Culligan MEDALLIST SERIES, MEDALLIST 8"", MEDALLIST 30 3, MEDALLIST 45 3 Service Manual

Cat. No. 01882311

Rev. D 09/17/02

DCO # 4625

Service

Manual

CULLIGAN

MEDALLIST SERIES

AUTOMATIC

WATER CONDITIONER

MODELS FROM 2002

™

©2002 Culligan International Company

Printed in USA

Attention Culligan Customer:

The installation, service and maintenance of this equipment should

be rendered by a qualied and trained service technician. Your local

independently operated Culligan dealer employs trained service

and maintenance personnel who are experienced in the installation,

function and repair of Culligan equipment. This publication is written

specically for these individuals and is intended for their use.

We encourage Culligan users to learn about Culligan products, but

we believe that product knowledge is best obtained by consulting

with your Culligan dealer. Untrained individuals who use this manual

assume the risk of any resulting property damage or personal

injury.

WARNING - PRIOR TO SERVICING EQUIPMENT,

DISCONNECT POWER SUPPLY TO PREVENT ELECTRICAL

SHOCK.

WARNING - IF INCORRECTLY INSTALLED, OPERATED

OR MAINTAINED, THIS PRODUCT CAN CAUSE SEVERE

INJURY. THOSE WHO INSTALL, OPERATE, OR MAINTAIN

THIS PRODUCT SHOULD BE TRAINED IN ITS PROPER

USE, WARNED OF ITS DANGERS, AND SHOULD READ

THE ENTIRE MANUAL BEFORE ATTEMPTING TO INSTALL,

OPERATE OR MAINTAIN THIS PRODUCT.

IF THIS EQUIPMENT IS TO BE USED IN THE

TREATMENT OF DRINKING WATER, THE WATER

MUST BE MICROBIOLOGICALLY SAFE.

CULLIGAN

Service

Manual

MEDALLIST SERIES

AUTOMATIC

WATER CONDITIONER

MODELS FROM 2002

Table of Contents

Introduction ................................................................ 2

Specications ............................................................ 3

Familiarization ........................................................... 4

Settings...................................................................... 7

Programming ............................................................11

Manual Cycling ........................................................ 15

Service Check ......................................................... 16

Board Diagnostics ................................................... 17

Parts Replacement Guide ....................................... 19

Troubleshooting Guide ............................................ 23

Wire Diagram ........................................................... 26

Flow Rate and Drain Line Charts ............................ 27

Flow Charts ............................................................. 29

Parts List..............................................................34

™

Page

Introduction

The Culligan Medallist Series™ Water Softeners are tested and validated by

WQA and certied by UL against ANSI/NSF Standard 44 for the effective reduction of calcium and magnesium along with Barium and Radium 226/228*.

Because the ability of the unit to remove Barium and Radium is based upon

reducing hardness to less than 1 gpg, effective hardness reduction should be

ANSI/NSF 44

Water Softener

81WN

periodically veried. Hardness sample kits are available through your local Culligan Dealer.

For installations in Massachusetts, Massachusetts Plumbing Code 248 CMR shall be adhered to. Consult

your licensed plumber for installation of this system.

SAFE PRACTICES

Throughout this manual there are paragraphs set off by special headings.

NOTICE: Notice is used to emphasize installation, operation or maintenance information which is important, but

does not present any hazard.

Example: NOTICE: The nipple must extend no more than 1 inch above the cover plate.

CAUTION: Caution is used when failure to follow directions could result in damage to equipment or

property. Example:

CAUTION: Disassembly while under water pressure can result in ooding.

WARNING: Warning is used to indicate a hazard which could cause injury or death if ignored. Example:

WARNING! ELECTRICAL SHOCK HAZARD! UNPLUG THE UNIT BEFORE

REMOVING THE COVER OR ACCESSING ANY INTERNAL CONTROL PARTS.

SERIAL NUMBERS

The control valve serial number is located on the back of the control.

The media tank serial number is located on the top surface of the tank.

NOTICE: Do not remove or destroy the serial number. It must be referenced on request for warranty repair or

replacement.

This publication is based on information available when approved for printing. Continuing design renement

could cause changes that may not be included in this publication.

* Veried utilizing hardness surrogate per ANSI/NSF Standard 44.

2 CULLIGAN MEDALLIST SERIES

Specications

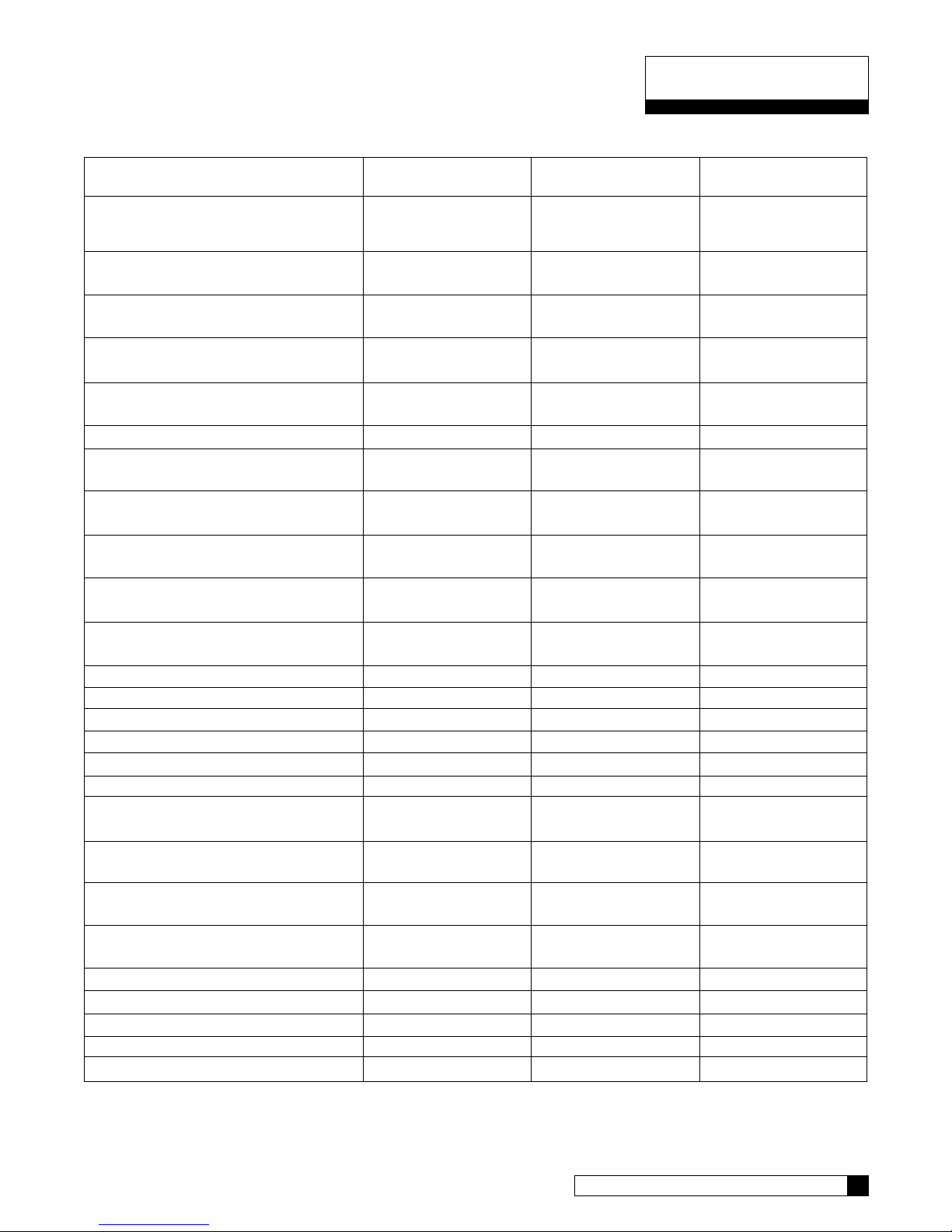

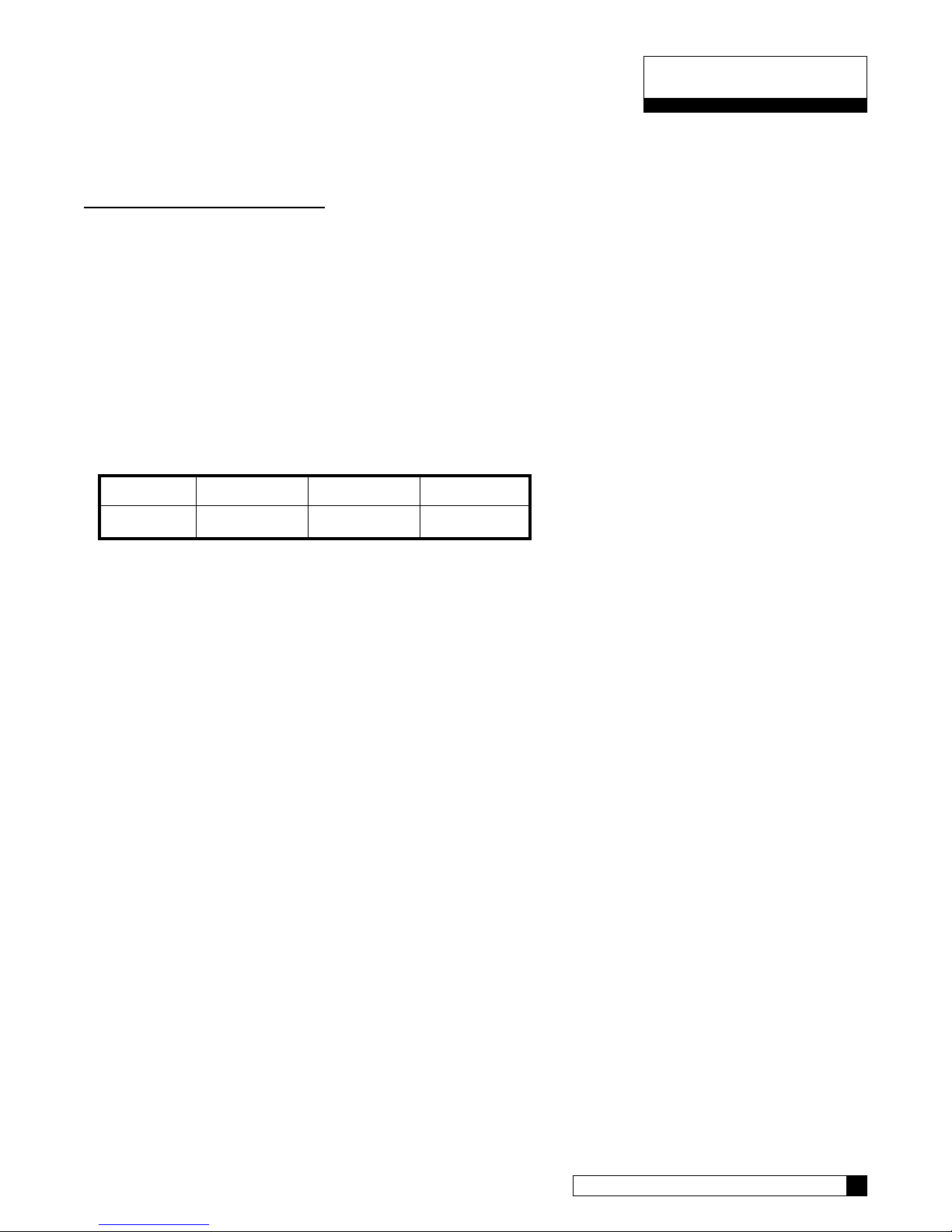

CULLIGAN MEDALLIST SERIES WATER CONDITIONER WITH TIMECLOCK OR SOFT MINDER METER

8" MODEL 303 MODEL 453 MODEL

Control Valve Type 5-cycle Reinforced 5-cycle Reinforced 5-cycle Reinforced

Thermoplastic Thermoplastic Thermoplastic

Overall Conditioner Height 51 in 49 in 63 in

1,295 mm 1,245 mm 1,600 mm

Media Tank Dimensions (Dia. x Ht.) 8 x 44 in 10 x 40 in 10 x 54 in

203 x 1,118 mm 254 x 1,016 mm 254 x 1,372 mm

Salt Storage Tank Dimensions 16 x 43 in 18 x 43 in 18 x 43 in

(Dia. x Ht.) 457 x 1,092 mm 457 x 1,092 mm 457 x 1,092 mm

18 x 43 in

457 x 1,092 mm

Exchange Media, Type and Quantity Cullex® Media, 0.7 ft3 Cullex Media, 1.0ft3 Cullex Media, 1.5 ft

Underbedding, Type and Quantity Cullsan® Underbedding, Cullsan Underbedding, Cullsan Underbedding,

6 lb. 8 lb. 8 lb.

Exchange Capacity 18,300 gr @ 4 lb 20,200 gr @ 5.0 lb 24,900 gr @ 6 lb

@ Salt Dosage Per Recharge

1

25,100 gr @ 9.0 lb 29,400 gr @11 lb 39,200 gr @14 lb

27,500 gr @ 12 lb 35,000 gr @17 lb 43,500 gr @ 20 lb

Efciency at Rated Sales Dosage5 4 lb. salt dosage: 5 lb. salt dosage 6 lb. salt dosage

4570 gr./lb. 4050 gr./lb. 4150 gr./lb.

Freeboard to Media2 20.5 - 21.5 in 17 - 18 in 19.75 - 21.75 in

Freeboard to Underbedding

3

42.0 - 42.5 in 39.6 - 40.1 in 53.8 - 54.3 in

Salt Storage Capacity 250 lb or 375 lb 375 lb 375 lb

Rated Service Flow @ Pressure Drop 5.9 gpm @ 12 psi 7.2 gpm @ 12 psi 7.0 gpm @ 13 psi

Total Hardness, Maximum 75 gpg 99 gpg 99 gpg

Total Iron, Maximum (dissolved) 5 ppm 5 ppm 5 ppm

Hardness to Iron Ratio, Minimum 8 gpg to 1 ppm 8 gpg to 1 ppm 8 gpg to 1 ppm

140 mg/L to 1 mg/L 140 mg/L to 1 mg/L 140 mg/L to 1 mg/L

Operating Pressure 20 - 125 psi 20 - 125 psi 20 - 125 psi

140 - 860 kPa 140 - 860 kPa 140- 860 kPa

Operating Pressure (Canada) 20 - 90 psi 20 - 90 psi 20 -90 psi

140 - 620 kPa 140 - 620 kPa 140 - 620 kPa

Operating Temperature 33 - 120°F 33 - 120°F 33 - 120°F

1 - 50°C 1 - 50°C 1 - 50°C

Electrical Requirements 24V/60 Hz 24V/60 Hz 24V/60 Hz

Electrical Power Consumption, Min./Max. 3 Watts/35 Watts 3 Watts/35 Watts 3 Watts/35 Watts

Drain Flow, Maximum4 1.1 gpm 2.0 gpm 2.1 gpm

Recharge Time, Average 85 min 64 min 64 min

Recharge Water Consumption 23.3 gal 61 gal 65 gal

1 Capacities and corresponding salt dosages pertain to low hardness waters. Capacities given per recharge

2 Measured from top of media to top of inlet tting (backwashed and drained)

3 Measured from top of underbedding to top of inlet tting

4 Backwash at 120 psi (830 kPa)

5 Efciency rating only valid at stated salt dosage on Soft-Minder® models and is efciency rated according to ANSE/

NSF Standard 44.

3

SPECIFICATIONS 3

Familiarization

CONTROL

The Culligan Medallist Series™ water softener uses the same power valve control as in our Culligan® Mark 89/812

models. It can be programmed as either a time clock or Soft-Minder® meter model. Each model has its own programming parameters which can be set to control the operation and regeneration of the system. These functions are

outlined in Table 1.

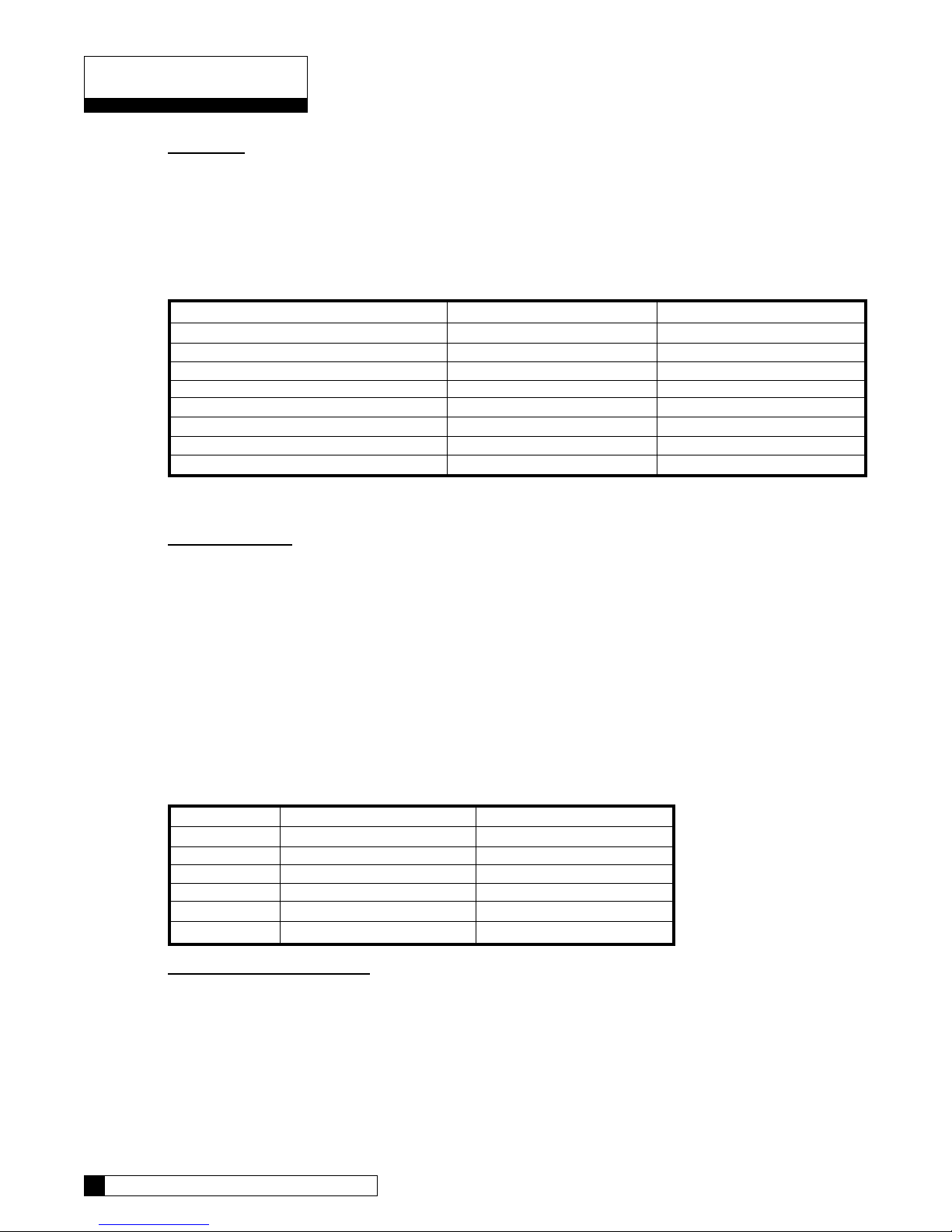

TABLE 1

Function Time Clock Soft-Minder Meter

Time of Day YES YES

Time of Regen. YES YES

Salt Dosage YES YES

Backwash Time YES YES

Brine Rinse Time YES YES

Gallons Capacity/Regen. Interval YES YES

Forced Regen. Interval NO YES*

Lock/Unlock display YES YES

* When Time Clock Backup is set to "ON".

CIRCUIT BOARD

The AccuSoft™ microprocessor circuit board controls every function of the Culligan Medallist Series water

softener. This board has several unique features which allows it to perform a variety of functions. Familiarization of

the board is essential for a thorough understanding of the softener.

The AccuSoft circuit board has a set of default settings that the microprocessor will reset to whenever a meter is

attached or removed from the control. Table 2 is a list of the default microprocessor settings.

It is recommended to always disconnect the power from the circuit board prior to replacing meter cable so that the

programmed settings are not lost.

TABLE 2

1 Time of Day 12:00 P.M.

2 Time of Regeneration 2:00 A.M.

4 Salt Dosage 10 lbs.

5 Backwash Time 10 min.

6 Brine Rinse 71 min.

8 Regeneration Interval 3 days or 870 gallons

10 Display Lock Out Disabled

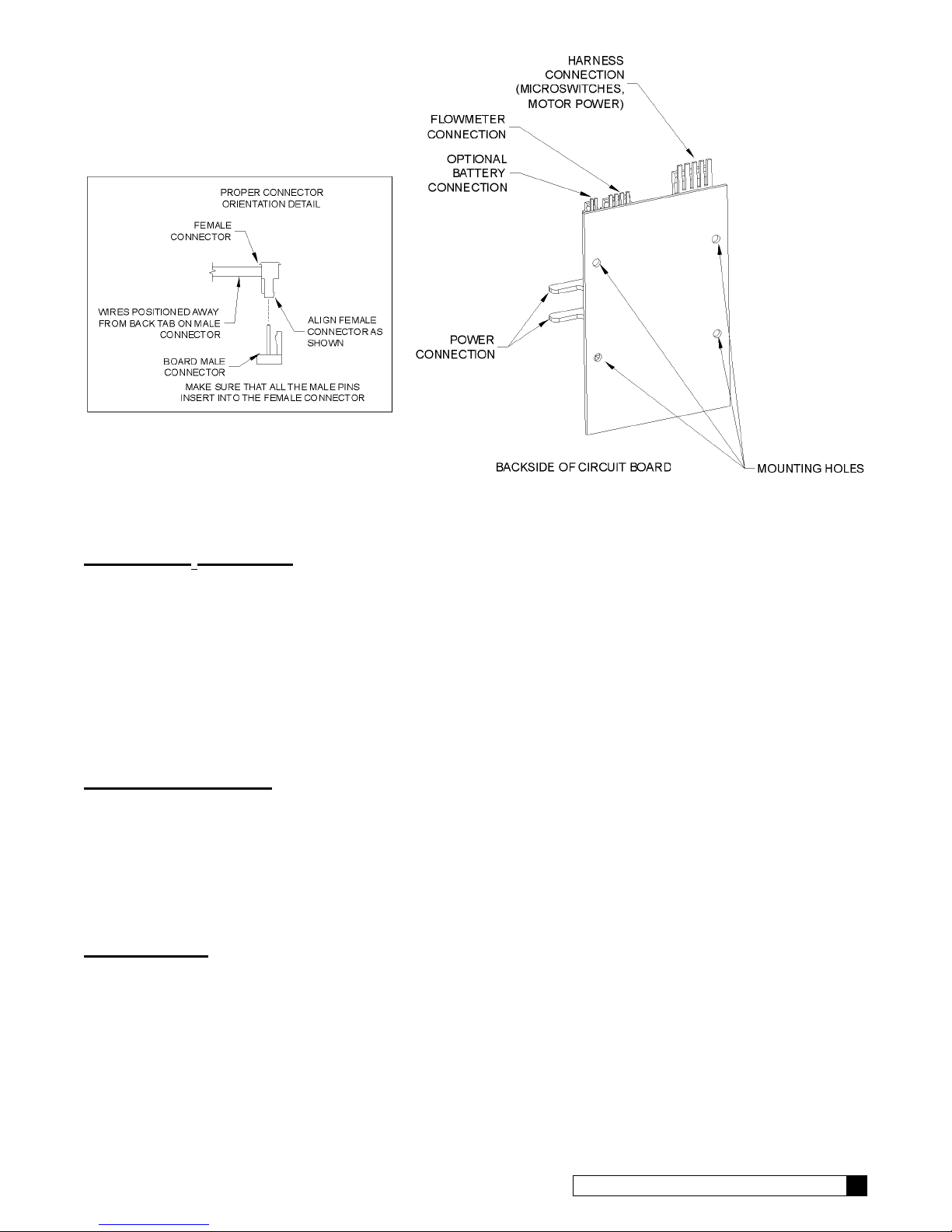

AUXILIARY CONNECTIONS

Refer to Figure 1 for all circuit board connections. Power terminals are located along the lower section of the circuit

board. The connection marked 'MAIN' is for the main wire harness. The Soft-Minder connection is located in the

upper left side of the board. Next to the meter connection is a connection marked 'BATT', which is for the optional

battery back-up. All terminals are clearly marked to ease installation.

4 CULLIGAN MEDALLIST SERIES

FIG. 1

SOFT-MINDER® OPERATION

The Soft-Minder meter utilizes a turbine impeller to accurately monitor the customer's water usage. After a predetermined amount of water has passed through the system, the microprocessor will signal a regeneration. The "REG"

enunciator will light at this point. The unit will perform a standard regeneration cycle at the preset time, unless the

programming option "dip2" is changed from "DEL" to "Id". When programming option "dip2" is changed from

"DEL" to "Id", a regeneration will begin immediately.

The programming of the Soft-Minder provides several settable variables, the Time-of-Day, Time-of-Regeneration,

Salt Dosage, Backwash Time, Brine/Rinse Time, Gallons to Signal and Timeclock Backup, if active. Refer to the

programming section for further information on programming the microprocessor.

TIMECLOCK OPERATION

When the microprocessor is set-up as a time clock unit, the Culligan® Medallist control will regenerate at xed

intervals. The regeneration interval can be set anywhere from 1 to 42 days.

The programming for the time clock models is limited to Time-of-Day, Time-of-Regeneration, Salt Dosage, Backwash

Time, Brine/Rinse Time, and the Regeneration Interval. Refer to the programming section for further information on

programming the microprocessor.

REGENERATION

There are several conditions that will cause the control to trip a regeneration. The "REG" enunciator will light when

the control has signaled for a regeneration. The "REG" enunciator will ash while the control is in regeneration. The

following are conditions that will call for regeneration, assuming "dip2" has been set to "DEL":

1. When the Soft-Minder meter has recorded the passage of a predetermined number or gallons

2. When the time clock has counted past the set number of days.

3. At the preset time, when the number of days without a regeneration is equal to the Timeclock Backup setting.

4. At the preset time, after the "REG" button is depressed once. "REG" will light.

5. Immediately, when the "REG" button is depressed for three seconds. "REG" will light and blink.

6. Immediately, if power to the unit has been off for more than 3 hours and time of day has been returned.

FAMILIARIZATION 5

If "dip2" is set to "Id", the unit will begin a regeneration immediately for instances 1 and 2. With "dip2" set to "del",

the regeneration will not begin until the preset regeneration time.

Note: If set to immediate mode as timeclock or timeclock backup, the unit will initiate regeneration at 12:00 AM.

In the delay mode, "REG" indicator will light at 12:00 AM and regeneration will occur at delayed time.

DISPLAY LOCKOUT

The Culligan Medallist Series™ control is equipped with a feature which will allow you to protect the programmed

settings from tampering by unauthorized individuals. When the lockout feature is activated, the only parameters

which can be adjusted are the Time-of-Day and the Time of Regeneration. Refer to the "Setting of the

Microprocessor" for activating this feature.

POWER LOSS

The AccuSoft® circuit board is equipped with a Hi-Cap Capacitor and EEPROM memory chip. The capacitor is

capable of maintaining the time, for at least two days (masked chip), in the event of a power outage. The EEPROM

ensures that the individual programming parameters of the softener are not lost.

If the power outage lasts long enough to drain the Hi-Cap Capacitor, the control will ash "12:00 PM" when power

is returned to the control. The unit will continue to keep time from the moment power is restored, and will initiate a full regeneration at the preset regeneration time. The time of day will need to be reset in order to return the

regeneration to its preset time.

FAILURE MODE

There are certain conditions that can be interpreted by the circuit board as a failure of the drive motor or motor

position switch. Upon failure detection the control will cease further operation. A telephone hand set symbol will be

shown in the upper left corner of the display and the error code will be shown. Listed below are the different error

codes.

1. Motor Always Turning

Error code "E1" occurs when the circuit board detects changes in the motor program switch when the motor is

not supposed to be turning. The phone icon and "E1" will be lit in the display.

2. Motor Never Turns

The Culligan Medallist Series control is equipped to detect no change in the motor position when the motor is

supposed to be turning (motor or piston locked in a frozen position). The AccuSoft circuit board will apply

power to the motor for 20 seconds. If there is no change in the motor homing or position switch, the control will

power down for 1 minute. The circuit board will repeat this procedure two more times in an attempt to remove the

obstruction. If no movement has been detected, the control will permanently power down and a phone icon and

an "E2" will appear in the display.

3. Homing Error

Error code "E3" occurs when the circuit board detects when the control is unexpectedly in the home position.

The phone icon and "E3" will be lit in the display.

Error Display Cancellation

The error code display can be removed by removing the power to the control for 1 minute. After clearing an error

condition, the control will default to the factory settings when power is restored.

6 CULLIGAN MEDALLIST SERIES

Settings

The mircoprocessor can be set in two distinct operation modes, Soft-Minder® meter or Timeclock. As shipped from

the factory, the control is set for 8" Timeclock operation.

CAPACITY AND SALT SETTINGS

As mentioned previously, the softener will regenerate once the amount of water equal to the treated water

volume set point has passed through the turbine for meter models or after a xed time interval for timeclock

models. Regeneration is either delayed until the selected regeneration time or immediate depending on how the

microprocessor is programmed. Before completing the programming, the following information must be determined:

1. Compensated Water Hardness.

If your water supply contains iron, compensate for it by the following procedure:

1. Multiply the iron by 0.1 and add the result to the hardness.

Example: (3 ppm of iron x 0.1) + 25 gpg of hardness = 25.3 gpg of total hardness

2. Choose the % capacity you want and refer to the table below for the appropriate multiplier.

Example: 67% capacity gives a multiplier of 1.5.

TABLE 3

% Capacity 50% 67% 75%

Multiplier 2 1.5 1.33

3. Multiply the result from Step 1 by the multiplier chosen in Step 2. This is the compensated hardness.

Example: 25.3 gpg total hardness x 1.5 = 38 gpg compensated hardness.

4. Use the effective hardness for sizing and to determine salt dosage and regeneration frequency.

5. The forced regeneration feature should be used for Soft-Minder meter operation to ensure the resin bed

does not become iron fouled due to lack of water ow. See "Programming the Option Settings" for the

forced regeneration feature.

2. Salt Dosage

From Table 4, select the salt dosage at which the softener will be operated.

• Low Setting — Maximum salt efciency, more frequent regeneration, reduced overall softening capacity.

• Medium Setting — Good combination of efciency and overall softening capacity.

• High Setting — Maximum softening capacity, less frequent regeneration, and reduced salt efciency.

Recommended whenever iron is present and for hardness levels above 30 Grains Per Gallon, or high volume

water usage.

SETTINGS 7

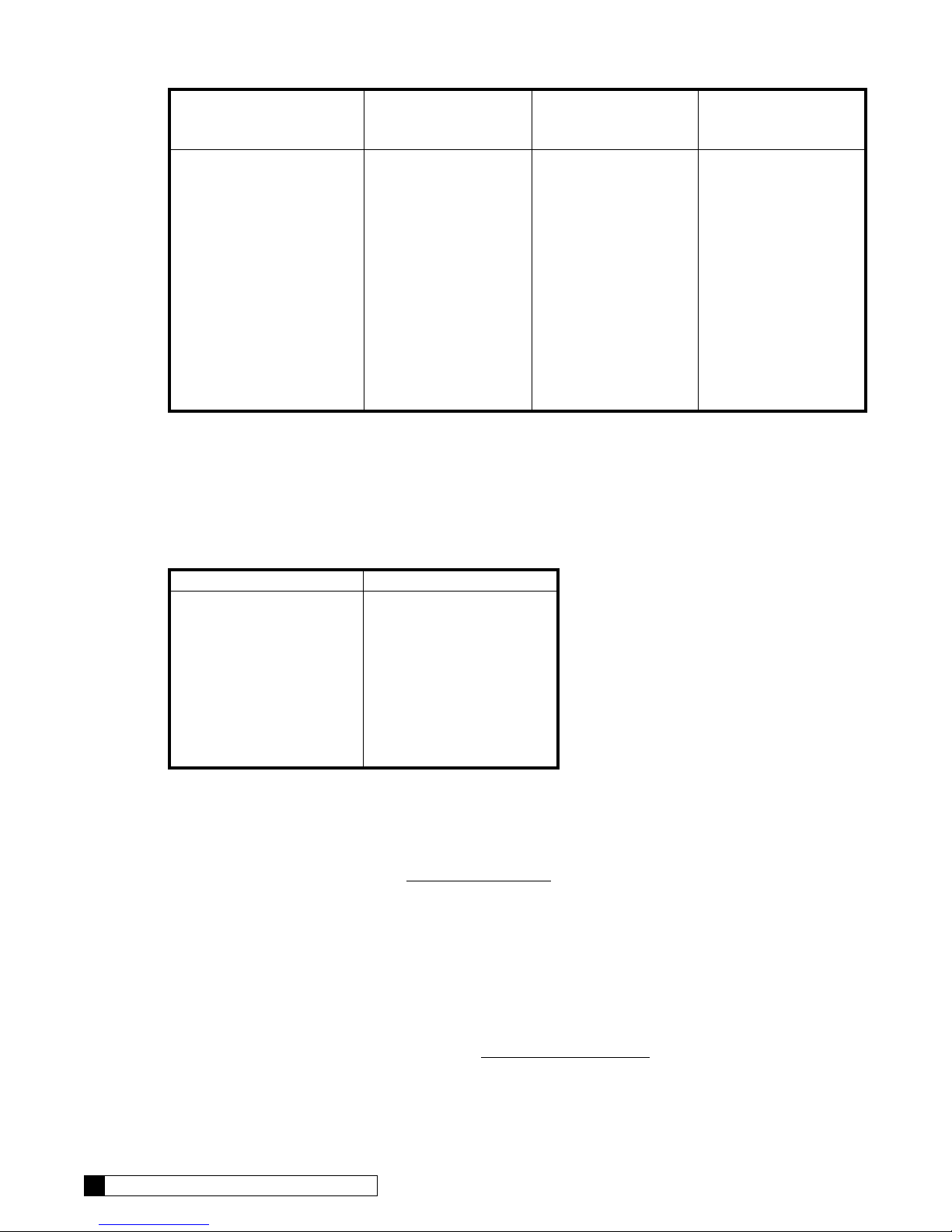

TABLE 4 - SALT DOSAGE

Capacity 160 lb. Brine Tank 250 lb. Brine Tank 375 lb. Brine Tank

"A"Dimension "A"Dimension "A"Dimension

Salt Capacity Secondary (Only) Secondary Primary Secondary Primary

Dosage

8" ft3 30 ft3 45 ft3 in. (cm) in. (cm) in. (cm) in. (cm) in. (cm)

4 18,300 X X 7-3/4 19.7 6-5/8 16.8 4-5/8 11.7 5-1/2 14.0 3-1/2 8.9

5 20,000 20,000 20,000 9-1/2 24.1 8 20.3 6 15.2 6-1/2 16.5 4-1/2 11.4

6 22,000 22,500 23,500 11-1/4 28.6 9-3/8 23.8 7-3/8 18.7 7-1/2 19 5-1/2 14

7 23,200 24,400 26,500 13 33 10-7/8 27.6 8-7/8 22.5 8-1/2 21.6 6-1/2 16.5

8 24,100 25,700 29,000 14-3/4 37.5 12-1/4 31.1 10-1/4 26 9-1/2 24.1 7-1/2 19

9 25,100 27,000 31,300 16-1/2 42 13-5/8 34.6 11-5/8 29.5 10-1/2 26.7 8-1/2 21.6

10 26,100 28,300 33,300 18-1/4 46.3 15 38.1 13 33 11-1/2 29.2 9-1/2 24.1

11 26,800 29,400 35,000 20 51 16-3/8 41.6 14-3/8 36.5 12-1/2 31.7 10-1/2 26.7

12 27,500 30,500 36,500 21-3/4 55.2 17-3/4 45.1 15-3/4 40 13-1/2 34.3 11-1/2 29.2

13 X 31,500 38,400 21-1/2 59.7 19-1/8 48.6 17-1/8 43.5 14-1/2 36.8 12-1/2 31.7

14 X 32,500 39,200 25-1/4 64.1 20-1/2 52.1 18-1/2 47 15-1/2 39.4 13-1/2 34.3

15 X 33,300 40,400 — — 21-7/8 55.5 19-7/8 50.5 16-1/2 42 14-1/2 36.8

16 X 34,100 41,200 — — 23-1/4 59 21-1/4 54 17-1/2 44.5 15-1/2 39.4

17 X 35,000 41,800 — — 24-5/8 62.5 22-5/8 57.5 18-1/2 47 16-1/2 42

18 X X 42,400 — — 26 66 24 61 19-1/2 49.5 17-1/2 44.5

19 X X 42,900 — — 27-3/8 69.5 25-3/8 64.5 20-1/2 52.1 18-1/2 47

20 X X 43,500 — — 28-3/4 73 26-3/4 68 21-1/2 54.6 19-1/2 49.5

3. Treated Water Volume Set Point

Calculate the treated water volume set point using the following information:

• Softening capacity — Grains (based upon salt dosage setting).

• Compensated hardness of water supply — Grains Per Gallon

• Estimated daily water usage — Gallons Per Day (refer to Table 5)

TABLE 5 - Daily Water Usage

PersonsinHousehold GallonsPerDay

2 150

3 225

4 300

5 375

6 450

7 525

8 600

9 675

10 750

Example - Meter: Softener Model Medallist 2M

Capacity @ 9 lb. Salt Dosage: 25,100 Grains

Compensated Water Hardness: 19 Grains Per Gallon

Estimated Daily Water Usage: 300 Gallons Per Day

Treated Water Volume Set Point = — Water Usage

Softener Capacity

Compensated Hardness

Softening Capacity 25,100 Grains

Divide by Compensated Hardness ÷ 19 Grains per Gallon

Result is total number of gallons 1,321 Gallons

of soft water per regeneration

Subtract daily Water Usage (needed — 300 Daily Water Usage (One Day Supply)

as a reserve to ensure continuous 1,021 Gallons

soft water until regeneration occurs).

Round down to nearest ten for Treated

Water Volume Set Point 1,020 Gallon Setting

Set "CAPG" to 102

8 CULLIGAN MEDALLIST SERIES

™

Example - Timeclock: Softener Model Medallist 2

Capacity @ 9 lb. Salt Dosage: 25,100 Grains

Compensated Water Hardness: 19 Grains Per Gallon

Estimated Daily Water Usage: 300 Gallons Per Day

Treated Water Volume Set Point = — Water Usage

Softener Capacity

Compensated Hardness

Softening Capacity 25,100 Grains

Divide by Compensated Hardness ÷ 19 Grains per Gallon

Result is total number of gallons 1,321 Gallons

of soft water per regeneration

Subtract daily Water Usage (needed — 300 Daily Water Usage (One Day Supply)

as a reserve to ensure continuous 1,021 Gallons

soft water until regeneration occurs).

Divide by daily water usage ÷ 300

3.4 Days

Round down to nearest day 3.0 Days

Set "CAP" to 3

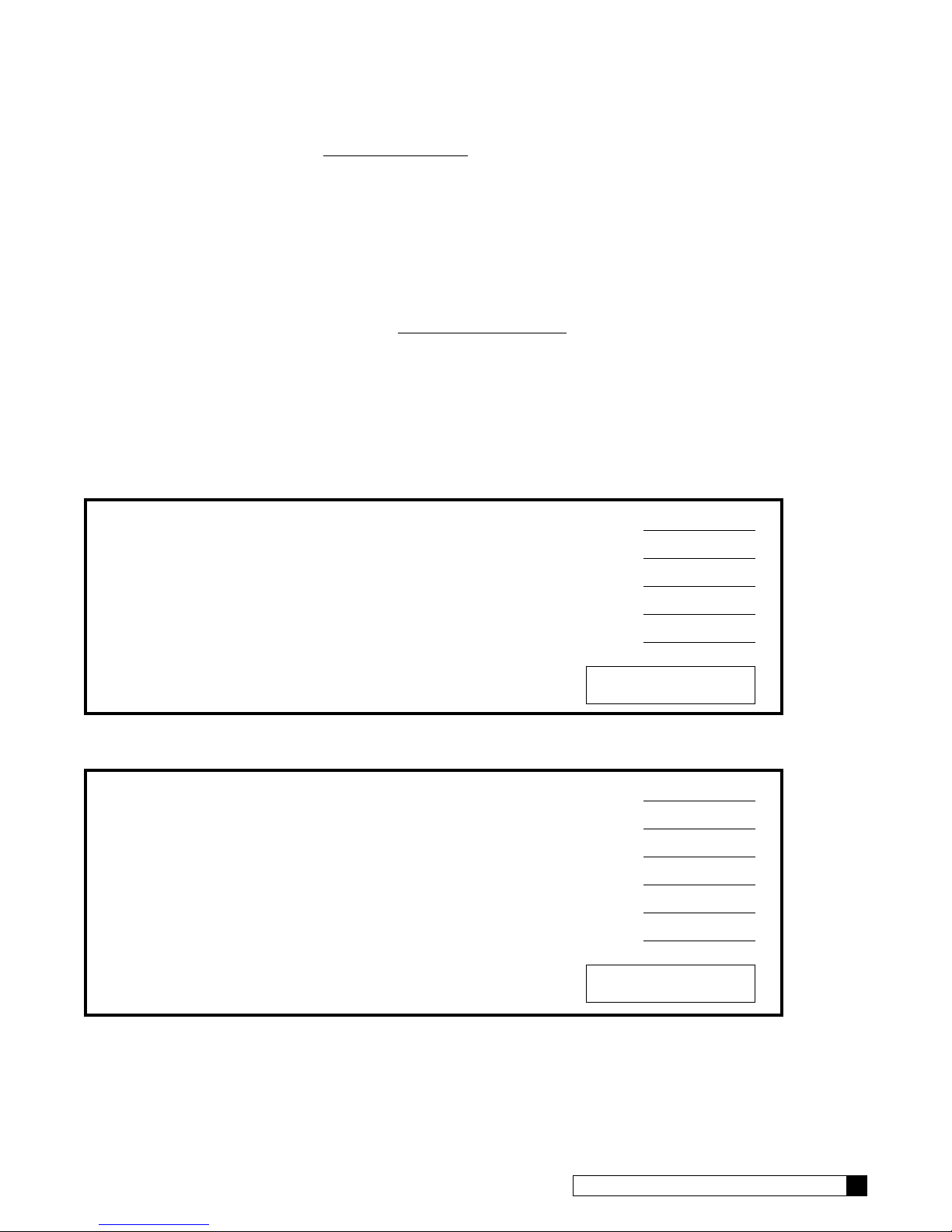

Use the following worksheets to calculate and record the proper settings.

TreatedWaterVolumeSetPointWorkSheet-MeterModels

1. Enter Softening Capacity

2. Divide by Compensation Hardness ÷

Result is Total Gallons of Soft Water Per Regeneration =

3. Subtract Daily Water Usage (Reserve —

Result =

Round down to nearest ten for Treated Water Volume Set Point Gallons

TreatedWaterVolumeSetPointWorkSheet-TimeclockModels

1. Enter Softening Capacity

2. Divide by Compensation Hardness ÷

Result is Total Gallons of Soft Water Per Regeneration =

3. Subtract Daily Water Usage (Reserve —

4. Divide by Daily Water Usage ÷

Result =

Round down to nearest ten for days between regeneration set point Days

Note: All Softening capacity is based on new Cullex® resin and using sodium chloride as the regenerate: If potassium chloride is used reduce the rated softening capacity by 20%.

SETTINGS 9

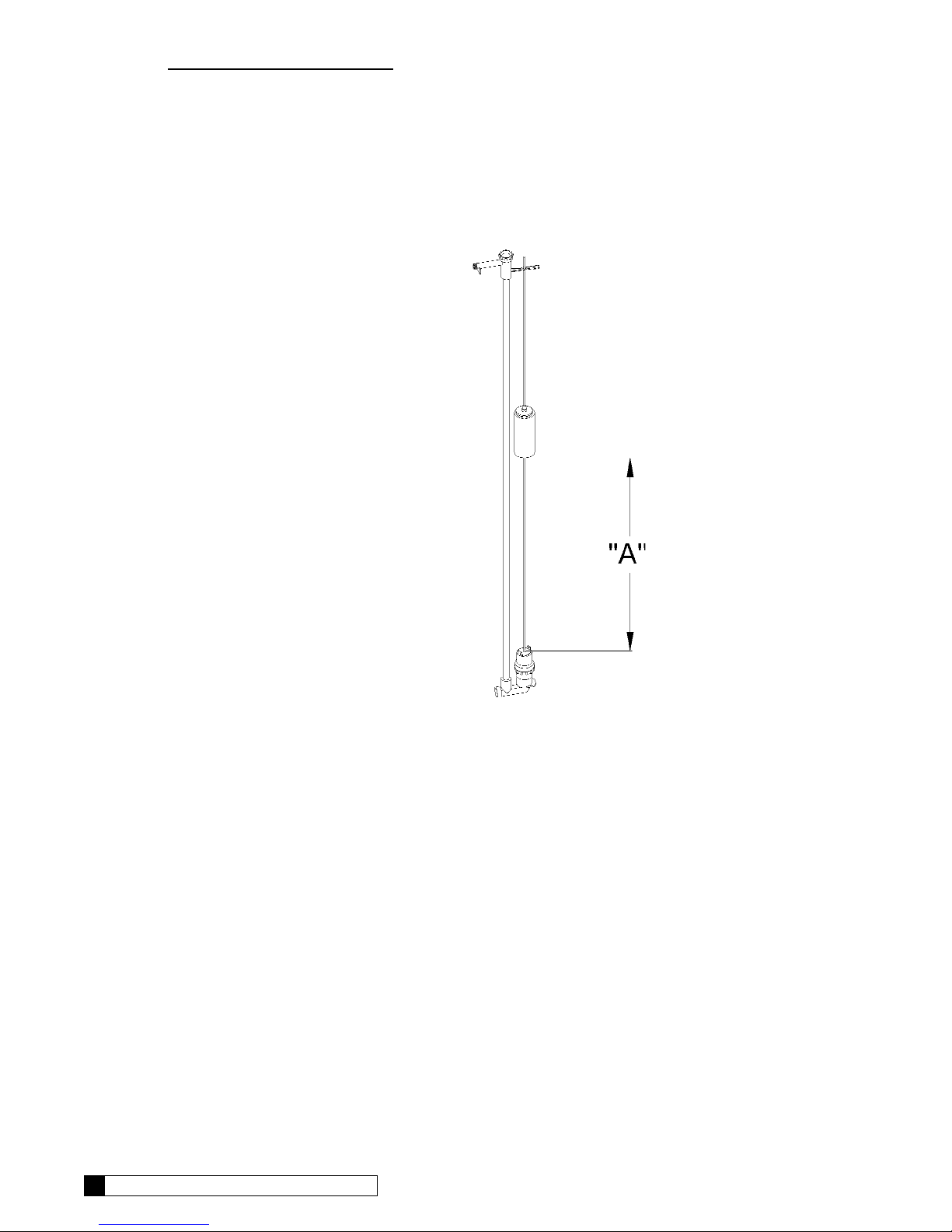

BRINE VALVE "A" DIMENSION

The brine valve contains a oat-actuated safety shut-off device to prevent overow of the brine tank in the unlikely

case of an electrical or mechanical failure during the brine tank rell cycle.

It is recommended that the brine valve oat be used as intended, that is, as a secondary, safety shut off. Remember,

the timer mechanism provides the primary rell shut-off. To use the oat as a safety shut-off, refer to Table 4 for

the salt dosage and brine tank size being used. The "A" dimension is the distance between the lter screen and the

bottom of the oat (Figure 2) when the oat stem is in its fully raised position; adjust the oat and rubber grommets

accordingly.

FIG. 2

10 CULLIGAN MEDALLIST SERIES

™

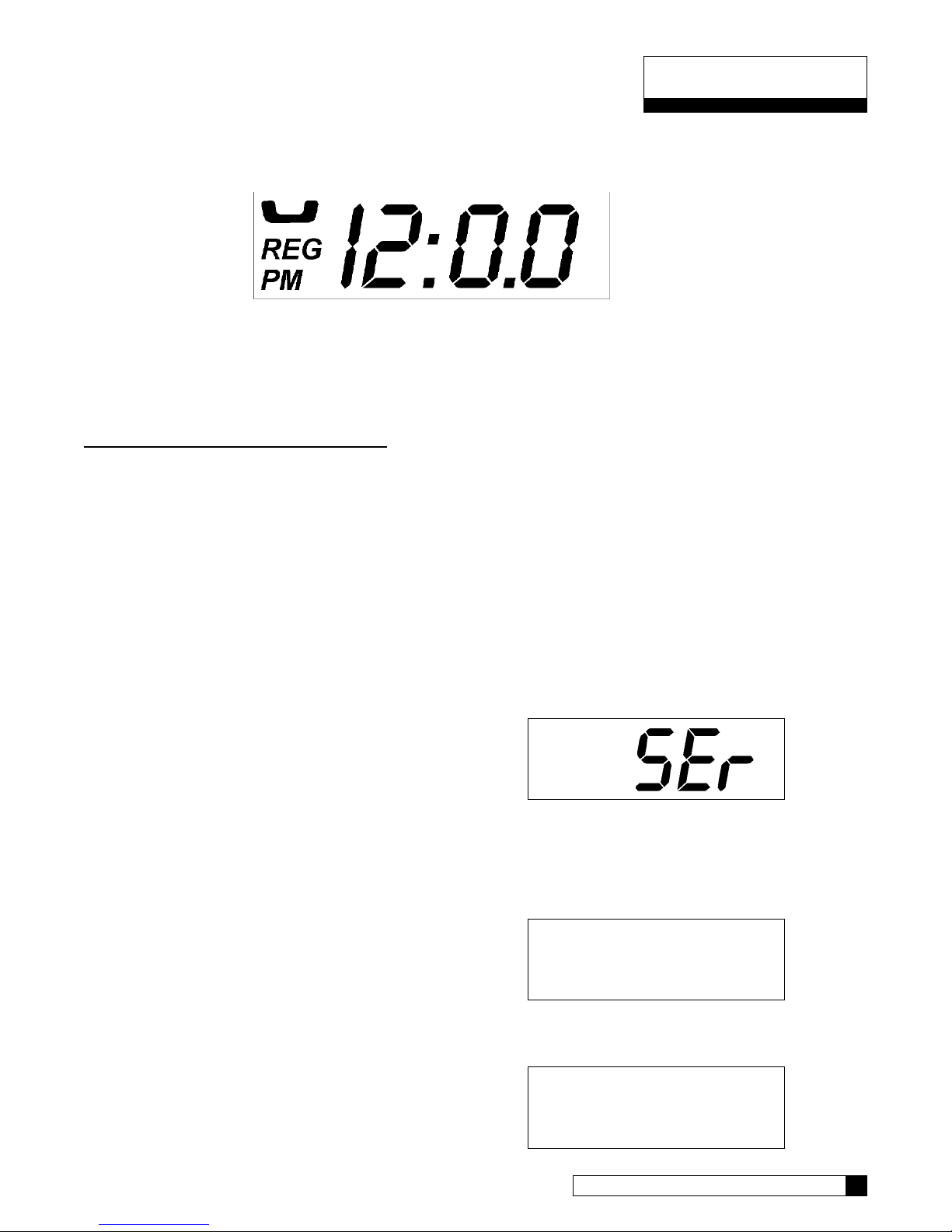

Programming

Make sure the inlet water supply is turned off, then supply power to the timer. The display will power up ashing

"12:00 PM" and the motor will energize and cycle the control, without stopping, to the home position. This is

required to ensure that the control is in the home position.

The timer uses four buttons:

FIG.3-CircuitBoardDisplay

1. STATUS: Advance timer through display options.

2. PLUS SIGN "+": Increase the setting.

3. MINUS SIGN "-": Decrease the setting.

4. REGEN.: Initiate a manual regeneration.

PROGRAMMING THE OPTION SETTINGS

The microprocessor has several programming options that can be changed for various additional functions. Listed

are the functions for the programming options used on the Culligan Medallist Series™ control.

Dip Switch Function Default Position

1 Service or Test Service

2 Delay or Immediate Regeneration Delayed Regeneration

3 Softener or Filter Softener

4 Time Clock Backup OFF

5 English or Metric English

6 12 or 24 Hour Clock 12 Hour

7 3/4" or 1" Meter 3/4" Meter

1 Service or Test Mode

P r e s s a n d h o l d t h e “ S T A T U S ” k e y u n t i l “ d I P 1 ” a p p e a r s i n t h e

display. “dIP1” will blink for 3 seconds and then the display will

show the status of this option (SEr or tES). Toggle the feature

with the “+” or “-” key.

Note: Pressing “STATUS” after changing option to test mode

will place the control in test mode. After testing is complete

press and hold “STATUS” for 3 seconds to return to “dIP1”

setting. Placing the unit in test mode will not change any of the

programmed values.

2 Delay or Immediate Regeneration

Press the “STATUS” key. The display will blink “dIP2” for 3

seconds and then show the current status. Toggle between

“DEL” (Delay) and “Id” (Immediate) with the “+” or “-” key.

Note: Changing this setting will not change any of the

programmed value with the exception that Step #2, time of

regeneration will be ignored when set to immediate.

del

3 Softener or Filter

Press the “STATUS” key. The display will blink “dIP3” for 3

seconds and then show the current status. Toggle between

“SOF” (Softener) and “FIL” (Filter) with the “+” or “-” key.

Note: Changing this setting will cause the unit to load the

Filter or Softener defaults.

4 Timeclock Backup

Press the “STATUS” key. The display will blink “dIP4” for 3

sof

PROGRAMMING 11

Loading...

Loading...