Page 1

SPECIFICATIONS

Operating Pressure Range: 10 - 125 psi (0.7 bar - 8.6 bar)

Operating Temperature Range: 35 - 100°F (2 - 38°C)

Service Flow Rate: 0.5 gpm (1.9 Lpm)

Capacity: 750 gal. (2,839L) Preferred 150

1000 gal. (3,785L) Preferred 250

300 gal. (1,135L) Preferred 350

For cold water use only

Note that some states require licensed installers, and some

states prohibit the use of saddle valves.

INSTALLATION

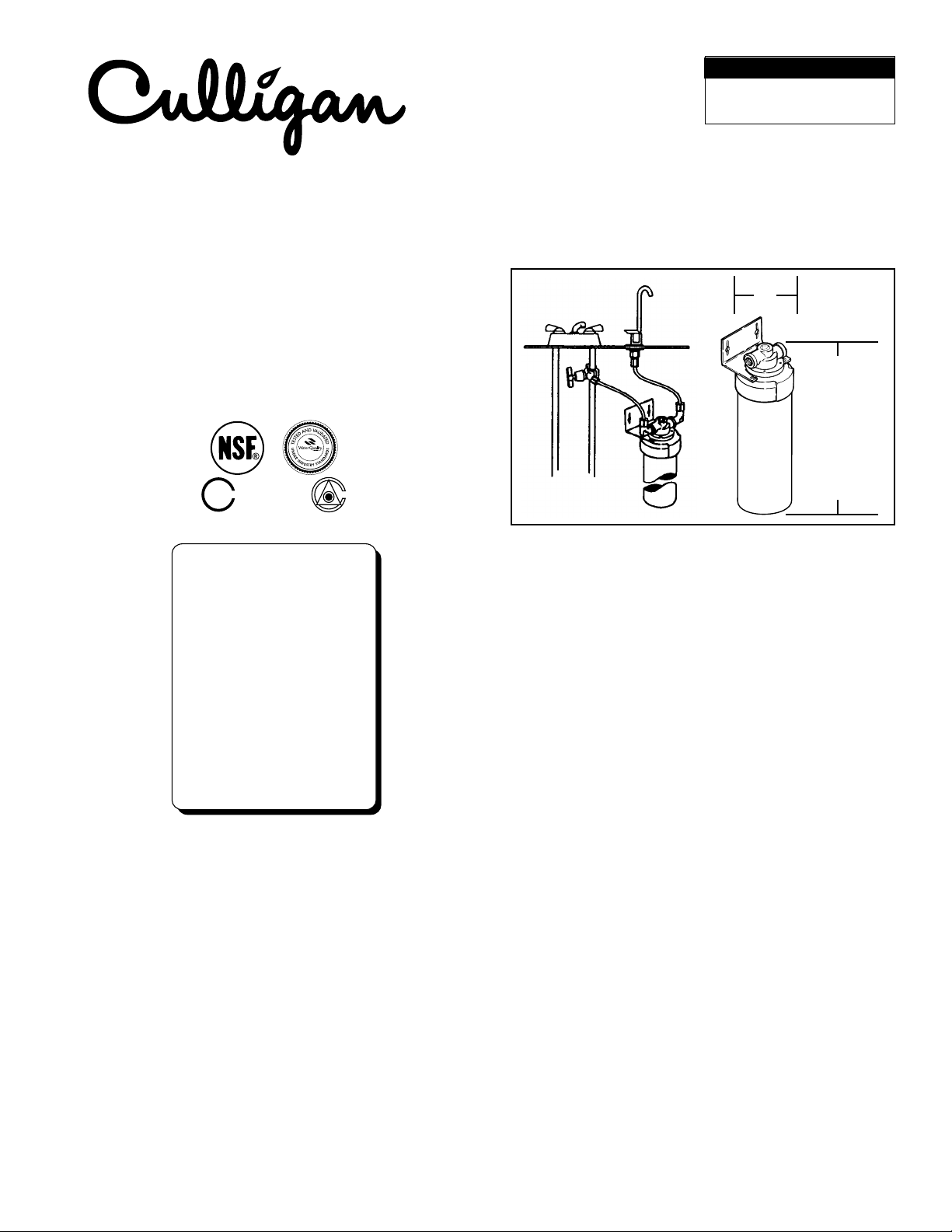

Culligan recommends that Preferred Series Drinking Water

Filters be installed with a faucet dedicated to dispensing only

filtered water. Such a faucet is available from Culligan by

ordering P/N 01-0035-37*. Refer to the plumbing schematic

shown in Figure 1 when completing this type of installation.

Other recommended applications include point-of-use

drinking water coolers, refrigerators, and ice makers.

®

Culligan®Preferred™ Series Drinking Water Filters

Installation, Operation, and Service Guide

NSF's Certification Program

is accredited by the Dutch

Council for Accreditation

ANSI

ACCREDITED

CERTIFICATION

PROGRAM

NSF's Certification Program

is accredited by the American

National Standards Institute

NSF/ANSI 42

NSF/ANSI 53

System Tested and Certified by NSF

International against NSF/ANSI

Standards 42 and 53 for the reduction of:

Standard No. 42: Aesthetic Effects

Chemical Unit

Taste and Odor Reduction

Chlorine Reduction

Mechanical Filtration Unit

Particulate Reduction

99.9+% reduction of particles

one-half micron and larger in size

Standard No. 53: Health Effects

Chemical Reduction Unit

Lead Reduction

VOC Reduction (350 Only)

Mechanical Filtration Unit

Turbidity Reduction

Cyst Reduction

Asbestos Reduction

Check for compliance with state and local laws and regulations.

Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the

system. Systems certified for cyst reduction may be used on

disinfected water that may contain filterable cysts.

This filter system is supplied with fittings which are

designed for use with 1/4 inch O.D. polyethylene tubing:

available from Culligan by ordering P/N 00-4021-84*.

1. Select a location for the filter assembly which:

• Provides a solid mount for the filter head.

• Allows a minimum 2 inches (5 cm) of clearance

under the cartridge.

•

Allows space for inlet and outlet water line connections.

Note: The filter must be mounted vertically.

2. Provide an inlet water supply for the filter by tapping

the cold water line. This connection should accommodate 1/4 inch O.D. polyethylene tubing and must

comply with state and local laws and regulations.

3. Install the faucet or dispensing device according to the

instructions provided with the device.

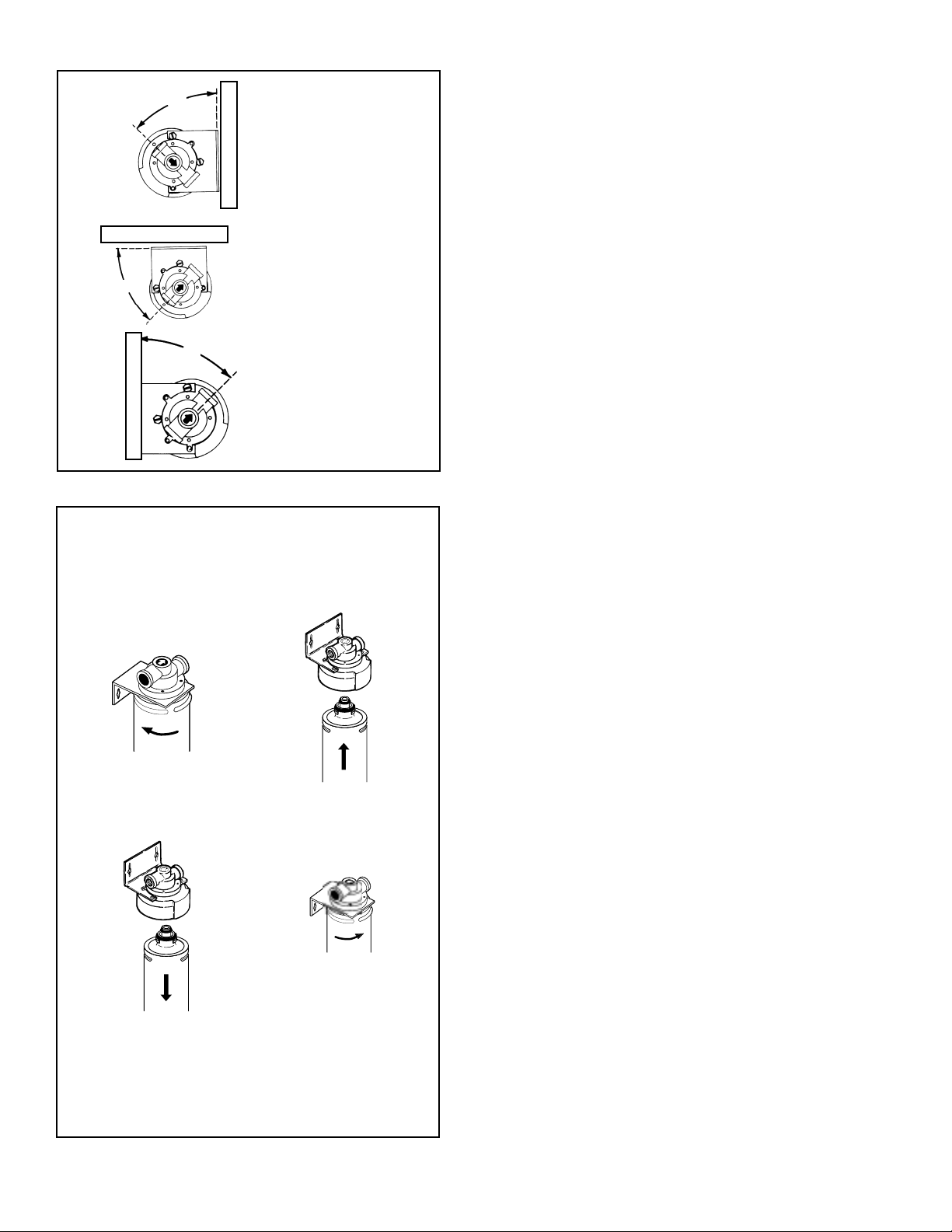

4. Refer to Figure 2 to determine the best filter bracket

position to accommodate the water connections.

5. Install the 0.5 gpm flow restrictor fitting into the outlet

port on the filter head using Teflon tape.

Note: The restrictor is built into one of the elbow fittings.

6. Install the remaining 1/4 inch tubing fitting into the filter head inlet using Teflon tape.

7. Mount the filter head using the screws and washers

provided.

8. Connect the inlet and outlet tubing to the inlet and

outlet fittings of the filter. Double check the water

connections to be sure that water will follow the

direction-of-flow arrow on top of the head; water

supply to inlet fitting, outlet fitting to faucet.

9. Install the filter cartridge as detailed in Figure 3.

10. Flush the cartridge for three minutes to purge the

system of air.

4” (10.7 cm)

Dia.

Unit Dimensions

with

• Preferred 150

Cartridge

12-3/4” (32.4 cm)

• Preferred 250

Cartridge

17-3/4” (45.1 cm)

• Preferred 350

Cartridge

20” (50.8 cm)

Cat. No. 01881923

Rev. D 01/06/03

DCO# 5378

Validated by WQ A according to NSF/ANSI 42

and 53 for the claims listed by NSF International

as verified and substantiated by test data.

Figure 1

*Not tested or certified by NSF.

Page 2

©2002 Culligan International Company

FILTER REPLACEMENT

These drinking water systems must be maintained according

to the manufacturer’s instructions, including timely

replacement of filter cartridges. Follow the guidelines below

to determine when the filter cartridge must be replaced in

each system. Refer to Figure 3 for the service sequence.

Preferred™ 150 Filter

The filter cartridge must be replaced after every 750 gallons

or one year of use (whichever comes first), or whenever

there is a change in taste or odor or a noticeable decrease in

flow. 750 gallons of water use is roughly equivalent to using

2 gallons of water daily for one year.

Preferred™ 250 Filter

The filter cartridge must be replaced after every 1000 gallons

or one year of use (whichever comes first), or whenever there

is a change in taste or odor or a noticeable decrease in flow.

1000 gallons of water use is roughly equivalent to using 2-1/2

gallons of water daily for one year.

Preferred™ 350 Filter

The filter cartridge must be replaced after every 300 gallons

or one year of use (whichever comes first), or whenever there

is a change in taste or odor or a noticeable decrease in flow.

300 gallons of water use is roughly equivalent to using 1-1/2

gallons of water daily for six months. Conforms to NSF/ANSI

53 for VOC reduction. See Performance Data Sheet for

individual contaniments and reduction performance.

Replacement Cartridge Part Numbers

Preferred 150 Filter Cartridge 01-0028-68

Preferred 250 Filter Cartridge 01-0028-69

Preferred 350 Filter Cartridge 01-0028-70

Replaceable components and service parts are available

through your local independent Culligan dealer. To learn

the name of your nearest dealer, contact:

Manufactured by:

CULLIGAN INTERNATIONAL COMPANY

One Culligan Parkway

Northbrook, IL 60062

USA

(847) 205-6000

http:\\www .culligan.com

WALL

WALL

WALL

45°

45°

Illustration A

Right Wall

Mounting

Illustration B

Back W all

Mounting

Illustration C

Left Wall

Mounting

Figure 2

Figure 3

CARTRIDGE

REMOVAL

1. Shut off water supply.

Open serviced faucet

to relieve pressure.

CARTRIDGE

INSTALLATION

1. Align cartridge lug

with head label.

2. Turn cartridge to the

left as far as possible.

2. Holding head firmly,

press cartridge fully

into head.

3. Holding head firmly,

pull cartridge downward and out of head.

3. Turn cartridge to right

until rotation stops.

4. Turn water on and run

water for 3 minutes to

purge cartridge of air.

45°

Head can

be rotated

a maximum of

45° from

wall.

Loading...

Loading...