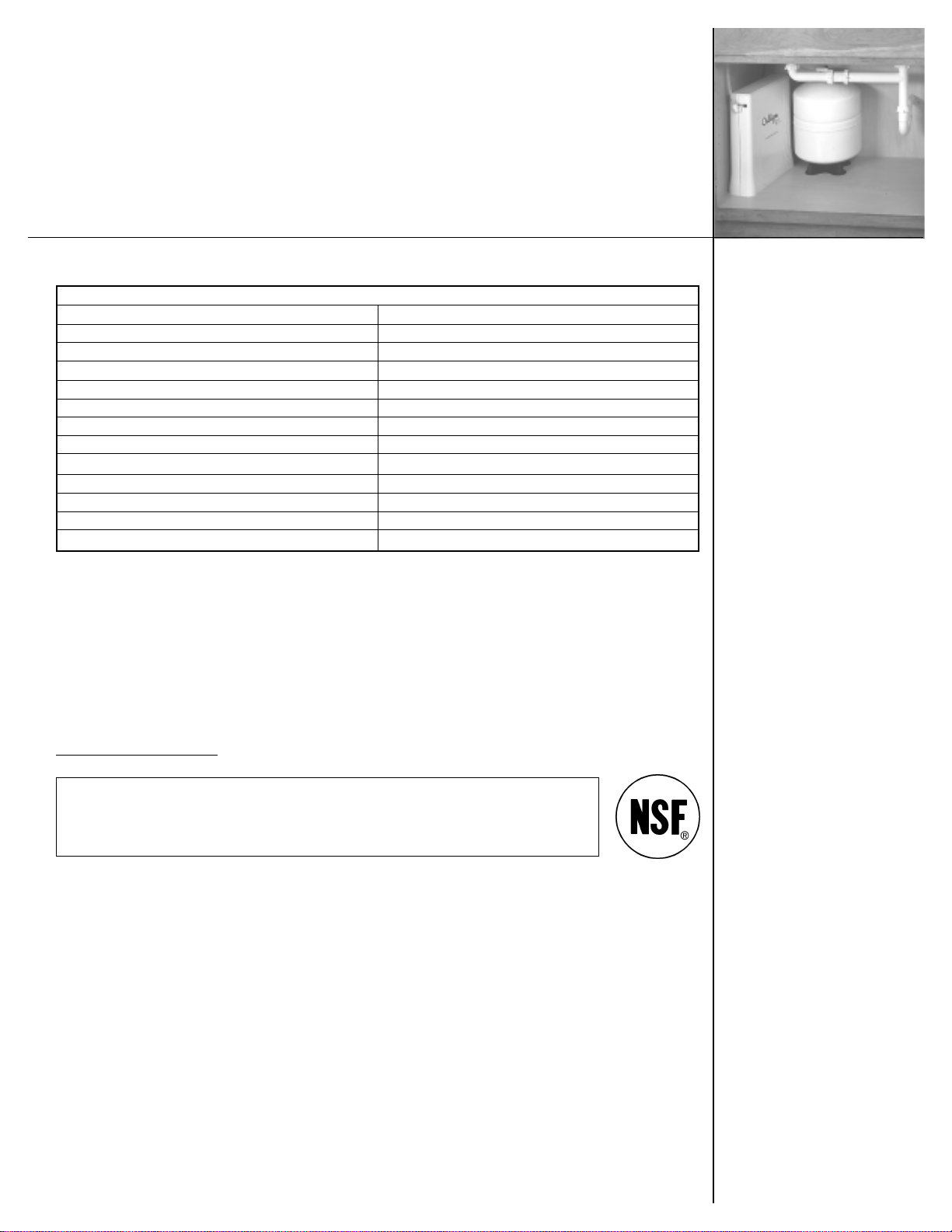

Table 1

Pressure

1

Temperature 40-100°F (4-38°C)

Total Dissolved Solids (TDS)

pH 3.0 - 11.0

Chlorine

3

Chloramine 0-2 ppm (0-2 mg/L)

Turbidity <1.0 NTU

Silt Density Index (SDI) <4

Hardness (CaCO

) <350 ppm

3

Hydrogen Sulfide (H2S) 0.00 ppm

Manganese (Mn) <0.05 ppm

Iron 0-1 ppm (0-0.1 mg/L)

Bacterial Quality

1

A pressure regulator is recommended for feed water pressures exceeding 80 psig (552 kPa)

2

See the Technical Manual for all applications where TDS exceeds 1000 ppm (1000 mg/L) to calculate

4

effective module pressure. A booster pump is strongly recommended.

3

The reverse osmosis membrane filter used in this system may be damaged by chlorine. This system

includes activated carbon which protects this element by reducing chlorine. Inf luent chlorine should not

exceed 2 mg/L.

4

Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

Influent Water Characteristics

2

35-100 psi (242-690 kPa)

0-2000 ppm (0-2000 mg/L)

0-2 ppm (0-2 mg/L)

Potable

Certified Performance

System Tested and Certified by NSF International against ANSI/NSF Standard 58

for thereduction of: Barium, Cadmium, Copper, Fluoride, Hexavalent Chromium,

Lead, Radium 226/228*, Selenium, Total Dissolved Solids, Trivalent Chromium,

Cysts, and Turbidity

The substances removed by this system are not necessarily in your untreated water. See

Performance Data Sheet for percentages of contaminant removal.

* Minimum removal based on approved testing methods with Barium as surrogate.

5

Page 8

Installation

This Owner’s Guide provides visual assembly reference only (Figure 2). Since specialized skills

are required in the assembly of the drinking water system, we recommend that you contact your

local independently operated Culligan® dealer to complete this installation.

Component Location

Product Water Faucet

Faucet may be located in any convenient location. Make sure underside of location is free of

obstruction.

Culligan Water Tower™ Module*

Module may be installed under sink or in any convenient location within 15 feet of source water

supply and product water faucet.

Storage Tank

Tank may be placed in any space within 15 feet of faucet, generally under kitchen sink or in

adjacent unused cabinet. Tubing length between components should be kept to a minimum,

avoiding sharp bends or kinks.

*For installations in Massachusetts, Massachusetts Plumbing Code 248CMR shall be

adhered to. Consult your licensed plumber for installation of this system. The use of

piercing valves is not permitted in Massachusetts.

The use of piercing valve is NOT permitted in Massachusetts.

FIG. 2

6

Page 9

Servicing Your System

Service Schedule

When properly maintained, your Culligan Water Tower

drinking water system will give you

™

years of dependable service. Use the following as a guide to get the most out of your system.

Service frequency may vary depending on your local water conditions. High sediment, chlorine,

turbidity or hardness levels may require more frequent service.

At least once per year

Replace:

• Sediment Filter Cartridge (Item 7)

• Activated Pre-Carbon Filter Cartridge (Item 8A)

• Activated Post-Carbon (Polishing) Filter Cartridge (Item 8B)

Check:

• RO Membrane Cartridge (Item 9)

- TDS Reduction Performance

- Flow Rates - Concentrate & Product

• Flow Control (Item 6)

Clean and Sanitize the System

Use the convenient chart inside the back cover of this booklet to keep track of your system’s

maintenance.

Equipment Needed

• Safety glasses

• Rubber gloves, sanitary

• Wash cloth, clean and lint-free

• Liquid dish soap

• Household bleach - unscented only (5-1/4% sodium hypochlorite)

• Plastic storage bag

• Manual air pump

• Plastic bucket

• Plastic bowl

• Silicone lubricant, FDA approved

Have all components and supplies on-hand and ready before beginning procedure.

A clean work area and equipment are essential to properly clean and/or sanitize the system (i.e.,

clean hands, tools, work surface and containers).

Cartridge Replacement

Culligan recommends that you have your Culligan Water Tower drinking water system serviced

by your local Culligan Man™. You can r ely on his or her experience and expertise to keep your

system in top operating condition.

7

Page 10

If you wish to service your system, the filters are available from your Culligan dealer. See the

Parts List at the end of this section for replacement numbers.

Cartridge Conditioning

The activated carbon, reverse osmosis, and polishing filter cartridges must be conditioned as

follows prior to installation into the Culligan Water Tower™ drinking water system. Your Culligan

Man

can do these important procedures at the time of purchase.

™

Activated Pre-Carbon Filter Cartridge - 2 gallon flush to remove carbon dust

RO Membrane Cartridge - 6 hour flush to remove preservative solution

Activated Post-Carbon (Polishing) Filter Cartridge - 2 gallon flush to remove carbon dust

Tubing Connectors

The Culligan Water Tower drinking water system features easy-to-use push-in tubing connectors

(Figure 3). Fittings consist of two parts: a body and a colored collet. Collet color cor responds to

tubing color to be used at that connection (Figure 3A).

1. To install a tube, lubricate the tubing end with water (only) and push it through collet

until it seats firmly at bottom of fitting (Figure 3B). You should feel the tubing pass

the O-rings. Cut ends must be square. Be sure the tubing is smooth and free of abrasions,

otherwise a leak may result. Cut tubing only with a new razor blade.

2. To remove a tube, push and hold the collet against the fitting body and pull the tube

from the fitting. (Figure 3C).

FIG. 3A FIG. 3B FIG. 3C

Cartridge Replacement, Cleaning and Sanitizing Procedure

1. Mix a mild cleaning solution of dish soa p and clean potable water in plastic bowl.

2. Empty storage tank and relieve system pressure. Verify tank valve is open. Close feed

water supply valve and open product water faucet.

Note: Additional point-of-use devices (i.e. icemakers) may use filters along their

supply line. Remove any filter or treatment device installed between module and

delivery device before preceding.

Icemaker: Transfer ice cubes from bin/tray to clean freezer container for storage

until procedure is done.

8

Page 11

3. Check product water storage tank air pre-charge using low-pressure gauge (PN

34002024). Air valve is located on tank base. Pre-charge should be 55 kPa (8 psig)

with tank empty and tank valve open.

Note: Use hand pump to avoid damaging tank. Verify product water faucet is open

before proceeding. Use caution when working with/inside enclosure. Wiring therein

connects monitor components. If wires, circuit board, or connections are damaged

and/or wetted, monitor will not function.

Item callouts refer to Figure 5 unless otherwise noted.

4. Remove enclosure front panel by pressing in push-in tabs and pull cover back.

(Figure 4)

FIG. 4

5. Remove each filter housing (Item 30) by turning it counter-clockwise. Remove each

filter cartridge (Figure 5).

a. Discard sediment (Item 7) and carbon (Item 8) cartridges

b. Examine membrane (Item 9). If it is performing satisfactorily, proceed to Step 6.

If it is depleted or fouled, discard it and proceed to Step 8.

Note: Wear gloves whenever cleaning/sanitizing system or handling new filter/

membrane cartridges.

6. Clean membrane outer wrap with washcloth and cleaning solution. Do not immerse

membrane in solution. Do not scrub wrap with abrasive cleaners. Rinse membrane

well with clean potable water.

7. Place membrane into clean plastic bag, close bag.

8. Remove filter housing O-rings and wash them with cleaning solution. Rinse them

well with clean potable water. Inspect them for damage such as nicks or scratches.

Replace damaged O-rings.

9

Page 12

FIG. 5

10

9. Clean filter housings/manifold, inside and outside, with washcloth and cleaning

solution. Do not use abrasive materials.

10. Rinse housings/manifold with clean potable water.

11. Inspect filter housing O-ring groove and manifold O-ring surface for damage such as

nicks or scratches. Replace if damaged.

12. Place a small amount of O-ring lubricant on surface of filter housing O-ring. Install

O-ring into housing.

TO SANITIZE THE SYSTEM: Complete Steps 13-33.

TO INSTALL FILTERS: Complete Ste ps 20-33.

Page 13

CAUTION: Wear safety glasses while performing this procedure.

CAUTION: Read “WARNINGS” information on bleach container

before using contents. Handle sanitizing solution carefully. Avoid

contact with unprotected areas.

13. Mix sanitizing solution of 1.5 ml (1/3 teaspoon) of household bleach and 3.8 L

(1 gallon) of clean, potable water in the bucket. Mix solution well.

Note: Excessive concentrations of bleach (sodium hypochlorite) may damage plastic and rubber

components. Rinse all parts that contact bleach thoroughly with clean potable water.

14. Add 236 ml (one cup or 8 oz.) of sanitizing solution to each filter housing and install

them onto the manifold (do not install filters or membrane at this time). Tighten

each filter housing by hand only.

Note: Tighten filter housings by hand only. Do not use tools as they will over-tighten and

damage housings.

15. Slowly open source water supply valve.

16. Close product water faucet as soon as water begins to flow from spout.

17. Wait 5 minutes, then close source water supply valve.

18. Wait 25 minutes, then open product water faucet. Let water flow to drain until

system is drained (flow stops), then close faucet.

Note: Remove filter housings only after water flow stops.

19. Remove filter housings and dispose of water. Rinse housings/manifold thoroughly

with clean, potable water.

Note: Do not remove protective plastic bag from replacement filter and membrane cartridges.

Note: For optimum monitor performance, the monitor must be re-set and the battery replaced

each time system is sanitized. However, a technician may wait until indicator lights fail to illuminate to replace battery.

20. Hold cartridge by its protective plastic bag and open protective bag to expose

cartridge cap and O-rings.

11

Page 14

21. Install cartridges. (Refer to Figure 5 for location of each cartridge).

a. Hold cartridge by its protective plastic bag.

b. Insert cartridge into manifold turning it 1/2 turn as it enter s por t. Slide bag from

cartridge and discard.

c. Install filter housing (Item 30) as each cartridge is inserted. Make sure housing

o-ring is properly lubricated.

Note: Tighten filter housings by hand only. Do not use tools as they will over-tighten and

damage housings. Take care not to cut or pinch the O-rings.

22. Turn feed water valve slowly to open position.

23. Confirm system is producing water. Unit will be sending rinse water to drain. Check

for leaks.

Note: Monitor must be re-set each time the system is serviced to ensure accurate

monitor performance.

TO RE-SET MONITOR or TO CHANGE BATTERY: Perform Steps 24-27

Refer to Figure 6 for component location.

Use caution when working inside enclosure. Wiring therein connects monitor components. If

wires, circuit board, or connections are damaged and/or wetted, monitor will not function.

12

Connect battery to monitor after system has been in production mode for at least 5 minutes.

This ensures sensing switch is in proper position to record data.

24. Disconnect battery. The connection is a snap type connector.

25. Remove battery by sliding it out of its holder.

FIG. 6

Page 15

Note: Replace battery with a new alkaline 9-volt battery (PN 31300001)

26. Carefully slide battery into its holder.

27. Connect battery by pressing clip onto batter y terminals.

28. Test monitor connection by activating monitor. Open product water faucet. If an

indicator light illuminates, connection is good.

Note: Close faucet immediately after light illuminates. Test confirms battery connection, not

water quality.

29. Install enclosure front panel (Item 3):

a. Place panel in position, aligning push-in tabs with openings. Verify circuit board

wiring is not pinched between panels.

b. Press panel inward until push-in tabs engage, securing the panel.

c. Check for leaks.

30. Open product water faucet. Let water flow until all air has been expelled from the

system.

31. Close product water faucet. Wait 30 minutes, check connections for leaks, and

correct if necessary.

Icemaker/Extra point of use: Check lines for leaks.

32. Allow storage tank to fill overnight.

DO NOT USE FIRST FULL STORAGE TANK OF WATER

33. Discard (to drain) first full tank of water by opening product water faucet until water

flow stops, then close faucet. This flushes sanitizing solution from system.

Icemaker: Let tray/bin fill with ice cubes. Discard all ice cubes to drain. This flushes sanitizing

solution from lines in icemaker. Replace delivery device filter (if applicable).

Note: System is ready to use. Should there be any aftertaste or odor, drain storage tank and

repeat Steps 32 and 33.

13

Page 16

Troubleshooting Guide

W ater Volume and Quality

Symptom Condition Action

No product water Water supply is turned OFF Turn water ON

Not enough Low water pressure Check source water line pressure

product water

Inlet water supply valve is blocked Clear restriction

Storage tank valve is closed Open storage tank valve

Storage tank is depleted Increase product water stora g e

capacity and/or install membrane

with higher output rating

Clogged pre-filter car tridg e(s) Replace pre-filter cartridg e(s)

Storage tank air pressure charge Empty water from storage tank

is low (product water faucet must remain

open while adjusting pressure) and

adjust pressure to 55 kPa (8 psig)

14

System does not Shut-off valve is not closing Contact your Culligan® Dealer

shut off

No drain water Clogged flow control Replace flow control (Item 6) in

parts list and contact your

Culligan® Dealer

Water has Carbon post-filter is depleted Drain storage tank, sanitize system

offensive taste and replace carbon post-filter

and/or odor cartridge

Membrane depleted or fouled Smartap® Quality Monitor reads

yellow, or if TDS test is

unsatisfactory, drain storage tank,

sanitize system and replace

membrane

Sanitizer not flushed out Drain storage tank and let it refill

overnight

Page 17

Leakage

Symptom Probable Cause Solution

Leak at fitting Tubing not pushed completely Push tube into fitting past

into fitting O-ring seal

Defective tube Cut damaged area from tube or

replace tube

Tubing makes too tight a bend Run the tubing to reduce the bend

near fitting

Leak at filter O-ring has not seated properly Remove O-ring and inspect

housings O-ring groove for debris. Clean

groove, lube and reseat O-ring

O-ring has nicks or scratches Replace O-ring

Leak from air gap Restricted drain tube Clear restriction

in faucet

Tubing from air gap to drain is Re-route tubing so tubing runs

routed incorrectly vertically with no sharp bends

or loops

Smartap® Quality Monitor Status Indications and Common Solutions

Indication Condition Action

Green Light System operating normally None

Orange Light (appears Shut-off valve is not closing Call your Culligan® dealer

with green or yellow light

Yellow Light Membrane exhausted Replace membrane

No Monitor Lights Light Assembly is not connected Plug connector into phone jack

Battery voltage low Replace battery

Battery is not connected Connect battery

15

Page 18

Parts List

16

Item Description Part No.

1 Culligan Faucet, Chrome body/spout 11403430

Culligan Faucet, White body/spout 11403431

Culligan Faucet, Almond body/spout 11403433

Culligan Faucet, Black body/spout 11403434

Culligan Faucet, Satin body/spout 11403436

Culligan Faucet, Black body/Polished spout 11403439

2 Battery, 9-volt alkaline 31300001

4 Bracket, Mounting 21100101

5 Screw, Mounting Bracket 32701002

6 Flow Control, Green Tape 40600037

7 Cartridge, Sediment Culligan

8 Cartridge, Carbon Culligan

9 Cartridge, RO Membrane - 41402004

Green Casing - Purple Tape Culligan

10 Tank, Product Water Storage - White 34500003

®

®

®

01013028

01013029

11 Valve, Shut-off w/O-ring 33503601

12 Elbow, 3/8” Stem w/white collet 33503504

Gauge Air Pressure 34002024

Part Numbers in bold italics are Valencia, CA Part Numbers

Page 19

Culligan Water Tower™ Service Log

Model Serial No.

Date Installed

For Service Call Culligan at:

Cartridge(s) Changed

Date Sediment Pre-Carbon RO Post-Carbon

Serviced Filter Filter Membrane Filter Sanitized

( ) —

Activated Activated

17

Page 20

Culligan Lifetime Limited Warranty

CULLIGAN WATER TOWER™ CWT-35 MODEL SERIES

You have just purchased one of the finest drinking water systems made. As an expression of our

confidence in Culligan International Company products, your drinking water system is warranted to the

original end-user, when installed in accordance with Culligan specifications, against defects in material

and workmanship from the date of original installation, as follows:

For the LIFETIME of the The entire reverse osmosis drinking water appliance,

original end-user EXCLUDING THE EXPENDABLE FILTER CARTRIDGES AND

REVERSE OSMOSIS MEMBRANE FILTER USED IN THIS APPLIANCE.

Pro rata for a period The original Culligan reverse osmosis membrane filter. Culligan will

of ONE YEAR reduce the cost of a replacement Culligan reverse osmosis

membrane filter by 1/12th of the then-current manufacturer's

suggested retail price for each month remaining in the year period

when the defect is found and confirmed by a Culligan dealer.

If a part described above is found defective within the specified period, you should notify your independently operated Culligan dealer and arrange a time during normal business hours for the dealer to inspect

the drinking water appliance on your premises. Any part found defective within the terms of this warranty

will be repaired or replaced by the dealer. If any p art is found defective, Culligan also reserves the right to

replace the drinking water appliance with a comparable Culligan drinking water system of equal or greater

quality. You pay only freight for repaired or replaced parts from our factory and local dealer charges,

including but not limited to labor charges, travel and transportation expenses and handling fees.

Damage caused by accident, fire, flood, freezing, Act of God, misuse, misapplication, neglect, alteration,

installation or operation contrary to our printed instructions, or by the use of accessories or components

which do not meet Culligan specifications, is not covered by this warranty.

18

ALL IMPLIED W ARRANTIES, INCLUDING WITHOUT LIMIT A TION WARRANTIES OF MERCHANT ABILITY AND FITNESS FOR P AR TICULAR PURPOSE, ARE LIMITED IN DURA TION TO THE PERIOD SPECIFIED ABOVE FOR THE PARTS DESCRIBED IN THIS LIMITED WARRANTY. As a manufacturer, we do

not know the characteristics of your water supply. The quality of water supplies may vary seasonally or

over a period of time. Your water usage rate may vary as well. Water characteristics can also change if

your drinking water appliance is moved to a new location. For these reasons, we assume no liability for

the determination of the proper equipment necessary to meet your requirements, and we do not authorize

others to assume such obligations for us. Further, we assume no liability and extend no warranties,

express or implied, for the use of this product with a non-potable water source or a water source which

does not meet the conditions for use described in the Owner's Guide and Performance Data Sheet.

CULLIGAN'S OBLIGATIONS UNDER THIS WARRANTY ARE LIMITED TO THE REPAIR OR

REPLACEMENT OF THE FAILED PARTS OF THE DRINKING WATER APPLIANCE, AND WE ASSUME

NO LIABILITY WHATSOEVER FOR DIRECT, INDIRECT, INCIDENTAL, CONSEQUENTIAL, SPECIAL,

GENERAL, OR OTHER DAMAGES, WHETHER FROM CORROSION OR OTHER CAUSES.

Some states do not allow limitations on how long an implied warranty last s, so the above limitation

may not apply to you. Similarly , some states do not allow the exclusion of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state. Consult

your telephone directory for your local independently operated Culligan dealer, or write Culligan

International Company for warranty and service information.

CULLIGAN INTERNATIONAL COMP ANY

One Culligan Parkway

Northbrook, Illinois 60062

01882203 (36105001*) DCO#1254 ©2000 Culligan International Company Printed in USA (Rev A. 8/21/00)

Page 21

Materials & description: 8-1/2 x 11, 20 page book, saddle stitched, three hole punched - Prints black

ink on 50# offset white

LET CHANGE BY APRVD DATE

A DCO 1254 TPD BL 8/21/00

This page contains materials and DCO

information. IT DOES NOT PRINT AS

PART OF THE DOCUMENT!

Loading...

Loading...