Page 1

Specifications

SY-2650

Temperature Range: 40–100°F (4.4–37.8°C)

Pressure Range: 30–125 psi (2.1–8.6 bar)

Service Flow Rate @60 psi (4.1 bar): 0.6 gpm (2.3 Lpm)

Rated Service Life: 500 gallons (1,893 L)

Dimensions: 9.18 in. x 4.70 in. x 12.72 in.

(233 mm x 119 mm x 323 mm)

Weight (filled with water): 6 lbs. (2.7 kg)

Parts Included

• Filter system with electronic monitor • Housing wrench

• D-250A cartridge set installed in system • 9-volt battery

•

1

/4-inch tubing • Faucet

• Installation hardware (mounting • Icemaker installation kit

screws, water supply adapter, quick

connect elbows)

Precautions

WARNING: Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the system. Systems

certified for cyst reduction may be used on disinfected waters that may contain

filterable cysts.

CAUTION: Filter must be protected against freezing, which can cause cracking of

the filter and water leakage.

CAUTION: The rubber O-ring provides the water-tight seal between the cap and

the bottom of the housing. It is important that the O-ring be properly seated in the

groove below the threads of the housing or a water leak could occur.

CAUTION: Because of the product’s limited service life and to prevent costly

repairs or possible water damage, we strongly recommend that the bottom of all

plastic housings be replaced every ten years. If the bottom of your housing has

been in use for longer than this period, it should be replaced immediately. Date

the bottom of any new or replacement housing to indicate the next recommended

replacement date.

NOTE:

• For cold water use only.

• Make certain that installation complies with all state and local laws and regulations.

• The contaminants or other substances removed or reduced by the selected

cartridge are not necessarily in your water. Ask your local water municipality

for a copy of their water analysis, or have your water tested by a reputable

water testing lab.

• After prolonged periods of non-use (such as during a vacation) it is

recommended that the system be flushed thoroughly. Let water run for 5–6

minutes before using.

• The filter cartridges used with this system have a limited service life. Changes

in taste, odor, and/or flow of the water being filtered indicate that the cartridge

should be replaced.

The Model SY-2650 is Tested and Certified by NSF International against NSF/ANSI

Standard 42 for the aesthetic reduction of Taste and Odor, Chlorine, and Particulate Class I.

Standard 53 for the reduction of MTBE, Lead, Mercury, VOC, Cyst, Asbestos, and Turbidity.

Monitored MTBE Filtration System

Installation and Operating Instructions

Model SY-2650

About Y our CULLIGAN

®

Monitored MTBE Filtration System

Thank you for purchasing a Culligan Monitored MTBE Filtration System. With only

minimal maintenance, your new system will provide you with safer, better-tasting

water for years to come. The filter cartridges should be changed after every 500

gallons of use or once every six months, whichever comes first. Filter life will vary

depending on usage and water conditions, and changes in taste, odor, and/or flow

of the water being filtered indicate that the filter cartridges should be replaced. The

SY-2650 incorporates an electronic monitor that measures the number of

gallons flowing through the system and alerts you when the filter cartridges need

to be replaced.

SY-2650 Monitored MTBE

Filtration System

The SY-2650 Monitored MTBE Filtration System uses two carbon filter cartridges

specially formulated to provide safer, cleaner, and better-tasting water. In addition

to the MTBE, chlorine, asbestos reduction and cyst removal, the SY-2650 filtration

system is NSF-certified to reduce lead, mercury, pesticides, herbicides, and various

Chemicals (VOC’s) in drinking water (see performance data on pg. 6 for specific

claims).

Lead is tasteless and colorless, and may enter your water supply through lead

pipes, lead solder, and brass fittings and faucets. High levels of lead in your

drinking water may lead to serious long-term health problems, especially in

children. The SY-2650 system has been Tested and Certified by NSF International

to reduce lead well below the USEPA Action Level.

A variety of pesticides, herbicides, and other chemicals (sometimes referred to as

Volatile Organic Chemicals or VOC’s) may be present in your water supply.

Common contaminants include Lindane, Atrazine, benzene, and trihalomethanes.

Trihalomethanes (THM) are a class of potentially harmful chemicals formed as a by

product of chlorination. The SY-2650 is NSF-Certified to reduce these and over 30

other chemicals to well below EPA drinking water standards. For a complete listing

of chemical reduction test results, see the Performance Data in this manual.

11/03 146410 Rev D

•Tape Measure

• Safety glasses

•Phillips head screwdriver

•Adjustable wrench

•Utility knife

•Pencil

If sink does not have hole for separate faucet:

•Center punch

•Hand or electric drill

(cordless recommended)

•1/4-inch and 1/2-inch drill bit

Tools and Materials Required

Page 2

Installation

• For standard under-sink installation on 1/2-inch 14 NPS threads (most common thread on

kitchen faucets) cold water line.

• Please read all instructions and precautions before installing and using your Monitored MTBE

Filtration System.

• Numbered diagrams correspond with numbered steps.

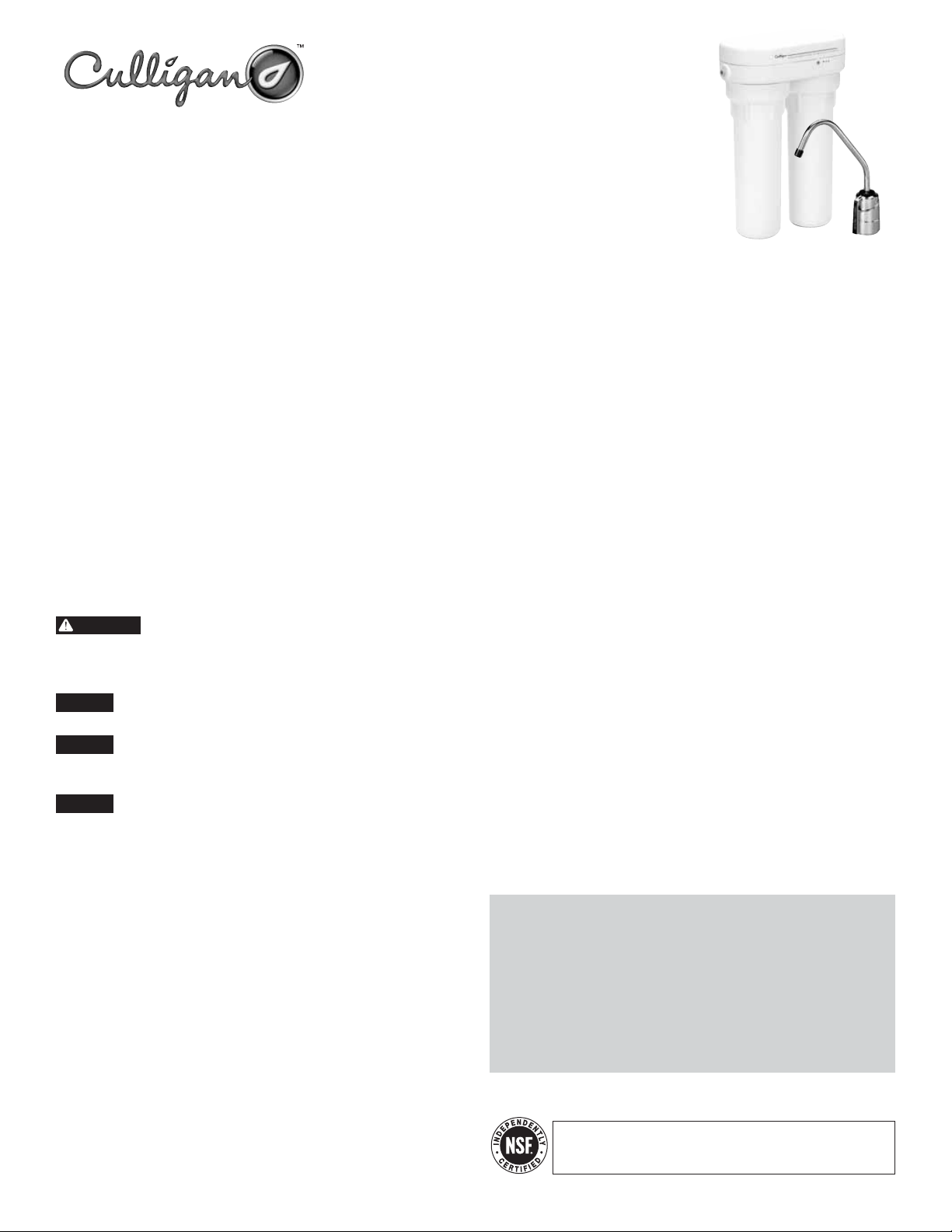

1. Installing the Water Supply Adapter

NOTE: The supply adapter fits 1/2-inch-14 NPS supply threads. If local codes permit, it may be

used to connect the SY-2650 to the cold water supply line. If local codes do not permit the use of

the supply adapter, alternate connectors can be obtained from your local plumbing supplier.

(A) Turn off the cold water supply. If cold water line does not have a shut-off valve under the sink,

you should install one.

(B) Turn on the cold water faucet and allow all water to drain from line.

(C) Disconnect cold water line from

1

/2-inch-14 NPS threaded stub on bottom of main faucet.

(D)Apply Teflon

®

tape onto threads of faucet stub and supply adapter. Screw the water supply

adapter to the threaded faucet stub as shown.

(E) Using the nut that previously connected the cold water line to the faucet, screw the cold water

line to the male supply adapter threads. (See diagram).

2. Selecting the Faucet Location

NOTE: The drinking water faucet should be positioned with function, convenience, and appearance

in mind. An adequate flat area is required to allow faucet base to rest securely. The faucet fits

through a

7

/16-inch hole. Most sinks have pre-drilled 1 3/8-inch or 1 1/2-inch diameter holes that

may be used for faucet installation. If these pre-drilled holes cannot be used or are in an inconvenient location, it will be necessary to drill a

1

/2-inch hole in the sink for the faucet.

CAUTION: This procedure may generate dusts which can cause severe irritation if inhaled or come

in contact with the eyes. The use of safety glasses and respirator for this procedure is recommended.

CAUTION: DO NOT ATTEMPT TO DRILL THROUGH AN ALL-PORCELAIN OR PORCELAIN-COATED

SINK. For applications on these types of sinks we recommend using the sprayer hole or

mounting the faucet through the countertop.

CAUTION: When drilling through a countertop make sure the area below the drilled area is free of

wiring and piping. Make certain that you have ample room to make the proper connections to the

bottom of the faucet.

CAUTION: Do not drill through a countertop that is more than 1-inch thick.

CAUTION: Do not attempt to drill through a tiled, marble, granite or similar countertop. Consult a

plumber or the countertop manufacturer for advice or assistance.

(A) Line bottom of sink with newspaper to prevent metal shavings, parts, or tools from falling

down drain.

(B) Place masking tape over the area to be drilled to prevent scratches if drill bit slips.

(C) Mark hole with center punch. Use a

1

/4-inch drill bit for a pilot hole, then, using a 1/2-inch

drill bit, drill a hole completely through the sink. Smooth rough edges with a file.

3. Mounting the Faucet

(A) Slide small black rubber gasket OR

(B) gasket, aluminum escutcheon plate (first remove protective plastic), and large gasket onto

threaded faucet stem. Lower faucet stem through hole in the sink.

NOTE: Black rubber gasket is designed for smaller holes in sink. Aluminum escutcheon plate with

gaskets is designed for larger, pre-drilled holes.

(C) Slide aluminum channel washer up faucet stem, followed by

(D)black plastic stem nut. Tighten nut with fingers.

NOTE: Do not use pliers to tighten stem-nut. Pliers may strip threads of faucet stem.

2

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

1

A

B

2

A

B

C

3

A

B

C

D

E

D

C

Page 3

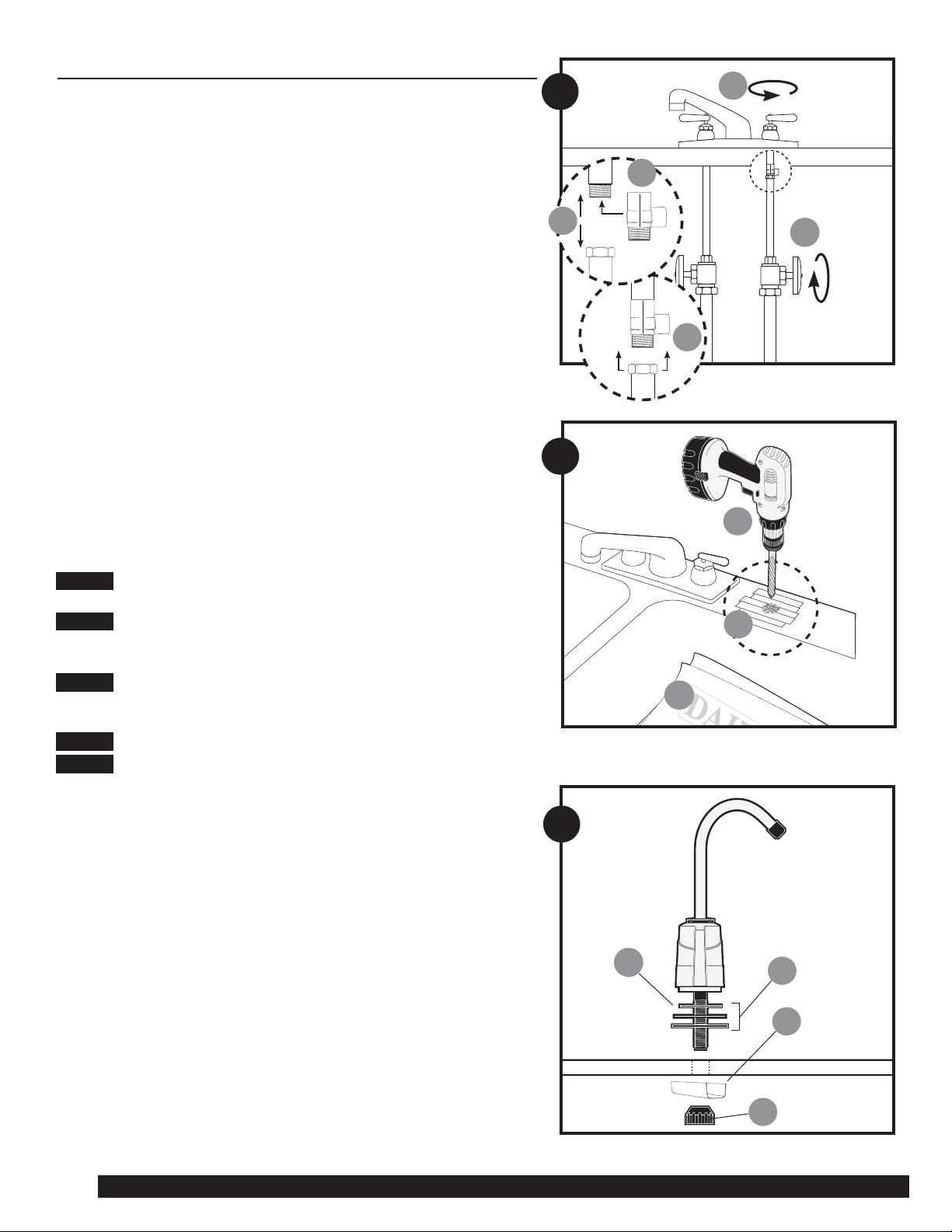

4. Mounting the System

(A) Center system between water supply adapter and drinking water faucet.

NOTE: Allow 1

1

/2-inches (38 mm) clearance below system for changing filter cartridges.

(B) Install mounting screws at least 13

3

/4-inches (350 mm) from cabinet floor and 4 1/8-inches

(124 mm) apart. Leave enough space (approximately

1

/2-inch [13 mm]) between the head of

the screw and the wall to slip system onto screws.

(C) Place system over screws on wall and slide downwards to lock into place.

CAUTION: Make certain system is firmly attached to wall to prevent it from falling and possibly

being damaged.

5. Connecting the Faucet

CAUTION: Do not over-tighten compression nut. Use caution not to bend or crimp tubes when

securing.

(A) Determine the length of plastic tubing needed to connect the outlet (right) side of the filter

with the faucet. Measure tubing short enough to prevent kinking and cut the tubing squarely.

Screw nut of faucet stem hand tight, then unscrew two turns.

NOTE: Compression nut should come preassembled with ferrules inside. If nut should come apart,

see figure 5A for proper assembly.

(B) Push the tubing firmly into the end of the faucet stem. Hand-tighten compression nut onto

threads until secure. Then tighten 1

1

/2to 2 turns with wrench.

6. Connecting the Supply Adapter

(A) Determine the length of plastic tubing needed to connect the inlet (left) side of the filter with

the supply adapter. Be sure to allow enough tubing to prevent kinking and cut the tubing

squarely. Place a mark

5

/8-inch from the end of the tubing.

(B) Wet tubing with water and insert into supply adapter

5

/8-inch until mark is flush with fitting.

NOTE: Disconnecting the Tubing from the Quick-Connect Fittings: Routine maintenance and

cartridge replacement will not require that you disconnect the tubing from the filter system;

however, tubing may be quickly and easily removed from the fittings if necessary. First, turn off the

water supply to the filter. Open faucet, then press in the gray collar around the fitting while pulling

the tubing with your other hand.

7. Connecting the System

(A) Assemble tubing with system as shown in Fig. 7A , inserting tubing into appropriate inlet or

outlet quick-connect fitting until it stops.

NOTE: In some installations, connecting the system to the supply adapter and/or drinking water

faucet causes the tubing to enter the quick-connect fitting at a sharp angle. This may exert

pressure on the quick-connect fitting and cause it to leak. In these situations, you may wish to use

one or both of the quick-connect elbows included with the installation kit. Simply push the quickconnect elbow directly into the quick-connect fitting on the system, then insert the tubing into the

quick-connect elbow.

(B) When cut between a set of black guide arrows, the tubing should be pushed into the fitting so

that the entrance of the fitting falls between the next set of guide arrows (approximately

5

/

8

inch [16 mm]).

3

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

5

B

A

4

A

B

C

1-1/2"

38 mm

13-3/4"

350 mm

6

A

B

A

4-1/8"

105 mm

5

/8"

16 mm

5

/8"

16 mm

7

A

B

5

/8"

16 mm

Page 4

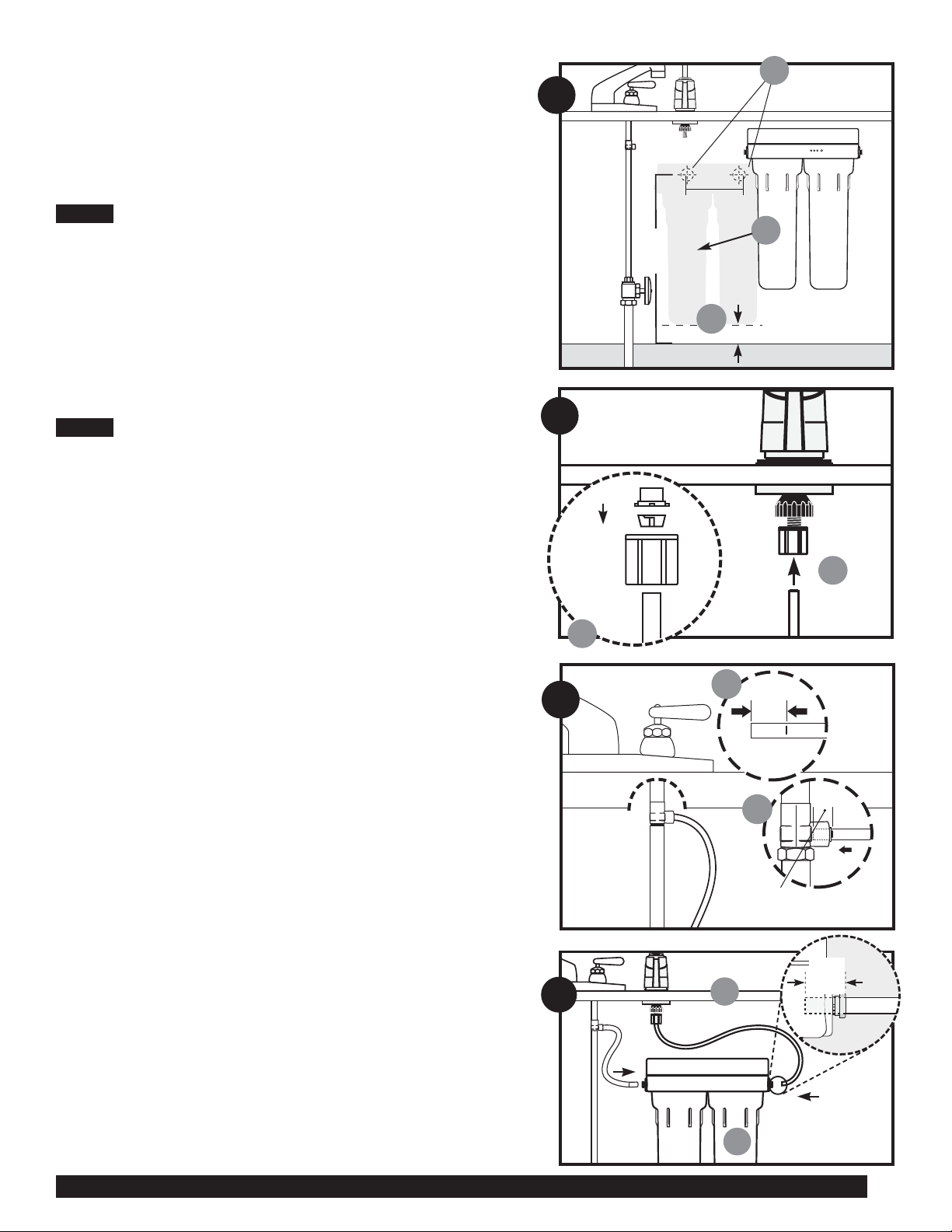

8. Installing the Battery

(A) Remove cover on top of system. Attach 9-volt battery (included) to connector, then place

battery in holder located to the left of the monitor panel as shown (Fig. 8A).

(B) Replace cover on top of system. Using a pen or pencil, press and release the blue reset button

on the front of the system (Fig. 8B). The electronic monitor should beep twice. If the monitor

has been reset properly, the two beeps will be followed by a sequence of two green, two

yellow, and two red lights. The monitor should be reset whenever a new set of filter cartridges

is installed.

9. Putting the System into Operation

(A) Slowly turn on cold water supply.

(B) Shut off cold water faucet opened before starting installation.

(C) Rotate base of drinking water faucet counter-clockwise to “ON” position. Allow water to run

for 5 minutes to flush air and carbon fines from filter cartridges. Turn off drinking water faucet.

Check system for leaks before leaving installation.

NOTE:

• It is recommended that you run the tap at least 20 seconds prior to using water for drinking or

cooking purposes.

• Initially, filtered water may appear cloudy. If you set a glass of water on a level surface, you

should be able to watch the cloudiness disappear from the bottom of the glass upwards. This

harmless cloudiness results from the release of trapped air within the cartridge and will

disappear within a few weeks after installation.

INSTALLATION IS NOW COMPLETE.

4

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

9

A

C

B

D

8

A

B

Electronic Monitor Operations

The SY-2650 system includes an electronic monitor that alerts you when it is time to change your

filter cartridges. Both filter cartridges should be changed at the same time to ensure that the

monitor works properly. The monitor measures actual water usage and is powered by a single

9-volt battery.

How the Electronic Monitor Works

The filter cartridges in the SY-2650 should be replaced every 500 gallons. The electronic monitor

uses a combination of lights and alarms to alert you at different stages during the life of the filter

cartridges. The lights are visible on the front panel of the filter system, to the left of the blue reset

button:

0-475 gallons No alarm. Green light flashes when water is turned on.

475-500 gallons Alarm BEEPS ONCE when water is turned on. Yellow light flashes when

water is on.

500+ gallons Alarm BEEPS TWICE when water is turned on. Red light flashes when water

is on.

Low or Dead batteryNo alarm. No lights. Replace battery.

NOTE: Gallons used while battery is dead will register on meter when battery is replaced

NOTE: To extend battery life, any sequence that includes any beeps will not be repeated if water is

turned on again in less than 15 minutes.

Reset Button

The blue reset button is located on the front panel of the system. This button should only be

pressed during initial installation or when new filter cartridges are installed. After pressing and

releasing the button, you will hear two beeps followed by a sequence of two green, two yellow,

and two red lights. This combination of beeps and lights indicates that the system has properly

reset the internal gallon counter.

Replacing the Battery

The battery should be replaced every time new filter cartridges are

installed or after 12 months of operation, whichever comes first.

Replacing Battery and Filters at the Same Time: Install new 9-volt

battery as described in Step Eight: Installing the Battery on p. 4.

Make sure to press blue reset button on front panel of system when

finished.

Replacing Battery Only:Remove the old battery and install the

new battery. DO NOT press the reset button on the front panel of the

system when finished.

Page 5

5

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

Filter Cartridge Replacement

• Filter cartridges for the SY-2650 will last about 500 gallons or six months

before they need to be replaced. Filter cartridge life varies depending on

usage, and/or water conditions. Changes in taste, color, and flow of the

water being filtered indicate that the cartridge should be replaced.

• Read all instructions before replacing filter cartridges.

WARNING: Use safety glasses and gloves when handling household

bleach to prevent bodily injury. Follow bleach manufacturer's instructions when

handling bleach.

1. Close water supply valve and open drinking water faucet to release pressure

from system.

2. Using the housing wrench, unscrew and remove bottom of filter housing.

Locate and remove large O-ring, wipe clean of lubricant, and set aside.

Repeat for second housing.

3. Discard used filter cartridges. Using a non-abrasive sponge or cloth, scrub

the bottom of filter housings, O-ring grooves, and caps with dish soap and

warm water. Rinse thoroughly. Fill bottom of each housing

1

/3full with

water. Add 1 teaspoon of household bleach and scrub to disinfect.

4. Lubricate O-rings with silicone grease. Insert each O-ring in groove and

press into place.

NOTE: This step is important to ensure a proper housing seal. Make certain

each O-ring is seated level in its groove or a leak may occur.

5. Screw bottom of housings with bleach water onto caps without filter

and hand-tighten. DO NOT OVER-TIGHTEN.

6. Turn on water supply. Let faucet run for about 10 seconds, then turn off

faucet and let stand for 20-30 minutes.

7. Turn on faucet and allow bleach water to run out (about 3-5 minutes).

8. Turn off water supply to system and open faucet to release pressure.

Remove bottom of housings and empty of water.

9. Insert each filter cartridge into appropriate filter housing:

SY-2650: D-250A Cartridge Set: White with green end caps in left housing.

Grey plastic cartridge in right housing

10. Screw bottom of housings onto caps and hand-tighten. DO NOT OVERTIGHTEN. Make certain cap standpipe slips into cartridge.

11. Open water supply valve and turn on drinking water faucet to release

pressure in system. Let faucet run for 5 minutes to remove trapped air

and carbon fines. Check system for leaks before leaving installation.

12. Press blue reset button.

NOTE:

• It is recommended that you run the tap at least 20 seconds prior to using

water for drinking or cooking purposes.

• Initially, filtered water may appear cloudy. If you set a glass of water on a

level surface, you should be able to watch the cloudiness disappear from

the bottom of the glass upwards This harmless cloudiness results from the

release of trapped air within the cartridge and will disappear within a few

weeks after installation.

Troubleshooting

Leaks:

…between cap and bottom of filter housing

Turn off water supply valve and turn on drinking water faucet to release pressure in

system. Remove bottom of housing. Clean O-ring and O-ring groove (located directly

beneath threads of housing). Lubricate O-ring with silicone grease and replace

securely into groove. Screw bottom of housing onto cap and hand-tighten. DO NOT

OVER-TIGHTEN. Turn on water supply valve and check for leaks.

…on system inlet/outlet connections

Turn off water supply valve and turn on drinking water faucet to release pressure in

system. Remove tubing from fitting (see NOTE under Step Six: Connecting the Supply

Adapter on p.3) and make sure end of tubing is cut squarely and free of scratches or

burrs. Reinsert tubing into quick-connect fittings, making sure to push securely until

tubing hits a hard stop. Turn on water supply valve and check for leaks.

…on supply adapter connection

Turn off water supply valve and turn on drinking water faucet to release pressure in

system. Loosen leaking threaded fitting on supply adapter or pull out leaking tubing

from fitting. Inspect to see if plastic tubing is scratched or supply adapter was properly

attached. If tubing is scratched, cut off

1

/2-inch to 5/8-inch and reinstall per Step Six:

Connecting the Supply Adapter. Reconnect tubing or tighten compression nut with

fingers, then tighten nut snugly

1

/2-turn with wrench. Turn on water supply valve and

check for leaks.

…on faucet/tubing connection

Turn off water supply valve and turn on drinking water faucet to release pressure in

system. Loosen and remove compression nut fitting on faucet stem. Make sure tubing

is inserted firmly into end of faucet stem, then retighten compression nut with fingers

until secure then tighten 1 turn with a wrench. Turn on water supply valve, then turn

off faucet to check for leaks.

NOTE: If leaks persist, or if there are other leaks on system, turn off water supply.

Call our technical support department at 1-800-645-5426.

Low Water Flow

1. Check flow at faucet. The SY-2650 system should fill a gallon jug in approximately

2 minutes. Flow rates will vary with individual household water pressure.

2. Check filter cartridge installation. Make certain both filter cartridges are properly

oriented in filter housings (See Filter Cartridge Replacement on p. 5).

3. Check to be certain that the water supply valve is completely open (turn handle

on valve counter-clockwise as far as it will go).

4. Check flow through empty system. To do this, turn off water supply valve and turn

on drinking water faucet to release pressure in system. Then remove filter

cartridges from housings and screw housings back onto caps. Turn on faucet to

check flow through empty system. Flow should be about one to two gallons per

minute. If flow is less than 0.4 gallons per minute, call Technical Support at

1-800-645-5426.

5. If flow through empty system is adequate, place one filter cartridge in system at

a time and check flow to make sure cartridge is not clogged. Replace clogged

cartridge if necessary.

Page 6

6

Performance Data

Important Notice: Read this performance data and compare the capabilities of this system with your actual water treatment needs. It is recommended that, before

installing a water treatment system, you have your water supply tested to determine your actual water treatment needs.

This system has been tested according to NSF/ANSI 42 and 53 for reduction of the substances listed below. The concentration of the indicated substances in water entering

the system was reduced to a concentration less than or equal to the permissible limit for water leaving the system, as specified in NSF/ANSI 42 and 53.

6

Organic Chemicals Included by Surrogate Testing:

Influent Challenge Maximum permissible

Substance Concentration mg/L product water concentration mg/L

alachor 0.050 0.001

atrazine 0.100 0.003

benzene 0.081 0.001

carbofuran 0.190 0.001

carbon tetrachloride 0.078 0.0018

chlorobenzene 0.077 0.001

chloropicrin 0.015 0.0002

2,4-D 0.110 0.0017

dibromochloropropane (DBCP) 0.052 0.00002

o-dichlorobenzene 0.080 0.001

p-dichlorobenzene 0.040 0.001

1,2-dichloroethane 0.088 0.0048

1,1-dichloroethylene 0.083 0.001

cis-1,2-dichloroethylene 0.170 0.0005

trans-1,2-dichloroethylene 0.086 0.001

1,2-dichloropropane 0.080 0.001

cis-1,3-dichloropropylene 0.079 0.001

dinoseb 0.170 0.0002

endrin 0.053 0.00059

ethylbenzene 0.088 0.001

ethylene dibromide (EDB) 0.044 0.00002

haloacetonitriles (HAN):

bromochloroacetonitrile 0.0022 0.0005

dibromoacetonitrile 0.024 0.0006

dichloroacetonitrile 0.0096 0.0002

trichloracetonitrile 0.0015 0.0003

haloketones (HK):

1,1-dichloro-2-propanone 0.0072 0.0001

1,1,1-trichloro-2-propanone 0.0082 0.0003

heptachlor 0.08 0.0004

heptachlor epoxide 0.0107 0.0002

hexachlorobutadiene 0.044 0.001

hexachlorocyclopentadiene 0.060 0.000002

lindane 0.055 0.00001

methoxychlor 0.050 0.0001

pentachlorophenol 0.096 0.001

simazine 0.120 0.004

styrene 0.150 0.0005

1,1,2,2-tetrachloroethane 0.081 0.001

tetrachloroethylene 0.081 0.001

toluene 0.078 0.001

2,4,5-TP (silvex) 0.270 0.0016

tribromoacetic acid 0.042 0.001

1,2,4-trichlorobenzene 0.160 0.0005

1,1,1-trichloroethane 0.084 0.0046

1,1,2-trichloroethane 0.150 0.0005

trichloroethylene 0.180 0.0010

trihalomethanes (includes):

chloroform (surrogate chemical)

bromoform 0.304 0.015

bromodichloromethane

chlorodibromomethane

xylenes (total) 0.070 0.001

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

State of California

Department of Health Services

Water Treatment Device

Certificate Number

Date Issued: May 17, 2000

Date Revised: March 9, 2001

1437

00-

Trademark/Model Designation

Replacement Element(s)

Culligan SY-2300 D-250A

Culligan SY-2300S D-250A

Culligan SY-2650 D-250A

Cysts (protozoan)

Turbidity

Asbestos

Lead

Mercury

MTBE

VOCs

Culligan

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section

116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity

Inorganic/Radiological Contaminants

Organic Contaminants

Alachlor

Bromodichloromethane

1

Carbon Tetrachloride

2,4-D

o-Dichlorobenzene

1,2-Dichloroethane

cis-1,2-Dichloroethylene

Dinoseb

Ethylbenzene

Hexachlorocyclopentadiene

Methoxychlor

Styrene

1,1,2,2-Tetrachloroethane

1,1,1-Trichloroethane

m-Xylene

1

Trihalomethanes

Benzene

Carbofuran

Chloroform

1

Chlorodibromomethane

1

1,1-Dichloroethylene

cis-1,3-Dichloropropylene

Endrin

Heptachlor Epoxide

Lindane

Simazine

Tetrachloroethylene

1,2,4-Trichlorobenzene

Trichloroethylene

p-Xylene

Atrazine

Bromoform

1

Chlorobenzene

DBCP

p-Dichlorobenzene

trans-1,2-Dichloroethylene

1,2-Dichloropropane

EDB

Heptachlor

Hexachlorobutadiene

Pentachlorophenol

2,4,5-TP (Silvex)

Toluene

1,1,2-Trichloroethane

o-Xylene

500 gallonsRated Service Capacity: 0.6 gpm

Rated Service Flow:

Do not use where water is microbiologically unsafe or with water of unknown quality, except that

systems claiming cyst reduction may be used on water containing cysts.

Manufacturer:

SY-2650

Substance Influent Challenge Max. Permissible Product Reduction Minimum Average

Concentration Water Concentration Requirements Reduction Reduction

Standard 42 Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 97%

Particulates at least 10,000 particles/mL ≥ 85% 96%

(0.5 to < 1µm)

Class I

Standard 53 Health Effects

MTBE 0.015 ±20% 0.005 mg/L 69% 90%

Cysts

2)

Minimum 50,000/L 99.95% 99.99% 99.99%

Turbidity 11 mg/L ±1 NTU 0.5 NTU 99.1% 99.4%

Asbestos 107to 108fibers/L >10 99% 99.9% 99.9%

Micrometers in length

Lead 6.5 pH 0.15 mg/L ± 10% 0.010 mg/L 99.3% 99.3%

Lead 8.5 pH 0.15 mg/L ± 10% 0.010 mg/L 94.1% 97.6%

Mercury 6.5 pH 0.006 mg/L ± 10% 0.002 mg/L 85% 90.8%

Mercury 8.5 pH 0.006 mg/L ± 10% 0.002 mg/L 80.6% 90%

Chloroform 0.304 mg/L 0.015 mg/L 99.7% 99.8%

(VOC surrogate chemical)

Flow Rate = 0.6 gpm (2.27 Lpm) Capacity = 500 gallons (1893 L) or 6 months

2)

Based on the use of microspheres or Cryptosporidium parvum oocysts

Testing was performed under standard laboratory conditions, actual performance may vary.

Page 7

7

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

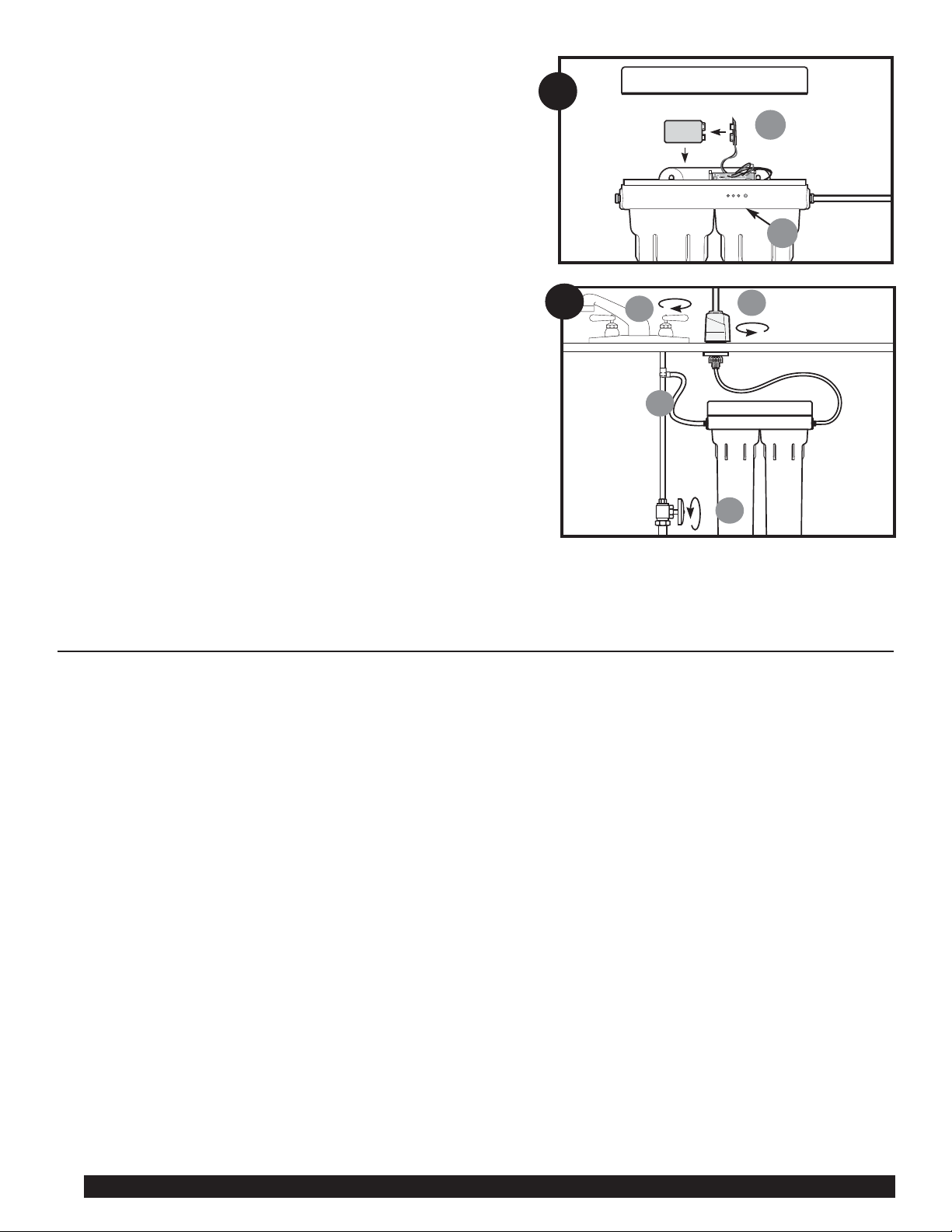

Replacement Parts

Replacement Filter Cartridges

SY-2650

1B/2B 155832 D-250A (Cartridges sold only as a set)

1B= White netting pre-filter

2B= Grey post filter

3. 153126 White housing bottom

4. 151231 O-ring (OR-233)

5. 151242 Faucet

6. 143431 Water Supply Valve

7. 150424 Housing Wrench (SW-5)

Circuit and Probe (not shown)

For replacement parts, contact your nearest Culligan

®

water filter retailer or call 1-888-777-7962.

4

5

6

7

3

B

1

B

2

Performance Data

WARNING: Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system. Systems certified for

cyst reduction may be used on disinfected waters that may contain filterable cysts.

NOTE: Substances reduced are not necessarily in your water. Filter must be maintained according to manufacturer's instructions, including replacement of filter cartridges.

Test Conditions

Flow Rate = as noted for filter system

Inlet Pressure = 60 psi (4.1 bar)

pH = 7.5±1

Temperature = 68°F±5°F (20°C±2.5°C)

Operating Requirements

Pressure = 30–125 psi (2.1–8.6 bar)

Temperature = 40–100°F (4.4–37.8°C)

Turbidity = 5 NTU Max.

Suggested Retail Price for Replacement Filter Cartridges:

SY-2650: D-250A = $50.39

NOTE: Price subject to change. Contact your local retailer or call: 1-888-777-7962 for current replacement cartridge pricing.

Page 8

WARRANTY

This warranty applies to the Filter Housings only. It does NOT apply to any disposable filter cartridge, which has a life expectancy that varies with the water being filtered. This warranty covers defects in

materials and workmanship only for one full year from original date of delivery. Culligan will replace any part which in Culligan’s opinion is defective, unless: (1) any part of the system has been subjected

to any type of tampering, alteration, or improper use after delivery, or (2) any part of the system has been repaired by anyone not approved by Culligan. Our obligation does not include the cost of

shipment of materials. Culligan is not responsible for damage in transit, and claims for such damage should be presented to the carrier by the customer.

This product has been designed solely for use as a housing for a disposable filter cartridge. It is NOT warranted against freezing, and neither this product nor its parts is warranted against defects or

deterioration caused by uses for which this product was not expressly intended.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, WHETHER ORAL OR ARISING BY USAGE OF TRADE OR COURSE OF DEALING, INCLUDING,

WITHOUT LIMITATION, ANY WARRANTIES OF FITNESS OR MERCHANTABILITY. THIS WARRANTY IS THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY. IN NO EVENT SHALL CULLIGAN BE LIABLE FOR ANY

ANTICIPATED OR LOST PROFITS, INCIDENTAL DAMAGES, CONSEQUENTIAL CHARGES OR OTHER LOSSES, WHETHER BASED ON BREACH OF CONTRACT, TORTIOUS CONDUCT OR ANY OTHER THEORY,

INCURRED IN CONNECTION WITH THE PURCHASE, INSTALLATION, REPAIR OR OPERATION OF THE OPAQUE FILTER HOUSING. CULLIGAN DOES NOT AUTHORIZE ANYONE TO ASSUME FOR IT ANY LIABILITY

OR MAKE ON ITS BEHALF ANY ADDITIONAL WARRANTIES IN CONNECTION WITH THE OPAQUE FILTER HOUSING OR ANY PART THEREOF.

For servicing under this warranty, return any defective part to YOUR RETAILER within the one-year period referred to above.

IOWA RESIDENTS ONLY:

Store or seller’s name:

Address:

City: State: Zip:

Telephone:

Seller’s signature:

Customer’s signature: Date:

Customer Service

M-F 7:30 a.m – 5:00 p.m. CST

Phone: 1-800-634-1455 Fax: 1-888-749-8826

International: Phone (920) 457-9435 • Fax (920) 457-2417

e-mail: customerservice@culligan.com

Sales & Marketing Correspondence

P.O. Box 1086 • Sheboygan, WI 53082-1086

Fax (847) 291-7632

e-mail: sales-marketing@culligan.com

©2003 Culligan International Company, Printed in U.S.A. 11/03 146410 Rev D

Culligan International Company

One Culligan Parkway

Northbrook, Illinois 60062

www.culligan.com

Page 9

Specifications

SY-2650

Temperature Range: 40–100°F (4.4–37.8°C)

Pressure Range: 30–125 psi (2.1–8.6 bar)

Service Flow Rate @60 psi (4.1 bar): 0.6 gpm (2.3 Lpm)

Rated Service Life: 500 gallons (1,893 L)

Dimensions: 9.18 in. x 4.70 in. x 12.72 in.

(233 mm x 119 mm x 323 mm)

Weight (filled with water): 6 lbs. (2.7 kg)

Parts Included

• Filter system with electronic monitor • Housing wrench

• D-250A cartridge set installed in system • 9-volt battery

•

1

/4-inch tubing • Faucet

• Installation hardware (mounting • Icemaker installation kit

screws, water supply adapter, quick

connect elbows)

Precautions

WARNING: Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the system. Systems

certified for cyst reduction may be used on disinfected waters that may contain

filterable cysts.

CAUTION: Filter must be protected against freezing, which can cause cracking of

the filter and water leakage.

CAUTION: The rubber O-ring provides the water-tight seal between the cap and

the bottom of the housing. It is important that the O-ring be properly seated in the

groove below the threads of the housing or a water leak could occur.

CAUTION: Because of the product’s limited service life and to prevent costly

repairs or possible water damage, we strongly recommend that the bottom of all

plastic housings be replaced every ten years. If the bottom of your housing has

been in use for longer than this period, it should be replaced immediately. Date

the bottom of any new or replacement housing to indicate the next recommended

replacement date.

NOTE:

• For cold water use only.

• Make certain that installation complies with all state and local laws and regulations.

• The contaminants or other substances removed or reduced by the selected

cartridge are not necessarily in your water. Ask your local water municipality

for a copy of their water analysis, or have your water tested by a reputable

water testing lab.

• After prolonged periods of non-use (such as during a vacation) it is

recommended that the system be flushed thoroughly. Let water run for 5–6

minutes before using.

• The filter cartridges used with this system have a limited service life. Changes

in taste, odor, and/or flow of the water being filtered indicate that the cartridge

should be replaced.

The Model SY-2650 is Tested and Certified by NSF International against NSF/ANSI

Standard 42 for the aesthetic reduction of Taste and Odor, Chlorine, and Particulate Class I.

Standard 53 for the reduction of MTBE, Lead, Mercury, VOC, Cyst, Asbestos, and Turbidity.

Monitored MTBE Filtration System

Installation and Operating Instructions

Model SY-2650

About Y our CULLIGAN

®

Monitored MTBE Filtration System

Thank you for purchasing a Culligan Monitored MTBE Filtration System. With only

minimal maintenance, your new system will provide you with safer, better-tasting

water for years to come. The filter cartridges should be changed after every 500

gallons of use or once every six months, whichever comes first. Filter life will vary

depending on usage and water conditions, and changes in taste, odor, and/or flow

of the water being filtered indicate that the filter cartridges should be replaced. The

SY-2650 incorporates an electronic monitor that measures the number of

gallons flowing through the system and alerts you when the filter cartridges need

to be replaced.

SY-2650 Monitored MTBE

Filtration System

The SY-2650 Monitored MTBE Filtration System uses two carbon filter cartridges

specially formulated to provide safer, cleaner, and better-tasting water. In addition

to the MTBE, chlorine, asbestos reduction and cyst removal, the SY-2650 filtration

system is NSF-certified to reduce lead, mercury, pesticides, herbicides, and various

Chemicals (VOC’s) in drinking water (see performance data on pg. 6 for specific

claims).

Lead is tasteless and colorless, and may enter your water supply through lead

pipes, lead solder, and brass fittings and faucets. High levels of lead in your

drinking water may lead to serious long-term health problems, especially in

children. The SY-2650 system has been Tested and Certified by NSF International

to reduce lead well below the USEPA Action Level.

A variety of pesticides, herbicides, and other chemicals (sometimes referred to as

Volatile Organic Chemicals or VOC’s) may be present in your water supply.

Common contaminants include Lindane, Atrazine, benzene, and trihalomethanes.

Trihalomethanes (THM) are a class of potentially harmful chemicals formed as a by

product of chlorination. The SY-2650 is NSF-Certified to reduce these and over 30

other chemicals to well below EPA drinking water standards. For a complete listing

of chemical reduction test results, see the Performance Data in this manual.

11/03 146410 Rev D

•Tape Measure

• Safety glasses

•Phillips head screwdriver

•Adjustable wrench

•Utility knife

•Pencil

If sink does not have hole for separate faucet:

•Center punch

•Hand or electric drill

(cordless recommended)

•1/4-inch and 1/2-inch drill bit

Tools and Materials Required

Page 10

Installation

• For standard under-sink installation on 1/2-inch 14 NPS threads (most common thread on

kitchen faucets) cold water line.

• Please read all instructions and precautions before installing and using your Monitored MTBE

Filtration System.

• Numbered diagrams correspond with numbered steps.

1. Installing the Water Supply Adapter

NOTE: The supply adapter fits 1/2-inch-14 NPS supply threads. If local codes permit, it may be

used to connect the SY-2650 to the cold water supply line. If local codes do not permit the use of

the supply adapter, alternate connectors can be obtained from your local plumbing supplier.

(A) Turn off the cold water supply. If cold water line does not have a shut-off valve under the sink,

you should install one.

(B) Turn on the cold water faucet and allow all water to drain from line.

(C) Disconnect cold water line from

1

/2-inch-14 NPS threaded stub on bottom of main faucet.

(D)Apply Teflon

®

tape onto threads of faucet stub and supply adapter. Screw the water supply

adapter to the threaded faucet stub as shown.

(E) Using the nut that previously connected the cold water line to the faucet, screw the cold water

line to the male supply adapter threads. (See diagram).

2. Selecting the Faucet Location

NOTE: The drinking water faucet should be positioned with function, convenience, and appearance

in mind. An adequate flat area is required to allow faucet base to rest securely. The faucet fits

through a

7

/16-inch hole. Most sinks have pre-drilled 1 3/8-inch or 1 1/2-inch diameter holes that

may be used for faucet installation. If these pre-drilled holes cannot be used or are in an inconvenient location, it will be necessary to drill a

1

/2-inch hole in the sink for the faucet.

CAUTION: This procedure may generate dusts which can cause severe irritation if inhaled or come

in contact with the eyes. The use of safety glasses and respirator for this procedure is recommended.

CAUTION: DO NOT ATTEMPT TO DRILL THROUGH AN ALL-PORCELAIN OR PORCELAIN-COATED

SINK. For applications on these types of sinks we recommend using the sprayer hole or

mounting the faucet through the countertop.

CAUTION: When drilling through a countertop make sure the area below the drilled area is free of

wiring and piping. Make certain that you have ample room to make the proper connections to the

bottom of the faucet.

CAUTION: Do not drill through a countertop that is more than 1-inch thick.

CAUTION: Do not attempt to drill through a tiled, marble, granite or similar countertop. Consult a

plumber or the countertop manufacturer for advice or assistance.

(A) Line bottom of sink with newspaper to prevent metal shavings, parts, or tools from falling

down drain.

(B) Place masking tape over the area to be drilled to prevent scratches if drill bit slips.

(C) Mark hole with center punch. Use a

1

/4-inch drill bit for a pilot hole, then, using a 1/2-inch

drill bit, drill a hole completely through the sink. Smooth rough edges with a file.

3. Mounting the Faucet

(A) Slide small black rubber gasket OR

(B) gasket, aluminum escutcheon plate (first remove protective plastic), and large gasket onto

threaded faucet stem. Lower faucet stem through hole in the sink.

NOTE: Black rubber gasket is designed for smaller holes in sink. Aluminum escutcheon plate with

gaskets is designed for larger, pre-drilled holes.

(C) Slide aluminum channel washer up faucet stem, followed by

(D)black plastic stem nut. Tighten nut with fingers.

NOTE: Do not use pliers to tighten stem-nut. Pliers may strip threads of faucet stem.

2

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

1

A

B

2

A

B

C

3

A

B

C

D

E

D

C

Page 11

4. Mounting the System

(A) Center system between water supply adapter and drinking water faucet.

NOTE: Allow 1

1

/2-inches (38 mm) clearance below system for changing filter cartridges.

(B) Install mounting screws at least 13

3

/4-inches (350 mm) from cabinet floor and 4 1/8-inches

(124 mm) apart. Leave enough space (approximately

1

/2-inch [13 mm]) between the head of

the screw and the wall to slip system onto screws.

(C) Place system over screws on wall and slide downwards to lock into place.

CAUTION: Make certain system is firmly attached to wall to prevent it from falling and possibly

being damaged.

5. Connecting the Faucet

CAUTION: Do not over-tighten compression nut. Use caution not to bend or crimp tubes when

securing.

(A) Determine the length of plastic tubing needed to connect the outlet (right) side of the filter

with the faucet. Measure tubing short enough to prevent kinking and cut the tubing squarely.

Screw nut of faucet stem hand tight, then unscrew two turns.

NOTE: Compression nut should come preassembled with ferrules inside. If nut should come apart,

see figure 5A for proper assembly.

(B) Push the tubing firmly into the end of the faucet stem. Hand-tighten compression nut onto

threads until secure. Then tighten 1

1

/2to 2 turns with wrench.

6. Connecting the Supply Adapter

(A) Determine the length of plastic tubing needed to connect the inlet (left) side of the filter with

the supply adapter. Be sure to allow enough tubing to prevent kinking and cut the tubing

squarely. Place a mark

5

/8-inch from the end of the tubing.

(B) Wet tubing with water and insert into supply adapter

5

/8-inch until mark is flush with fitting.

NOTE: Disconnecting the Tubing from the Quick-Connect Fittings: Routine maintenance and

cartridge replacement will not require that you disconnect the tubing from the filter system;

however, tubing may be quickly and easily removed from the fittings if necessary. First, turn off the

water supply to the filter. Open faucet, then press in the gray collar around the fitting while pulling

the tubing with your other hand.

7. Connecting the System

(A) Assemble tubing with system as shown in Fig. 7A , inserting tubing into appropriate inlet or

outlet quick-connect fitting until it stops.

NOTE: In some installations, connecting the system to the supply adapter and/or drinking water

faucet causes the tubing to enter the quick-connect fitting at a sharp angle. This may exert

pressure on the quick-connect fitting and cause it to leak. In these situations, you may wish to use

one or both of the quick-connect elbows included with the installation kit. Simply push the quickconnect elbow directly into the quick-connect fitting on the system, then insert the tubing into the

quick-connect elbow.

(B) When cut between a set of black guide arrows, the tubing should be pushed into the fitting so

that the entrance of the fitting falls between the next set of guide arrows (approximately

5

/

8

inch [16 mm]).

3

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

5

B

A

4

A

B

C

1-1/2"

38 mm

13-3/4"

350 mm

6

A

B

A

4-1/8"

105 mm

5

/8"

16 mm

5

/8"

16 mm

7

A

B

5

/8"

16 mm

Page 12

8. Installing the Battery

(A) Remove cover on top of system. Attach 9-volt battery (included) to connector, then place

battery in holder located to the left of the monitor panel as shown (Fig. 8A).

(B) Replace cover on top of system. Using a pen or pencil, press and release the blue reset button

on the front of the system (Fig. 8B). The electronic monitor should beep twice. If the monitor

has been reset properly, the two beeps will be followed by a sequence of two green, two

yellow, and two red lights. The monitor should be reset whenever a new set of filter cartridges

is installed.

9. Putting the System into Operation

(A) Slowly turn on cold water supply.

(B) Shut off cold water faucet opened before starting installation.

(C) Rotate base of drinking water faucet counter-clockwise to “ON” position. Allow water to run

for 5 minutes to flush air and carbon fines from filter cartridges. Turn off drinking water faucet.

Check system for leaks before leaving installation.

NOTE:

• It is recommended that you run the tap at least 20 seconds prior to using water for drinking or

cooking purposes.

• Initially, filtered water may appear cloudy. If you set a glass of water on a level surface, you

should be able to watch the cloudiness disappear from the bottom of the glass upwards. This

harmless cloudiness results from the release of trapped air within the cartridge and will

disappear within a few weeks after installation.

INSTALLATION IS NOW COMPLETE.

4

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

9

A

C

B

D

8

A

B

Electronic Monitor Operations

The SY-2650 system includes an electronic monitor that alerts you when it is time to change your

filter cartridges. Both filter cartridges should be changed at the same time to ensure that the

monitor works properly. The monitor measures actual water usage and is powered by a single

9-volt battery.

How the Electronic Monitor Works

The filter cartridges in the SY-2650 should be replaced every 500 gallons. The electronic monitor

uses a combination of lights and alarms to alert you at different stages during the life of the filter

cartridges. The lights are visible on the front panel of the filter system, to the left of the blue reset

button:

0-475 gallons No alarm. Green light flashes when water is turned on.

475-500 gallons Alarm BEEPS ONCE when water is turned on. Yellow light flashes when

water is on.

500+ gallons Alarm BEEPS TWICE when water is turned on. Red light flashes when water

is on.

Low or Dead batteryNo alarm. No lights. Replace battery.

NOTE: Gallons used while battery is dead will register on meter when battery is replaced

NOTE: To extend battery life, any sequence that includes any beeps will not be repeated if water is

turned on again in less than 15 minutes.

Reset Button

The blue reset button is located on the front panel of the system. This button should only be

pressed during initial installation or when new filter cartridges are installed. After pressing and

releasing the button, you will hear two beeps followed by a sequence of two green, two yellow,

and two red lights. This combination of beeps and lights indicates that the system has properly

reset the internal gallon counter.

Replacing the Battery

The battery should be replaced every time new filter cartridges are

installed or after 12 months of operation, whichever comes first.

Replacing Battery and Filters at the Same Time: Install new 9-volt

battery as described in Step Eight: Installing the Battery on p. 4.

Make sure to press blue reset button on front panel of system when

finished.

Replacing Battery Only:Remove the old battery and install the

new battery. DO NOT press the reset button on the front panel of the

system when finished.

Page 13

5

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

Filter Cartridge Replacement

• Filter cartridges for the SY-2650 will last about 500 gallons or six months

before they need to be replaced. Filter cartridge life varies depending on

usage, and/or water conditions. Changes in taste, color, and flow of the

water being filtered indicate that the cartridge should be replaced.

• Read all instructions before replacing filter cartridges.

WARNING: Use safety glasses and gloves when handling household

bleach to prevent bodily injury. Follow bleach manufacturer's instructions when

handling bleach.

1. Close water supply valve and open drinking water faucet to release pressure

from system.

2. Using the housing wrench, unscrew and remove bottom of filter housing.

Locate and remove large O-ring, wipe clean of lubricant, and set aside.

Repeat for second housing.

3. Discard used filter cartridges. Using a non-abrasive sponge or cloth, scrub

the bottom of filter housings, O-ring grooves, and caps with dish soap and

warm water. Rinse thoroughly. Fill bottom of each housing

1

/3full with

water. Add 1 teaspoon of household bleach and scrub to disinfect.

4. Lubricate O-rings with silicone grease. Insert each O-ring in groove and

press into place.

NOTE: This step is important to ensure a proper housing seal. Make certain

each O-ring is seated level in its groove or a leak may occur.

5. Screw bottom of housings with bleach water onto caps without filter

and hand-tighten. DO NOT OVER-TIGHTEN.

6. Turn on water supply. Let faucet run for about 10 seconds, then turn off

faucet and let stand for 20-30 minutes.

7. Turn on faucet and allow bleach water to run out (about 3-5 minutes).

8. Turn off water supply to system and open faucet to release pressure.

Remove bottom of housings and empty of water.

9. Insert each filter cartridge into appropriate filter housing:

SY-2650: D-250A Cartridge Set: White with green end caps in left housing.

Grey plastic cartridge in right housing

10. Screw bottom of housings onto caps and hand-tighten. DO NOT OVERTIGHTEN. Make certain cap standpipe slips into cartridge.

11. Open water supply valve and turn on drinking water faucet to release

pressure in system. Let faucet run for 5 minutes to remove trapped air

and carbon fines. Check system for leaks before leaving installation.

12. Press blue reset button.

NOTE:

• It is recommended that you run the tap at least 20 seconds prior to using

water for drinking or cooking purposes.

• Initially, filtered water may appear cloudy. If you set a glass of water on a

level surface, you should be able to watch the cloudiness disappear from

the bottom of the glass upwards This harmless cloudiness results from the

release of trapped air within the cartridge and will disappear within a few

weeks after installation.

Troubleshooting

Leaks:

…between cap and bottom of filter housing

Turn off water supply valve and turn on drinking water faucet to release pressure in

system. Remove bottom of housing. Clean O-ring and O-ring groove (located directly

beneath threads of housing). Lubricate O-ring with silicone grease and replace

securely into groove. Screw bottom of housing onto cap and hand-tighten. DO NOT

OVER-TIGHTEN. Turn on water supply valve and check for leaks.

…on system inlet/outlet connections

Turn off water supply valve and turn on drinking water faucet to release pressure in

system. Remove tubing from fitting (see NOTE under Step Six: Connecting the Supply

Adapter on p.3) and make sure end of tubing is cut squarely and free of scratches or

burrs. Reinsert tubing into quick-connect fittings, making sure to push securely until

tubing hits a hard stop. Turn on water supply valve and check for leaks.

…on supply adapter connection

Turn off water supply valve and turn on drinking water faucet to release pressure in

system. Loosen leaking threaded fitting on supply adapter or pull out leaking tubing

from fitting. Inspect to see if plastic tubing is scratched or supply adapter was properly

attached. If tubing is scratched, cut off

1

/2-inch to 5/8-inch and reinstall per Step Six:

Connecting the Supply Adapter. Reconnect tubing or tighten compression nut with

fingers, then tighten nut snugly

1

/2-turn with wrench. Turn on water supply valve and

check for leaks.

…on faucet/tubing connection

Turn off water supply valve and turn on drinking water faucet to release pressure in

system. Loosen and remove compression nut fitting on faucet stem. Make sure tubing

is inserted firmly into end of faucet stem, then retighten compression nut with fingers

until secure then tighten 1 turn with a wrench. Turn on water supply valve, then turn

off faucet to check for leaks.

NOTE: If leaks persist, or if there are other leaks on system, turn off water supply.

Call our technical support department at 1-800-645-5426.

Low Water Flow

1. Check flow at faucet. The SY-2650 system should fill a gallon jug in approximately

2 minutes. Flow rates will vary with individual household water pressure.

2. Check filter cartridge installation. Make certain both filter cartridges are properly

oriented in filter housings (See Filter Cartridge Replacement on p. 5).

3. Check to be certain that the water supply valve is completely open (turn handle

on valve counter-clockwise as far as it will go).

4. Check flow through empty system. To do this, turn off water supply valve and turn

on drinking water faucet to release pressure in system. Then remove filter

cartridges from housings and screw housings back onto caps. Turn on faucet to

check flow through empty system. Flow should be about one to two gallons per

minute. If flow is less than 0.4 gallons per minute, call Technical Support at

1-800-645-5426.

5. If flow through empty system is adequate, place one filter cartridge in system at

a time and check flow to make sure cartridge is not clogged. Replace clogged

cartridge if necessary.

Page 14

6

Performance Data

Important Notice: Read this performance data and compare the capabilities of this system with your actual water treatment needs. It is recommended that, before

installing a water treatment system, you have your water supply tested to determine your actual water treatment needs.

This system has been tested according to NSF/ANSI 42 and 53 for reduction of the substances listed below. The concentration of the indicated substances in water entering

the system was reduced to a concentration less than or equal to the permissible limit for water leaving the system, as specified in NSF/ANSI 42 and 53.

6

Organic Chemicals Included by Surrogate Testing:

Influent Challenge Maximum permissible

Substance Concentration mg/L product water concentration mg/L

alachor 0.050 0.001

atrazine 0.100 0.003

benzene 0.081 0.001

carbofuran 0.190 0.001

carbon tetrachloride 0.078 0.0018

chlorobenzene 0.077 0.001

chloropicrin 0.015 0.0002

2,4-D 0.110 0.0017

dibromochloropropane (DBCP) 0.052 0.00002

o-dichlorobenzene 0.080 0.001

p-dichlorobenzene 0.040 0.001

1,2-dichloroethane 0.088 0.0048

1,1-dichloroethylene 0.083 0.001

cis-1,2-dichloroethylene 0.170 0.0005

trans-1,2-dichloroethylene 0.086 0.001

1,2-dichloropropane 0.080 0.001

cis-1,3-dichloropropylene 0.079 0.001

dinoseb 0.170 0.0002

endrin 0.053 0.00059

ethylbenzene 0.088 0.001

ethylene dibromide (EDB) 0.044 0.00002

haloacetonitriles (HAN):

bromochloroacetonitrile 0.0022 0.0005

dibromoacetonitrile 0.024 0.0006

dichloroacetonitrile 0.0096 0.0002

trichloracetonitrile 0.0015 0.0003

haloketones (HK):

1,1-dichloro-2-propanone 0.0072 0.0001

1,1,1-trichloro-2-propanone 0.0082 0.0003

heptachlor 0.08 0.0004

heptachlor epoxide 0.0107 0.0002

hexachlorobutadiene 0.044 0.001

hexachlorocyclopentadiene 0.060 0.000002

lindane 0.055 0.00001

methoxychlor 0.050 0.0001

pentachlorophenol 0.096 0.001

simazine 0.120 0.004

styrene 0.150 0.0005

1,1,2,2-tetrachloroethane 0.081 0.001

tetrachloroethylene 0.081 0.001

toluene 0.078 0.001

2,4,5-TP (silvex) 0.270 0.0016

tribromoacetic acid 0.042 0.001

1,2,4-trichlorobenzene 0.160 0.0005

1,1,1-trichloroethane 0.084 0.0046

1,1,2-trichloroethane 0.150 0.0005

trichloroethylene 0.180 0.0010

trihalomethanes (includes):

chloroform (surrogate chemical)

bromoform 0.304 0.015

bromodichloromethane

chlorodibromomethane

xylenes (total) 0.070 0.001

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

State of California

Department of Health Services

Water Treatment Device

Certificate Number

Date Issued: May 17, 2000

Date Revised: March 9, 2001

1437

00-

Trademark/Model Designation

Replacement Element(s)

Culligan SY-2300 D-250A

Culligan SY-2300S D-250A

Culligan SY-2650 D-250A

Cysts (protozoan)

Turbidity

Asbestos

Lead

Mercury

MTBE

VOCs

Culligan

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section

116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity

Inorganic/Radiological Contaminants

Organic Contaminants

Alachlor

Bromodichloromethane

1

Carbon Tetrachloride

2,4-D

o-Dichlorobenzene

1,2-Dichloroethane

cis-1,2-Dichloroethylene

Dinoseb

Ethylbenzene

Hexachlorocyclopentadiene

Methoxychlor

Styrene

1,1,2,2-Tetrachloroethane

1,1,1-Trichloroethane

m-Xylene

1

Trihalomethanes

Benzene

Carbofuran

Chloroform

1

Chlorodibromomethane

1

1,1-Dichloroethylene

cis-1,3-Dichloropropylene

Endrin

Heptachlor Epoxide

Lindane

Simazine

Tetrachloroethylene

1,2,4-Trichlorobenzene

Trichloroethylene

p-Xylene

Atrazine

Bromoform

1

Chlorobenzene

DBCP

p-Dichlorobenzene

trans-1,2-Dichloroethylene

1,2-Dichloropropane

EDB

Heptachlor

Hexachlorobutadiene

Pentachlorophenol

2,4,5-TP (Silvex)

Toluene

1,1,2-Trichloroethane

o-Xylene

500 gallonsRated Service Capacity: 0.6 gpm

Rated Service Flow:

Do not use where water is microbiologically unsafe or with water of unknown quality, except that

systems claiming cyst reduction may be used on water containing cysts.

Manufacturer:

SY-2650

Substance Influent Challenge Max. Permissible Product Reduction Minimum Average

Concentration Water Concentration Requirements Reduction Reduction

Standard 42 Aesthetic Effects

Chlorine 2.0 mg/L ± 10% ≥ 50% 97%

Particulates at least 10,000 particles/mL ≥ 85% 96%

(0.5 to < 1µm)

Class I

Standard 53 Health Effects

MTBE 0.015 ±20% 0.005 mg/L 69% 90%

Cysts

2)

Minimum 50,000/L 99.95% 99.99% 99.99%

Turbidity 11 mg/L ± 1 NTU 0.5 NTU 99.1% 99.4%

Asbestos 107to 108fibers/L >10 99% 99.9% 99.9%

Micrometers in length

Lead 6.5 pH 0.15 mg/L ± 10% 0.010 mg/L 99.3% 99.3%

Lead 8.5 pH 0.15 mg/L ± 10% 0.010 mg/L 94.1% 97.6%

Mercury 6.5 pH 0.006 mg/L ± 10% 0.002 mg/L 85% 90.8%

Mercury 8.5 pH 0.006 mg/L ± 10% 0.002 mg/L 80.6% 90%

Chloroform 0.304 mg/L 0.015 mg/L 99.7% 99.8%

(VOC surrogate chemical)

Flow Rate = 0.6 gpm (2.27 Lpm) Capacity = 500 gallons (1893 L) or 6 months

2)

Based on the use of microspheres or Cryptosporidium parvum oocysts

Testing was performed under standard laboratory conditions, actual performance may vary.

Page 15

7

Technical Support: 1-800-645-5426, Monday-Friday, 7:30 am–5:00 pm, CST

Replacement Parts

Replacement Filter Cartridges

SY-2650

1B/2B 155832 D-250A (Cartridges sold only as a set)

1B= White netting pre-filter

2B= Grey post filter

3. 153126 White housing bottom

4. 151231 O-ring (OR-233)

5. 151242 Faucet

6. 143431 Water Supply Valve

7. 150424 Housing Wrench (SW-5)

Circuit and Probe (not shown)

For replacement parts, contact your nearest Culligan

®

water filter retailer or call 1-888-777-7962.

4

5

6

7

3

B

1

B

2

Performance Data

WARNING: Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system. Systems certified for

cyst reduction may be used on disinfected waters that may contain filterable cysts.

NOTE: Substances reduced are not necessarily in your water. Filter must be maintained according to manufacturer's instructions, including replacement of filter cartridges.

Test Conditions

Flow Rate = as noted for filter system

Inlet Pressure = 60 psi (4.1 bar)

pH = 7.5±1

Temperature = 68°F±5°F (20°C±2.5°C)

Operating Requirements

Pressure = 30–125 psi (2.1–8.6 bar)

Temperature = 40–100°F (4.4–37.8°C)

Turbidity = 5 NTU Max.

Suggested Retail Price for Replacement Filter Cartridges:

SY-2650: D-250A = $50.39

NOTE: Price subject to change. Contact your local retailer or call: 1-888-777-7962 for current replacement cartridge pricing.

Page 16

WARRANTY

This warranty applies to the Filter Housings only. It does NOT apply to any disposable filter cartridge, which has a life expectancy that varies with the water being filtered. This warranty covers defects in

materials and workmanship only for one full year from original date of delivery. Culligan will replace any part which in Culligan’s opinion is defective, unless: (1) any part of the system has been subjected

to any type of tampering, alteration, or improper use after delivery, or (2) any part of the system has been repaired by anyone not approved by Culligan. Our obligation does not include the cost of

shipment of materials. Culligan is not responsible for damage in transit, and claims for such damage should be presented to the carrier by the customer.

This product has been designed solely for use as a housing for a disposable filter cartridge. It is NOT warranted against freezing, and neither this product nor its parts is warranted against defects or

deterioration caused by uses for which this product was not expressly intended.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, WHETHER ORAL OR ARISING BY USAGE OF TRADE OR COURSE OF DEALING, INCLUDING,

WITHOUT LIMITATION, ANY WARRANTIES OF FITNESS OR MERCHANTABILITY. THIS WARRANTY IS THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY. IN NO EVENT SHALL CULLIGAN BE LIABLE FOR ANY

ANTICIPATED OR LOST PROFITS, INCIDENTAL DAMAGES, CONSEQUENTIAL CHARGES OR OTHER LOSSES, WHETHER BASED ON BREACH OF CONTRACT, TORTIOUS CONDUCT OR ANY OTHER THEORY,

INCURRED IN CONNECTION WITH THE PURCHASE, INSTALLATION, REPAIR OR OPERATION OF THE OPAQUE FILTER HOUSING. CULLIGAN DOES NOT AUTHORIZE ANYONE TO ASSUME FOR IT ANY LIABILITY

OR MAKE ON ITS BEHALF ANY ADDITIONAL WARRANTIES IN CONNECTION WITH THE OPAQUE FILTER HOUSING OR ANY PART THEREOF.

For servicing under this warranty, return any defective part to YOUR RETAILER within the one-year period referred to above.

IOWA RESIDENTS ONLY:

Store or seller’s name:

Address:

City: State: Zip:

Telephone:

Seller’s signature:

Customer’s signature: Date:

Customer Service

M-F 7:30 a.m – 5:00 p.m. CST

Phone: 1-800-634-1455 Fax: 1-888-749-8826

International: Phone (920) 457-9435 • Fax (920) 457-2417

e-mail: customerservice@culligan.com

Sales & Marketing Correspondence

P.O. Box 1086 • Sheboygan, WI 53082-1086

Fax (847) 291-7632

e-mail: sales-marketing@culligan.com

©2003 Culligan International Company, Printed in U.S.A. 11/03 146410 Rev D

Culligan International Company

One Culligan Parkway

Northbrook, Illinois 60062

www.culligan.com

Loading...

Loading...