Craftsman 13953920DM Owner’s Manual

Owner's Manual/ManualDel Propietario

CRRFTSMRN°[

1/2 HP

315MHz GARAGEDOOROPENER

ABRIDORDEPUERTADECOCHERADE

ForResidentialUseOnly/S61opara usoresidencial

Model/Modelo• 139.53920DM

_315MHz

I"I'1

z

Readandfollowall safetyrulesand

operatinginstructionsbeforefirstuseof

thisproduct.

Fastenthe manualnearthe garagedoor

afterinstallation.

Periodic checksof theopenerarerequired

to ensuresafeoperation.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

www.sears.com/craftsman

Leeryseguirtodaslasreglasdeseguridad

y lasinstruccionesde operaci6nantesde

usaresteproductoporprimeravez.

Guardarestemanualcercade la puerta de

la cochera.

Se debenrealizarrevisionesperi6dicas del

abridorde puertas para asegurarsu

operaci6n segura.

I'll

"o

z_

0

TABLE OF CONTENTS

Introduction 2-7

Safetysymbol andsignal word review ..................... 2

Preparingyour garagedoor ............................. 3

Tools needed......................................... 3

Planning 4-5

Carton inventory ...................................... 6

Hardware inventory.................................... 7

Assembly 8-11

Assemblethe railand install thetrolley ..................... 8

Fastenthe railto the motor unit and

install the idler pulley .................................. 9

Install the chain/cable................................. 10

Tighten the chain .................................... 11

Installation 11-26

Installation safetyinstructions .......................... 11

Determinethe headerbracket location .................... 12

Install the headerbracket .............................. 13

Attachthe rail to the headerbracket ...................... 14

Position theopener................................... 15

Hangthe opener..................................... 16

Install the door control ................................ 17

Install the lights ..................................... 18

Attachthe emergency releaseropeand handle.............. 18

Electricalrequirements ................................ 19

Install The Protector System®........................ 20-22

Fastenthe door bracket............................. 23-24

Connectthe door arm to the trolley ................... 25-26

Adjustment 27-29

Adjust thetravel limits ................................ 27

Adjust theforce...................................... 28

Testthe safety reversalsystem.......................... 29

TestThe Protector System®............................ 29

Operation 30-34

Operationsafety instructions ........................... 30

Usingyour garagedoor opener ......................... 30

Usingthe wall-mounted door control ..................... 31

To open thedoor manually............................. 31

Careof your garagedoor opener ........................ 32

Havinga problem? ................................... 33

Diagnosticchart ..................................... 34

Programming 35-36

To add or reprogram ahand-heldremotecontrol ............ 35

To erase all codes.................................... 35

3-Function Remotes.................................. 35

To add, reprogram or change a KeylessEntry PIN ........... 36

Repair Parts 37-38

Railassembly parts................................... 37

Installation parts ..................................... 37

Motor unit assembly parts ............................. 38

Accessories 39

Warranty

RepairPartsandService

Back cover

39

INTRODUCTION

SafetySymbolandSignalWordReview

This garage door opener has beendesigned and testedto offer safe serviceprovided it is installed,operated, maintained andtested in

strict accordancewith the instructions and warnings containedinthis manual.

Whenyou seethese Safety Symbols andSignal Words on the

following pages,they will alert you to the possibility of serious

Mechanical

Electrical

injury or deathif you do not comply with the warnings that

accompanythem. Thehazardmay comefrom something

mechanicalor from electric shock.Readthe warnings carefully.

Whenyou seethis SignalWord on thefollowing pages,it will

alertyou to the possibility of damageto your garagedoor and/or

the garage dooropener if you do not comply with the cautionary

statementsthat accompanyit. Readthem carefully.

Preparingyourgaragedoor

Beforeyou begin:

• Disablelocks.

• Removeany ropesconnectedto garagedoor.

• Completethe followingtestto makesureyour garagedoor is

balancedand isnot sticking or binding:

1. Lift the door abouthalfwayas shown. Releasethe door.

If balanced, it should stay in place,supported entirely by its

springs.

2. Raiseand lowerthe door to seeif there is any binding or

sticking.

If your door binds, sticks, or is out of balance,call a trained door

systems technician.

To prevent possibleSERIOUSINJURYor DEATH:

• ALWAYScall atrained door systems technician if garagedoor

binds, sticks,or is out of balance.Anunbalancedgaragedoor

may NOTreversewhen required.

• NEVERtry to loosen, move or adjust garagedoor, door

springs, cables, pulleys,brackets or their hardware,ALLof

which areunderEXTREMEtension.

• DisableALL locksand removeALL ropesconnectedto garage

door BEFOREinstalling and operatinggaragedoor openerto

avoid entanglement.

To preventdamageto garagedoorandopener:

• ALWAYSdisable locks BEFOREinstalling andoperating the

opener.

• ONLYoperate garage door opener at 120V,60 Hzto avoid

malfunction anddamage.

SectionalDoor

One-Piece Door

Drill

Tape Measure

Drill Bits_

3/16", 5/16"

and 5/32"

Toolsneeded

During assembly, installation and adjustment of the opener,

instructions will call for hand tools as illustrated below.

Pencil

Hack Saw

Claw Hammer

Wire Cutters

Stepladder

0

Pliers

Screwdriver

Adjustable EndWrench

P_nnmg

Identify the typeand height of your garagedoor. Surveyyour

garageareato see if anyof the conditions below applyto your

installation. Additional materials may be required.You mayfind it

helpfulto refer backto this pageandthe accompanying

illustrations asyou proceedwith the installation ofyour opener.

Dependingon your requirements,there areseveralinstallation

steps which may call for materialsor hardwarenot included in the

carton.

• Installation Step 1- Look at the wall or ceiling abovethe garage

door. Theheaderbracketmust besecurelyfastenedto

structural supports.

• Installation Step 5- Do you have afinished ceiling in your

garage? If so,a support bracketand additional fastening

hardwaremay berequired.

• Installation Step 10- Dependingupon garageconstruction,

extension bracketsor wood blocks may be neededto install

sensors.

• Installation Step 10- Alternate floor mounting of the safety

reversing sensorwill require hardware not provided.

Doyou havean accessdoor in addition to the garagedoor?

If not, Model 53702 EmergencyKeyReleaseis required.See

Accessoriespage.

Look at the garagedoor where it meetsthe floor. Any gap

betweenthefloor andthe bottom of the door must not exceed

1/4" (6 mm). Otherwise,the safety reversalsystem maynot

work properly.SeeAdjustment Step3. Floor or door should be

repaired.

SECTIONALDOORINSTALLATIONS

• Doyou havea steel, aluminum, fiberglass orglass paneldoor?

If so,horizontal andvertical reinforcement is required

(Installation Step11).

• Theopenershould be installed abovethe centerof the door.

If there isa torsion spring or center bearing platein theway of

the headerbracket,it may be installed within 4 feet (1.22 m) to

the left or right of the door center.SeeInstallation Steps1

and 11.

• If your door is more than 7 feet (2.13 m) high,see rail extension

kits listed on Accessories page.

SECTIONALDOORINSTALLATION

Horizontal and vertical reinforcement is

neededfor lightweight garage doors

(fiberglass, steel,aluminum, door with

glass panels, etc.). See page 23for details.

HeaderWall

Centerline

of Garage_

Door _z_

Gapbetween floor and

bottom of door must not

exceed 1/4" (6 mm).

Safety Reversing Sensor

Slack in chain tension

is normal when garage

door is closed.

Torsion Spring

Wall-mounted

Door Control

Safety

Reversing Sensor

Extension Spring

OR

Access

Door

FINISHEDCEILING

Support bracket&

fastening hardware

is required.

See page16.

O

Motor Unit

CLOSEDPOSITION

Header

Bracket Trolle

Garage

Door- /_/ E_ unam

I

ht_

_J Arm | j Emergency

__ Rope&Handle

\_1 P_ \ Curved

HI \ ' Door

__1 I_oor Arm

i

,_o°j/ _ .... _ ReleaSe..

ij Bracket

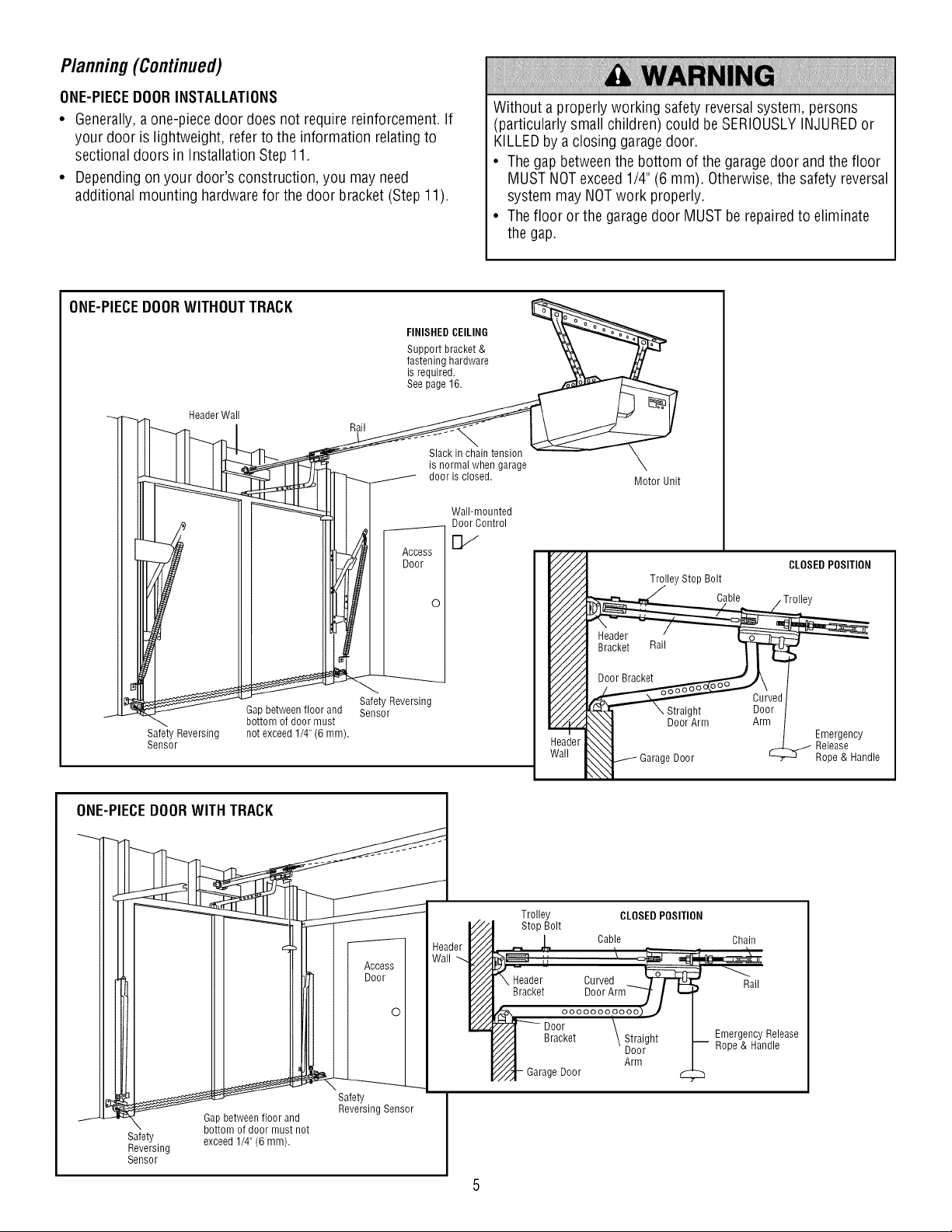

Planning(Continued)

ONE-PIECEDOORINSTALLATIONS

• Generally,a one-piece door does not requirereinforcement. If

your door is lightweight, refer to the information relatingto

sectional doors in Installation Step11.

• Dependingon your door's construction, you mayneed

additional mounting hardwarefor the door bracket (Step 11).

ONE-PIECEDOORWITHOUTTRACK

EINIS,EDCEILINO '&__

Support bracket& _

fastening hardware _

is required. _

See page 16. _ _.,_,_,_r /_,

_ Header Wall //I \ _ II

II1Ill I _ is_i_l_i_e;si_; e X

_ _ [_ ............. Motorunit

IIII o I _11 I _ _Wo1';_°_tnrtold

Without a properly working safetyreversalsystem, persons

(particularly small children) could be SERIOUSLYINJUREDor

KILLEDby a closing garagedoor.

• Thegap betweenthe bottom of the garagedoor and the floor

MUSTNOTexceed1/4"(6 mm). Otherwise,the safetyreversal

system may NOTwork properly.

• Thefloor orthe garagedoor MUSTberepairedto eliminate

the gap.

_ I II_iII I _oor I_ CLOSEDPOS,T,O.

IIIdl_ I Ill'Ill I I V/./_I T_,,eystopBo,t

• I IIIII_l I I o I V/./ _ Cab,eTro,,oy

oii,m!!!!

Sensor le

Trolley

Stop Bolt

_,, Cab!e L

_eader Curved_ W_

Bracket D00rArm7 / i._

_ ooooooooooo_J

p_- Door \

//_.._ Bracket \ Straight

////_ Door

//".-! Arm

Y_'/-_-Garage Door

CLOSEDPOSITION

Chain

) Rail

EmergencyRelease

-- Rope & Handle

I __ Safety. I

._J. _ 14_ GoatPtbetoWfe_nH f'^..oor°l_lru_dnot Reversing Sensor I

SaefveertYing exceed 1/4" (6 mnl). I

Sensor J

5

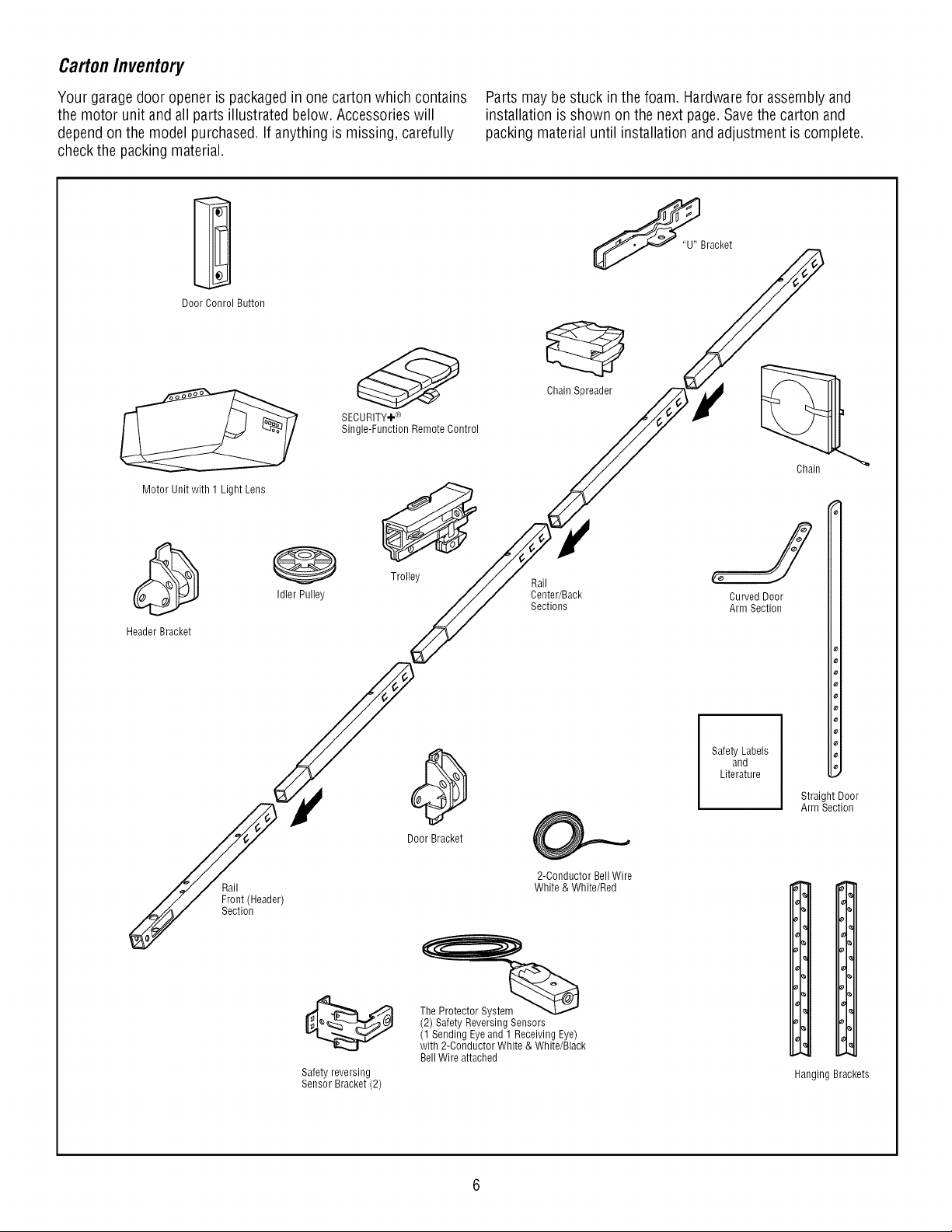

CartonInventory

Your garage door opener is packagedin onecarton which contains

the motor unit and allparts illustrated below.Accessorieswill

dependon the model purchased.If anything is missing, carefully

checkthe packingmaterial.

Door Conrol Button

SECURITY÷®

Single-Function Remote Control

Motor Unit with 1 Light Lens

Parts may be stuck in the foam. Hardwarefor assembly and

installation isshown onthe next page.Savethe carton and

packing material until installation andadjustment is complete.

Chain Spreader

Chain

Header Bracket

Rail

Front (Header)

Section

Idler Pulley

Safety reversing

Sensor Bracket (2)

Trolley

Door Bracket

The Protector Systerr_ _

(2) Safety Reversing Sensors

(1 Sending Eyeand 1 Receiving Eye)

with 2-Conductor White & White/Black

Bell Wire attached

Rail

Center/Back

Sections

2-Conductor BellWire

White & White/Red

Curved Door

Arm Section

Safety Labels

and

Literature

_'1

J

Straight Door

Arm Section

I,

1,

%

I.

%

_1°

Hanging Brackets

HardwareInventory

Separateall hardwareandgroup asshown below for the assembly and installation procedures.

ASSEMBLYHARDWARE

Lock Nut Washer 5/8" (2) Lock Washer Nut

1/4"-20 (2) 3/8" (1) 3/8" (1)

Bolt 1/4"-20xl-3/4" (1)

1

0

Bolt 1/4"-20x2-1/2 (1)

[o

)lii;)l)))i!))l!_)

Spacer (2)

Trolley Threaded Shaft (1)

i

Master

Link (2)

Idler Bolt(l)

Carriage Bolt

1/4"-20xl/2" (2)

Lag Screw

5/16"-9xl-5/8" (2)

111111111111_>

Lag Screw

5/16"-18xl-7/8" (2)

_ng Screw

1/4"-14x5/8" (2)

Wing Nut

1/4"-20 (2)

INSTALLATIONHARDWARE

© %

Ring Nut 5/16"-18 (6)

Fastener (3)

_llllllllll) _:_

Hex Bolt

5/16"-18x7/8" (4) Lock Washer 5/16" (5)

_lllllllllllllllllllllllll}

Screw

6ABx1-1/4" (2)

iiii_;i -h

III/HI

Drywall Anchors (2)

_ ifiii-fiiiiNfiiifii]iiiiii fiii';:>

Screw 6ABxl-1/2"

Lighted Door Control Button

Handle

Insulated

Staples (30)

111111111111111111111

Screw 6-32xl" (2)

Rope

ol

Clevis Pin Clevis Pin Clevis Pin

5/16"x1-1/2" (1) 5/16"x1" (1) 5/16"x1-1/4" (1)

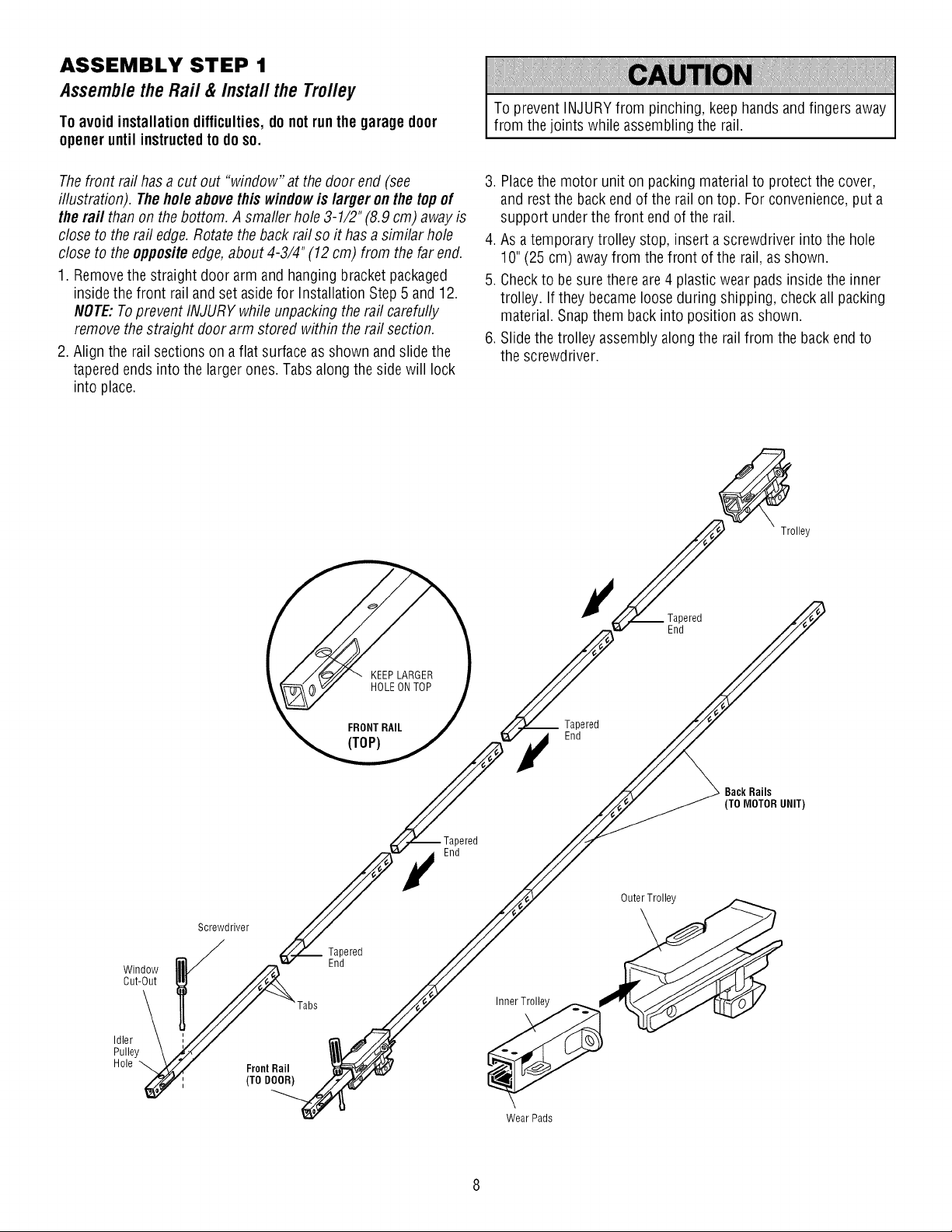

ASSEMBLY STEP 1

Assemble the Rail & Install the Trolley

To avoidinstallationdifficulties,donotrunthe garagedoor

openeruntil instructedtodo so.

To prevent INJURYfrom pinching, keephandsand fingers away

from thejoints while assemblingthe rail.

Thefront rafthas a cut out "window" at the door end (see

illustration). Theholeabovethis windowis larger onthe topof

the rail than on the bottom. Asmaller hole3-1/2" (8.9 cm) away is

close to therail edge.Rotatethe back rail soit hasasimilar hole

close to theoppositeedge,about 4-3/4" (12 cm) from the far end.

1. Removethe straight door arm andhangingbracket packaged

insidethe front rail and set aside for Installation Step 5and 12.

NOTE:Toprevent INJURYwhileunpacking therail carefully

removethe straight doorarm stored within the rail section.

2. Align the railsectionson aflat surface asshown and slidethe

taperedends into the largerones.Tabs along the sidewill lock

into place.

3. Placethe motor unit on packing materialto protect the cover,

and rest the backendof the rail on top. Forconvenience,put a

support underthe front end of the rail.

4.As atemporary trolley stop, insert ascrewdriver into the hole

10"(25 cm) awayfrom the front of the rail, asshown.

5. Checkto besure there are4 plasticwear pads insidethe inner

trolley. If they became loose during shipping, checkall packing

material.Snap themback into position asshown.

6. Slidethe trolley assembly along the railfrom the backendto

the screwdriver.

Trolley

)ered

End

Window

Cut-Out

Idler

Pulley

Hole

Screwdriver

FrontRail

(TO DOOR)

Tapered

End

End

Tapered

End

)ered

Inner Trolley __

Wear Pads

BackRails

(TO MOTORUNIT)

OuterTrolley

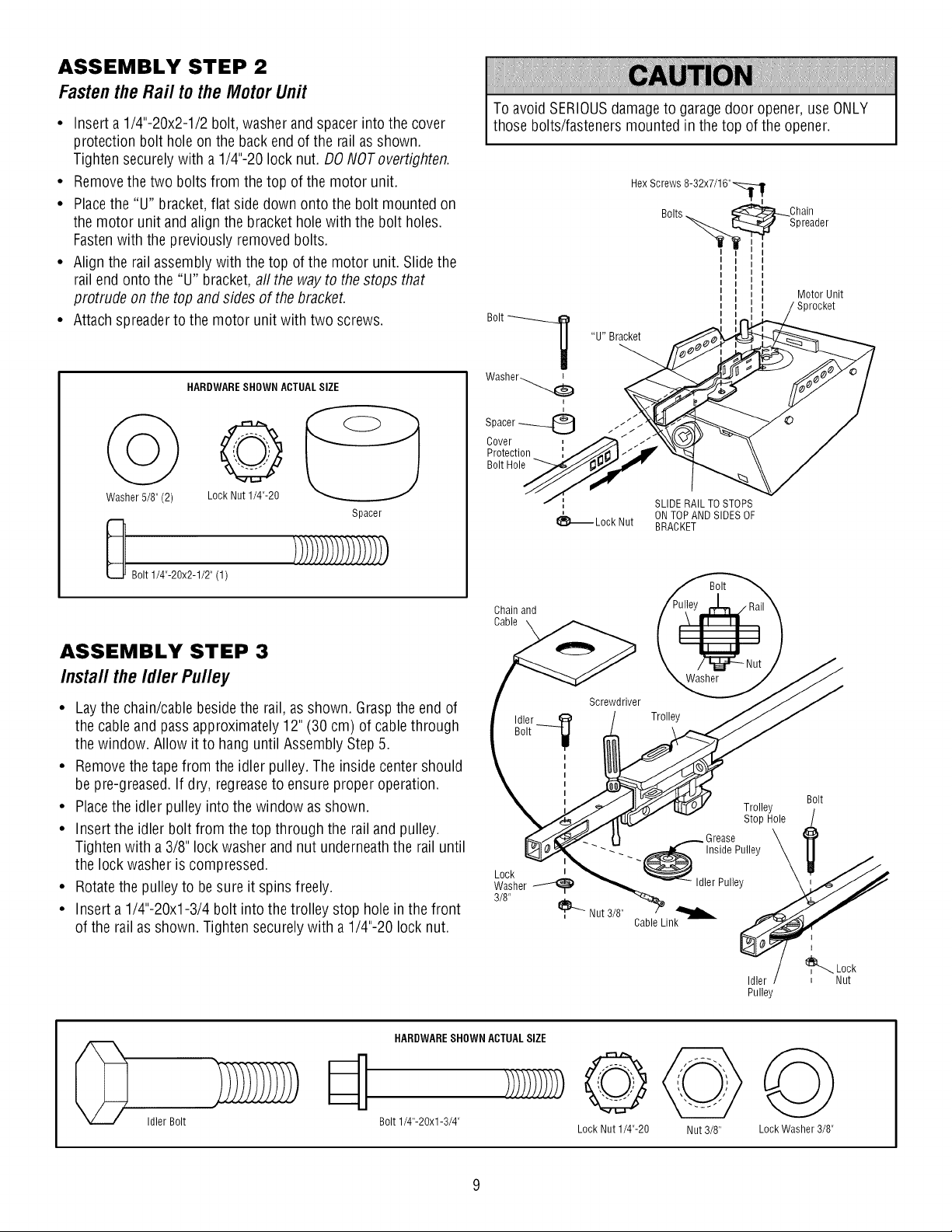

ASSEMBLY STEP 2

FastentheRail to theMotorUnit

• Inserta1/4"-20x2-1/2 bolt, washerandspacerintothe cover

protection bolt holeon the backendof the railasshown.

Tighten securelywith a 1/4"-20 locknut. DONOToverfighten.

• Removethe two bolts from the top of the motor unit.

• Placethe "U" bracket,flat side down onto the bolt mountedon

the motor unit and alignthe brackethole with the bolt holes.

Fastenwith the previously removed bolts.

• Align the rail assemblywith thetop of the motor unit. Slide the

rail end onto the "U" bracket, all the way to thestops that

protrude on the top and sides of thebracket.

• Attachspreader to the motor unit with two screws.

To avoid SERIOUSdamageto garagedoor opener,use ONLY

those bolts/fastenersmounted in the top of theopener.

Hex Screws 8-32x7/16"_,

Bolts_ _ _L_Ohain

-____. [::_:._ Spreader

I

Motor Unit

Sprocket

"U" Bracket

Bolt___

HARDWARESHOWN ACTUALSIZE

o@

Washer 5/8" (2)

Bolt 1/4"-20x2-1/2" (1)

ASSEMBLY STEP 3

Installthe IdlerPulley

• Laythe chain/cablebesidethe rail, as shown. Graspthe endof

the cable and pass approximately 12" (30 cm) of cable through

the window. Allow it to hanguntil Assembly Step 5.

• Removethe tape from the idler pulley.The inside centershould

be pre-greased. If dry, regreaseto ensureproper operation.

• Placethe idler pulleyinto the window as shown.

• Insertthe idler bolt from the top through the railandpulley.

Tighten with a3/8" lock washer and nut underneaththe rail until

the lock washer is compressed.

• Rotatethe pulley to besure it spins freely.

• Inserta 1/4"-20xl-3/4 bolt into the trolley stop holeinthe front

of the railasshown. Tightensecurelywith a 1/4"-20 lock nut.

LockNut1/4"-20

Spacer

Washer_

i

Spacer_

Cover

Protection

Bolt Hole

SLIDE RAIL TOSTOPS

1_ Lock Nut BRACKET

Chain and

Cable

Screwdriver

WasherL°Ck_ _ Idler Pulley

3/8" _, Nut 3/8"

ONTOPAND SIDES OF

Washer

Trolley

Grease

_ _ _ _ -Inside Pulley

Cable Link

Trolley

Stop Hole

Bolt

Idler Bolt

HARDWARESHOWN ACTUALSIZE

Bolt 1/4"-20xl-3/4"

@

Lock Nut 1/4"-20

Nut 3/8"

Idler

Pulley

Lock Washer 3/8"

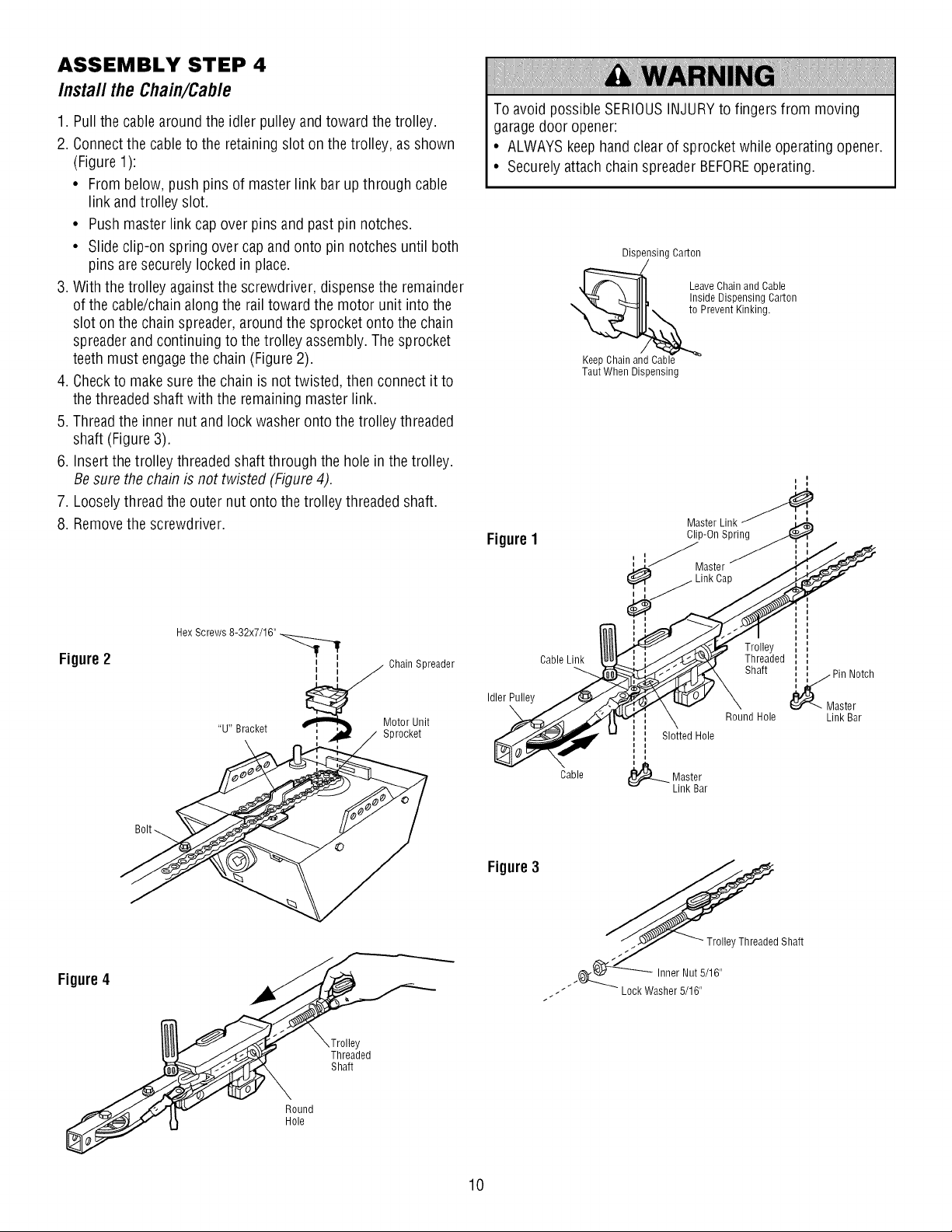

ASSEMBLY STEP 4

Install the Chain/Cable

1. Pull thecablearound the idler pulleyand toward the trolley.

2. Connectthe cableto the retainingslot on the trolley, asshown

(Figure1):

• From below, push pins of masterlink bar up through cable

link and trolley slot.

• Pushmaster link cap over pinsand pastpin notches.

• Slide clip-on spring over capandonto pin notches until both

pins aresecurely locked in place.

3. With thetrolley againstthe screwdriver, dispensethe remainder

of the cable/chainalong the railtoward the motor unit into the

slot onthe chain spreader, around the sprocketonto the chain

spreaderand continuingto thetrolley assembly.Thesprocket

teeth must engagethe chain (Figure2).

4. Checkto makesure the chain is nottwisted, then connect it to

thethreaded shaft with the remainingmaster link.

5. Threadthe inner nut andlock washer onto thetrolley threaded

shaft (Figure 3).

6. Insert thetrolley threadedshaft through the hole in thetrolley.

Be surethe chain is not twisted (Figure 4).

7. Looselythread the outer nut ontothe trolley threadedshaft.

8. Removethe screwdriver.

Figure2

Hex Screws 8-32x7/16"

Chain Spreader

Motor Unit

Sprocket

To avoid possibleSERIOUSINJURYto fingers from moving

garagedoor opener:

• ALWAYSkeephand clearof sprocket while operating opener.

• Securely attachchain spreaderBEFOREoperating.

Dispensing Carton

:_ Leave Chain and Cable

t_Cabl_e to Prevent Kinking.

Taut When Dispensing

FigureI

Inside Dispensing Carton

Master Link

Clip-On Spring

astor

®

I

II

/ II t

Cable Link__.

/_ Threaded : ',

Shaft _ Pin Notch

•" \ _ \ Er'---- Master

\ Round Hole Link Bar

', Slotted Hole

i

Figure4

Round

Hole

Y

Threaded

Shaft

Figure3

10

/

Cable

J

----- Lock Washer 5/16"

t

(_)-_ Master

Link Bar

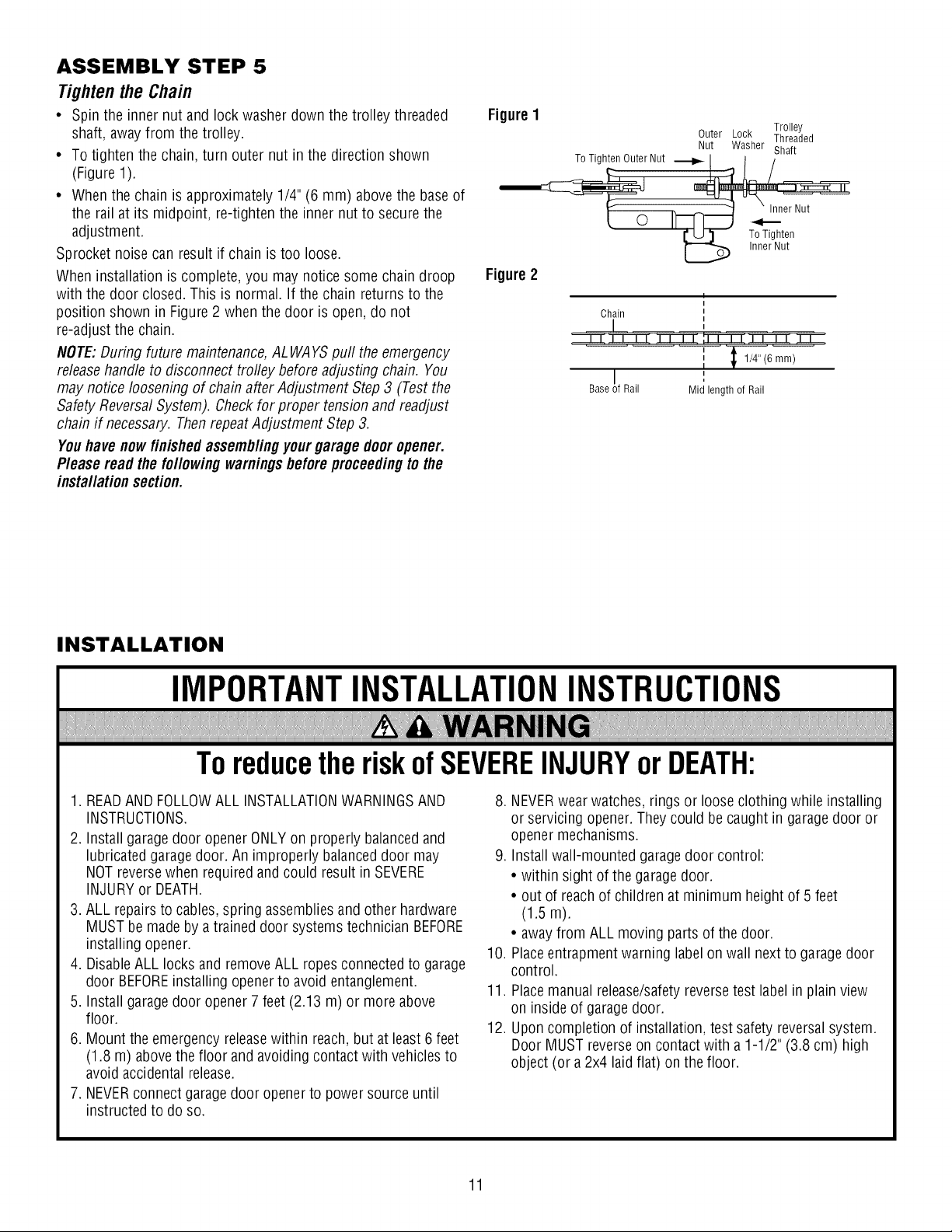

ASSEMBLY STEP 5

TightentheChain

• Spin the innernut andlockwasher down the trolley threaded

shaft, awayfrom the trolley.

• To tighten the chain,turn outer nut inthe direction shown

(Figure 1).

• Whenthe chain is approximately 1/4" (6 mm) abovethe base of

the rail at its midpoint, re-tightenthe inner nut to securethe

adjustment.

Sprocket noise can result if chain is too loose.

When installation is complete, you may noticesome chaindroop

with the door closed. This is normal. If the chain returns to the

position shown in Figure 2 when the door is open,do not

re-adjust the chain.

NOTE:During future maintenance,ALWAYSpuff the emergency

releasehandle todisconnect trofley beforeadjusting chain. You

may noticeloosening of chainafter Adjustment Step3 (Testthe

Safety ReversalSystem). Checkfor proper tension and readjust

chain if necessary. ThenrepeatAdjustment Step3.

Youhave nowfinishedassemblingyourgarage dooropener.

Please read thefollowingwarningsbeforeproceedingto the

installationsection.

Figure1

Figure2

To Tighten Outer Nut

Chain

Base Rail

Outer Lock Threaded

Nut Washer Shaft

I

Mid length of Rail

Trolley

Inner Nut

To Tighten

Inner Nut

1/4" (6 mm)

INSTALLATION

IMPORTANTINSTALLATIONINSTRUCTIONS

ToreducetheriskofSEVEREINJURYorDEATH:

1. READAND FOLLOWALL INSTALLATIONWARNINGSAND

INSTRUCTIONS.

2. Installgaragedoor openerONLYon properly balancedand

lubricated garage door. Animproperly balanceddoor may

NOTreversewhen requiredand could resultin SEVERE

INJURYor DEATH.

3. ALL repairsto cables, spring assembliesand other hardware

MUSTbe madeby a traineddoor systemstechnician BEFORE

installing opener.

4. DisableALL locks and removeALL ropesconnectedto garage

door BEFOREinstalling openerto avoid entanglement.

5. Install garagedoor opener7 feet (2.13 m) or more above

floor.

6. Mount the emergencyreleasewithin reach,but at least6feet

(1.8 m) abovethefloor and avoiding contactwith vehiclesto

avoid accidental release.

7. NEVERconnect garagedoor openerto power sourceuntil

instructed to do so.

8. NEVERwear watches,rings or looseclothing while installing

or servicing opener.They could be caughtin garagedoor or

opener mechanisms.

9. Installwall-mounted garagedoor control:

• within sight of the garage door.

• out of reachof children at minimum height of 5 feet

(1.5 m).

• awayfrom ALL moving parts of thedoor.

10. Placeentrapmentwarning labelon wall next to garagedoor

control.

11. Placemanual release/safetyreversetest labelin plainview

on inside of garagedoor.

12. Uponcompletion of installation,test safety reversalsystem.

Door MUST reverseon contact with a 1-1/2" (3.8 cm) high

object (or a2x4 laid flat) on the floor.

11

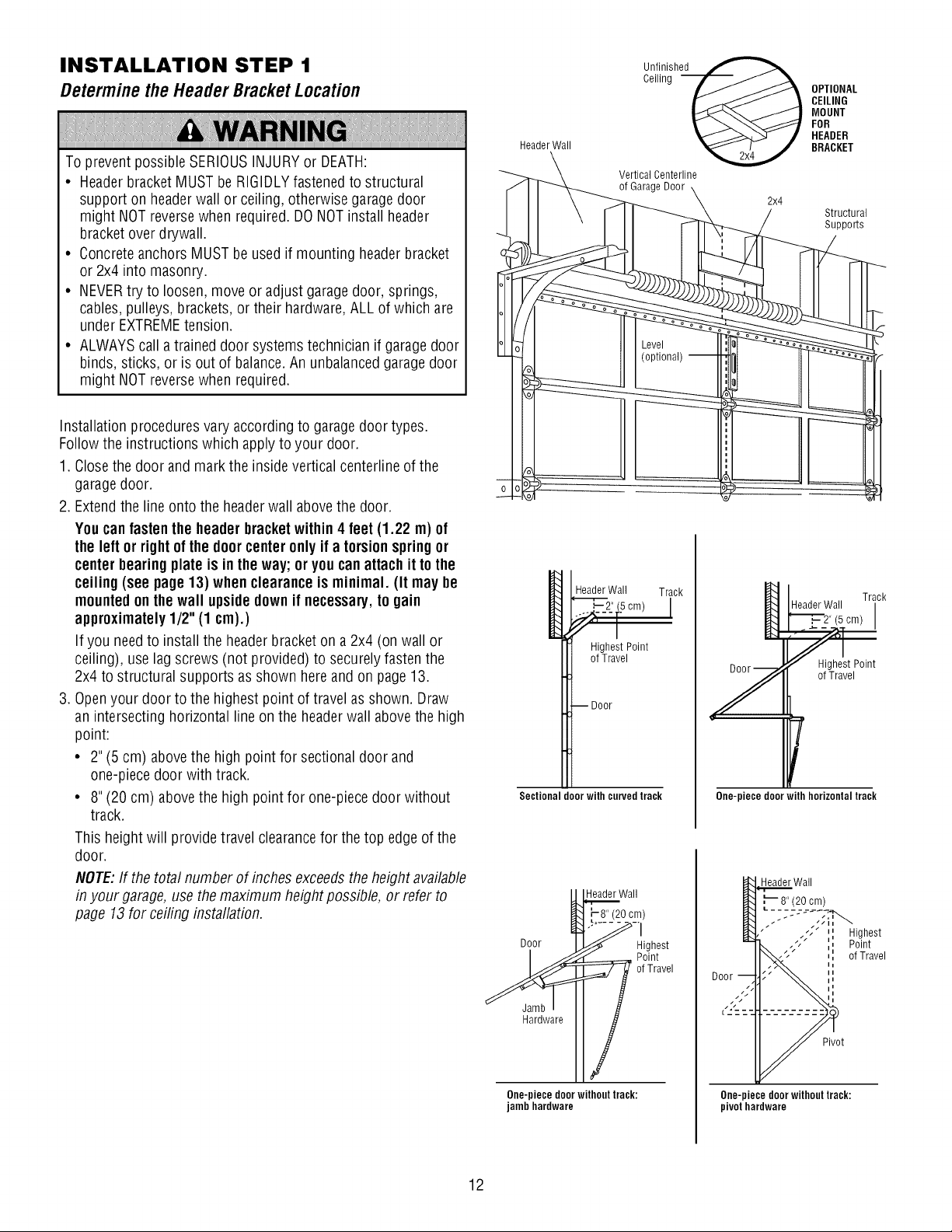

INSTALLATION STEP 1

DeterminetheHeaderBracketLocation

To prevent possibleSERIOUSINJURYor DEATH:

• Headerbracket MUSTbeRIGIDLYfastenedto structural

support on headerwall or ceiling,otherwise garagedoor

might NOTreversewhen required. DONOTinstall header

bracketover drywall.

• Concreteanchors MUST be usedif mounting headerbracket

or 2x4 into masonry.

• NEVERtry to loosen, move or adjust garagedoor, springs,

cables,pulleys, brackets,or their hardware,ALLof which are

under EXTREMEtension.

• ALWAYScall atraineddoor systems technician if garage door

binds, sticks,or is out of balance.Anunbalancedgarage door

might NOTreversewhen required.

Installation proceduresvaryaccording to garagedoor types.

Follow the instructions which applyto your door.

1. Closethe door and mark the insidevertical centerlineof the

garagedoor.

2. Extendthe line onto the headerwall abovethe door.

Youcanfastenthe headerbracketwithin4 feet (1.22 m) of

the left or rightof the doorcenteronlyif atorsionspringor

centerbearingplateis inthe way;or youcanattachit tothe

ceiling(see page13) whenclearance is minimal. (It may be

mountedonthe wall upsidedown if necessary,to gain

approximately1/2"(1 cm).)

If you needto installthe headerbracket ona 2x4 (on wall or

ceiling), uselag screws (not provided) to securelyfastenthe

2x4 to structural supports asshown here and on page 13.

3. Openyour door to the highest point of travelas shown. Draw

an intersecting horizontalline on the headerwall abovethe high

point:

• 2" (5 cm) abovethe high point for sectional door and

one-piecedoor with track.

• 8" (20 cm) abovethe high point for one-piecedoor without

track.

This height will provide travel clearancefor the top edge of the

door.

NOTE:If the totalnumber of inches exceedsthe height available

in your garage,usethe maximum height possible, or refer to

page 13for ceiling installation.

Header Wall

HeaderWall Track

Unifliinnghe_

Vertical Centerline

of GarageDoor

_2_" (.5cm)

<,[ i

HighestPoint

ofTravel

--Door

Sectional door with curved track

HeaderWall

-8" (20cm)

OPTIONAL

CEILING

MOUNT

FOR

HEADER

BRACKET

2x4

Structural

Suppo_s

HeaderWall

"_',_ 2" (5 cm)

_et Point

ofTravel

Y

r

One-piece doorwith horizontal track

Header Wall

Track

Hardware

One-piecedoorwithouttrack:

jambhardware

12

Highest

Point

of Travel

Pivot

One-piece doorwithout track:

pivot hardware

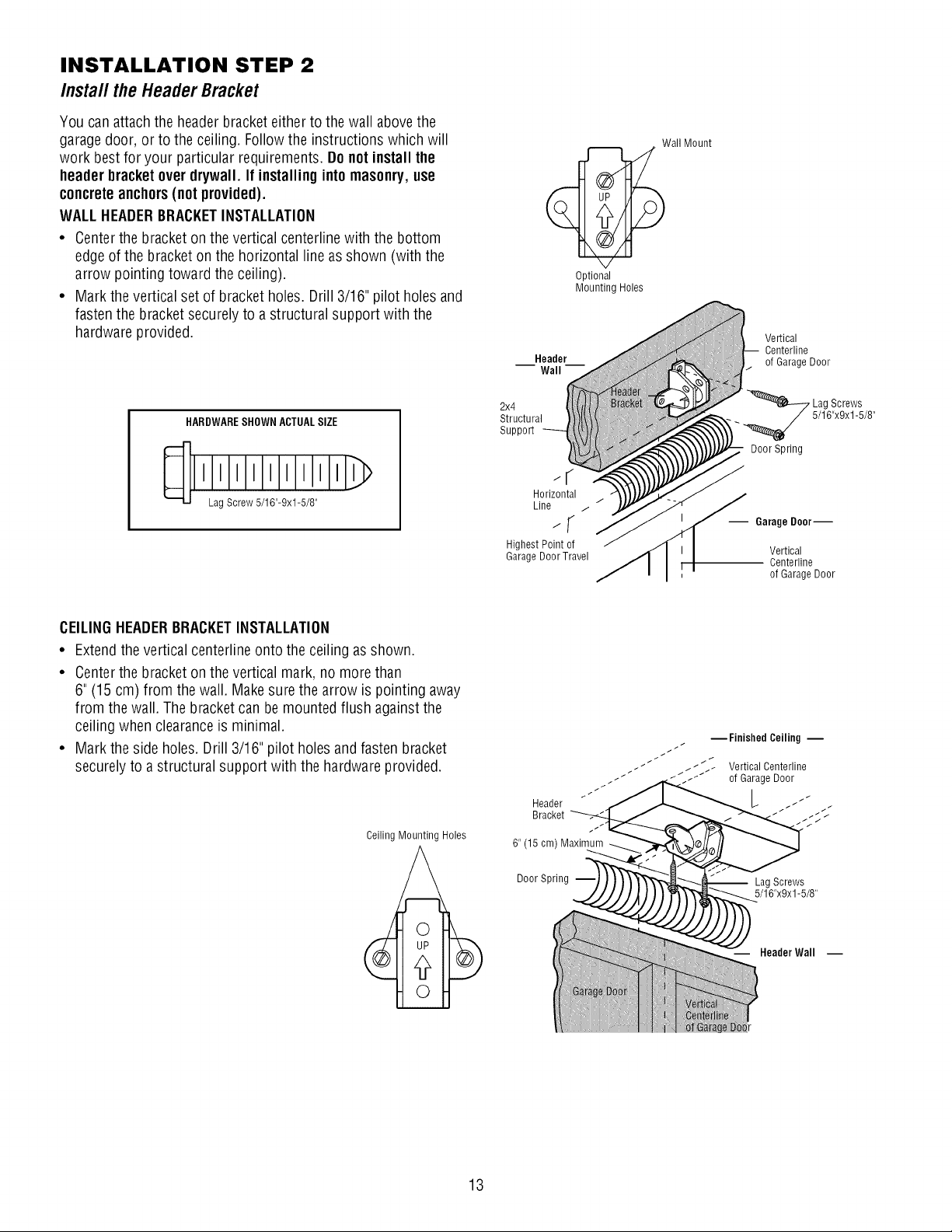

INSTALLATION STEP 2

Installthe HeaderBracket

You can attachthe headerbracketeither to the wallabovethe

garagedoor, or to theceiling. Follow the instructions which will

work bestfor your particular requirements. Do notinstall the

header bracketoverdrywall. If installinginto masonry,use

concreteanchors(notprovided),

WALLHEADERBRACKETINSTALLATION

• Centerthe bracketon thevertical centerlinewith the bottom

edge of thebracketon the horizontal lineasshown (with the

arrow pointing toward the ceiling).

• Mark thevertical setof bracketholes. Drill 3/16" pilot holes and

fastenthe bracketsecurely to astructural support with the

hardware provided.

Optional

MountingHoles

Wall Mount

Vertical

Centerline

of GarageDoor

HARDWARESHOWN ACTUALSIZE

LagScrew 5/16"-9xl-5/8"

CEILINGHEADERBRACKETINSTALLATION

• Extendthe vertical centerline onto the ceiling asshown.

• Centerthe bracketon thevertical mark, no more than

6" (15cm) from the wall. Makesure the arrow is pointing away

from the wall. Thebracketcan bemountedflush againstthe

ceiling when clearanceis minimal.

• Mark theside holes. Drill 3/16" pilot holesand fastenbracket

securelyto a structural support with the hardwareprovided.

Ceiling Mounting Holes

Horizontal

Line / /

-; S

HighestPoint of

Garage DoorTravel

Header

Bracket

6" (15 cm) Maximum

. 5/16"x9x1-5/8"

Door Spring

-- Garage Door--

Vertical

Centerline

of GarageDoor

_Finished Ceiling m

_../_::_ Vertical Centerline

_ of GarageDoor

Lag Screws

13

Door Spring

Lag Screws

5/16"x9x1-5/8"

Header Wall --

Wall

-- Idler Pulley

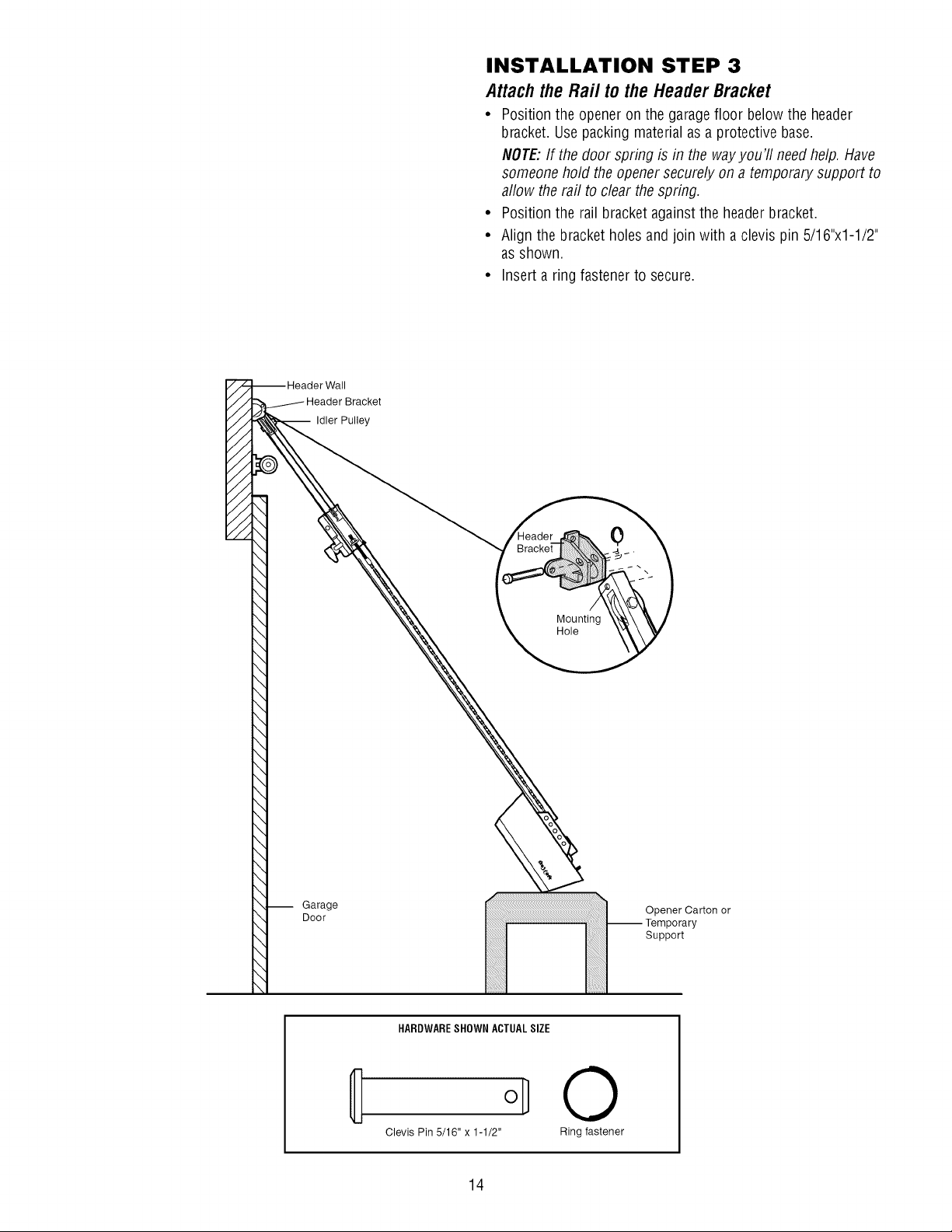

INSTALLATION STEP 3

Attach the Raft to the Header Bracket

• Position the openeron the garagefloor below the header

bracket. Usepacking materialasa protective base.

NOTE:If the door spring is in the wayyou'll need help. Have

someone hold the opener securely ona temporary support to

allow the rail to clear the spring.

• Position the rail bracket againstthe headerbracket.

• Align the bracket holesand join with a clevis pin 5/16"x1-1/2"

as shown.

• Insert a ring fastener to secure.

-- Garage

Door

Mounting

Hole

0

Opener Carton or

-- Temporary

Support

HARDWARESHOWN ACTUALSIZE

Clevis Pin 5/16" x 1-1/2"

14

©

Ring fastener

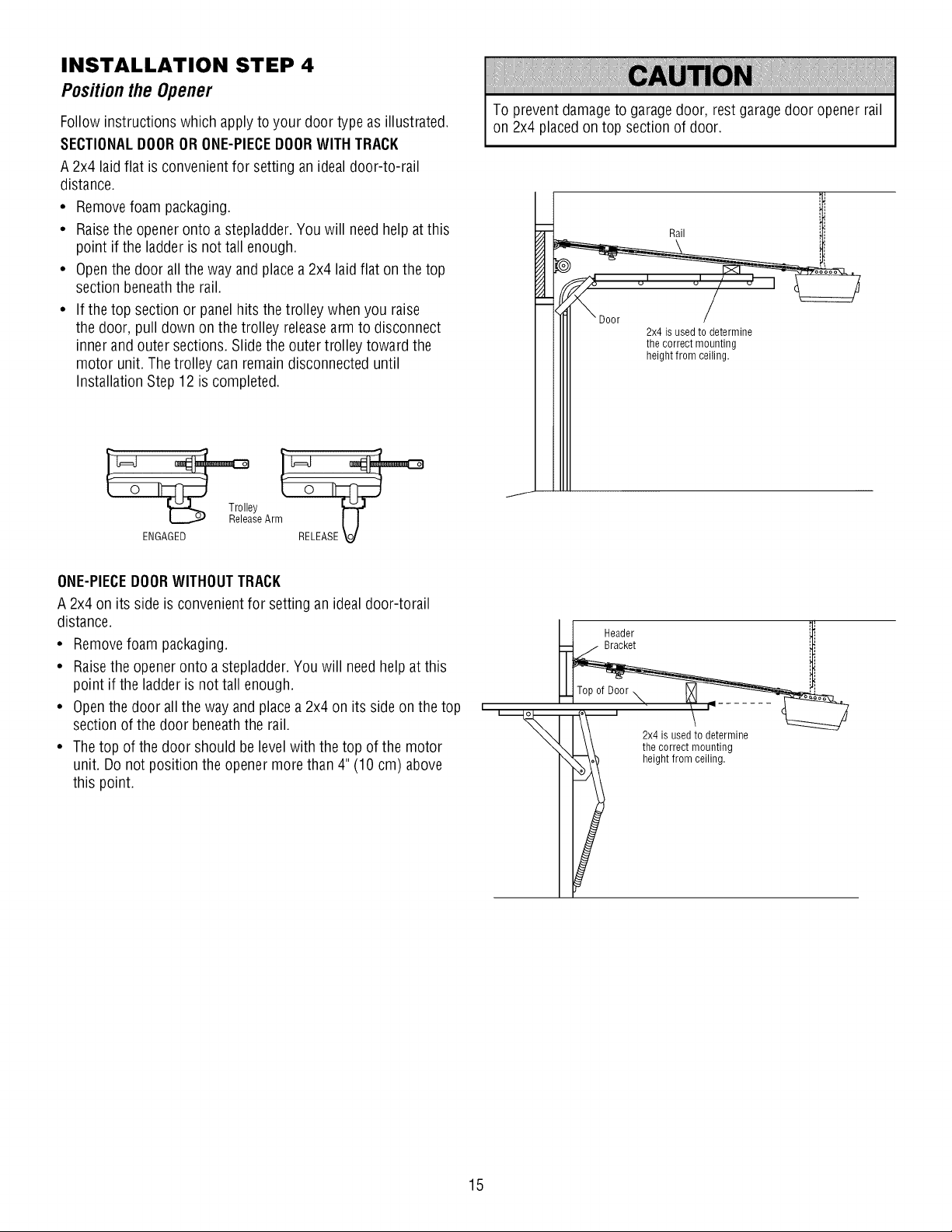

INSTALLATION STEP 4

PositiontheOpener

Follow instructions which applyto your door type as illustrated.

SECTIONALDOORORONE-PIECEDOORWITH TRACK

A 2x4 laid flat is convenientfor setting anidealdoor-to-rail

distance.

• Removefoam packaging.

• Raisethe openeronto astepladder.You will needhelp atthis

point if the ladderis not tall enough.

• Openthedoor allthe wayand placea2x4 laidflat onthe top

section beneaththe rail.

• If the top section or panelhits thetrolley when you raise

the door, pull down on the trolley releasearm to disconnect

inner and outer sections. Slide the outertrolley toward the

motor unit. Thetrolley can remain disconnected until

Installation Step 12is completed.

y }-=€'

seArm [J

ENGAGED RELEASE V

To preventdamageto garagedoor, restgaragedoor openerrail

on 2x4 placedon top section of door.

Rail

2x4 is usedto determine

the correct mounting

height from ceiling.

ONE-PIECEDOORWITHOUTTRACK

A 2x4 on its side is convenientfor setting an ideal door-torail

distance.

• Removefoam packaging.

• Raisethe openeronto a stepladder.Youwill needhelp at this

point if the ladder is not tall enough.

• Openthedoor allthe way andplacea 2x4 on its side on thetop

section of thedoor beneaththe rail.

• Thetop of the door should be levelwith the top of the motor

unit. Do not position theopener more than4"(10 cm) above

this point.

I 1 Header

; 4, used!o2rm, e

i _hegh_r_2,tlln___nnt;n,g

15

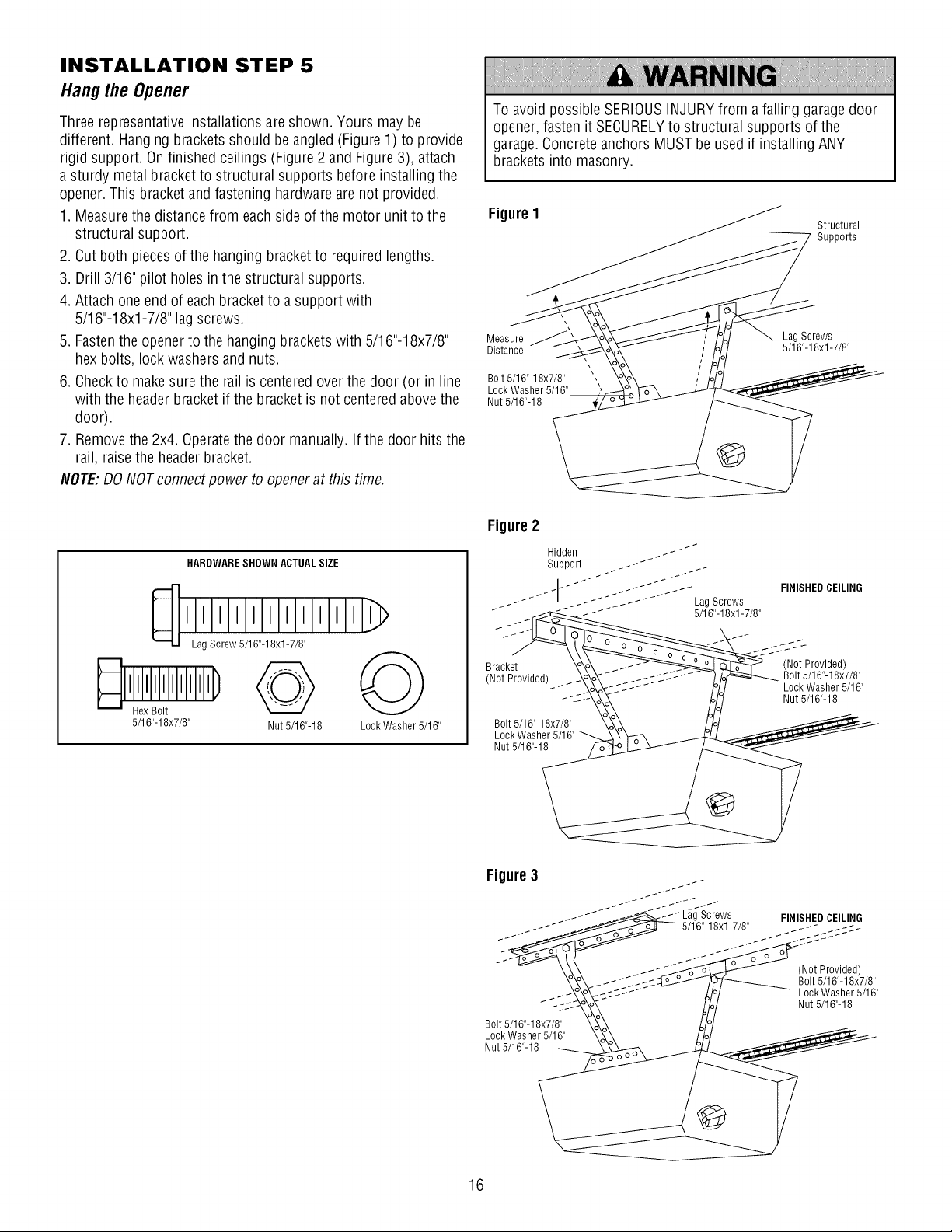

INSTALLATION STEP 5

Hangthe Opener

Threerepresentativeinstallations areshown. Yours may be

different. Hangingbracketsshould beangled(Figure1) to provide

rigid support. On finished ceilings (Figure2 and Figure3), attach

a sturdy metal bracket to structural supports before installing the

opener.This bracketand fastening hardware are not provided.

1. Measurethe distancefrom each sideof the motor unit to the

structural support.

2. Cut both piecesof the hanging bracket to required lengths.

3. Drill 3/16"pilot holesinthe structural supports.

4. Attach oneend of each bracketto a support with

5/16"-18xl-7/8" lagscrews.

5. Fastenthe openerto the hanging brackets with 5/16"-18x7/8"

hex bolts, lock washersand nuts.

6. Checkto makesure the rail is centeredover the door (or in line

with the header bracket if the bracket is not centeredabove the

door).

7. Removethe 2x4. Operatethe door manually. Ifthe door hits the

rail, raise the headerbracket.

NOTE:DONOTconnectpower to openerat this time.

To avoid possible SERIOUSINJURYfrom a falling garagedoor

opener,fasten it SECURELYto structural supports of the

garage.Concrete anchors MUSTbeused if installing ANY

brackets into masonry.

FigureI

Measure Lag Screws

Distance 5/16"-18xl -7/8"

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

\

Structural

Supports

HARDWARESHOWN ACTUALSIZE

Lag Screw 5/16"-18xl -7/8"

5/16"-18x7/8" Nut 5/16"-18 Lock Washer 5/16"

Figure2

Hidden _ - _"""

Support _. - _"

_- Lag Screws

Bracket \o_o_ _- (Not Provided)

Not Provided/ _o_o_- _1-cc-J .... _/_ Bolt 5/16"-18x7/8"

- , _- __o_o_T-_ .... /oi,j LockWasher 5/16"

J-=--_ Mo7 Nut 5/16"-18

Bolt 5/16'-18X7/8' _ o__/o/

Figure3

_'_- .-I Lag Screws FINISHEDCEILING

-_ _" _ 5116"-18xl-7/8"

(Not Provided)

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

Bolt 5/16"-18x7/8"

Lock Washer 5/16"

Nut 5/16"-18

16

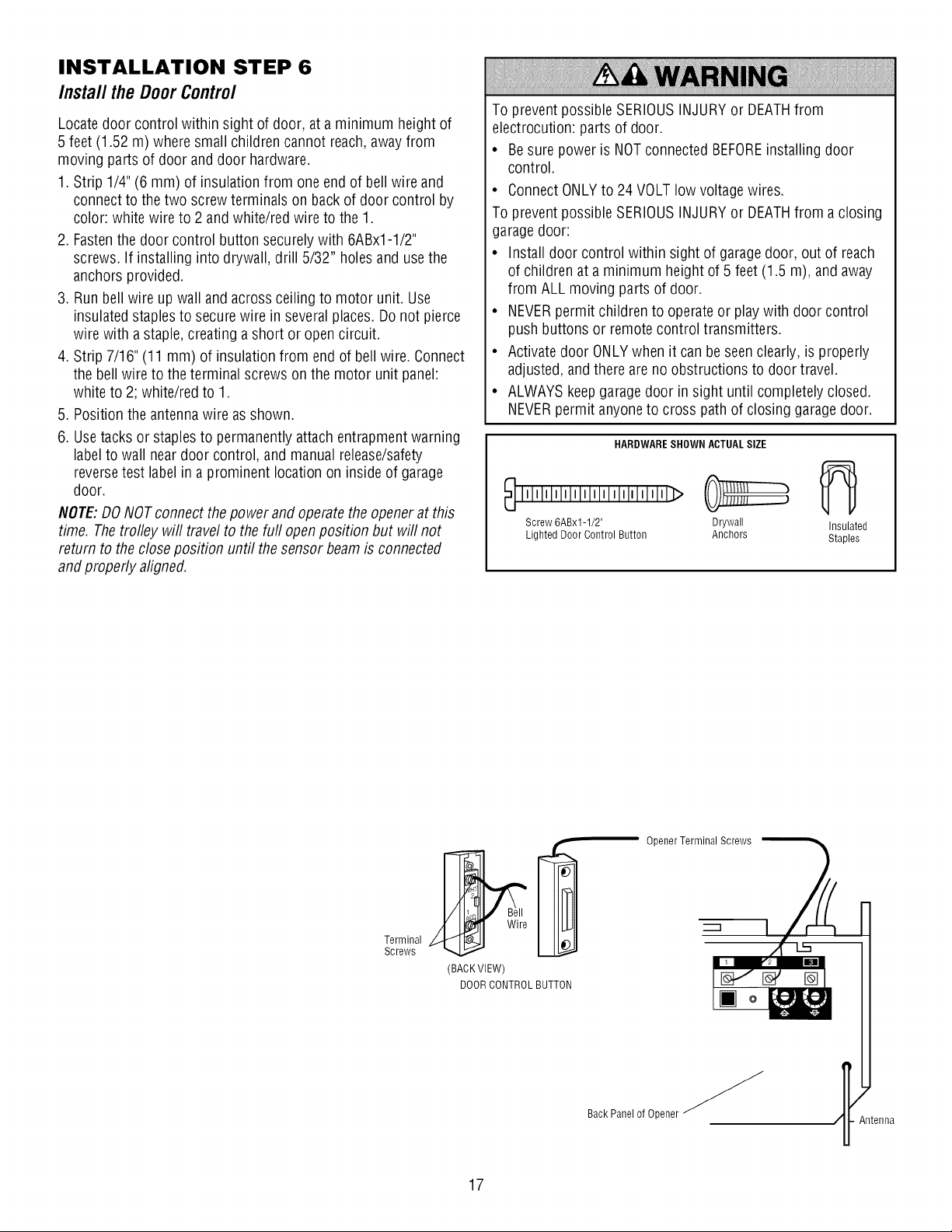

INSTALLATION STEP 6

Install the DoorControl

Locate door control within sight of door, ata minimum heightof

5 feet (1.52 m) where small children cannot reach,away from

moving partsof door anddoor hardware.

1. Strip 1/4"(6 mm) of insulation from one end of bellwire and

connectto thetwo screwterminals on back of door control by

color: whitewire to 2andwhite/red wire to the 1.

2. Fastenthe door control button securelywith 6ABx1-1/2"

screws. If installing into drywall, drill 5/32" holes and usethe

anchors provided.

3. Runbellwire up wall andacrossceiling to motor unit. Use

insulated staplesto securewire in several places. Donot pierce

wire with a staple, creating ashort or opencircuit.

4. Strip 7/16" (11 mm) of insulation from end of bellwire. Connect

the bell wireto the terminal screwsonthe motor unit panel:

white to 2; white/red to 1.

5. Position theantennawire as shown.

6. Usetacks or staplesto permanentlyattach entrapmentwarning

label to wallnear door control, and manualrelease/safety

reversetest labelin a prominent location oninside of garage

door.

NOTE:DONOTconnect thepower and operatethe opener atthis

time. Thetrolley will travel to the furl openposition but will not

return to the closeposition until thesensor beamis connected

and properly aligned.

To prevent possibleSERIOUSINJURYor DEATHfrom

electrocution: parts of door.

• Besure poweris NOTconnected BEFOREinstalling door

control.

• ConnectONLYto 24 VOLT low voltagewires.

To prevent possibleSERIOUSINJURYor DEATHfrom a closing

garage door:

• Install door control within sight of garage door, out of reach

of children at a minimum height of 5 feet (1.5 m), and away

from ALLmoving partsof door.

• NEVERpermit children to operateor playwith door control

pushbuttons or remotecontrol transmitters.

• Activate door ONLYwhen it can beseenclearly, is properly

adjusted, andthere are no obstructions to door travel.

• ALWAYSkeepgaragedoor in sight until completely closed.

NEVERpermit anyoneto cross path of closing garagedoor.

HARDWARESHOWN ACTUALSIZE

Screw 6ABx1-1/2" Drywall Insulated

Lighted Door Control Button Anchors Staples

Terminal

Screws

Opener Terminal Screws

(BACKVIEW)

DOORCONTROLBUTTON

BackPanel of Opener _

Antenna

17

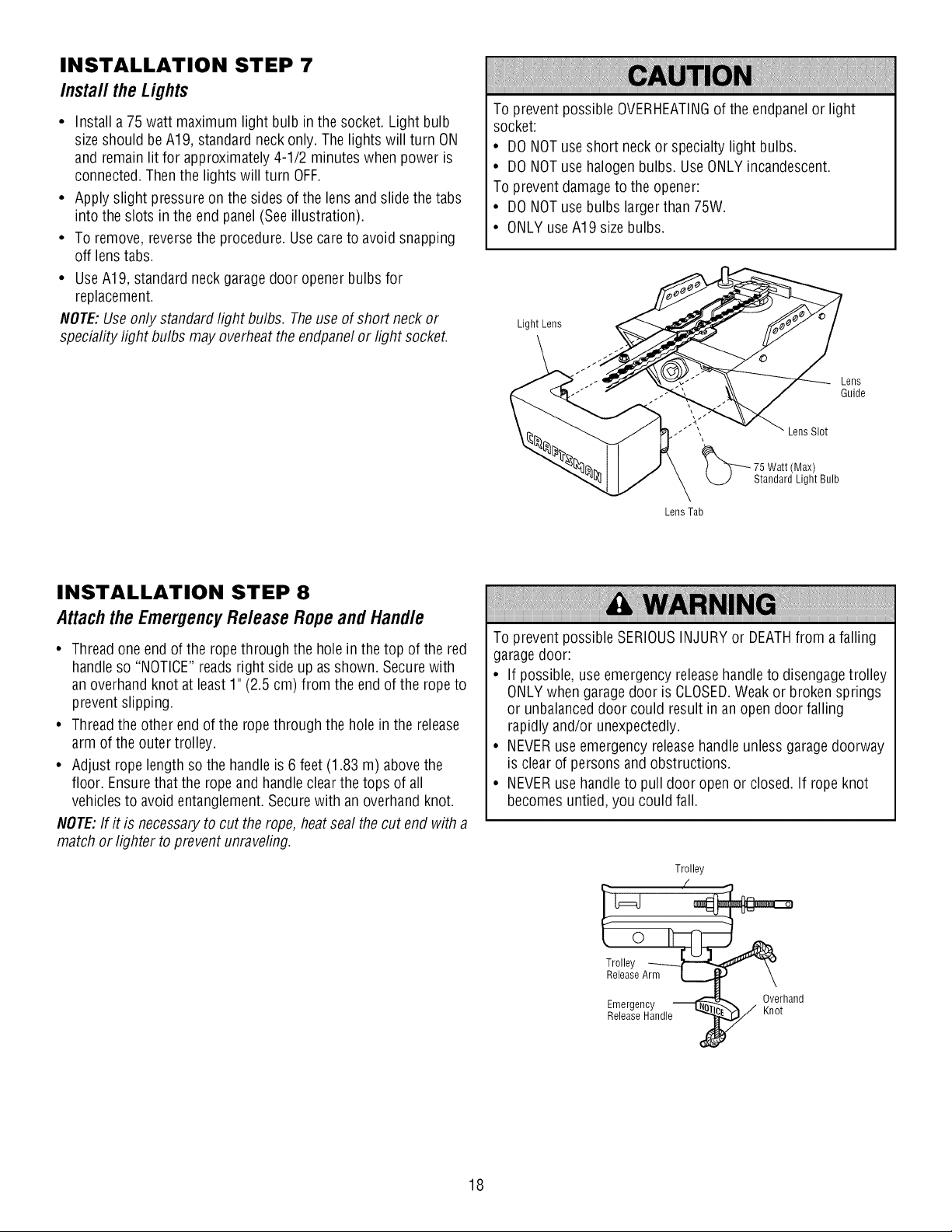

INSTALLATION STEP 7

Install theLights

• Install a 75 watt maximum light bulb inthe socket. Light bulb

size should beA19, standardneckonly.The lights will turn ON

and remainlit for approximately 4-1/2 minutes when power is

connected.Thenthe lights will turn OFF.

• Apply slight pressure on the sidesof the lens and slide the tabs

into the slots in the endpanel (Seeillustration).

• To remove, reversethe procedure. Use careto avoid snapping

off lenstabs.

• UseA19, standardneck garagedoor openerbulbs for

replacement.

NOTE:Use onlystandardlight bulbs. Theuseof short neck or

speciality light bulbs may overheatthe endpanelor light socket.

To prevent possibleOVERHEATINGof the endpanelor light

socket:

• DONOTuseshort neck or specialty light bulbs.

• DONOTusehalogen bulbs. UseONLYincandescent.

To preventdamageto the opener:

• DONOTusebulbs largerthan 75W.

• ONLYuseA19 sizebulbs.

Light Lens

Lens

Guide

Lens Slot

75 Watt (Max)

Standard Light Bulb

Lens Tab

INSTALLATION STEP 8

Attachthe EmergencyRe/easeRopeand Hand/e

• Threadoneendof the ropethrough the holein thetop of the red

handle so "NOTICE"readsright side up asshown. Securewith

an overhandknot at least 1" (2.5 cm) from the endof the rope to

prevent slipping.

• Threadthe other endof the ropethrough the holein the release

arm of the outer trolley.

• Adjust rope length sothe handleis 6feet (1.83 m) abovethe

floor. Ensurethat the ropeand handleclear the tops of all

vehiclesto avoid entanglement.Secure with an overhand knot.

NOTE:If it is necessaryto cut therope, heatsealthe cut endwith a

match or lighter to preventunraveling.

To prevent possibleSERIOUSINJURYor DEATHfrom afalling

garagedoor:

• If possible, useemergencyreleasehandle to disengagetrolley

ONLYwhen garagedoor is CLOSED.Weak or broken springs

or unbalanceddoor could result in an open door falling

rapidly and/or unexpectedly.

• NEVERuseemergency releasehandle unlessgaragedoorway

is clear of persons and obstructions.

• NEVERusehandleto pull door openor closed. If rope knot

becomesuntied, youcould fall.

Trolley

Release Handle Knot

Emergency _ _ Overhand

18

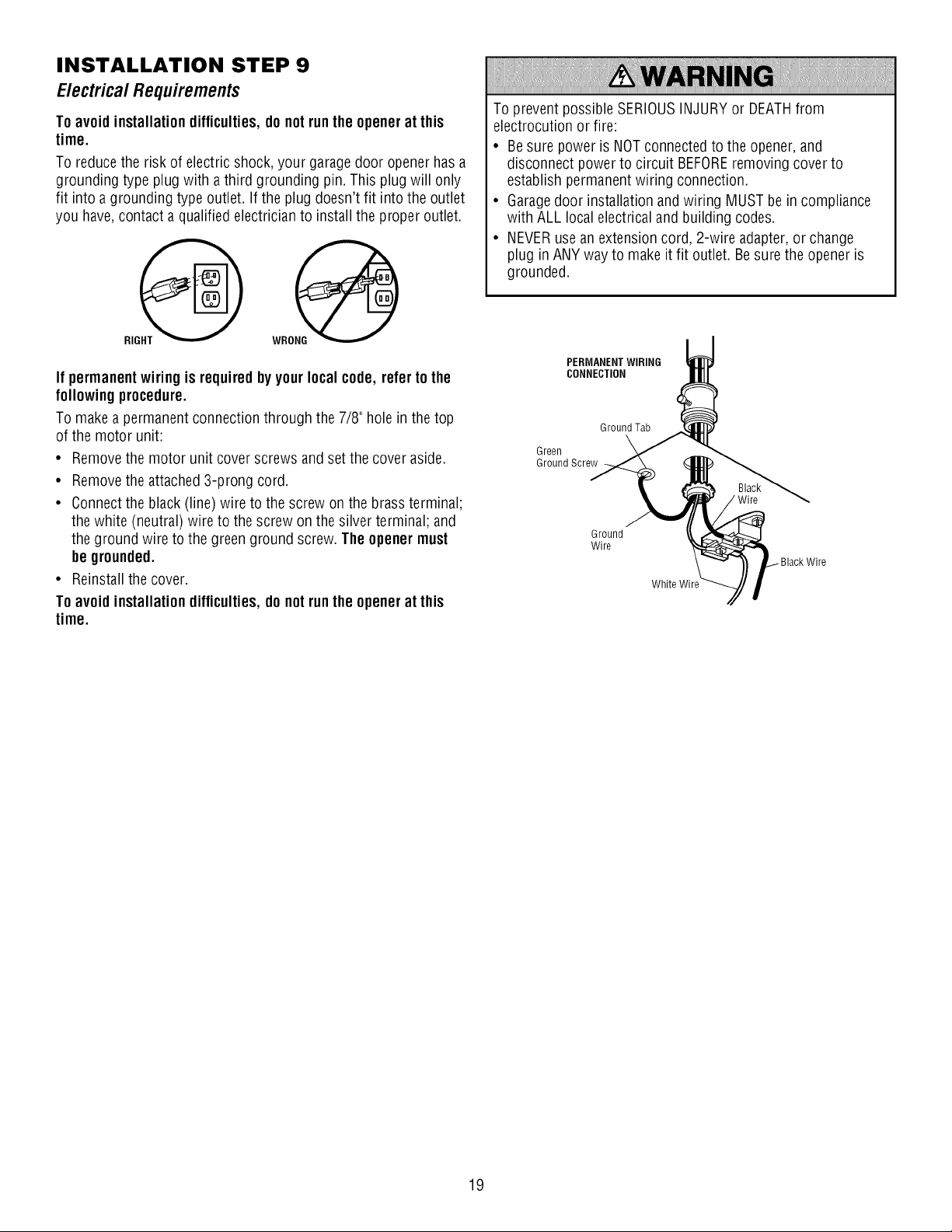

INSTALLATION STEP 9

Electrica/ Requirements

Toavoidinstallationdifficulties,do notruntheopenerat this

time.

To reducethe risk of electricshock, your garagedoor openerhasa

grounding typeplug with athird grounding pin. This plug will only

fit into a grounding type outlet. If the plug doesn'tfit into the outlet

you have,contact a qualifiedelectricianto installthe proper outlet.

If permanent wiring isrequiredby yourlocal code,refertothe

followingprocedure.

Tomake apermanent connection through the 7/8" hole in the top

of the motor unit:

• Removethe motor unit cover screws andset the cover aside.

• Removethe attached3-prong cord.

• Connectthe black(line)wire to the screw on the brass terminal;

thewhite (neutral) wire to the screw on the silverterminal; and

theground wire to the greenground screw. The openermust

begrounded.

• Reinstallthe cover.

Toavoidinstallationdifficulties,do notruntheopenerat this

time.

To prevent possibleSERIOUSINJURYor DEATHfrom

electrocution orfire:

• Besure poweris NOTconnectedto the opener,and

disconnect powerto circuit BEFOREremoving cover to

establish permanentwiring connection.

• Garagedoor installation and wiring MUSTbe in compliance

with ALL localelectricaland building codes.

• NEVERusean extension cord, 2-wire adapter, orchange

plug inANYway to makeit fit outlet. Besurethe openeris

grounded.

PERMANENTWIRING

CONNECTION

Ground Tab

Green

Ground Screw

Ground

Wire

Wire

White Wire

19

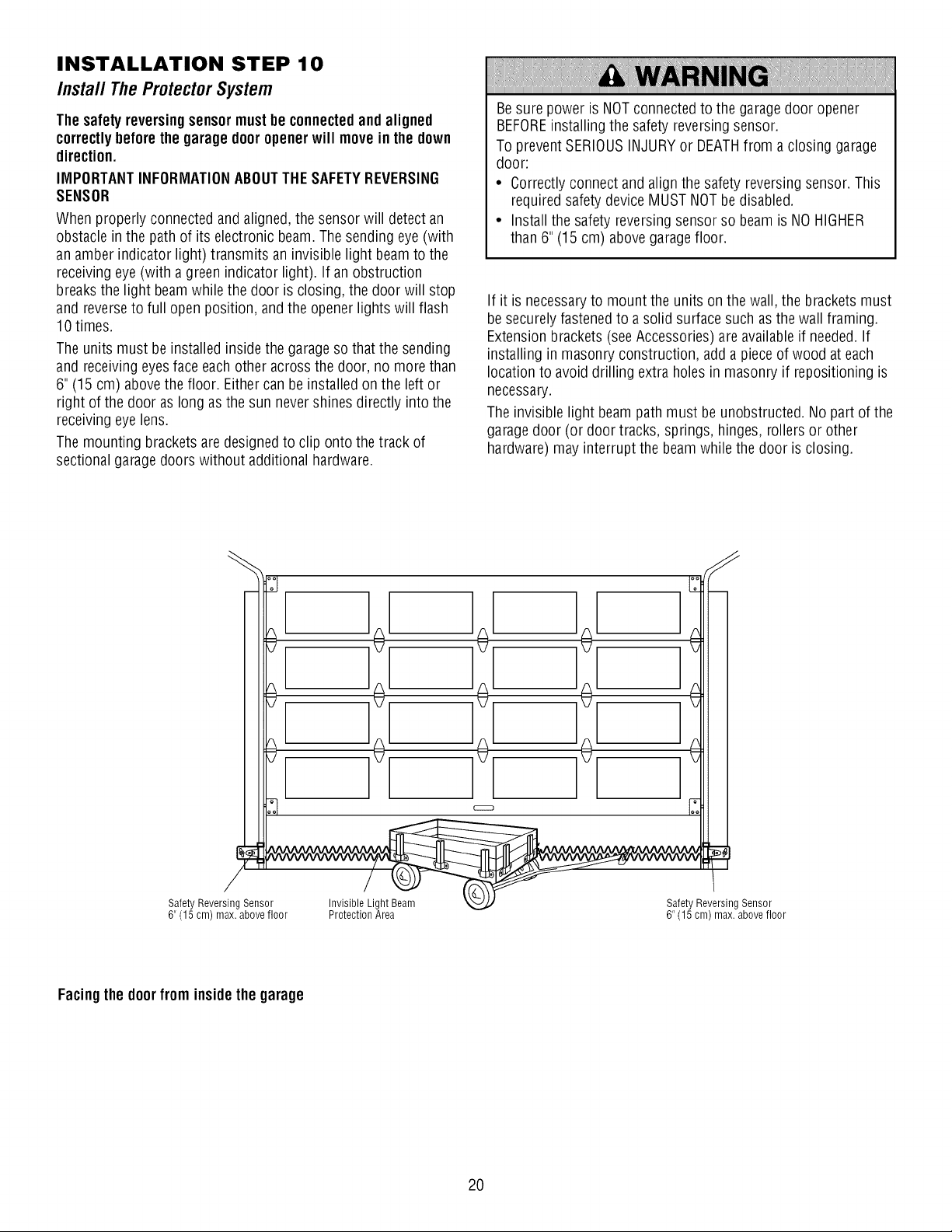

INSTALLATION STEP 10

Install TheProtectorSystem

Thesafety reversingsensormustbeconnectedandaligned

correctlybeforethe garagedooropenerwill movein the down

direction.

IMPORTANTINFORMATIONABOUTTHESAFETYREVERSING

SENSOR

Whenproperly connected andaligned, thesensor will detect an

obstacle in thepathof its electronic beam.Thesending eye (with

an amber indicator light) transmits an invisible light beamto the

receiving eye(with agreen indicator light). If an obstruction

breaksthe light beamwhile the door is closing, the door will stop

and reverseto full open position, andthe openerlights will flash

10 times.

Theunits must beinstalledinsidethe garageso that the sending

and receivingeyesface eachother acrossthe door, no more than

6"(15 cm) abovethe floor. Eithercan be installed onthe left or

right of the door aslong asthe sun nevershines directly into the

receiving eyelens.

Themounting brackets are designedto clip ontothe track of

sectionalgarage doorswithout additional hardware.

Besure poweris NOTconnectedto the garagedoor opener

BEFOREinstalling the safety reversingsensor.

To preventSERIOUSINJURYor DEATHfrom a closing garage

door:

• Correctly connect andalignthe safety reversing sensor. This

requiredsafety device MUSTNOTbedisabled.

• Installthe safety reversingsensor so beam is NOHIGHER

than 6" (15 cm) abovegaragefloor.

If it is necessaryto mount the units on the wall,the bracketsmust

be securelyfastenedto asolid surfacesuch as the wall framing.

Extensionbrackets (seeAccessories) are availableif needed.If

installing in masonry construction, adda pieceof wood at each

location to avoiddrilling extraholes in masonry if repositioning is

necessary.

Theinvisible light beampathmust be unobstructed. No part ofthe

garagedoor (or door tracks, springs, hinges, rollers or other

hardware) may interrupt the beamwhile the door is closing.

/

Safety Reversing Sensor Invisible Light Beam

6" (15 cm) max. above floor Protection Area

Facingthe doorfrom insidethe garage

]o[

]o[

]÷[

Safety Reversing Sensor

6" (15 cm) max. above floor

2O

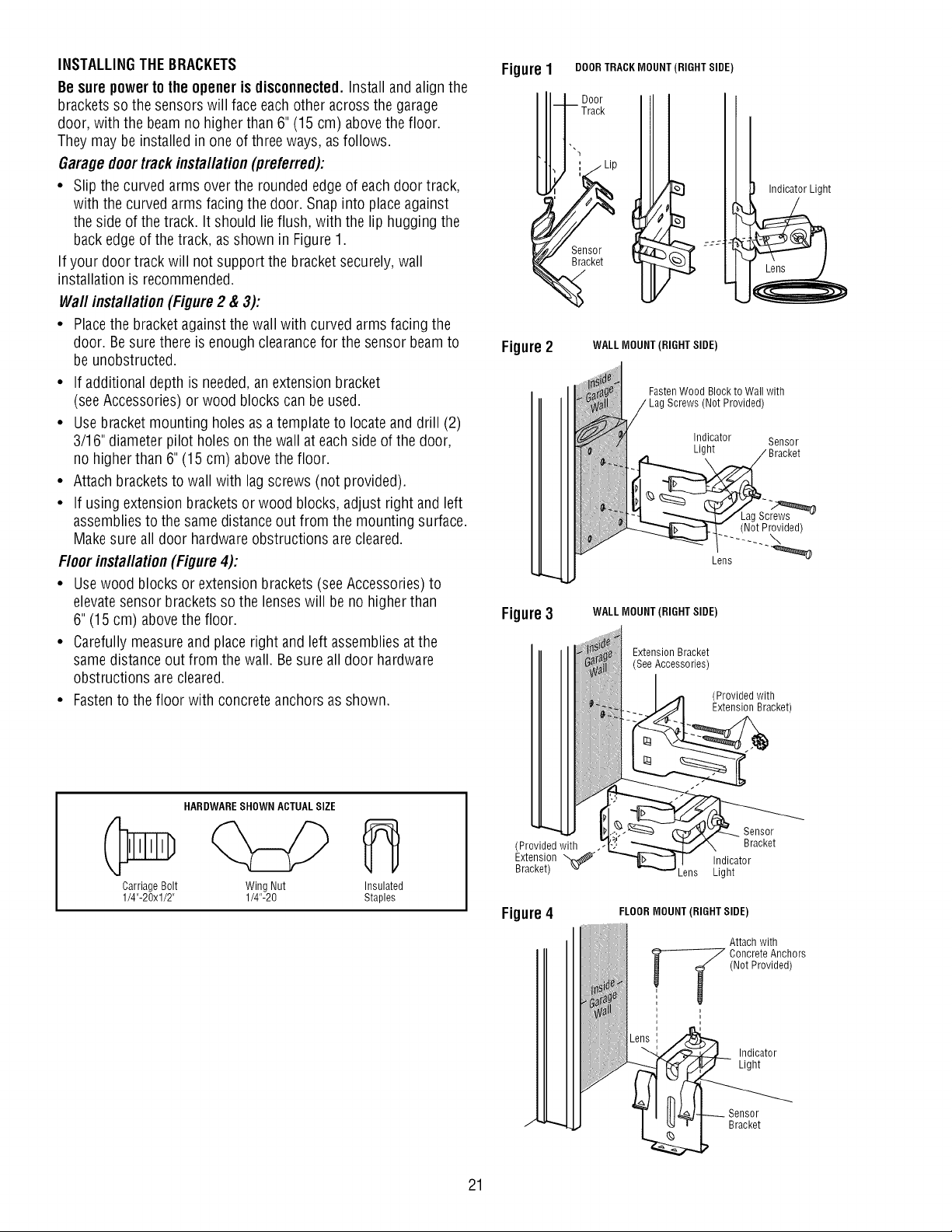

INSTALLINGTHEBRACKETS

Besurepower tothe opener is disconnected.Installand align the

brackets sothe sensors will faceeachother across the garage

door, with the beam no higher than 6"(15 cm) abovethe floor.

They may be installed in one of threeways, as follows.

Garagedoortrackinstallation(preferred):

• Slip the curvedarms overthe rounded edgeof eachdoor track,

with the curved arms facing the door. Snap into placeagainst

the side of the track. It should lie flush, with the lip huggingthe

back edgeof the track, asshown in Figure1.

If your door track will not support the bracket securely, wall

installation is recommended.

Waftinstallation (Figure2 & 3):

• Placethe bracketagainstthe wall with curved arms facing the

door. Besurethere is enoughclearancefor the sensor beamto

be unobstructed.

• If additional depth is needed,anextension bracket

(seeAccessories) or wood blocks can be used.

• Usebracketmounting holes asatemplateto locateanddrill (2)

3/16" diameter pilot holeson the wall at eachside ofthe door,

no higherthan 6" (15 cm) abovethe floor.

• Attach bracketsto wall with lag screws (not provided).

• If using extension bracketsor wood blocks, adjust right andleft

assembliesto thesame distanceout from the mounting surface.

Make sureall door hardware obstructions arecleared.

Floorinstallation (Figure4):

• Usewood blocks orextension brackets (seeAccessories) to

elevatesensor brackets sothe lenses will beno higher than

6"(15 cm) abovethe floor.

• Carefullymeasureand placeright andleft assembliesat the

same distanceout from the wall. Besure alldoor hardware

obstructions are cleared.

• Fastento the floor with concreteanchors as shown.

FigureI DOORTRACKMOUNT(RIGHT SIDE)

t Door

, Track

;zz -

Figure2 WALLMOUNT (RIGHT SIDE)

Figure3

FastenWood Blockto Wall with

WALLMOUNT (RIGHT SIDE)

(Not Provided)

Indicator Sensor

Light

_k Bracket

Y L2g._

Lens

Exteos,ooorac et

(SeeAccessories)

(Provided with

a

(Not Provided)

HARDWARESHOWN ACTUALSIZE

Carriage Bolt Wing Nut Insulated

1/4"-20xl/2" 1/4"-20 Staples

21

!I___:'- _acket)

"" _ Sensor

(Provided with .-__ Bracket

Extension _ b_.. -- I! Indicator

Bracket) ,.v _Lens Light

Figure4

J

FLOORMOUNT (RIGHT SIDE)

Attach with

Concrete Anchors

(Not Provided)

Sensor

Bracket

Indicator

Light

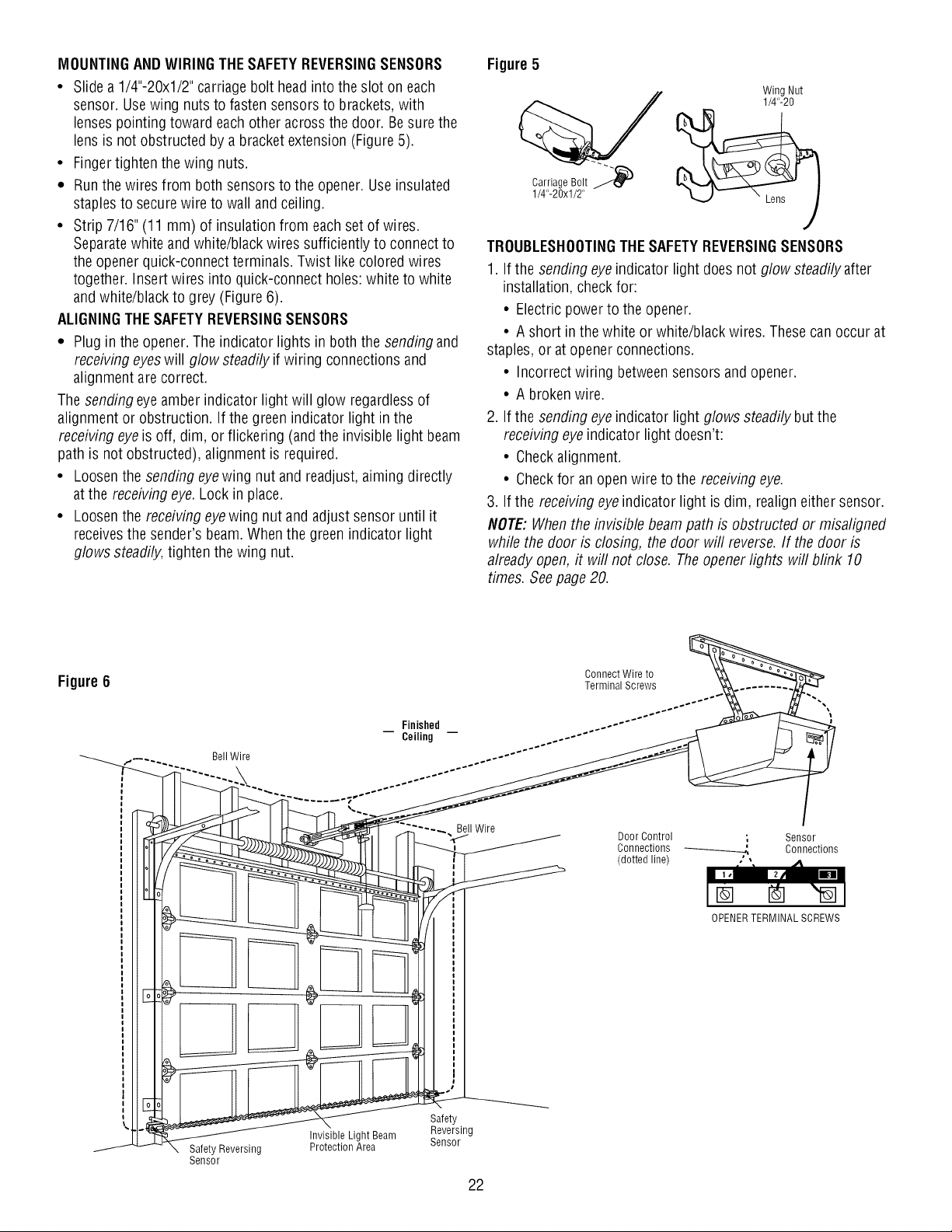

MOUNTINGAND WIRINGTHESAFETYREVERSINGSENSORS

• Slide a 1/4"-20xl/2" carriagebolt headinto the slot on each

sensor. Usewing nuts to fasten sensorsto brackets,with

lenses pointing toward each other across the door. Besure the

lens is not obstructed by abracket extension (Figure5).

• Fingertighten thewing nuts.

• Runthe wires from both sensorsto the opener. Useinsulated

staplesto securewire to wall andceiling.

• Strip 7/16" (11 mm) of insulationfrom eachset of wires.

Separatewhite andwhite/black wires sufficiently to connectto

the opener quick-connectterminals. Twist like coloredwires

together. Insert wires into quick-connect holes:white to white

and white/black togrey (Figure 6).

ALIGNINGTHESAFETYREVERSINGSENSORS

• Plugin the opener. Theindicator lights in both the sendingand

receivingeyeswill glow steadilyif wiring connections and

alignment are correct.

Thesending eyeamber indicator light will glow regardlessof

alignment or obstruction. If the greenindicator light inthe

receiving eyeis off, dim, orflickering (and the invisible light beam

path is not obstructed), alignmentis required.

• Loosenthe sending eyewing nut and readjust, aiming directly

atthe receiving eye.Lock inplace.

• Loosenthe receivingeyewing nut and adjust sensor until it

receivesthe sender's beam. When the greenindicator light

glows steadily,tightenthe wing nut.

Figure5

Wing Nut

1/4"-20

1/4"-20xl/2"

Carriage Bolt _

TROUBLESHOOTINGTHESAFETYREVERSINGSENSORS

1. If the sending eyeindicatorlight does not glow steadily after

installation, checkfor:

• Electricpower to the opener.

• A short in the white orwhite/black wires. These can occur at

staples, or atopener connections.

• Incorrect wiring betweensensors andopener.

• A broken wire.

2. If the sending eyeindicatorlight glows steadilybut the

receivingeyeindicator light doesn't:

• Checkalignment.

• Checkfor anopenwire to the receiving eye.

3. If the receivingeyeindicator light isdim, realigneithersensor.

NOTE:When the invisiblebeam path is obstructed or misaligned

while the door is closing, the door will reverse.If the door is

already open, it will not close. The openerlights will blink 10

times. Seepage20.

Figure6

Finished

Ceiling

Connect Wire to

Terminal Screws

DoorControl ; Sensor

Connections Connections

(dotted line)

OPENERTERMINAL SCREWS

22

INSTALLATION STEP 1 1

FastentheDoorBracket

Follow instructions which applyto your door typeas illustrated

below or on the following page.

A horizontalreinforcementbraceshouldbe longenoughto be

securedto two orthree vertical supports.Avertical

reinforcementbraceshouldcoverthe heightof thetop panel.

Figure1 shows one pieceof angle iron as the horizontal brace.

Forthe vertical brace, 2 pieces of angle iron are usedto createa

U-shaped support. Thebest solution isto checkwith your garage

door manufacturerfor an openerinstallation door reinforcement

kit.

NOTE:Many door reinforcementkits provide for direct

attachment of the clevis pin and doorarm. In this caseyou will

not need the doorbracket,proceed to Step 12.

SECTIONALDOORS

1. Centerthe door bracketon the previously marked vertical

centerline usedfor the headerbracket installation. Notecorrect

UPplacement,as stamped insidethe bracket.

2. Position the top edgeof the bracket2"-4"(5-10 cm) below the

top edge ofthe door, ORdirectly below any structural support

across the top of the door.

3. Mark, drill holes and install as follows, depending on your

door's construction:

Metal orlight weightdoorsusinga verticalangleiron brace

betweenthe doorpanel supportand the doorbracket:

• Drill 3/16" fastening holes. Securethe door bracket using the

two 1/4"-14x5/8"self-threading screws. (Figure2A)

• Alternately, usetwo 5/16" bolts, lock washers andnuts

(not provided). (Figure2B)

Metal, insulatedor light weightfactoryreinforceddoors:

• Drill 3/16" fastening holes. Securethe door bracket using the

self-threading screws (Figure3).

WoodDoors:

• Usetop and bottom or sideto side door bracket holes. Drill

5/16" holes through the door and secure bracket with 5/16"x2"

carriage bolts, lock washersand nuts (not provided). (Figure4)

NOTE:The1/4"-14x5/8"self-threading screws are not intended for

use on wood doors.

HARDWARE SHOWN

ACTUAL SIZE

Self-Threading

Screw

1/4"-14x5/8"

Fiberglass,aluminum or lightweight steel garagedoors WILL

REQUIREreinforcement BEFOREinstallation of door bracket.

Contactyour door manufacturer for reinforcement kit.

Door

Bracket

Location

HORIZONTALANDVERTICAL

REINFORCEMENTIS NEEDEDFOR

Vertical

Centerline

of Garage

Door

LIGHTWEIGHTGARAGEDOORS

(FIBERGLASS,ALUMINUM, STEEL,

DOORSWITH GLASS PANEL, ETC.).

(NOT PROVIDED)

III IIII I

Figure 1

Vertical

_fl_,,_olOlVerti:_iC_ri:trline

arage Door

Door gracket_" _-UP

Self-Threading---"_

Screw 1/4"-14x5/8"

Figure 2A

ertical

Centerline

of GarageDoor

Self-Threading

Screw

1/4"-14x5/8"

Figure 3

(Not Provided 11_

_'C_% [Io101 VerticalCenterline

"%." [Io101 of Garage Door

- iloH ==

Door Bracket

Lock Washer 5/16'_.

Nut 5/16"- 18

J

5/16"x2" -.

(Not Provided)

Bolt

Vertical

Centerline

of Garage

Door

Figure 2B

Inside Edge

of Door or

Reinforcement Board

Figure 4

23

Loading...

Loading...