Creda Heating Solution User Manual

Uniclass L7522 |

EPIC L22 |

|

|

Cl/SfB |

(56) |

|

2008/2009 Product Directory

Heating Solutions

Creda Heating

Introducing the fuel of the future!

“For over 40 years Creda has been dedicated to heating the nation. In the future low carbon electricity will make electric heating the first choice for a lower carbon footprint and low

lifetime cost of ownership. ”

Our heating technology has been developed with today’s lifestyles in mind, so attention to style as well as efficiency and economy are paramount. At Creda we never forget, however, that safety is the number one concern.

With a renowned safety record, ease of installation or upgrade, virtually no maintenance and low cost of ownership, electric heating continues to grow in popularity in the UK and across the world.

As electricity generation gets ever greener, the world is turning to electric heating. In the UK our heating products are designed to comply with Part L of the Building Regulations which focuses on reducing carbon emissions and the conservation of fuel and power. For more details on meeting these regulations see pages 6 & 7 of this brochure. For advice on helping to save the Earth by saving energy and saving money too - see the guide at the back of this brochure.

Our advanced heating control options assist in achieving the best possible SAP ratings. (SAP is the Standard Assessment Procedure for energy ratings and is also used within Part L).

As pioneers in electric heating, we continue to lead the field with innovative and contemporary product design, backed by nationwide after-sales support and a dedicated specification team.

We are here to help you develop the most effective, economical and environmental heating solution.

Welcome to the fuel of the future!

TPRIII Electronic pilot plus panel heaters with plug-in timer options or 4 zone central control.

Proline II Ladder style electric towel rails with fast response heating technology.

Eco-Response storage radiant heaters offer advanced heating technology with rapid response, touch temperature control.

2

Index

Introduction |

Creda Heating Introducing the fuel of the future! |

2 |

|

Creda Heating A low carbon future |

4 |

|

Creda Heating Design application support |

5 |

|

Meeting Part L The quick start guide! |

6-7 |

|

|

|

Advanced control |

Eco-Response Intelligent heating technology / Storage radiant heaters |

8-9 |

|

|

|

heating systems43 |

Contour100 Electronic panels |

10-11 |

TPRIII E Electronic pilot plus panel heaters |

|

|

|

12-13 |

|

|

TPRIII M / MT Mechanical thermostatic panel heaters |

14 |

|

TPRIII NC No controls panels |

15 |

|

Newera Style Panel heaters |

16 |

|

Newera Electronic Panel heaters |

17 |

|

Newera Plus Panel heaters |

17 |

|

RF Electronic radio frequency panels and control options |

18-19 |

|

Control Options |

20-21 |

|

|

|

Electric storage |

Sensair Automatic Electric storage fan heaters |

22 |

heating3 |

TSR Supaslim Combi Storage fan heaters |

23 |

|

|

|

|

TSR Sensor Plus & Slimline Electric storage heaters |

24 |

|

TSF Turbo Commercial storage fan heaters |

25 |

|

Storage Heater Accessories |

26 |

|

|

|

Towel rails & |

Outline Thermostatic integral control towel rails |

27 |

bathroom warmers |

Proline II PL Fast response electric ladder towel rails |

28-29 |

|

|

|

|

TD Traditional style electric towel rails |

30 |

|

Solarail and LRC Electric towel rails |

31 |

|

|

|

Underfloor heating |

CDF Compact Downflow fan heaters |

32 |

& fan heaters |

PH2 Electric plinth heaters for base units |

33 |

Soleglow Underfloor electric heating |

|

|

|

34 |

|

|

|

|

|

Sunplus Outdoor patio heaters |

35 |

Commercial |

Sunquartz Shortwave infra-red radiant heaters |

36 |

space heating |

Ceramic Emitters Long wave infra-red heaters |

37 |

Sunslim Commercial radiant heaters |

|

|

|

38 |

|

|

Suntube Tubular heaters |

39 |

|

Sunfan High level fan heater |

40 |

|

Sunscreen Warm air curtains |

41 |

|

|

|

|

Creda Heating Cable and connection points |

42-43 |

Technical |

Sizing Guide Storage and panel heaters |

44 |

information |

Sizing Guide Commercial space heaters |

45 |

Design Request Application Design Survey Information Sheet |

|

|

|

46 |

|

|

Good Practice Helping you save energy |

47 |

|

|

|

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

3 |

Creda Heating

A low carbon future

a low carbon future.

“Creda continues to invest in the bright future of electric heating. The 2008 Energy Bill promoted the production of heating from low carbon electricity, as ever more central generation flows from low carbon sources. ”

Low carbon electricity, generated here in the UK and not imported from around the world, gives us security of energy supplies and contributes to reducing the devastating impact of climate change.

Low carbon electricity provides low carbon heating from electric panel and storage heaters. Creda are at the forefront of these developments with the latest technology, advanced energy-saving controls and contemporary styling to suit the homes

of today.

Part L and SAP

(Standard Assessment Procedure)

The April 2006 revision to Part L of the Building Regulations requires that all new buildings do not exceed a Target Carbon Emission Rate (TER) as measured by a Standard Assessment Procedure (SAP). For more details on how to comply see our ‘quick start’ guide on pages 6 & 7 of this brochure.

Every day, across the country, we design electric heating systems that improve SAP scores and achieve full compliance with Part L of the Building Regulations for buildings of all shapes and sizes. See page 5 for information on how!

Decent Homes and Sustainable Communities

By 2010, the government has committed to bring 95% of all social housing in the UK into a decent condition and the remainder are to be improved soon after.

The new Housing and Regeneration Bill has also committed the government to building 3 million new affordable and sustainable homes by 2020. The provision of modern facilities are along with the building improvements required to meet this legal obligation, brings energy efficiency to the fore. Improved air-tightness combined with new heating systems, kitchen and bathroom facilities and effective ventilation strategies will all be needed. Our sister brand Redring has a successful track record in providing affordable hot water and showering into Decent Homes projects (see www.redring.co.uk) and Xpelair are experts in the field of low carbon ventilation, with the Xpelair Carbonlite boasting a range of low energy and long-life product

(see www.xpelair.co.uk). Here at Creda we are the heating experts.

Warmth is a pre-requisite of decent housing and low carbon electricity is the route to sustainable communities. We believe electricity is the fuel of the future; homes built today may well last 60 to 100 years, so we must build for the future today!

Creda electric heating can meet and exceed the needs of the Decent Homes Standard. Our website provides on-line help, tutorials and CPD accredited courses for those wishing to ensure their development is compliant with the regulations.

Creda on the web

Visit www.creda-heating.co.uk for downloads, brochures, product specifications and more information on Part L, SAP and the Decent Homes Standard.

4 |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

Creda Heating

Design application support

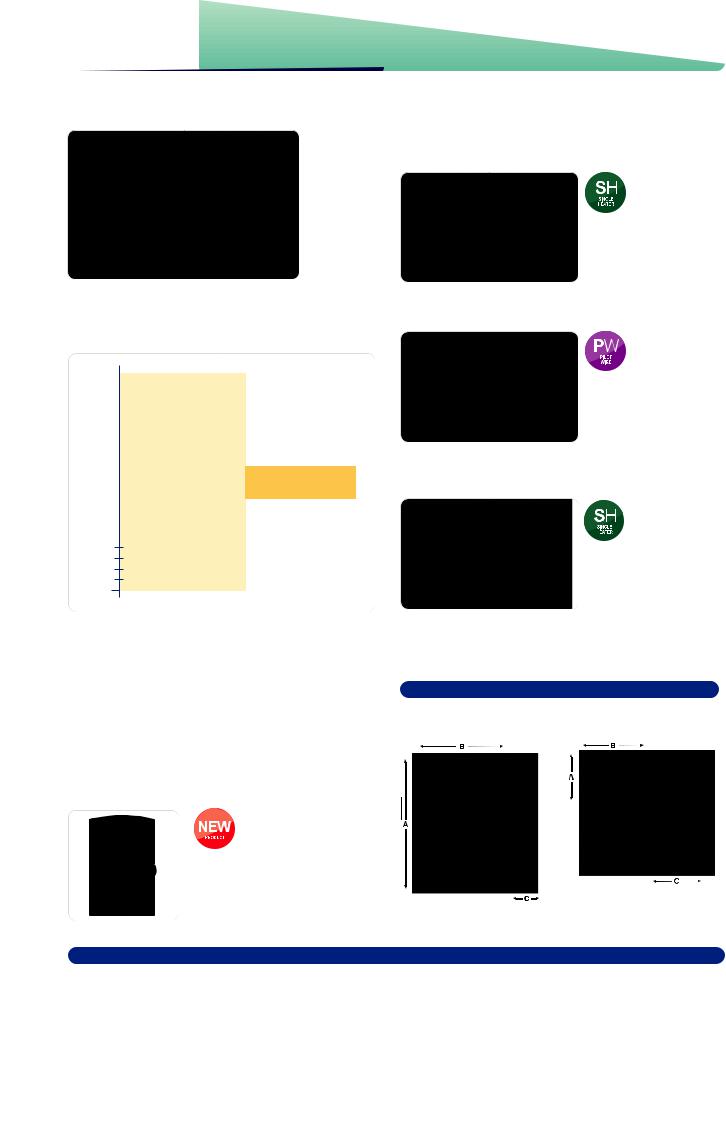

Electric heating is cheaper than gas

Annualised installation costs (based on manufacturers’ quoted average lifetimes and typical installation costs for 6 electric panels or 6 wet-radiators and a

gas boiler).

Annual safety check and maintenance costs (to comply with manufacturers’ conditions of guarantee - using lowest priced British Gas service contract to include boiler, controls and radiators).

Annual fuel costs (based on guidance from the Energy Saving Trust publication CE185 and Npower standard gas and electricity prices on Feb 10th 2008).

Low carbon electricity from renewable sources makes electric heating the fuel of the future; but already electric heating is cheaper than gas.

In recent times all energy prices have risen but none more so than gas. Creda electric heating is now cheaper over its entire lifetime than gas, when all the facts are considered.

Electric heating products cost less to buy in the first place and are quick and easy to install or upgrade. They offer total flexibility in the building design, with no complicated pipe runs, which also leave gaps in the building fabric; a problem when air-tightness is a key factor in improving the carbon footprint of a building and meeting Part L of the building regulations. Once installed, electric heating requires virtually no maintenance. Unlike gas there is no legal requirement for an annual landlord safety certificate.

Year in and year out, electric heating provides instant, responsive and safe heating on demand. Recent calculations have shown that when all these factors are taken into account there is a minimum overall cost saving of at least 13% a year in comparison to gas central heating.

Apartments and flats often favour electric heating for all these reasons. It is the simplest and most cost effective solution for many hotels, gyms, crèches, nurseries, surgeries, care homes, offices and shops all over the UK.

Application design

We have over 40 years experience in designing and supporting electrical heating installations. We are able to offer an expert application design service for all our products, helping new and existing customers alike to specify Creda products into real buildings and live projects, either off-plan, commenced new-build or refurbishments.

In recent times the proliferation of environmental legislation and revisions to Building Regulations, all designed to reduce carbon intensity and improve energy efficiency, have made the design process more complex. We are here to help with two levels of design service.

Level 1:

Our standard design service is free of charge and will provide a clear and simple indication of the products required and the associated costs. This service can be provided from basic plans and drawings.

Level 2:

Our enhanced design service incurs a very competitive fee to cover third-party costs and a small contribution to the work of our accredited SAP assessors. In return a dedicated assessor will provide schematic designs and confirmation of regulatory compliance including Part L of the Building Regulations and a SAP score, as well as the product requirements and costs to achieve this. Full architectural drawings are required to complete this service and work cannot commence without them.

For further information send a description of your project, contact details and drawings to aedesign@applied-energy.com

Technical services

Our technical services call centre is staffed by a team trained in diagnosing and rectifying potential concerns over the phone.

If for any reason they are unable to solve a problem by phone, they will brief an engineer on your behalf prior to the service visit to ensure that, wherever possible, the problem is fixed first time.

The team also provides advice on product selection, application, installation and operation; ensuring maximum value is gained from selecting a Creda heating product.

For further information:

Tel: 08709 000430 Fax: 08709 000530

The Building Centre

Building specifiers within easy reach of Central London can see a permanent exhibition of selected Creda products at the Building Centre in Store Street, WC1E 7BT. The centre also offers a full library support and literature distribution service for visitors, to assist them in identifying the most appropriate products for any given application.

Details of the Building Centre can be seen by the following the link at www.creda-heating.co.uk

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

5 |

Meeting Part L

The quick start guide!

Xpelair Xcell 270

“Electric heating continues to grow in popularity. In April 2006 the revision to Part L of the Building Regulations meant the way you comply for new buildings changed. This is the quick-start guide to complying

with Part L. ” Block Assessment

All the old methods of compliance have been abolished and replaced with a Target Carbon Emission Rate (TER).

Whatever fuel type you choose for the heating and hot water of your new building - gas, oil, LPG or electric - you have to show that the overall carbon emission rate is less than the target for that building type.

There are also new minimum standards for U-values and airtightness, which must be tested on completion of the building. However, even meeting all the minimum standards will not guarantee a pass.

The biggest change is that under the new rules the whole building is taken into consideration. Every factor that can influence carbon emissions is relevant and it’s the whole building that must pass.

So just building to minimum standards may not guarantee a pass because the whole building may still exceed the target

carbon emission rate.

What’s my target?

The target is set in terms of Kilograms of carbon dioxide for every square metre of the building, over the course of a year (KgCO2/m2/yr).

A range of sample buildings is used to set the target, which is then adjusted for the size and shape of the actual design and the heating and hot water plan.

The complex calculation of both the target and the actual score of your new building can be performed within special SAP 2005 approved software. (The government’s adopted Standard Assessment Procedure). An accredited SAP assessor is required to complete this.

The targets created under Part L 2006 demand a 20% reduction in carbon emissions compared with the previous rules. This new tougher target was set to improve the country’s energy efficiency and dependence on imported fuel and to reduce the devastating effects of climate change.

The tougher target applies to all relevant buildings, all products and all fuel types. It’s the whole building that must comply, not any given product or building service.

Part L 2006 has important rules for setting and achieving the targets in flats and apartments. So called ‘Block Assessment’ allows for all the flats or apartments in a building to be assessed in one go.

Each flat or apartment can be dealt with as the developer or specifier feels appropriate for meeting the overall TER, across the different floors and sides of the building. Any given flat or apartment does not have to meet an individual TER as long as the whole building does.

This allows the developer or specifier flexibility in how to achieve the target. For example, mechanical ventilation with heat recovery (see picture above) may be installed which would create carbon savings which can be shared out across the whole building.

It also reduces running costs and becomes a major selling feature. For more advice on saving energy see the guide at the back of this brochure.

Can you comply using electric heating and hot water?

Yes.

The only test for compliance is that the building does not exceed the target carbon emission rate. We continue to supply electric heating and hot water solutions into fully compliant buildings. Electric heating has also been shown to have lower lifetime costs of ownership than gas, is easier and quicker to install,

is maintenance free, offers great design flexibility and has lower initial capital costs.

Electric heating is the fuel of the future. Low carbon electricity from UK sources produces low carbon heating only with electric products.

How do I reduce the carbon emission rate of a building?

There are a number approaches that are proving most effective at reducing the carbon emission rate of a building. We recommend you consider the following options. In isolation or in combination, all of these options have been used in conjunction with modern electric heating.

6 |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

Meeting Part L

The quick start guide!

Creda Eco-Response

1Improve the air-tightness:

It is now mandatory to test the air-tightness of a building on its completion. There are minimum levels required under the new regulations but improving on these has been shown to be one of the best ways to reduce the carbon emission rate and therefore comply with Part L. Electric heating is helpful in this regard as it results in less holes and gaps in the building fabric than gas heating systems. The regulations require a minimum air-tightness of 10 cubic metres per hour per square metre of floor area at 50 Pascals of pressure. (10m3/h/m2 @ 50Pa). Many developments can now achieve 7 or 5 and some even 3m3/h/m2 @ 50Pa.

2Install mechanical ventilation with heat recovery:

Used in conjunction with improved air-tightness, so called MVHR recovers otherwise wasted heat and is a great advantage to the ventilation strategy. There are specific provisions within SAP (Appendix Q) which show how using MVHR can reduce the carbon emissions rate and help compliance with Part L. Xpelair offers leading MVHR systems as part of the Carbonlite range,

see www.xpelair.co.uk.

3Improve the building fabric:

There are minimum U-values for all elements of the building fabric. U-values are a measure of how much heat energy can escape through a given element of a building. However, simply meeting these alone does not guarantee compliance. By exceeding the minimum requirement significant improvements can be made on the carbon emission rate. It is possible to show compliance with Part L just by improving building fabric U-values. However, a combination of improved airtightness, MVHR and modest improvements in building fabric U-values has proved most cost effective in many building developments. Consider reducing U-values for roofs to 0.14, walls to 0.3, floors to 0.2 and glazing to 1.8 but, generally speaking, the lower the better.

4Consider glazing as a percentage of the building floor area:

The regulations assume that glazing coverage is equivalent to 25% of the floor area, which is more than most developments. Where this can be sensibly reduced it will improve the carbon emission rate of the building. If the specification of glazing is also improved the impact is increased. Consider gas filled or triple glazing.

5Go renewable:

The installation of solar thermal hot water systems, heat-pumps

or micro wind-turbines can have a number of major benefits. Often the installation of some of these products can turn an otherwise non-compliant building into a fully compliant one. However, many developers now also see this as the preferred route to meeting other planning requirements or aspirational targets for the use of micro-generation technologies. They can significantly reduce running costs and can be a great selling point. Redring offers one of the most efficient solar thermal hot water systems in the UK - see www.redring.co.uk - and Xpelair has a world-class micro wind-turbine (see www.xpelair.co.uk).

6Improve the lighting plan:

In some buildings the carbon impact of the lighting can be significant and expert advice can assist in demonstrating compliance with Part L.

Modular lighting strategies should be considered. The traditional rules of thumb based on the number of rooms should give way to a recommended number of lighting points by square metre of floor area. It is good practice to install low energy fittings as standard indoors, with consideration given to highly effective control. Externally the regulations require a maximum 150W with automatic switch-off via PIR, photocell and timers.

7Controllability reduces emissions:

It has been shown that easy to use, highly responsive heating systems actually reduce carbon emissions. When heating responds quickly it tends, in practice, to be used more effectively. Where controls are simple to use, people make better use of them. Modern electric heating is highly controllable and responsive. This is recognised within SAP. We offer leading edge electric heating with our Eco-Response technology. Integrated and sensitive thermostats within Creda electric heating products allow precise control room by room, ensuring solar gain is taken into account in maintaining a desired temperature and reducing carbon emissions.

8Background heat:

By ensuring there is a low level background heat throughout the common walkways, like stairwells and landings in apartment blocks, adjoining walls are only considered semi-exposed for calculation purposes, reducing heat losses and improving the carbon emission rate. We offer modern electric heating solutions designed for this purpose.

9Size the cylinder:

The regulations now assume a 170l water cylinder. By ensuring the cylinder is not oversized for its application, heat losses are reduced. If the cylinder size is reduced below 170l then the carbon emission rate is improved. Redring offers cylinders at 90, 125, 150 and 170 litre capacities, as well as larger sizes where necessary. See www.redring.co.uk for a full range of instant water heating products that have no standing losses at all!

Redring LWSS Stainless Steel Cylinder

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

7 |

Eco-Response |

Advanced control |

|

Intelligent heating technology |

heating systems |

|

|

|

|

|

|

|

“Eco-Response offers advanced electric heating for the future, challenging expected norms with superior efficiency and controllability. ”

Warmth where it's needed, when it's needed...

in a single room or across the house. A constant low level of background heat prevents the fabric of the building from cooling. On demand, this fast-acting appliance raises the temperature to meet your needs, providing total control and the peace of mind that comes with low running costs.

Key features

•Economical use of energy utilising the best of stored and direct acting heating technologies

•Contemporary design - looks good in any home

•Unobtrusive - takes up no more space than a traditional wet radiator

Stored heat - maintains low level background heat to keep the fabric of the building warm, utilising economy off-peak electricity

Simple integral control on top of the heater - allows easy adjustment to achieve the user’s preferred comfort temperature

Radiant heat - rapidly raises temperature to required comfort level on demand

PART L and SAP 2005

The Creda Eco-Response has been developed to help meet the needs of Part L 2006 Building Regulations and provides enhanced SAP scores.

Specifiers will benefit from the ‘integrated storage/direct acting heater’ category within table 4a of SAP 2005 which rewards the enhanced controllability of Eco-Response with a 100% efficiency rating, placing this leading technology in heating type 2 with a responsiveness weighting of 0.75.

•One-touch electronic controls with child lock facility

•Simple ‘+ or -’ touch temperature control for accuracy and flexibility

•Rapid response to changing temperature demands

•Pre-wired with 2 x 1.6 metre lengths of cable for storage and direct acting power supplies - for ease of connection

•Designed for rapid assembly to keep installation costs down

•Requires no annual maintenance

•Optional central controller for 4 zone pilot wire linked heating system

300kg saving

Average carbon saving of up to 300kg per annum when compared to auto slimline storage heaters*

*Based on a semi-detached house with a floorspace of 130m2

Product Selector

Model |

Reference |

Nominal |

Charge |

Input Rating |

Input Rating |

Number |

Number |

Weight |

|

|

Output |

Acceptance |

(Off Peak) |

(Radiant Elt.) |

of Elements |

of Bricks |

|

ER300 |

75 773301 |

0.7kW |

9.1kWh |

1.3kW |

0.28kW |

2 |

8 |

65kg |

ER400 |

75 773302 |

1.1kW |

13.65kWh |

1.95kW |

0.34kW |

3 |

12 |

94kg |

ER500 |

75 773303 |

1.5kW |

18.2kWh |

2.6kW |

0.39kW |

4 |

16 |

124kg |

|

|

|

|

|

|

|

||

PW E4ZC |

75 770916 |

4 zone pilot wire central controller |

|

|

|

|

||

8 |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

Eco-Response |

Advanced control |

Storage radiant heaters |

heating systems |

Conventional heater |

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

With a conventional ‘wet’ |

The building shell has |

This takes time and |

|||||||||

heating system, when |

to then be warmed |

energy - slow response. |

|||||||||

heating goes off, |

again before room |

|

|

|

|

|

|||||

building shell cools. |

feels comfortable. |

|

|

|

|

|

|||||

Eco-Response |

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

It is smarter to |

|

The room temperature |

|

|

|

|

|||

|

|

Economical. |

|||||||

|

|

||||||||

maintain low level |

|

can be raised quickly |

|

Responsive. |

|||||

background heat. |

|

and efficiently when |

|

Intelligent. |

|||||

|

|

needed. |

|

|

|

|

|||

Control options

4 zone pilot wire central controller

Allows 7 day programming of comfort/setback time settings of multiple pilot wire linked heaters in up to 4 separate zones.

Ref: 75 770916

Technical Specification

•Elements (Storage) - 650W incoloy sheathed, mineral filled elements

•Element (Direct Acting) - cable-on-foil thin facia panel

•Thermostat (Input) - integral electronic charge limiter Maximum core temperature 670oC/690oC at full charge

•Thermostat (Output) - integral electronic thermostat with child lock facility

•Thermal Insulation - Carbowool 128kg/m2, Microtherm G and calcium silicate

•Energy Retention Cells - high density bonded magnetite

•Protection (Storage) - automatic reset core limit thermostat and manual over-temperature cut out

•Protection (Direct Acting) - automatic reset limit thermostat and automatic reset over-temperature cut out

•Finish - white polyester and zinc coated steel with grey base

•Cable (Storage) - 1.6m 2.5mm2 3 core

•Cable (Direct Acting) - 1.6m 0.75mm2 2 core

•Supply - 230/240V AC single phase

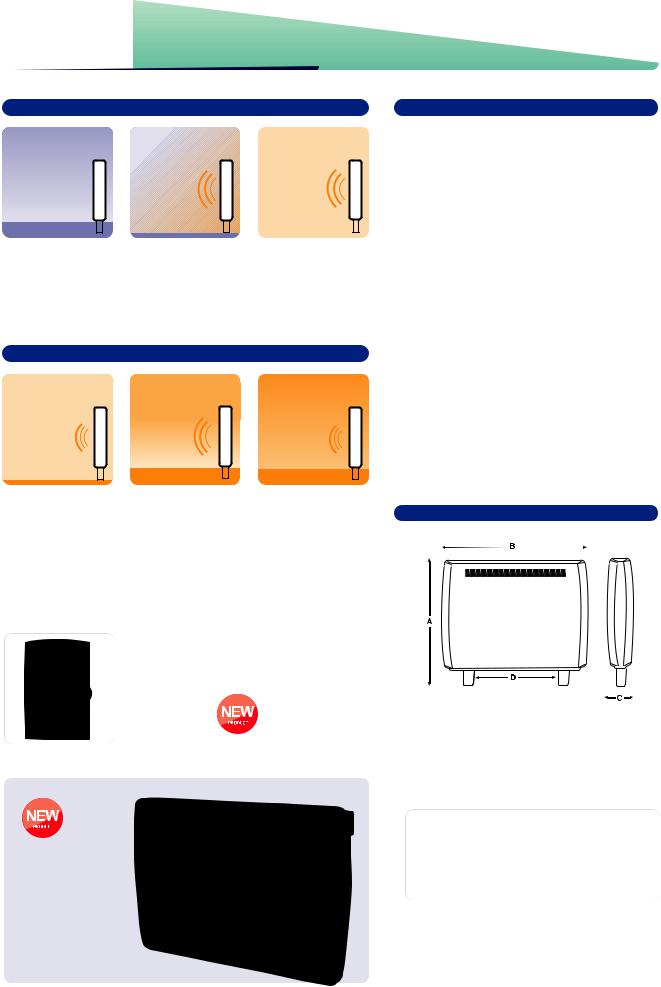

Dimensions

Model |

Height A |

Width B |

Depth C |

Feet Position D |

|

|

|

|

|

ER300 |

712mm |

600mm |

130mm+10mm |

295mm |

|

|

|

|

|

ER400 |

712mm |

830mm |

130mm+10mm |

523mm |

|

|

|

|

|

ER500 |

712mm |

1060mm |

130mm+10mm |

751mm |

|

|

|

|

|

Matching TPRIII E Electronic panel heaters also available for pilot wire linked heating systems (See page 12-13).

Minimum clearance required

•75mm either side of heater

•150mm in front of the heater

•250mm directly above the heater

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

9 |

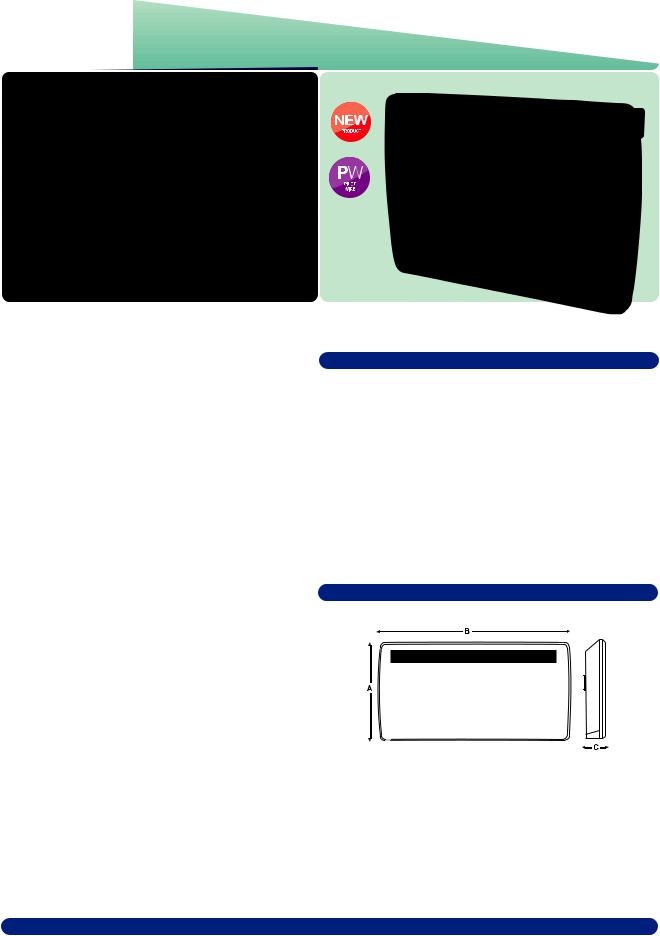

Contour100

Electronic panel heater

“The all new Contour100 panel heater range offers high quality build and panel finish with contemporary radiator styling.”

Contour100 panel heaters incorporate electronic thermostatic controls which allow very precise regulation of room temperatures.

Key features

•Contemporary radiator styling

•Electronic thermostatic control, accurate to +/-0.3OC

•Convected heat for rapid warm up

•Silent operation

•Pre-set background temperature at 5OC below thermostat setting (when connected to a programming unit supporting setback feature)

•IPX4 rated (splashproof)

•Being electronic, control is totally silent and reliable

•Hidden thermostat range limiter feature - for additional economy

•Range of optional plug-in electronic timer modules, including:

-24 hour digital timer

-Single zone 7 day pilot wire programmer

-Runback timer

•Compatible with Creda 4 zone pilot wire central controller

Advanced control heating systems

Technical Specification

•Elements - finned, mineral-filled sheath type

•Thermostat - electronic with 5ºC setback control capability

•Finish - white powder coated steel and thermoplastic

•Protection - auto reset thermal cutout

•Cable - 1.2 metres, 4 core (live, neutral, pilot and earth)

•IP rating - IPX4 (splashproof)

•Supply - 230/240V AC single phase

Dimensions

Product Selector

Model |

Reference |

Rating |

Height A |

Width B |

Depth C |

Weight |

CEP 500E |

75 775101 |

0.5kW |

536mm |

503mm |

104mm |

12kg |

CEP 750E |

75 775102 |

0.75kW |

536mm |

503mm |

104mm |

12kg |

CEP 1000E |

75 775103 |

1kW |

536mm |

671mm |

104mm |

15kg |

CEP 1500E |

75 775104 |

1.5kW |

536mm |

741mm |

104mm |

17.5kg |

CEP 2000E |

75 775105 |

2kW |

536mm |

911mm |

104mm |

22kg |

10 |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

Contour100 |

Advanced control |

Electronic panel heater |

heating systems |

Contour100 Electronic panel features |

Control options |

||

|

A range of optional plug-in control modules, which can be |

||

|

removed from the heater for easy programming, provide the |

||

|

flexibility for TPRIII to meet a wide range of control specifications: |

||

|

|

|

|

|

|

|

|

•High quality build and panel finish

•Forward angled facing grille to assist heat circulation

•Electronic thermostat for accuracy

+2OC |

|

|

|

MECHANICAL |

ELECTRONIC |

|

|

|

|

||||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

THERMOSTATS |

THERMOSTATS |

|

|

|

|

|

||

+1OC |

|

|

|

|

MAY OVERSHOOT |

ARE ACCURATE |

|

|

|

|

|||

+0.3OC |

|

|

|

BY UP TO 2OC |

TO ±0.3OC |

|

|

|

|

||||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

-0.3OC |

|

|

|

SET TEMPERATURE |

||

|

|

|

|

|

||

-1OC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-2OC

Both Contour100 and TPRIII E electronic panel heaters feature highly accurate electronic thermostats (+/-0.3OC), providing superior comfort and operating efficiency.

As the room temperature nears the desired set point, power to the elements is reduced. The room temperature is closely monitored to an accuracy of less than 0.3ºC, minimising overshoot and temperature drift, resulting in better energy efficiency and user comfort.

Control options

4 zone pilot wire central controller

Allows 7 day programming of comfort/setback time settings of multiple pilot wire linked heaters in up to 4 separate zones (see page 20).

• TPR E24T 24 hour digital timer. Provides 24 hour programmable on/off control

•TPR E7DT single zone, pilot wire programmer controls up to 10 slave heaters. Provides 7 day programmable on/off control

•TPR ERBT runback timer. Provides installer programmable runback time up to 4 hours (in 30 minute increments). Can be locked into heater

Dimensions

4 zone pilot wire controller |

Plug-in timer module |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Selector

Model |

Reference |

Product Description |

Height A |

Width B |

Depth C |

TPR E24T |

75 770912 |

24 hour plug-in timer module |

50mm |

70mm |

145mm |

TPR E7DT |

75 770913 |

7 day single zone plug-in timer module |

50mm |

70mm |

145mm |

TPR ERBT |

75 770914 |

4 hour run back timer plug-in module |

50mm |

70mm |

145mm |

PW E16A |

75 770915 |

16 amp pilot wire interface unit |

86mm |

86mm |

22mm |

PW E4ZC |

75 770916 |

4 zone pilot wire central controller |

132mm |

86mm |

38mm |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

11 |

TPRIII E

Electronic pilot plus panel heaters

“The TPRIII Electronic pilot plus panel heater range - unites smooth styling with superior control performance options

to give flexible heating solutions. ”

TPRIII Electronic pilot plus panel heaters incorporate electronic thermostatic controls to allow precise regulation of room temperatures - essential when comfort,

economy and energy efficiency need to be considered in equal measure. To meet the needs of most applications the TPRIII Electronic pilot plus panel heaters can also be controlled by a new range of plug-in timers or by pilot wired signalling from a 4 zone pilot wire central controller.

Key features

•Front facing grille for best possible heat projection

•Styling to complement Eco-Response radiators with pure white finish

•Electronic thermostatic control - +/-0.3ºC, completely silent operation

•Pre-set background temperature at 5ºC below thermostat setting (when connected to a programming unit supporting setback feature)

•Optional plug-in electronic timer modules, including:

-24 hour digital timer

-Single-zone pilot wire programmer

-Runback timer

•Compatible with Creda 4 zone, wall mounted pilot wire signalling multi-heater programmers

•IPX4 rated (splashproof)

•Hidden thermostat range limiter feature - for additional economy

•Simple detachable wall bracket for easy installation

Advanced control heating systems

Technical Specification

•Element - finned, mineral-filled sheathed type

•Thermostat - electronic with fixed 5ºC setback facility

•Finish - white powder coated steel and thermoplastic

•Protection - auto reset thermal cut-out

•IP rating - IPX4 (splashproof)

•Cable - 1.2 metres, 4 core cable (live, neutral, pilot and earth)

•Supply - 230/240V AC single phase

Dimensions

Product Selector

Model |

Reference |

Loading |

Height A |

Width B |

Depth C |

Weight |

TPRIII 500E |

75774440 |

0.5kW |

430mm |

450mm |

108mm |

5.2kg |

TPRIII 750E |

75774441 |

0.75kW |

430mm |

620mm |

108mm |

6.6kg |

TPRIII 1000E |

75774442 |

1kW |

430mm |

620mm |

108mm |

6.6kg |

TPRIII 1250E |

75774443 |

1.25kW |

430mm |

690mm |

108mm |

7.1kg |

TPRIII 1500E |

75774444 |

1.5kW |

430mm |

690mm |

108mm |

7.1kg |

TPRIII 2000E |

75774445 |

2kW |

430mm |

860mm |

108mm |

8.5kg |

12 |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

TPRIII E |

Advanced control |

Electronic pilot plus range controls |

heating systems |

TPRIII E Electronic rotary thermostat |

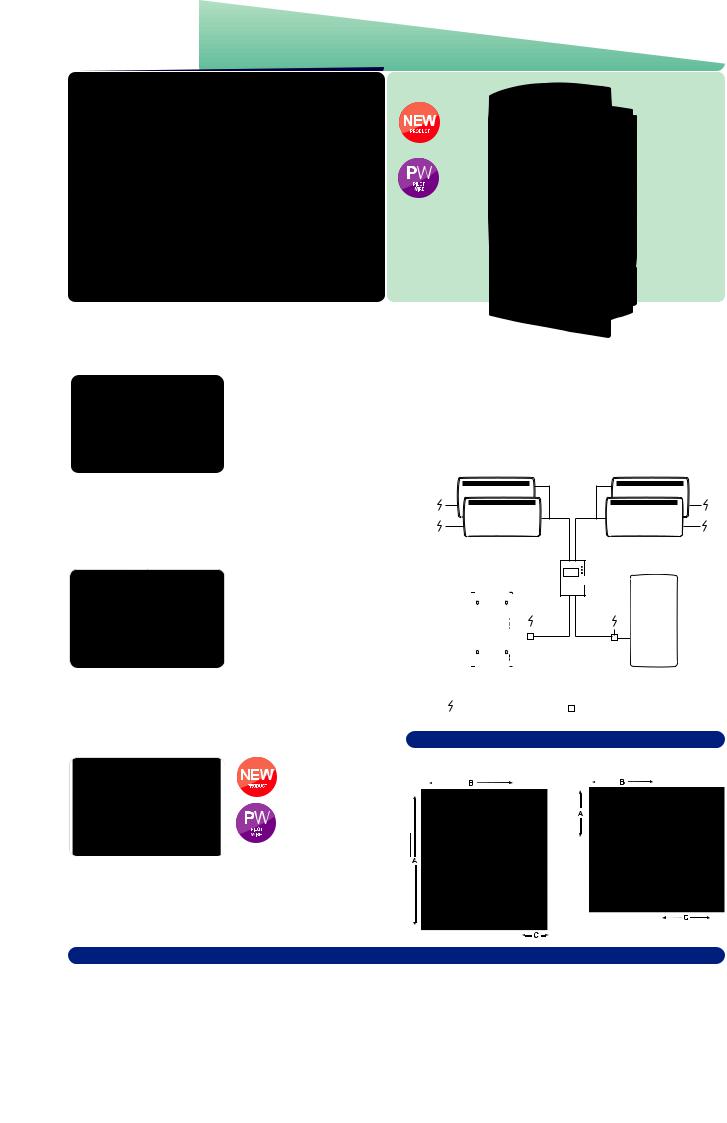

Pilot wire heating system |

|

|

|

The PW E4ZC central controller allows 7 day programming for comfort and setback |

|

|

|

|

|

temperature periods of multiple pilot wire linked heaters in up to four separate zones. |

|

|

• 4 Separate heating zones |

|

|

• Heater modes - Comfort/Setback, Comfort/Frost or Comfort/Off |

|

|

• Wall mounted mains powered controller with capacitor back up (approx. 4 hrs) |

|

|

|

Improved economy may be achieved by limiting the thermostat rotational range, by means of the mechanical ‘peg and hole’ feature hidden beneath a removable cap on the thermostat knob.

Zone 1 |

Zone 2 |

Control Options

TPRIII E Electronic panel heaters will accept the same range of plug-in timer modules as Contour100 electronic panel heaters (featured on page 11).

Pilot wire auxiliary interface unit

The PW E16A pilot wire auxiliary interface unit enables heaters without electronic controls to be central programmed, for on/off time periods only, as part of a pilot wire linked heating system.

(Max. 3kW. Requires a 38mm deep metal box or surface patress).

Product Selector

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Zone 3 |

|

|

|

|

|

|

|

Zone 4 |

||||||

|

240v mains supply |

|

|

|

|

PW E16A Interface unit |

|||||||||||

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|||||||||||||

Dimensions |

|

|

|

|

|

|

|

|

|||||||||

4 zone pilot wire controller |

|

|

Plug-in timer module |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

Reference |

Product Description |

Height A |

Width B |

Depth C |

TPR E24T |

75 770912 |

24 hour plug-in timer module |

50mm |

70mm |

145mm |

TPR E7DT |

75 770913 |

7 day single zone plug-in timer module |

50mm |

70mm |

145mm |

TPR ERBT |

75 770914 |

4 hour run back timer plug-in module |

50mm |

70mm |

145mm |

PW E16A |

75 770915 |

16 amp pilot wire interface unit |

86mm |

86mm |

22mm |

PW E4ZC |

75 770916 |

4 zone pilot wire central controller |

132mm |

86mm |

38mm |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

13 |

TPRIII M / MT

Mechanical thermostatic panel heaters

“TPRIII mechanical thermostat panel heaters offer a versatile choice of models with built-in timer options or panels with no controls at all. ”

Popular with specifiers and contractors to complement Creda electric storage heaters, TPRIII mechanical thermostatic panels are most commonly used to warm bedrooms, bathrooms, kitchens and other areas which only require heating for short periods of the day. Cost effective, they offer an efficient way to extend an existing heating system. The ranges come with control options to fulfil the widest range of applications, from single room background heating through to commercial applications.

Key features

•TPRIII (MT) models have programmable 24 hour timers

•TPRIII (MT7) model has a programmable 7 day timer

•TPRIII (NC) models with no built-in controls

•Full or half power output selection on thermostatic models

•Adjustable thermostat (5-30OC) on thermostatic models

•Convected heat for rapid warm-up. Suitable for domestic or commercial use

•IPX4 rated (splashproof)

Advanced control heating systems

•Frost protection setting on thermostatic models

•2kW model available with 7 day timer

•Front heat outlet grille for efficient heat circulation

•Lockable dust cover (on thermostatic models)

•Detachable hinged wall mounting bracket for fast installation and easy cleaning

Technical Specification

•Element - mineral-filled sheathed type

•Thermostat - capillary type (MT models only)

•Finish - white powder coated steel

•Protection - auto reset thermal cut-out

•IP rating - IPX4 (splashproof)

•Supply - 230/240V AC single phase

Dimensions

Product Selector

Model |

Reference |

Loading |

Height A |

Width B |

Depth C |

Weight |

Thermostat only models |

|

|

|

|

|

|

TPRIII 500M |

75 774440 |

0.5kW |

430mm |

450mm |

108mm |

4.8kg |

TPRIII 750M |

75 774401 |

0.75kW |

430mm |

620mm |

108mm |

6.2kg |

TPRIII 1000M |

75 774402 |

1kW |

430mm |

620mm |

108mm |

6.2kg |

TPRIII 1250M |

75 774403 |

1.25kW |

430mm |

690mm |

108mm |

6.6kg |

TPRIII 1500M |

75 774404 |

1.5kW |

430mm |

690mm |

108mm |

6.6kg |

TPRIII 2000M |

75 774405 |

2.kW |

430mm |

860mm |

108mm |

8.0kg |

Timer models 24hr |

|

|

|

|

|

|

TPRIII 500MT |

75 774410 |

0.5kW |

430mm |

450mm |

108mm |

4.8kg |

TPRIII 750MT |

75 774411 |

0.75kW |

430mm |

620mm |

108mm |

6.2kg |

TPRIII 1000MT |

75 774412 |

1.kW |

430mm |

620mm |

108mm |

6.2kg |

TPRIII 1250MT |

75 774413 |

1.25kW |

430mm |

690mm |

108mm |

6.6kg |

TPRIII 1500MT |

75 774414 |

1.5kW |

430mm |

690mm |

108mm |

6.6kg |

TPRIII 2000MT |

75 774415 |

2.kW |

430mm |

860mm |

108mm |

8.0kg |

Timer model 7 day |

|

|

|

|

|

|

TPRIII 2000MT7 |

75 774435 |

2.kW |

430mm |

860mm |

108mm |

8.0kg |

14 |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

TPRIII NC |

Advanced control |

|

‘No controls panel heaters’ |

heating systems |

|

|

|

|

|

|

|

TPRIII Thermostatic panel heater ranges |

TPRIII No controls panel heater range |

TPRIII M mechanical thermostat without timer (500W - 2000W models).

TPRIII NC a range of panel heaters without any integral controls for use in applications where external control of temperature and time programming is required.

Technical Specification

• Element - mineral-filled sheathed type

• Finish - white powder coated steel

• Protection - auto reset thermal cut-out

• IP rating - IPX4 (splashproof)

• Supply - 230/240V AC single phase

TPRIII MT mechanical thermostat with 24hr timer (500W - 2000W models).

Dimensions

TPRIII MT7 mechanical thermostat with 7 day timer (available in 2000W model only).

Product Selector

Model |

Reference |

Loading |

Height A |

Width B |

Depth C |

Weight |

No controls models |

|

|

|

|

|

|

TPRIII 500NC |

75 774300 |

0.5kW |

430mm |

450mm |

108mm |

4.8kg |

TPRIII 750NC |

75 774301 |

0.75kW |

430mm |

620mm |

108mm |

6.2kg |

TPRIII 1000NC |

75 774302 |

1kW |

430mm |

620mm |

108mm |

6.2kg |

TPRIII 1250NC |

75 774303 |

1.25kW |

430mm |

690mm |

108mm |

6.6kg |

TPRIII 1500NC |

75 774304 |

1.5kW |

430mm |

690mm |

108mm |

6.6kg |

TPRIII 2000NC |

75 774305 |

2kW |

430mm |

860mm |

108mm |

8.0kg |

+44 (0) 1733 456789 |

www.creda-heating.co.uk |

15 |

Loading...

Loading...