Page 1

Revision 1

April 2001

1-1

Page 2

1-2

Page 3

TABLE OF CONTENTS

INTRODUCTION ............................................SECTION 1

COMPONENT DISCRIPTIONS......................SECTION 2

Battery Pack...................................................................... 2-1

Battery charger.................................................................. 2-2

Electric Drive Motor........................................................... 2-3

Motor Controller ................................................................ 2-3

Instrument Cluster............................................................. 2-5

ELECTRICAL & CHEMICAL SAFETY............SECTION 3

High Voltage Safety.......................................................... 3-1

Chemical Safety................................................................ 3-3

REMOVAL & INSTALLATION.........................SECTION 4

Canopy.............................................................................. 4-3

Utility Bed.......................................................................... 4-7

Motor/Speed Sensor......................................................... 4-9

Motor Contactor.............................................................. 4-15

Controller ........................................................................ 4-19

Battery Modules.............................................................. 4-23

Battery Charger............................................................... 4-29

Lights .............................................................................. 4-33

Headlight, Horn, Hazard Light Switches..........................4-35

Ignition Switch................................................................. 4-37

Turn Signal Switch.......................................................... 4-39

Accelerator Pot (Throttle Sensor).................................... 4-41

Instrument Cluster........................................................... 4-43

Park Brake Switch........................................................... 4-45

Brake Light Switch .......................................................... 4-47

Horn................................................................................ 4-51

TEST PROCEDURES.....................................SECTION 5

Ignition Switch & Jumper Harness.................................... 5-3

Accelerator Pot (Throttle Sensor)...................................... 5-9

Motor............................................................................... 5-11

Motor Contactor.............................................................. 5-15

Speed Sensor................................................................. 5-19

Brake Switch................................................................... 5-21

Park Brake Switch........................................................... 5-23

Directional Signal Switch................................................. 5-25

Instrument Cluster........................................................... 5-27

Charger........................................................................... 5-29

Battery Pack Evaluation.................................................. 5-31

1-3

Page 4

TROUBLESHOOTING....................................SECTION 6

Fault Indication Table........................................................ 6-2

Motor Will Not Operate...................................................... 6-4

Nothing Works .................................................................. 6-5

Will Not Operate In All Modes........................................... 6-6

Horn Does Not Work......................................................... 6-7

Battery Charger Does Not Operate................................... 6-7

Low Range........................................................................ 6-8

Temperature Gauge.......................................................... 6-8

Battery Gauge................................................................... 6-8

Speedometer Does Not Work ........................................... 6-9

Instrument Cluster LED Indicators.................................. 6-10

Headlights & Taillights..................................................... 6-11

Rear Lights...................................................................... 6-12

Front Lights..................................................................... 6-12

Hazard Lights.................................................................. 6-13

Brake Lights.................................................................... 6-13

Directional Signals .......................................................... 6-14

Twist Lock Connector Pinouts......................................... 6-15

1-4

Page 5

SECTION 1: INTRODUCTION

The FunRunner is an all-electric utility vehicle.

The energy for the FunRunner’s propulsion as

well as the operation of its lights, instruments,

horn, and etc., come from its 48-volt battery

pack. Being electric, the FunRunner emits no

exhaust and is therefore a zero emissions

vehicle. It is an environmentally friendly vehicle.

The FunRunner is also much quieter than an

internal combustion vehicle. It is well suited for

use in areas that are considered noise sensitive

or indoors where harmful gasoline emissions are

a concern.

Because gasoline powered vehicles have

electrical systems for cranking, ignition, lights,

etc., some of the service procedures used with

them are similar to those used with the

FunRunner. Other procedures will be unique to

the FunRunner.

The main components of the FunRunner are the

battery pack, electric motor, controller, battery

charger, and instrument cluster. The

FunRunner uses a 48V battery pack that is

considered to be high voltage.

voltage can be dangerous and requires an

extra measure of safety procedures not

normally associated with the service of

gasoline vehicles and equipment.

The high

Figure 1-1: FunRunner

1-1

Page 6

1-2

Page 7

SECTION 2: COMPONENT DESCRIPTION

Battery Pack

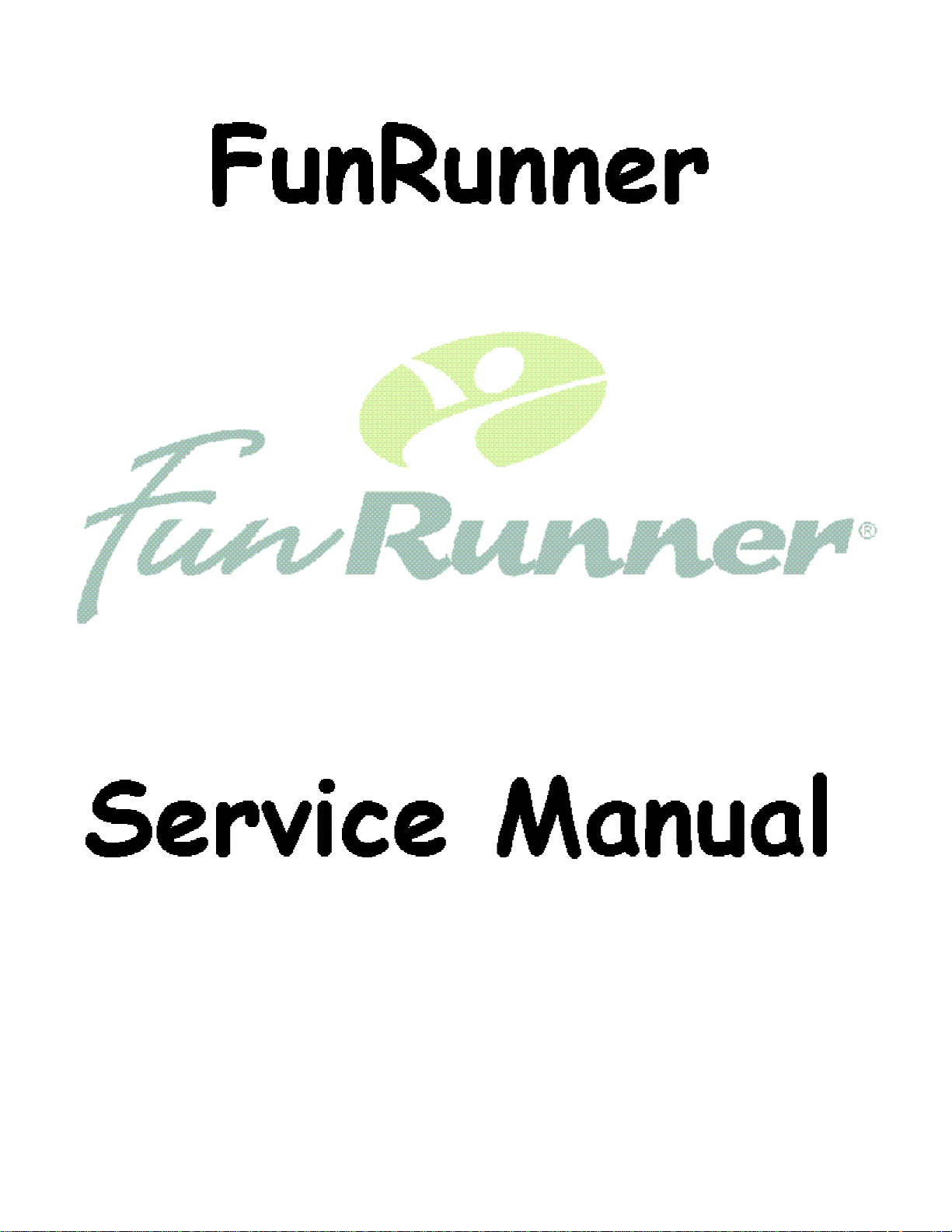

The battery pack of the FunRunner consists of

four 12-volt sealed lead acid battery modules.

The modules are situated in the vehicle under

the seat and are covered by the rear body panel.

See Figure 2-1. Since the modules are sealed

and valve regulated, no water or electrolyte can

be added to the batteries.

Figure 2-1:

Each module has a rated capacity of 73 amperehours (Ah) at a 20-hour discharge rate and 48

Ah at the 1-hour discharge rate. The capacity is

the available quantity of electricity in a battery

measured in Ah. Capacity is always related to

some quantity of current in amperes (amps) and

the length of time that the given current can be

produced. The minutes of reserve is a capacity

rating in which the amount of current is set at a

given rate, usually 25 amps, then the length of

time it takes for the battery to reach its

discharged cut-off voltage is measured. This

amount of time in minutes is the reserve

capacity of the battery.

For an electric vehicle like the FunRunner, the

capacity available from the batteries determines

the range of the vehicle. The range is the

distance that can be driven on one battery

charge.

temperature for rating a battery is 78°F. At

temperatures above 78°F, the capacity will be

higher than the rated capacity. The capacity will

be lower than rated capacity when temperatures

are below 78°F. At 32°F only about 70 percent

of the rated capacity is available. This is

significant, because if the FunRunner is

operated when the temperature is around 32°F,

the range will be reduced by 30 percent.

Another factor effecting capacity is the rate of

discharge. The battery modules in the

FunRunner are rated at 73 Ah for the 20-hour

rate and 48 Ah for the 1-hour rate. That’s a

large difference in the available Ah’s produced

between the two discharge rates. At the 20-hour

rate, the current drawn from the battery is set to

a low value that will take 20 hours to bring the

battery down to its cut-off voltage. The rate of

current in amps times the 20 hours is the

capacity rating. At the 1-hour rate, the current is

set at a much higher rate to bring the battery

down to the cut-off voltage in one hour. With a

73 Ah rating for 20 hours and a 48 Ah rating for

1 hour, it is obvious that the higher the rate of

current draw, the lower the capacity.

The FunRunner will use current at a fairly high

rate, and the higher the rate the shorter the

range will be. If it is driven faster or up hill

frequently, then the current rate will be higher

and the capacity of the battery pack will be

reduced.

The normal chemical process in the battery over

time will reduce the amount of active material on

the plates of the battery. This reduction in active

material will cause a reduction in capacity. In

other words, as the battery ages and more and

more charge/discharge cycles have occurred,

the capacity of the battery will begin to

decrease. When the aging process of the

battery has caused a decrease in capacity so

that the FunRunner no longer has a useable

range, the batteries must be replaced.

The normal driving range of the FunRunner is

approximately 30 miles when the batteries are

performing at their rated capacity. The battery

capacity and therefore the range can be affected

by several factors however.

Temperature has a dramatic effect on a lead

acid battery’s capacity. The standard

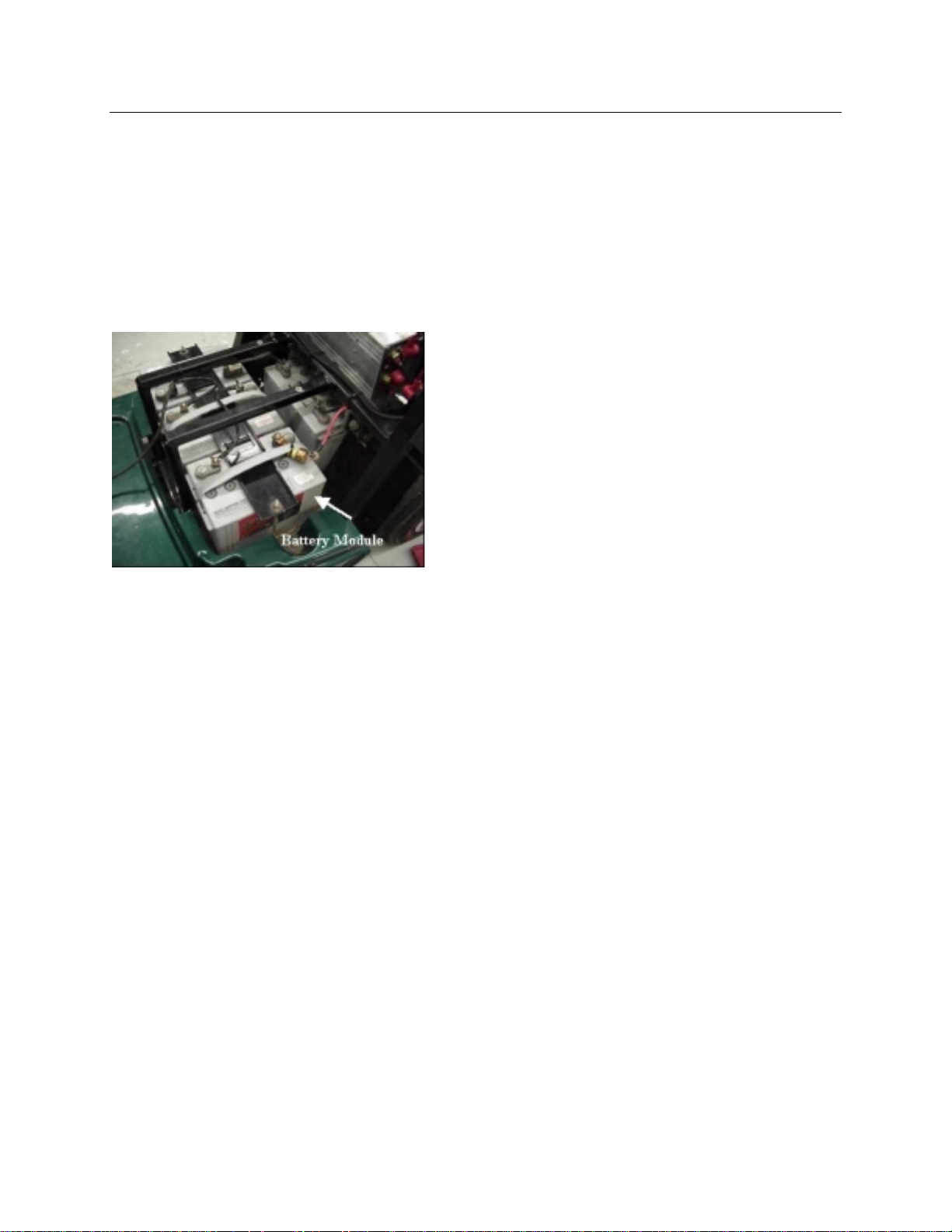

The four battery modules of the FunRunner are

wired in series to form a 48-volt battery pack.

When connecting battery modules in series, the

voltage of the pack is the total of the modules in

the series string. See Figure 2-2.

2-1

Page 8

Figure 2-3:

Figure 2-2:

The modules must be connected from the

positive terminal of one module to the negative

terminal of the next. The one positive and one

negative terminal remaining on the modules are

the main terminals. The voltage at the main

terminals is 48V nominal.

When battery modules are connected in series,

the voltage of the system is added (i.e. 48 volts)

and the capacity of the modules not added. The

capacity of the series string is equal to the

capacity of one module. In fact, the capacity of

the series string is actually equal to the module

with the least capacity. However, because the

voltage is four times higher, the power and

energy of the pack is four times that of one

module.

As the capacity of the battery is reduced by the

various factors, the power of the battery is

normally not effected. The energy (power used

over time) is reduced however. This means that

no loss of speed, acceleration, or feel of power

will be experienced when a battery pack’s

capacity is reduced. A battery pack with only 15

Ah capacity wi ll have the same power as one

with 48 Ah capacity when both are fully charged.

What will be noticed is a reduction in the range

of the vehicle.

The charger receives its power from a 110 VAC

outlet when a cord is plugged into the charger

input connector located in the front of the rear

body panel below the seat. The AC power is

converted to DC and conditioned to the proper

voltage and current output levels to charge the

battery. It will take the charger about 7-8 hours

to restore a battery pack from fully discharged to

fully charged.

Located on the top of the battery charger are

one green and one red LED. See Figure 2-4.

During charging, the red LED is illuminated.

When the battery pack reaches a full charge, the

green LED will come on and the red LED will go

out. These LED indicators are not visible unless

the trunk basket panel is removed. The battery

charge gauge on the instrument panel cluster is

the indicator normally used for state of charge

reference.

Battery Charger

The FunRunner has an on-board battery charger

located at the rear of the vehicle just in front of

the rear bumper. See Figure 2-3. The function

of the charger is to replenish the used energy

from the battery pack.

Figure 2-4:

The battery charger is designed to never

overcharge or overheat the batteries due to

prolonged charging. Leaving the charger

plugged in will allow it to maintain a full charge

2-2

Page 9

without overcharging. It is desirable to leave the

charger plugged in for long periods periodically

to equalize the charge of the battery pack

modules. Doing this will increase batt ery life.

Electric Drive Motor

The FunRunner uses a 48-volt brush type DC

motor. The motor uses permanent magnets for

the field and has a wound armature with a

commutator that the brushes ride on. See

Figure 2-5.

Motor Controller Assembly

The motor controller assembly on the

FunRunner is located just ahead of the trunk

basket panel under the rear body section. See

Figure 2-7. The controller is rated at 150 amps

and 48 volts. It is a four-quadrant controller that

uses pulse width modulation. The four-quadrant

design allows the motor to be reversed,

eliminating the need for a mechanical reverse

gear. The pulse width modulation ensures

smooth acceleration and power de li very while

operating at an extremel y high effic ienc y level.

Figure 2-5:

The motor is connected to the rear wheels

through a fixed ratio drive axle with differential.

Reverse for the FunRunner is accomplished by

reversing the direction of rotation of the electric

drive motor. There are no reverse gears in the

drive assembly. The motor receives power from

the controller.

The motor has no serviceable parts and is

replaced as an assembly if it fails. There is a

speed sensor located on the spacer between the

motor and drive axle. The speed sensor is

supplied as a service part. See Figure 2-6.

Figure 2-6:

Figure 2-7:

Figure 2-8:

The controller can be switched to either high or

low forward speeds or reverse. See Figure 2-8.

When selected to high speed, the controller will

allow a maximum speed of 12 mph. In low

speed mode, the controller will reduce the output

voltage as needed to reduce the max speed to 8

mph. Reverse mode is 6 mph maximum.

2-3

Page 10

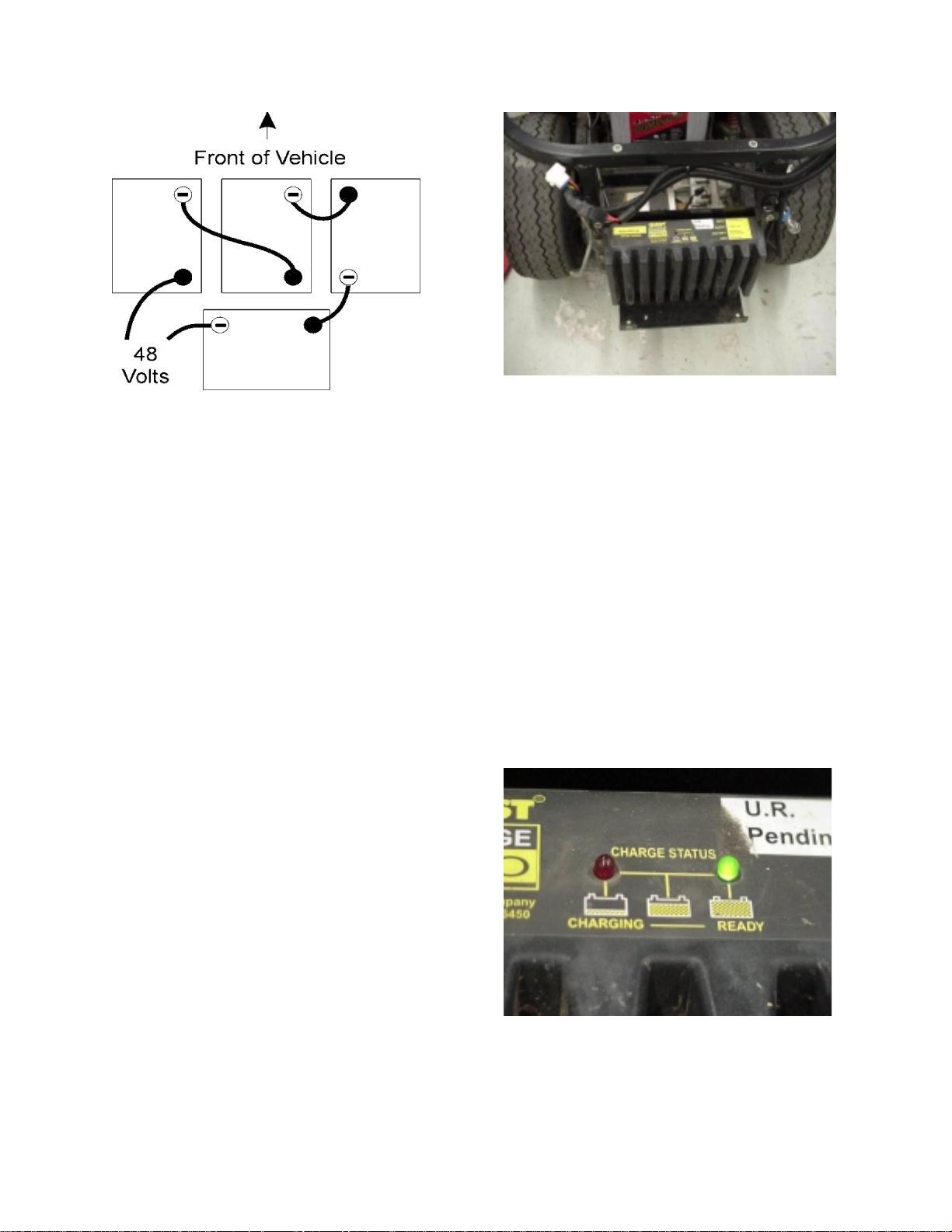

Of course, the controller must be able to provide

fully variable speed in each drive mode. The

throttle sensor is attached to the accelerator

pedal assembly and wired as an input to the

controller. See Figure 2-9. The sensor is a

potentiometer (a type of variable resistor often

called a pot) that will give a continual ly variable

signal from the fully released to fully depressed

pedal positions.

Figure 2-9:

The controller will monitor the throttle sensor

signal and adjust the output voltage to the motor

according to the demands of the operator

through the accelerator pedal.

The controller is also equipped with regenerative

braking. Regenerative braking is a feature

where the motor becomes a generator when the

vehicle is coasting or stopping. The kinetic

energy of the vehicle is turning the armature of

the motor through the permanent magnet field

producing a current in the armature that goes to

the controller. The current produced is opposite

of that used by the motor to drive the vehicle.

The controller will pass this current to the battery

pack replenishing a small portion of its charge.

The regenerative braking provides two benefits:

it increases range by adding some charge to the

battery pack and provides braking action that

assists the mechanical brakes. You can feel the

regenerative braking when re le asing the

accelerator even if the brake pedal is not

depressed.

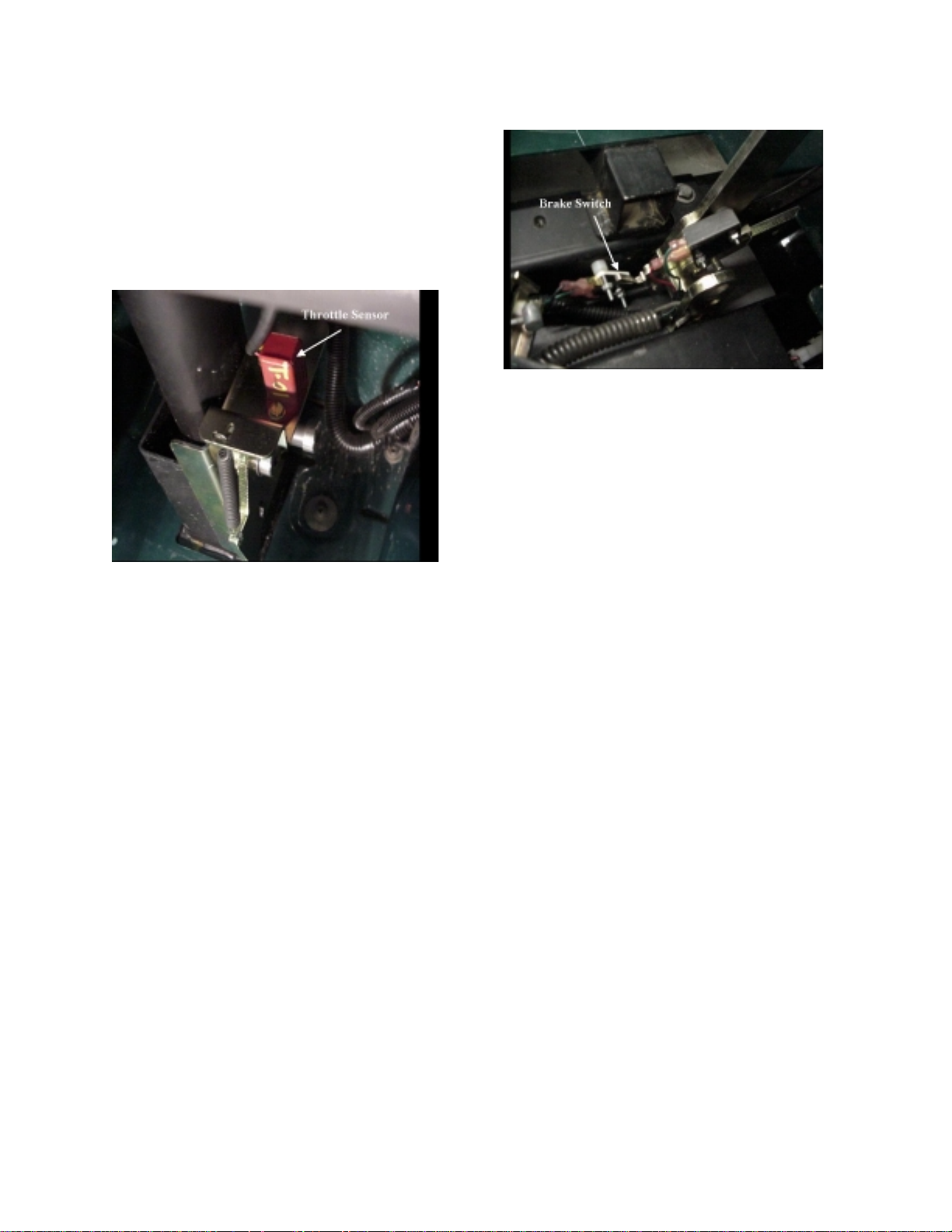

The brake switch is connected to the controller

so that when the controller sees an input

indicating the brake has been depressed, it will

not allow power to flow to the motor even if the

accelerator pedal is depressed. See Figure

2-10.

Figure 2-10:

A signal is sent from the charger to the controller

during charging of the FunRunner. When the

controller senses the charging signal, none of

the propulsion modes can be activated. The

output from the charger passes thru the

controller to the batteries.

The FunRunner’s motor controller is unique in

that it controls all of the electrical systems on the

vehicle in addition to the motor. The controller

supplies power to each electrical system when

an input to the controller for the particular

system is activated. You can think of the

controller as a relay for each system. It

operates in a manner similar to a starter relay

connecting power to the starter when the ignition

or start switch energizes the coil of the relay.

An example of this would be the headlights.

The controller sends a voltage to the headlight

switch and monitors this voltage to see if it is

returned (pulled low) by the switch. When the

headlight switch is turned on, it closes

connecting the voltage to the return and the

controller sees the headlight switch wire pulled

low. The controller responds by supplying 12

volts to the headlight and taillight bulbs. The

headlight switch does not feed power directly to

the lights.

Other systems such as turn signals, brake lights,

hazard lights, horn, parking brake indicator and

etc., are controlled in the same way. These are

systems activated by the person operating the

vehicle. The controller will give outputs to other

electrical systems based on inputs not activated

by the operator. Examples are the state of

charge gauge and the speedometer. The

controller will adjust the state of charge meter

based on battery pack voltage. The controller

2-4

Page 11

will output a signal to the speedometer based on

an input from the speed sensor.

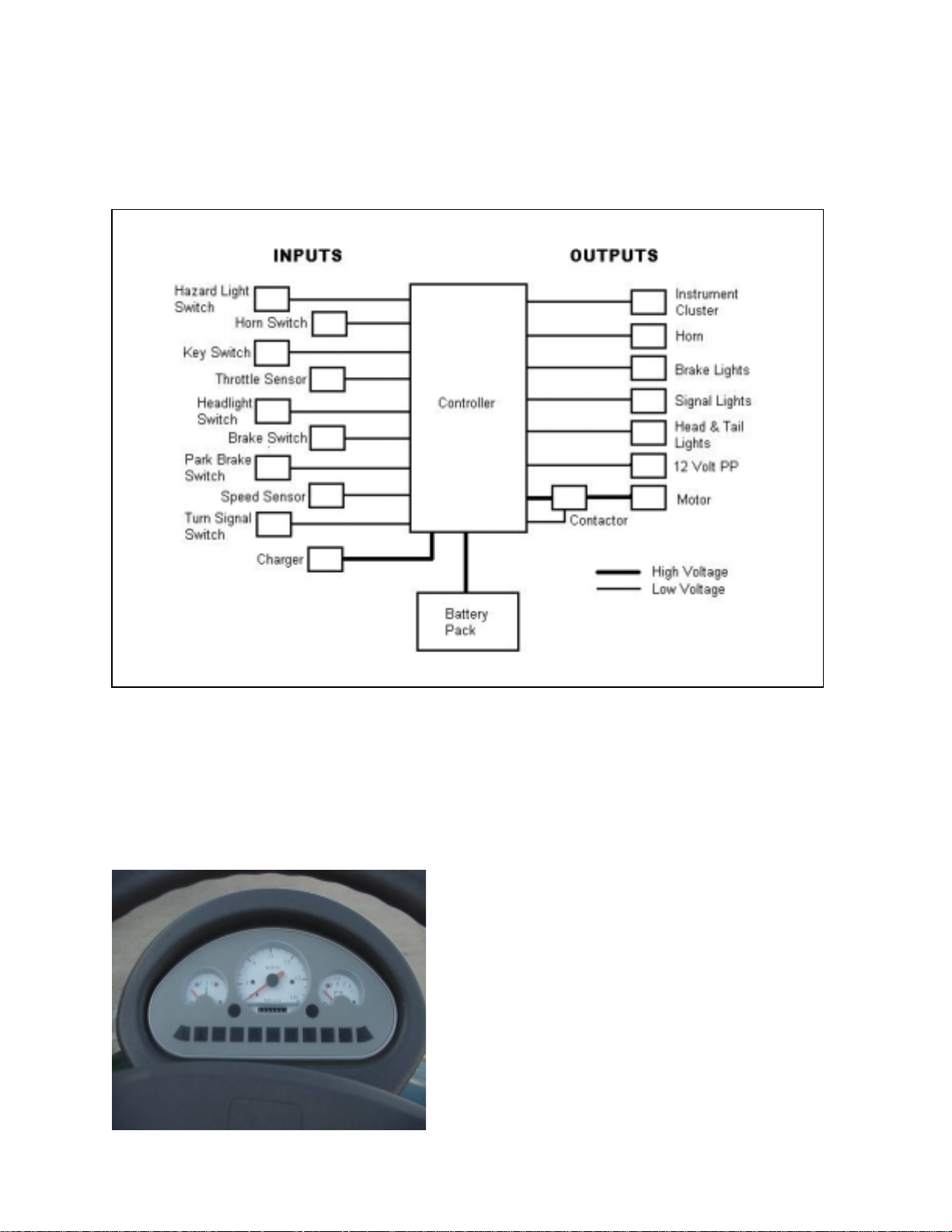

All of the controller inputs and outputs are

shown in Figure 2-11. The diagram shows how

the controller is the master of the electrical

systems on the FunRunner.

Figure 2-11

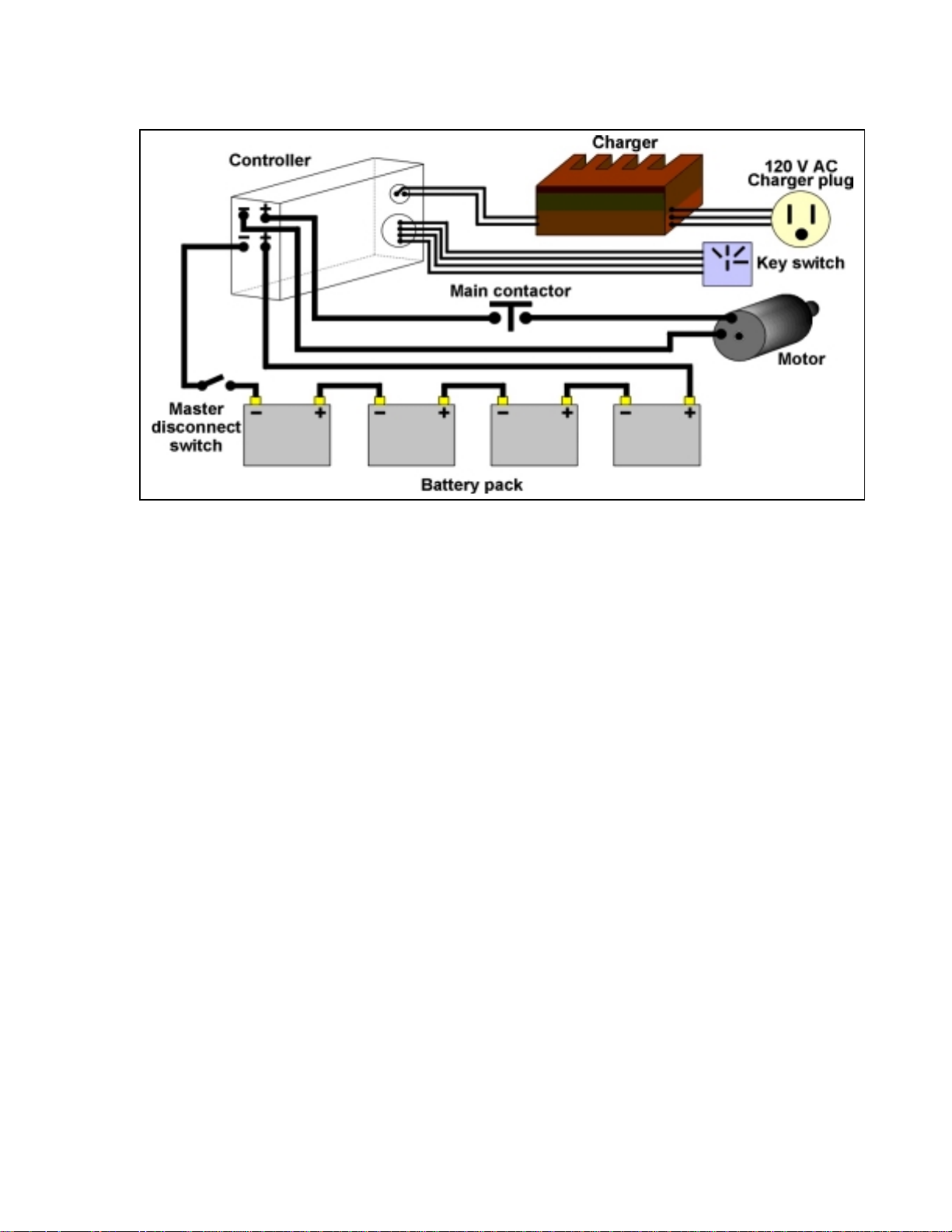

Instrument Cluster

The instrument cluster has three indicator

gauges across the top and several LED

indicators along the bottom of the cluster. See

Figure 2-12. The cluster is the inform ation

center for the operator.

Figure 2-12:

The center gauge is a speedometer with

odometer. The temperature gauge is on the left

and it displays the temperature of the controller

heat sink. The battery gauge is on the right side

and it displays the state of charge of the battery

pack.

The fault, temperature, battery, reverse, on,

high, low, charging, park brake, and headlights

indicators make up the bottom row of LED’s.

Above these indicator lights are the turn signal

indicators. These lights will illuminate when the

corresponding signal of its function is activated.

The fault, battery, charge, and temperature

indicators and an audible beep from the

controller are used to relay fault codes.

2-5

Page 12

2-6

Page 13

SECTION 3: ELECTRICAL AND CHEMICAL SAFETY

Electrical safety is foremost on the FunRunner,

since voltage levels present can cause severe

burns, shock, or death.

High voltage electric shock can cause muscle

contractions. A current of only 10mA can cause

muscles to contract. Hands that are exposed to

enough electrical current clinch

release their grip.

Even a small amount of current can cause body

tissue damage. Damage to tissue is caused by

heat generated from current flow. When the

heat passes a point where it can be dissipated,

the body tissue is burned.

Fibrillation

heartbeat, can be caused by electrical shock.

The current must pass through the body, such

as with a hand-to-hand connection, in order for

fibrillation to occur.

Arcing

across a circuit gap. The heat at the ends of an

arc can be four times the surface temperature of

the sun. Severe burns can be caused when a

person is near or in contact with an arc.

An arc can cause an electric

the expansion of the air and molten metal,

usually copper, from the rapid heating taking

place.

, the disruption of the body’s normal

occurs when electricity is discharged

tight and cannot

blast

. The blast is

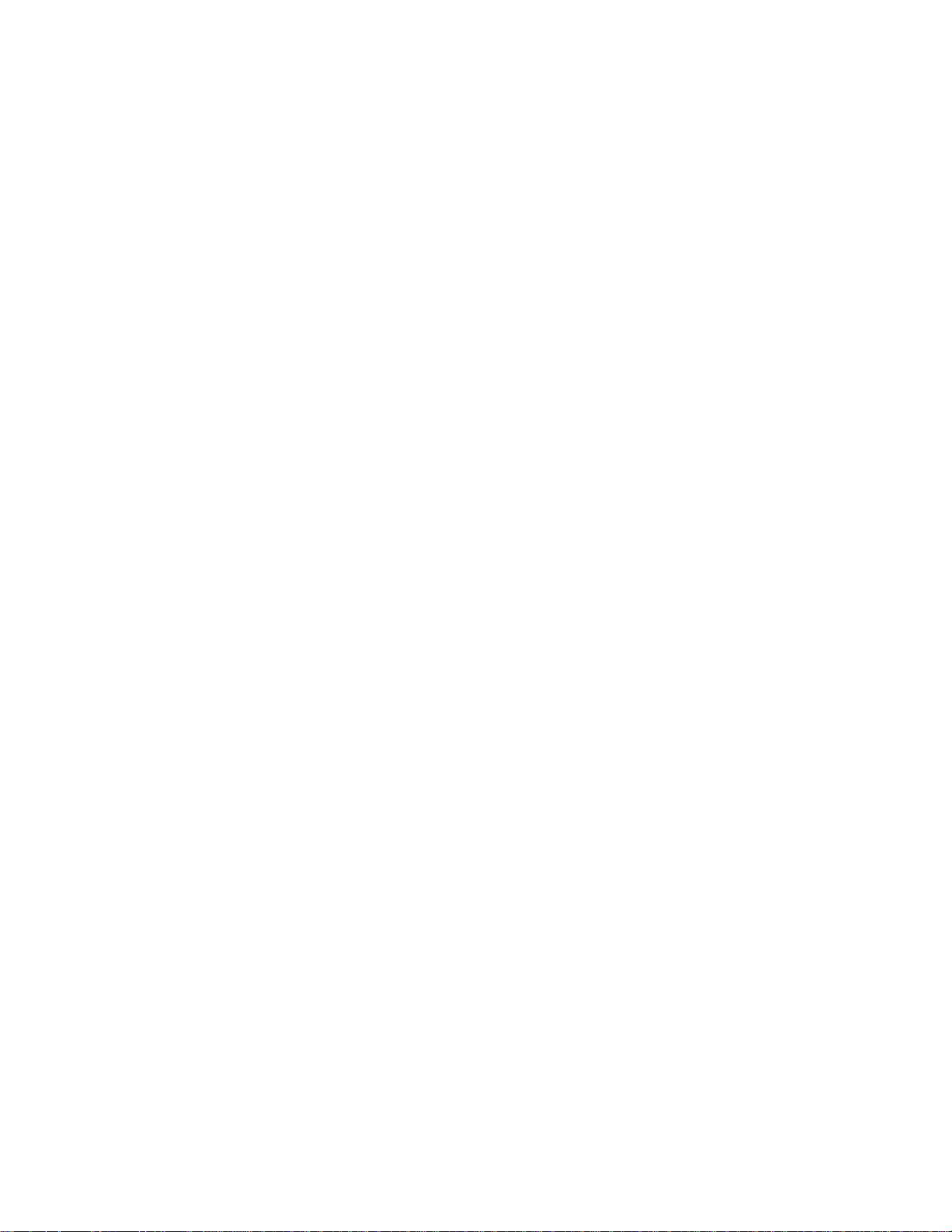

The FunRunner is equipped with a master

disconnect switch. See Figure 3-1.

Figure 3-1:

The master switch is a safety device that allows

the battery pack voltage to be removed from the

controller. The switch is to be used to

disconnect the battery from the controller before

starting any repairs to the high voltage portion of

the vehicle.

The master switch is located behind the seat.

See Figure 3-2. It can be turned off by sliding

the seat forward, reaching behind the seat and

twisting the red knob. The knob can be pulled

off of the switch when in the off position to

ensure that it is not inadvertently turned back on.

High Voltage Safety Procedures

The FunRunner’s high voltage and low voltage

systems are isolated from chassis ground under

normal circumstances. You must touch both a

positive and negative point in the circuit in order

to receive an electric shock. You should never

ground any wire on the FunRunner to the

chassis. Doing so could put the operator and

any service personnel in danger.

Figure 3-2:

The FunRunner has high voltage in the

propulsion, charging and ignition switch circuits.

See Figure 3-3.

3-1

Page 14

Figure 3-3: FunRunner High Voltage Wiring

Practicing safety around hig h vol tage (HV)

will protect you and those around you. Keep

in mind the following HV safety precautions:

•

Have ample light in the work area.

•

Do not work in wet or damp areas.

•

Use proper tools, equipment, and

protective devices.

•

Remove all jewelry and metallic items.

•

Keep your tools and equipment in good

condition.

•

Never assume that voltage is not

present; check it with a known good

meter or other test device.

•

Verify that any capacitors have been

discharged.

•

Never try to bypass or override a safety

device, such as a fuse, unless specified

to do so with an approved tool as

described by the manufacturer’s

procedures.

•

Always use the correct replacement

parts.

•

Never use water on an electrical fire;

have an approved fire extinguisher

available.

•

Use only one hand when possible.

•

Wear eye protection.

•

Never work on high voltage when you

are totally alone; someone else should

be present in case an emergency

arises.

•

Follow the manufacturer’s procedures.

•

Take your time, think first and do not

rush.

•

Know emergency policies and

procedures for your work area.

•

Wear natural fabric clothing such as

cotton; polyester clothing will melt to

the skin when exposed to electrical

arcs.

•

Use insulated tools and inspect them

regularly for damaged insulation.

•

Know where eyewash stations, fire

extinguishers, reach poles and other

safety equipment is located.

•

Never lay tools or any conductive

material on any HV component or

battery pack.

The longer someone is in contact with an

electrical current, the less chance there is

for survival. The victim may stop breathing

and become somewhat stiff. In the case of

electrical shock, the following procedures

should be followed:

•

Call 911 or the appropriate emergency

numbers for your area.

•

Break the electrical connection as

quickly as possible, but do not expose

yourself to any electrical current.

•

If the current cannot be removed, use a

fiberglass reach pole or a dry board to

separate the victim from the circuit. Do

not touch the victim with your bare

3-2

Page 15

hands until you are sure they have

been removed from the electrical

current.

•

If the victim has stopped breathing or

his/her heart is not pumping, use CPR

until help arrives. Only a trained

person should administer CPR.

•

If the victim must be moved, take

precautions in doing so. Use a

stretcher if possible.

Fire is always a possibility when working on

an electric vehicle. High voltage and

chemical batteries have the potential to

cause both fire and explosion when a faulty

condition exists.

Work areas should be clean and not

cluttered with combustible materials.

Flammable liquids should be stored in

approved storage areas.

You should know the location of fire

extinguishers and fire alarms. You should

also know how to contact the fire

department. Make sure you know how to

operate the fire extinguishers and what type

of fire they are rated for. Figure 3-4 shows

the classes of fires. Fire extinguishers

should be inspected monthly to verify they

have a full charge.

Figure 3-4:

eyes. The neutralizing agent for sulfuric

acid is bicarbonate soda. One pound of

soda dissolved in one gallon of water makes

a good neutralizing solution that can be

used in a spray bottle or poured on a spill.

When sulfuric acid contacts the skin, eyes,

or clothing, the first line of defense is water

and plenty of it. Flush the area with clean

water and soda mixture for 15 minutes. If

there is not enough soda-water mixture to

flush for 15 minutes, continue to flush with

clean water for a minimum of 15 additional

minutes and get prompt medical atten tio n.

If acid is accidentally swallowed, drink large

quantities of milk or water, followed by milk

of magnesia, a beaten egg, or vegetable oil.

Consult a physician immediately.

Chemical Safety

Batteries in the FunRunner contain

electrolyte that is very corrosive. Contact of

electrolyte with skin or eyes should be

avoided.

The FunRunner uses sealed batteries that

contain electrolyte in a gel between the

plates. While these types of batteries

cannot spill large amounts of electrolyte,

care should still be taken to avoid chemical

contact with the skin and eyes.

When working around batteries where there

is the possibility of chemical exposure, eye

protection should be worn, rubber gloves

and a rubber apron are recommended. An

emergency shower and eye wash stat ion

should be available as well as a first-aid kit

and electrolyte neutrali zing solu tio ns .

Lead acid batteries have a sulfuric acidwater solution as the electrolyte. Sulfuric

acid is very corrosive and can burn skin and

3-3

Page 16

3-4

Page 17

SECTION 4: REMOVAL & INSTALLATION

Canopy................................................................4-3

Utility Bed............................................................4-7

Motor/Speed Sensor...........................................4-9

Motor Contactor ................................................4-15

Controller ..........................................................4-19

Battery Modules................................................4-23

Battery Charger.................................................4-29

Lights ................................................................4-33

Headlight, Horn, Hazard Light Switches............4-35

High/Low/Reverse Switch..................................4-37

Turn Signal Switch............................................4-39

Accelerator Pot (Throttle Sensor)......................4-41

Instrument Cluster.............................................4-43

Park Brake Switch.............................................4-45

Brake Light Switch.............................................4-47

Horn..................................................................4-51

4-1

Page 18

Figure 4-1

Figure 4-2 Figure 4-3

Figure 4-1A

4-2

Page 19

SECTION 4: CANOPY INSTALLATION & REMOVAL

PARTS REQUIRED

710-0642 Hex Washer Screw 1/4-20 x .75 (8)

736-0342 Flat Washer .283 ID x .75 OD (12)

731-2337 Canopy Panel

749-1265 Rear Canopy Frame

749-1266 Front Canopy Frame

710-0136 Hex Cap Screw 1/4-20 x 1.75 (2)

710-1122 Hex Cap Screw 1/4-20 x 2.5 (2)

750-1298 Spacer .280 ID x 437 OD x .250 Lg (2)

750-1299 Spacer .280 ID x 437 OD x .850 Lg (2)

TOOLS REQUIRED

Phillips head screwdriver - #2

3/16” Allen wrench

Note: you may need one person to help.

STEP DETAILS

Get tools and check parts. See list above.

Assemble molded canopy and supports

(Figure 4-1).

Install canopy and support assembly.

Note: Nylon bushings are installed between

the vehicle body and the threaded screw

holes used to fasten the canopy supports.

Be careful to place bushings in position

properly.

Note: Screws have spacers under

canopy supports that must be installed to

protect body from deflection (Figure 1A).

Align screw holes with holes in supports.

Install and tighten Hex washer screws with

flat washers through canopy into threaded

holes in supports.

Remove two cap plugs on top of body just

behind seating area.

Remove two Allen screws and spacers on

top of body directly in front of the dash.

Insert the shorter spacers in the front holes

and the longer spacers in the rear holes.

Gently set canopy/support assembly on

vehicle with curved end facing to the front.

(Figure 4-2).

Insert and tighten Hex cap screws with flat

washers in front and rear supports. Tighten

to 65 to 75 in. lbs. (Figure 4-3).

Save extra parts. Store Allen screws for use if top is removed.

4-3

Page 20

4-4

Page 21

Remove canopy assembly. Remove 4 Hex cap screws from supports and

set canopy assembly aside.

Remove spacers and store screws.

If canopy assembly is not to be replaced, place

cap plugs in rear body section and install

original Allen screws and spacers in front body

panel

Remove molded canopy.

Note: If canopy is to be re-installed, this step

is not necessary.

Remove 8 Phillips head, ¼” x ¾” screws from

canopy.

Lift canopy from supports and set aside.

Store screws for replacing canopy.

4-5

Page 22

Figure 4-4

Figure 4-5

Figure 4-6

4-6

Page 23

UTILITY BED INSTALLATION

PARTS REQUIRED

607-0013 Utility Box Assembly

710-1832 Machine Screw 1/4-20 x 2” (4)

736-0173 Flat Washer .28 ID x .74 OD (4)

#2 Phillips screwdriver

1/16” Allen wrench

STEP DETAILS

Remove rear trunk lid and trunk basket

(Figure 4-4).

Remove body retaining screws

(Figure 4-5).

Raise cover so hinge rod is visible.

Loosen 1/16” Allen set screw on each hinge rod

locking collar.

Slide hinge rod toward one side to remove rod,

spacers and trunk lid.

Be careful not to loose spacers. Remove trunk

basket.

Remove 4 Phillips head screws and washers

holding body to frame around storage area.

Disconnect trunk lock from back of vehicle by

removing the two cap screws.

TOOLS REQUIRED

Store screws for possible future use.

Install utility bed (Figure 4-6). Place bed on frame so tailgate is to the rear.

Line up holes in bed with holes in frame.

Install 4 screws and flat washers provided

through bed into frame.

Tighten screws to 40-45 in. lbs. and check bed

secure.

Clean up. Store parts and tools.

4-7

Page 24

Figure 4-7

Figure 4-8

Figure 4-9

Figure 4-10

4-8

Page 25

MOTOR/SPEED SENSOR REMOVAL & INSTALLATION

TOOLS REQUIR ED

Wrenches - 3/8”, 1/2”, 9/16”, and 5/8” - socket and box end preferred

Pliers

Lift or jack - suitable for raising rear of vehicle and being clear when axle/wheel assembly is slid

out to the side.

Phillips screwdriver - #2

Allen wrench – 3/16”

STEP DETAILS

Make vehicle safe and accessible.

WARNING:

IF MASTER POWER SWITCH IS NOT OFF

BATTERY IS STILL CONNECTED TO

CONTROLLER. USE EXTREME CARE TO

AVOID INJURY OR DAMAGE.

Turn master power switch to off. Key operated switch mounted below

Disconnect motor cables from contactor and

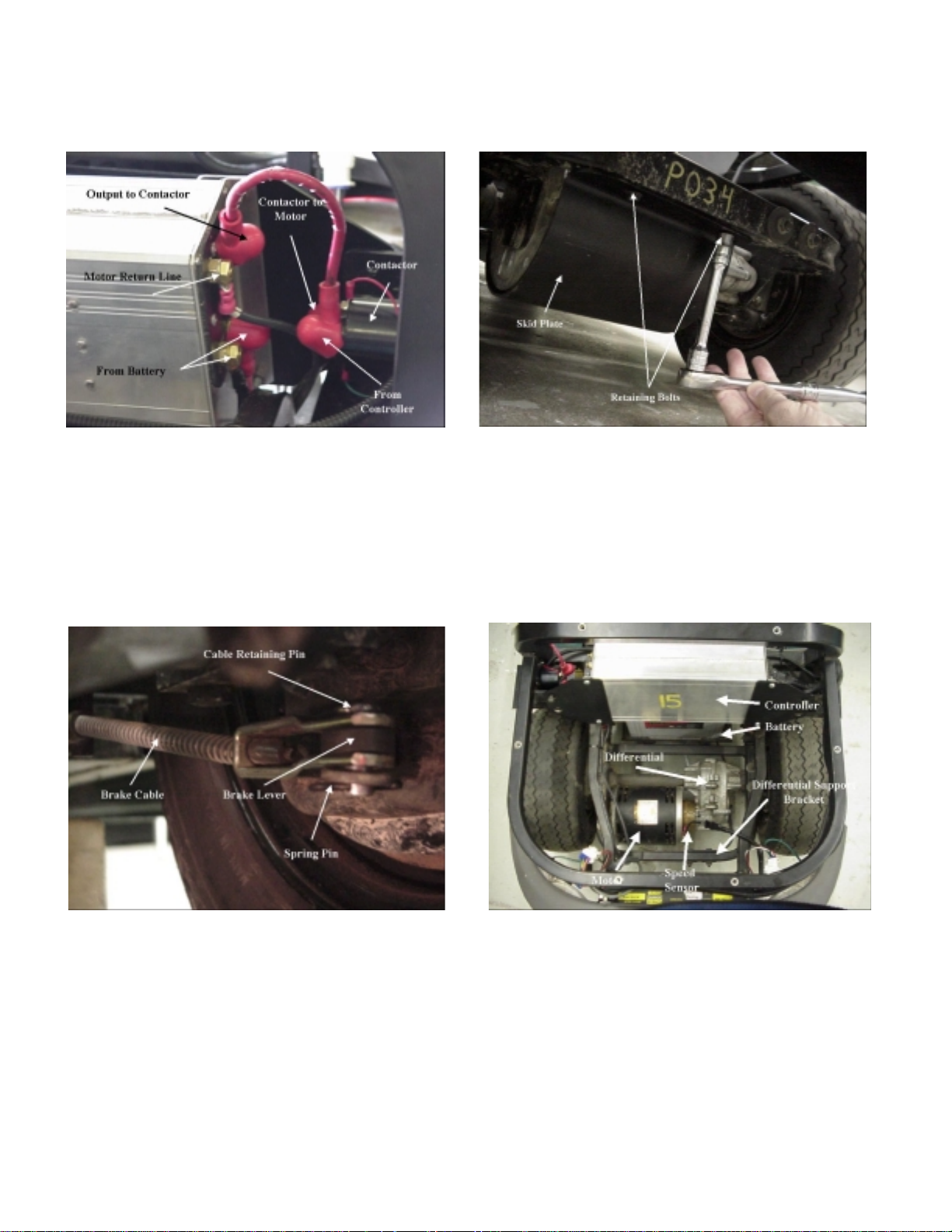

controller (Figure 4-7).

Note: use care that washer or nut cannot fall

into motor.

Remove skid plate (Figure 4-8). From under motor.

Make sure switch is off and key removed.

Place chocks under all 4 wheels, front and

back of each wheel if any chance of rolling.

Remove utility bed if installed (4 screws)

Remove storage compartment.

controller.

Disconnect motor lead from motor side of

contactor.

Move controller as necessary to reach left side

power cable terminals.

Disconnect top-front power cable on lef t sid e

of controller (goes to motor).

Front cable connected with 9/16” nut and star

washer. (rear cable connected with 5/8” nut

and star washer. Do not remove for this step).

Fastened to frame in front and rear of motor

with 4 screws, ¼” x ½” with 3/8” hex head.

.

Disconnect brake cables (Figure 4-9). From rear brake levers, right and left rear

wheels.

Pull spring pins from brake cable retaining

pins.

Lift retaining pins from cable shackles.

Disconnect speed sensor. Unfasten differential

support bracket (Figure 4-10).

Unplug (plug in line inside rear compartment).

Bracket is bolted to frame with two large

washers on outside of frame.

4-9

Page 26

Figure 4-11

Figure 4-12

Figure 4-13

Figure 4-14

Figure 4-15

4-10

Page 27

Warning:

After axle assembly is completely loosened,

motor can fall and catch a hand unless care

is used. Suggest a block be placed under

differential bracket before axle is completely

loosened.

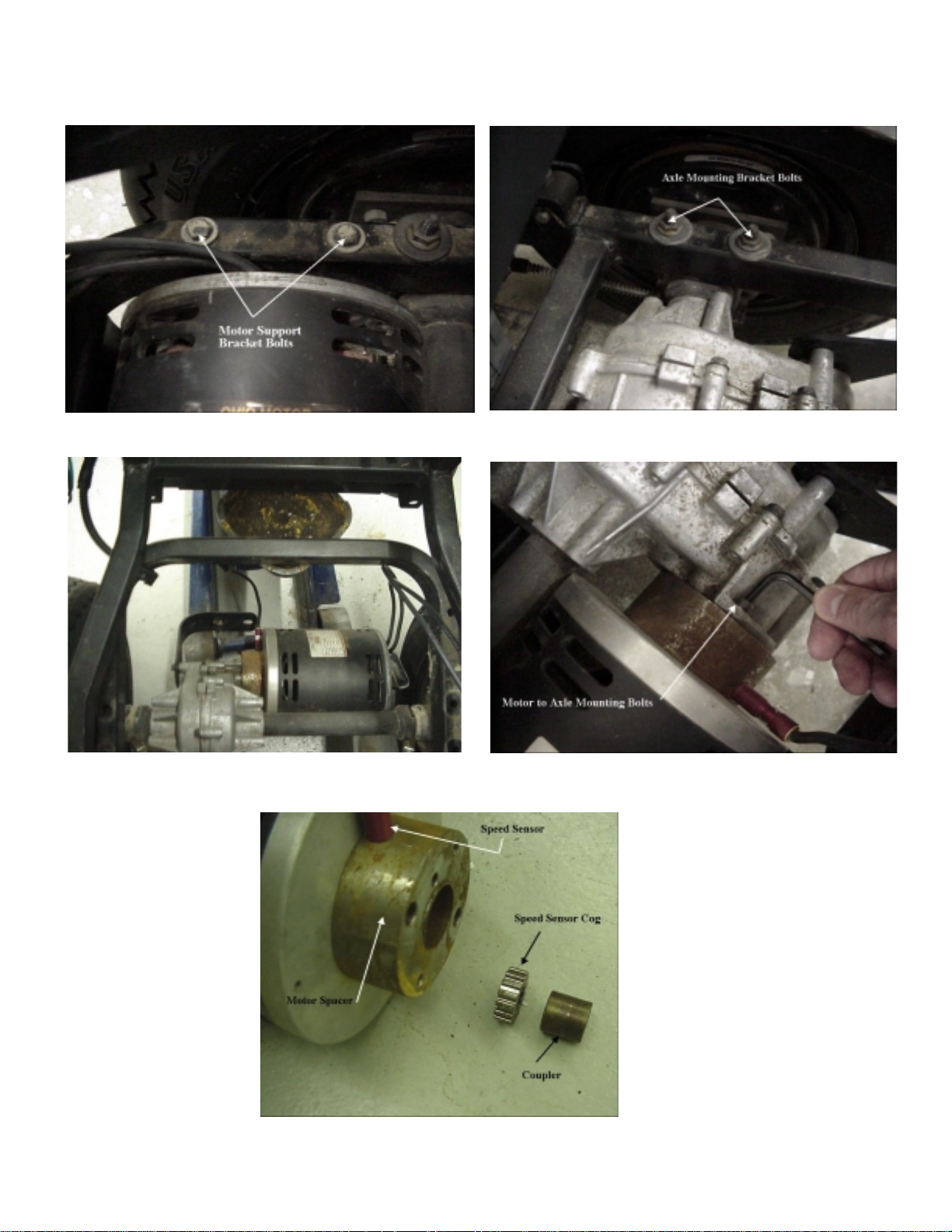

Disconnect motor support bracket

(Figure 4-11).

Bolted to motor and frame on left side of

vehicle.

2 bolts, ¼” x ½” - need 3/8” wrench.

Remove axle mounting brackets

(Figure 4-12).

Slide axle assembly from under vehicle

(Figure 4-13).

Remove motor (Figure 4-14). Place support under motor.

Remove parts from motor. Slide coupler and speed sensor cog from

Need ½” box end and ½” ratchet wrenches.

Attach lift to rear of frame, or use floor jack,

and raise vehicle high enough to slide rear

axle/motor assembl y out to side.

Place supports under rear of battery pack to

be sure vehicle cannot fall.

Use 3/16” Allen wrench to remove two

mounting screws.

Tilt rear of motor down and remove from drive

axle.

motor shaft.

Remove motor support bracket -two bolts -

3/8” wrench.

Loosen 1/8” Allen screw in end of spacer and

unscrew speed sensor.

Install parts on new motor (Figure 4-15). Bolt motor support bracket to new motor.

Insert speed sensor cog and coupler into

spacer and onto new motor shaft.

Install speed sensor in spacer.

Set speed sensor depth. Make sure speed sensor cog is inserted on

motor shaft

Screw speed sensor into spacer until it

touches cogs on sensor gear.

Unscrew speed sensor ¾ to 1 turn and make

sure it does not touch cogs when motor turns.

Tighten set screw to lock speed sensor in

place. Caution: do not over tighten set screw

causing damage to sensor threads.

4-11

Page 28

Figure 4-16

Figure 4-17

4-12

Page 29

Install new motor on axle assembly. Place motor on support so differential can be

rotated and lined up with motor.

Mate motor to differential with speed sensor

pointing away from axle. Make sure speed

sensor cog and coupler are in place.

Replace motor mounting screws using 3/16”

Allen wrench. Tighten securel y.

Mount axle assembly on vehicle. Slide assembly under rear of vehicle and

locate close to proper position.

Place block under differential support bracket

so bracket will be in position when ve hic l e is

lowered.

Lift vehicle slightly and remove supports from

under battery pack.

Slowly lower vehicle while adjusting position of

axle assembly so assem bl y will be in proper

position when vehicle is com pletely down on

the axle.

Bolt differential and motor supports to frame.

Install axle mounting brackets and tighten.

Connect brake cables. Place pins, from the top, through shackles and

brake levers.

Insert spring pins into brake connecting pins.

Connect motor power cables (Figure 4-16). Negative cable goes to top-front terminal on

left side of controller.

Positive cable with red terminal cover goes to

terminal on motor side of contactor.

Mount controller (Figure 4-17). Bolt mounting plates to frame (4 bolts).

Connect speed sensor. Plug into connection inside rear compartment.

Test unit. Turn on master power switch and test for

normal operation.

Install utility bed (if appropriate). Line up 4 bolt holes, install and tighten bolts.

4-13

Page 30

Mounting

Mounting

Screws

Screws

From

From

Controller

To

To

Motor

Motor

Figure 4-18

Figure 4-20

Activation Wire

Activation Wire

Terminals

Terminals

Figure 4-19

Figure 4-21

From

From

Controller

Controller

Figure 4-22

4-14

Page 31

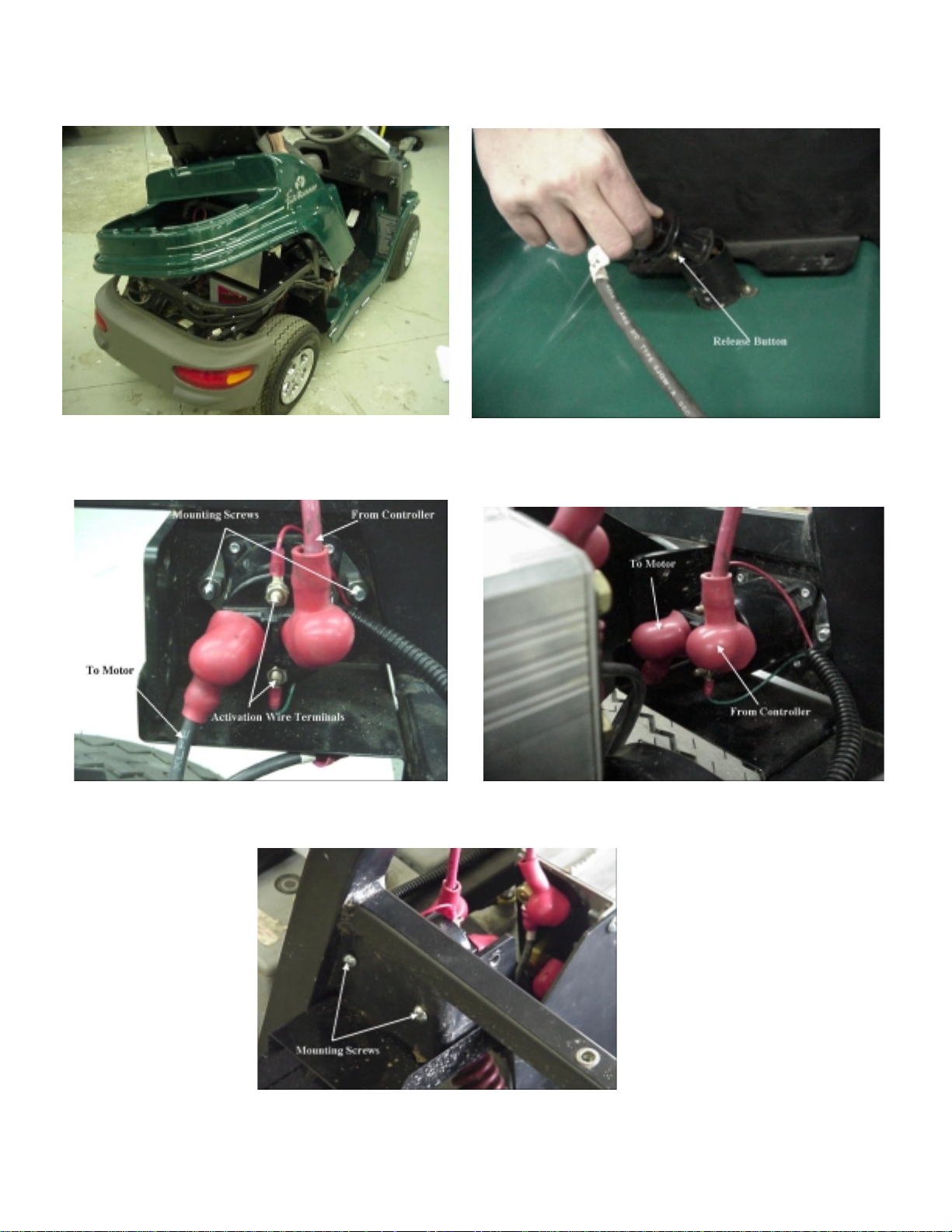

MOTOR CONTACTOR REMOVAL & INSTALLATION

STEP DETAILS

Make sure vehicle is safe. Switch off and key removed.

Parking brake set.

Remove canopy assembly (if installed).

Remove utility bed (if installed). Remove 4 Phillips head screws.

Lift bed off and set aside.

Turn off master power switch. Located behind seat.

Remove rear body section (Figure 4-18). 4 screws at front below seat.

Two screws each side beside seat.

Two screws below rear of seat (over battery).

4 screws around top of storage compartment.

Lift rear of section and work it free. May have to

cut one or more electric tie wraps so section can

be lifted off without placing strain on charger

cable and plug.

Unplug charger power cable (Figure 4-19). Inside front of rear body section.

Press button in side of plug and disconnect.

Disconnect activation wire terminals

(Figure 4-20).

Disconnect cables from controller and to motor

(Figure 4-21).

Remove contactor (Figure 4-22). Note: two nuts will come loose and fall when

Connect cables to motor and from controller. Connect cable to motor then cable from

Connect activation wire terminals. In the same positions they were before (red

Remove nuts and note location of wires.

Slide terminal covers off.

Disconnect cable from controller then cable to

motor.

screws are removed.

Remove two common point screws on outside

of frame.

Slide contactor off the mounting screws to

inside of frame.

controller.

Slide terminal covers onto terminals.

lead near power cable from controller)

4-15

Page 32

4-16

Page 33

Test operation. Turn on master power switch (behind seat).

Make sure vehicle will operate properly.

Install parts removed. Install rear body section, utility bed and canopy

assembly.

4-17

Page 34

Figure 4-23

Figure 4-24

Figure 4-25

4-18

Page 35

CONTROLLER REMOVAL & INSTALLATION

TOOLS REQUIRED

Note:

It is

½” Socket wrench

9/16” wrench

5/8” wrench

# 2 Phillips screwdriver

STEP DETAILS

easier and safer

section and disconnect batteries before

removing/replacing controller

to remove rear body

Check vehicle safe status.

Warning:

Charged capacitors are present in controller.

As soon as switch is turned off press horn

switch until one capacitor discharges (horn

will whine and fade out).

Remove utility bed or storage compartment

(storage compartment lifts out).

Turn master power switch to off. Switch mounted below controller.

Remove controller mounting bolts (Figure 4-23). 4 - 5/16 x ¾” bolts holding controller supports

Disconnect two connectors (twist lock plugs)

(Figure 4-24).

Pull controller back (Figure 4-25).

Make sure switch is off and key removed.

Make sure vehicle will not roll while work is

being done.

If installed.

May be necessary to tie up rear compartm ent

cover or remove it.

to frame - 2 each side.

From right side of controller.

Carefully to the rear until power cable

terminals on left side are accessible.

Warning:

48 volts present in battery pack. Dangerous.

Be sure cable ends are kept from making

contact with frame, tools or with

battery terminals are disconnected

you

until

.

4-19

Page 36

Figure 4-26

Figure 4-27

Figure 4-28

Figure 4-30

Figure 4-29

Figure 4-31

4-20

Page 37

Disconnect motor and battery power cables

(Figure 4-26).

Note: it is a smart move to lay a cover over

the motor before removing cables. A loose

washer inside the motor is no fun.

Disconnect motor and battery power cables. Use 5/8” wrench for rear terminals and 9/16”

Check fuse in battery cable (Figure 4-27). If failure is possible cause of problem.

Get new controller. If replacement is necessary.

Insure master switch is off. Place

voltmeter across battery terminals on

controller and bleed charge off the second

capacitor installed in controller until

Two top cables are motor power output and

two bottom cables are from the battery.

wrench for front terminals.

Even though the front and rear studs are

different size, it might be a good idea to mark

cables for future reference.

Use ohmmeter. Should show very little

resistance.

Warning:

voltage is below 5v.

Connect battery cables (Figure 4-28). To two bottom terminals on controller.

Note: most terminal studs are soft metal. Do

not over tighten.

Connect motor power cables (Figure 4-29). To two top terminals on controller.

Connect twist lock plugs (Figure 4-30). To receptacles on right side of controller.

Work controller into position and bolt in place

(Figure 4-31).

Turn on master power switch.

Replace parts previously removed. Rear body and canopy if appropriate.

Check vehicle. For loose fastenings, missing parts, etc.

Might require some “wiggling” so be patient.

Replace 4 hex head 5/16” x ¾” bolts holding

supports to frame.

Utility bed or storage compartment.

Check for proper operation.

4-21

Page 38

Figure 4-32

Figure 4-33

Figure 4-34

4-22

Page 39

BATTERIES REMOVAL & INSTALLATION

STEP DETAILS

Make sure parts on hand. Batteries (total of 4 in vehicle)

Deka - “Dominator”

Model 8G24 - 12v

Get required tools. #2 Phillips screwdriver

5/8” wrench

9/16” wrench

1/2” ratchet wrench

Insulated pliers

3/16” Allen wrench

Make vehicle safe. Switch off and key removed.

Parking brake set.

Remove canopy assembly. If installed.

Remove utility bed. If installed.

4 Phillips screws.

Note: if utility bed not installed, lif t stor age

container from rear compartment.

Turn off master power switch. Located behind seat.

Remove rear body section (Figure 4-32) and

(Figure 4-33).

Unplug charger power cable (Figure 4-34). Inside front of rear body section.

4 screws at front below seat.

Two screws each side beside seat.

Two screws below rear of seat (over battery).

4 screws around top of rear compartment

(same screws used to mount utility bed).

Lift rear body section and work it free. May

have to cut one or more electric tie wraps so

section can be lifted off without placing strain

on charger cable and plug.

Press button on side of plug and disconnect.

4-23

Page 40

Figure 4-35

Figure 4-36

Figure 4-37

Figure 4-38

Figure 4-39

4-24

Page 41

Disconnect batteries (Figure 4-35) .

Warning:

Batteries are probably charged and “hot”.

Use care to not short cables to frame or

other battery terminals.

Remove hold down bars. Two bars, one over front 3 batteries and one

Remove batteries (Figure 4-36). Do not let battery terminals short to frame.

Check fuse. If damage to fuse is suspected.

Replace batteries. Be sure rear battery positive terminal is toward

Disconnect cables going from battery to battery

first.

Loosen wing nuts and slide connectors off.

Disconnect cables from battery to controller

last.

over rear battery. Be careful not to short bars

across batteries.

Place insulation over all battery terminals if

necessary to prevent shorting (electrical tape if

nothing better available).

In the event the fuse is damaged, find the

cause before reconnecting batteries.

the right side, right front battery positive

terminal is on front of battery, and positive

terminals on other two on the rear of those

batteries (See Figure 2-2 in Section 2).

Replace hold down bars (Figure 4-37). Long bar between terminals, side to side,

across three front batteries and the short bar

across the rear battery.

Reconnect battery cables (Figure 4-38). Connect fused cable to positive terminal on left

front battery.

Connect other controller power cable from

master switch to negative terminal on rear

battery.

Connect rest of battery terminals in series

(positive on one battery to negative on the

next) (See Figure 2-2 in Section 2).

Connect charger cable (Figure 4-39). To receptacle in front of rear body section.

4-25

Page 42

4-26

Page 43

Install rear body section. Lift body section and work into position so

screw holes are lined up.

Replace electrical tie wraps if necessary to

hold cables.

4 screws at front below seat.

Two screws each side beside seat.

Two screws below rear of seat (over battery).

4 screws around top of storage compartment

(leave out if utility bed to be mounted).

Turn on master power switch. Located behind seat.

Operate vehicle. Make sure all parts are operating properly.

Install utility bed. Make sure spacers are in position to prevent

warping rear body section.

Insert and tighten 4 mounting screws.

Install canopy assembly. If appropriate.

Lift assembly into position so canopy support

mounting holes line up with mounting screw

holes in body.

Install and tighten mounting screws (2 ½”

screws in rear support, 2” screws in front).

Charge battery pack. Plug in charger and charge battery pack

overnight to balance the battery modules.

4-27

Page 44

Figure 4-40

Figure 4-41

Figure 4-42

Figure 4-43

4-28

Page 45

BATTERY CHARGER REMOVAL & INSTALLATION

STEP DETAILS

Get required tools. #2 Phillips screwdriver

½” wrenches (2)

Tool for cutting tie wraps

Note: charger cable runs from receptacle on

front of rear body section to charger mounted on

rear of vehicle frame.

Check machine safe. Switch off and key removed.

Set parking brake.

Remove canopy assembly and utility bed or

storage container.

Turn off master power switch. Located behind seat.

Remove rear body section (Figure 4-40). Remove all mounting screws.

If installed.

Lift body section off and disconnect charger plug

inside front of section.

Remove rear bumper (Figure 4-41) and

(Figure 4-42).

Remove charger (Figure 4-43). Cut all electrical tie wraps from charger cable.

Replace charger.

Caution:

Use care to not damage cables coming

out of the bottom of the charger.

Unplug tail light connections inside storage

compartment.

Remove 4 Phillips head screws.

Pull bumper off and lay aside.

Disconnect cable going from charger to controller

(connector plug on cable, from left bottom of

charger, inside storage compartment).

Unbolt charger from rear of vehicle frame (4

bolts).

Remove charger and cables.

Bolt charger to frame.

Run cable through to reach the front of the rear

body section when it is replaced.

Use electrical tie wraps to hold cable in position

clear of moving parts and frame.

Connect plug in cable from charger to controller.

4-29

Page 46

4-30

Page 47

Turn on master power switch. Located behind seat.

Test charger. Make sure it is actually sending current to battery

(voltage rises and charge status light comes on

when plugged in).

Replace rear bumper. 4 Phillips head screws.

Connect tail light cables inside storage

compartment.

Replace rear body section. Connect charger cable to receptacle inside front

of body section.

Lift body section into place and install screws.

Replace storage container or utility bed and

canopy assembly.

If previously removed.

4-31

Page 48

Figure 4-44

Figure 4-46 Figure 4-47

Figure 4-45

4-32

Page 49

LIGHTS REMOVAL & INSTALLATION

STEP DETAILS

Make vehicle safe. Switch off and key removed.

Parking brake set.

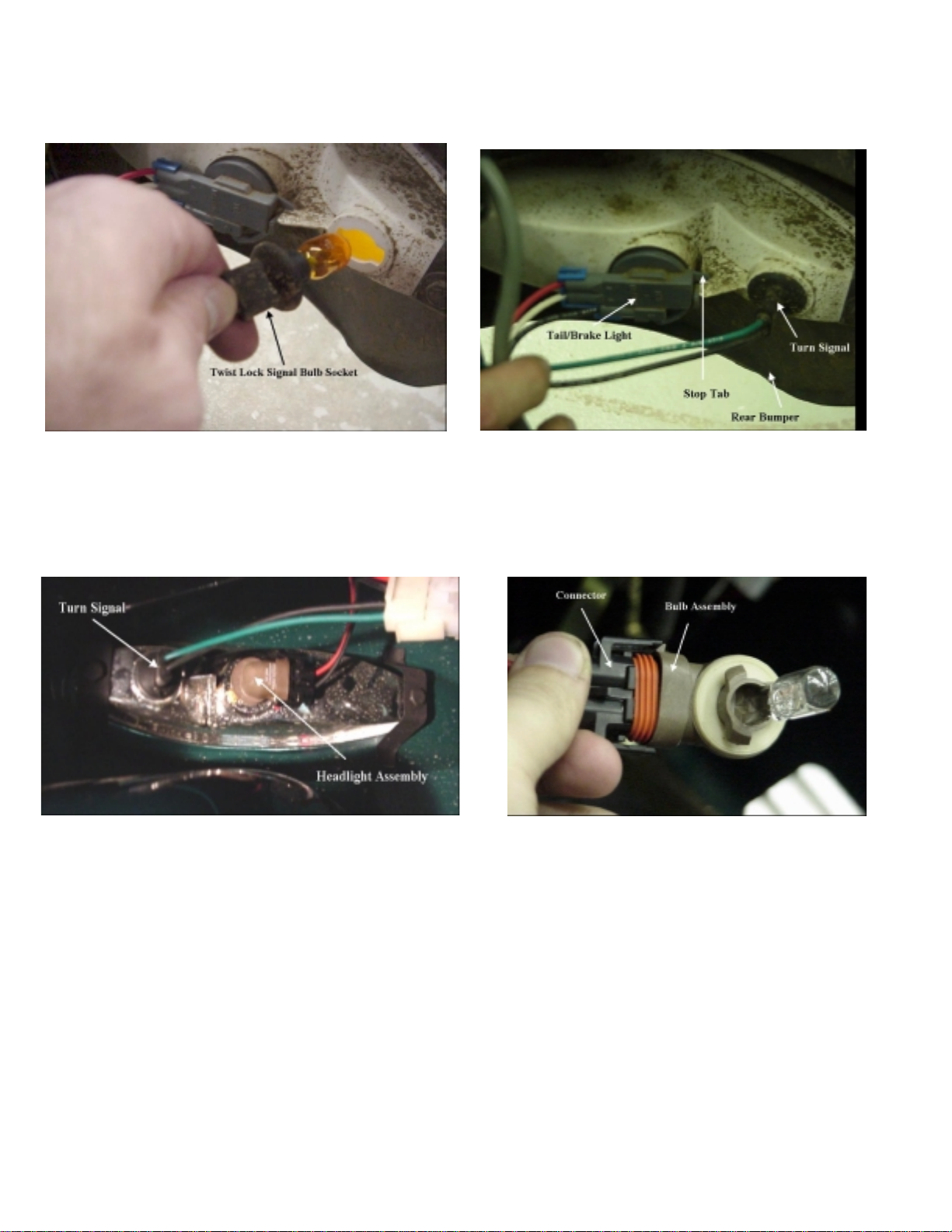

Replace turn signal bulb (Figure 4-44). Twist turn signal receptacle about ¼ turn

counterclockwise and remove from fixture.

Unplug bulb and replace.

Insert receptacle into fixture and turn clockwise

¼ turn into detent.

Replace tail/brake light bulb (Figure 4-45). Press locking tab down from inside slot and

rotate receptacle about ¼ turn to remove from

fixture.

Unplug bulb and replace.

Insert receptacle into fixture and turn clockwise

¼ turn until tab on receptacle contacts flange on

fixture.

Replace headlight bulb (Figure 4-46) and

Figure 4-47).

Check lights. Make sure new bulb is operating properly.

Rotate headlight assembly counterclockwise and

extract from fixture.

Release catches and unplug bulb assembly from

its base plug.

Replace bulb assembly.

Insert bulb assembly into fixture and rotate

clockwise until seated.

4-33

Page 50

Figure 4-48

Figure 4-49

4-34

Page 51

HEADLIGHT, HORN, HAZARD LIGHT SWITCHES

REMOVAL & INSTALLATION

STEP DETAILS

Check vehicle safe. Switch off and key removed.

Set parking brake.

Remove switch from panel (Figure 4-48). Reach behind panel and press switch

assembly out to the front of the panel

(driver’s side).

Disconnect switch (Figure 4-49). From wiring harness.

Release catches and unplug switch .

Replace switch. Plug in new switch and press assembly back

into panel.

Test operation. Check switch operating properly.

4-35

Page 52

Figure 4-50

Figure 4-51

4-36

Page 53

IGNITION SWITCH REMOVAL & INSTALLATION

STEP DETAILS

Make sure vehicle safe. Switch off and key removed.

Set parking brake.

Turn master power switch off (behind seat).

Warning:

Voltage is applied to the switch unless the

master power switch is off. Be careful.

Remove switch (Figure 5-50). Remove hex nut from switch at front of panel.

Pull switch out from rear of panel.

Unplug switch from jumper harness.

Install new switch (Figure 4-51). Plug into wiring harness.

Turn switch so key slot is oriented as desired

and insert switch through rear of panel.

Screw hex nut to front of switch until nut is

about the right position.

Adjust rear hex nut so switch is located at

right depth.

Tighten front nut.

Tie wrap excess wire so it is out of the way.

Turn master power switch on. Located behind seat.

Test unit. Make sure switch operates properly in all

positions.

4-37

Page 54

Figure 4-52

Figure 4-53

4-38

Page 55

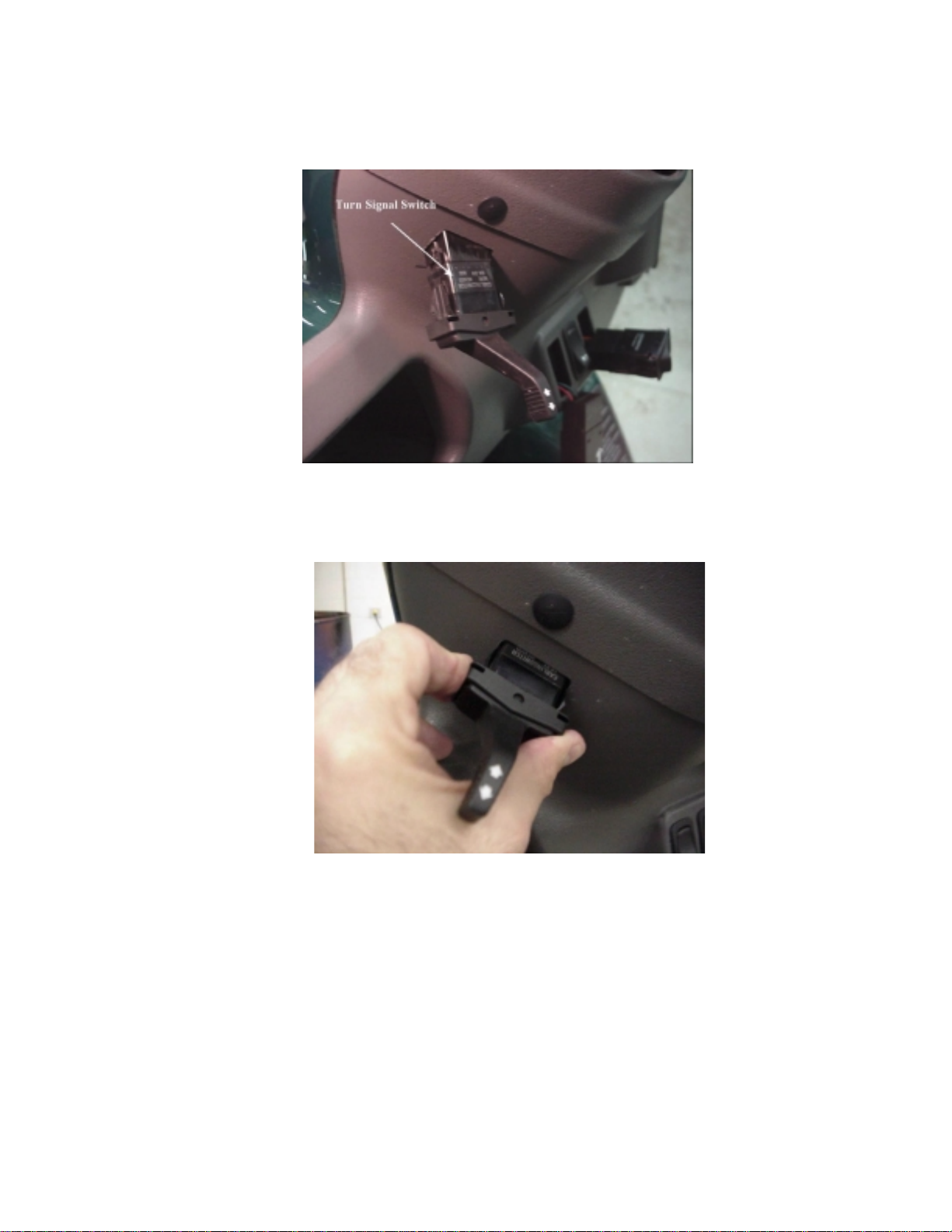

TURN SIGNAL SWITCH REMOVAL & INSTALLATION

STEP DETAILS

Make sure vehicle safe. Switch off and key removed.

Set parking brake.

Remove switch (Figure 4-52). Use screwdriver to

panel.

Unplug switch.

Install new switch (Figure 4-53). Plug new switch into wiring harness.

Turn switch so it is properly oriented and press

into panel.

Test. Switch on.

Press switch lever up for right turn signal,

down for left.

Tie wrap any excess wire so it is out of the

way.

gently

pry switch out from

4-39

Page 56

Figure 4-54

Figure 4-55

4-40

Page 57

ACCELERATOR POT (THROTTLE SENSOR) REMOVAL

& INSTALLATION

STEP DETAILS

Make sure vehicle is safe. Switch off and key removed.

Set parking brake.

Remove pot (Figure 4-54). Two screws – need 5/16” socket wrench or

common point screwdriver.

Disconnect pot (Figure 4-55). From wiring harness.

Install new pot. Mount with two screws.

Plug into wiring harness.

Make sure any excess wire is tie wrapped out of

the way.

Test new pot. Check vehicle acceleration and speed are

normal.

4-41

Page 58

Figure 4-56

Figure 4-57

4-42

Page 59

INSTRUMENT CLUSTER REMOVAL & INSTALLATION

STEP DETAILS

Make sure vehicle is safe. Switch off and key removed.

Set parking brake.

Pry instrument cluster loose from panel

(Figure 4-56).

Unplug instrument cluster (Figure 4-57). From wiring harness.

Install new instrument cluster. Plug new cluster into wiring harness.

Check instruments. Make sure all instruments operating properly.

Use care to not damage cluster or panel.

Press new cluster into housing.

Turn switch off and remove key.

4-43

Page 60

Figure 4-58

Figure 4-59

Figure 4-60

Figure 4-61

4-44

Page 61

PARK BRAKE SWITCH REMOVAL & INST ALLATION

STEP DETAILS

Check machine safe. Switch off and key removed.

Block wheels if necessary.

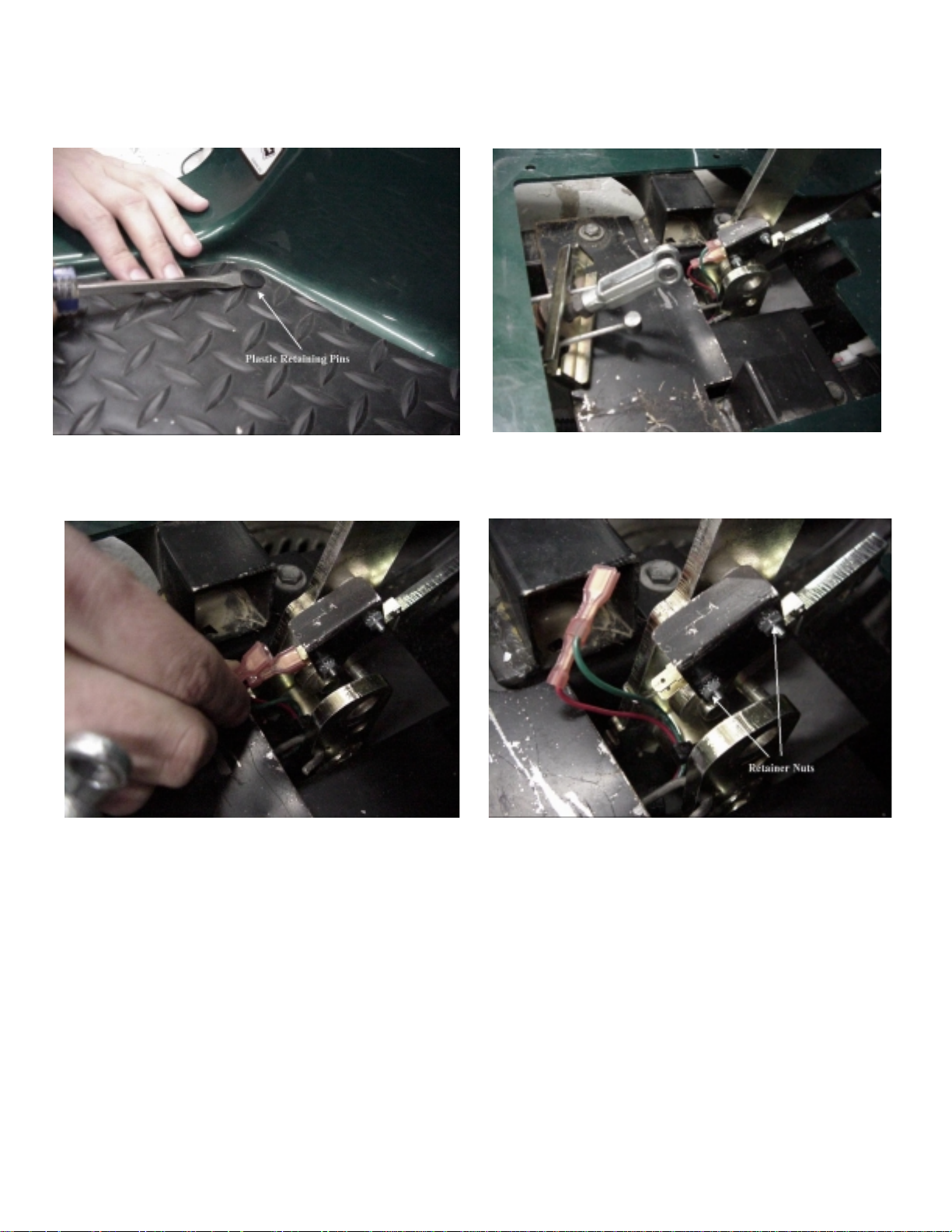

Remove floor mat and guard plate

(Figure 4-58).

Uncouple brake cable connection

(Figure 4-59).

Disconnect parking brake indicator light

switch wires (Figure 4-60).

Check switch. When brake is fully up, switch should be

Pry plastic retaining pins loose. Be careful to

not tear floor mat.

Guard plate lifts off when floor mat removed.

Remove spring retainer from clevis pin.

Pull clevis pin out and push cables and rod to

rear to allow switch removal.

Pull two connectors from tabs at on parking

brake indicator light switch. Green from top

tab and red from second tab.

closed between common and next contact.

Switch should be open when park ing brak e is

set.

If switch does not show closed when brake is

up check switch activator arm. Try raising it

slightly and see if switch will close. If this

works, bend arm just enough to cause switch

to close when brake is up.

Change switch if necessary (Figure 4-61). Remove retainer nuts, slide switch and switch

guard off and replace.

Note: be careful to not over-tighten nuts.

Connect wiring. Red wire plugs onto second tab and green

wire to top tab.

Connect brake cables. Install clevis on brake lever.

Make sure clevis pin and spring pin are

secure.

Check lights. Make sure parking brake indicator light is

operating properly.

Replace guard plate. So pins in floor mat will hold it in place.

Replace floor mat. Press pins into holes in floor.

4-45

Page 62

Figure 4-62

Figure 4-63

Figure 4-64

Figure 4-65

Figure 4-66

4-46

Page 63

BRAKE LIGHT SWITCH REMOVAL & INSTALLATION

STEP DETAILS

Check machine safe. Switch off and key removed.

Block wheels if necessary.

Remove floor mat and upper guard plate

(Figure 4-62).

Uncouple brake cable connection

(Figure 4-63).

Remove lower guard plate (Figure 4-64). Unscrew two 7/16” hex head bolts and

Disconnect brake light switch wires (Figure 4-

65).

Check switch. When brake is fully up, switch should be

Pry plastic retaining pins loos e.

Guard plate lifts off when floor mat removed.

Remove spring retainer from clevis pin.

Pull clevis pin out and push cables and rod to

rear to allow switch removal.

carefully remove plate.

Green wire from bottom (common) tab and

black wire from next tab up.

closed between common and next contact.

Switch should be open when brak e is

depressed.

If switch does not show closed when brake is

up check switch activator arm. Try raising it

slightly and see if switch will close. If this

works, bend arm just enough to cause switch

to close when brake is up.

Change switch if necessary (Figure 4-66). Remove retainer nuts, slide switch off and

replace.

Note: be careful to not over-tighten nuts.

Connect wiring. Green wire to bottom tab and black wire to

next tab up.

Install lower guard plate. Work plate carefully into position.

Install and tighten two bolts.

4-47

Page 64

4-48

Page 65

Connect brake cables. Install clevis on brake lever.

Make sure clevis pin and spring pin are

secure.

Check lights. Make sure brake light is operating properly.

Replace upper guard plate. So pins in floor mat will hold it in place.

Replace floor mat. Press pins into holes in floor.

4-49

Page 66

Figure 4-67

Figure 4-68

4-50

Page 67

HORN REMOVAL & INSTALLATION

STEP DETAILS

Make sure vehicle safe. Switch off and key out.

Parking brake set.

Adjust steering. Turn front wheels as far to the right as

possible.

Horn is accessible through right wheel well.

Disconnect horn (Figure 4-67). Remove spade connectors from tabs on horn.

Note that green wire is connected to positive

and black to negative terminals.

Remove horn from bracket (Figure 4-68). Reach between front bumper and horn

mounting bracket and unscrew front of horn

(by hand).

Pull horn out of bracket.

Place new horn in bracket. Insert rear part of horn in bracket and screw

front of horn onto rear. Tighten hand tight.

Connect horn wires. Slide connections onto terminals. Be sure

green wire is connected to positive terminal

and black wire to negative.

Test unit. Switch on and depress horn switch.

4-51

Page 68

4-52

Page 69

SECTION 5: TEST PROCEDURES

Ignition Switch & Jumper Harnes s.......................5-3

Accelerator Pot (Throttle Sensor)........................5-9

Motor.................................................................5-11

Motor Contactor ................................................5-15

Speed Sensor ...................................................5-19

Brake Switch.....................................................5-21

Park Brake Switch.............................................5-23

Directional Signal Switch...................................5-25

Instrument Cluster.............................................5-27

Charger.............................................................5-29

Battery Pack Evaluation....................................5-31

5-1

Page 70

SECTION 5:

Figure 5-1

Figure 5-2

5-2

Page 71

IGNITION SWITCH & JUMPER HARNESS TEST

PROCEDURES

STEP DETAILS

Make vehicle safe. Ignition switch off and key removed.

Parking brake set.

Disconnect jumper harness from main

harness.

Connect ohmmeter leads to pins 3 and 4 of

jumper harness (See Figure 5-1).

Connect ohmmeter leads to pins 2 and 3

(readings same as pins 3 and 4). See Figure

5-1.

Connect ohmmeter leads to pins 2 and 4.

See Figure 5-1

Further action. If any readings are not as shown (or very close),

Connect ohmmeter leads to pins 32 and 33

on large controller connector. See Figure 5-

2.

Reconnect jumper harness to main harness.

Readings should be as shown below when

ignition switch is in position shown:

Reverse………………1 k ohms

Off……………………..open circuit

Hi………………………. 2 k ohms

Lo……………………… 4 k ohms

Readings should be as shown below when hi-lo-

reverse switch is in position shown:

Reverse………………1 k ohms

Off……………………..open circuit

Hi………………………. 2 k ohms

Lo……………………… 4 k ohms

Should show near zero ohms in all switch

positions except “off”. Off position should show

open circuit.

disconnect jumper harness from switch and

check jumper harness and switch individually.

If readings were ok, go to next steps.

Readings should be as shown below when hi-lo-

reverse switch is in position shown:

Reverse………………1 k ohms

Off……………………..open circuit

Hi………………………. 2 k ohms

Lo……………………… 4 k ohms

Connect ohmmeter leads to pins 32 and 31

on large controller connector. See Figure 5-

2.

Connect ohmmeter leads to pins 31 and 33

on large controller connector. See Figure 5-

2.

Replace wiring harness. If any reading taken through main harness shows

Readings should be as shown below when

ignition switch is in position shown:

Reverse………………1 k ohms

Off……………………..open circuit

Hi………………………. 2 k ohms

Lo……………………… 4 k ohms

Should show short circuit in all switch positions

except “off”. Off position should show open

circuit.

different than described.

5-3

Page 72

Figure 5-3

5-4

Page 73

JUMPER HARNESS TESTING PROCEDURES

Step Details

Jumper harness has resistors in the wiring and must be tested separately from the switch when

switch malfunction is suspected. Problem might be in harness and not switch.

An ohmmeter is required.

Make vehicle safe. Switch off and key removed.

Parking brake set.

Remove harness section. Unplug from back of switch.

Disconnect from main harness.

Measure resistances between pins as

shown in Figure 5-3.

If measurements are significantly different

than those shown, the problem is probably in

the jumper harness.

If all measurements are good, check switch.

Measure from pin 4 to pin:

A – open circuit.

B – open circuit

C – 2 k ohms

D – 0 ohms

E – 4 k ohms

F – 1 k ohms

Measure from pin 3 to pin:

A – open circuit

B – 0 ohms

C – open circuit

D – open circuit

E – open circuit

F – open circuit

Measure from pin 2 to pin:

A – 0 ohms

B – open circuit

C – open circuit

D – open circuit

E – open circuit

F – open circuit

Measure from pin 1 to pin:

A – open circuit

B – open circuit

C – 2 k ohms

D – 4 k ohms

E – 0 ohms

F – 3 k ohms

5-5

Page 74

Figure 5-4

5-6

Page 75

IGNITION SWITCH TESTING PROCEDURES

STEP DETAILS

Make vehicle safe. Switch off and key removed.

Parking brake set.

Remove switch. Remove retainer nut and pull switch out from

back of panel.

Unplug jumper harness from switch.

Check switch continuity. See Figure 5-4. Use ohmmeter to check pins as shown on

Figure 5-4. Pins shown should show near zero

ohms when switch is in positions shown below.

Reverse: B to F D to A

Off position: none of the listed pins connected.

High: B to C D to A

Low: B to E D to A

Replace switch. If resistance readings are not correct.

5-7

Page 76

Figure 5-5

Figure 5-6

5-8

Page 77

ACCELERATOR POT (THROTTLE SENSOR) TESTING

PROCEDURES

STEP DETAILS

Make sure vehicle safe. Turn ignition switch off and remove key.

Set parking brake.

Check resistance of pot. See Figure 5-5. Disconnect pot from harness and take

measurements on pot side of connection while

depressing accelerator. Pin numbers are on the

connector.

Pin 1 to pin 3………… 5 k ohms at all times.

Pin 1 to pin 2………… 15 k ohms to 10 k ohms.

Pin 2 to pin 3………… 10 k ohms to 15 k ohms.

Measure continuity. See Figure 5-6. Of combined harness and pot circuit. Plug pot

connector into main harness.

Measure resistance from pin 27 to pin 28 on the

large controller connector. When accelerator is

depressed resistance should go from 15 k ohms

to 10 k ohms.

Measure from pin 28 to pin 29. Resistance

should go from 10 k ohms to 15 k ohms.

Measure from pin 27 to pin 29. Resistance

should stay at 5 k ohms.

If resistances are correct then pot and harness

are ok. If resistances different than those

shown, proceed to next step.

What to do??? If entire harness and pot check good, problem

must be somewhere else.

If pot is good and harness and pot showed bad,

must be fault in harness.

If pot readings not correct, change pot.

5-9

Page 78

Figure 5-7

5-10

Page 79

MOTOR TEST PROCEDURES

STEP DETAILS

Make vehicle safe. Ignition switch off and key removed.

Parking brake set.

Remove utility bed (or storage compartment). Whichever is installed.

Remove 4 screws from utility bed or lift storage

compartment out.

Turn off master power switch. Located behind seat.

Remove canopy assembly. If installed, refer to Section 4.

Remove rear body section. Refer to Section 4.

Disconnect one motor cable. Recommend disconnect motor return cable from

controller.

Raise and support vehicle. Raise rear until wheels are clear.

Place supports under vehicle.

Attach ohmmeter leads. See Figure 5-7. To motor cable terminal ends.

Check resistance in motor.

Note: Check resistance from motor lead

to case on motor to make sure lead is not

grounded

motor housing, replace motor.

High resistance or large changes indicate

problems with brushes or commutator in

motor.

Lower vehicle. Remove supports and lower.

Reconnect motor cable. To original position.

Turn on master power switch. Located behind seat.

If motor lead has continuity to

.

Should be less than one ohm.

Rotate wheels in small increments (stopping to

read resistance) and make sure resistance is

not more than one ohm at any position

Replace motor

.

5-11

Page 80

Figure 5-8

5-12

Page 81

Test motor current draw (Figure 5-8).

Note: Test should be done with driver

only, (no payload) and on level ground.

Install rear body section.

Install canopy.

If motor is weak, performance is bad or is

suspected to cause low range or overheating of

controller.

Connect clamp on inductive current sensor to

one of the motor cables and set meter to read

current of up to 150 amps. Drive vehicle and

record current readings at various speeds as

follows. Drive at a steady speed on level ground.

5mph – 25 to 35 amps

12mph – 30 to 45 amps

Note: Values are approximate and may vary

some with different terrain and driver

weights. If amperage is considerably higher

than it should be, the motor is not operating

efficiently. Make sure there is no mechanical

problem causing motor to overwork, such as

dragging brakes.

Install utility bed or storage compartment.

Note: Storage compartment fits into rear

area with no fasteners.

For utility bed, make sure spacers are positioned

to keep bed from distorting body section when

screws are tightened.

5-13

Page 82

Figure 5-9

Figure 5-10

5-14

Page 83

MOTOR CONTACTOR TEST PROCEDURES

STEP DETAILS

Make vehicle safe. Ignition switch off and key removed.

Parking brake set.

Turn off master power switch. Switch behind seat.

Remove utility bed (or storage compartment). Whichever is installed.

Remove canopy assembly. If installed, refer to Section 4.

Remove rear body section. Refer to Section 4.

Disconnect large controller (positive motor

output) cable from contactor.

Check voltage on contactor activation

terminals (Figure 5-9).

Note: 12 volts is applied to the activation

terminals initially to activate the contactor.

Then voltage is pulsed to hold contactor

closed. The pulsed voltage will read about

5 volts with a digital voltmeter.

Note: If the voltage at the activation

terminals continues to read 12 volts, the

coil circuit of the contactor is most likely

“open.”

Shield terminal end of cable so it cannot touch

you or anything else (cover with tape or other

suitable insulatio n) .

Turn on master power switch.

Turn ignition switch to a run position.

Check voltage on activation terminals. Should

be about 5 volts.

If voltage is present and contactor “clicks”

closed, check resistance between motor and

controller power terminals on contactor.

Should be less than 1 ohm. (See Figure 5-10)

If no voltage present, check continuity of

activation wires to large twist lock connector at

controller.

Orange wire to pin 11

White wire to pin 12

If no continuity, repair or replace harness as

needed.

If continuity is good on both wires, controller

may be bad if no other faults are present.

5-15

Page 84

5-16

Page 85

Replace contactor if necessary. If voltage is present at activator terminals but

does not cause contactor to close.

If contactor closes but more than one ohm of

resistance is present between motor power

terminals.

Reconnect motor power cable. To original position.

Turn on master power switch. Located behind seat.

Check operation. Make sure vehicle operates properly.

Reassemble. Rear body section.

Utility bed or storage container.

Canopy assembly.

5-17

Page 86

blue

blue

Speed

Speed

Sensor

Sensor

Figure 5-11

black

black

brown

brown

1 2 3

1 2 3

Sensor Plug

Sensor Plug

1K

1K

Volts

Volts

Ω

Ω

_

_

Battery

Battery

+

+

5-18

Page 87

SPEED SENSOR TEST PROCEDURES

STEP DETAILS

Remove utility bed. If equipped.

Remove trunk basket. Lifts out.

Test speed sensor using test tool.

Note: This test can be done with a DMM,

but it is more easily done with an analog

voltmeter.

Test speed sensor without test tool.

See Figure 5-11.

Note: This test is only to be used when test

tool is not available.

Jack and support rear of vehicle with tires off

floor. Plug tool to the speed sensor. Connect

voltmeter to tool. Turn switch to “on.”

Slightly move the tire until voltage reads

approximately 9 volts. Slightly move the tire

more until the voltage reads near zero.

If the tire can be moved so that the voltage

reads 9 volts and near zero volts, speed sensor

is operating properly.

Note: If speed sensor is to be tested while

out of the vehicle, connect tool and put a

piece of ferrite metal in front of sensor pick

up and then remove. With metal in place,

the voltage should be near zero, and with

metal removed, voltage should be

approximately 9 volts.

Unplug speed sensor.

Connect a 1K-ohm resistor across pin 2 (black

wire) and pin 3 (brown wire) of sensor plug.

Connect a battery across pin 1 (blue wire) and

pin 3 (brown wire).

(Use a 9 volt transistor battery or a 12 volt

cranking battery)

Measure voltage between pin 1 and pin 2.

Move tire slightly to get a voltage reading that

is approximately equal to the battery voltage.

Then slightly move tire to a point where voltage

is near zero.

If voltage can be changed from the battery

voltage to near zero volts the sensor is good.

5-19

Page 88

Figure 5-12

Figure 5-13

5-20

Page 89

BRAKE SWITCH TEST PROCEDURES

STEP DETAILS

Remove rubber floor mat. Pry out plastic retaining pins.

Remove upper guard plate. Lifts off.

Remove brake pull and lower guard plate. See

Figure 5-12.

Test switch. See Figure 5-13.

Note: Wires should be attached to two

lower spade terminals of switch.

Note: Check switch lever to make sure

brake pedal arm is pushing and releasing

switch lever.

Remove spring clip and clevis pin from brake

pull. Remove two hex head bolts from lower

guard plate. Remove guard plate and remove

brake pull or secure out of way.

With both wires still plugged to switch and key

to an “on” position. Check instrument cluster to

make sure the selected mode and on lights are

illuminated (block wheels or raise rear wheels

off ground to prevent accidental runaway of

vehicle). Touch the voltmeter leads to the

spade terminals just in front of the wire

connectors (polarity not im portant) . Be careful

to touch only the spade terminals with the

voltmeter leads.

Pedal up – should be 0 volts.

Pedal depressed – should be approximately 6

volts (polarity not important).

If both voltages are correct, then the switch and

wiring from controller are good.

If both voltages are approximately 6 volts, then

the switch is bad (open).

Note: There is a connector on the inside of

right frame rail to the right of the brake

pedal in this circuit. If no continuity, check

connector.

If both voltages are zero, then unplug the wires

and check voltage at wires. If voltage of

approximately 6 volts is present, then switch is

bad (shorted).

If no voltage on wires, check continuity of wires

to controller (should be less than 1 ohm).

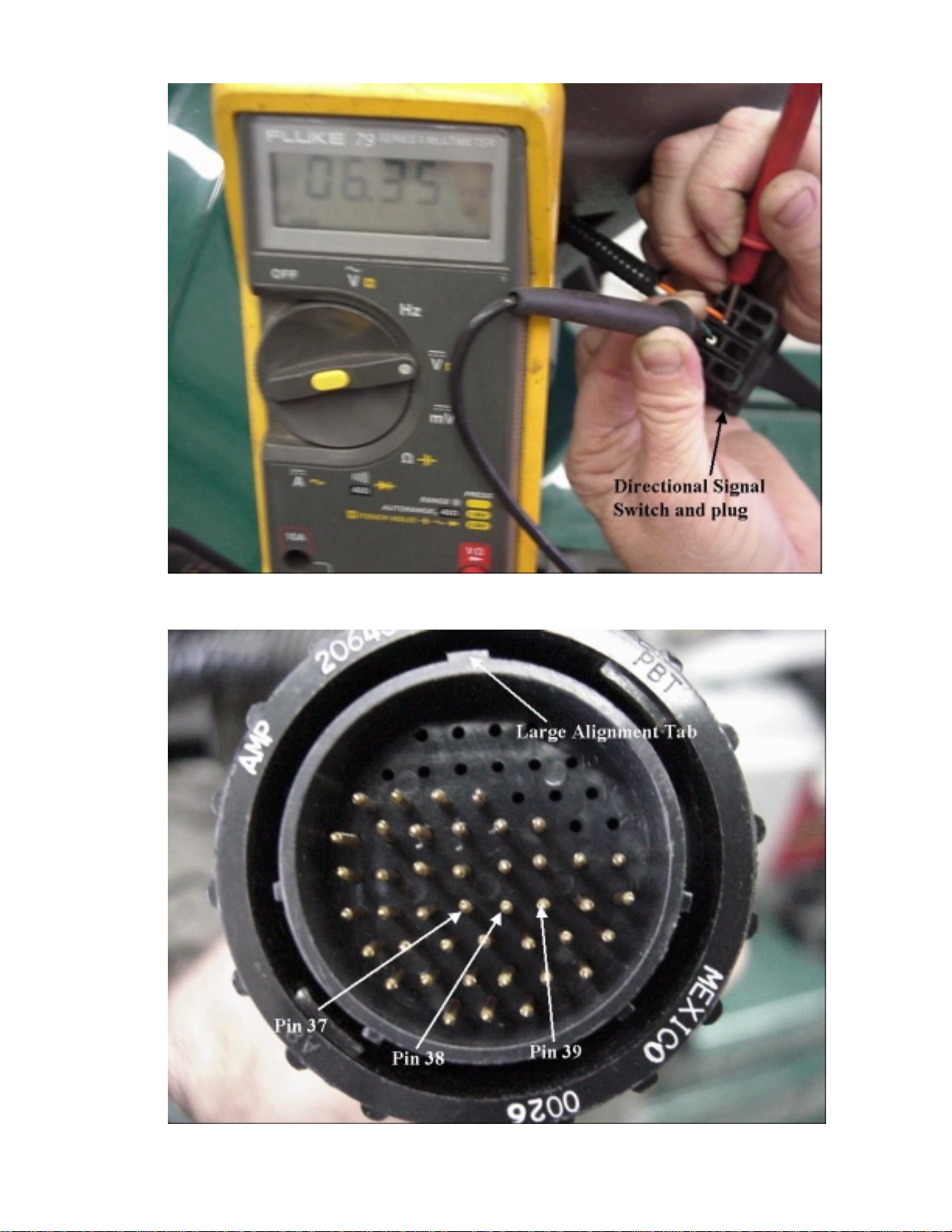

Black wire to pin 18 of large twist lock

connector.

Green wire to pin 38 of large twist lock

connector.

If either wire does not have continuity to

controller, repair wire or replace harness as

needed and retest.