Page 1

Installation and Operating Instructions

Under Sink Water Filter

Model US-550

1

Technical Support: 1-800-645-5426

(M-F 7:30 am - 5:00 pm CST)

11/03 145765 Rev C

NOTE: This filter housing does not include a filter cartridge.

Choose the appropriate filter cartridge for your needs and install in housing according

to the Cartridge Replacement instructions (page 3) before proceeding with

installation. See Cartridge Selection Guide (below) to determine the best

cartridge for your filtration needs.

Operating Specifications

Pressure Range: 30–125 psi (2.1–8.6 bar)

Temperature Range: 40–100°F (4.4–37.7°C)

Parts Included

• filter housing

• mounting bracket kit

Tools Required & Materials Required (not included)

• screwdriver

• file

• pencil

• pipe cutter or hacksaw

• 2 adjustable wrenches

• 3/8-inch compression fittings for standard 3/8-inch under-sink installation

• 3/8-inch plastic tubing

• Teflon

®

tape

Optional Materials

• SW-1 housing wrench

• FT-10 faucet kit (recommended for use with D-40 filter cartridge)

Precautions

WARNING: Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the

system. Systems certified for cyst reduction may be used on disinfected

waters that may contain filterable cysts.

CAUTION: Filter must be protected against freezing, which can cause cracking of

the filter and water leakage.

CAUTION: The rubber o-ring provides the water-tight seal between the cap and

the bottom of the housing. It is important that the o-ring be properly

seated in the groove below the threads of the housing or a water

leak could occur.

CAUTION: Because of the product’s limited service life and to prevent costly repairs

or possible water damage, we strongly recommend that the bottom of

all plastic housings be replaced every ten years. If the bottom of your

housing has been in use for longer than this period, it should be replaced

immediately. Date the bottom of any new or replacement housing to

indicate the next recommended replacement date.

NOTE:

• For cold water use only.

• Make certain that installation complies with all state and local laws and

regulations.

• The contaminants or other substances removed or reduced by the selected

cartridge are not necessarily in your water. Ask your local water municipality

for a copy of their water analysis, or have your private well tested by a

reputable water testing lab.

• After prolonged periods of non-use (such as during a vacation) it is

recommended that the system be flushed thoroughly. Let water run for 5–6

minutes before using.

• The filter cartridge used with this system has a limited service life. Changes in

taste, odor, color, and/or flow of the water being filtered indicate that the

cartridge should be replaced.

• Some harmless bacteria may attack cellulose media cartridges (such as the D-

10). If your cartridge seems to disintegrate or develops a musty or moldy

odor, switch to a synthetic media cartridge or call Technical Support.

The US-550 is Tested and Certified by NSF International to NSF/ANSI Standards

42/53 with cartridges D-10, D-20, D-30 and D-40.

See Performance Data Sheet in Manual for specific claims.

Cartridge Selection Guide

Select the right cartridge D-10 D-20 D-30 D-40†

for your water needs. 155528 155532 155465 155466

Sediment • • •

Bad taste & odor ••••

Chlorine: taste & odor ••••

Giardia/Cryptosporidium • •

Asbestos • •

Lead/Mercury •

Lindane/Atrazine •

filter life in gallons (months)* 250 (3) 1000 (12) 1000 (12) 600 (6)

service flow rate gpm (Lpm)** 1.0 (3.8) 1.0 (3.8) 0.9 (3.4) 0.6 (2.3)

* Filter cartridge life varies depending on filter type, usage and water conditions.

**Flow rates measured at 60 psi (4.1 bar).

†

Contains built in flow control at 0.6 gpm (2.3 Lpm). For use with separate faucet

(FT-10) in under-sink installations.

NOTE: Substances reduced are not necessarily in your water. Filter must be maintained

according to manufacturer’s instructions, including replacement of filter cartridges.

Page 2

Installation

NOTE:

• For standard under-sink installation on 3/8-inch (10 mm) cold water line (copper or PVC

pipe).

• Please read all instructions, specifications, and precautions before installing and using your

water filter.

• Install filter cartridge in housing before proceeding with installation (see Filter Cartridge

Replacement on page 3).

• Numbered diagrams correspond with numbered steps.

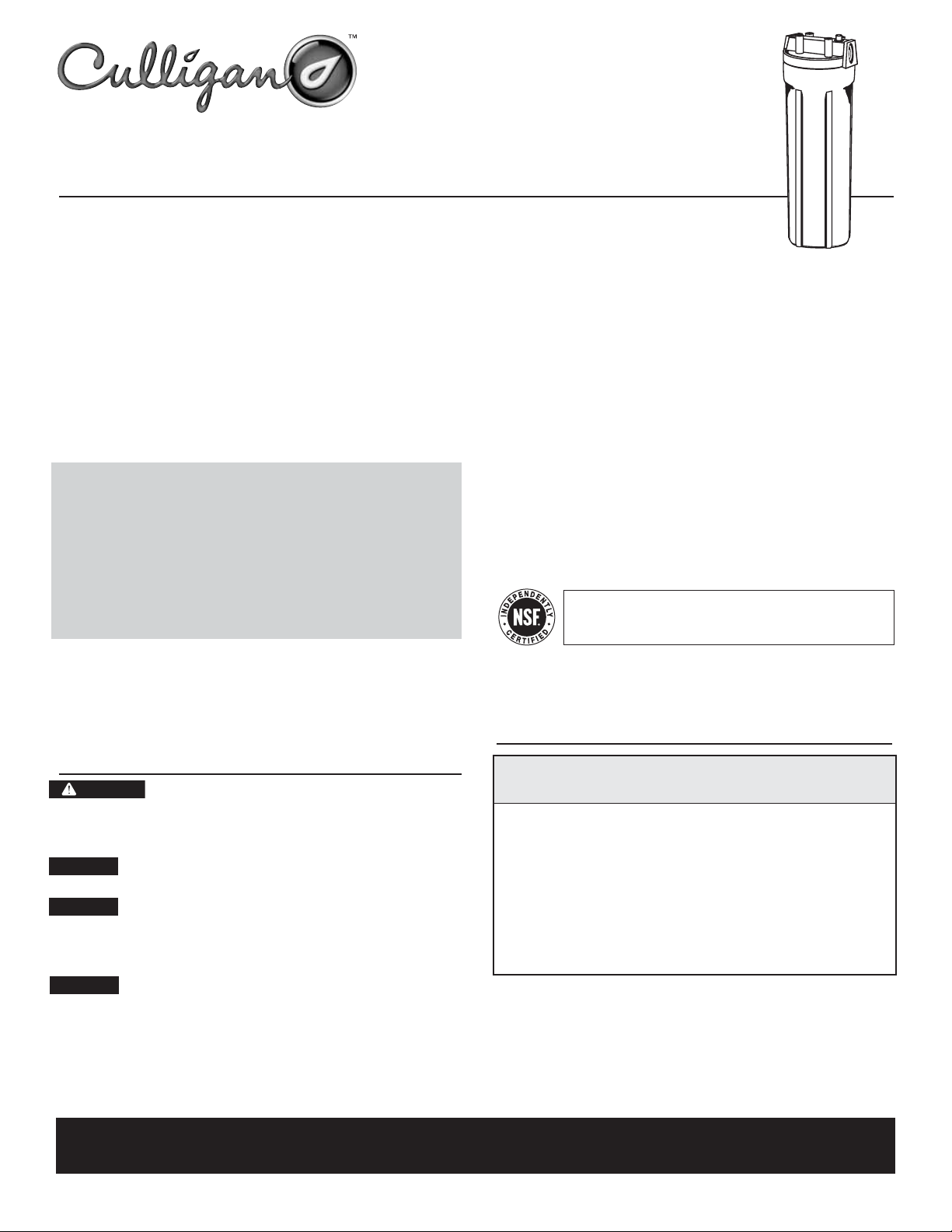

1. Prepare Area and Adapters

(A) Turn off cold water supply and open nearest faucet to release pressure in pipes before

starting installation. Place a tray or towel under the cold water line to catch excess water.

(B) Apply about 3–4 inches (76–102 mm) of Teflon

®

tape in clockwise direction to pipe

threads of each adapter.

2. Attach Mounting Bracket

Using the self-tapping screws, attach mounting bracket to cap, then mark location under

sink where filter is to be mounted.

NOTE: Allow 1-1/2 inches (33 mm) under filter to enable filter cartridge changes.

3. Attach Pipe Adapters to Filter Cap

Start connector into inlet on filter cap by hand. Using an adjustable wrench, tighten connector firmly. DO NOT OVERTIGHTEN. About one thread should remain visible. Repeat

for outlet on filter cap.

Mount filter in marked location with mounting bracket.

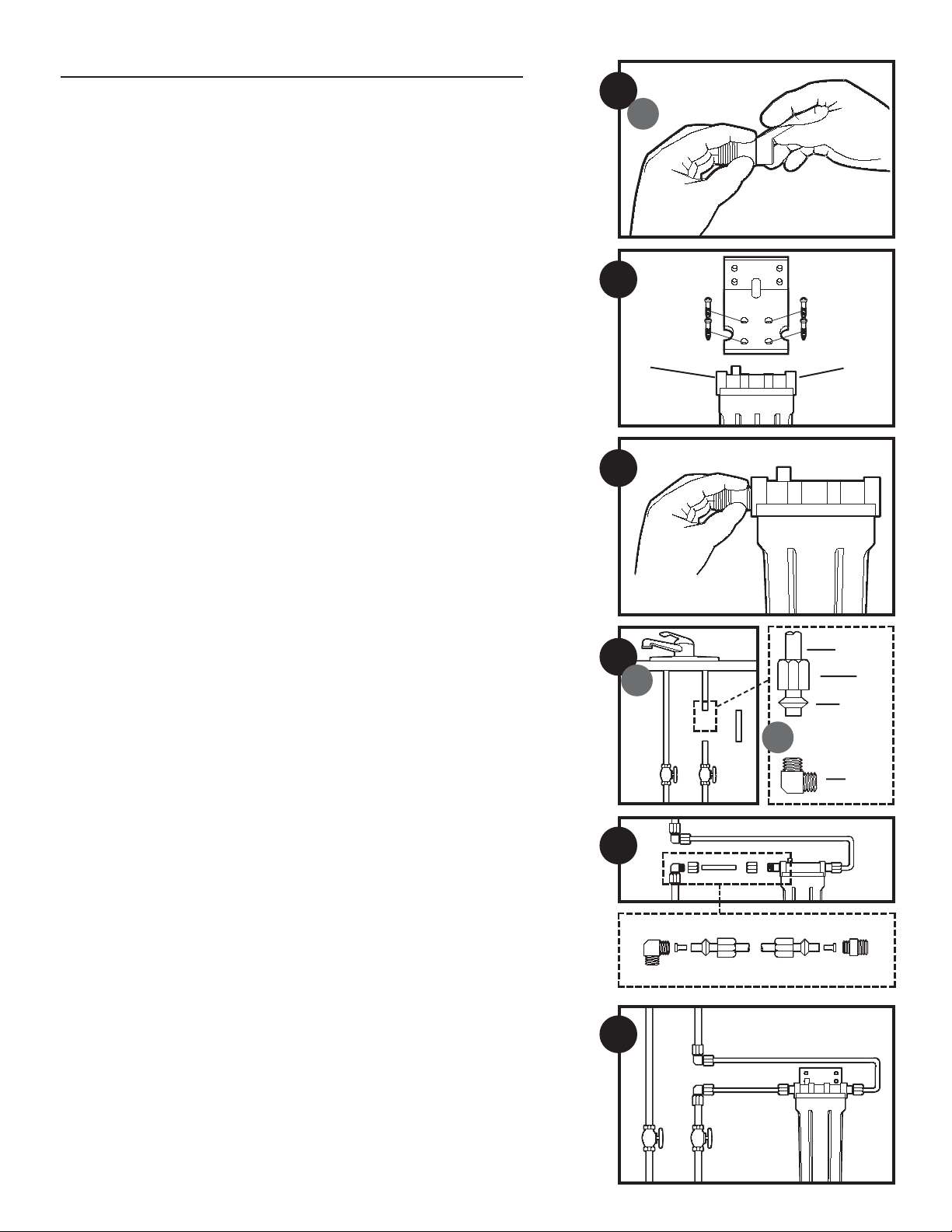

4. Attach to Cold Water Line

(A) Using a pipe cutter or hacksaw, remove a 3-inch (76 mm) section of pipe from the cold

water line. Deburr ends of remaining pipe with a file.

(B) Disassemble nuts and ferrules from compression elbows. Install a compression elbow onto

each end of remaining cold water line as shown. Using two wrenches, tighten compression

nuts firmly.

NOTE: Use metal ferrules with copper pipe and plastic ferrules with plastic pipe.

5. Installing the Tubing

Determine the lengths of tubing needed to connect the inlet and outlet sides of filter to the

compression elbows on the cold water line. Measure tubing short enough to prevent

kinking. Assemble as shown. Using two wrenches, tighten compression nuts 1–2 turns.

6. Completing the Installation

Turn on the water supply to allow filter to slowly fill with water and then press the red

pressure-relief button on top of the housing to release trapped air. Check for leaks and

tighten as needed.

NOTE: A drinking water cartridge may contain carbon fines (very fine black powder). After

installation, flush the cartridge for 5 minutes before using the water.

It is recommended that you run the tap at least 20 seconds prior to using the water for

drinking or cooking purposes.

2

1

4

5

6

3

2

IN OUT

3”

cold water line

nut

ferrule

elbow

B

B

A

Page 3

Filter Cartridge Replacement

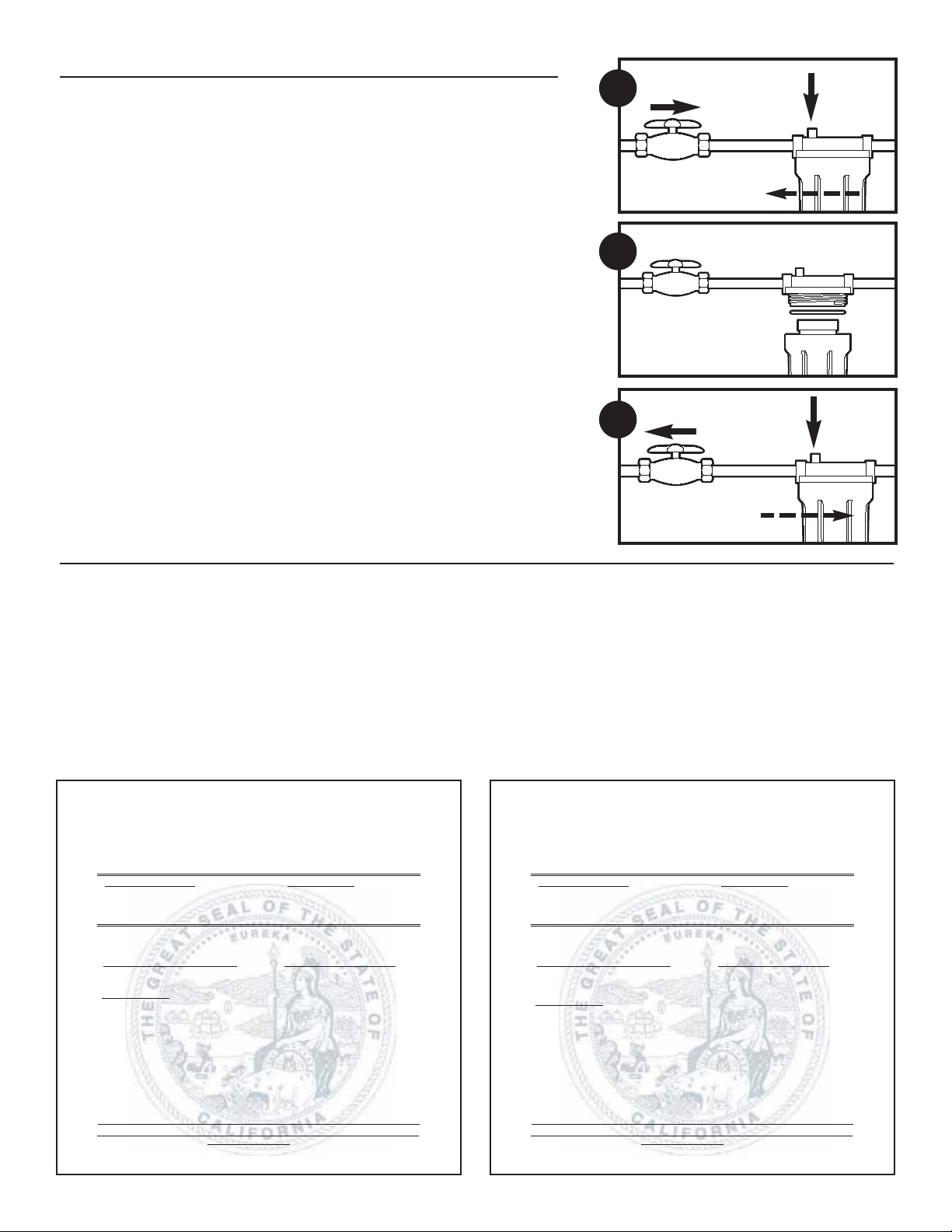

(A) 1. Turn off water supply to filter.

2. Depress red pressure-relief button on top of filter.

3. Unscrew and remove bottom of housing.

(B) Locate and remove large o-ring, wipe clean of lubricant and set aside. Discard used cartridge.

Rinse out bottom of housing and fill 1/3 full with water. Add about 2 tablespoons of bleach and

scrub cap and bottom of housing with non-abrasive sponge or cloth. Rinse thoroughly.

Lubricate o-ring with clean silicone grease. Insert o-ring back into groove and smooth into place

with finger.

NOTE: This step is important to ensure a proper housing seal. Make certain o-ring is seated level

in the groove.

Insert new cartridge over standpipe in bottom of housing. Cartridges with one gasket should be

inserted with the gasketed end towards the threads of the housing. (gasketed end would point

upwards if housing is mounted as shown in illustrations).

(C) 4. Screw bottom of housing onto the cap and hand-tighten. DO NOT OVER-TIGHTEN.

5. Turn on water supply slowly to allow filter to fill with water.

6. Depress red pressure-relief button to release trapped air.

Check for leaks before leaving installation.

NOTE: A drinking water cartridge may contain carbon fines (very fine black powder). After

installation, flush the cartridge for 5 minutes to remove the fines before using the water. You

should run the tap at least 20 seconds prior to using the water for drinking or cooking purposes.

3

A

C

B

1

2

3

5

6

4

Troubleshooting

Leaks:

...between cap and bottom of housing:

1. Turn off water supply and press pressure-relief button. Remove bottom of housing.

2. Clean o-ring and o-ring groove (located directly beneath threads of housing). Lubricate o-ring with clean silicone grease and replace securely into groove. Screw bottom

of housing back on cap and hand-tighten. DO NOTOVER-TIGHTEN.

...on inlet/outlet connections:

1. Turn off water supply. For brass fittings, tighten nut snugly 1/2-turn with wrench.

2. Turn on water supply. If leaks persist, or if there are other leaks on system, turn off water supply. Call Technical Support at 1-800-645-5426.

State of California

Department of Health Services

Water Treatment Device

Certificate Number

154403-

Date Issued: January 21, 2003

Trademark/Model Designation

US-600 D-30

US-550 D-30

Manufacturer: Culligan

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section

116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity

Cysts

Turbidity

Organic Contaminants

None

Replacement Elements

Inorganic/Radiological Contaminants

Asbestos

Trademark/Model Designation

US-600 D-40

US-550 D-40

Manufacturer: Culligan

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section

116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity

Cysts

Turbidity

Organic Contaminants

Atrazine

Lindane

State of California

Department of Health Services

Water Treatment Device

Certificate Number

154603-

Date Issued: January 21, 2003

Replacement Elements

Inorganic/Radiological Contaminants

Asbestos

Lead

Mercury

1000 gal.Rated Service Capacity: 0.9 gpm

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems certified for

cyst reduction may be used on disinfected waters that may contain filterable cysts.

Conditions of Certification:

Rated Service Flow:

600 gal.Rated Service Capacity: 0.6 gpm

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems certified for

cyst reduction may be used on disinfected waters that may contain filterable cysts.

Conditions of Certification:

Rated Service Flow:

Page 4

Replacement Parts

1 151039 Pressure-Relief Assembly

2 154159 White Cap

3 151121 o-ring (OR-38)

4 153049 Opaque Housing

5 150294 SW-1 Housing Wrench

(not included) not shown

For replacement parts, contact your nearest retailer or call

Culligan Consumer Services at 1-888-777-7962.

Performance Data

Important Notice: Read this performance data and compare the capabilities of

this system with your actual water treatment needs. It is recommended that, before

installing a water treatment system, you have your water supply tested to determine your actual water treatment needs.

This system has been tested according to NSF/ANSI 42 and 53 for reduction of the

substances listed below. The concentration of the indicated substances in water

entering the system was reduced to a concentration less than or equal to the permissible limit for water leaving the system, as specified in NSF/ANSI 42 and 53.

D-10 Cartridge

Substance Influent Challenge Max. Permissible Product Reduction Minimum Average

Concentration Water Concentration Requirements Reduction Reduction

Standard 42 Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 95%

Particulates at least 10,000 particles/mL ≥ 85% >85%

(1 to < 5 µm)

Class II

Flow Rate = 1 gpm (3.78Lpm)Capacity = 250 gallons (946 L) or 3 months

D-20 Cartridge

Substance Influent Challenge Max. Permissible Product Reduction Minimum Average

Concentration Water Concentration Requirements Reduction Reduction

Standard 42 Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 89%

Flow Rate = 1 gpm (3.78 Lpm)Capacity = 1000 gallons (3785 L) or 12 months

D-30 Cartridge

Substance Influent Challenge Max. Permissible Product Reduction Minimum Average

Concentration Water Concentration Requirements Reduction Reduction

Standard 42 Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 97%

Particulates at least 10,000 particles/mL ≥ 85% 96%

(0.5 to < 1µm)

Class I

Standard 53 Health Effects

Cysts

2)

Minimum 50,000/L 99.95% 99.99% 99.99%

Turbidity 11 ± 1 NTU 0.5 NTU 95.4% 97.4%

Asbestos 10

7

to 108fibers/L >10 99% 99.95% 99.95%

Micrometers in length

Flow Rate = 0.9 gpm (3.4 Lpm)Capacity = 1000 gallons (3785 L) or 12 months

D-40 Cartridge

Substance Influent Challenge Max. Permissible Product Reduction Minimum Average

Concentration Water Concentration Requirements Reduction Reduction

Standard 42 Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 97%

Particulates at least 10,000 particles/mL ≥ 85% 96%

(0.5 to < 1µm)

Class I

Standard 53 Health Effects

Cysts

2)

Minimum 50,000/L 99.95% 99.99% 99.99%

Turbidity 11 ± 1 NTU 0.5 NTU 95.4% 97.4%

Asbestos 10

7

to 108fibers/L >10 99% 99.95% 99.95%

Micrometers in length

Lead 6.5 pH 0.15 mg/L ±10% 0.010 mg/L 99.3% 99.3%

Lead 8.5 pH 0.15 mg/L ±10% 0.010 mg/L 94.1% 97.6%

Mercury 6.5 pH 0.006 mg/L ±10% 0.002 mg/L 72% 88.5%

Mercury 8.5 pH 0.006 mg/L ±10% 0.002 mg/L 95% 96.7%

Atrazine 0.009 mg/L ± 10% 0.003 mg/L 91.8% 93.8%

Lindane 0.002 mg/L ± 10% 0.0002 mg/L 97.3% 97.3%

Flow Rate = 0.6 gpm (2.27 Lpm)Capacity = 600 gallons (2271 L) or 6 months

2) Based on the use of microspheres or Cryptosporidium parvum oocysts

Testing was performed under standard laboratory conditions, actual performance may vary.

IOWA RESIDENTS ONLY:

Store or seller’s name

Address

City State Zip

Telephone

Seller’s signature

Customer’s signature Date

4

WARRANTY

This warranty applies to the Culligan US-550 Filter Housings only. It does NOT apply to any disposable filter cartridge, which has a life expectancy that varies with the water being filtered. This

warranty covers defects in materials and workmanship only for five full years from original date of

delivery. Culligan will replace any part which in Culligan’s opinion is defective, unless: (1) any

part of the system has been subjected to any type of tampering, alteration, or improper use after

delivery, or (2) any part of the system has been repaired by anyone not approved by Culligan.

Our obligation does not include the cost of shipment of materials. Culligan is not responsible for

damage in transit, and claims for such damage should be presented to the carrier by the

customer.

This product has been designed solely for use as a housing for a disposable filter cartridge. It is

NOT warranted against freezing, and neither this product nor its parts is warranted against

defects or deterioration caused by uses for which this product was not expressly intended.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, WHETHER ORAL OR ARISING BY USAGE OF TRADE OR COURSE OF

DEALING, INCLUDING, WITHOUT LIMITATION, ANY WARRANTIES OF FITNESS OR

MERCHANTABILITY. THIS WARRANTY IS THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY. IN NO

EVENT SHALL CULLIGAN. BE LIABLE FOR ANY ANTICIPATED OR LOST PROFITS, INCIDENTAL

DAMAGES, CONSEQUENTIAL CHARGES OR OTHER LOSSES, WHETHER BASED ON BREACH OF

CONTRACT, TORTIOUS CONDUCT OR ANY OTHER THEORY, INCURRED IN CONNECTION WITH THE

PURCHASE, INSTALLATION, REPAIR OR OPERATION OF THE OPAQUE FILTER HOUSING. CULLIGAN

DOES NOT AUTHORIZE ANYONE TO ASSUME FOR IT ANY LIABILITY OR MAKE ON ITS BEHALF ANY

ADDITIONAL WARRANTIES IN CONNECTION WITH THE OPAQUE FILTER HOUSING OR ANY PART

THEREOF.

For servicing under this warranty, return any defective part to YOUR RETAILER within the five-year

period referred to above.

1

2

3

4

Customer Service

M-F 7:30 a.m – 5:00 p.m. CST

Phone: 1-800-634-1455 Fax: 1-888-749-8826

International: Phone (920) 457-9435 • Fax (920) 457-2417

e-mail: customerservice@culligan.com

Sales & Marketing Correspondence

P.O. Box 1086 • Sheboygan, WI 53082-1086

Fax (847) 291-7632

e-mail: sales-marketing@culligan.com

©2003 Culligan International Company, Printed in U.S.A. 11/03 145765 Rev C

Culligan International Company

One Culligan Parkway

Northbrook, Illinois 60062

www.culligan.com

Page 5

Guía para Seleccionar

Cartuchos Filtrantes

Seleccione el cartucho filtrante D-10 D-20 D-30 D-40†

más apropiado para las 155528 155532 155465 155466

necesidades de su agua.

Sedimento • • •

Sabor desagradable y olor ••••

Cloro: sabor y olor ••••

Quistes como Giardia/Cryptosporidium

••

Asbestos • •

Plomo/Mercurio •

Lindane/Atrazine

•

Duración útil del filtro en Galones/meses*

250/3 1000/12 1000/12 600/6

Régimen de Flujo durante Servicio/Lpm**

1.0/3.8 1.0/3.8 0.9/3.4 0.6/2.3

*Duración útil del cartucho varía dependiendo en su clase, uso y condiciones del agua.

**Régimen de flujo medido a 60 psi/4.1 bar.

†Contiene un control de flujo de 0.6 gpm/2.3Lpm. Para usar con un grifo separado

(FT-10) en las instalaciones debajo del fregadero.

NOTA:

substancias reducidas no se encuentran en su agua necesariamente. El sistema y

el

cartucho filtrante se deben mantener de acuerdo con las instrucciones del fabricante.

Instrucciones De Instalación Y Funcionamiento

Filtro de Agua Para Instalar debajo del fregadero

Modelo US-550

1

Asistencia Técnica: 1-800-645-5426

(M-F 7:30 am - 5:00 pm CST)

11/03 145765 Rev C

NOTA: este portafiltro (carcaza) no incluye el cartucho filtrante.

Debe seleccionar el cartucho apropiado para sus necesidades e instalarlo en el pocillo

apropiado de acuerdo con las instrucciones para reemplazar el cartucho filtrante (pag. 3)

antes de proceder con la instalación. Mire la guía para seleccionar el cartucho filtrante en

la pag. 4 para determinar el mejor cartucho filtrtante para sus necesidades.

Especificaciones

Presión: 30-125 psi / 2.1-8.6 bar

Temperatura: 40–100°F / 4.4–37.7°C

Piezas Incluídas:

• Pocillo

• juego de artículos para el Soporte de montaje

Herramienta Necesaria Materiales Necesarios (No Son Incluidos)

• Destornillador

• Lima

• Lápiz

• Sierra de metales, o un cortatubos

• 2 Llaves ajustables

• Accesorios de compresión de 3/8 de pulgada / 10 mm para una instalación

normal debajo del fregadero con tubería de 3/8 de pulgada.

• Tubería plástica de 3/8 de pulgada / 10 mm.

• Cinta de Teflón

®

Materiales Opcionales

• SW-1 Llave para el pocillo.

• Grifo para tomar agua. (recomendado con el uso del cartucho filtrante D-40).

Precauciones

ADVERTENCIA: no use con agua que tiene peligro de microbiología, o la

calidad del agua es desconocida sin desinfectarla adecuadamente

antes o después del sistema filtrante. Sistemas los cuales han sido

certificados para la reducción de quistes, se pueden usar en aguas

desinfectadas que pueden contener quistes filtrables.

PRECAUCIÓN:este portafiltro (carcaza) tiene que protegerse contra congelación.

Fracaso de hacerlo puede resultar en grietas en el pocillo causando goteras.

PRECAUCIÓN: la arandela de caucho provee un sello hermético entre la tapa y el

pocillo. Es muy importante que la arandela se sienta correctamente

en la ranura del pocillo o goteras pueden ocurrir.

PRECAUCIÓN:debido a la duración limitada de este producto y para prevenir

reparos costosos o posibles daños causados por el agua, nosotros

recomendamos que todos los pocillos se reemplazen de menos cada

diez años. Si el pocillo se ha usado por más de este tiempo,se debe

reemplazar inmediatamente. Ponga la fecha debajo del pocillo nuevo

o cuando lo reemplasca para indicar la próxima fecha de reemplazo.

NOTA:

• Usese con agua fria solamente.

• Asegúrese de que la instalación conforme con todas las leyes y regulaciones

locales y estatales.

• Los contaminantes u otras substancias que se quitan o que son reducidas por

los cartuchos filtrantes que usted seleccione no se encuentran en su agua

necesariamente. Pregunte por una copia del análisis del agua de su municipalidad

local, u obtenga un análisis de su pozo privado por un laboratorio respetable

de analizar agua.

• Después de periodos extendidos sin uso (p. ej. durante vacaciones) se recomienda

fluir el sistema completamente. Deje fluir el agua por 5-6 minutos antes de usarla.

• El cartucho filtrante usado con este sistema tiene una duración limitada.

Cambios en el sabor, olor, color y/o flujo del agua indica que el cartucho filtrante

se debe reemplazar.

• Alguna bacteria inocua puede atacar el cartucho hecho con agente celuloso

(como el D-10). Si su cartucho filtrante se desintegra o adquiere un olor a

moho, reemplaze con un cartucho filtrante hecho con agente sintético o llame

al departamento de asistencia técnica en Culligan.

El US-550 es Analizado y Certificado por NSF Internacional bajo

NSF/ANSI Norma 42 y 53 con los cartuchos filtrantes D-10, D-20, D-30 y

D-40. Mire la hoja de datos de funcionamiento en el manual para ver

reclamaciones específicas.

Page 6

2

1

4

5

6

3

2

ENTRADA

SALIDA

3”

Tubería de

Agua fria

Tuerca

Virola

Codo

B

B

A

Instalación

NOTA:

• Para instalación debajo del fregadero normal de 3/8 de pulgada /10 mm en tubería de

agua fria (tubería de cobre o PVC).

• Lea todas las instrucciones, especificaciones, y precauciones antes de instalar o de usar este

filtro.

• Inserte el cartucho filtrante en el pocillo antes de continuar con la instalación. (mire las

Instrucciones para Reemplazar el Cartucho Filtrante en la página 3).

• El número en el diagrama corresponde con el número del paso.

1. Prepare los Adaptadores

(A) Cierre el abastecimiento de agua fria y abra el grifo más cercano para dejar escapar el aire

atrapado en la tubería antes de empezar la instalación. Ponga un balde debajo de la

tubería de agua fria para colectar el exceso de agua.

(B) Aplique más o menos 3-4 pulgadas / 76 mm – 102 mm de cintra de Teflón

®

en el sentido

de las agujas del reloj en las roscas de la tubería en cada adaptador.

2. Sujete el Soporte de Montaje

Usando los tornillos autorroscantes, debe sujetar el soporte de montaje a la tapa, y marque

el lugar debajo fregadero donde desea instalar el filtro.

NOTA:deje un espacio libre de 1-1/2 de pulgada / 38 mm debajo del pocillo para facilitar

el reemplazo del cartucho filtrante.

3. Conecte Adaptadores a la Tapa

Manualmente atornille el conector entre la entrada la tapa. Usando una llave ajustable,

apriete el conector firmemente. NO APRIETE CON EXAGERACIÓN. Más o menos una

rosca debe permanecer visible. Repita este paso con la salida de la tapa.

NOTA:Instale el filtro en el lugar marcado con el soporte de montaje.

4. Conecte la Linea de Agua Fria

(A) Usando una sierra o un cortatubos, corte 3 pulgadas / 76 mm de la tubería del agua fria.

Pula las puntas sobrantes de la tubería con una lima.

(B) Desarme las tuercas y virolas de los codos de compresión en cada punta sobrante de la

línea de agua fria como se ilustra. Apriete las tuercas de compresión firmemente usando

dos llaves ajustables.

NOTA:use las virolas de cobre con la tubería de cobre y use las virolas plásticas con la

tubería plástica.

5. Instale el Tubo

Determine la longitud de la tubería necesaria para conectar la entrada y salida del filtro a

los codos de compresión en la tubería de agua fria. Deje solo tubería suficientemente para

prevenir retorcimientos. Arme como se ilustra.

6. Complete la Instalación

Abra el abastecimiento de agua fria para permitir que el filtro se llene complemente de

agua y luego oprima el botón rojo para dejar escapar el aire atrapado en el portafiltro.

Inspeccione por goteras y apriete el pocillo si es necesario.

NOTA:el cartucho filtrante puede contener pedazos muy finos de carbón (polvo fino

negro). Después de instalarlo, debe fluirlo por 5 minutos para quitar estos, antes de usar el

agua.

Usted debe dejar correr el agua por mínimo de 20 segundos antes de usar el agua para

beber o cocinar.

Page 7

Instrucciones para Reemplazar el

Cartucho Filtrante

A. 1. Cierre el abastecimiento de agua al filtro.

2. Oprima el botón rojo para dejar escapar la presión.

3. Destornille y quite el pocillo.

B. Localice y quite la arandela redonda grande, límpiela de lubricante y póngala a un lado.

Deseche del filtro usado. Enjuágue el pocillo y llénelo 1/3 con agua. Agregue 2 cucharadas de descolorante

y restriégue el pocillo y la tapa usando una esponja o un trapo sin abrasivo. Enjuáguelos completamente.

Lubrique la arandela redonda con grasa de silicone. Inserte la arandela redonda en la ranura y

oprímala entre la ranura con un dedo

NOTA: este paso es muy importante para asegurar un sello apropiado. Asegúrese de que la arandela

se sienta nivelada en la ranura.

Inserte el cartucho nuevo asegurándose de que caiga encima del tubo vertical plástico en el fondo

del pocillo. Cartuchos filtrantes con una arandela deben insertansen de manera que el lado con la

arandela esté hacia las roscas del portafiltro.

C. 4. Atornille el pocillo entre la tapa y aprételo manualmente. NO APRIETE CON EXAGERACIÓN.

Asegúrese de que el cartucho caiga encima de el tubo vertical plástico en el fondo del pocillo.

5. Lentamente abra el abastecimiento de agua para dejar que el filtro se llene con agua.

6. Oprima el botón rojo, para dejar escapar el aire atrapado. Cuando acabe con la instalación

inspeccione por goteras.

NOTA:cartuchos para agua potable pueden contener pedazos muy finos de carbón (polvo muy

fino negro). Después de instalarlo, fluja el cartucho por 5 minutos antes de usar el agua. Debe fluir

el grifo un mínimo de 20 segundos antes de usar el agua para beber o cocinar.

3

A

C

B

1

2

3

5

6

4

Reparaciones

...Goteras entre el pocillo y la tapa:

1. Cierre el abastecimiento de agua y oprima el botón rojo. Quite el pocillo.

2. Limpie la arandela y su ranura (directamente debajo de las roscas del portafiltro). Lubrique la arandela con grasa de silicone y póngala de nuevo en la ranura. Atornille

el pocillo entre la tapa y aprételo manualmente. ASEGÚRESE DE NO SOBREAPRETARLO.

...En las Conexiones de entrada o Salida:

1. Cierre el abastecimiento de agua. Con accesorios de cobre, apriete la tuerca dándole 1/2 vuelta con una llave.

2. Abra el abastecimiento de agua. Si las goteras continúan o si tiene otras goteras en el sistema, cierre el abastecimiento de agua y llame gratis al Departamento de

Asistencia Técnica al: 1-800-645-5426.

State of California

Department of Health Services

Water Treatment Device

Certificate Number

154403-

Date Issued: January 21, 2003

Trademark/Model Designation

US-600 D-30

US-550 D-30

Manufacturer: Culligan

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section

116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity

Cysts

Turbidity

Organic Contaminants

None

Replacement Elements

Inorganic/Radiological Contaminants

Asbestos

Trademark/Model Designation

US-600 D-40

US-550 D-40

Manufacturer: Culligan

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section

116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity

Cysts

Turbidity

Organic Contaminants

Atrazine

Lindane

State of California

Department of Health Services

Water Treatment Device

Certificate Number

154603-

Date Issued: January 21, 2003

Replacement Elements

Inorganic/Radiological Contaminants

Asbestos

Lead

Mercury

1000 gal.Rated Service Capacity: 0.9 gpm

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems certified for

cyst reduction may be used on disinfected waters that may contain filterable cysts.

Conditions of Certification:

Rated Service Flow:

600 gal.Rated Service Capacity: 0.6 gpm

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems certified for

cyst reduction may be used on disinfected waters that may contain filterable cysts.

Conditions of Certification:

Rated Service Flow:

Page 8

Repuestos

1 151039 Ensamble Para Sacar La Presión

2 154159 Tapa Blanca

3 151121 Arandela (OR-38)

4 153049 Pocillo Opaco

5 150294 SW-1 Llave para el pocillo

(no es incluída) no está demonstrada.

Para comprar piezas de repuestos, llame al vendedor más

cercano o llame gratis al Departmento de Servicios para los

Consumidores de Culligan: 1-888-777-7962.

El sistema filtrante US-550 es cubierto por una garantía

limitada de cinco años. Mire la garantía por detalles.

Datos de Funcionamiento

Aviso Importante:lea estos datos de funcionamiento y compare la capacidad de

este sistema con las necesidades de su agua. Se recomienda que, antes de instalar

un sistema para tratar el agua, se debe obtener un análisis de su abastecimiento

de agua para determinar cuales son las necesidades de su agua.

Este sistema ha sido probado de acuerdo a las normas NSF/ANSI 42 y 53 para la

reducción de las substancias indicadas a continuación. La concentración de las

substancias indicadas en el agua entrante al sistema se redujo a una concentración

inferior o igual al límite permitido para el agua que sale del sistema, según se

especifica en las normas NSF/ANSI 42 y 53.

Cartucho Filtrante D-10

Substancia Concentración desafiante Concentración máxima del Requisitos Mínimo Promedio

del afluente producto permitida en el agua de reducción de reducción de reducción

Norma 42 Efectos Esteticos

Cloro 2.0 mg/L ±10% ≥ 50% 95%

Partículas at least 10,000 particles/mL ≥ 85% >85%

(1 to < 5 µm)

Class II

Régimen de Flujo = 1 gpm (3.78Lpm) Capacidad = 250 gallons (946 L) or 3 months

Cartucho Filtrante D-20

Substancia Concentración desafiante Concentración máxima del Requisitos Mínimo Promedio

del afluente producto permitida en el agua de reducción de reducción de reducción

Norma 42 Efectos Esteticos

Cloro 2.0 mg/L ±10% ≥ 50% 89%

Régimen de Flujo = 1 gpm (3.78 Lpm) Capacidad = 1000 gallons (3785 L) or 12 months

Cartucho Filtrante D-30

Substancia Concentración desafiante Concentración máxima del Requisitos Mínimo Promedio

del afluente producto permitida en el agua de reducción de reducción de reducción

Norma 42 Efectos Esteticos

Cloro 2.0 mg/L ±10% ≥ 50% 97%

Partículas at least 10,000 particles/mL ≥ 85% 96%

(0.5 to < 1µm)

Class I

Norma 53 Efectos para la Salud

Quistes

2)

Minimum 50,000/L 99.95% 99.99% 99.99%

Turbiedad 11 ± 1 NTU 0.5 NTU 95.4% 97.4%

Asbestos 10

7

to 108fibers/L >10 99% 99.95% 99.95%

Micrometers in length

Régimen de Flujo = 0.9 gpm (3.4 Lpm) Capacidad = 1000 gallons (3785 L) or 12 months

Cartucho Filtrante D-40

Substancia Concentración desafiante Concentración máxima del Requisitos Mínimo Promedio

del afluente producto permitida en el agua de reducción de reducción de reducción

Norma 42 Efectos Esteticos

Cloro 2.0 mg/L ±10% ≥ 50% 97%

Partículas at least 10,000 particles/mL ≥ 85% 96%

(0.5 to < 1µm)

Class I

Norma 53 Efectos para la Salud

Quistes

2)

Minimum 50,000/L 99.95% 99.99% 99.99%

Turbiedad 11 ± 1 NTU 0.5 NTU 95.4% 97.4%

Asbestos 10

7

to 108fibers/L >10 99% 99.95% 99.95%

Micrometers in length

Plomo 6.5 pH 0.15 mg/L ±10% 0.010 mg/L 99.3% 99.3%

Plomo 8.5 pH 0.15 mg/L ±10% 0.010 mg/L 94.1% 97.6%

Mercurio 6.5 pH 0.006 mg/L ±10% 0.002 mg/L 72% 88.5%

Mercurio 8.5 pH 0.006 mg/L ±10% 0.002 mg/L 95% 96.7%

Atrazine 0.009 mg/L ± 10% 0.003 mg/L 91.8% 93.8%

Lindane 0.002 mg/L ± 10% 0.0002 mg/L 97.3% 97.3%

Régimen de Flujo = 0.6 gpm (2.27 Lpm) Capacidad = 600 gallons (2271 L) or 6 months

2) Basado en el uso de micro esferas o Cryptosporidium parvum oocysts.

Pruebas hechas en condiciones normales de laboratorio, el desempeño actual puede variar.

Residentes de Iowa Solamente:

Nombre de la tienda o el vendedor

Dirección

Ciudad Estado Código postal

Teléfono

Firma del vendedor

Firma del cliente Fecha

4

GARANTÍA

Esta garantía es aplicable al portafiltro (carcaza) solamente. NO es aplicable a los cartuchos filtrantes

desechables, donde la duración expectativa varía con el agua que está filtrando. Esta garantía cubre

defectos en los materiales y fabricación solamente por cinco años desde la fecha de entrega. Culligan

reemplazará cualquier pieza la cual en la opinión de Culligan es defectuosa, al menos que: (1)

cualquier pieza del sistema haya sido sujetado a cualquier clase de interferencia, alteración, o uso

inapropiado después de entrega, o (2) cualquier pieza del sistema ha sido reparada por alguien que

no ha sido autorizado por Culligan. Nuestra obligación no incluye el costo de flete de los materiales.

Culligan no es responsable por daños causados durante transportación, y reclamos de esa clase se

deben hacer al portador por el consumi-dor directamente.

Este producto ha sido diseñado solamente para uso como recipiente para los cartuchos filtrantes

desechables. NO ESTÁ garantizado contra congelación, y ni este producto o sus piezas son garantizados contra defectos o deterioros causados por usos los cuales este producto ha sido expresamente

proyectado.

LA GARANTÍA PREVIA ES EXCLUSIVA Y REEMPLAZA CUALQUIER OTRA GARANTÍA, EXPRESADA O

IMPLICITADA, SEA ORAL, O RESULTADO POR USO COMÚN O UN ACUERDO MUTUO, INCLUYENDO,

SIN LIMITACIÓN, CUALQUIER GARANTÍA DE OPORTUNIDAD DE MEDIDA O CONDICIONES VENDIBLES.

ESTA GARANTÍA ES EXCLUSIVA Y ES EL ÚNICO RECURSO LEGAL DEL COMPRADOR. DE NINGUNA

MANERA CULLIGAN SERÁ RESPONSIBLE POR CUALQUIER PÉRDIDA DE GANANCIAS O GANANCIAS

ANTICIPADAS, DAÑOS INCIDENTALES, DAÑOS CONSECUENTES, U OTROS PÉRDIDAS, SEAN SOBRE

UN INCUMPLIMIENTO DE UN CONTRATO, IMCUMPLIMIENTO DE ACCIONES O CUALQUIER OTRA

TEORÍA, INCURRIDAS EN CONEXIÓN CON LA COMPRA, INSTALACIÓN, REPAROS O FUNCIONAMIENTO

DEL PORTAFILTRO (CARCAZA) OPACO. CULLIGAN NO AUTORIZA A NADIE A ASUMIR POR ELLA

CUALQUIER RESPONSABILIDAD O HACER POR ELLA CUALQUIER GARANTÍA ADICIONAL EN CONEXÍON

CON EL PORTAFILTRO (CARCAZA) OPACO O CUALQUIERA DE SUS PIEZAS.

Tiene que devolver cualquier pieza defectuosa a SU MINORISTA durante el periodo de cinco años

referído arriba.

1

2

3

4

Customer Service

M-F 7:30 a.m – 5:00 p.m. CST

Phone: 1-800-634-1455 Fax: 1-888-749-8826

International: Phone (920) 457-9435 • Fax (920) 457-2417

e-mail: customerservice@culligan.com

Sales & Marketing Correspondence

P.O. Box 1086 • Sheboygan, WI 53082-1086

Fax (847) 291-7632

e-mail: sales-marketing@culligan.com

©2003 Culligan International Company, Printed in U.S.A. 11/03 145765 Rev C

Culligan International Company

One Culligan Parkway

Northbrook, Illinois 60062

www.culligan.com

Loading...

Loading...