Page 1

Culligan®

Sulfur-Cleer

Automatic

Water Filter

Owners Guide

™

Page 2

Thank You

And Welcome To Your New World Of Better Living With

Culligan Water.

This system and its installation must comply with state and local regulations. The System is ONLY to be

supplied with cold water.

The Culligan® Sulfur-Cleer™ water filters have been tested against WQA S-200 for

the effective reduction of iron up to 1,000 gallons and WQA Test Protocol 04-001

and NSF/ANSI Standard 42 for the effective reduction of hydrogen sulfide as

verified and substantated by test data.

Do not use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after the system.

For installations in Massachusetts, the Commonwealth of Massachusetts Plumbing

Code 248 CMR shall be adhered to. Consult your licensed plumber for installation

of the system. This system and its installation must comply with state and local

regulations. The use of saddle valves is not permitted.

If this is your first experience having filtered, conditioned water in your home, you’ll be amazed at the

marvelous difference it makes. We promise that you’ll never want to be without it again.

Congratulations, too, on selecting one of the “first family” of water filters in the prestigious Culligan

Sulfur-Cleer™. With Culligan’s many years of knowledge and experience in water treatment, you

can be confident that the model you selected has been designed and engineered to provide years of

service with a minimum of care and attention.

Products manufactured and marketed by Culligan International Company (Culligan) and its affiliates

are protected by patents issued or pending in the United States and other countries. Culligan reserves

the right to change the specifications referred to in this literature at any time, without prior notice.

Culligan, Culligan Sulfur-Cleer, Cullar, Filtr-Cleer, Cullneu, Accusoft, Culligan Man and www.culligan.

com are trademarks of Culligan International Company or its affiliates.

ii

Page 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Familiarization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Statistic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

When and How to Bypass your Water Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Regeneration with Bleach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Things to Check Before You Call for Service . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Performance Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Records and Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table of

Contents

iii

Page 4

This page intentionally left blank.

iv

Page 5

Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1” 5-cycle reinforced thermoplastic

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic Circuit Board

Overall Conditioner Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61”

Media Tank Dimensions (D x H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10” x 54”

Filter Media Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 cu. ft. CIM

Underbedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cullsan®, 20 lbs.

Capacity1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000 gallons

Freeboard2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18”

Max. Clear Water (Soluble) Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 ppm

Max. Hydrogen Sulfide5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 ppm

Minimum Alkalinity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 ppm

pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.0 - 8.5

Service Flow @ Pressure Drop (Clean Bed) Normal . . . . . . . . . . . . . . . . . . . . . . . . . 5 gpm @ 4 psi

Maximum3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 gpm @ 5 psi

Operating Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-60 psi

Operating Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-120° F (1-48° C)

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 Volts/60 Hz

Power Consumption, Continuous/Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 watts/270 watts

Drain Flow, Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5 gpm

Backwash Regeneration Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 99 minutes

Eduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 99 minutes

Fast Rinse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 99 minutes

SpecificationsCulligan® 10” Sulfur-Cleer™ Filter with Fiberglass Tank

1 Capacity based on 5 gpm (10” unit) and 10 mg/L of dissolved iron

2 Measured from top of media bed to top of surface of tank threads (backwashed and drained)

3 Max flow rates and pressure drop characteristics have not been certified by the Water Quality

Association.

4 For the purposes of plumbing sizing, only the service flow rate and corresponding pressure drop

may be used.

5 Hydrogen Sulfide will be reduced significantly on water containing less than 5 ppm.

The max specified flow rate at which the system will deliver treated water as certified by the Water

Quality Association is defined as service flow.

1

Page 6

Introduction

Operation

Step 1.

Service Cycle

In the service cycle, raw water enters the inlet port of the media tank. The oxidation process begins.

This air/water contact oxidizes the iron and hydrogen sulfide in the water. Oxidized iron particles

are trapped by the filter bed as the water passes through. Filtered water enters the lower distributor

and travels up the distributor tube to the outlet port on the filter valve.

Step 2.

Aeration Operation Air Recharge Cycle

When energized, the air pump sends air through the solenoid valve into one end of the shuttle valve.

Once air pressure in the shuttle valve is greater than the water supply pressure at the other end of the

shuttle valve, the piston shifts to the open position. In the open position, the bleed-off port discharges

excess water and old air to the drain port through a flow restrictor. Simultaneously, the air inlet port

opens to provide a direct connection between the air pump and the top of the media tank. The air

pump runs for a preset period of time recharging the head of air in the media tank.

Air Recharge Shut Off

The timer turns power off to the air pump and the solenoid valve at the end of the recharge cycle. The

solenoid valve then closes the port between the air pump and the shuttle valve. The port between the

shuttle valve and the atmosphere opens and releases air pressure. This allows water pressure to shift

the piston to the closed position. With the piston in the closed position, the air recharge inlet port is

closed and direct communication between the bleed off tube and the drain port is also closed.

Timer Operation

A timer controls the air recharge cycle and how frequently it occurs. The timer simultaneously

energizes the air pump and the solenoid valve. After a preset amount of time, the timer shuts off the

air pump and de-energizes the solenoid valve.

Solenoid Valve Operation

The solenoid valve is a three-way valve having ports that connect to the air pump, shuttle valve and

the atmosphere. In the service cycle, the solenoid valve is de-energized and closes the port to the

air pump, providing a positive shut-off to the pump. This prevents water from backing up into the air

pump and damaging the pump. In the air recharge cycle, the solenoid valve closes the port to the

atmosphere and opens the port from the air pump.

Shuttle Valve Operation

In the service position, water pressure holds the shuttle valve piston in the closed position, trapping the

airhead in the media tank and closes the air recharge inlet port and drain port. During air recharge

cycle, air pressure is greater than the water pressure and forces the shuttle valve piston in the open

piston. The shuttle valve has an internal pressure relief valve that will relieve pressure (greater than

100 psi) that may build up in the media tank. This precautionary function protects components from

failure due to excessive pressure.

2

Page 7

Step 3.

Filter Tank Operation - Backwash Cycle

Reversing the flow of water through the filter bed and backwashing dirty water to the drain cleans

the filter bed. Raw water enters the filter control valve through the inlet port and is directed down the

distributor tube and out the lower distributor at the bottom of the tank, flowing upward through the

multimedia filter bed toward the top of the tank into the control valve. Water is then directed through a

specific flow restrictor and out the drain port to be discharged to drain.

Step 4.

Filter Tank Operation - Rinse Cycle

The rinse cycle packs the clean filter bed. Raw water enters the control valve through the inlet port

and is directed downward through the filter bed into the bottom distributor, up the distributor tube into

the control valve. Water is then directed through a specific flow restrictor and out the drain port to be

discharged to drain.

Operation Of Aeration Pump

The Sulfur-Cleer™ system introduces air into the media tank and bleeds off the old head of air

automatically. The exchange of the air into the media tank is controlled independently of the recharge

frequency of the filter media tank, allowing the air to be exchanged on a more frequent basis. During

an air exchange cycle, the air compressor pumps fresh air into the media tank and the air eliminator

solenoid exhausts the old air.

Introduction

(cont.)

Iron and Trace Hydrogen Sulfide

When applying the filter on water sources with only iron present or with levels of hydrogen sulfide less

than 1 ppm, only backwashing will be needed to regenerate the filter. In some applications, odors

may develop over time and the media bed may need to be sanitized. In general, bleach will not be

required more than once per month and users generally find that it is needed no more than once every

four to six months, if at all.

Hydrogen Sulfide - Over 1 PPM

When applying the filter on water sources with hydrogen sulfide levels of 1 - 5 ppm, backwashing

every three days and eduction of diluted non-scented bleach on occasion may be needed.

Regeneration with bleach is only necessary when hydrogen sulfide is present in the product water.

Although the air compressor provides much of the action needed to reduce hydrogen sulfide, the

bleach will “super oxygenate” the Culligan CIM media to enhance effectiveness. Overdosing with

bleach will cause a faster breakdown of the media. Therefore, any chlorine dosing scheme involves a

compromise between media life and hydrogen sulfide reduction.

3

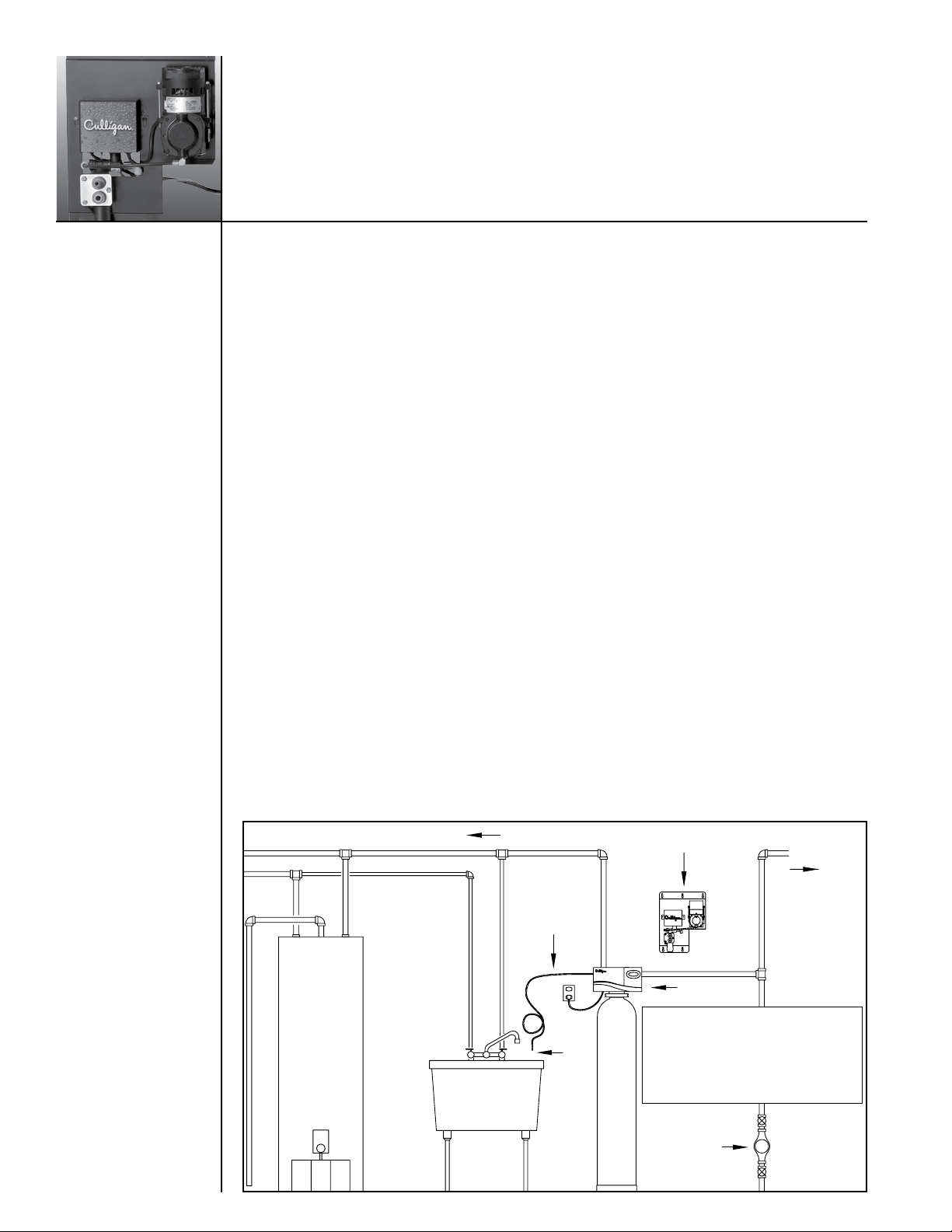

Page 8

Operating

Water

Meter

Filter

Drain

Line

Unfiltered

Water

Filtered Water

Water

Heater

Air

Gap

Wall Mounted

Aeration Assemby

To

Hose Bibs

Conditions

The concentration limits listed below reflect the minimum or maximum individual limit that each

contaminant was tested for separately without any interference of other contaminants in the influent

water.

In reality, however, we know that these contaminants may be present in combination which may limit

the filter’s ability to remove these contaminants in higher concentrations. In some cases, individual

sellers of this equipment have had success removing higher concentrations of contaminants - iron, for

example - above the limitations we have listed. If you are considering the installation of this system

for the reduction/removal of iron, manganese and/or hydrogen sulfide beyond the printed operating

conditions below, we recommend that you consult the manufacturer for proper application. Installation

of this system under these circumstances may void part(s) and/or all of the system warranty.

General Instructions — Observe all state and plumbing codes, electrical codes and drain

restrictions. The system and installation must comply with all state and local laws and regulations. Most

codes require an anti-syphon device or airgap.

For installations in Massachusetts, the Commonwealth of Massachusetts Plumbing

Code 248 CMR shall be adhered to. Consult with your licensed plumber for

installation of this system. The use of saddle valves is not permitted.

Alkalinity — A minimum alkalinity of 100 ppm is required for efficient removal of iron and hydrogen

sulfide.

Hydrogen Sulfide — Often referred to as rotten egg odor, hydrogen sulfide will be reduced

significantly on water supplies containing less than 5 ppm as tested by Culligan. Consult the factory if

hydrogen sulfide concentrations are greater than 5 ppm.

Iron — This system is rated for a maximum of 10 ppm of ferrous (clear water) iron. Consult the

factory if iron bacteria is present.

Organic Matter (Tannins) — The presence of organic matter such as tannins will prevent the

oxidation process of converting the dissolved element, such as iron or manganese, to a non-soluble

precipitate or solid substance, allowing it to be filtered out. The Sulfur-Cleer™ is not designed to

remove organic bound iron.

pH — The pH level of the influent water must be 7.0 - 8.5.

4

Figure 1

Note: Waste connections or drain

outlets shall be designed and

constructed to provide for connection

to the sanitary waste system through

an air gap of 2 pipe diameters or

25.4 mm (1 in.) whichever is larger.

Page 9

Power Loss

The Circuit board is equipped with a Hi-Cap Capacitor and EEPROM memory chip. The capacitor is

capable of maintaining the time, for at least two days, in the event of a power outage. The EEPROM

ensures that the individual programming parameters of your filter are not lost.

If the power outage lasts long enough to drain the Hi-Cap Capacitor, the control will flash “12:00 PM”

when power is returned to the control. The unit will continue to keep time from the moment power is

restored, and will initiate a full regeneration at the preset regeneration time. The time of day will need

to be reset in order to return the regeneration to its preset time.

If you live in an area where power outages occur with a regular frequency, a battery backup option

is available for ensuring that the time of day is properly maintained. Contact your Culligan Dealer for

more information.

Regeneration

To initiate a regeneration at the preset time, press the “REGEN” button. The “REG” light will light. To

initiate an immediate regeneration, press and hold the “REGEN” button for at least five seconds. The

“REG” will light and blink. An immediate regeneration will also occur if a power outage has lasted

for more than four hours and the Immediate Regeneration option is chosen. Ask your Culligan Dealer

about this feature.

A regeneration at the Time of Regeneration will occur if so signaled by the Soft-Minder meter. The

“REG” enunciator on the display will also be lit.

Familiarization

Service

Culligan’s Sulfur-Cleer™ water filter is equipped with a self diagnostic program to insure optimal

operation of your water filter. Should service become necessary, a phone icon will appear in the

display. If this condition occurs, call your local Culligan Dealer for assistance. The phone icon and

error code will be the only items displayed when service is required on the control.

5

Page 10

Familiarization

(cont.)

Modes of Operation

Manual Regeneration

Pressing and holding the regen button for 5 seconds will initiate an immediate regeneration. The

beeper is to give one beep at the start of manual regeneration (when the motor starts to turn). In delay

mode, pressing and releasing the regen button will light the regen icon for regeneration to occur at the

set delay time. Pressing and releasing the regen button again will turn off the regen icon.

Power Loss

The circuit board is equipped with a Hi-Cap Capacitor and EEPROM memory chip. The capacitor is

capable of maintaining the time, for at least one day, in the event of a power outage. The EEPROM

ensures that the individual programming parameters of your softener are not lost.

If the power outage lasts long

enough to drain the Hi-Cap

Capacitor, the control will flash

“12:00 PM” when power is

returned to the control. The

unit will continue to keep time

from the moment power is

restored, and will initiate a

full regeneration at the preset

regeneration time. The time

of day will need to be reset in

order to return the regeneration

to its preset time.

If you live in an area where

power outages occur with a

regular frequency, a battery

backup option is available for

ensuring that the time of day is

properly maintained. Contact

your Culligan Dealer for more

information.

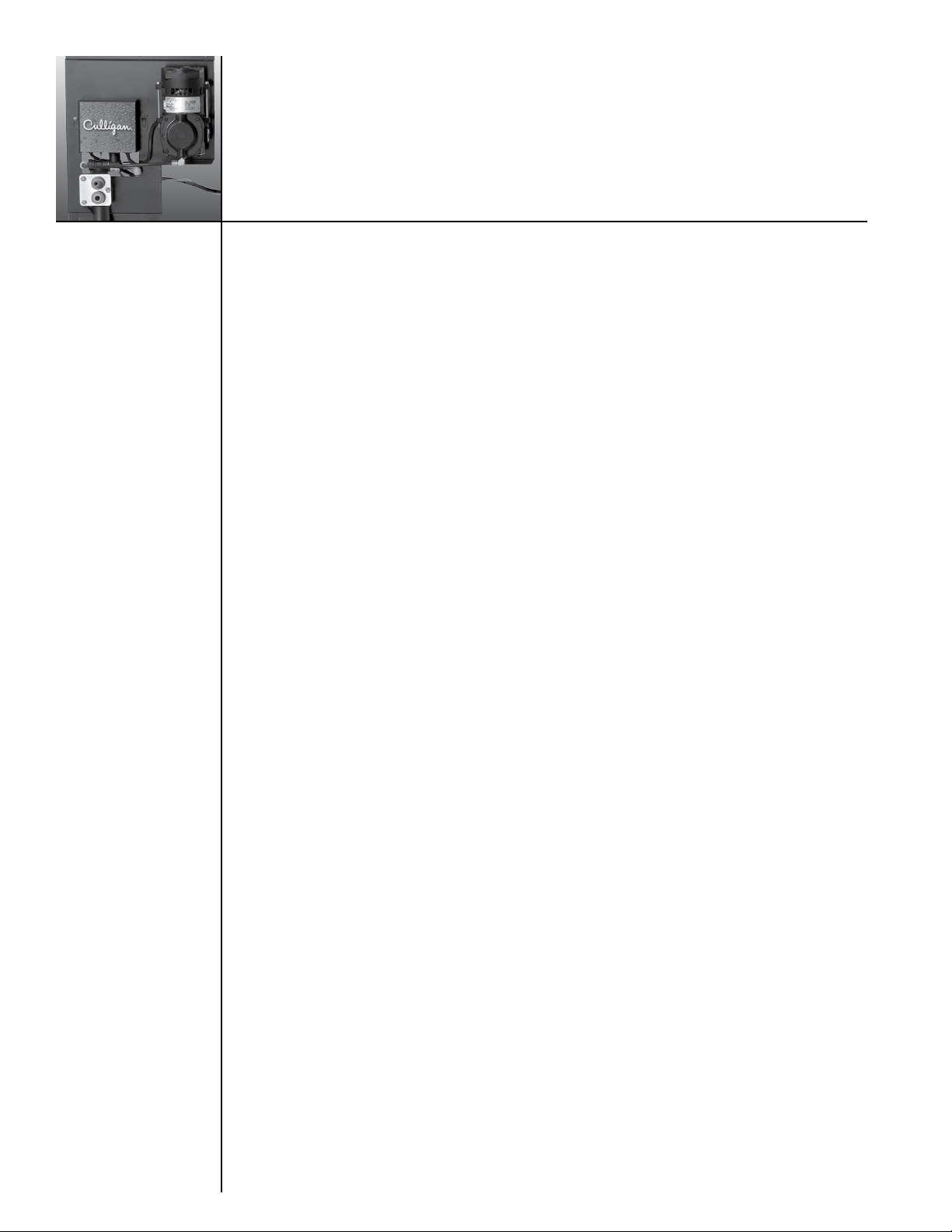

Status/

Program

Key

Toggle

(-) Down

Display

Regeneration

Key

Statistics/

Information

Key

Toggle

(+) Up

Display Back-lit LCD display.

Program Key Depress to enter and move through the programming steps.

Regeneration

Key

Information

Key

Toggle (-)

Down Key

Toggle (+)

Up Key

6

Press and hold the key for five (5) seconds to initiate an immediate regeneration.

When pressed during programming the time of day, this key will allow the user to

toggle between the hours and minutes setting of timing program segments.

Each time depressed, the Statistics key will display statistical information such a

flow rate, time of day. Use with the Toggle Down key to display other statistical

information.

In the programming mode this key will move the user through the programming

function in a descending mode. If depressed for greater than three seconds, the rate

at which the display scrolls through data will increase.

In the programming mode this key will move the user through the programming

function in an ascending mode. If depressed for greater than five seconds, the rate at

which the display scrolls through the data will increase.

This key will also allow the user to manually step through the cycles of regeneration.

Page 11

The circuit board controls all of the filter functions. These settings are programmed at the time of

installation. The following is a list of all the microprocessor functions, in the event that any of the

settings need to be adjusted.

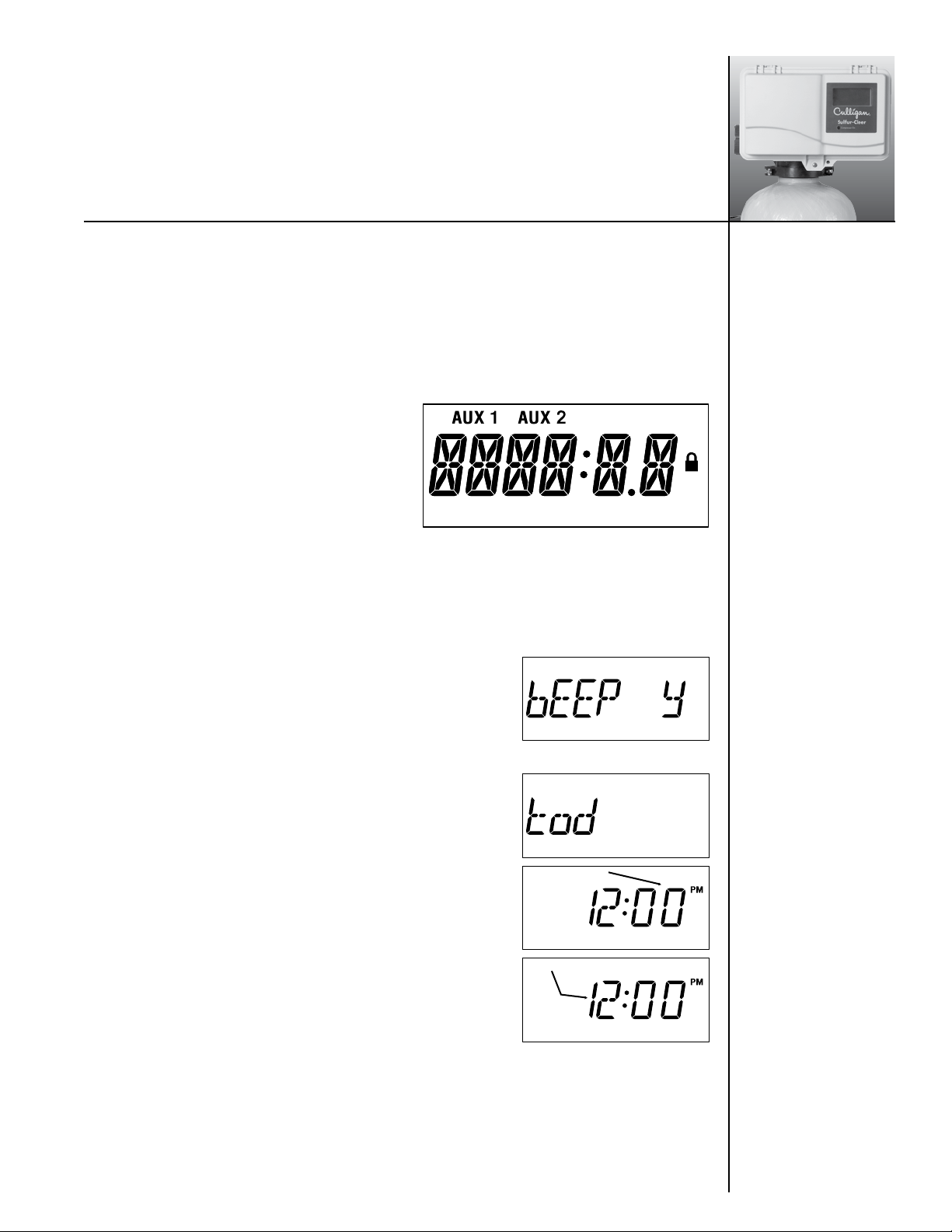

Display Icons

The display is to be backlit and have the icons as shown.

PM

Custom LCD Display

Six standard 12-segment alpha-numeric characters,

a decimal separating the first and second character,

a colon separating the second and third character

positions.

A further description of each programming setting and the corresponding display is outlined below.

For a display that has an icon that is displayed solid for the 2 second time period prior to bringing up

the settings, the settings menu can be reached prior to the two second time out by pressing the “+” or

“-” key.

• Beeper Setting - Beeper Setting – This setting is used to turn

the beeper on or off for each key press actuation. The display will

show “bEEP X” where X is either “Y” or “N”. The “Y” or “N” will

be toggled with the “+” and “-“ keys.

Pressing the “Status” key will move to the next programming step.

REGEN RECLAIM

MASTER

x10

x100

AM

Programming

• Time of Day -

day. When in this step, the display will first show “tod” for two

seconds, then the time.

After “tod” is displayed, “12:00 PM” will display (or the current

set time if already programmed) and the minutes will flash. The

minutes are adjusted with the “+” or “-“ key until the correct value

is displayed. Press the “Regen” key to flash the hours. Adjust

with the “+” or “-“ key until the correct time is displayed.

Pressing the “Status” key will save the setting and move to the

next programming step. Pressing “Regen” will move back to the

minutes adjust.

This setting is used to program the current time of

Minutes Flashing

Hours Flashing

7

Page 12

Programming

(cont.)

• Time of Regeneration - This setting is used to program the

time at which a regeneration is to occur in the delay mode. The

display will first show “tor” for two seconds.

After “tor” is shown the display will then show the default of 2:00

AM (or the current programmed time of regeneration if already

set). The time can be adjusted in 30 minute increments by

pressing the “+” or “-“ keys.

Pressing the “Status” key will save the setting and move to the next

programming step.

• Meter Factor (Use the default of 80 for meter factor.

80 is the proper setting for the standard Culligan 1”

meter.) – This setting is used to determine the number of pulses

that are to be counted to represent a set volume of water (IE:

gallon or liter). This factor will be used for all flow calculations. It

will only appear if a flow meter is connected to the circuit board.

The display will first show “meter” for two seconds and then

display the meter factor default (or the previously programmed

value). Adjust the value with the “+” or “-“ keys.

Pressing the “Status” key will save the setting and move to the next

programming step.

• Regeneration Interval - This setting is used to set the days

between regenerations in time clock mode. It is also active in

meter mode if the time clock backup DIPswitch # 6 is set to “on”.

The display will show “REGEN” icon with “dAYS” and the value

to set. Adjust the value with the “+” or “-“ keys.

Pressing the “Status” key will save the setting and move to the next

programming step.

For single unit time clock mode only ( Meter not connected), the

following optional “day of week” setting will be available to

trigger a regeneration.

The display will show “dAYoWK” for 2 seconds followed by

“NO”. The “+” or “-“ key will toggle “yes” or “no” (default is

NO). A “yes” response will indicate that the control is to perform

a regeneration on specific days of the week.

Pressing “STATUS” will save and advance to the next step. If

“NO” was chosen, then the control will only initiate regenerations

based upon the interval (in number of days) and the display will

show “days 03”, as shown above.

If “YES” was chosen, then the specific days of the week to

regenerate will be selected as follows.

The display will show “dAY” for two seconds followed by “SUN

N”. The “regen” key toggles the days of the week and the “+”

and “-“ keys toggle “Y or N”.

Pressing the “STATUS” key saves and advances to the next step.

Time Flashing

REGEN

REGEN

REGEN

REGEN

REGEN

8

Page 13

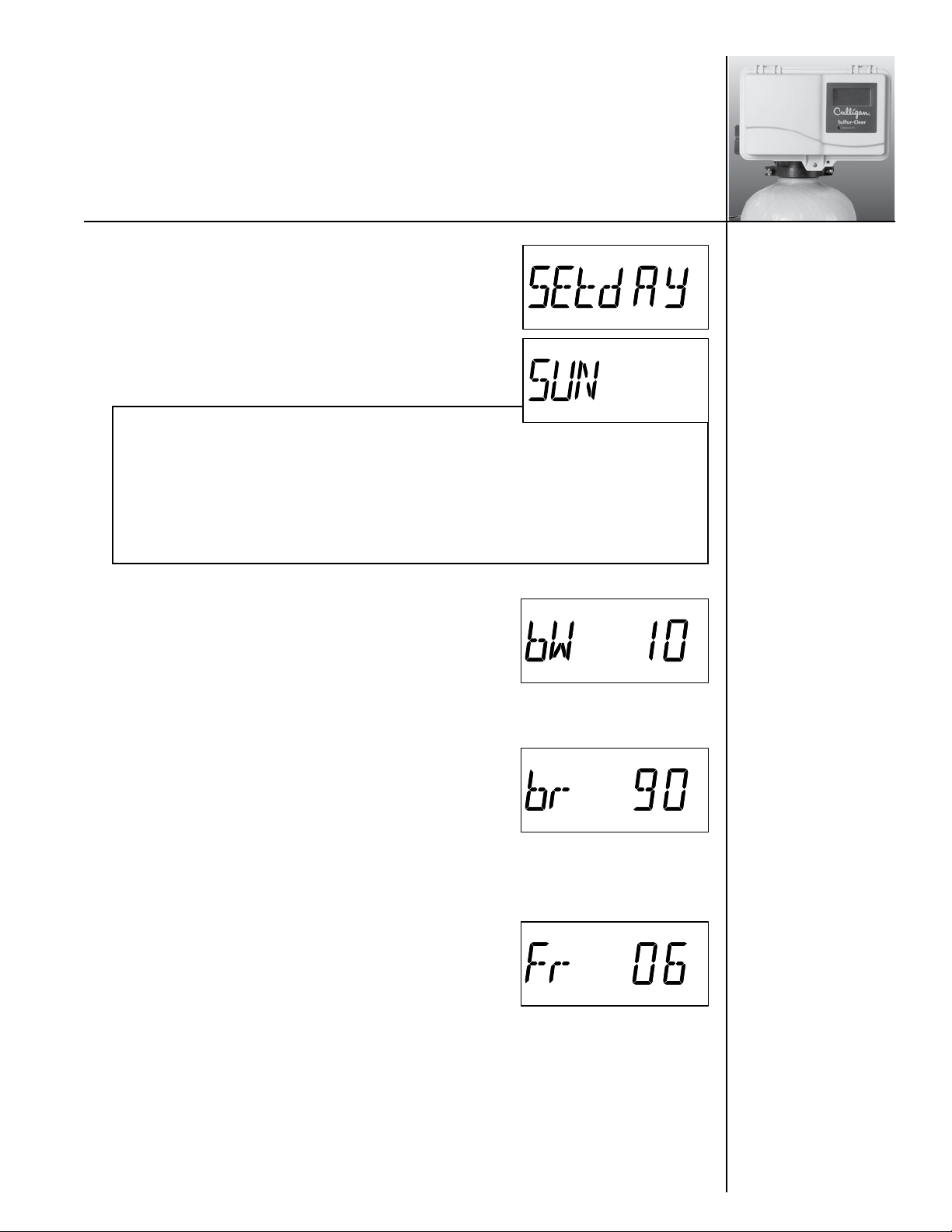

If any of the days were set to “yes”, the display will show

“SETDAY” followed by “SUN”. This selects the current day of the

week. The “+” or “-“ key toggles through the days of the week

and pressing the “STATUS” key saves the setting and advances to

the next programming step.

If ALL of the days were set to “no”, then “days 03” will appear

as shown above and the regeneration interval will be set in

number of days. Pressing the “STATUS” key saves the setting and

advances to the next programming step.

NOTE:

1. If any day of the week is set to “yes”, the regeneration interval in number of days (“Days

03”) will no longer appear when going through the programming menu at a later time.

To go back from specific day of week regeneration to interval in number of days, choose

“NO” at “dAYoWK”.

2. If a DIPswitch is changed anytime after the control has been programmed to regenerate

on any specific day, all settings will revert back to default; specific days to regenerate and

current day will have to be reprogrammed.

• Cycle 1 Time (Backwash) - This setting is used to program

the cycle 1 time that is usually backwash. The time of the cycle is

kept in minutes. The display will show “bw” in the left most digits

and the cycle time in the right most digits. Adjust the value with

the “+” or “-“ keys. Use the default value of 10 minutes, or the

appropriate time to allow the drain flow to be clear.

Pressing the “Status” key will save the setting and move to the next programming step.

REGEN

REGEN

Programming

(cont.)

• Cycle 2 Time (Brine Draw/Slow Rinse) - This setting is

used to set the time in minutes for cycle 2. This cycle is usually

brine draw / slow rinse for softeners and a settling time for filters.

The display will show “br” in the left most digits and the cycle time

in the right most digits. Adjust the value with the “+” or “-“ keys.

Adjust this cycle to 90 minutes if educting diluted bleach. Adjust

this cycle to 2 minutes if not educting diluted bleach.

Pressing the “Status” key will save the setting and move to the next programming step.

• Cycle 3 Time (Fast Rinse/Refill) - This setting is used to set

the time in minutes for cycle 3. This cycle is usually fast rinse for

softeners and filters. The display will show “Fr” followed by the

cycle time for this step. Adjust the value with the “+” or “-“ keys.

Adjust the cycle time to 6 minutes.

Pressing the “Status” key will save the setting and move to the

next programming step.

9

Page 14

Programming

(cont.)

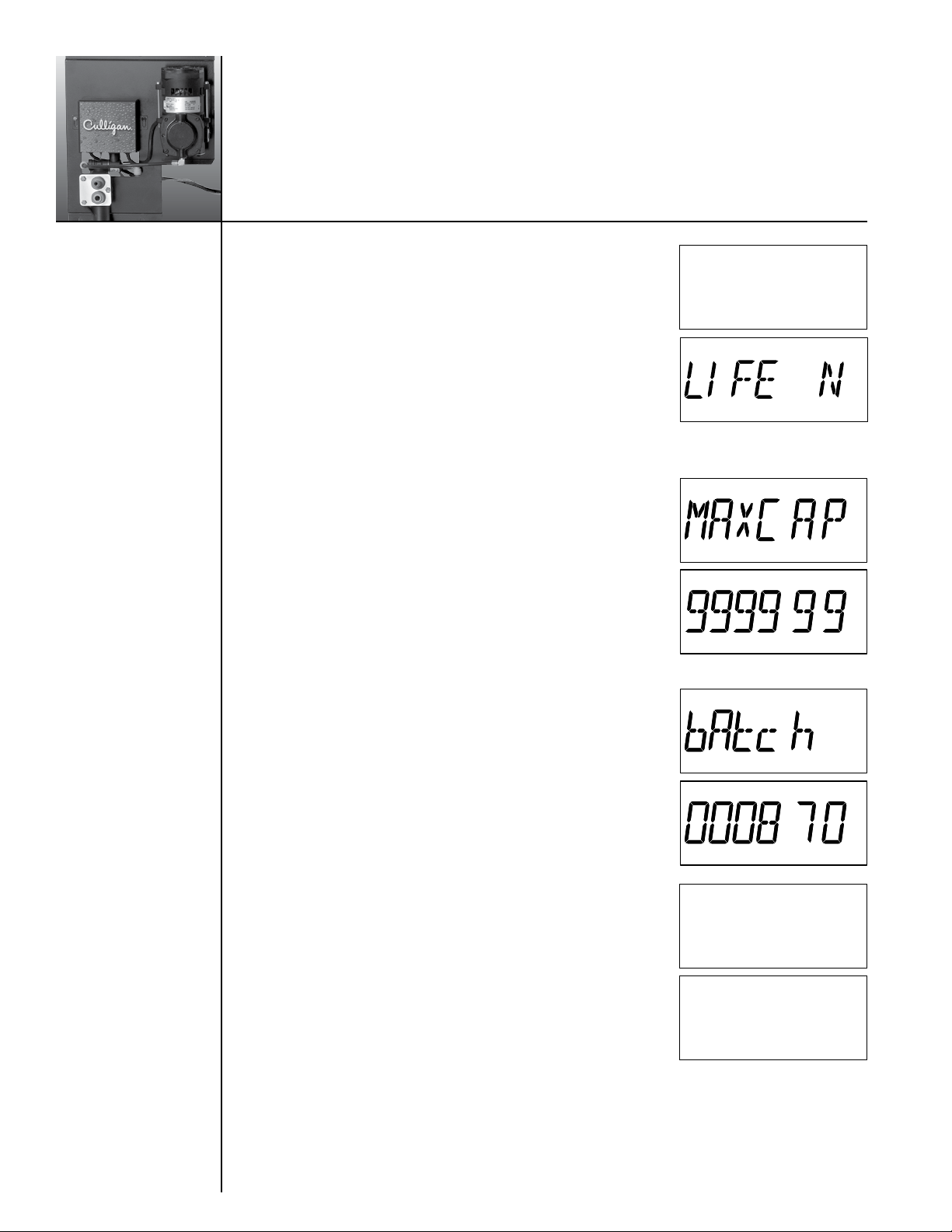

• Filter Media Life - This setting is available only with flow meter

attached. It enables or disables an alert code (CHANGE MEDIA) that

indicates the end of life for the filter media. The display will show

“LIFE” in the left most characters and toggle between “Y” and “N”

in the right most character with the “+” and “-“ keys. If “NO”

is selected, the alarm is disabled and the ‘Maximum Capacity’

setting will be treated as it normally would by triggering an

immediate regen. If “YES” is selected the alert is enabled and

will sound when the ‘Total Flow/Life of Unit’ statistic = ‘Maximum

Capacity’ setpoint, indicating that it is time to change the filter

media.

Pressing the “Status” key will save the setting and move to the next programming step.

• Maximum Capacity Set Point - This setting is used to

program a value that corresponds to the maximum capacity that

can be expected from a unit before it is completely exhausted.

If the unit reaches this set point an immediate regeneration will

occur with dip#4 is set to delay mode and “IMMED” set in the

hidden menu. This setting will only appear if a flow meter is

connected to the circuit board. Adjust the value with the “+” or

“-“ keys. The display will show the “REGEN” icon and “MAXCAP”

for two seconds and then display the “REGEN” icon, and the

setting numbers to adjust.

Pressing the “Status” key will save the setting and move to the next

programming step.

CHANGE

MEDIA

REGEN

REGEN

• Batch Set Point -

regeneration when in flow meter operation. It will only appear

if a flow meter is connected to the circuit board. The display will

show the “REGEN” icon and “bAtch” for two seconds and then

display the “REGEN” icon and the setting numbers to adjust.

Adjust the value with the “+” or “-“ keys.

Pressing the “Status” key will save the setting and move to the next

programming step.

• Maintenance Interval - This setting is active only when dip

#2 is on. It used to trigger a notice indicating that a maintenance

inspection for the system should occur, after counting down the

programmed number of days. The display will show “MAINT”

for two seconds, followed by the value to adjust. Adjust the value

with the “+” or “-“ keys. After the programmed number of days

has counted down, the Maintenance Alert shall appear on the

display (MAINT) every 10 seconds, for 2 seconds at a time, and the

beeper shall beep every 30 seconds.

This setting is used to set the trip point for a

REGEN

REGEN

MAINT

365

10

Page 15

• Auxiliary Output #1 “ON” Time - This setting is used to

control the “ON” time of the aux1 output which turns on the

compressor and vent solenoid. The aux 1 output should act

independently, however, it should never be activated during a

regeneration. Upon power up or immediately after a regen, the

“ON” time should start. The “ON” can also be started manually.

The display will show the “AUX 1” icon with “ON” and the value to be set (unit of measure is

seconds). Adjust the value with the “+” or “-“ keys.

Whenever the output is energized, AUX 1 icon is to light and the led indicator on the front of the

circuit board will flash

Pressing the “Status” key save the setting and will move to the next programming step.

• Auxiliary Output #1 Gallons to Signal (Meter Mode

only) - This setting is used to control when the aux1 output

(Compressor) “ON” time actually starts. Once the programmed

number of gallons has flowed, the output will turn on for the

programmed amount of “ON” time. Once the “ON” time expires

and the output turns off, the gallon counter will reset. The display

will show the “AUX 1” icon with “GAL” and the value to be set (unit of measure is in gallons).

Adjust the value with the “+” or “-“ keys.

Pressing the “Status” key save the setting and will move to the next programming step.

• Auxiliary Output #1 “OFF” Time - Always available in

Time Clock mode; Available in Meter Mode only with dip#3

on. This setting is used to control the interval of time, in minutes,

between the compressor “ON” times. In meter mode, this setting

will not appear unless dip #3 is on (Compressor Saver feature);

should the meter not see any flow, this will act as a backup.

Note! The range is 1 – 9999; if the setting goes over 999, then the second “F” in the display

will become a number.

Pressing the “Status” key will save the setting and will move to the next programming step.

Programming

(cont.)

• Auxiliary Output #2 Contact Status / Cycle Number /

Cycle Time - This setting is used to control the aux 2 output The

aux 2 output is not used on the standard Sulfur-Cleer™ product, so

this menu can be skipped.

11

Page 16

Statistic

Functions

The statistical functions are reached by pressing the “Information” key. Repetitive presses of the

“Statistics” key will cycle through the standard statistics mode until cycled back to time of day display.

Once either of the Information menus is entered the information shown for each display is outlined

below:

• Flow Rate (Meter mode only) - The display shall show the

current flow rate of the water passing through the control. The

display will first show “FLOW” for two seconds and then display

the current flow rate for 10 seconds. The meter factor must be set

properly for flow to be recorded accurately. This circuit board

has a default meter factor of 80 which is the proper setting for use

with Culligan standard 1” meter.

• Today’s Water Usage (Meter mode only) - This display

will show the accumulated flow of water for the current day. The

value should reset to zero daily at 12:00am. The display will

show “tU” with the gallon value (the x10 should appear when

necessary if the amount counts past 999 gallons; rollover at 10k

gallons).

FLOW

I8.0

TU I 23

• Average Daily Water Usage -

running 7-day average of daily water usage. The display should

update daily at 12:00am. The display will show “AVG” with

the gallon value (the x10 should appear when necessary if the

amount counts past 999 gallons; rollover at 10k gallons).

• Number of Regenerations in Last 14 Days -

will show the number of regenerations that have occurred in

the last 14 days. The display will first show “14dAY” for two

seconds and then display the number of regenerations that have

occurred for 10 seconds. The days counter is to be updated at

the programmed time of regeneration for delayed regeneration

settings and at 12:00 AM (24:00) for immediate regeneration

settings. The counter is not to be updated during programming of

time of day if the days setting point is crossed.

• Maintenance Interval (Only available with dip #2

on) - This display indicates the number of days remaining

of the programmed maintenance interval. When this value

reaches zero, the “MAINT” alert will be activated. This setting

is resettable by holding the regen key for 10 seconds while at

this display, also it will clear the “MAINT” alert. The display will

show “MAINT” for 2 seconds followed by the number of days

remaining for 10 seconds.

This display will show a

This display

AVG I 23

I4 DAY

I0

MAINT

365

12

Page 17

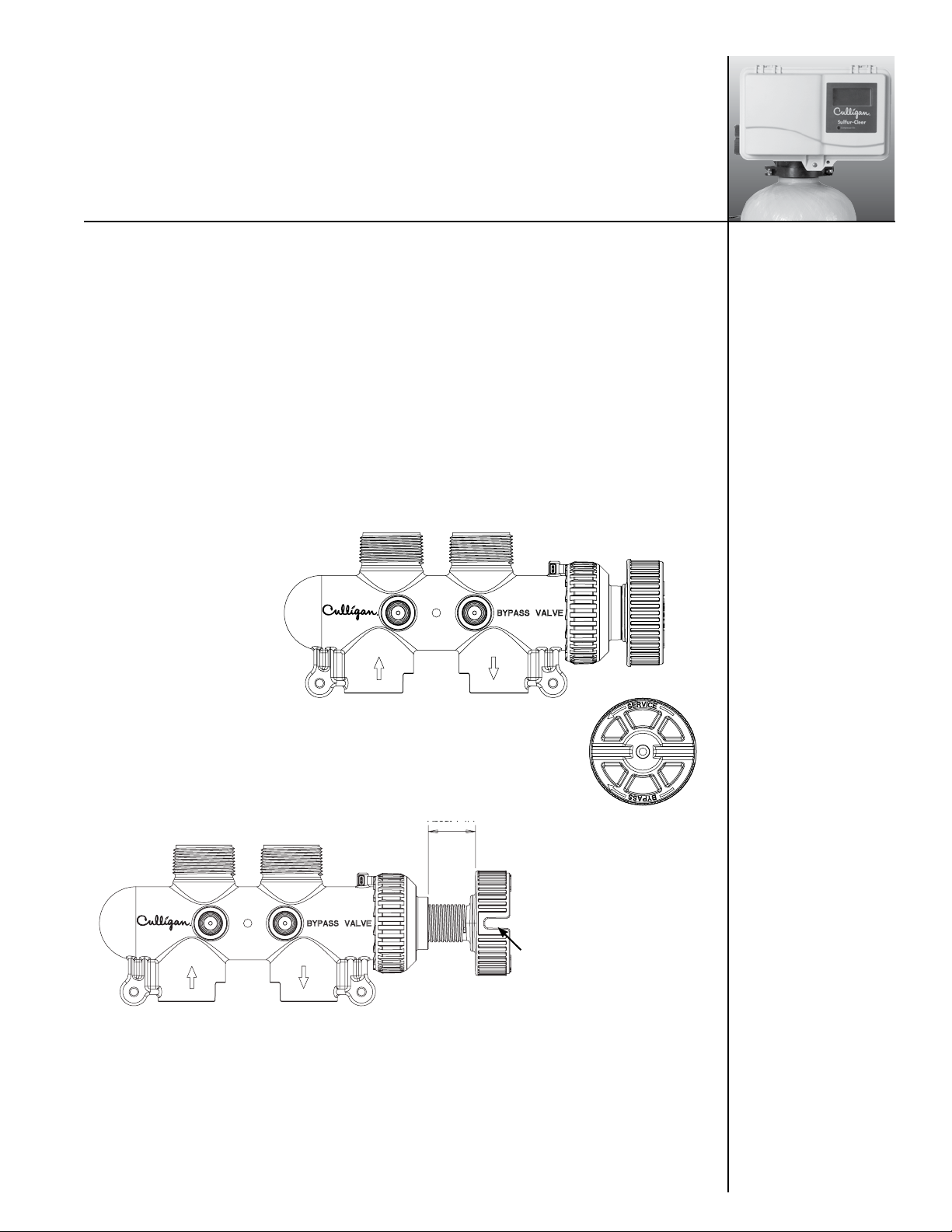

Normally, all water except outside lines passes through the water conditioner. There are times when

About 1-1/4”

the water conditioner should be bypassed, using the push-button Cul-Flo-Valv® Bypass, or a 3-way

bypass valve. You should bypass:

1. If lines to outside faucets do not bypass the water conditioner, and you do not want to waste soft

water on lawn sprinkling or other outside uses.

2. If you are going away on vacation and want to save salt by not having the unit recharge while

you’re away.

Bypass Valve

In the back of Culligan water conditioners is a Cul-Flo-Valv® Bypass. To bypass unit, simply turn the

blue knob clockwise. To return to soft water service, reverse the procedure - turn the blue knob counterclockwise.

When and

How to

Bypass

Your Water

Conditioner

Bypassed

To BYPASS, turn the blue knob clockwise (see directional arrow on end of knob)

until the knob stops as shown. DO NOT OVERTIGHTEN!

A screwdriver shank may be

used in the slot (arrow) as a

lever for extra turning force if

needed.

Soft Water

To return to SERVICE, turn the blue knob counter-clockwise (see directional arrow on end of knob) until

the knob stops as shown. DO NOT OVERTIGHTEN!

13

Page 18

Regeneration

with Bleach

Caution! USE AND HANDLING OF HOUSEHOLD BLEACH

Bleach is a strong oxidizing agent. It can cause severe irritation or damage to eyes and

skin. Observe all precautions stated on the bleach container.

• Store the bleach in a cool dry place out of reach of children and pets.

• Do not store an unmarked container or a container with any markings which could

mislead someone as to its actual contents.

• Keep the bleach covered when not in use and tightly closed.

When bleach is used to regenerate the Sulfur-Cleer™, Culligan strongly recommends the dealer set-up a

service contract with the customer to initiate the regeneration when required.

If a service contract is not practical, then Culligan recommends the dealer and the customer strictly

abide by the following procedure when regenerating with bleach:

• The dealer must instruct the customer on the handling of chlorine and review the DANGER

statements on the bleach bottle with the customer.

• The dealer must review the first aid instructions on the bleach bottle with the customer.

• The dealer must be present with the customer during the first regeneration.

• Protective eyewear and gloves are required.

See the Installation and Operation Manual or contact the Culligan Dealer for regeneration procedure

with bleach.

14

Page 19

If you unexpectedly experience problem water, make these simple checks before calling your Culligan

dealer. One of the following conditions may be the reason for your interruption of service.

Important

If any of the following conditions is found, the water filter should be manually recharged according to

instructions on page 5 after you have corrected the problem.

Power Supply

Check your power supply cord. Is it plugged fully into the electric outlet? Be certain that the outlet is

not controlled by a wall switch which has been turned off. Reset conditioner to proper time of day and

then plug in.

Blown Fuse

Check the house fuse or circuit breaker panel. Replace a blown-out fuse or reset an open circuit

breaker.

Power Failure

Any interruption in your power supply or time changes - such as daylight savings - will disrupt your

filter’s recharge schedule by causing the timer to run off-schedule. Reset timer to proper time of day.

Bypass Valves

Check to see if they are in the proper position. Cul-Flo-Valv® Bypass, if used, should be in the

“Service” position. If hand valves are used, see that inlet and outlet valve are opened and that the

bypass valve is closed.

Things to

Check Before

You Call for

Service

No Water

If you aren’t getting any water flow at all, make sure your water supply is working. Open a tap ahead

of the filter (outside tap) to see if you have any water pressure. If you have water pressure, check the

bypass valve. If it is in the Service position, put it into the bypass and call your Culligan dealer for

service.

Increased Usage

Guests, family additions, new water-using appliances, etc., all will result in more water usage and will

require more capacity from your filter. You can reprogram your recharging schedule by following the

directions on pages 7 and 8. Call your Culligan dealer for advice and save a service call.

15

Page 20

Preventative

Maintenance

16

The Culligan Sulfur-Cleer™ water filter has been designed to provide a good, consistent service life.

Because of the nature of problem water, we recommend that the local Culligan dealer provide regular

maintenance/service contracts for the proper operation of your systems. The water filter service

begins with a multi point inspection of your water filter system in an effort to uncover any and all

problems that may exist. Listed below is a recommended list of maintenance items to be inspected at

a minimum of once a year (or more frequently depending on the raw water quality).

Test Water

Hardness

Hydrogen Sulfide

Chlorine

Comments:

Bypass Valve

Bypass in Service or Bypass?

Condition of bypass valve

Operation OK?

Control Valve

Condition of Eductor (Sulfur-Cleer™)

Condition of Solution Valve (Sulfur-Cleer™)

Condition of Seal Pack and Brine Piston

Condition of Solenoid Valve

Condition of Motor:

Condition of Flow Control

Condition of Switches:

Condition of Check Valve

Condition of Compressor

Control settings Before After

Check / reset time of day

Check time of regeneration

Compressor setting “On Time” in seconds

Compressor setting “Off Time” in minutes

Backwash minutes

Chemical Draw/Slow Rinse (Sulfur-Cleer™)

minutes

Fast Rinse minutes

Cycle control Test Cycle OK?

Media Tank

Freeboard inches:

Media Condition

Feed Product

Iron

TDS

Other

Output PSI

Backwash

Chemical draw

Slow rinse

Fast rinse

Page 21

Complaint Problem Cause Solution

Iron bleedthrough or

staining.

A. Inadequate

backwash of filter

B. Fails to

regenerate

1. Plugged drain line flow

control

2. Insufficient water supply from

well.

3. Plugged media tank inlet

diffuser or pick-up tube.

4. Media bed fouled. 4. Call your Culligan dealer for

1. Interrupted electrical service. 1. Assure continuous electrical

2. Faulty circuit board. 2. Replace circuit board.

3. Faulty drive motor. 3. Replace drive motor.

4. Circuit board set incorrectly. 4. Reset circuit board.

1. Call your Culligan dealer for

service.

2. Check for minimum specified

flow and pressure requirements

of filter system.

3. Call your Culligan dealer for

service.

service.

supply (check plug, breaker,

fuses, etc.).

Troubleshooting

Guide

C. Water

contaminant

levels are greater

than limits

established by

Culligan.

D. Inadequate

aeration

E. Exceeding

recommended

filter system flow

rate.

F. Regeneration

during service

flow demand.

G. Raw water

bleeding through

filter.

1. It is not uncommon for local

water conditions to change.

1. Loss of air through inlet check

valve.

2. Loss of air through air leak. 2. Call your Culligan dealer for

3. Faulty aeration pump.

a. Electrical failure a. Assure permanent electrical

b. Pneumatic failure b. Call your Culligan dealer for

c. Damp environment c. Call your Culligan dealer for

4. Air loss through high demand. 4. Call your Culligan dealer for

1. Service flow rate demand is

higher than filter system design

flow rate.

1. Time of day set incorrectly. 1. Call your Culligan dealer for

1. Internal control valve leak. 1. Call your Culligan dealer for

1. Call your Culligan dealer for

service.

1. Call your Culligan dealer for

service.

service.

service (check plug, breaker,

fuses, terminal block on control

valve, etc.).

service.

service.

service.

1. Call your Culligan dealer for

service.

service.

service.

17

Page 22

Troubleshooting

Guide (cont.)

Complaint Problem Cause Solution

Water leaking

from relief

valve.

Water is

effervescent

Loss of pressure A. See complaint #1, problem A & B

Air spurting at

outside or nonfiltered water

fixtures.

Air spurting

from filtered

water fixtures.

Loss of media

through drain

line.

Excessive

noise during

regeneration.

A. Dirt lodged under

seat of valve.

B. Faulty or defective

relief valve

A. This can be

expected when water

is aerated under

pressure.

A. Inlet check valve

not sealing.

A. Reduced pressure

in distribution system.

A. New filter

backwashed during

first 24 hours after

installation.

B. Air passing

through filter during

backwash.

A. Howling or

whistling noise

during regeneration

cycle.

1. Pressure has exceeded

rating on relief valve and

caused valve to open

1. Water supply has been

naturally aerated under well

system pressure. As water is

released to the atmosphere,

air molecules separate from

the water molecules.

1. Improper installation

location.

2. Foreign material preventing

check valve.

3. Worn or faulty check valve. 3. Call your Culligan dealer

1. Service flow demand is

greater than water supply

available from well pump

system.

2. Water flow is restricted by

supply piping and/or water

treatment equipment.

1. New filter media is shipped

in a dry condition and must

soak for 24 hours to become

fully saturated before a

backwash cycle.

1. Excess air accumulated

in media tank from aeration

pump.

2. Excess air accumulated in

filter system from water supply

or well pump.

1. Inadequate drain line size. 1. Call your Culligan dealer

2. Drain line is vibrating

against other pipes, conduits,

pipe hangers, heat ducts, floor

joists,etc.

1. Call your Culligan dealer

for service.

1. Call your Culligan dealer

for service.

1. This natural phenomenon

will typically dissipate to the

atmosphere in a matter of

seconds. If preferred, water

can be drawn and stored

in an open container prior

to use (i.e. fill a pitcher and

store in the refrigerator for

cool, fresh drinking water).

1. Call your Culligan dealer

for service.

2. Call your Culligan dealer

for service.

for service.

1. Repair or replace well

pump system.

2. Call your Culligan dealer

for service.

1. Clean drain line flow

control, control valve body,

seals, spacers and piston

assemblies

1. Call your Culligan dealer

for service.

2a. Repair well pump

system.

2b. If the cause was due

to temporary loss of water

main pressure; the problem

will most likely correct itself

with the return of continuous

pressure.

for service.

2. Call your Culligan dealer

for service.

18

Page 23

Complaint Problem Cause Solution

Water is

running

to drain

continuously.

Blue green

staining.

Compressor

doesn’t run.

Compressor run

with excessive

noise.

Compressor

runs

continuously.

A. Control valve is

stuck in regeneration

cycle.

A. Corrosive water

condition in copper

distribution piping

system.

1. Electrical service

to control(s) has been

interrupted.

2. Faulty circuit board. 2. Replace circuit board..

3. Faulty drive motor. 3. Call your Culligan dealer

4. Foreign material lodged in

piston.

1. Low pH condition of the

raw water supply.

2. In rare occasions, highly

aerated water in combination

with a specific water supply

can create a slightly corrosive

condition.

1. Compressor unplugged. 1. Plug it in.

2. Relay settings incorrect. 2. Call your Culligan dealer

3. Bad relay. 3. Call your Culligan dealer

1. Dead head pressure is 65

psi.

2. Dead head pressure is 65

psi.

1. Incorrect relay settings 1. Call your Culligan dealer

2. Bad relay. 2. Call your Culligan dealer

1. Assure continuous

electrical service is

available. (check plug,

breaker, fuse, etc.)

for service.

4. Call your Culligan dealer

for service.

1. Call your Culligan dealer

for service.

2. Call your Culligan dealer

for service.

for service.

for service.

1. Call your Culligan dealer

for service.

2. Call your Culligan dealer

for service.

for service.

for service.

Troubleshooting

Guide (cont.)

19

Page 24

Performance

Data Sheet

Culligan® Sulfur-Cleer™ Water Filter

Important Notice — Read this data sheet and compare the capabilities of the unit to your actual

water treatment needs. Culligan recommends that you have your water supply tested to determine

these needs before purchasing a water treatment unit.

Culligan knows the more informed you are about your water treatment system, the more confident

you will be about its performance. It’s because of this more than seventy years of commitment to our

customers that Culligan is providing this Performance Data Sheet to its customers.

Manufacturer Culligan International Company

9399 W. Higgins Rd., Suite 1100, Rosemont, IL 60018

1-800-CULLIGAN or (847) 430-2800

www.culligan.com

Substance Reduction

Model Substance

Sulfur-Cleer

Hydrogen

10” Fiberglass

Sulfur-

Hydrogen

Cleer 10”

Quadrahull

Sulfide

Iron

Sulfide

Iron

USEPA SDWA*

MCL (MG/L)

0.3 mg/L 98.7% 10.4 mg/L 0.14 mg/L

0.3 mg/L 98.7% 10.4 mg/L 0.14 mg/L

* United States Environmental Protection Agency Safe Drinking Water Act

Percent

Reduction

Average Influent

Concentration Level

98.9% 8.2 mg/L 0.091 mg/L

98.9% 8.2 mg/L 0.091 mg/L

Testing Conditions

Capacity: 1,000 gallons)

Temperature: 63°F - 73°F

(17°C - 23°C)

Flow Rate: 5 gpm

pH: 8.0

Pressure: 20-60 psi

(1.4 - 4.2 Kgf/cm2)

Acidity: Non-Corrosive

Rated Pressure Drop @ 3 gpm: 5 psi

Operating Conditions

Water Pressure Limits: 20 - 60 psi

Temperature Limits: 33 - 120°F

Electrical Characteristics: 120V/60 Hz 7 Watts continuous

Average Effluent

Concentration Level

20

Systems tested against WQA S-200 for the effective reduction of iron, and WQA Test Protocol 04-001 and NSF/

ANSI 42 for the efective reduction of hydrogen sulfide as verified and substantiated by test data.

This system has been tested according to NSF/ANSI 42 for the reduction of iron and hydrogen sulfide. The

concentration of iron and hydrogen sulfide in water entering the system was reduced to a concentration less than or

equal to the permissible limit for water leaving the system as specified in NSF/ANSI 42.

Testing was performed under laboratory conditions, actual results may vary.

Performance Indicator: If water flow decreases or a noticeable odor returns, the filter should be reconditioned. If

conditions do not improve, contact your local Culligan dealer. He can determine if your filter requires servicing.

Regeneration Frequency: Regeneration frequency will vary depending upon water conditions.

Refer to your Installation and Operation Instructions, Parts List and Printed Warrantees for more specific product

information. To avoid contamination from improper handling and installation, your system should only be installed

and serviced by your Culligan Man. Performance may vary based on local water conditions. The substances

reduced by this product are not necessarily in your water.

Buyer Signature Date

Seller Signature Date

Page 25

Important Data on Your Water Filter

It is advisable to have the salesperson or installer fill in the information below for your future reference.

If this has not been done, please ask for it, as it is necessary if you contact your dealer.

Identification

Model Name Catalog No.

Control Model No. Control Serial No.

Date of Installation Tank Serial No.

Settings

Time of Recharge: ______ a.m. ______ p.m.

Regeneration Interval __________ days (Time clock models)

Records and

Data

Number of people in household

Water Analysis

Total Hardness _______ (gpg) Total Iron _______ (ppm)

Hydrogen Sulfide____________ (ppm)

Other

21

Page 26

Culligan

Limited

Warranty

Culligan® Sulfur-Cleer™ Automatic Water Filters

You have just purchased one of the finest water conditioners made. As an expression of our

confidence in Culligan International Company products, your water conditioner is warranted to the

original end-user, when installed in accordance with Culligan specifications, against defects in material

and workmanship from the date of original installation, as follows:

For a period of ONE YEAR The entire conditioner

For a period of FIVE YEARS The circuit board

For a period of TEN YEARS The control valve body, excluding internal parts

The conditioner tank

If a part described above is found defective within the specified period, you should notify your independently operated Culligan dealer and arrange a time during normal business hours for the dealer

to inspect the water conditioner on your premises. Any part found defective within the terms of this

warranty will be repaired or replaced by the dealer. You pay only freight from our factory and local

dealer charges.

We are not responsible for damage caused by accident, fire, flood, freezing, Act of God, misuse,

misapplication, neglect, oxidizing agents (such as chlorine, ozone, chloramines and other related

components), alteration, installation or operation contrary to our printed instructions, or by the use of

accessories or components which do not meet Culligan specifications, is not covered by this warranty.

Refer to the specifications section in the Installation and Operating manual for application parameters.

Our product performance specifications are furnished with each water conditioning unit. To the

extent permitted by law, culligan disclaims all implied warranties, including without

limitation warranties of merchantability and fitness for particular purpose; to the

extent required by law, any such implied warranties are limited in duration to the

one-year period specified above for the entire conditioner. As a manufacturer, we do not

know the characteristics of your water supply or the purpose for which you are purchasing a water

conditioner. The quality of water supplies may vary seasonally or over a period of time, and your

water usage rate may vary as well. Water characteristics can also differ considerably if your water

conditioner is moved to a new location. For these reasons, we assume no liability for the determination

of the proper equipment necessary to meet your requirements, and we do not authorize others to

assume such obligations for us. Further, we assume no liability and extend no warranties, express or

implied, for the use of this product with a non-potable water source. Our obligations under this

warranty are limited to the repair or replacement of the failed parts of the water

conditioner, and we assume no liability whatsoever for direct, indirect, incidental,

consequential, special, general, or other damages.

22

Some states do not allow the exclusion of implied warranties or limitations on how long an implied

warranty lasts, so the above limitation may not apply to you. Similarly, some states do not allow the

exclusion of incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state. Consult your telephone directory for your local independently operated Culligan

dealer, or write Culligan International Company for warranty and service information.

Culligan International Company

9399 W. Higgins Road., Suite 1100

Rosemont, Illinois 60018

1-800-CULLIGAN or (847) 430-2800

www.culligan.com

Page 27

You Get Your Water Expert, The Culligan Man

We’re here to provide you with fast, dependable service, making sure any problems you have are

taken care of. The Culligan Man has been around for over seventy years, delivering dependable

service all along. That’s why people say “Hey, Culligan Man!”® Because we’re the water experts.

And that’s who you want taking care of your water.

®

The Culligan Promise

At Culligan, we understand that a water quality improvement system is an investment in your family’s

well-being. That’s why our 1,350 independently operated dealers worldwide don’t just sell products;

they sell water quality you can count on. We stand behind our products with written limited warranties

and our unequaled Culligan service. No matter where you live, you can depend on Culligan expertise

to work for you — today and tomorrow.

© 2007 Culligan International Company 01019837A

23

Loading...

Loading...